Page 1

STIHL GHE 150, GHE 250, GHE 250 S

EN

Instruction manual

GHE 150.0 GHE 250.0 GHE 250.0 S

B

Page 2

0478 201 8313 B. E20 © 2020 STIHL Tirol GmbH

Page 3

1

0478 201 8313 B

1

Page 4

2

0478 201 8313 B

Page 5

Dear Customer,

Thank you for choosing STIHL. We

develop and manufacture our quality

products to meet our customers'

requirements. The products are designed

for reliability even under extreme

conditions.

STIHL also stands for premium service

quality. Our specialist dealers guarantee

competent advice and instruction as well

as comprehensive service support.

We thank you for your confidence in us

and hope you will enjoy working with your

STIHL product.

Dr. Nikolas Stihl

IMPORTANT: READ BEFORE USE AND

KEEP IN A SAFE PLACE.

1. Table of contents

Notes on the instruction manual 4

General 4

Instructions for reading the

instruction manual 4

Machine overview 6

For your safety 7

General 7

Warning – dangers caused by

electrical current 8

Clothing and equipment 8

Transporting the machine 8

Before operation 9

Working with your machine 9

Maintenance and repairs 11

Storage for prolonged periods

without operation 11

Disposal 12

Description of symbols 12

Standard equipment 13

Preparing the machine for

operation 14

Attaching the wheel axle and

wheels 14

Installing the chassis and ejection

chute 15

Opening and closing the discharge

flap 16

Attaching the upper chute 17

Mounting the cable clip 17

Notes on working with the

machine 17

What material can be processed? 17

What material cannot be

processed? 18

Maximum branch diameter 18

Working area for operator 18

Correct machine load 18

Overload protection 18

If the cutting unit of the garden

shredder is blocked 18

Feeding the garden shredder 19

Safety devices 19

Motor restart inhibitor 19

Safety interlock 19

Motor run-down brake 19

Protective covers 19

Operating the machine 19

Electrical connection of garden

shredders 20

Switching on the garden shredder 20

Switching off the garden shredder 20

Shredding 20

Maintenance 21

Cleaning the machine 21

Installing the feed chute 21

Removing the feed chute 21

Locking the blade disc 22

Removing the blade set 22

Installing the blade set 23

Blade maintenance 23

Reversing the blades 24

Electric motor and wheels 25

Storage and winter break 25

Transport 25

Winding up the cable 25

Pulling or pushing the garden

shredder 26

Lifting or carrying the garden

shredder 26

Transporting the garden shredder

on a load floor 26

EN

0478 201 8313 B - EN

Printed on chlorine-free bleached paper. Paper is recyclable. Cover is halogen free.

3

Page 6

Minimising wear and preventing

damage 27

Standard spare parts 27

Environmental protection 27

Technical specifications 28

Troubleshooting 28

Service schedule 29

Handover confirmation 29

Service confirmation 29

2. Notes on the instruction manual

2.1 General

This instruction manual constitutes

original manufacturer’s instructions in

the sense of EC Directive 2006/42/EC.

STIHL is continually striving to further

develop its range of products; we therefore

reserve the right to make alterations to the

form, technical specifications and

equipment level of our standard

equipment.

For this reason, the information and

illustrations in this manual are subject to

alterations.

This instruction manual may describe

models that are not available in all

countries.

This instruction manual is protected by

copyright. All rights reserved, especially

the right of reproduction, translation and

processing using electronic systems.

2.2 Instructions for reading the instruction manual

Illustrations and texts describe specific

operating steps.

All symbols which are affixed to the

machine are explained in this instruction

manual.

Viewing direction:

Viewing direction when left and right are

used in the instruction manual:

the user is standing behind the machine

(working position).

Section reference:

References to relevant sections and

subsections for further descriptions are

made using arrows. The following example

shows a reference to a section: (Ö 3.)

Designation of text passages:

The instructions described can be

identified as in the following examples.

Operating steps which require intervention

on the part of the user:

● Release screw (1) using a screwdriver,

operate lever (2)...

General lists:

– Use of the product for sporting or

competitive events

Texts with added significance:

Text passages with added significance are

identified using the symbols described

below in order to especially emphasise

them in the instruction manual:

Danger

Risk of accident and severe injury

to persons. A certain type of

behaviour is necessary or must be

avoided.

Warning

Risk of injury to persons. A certain

type of behaviour prevents possible

or probable injuries.

Caution

Minor injuries or material damage

can be prevented by a certain type

of behaviour.

Note

Information for better use of the

machine and in order to avoid

possible operating errors.

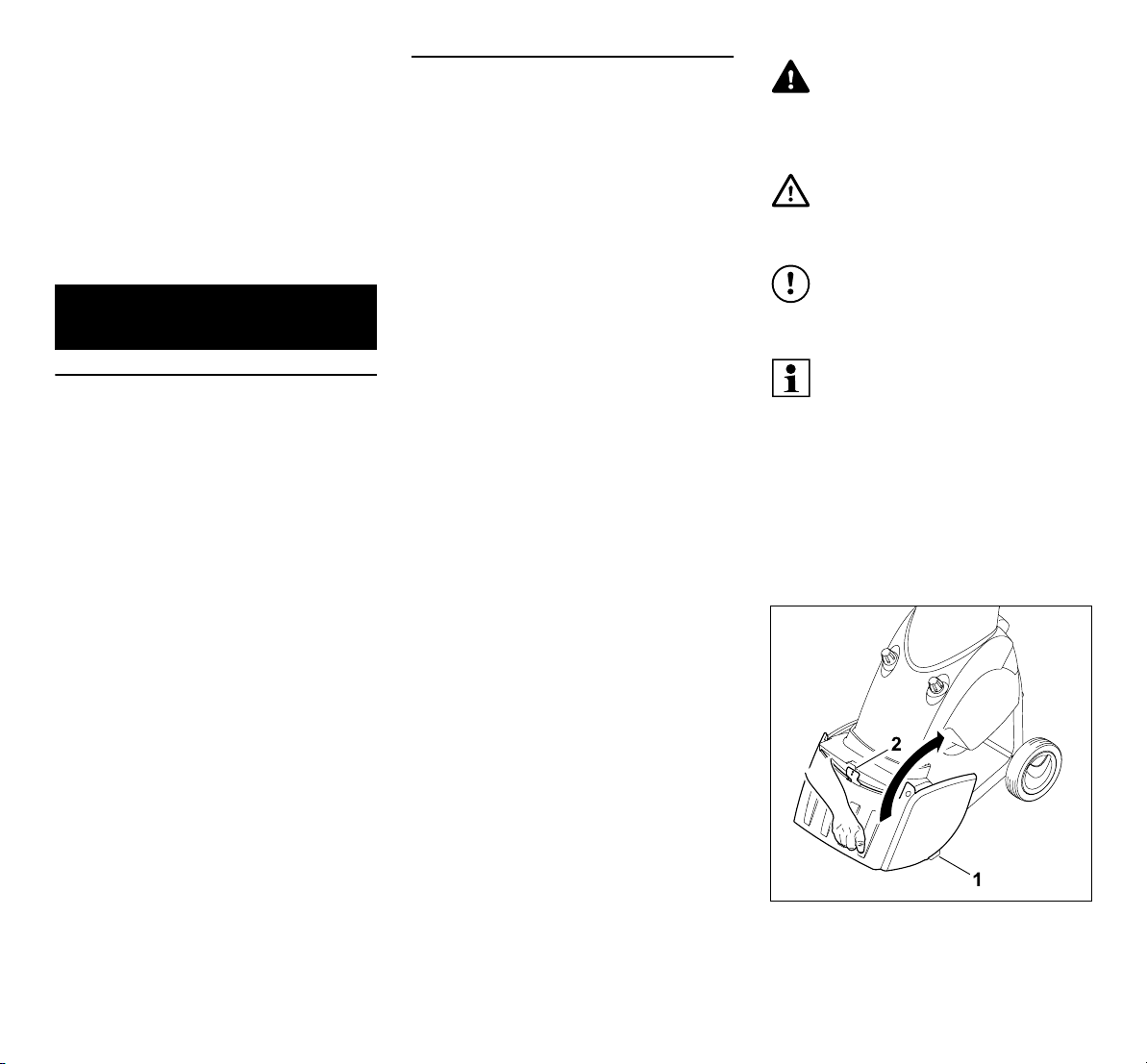

Illustrations with text passages:

Operating steps relating directly to the

illustration can be found immediately after

the illustration, with a corresponding

reference to the item numbers.

Example:

For shredding, fold discharge flap (1)

upwards and allow tab (2) to engage in the

ejection chute extension.

4

0478 201 8313 B - EN

Page 7

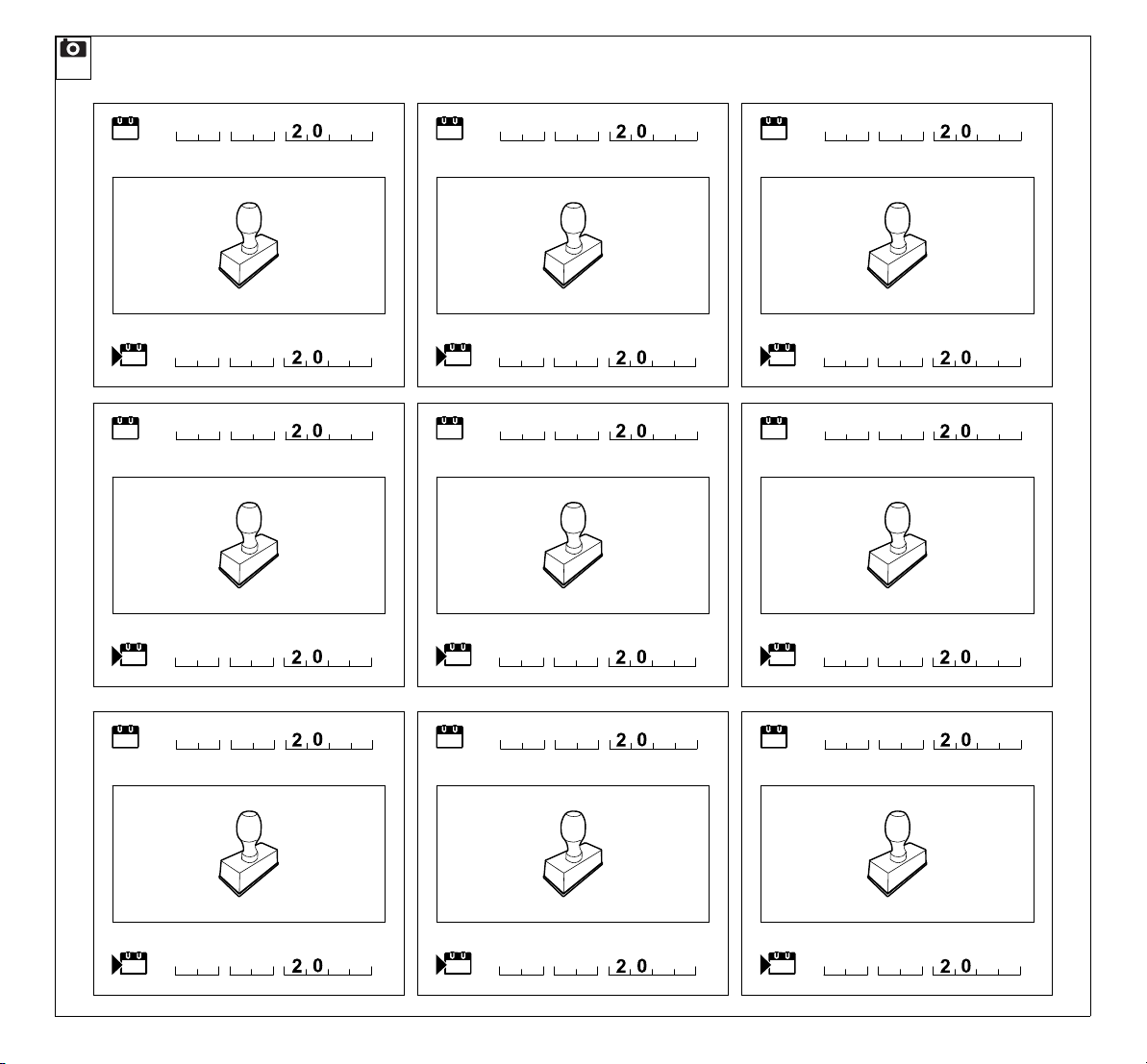

Texts relating to illustrations:

Illustrations relating to use of the machine

can be found in the front of this instruction

manual.

The camera symbol serves to link

the figures on the illustration pages

with the corresponding text

passages in the instruction manual.

1

EN

0478 201 8313 B - EN

5

Page 8

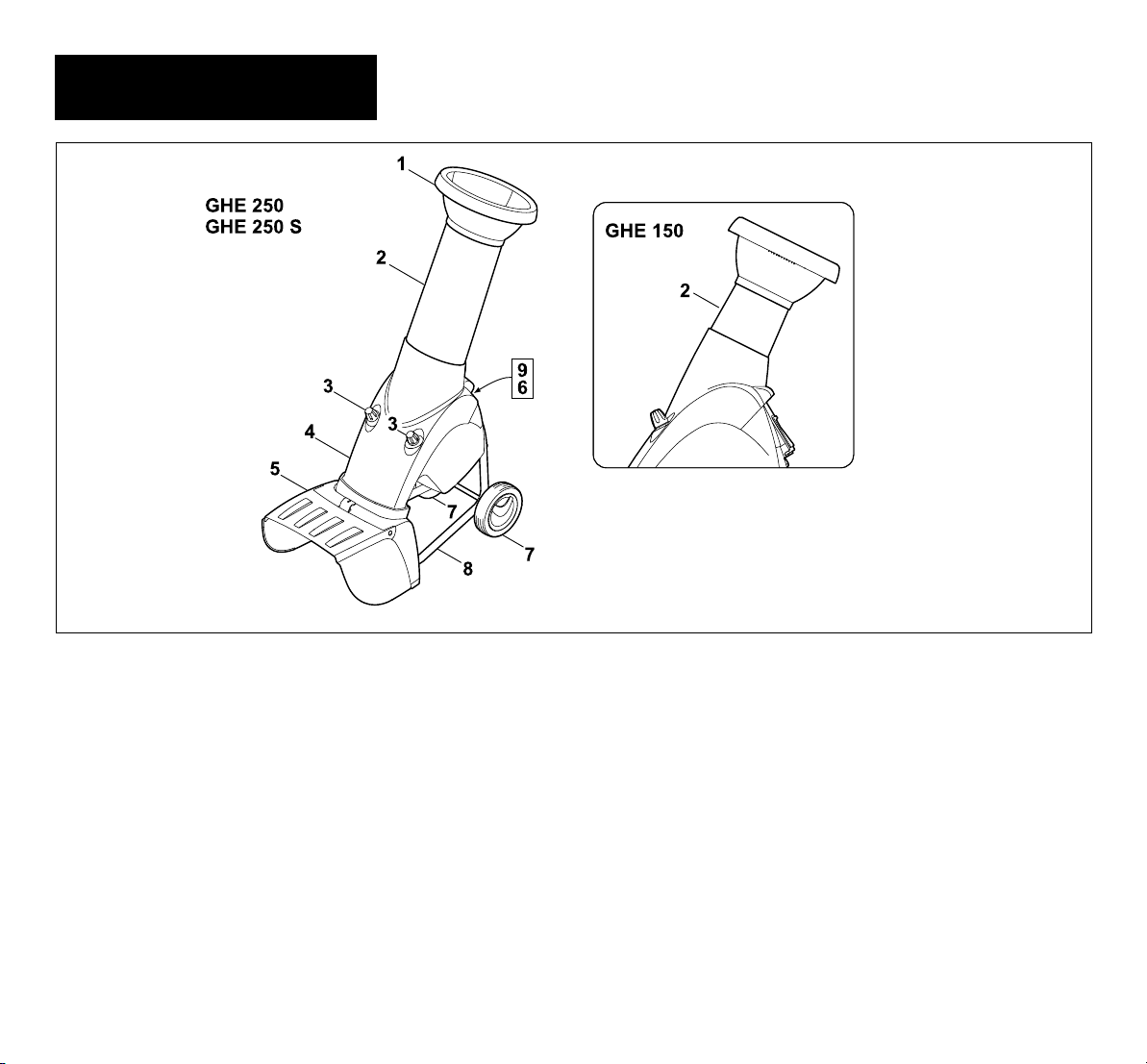

3. Machine overview

1 Upper chute

2 Lower chute

3 Closure screws

4 Basic unit

5 Ejection chute

6 On/off switch with mains connection

7 Wheels

8 Wheel carrier

9 Rating plate with machine number

6

0478 201 8313 B - EN

Page 9

4. For your safety

4.1 General

These safety regulations must

be observed when working with

the machine.

Read the entire instruction

manual before using the

machine for the first time. Keep

the instruction manual in a safe

place for future reference.

These safety precautions are essential for

your safety, however the list is not

exhaustive. Always use the machine in a

reasonable and responsible manner and

be aware that the user is responsible for

accidents involving third parties or their

property.

Make sure that you are familiar with the

controls and use of the machine.

The machine must only be used by

persons who have read the instruction

manual and are familiar with operation of

the machine. The user should seek expert

and practical instruction prior to initial

operation. The user must receive

instruction on safe use of the machine

from the vendor or another expert.

During this instruction, the user should be

made aware that the utmost care and

concentration are required for working with

the machine.

Residual risks persist even if you operate

this machine according to the instructions.

Risk of death from suffocation!

Packaging material is not a toy danger of suffocation! Keep

packaging material away from

children.

Only give or lend the machine, including

any accessories, to persons who are

familiar with this model and how to operate

it. The instruction manual forms part of the

machine and must always be provided to

persons borrowing it.

Make sure that the user is physically,

sensorily and mentally capable of

operating the machine and working with it.

If the user is physically, sensorily or

mentally impaired, the machine must only

be used under supervision or following

instruction by a responsible person.

Make sure that the user is of legal age or

being trained under supervision in a

profession in accordance with national

regulations.

The machine must only be operated by

persons who are well rested and in good

physical and mental condition. If your

health is impaired, you should consult your

doctor to determine whether working with

the machine is possible. The machine

should not be operated after the

consumption of alcohol, drugs or

medications which impair reactions.

The machine is intended for private use.

Caution – risk of accident!

STIHL garden shredders are suitable for

shredding branch material and plant

trimmings. Their use for other purposes is

not permitted and may be dangerous or

result in damage to the machine.

The garden shredder must not be used

(incomplete list):

– for any other materials (e.g. glass,

metal).

– for tasks other than those described in

this instruction manual.

– for the preparation of foodstuffs

(e.g. crushing ice, mashing pulp).

For safety reasons, any modification to the

machine, except the proper installation of

accessories approved by STIHL, is

forbidden and results in voiding of the

warranty cover. Information regarding

approved accessories can be obtained

from your STIHL specialist dealer.

In particular, any tampering with the

machine which increases the power output

or speed of the engine or motor is

forbidden.

It is not permitted to transport objects,

animals or persons, particularly children,

on the machine.

Particular care is required during use in

public green spaces, parks, sports fields,

along roads and in agricultural and forestry

businesses.

EN

0478 201 8313 B - EN

7

Page 10

4.2 Warning – dangers caused by electrical current

Warning:

Risk of electric shock!

Particularly important for

electrical safety are the

power cable, mains plug,

On / Off switch and

electric cable. Damaged cables,

connectors and plugs, or electric

cables that do not conform to

regulations must not be used, to

prevent any risk of electric shocks.

Therefore, check the electric cable

regularly for signs of damage or

ageing (brittleness).

Only operate machine with fully uncoiled

power cable.

Extension reels must always be fully

unwound before use.

Never use a damaged extension cable.

Replace defective cables with new ones

and never repair extension cables.

If the power cable or extension cable is

damaged during operation, immediately

disconnect the power cable or extension

cable from the power supply. Never touch

the damaged power cable or extension

cable.

Never use the machine if the cables are

damaged or worn. Check the power cable

in particular for damage and ageing.

Maintenance and repair work on power

cables must only be performed by

specially qualified technicians.

Danger of electric shock!

Do not connect a damaged cable to the

mains and only touch a damaged cable

once it has been disconnected from the

mains.

Only touch the cutting units (blades) when

the machine is disconnected from the

mains.

Always ensure that the power cables used

are adequately protected by a fuse.

Do not work in the rain or in a

wet environment.

Only use extension cables that

are insulated against moisture

for outdoor use which are suitable for use

with the machine (Ö 10.1).

Detach electric cables at the plug and

socket and not by pulling on the electric

cable.

Do not leave the machine unprotected in

the rain.

It must be noted that current fluctuations

can damage the machine when it is

connected to a power generator.

Only connect the machine to a power

supply that is protected by means of a

residual current-operated protective

device with a release current of a

maximum of 30 mA. Your electrician can

provide further information.

4.3 Clothing and equipment

Always wear sturdy footwear

with high-grip soles when

working. Never work barefoot

or, for example, in sandals.

Also always wear sturdy gloves

when working and in particular

also when performing

maintenance operations or

transporting the machine.

Always wear safety glasses and

hearing protection when

working. Wear them at all times.

Wear suitable, close-fitting

clothing when working with the

machine, e.g. overalls, but not

work coats. Do not wear

scarves, ties, jewellery, clothing with

dangling straps or cords or other

protruding articles of clothing when

working with the machine.

Long hair must be tied up and secured

(headscarf, cap, etc.) at all times when

operating or performing work on the

machine.

4.4 Transporting the machine

Always wear gloves in order to prevent

injuries due to sharp-edged and hot

components.

Do not transport the machine with the

motor running. Switch off the motor, allow

the blades to come to a standstill and

disconnect the mains plug prior to

transport.

Only transport the machine once the motor

has cooled down.

Only transport the machine with the feed

chute properly fitted

Risk of injury due to exposed blades.

Pay particular attention to the weight of the

machine, especially when tilting.

Use suitable loading aids (loading ramps,

lifters).

8

0478 201 8313 B - EN

Page 11

Secure the machine on the load floor using

adequately dimensioned fastening

material (straps, ropes etc.) at the

fastening points described in this

instruction manual. (Ö 12.)

Push or pull the machine at walking pace

only. Do not tow!

When transporting the machine, always

observe regional legislation, especially

regarding load security and the transport

of objects on load floors.

4.5 Before operation

Make sure that only persons who are

familiar with the instruction manual are

permitted to use the machine.

Observe the local regulations regarding

permitted operating times for gardening

power tools with combustion engines or

electric motors.

All faulty, worn or damaged parts must be

replaced before using the machine.

Replace any illegible or damaged danger

signs and warnings on the machine. Your

STIHL specialist has a supply of

replacement stickers and all the other

spare parts.

Before initial operation, it must be ensured

– that the machine is in good operational

condition. This means that the covers

and guards must be in place and in

good condition.

– that it is connected electrically to a

properly installed socket.

– that the insulation of the electric cable,

extension cable, plug and connector is

in good condition.

– that the complete machine (motor

housing, guards, fastening elements,

blades, blade shaft, blade discs etc.) is

neither worn nor damaged.

– that there is no shredding material in

the machine and that the feed chute is

empty.

– that all screws, bolts, nuts and other

fastening elements are in place and

properly tightened. Tighten any loose

screws, bolts and nuts prior to initial

operation (observe tightening torques).

Only use the machine out-of-doors and not

close to walls or any other solid objects in

order to prevent the risk of injuries and

property damage (no escape for the user,

broken windows, scratched cars etc.).

The machine must placed in a stable

position on firm and level ground.

Do not use the machine on a paved or

gravel-covered surfaces, as ejected or

thrown-up material could cause injuries.

Before using the machine, always check

that it is properly closed. (Ö 11.2)

Make sure that you are familiar with the

On / Off switch so that you can react

quickly and correctly in any emergency

situation.

The splash guard in the feed chute must

cover the feed opening and must be

undamaged – replace the splash guard if

damaged.

Risk of injury:

Only operate the machine when properly

assembled. If parts of the machine

(e.g. wheels) are missing, the specified

safety distances are no longer maintained

and the stability of the machine may also

be reduced.

Before using the machine, always carry

out a visual check to ensure that it is in

good operating condition.

"Good operating condition" means that the

machine is fully assembled, in particular:

– Upper chute is installed on lower chute

– Feed chute is installed on basic unit and

both closure screws are fastened handtight

– Wheel carrier assembly is installed

– Both wheels are mounted

– All safety devices (ejection chute,

splash guard etc.) must be present and

functional

– Cutting unit (blade disc) is installed

– All blades are properly installed

The switch and safety devices installed in

the machine must not be removed or

bypassed.

Visually inspect the blade disc for damage

and deformation; replace if necessary.

4.6 Working with your machine

Never work when animals or

persons, particularly children,

are in the danger area.

Do not operate the machine in the rain or

during thunder storms, particularly when

there is a risk of lightning strike.

The risk of accidents is higher if the ground

is damp due to increased danger of

slipping.

Particular caution should be exercised

during working in order to prevent slipping.

If possible, avoid using the machine when

the ground is damp.

EN

0478 201 8313 B - EN

9

Page 12

Only work during the day or with good

artificial light.

Keep the working area neat and tidy at all

times. Remove tripping hazards such as

stones, branches, cables etc.

The operator should not stand any higher

than the level of the base of the machine.

Starting:

Place the machine in a stable and upright

position prior to starting. The machine

must never be operated in a horizontal

position.

Exercise care when switching on the

machine and observe the instructions in

the section "Operating the machine".

(Ö 10.)

Do not stand in front of the discharge

opening when starting the engine or

switching on the motor. There must be no

shredding material in the garden shredder

when it is started or switched on.

Shredding material may be ejected and

lead to injuries.

The machine must not be tilted during

start-up.

Avoid switching the machine on repeatedly

within a short period of time; particularly

avoid "playing" with the On / Off switch.

Risk of motor overheating.

Owing to the voltage fluctuations caused

by this machine during the start-up, other

devices connected to the same circuit may

be subject to interference in the case of

unfavourable power supply conditions.

In this case, appropriate steps should be

taken (e.g. connection to a different circuit

than the one used by the affected device,

or operation of the machine using a circuit

with a lower impedance).

Working:

Risk of injury!

Never place your hands or feet

above, underneath or on rotating

parts.

When the machine is running, never put

your face or any other part of your body

above the feed chute or in front of the

ejection opening. Always keep you head

and body away from the feed opening.

Never put your hands or any

other part of your body or

clothing into the feed chute or

ejection chute. There is a

considerable risk of injury to eyes, face,

fingers, hands etc.

Always maintain your balance and firm

footing. Do not stretch forward.

The splash guard must not be tampered

with (removed, folded up, jammed into

position, damaged etc.) during operation.

The operator must stand in the working

area described when feeding the

shredder. Stay inside the working area and

outside of the ejection zone at all times

during operation of the machine. (Ö 8.4)

Risk of injury:

Shredding material may be ejected back

up during operation. Always wear safety

glasses and keep your face away from the

feed opening.

Never tilt the machine when the engine or

motor is running.

If the machine falls over during operation,

immediately switch off the motor and

disconnect the mains plug.

Make sure that there is no shredding

material blocking the ejection chute, as

this could result in a poor shredding

performance or kickbacks.

When feeding the garden shredder, pay

particular attention to ensuring that no

foreign objects such as bits of metal,

stones, plastic, glass, etc. get into the

shredding chamber as this could result in

damage or kickbacks from the feed chute.

Remove blockages for the same reason.

Kickbacks can occur when feeding the

garden shredder with branch material.

Wear gloves.

Beware of the cutting tool

running on for several seconds

before coming to a standstill.

Switch off the motor, disconnect

the mains plug and allow all

rotating tools to reach a complete standstill

– before leaving the machine unattended

– before repositioning, lifting, carrying,

tilting, pushing or pulling the machine

– before unscrewing the closure screws

and opening the machine

– before transporting the machine

– before removing blockages at the

cutting unit, in the feed chute or in the

discharge chute

– before carrying out any work on the

blade disc

– before checking or cleaning the

machine or before carrying out any

other work on it.

If foreign objects get into the cutting tool or

if the machine makes unusual noises or

vibrates in an unusual way, switch off the

motor immediately and allow the machine

to come to rest. Detach the mains plug,

remove the feed chute and perform the

following steps:

10

0478 201 8313 B - EN

Page 13

– Check the machine, in particular the

cutting unit (blade, blade discs, blade

mounting, blade fastening screw,

clamping ring) for damage and have

any necessary repairs carried out by a

technician before starting again and

working with the machine.

– Check that all parts of the cutting unit

are seated securely, retighten the

screws if necessary (observe tightening

torques).

– Have damaged parts replaced or

repaired by a technician; the parts must

be of similar quality.

4.7 Maintenance and repairs

Before carrying out any

maintenance operations

(cleaning, repair etc.) and

before checking whether the

electric cable is entwined or damaged,

park the machine on firm, level ground,

switch off the motor and disconnect the

mains plug.

Allow the machine to cool down for

approx. 5 minutes before performing any

maintenance operations.

Before performing maintenance of the

cutting tool, ensure that the cutting tool can

still be turned despite the locking device,

even when the power supply is switched

off.

The power cable must only be repaired or

replaced by authorised electricians.

Cleaning:

The complete machine must be cleaned

thoroughly following use. (Ö 11.1)

Never use high-pressure cleaners and do

not clean the machine under running water

(e.g. using a garden hose).

Do not use aggressive cleaning agents.

These can damage plastics and metals,

impairing the safe operation of your STIHL

machine.

Maintenance operations:

Only maintenance operations described in

this instruction manual may be carried out.

Have all other work performed by a

specialist dealer.

If you do not have the necessary expertise

or auxiliary equipment, please always

contact a specialist dealer.

STIHL recommends that you have

maintenance operations and repairs

performed exclusively by a STIHL

specialist dealer.

STIHL specialist dealers regularly attend

training courses and are provided with

technical information.

Only use tools, accessories or

attachments approved for this machine by

STIHL or technically identical parts.

Otherwise, there may be a risk of

accidents resulting in personal injury or

damage to the machine. If you have any

questions, please consult a specialist

dealer.

The characteristics of original STIHL tools,

accessories and spare parts are optimally

adapted to the machine and the user's

requirements. Genuine STIHL spare parts

can be recognised by the STIHL spare

parts number, by the STIHL lettering and,

if present, by the STIHL spare parts

symbol. On smaller parts, only the symbol

may be present.

Always keep warning and information

stickers clean and readable. Damaged or

missing stickers must be replaced by new,

original plates from your STIHL specialist

dealer. If a component is replaced with a

new component, ensure that the new

component is provided with the same

stickers.

Only perform work on the cutting unit when

wearing thick work gloves and exercising

extreme care.

Ensure that all nuts, pins and screws,

especially all the cutting unit screws, are

securely tightened, so that the machine is

in a safe operating condition.

Check the entire machine for wear or

damage on a regular basis, particularly

before extended periods when the

machine is not in use (e.g. over winter).

For safety reasons, worn or damaged

parts must be replaced immediately to

ensure that the machine is always in a safe

operating condition.

Components or guards that are removed

for maintenance operations must be

properly reinstalled immediately.

4.8 Storage for prolonged periods without operation

Allow the machine to cool for approx. 5

minutes before storing it in an enclosed

space.

Ensure that the machine is protected from

unauthorised use (e.g. by children).

Thoroughly clean the machine before

storage (e.g. winter break).

Store the machine in good operational

condition.

Only transport the garden shredder with

the feed chute fitted.

Risk of injury due to exposed blades.

EN

0478 201 8313 B - EN

11

Page 14

4.9 Disposal

Waste products can be harmful to people,

animals and the environment. They must

consequently be disposed of properly.

Consult your recycling centre or your

specialist dealer for information on the

proper disposal of waste products. STIHL

recommends STIHL specialist dealers.

Ensure that old machines are properly

disposed of. Render the machine

unusable prior to disposal. In order to

prevent accidents, always remove the

power cable and electric cable to the

motor.

Risk of injury!

Switch off the motor and disconnect the power cable

from the machine before

working on the cutting tool,

before performing maintenance and cleaning work,

before checking whether the

electric cable is entwined or

damaged and before leaving

the machine unattended.

Wear hearing protection.

Wear safety glasses.

Wear work gloves.

5. Description of symbols

Caution!

Read the instruction manual before initial use.

Risk of injury!

Keep other persons out of

the danger area.

Risk of injury!

Rotating tools.

Keep hands and feet away

from apertures when

machine is running.

Risk of injury:

Do not climb onto the

machine.

Risk of injury:

Never put your hands or any

other part of your body or

clothing into the feed chute

or ejection chute.

12

0478 201 8313 B - EN

Page 15

6. Standard equipment

EN

Item Designation Qty.

A Basic unit with lower chute 1

B Wheel carrier 1

C Wheel axle 1

D Wheel lock 2

E Bolt, M6 x 55 2

F Hexagon nut 2

H Quick fastener 2

I Wheel 2

J Wheel cap 2

K Square nut 2

0478 201 8313 B - EN

Item Designation Qty.

L Washer Ø 17 mm 4

M Bolt, M6 x 50 2

N Discharge flap 1

O Ejection chute extension 1

P Strip 1

Q Pin 2

R Torx screw P5 x 20 3

S Upper chute 1

T Safety screw 4

U Torx screw P5 x 10 2

Item Designation Qty.

V Combination spanner 1

W Cable clip 1

x Instruction manual 1

13

Page 16

7. Preparing the machine for operation

7.1 Attaching the wheel axle and wheels

● Push wheels (I) onto the mounted

wheel axle.

Quick fasteners must be pushed

onto the wheel axle only to the

extent that the wheels can still turn

freely.

Quick fasteners are not reuseable

following removal.

● Push quick fastener (H) onto the wheel

axle with the convex side facing

outwards.

● Press wheel caps (J) onto the wheels.

● Attach wheel axle (C) with wheel

locks (D), bolts (E) and hexagon

nuts (F) to wheel carrier (B) and tighten

using combination spanner (V)

(4 - 6Nm).

14

0478 201 8313 B - EN

Page 17

7.2 Installing the chassis and ejection chute

EN

1 Install the ejection chute extension

● Place basic unit (A) onto a block of

wood with a height of approx. 1520 cm.

● Engage hooks (1) of ejection chute

extension (O) into openings (2) on the

rear of basic unit (A) and turn the

extension downwards so that the front

part of the basic unit is precisely

inserted in the opening of the ejection

chute extension.

● Fasten screws (U) in the lugs of

hooks (1) (1 - 2Nm).

0478 201 8313 B - EN

2 Attach the chassis

● Press square nuts (K) and washers (L)

in the recesses provided on the basic

unit (3).

● Push the chassis with both wheel

carriers (4) up to the stop in the guides

on the basic unit (5).

● Push bent section of wheel carrier (6)

into the recess on the ejection chute

extension (7).

● Insert the screws (M) with washers (L)

the openings in the wheel carriers (8)

and fasten using combination

spanner (V) (4 - 6Nm).

15

Page 18

3 Install the strip

The bent section of wheel

carrier (6) must be precisely

inserted in the recesses on ejection

chute extension (7).

● Position strip (P) and screw in

screws (R) (1 - 2Nm).

● Lift the machine into the upright

position.

4 Install the discharge flap

● Attach discharge flap (N) and press in

pin (Q) (use a plastic hammer if

necessary).

Ensure that ribs (9) inside the discharge

flap on the left and right are all correctly

located in the guide groove of ejection

chute extension (10).

7.3 Opening and closing the discharge

flap

Opening the discharge flap:

16

● For shredding, fold discharge flap (1)

upwards and allow tab (2) to engage in

the ejection chute extension.

0478 201 8313 B - EN

Page 19

Closing the discharge flap:

● For transport or space-saving storage,

lift tab (2) slightly and fold away

discharge flap (1) downwards.

7.4 Attaching the upper chute

The chute can only be installed by a

specialist dealer using special

tools. STIHL recommends STIHL

specialist dealers.

● Place upper chute (S) with symbol (1)

facing forwards on lower chute (3) in

the direction of closure screws (2).

We recommend following the

described installation sequence to

prevent the splash guard slipping

off when screwing in the screws.

● Screw in screws (T) in the sequence

shown (1 2 3 4).

7.5 Mounting the cable clip

● Press electric cable (1) into the

designated recesses in cable clip (2) as

shown.

8. Notes on working with the machine

8.1 What material can be processed?

– Feeding the garden shredder. (Ö 8.8)

GHE 150, GHE 250 S:

Tree and hedge cuttings as well as thick

branch material with side shoots.

EN

0478 201 8313 B - EN

17

Page 20

GHE 250:

Organic plant trimmings such as fruit and

vegetable cuttings, flower cuttings, leaves,

tree and hedge cuttings, as well as thick

branches with side shoots and twigs.

Tree and hedge cuttings should be

processed when fresh, as the

shredding performance is better

with fresh than with dried-out or wet

material.

8.2 What material cannot be processed?

Stones, glass, bits of metal (wire, nails,

etc.) or plastic must not be fed into the

garden shredder.

As a general rule:

Any materials that do not belong on the

compost heap should not be processed

using the garden shredder.

8.3 Maximum branch diameter

The data relates to freshly cut branch

material:

Maximum branch diameter

GHE 150, GHE 250, GHE 250 S: 35 mm

8.4 Working area for operator

● For safety reasons, the operator must

stay within the working area (grey

area X) for the entire operating period

(while the motor is switched on or the

engine is running), particularly in order

to prevent injuries due to shredding

material that is ejected backwards.

8.5 Correct machine load

The load on the motor or engine of the

garden shredder must never cause the

speed to drop significantly. Always feed

the garden shredder continuously and

steadily. If the speed drops when working

with the garden shredder, stop feeding the

machine in order to relieve the load on the

motor or engine.

Only switch off the motor when

there is no longer any shredding

material in the machine. Otherwise,

the blade disc may become blocked

when operation is resumed.

8.6 Overload protection

If an overload of the motor occurs during

operation, the built-in overload protection

device automatically switches off the

motor.

The garden shredder can be started up

again after a cooling period of

approx. 10 minutes. Frequent triggering

of the overload protection may be

attributable to the following causes:

– Unsuitable electric cable (Ö 10.1)

– Power overload

– Machine overloaded due to excessive

quantities of shredding material or blunt

blades

8.7 If the cutting unit of the garden shredder is blocked

If the cutting unit of the garden shredder

becomes blocked during shredding,

immediately switch off the motor and

disconnect the power cable. Then remove

the feed chute and eliminate the cause of

the fault.

18

0478 201 8313 B - EN

Page 21

8.8 Feeding the garden shredder

Risk of injury!

Carefully read the "For your safety"

section (Ö 4.), "Working with your

machine" sub-section (Ö 4.6) in

particular, and follow all the safety

instructions before feeding the

garden shredder. It is only

permitted for one person to feed the

garden shredder.

Risk of injury!

Never reach into the feed

opening.

● Before feeding the garden shredder,

note the working area. (Ö 8.4)

● Start the garden shredder. (Ö 10.2)

Damp or wet soft material will

cause blockages in the machine

more quickly. For this reason, feed

the garden shredder more slowly

and pay particular attention to the

motor speed. It should not drop

during feeding.

Hard material:

Cut up thick branches and

branches with side shoots (note the

maximum branch thickness

(Ö 8.3)) beforehand using loppers.

● Feed tree and hedge cuttings as well as

branch material slowly into the feed

opening (1). The hard material is

automatically drawn in by the machine.

Risk of injury!

The inclined blade unit can cause

branches to kick back.

In order to prevent injuries caused

by kickback, the garden shredder

must be fed with hard material in

the correct manner:

Insert longer branches at a slight

angle and guide them along the

right-hand chute wall to the blade

unit in accordance with the

symbol (2).

Observe the correct motor load.

(Ö 8.5)

9.2 Safety interlock

The motor/shredding tool may only be

operated when the feed chute has been

properly closed. If the right closure screw

(machine viewed from the front) becomes

loose during operation, the motor is

switched off automatically and after a few

seconds the shredding tool comes to a

standstill.

9.3 Motor run-down brake

The motor run-down brake shortens the

run-down time from when the machine is

switched off until the blades stop to a few

seconds.

9.4 Protective covers

The garden shredder is equipped with

protective covers in the feeding and

ejection areas. These include the

complete feed chute with the upper chute

and splash guard, the ejection chute

extension and the discharge flap.

The protective covers ensure that a safe

distance is maintained from the shredding

blades.

EN

Soft material:

● Throw organic plant trimmings such as

fruit and vegetable waste, flower

cuttings, leaves, thin branches, etc. into

the feed opening (1).

0478 201 8313 B - EN

9. Safety devices

9.1 Motor restart inhibitor

The machine can only be started via the

switch and not by plugging the electric

cable into the mains socket.

10. Operating the machine

Risk of injury:

Carefully read the section entitled

"For your safety" (Ö 4.) and follow

all the safety instructions before

operating the garden shredder.

19

Page 22

10.1 Electrical connection of garden

shredders

Risk of injury!

Observe the instructions in the

"Warning – dangers caused by

electrical current" section (Ö 4.2).

Power supply and operating voltage must

correspond (see rating plate).

The power cable must be adequately

protected by fuse in line with the

respective national electrical installation

regulations. (Ö 16.)

Only electric cables which are no lighter

than rubber sheathed cables H07 RN-F

may be used.

The minimum cross-section of the power

cable must be 3x1.5mm² for a length of

up to 25 m or 3x2.5mm² for a length of

over 25 m.

The plug connections must be splash

proof.

Unsuitable extension cables lead to a loss

of power and may result in damage to the

motor.

Extension cable plugs and connectors

must conform to the standard AS/NZS

3112.

Use a splash-proof coupling box

(protection class IPX4) when using an

extension cable.

This machine is intended for operation with

a power supply having a system

impedance of Z

at the transfer point

max

(house connection) of maximum

0.323 ohms at 50 Hz.

The user must ensure that the machine is

only operated with a power supply which

meets this requirement.

If necessary, this information can be

obtained from the local electric power

company.

Your electrician can provide further

information on mains connection.

10.2 Switching on the garden shredder

There must be no shredding

material in the machine when it is

switched on as it may be expelled.

The blade disc locking device must

always be tilted back to the stop.

(Ö 11.4)

● Connect the power cable.

● Press green button (1) on the switch.

The garden shredder starts up.

Only begin to feed the shredding

material once the motor has

reached the maximum speed (idling

speed).

10.3 Switching off the garden shredder

Risk of injury!

Do not step into the ejection area

when switching off!

Stand to the side of the machine to

do so.

Beware of the work tools running

on for several seconds before

coming to a standstill after

switching off the motor.

● Press red button (1) on the switch.

The garden shredder motor is switched off

and braked automatically.

Only switch off the motor when

there is no longer any shredding

material in the machine. Otherwise,

the blade disc may become blocked

when operation is resumed.

10.4 Shredding

● Push the garden shredder onto firm and

level ground and set down safely.

20

0478 201 8313 B - EN

Page 23

● Put on thick gloves, safety glasses and

hearing protection.

● Open the discharge flap. (Ö 7.3)

● Connect the power cable of the garden

shredder.

● Start the garden shredder. (Ö 10.2)

● Wait until the garden shredder has

reached its maximum speed (idling

speed).

● Feed the garden shredder with

shredding material in the correct way.

(Ö 8.8)

● Switch off the garden shredder.

(Ö 10.3)

11. Maintenance

Risk of injury:

Carefully read the section "For your

safety" (Ö 4.), particularly the

subsection "Maintenance and

repairs" (Ö 4.7), and follow all

safety instructions exactly before

performing any maintenance or

cleaning operations on the

machine.

Disconnect the mains plug before

performing any maintenance

operations.

11.1 Cleaning the machine

Maintenance interval:

After each use

Clean the machine thoroughly each time it

has been used. Care of the machine will

protect it against damage and extend its

service life.

Electric motors are splashproof.

Protect shredding tools, incl. the shredding

chamber using a commercially available

anti-corrosion agent (e.g. rapeseed oil).

It is only permitted to clean the machine in

the position shown.

● Remove the feed chute. (Ö 11.3)

Remove dirt from the cooling air guide

(inlet slots) on the motor housing to ensure

that the motor is adequately cooled.

Never spray water onto

motor or engine components,

seals, bearing points or

electrical parts such as

switches. This would result in

expensive repairs.

If you are unable to remove

the dirt and accumulated

deposits with a brush, a damp

cloth or a stick, STIHL

recommends the use of a

special cleaner (e.g. STIHL special

cleaner).

Do not use aggressive cleaning agents.

Clean the blade discs regularly.

11.2 Installing the feed chute

The closure screws are securely

fastened to the feed chute.

EN

● Attach feed chute (1) to the fastening

hooks on basic unit (2) and pivot

forwards.

● Tighten both closure screws (3)

simultaneously.

11.3 Removing the feed chute

0478 201 8313 B - EN

21

Page 24

● Loosen both closure screws (1) until

they turn freely. They remain on the

feed chute.

● Pivot feed chute (2) to the rear and

remove.

11.4 Locking the blade disc

Risk of injury!

Always wear gloves!

Do not touch the blades

until they have come to a

standstill.

11.5 Removing the blade set

22

● Remove the feed chute. (Ö 11.3)

● Turn blade disc (1) until recess (2) is

located in front of locking device (3).

● Fold up locking device (3).

0478 201 8313 B - EN

Page 25

● Lock blade disc (5). (Ö 11.4)

● Loosen bolt (1) using combination

spanner (V).

● Remove bolt (1), retaining washer (2),

clamping ring (3), wing blade (4), wing

blade (6, only with GHE 250) and blade

disc (5).

● Remove the reversible blade. (Ö 11.8)

● GHE 250: Unscrew bolts (7) and

remove together with nuts (9). Remove

shredding blades (8) downwards.

11.6 Installing the blade set

The installation sequence and

specified tightening torque must be

observed.

● Install the reversible blade on the blade

disc. (Ö 11.8)

● GHE 250: Position shredding

blades (8) on the underside of blade

disc (5) and tighten using nuts (9) and

bolts (7) (10 Nm).

● Insert blade disc (5) in the housing and

lock. (Ö 11.4)

● Install wing blade (6, only on GHE 250),

wing blade (4), clamping ring (3) and

retaining washer (2) and tighten using

bolt (1) (50 Nm).

● Fold the locking device back so that the

blade disc can turn freely again.

(Ö 11.4)

● Install the feed chute. (Ö 11.2)

11.7 Blade maintenance

Risk of injury!

Always wear thick

gloves!

Maintenance interval:

Before each use

● Remove the feed chute. (Ö 11.3)

● Lock the blade disc. (Ö 11.4)

● Check the blades for damage (notches

or cracks) and wear; reverse or replace

if necessary.

Wear limits of the blades:

The blades must be reversed or

replaced before the specified wear

limits are reached. STIHL

recommends STIHL specialist

dealers.

1 Reversible blade

● On the blades, measure the

distance (A) between the bore to the

edge of the blade at several points.

Minimum clearance:

A=6mm

EN

0478 201 8313 B - EN

23

Page 26

2 Wing blade

● Measure the blade width (B) at the

upward-pointing curved edge of the

wing blade.

Minimum blade width:

B=15mm

4 Shredding blades (GHE 250)

● Measure the blade width (D) at the

upward-pointing curved edge of the

shredding blade.

Minimum blade width:

D=13mm

3 Wing blade (GHE 250)

● Measure the blade width (C) at the

upward-pointing curved edge of the

wing blade.

Minimum blade width:

C=19mm

24

11.8 Reversing the blades

Blunt reversible blades can be

reversed once. Always reverse

both blades.

● Remove the blade set. (Ö 11.5)

● Unscrew bolts (1) and remove together

with nuts (2).

● Remove blade (3) upwards.

● Clean the blade disc.

● Reverse blade (3) and place onto the

blade disc with the sharp edge exposed

and align the bores.

● Insert bolts (1) through the bores and

screw on nuts (2). Tighten nuts (2) to

10 Nm.

● Install the blade set. (Ö 11.6)

0478 201 8313 B - EN

Page 27

Sharpening the blades:

Blades which are blunt on both sides must

be sharpened before resuming work.

In order to ensure optimum machine

operation, the blades should only be

sharpened by a technician. STIHL

recommends STIHL specialist dealers.

● Remove the blades for sharpening.

● Cool the blades when sharpening,

e.g. with water. The blade must not be

allowed to display blue colouring, as

this would reduce its cutting quality.

● Sharpen the blade evenly to prevent

vibrations due to imbalance.

● Check blades for damage before

installing: the blades must be replaced

if notches or cracks are visible or if the

blades have reached the wear limits.

● Sharpen blades at a sharpening angle

of 30°.

● Sharpen the blades against the cutting

edge.

● After sharpening, remove any

sharpening burr at the cutting edge

using fine sandpaper.

● Observe the tightening torques

contained in the "Reversing the blades"

section when installing the blades.

11.10 Storage and winter break

Store the garden shredder in a dry and

locked place that is generally free of dust.

Make sure that the machine is kept out of

the reach of children.

Only store the garden shredder in good

operating condition and with the feed

chute fitted.

Note the following points when storing the

garden shredder for extended periods

(over winter):

● Thoroughly clean all external parts of

the machine.

● Thoroughly lubricate/grease all moving

parts.

12. Transport

Risk of injury!

Before transporting, carefully read

and observe the section "For your

safety", in particular the

"Transporting the machine" section.

(Ö 4.4)

12.1 Winding up the cable

● Attach cable clip (1) at the edge of

opening (2).

● Store the rest of the electric cable on

the cable clip.

EN

11.9 Electric motor and wheels

The electric motor is maintenance-free.

The wheel bearings are maintenance-free.

0478 201 8313 B - EN

25

Page 28

12.2 Pulling or pushing the garden shredder

● Hold the garden shredder at the upper

chute (1) and tilt to the rear.

● The garden shredder can be pulled or

pushed slowly (walking pace).

12.3 Lifting or carrying the garden

shredder

At least two persons are always

required to lift and carry the

machine.

Wear suitable protective clothing;

the lower arms and upper part of

the body must be fully covered.

● Secure the machine against slipping

using suitable fastening materials.

Attach ropes or straps to wheel

carrier (1) or feed chute (2).

● 1st person: Hold the garden shredder at

the handles on the upper chute (1).

● 2nd person: Hold the garden shredder

at the strip of the ejection chute

extension (2).

● Lift the garden shredder

simultaneously.

12.4 Transporting the garden shredder

on a load floor

26

0478 201 8313 B - EN

Page 29

13. Minimising wear and preventing damage

Important information on maintenance

and care of the product group

Electric garden shredder (STIHL GHE)

STIHL assumes no liability for material or

personal damage caused by the nonobservance of information contained in the

operating instructions, in particular with

regard to safety, operation and

maintenance, or which arise through the

use of unauthorised attachment or spare

parts.

Please always observe the following

important information for the prevention of

damage or excessive wear to your STIHL

machine:

1. Wearing parts

Some parts of the STIHL machine are

subject to normal wear even when used

properly and must be replaced in due time

depending on type and duration of use.

These include:

–Blade

–Blade disc

2. Compliance with the information in

this instruction manual

The STIHL machine must be used,

maintained and stored with the care

described in this instruction manual. Any

damage caused by non-compliance with

the safety, operating and maintenance

instructions is the sole responsibility of the

user.

This applies in particular to:

– Inadequately dimensioned power

cables (cross section)

– Incorrect electrical connection (voltage)

– Product modifications not approved by

STIHL

– Use of tools or accessories which are

not approved or suitable for the

machine, or are of inferior quality

– Improper use of the product

– Use of the product for sporting or

competitive events

– Resultant damage due to continued use

of the product with defective

components.

3. Maintenance operations

All operations listed in the section

"Maintenance" must be performed

regularly.

If these maintenance operations cannot be

carried out by the user, a specialist dealer

must be commissioned to perform them.

STIHL recommends that you have

maintenance operations and repairs

performed exclusively by a STIHL

specialist dealer.

STIHL specialist dealers regularly attend

training courses and are provided with

technical information.

If these operations are neglected, faults

may arise which are the responsibility of

the user.

These include:

– Damage to the motor as a result of

inadequate cleaning of the cooling air

guide (inlet slots, cooling ribs, fan

wheel).

– Corrosive and other resultant damage

caused by incorrect storage.

– Damage to the machine through the

use of inferior-quality spare parts.

– Damage due to untimely or inadequate

maintenance or damage due to

maintenance or repair work not

performed in the workshops of

specialist dealers.

14. Standard spare parts

Reversible blade:

6008 702 0121

Wing blade:

6008 702 0300

GHE 150, GHE 250 S

Blade disc assembly:

6008 700 5120

GHE 250

Blade disc assembly:

6008 700 5117

Wing blade:

6008 702 0310

Shredding blades:

6008 702 0110

15. Environmental protection

Shredding material should be

composted and not disposed of

in household waste.

The machine, its packaging and

accessories are all produced

from recyclable materials and must be

disposed of accordingly.

By disposing of materials separately, and

in an environmentally friendly manner,

valuable resources can be re-used. For

this reason, the machine should be

disposed of for recycling at the end of its

useful life.

EN

0478 201 8313 B - EN

27

Page 30

16. Technical specifications

GHE 150.0/GHE 250.0/GHE 250.0 S:

Motor, design Electric motor

Power 2200 W

Amperage rating 10 A

Rated voltage 230 V~

Speed 2800 rpm

Main fuse

Frequency 50 Hz

Protection class I

Type of protection Splash proof

Operating conditions P40

GHE 150.0:

In accordance with

Directive

2000/14/EC:

Guaranteed sound

power level L

In accordance with

Directive

2006/42/EC:

Sound pressure level

at workplace L

Uncertainty K

Bolt tightening torques:

Blade disc 50 Nm

Reversible blade 10 Nm

Weight 27 kg

L/W/H 95/48/114 cm

1

10 A

(IPX4)

40 s load time

60 s idle time

WAd

pA

pA

99 dB(A)

89 dB(A)

2 dB(A)

GHE 250.0/GHE 250.0 S:

In accordance with

Directive

2000/14/EC:

Guaranteed sound

power level L

WAd

103/100 dB(A)

In accordance with

Directive

2006/42/EC:

Sound pressure level

at workplace L

Uncertainty K

pA

pA

92/90 dB(A)

3dB(A)

Bolt tightening torques:

Blade disc 50 Nm

Reversible blade 10 Nm

Shredding blades

2

10 Nm

Weight 29/28 kg

L/W/H 107/48/143 cm

1) Caution!

In the case of mains fuses of less

than 15 A, these may be tripped during start-up or in the case of high

load operation of the machine.

2) For model GHE 250.0

17. Troubleshooting

# If necessary, contact a specialist

dealer; STIHL recommends STIHL

specialist dealers.

Fault:

Motor does not start

Possible cause:

– Motor overload protection activated

– No mains voltage

– Electric cable, plug, plug connector or

switch defective

– Feed chute not properly closed - safety

cut-off switch actuated (motorstop)

– Blade disc blocked

– Locking device is not reset

Remedy:

– Allow machine to cool down (Ö 8.6)

– Check power cable and fuse

# (Ö 10.1)

– Check cable, plug, connector and

switch and replace if necessary (by

electrician) # (Ö 10.1)

– Close feed chute properly and tighten

screws (Ö 11.2)

– Remove feed chute and remove

shredder deposits from the housing

(Important: disconnect the power cable)

(Ö 11.3)

– Reset locking device (Ö 11.4)

Fault:

Reduced shredding performance

Possible cause:

– Blunt blades

Remedy:

– Reverse, re-sharpen or replace

shredding blades # (Ö 11.7)

28

0478 201 8313 B - EN

Page 31

18. Service schedule

18.1 Handover confirmation

18.2 Service confirmation

Please hand this instruction manual

to your STIHL specialist dealer in

the case of maintenance operations.

He will confirm the service operations

performed in the pre-printed boxes.

EN

1

Service performed on

Next service date

0478 201 8313 B - EN

29

Page 32

STIHL GHE 150, GHE 250, GHE 250 S

B

0478 201 8313 B

Loading...

Loading...