Stihl FS 510 C, FS 560 C, FS 410 C-M, FS 460 C-M Instruction Manual

{

STIHL FS 510 C, 560 C

Instruction Manual

Notice d’emploi

G Instruction Manual

1 - 52

F Notice d’emploi

53 - 108

Original Instruction ManualPrinted on chlorine-free paper

Printing inks contain vegetable oils, paper can be recycled.

© ANDREAS STIHL AG & Co. KG, 2016

0458-772-8221-A. VA0.J16.

0000005287_011_GB

FS 510 C, FS 560 C

English

1

{

This instruction manual is protected by copyright. All rights reserved, especially the rights to reproduce, translate and process

with electronic systems.

Contents

Dear Customer,

Thank you for choosing a quality

engineered STIHL product.

It has been built using modern

production techniques and

comprehensive quality assurance.

Every effort has been made to ensure

your satisfaction and troublefree use of

the product.

Please contact your dealer or our sales

company if you have any queries

concerning this product.

Your

Dr. Nikolas Stihl

Guide to Using this Manual 2

Safety Precautions and Working

Techniques 2

Approved Combinations of Cutting

Attachment, Deflector, Limit Stop

and Harness 13

Mounting the Bike Handle 14

Adjusting the Throttle Cable 18

Mounting the Deflector 18

Mounting the Cutting Attachment 22

Fuel 27

Fueling 28

Fitting the Full Harness 29

Balancing the Machine 30

Starting / Stopping the Engine 30

Transporting the Unit 33

Operating Instructions 34

Air filter 35

Engine Management 36

M-Tronic 36

Winter Operation 36

Spark Plug 38

Engine Running Behavior 39

Storing the Machine 39

Sharpening Metal Cutting Blades 40

Maintaining the Mowing Head 40

Inspection and Maintenance by

User 41

Inspections and Maintenance by

Dealer 42

Maintenance and Care 44

Main Parts 46

Specifications 48

Maintenance and Repairs 49

Disposal 50

STIHL Limited Emission Control

Warranty Statement 50

FS 510 C, FS 560 C

English

2

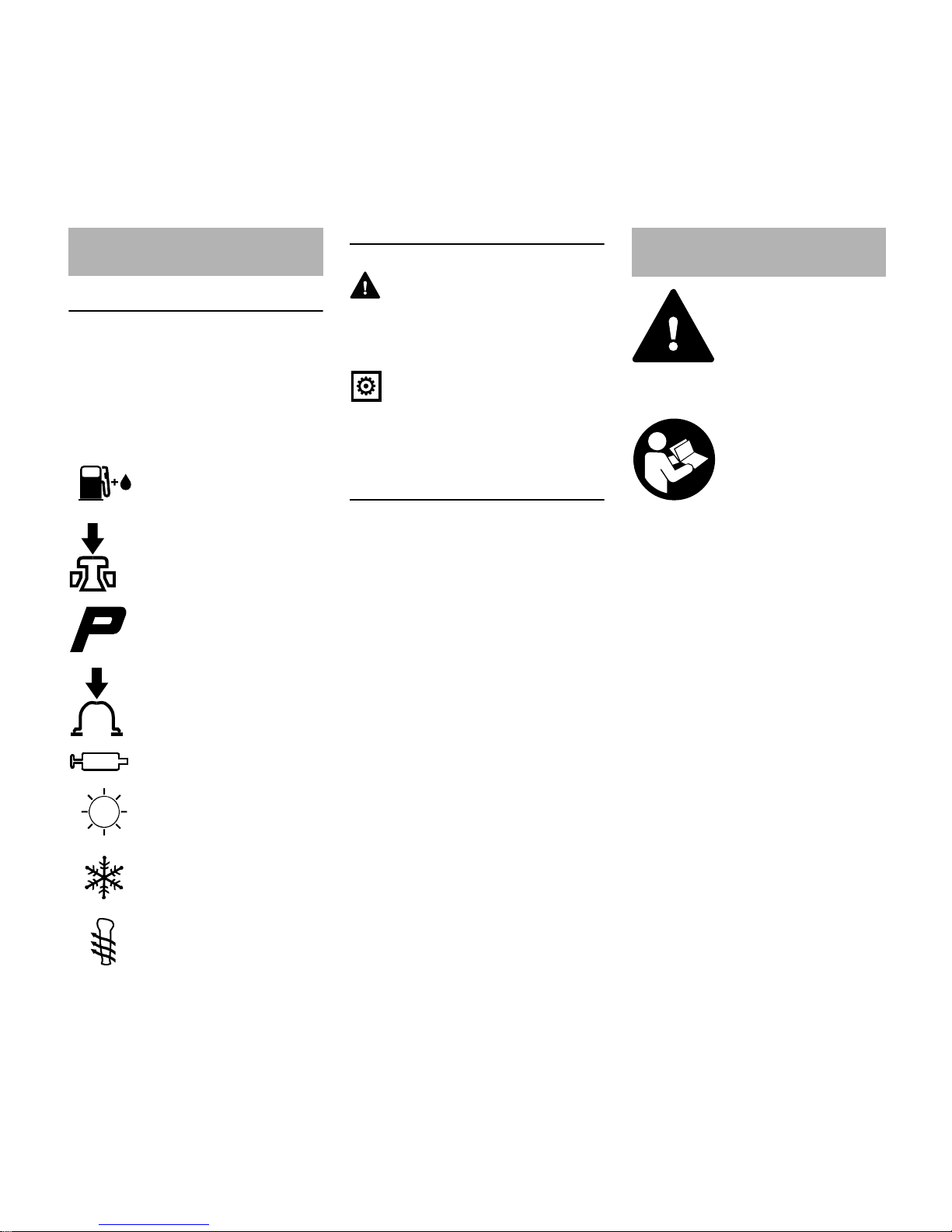

Pictograms

The meanings of the pictograms

attached to the machine are explained in

this manual.

Depending on the model concerned, the

following pictograms may be attached to

your machine.

Symbols in text

WARNING

Warning where there is a risk of an

accident or personal injury or serious

damage to property.

NOTICE

Caution where there is a risk of

damaging the machine or its individual

components.

Engineering improvements

STIHL's philosophy is to continually

improve all of its products. For this

reason we may modify the design,

engineering and appearance of our

products periodically.

Therefore, some changes, modifications

and improvements may not be covered

in this manual.

Observe all applicable local safety

regulations, standards and ordinances.

If you have not used this type of power

tool before: Have your dealer or other

experienced user show you how to

operate your machine or attend a

special course in its operation.

Minors should never be allowed to use a

power tool.

Keep bystanders, especially children,

and animals away from the work area.

When the power tool is not in use, shut it

off so that it does not endanger others.

Secure it against unauthorized use.

The user is responsible for avoiding

injury to third parties or damage to their

property.

Do not lend or rent your power tool

without the instruction manual. Be sure

that anyone using it understands the

information contained in this manual.

Guide to Using this Manual

Fuel tank; fuel mixture of

gasoline and engine oil

Operate decompression

valve

Manual fuel pump

Operate manual fuel

pump

Tube of grease

Intake air: Summer

operation

Intake air: Winter

operation

Handle heating

Safety Precautions and

Working Techniques

Some special safety precautions have to be

observed when working

with this power tool

because of the very high

speed of the cutting

attachment.

It is important that you

read the instruction manual before first use and

keep it in a safe place for

future reference. Nonobservance of the

instruction manual may

result in serious or even

fatal injury.

FS 510 C, FS 560 C

English

3

The use of noise emitting power tools

may be restricted to certain times by

national or local regulations.

To operate the power tool you must be

rested, in good physical condition and

mental health.

If you have any condition that might be

aggravated by strenuous work, check

with your doctor before operating a

power tool.

Persons with pacemakers only: The

ignition system of your power tool

produces an electromagnetic field of a

very low intensity. This field may

interfere with some pacemakers. STIHL

recommends that persons with

pacemakers consult their physician and

the pacemaker manufacturer to reduce

any health risk.

Do not operate the power tool if you are

under the influence of any substance

(drugs, alcohol) which might impair

vision, dexterity or judgment.

Depending on the cutting attachment

fitted, use your power tool only for

cutting grass, wild growth, shrubs,

scrub, bushes, small diameter trees and

similar materials.

Do not use your power tool for any other

purpose because of the increased risk of

accidents.

Only use cutting attachments and

accessories that are explicitly approved

for this power tool model by STIHL or

are technically identical. If you have any

questions in this respect, consult a

servicing dealer. Use only high quality

tools and accessories in order to avoid

the risk of accidents and damage to the

machine.

STIHL recommends the use of genuine

STIHL tools and accessories. They are

specifically designed to match the

product and meet your performance

requirements.

Never attempt to modify your machine in

any way since this may increase the risk

of personal injury. STIHL excludes all

liability for personal injury and damage

to property caused while using

unauthorized attachments.

Do not use a pressure washer to clean

the unit. The solid jet of water may

damage parts of the unit.

The deflector on this power tool cannot

protect the operator from all objects

thrown by the cutting attachment

(stones, glass, wire, etc.). Such objects

may ricochet and then hit the operator.

Clothing and Equipment

Wear proper protective clothing and

equipment.

Avoid clothing that could get caught on

branches or brush or moving parts of the

machine. Do not wear a scarf, necktie or

jewelry. Tie up and confine long hair

(e.g. with a hair net, cap, hard hat, etc.).

Sturdy shoes with non-slip soles may be

worn as an alternative only when using

mowing heads.

WARNING

Wear a face shield and make sure it is a

good fit. A face shield alone does not

provide adequate eye protection.

Wear hearing protection, e.g. earplugs

or ear muffs.

Wear a safety hard hat for thinning

operations, when working in high scrub

and where there is a danger of head

injuries from falling objects.

STIHL offers a comprehensive range of

personal protective clothing and

equipment.

Clothing must be sturdy

but allow complete freedom of movement. Wear

snug-fitting clothing, an

overall and jacket combination, do not wear a

work coat.

Wear steel-toed safety

boots with non-slip soles.

To reduce the risk of eye

injuries, wear snug-fitting

safety glasses in accordance with European

Standard EN 166. Make

sure the safety glasses

are a good fit.

Wear heavy-duty work

gloves made of durable

material (e.g. leather).

FS 510 C, FS 560 C

English

4

Transporting the Power Tool

Always stop the engine.

Carry the unit hanging from the shoulder

strap or properly balanced by the drive

tube. Fit transport guard on metal cutting

attachments to avoid the risk of injury

from blade contact

Transporting by vehicle: Properly secure

your power tool to prevent turnover, fuel

spillage and damage.

Fueling

Always shut off the engine before

refueling.

Do not fuel a hot engine – fuel may spill

and cause a fire.

Open the fuel cap carefully to allow any

pressure build-up in the tank to release

slowly and avoid fuel spillage.

Fuel your power tool only in wellventilated areas. If you spill fuel, wipe

the machine immediately – if fuel gets on

your clothing, change immediately.

This reduces the risk of unit vibrations

causing the fuel cap to loosen or come

off and spill quantities of fuel.

To reduce the risk of serious or fatal

burn injuries, check for fuel leakage. If

fuel leakage is found, do not start or run

the engine until leak is fixed.

Before Starting

Check that your power tool is properly

assembled and in good condition – refer

to appropriate chapters in the instruction

manual.

– Check the fuel system for leaks,

paying special attention to visible

parts such as the tank cap, hose

connections and the manual fuel

pump (on machines so equipped). If

there are any leaks or damage, do

not start the engine – risk of fire.

Have your machine repaired by a

servicing dealer before using it

again.

– Use only an approved combination

of cutting attachment, deflector,

handle and harness. All parts must

be assembled properly and

securely.

– The stop switch must move freely.

– Check smooth action of choke

knob, throttle trigger lockout and

throttle trigger – the throttle trigger

must return automatically to the idle

position. The choke knob must

spring back from the } position to

the run position F when the throttle

trigger lockout and throttle trigger

are squeezed.

– Check that the spark plug boot is

secure – a loose boot may cause

arcing that could ignite combustible

fumes and cause a fire.

– Check cutting tool or attachment for

correct and secure assembly and

good condition.

– Check protective devices (e.g.

deflector for cutting attachment,

rider plate) for damage or wear.

Always replace damaged parts. Do

not operate your machine with a

damaged deflector or worn rider

plate (lettering and arrows no longer

legible).

– Never attempt to modify the controls

or safety devices in any way.

To reduce the risk of serious burn injuries, avoid

touching hot parts of the

machine, including the

gearbox housing.

Gasoline is an extremely

flammable fuel. Keep

clear of naked flames. Do

not spill any fuel – do not

smoke.

002BA479 KN

After fueling, tighten

down the screw-type fuel

cap as securely as

possible.

FS 510 C, FS 560 C

English

5

– Keep the handles dry and clean –

free from oil and dirt – for safe

control of the power tool.

– Adjust the harness and handle(s) to

suit your height and reach. See

chapters on "Fitting the Harness"

and "Balancing the Machine".

To reduce the risk of accidents, do not

operate your power tool if it is damaged

or not properly assembled.

If you use a shoulder strap or full

harness: Practice removing and putting

down the power tool as you would in an

emergency. To avoid damage, do not

throw the power tool to the ground when

practicing.

Starting the Engine

Start the engine at least 3 meters from

the fueling spot, outdoors only.

Place the unit on firm ground in an open

area. Make sure you have good balance

and secure footing. Hold the unit

securely. The cutting attachment must

be clear of the ground and all other

obstructions because it may begin to run

when the engine starts.

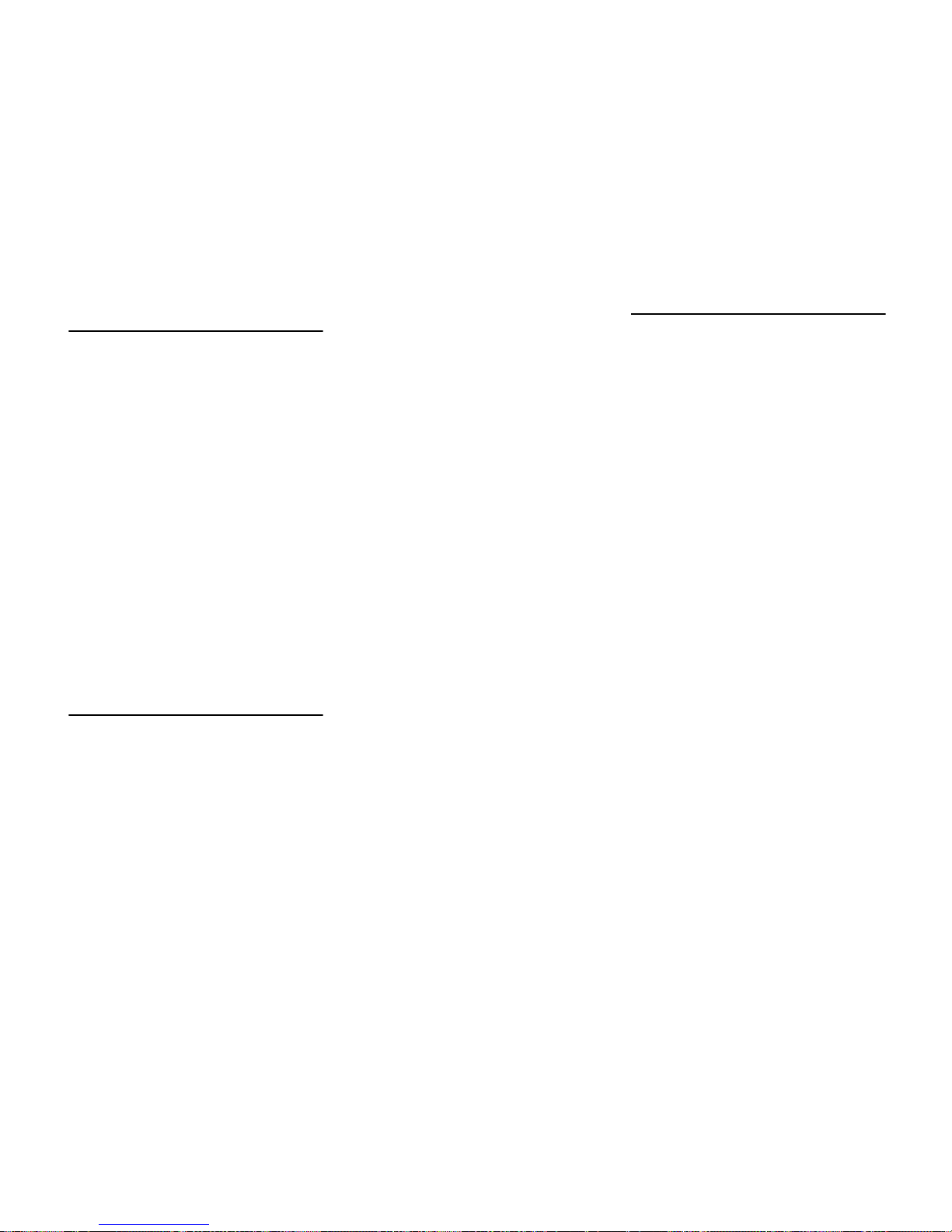

Your power tool is a one-person unit. To

reduce the risk of injury from thrown

objects, do not allow other persons

within a radius of 15 meters of your own

position – even when starting.

To reduce the risk of fire, keep hot

exhaust gases and hot muffler away

from easily combustible materials (e.g.

wood chips, bark, dry grass, fuel).

Holding and Controlling the Power Tool

Always hold the power tool firmly with

both hands on the handles.

Make sure you always have good

balance and secure footing.

Right handle on control handle, left hand

on left handle.

During Operation

Make sure you always have good

balance and secure footing.

In the event of imminent danger or in an

emergency, press the stop switch to

shut off the engine.

The cutting attachment may catch and

fling objects a great distance and cause

injury - therefore, do not allow any other

persons within a radius of 15 meters of

your own position. To reduce the risk of

damage to property, also maintain this

distance from other objects (vehicles,

windows). Even maintaining a distance

of 15 meters or more cannot exclude the

potential danger.

The correct engine idle speed is

important to ensure that the cutting

attachment stops rotating when you let

go of the throttle trigger. If the cutting

attachment continues to rotate when the

engine is idling, have the machine

checked by your servicing dealer. STIHL

recommends an authorized STIHL

servicing dealer.

Take special care in slippery conditions

(ice, wet ground, snow) – on slopes or

uneven ground.

Watch out for obstacles: Roots and tree

stumps which could cause you to trip or

stumble.

Always stand on the ground while

working, never on a ladder, work

platform or any other insecure support.

Be particularly alert and cautious when

wearing hearing protection because

your ability to hear warnings (shouts,

alarms, etc.) is restricted.

To reduce the risk of

injury, avoid contact with

the cutting attachment.

Do not drop start the

power tool – start the

engine as described in

the instruction manual.

Note that the cutting

attachment continues to

run for a short period

after you let go of the

throttle trigger – flywheel

effect.

002BA480 KN

15m (50ft)

FS 510 C, FS 560 C

English

6

To reduce the risk of accidents, take a

break in good time to avoid tiredness or

exhaustion.

Work calmly and carefully – in daylight

conditions and only when visibility is

good. Stay alert so as not to endanger

others.

To reduce the risk of serious or fatal

injury from breathing toxic fumes,

ensure proper ventilation when working

in trenches, hollows or other confined

locations.

To reduce the risk of accidents, stop

work immediately in the event of

nausea, headache, visual disturbances

(e.g. reduced field of vision), problems

with hearing, dizziness, deterioration in

ability to concentrate. Apart from other

possibilities, these symptoms may be

caused by an excessively high

concentration of exhaust gases in the

work area.

Operate your power tool so that it

produces a minimum of noise and

emissions – do not run the engine

unnecessarily, accelerate the engine

only when working.

To reduce the risk of fire, do not smoke

while operating or standing near your

power tool. Note that combustible fuel

vapor may escape from the fuel system.

The dusts, vapor and smoke produced

during operation may be dangerous to

health. If the work area is very dusty or

smoky, wear a respirator.

If your power tool is subjected to

unusually high loads for which it was not

designed (e.g. heavy impact or a fall),

always check that it is in good condition

before continuing work – see also

"Before Starting".

Check the fuel system in particular for

leaks and make sure the safety devices

are working properly. Do not continue

operating your power tool if it is

damaged. In case of doubt, consult your

servicing dealer.

Special care must be taken when

working in difficult, over-grown terrain.

When cutting high scrub, under bushes

and hedges: Keep cutting attachment at

a minimum height of 15 cm to avoid

harming small animals.

Always shut off the engine before

leaving the unit unattended.

Check the cutting attachment at regular

short intervals during operation or

immediately if there is a noticeable

change in cutting behavior:

– Turn off the engine. Hold the unit

firmly and wait for the cutting

attachment to come to a standstill.

– Check condition and tightness, look

for cracks.

– Check sharpness.

– Replace damaged or dull cutting

attachments immediately, even if

they have only superficial cracks.

Clean grass and plant residue off the

cutting attachment mounting at regular

intervals – remove any build up of

material from the cutting attachment and

deflector.

To reduce the risk of injury

, shut off the

engine before changing the cutting

attachment.

Do not continue using or attempt to

repair damaged or cracked cutting

attachments by welding, straightening or

modifying the shape (out of balance).

Your power tool produces

toxic exhaust fumes as

soon as the engine is

running. These fumes

may be colorless and

odorless and contain

unburned hydrocarbons

and benzol. Never run

the engine indoors or in

poorly ventilated locations, even if your model

is equipped with a catalytic converter.

To reduce the risk

of injury from

thrown objects,

never operate the

unit without the

proper deflector for

the type of cutting

attachment being

used.

Inspect the work area:

Stones, pieces of metal

or other solid objects may

be thrown more than 15

meters and cause personal injury or damage

the cutting attachment

and property (e.g. parked

vehicles, windows).

The gearbox becomes

hot during operation. To

reduce the risk of burn

injury, do not touch the

gearbox housing.

FS 510 C, FS 560 C

English

7

This may cause parts of the cutting

attachment to come off and hit the

operator or bystanders at high speed

and result in serious or fatal injuries.

When using mowing heads

Use only the deflector with properly

mounted line limiting blade to ensure the

mowing lines are automatically trimmed

to the approved length.

To reduce the risk of injury, always turn

off the engine before adjusting the nylon

line of manually adjustable mowing

heads

Using the unit with over-long nylon

cutting lines reduces the motor's

operating speed. The clutch then slips

continuously and this causes

overheating and damage to important

components (e.g. clutch, polymer

housing components) – and this can

increase the risk of injury from the

cutting attachment rotating while the

engine is idling.

Using metal cutting attachments

STIHL recommends the use of original

STIHL metal cutting attachments. They

are specifically designed to match your

model and meet your performance

requirements.

Metal cutting attachments rotate at very

high speed. The forces that occur act on

the machine, the attachment and the

material being cut.

Sharpen metal cutting attachments

regularly as specified.

Unevenly sharpened metal cutting

attachments cause out-of-balance

which can impose extremely high loads

on the machine and increase the risk of

breakage.

Dull or improperly sharpened cutting

edges can put a higher load on the

cutting attachment and increase the risk

of injury from cracked or broken parts.

Inspect metal cutting attachments for

cracks or warping after every contact

with hard objects (e.g. stones, rocks,

pieces of metal). To reduce the risk of

injury, remove burrs and other visible

build-ups of material (use a file) because

they may become detached and be

thrown at high speed during operation.

If a rotating metal cutting attachment

makes contact with a rock or other solid

object there is a risk of sparking which

may cause easily combustible material

to catch fire under certain

circumstances. Dry plants and scrub are

also easily combustible, especially in hot

and dry weather conditions. If there is a

risk of fire, do not use metal cutting

attachments near combustible

materials, dry plants or scrub. Always

contact your local forest authority for

information on a possible fire risk.

To reduce the above-mentioned risks

when using a metal cutting attachment,

never use a metal cutting attachment

with a diameter larger than specified. It

must not be too heavy. It must be

manufactured from materials of

adequate quality and its geometry must

be correct (shape, thickness).

To reduce the risk of injury, a metal

cutting attachment not manufactured by

STIHL must not be heavier, thicker,

have a different shape or a diameter

larger than the largest metal cutting

attachment approved by STIHL for this

power tool model.

Vibrations

Prolonged use of the power tool may

result in vibration-induced circulation

problems in the hands (whitefinger

disease).

No general recommendation can be

given for the length of usage because it

depends on several factors.

The period of usage is prolonged by:

– Hand protection (wearing warm

gloves)

– Work breaks

The period of usage is shortened by:

– Any personal tendency to suffer

from poor circulation (symptoms:

frequently cold fingers, tingling

sensations).

– Low outside temperatures.

– The force with which the handles

are held (a tight grip restricts

circulation).

Continual and regular users should

monitor closely the condition of their

hands and fingers. If any of the above

symptoms appear (e.g. tingling

sensation in fingers), seek medical

advice.

FS 510 C, FS 560 C

English

8

Maintenance and Repairs

Service the machine regularly. Do not

attempt any maintenance or repair work

not described in the instruction manual.

Have all other work performed by a

servicing dealer.

STIHL recommends that you have

servicing and repair work carried out

exclusively by an authorized STIHL

servicing dealer. STIHL dealers are

regularly given the opportunity to attend

training courses and are supplied with

the necessary technical information.

Only use high-quality replacement parts

in order to avoid the risk of accidents

and damage to the machine. If you have

any questions in this respect, consult a

servicing dealer.

STIHL recommends the use of original

STIHL replacement parts. They are

specifically designed to match your

model and meet your performance

requirements.

To reduce the risk of injury from

unintentional engine startup, always

shut off the engine and disconnect the

spark plug boot before performing any

repairs, maintenance or cleaning work. –

Exception: Carburetor and idle speed

adjustments.

Do not turn the engine over on the

starter with the spark plug boot or spark

plug removed since there is otherwise a

risk of fire from uncontained sparking.

To reduce the risk of fire, do not service

or store your machine near open flames.

Check the fuel filler cap for leaks at

regular intervals.

Use only a spark plug of the type

approved by STIHL and make sure it is

in good condition – see "Specifications".

Inspect the ignition lead (insulation in

good condition, secure connection).

Check the condition of the muffler.

To reduce the risk of fire and damage to

hearing, do not operate your machine if

the muffler is damaged or missing. –

Do not touch a hot muffler since burn

injury will result.

Vibration behavior is influenced by the

condition of the AV elements – check the

AV elements at regular intervals.

Maintenance, replacement, or repair of

the emission control devices and

systems may be performed by any

nonroad engine repair establishment or

individual. However, if you make a

warranty claim for a component which

has not been serviced or maintained

properly or if nonapproved replacement

parts were used, STIHL may deny

coverage.

For any maintenance please refer to the

maintenance chart and to the warranty

statement near the end of the instruction

manual.

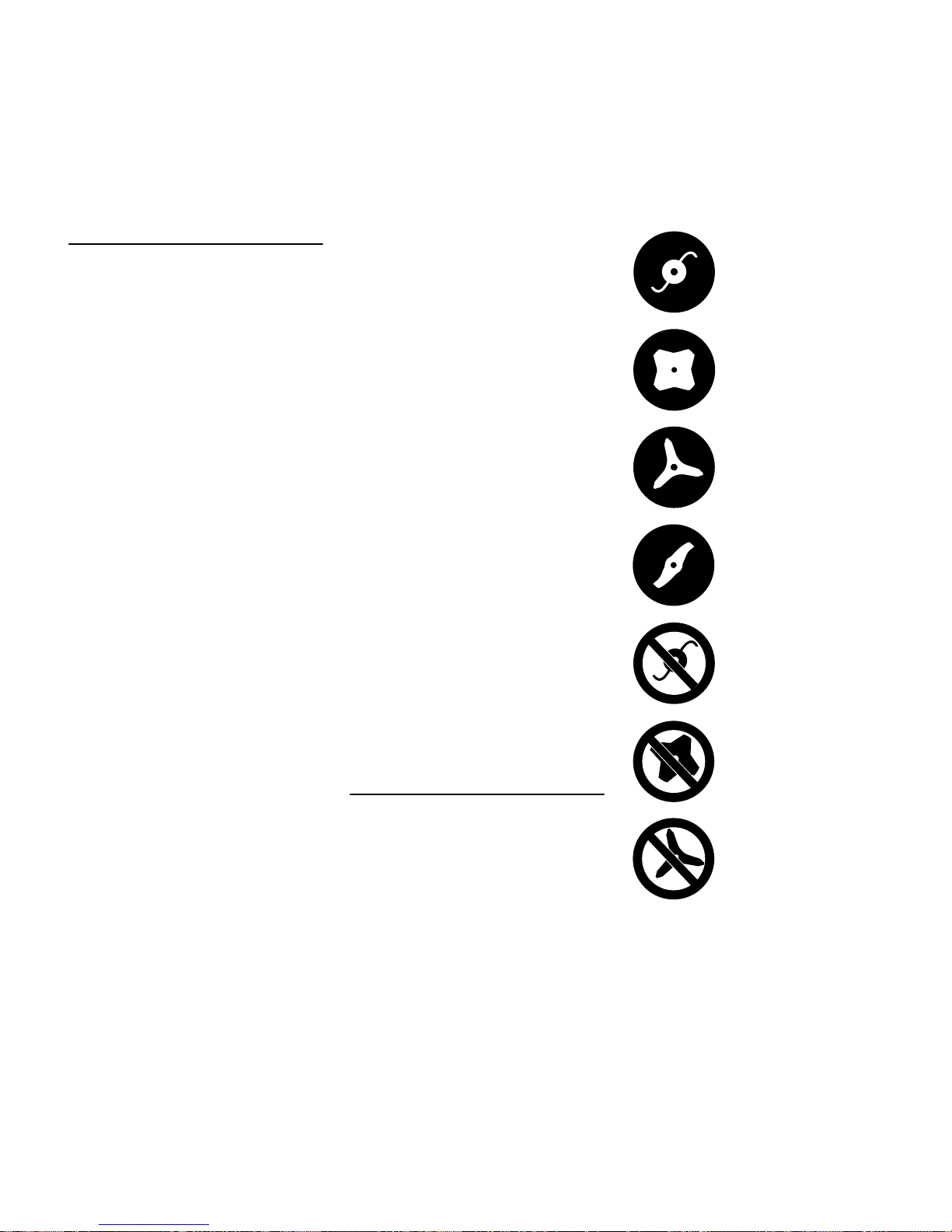

Symbols on Deflectors

An arrow on the deflector shows the

correct direction of rotation of the cutting

attachments.

Some of the following symbols are

applied to the outside of the deflector to

indicate the approved combination of

cutting attachment and deflector.

Deflector may be used

with mowing heads.

Deflector may be used

with grass cutting blades.

Deflector may be used

with brush knives.

Deflector may be used

with shredder blades.

Deflector must not be

used with mowing heads.

Deflector must not be

used with grass cutting

blades.

Deflector must not be

used with brush knives.

FS 510 C, FS 560 C

English

9

Harness

The harness is included with the

machine or available as a special

accessory.

N Use the harness.

N With the engine running, attach the

machine to the harness.

All cutting attachments must be used in

combination with a full harness with a

quick-release system.

Mowing Head with Nylon Line

Nylon line achieves a soft cut for edging

and trimming around trees, fence posts,

etc. – less risk of damaging tree bark.

The mowing head comes with an

instruction leaflet. Refill the mowing

head with nylon line as described in the

instruction leaflet.

WARNING

To reduce the risk of serious injury,

never use wire or metal-reinforced line in

place of the nylon line.

STIHL DuroCut

Check the wear limit marks!

If one of the wear limit marks imbedded

in the baseplate of the DuroCut

(exclamation marks) becomes visible,

do not continue using the mowing head

since it may otherwise be damaged.

Replace the worn baseplate.

The mowing head comes with

instruction leaflets. Equip the mowing

head only with nylon line as described in

the instruction leaflets.

WARNING

Never use wire in place of the nylon

mowing line – risk of injury.

STIHL Polycut Mowing Head with

Polymer Blades

For mowing unobstructed edges of

meadows (without posts, fences, trees

or similar obstacles).

Check the wear limit marks!

Deflector must not be

used with shredder

blades.

Deflector must not be

used with circular saw

blades.

002BA397 KN

000BA015 KN

681BA209 KN

FS 510 C, FS 560 C

English

10

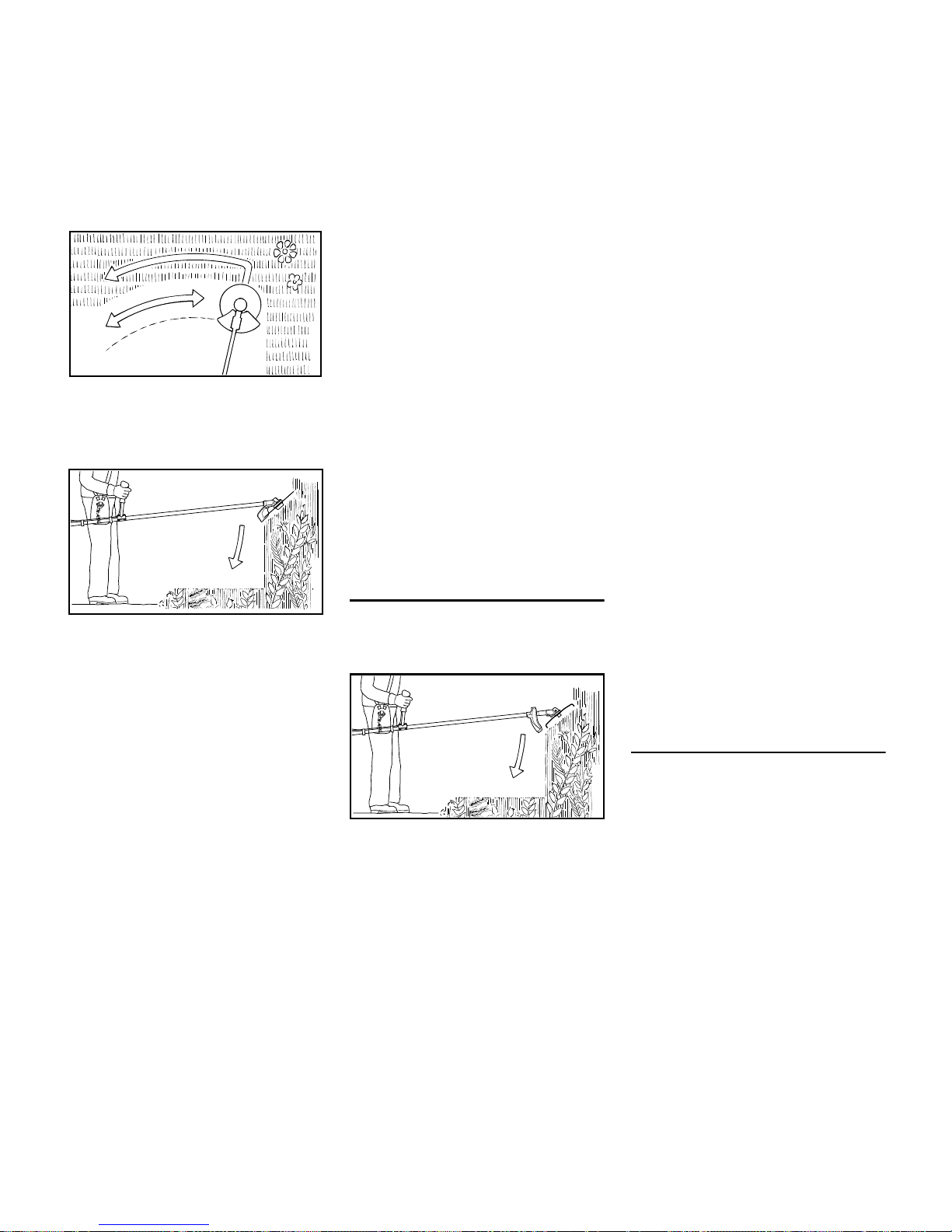

If one of the wear limit marks on the

PolyCut mowing head is worn through

(arrow): Do not continue using the

mowing head. Install a new one. There

is otherwise a risk of injury from thrown

parts of the head.

It is important to follow the maintenance

instructions for the PolyCut mowing

head.

The PolyCut can also be equipped with

mowing line in place of the polymer

blades.

The mowing head comes with

instruction leaflets. Equip the mowing

head with polymers blades or nylon line

as described in the instruction leaflets.

WARNING

Never use wire in place of the nylon

mowing line – risk of injury.

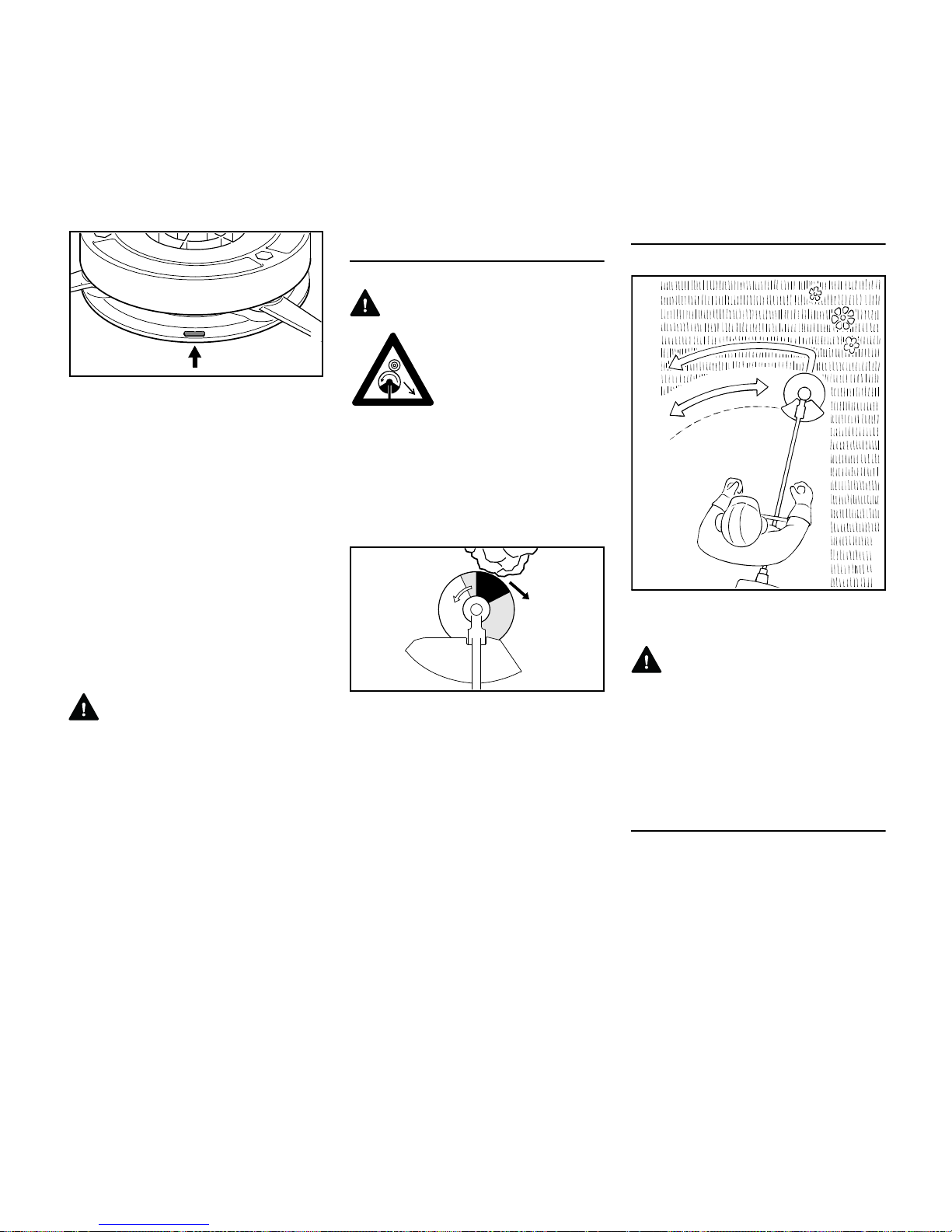

Risk of Kickout (Blade Thrust) with Metal

Cutting Attachments

WARNING

The risk of kickout is greatest when the

black area of the rotating cutting

attachment comes into contact with a

solid object.

Grass Cutting Blade

Use for grass and weeds only – sweep

the brushcutter in an arc like a scythe.

WARNING

Improper use may damage the grass

cutting blade – risk of injury from thrown

parts.

Resharpen the grass cutting blade

according to instructions when it has

dulled noticeably.

Brush Knife

For cutting matted grass, wild growth

and scrub and thinning young stands

with a stem diameter of no more than

2 cm – do not cut thicker stems – risk of

accidents.

002BA396 KN

When using metal cutting attachments there is

a risk of kickout when the

rotating blade comes into

contact with a solid object

such as a tree trunk,

branch, tree stump, rock

or similar. The machine is

thrown to the right or to

the rear – opposite to the

attachment's direction of

rotation.

002BA135 KN

000BA020 KN

FS 510 C, FS 560 C

English

11

Use the brushcutter like a scythe (sweep

it to the right and left) at ground level

when cutting grass and thinning young

stands.

To cut wild growth and scrub, lower the

brush knife down onto the growth to

achieve a shredding effect – always

keep the cutting attachment below hip

level during this process.

Exercise extreme caution when using

this method of cutting. The higher the

cutting attachment is off the ground, the

greater the risk of injury from cuttings

being thrown sideways.

Warning! Improper use of a brush knife

may cause it to crack, chip or shatter –

risk of injury from thrown parts.

To reduce the risk of injury it is essential

to take the following precautions:

– Avoid contact with stones, rocks,

pieces of metal and other solid

foreign objects.

– Never cut wood or shrubs with a

stem diameter of more than 2 cm –

use a circular saw blade for such

work.

– Inspect the brush knife at regular

short intervals for signs of damage.

Do not continue working with a

damaged brush knife.

– Resharpen the brush knife regularly

and whenever it has dulled

noticeably, and have it balanced if

necessary (STIHL recommends a

STIHL servicing dealer).

Shredder Blade

Suitable for thinning and shredding

tough, matted grass and scrub.

To cut wild growth and scrub, lower the

shredder blade down onto the growth to

achieve a shredding effect – always

keep the cutting attachment below hip

level during this process.

Exercise extreme caution when using

this method of cutting. The higher the

cutting attachment is off the ground, the

greater the risk of injury from cuttings

being thrown sideways.

Warning! Improper use may damage the

shredder blade – risk of injury from

thrown parts.

To reduce the risk of injury it is essential

to take the following precautions:

– Avoid contact with stones, rocks,

pieces of metal and other solid

foreign objects.

– Never cut wood or shrubs with a

stem diameter of more than 2 cm –

use a circular saw blade for such

work.

– Inspect the shredder blade at

regular short intervals for signs of

damage. Do not continue working

with a damaged shredder blade.

– Resharpen the shredder blade

regularly and whenever it has dulled

noticeably, and have it balanced if

necessary (STIHL recommends a

STIHL servicing dealer).

Circular Saw Blade

Suitable for cutting shrubs and trees with

a maximum stem diameter of 7 cm.

Before starting the cut, accelerate the

engine up to full throttle. Perform cut

with uniform pressure.

Use circular saw blades only with a

matching limit stop of the correct

diameter.

002BA355 KN

002BA509 KN

002BA210 KN

FS 510 C, FS 560 C

English

12

WARNING

To reduce the risk of blade damage,

avoid contact with stones and the

ground. Resharpen the blade properly in

good time – dull teeth may result in the

blade cracking and shattering and

causing serious injury.

When felling, maintain a distance of at

least two tree lengths from the next

felling site.

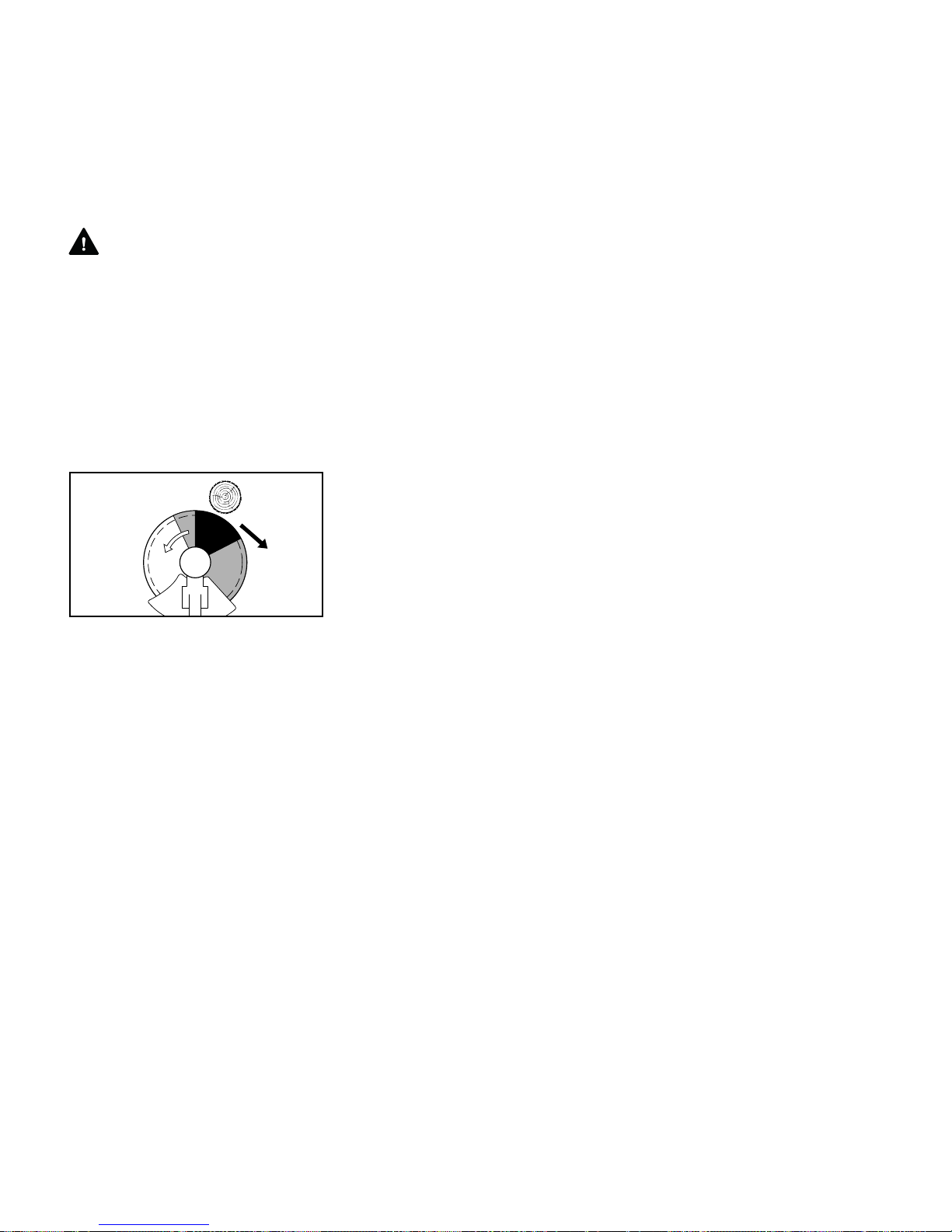

Risk of kickout

The risk of kickout is highest in the black

area of the blade: Do not use this area of

the circular saw blade for cutting.

There is also a risk of kickout when

using the lighter shaded areas of the

blade: These areas of the blade should

only be used by experienced operators

with specialized training.

STIHL recommends that you use the

non-shaded area of the circular saw

blade. Always start the cut with this area

of the blade.

002BA449 KN

FS 510 C, FS 560 C

English

13

Approved Combinations of Cutting Attachment, Deflector, Limit Stop and Harness

Cutting Attachment Deflector, Limit Stop Harness

10

11

12

13

17

16

15

14

7

9

0000-GXX-0377-A0

5

8

6

18

2

1

4

3

FS 510 C, FS 560 C

English

14

Approved Combinations

Select correct combination from the

table according to the cutting

attachment you intend to use.

WARNING

For safety reasons only the cutting

attachments and deflectors or limit stops

shown in each row of the table may be

used together. No other combinations

are permitted because of the risk of

accidents.

Cutting Attachments

Mowing heads

1 STIHL AutoCut 40-4

2 STIHL AutoCut 56-2

3 STIHL TrimCut 51-2

4 STIHL DuroCut 40-4

5 STIHL PolyCut 41-3

Metal cutting attachments

6 Grass cutting blade 255-8

(255 mm dia.)

7 Grass cutting blade 250-40 Spezial

(250 mm dia.)

8 Brush knife 305-2 Spezial

(305 mm dia.)

9 Brush knife 350-3

(350 mm dia.)

10 Shredder blade 320-2

(320 mm dia.)

11 Scratcher tooth circular saw blade

225

(225 mm dia.)

12 Chisel tooth circular saw blade 225

(225 mm dia.)

13 Carbide tipped circular saw blade

225

(225 mm dia.)

WARNING

Non-metal grass cutting blades, brush

knives, shredder blades and circular

saw blades are not approved.

Deflectors, Limit Stop

14 Deflector for mowing heads

15 Deflector for metal cutting

attachments, items 6 to 9

16 Deflector for shredder blade

17 Limit stop for circular saw blades

Harness

18 Full harness must be used

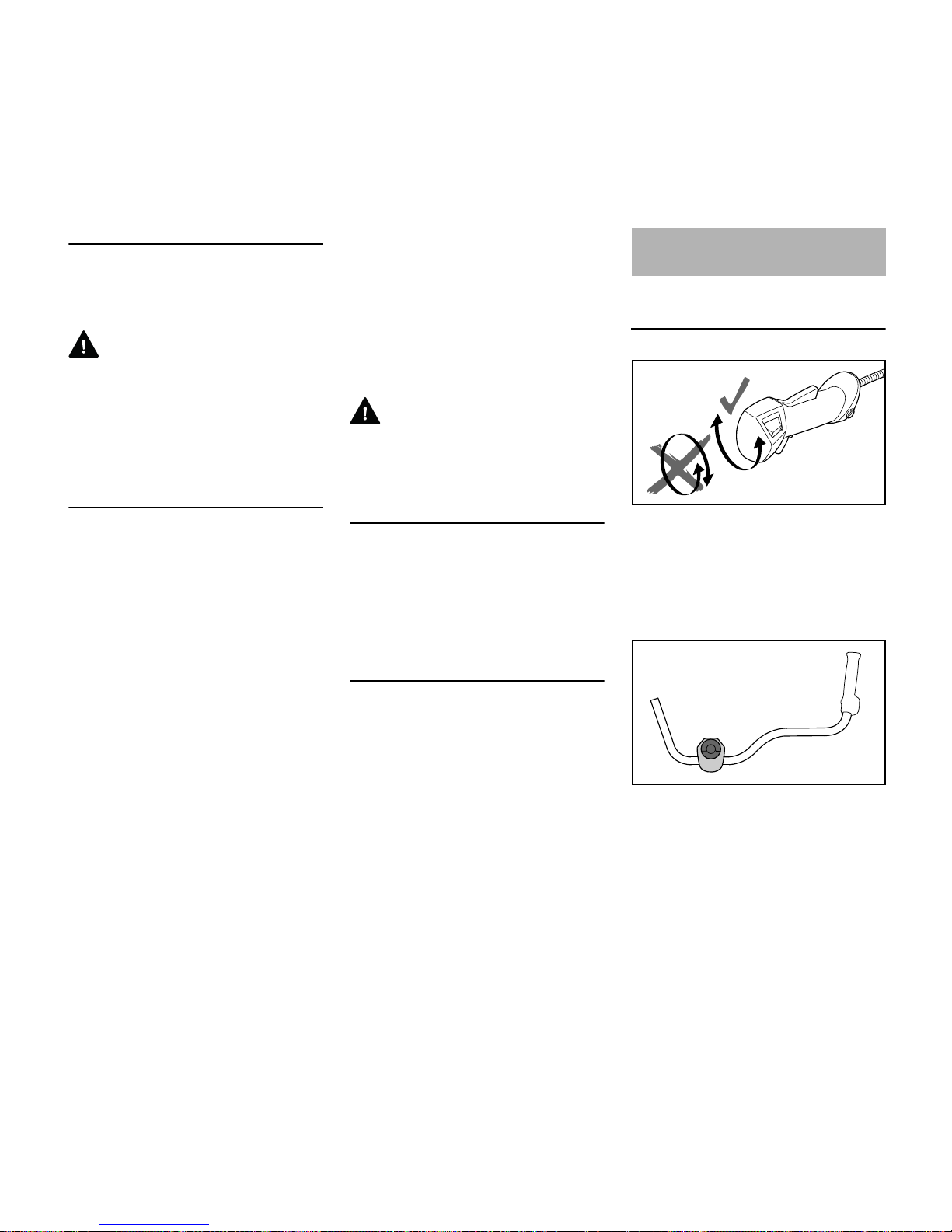

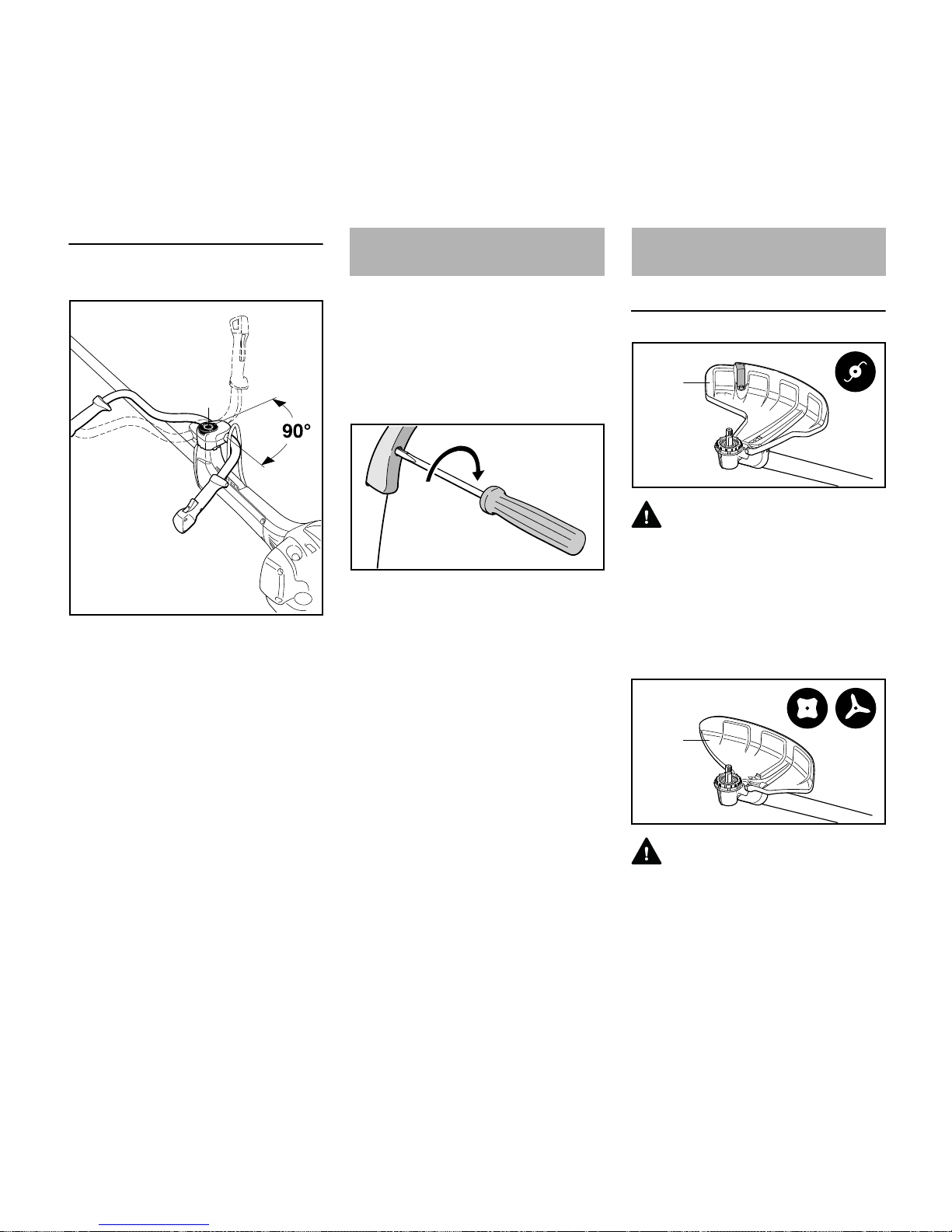

Mounting Bike Handle with Swiveling

Handle Support

Do not rotate the control handle (1)

between unpacking and mounting it on

the handlebar; see also chapter on

"Adjusting the Throttle Cable".

The brushcutter is available with two

different handlebars:

2 Handlebar for machines used

primarily for mowing, brushcutting

and shredding, but also for

occasional sawing.

Mounting the Bike Handle

1

3BA003 KN

3BA004 KN

4

2

FS 510 C, FS 560 C

English

15

3 Handlebar for machines used

mainly for sawing, but also for

mowing and brushcutting.

The machine is supplied with the clamp

moldings (4) mounted on the handlebars

(2, 3).

N Do not change the position of the

clamp moldings on the handlebar

until it is mounted on the handle

support.

The mounting procedure is the same for

both types of handlebar. Therefore, the

following description only shows

handlebar (2).

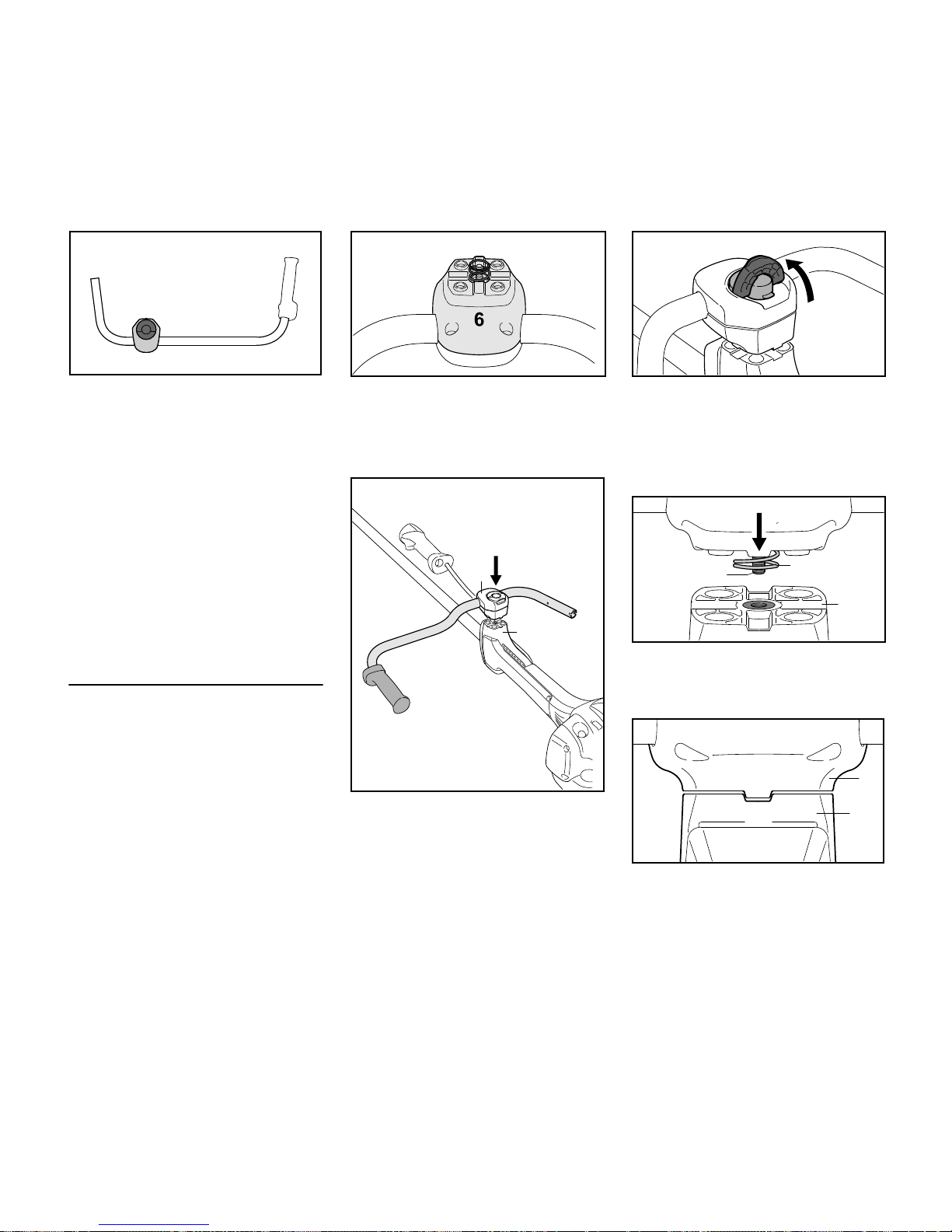

Mounting the Handlebar

Assembly of the swivelling handle

support involves equipping the clamp

moldings with a spring and mounting

them on the handle support.

N Use the spring (5) from the parts kit

supplied with the machine.

N Push the spring (5) into the lower

clamp molding (6).

N Position the clamp moldings (4) with

handlebar (2) on the handle support

(7).

N Do not turn the handlebar in the

clamp moldings.

N Raise the grip of the wing screw (8)

to the upright position.

N Rotate the wing screw

counterclockwise and tighten it only

moderately.

N Position wing screw (8) in threaded

insert in handle support (7) – against

pressure of spring (5).

N Position the clamp moldings so that

the tabs (9) on the lower clamp

molding (6) line up with the slots

(10) in the handle support (7).

2BA001 KN

4

3

3BA005 KN

5

4900BA002 KN

7

2

4

8

3BA007 KN

5

8

3BA008 KN

7

6

10

7

9

3BA0009 KN

FS 510 C, FS 560 C

English

16

N Rotate wing screw clockwise until

the lower clamp molding (6) butts

against the handle support (7).

N Swing the handebar (2) forwards

through 180°.

N Only tighten the wing screw

moderately.

N Fold the grip of the wing screw down

so that it is flush.

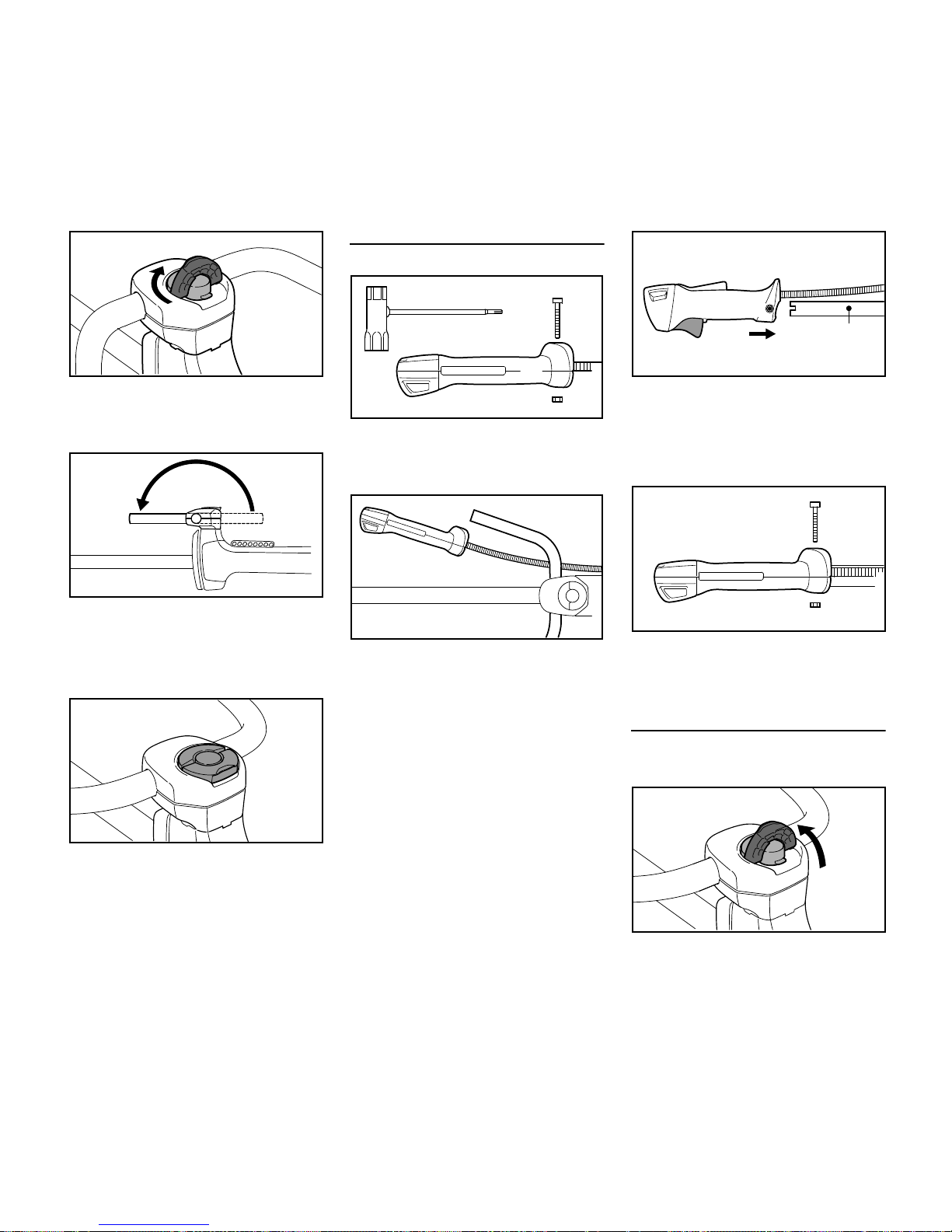

Mounting the Control Handle

N Take out the screw (11) and remove

the nut (12) from the control handle

(1).

N Hold the control handle in front of

the right-hand end of the handlebar

so that the throttle cable (13) is on

the inboard side of the handlebar

(2).

N Push the control handle (1) in this

position onto the end of the

handlebar (2) until the holes (15)

line up – throttle trigger (14) facing

down.

N Fit the nut (12) in the control handle,

insert the screw (11) and tighten it

down firmly.

Adjusting the Handlebar

Opening the wing screw

N Raise the grip of the wing screw to

the upright position.

7

6

3BA010 KN

2

4900BA003 KN

4900BA004 KN

11

12

1

002BA451 KN

13

2

4900BA005 KN

14

15

15

2

4900BA007 KN

1

11

12

4900BA008 KN

4900BA009 KN

FS 510 C, FS 560 C

English

17

N Turn the wing screw

counterclockwise until the handle

support can be moved.

Lining up the handlebar

N Move the handlebar to the required

position.

N Position the handlebar (2) so that

distance A is about 7 in (17 cm).

Do not clamp the curved part of the

handlebar.

Closing the wing screw

N Rotate the wing screw clockwise

until it becomes difficult to turn.

N Tighten down the wing screw firmly.

N Fold the grip of the wing screw down

so that it is flush.

Checking the Throttle Cable

N After mounting the control handle,

check the throttle cable – see

chapter on "Adjusting the Throttle

Cable".

4900BA010 KN

4900BA011 KN

4900BA012 KN

2

A

4900BA013 KN

4900BA014 KN

FS 510 C, FS 560 C

English

18

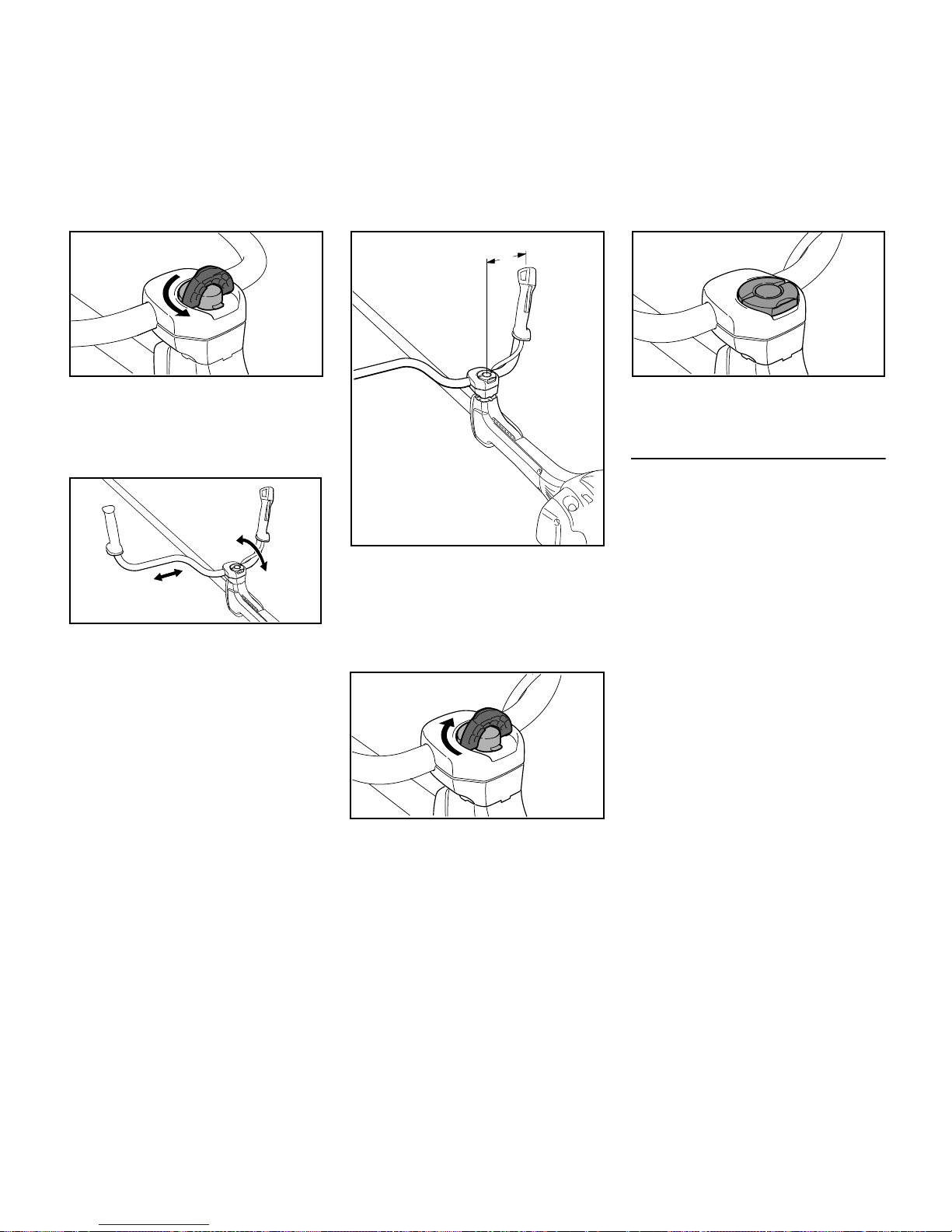

Swiveling the Handlebar

Transport position

N Loosen the wing screw (8) and

unscrew it until the handlebar (2)

can be turned clockwise.

N Turn the handlebar 90° and then

swing the handles down.

N Tighten down the wing screw (8)

firmly.

Working position

N Reverse the sequence described

above to swing the handles up and

turn the handlebar

counterclockwise.

It may be necessary to correct the

adjustment of the throttle cable after

assembling the machine or after a

prolonged period of operation.

Adjust the throttle cable only when the

unit is completely and properly

assembled.

N Set the throttle trigger to the full

throttle position.

N Carefully rotate the screw in the

throttle trigger in the direction of the

arrow until you feel initial resistance.

Then rotate it another half turn in the

same direction.

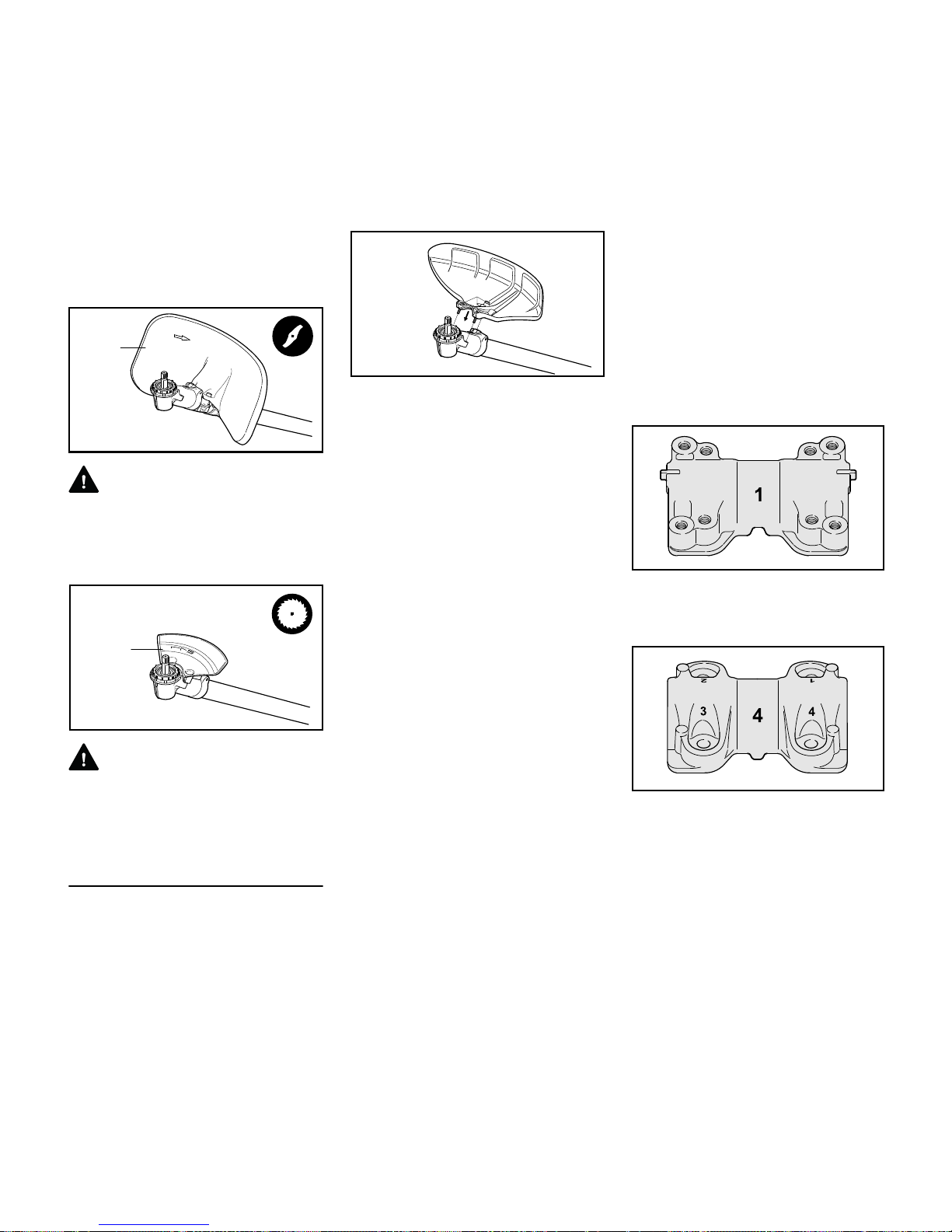

Use the Right Deflector

WARNING

Deflector (1) is approved for mowing

heads only and must therefore be

mounted before fitting a mowing head.

Recommendation: Use mowing heads

with a grass shield on the gearbox, see

chapters on "Mounting the Deflector" /

"Mounting the Grass Shield".

WARNING

Deflector (2) is approved for grass

cutting blades and brush knives only and

must therefore be mounted before fitting

a grass cutting blade or brush knife.

4900BA015 KN

2

8

Adjusting the Throttle Cable

002BA655 KN

Mounting the Deflector

1

002BA461 KN

2

002BA462 KN

FS 510 C, FS 560 C

English

19

Recommendation: Use grass cutting

blades with a grass shield on the

gearbox, see chapters on "Mounting the

Deflector" / "Mounting the Grass Shield".

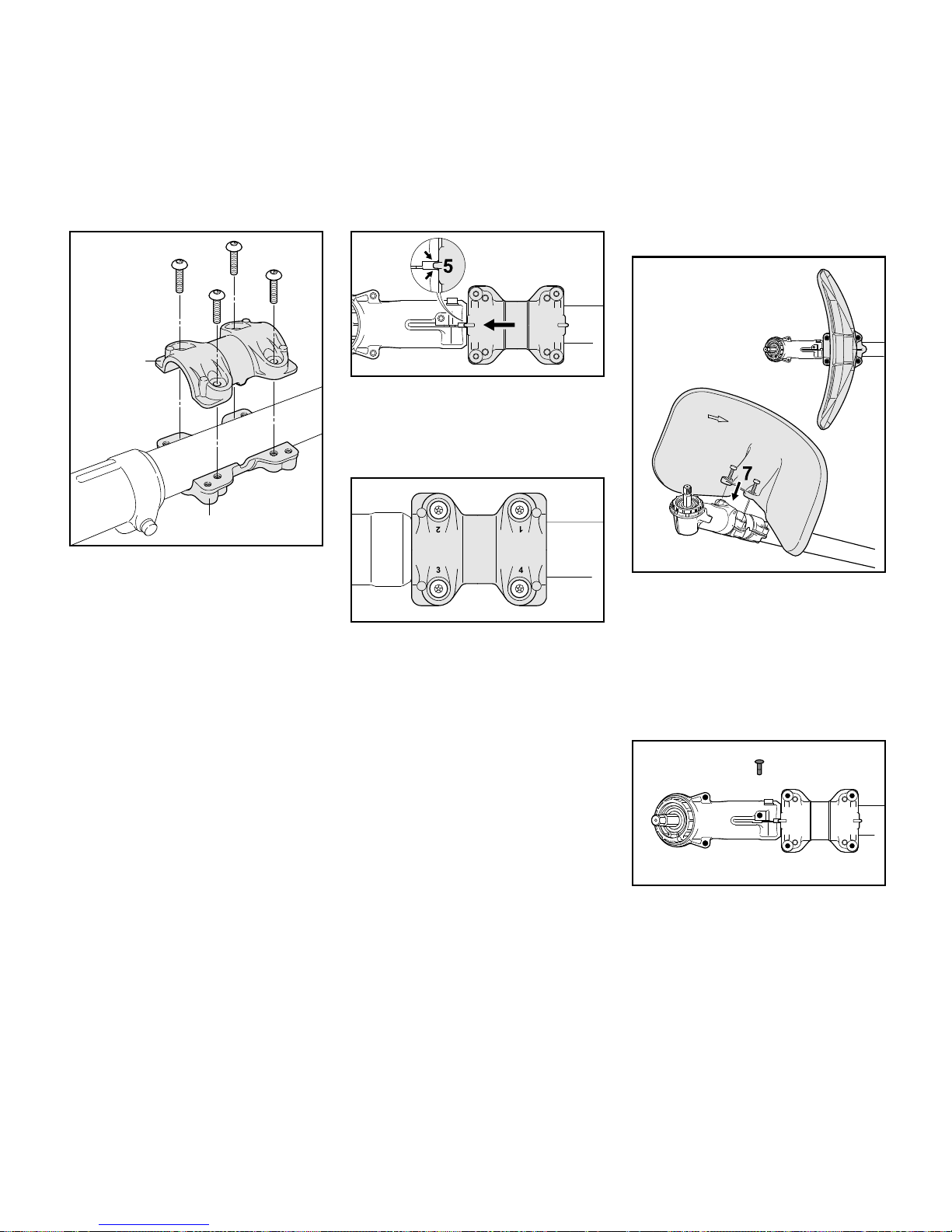

WARNING

Deflector (3) is approved for shredder

blades only and must therefore be

mounted before fitting a shredder blade,

see chapter on "Mounting the Deflector".

WARNING

Stop (4) is approved for circular saw

blades only and must therefore be

mounted before fitting a circular saw

blade.

Mounting the Deflector

Deflectors (1, 2 and 4) are mounted to

the gearbox in the same way.

N Remove dirt from joints on gearbox

and deflector – make sure that no

dirt gets into the screw holes in the

gearbox – see section on "Plugs".

N Place the deflector on the gearbox

(5).

N Insert the screws (6) and tighten

them down firmly.

Mounting shredder deflector

Owing to the high loads on the shredder

deflector (3) and country-specific

regulations on the use of the machine for

shredding, the deflector must be

properly mounted to the machine.

A special screwdriver bit is required to

mount this deflector. The bit is available

only from specialist retailers. It has a

special drive for rotating the screws and

only allows the screws to be tightened.

Once tightened, the screws can no

longer be loosened – not even with the

special tool.

STIHL therefore recommends: Have the

shredder deflector mounted by your

STIHL dealer.

A "shredder deflector mounting kit" is

available as a special accessory for

retrofitting machines with a shredder

deflector. Depending on the machine's

original equipment, a "shredder blade

retrofit kit" may also be needed for the

conversion. Neither of these kits include

the shredder blade – it must be ordered

separately.

The "shredder blade retrofit kit" contains

clamps which butt against the gearbox

and have to be secured to the drive tube.

The kit also contains the shredder

deflector which is mounted to the

clamps.

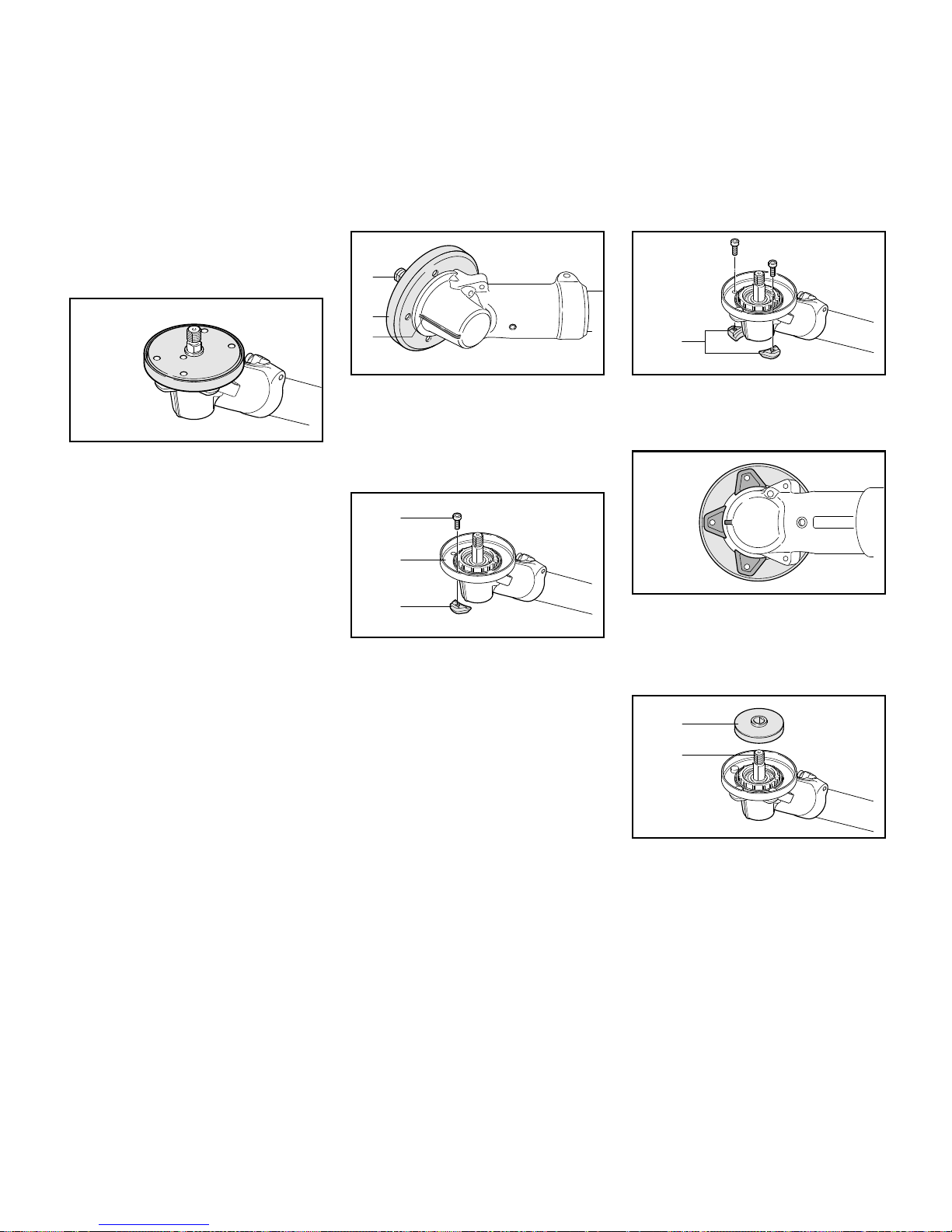

– Installing the clamps

– Lower clamp (1): Identified by two

lugs (2) on its longitudinal axis, eight

tapped holes and a lateral notch (3).

– Upper clamp (4): Identified by holes

marked 1 to 4 and a lateral lug (5).

3

002BA463 KN

4

002BA464 KN

5

6

002BA465 KN

002BA495 KN

3

2

2

002BA496 KN

5

FS 510 C, FS 560 C

English

20

N Position the lower clamp (1) against

the underside of the drive tube next

to the gearbox.

N Position the upper clamp (4) on the

drive tube so that the lug (5)

engages the notch (3).

N Hold both clamps steady in this

position.

N Insert a screw into the hole marked

1 on the upper clamp (4) and wind it

only a few turns into the lower clamp

(1).

N Insert a screw in each of the holes

marked 2, 3 and 4 and wind them

only a few turns into the lower

clamp.

N Slide the clamps up against the

gearbox and engage the lug (5) in

the gearbox gap (arrows).

N Hold both clamps in this position.

N Screw home the screws in holes 1

and 2 as far as stop.

N Tighten down the screws in holes 1

and 2 to a torque of 8 Nm.

N Screw home the screws in holes 3

and 4 in that order and tighten them

down to a torque of 8 Nm.

– Mounting the shredder deflector

N Position the shredder deflector on

the lower clamp with its concave

side facing the gearbox (6).

N Insert the screws (7) and tighten

them down firmly.

– Plugs

Plugs (9) are available as special

accessories to help prevent dirt getting

into the unused tapped holes for the

deflector in the gearbox (6) and clamps

(8).

5

3

002BA497 KN

1

4

002BA498 KN

002BA499 KN

6

002BA500 KN

002BA466 KN

8

9

6

FS 510 C, FS 560 C

English

21

Four plugs (9) are supplied with the

shredder deflector.

Fitting the grass shield

A grass shield is mounted to the gearbox

when using mowing heads and grass

cutting blades. It greatly reduces the

amount of grass, plant residue, etc. that

wraps itself around the gearbox and

cutting attachment.

Machines which have a mowing head or

grass cutting blade as original

equipment are supplied with a grass

shield. A "grass shield kit" is available as

a special accessory for retrofitting to

machines.

N Install the grass shield before

mounting the deflector – if

necessary, remove the deflector

that is already fitted on the gearbox.

N Hold the gearbox so that the shaft

(1) faces up.

N Place the grass shield (2) on the

gearbox so that the middle hole is in

line with the rib (3).

N Hold one of the three retainers (4)

against the gearbox and grass

shield so that the hole in the retainer

lines up with the middle hole.

N Insert the screw (5) in the retainer

and tighten it down only moderately

so that the grass shield (2) can still

be rotated on the gearbox.

N Fit the other two retainers (4) on the

gearbox and tighten down the

screws only moderately.

N Align the grass shield so that the

center of the front retainer is in line

with the rib on the gearbox.

N Tighten down the screws firmly.

N Fit the 60-mm diameter thrust plate

(5) on the shaft (1).

002BA501 KN

002BA502 KN

1

2

3

002BA503 KN

4

2

5

002BA504 KN

4

002BA512 KN

002BA505 KN

5

1

FS 510 C, FS 560 C

English

22

NOTICE

Only use the 60-mm diameter thrust

plate. The 65-mm diameter thrust plate

is too big and must not be used – see

chapters "Mounting the Cutting

Attachment" / "Mounting the Mowing

Head" / "Mounting Grass Cutting

Blades".

N Place the guard washer (6) on the

thrust washer – the whole collar

(arrows) on the shaft (1) must be

visible.

Placing power tool on the ground

N Shut off the engine.

N Lay your power tool on its back so

that the cutting attachment

mounting face is pointing up.

Mounting Hardware for Cutting

Attachment

The mounting hardware supplied

depends on the cutting attachment that

comes as original equipment with the

new machine.

The appropriate deflectors and

mounting hardware are available as

special accessories for subsequently

equipping the machine with different

cutting attachments – see chapter on

"Special Accessories".

WARNING

Always use and assemble the cutting

attachment mounting hardware as

described in the chapter on "Mounting

the Cutting Attachment".

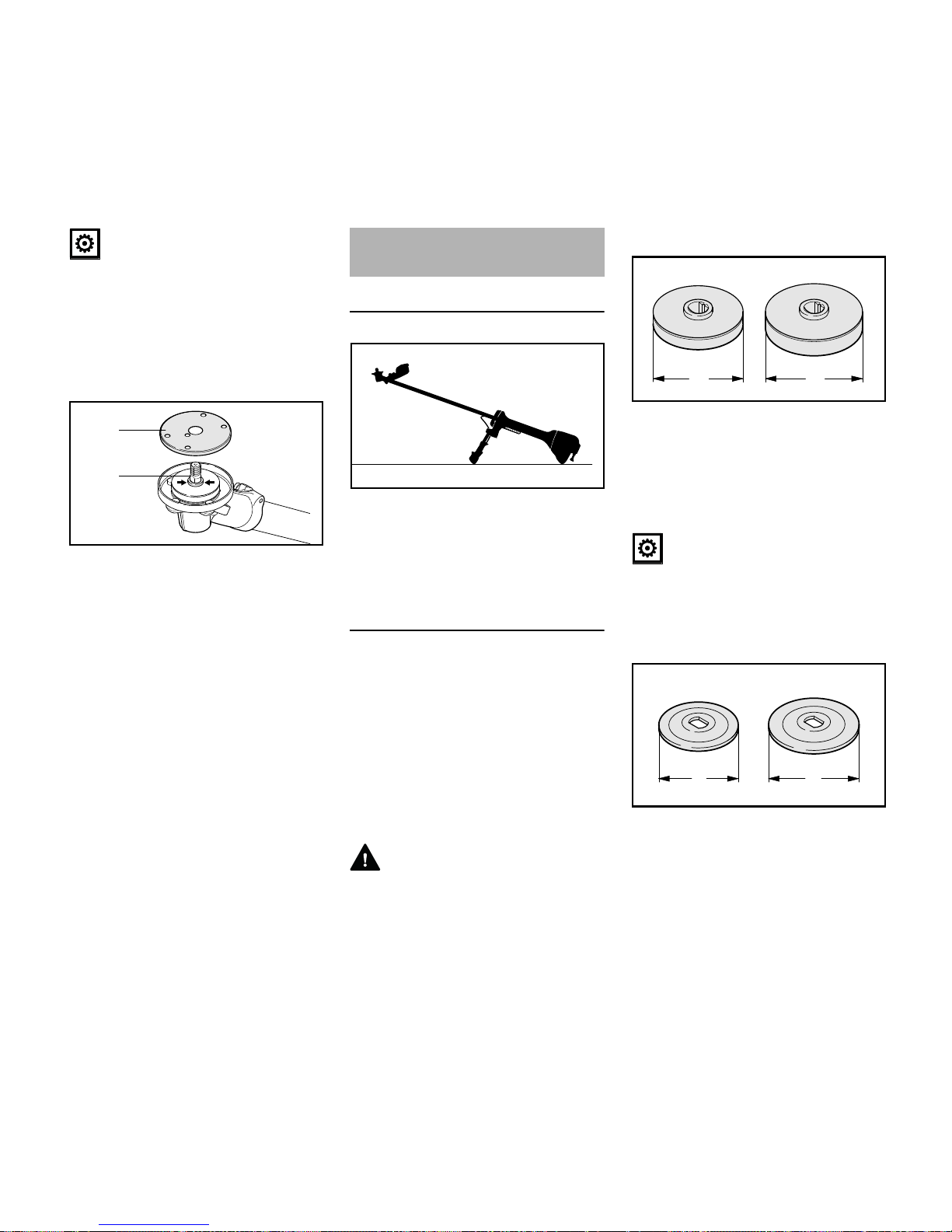

Thrust plate

– 60 mm (2.4 in) diameter (A) version

for mounting mowing heads and

grass cutting blades

– 65 mm (2.6 in) diameter (A) version

for mounting brush knives, shredder

blades and circular saw blades

NOTICE

The thrust plate is necessary for

mounting all cutting attachments to the

gearbox.

Thrust washers

– 60 mm (2.4 in) diameter (A) version

for mounting grass cutting blades

and circular saw blades

– 70 mm (2.8 in) diameter (A) version

for mounting brush knives and

shredder blades

002BA506 KN

6

1

Mounting the Cutting

Attachment

002BA406 KN

681BA188 KN

A

A

681BA189 KN

A

A

FS 510 C, FS 560 C

English

23

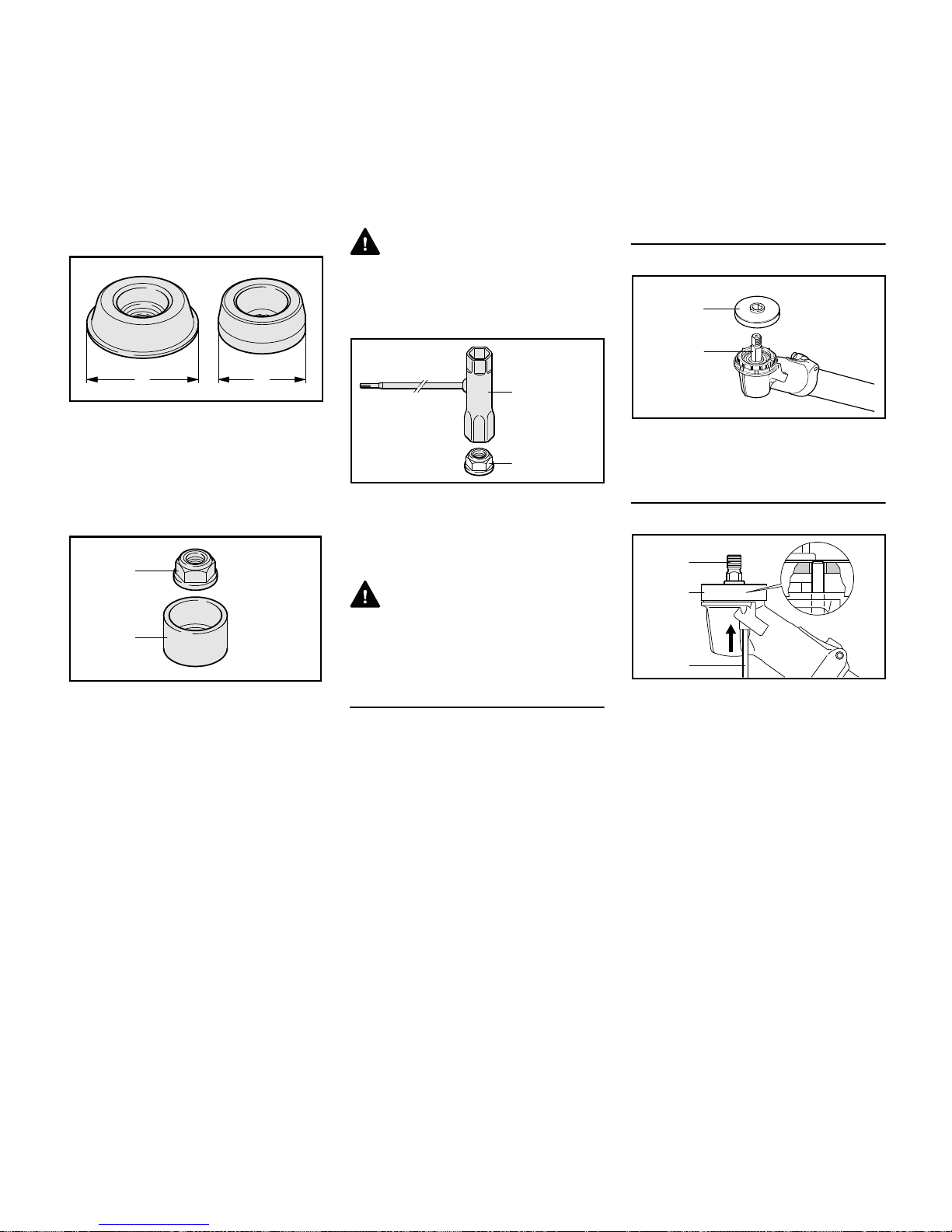

Rider plates, guard ring and nut

– Approximately 80 mm (3.2 in)

diameter (A) rider plate (1) for

grass cutting blades

– Approximately 63 mm (2.5 in)

diameter (A) rider plate (2) for

circular saw blades

– Guard ring (3) for brush knives and

shredder blades.

Both these parts have the same

function:

– Nut (4) and thread on shaft are

protected against wear.

– Ground contact with metal cutting

attachment is minimized.

– Rider plate allows cutting

attachment to glide along close to

ground.

WARNING

Always replace a worn rider plate and

guard ring in good time.

Nut and combination wrench

Metal cutting attachments are mounted

to the gearbox with the nut (4).

N Loosen and tighten the nut (4) with

the combination wrench (5).

WARNING

If the mounting nut has become too

loose, fit a new one.

Cleaning the Gearbox and Cutting

Attachment Mounting Hardware

Clean the gearbox, the area surrounding

it, inside the grass shield and the cutting

attachment mounting hardware at

regular intervals. Also check for

contamination when changing the

cutting attachment and clean thoroughly

if necessary.

N Remove all cutting attachment

mounting hardware from the

gearbox for this purpose.

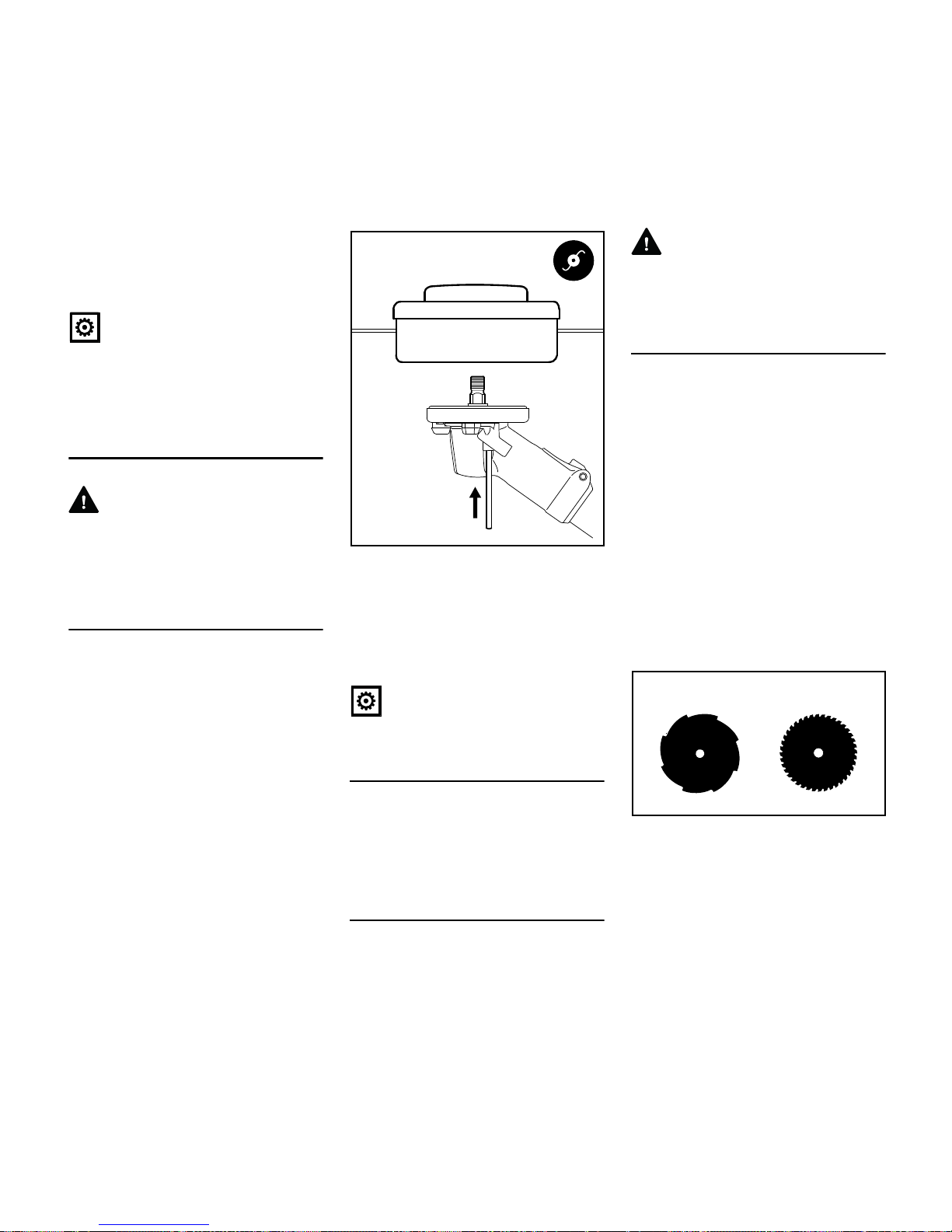

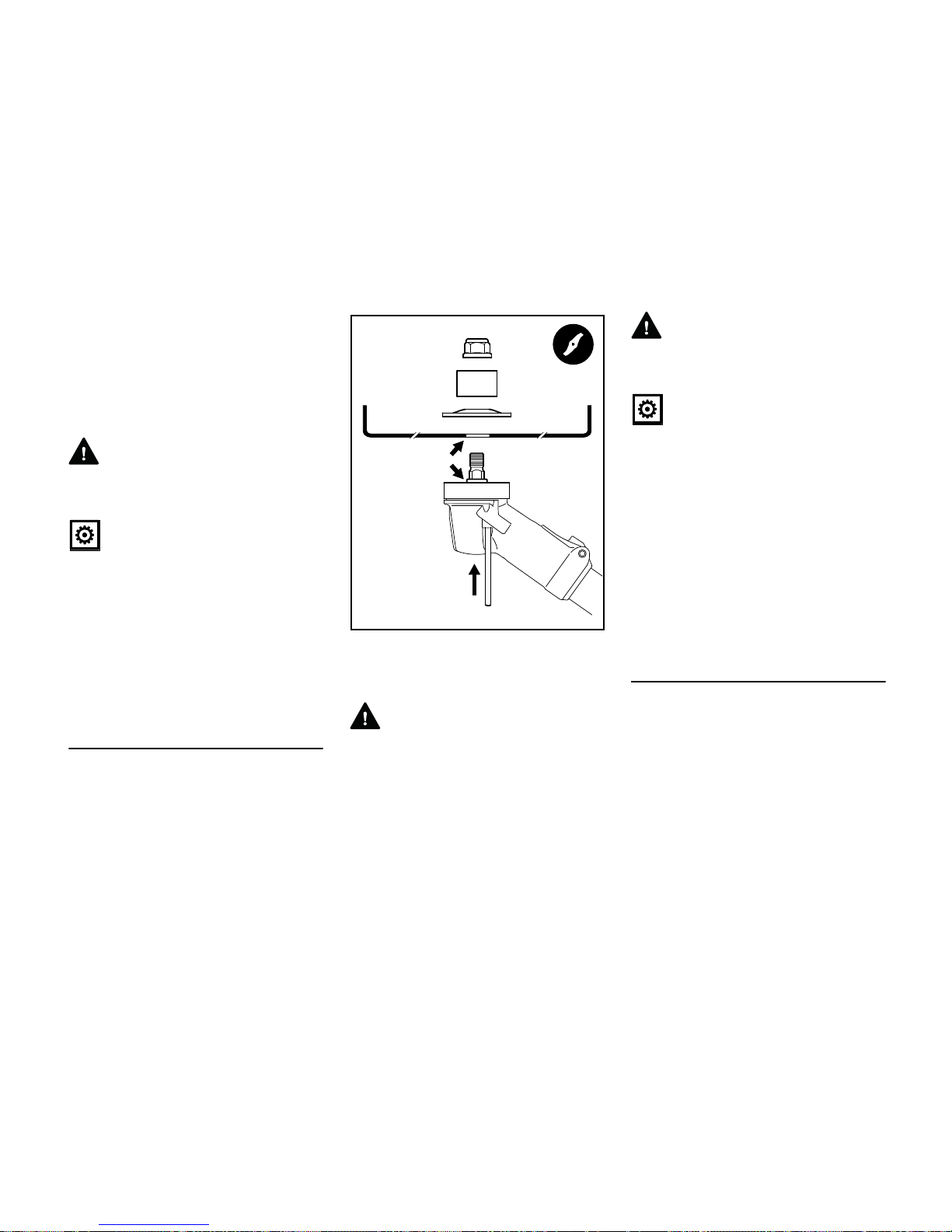

Fitting the Thrust Plate

N Slip the thrust plate (1) over the

shaft (2).

Block the shaft.

The shaft (2) must be blocked to install

and remove cutting attachments.

The shaft (2) can be blocked only if the

thrust plate (1) is properly fitted – the

stop pin (3) has to engage the thrust

plate.

N Insert the stop pin (3) in the bore in

the gearbox – apply slight pressure.

N Rotate shaft or cutting attachment

until the stop pin slips into position

and blocks the shaft.

The stop pin is held in position in the

gearbox by a rubber element.

681BA190 KN

A

A

681BA191 KN

4

3

4

681BA192 KN

5

002BA467 KN

1

2

002BA507 KN

1

2

3

FS 510 C, FS 560 C

English

24

N Fit or remove the cutting attachment

– see chapter on "Mounting the

Cutting Attachment".

N Remove the stop pin.

NOTICE

Always remove the stop pin used to

block the shaft since the drive train will

otherwise be damaged when the engine

runs.

Mounting the cutting attachment

WARNING

Use a deflector that matches the cutting

attachment – see "Mounting the

Deflector".

Fitting Mowing Head with Screw

Mounting

Keep the instruction leaflet for the

mowing head in a safe place.

All approved mowing heads are

mounted to the gearbox in the same

way.

N Check that the deflector on the

machine is approved for mowing

heads – if not, perform the next two

steps.

N Remove grass shield with thrust

plate – if fitted.

N Remove the non-approved

deflector.

N Mount deflector for mowing heads.

N Fit grass shield together with 60 mm

(2.4 in) diameter thrust plate.

N Screw the mowing head

counterclockwise on to the shaft (1)

as far as stop.

N Block the shaft.

N Tighten down the mowing head

firmly.

NOTICE

Remove the tool used to block the shaft.

Remove the mowing head.

N Block the shaft.

N Unscrew the mowing head

clockwise.

Removing and Installing Metal Cutting

Attachments

Before removing and installing metal

cutting attachments:

WARNING

Wear protective gloves to reduce the

risk of direct contact with the sharp

cutting edges.

Mounting Grass Cutting Blades

N Check that the deflector on the

machine is approved for grass

cutting blades – if not, perform the

next two steps.

N Remove grass shield with thrust

plate – if fitted.

N Remove the non-approved

deflector.

N Mount deflector for grass cutting

blades and brush knives.

N Fit grass shield together with 60 mm

(2.4 in) diameter thrust plate.

Check direction of rotation of cutting

attachment

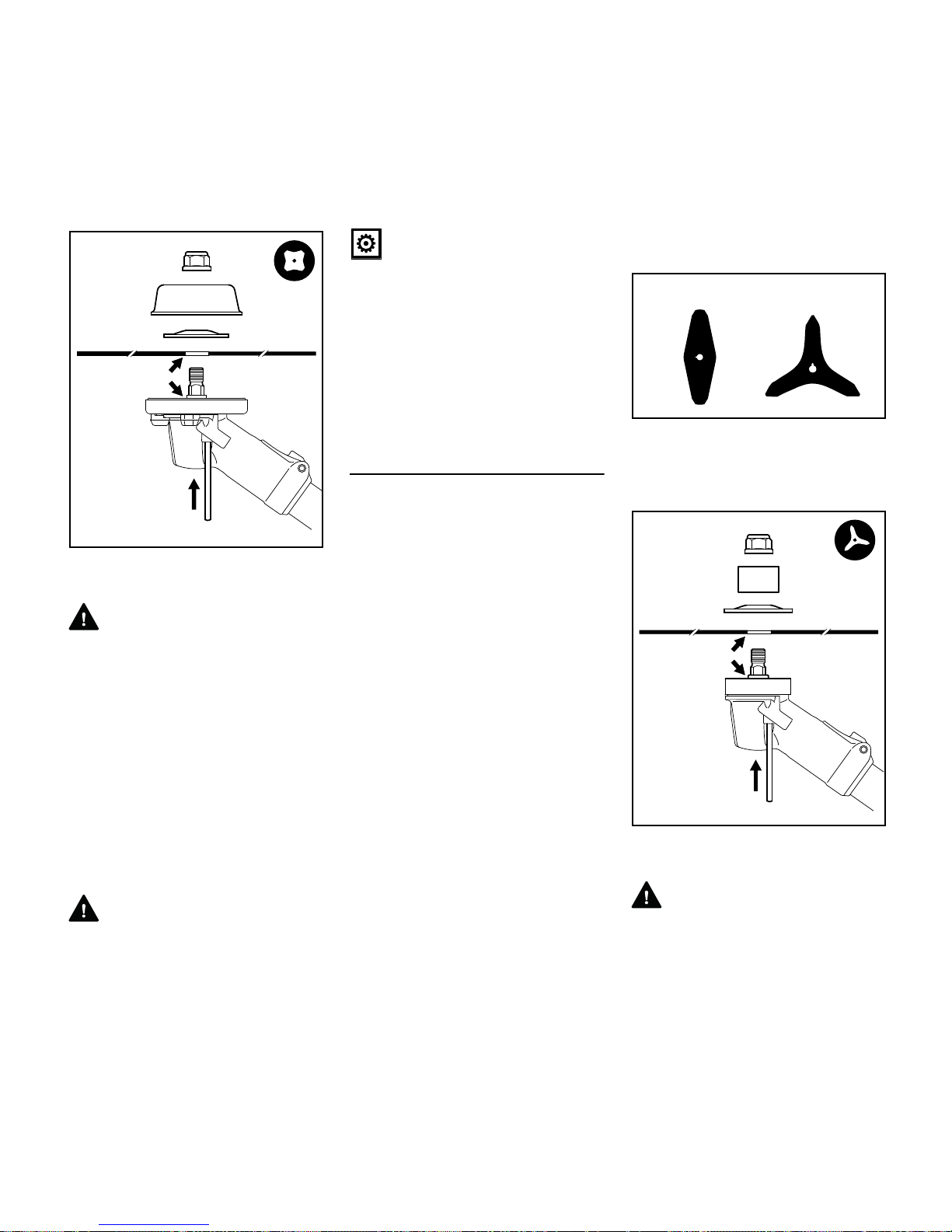

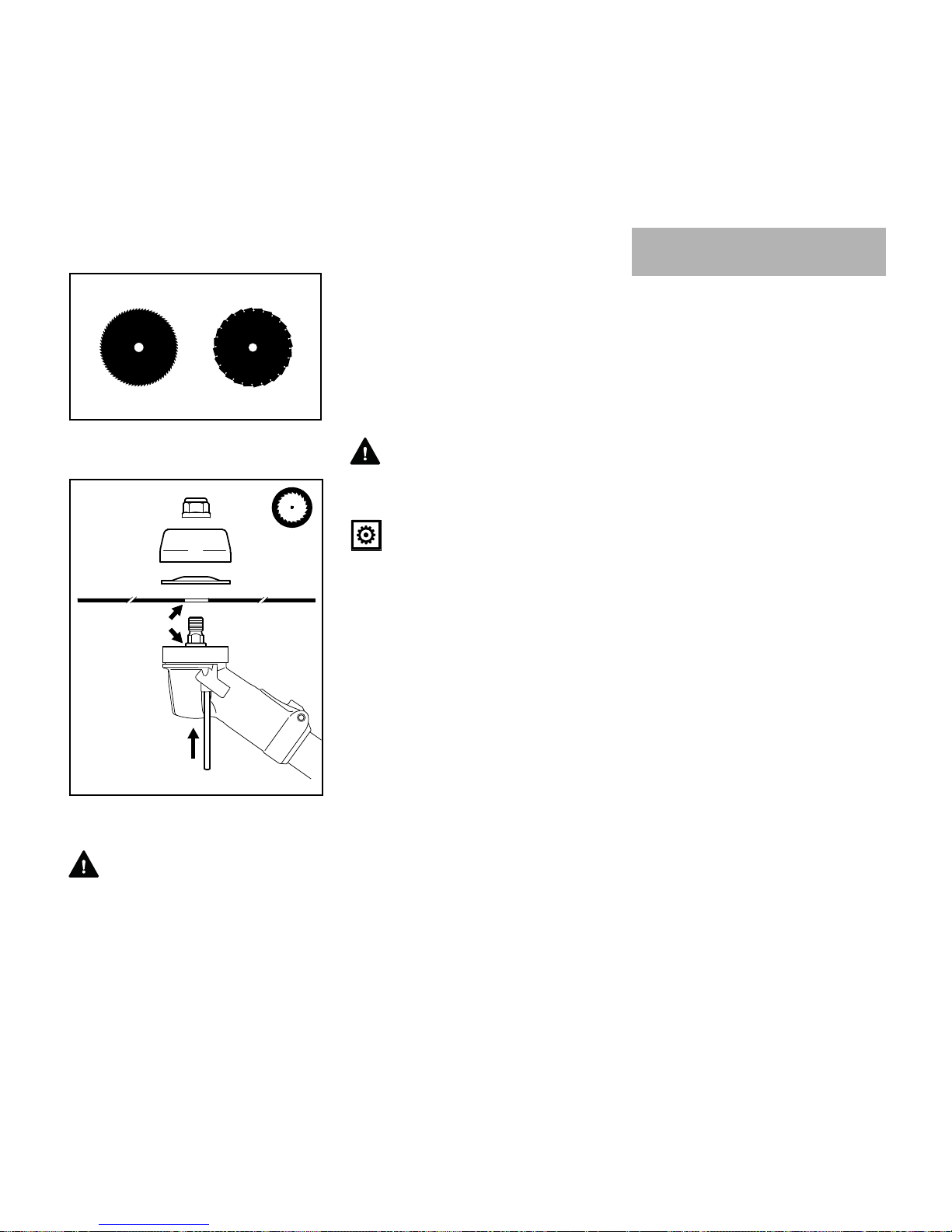

The cutting edges of the grass cutting

blades 255-8 (1) and 250-40 Spezial (2)

must point clockwise.

1

002BA468 KN

1

2

681BA186 KN

FS 510 C, FS 560 C

English

25

N Place the cutting attachment (3) in

position.

WARNING

Collar (a) must locate in the cutting

attachment's mounting hole (b).

Securing the cutting attachment

N Fit the 60 mm (2.4 in) diameter

thrust washer (4) – convex side

must face up.

N Fit the 80 mm (3.2 in) diameter (A)

rider plate (5).

N Block the shaft.

N Screw on the nut (6)

counterclockwise and tighten it

down firmly.

WARNING

If the mounting nut has become too

loose, fit a new one.

NOTICE

Remove the tool used to block the shaft.

Removing the Cutting Attachment

N Block the shaft.

N Unscrew the mounting nut (6)

clockwise.

N Pull the cutting attachment with its

mounting hardware off the

gearhead.

Mounting Brush Knives

N Check that the deflector on the

machine is approved for brush

knives – if not, perform the next two

steps.

N Remove grass shield with thrust

plate – if fitted.

N Remove the non-approved

deflector.

N Mount deflector for grass cutting

blades and brush knives.

N Fit the 65 mm (2.6 in) diameter

thrust plate.

Check direction of rotation of cutting

attachment

Brush knives 305-2 (1) and 350-3(2)

may point in either direction – these

cutting attachments must be turned over

regularly to help avoid one-sided wear.

N Place the cutting attachment (3) in

position.

WARNING

Collar (a) must locate in the cutting

attachment's mounting hole (b).

a

002BA469 KN

b

4

5

3

6

1

2

681BA187 KN

3

002BA494 KN

3

6

4

b

a

5

FS 510 C, FS 560 C

English

26

Securing the cutting attachment

N Fit the 70 mm (2.8 in) diameter

thrust washer (4) – convex side

must face up.

N Fit the guard ring (5) for brush

knives – opening must face up.

N Block the shaft.

N Screw on the nut (6)

counterclockwise and tighten it

down firmly.

WARNING

If the mounting nut has become too

loose, fit a new one.

NOTICE

Remove the tool used to block the shaft.

Removing the Cutting Attachment

N Block the shaft.

N Unscrew the mounting nut

clockwise.

N Pull the cutting attachment with its

mounting hardware off the gearbox.

Mounting Shredder Blade 320-2

N Check that the deflector on the

machine is approved for shredder

blades – if not, perform the next two

steps.

N Remove grass shield with thrust

plate – if fitted.

N Remove the non-approved

deflector.

N Mount deflector for shredder blade.

N Fit the 65 mm (2.6 in) diameter

thrust plate.

N Seal the unused tapped holes with

plugs.

N Place the shredder blade (1) in

position – the cutting edges must

point upwards.

WARNING

Collar (a) must locate in the cutting

attachment's mounting hole (b).

Securing the cutting attachment

N Fit the 70 mm (2.8 in) diameter

thrust washer (2) – convex side

must face up.

N Fit the shredder blade guard ring (3)

– opening must face up.

N Block the shaft.

N Screw on the nut (4)

counterclockwise and tighten it

down firmly.

WARNING

If the mounting nut has become too

loose, fit a new one.

NOTICE

Remove the tool used to block the shaft.

Removing the Cutting Attachment

N Block the shaft.

N Unscrew the mounting nut

clockwise.

N Pull the cutting attachment with its

mounting hardware off the gearbox.

N If you intend to use a different

cutting attachment – remove the

shredder deflector.

Mounting circular saw blades 225

N Check that the stop for circular saw

blades is already mounted to the

machine – if not, perform the next

two steps.

N Remove grass shield – if fitted.

N Remove deflector – if fitted.

N Mount limit stop for circular saw

blades.

N Fit the 65 mm (2.6 in) diameter

thrust plate.

N Seal the unused tapped holes with

plugs.

002BA470 KN

3

4

2

1

b

a

FS 510 C, FS 560 C

English

27

Check direction of rotation of cutting

attachment

Cutting edges of circular saw blades

must point clockwise.

N Place the cutting attachment (1) in

position.

WARNING

Collar (a) must locate in the cutting

attachment's mounting hole (b).

Securing the cutting attachment

N Fit the 60 mm (2.4 in) diameter

thrust washer (2) – convex side

must face up.

N Fit the 63 mm (2.5 in) diameter rider

plate (3).

N Block the shaft.

N Screw on the nut (4)

counterclockwise and tighten it

down firmly.

WARNING

If the mounting nut has become too

loose, fit a new one.

NOTICE

Remove the tool used to block the shaft.

Removing the Cutting Attachment

N Block the shaft.

N Unscrew the mounting nut

clockwise.

N Pull the cutting attachment with its

mounting hardware off the gearbox.

This engine is certified to operate on

unleaded gasoline and with the mix ratio

50:1.

Your engine requires a mixture of highquality premium gasoline and highquality two-stroke air-cooled engine oil.

Use premium branded unleaded

gasoline with a minimum octane rating

of 89 (R+M)/2.

Note: Models equipped with a catalytic

converter require unleaded gasoline. A

few tankfuls of leaded gasoline can

reduce the efficiency of the catalytic

converter by more than 50%.

Fuel with a lower octane rating may

result in preignition (causing "pinging")

which is accompanied by an increase in

engine temperature. This, in turn,

increases the risk of the piston seizure

and damage to the engine.

The chemical composition of the fuel is

also important. Some fuel additives not

only detrimentally affect elastomers

(carburetor diaphragms, oil seals, fuel

lines etc.), but magnesium castings as

well. This could cause running problems

or even damage the engine. For this

reason it is essential that you use only

high-quality fuels!

Fuels with different percentages of

ethanol are being offered. Ethanol can

affect the running behaviour of the

engine and increase the risk of lean

seizure.

681BA165 KN

2

1

4

002BA471 KN

3

b

a

Fuel

FS 510 C, FS 560 C

English

28

Gasoline with an ethanol content of

more than 10% can cause running

problems and major damage in engines

with a manually adjustable carburetor

and should not be used in such engines.

Engines equipped with M-Tronic can be

run on gasoline with an ethanol content

of up to 25% (E25).

Use only STIHL two-stroke engine oil or

equivalent high-quality two-stroke aircooled engine oils for mixing.

We recommend STIHL 50:1 two-stroke

engine oil since it is specially formulated

for use in STIHL engines.

To ensure the maximum performance of

your STIHL engine, use a high quality 2cycle engine oil. To help your engine run

cleaner and reduce harmful carbon

deposits, STIHL recommends using

STIHL HP Ultra 2-cycle engine oil or ask

your dealer for an equivalent fully

synthetic 2-cycle engine oil.

To meet the requirements of EPA and

CARB we recommend to use STIHL HP

Ultra oil.

Do not use BIA or TCW (two-stroke

water cooled) mix oils!

Use only STIHL 50:1 heavy-duty engine

oil or an equivalent quality two-stroke

engine oil for the fuel mix in models

equipped with a catalytic converter.

Take care when handling gasoline.

Avoid direct contact with the skin and

avoid inhaling fuel vapour.

The canister should be kept tightly

closed in order to avoid any moisture

getting into the mixture.

The fuel tank and the canister in which

fuel mix is stored should be cleaned

from time to time.

Fuel mix ratio

Only mix sufficient fuel for a few days

work, not to exceed 30 days of storage.

Store in approved safety fuel-canisters

only. When mixing, pour oil into the

canister first, and then add gasoline.

Dispose of empty mixing-oil canisters

only at authorized disposal locations.

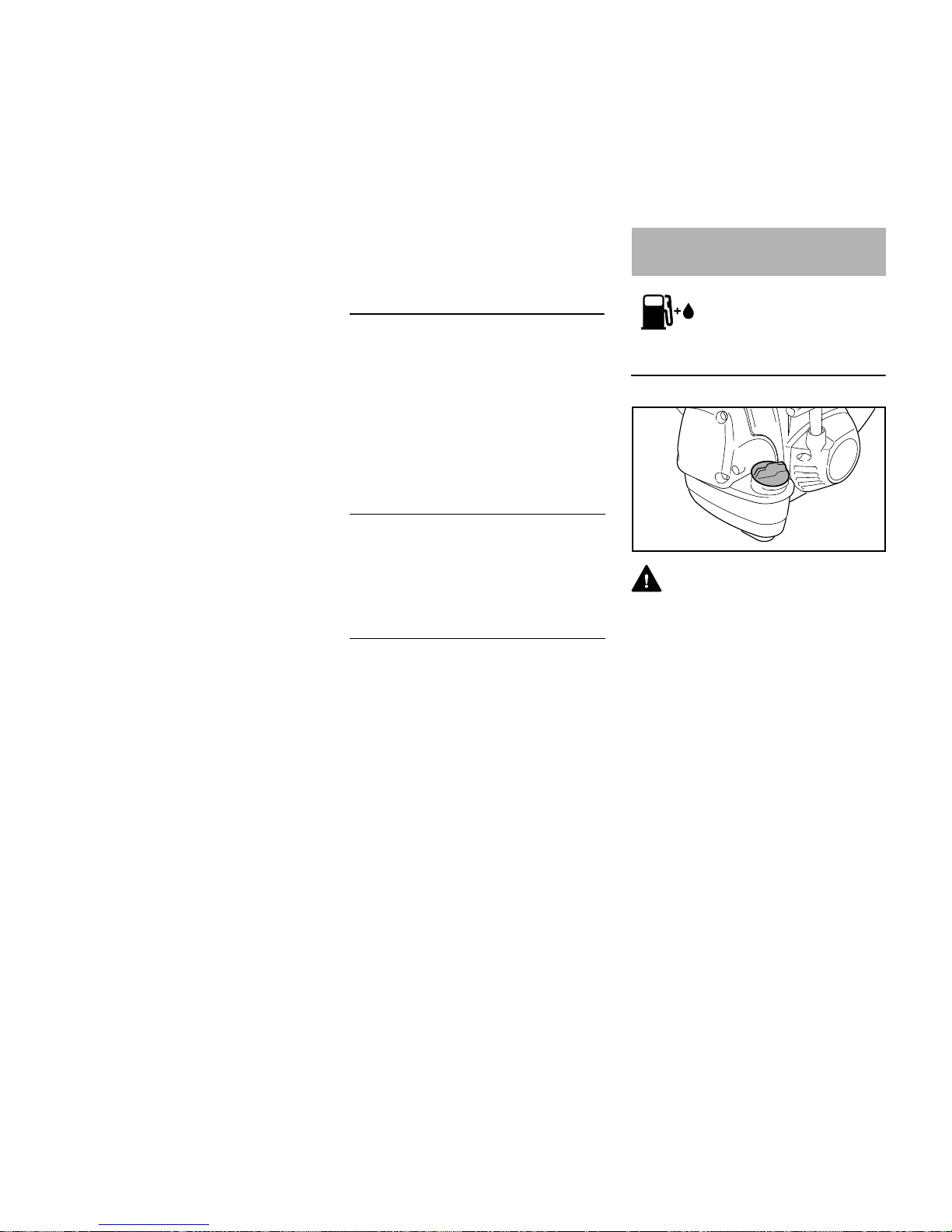

Preparations

WARNING

When fueling on a slope, always position

the machine with the filler cap facing

uphill.

N On level ground, position the

machine so that the filler cap is

facing up.

N Before fueling, clean the filler cap

and the area around it to ensure that

no dirt falls into the tank.

Examples

Gasoline Oil (STIHL 50:1 or equiva-

lent high-quality oils)

liters liters (ml)

10.02(20)

5 0.10 (100)

10 0.20 (200)

15 0.30 (300)

20 0.40 (400)

25 0.50 (500)

Fueling

4900BA016 KN

Loading...

Loading...