STIHL FS 561 C-M

Instruction Manual

Notice d’emploi

G Instruction Manual

1 - 50

F Notice d’emploi

51 - 106

Contents

English

Guide to Using this Manual 2

Safety Precautions and Working

Techniques 3

Approved Combinations of Cutting

Attachment, Deflector, Limit Stop

and Harness 13

Mounting the Bike Handle 15

Adjusting the Throttle Cable 18

Mounting the Deflector 19

Original Instruction ManualPrinted on chlorine-free paper

Mounting the Cutting Attachment 21

Fuel 27

Fueling 28

Fitting the Full Harness 28

Balancing the Machine 29

Starting / Stopping the Engine 30

Transporting the Unit 32

Operating Instructions 34

Air filter 34

Engine Management 35

M-Tronic 35

Winter Operation 36

Spark Plug 38

Printing inks contain vegetable oils, paper can be recycled.

Engine Running Behavior 39

Lubricating the Gearbox 39

Storing the Machine 39

Sharpening Metal Cutting Blades 40

Maintaining the Mowing Head 40

Inspection and Maintenance by

User 41

Inspections and Maintenance by

Dealer 42

Maintenance and Care 43

Main Parts 45

Specifications 47

Maintenance and Repairs 48

Disposal 48

STIHL Limited Emission Control

Warranty Statement 49

Allow only persons who fully understand

this manual to operate your clearing

saw.

To receive maximum performance and

satisfaction from your STIHL clearing

saw, it is important that you read,

understand and follow the safety

precautions and the operating and

maintenance instructions in chapter

"Safety Precautions and Working

Techniques" before using your clearing

saw. For further information you can go

to www.stihlusa.com.

Contact your STIHL dealer or the STIHL

distributor for your area if you do not

understand any of the instructions in this

manual.

WARNING

Because a clearing saw is a high-speed

cutting tool some special safety

precautions must be observed to reduce

the risk of personal injury. Careless or

improper use may cause serious or even

fatal injury.

Make sure your unit is equipped with the

proper deflector or limit stop, handle and

harness for the type of cutting

attachment being used. Always wear

proper eye protection.

© ANDREAS STIHL AG & Co. KG, 2022

0458-856-8221-A. VA4.B22.

0000009340_004_GB

FS 561 C-M

This instruction manual is protected by copyright. All rights reserved, especially the rights to reproduce, translate and process

with electronic systems.

1

English

Guide to Using this Manual

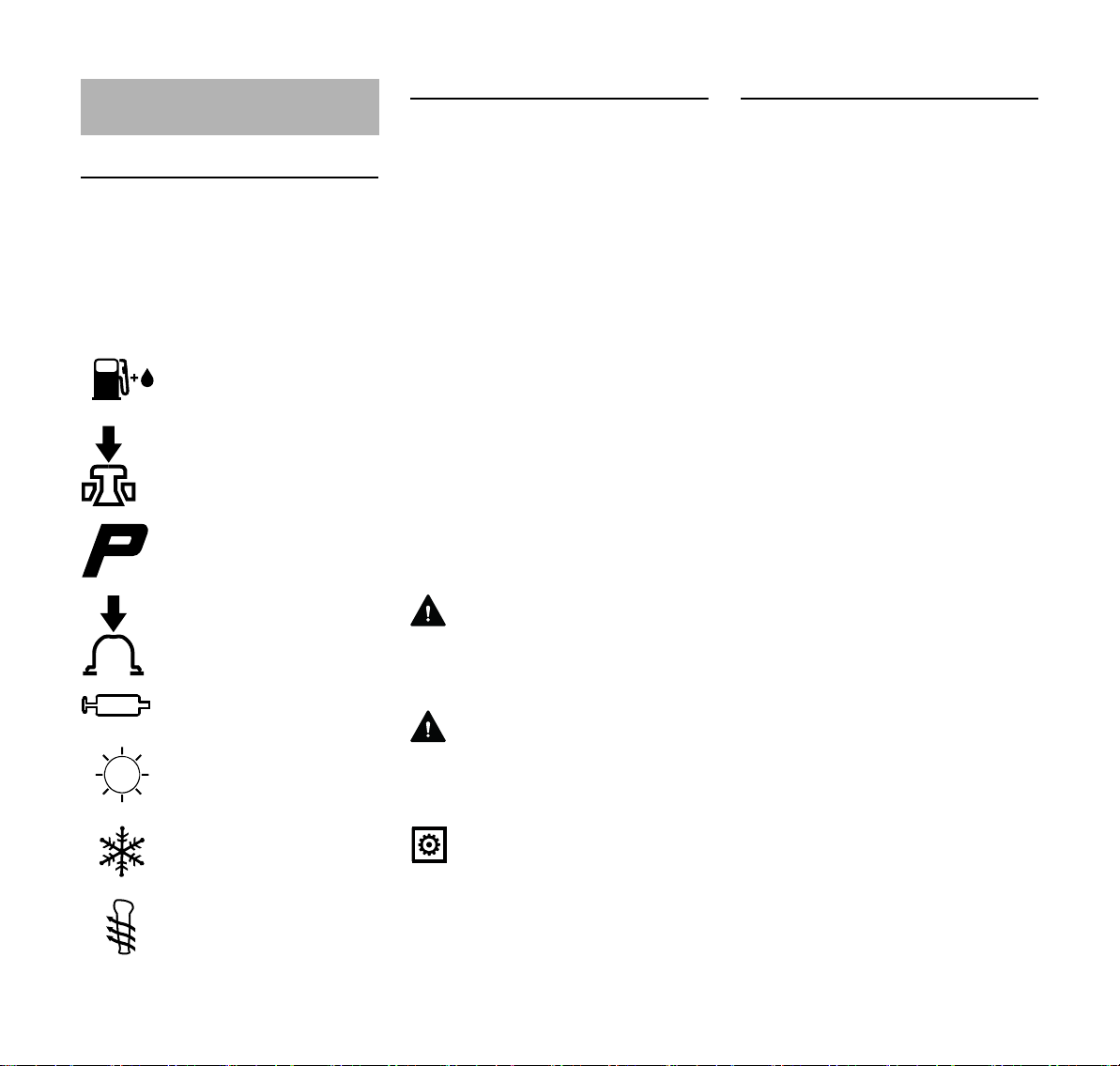

Pictograms

The meanings of the pictograms

attached to or embossed on the

machine are explained in this manual.

Depending on the model concerned, the

following pictograms may be on your

machine.

Fuel tank for gasoline

and engine oil mixture

Press to operate decom

pression valve

Manual fuel pump

Press to operate manual

fuel pump

Filler hole for gear

lubricant

Air intake summer mode

Air intake winter mode

Handle heating

Symbols in Text

Many operating and safety instructions

are supported by illustrations.

The individual steps or procedures

described in the manual may be shown

in different ways:

N A bullet indicates a step or

procedure.

A description of a step or procedure that

refers directly to an illustration may

contain item numbers that appear in the

illustration. For example:

N Remove the screw (1)

N Pull the spark arresting screen (2)

-

upwards out of the muffler

In addition to the operating instructions,

this manual may contain paragraphs

that require your special attention. Such

paragraphs are indicated with the

symbols and signal words described

below:

DANGER

Indicates a hazardous situation that, if

not avoided, will result in death or

serious injury.

WARNING

Indicates a hazardous situation that, if

not avoided, could result in death or

serious injury.

NOTICE

Indicates a risk of property damage,

including damage to the machine or its

individual components.

Engineering Improvements

STIHL’s philosophy is to continually

improve all of its products. As a result,

engineering changes and improvements

are made from time to time. Therefore,

some changes, modifications and

improvements may not be covered in

this manual. If the operating

characteristics or the appearance of

your machine differs from those

described in this manual, please contact

your STIHL dealer or the STIHL

distributor for your area for assistance.

2

FS 561 C-M

English

Safety Precautions and

Working Techniques

Because the machine is a

high-speed fast-cutting

power tool, special safety

precautions must be

observed to reduce the

risk of personal injury.

It is important you read

and understand the User

Manual before commis

sioning and keep it in a

safe place for future ref

erence. Non-compliance

with the User Manual

may cause serious or

even fatal injury.

Observe all applicable local safety

regulations, e.g. by trade organizations,

social insurance institutions, labor safety

authorities etc.

If you have never used a power tool

before: Have your dealer or other

experienced user show you how to

operate your machine – or attend a

special course to learn how to operate it.

Minors should never be allowed to use

the machine – except for apprentices

over the age of 16 when working under

supervision.

Children, animals and bystanders must

remain at a distance.

When not using the machine, it must be

laid down in such a way that it does not

endanger anyone. Ensure that the

machine cannot be used without

authorization.

-

-

The user is responsible for accidents or

risks involving third parties or their

property.

Do not lend or rent your power tool

without the User Manual. Be sure that

anyone using it understands the

information contained in this manual.

The use of machines that emit noise

may be limited to certain hours of the

day as specified by national and/or

regional or local regulations.

Anyone operating the machine must be

well rested, in good physical health and

in good mental condition.

If you have any condition that might be

aggravated by strenuous work, check

with your doctor before operating a

machine.

If you have a pacemaker: The ignition

system of your machine produces an

electromagnetic field of very low

intensity. This field may interfere with

some pacemakers. STIHL recommends

that persons with pacemakers consult

their physician and the pacemaker

manufacturer to reduce any health risk.

Anyone who has consumed alcohol or

drugs or medicines affecting their ability

to react must not operate a power tool.

Depending on the cutting attachment

fitted, use your power tool only for

cutting grass, wild growth, shrubs,

scrub, bushes, small diameter trees and

similar materials.

The machine must not be used for any

other purposes – risk of accidents!

Only use cutting attachments and

accessories that are explicitly approved

for this power tool model by STIHL or

are technically identical. If you have any

questions in this respect, consult your

dealer. Use only high quality parts and

accessories. in order to avoid the risk of

accidents and damage to the machine.

STIHL recommends the use of original

STIHL tools and accessories. They are

specifically designed to match the

product and meet your performance

requirements.

Never attempt to modify your power tool

in any way since this may increase the

risk of personal injury. STIHL excludes

all liability for personal injury and

damage to property caused while using

unauthorized attachments.

Do not use a high-pressure washer to

clean the power tool. The solid jet of

water may damage parts of the unit.

The guard provided with your machine

may not protect the operator from all

foreign objects (gravel, glass, wire etc.)

ejected by the revolving cutting

attachment. Ejected objects may also

ricochet and strike the operator.

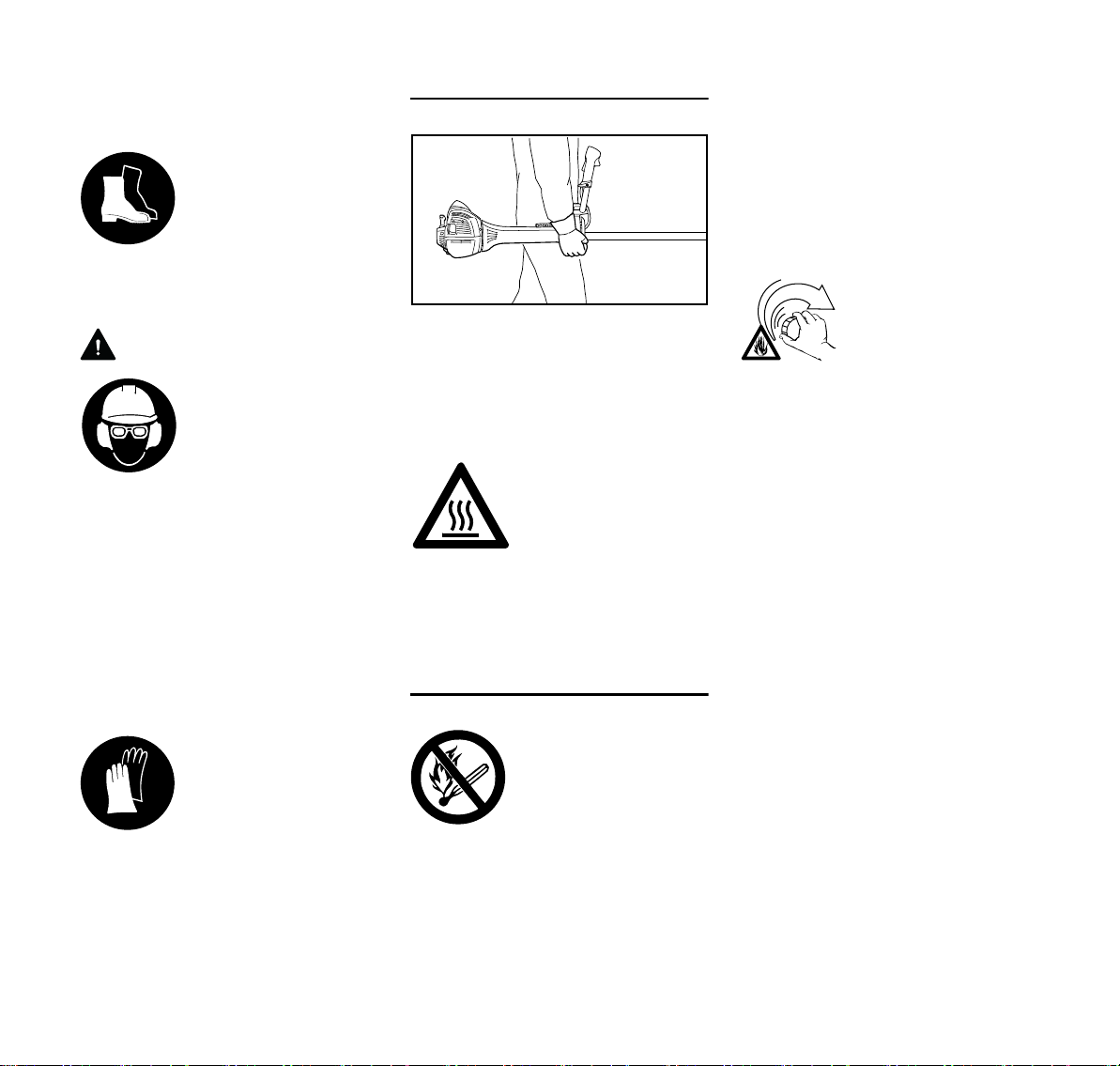

Clothing and equipment

Wear proper protective clothing and

equipment.

Clothing must be sturdy

but allow complete free

dom of movement. Wear

close-fitting clothes such

as a boiler suit, not a

loose jacket.

Do not wear clothing which could

become trapped in wood, brush or

moving parts of the machine. Do not

-

FS 561 C-M

3

English

002BA479 KN

wear a scarf, necktie or jewelry. Tie up

and confine long hair above your

shoulders.

Wear safety boots with

steel toe caps and nonslip soles.

Sturdy shoes with non-slip shoes are

permissible only when using mowing

heads.

WARNING

To reduce the risk of eye

injuries, wear close-fit

-

ting safety glasses in

accordance with Euro

-

pean Standard EN 166.

Make sure the safety

glasses are a snug fit.

Wear face protection and make sure it is

a good fit. Face protection alone is not

sufficient to protect the eyes.

Wear "personal" sound protection, e.g.

ear defenders.

Wear a safety hard hat for thinning

operations, when working in high scrub

and where there is a danger of head

injuries from falling objects.

Wear sturdy protective

gloves made of a resist

-

ant material (e. g.

leather).

Transporting the machine

Always stop the engine.

Carry the machine hanging on the

harness or by the shaft so that it is

balanced. Fit transport guard on metal

cutting attachments to avoid the risk of

injury from blade contact

Avoid touching hot parts

of the machine and gear

box – risk of burns!

By vehicle: When transporting in a

vehicle, properly secure your machine to

prevent turnover, damage and fuel

spillage.

Refueling

Gasoline is highly flam

-

mable – keep away from

fire or flame – do not spill

any fuel – no smoking.

Open the fuel cap carefully to allow any

pressure build-up in the tank to release

slowly and avoid fuel spillage.

Only refuel the machine in a well

ventilated place. If fuel has been spilled,

immediately clean the machine – do not

allow your clothes to be splashed with

fuel. If that happens, change your

clothes at once.

After fueling, tighten

down the screw-type fuel

cap as securely as

possible.

This helps reduce the risk of engine

vibrations causing an incorrectly

tightened fuel cap to loosen or come off

and spill fuel.

Check for leaks. Do not start the engine

-

if there is a fuel leak – serious or fatal

burns could result!

STIHL can supply a comprehensive

range of personal protective equipment.

4

Always shut off the engine before

refueling.

Do not fuel a hot engine – fuel may spill

and cause a fire.

FS 561 C-M

English

002BA480 KN

Before starting

Check that your power tool is properly

assembled and in good condition – refer

to appropriate chapters in the User

Manual.

– Check the fuel system for leaks,

especially the visible parts, e. g.,

fuel cap, hose connections, manual

fuel pump (only in machines with a

manual fuel pump). In case of

leakage and damage, do not start

the engine – risk of fire! Have the

machine serviced by a dealer

before using it

– Use only an approved combination

of cutting attachment, deflector,

handle and harness. All parts must

be assembled properly and

securely

– The stop switch must be easy to

push

– Check the choke lever, throttle

trigger and throttle trigger lockout

for smooth action - throttle trigger

must return automatically to idle

position. The choke lever must

spring back from the } position to

the run position F when the throttle

trigger lockout and throttle trigger

are squeezed.

– Check that the spark plug boot is

secure – a loose boot may cause

sparking that could ignite

combustible fumes and cause a fire!

– Cutting attachment or

interchangeable attachment:

correctly fitted, secure and in

perfect condition

– Safety devices (e. g., deflector for

cutting attachments, rider plate) for

damage and/or wear. Always

replace damaged parts. Do not use

the machine with a damaged

deflector or worn rider plate (if the

writing and arrows are no longer

discernible)

– Never attempt to modify the controls

or safety devices

– Keep the handles dry and clean –

free from oil and dirt – this is

important for safe control of the

machine

– Adjust the harness and handle(s) to

suit your height and reach Note the

information in the chapters "Fitting

the Harness" and "Balancing the

Machine".

To reduce the risk of personal injury, do

not operate your power tool if it is

damaged or not properly assembled!

To prepare for emergencies when using

a harness: Practice setting down the

machine quickly. To avoid damage, do

not throw the unit to the ground when

practicing.

Starting the engine

Start the engine at least 3 meters from

the fueling spot, outdoors only.

Place the unit on firm ground in an open

area. Make sure you have good balance

and secure footing. Hold the unit

securely. The cutting attachment must

be clear of the ground and all other

obstructions because it may begin to run

when the engine starts.

This is a one-person machine – ensure

that there is no-one within 15 meters of

the machine, not even when starting the

power tool! Risk of injury due to ejected

objects!

Avoid contact with the

cutting attachment – risk

of injury!

Do not drop-start the

power tool – start the

engine as described in

the User Manual. The

cutting attachment runs

on for a short while after

releasing the throttle trig

ger – coasting effect!

Keep easily combustible materials

(e. g., wood chips, bark, dry grass, fuel)

away from hot exhaust gases and hot

muffler surfaces – risk of fire!

Holding and guiding the machine

Always hold the unit firmly with both

hands on the handles.

Make sure you always have good

balance and secure footing.

Right hand on control handle, left hand

on grip on handlebar.

-

FS 561 C-M

5

English

15m (50ft)

While working

Make sure you always have good

balance and secure footing.

In the event of imminent danger or in an

emergency, push the stop switch to stop

the engine.

Within a wide area around the

workplace, there is a risk of accident by

ejected objects, therefore ensure that

there is no-one within a 15 m radius of

the machine. This distance must also be

maintained in relation to objects

(vehicles, window panes) – risk of

property damage! Even at a distance

over 15 m, danger cannot be ruled out.

Check that the engine is properly idling

so that the cutting tool will not continue

rotating after you release the throttle

trigger. If the cutting attachment still

rotates at idle speed, have your dealer

make proper adjustments or repairs.

STIHL recommends you have this work

done by a STIHL servicing dealer.

Take special care in slippery conditions

– damp, snow, ice, on slopes or uneven

ground.

Watch out for obstacles: tree stumps,

roots – risk of tripping or stumbling!

Only work while standing on the ground,

never on a ladder, work platform or other

unstable surface.

Be particularly alert and cautious when

wearing hearing protection because

your ability to hear warnings (shouts,

alarms, etc.) is restricted.

Take breaks when you start getting tired

or feeling fatigue – risk of accidents!

Work calmly and carefully – in daylight

conditions and only when visibility is

good. Proceed with caution, do not put

others in danger.

As soon as the engine is

running, the power

machine generates toxic

exhaust gas. These

gases may be odorless

and invisible and may

contain unburned hydro

carbons and benzene.

Never run the engine

indoors or in poorly venti

lated locations, even if

your model is equipped

with a catalytic converter.

To reduce the risk of serious or fatal

injury from breathing toxic fumes,

ensure proper ventilation when working

in trenches, hollows or other confined

locations.

Stop work immediately if you start

suffering from nausea, headaches,

impaired vision (e.g. your field of vision

gets smaller), impaired hearing,

dizziness, or impaired concentration –

these symptoms may possibly be the

result of too-high exhaust gas

concentration – Risk of accidents!

Operate your power tool so that it

produces a minimum of noise and

emissions – do not run the engine

unnecessarily, accelerate the engine

only when working.

To reduce the risk of fire, do not smoke

while operating or standing near your

power tool. Combustible fuel vapor may

escape from the fuel system.

Dust, fumes and smoke produced while

working may be hazardous to your

health. Wear respiratory protection in

case of heavy dust or smoke emission.

If your power tool is subjected to

unusually high loads for which it was not

designed (e.g. heavy impact or a fall),

always check that it is in good condition

before continuing work – see also

"Before Starting".

Check in particular that the fuel system

has no leaks and the safety equipment is

-

fully operative. Never use a power tool

that is no longer safe to operate. In case

of doubt, contact a dealer.

-

To reduce the risk

of injuryfrom

thrown objects,

never operate the

unit without the

proper deflector for

the type of cutting

attachment being

used.

Check the work site –

rocks, metal objects etc.

may be caught up and

ejected – possibly over a

distance of 15 m – risk of

injury! – They can also

damage the cutting

attachment and other

property (e. g. parking

vehicles, windows).

Be particularly careful when working on

difficult, densely grown terrain.

6

FS 561 C-M

English

When mowing in high shrubbery, under

shrubbery and hedges: Hold the cutting

tool at a working height of at least 15 cm

– avoid risks to animals.

Always shut off the engine before

leaving the unit unattended.

Examine the cutting attachment

periodically at short intervals and as

soon as you note any noticeable

changes:

– Stop the engine, hold the machine

securely, allow the cutting

attachment to come to a stop

– Check condition and secure fitting;

watch out for cracks

– Ensure that the cutting blades are

sharp

– Replace damaged or blunt cutting

attachments immediately, even in

the event of minor hairline cracks

Clean grass and plant residue off the

cutting attachment mounting at regular

intervals – remove any build up of

material from the cutting attachment and

deflector.

To reduce the risk of injury, shut off the

engine before replacing the cutting

attachment.

The gearbox gets hot

during operation. Never

touch the gearbox – risk

of burns!

Do not continue using or attempt to

repair damaged or cracked cutting

attachments by welding, straightening or

modifying the shape (out of balance).

Particles or pieces may come off and hit

the operator or a bystander at a high

speed – risk of most severe injuries!

If a rotating cutting attachment touches a

rock or another hard object, sparks may

be generated which may possibly ignite

combustible materials. Also dried-out

plants and brushwood are combustible,

above all in hot and dry weather. If there

is a risk of fire, do not use cutting

attachments in the vicinity of

combustible materials, dried-out plants

or brushwood. It is mandatory that you

ask the responsible forestry office about

the current fire hazard.

Using mowing heads

Use only the deflector with properly

mounted line limiting blade to ensure the

mowing lines are automatically trimmed

to the approved length.

Always switch off the engine to adjust

the mowing line for manually adjustable

mowing heads – risk of injury!

Misuse with mowing lines that are too

long reduces the working speed of the

engine. The constant slipping of the

clutch causes overheating and damage

to important components (e. g. clutch,

plastic housing parts) – e. g. due to the

cutting attachment rotating during idling

– risk of injury!

When using metal cutting attachments

STIHL recommends the use of original

STIHL metal cutting attachments. These

have been optimized for the machine

and the user’s requirements.

Metal cutting attachments rotate very

fast, generating forces acting on the

attachments and on the cuttings.

Metal cutting attachments must be

sharpened in regular intervals in

accordance with the instructions.

Unevenly sharpened metal cutting

attachments generate an imbalance

which may cause extreme loads on the

machine – risk of breakage!

Dull or improperly sharpened cutting

edges can put a higher load on the

cutting attachment and increase the risk

of injuryfrom cracked or broken parts.

After each contact of the metal cutting

attachment with hard objects (e.g.

stones, rocks, metal parts), check it for

damage (e.g. tears and deformation).

Burrs and other visible material

accumulations must be removed since

they may come loose at any time while

the machine is running and then be

ejected – risk of injury!

To reduce the above-named risks

involved in operating a metal cutting

attachment, ensure that the diameter of

your metal cutting attachment is not too

big. Also, the attachment must not be

too heavy. It must be made of highquality materials and have a suitable

geometry (shape, thickness).

A metal cutting attachment not made by

STIHL must not have a different weight,

thickness, shape and a larger diameter

than the largest STIHL metal cutting

attachment approved for this metal

cutting attachment – risk of injury!

FS 561 C-M

7

English

Vibrations

Prolonged use of the power tool may

result in vibration-induced circulation

problems in the hands (whitefinger

disease).

No general recommendation can be

given for the length of usage because it

depends on several factors.

The period of usage is prolonged by:

– Hand protection (wearing warm

gloves)

– Work breaks

The period of usage is shortened by:

– Any personal tendency to suffer

from poor circulation (symptoms:

frequently cold fingers, tingling

sensations).

– Low outside temperatures.

– The force with which the handles

are held (a tight grip restricts

circulation).

Continual and regular users should

monitor closely the condition of their

hands and fingers. If any of the above

symptoms appear (e.g. tingling

sensation in fingers), seek medical

advice.

Maintenance and Repairs

Service the machine regularly. Do not

attempt any maintenance or repair work

not described in the instruction manual.

Have all other work performed by a

servicing dealer.

STIHL recommends that you have

servicing and repair work carried out

exclusively by an authorized STIHL

servicing dealer. STIHL dealers are

regularly given the opportunity to attend

training courses and are supplied with

the necessary technical information.

Only use high-quality replacement parts

in order to avoid the risk of accidents

and damage to the machine. If you have

any questions in this respect, consult a

servicing dealer.

STIHL recommends the use of original

STIHL replacement parts. They are

specifically designed to match your

model and meet your performance

requirements.

To reduce the risk of injury from

unintentional engine startup, always

shut off the engine and disconnect the

spark plug boot before performing any

repairs, maintenance or cleaning work. –

Exception: Carburetor and idle speed

adjustments.

Do not turn the engine over on the

starter with the spark plug boot or spark

plug removed since there is otherwise a

risk of fire from uncontained sparking.

To reduce the risk of fire, do not service

or store your machine near open flames.

Check the fuel filler cap for leaks at

regular intervals.

Use only a spark plug of the type

approved by STIHL and make sure it is

in good condition – see "Specifications".

Inspect the ignition lead (insulation in

good condition, secure connection).

Check the condition of the muffler.

To reduce the risk of fire and damage to

hearing, do not operate your machine if

the muffler is damaged or missing. –

Do not touch a hot muffler since burn

injury will result.

Vibration behavior is influenced by the

condition of the AV elements – check the

AV elements at regular intervals.

Maintenance, replacement, or repair of

the emission control devices and

systems may be performed by any

nonroad engine repair establishment or

individual. However, if you make a

warranty claim for a component which

has not been serviced or maintained

properly, STIHL may deny coverage.

For any maintenance please refer to the

maintenance chart and to the warranty

statement near the end of the instruction

manual.

Symbols on Deflectors

An arrow on the deflector shows the

correct direction of rotation of the cutting

attachments.

Some of the following symbols are

applied to the outside of the deflector to

indicate the approved combination of

cutting attachment and deflector.

Deflector may be used

with mowing heads.

8

FS 561 C-M

English

002BA397 KN

000BA015 KN

Deflector may be used

with grass cutting blades.

Deflector may be used

with brush knives.

Deflector may be used

with shredder blades.

Deflector must not be

used with mowing heads.

Deflector must not be

used with grass cutting

blades.

Deflector must not be

used with brush knives.

Deflector must not be

used with shredder

blades.

Deflector must not be

used with circular saw

blades.

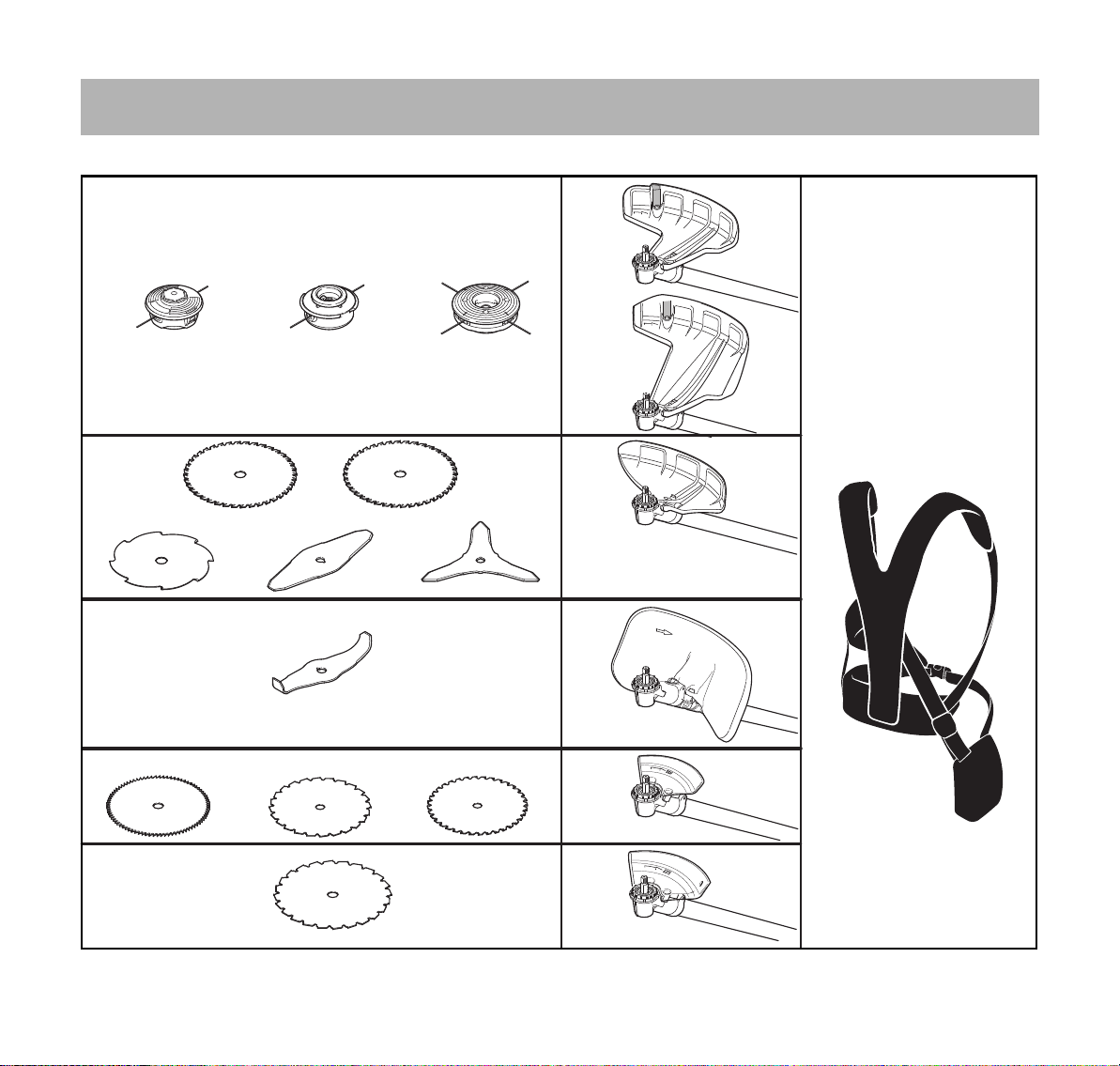

Harness

The harness is included with the

machine or available as a special

accessory.

N Use the harness.

N With the engine running, attach the

machine to the harness.

All cutting attachments must be used in

combination with a full harness with a

quick-release system.

Mowing Head with Nylon Line

Nylon line achieves a soft cut for edging

and trimming around trees, fence posts,

etc. – less risk of damaging tree bark.

The mowing head comes with an

instruction leaflet. Refill the mowing

head with nylon line as described in the

instruction leaflet.

WARNING

To reduce the risk of serious injury,

never use wire or metal-reinforced line in

place of the nylon line.

STIHL DuroCut

FS 561 C-M

Check the wear limit marks!

9

English

681BA209 KN

002BA396 KN

002BA135 KN

If one of the wear limit marks imbedded

in the baseplate of the DuroCut

(exclamation marks) becomes visible,

do not continue using the mowing head

since it may otherwise be damaged.

Replace the worn baseplate.

The mowing head comes with

instruction leaflets. Equip the mowing

head only with nylon line as described in

the instruction leaflets.

WARNING

Never use wire in place of the nylon

mowing line – risk of injury.

STIHL Polycut Mowing Head with

Polymer Blades

For mowing unobstructed edges of

meadows (without posts, fences, trees

or similar obstacles).

Check the wear limit marks!

If one of the wear limit marks on the

PolyCut mowing head is worn through

(arrow): Do not continue using the

mowing head. Install a new one. There

is otherwise a risk of injury from thrown

parts of the head.

It is important to follow the maintenance

instructions for the PolyCut mowing

head.

The PolyCut can also be equipped with

mowing line in place of the polymer

blades.

The mowing head comes with

instruction leaflets. Equip the mowing

head with polymers blades or nylon line

as described in the instruction leaflets.

WARNING

Never use wire in place of the nylon

mowing line – risk of injury.

Risk of Kickout (Blade Thrust) with Metal

Cutting Attachments

WARNING

When using metal cut

-

ting attachments there is

a risk of kickout when the

rotating blade comes into

contact with a solid object

such as a tree trunk,

branch, tree stump, rock

or similar. The machine is

thrown to the right or to

the rear – opposite to the

attachment's direction of

rotation.

The risk of kickout is greatest when the

black area of the rotating cutting

attachment comes into contact with a

solid object.

10

FS 561 C-M

English

000BA020 KN

002BA355 KN

002BA509 KN

002BA210 KN

Grass Cutting Blade

Use for grass and weeds only – sweep

the brushcutter in an arc like a scythe.

WARNING

Improper use may damage the grass

cutting blade – risk of injury from thrown

parts.

Resharpen the grass cutting blade

according to instructions when it has

dulled noticeably.

Brush Knife

For cutting matted grass, wild growth

and scrub and thinning young stands

with a stem diameter of no more than

2 cm – do not cut thicker stems – risk of

accidents.

Use the brushcutter like a scythe (sweep

it to the right and left) at ground level

when cutting grass and thinning young

stands.

To cut wild growth and scrub, lower the

brush knife down onto the growth to

achieve a shredding effect – always

keep the cutting attachment below hip

level during this process.

Exercise extreme caution when using

this method of cutting. The higher the

cutting attachment is off the ground, the

greater the risk of injury from cuttings

being thrown sideways.

Warning! Improper use of a brush knife

may cause it to crack, chip or shatter –

risk of injury from thrown parts.

To reduce the risk of injury it is essential

to take the following precautions:

– Avoid contact with stones, rocks,

pieces of metal and other solid

foreign objects.

– Never cut wood or shrubs with a

stem diameter of more than 2 cm –

use a circular saw blade for such

work.

– Inspect the brush knife at regular

short intervals for signs of damage.

Do not continue working with a

damaged brush knife.

– Resharpen the brush knife regularly

and whenever it has dulled

noticeably, and have it balanced if

necessary (STIHL recommends a

STIHL servicing dealer).

Shredder Blade

Suitable for thinning and shredding

tough, matted grass and scrub.

To cut wild growth and scrub, lower the

shredder blade down onto the growth to

achieve a shredding effect – always

keep the cutting attachment below hip

level during this process.

FS 561 C-M

11

English

002BA449 KN

Exercise extreme caution when using

this method of cutting. The higher the

cutting attachment is off the ground, the

greater the risk of injury from cuttings

being thrown sideways.

Warning! Improper use may damage the

shredder blade – risk of injury from

thrown parts.

To reduce the risk of injury it is essential

to take the following precautions:

– Avoid contact with stones, rocks,

pieces of metal and other solid

foreign objects.

– Never cut wood or shrubs with a

stem diameter of more than 2 cm –

use a circular saw blade for such

work.

– Inspect the shredder blade at

regular short intervals for signs of

damage. Do not continue working

with a damaged shredder blade.

– Resharpen the shredder blade

regularly and whenever it has dulled

noticeably, and have it balanced if

necessary (STIHL recommends a

STIHL servicing dealer).

Circular Saw Blade

Suitable for cutting shrubs and trees with

a maximum stem diameter of 7 cm.

Before starting the cut, accelerate the

engine up to full throttle. Perform cut

with uniform pressure.

Use circular saw blades only with a

matching limit stop of the correct

diameter.

WARNING

To reduce the risk of blade damage,

avoid contact with stones and the

ground. Resharpen the blade properly in

good time – dull teeth may result in the

blade cracking and shattering and

causing serious injury.

When felling, maintain a distance of at

least two tree lengths from the next

felling site.

Risk of kickout

The risk of kickout is highest in the black

area of the blade: Do not use this area of

the circular saw blade for cutting.

There is also a risk of kickout when

using the lighter shaded areas of the

blade: These areas of the blade should

only be used by experienced operators

with specialized training.

STIHL recommends that you use the

non-shaded area of the circular saw

blade. Always start the cut with this area

of the blade.

12

FS 561 C-M

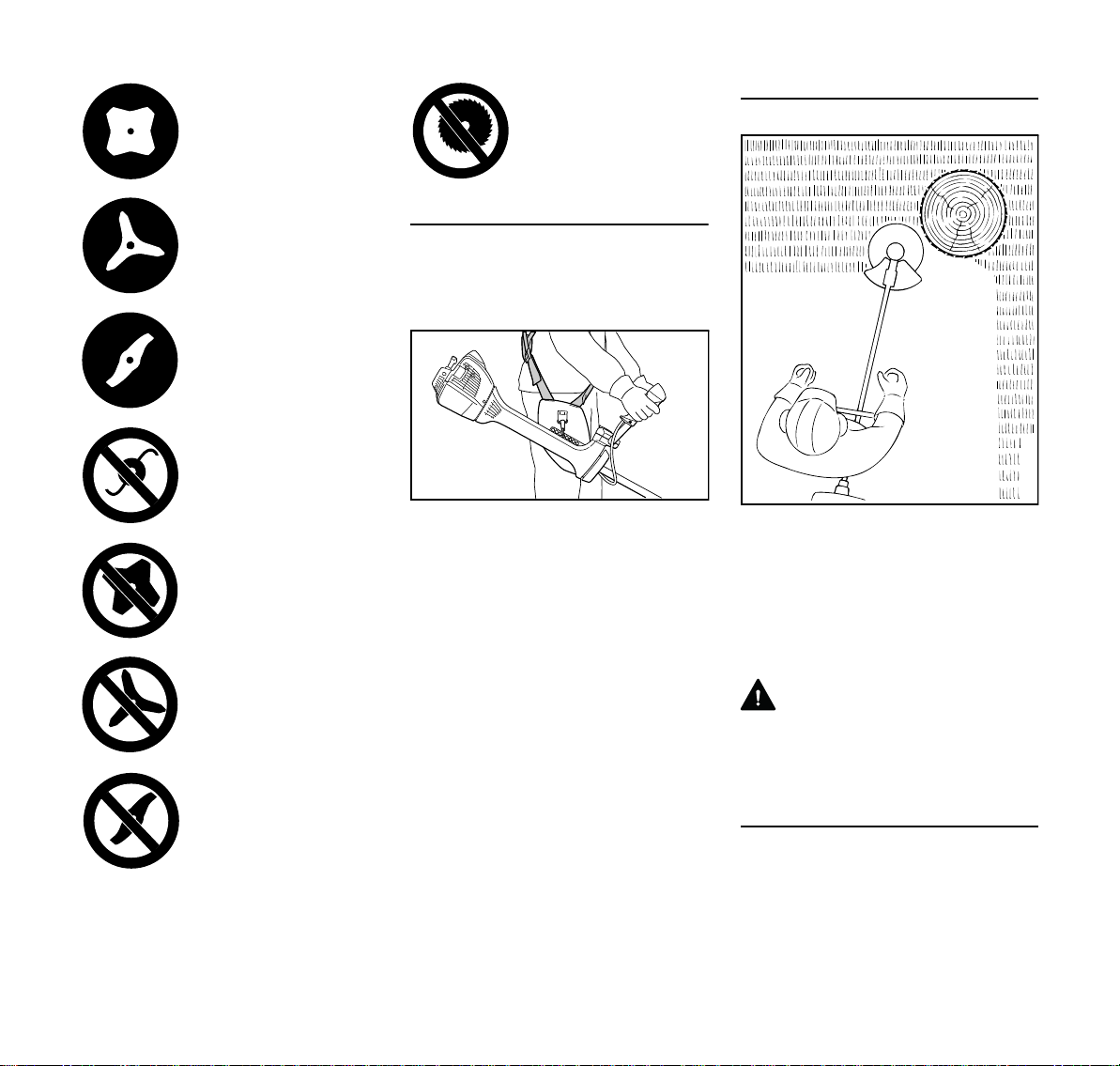

Approved Combinations of Cutting Attachment, Deflector, Limit Stop and Harness

9

10

11

12

18

17

16

14

5

8

0000098045_001

7

6

20

1

3

2

4

15

13

19

Cutting attachment Deflector, limit stop Carrying strap

English

FS 561 C-M

13

English

Permissible combinations

Choose the correct combination from

the table depending on the cutting tool!

WARNING

For safety reasons only the cutting

attachments and deflectors and/or limit

stops within one line of the table may be

combined with one another. No other

combinations are permitted because of

the risk of accidents!

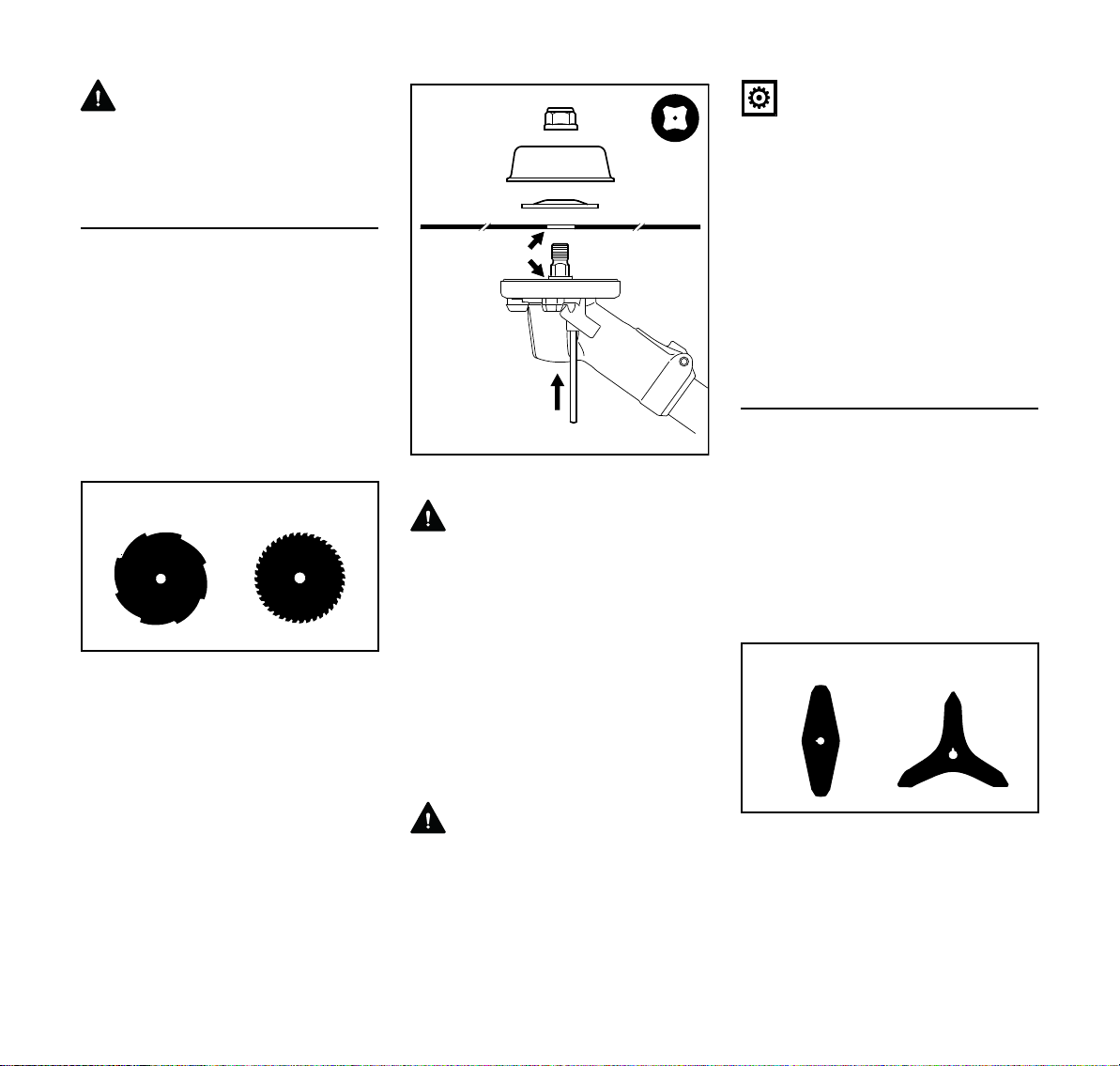

Cutting attachments

Mowing heads

1 STIHL AutoCut 56-2

2 STIHL TrimCut C 52-2

3 STIHL DuroCut 40-4

Metal cutting tools

4 Grass cutting blade 250-32 Spezial

(Ø 250 mm)

5 Grass cutting blade 250-40 Spezial

(Ø 250 mm)

6 Grass cutting blade 255-8

(Ø 255 mm)

7 Brush knife 305-2 Spezial

(Ø 305 mm)

8 Brush knife, 350-3

(Ø 350 mm)

9 Shredder blade 320-2

(Ø 320 mm)

10 Circular saw blade 225 scratcher

tooth

(Ø 225 mm)

11 Circular saw blade 225 chisel tooth

(Ø 225 mm)

12 Carbide tipped circular saw blade

225

(Ø 225 mm)

13 Circular saw blade 250, chisel tooth

(250 mm dia.)

WARNING

Non-metal grass cutting blades, brush

knives, shredder blades and circular

saw blades are not permitted.

Deflectors, limit stop

14 Deflector for mowing heads

(Ø 480 mm)

15 Deflector for mowing heads

(Ø 560 mm)

16 Guard for metal cutting tools,

items 4 to 8

17 Guard for shredder blades

18 Limit stop for circular saw blades

(Ø 225 mm)

19 Limit stop for circular saw blades

(Ø 250 mm)

Carrying strap

20 Full harness must be used

WARNING

Based on the cutting attachment being

used:

Choose the proper deflector in order to

reduce the risk of injury from thrown

objects and contact with the cutting

attachment.

Make sure your unit is equipped with the

proper handle and harness in order to

reduce the risk of injury from loss of

control and contact with the cutting

attachment.

Use grass cutting metal blades, brush

knifes and circular saw blades on this

unit only if equipped with a bike handle.

Do not use rigid polymer blades on this

unit.

14

FS 561 C-M

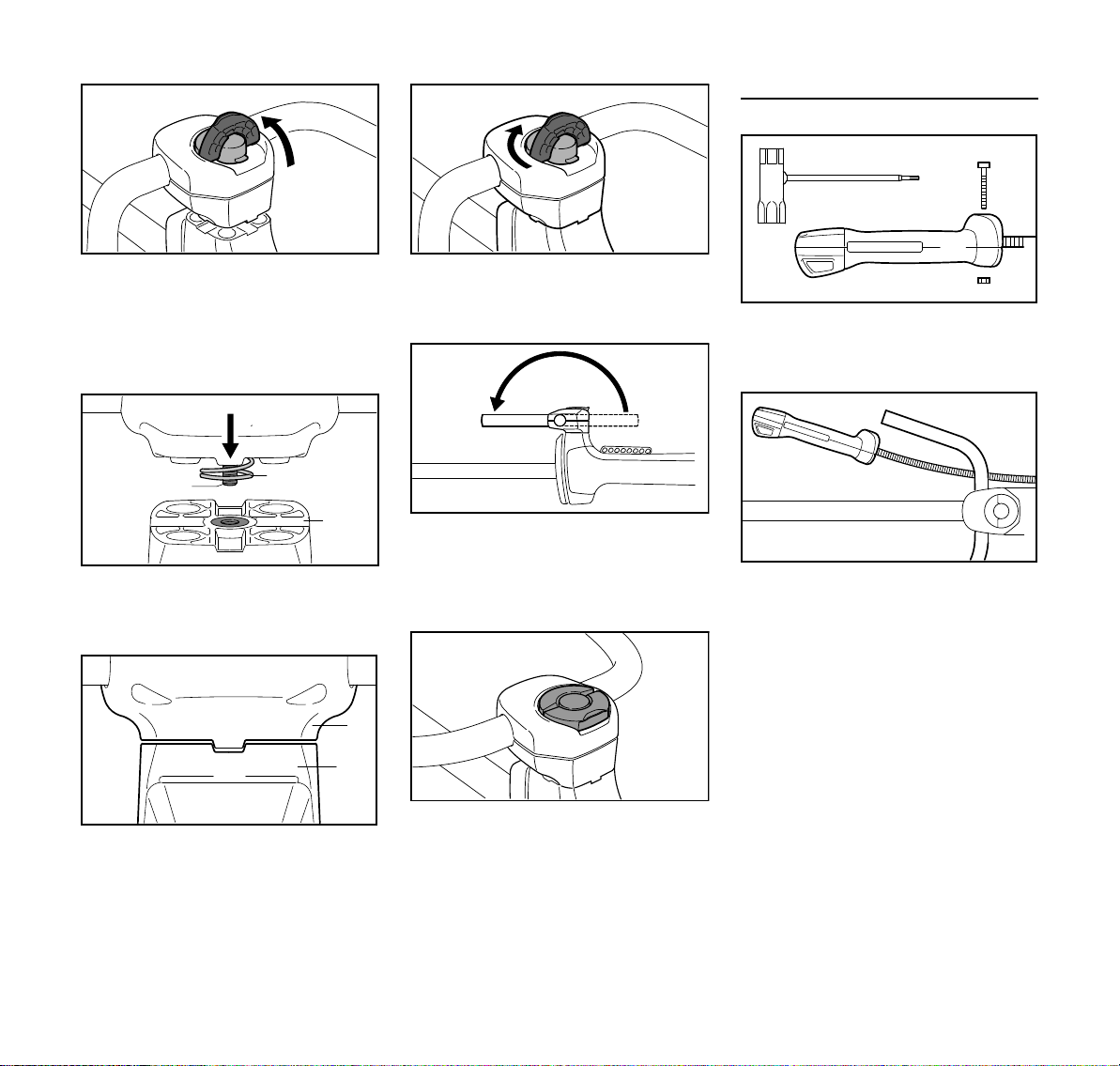

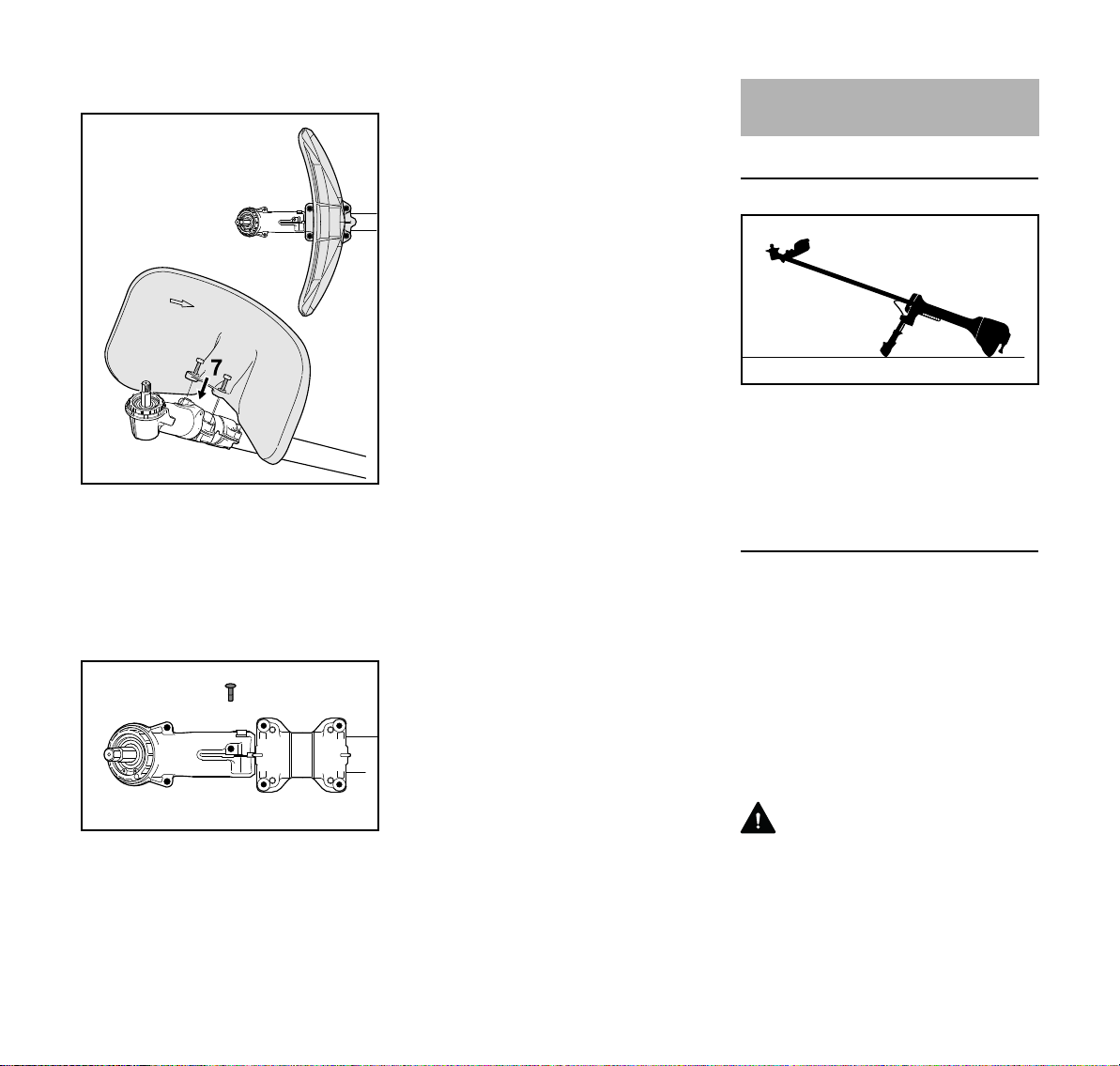

Mounting the Bike Handle

1

3BA003 KN

3BA004 KN

4

2

2BA001 KN

4

3

3BA005 KN

5

4900BA002 KN

7

2

4

Mounting Bike Handle with Swiveling

Handle Support

English

Do not rotate the control handle (1)

between unpacking and mounting it on

the handlebar; see also chapter on

"Adjusting the Throttle Cable".

The brushcutter is available with two

different handlebars:

2 Handlebar for machines used

primarily for mowing, brushcutting

and shredding, but also for

occasional sawing.

3 Handlebar for machines used

mainly for sawing, but also for

mowing and brushcutting.

The machine is supplied with the clamp

moldings (4) mounted on the handlebars

(2, 3).

N Do not change the position of the

clamp moldings on the handlebar

until it is mounted on the handle

support.

The mounting procedure is the same for

both types of handlebar. Therefore, the

following description only shows

handlebar (2).

Mounting the Handlebar

Assembly of the swivelling handle

support involves equipping the clamp

moldings with a spring and mounting

them on the handle support.

N Use the spring (5) from the parts kit

supplied with the machine.

N Push the spring (5) into the lower

clamp molding (6).

N Position the clamp moldings (4) with

handlebar (2) on the handle support

(7).

N Do not turn the handlebar in the

clamp moldings.

FS 561 C-M

15

English

8

3BA007 KN

5

8

3BA008 KN

7

6

10

7

9

3BA0009 KN

7

6

3BA010 KN

2

4900BA003 KN

4900BA004 KN

11

12

1

002BA451 KN

13

2

4900BA005 KN

Mounting the Control Handle

N Raise the grip of the wing screw (8)

to the upright position.

N Rotate the wing screw

counterclockwise and tighten it only

moderately.

N Position wing screw (8) in threaded

insert in handle support (7) – against

pressure of spring (5).

N Rotate wing screw clockwise until

the lower clamp molding (6) butts

against the handle support (7).

N Swing the handebar (2) forwards

through 180°.

N Only tighten the wing screw

moderately.

N Take out the screw (11) and remove

the nut (12) from the control handle

(1).

N Hold the control handle in front of

the right-hand end of the handlebar

so that the throttle cable (13) is on

the inboard side of the handlebar

(2).

N Position the clamp moldings so that

the tabs (9) on the lower clamp

molding (6) line up with the slots

(10) in the handle support (7).

16

N Fold the grip of the wing screw down

so that it is flush.

FS 561 C-M

English

14

15

15

2

4900BA007 KN

1

11

12

4900BA008 KN

4900BA009 KN

4900BA010 KN

4900BA011 KN

4900BA012 KN

2

A

4900BA013 KN

N Push the control handle (1) in this

position onto the end of the

handlebar (2) until the holes (15)

line up – throttle trigger (14) facing

down.

N Fit the nut (12) in the control handle,

insert the screw (11) and tighten it

down firmly.

Adjusting the Handlebar

Opening the wing screw

N Turn the wing screw

counterclockwise until the handle

support can be moved.

Lining up the handlebar

N Move the handlebar to the required

position.

N Position the handlebar (2) so that

distance A is about 7 in (17 cm).

Do not clamp the curved part of the

handlebar.

Closing the wing screw

N Rotate the wing screw clockwise

until it becomes difficult to turn.

N Tighten down the wing screw firmly.

N Raise the grip of the wing screw to

the upright position.

FS 561 C-M

17

English

4900BA014 KN

4900BA015 KN

2

8

002BA655 KN

N Fold the grip of the wing screw down

so that it is flush.

Checking the Throttle Cable

N After mounting the control handle,

check the throttle cable – see

chapter on "Adjusting the Throttle

Cable".

Swiveling the Handlebar

Transport position

N Loosen the wing screw (8) and

unscrew it until the handlebar (2)

can be turned clockwise.

N Turn the handlebar 90° and then

swing the handles down.

N Tighten down the wing screw (8)

firmly.

Working position

N Reverse the sequence described

above to swing the handles up and

turn the handlebar

counterclockwise.

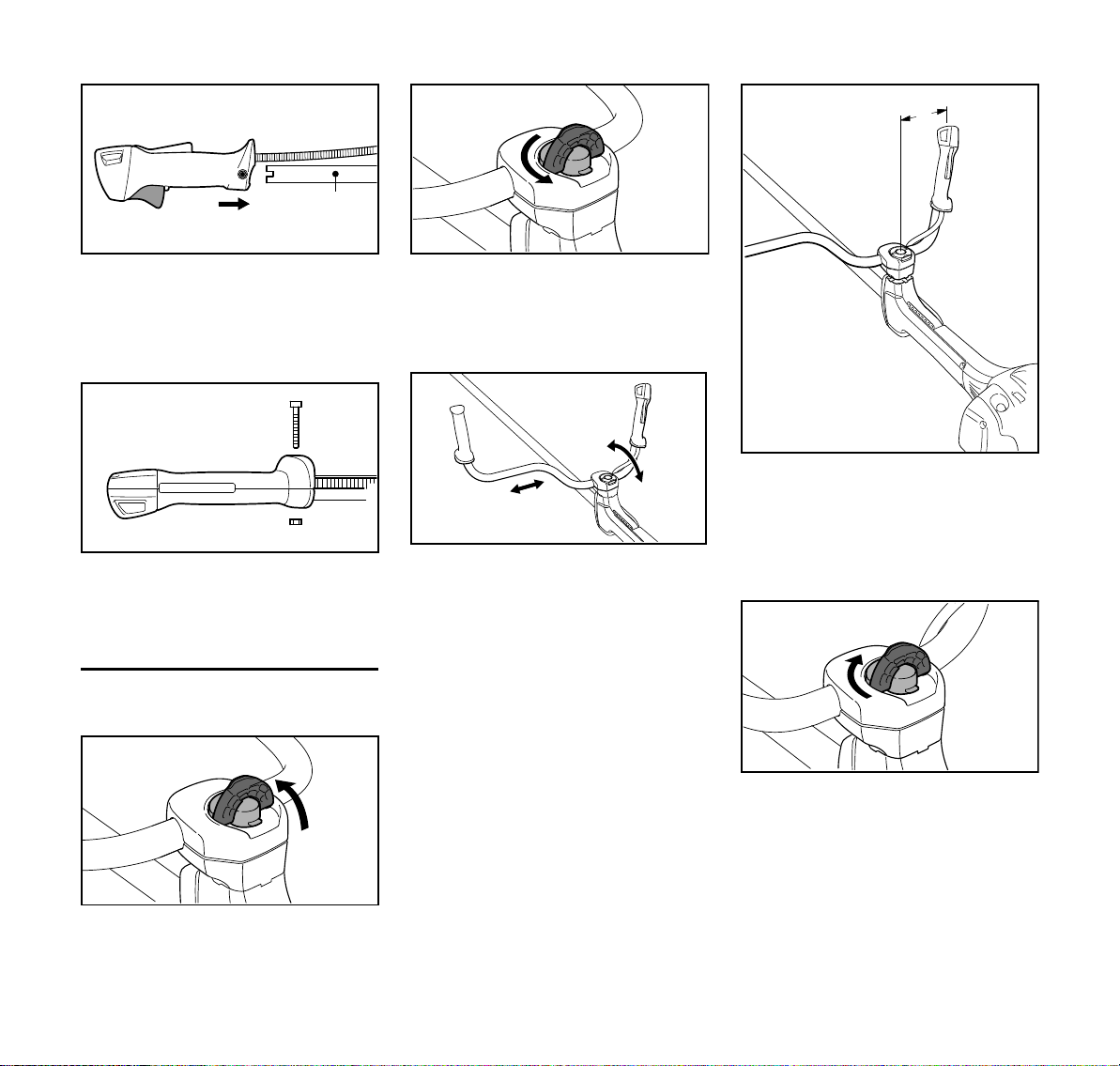

Adjusting the Throttle Cable

It may be necessary to correct the

adjustment of the throttle cable after

assembling the machine or after a

prolonged period of operation.

Adjust the throttle cable only when the

unit is completely and properly

assembled.

N Set the throttle trigger to the full

throttle position.

N Carefully rotate the screw in the

throttle trigger in the direction of the

arrow until you feel initial resistance.

Then rotate it another half turn in the

same direction.

18

FS 561 C-M

Mounting the Deflector

1

002BA461 KN

2

002BA462 KN

3

002BA463 KN

4

002BA464 KN

5

6

002BA465 KN

Using the Proper Deflector

English

WARNING

Deflector (1) is approved only for

mowing heads, thus deflector (1) must

be attached before attaching a mowing

head.

WARNING

Deflector (2) is approved only for grass

cutting blades and brush knives, thus

deflector (2) must be attached before

attaching a grass cutting blade or brush

knife.

FS 561 C-M

WARNING

Deflector (3) is approved only for

shredder blades, thus deflector (3) must

be attached before attaching a shredder

blade, see section "Mounting deflector".

WARNING

Limit stop (4), which acts as a deflector,

is approved only for circular saw blades,

thus limit stop (4) must be attached

before attaching a circular saw blade.

Mounting the guard

Deflectors (1, 2 and 4) are mounted to

the gearbox in the same way.

N Remove dirt from joints on gearbox

and deflector – make sure that no

dirt gets into the screw holes in the

gearbox – see section on "Plugs"

N Place the deflector on the gearbox

(5)

N insert the screws (6) and tighten

them down to a torque of 89 lbf. in.

(10 Nm).

Mounting shredder deflector

Owing to the high loads on the shredder

deflector (3) and country-specific

regulations on the use of the machine for

shredding, the deflector must be

properly mounted to the machine.

A special screwdriver bit is required to

mount this deflector. The bit is available

only from specialist retailers. It has a

special drive for rotating the screws and

only allows the screws to be tightened.

Once tightened, the screws can no

longer be loosened – not even with the

special tool!

STIHL therefore recommends: Have the

shredder deflector mounted by your

STIHL dealer.

A "shredder deflector mounting kit" is

available as a special accessory for

retrofitting machines with a shredder

deflector. Depending on the machine's

original equipment, a "shredder blade

19

English

002BA495 KN

3

2

2

002BA496 KN

5

5

3

002BA497 KN

1

4

002BA498 KN

002BA499 KN

retrofit kit" may also be needed for the

conversion. Neither of these kits include

the shredder blade – it must be ordered

separately.

The "shredder blade retrofit kit" contains

clamps which butt against the gearbox

and have to be secured to the drive tube.

The kit also contains the shredder

deflector which is mounted to the

clamps.

– Installing the clamps

– Lower clamp (1): Identified by two

lugs (2) on its longitudinal axis, eight

tapped holes and a lateral notch (3)

– Upper clamp (4): Identified by holes

marked 1 to 4 and a lateral lug (5)

N Position the lower clamp (1) against

the underside of the drive tube next

to the gearbox

N position the upper clamp (4) on the

drive tube so that the lug (5)

engages the notch (3)

N hold both clamps steady in this

position

N insert a screw in the upper clamp (4)

in the hole marked with number 1

and turn it only a few turns in the

lower clamp (1)

N Insert a screw in each of the holes

marked 2, 3 and 4 and wind them

only a few turns into the lower clamp

N Slide the clamps up against the

gearbox and engage the lug (5) in

the gearbox gap (arrows)

N hold both clamps in this position!

N Screw home the screws in holes 1

and 2 as far as stop

N Tighten down the screws in holes 1

and 2 to a torque of 8 Nm

N Screw home the screws in holes 3

and 4 in that order and tighten them

down to a torque of 8 Nm

20

FS 561 C-M

English

6

002BA500 KN

002BA466 KN

8

9

6

002BA406 KN

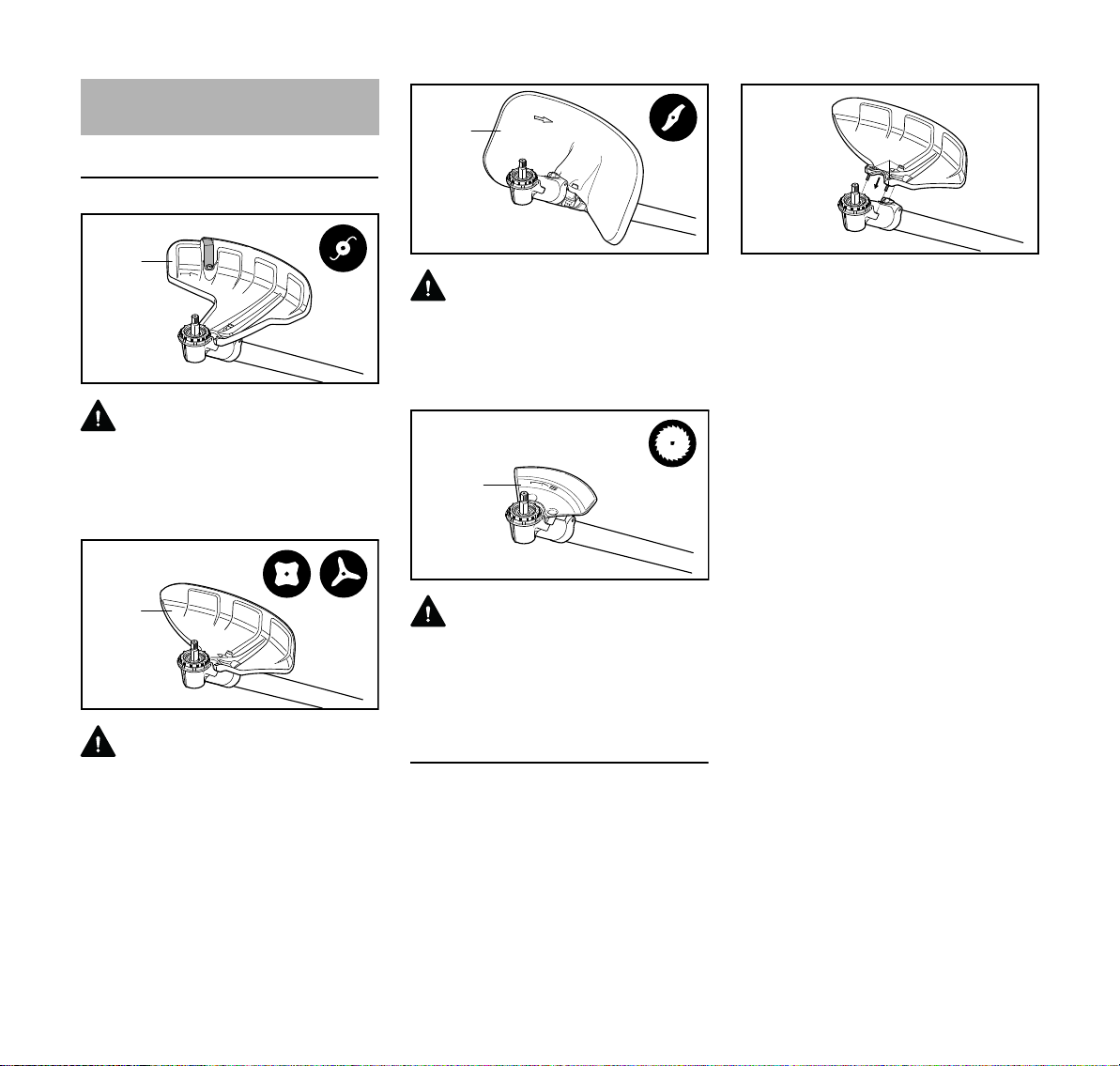

– Mounting the shredder deflector

N Position the shredder deflector on

the lower clamp with its concave

side facing the gearbox (6)

N Screw in and tighten the screws (7)

– Plugs

Four plugs (9) are supplied with the

shredder deflector.

Mounting the Cutting

Attachment

Placing power tool on the ground

N Shut off the engine.

N Lay your power tool on its back so

that the cutting attachment

mounting face is pointing up.

Mounting Hardware for the Cutting

Attachment

The mounting hardware supplied

depends on the cutting attachment that

comes as original equipment with the

new machine.

The appropriate deflectors and

mounting hardware are available as

special accessories for subsequently

equipping the machine with different

cutting attachments – see chapter on

"Special Accessories".

To prevent the unused threaded holes

for protection in the gear unit (6) and

clamps (8) from becoming

contaminated, plugs (9) are available as

optional accessories.

FS 561 C-M

WARNING

Always use and assemble the cutting

attachment mounting hardware as

described in the chapter on "Mounting

the Cutting Attachment".

21

English

681BA191 KN

4

3

4

681BA192 KN

5

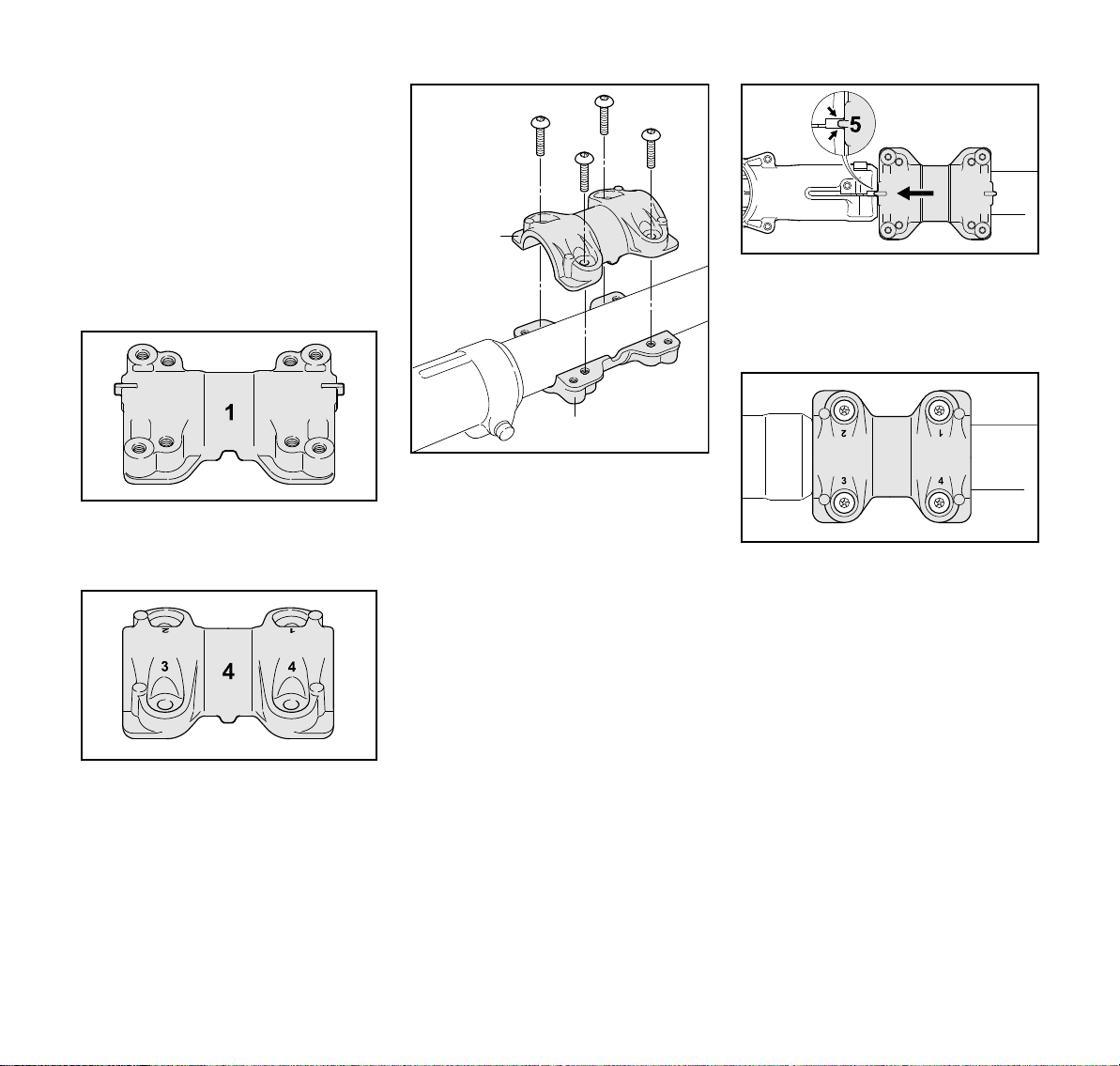

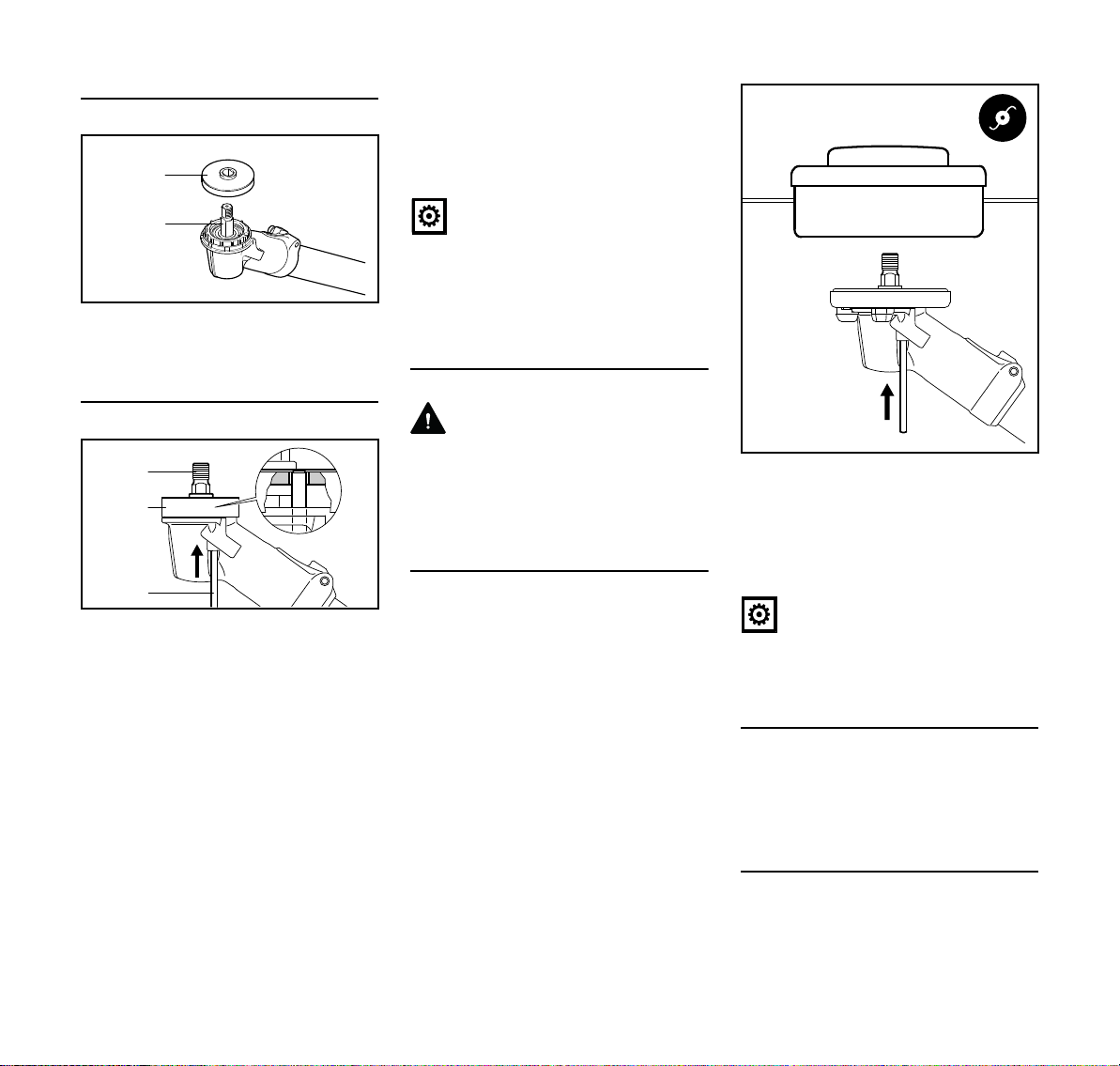

Thrust Plate

A

– For fixing mowing heads, grass

cutting blades, brush knives,

shredder blades and circular saw

blades

NOTICE

The thrust plate is needed to mount all

cutting attachments on the gearbox.

Thrust washer

A

– For fixing grass cutting blades,

brush knives, shredder blades and

circular saw blades

Rider plates, guard ring and nut

A

681BA188 KN

– For fixing grass cutting blades,

brush knives and circular saw

blades

– Guard ring (3) for brush knives and

shredder blades

Both these parts have the same

function:

– Nut (4) and thread on shaft are

681BA189 KN

protected against wear.

– Ground contact with metal cutting

attachment is minimized.

– Rider plates allow the cutting

attachment to glide along close to

ground.

Nut and combination wrench

681BA190 KN

Metal cutting attachments are mounted

to the gearbox with the nut (4).

N Loosen and tighten the nut (4) with

the combination wrench (5).

WARNING

Nuts that move too easily must be

replaced.

Cleaning gearbox and mounting

hardware for the cutting attachment

The gearbox, its surroundings, the

interior of the shield and the individual

mounting hardware for the cutting

attachment should be inspected for dirt

regularly and when changing the cutting

attachment and thoroughly cleaned if

necessary. To do this:

N Remove all mounting hardware for

the cutting attachment from the

gearbox

WARNING

Always replace a worn rider plate and

guard ring in good time.

22

FS 561 C-M

English

002BA467 KN

1

2

002BA507 KN

1

2

3

1

002BA468 KN

Attaching the thrust plate

N Slip the thrust plate (1) over the

shaft (2).

Retaining the Shaft

The shaft (2) must be blocked to install

and remove cutting attachments.

The shaft (2) can be blocked only if the

thrust plate (1) is properly fitted – the

stop pin (3) has to engage the thrust

plate.

N Insert the stop pin (3) in the bore in

the gearbox – apply slight pressure.

N Turn the shaft, nut or cutting

attachment until the stop pin

engages and the shaft is blocked

The stop pin is held in position in the

gearbox by a rubber element.

FS 561 C-M

N Fit or remove the cutting attachment

– see chapter on "Mounting the

Cutting Attachment"

N Remove the stop pin from the

gearbox

NOTICE

Always remove the stop pin used to

block the shaft since the drive train will

otherwise be damaged when the engine

runs.

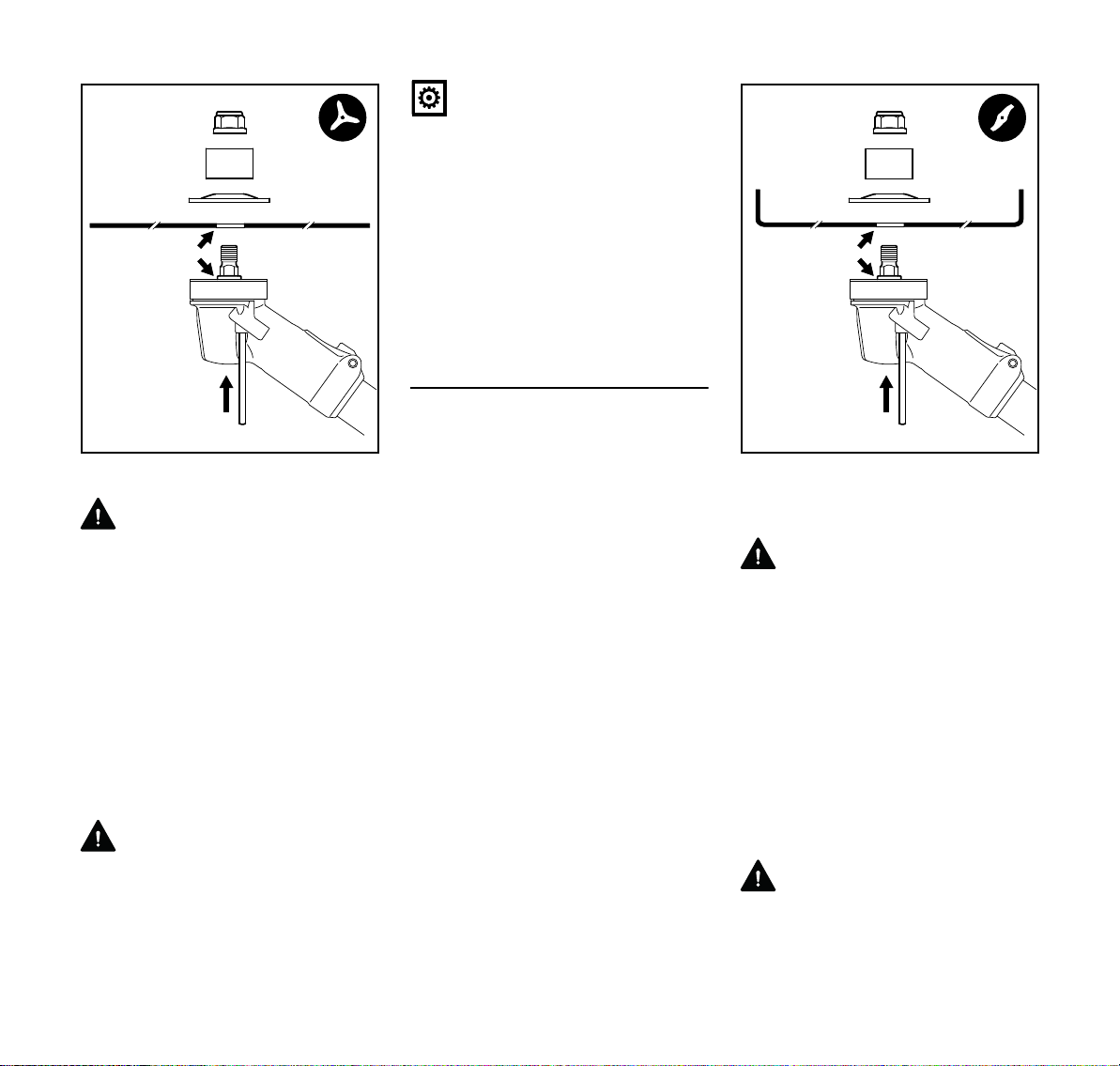

Mounting the Cutting Attachment

WARNING

Use a deflector that matches the cutting

attachment – see "Mounting the

Deflector".

Fitting the mowing head with screw

mounting

Keep the supplement sheet for the

mowing head in a safe place.

All approved mowing heads are

mounted to the gearbox in the same

way.

N Check whether the fitted deflector is

approved for mowing heads – if not,

remove the deflector not approved

for mowing heads

N Mount the deflector for mowing

heads

N Attaching the thrust plate

N Turn the mowing head

anticlockwise on the shaft (1) as far

as it will go

N Retain the shaft

N Tighten the mowing head

NOTICE

Remove the tool that was used to block

the shaft.

Removing the Mowing Head

N Retain the shaft

N Turn the mowing head clockwise

Mounting and removing the metal

cutting attachment

To mount and remove metal cutting

attachments:

23

English

1

2

681BA186 KN

a

002BA469 KN

b

4

5

3

6

1

2

681BA187 KN

WARNING

Put on protective gloves – risk of injury

by the sharp cutting edges

Mounting Grass Cutting Blades or Brush

Knives

N check whether the fitted deflector is

approved for grass cutting blades or

brush knives – if not, remove the

deflector not approved for grass

cutting blades or brush knives

N Mount the deflector for grass cutting

blades and brush knives

N Attaching the thrust plate

Positioning the cutting attachment

The cutting edges of the grass cutting

blades with more than 4 blades must

point clockwise.

N Position the cutting attachment (3)

WARNING

The collar (a) must engage the hole (b)

in the cutting attachment!

Securing the cutting attachment

N Fit the thrust washer (4) – curvature

faces upward

N Fit the rider plate (5)

N Retain the shaft

N Screw on the nut (6)

counterclockwise and tighten it

down firmly

NOTICE

Remove the tool that was used to block

the shaft.

Removing the cutting attachment

N Retain the shaft

N Unscrew the mounting nut (6)

clockwise.

N Remove the cutting attachment and

its mounting hardware from the

gearbox

Mounting the brush knife (with protective

ring)

N Check whether the fitted deflector is

approved for brush knives – if not,

remove the deflector not approved

for brush knives

N Mount the deflector for grass cutting

blades and brush knives

N Using the thrust plate

Positioning the cutting attachment

24

WARNING

Nuts that move too easily must be

replaced.

Brush knives 305-2 (1) and 350-3(2)

may point in either direction – these

cutting attachments must be turned over

regularly to help avoid one-sided wear.

FS 561 C-M

N Position the cutting attachment (3)

3

002BA494 KN

3

6

4

b

a

5

002BA470 KN

3

4

2

1

b

a

WARNING

The collar (a) must engage the hole (b)

in the cutting attachment!

Securing the cutting attachment

N Fit the thrust washer (4) – curvature

faces upward

N Fit the guard ring (5) for brush

knives – opening must face up

N Retain the shaft

N Screw on the nut (6)

counterclockwise and tighten it

down firmly

WARNING

Nuts that move too easily must be

replaced.

NOTICE

Remove the tool that was used to block

the shaft.

Removing the cutting attachment

N Retain the shaft

N Unscrew the mounting nut

clockwise

N Remove the cutting attachment and

its mounting hardware from the

gearbox

Mounting shredder blade 320-2

N Check whether the fitted deflector is

approved for shredder blades – if

not, remove the deflector not

approved for shredder blades

N Mounting deflector for shredder

blade

N Using the thrust plate

N Seal the unused tapped holes with

plugs

English

N Place the shredder blade (1) in

position – the cutting edges must

point upwards

WARNING

The collar (a) must engage the hole (b)

in the cutting attachment!

Securing the cutting attachment

N Fit the thrust washer (2) – curvature

faces upward

N Fit the shredder blade guard ring (3)

– opening must face up.

N Retain the shaft

N Screw on the nut (4)

counterclockwise and tighten it

down firmly

WARNING

Nuts that move too easily must be

replaced.

FS 561 C-M

25

English

681BA165 KN

2

1

4

002BA471 KN

3

b

a

NOTICE

Remove the tool that was used to block

the shaft.

Removing the cutting attachment

N Retain the shaft

N Unscrew the mounting nut

clockwise

N Remove the cutting attachment and

its mounting hardware from the

gearbox

N If you intend to use a different

cutting attachment – remove the

shredder deflector.

Mounting Circular Saw Blades 225

N Check whether the stop for circular

saw blades is already mounted to

the machine

N If mounted, remove the deflector

N Mount the limit stop for circular saw

blades

N Using the thrust plate

N Seal the unused tapped holes with

plugs

Positioning the cutting attachment

With circular saw blades, the cutting

edges must face clockwise.

N Retain the shaft

N Screw on the nut (4)

counterclockwise and tighten it

down firmly

WARNING

Nuts that move too easily must be

replaced.

NOTICE

Remove the tool that was used to block

the shaft.

Removing the cutting attachment

N Retain the shaft

N Unscrew the mounting nut

clockwise

N Remove the cutting attachment and

its mounting hardware from the

gearbox

26

N Position the cutting attachment (1)

WARNING

The collar (a) must engage the hole (b)

in the cutting attachment!

Securing the cutting attachment

N Fit the thrust washer (2) – curvature

faces upward

N Fit the rider plate (3)

FS 561 C-M

English

Fuel

This engine is certified to operate on

unleaded gasoline and with the mix ratio

50:1.

Your engine requires a mixture of highquality premium gasoline and highquality two-stroke air-cooled engine oil.

Use premium branded unleaded

gasoline with a minimum octane rating

of 89 (R+M)/2.

Note: Models equipped with a catalytic

converter require unleaded gasoline. A

few tankfuls of leaded gasoline can

reduce the efficiency of the catalytic

converter by more than 50%.

Fuel with a lower octane rating may

result in preignition (causing "pinging")

which is accompanied by an increase in

engine temperature. This, in turn,

increases the risk of the piston seizure

and damage to the engine.

The chemical composition of the fuel is

also important. Some fuel additives not

only detrimentally affect elastomers

(carburetor diaphragms, oil seals, fuel

lines etc.), but magnesium castings as

well. This could cause running problems

or even damage the engine. For this

reason it is essential that you use only

high-quality fuels!

Fuels with different percentages of

ethanol are being offered. Ethanol can

affect the running behaviour of the

engine and increase the risk of lean

seizure.

Gasoline with an ethanol content of

more than 10% can cause running

problems and major damage in engines

with a manually adjustable carburetor

and should not be used in such engines.

Engines equipped with M-Tronic can be

run on gasoline with an ethanol content

of up to 25% (E25).

Use only STIHL two-stroke engine oil or

equivalent high-quality two-stroke aircooled engine oils for mixing.

We recommend STIHL 50:1 two-stroke

engine oil since it is specially formulated

for use in STIHL engines.

To ensure the maximum performance of

your STIHL engine, use a high quality 2cycle engine oil. To help your engine run

cleaner and reduce harmful carbon

deposits, STIHL recommends using

STIHL HP Ultra 2-cycle engine oil or ask

your dealer for an equivalent fully

synthetic 2-cycle engine oil.

To meet the requirements of EPA and

CARB we recommend to use STIHL HP

Ultra oil.

Do not use BIA or TCW (two-stroke

water cooled) mix oils!

Use only STIHL 50:1 heavy-duty engine

oil or an equivalent quality two-stroke

engine oil for the fuel mix in models

equipped with a catalytic converter.

Take care when handling gasoline.

Avoid direct contact with the skin and

avoid inhaling fuel vapour.

The canister should be kept tightly

closed in order to avoid any moisture

getting into the mixture.

The fuel tank and the canister in which

fuel mix is stored should be cleaned

from time to time.

Fuel mix ratio

Only mix sufficient fuel for a few days

work, not to exceed 30 days of storage.

Store in approved safety fuel-canisters

only. When mixing, pour oil into the

canister first, and then add gasoline.

Examples

Gasoline Oil (STIHL 50:1 or equiva

lent high-quality oils)

liters liters (ml)

1 0.02 (20)

5 0.10 (100)

10 0.20 (200)

15 0.30 (300)

20 0.40 (400)

25 0.50 (500)

Dispose of empty mixing-oil canisters

only at authorized disposal locations.

-

FS 561 C-M

27

English

4900BA016 KN

2709BA003 KN

2709BA004 KN

3

002BA411 KN

1

2

Fueling

Preparations

WARNING

When fueling on a slope, always position

the machine with the filler cap facing

uphill.

N On level ground, position the

machine so that the filler cap is

facing up.

N Before fueling, clean the filler cap

and the area around it to ensure that

no dirt falls into the tank.

28

Opening the filler cap

N Turn the cap counterclockwise until

it can be removed from the tank

opening.

N Remove the cap.

Filling Up with Fuel

Take care not to spill fuel while fueling

and do not overfill the tank.

STIHL recommends you use the STIHL

filler nozzle for fuel (special accessory).

N Fill up with fuel.

Closing the filler cap

N Place the cap in the opening.

N Turn the cap clockwise as far as

stop and tighten it down as firmly as

possible by hand.

Fitting the Full Harness

Fitting the full harness is described in

detail in the leaflet supplied with the

harness.

The type and style of the harness

depend on the market.

Fitting the Harness

N Put on the full harness (1).

N Adjust the length of the strap so that

the carabiner (2) is about a hand’s

width below your right hip.

N Attach the carabiner to the

machine's perforated rail (3) – see

“Attaching Machine to Harness”.

N Find the right attachment point for

the cutting attachment you are

using – see "Balancing the

Machine".

FS 561 C-M

English

2

1

002BA631 KN

1

2

2

1

002BA632 KN

1

2

6BA009 KN

6BA010 KN

Attaching Machine to Harness

N Attach the carabiner (1) to the

perforated rail (2) on the drive tube.

Disconnecting Machine from Harness

N Press down the bar on the

carabiner (1) and pull the perforated

rail (2) out of the carabiner.

Balancing the Machine

The machine will balance differently

depending on the cutting attachment

mounted.

N Let the machine swing on the

harness until it stops moving –

change the connection point if

necessary

Hanging positions

Mowing heads, grass cutting blades,

brush knives and shredder blades

should rest lightly on the ground.

Putting down the machine in an

emergency

WARNING

As soon as it becomes apparent that a

dangerous situation is developing, the

machine must be put down quickly.

Practice setting down the machine

quickly. In order to avoid damage, when

practicing, do not throw the machine on

the ground.

FS 561 C-M

Circular saw blades should "hover"

approx. 20 cm above the ground.

29

English

1

002BA474 KN

2

3

002BA481 KN

4

4900BA017 KN

5

4900BA018 KN

6BA011 KN

Starting / Stopping the

Symbols on choke knob

Engine

Controls

N If the engine is cold: Depress in the

Run position F – a hot engine is started

in this position or the engine runs in this

position.

Start position } – a cold engine is

started in this position.

Starting the Engine

1 Throttle trigger lockout

2 Throttle trigger

3 Stop switch with Run and Stop

positions. Depress the stop switch

(…) to switch off the ignition.

Function of stop switch and ignition

system

The stop switch is normally in the Run

position, i.e. when it is not depressed:

The ignition is switched on – the engine

is ready to start. Operate the stop switch

to switch off the ignition. The ignition is

switched on again automatically after

the engine stops.

N Press the manual fuel pump

bulb (4) at least five times – even if

the bulb is filled with fuel.

The choke knob is in the normal run

position F.

outer edge (arrows) of the choke

knob (5) and then turn it to Start }.

Cranking

N Place the unit on the ground: It must

rest securely on the engine's guard

plate and the deflector. Check that

the cutting attachment is not

touching the ground or any other

obstacles.

N Make sure you have a firm footing,

either standing, stooping or

kneeling.

N Hold the unit firmly on the ground

with your left hand and press down

– do not touch the throttle trigger or

throttle trigger lockout.

NOTICE

Do not stand or kneel on the drive tube.

30

FS 561 C-M

Stopping the Engine

6BA012 KN

6BA014 KN

002BA485 KN

6BA024 KN

English

N Hold the starter grip with your right

hand.

NOTICE

Do not pull out the starter rope all the

way – it might otherwise break.

N Do not let the starter grip snap back.

Guide it slowly back into the housing

so that the starter rope can rewind

properly.

N Continue cranking until the engine

runs.

N If the engine does not start: Turn the

choke knob to the start position }

and repeat starting procedure.

Using the Machine

If you have started the machine for the

first time, refer to the notes on "Starting

for first time" in section "Other Hints on

Starting".

N If the engine was started in the start

position }: Briefly press down the

trigger lockout and the pull the

throttle trigger at the same time –

the choke knob moves to the run

position (F) and the engine settles

down to idling speed.

Your machine is now ready for

operation.

WARNING

The cutting attachment must not rotate

in the Run F position with the engine at

idling speed.

If the cutting attachment rotates when

the engine is idling, refer to notes in

chapter on "Adjusting the Throttle

Cable" or have the machine serviced by

your dealer. STIHL recommends an

authorized STIHL servicing dealer.

N Attach the machine to the shoulder

strap.

N Machine is ready for use.

N Depress the momentary contact

stop switch – the engine stops –

release the stop switch – it springs

back to the run position.

Other Hints on Starting

Starting for first time

N Depress the throttle trigger – do not

press down the throttle trigger

lockout.

If engine speed increases or the cutting

attachment rotates:

N Go to section "Stopping the

Engine".

N Go to "Adjusting the Throttle Cable".

If the engine speed does not increase,

your machine is ready for operation.

FS 561 C-M

31

English

681BA301 KN

681BA275 KN

1.

2.

0000-GXX-0423-A0

681BA281 KN

2.

At very low outside temperatures

N Set the engine to winter operation if

necessary, see "Winter Operation".

N If the machine is very cold (frost on

machine), allow the engine to warm

up in the start position } after

starting until normal operating

temperature is reached. Warning:

The cutting attachment runs.

At very high outside temperatures

If the engine does not start after 10 pulls

in the Start } position:

N Start the engine in the Run F

position.

If the engine does not start

N Check that all settings are correct.

N Check that there is fuel in the tank

and refuel if necessary.

N Check that the spark plug boot is

properly connected.

N Repeat the starting procedure.

Engine is flooded

N Move the choke knob to F and

continue cranking until the engine

runs.

Fuel tank run until completely dry

N After refueling, press the manual

fuel pump bulb at least five times –

even if the bulb is filled with fuel.

N Now start the engine.

Transporting the Unit

Using Transport Guard

The type of transport guard depends on

the metal cutting attachment supplied

with the machine. Transport guards are

available as special accessories.

Grass cutting blades, 250 and 255

N Disconnect wire rod from the

transport guard.

N Swing wire rod outwards.

N Fit the transport guard on the cutting

attachment from below.

N Hook wire rod to the transport

guard.

N Swing wire rod into position.

32

FS 561 C-M

English

681BA302 KN

681BA275 KN

1.

2.

681BA276 KN

681BA277 KN

2.

681BA293 KN

681BA294 KN

1.

2.

2.

681BA295 KN

Circular saw blades, 225

N Disconnect wire rod from the

transport guard.

Universal transport guard for metal

cutting attachments

The universal transport guard can be

used for shredder blades, grass cutting

blades and brush knives.

N Swing wire rod outwards.

N Fit the transport guard on the cutting

attachment from below, making

sure the limit stop is properly seated

in the recess.

N Disconnect wire rod from the

transport guard and swing it

outwards.

FS 561 C-M

N Swing wire rod into position.

N Hook wire rod to the transport

guard.

N Fit the transport guard on the cutting

attachment from below.

N Attach wire rod to the hook on the

transport guard.

33

English

4900BA019 KN

1

4900BA020 KN

3

2

Operating Instructions Air filter

During break-in period

A factory-new machine should not be

run at high revs (full throttle off load) for

the first three tank fillings. This avoids

unnecessary high loads during the

break-in period. As all moving parts

have to bed in during the break-in

period, the frictional resistances in the

engine are greater during this period.

The engine develops its maximum

power after about 5 to 15 tank fillings.

During Operation

After a long period of full throttle

operation, allow the engine to run for a

short while at idle speed so that engine

heat can be dissipated by the flow of

cooling air. This protects enginemounted components (ignition,

carburetor) from thermal overload.

After Finishing Work

Storing for a short period: Wait for the

engine to cool down. Empty the fuel tank

and keep the machine in a dry place,

well away from sources of ignition, until

you need it again. For longer out-ofservice periods – see "Storing the

Machine".

Basic information

The filter has an extremely long service

life.

Do not dismantle the filter cover and fit a

new air filter unless there is a noticeable

loss of engine power.

Soiled air filters reduce the engine

power, increase the fuel consumption,

and hinder engine start-up.

Changing the air filter

Only if there is a noticeable loss of

engine power

N Set the choke lever to }

N Undo the fixing screws (1)

N Remove the filter cover (2)

N Remove coarse dirt from inside the

filter cover and around the filter (3)

The filter (3) filters the air through

pleated paper.

N Remove and check the filter

element (3) – replace if paper or

frame is dirty or damaged.

N Unpack the new filter

NOTICE

Do not bend or twist the filter before

installation as it might otherwise be

damaged – do not use damaged filters.

N Insert filter in filter housing

N Attach filter cover

Only use high-quality air filters so that

the engine is protected from the entry of

abrasive dust.

STIHL recommends the use of original

STIHL air filters. The high quality

standard of these spare parts

guarantees smooth operation, a long

engine service life and very long filter

service lives.

34

FS 561 C-M

English

1

min

AB C

s> 30 s30-60 s

0000-GXX-4580-A0

Filter insert for winter operation

Maintenance and care of the special

filter insert for winter operation are

described in the section "Winter

operation".

Engine Management M-Tronic

Exhaust emissions are controlled by the

design of the engine and components

(e.g. carburation, ignition, timing and

valve or port timing).

The clearing saw adjusts itself

automatically for optimum performance

during operation. Calibration enables

the clearing saw to be adjusted faster for

optimum performance.

N Remove mowing head or metal

cutting attachment. This allows the

clearing saw to reliably adjust to the

optimum performance.

If the external temperature is below 10°C or the engine is cold:

N Start the engine.

N warm up engine for about 1 minute

by blipping the throttle.

N Shut off the engine.

To calibrate the clearing saw, carry out

the following steps:

FS 561 C-M

N Set the master control lever to }

position.

N Start the engine without depressing

the throttle trigger. The engine runs

and the master control lever

remains in position }.

N Run the engine for at least 30

seconds but no more than 60

seconds without depressing the

throttle trigger.

35

English

2

1

9926BA016 KN

2

9926BA017 KN

3

NOTICE

The calibration process is aborted if the

throttle trigger is released before the

clearing saw is properly calibrated. It is

then necessary to restart the calibration

process.

N Keep the throttle trigger fully

depressed.

NOTICE

The clearing saw may be incorrectly

calibrated if the throttle trigger is not kept

fully depressed during calibration. The

clearing saw may be damaged.

N Keep the throttle trigger fully

depressed.

N tDepress the throttle trigger for at

least 30 seconds and hold it in that

position.

The engine accelerates and the clearing

saw is calibrated. The engine speed

fluctuates and increases perceptibly

during calibration.

If the engine stops:

N Try again to calibrate the clearing

saw.

If the engine keeps stalling:

N Do not use the clearing saw.