Page 1

STIHL HL 100

WARNING

Read Instruction Manual thoroughly

before use and follow all safety

precautions – improper use can

cause serious or fatal injury.

ADVERTENCIA

Antes de usar la máquina lea y siga

todas las precauciones de

seguridad dadas en el manual de

instrucciones – el uso incorrecto

puede causar lesiones graves o

mortales.

{

Instruction Manual

Manual de instrucciones

Page 2

Instruction Manual

1 - 40

Manual de instrucciones

41 - 84

Page 3

Contents

English

Guide to Using this Manual 2

Safety Precautions and Working

Techniques 3

Using the Unit 12

Approved Power Tool Attachments 14

Assembling the Unit 15

4-MIX Engine 16

Fuel 17

Original Instruction ManualPrinted on chlorine-free paper

Fueling 18

Adjusting the Cutter Bar 19

Fitting the Harness 21

Starting / Stopping the Engine 21

Operating Instructions 23

Cleaning the Air Filter 24

Engine Management 24

Adjusting the Carburetor 24

Spark Arresting Screen in Muffler 26

Checking the Spark Plug 26

Lubricating the Gearbox 27

Rewind Starter 28

Sharpening Instructions 28

Storing the Machine 29

Printing inks contain vegetable oils, paper can be recycled.

Maintenance and Care 30

Main Parts 32

Specifications 34

Maintenance and Repairs 35

Disposal 35

STIHL Incorporated Federal

Emission Control Warranty

Statement 35

STIHL Incorporated California

Exhaust and Evaporative

Emissions Control Warranty

Statement 37

Trademarks 40

Allow only persons who fully understand

this manual to operate your hedge

cutter.

To receive maximum performance and

satisfaction from your STIHL hedge

cutter, it is important that you read,

understand and follow the safety

precautions and the operating and

maintenance instructions in chapter

"Safety Precautions and Working

Techniques" before using your hedge

cutter. For further information you can

go to www.stihlusa.com.

Contact your STIHL dealer or the STIHL

distributor for your area if you do not

understand any of the instructions in this

manual.

WARNING

Because a hedge cutter is a high-speed

cutting tool some special safety

precautions must be observed to reduce

the risk of personal injury. Careless or

improper use may cause serious or even

fatal injury.

{

© ANDREAS STIHL AG & Co. KG, 2014

0458-388-8621-E. VA4.K14.

0000000572_008_GB

HL 100, HL 100 K

This instruction manual is protected by copyright. All rights reserved, especially the rights to reproduce, translate and process

with electronic systems.

1

Page 4

English

Guide to Using this Manual

Pictograms

The meanings of the pictograms

attached to or embossed on the

machine are explained in this manual.

Depending on the model concerned, the

following pictograms may be on your

machine.

Fuel tank for gasoline

and engine oil mixture

Press to operate manual

fuel pump

Filler hole for gear

lubricant

Starting lock

Rotating rear handle

A description of a step or procedure that

refers directly to an illustration may

contain item numbers that appear in the

illustration. Example:

N Loosen the screw (1).

N Lever (2) ...

In addition to the operating instructions,

this manual may contain paragraphs

that require your special attention. Such

paragraphs are marked with the

symbols and signal words described

below:

DANGER

Indicates an imminent risk of severe or

fatal injury.

WARNING

Indicates a hazardous situation which, if

not avoided, could result in severe or

fatal injury.

NOTICE

Indicates a risk of property damage,

including damage to the machine or its

individual components.

described in this manual, please contact

your STIHL dealer or the STIHL

distributor for your area for assistance.

Symbols in Text

Many operating and safety instructions

are supported by illustrations.

The individual steps or procedures

described in the manual may be marked

in different ways:

N A bullet marks a step or procedure.

2

Engineering Improvements

STIHL’s philosophy is to continually

improve all of its products. As a result,

engineering changes and improvements

are made from time to time. Therefore,

some changes, modifications and

improvements may not be covered in

this manual. If the operating

characteristics or the appearance of

your machine differs from those

HL 100, HL 100 K

Page 5

English

Safety Precautions and

Working Techniques

Because a hedge trim

mer is a high-speed, fastcutting power tool with

sharp cutting blades,

special safety precau

tions must be observed to

reduce the risk of per

sonal injury.

It is important that you

read, fully understand

and observe the following

safety precautions and

warnings. Read the

instruction manual and

the safety precautions

periodically. Careless or

improper use may cause

serious or fatal injury.

Have your STIHL dealer show you how

to operate your power tool. Observe all

applicable local safety regulations,

standards and ordinances.

WARNING

Do not lend or rent your power tool

without the instruction manual. Be sure

that anyone using it understands the

information contained in this manual.

WARNING

The use of this machine may be

hazardous. If the cutting tool comes in

contact with your body, it will cut you.

Use your hedge trimmer only for cutting

hedges, shrubs, scrub, bushes and

similar material.

-

-

-

WARNING

Do not use it for other purposes, since

misuse may result in personal injury or

property damage, including damage to

the machine.

WARNING

Minors should never be allowed to use

this power tool. Bystanders, especially

children, and animals should not be

allowed in the area where it is in use.

WARNING

To reduce the risk of injury to bystanders

and damage to property, never let your

power tool run unattended. When it is

not in use (e.g. during a work break),

shut it off and make sure that

unauthorized persons do not use it.

Most of these safety precautions and

warnings apply to the use of all STIHL

hedge trimmers. Different models may

have different parts and controls. See

the appropriate section of your

instruction manual for a description of

the controls and the function of the parts

of your model.

Safe use of a hedge trimmer involves

1. the operator

2. the power tool

3. the use of the power tool.

THE OPERATOR

Physical Condition

You must be in good physical condition

and mental health and not under the

influence of any substance (drugs,

alcohol, etc.) which might impair vision,

dexterity or judgment. Do not operate

this machine when you are fatigued.

WARNING

Be alert – if you get tired, take a break.

Tiredness may result in loss of control.

Working with any power tool can be

strenuous. If you have any condition that

might be aggravated by strenuous work,

check with your doctor before operating

this machine.

WARNING

Prolonged use of a power tool (or other

machines) exposing the operator to

vibrations may produce whitefinger

disease (Raynaud's phenomenon) or

carpal tunnel syndrome.

These conditions reduce the hand's

ability to feel and regulate temperature,

produce numbness and ing sensations

and may cause nerve and circulation

damage and tissue necrosis.

All factors which contribute to whitefinger disease are not known, but cold

weather, smoking and diseases or

physical conditions that affect blood

vessels and blood transport, as well as

high vibration levels and long periods of

exposure to vibration are mentioned as

factors in the development of whitefinger

HL 100, HL 100 K

3

Page 6

English

disease. In order to reduce the risk of

whitefinger disease and carpal tunnel

syndrome, please note the following:

Most STIHL power tools are available

with an anti-vibration ("AV") system

designed to reduce the transmission of

vibrations created by the machine to the

operator's hands. An AV system is

recommended for those persons using

power tools on a regular or sustained

basis.

– Wear gloves and keep your hands

warm.

– Keep the AV system well

maintained. A power tool with loose

components or with damaged or

worn AV elements will tend to have

higher vibration levels.

– Maintain a firm grip at all times, but

do not squeeze the handles with

constant, excessive pressure. Take

frequent breaks.

All the above-mentioned precautions do

not guarantee that you will not sustain

whitefinger disease or carpal tunnel

syndrome. Therefore, continual and

regular users should closely monitor the

condition of their hands and fingers. If

any of the above symptoms appear,

seek medical advice immediately.

WARNING

The ignition system of the STIHL unit

produces an electromagnetic field of a

very low intensity. This field may

interfere with some pacemakers. To

reduce the risk of serious or fatal injury,

persons with a pacemaker should

consult their physician and the

pacemaker manufacturer before

operating this tool.

Proper Clothing

WARNING

To reduce the risk of injury, the operator

should wear proper protective apparel.

WARNING

To reduce the risk of

injury to your eyes never

operate your power tool

unless wearing goggles

or properly fitted protec

tive glasses with

adequate top and side

protection complying with

ANSI Z87 "+" (or your

applicable national stand

ard). To reduce the risk of

injury to your face STIHL

recommends that you

also wear a face shield or

face screen over your

goggles or protective

glasses

Power tool noise may

damage your hearing.

Wear sound barriers (ear

plugs or ear mufflers) to

protect your hearing.

Continual and regular

users should have their

hearing checked

regularly

Be particularly alert and cautious when

wearing hearing protection because

your ability to hear warnings (shouts,

alarms, etc.) is restricted.

-

Always wear heavy duty

work gloves (e.g. made of

leather or other wear

resistant material) when

handling the machine

and the cutting tool.

Heavy-duty, nonslip

gloves improve your grip

and help to protect your

hands.

Clothing must be sturdy

and snug-fitting, but allow

complete freedom of

movement. Wear long

pants made of heavy

material to help protect

your legs. Do not wear

-

shorts, sandals or go

barefoot.

Avoid loose-fitting jack

ets, scarfs, neckties,

jewelry, flared or cuffed

pants, unconfined long

hair or anything that

could become caught on

branches, brush or the

moving parts of the unit.

Secure hair so it is above

shoulder level.

Good footing is very

important. Wear sturdy

boots with nonslip soles.

Steel-toed safety boots

are recommended.

Wear an approved safety

hard hat to reduce the

risk of injury to your head

when there is a danger of

head injuries.

-

4

HL 100, HL 100 K

Page 7

English

389BA019 KN

THE POWER TOOL

For illustrations and definitions of the

power tool parts see the chapter on

"Main Parts and Controls".

WARNING

Never modify this power tool in any way.

Only attachments supplied by STIHL or

expressly approved by STIHL for use

with the specific STIHL model are

authorized. Although certain

unauthorized attachments are useable

with STIHL power tools, their use may,

in fact, be extremely dangerous.

If this tool is subjected to unusually high

loads for which it was not designed (e.g.

heavy impact or a fall), always check

that it is in good condition before

continuing work. Check in particular that

the fuel system is tight (no leaks) and

that the controls and safety devices are

working properly. Do not continue

operating this machine if it is damaged.

In case of doubt, have it checked by your

STIHL servicing dealer.

THE USE OF THE POWER TOOL

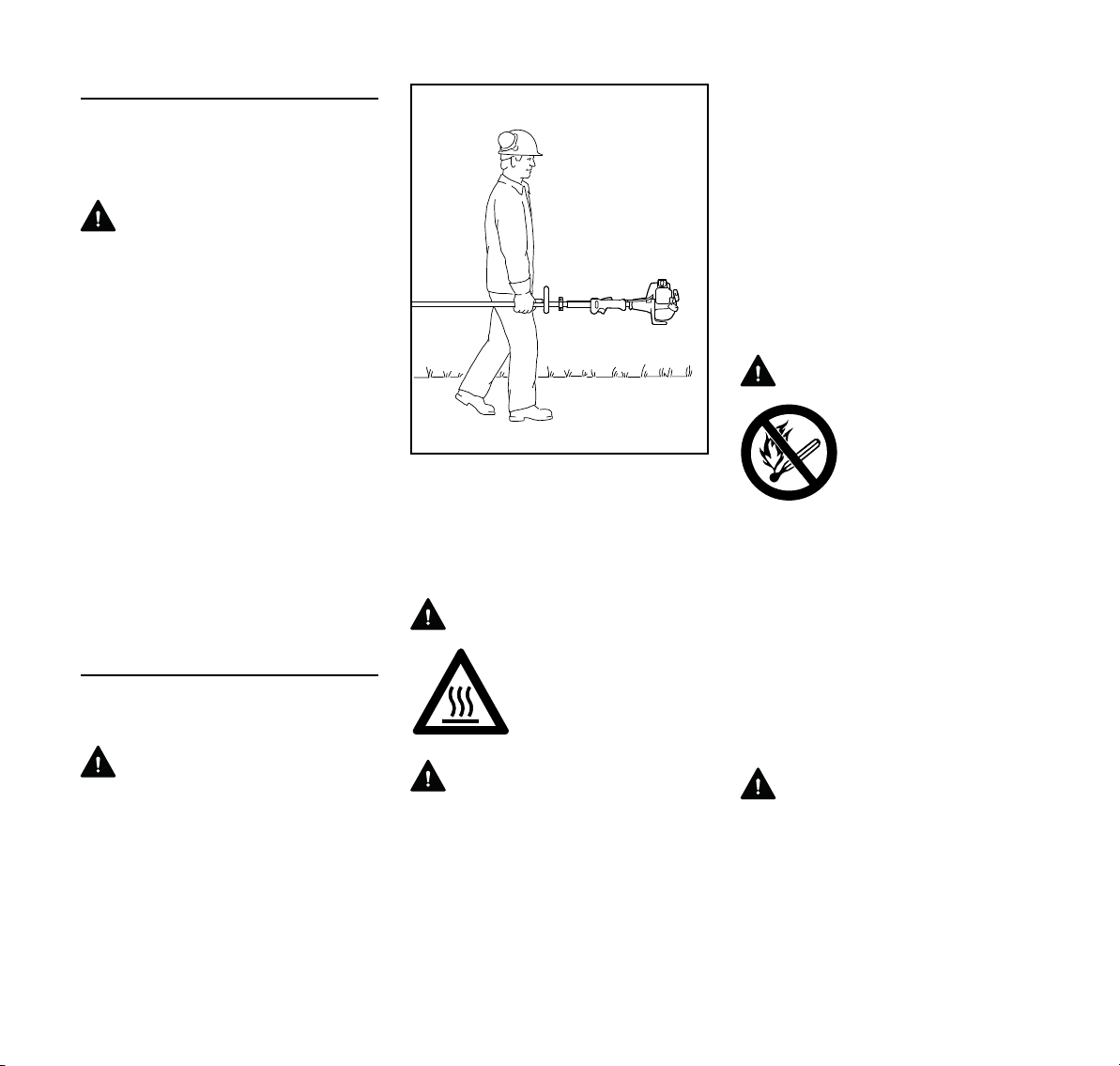

Transporting the Power Tool

WARNING

To reduce the risk of injury from blade

contact, never carry or transport your

power tool with the cutter blades

moving.

It may be carried only in a horizontal

position. Grip the shaft in a manner that

the machine is balanced horizontally.

Keep the hot muffler away from your

body and the cutting attachment behind

you.

WARNING

To reduce the risk of burn

injury, do not touch hot

parts of the machine and

the gear housing when

they are hot.

WARNING

Always switch off the engine and fit the

scabbard over the cutter blades before

transporting the power tool over long

distances. When transporting it in a

vehicle, properly secure it to prevent

turnover, fuel spillage and damage to

the unit.

On machines with an adjustable cutter

bar: Make sure the cutter bar is secured

in position. See chapter in instruction

manual entitled "Adjusting Cutter Bar

Angle." On machines with a transport

position: Move cutter bar to transport

position and secure.

Fuel

Your STIHL power tool uses an oil-

gasoline mixture for fuel (see the

chapter on "Fuel" of your instruction

manual).

WARNING

Gasoline is an extremely

flammable fuel. If spilled

and ignited by a spark or

other ignition source, it

can cause fire and seri

-

ous burn injury or

property damage. Use

extreme caution when

handling gasoline or fuel

mix. Do not smoke or

bring any fire or flame

near the fuel or the power

tool. Note that combusti

ble fuel vapor may

escape from the fuel

system.

Fueling Instructions

WARNING

To reduce the risk of serious injury from

burns, never attempt to refuel the unit

until it has been completely removed

from the operator.

-

HL 100, HL 100 K

5

Page 8

English

001BA220 KN

001BA227 KN

001BA226 KN

WARNING

Fuel your power tool in well-ventilated

areas, outdoors. Always shut off the

engine and allow it to cool before

refueling. Gasoline vapor pressure may

build up inside the fuel tank depending

on the fuel used, the weather conditions

and the tank venting system.

In order to reduce the risk of burns and

other personal injury from escaping gas

vapor and fumes, remove the fuel filler

cap on your power tool carefully so as to

allow any pressure build-up in the tank

to release slowly. Never remove the fuel

filler cap while the engine is running.

Select bare ground for fueling and move

at least 10 feet (3 m) from the fueling

spot before starting the engine. Wipe off

any spilled fuel before starting your

machine.

WARNING

Check for fuel leakage

while refueling and during

operation. If fuel leakage

is found, do not start or

run the engine until the

leak is fixed and any

spilled fuel has been

wiped away. Take care

not to get fuel on your

clothing. If this happens,

change your clothing

immediately.

WARNING

In order to reduce the risk of fuel spillage

and fire from an improperly tightened

fuel cap, correctly position and tighten

the fuel cap in the fuel tank opening.

Different models may be equipped with

different fuel caps.

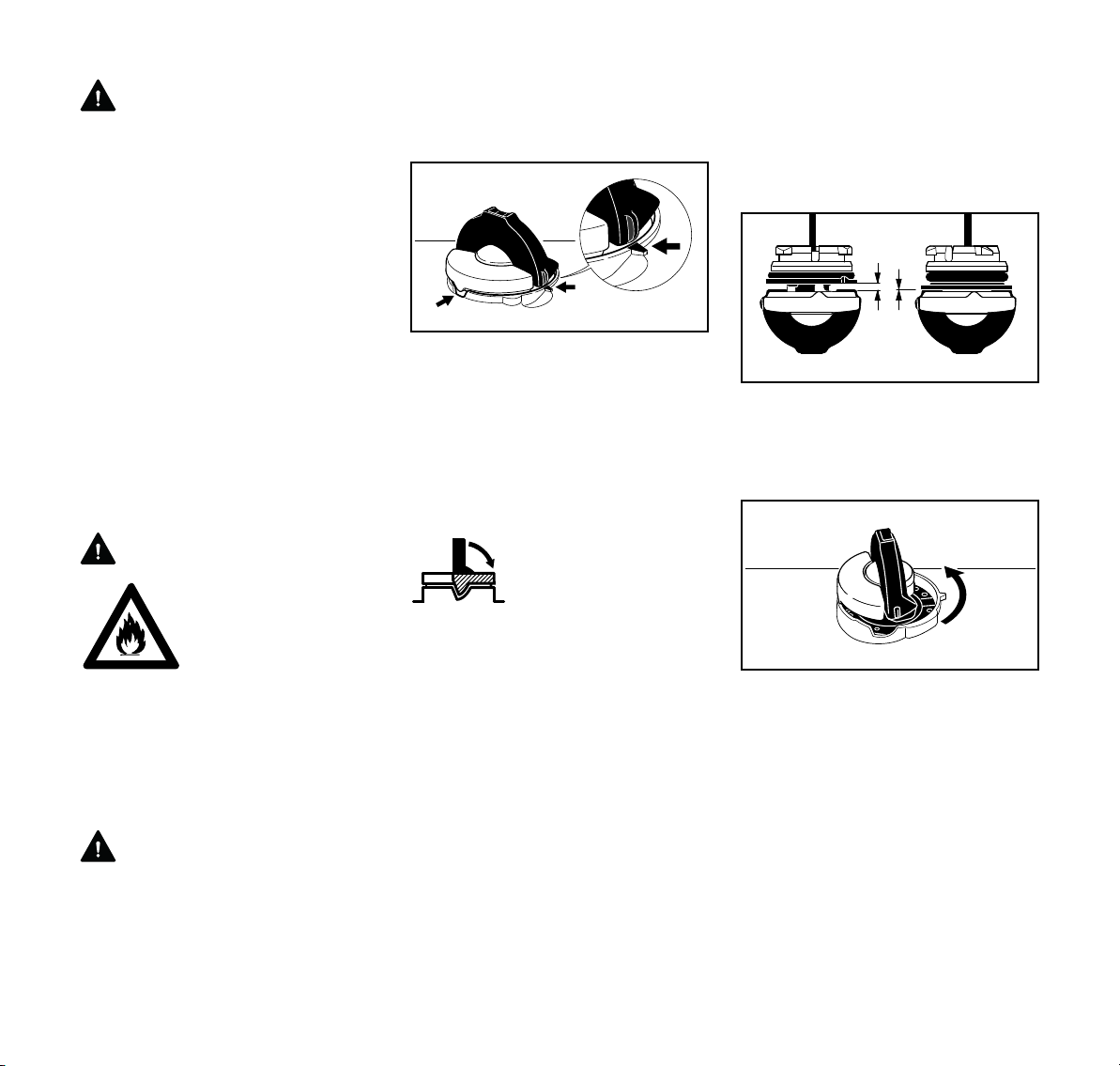

Toolless cap with grip

To do this with this STIHL cap, raise the

grip on the top of the cap until it is upright

at a 90° angle. Insert the cap in the fuel

tank opening with the raised positioning

marks on the grip of the cap and on the

fuel tank opening lining up. Using the

grip, press the cap down firmly while

turning it clockwise as far as it will go

(approx. 1/4 turn).

Fold the grip flush with

the top of the cap. Grip

the cap and check for

tightness. If the grip does

not lie completely flush

with the cap and the

detent on the grip does

not fit in the correspond

-

ing recess in the filler

opening, or if the cap is

loose in the filler opening,

the cap is not properly

seated and tightened and

you must repeat the

above steps.

Misaligned, damaged or broken cap

N If the cap does not drop fully into the

opening when the positioning marks

line up and/or if the cap does not

tighten properly when twisted, the

base of the cap may be prematurely

rotated (vis-à-vis the top) to the

closed position. Such misalignment

can result from handling, cleaning

or an improper attempt at

tightening.

Left: Base of cap in closed posi

tion (with open space)

Right: Base of cap correctly posi

tioned for installation

N To return the cap to the open

position for installation, turn the cap

(with the grip up) until it drops fully

into the tank opening. Next, twist the

cap counterclockwise as far as it will

go (approx. 1/4 turn) – this will twist

-

-

6

HL 100, HL 100 K

Page 9

English

the base of the cap into the correct

position. Then, twist the cap

clockwise, closing it normally.

N If your cap still does not tighten

properly, it may be damaged or

broken; immediately stop use of the

unit and take it to your authorized

STIHL dealer for repair.

Screw Cap

WARNING

Unit vibrations can cause

an improperly tightened

fuel filler cap to loosen or

come off and spill quanti

ties of fuel. In order to

reduce the risk of fuel

spillage and fire, tighten

the fuel filler cap by hand

as securely as possible.

See also the "Fueling" chapter in your

Instruction Manual for additional

information.

Before Starting

WARNING

Always check your power tool for proper

condition and operation before starting,

particularly the throttle trigger, throttle

trigger lockout, stop switch and cutting

tool. The throttle trigger (if applicable)

must move freely and always spring

back to the idle position. Never attempt

to modify the controls or safety devices.

WARNING

Check fuel system for leaks, especially

the visible parts, e.g., filler cap, hose

connections, manual fuel pump (only for

power tools equipped with a manual fuel

pump). Do not start the engine if there

are leaks or damage – risk of fire! Have

the machine repaired by a servicing

dealer before using it.

WARNING

Never operate your power tool if it is

damaged, improperly adjusted or

maintained, or not completely or

securely assembled.

WARNING

Check that the spark plug boot is

securely mounted on the spark plug – a

-

loose boot may cause arcing that could

ignite combustible fumes and cause a

fire.

Keep the handles clean and dry at all

times; it is particularly important to keep

them free of moisture, pitch, oil, grease

or resin in order for you to maintain a firm

grip and properly control your power

tool.

WARNING

The cutting tool must be properly

tightened and in safe operating

condition. Inspect for loose parts (nuts,

screws, etc.) and for cracked, bent,

warped or damaged blades. Regularly

check the condition and tightness of the

cutter blades – with the engine stopped!

Replace damaged cutter blades before

using the power tool. Always keep

blades sharp.

STIHL recommends that you always

spray the cutter blades with STIHL resin

solvent before starting work – with the

engine stopped! You can obtain this

protective spray from your dealer. Apply

generously.

Adjust carrying harness and hand grip to

suit your size before starting work.

Starting

On machines with an adjustable cutter

bar: Secure the cutter bar in the starting

position as described in the chapter

"Starting/Stopping the Engine." If this

starting position is not the desired

cutting position, you will then need to

carefully adjust the machine to the

desired position once the engine has

returned to idle and the blades are no

longer moving.

On machines with a defined transport

position (cutter bar folded against the

drive tube): Never start the machine in

the transport position, since the blades

are not engaged in that position and you

therefore cannot visually check to see

that they will be stopped at idle when

you start to adjust the cutter bar to the

desired cutting position (where the

blades are engaged).

Start the engine at least 10 feet (3 m)

from the fueling spot, outdoors only.

HL 100, HL 100 K

7

Page 10

English

389BA023 KN

388BA025 KN

388BA026 KN

For specific starting instructions, see the

appropriate section of your manual.

Place the power tool on firm ground or

other solid surface in an open area.

Maintain good balance and secure

footing.

WARNING

To reduce the risk of injury from blade

contact, be absolutely sure that the

cutting tool is clear of you and all other

obstructions and objects, including the

ground, because when the engine starts

at starting-throttle, engine speed will be

fast enough for the clutch to engage and

move the blades on the cutting tool.

Once the engine has started,

immediately blip the throttle trigger,

which should release the starting throttle

and allow the engine to slow down to

idle.

With the engine running only at idle,

attach the power tool to the spring hook

of your harness (see appropriate

chapter of this manual).

WARNING

Your power tool is a one-person

machine. Do not allow other persons in

the general work area, even when

starting.

WARNING

To reduce the risk of injury from loss of

control, do not attempt to "drop start"

your power tool.

WARNING

When you pull the starter grip, do not

wrap the starter rope around your hand.

Do not let the grip snap back, but guide

the starter rope to rewind it properly.

Failure to follow this procedure may

result in injury to your hand or fingers

and may damage the starter

mechanism.

Important Adjustments

WARNING

To reduce the risk of personal injury

from loss of control or contact with the

running cutting tool, do not use your unit

with incorrect idle adjustment. At correct

idle speed, the cutting tool should not

move. For directions on how to adjust

idle speed, see the appropriate section

of your instruction manual.

If you cannot set the correct idle speed,

have your STIHL dealer check your

power tool and make proper

adjustments and repairs.

During Operation

Holding and Controlling the Power Tool

Always hold the unit firmly with both

hands on the handles while you are

working.

Models with loop handle

Right hand on control handle, left hand

on loop handle on drive tube, even if you

are left-handed. Wrap your fingers and

thumbs around the handles.

Models with handle hose

Right hand on control handle, left hand

on handle hose on drive tube, even if

you are left-handed. Wrap your fingers

and thumbs around the handles.

8

HL 100, HL 100 K

Page 11

English

WARNING

Never attempt to operate

your power tool with one

hand. Loss of control of

the power tool resulting in

serious or fatal injury may

result. To reduce the risk

of cut injuries, keep

hands and feet away

from the cutting tool.

Never touch a moving

cutting tool with your

hand or any other part of

your body.

WARNING

Do not overreach. Keep proper footing

and balance at all times. Special care

must be taken in slippery conditions (wet

ground, snow) and in difficult, overgrown

terrain. Watch for hidden obstacles such

as tree stumps, roots and ditches to

avoid stumbling. For better footing, clear

away fallen branches, scrub and

cuttings. Be extremely cautious when

working on slopes or uneven ground.

WARNING

To reduce the risk of injury from loss of

control, never work on a ladder, in a tree

or any other insecure support. Never

hold the machine above shoulder

height.

Working Conditions

Operate and start your power tool only

outdoors in a well ventilated area.

Operate it under good visibility and

daylight conditions only. Work carefully.

WARNING

As soon as the engine is

running, this product gen

erates toxic exhaust

fumes containing chemi

cals, such as unburned

hydrocarbons (including

benzene) and carbon

monoxide, that are

known to cause respira

tory problems, cancer,

birth defects, or other

reproductive harm. Some

of the gases (e.g. carbon

monoxide) may be color

less and odorless. To

reduce the risk of serious

or fatal injury/illness from

inhaling toxic fumes,

never run the machine

indoors or in poorly venti

lated locations.

WARNING

If the vegetation being cut or the

surrounding ground is coated with a

chemical substance (such as an active

pesticide or herbicide), read and follow

the instructions and warnings that

accompanied the substance at issue.

WARNING

Inhalation of certain dusts, especially

organic dusts such as mold or pollen,

can cause susceptible persons to have

an allergic or asthmatic reaction.

Substantial or repeated inhalation of

dust and other airborne contaminants, in

particular those with a smaller particle

size, may cause respiratory or other

illnesses. Control dust at the source

-

-

where possible. Use good work

practices, such as operating the unit so

that the wind or operating process

directs any dust raised by the power tool

-

away from the operator. Follow the

recommendations of

EPA/OSHA/NIOSH and occupational

and trade associations with respect to

dust ("particulate matter"). When the

inhalation of dust cannot be

substantially controlled, i.e., kept at or

near the ambient (background) level, the

operator and any bystanders should

wear a respirator approved by

NIOSH/MSHA for the type of dust

encountered.

-

Operating Instructions

WARNING

Do not operate your power tool using the

-

starting throttle lock, as you do not have

control of the engine speed.

In the event of an emergency, switch off

the engine immediately – move the slide

control / stop switch to 0 or STOP.

WARNING

The cutter blades continue to move for a

short period after the throttle trigger is

released (flywheel effect).

Accelerating the engine while the blades

are blocked increases the load and will

cause the clutch to slip continuously.

This may result in overheating and

damage to important components (e.g.

clutch, polymer housing components) –

which can then increase the risk of injury

from the blades moving while the engine

is idling.

HL 100, HL 100 K

9

Page 12

English

15m (50ft)

WARNING

On units with an adjustable cutter bar:

To reduce the risk of injury, never touch

the blades while making adjustments.

The power tool

has a large range.

In order to reduce

the risk of personal

or even fatal injury

to bystanders from

falling objects or inadvertent contact with

the moving cutter blades of your power

tool always keep bystanders at least

50 feet (15 m) away when the power tool

is running.

Stop the engine and cutting tool

immediately if you are approached.

WARNING

Before you start work, examine the

hedge area for stones, fence wire, metal

or other solid objects which could

damage the cutter blades.

Take particular care when cutting

hedges next to or against wire fences.

Do not touch the wire with the cutting

blades. When working close to the

ground, make sure that no sand, grit or

stones get between the cutter blades.

Striking solid foreign objects such as

stones, fence wire or metal could

damage the cutting attachment and may

cause blades to crack, chip or break.

STIHL does not recommend the use of

your power tool when cutting in areas

where the blades could contact such

objects.

WARNING

Observe the cutting blades at all times –

do not cut any areas of the hedge that

you cannot see. When cutting the top of

a taller hedge, check the other side of

the hedge frequently for bystanders,

animals and obstructions.

DANGER

Your power tool is not

insulated against electric

shock. To reduce the risk

of electrocution, never

operate this power tool in

the vicinity of any wires or

cables (power, etc.)

which may be carrying

electric current.

WARNING

If the cutting tool becomes clogged or

stuck, always turn off the engine and

make sure the cutting tool has stopped

before cleaning. Grass, weeds, etc.

should be cleaned off the cutting tool at

regular intervals.

Check the cutting blades at regular short

intervals during operation, or

immediately if there is a noticeable

change in cutting behavior:

– Shut off the engine.

– Wait until the cutting blades have

come to a complete standstill.

– Check condition and tightness, look

for cracks.

– Check sharpness.

– Replace damaged or dull cutting

tools immediately, even if they have

only superficial cracks.

WARNING

The gearbox becomes

hot during operation. To

reduce the risk of burn

injury, do not touch the

gear housing when it is

hot.

WARNING

Never modify your muffler. Any

modification could cause an increase in

heat radiation, sparks or sound level,

thereby increasing the risk of fire, burn

injury or hearing loss. You may also

permanently damage the engine. Have

your muffler serviced and repaired by

your STIHL servicing dealer only.

WARNING

The muffler and other parts of the engine

(e.g. fins of the cylinder, spark plug)

become hot during operation and remain

hot for a while after stopping the engine.

To reduce risk of burns, do not touch the

muffler and other parts while they are

hot. Keep the area around the muffler

clean. Remove excess lubricant and all

debris such as pine needles, branches

or leaves. Let the engine cool down

sitting on concrete, metal, bare ground

or solid wood (e.g. the trunk of a felled

tree) away from any combustible

substances.

10

HL 100, HL 100 K

Page 13

English

WARNING

An improperly mounted or damaged

cylinder housing or a

damaged/deformed muffler shell may

interfere with the cooling process of the

muffler. To reduce the risk of fire or burn

injury, do not continue work with a

damaged or improperly mounted

cylinder housing or a

damaged/deformed muffler shell.

Your muffler is furnished with a spark

arresting screen designed to reduce the

risk of fire from the emission of hot

particles. Never operate your unit with a

missing or damaged spark arresting

screen. If your gas/oil mix ratio is correct

(i.e., not too rich), this screen will

normally stay clean as a result of the

heat from the muffler and need no

service or maintenance. If you

experience loss of performance and you

suspect a clogged screen, have your

muffler maintained by a STIHL servicing

dealer. Some state or federal laws or

regulations may require a properly

maintained spark arrestor for certain

uses. See the "Maintenance, Repair and

Storing" section of these Safety

Precautions. Remember that the risk of

a brush or forest fire is greater in hot or

dry conditions.

WARNING

Some STIHL power tools

are equipped with a cata

lytic converter, which is

designed to reduce the

exhaust emissions of the

engine by a chemical

process in the muffler.

Due to this process, the

muffler does not cool

down as rapidly as con

-

ventional mufflers when

the engine returns to idle

or is shut off. To reduce

the risk of fire and burn

injuries when using a cat

alytic converter, always

set your power tool down

in the upright position and

never locate it where the

muffler is near dry brush,

grass, wood chips or

other combustible materi

als while it is still hot.

After Finishing Work

Always clean dust and dirt off the

machine – do not use any grease

solvents for this purpose.

Spray the blades with STIHL resin

solvent. Start and run the engine briefly

so that the solvent is evenly distributed.

MAINTENANCE, REPAIR AND

STORING

Maintenance, replacement, or repair of

the emission control devices and

systems may be performed by any

nonroad engine repair establishment or

individual. However, if you make a

warranty claim for a component which

has not been serviced or maintained

properly or if nonapproved replacement

-

parts were used, STIHL may deny

coverage.

WARNING

Use only identical STIHL replacement

parts for maintenance and repair. Use of

non-STIHL parts may cause serious or

fatal injury.

Strictly follow the maintenance and

repair instructions in the appropriate

section of your instruction manual.

Please also refer to the maintenance

-

chart in this manual.

WARNING

Always stop the engine and make sure

that the cutting blades are stopped

before doing any maintenance or repair

-

work or cleaning the power tool. Do not

attempt any maintenance or repair work

not described in your instruction manual.

Have such work performed by your

STIHL servicing dealer only.

Wear gloves when handling or

performing maintenance on blades.

WARNING

Use the specified spark plug and make

sure it and the ignition lead are always

clean and in good condition. Always

press spark plug boot snugly onto spark

plug terminal of the proper size. (Note: If

terminal has detachable SAE adapter

nut, it must be securely attached.) A

loose connection between spark plug

terminal and the ignition wire connector

HL 100, HL 100 K

11

Page 14

English

in the boot may create arcing that could

ignite combustible fumes and cause a

fire.

WARNING

Never test the ignition system with the

ignition wire boot removed from the

spark plug or with a removed spark plug,

since uncontained sparking may cause

a fire.

WARNING

Do not operate your power tool if the

muffler is damaged, missing or modified.

An improperly maintained muffler will

increase the risk of fire and hearing loss.

Your muffler is equipped with a sparkarresting screen to reduce the risk of

fire; never operate your power tool if the

screen is missing, damaged or clogged.

Remember that the risk of a brush or

forest fire is greater in hot or dry

weather.

In California, it is a violation of § 4442 or

§ 4443 of the Public Resources Code to

use or operate gasoline-powered tools

on forest-covered, brush-covered or

grass-covered land unless the engine’s

exhaust system is equipped with a

complying spark arrester that is

maintained in effective working order.

The owner/operator of this product is

responsible for properly maintaining the

spark arrester. Other states or

governmental entities/agencies, such as

the U.S. Forest Service, may have

similar requirements. Contact your local

fire agency or forest service for the laws

or regulations relating to fire protection

requirements.

WARNING

Never repair damaged cutting attachments by welding, straightening or

modifying the shape. This may cause

parts of the cutting blades to come off

and result in serious or fatal injuries.

Keep the cutting blades sharp. Tighten

all nuts, bolts and screws, except the

carburetor adjustment screws, after

each use.

Do not clean your machine with a

pressure washer. The solid jet of water

may damage parts of the machine.

Store the power tool in a dry and high or

locked location out of reach of children.

Before storing for longer than a few

days, always empty the fuel tank. See

chapter "Storing the machine" in this

manual.

Using the Unit

Cutting Season

Observe country-specific or municipal

rules and regulations for cutting hedges.

Do not use your hedge trimmer during

rest periods customary in the

neighborhood.

Cutting Sequence

If a radical cut is necessary, cut a little at

a time in several stages.

Use lopping shears to cut out thick

branches first.

Cut the sides of the hedge first, then the

top.

Disposal

Do not throw cuttings into the garbage

can – they can be composted.

12

HL 100, HL 100 K

Page 15

English

388BA029 KN

388BA030 KN

389BA050 KN

Working Technique

Horizontal Cut (with cutter bar at an

angle)

Cutting close to the ground from a

standing position, e.g. low shrubs.

Vertical Cut (with cutter bar at an angle)

Cutting without standing directly next to

the hedge, e.g. flowerbed between

operator and hedge.

Swing the cutter bar up and down in an

arc as you move along the hedge – use

both sides of the cutting blades.

Vertical Cut (with straight cutter bar)

Extra long reach without the need for

other aids.

Swing the cutter bar up and down in an

arc as you move along the hedge – use

both sides of the cutting blades.

WARNING

The K version (HL 100 K) is not

approved for cutting close to the ground.

HL 100, HL 100 K

13

Page 16

English

388BA031 KN

388BA033 KN

228BA047 KN

BF

FH

FCS

KB

KW

HT

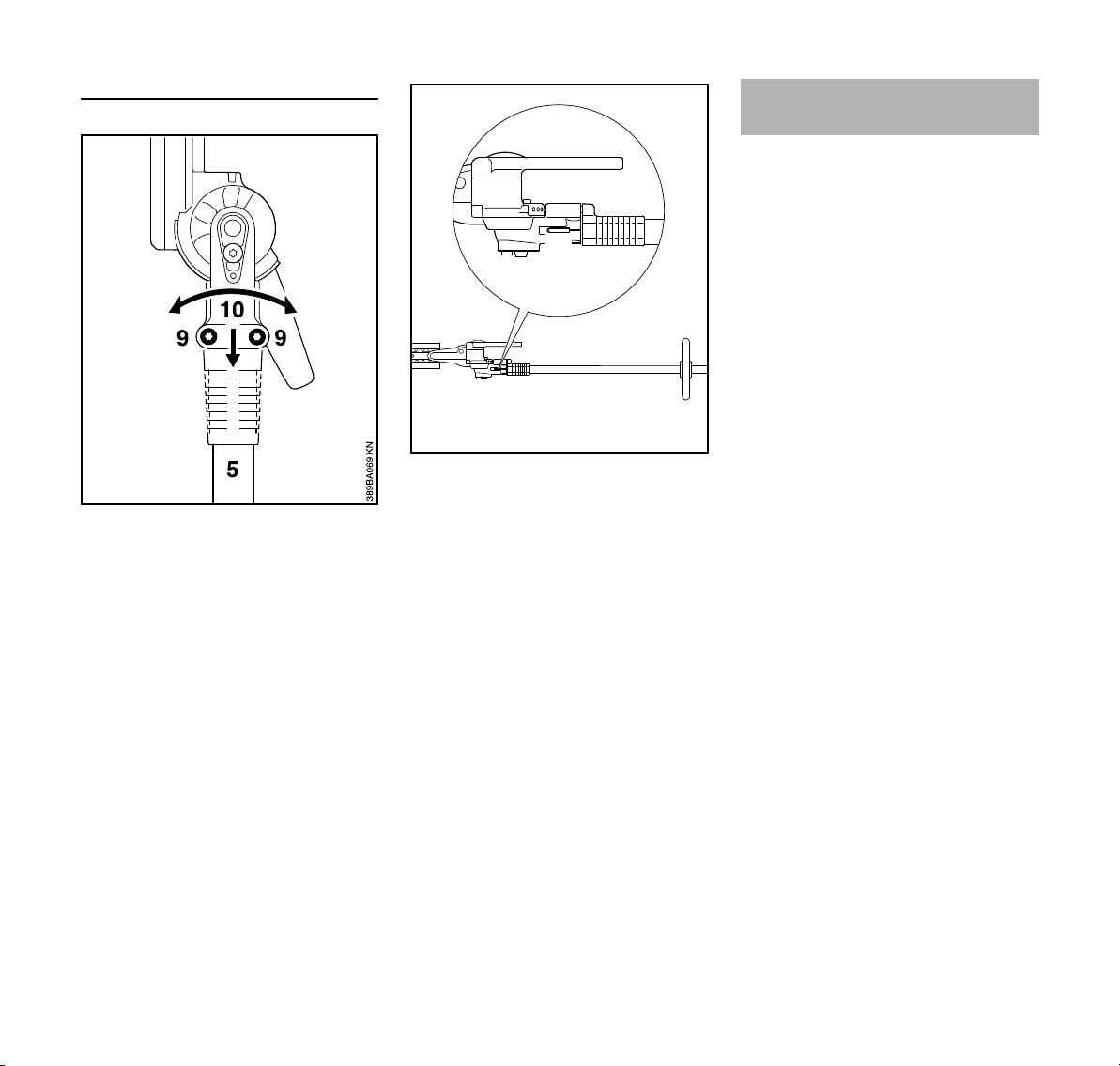

Overhead Cut (with cutter bar at an

angle)

Hold the hedge trimmer vertically and

swing it in an arc to make maximum use

of its reach.

WARNING

Any working position above head height

is tiring. To minimize the risk of

accidents, work in such positions for

short periods only. Set angle of

adjustable cutter bar to maximum so that

the unit can be held in a lower, less tiring

position (with shoulder strap) while still

providing adequate reach.

Horizontal Cut (with straight cutter bar)

Cutting without standing directly next to

the hedge, e.g. flowerbed between

operator and hedge.

Hold the cutter bar at an angle of 0° to

10° as you swing the hedge trimmer

horizontally.

Swing the cutter bar in an arc towards

the outside of the hedge so that the

cuttings are swept to the ground.

Approved Power Tool

Attachments

The following STIHL attachments may

be mounted to the basic power tool:

14

HL 100, HL 100 K

Page 17

English

7

8

2

388BA034 KN

1

6

7

8

9

9

3

388BA035 KN

2

A

Attachment

1) 2)

FCS

1) 2)

FH

HL 0° Long reach hedge

HL 135°

HT

BF

KB (4601)

KW (4601)

1)

2)

3)

3)

1)

1) 2)

1) 2)

may not be mounted to versions

with a short drive tube (HL 95 K,

HL 100 K)

loop handle necessary on versions

with a long drive tube (HL 95,

HL 100)

loop handle is necessary

Application

Edger

Power scythe

trimmer

Long reach hedge

trimmer

Pole pruners

Pick tines

Bristle brush

1) 2)

PowerSweep

Assembling the Unit

Mounting the Loop Handle

Necessary on versions with long drive

tube and 135° adjustable cutter bar (not

on HL 100 K).

N Align the loop handle (2) and move

it to the most comfortable position.

Distance (A) must not be more than

21.6 in (55 cm) (recommended:

about 13.8 in (35 cm)).

N Tighten down the screws firmly.

HL 100, HL 100 K

N Place the clamp (1) in the loop

handle (2) and position them both

against the drive tube (5) between

the carrying ring (3) and handle

hose (4).

N Place the clamp (6) against the

drive tube.

N Line up the holes.

N Insert the screws (7) with

washers (8).

N Fit the square nuts (9) and screw

home the screws.

15

Page 18

English

10

388BA036 KN

11

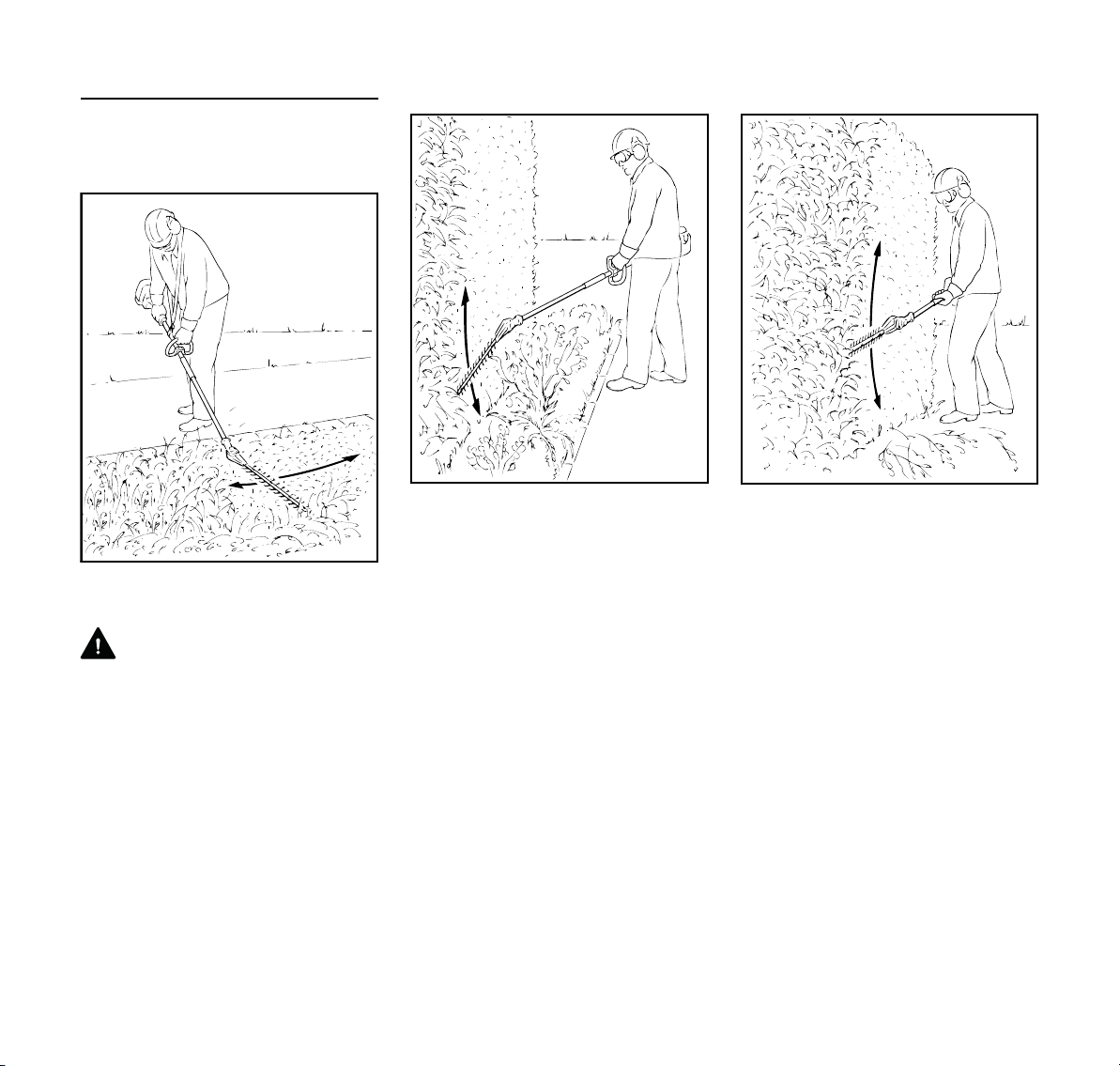

Mounting the Gearbox

N Loosen the clamp screws (9).

N Push the gearbox (10) onto the

drive tube (5), turn the gearbox (10)

back and forth as necessary.

4-MIX Engine

The STIHL 4-MIX engine features

mixture lubrication and must be run on a

fuel mixture of gasoline and engine oil.

It operates otherwise on the 4-stroke

principle.

Once the end of the drive tube is

inserted beyond the slot in the

clamp (11):

N Push the gearbox (10) fully home as

far as stop.

N Tighten down the clamp screws

moderately.

N Line up the gearbox (10).

N Tighten down the clamp screws

firmly.

16

HL 100, HL 100 K

Page 19

English

Fuel

This engine is certified to operate on

unleaded gasoline and the STIHL twostroke engine oil at a mix ratio of 50:1.

Your engine requires a mixture of highquality gasoline and two-stroke air

cooled engine oil.

Use mid-grade unleaded gasoline with a

minimum octane rating of 89 ((R+M)/2)

and no more than 10% ethanol content.

Fuel with a lower octane rating may

increase engine temperatures. This, in

turn, increases the risk of piston seizure

and damage to the engine.

The chemical composition of the fuel is

also important. Some fuel additives not

only detrimentally affect elastomers

(carburetor diaphragms, oil seals, fuel

lines, etc.), but magnesium castings and

catalytic converters as well. This could

cause running problems or even

damage the engine. For this reason

STIHL recommends that you use only

high-quality unleaded gasoline!

Gasoline with an ethanol content of

more than 10% can cause running

problems and major damage in engines

and should not be used.

The ethanol content in gasoline affects

engine running speed – it may be

necessary to readjust the carburetor if

you use fuels with various ethanol

contents.

WARNING

To reduce the risk of personal injury

from loss of control and / or contact with

the running cutting tool, do not use your

unit with incorrect idle adjustment. At

correct idle speed, the cutting tool

should not move.

If your power tool shows an incorrect idle

adjustment, have your STIHL dealer

check your power tool and make proper

adjustments and repairs.

The idle speed and maximum speed of

the engine change if you switch from a

fuel with a certain ethanol content to

another fuel with a much higher or lower

ethanol content.

This problem can be avoided by always

using fuel with the same ethanol

content.

Use STIHL HP Ultra oil or ask your

dealer for an equivalent high quality oil

to ensure the maximum performance of

the product for the full lifetime.

To meet the requirements of EPA

40CFR90/1054 we recommend to use

STIHL HP Ultra oil.

Do not use BIA or TCW rated (twostroke water cooled) mix oils or other

mix oils that state they are for use in both

water cooled and air cooled engines

(e.g., outboard motors, snowmobiles,

chain saws, mopeds, etc.).

Take care when handling gasoline.

Avoid direct contact with the skin and

avoid inhaling fuel vapor. When filling at

the pump, first remove the container

from your vehicle and place the

container on the ground before filling. To

reduce the risk of sparks from static

discharge and resulting fire and/or

explosion, do not fill fuel containers that

are sitting in or on a vehicle or trailer.

The container should be kept tightly

closed in order to limit the amount of

moisture that gets into the mixture.

The machine’s fuel tank should be

cleaned as necessary.

Fuel mix ages

Only mix sufficient fuel for a few days

work, not to exceed 30 days of storage.

Store in approved fuel-containers only.

When mixing, pour oil into the container

first, and then add gasoline. Close the

container and shake it vigorously by

hand to ensure proper mixing of the oil

with the fuel.

Gasoline Oil (STIHL 50:1 or equiva

lent high-quality oils)

Liters Liters (ml)

1 0.02 (20)

5 0.10 (100)

10 0.20 (200)

20 0.40 (400)

US gal. US fl.oz.

12.6

2 1/2 6.4

512.8

Dispose of empty mixing-oil containers

only at authorized disposal locations.

-

HL 100, HL 100 K

17

Page 20

English

002BA420 KN

002BA418 KN

002BA419 KN

249BA053 KN

249BA054 KN

249BA055 KN

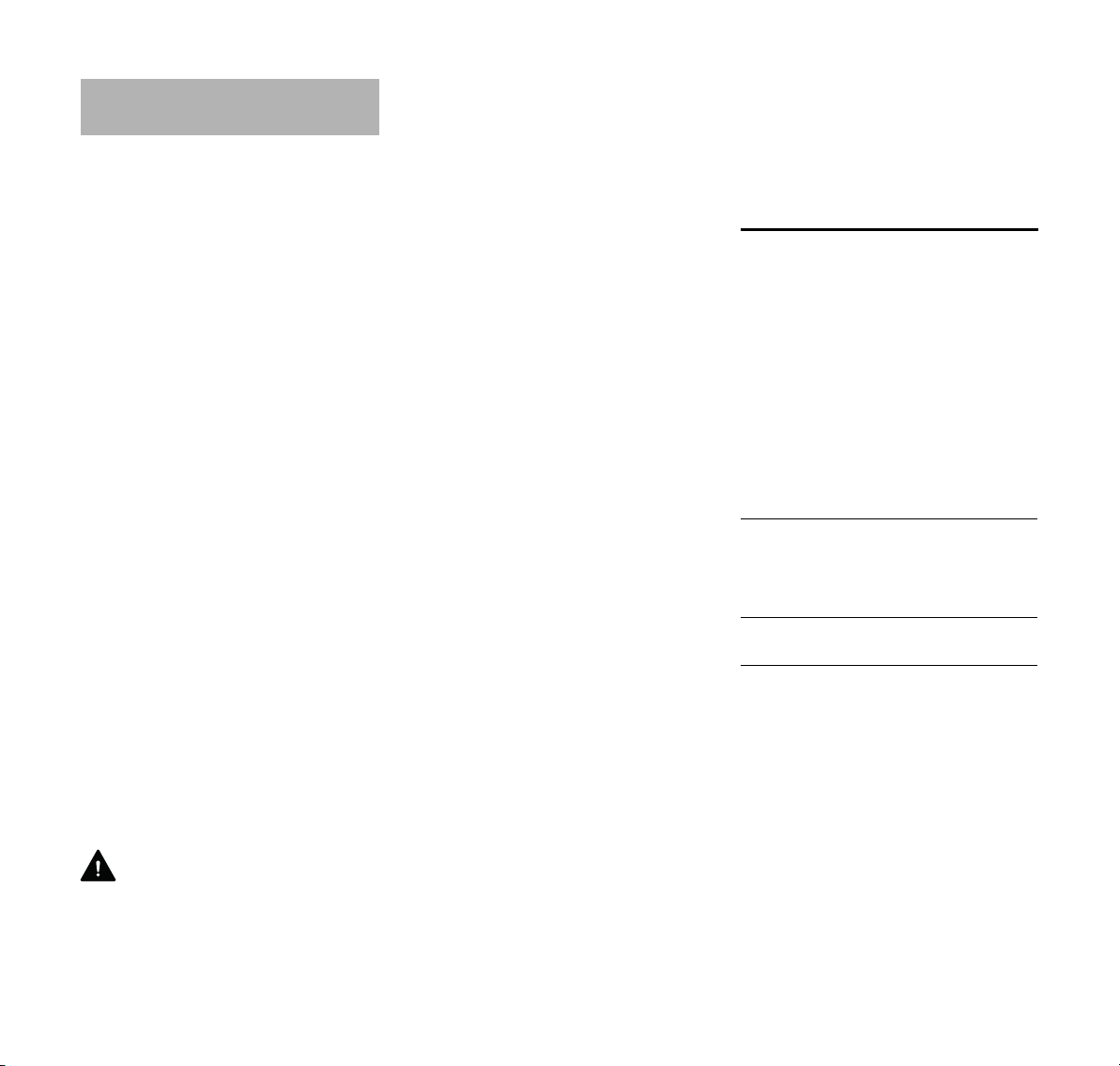

Fueling

Preparations

N Before fueling, clean the filler cap

and the area around it to ensure that

no dirt falls into the tank.

Always thoroughly shake the mixture in

the canister before fueling your

machine.

N Position the machine so that the

filler cap is facing up.

WARNING

In order to reduce the risk of fire and

personal injury from escaping gas vapor

and fumes, remove the fuel filler cap

carefully so as to allow any pressure

build-up in the tank to release slowly.

One of two different filler caps is

installed as standard at the factory.

Toolless filler cap (with folding grip)

Threaded filler cap

Opening the toolless filler cap

N Swing the grip into an upright

position.

N Turn the cap counterclockwise

(approx. 1/4 turn).

N Remove the filler cap.

Refueling

Take care not to spill fuel while fueling,

and do not overfill the tank.

Closing the toolless filler cap

N Position the cap with the grip in an

upright position; the raised

positioning marks must line up.

N Turn cap clockwise as far as it will

go (approx. 1/4 turn).

18

HL 100, HL 100 K

Page 21

English

249BA056 KN

002BA447 KN

002BA448 KN

N Fold the grip down so that it is flush

with the surface.

If the grip is not flush with the surface

and the lug on the clip does not engage

entirely in the recess (arrow), the cap is

not properly closed and the steps

described above must be repeated. See

also the "Toolless cap with grip" section

in the Safety Precautions.

Opening the threaded filler cap

N Turn the cap counterclockwise until

it can be removed from the tank

opening.

N Remove the filler cap.

Refueling

Take care not to spill fuel while fueling

and do not overfill the tank.

Closing the threaded filler cap

N Position cap.

N Turn the cap clockwise as far as it

will go and tighten it as securely as

possible by hand.

Adjusting the Cutter Bar

135° Version

The angle of th cutter bar can be

adjusted upwards in 4 stages from 0°

(straight) to 45°, and downwards in 8

stages from 0° to 90° (right angle facing

down). There are therefore 13 possible

working positions.

There is also a special transport position

for the cutter bar.

WARNING

To reduce the risk of injury, carry out the

adjustment only when the cutting blades

are at a standstill – engine at idle speed.

HL 100, HL 100 K

19

Page 22

English

WARNING

The gearbox becomes hot during

operation. To reduce the risk of burn

injury, do not touch the gear housing.

WARNING

To reduce the risk of injury, never touch

the blades while making adjustments.

N Pull back the sliding sleeve (1) and

use the lever (2) to adjust the joint

by one or several holes.

N Release the sliding sleeve (1) and

make sure the lock pin engages the

quadrant (3).

The sliding sleeve butts against the

housing when the pin is properly

engaged (after making adjustment).

Transport Position

The cutter bar can be folded flat against

the drive tube and locked in position to

save space during transportation.

WARNING

To reduce the risk of injury, always shut

off the engine – move slide control to

STOP or stop switch to 0 – and fit the

blade scabbard before moving the cutter

bar to the transport position or from the

transport position to the normal working

position.

WARNING

The gearbox becomes hot during

operation. To reduce the risk of burn

injury, do not touch the gear housing.

N Shut off the engine.

N Fit the blade scabbard.

N Pull back the sliding sleeve (1) and

use the lever (2) to swing the joint

upwards – in direction of drive tube

– until the cutter bar is flat against

the drive tube.

N Release the sliding sleeve (1) and

make sure the lock pin engages the

quadrant (3).

The sliding sleeve butts against the

housing when the pin is properly

engaged (after making adjustment).

20

HL 100, HL 100 K

Page 23

English

1

388BA037 KN

3

2

388BA038 KN

3

3

STOP

2

5

6

4

7

002BA181 KN

START

STOP-

1

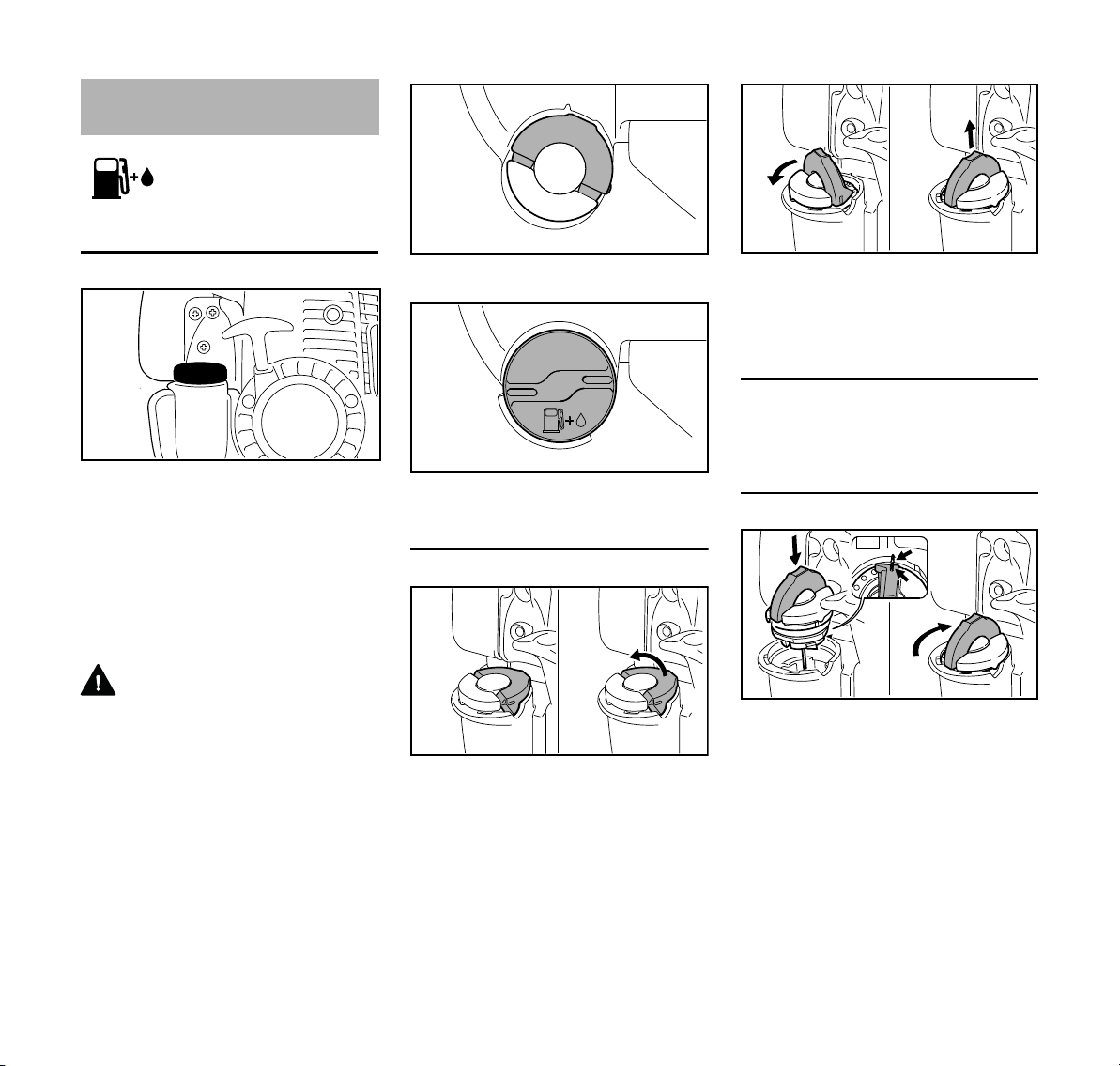

Fitting the Harness

Some versions of the machine can be

carried on a harness.

The type and style of the harness

depend on the market.

Shoulder strap

Full harness

N Put on the full harness (2).

N Adjust the length of the strap.

N With the power tool attached, the

carabiner (3) must be at about the

same height as your right hip.

Starting / Stopping the

Engine

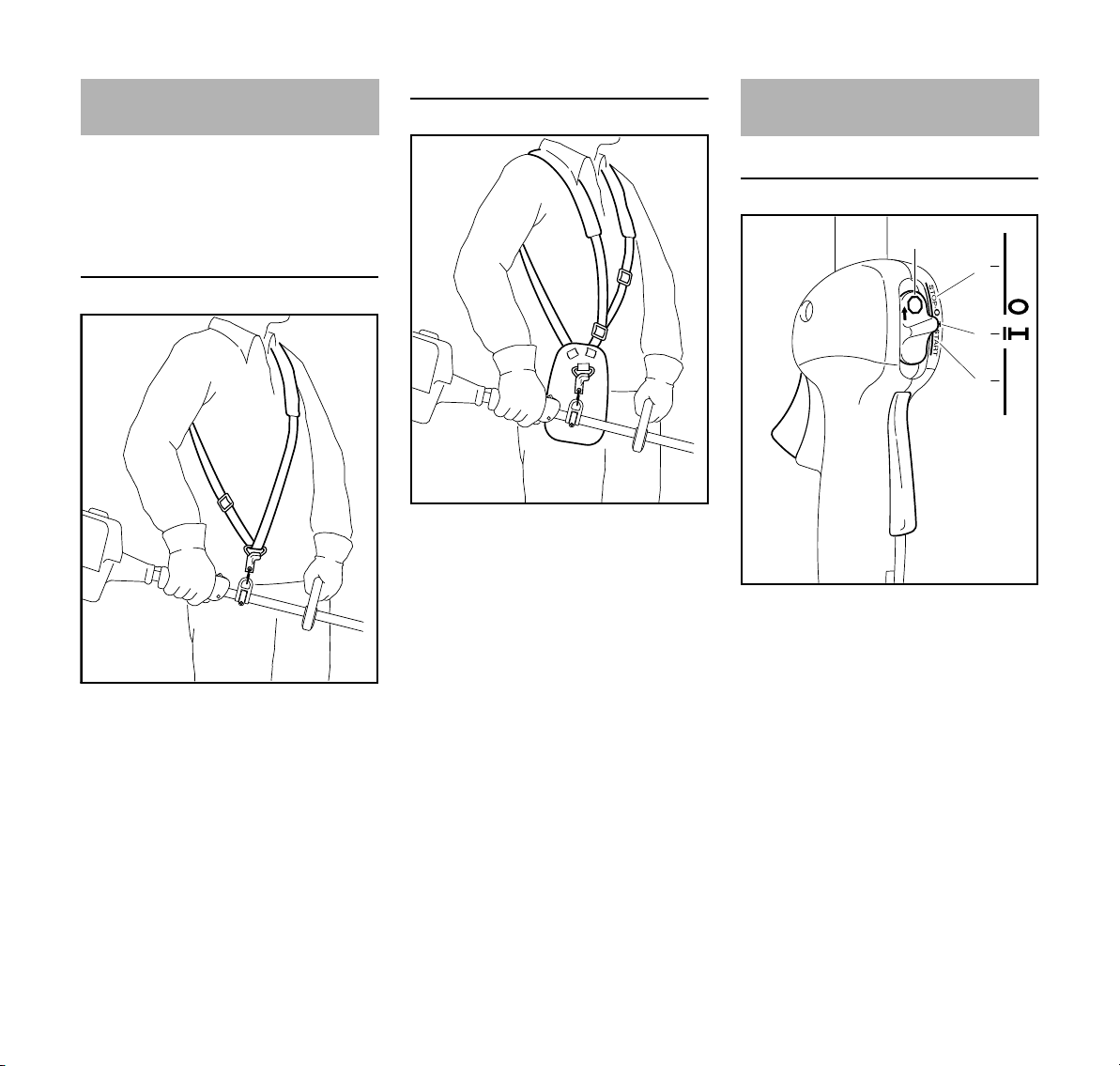

Controls

1 Throttle trigger lockout

2 Throttle trigger

3 Slide control

N Put on the shoulder strap (1).

N Adjust the length of the strap.

N With the power tool attached, the

carabiner (3) must be at about the

same height as your right hip.

HL 100, HL 100 K

Positions of slide control

4STOP-0 – engine off – the ignition is

switched off

5 F – normal run position – the engine

is running or can start

6START – ignition is switched on –

the engine can start

21

Page 24

English

249BA057 KN

9

8

388BA039 KN

Symbol on slide control

7 h – stop symbol and arrow. To stop

the engine, push the slide control in

the direction of the arrow on the stop

symbol (h) to STOP-0.

Starting

N Press down the trigger lockout lever

and squeeze the throttle trigger

N and hold them in that position.

N Move the slide control to START

and hold it there.

N Now release the throttle trigger,

slide control and trigger interlock in

that order. This is the starting

throttle position.

N Set the choke knob (8):

For cold start to g

For warm start to e – also use this

position if the engine has been running

but is still cold.

N Press the manual fuel pump

bulb (9) at least five times – even if

the bulb is already filled with fuel.

N Put the unit on the ground: It must

rest securely on the engine support

and the gearbox.

N On units with an adjustable cutter

bar and defined transport position:

Set the cutter bar to the straight (0°)

position.

N Remove the blade scabbard. Check

that the cutting tool is not touching

the ground or any other obstacles. If

necessary, rest the gearbox on a

raised support (e.g. mound, brick or

something similar).

N Make sure you have a firm footing.

N Hold the unit with your left hand and

press it down firmly – your thumb

should be under the fan housing.

NOTICE

Do not stand or kneel on the drive tube

since it will otherwise be permanently

bent and damaged.

N Pull the starter grip slowly with your

right hand until you feel it engage

and then give it a brisk strong pull.

Do not pull out the starter rope to full

length – it might otherwise break.

N Do not let the starter grip snap back.

Guide it slowly back into the housing

so that the starter rope can rewind

properly.

N Crank the engine until it begins to

fire. After no more than five

attempts, turn the choke knob to e.

N Continue cranking.

N As soon as the engine runs, blip the

throttle trigger so that the slide

control moves to the normal run

position F and the engine settles

down to idle speed.

Make sure the carburetor is correctly

adjusted. The cutting blades must not

move when the engine is idling.

Your machine is now ready for

operation.

At very low outside temperatures

As soon as the engine runs:

N Blip the throttle trigger to disengage

the starting throttle position. The

slide control moves to the normal

run position F – and the engine

settles down to idle speed.

N Open the throttle slightly and warm

up the engine for a brief period.

22

HL 100, HL 100 K

Page 25

English

10

249BA058 KN

Stopping the engine

N Push the slide control in the

direction of the arrow on the stop

symbol (h) to STOP-0.

If engine does not start

Choke knob

If you did not turn the choke knob to e

quickly enough after the engine began to

fire, the combustion chamber is flooded.

N Turn the choke knob to e

N Set the slide control, lockout lever

and throttle trigger to the starting

throttle position and start the engine

by giving the starter rope a brisk

strong pull. 10 to 20 pulls may be

necessary.

If the engine still does not start

N Refit the spark plug. Connect the

spark plug boot (press it down

firmly).

N Move the slide control to START.

N Set the choke knob to e – even if

the engine is cold.

N Now start the engine.

Adjusting the Throttle Cable

N Check adjustment of throttle cable –

see chapter on "Adjusting the

Throttle Cable".

Fuel tank run until completely dry

N After refueling, press the manual

fuel pump bulb at least five times –

even if the bulb is filled with fuel.

N Set the choke knob according to

engine temperature.

N Now start the engine.

Operating Instructions

During break-in period

A factory-new machine should not be

run at high revs (full throttle off load) for

the first three tank fillings. This avoids

unnecessary high loads during the

break-in period. As all moving parts

have to bed in during the break-in

period, the frictional resistances in the

engine are greater during this period.

The engine develops its maximum

power after about 5 to 15 tank fillings.

During Operation

After a long period of full throttle

operation, allow the engine to run for a

short while at idle speed so that engine

heat can be dissipated by the flow of

cooling air. This protects enginemounted components (ignition,

carburetor) from thermal overload.

N Move the slide control to STOP-0.

N Remove the spark plug boot (10).

N Unscrew and dry off the spark plug.

N Open the throttle wide and pull the

starter rope several times to clear

the combustion chamber.

HL 100, HL 100 K

After Finishing Work

Storing for a short period: Wait for the

engine to cool down. Empty the fuel tank

and keep the machine in a dry place,

well away from sources of ignition, until

you need it again. For longer out-ofservice periods – see "Storing the

Machine".

23

Page 26

English

1

273BA006 KN

2

4

Cleaning the Air Filter

If there is a noticeable loss of engine

power

N Turn the choke knob to g

N Take out the screw (1) and remove

the filter cover (2).

N Clean away loose dirt from around

the filter.

N Grip the filter element (3) at the

cutout (arrow) in the filter

housing (4) and remove it.

N Fit a new filter element. As a

temporary measure you can knock it

out on the palm of your hand or blow

it out with compressed air. Do not

wash.

N Replace damaged parts.

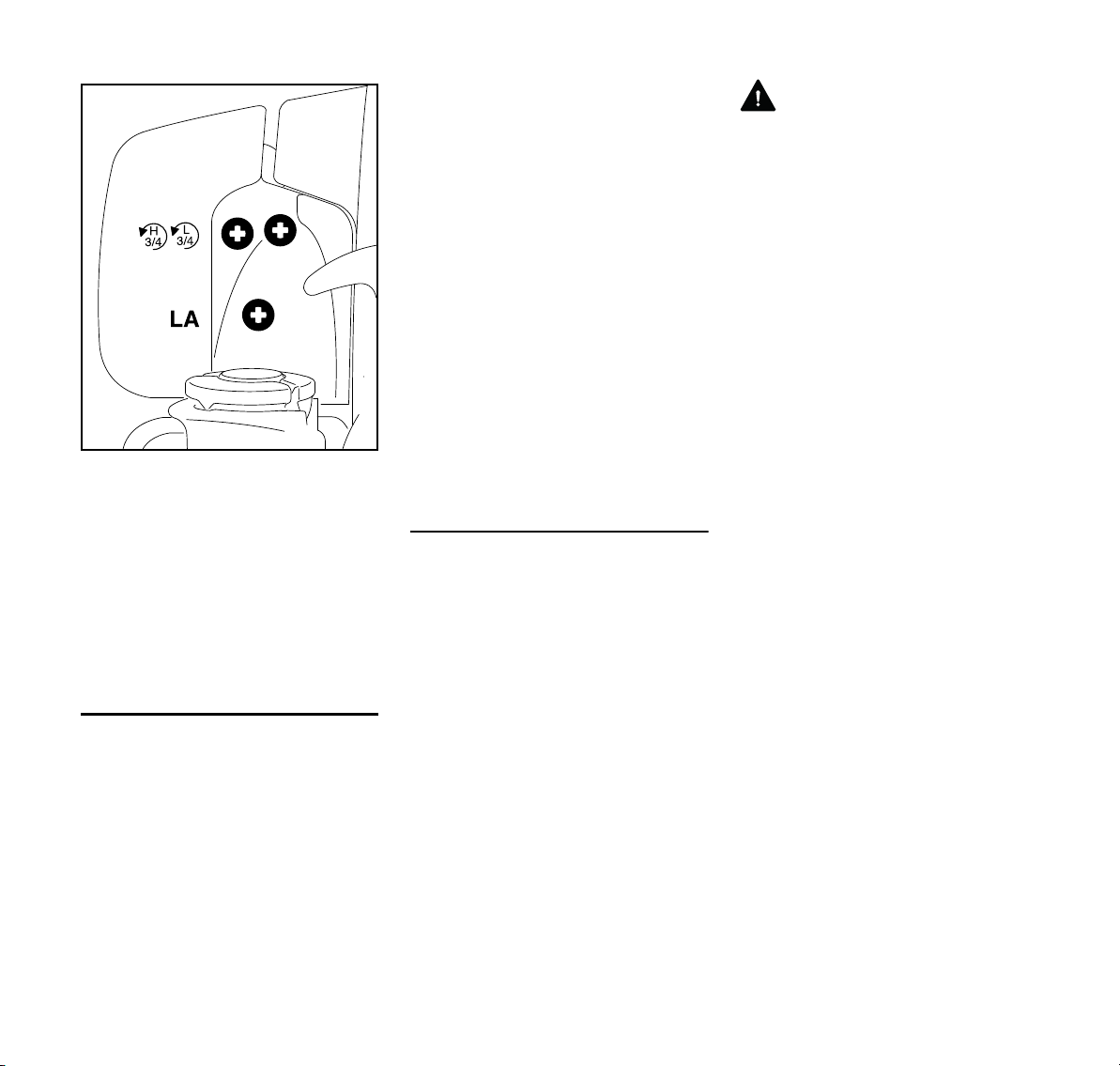

Engine Management Adjusting the Carburetor

Exhaust emissions are controlled by the

design of the fundamental engine

parameters and components (e.g.

carburation, ignition, timing and valve or

port timing) without the addition of any

major hardware.

The carburetor comes from the factory

with a standard setting.

This setting provides an optimum fuel-air

mixture under most operating

conditions.

With this carburetor it is only possible to

adjust the high speed and low speed

screws within fine limits.

Standard Setting

N Shut off the engine

N Inspect the cutting blades and clean

if necessary (they must be clean,

move freely and not be warped).

N Check that the throttle cable is

properly adjusted – readjust if

necessary – see chapter on

"Adjusting the Throttle Cable".

N Check the spark arresting screen

(not in all versions) and clean or

replace as necessary.

N Check the air filter and clean or

replace as necessary.

Installing the filter

N Install the filter element in the filter

housing and fit the cover.

N Insert the screw and tighten it down

firmly.

24

HL 100, HL 100 K

Page 27

English

249BA051 KN

N Carefully turn both adjusting screws

counterclockwise as far as stop.

High speed screw (H) is open a 3/4 turn,

and the low speed screw (L) is open a

3/4 turn.

N Start and warm up the engine.

N Adjust idle speed with the idle speed

screw (LA) so that the cutting

blades do not run.

Fine Tuning

A slight correction of the setting of the

high speed screw (H) may be necessary

if engine power is not satisfactory when

operating at high altitude or at sea level.

N Turn the high speed screw (H)

about one quarter of a turn for every

3300 ft (1000 m) change in altitude.

N Carry out the standard setting

without disturbing the high speed

screw (H).

N Warm up the engine for about 3

minutes.

N Open the throttle wide.

At high altitude

N Turn the high speed screw (H)

clockwise (leaner), no further than

stop, until there is no noticeable

increase in engine speed.

At sea level

N Turn the high speed screw (H)

counterclockwise (richer), no further

than stop, until there is no further

noticeable increase in engine

speed.

It is possible that maximum engine

speed may be reached with the standard

setting in each case.

Adjusting Idle Speed

It is usually necessary to change the

setting of the idle speed screw (LA) after

every correction to the low speed

screw (L).

N Warm up the engine for about 3

minutes.

Engine stops while idling

N Turn the idle speed screw (LA)

slowly clockwise until the engine

runs smoothly – the cutting blades

must not run.

Cutting blades run when engine is idling

N Turn the idle speed screw (LA)

counterclockwise until the cutting

blades stop running and then turn

the screw about another 1/2 to

3/4 turn in the same direction.

WARNING

If the cutting blades continue to run

when the engine is idling, have your

machine checked and repaired by your

servicing dealer.

Erratic idling behavior, engine stops

even though setting of LA-screw has

been corrected, poor acceleration

Idle setting is too lean

N Turn the low speed screw (L)

counterclockwise, no further than

stop, until the engine runs and

accelerates smoothly.

Erratic idling behavior

Idle setting is too rich

N Turn the low speed screw (L)

clockwise, no further than stop, until

the engine runs and accelerates

smoothly.

HL 100, HL 100 K

25

Page 28

English

249BA059 KN

1

2

3

2

249BA060 KN

000BA039 KN

A

Spark Arresting Screen in

Muffler

The muffler is equipped with a spark

arresting screen.

N If the engine is down on power,

check the spark arresting screen in

the muffler.

N Wait for the muffler to cool down.

N Move the slide control to STOP-0.

N Take out the screw (1).

N Take out the screws (2) and remove

the shroud (3).

N Take out the screw (4).

N Lift the spark arresting screen (5)

and pull it out.

N Clean the spark arresting screen. If

the screen is damaged or heavily

carbonized, fit a new one.

N Refit the spark arresting screen.

N Insert screw and tighten it down

firmly.

N Install the shroud.

Checking the Spark Plug

Wrong fuel mix (too much engine oil in

the gasoline), a dirty air filter and

unfavorable running conditions (mostly

at part throttle etc.) affect the condition

of the spark plug. These factors cause

deposits to form on the insulator nose

which may result in trouble in operation.

If engine is down on power, difficult to

start or runs poorly at idling speed, first

check the spark plug.

N Remove spark plug – see "Starting /

Stopping the Engine".

N Clean dirty spark plug.

N Check electrode gap (A) and

readjust if necessary – see

"Specifications".

N Use only resistor type spark plugs of

the approved range.

Rectify problems which have caused

fouling of spark plug:

N Too much oil in fuel mix.

N Dirty air filter.

N Unfavorable running conditions,

e.g. operating at part load.

26

HL 100, HL 100 K

Page 29

English

000BA036 TR

1

Fit a new spark plug after approx. 100

operating hours or earlier if the

electrodes are badly eroded.

WARNING

To reduce the risk of fire and burn injury,

use only spark plugs authorized by

STIHL. Always press spark plug boot (2)

snugly onto spark plug terminal (1) of the

proper size. (Note: If terminal has

detachable SAE adapter nut, it must be

attached.) A loose connection between

spark plug boot and ignition wire

connector in the boot may create arcing

that could ignite combustible fumes and

cause a fire.

Lubricating the Gearbox

Blade Drive Gear

Lubricate the blade drive gear with

STIHL gear lubricant for hedge trimmers

(Special Accessory).

0° version

Adjustable 135° version

N Check the lubricant level at regular

intervals of about every 25 hours of

operation. Unscrew the filler

plug (1) – if no grease can be seen

on the inside of the filler plug, screw

the tube of grease into the filler hole.

N Squeeze up to 5 g (1/5 oz) grease

into the gearbox.

NOTICE

Do not completely fill the gearbox with

grease.

N Refit the filler plug and tighten it

down firmly.

Angle Drive

Lubricate the angle drive with STIHL

gear lubricant for brushcutters (Special

Accessory).

HL 100, HL 100 K

27

Page 30

English

0° version

Adjustable 135° version

N Check the lubricant level at regular

intervals of about every 25 hours of

operation. Unscrew the filler

plug (2) – if no grease can be seen

on the inside of the filler plug, screw

the tube of grease into the filler hole.

N Squeeze up to 5 g (1/5 oz) grease

into the gearbox.

NOTICE

Do not completely fill the gearbox with

grease.

N Refit the filler plug and tighten it

down firmly.

Rewind Starter Sharpening Instructions

To help prolong the wear life of the

starter rope, observe the following

points:

N Pull the starter rope only in the

direction specified.

N Do not pull the rope over the edge of

the guide bushing.

N Do not pull out the rope more than

specified.

N Do not allow the starter grip to snap

back, guide it back into the housing

slowly – see chapter on "Starting /

Stopping the Engine."

Have a damaged starter rope replaced

by your dealer before it breaks

completely. STIHL recommends that

you have servicing and repair work

carried out exclusively by an authorized

STIHL servicing dealer.

When cutting performance and behavior

begin to deteriorate, i.e. blades

frequently snag on branches:

Resharpen the cutting blades.

It is best to have the cutting blades

resharpened by a dealer on a workshop

sharpener. STIHL recommends a STIHL

servicing dealer.

It is also possible to use a flat crosscut

sharpening file. Hold the sharpening file

at the prescribed angle (see

"Specifications").

N Only sharpen the cutting edge – do

not file blunt projecting parts of the

cutting blade or the cutting blade

guard (see "Main Parts and

Controls")

N Always file towards the cutting

edge.

N The file only sharpens on the

forward stroke – lift it off the blade

on the backstroke.

N Use a whetstone to remove burr

from cutting edge.

N Remove as little material as

possible.

N After sharpening, clean away filing

or grinding dust and then spray the

cutting blades with STIHL resin

solvent.

NOTICE

Do not operate your machine with dull or

damaged cutting blades. This may

cause overload and will give

unsatisfactory cutting results.

28

HL 100, HL 100 K

Page 31

Storing the Machine

For periods of 3 months or longer

N Drain and clean the fuel tank in a

well ventilated area.

N Dispose of fuel properly in

accordance with local

environmental requirements.

N Run the engine until the carburetor

is dry – this helps prevent the

carburetor diaphragms sticking

together.

N Clean the cutting blades, check

condition and spray with STIHL

resin solvent.

N Fit the blade scabbard.

N Thoroughly clean the machine – pay

special attention to the cylinder fins

and air filter.

N Store the machine in a dry, high or

locked location. Out of the reach of

children and other unauthorized

persons.

English

HL 100, HL 100 K

29

Page 32

English

Maintenance and Care

The following intervals apply to normal operating conditions only. If your daily work

ing time is longer or operating conditions are difficult (very dusty work area, etc.),

shorten the specified intervals accordingly.

Complete machine

Control handle Check operation XX

Air filter

Manual fuel pump (if fitted)

Pickup body in fuel tank

Fuel tank Clean XX

Carburetor

Spark plug

Cooling inlets

Valve clearance

Combustion chamber

Spark arresting screen in muffler

All accessible screws and nuts (not adjust

ing screws)

1)

1) 2)

Visual inspection (condition, leaks) XX

Clean X

Clean XX

Replace X

Check X

Have repaired by servicing dealer

Have checked by servicing dealer

Have replaced by servicing dealer

Check idle adjustment XX

Adjust idle speed X

Readjust electrode gap X

Replace after every 100 operating hours

Visual inspection X

Clean X

Check and, if necessary, have adjusted

by dealer after first 139 hours of

operation

Decoke after first 139 hours of opera

tion, then every 150 hours of operation

Check XX

Clean or replace XX

-

Retighten X

-

before starting work

after finishing work or daily

after each refueling stop

weekly

monthly

every 12 months

if problem

if damaged

as required

1)

1)

1)

-

XXX

X

X

X

X

30

HL 100, HL 100 K

Page 33

English

The following intervals apply to normal operating conditions only. If your daily work

ing time is longer or operating conditions are difficult (very dusty work area, etc.),

shorten the specified intervals accordingly.

Anti-vibration elements (rubber buffers,

springs)

Check XXX

Have replaced by servicing dealer

-

before starting work

after finishing work or daily

after each refueling stop

weekly

monthly

every 12 months

if problem

1)

Visual inspection XX

Cutting blades

Gearbox lubrication

3)

Clean

Sharpen

3)

X

Check X

Replenish X

Safety labels Replace X

1)

STIHL recommends an authorized STIHL servicing dealer.

2)

CARB licensed engines only

3)

Spray with STIHL resin solvent after cleaning

if damaged

as required

X

XX

HL 100, HL 100 K

31

Page 34

English

24

22

18

19

21

23

18

12

13

14

15

16

#

10

6

7

5

4

3

2

1

8

9

11

17

19

20

388BA040 KN

Main Parts

1 Loop Handle (HL 100)

2 Carrying Ring (HL 100)

3 Slide Control

4 Throttle Trigger Lockout

5 Throttle Trigger

6 Choke Knob

7 Spark Plug Boot

8 Air Filter Cover

9 Fuel Tank

10 Machine Support

11 Handle Hose (HL 100 K)

12 Fuel Filler Cap

13 Carburetor Adjusting Screws

14 Manual Fuel Pump

15 Starter Grip

16 Muffler with Spark Arresting Screen

17 Cutting Blades

18 Blade Drive Gear

19 Angle Drive

20 Drive Tube

21 Sliding Sleeve

22 Adjusting Lever

23 Quadrant

24 Blade Scabbard

# Serial Number

32

HL 100, HL 100 K

Page 35

English

Definitions

1. Loop Handle

For easy control of machine during

cutting work.

2. Carrying Ring

Connects the unit to the harness.

3. Slide Control

For starting throttle, run and stop.

Keeps the choke partially open

during starting and switches off the

ignition to stop the engine.

4. Throttle Trigger Lockout

Must be depressed before the

throttle trigger can be activated.

5. Throttle Trigger

Controls the speed of the engine.

6. Choke Knob

Eases engine starting by enriching

mixture.

7. Spark Plug Boot

Connects the spark plug with the

ignition lead.

8. Air Filter Cover

Covers and protects the air filter

element.

9. Fuel Tank

For fuel and oil mixture.

10. Machine Support

For resting machine on the ground.

11. Handle Hose

For holding and controlling the unit

with the hand during operation.

12. Fuel Filler Cap

For closing the fuel tank.

13. Carburetor Adjusting Screws

For tuning the carburetor.

14. Manual Fuel Pump

Provides additional fuel feed for a

cold start.

15. Starter Grip

The grip of the pull starter, for

starting the engine.

16. Muffler with Spark Arresting Screen

Muffler reduces exhaust noises and

diverts exhaust gases away from

operator. Spark arresting screen is

designed to reduce the risk of fire.

17. Cutting Blades

Steel blades for cutting hedges and

shrubs.

18. Blade Drive Gear

Converts rotary movement of angle

drive into reciprocating movement

of cutting blades.

19. Angle Drive

Transmits rotary movement of drive

shaft to the blade drive gear.

20. Drive Tube

Encloses and protects the drive

shaft between the engine and

gearbox.

21. Sliding Sleeve

Locks and unlocks the cutter bar

adjusting mechanism.

22. Adjusting Lever

Used to set cutter bar to the

required angle.

23. Quadrant

Locks the cutter bar in the required

position.

24. Blade Scabbard

Covers cutting blades when hedge

trimmer is not in use.

HL 100, HL 100 K

33

Page 36

English

Specifications

EPA / CEPA

The Emission Compliance Period

referred to on the Emissions

Compliance Label indicates the number

of operating hours for which the engine

has been shown to meet Federal

emission requirements.

Category

A = 300 hours

B = 125 hours

C = 50 hours

CARB

The Emission Compliance Period used

on the CARB-Air Index Label indicates

the terms:

Extended = 300 hours

Intermediate = 125 hours

Moderate = 50 hours

STIHL single cylinder four-stroke engine

with mixture lubrication

HL 100, HL 100 K

Displacement: 1.92 cu. in

(31.4 cm