Page 1

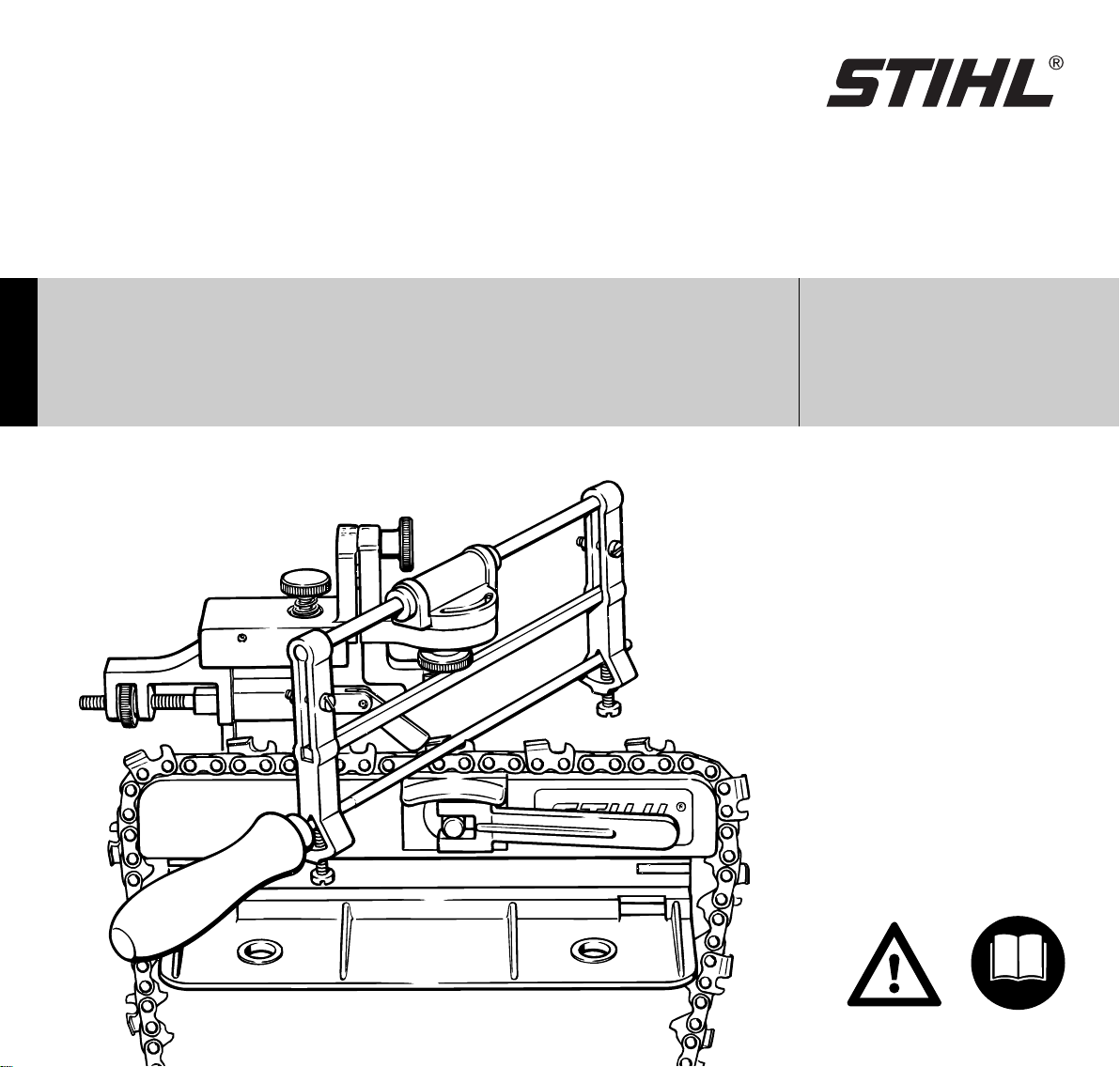

STIHL FG 2

Gebrauchsanleitung

Instruction Manual

Notice d’emploi

Instrucciones de servicio

Istruzioni d’uso

Instruções de serviço

Handleiding

Page 2

G Instruction Manual

13 - 24

E Instrucciones de

servicio

37 - 48

Page 3

Contents

English

Guide to Using this Manual ............ 14

Safety Precautions ......................... 15

Application ...................................... 15

Mounting the Tool ........................... 16

Selecting and Fitting File ................ 17

Setting Up ....................................... 17

Adjustments .................................... 18

BA_SE_145_001_01_01.fmPrinted on chlorine-free paper.

Sharpening ..................................... 20

Main Parts ...................................... 24

Printing inks contain vegetable oils; paper can be recycled.

Dear Customer,

Thank you for choosing a quality

engineered STIHL product.

This machine has been built using

modern production techniques and

comprehensive quality assurance.

Every effort has been made to ensure

your satisfaction and troublefree use

of the machine.

Please contact your dealer or our

sales company if you have any

queries concerning your machine.

Hans Peter Stihl

STIHl

© ANDREAS STIHL AG & Co. KG, 2003

0458 564 7721. M2. M3. T. Printed in Germany

13FG 2

Page 4

English

Guide to Using this Manual

Pictograms

All the pictograms attached to the

machine are shown and explained in

this manual.

The operating and handling instructions

are supported by illustrations.

Symbols in text

The individual steps or procedures

described in the manual may be marked

in different ways:

: Step or procedure without direct

reference to an illustration.

Description of step or procedure that

refers directly to the illustration and

contains item numbers that appear in

the illustration.

Example:

Loosen the screw (1)

Lever (2) ...

In addition to the operating instructions,

this manual may contain paragraphs

that require your special attention. Such

paragraphs are marked with the

symbols described below:

Warning where there is a risk of an

accident or personal injury or

serious damage to property.

Warning where there is a risk of

damaging the machine or individual

components.

Note or hint which is not essential

for using the machine, but may

improve the operator’s understanding of the situation and result

in better use of the machine.

Note or hint on correct procedure in

order to avoid damage to the

environment.

Equipment and features

This instruction manual refers to

several models with different

features. Components that are not

installed in all models and related

applications are marked thus

Such components are available as

special accessories from your

STIHL dealer.

*.

Engineering improvements

STIHL’s philosophy is to continually

improve all of its products. As a result,

engineering changes and improvements

are made from time to time. If the

operating characteristics or the

appearance of your machine differ from

those described in this manual, please

contact your STIHL dealer for

assistance.

Therefore, we cannot be responsible for

changes, modifications or

improvements not covered in this

manual.

14

FG 2

Page 5

Safety Precautions Application

English

To reduce the risk of

personal injury, special

safety precautions must

be observed while

operating the filing tool.

Read the instruction

manual carefully and

keep it in a safe place for

later reference.

Wear gloves.

It is absolutely essential to comply with

the angles and dimensions specified in

these instructions. If the saw chain is

incorrectly sharpened – and in

particular if the depth gauges are set too

low – there is a risk of increased saw

kickback and personal injury.

Observing the safety precautions and

specifications in this manual and the

instruction manual of the saw model on

which the filing tool is mounted can help

reduce the risk of injury and damage to

the tool and saw.

The STIHL filing tool can be used to

sharpen all STIHL Oilomatic saw chains

with the exception of square ground

chains (RSL, RSLF, RSLH) and carbidetipped chains (RD, RDS).

File correctly

– Sharpen the chain frequently, take

away as little metal as possible –

two or three strokes of the file are

usually enough.

– Always file from the inside to the

outside of the cutter.

– The file only sharpens on the

forward stroke – lift the file off the

cutter on the backstroke.

– Avoid touching the tie straps and

drive links with the file.

15FG 2

Page 6

English

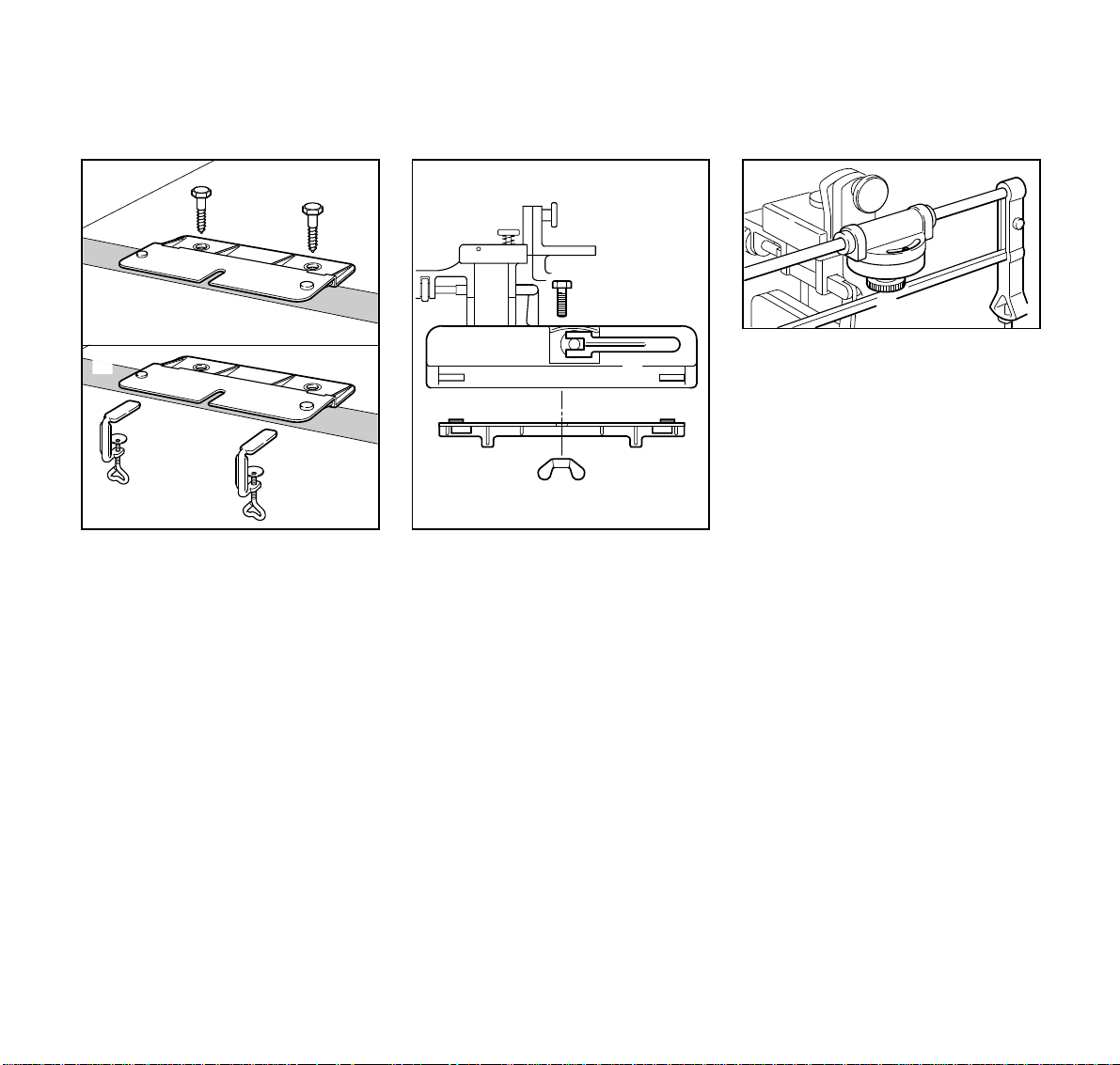

Mounting the Tool

A

7

8

B

: Secure the base plate to the bench

using either the wood screws (A)

provided or the screw clamps (B)

available as special accessories.

5

1

44

2

6

564BA000 KN

: Place the chain rest (1) on the base

plate (2) – the clamping lever (3)

must face away from the bench.

: Make sure the studs (4) engage the

holes.

: Fit the hex head screw (5) through

the center hole from above.

: Fit and tighten down the wingnut (6)

firmly.

9

3

: Position the filing frame (7) on the

swivel arm (8) so that the stop pin

engages the slot.

: Tighten down the nut (9) firmly.

564BA001 KN

564BA002 KN

16

FG 2

Page 7

English

Selecting and Fitting File

Use only special saw chain sharpening

files. Other files have the wrong shape

and cut and are unsuitable for

sharpening saw chain.

: Select the round file (special

accessory) that matches the chain

pitch.

Chain Pitch Round File Ø

inch mm mm inch

1/4 6.35 4.0 5/32

3/8 PMN 9.32 4.0 5/32

3/8 P 9.32 4.0 5/32

0.325 8.25 4.8 3/16

3/8 9.32 5.2 13/64

0.404 10.26 5.5 7/32

1

2

: Place the selected file (1) in the

filing frame.

: Tighten down the screws (2)

moderately.

2

Setting Up

Check the Saw Chain

: Replace any damaged or worn parts

of the chain and match the new

parts to the shape and size of the

original parts.

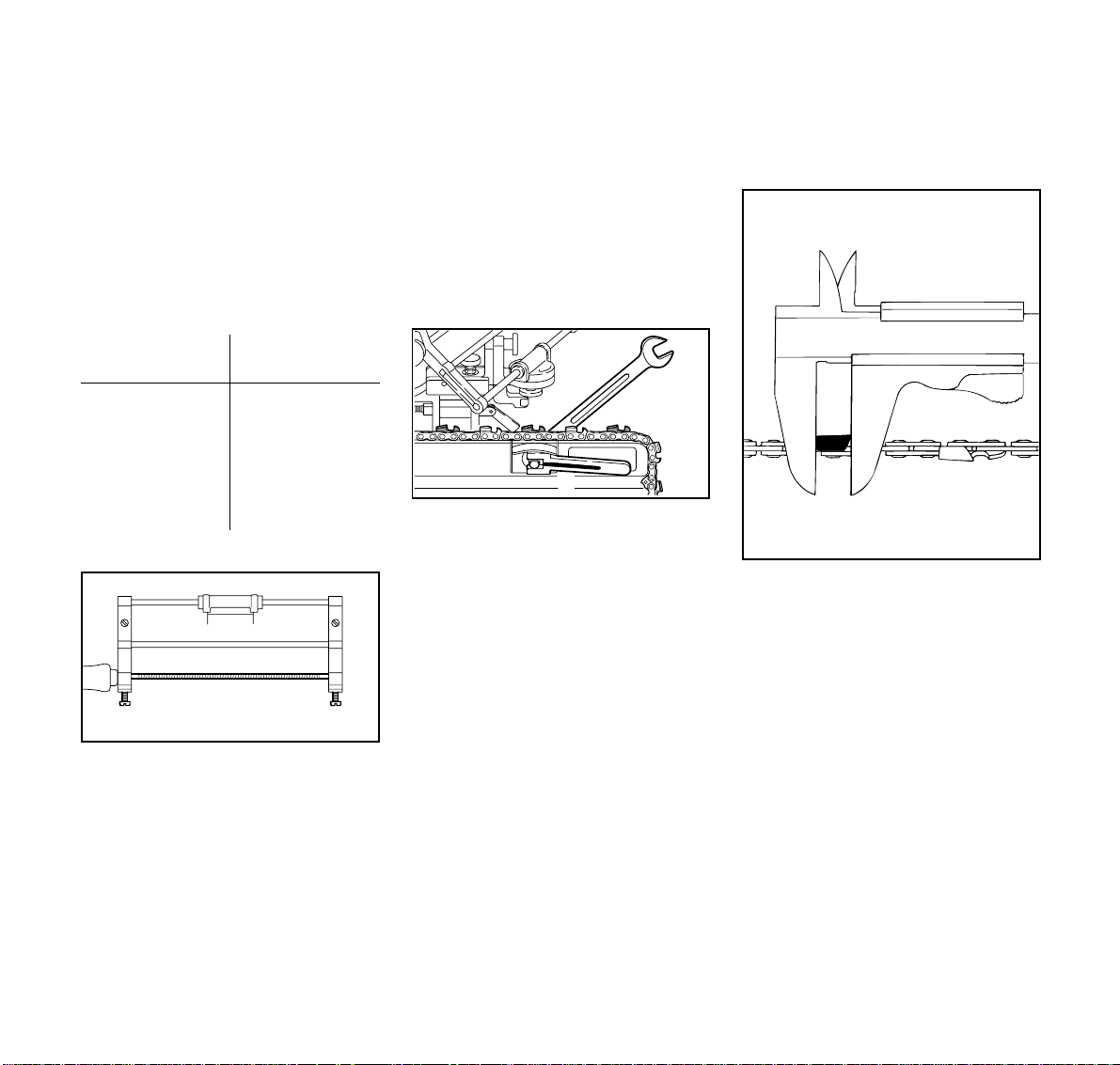

Clamping the Saw Chain

2

1

: Place the saw chain in the chain rest

– the cutting edges must point to the

right.

: Turn the clamping lever (1) to the

right – the longitudinal rib on the

clamping lever must face outwards.

: Tighten down the lock nut (2)

moderately until the chain is locked

in position.

: Turn the clamping lever to the left to

564BA003 KN

release the chain and to the right to

lock the chain.

Finding the Master Cutter

564BA004 KN

523BA012 KN

The shortest cutter is used as the master

cutter for filing all other cutters.

: Use a slide caliper to find the

shortest cutter and mark it, e.g. with

chalk.

17FG 2

Page 8

English

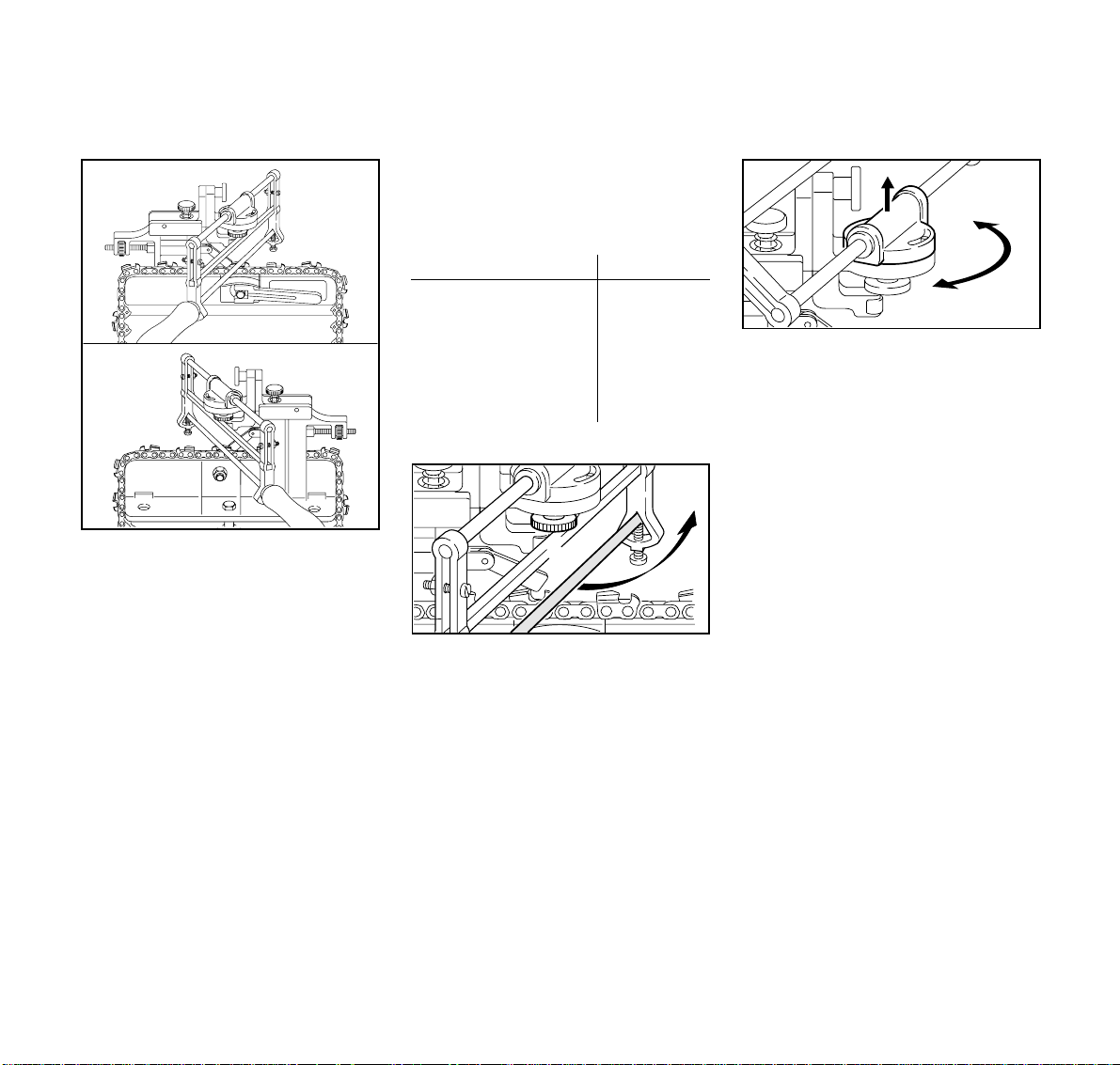

Adjustments

A

B

Turn the chain rest to suit the position of

the master cutter:

: Set the chain rest as shown in

illustration A if the master cutter is in

the left-hand row.

: Set the chain rest as shown in

illustration B if the master cutter is in

the right-hand row.

The sharpening procedure described

below assumes the master cutter is in

the left-hand row.

The procedure is the same if the master

cutter is in the right-hand row. Move the

chain rest to the position shown in

illustration B, reset the file, adjust angle.

Adjusting Filing Angle

: Check filing angle in the following

table.

Chain Type Filing Angle

Rapid Standard (RC) 30 °

Rapid Micro (RM) 30 °

Rapid Super (RS) 30 °

Picco Micro (PM/PMN) 30 °

RCX, RMX, PMX

(ripping chain)

564BA005 KN

10 °

1

: Swing the filing frame upwards.

: Loosen the nut (1).

564BA007 KN

: To rotate guide, lift it clear of the

teeth.

564BA006 KN

18

FG 2

Page 9

English

2

1

3

2

: Set the filing angle (2) – to sharpen

the left-hand row of cutters, turn the

guide to the right (clockwise).

: Tighten down the nut.

: Position the master cutter (3) below

the center of the nut (1).

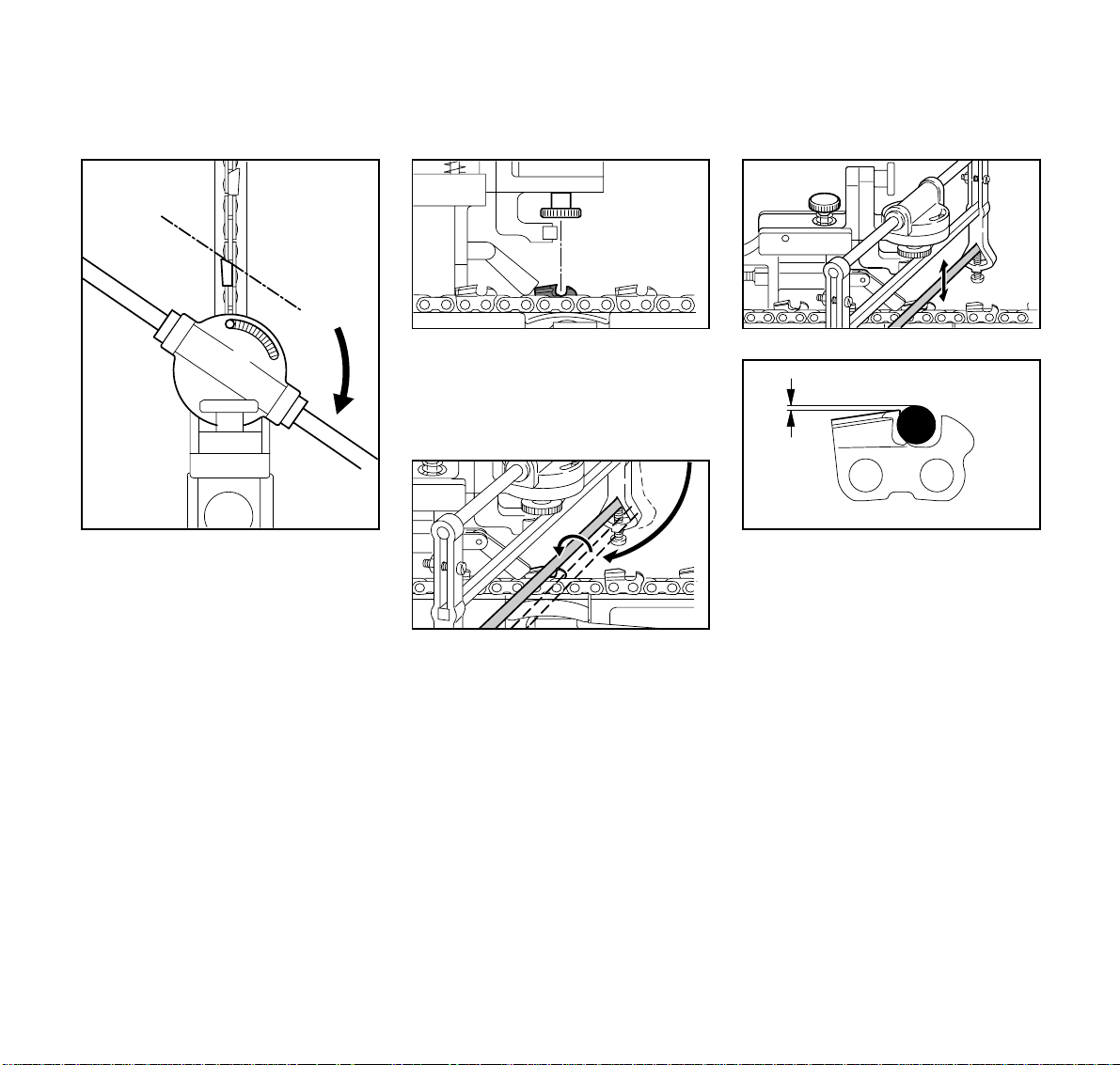

Aligning the Filing Frame

564BA008 KN

1

: Position the round file (1) between

the side plate and depth gauge of

the master cutter by swinging and

lifting the filing frame.

564BA009 KN

1/10 ø

: Turn the adjusting screw (2)

(counterclockwise to lower file –

564BA010 KN

clockwise to raise file) until about

1/10 of file diameter projects above

the top plate.

564BA011 KN

564BA028 KN

19FG 2

Page 10

English

3

: Turn the knurled nut (3) until the

stop (4) butts against the back of the

cutter to be sharpened (master

cutter).

5

6

4

5

6

7

: Then turn the knurled nut a little

further until the side plate presses

against the file and the stop bar (6)

lifts about 0.1 to 0.2 mm away from

the stop roller (5).

: Turn the clamping lever (7) to the

right – the saw chain is locked in

position.

Sharpening

Sharpening the Master Cutter

2

1

3

2

564BA012 KN

Sharpen the master cutter with 2 to 3

firm strokes of the file, from the inside to

the outside of the side plate.

: After sharpening, the stop bar (1)

should butt against the stop

roller (2).

If this is not the case, readjust the

stop (3) slightly and move the chain

up against it – check the stop

position again.

1

564BA013 KN

20

FG 2

Page 11

English

Sharpening the Next Cutter

Use the setting for the master cutter to

sharpen all the other cutters in the row.

: Open the clamping lever.

: Pull the chain along to the next

cutter in the row – push cutter

against the stop.

3

Make sure the stop (3) always

locates properly against the back of

the cutter to be sharpened.

: Close the clamping lever.

: Sharpen the cutter.

: Repeat the procedure until all

cutters in one row have been

sharpened.

Sharpening the Second Row of

Cutters

1

: Swing the filing frame upwards and

loosen the nut (1).

564BA014 KN

: Lift the guide clear of the teeth and

turn it to the same filing angle on the

opposite side.

: Tighten down the nut.

: Turn the chain rest 180°, as

564BA006 KN

described under "Setting Up".

: Reset the file.

: Swing the filing frame down.

: Position the round file between the

side plate and depth gauge of the

first cutter in the second row.

564BA007 KN

564BA015 KN

21FG 2

Page 12

English

A

: Sharpen the first cutter in the

second row.

: Check the cutter length (A).

3

Depth Gauges

: Select the filing gauge (special

accessory) that matches the chain

pitch.

Chain Pitch Filing Gauge

inch mm Part No.

564BA016 KN

1

/

4

3

/8 PMN 9.32 0000 893 4000

3

/8 P 9.32 1110 893 4000

0.325 8.25 1110 893 4000

3

/

8

0.404 10.26 1106 893 4000

6.35 1110 893 4000

9.32 1110 893 4000

35

30

: Set the filing angle on the guide

to 0°.

: Fit triangular file (special accessory)

in place of the round file.

: Pull chain along until a depth gauge

is under the file.

564BA018 KN

: If it differs from the length of the

master cutter, move the stop (3)

forwards or backwards, resharpen

and check length (A) again.

: If the length is correct, sharpen all

cutters in the second row using this

setting.

22

564BA023 KN

: Place the selected filing gauge

on the chain. If the depth gauge

projects above the filing gauge, it

has to be lowered.

2

33

564BA017 KN

: Adjust the stop (3) so that the file (2)

does not touch the cutting edge.

564BA019 KN

FG 2

Page 13

English

4

: Adjust height adjusting screw (4) so

that the depth gauge is filed back to

the required height (flush with the

gauge). Then remove the filing

gauge and file down all depth

gauges to the same setting.

: Finish off by filing the slope by hand,

parallel to the service mark (see

arrow) – take care not to lower the

highest point of the depth gauge in

this process.

564BA020 KN

: Place the filing gauge on the chain –

the highest point of the depth gauge

must be flush with the filing gauge.

The risk of the saw kicking back

increases if the depth gauges are

set too low.

564BA026 KN

: Lubricate the guide with oil at

regular intervals.

Rotate the file at regular intervals

while filing to avoid one-sided wear.

564BA025 KN

Oil

564BA024 KN

23FG 2

Page 14

English

Main Parts

1

2

3

4

5

6

1 Adjusting screw

2 Guide

3 Filing frame

4 Stop rail

5 Nut

6 File

7 Clamping lever

7

564BA021 KN

8 Knurled nut

9 Stop

10 Chain rest

8

9

11 Base plate

12 Lock nut

13 Wingnut

14 Screw

24

10

12

11

13

14

564BA022 KN

FG 2

Page 15

Indice

español

Notas referentes a estas

instrucciones de servicio ................ 38

Para su seguridad .......................... 39

Uso previsto ................................... 39

Montar la máquina .......................... 40

Elegir, montar la lima ...................... 41

Preparación .................................... 41

BA_SE_145_001_03_01.fmImpreso en papel blanqueado sin cloro.

Ajuste ............................................. 42

Afilado ............................................ 44

Componentes importantes ............. 48

Las tintas de imprenta contienen aceites vegetales, el papel es reciclable.

Estimados clientes:

Muchas gracias por haber depositado su confianza en un producto de

calidad de la empresa STIHL.

Este producto ha sido fabricado con

modernos sistemas de fabricación y

con amplias medidas para asegurar

su calidad. Procuramos hacer todo lo

posible con el fin de que Ud. esté

contento con este implemento, y

pueda trabajar con él sin problemas.

En el caso de que tenga Ud. preguntas sobre su implemento, diríjase a

su Distribuidor STIHL, o directamente

a nuestra empresa de distribución.

Atentamente

Hans Peter Stihl

STIHl

© ANDREAS STIHL AG & Co. KG, 2003

0458 564 7721. M2. M3. T. Printed in Germany

37FG 2

Page 16

español

Notas referentes a estas

instrucciones de servicio

Símbolos gráficos

Todos los símbolos gráficos que se

pueden ver en el motoimplemento están

explicados en estas instrucciones de

servicio.

El manejo correcto está descrito y

explicado adicionalmente con

ilustraciones.

Marcación de los párrafos de

texto

Los pasos de manejo descritos pueden

tener distintas marcaciones:

: Paso de manejo que no tiene

relación directa con la ilustración

Paso de manejo que tiene relación

directa con la ilustración situada por

encima o al margen del texto con

referencia a un número de posición.

Ejemplo:

Aflojar el

1 = tornillo

2 = Palanca ...

Estas instrucciones de servicio pueden

contener, además de la descripción del

manejo, párrafos de texto con un

significado adicional. Estos párrafos

están marcados con uno de los

símbolos descritos a continuación:

Advertencia de peligro de accidente

y de riesgo de lesiones para

personas y advertencia de graves

daños materiales.

Advertencia de daños o deterioros

del motoimplemento o de los

diferentes componentes.

Advertencia que no es realmente

necesaria para el manejo del

motoimplemento pero, sin

embargo, puede facilitar tanto la

comprensión del texto como la

utilización del motoimplemento.

Advertencia para evitar daños

ecológicos.

Volumen de suministro /

equipamiento

Estas instrucciones de servicio se

refieren a modelos que se entregan

en distintas versiones. Piezas que

no están montadas en todos los

modelos y las respectivas

aplicaciones resultantes están

marcadas con *. Las piezas no

contenidas en el volumen de

suministro y marcadas con

disponibles como accesorios

especiales en la tienda de su

distribuidor STIHL.

* están

Perfeccionamiento técnico

STIHL trabaja constantemente en el

desarrollo de todos sus motoimplementos. Nos reservamos el

derecho de introducir modificaciones

referentes al diseño, la técnica y al

equipamiento.

Por esta razón no se puede hacer valer

ningún derecho en base de los datos y

las ilustraciones incluidos en estas

instrucciones de servicio.

38

FG 2

Page 17

Para su seguridad Uso previsto

español

Será necesario observar

medidas de seguridad

especiales al trabajar con

la afiladora para evitar

lesiones.

Leer detenidamente la

totalidad de las

Instrucciones de servicio

y guardarlas en un lugar

seguro para posteriores

consultas.

Llevar guantes.

Los ángulos y medidas que figuran a

continuación se han de observar sin

falta. Una cadena de aserrado

erróneamente afilada – especialmente

si los limitadores de profundidad quedan

demasiado bajos – puede aumentar la

tendencia al rebote de la motosierra –

¡peligro de lesiones!

La observancia de las medidas de

seguridad y de las indicaciones de estas

Instrucciones de servio y de las de la

máquina en la que se va a montar la

afiladora puede evitar lesiones y daños

en la máquina.

Con la limadora STIHL pueden afilarse

todas las cadenas STIHL Oilomatic

excepto las cadenas con filo de arista

(RSL, RSLF y RSLH) y las cadenas de

metal duro (RD, RDS).

Afilar correctamente

– Afilar frecuentemente, quitar poca

cantidad – para el reafilado simple

normalmente son suficientes dos o

tres pasadas con la lima

– Limar únicamente desde dentro

hacia fuera

– La lima muerde solamente en la

pasada de movimiento hacia

adelante

– Al retroceder, alzar la lima

– No limar los eslabones de unión o

los eslabones motrices.

39FG 2

Page 18

español

Montar la máquina

A

7

8

B

Fijar la placa giratoria sobre la placa

de trabajo

A = con los tornillos para madera

adjuntados

B = con prensas de tornillo

(accesorio especial)

5

1

44

2

6

564BA000 KN

Asentar el

1 = caballete de afilado sobre la

2 = placa giratoria

La

3 = palanca tensora debe estar

orientada en sentido contrario al de

la placa de trabajo

Los

4 = pivotes tienen que estar alojados en

los taladros

Pasar el

5 = tornillo hexagonal desde arriba a

través del taladro central

Apretar firmemente la

6 = tuerca de mariposa

9

3

564BA001 KN

Insertar el

7 = bastidor de afilado sobre la

8 = pieza giratoria, de manera que la

espiga de tope encaje en el taladro

oblongo en forma de arco de círculo

Apretar la

9 = tuerca.

564BA002 KN

40

FG 2

Page 19

español

Elegir, montar la lima

Emplear únicamente limas de afilar

cadenas de aserrado especiales.

Las limas de taller no son apropiadas

para afilar cadenas por su forma y el

picado.

: Elegir una lima redonda apropiada

para el paso de cadena (accesorios

especiales)

Paso de cadena Ø lima redonda

pulgadas mm mm pulgadas

1/4 6,35 4,0 5/32

3/8 PMN 9,32 4,0 5/32

3/8 P 9,32 4,0 5/32

0.325 8,25 4,8 3/16

3/8 9,32 5,2 13/64

0.404 10,26 5,5 7/32

1

2

Colocar la

1 = lima redonda elegida en el bastidor

de afilado

Fijar los

2 = tornillos y apretarlos

moderadamente

2

Preparación

Controlar la cadena de aserrado

: Renovar las piezas dañadas o

desgastadas de la cadena y adaptar

las piezas nuevas a las demás en la

forma y el grado de desgaste –

adaptarlas correspondientemente

Fijar la cadena de aserrado

2

1

: Colocar la cadena sobre la regleta

de guía – los cantos de corte tienen

que estar orientados hacia la

derecha

Accionar la

1 = palanca tensora hacia la derecha –

la nervadura longitudinal de la

palanca tiene que estar orientada

en sentido contrario al de la

564BA003 KN

máquina

Apretar moderadamente la

2 = tuerca de retención, hasta que

quede inmovilizada la cadena

: Para aflojar la cadena, accionar la

palanca tensora hacia la izquierda –

para tensarla, hacia la derecha

Determinar el diente patrón

564BA004 KN

523BA012 KN

El diente más corto de la cadena se

constituye en diente patrón. En éste se

orienta la longitud de todos los demás

dientes de corte de la cadena.

: Con un pie de rey, determinar el

diente más corto y marcarlo p. ej.

con tiza.

41FG 2

Page 20

español

Ajuste

A

B

En función de la posición del diente

patrón en la fila de dientes –

girar el caballete de afilado:

A = con diente patrón en la fila

de dientes izquierda

B = con diente patrón en la fila

de dientes derecha

La descripción que figura a continuación

muestra cómo se ha de proceder con un

diente patrón situado en la fila de

dientes izquierda.

Al tratarse de un diente patrón en la fila

de dientes derecha, proceder en

sentido análogo.

Con arreglo a la ilustración B, girar el

caballete de afilado, modificar el

tensado de la lima y ajustar el ángulo.

Ajustar el ángulo de afilado

: Determinar el ángulo de afilado en

base a la siguiente tabla

Tipo de cadena Angulo

de afilado

Rapid-Standard (RC) 30 °

Rapid-Micro (RM) 30 °

Rapid-Super (RS) 30 °

Picco-Micro (PM/PMN) 30 °

RCX, RMX, PMX

(corte longitudinal)

564BA005 KN

10 °

1

: Girar el bastidor de afilado hacia

arriba

Aflojar la

1 = tuerca

564BA007 KN

: La pieza de guía se ha de elevar por

completo del dentado para girarla

564BA006 KN

42

FG 2

Page 21

español

2

1

3

2

Ajustar el

2 = ángulo de afilado – para afilar la fila

de dientes de corte izquierda, girar

la pieza de guía hacia la derecha

(en el sentido de las agujas del

reloj)

: Apretar la tuerca

Poner el

3 = diente patrón debajo del centro

de la

1 = tuerca

Alinear el bastidor de limado

564BA008 KN

1

Girando y elevando el bastidor

de afilado, poner la

1 = lima redonda hacia abajo, entre la

cara de ataque y el limitador de

profundidad del diente patrón

564BA009 KN

1/10 ø

Girar el

2 = tornillo de ajuste

(giro hacia la izquierda – la lima

baja; giro hacia la derecha – la lima

564BA010 KN

sube), hasta que la lima sobresalga

aprox. 1/10 de su diámetro sobre el

techo del diente

564BA011 KN

564BA028 KN

43FG 2

Page 22

español

3

Girando la

3 = tuerca moleteada, modificar el

4 = tope, hasta que éste quede aplicado

al dorso del diente a afilar (diente

patrón)

5

6

4

5

6

7

Seguir girando un poco la tuerca

moleteada, hasta que la cara de

ataque presione contra la lima y la

6 = barra de tope se alce

aprox. 0,1 hasta 0,2 mm del

5 = rodillo de tope

Accionar la

7 = palanca tensora hacia la derecha –

la cadena de aserrado estará fijada

Afilado

Afilar el diente patrón

2

1

3

2

564BA012 KN

Afilar con 2 hasta 3 pasadas de lima

sostenidas. Guiar la lima siempre sólo

desde el borde interior hacia el exterior

de la cara de ataque del diente.

Tras el afilado, la

1 = barra de tope debe quedar

aplicada al

2 = rodillo de tope

De no ser así, reajustar un poco el

3 = tope y colocar la cadena

correspondientemente –

volver a controlar la posición del

tope

1

564BA013 KN

44

FG 2

Page 23

español

Afilar el siguiente diente

Afilar todos los dientes de corte de la

misma fila con el ajuste efectuado en el

diente patrón.

: Abrir la palanca tensora

: Pasar la cadena hasta el siguiente

diente de la misma fila – empujar el

diente contra el tope

3

Prestar atención a que el

3 = tope quede aplicado siempre

exactamente al dorso del diente

a afilar

: Cerrar la palanca tensora

: Afilar el diente

: Repetir la operación, hasta que

estén afilados todos los dientes

de una misma fila

Afilar la segunda fila de dientes

1

: Girar el bastidor de afilado hacia

arriba

Aflojar la

1 = tuerca

564BA014 KN

: Alzar por completo la pieza

de guía del dentado –

girarla a la correspondiente

marcación de ángulo del lado

opuesto

: Apretar la tuerca

564BA015 KN

564BA006 KN

: Girar el caballete de afilado 180°, tal

como se describe en “Preparación”

: Cambiar la posición de la lima

: Girar el bastidor de afilado hacia

abajo

: Poner la lima redonda entre

la cara de ataque y el limitador

de profundidad del primer diente

de la segunda fila

564BA007 KN

45FG 2

Page 24

español

A

: Afilar el primer diente

de la segunda fila

Medir la

A = longitud de diente

3

Limitador de profundidad

: Elegir el calibre de limado

(accesorios especiales)

correspondiente al paso de cadena

Paso de cadena Calibre de limado

pulgadas mm número de pieza

564BA016 KN

1

/

4

3

/8 PMN 9,32 0000 893 4000

3

/8 P 9,32 1110 893 4000

0.325 8,25 1110 893 4000

3

/

8

0.404 10,26 1106 893 4000

6,35 1110 893 4000

9,32 1110 893 4000

35

30

: Ajustar el ángulo de afilado a 0° en

la pieza de guía

: Sustituir la lima redonda por la lima

de tres cantos (accesorio especial)

: Hacer pasar la cadena, hasta que

se encuentre un limitador de

profundidad debajo de la lima

564BA018 KN

Si difiere de la longitud del diente

patrón, poner el

3 = tope hacia delante o atrás y

controlar la

A = longitud de diente tras

volver a afilarlo –

si no existe ya divergencia alguna,

afilar todos los dientes de la

segunda fila con este ajuste

46

564BA023 KN

: Colocar el calibre de limado elegido

sobre la cadena de aserrado. Si el

limitador de profundidad sobresale

del calibre, habrá que repasarlo

2

33

564BA017 KN

564BA019 KN

Ajustar el

3 = tope, de manera que la

2 = lima no toque el filo de corte

FG 2

Page 25

español

4

Ajustar el

4 = tornillo de ajuste de la profundidad,

de manera que el limitador de

profundidad se pueda limar a la

altura necesaria (enrasado

respecto al calibre). Luego, quitar el

calibre de limado y repasar con la

lima todos los limitadores de

profundidad con este ajuste

: A continuación, reafilar

oblicuamente el techo del limitador

de profundidad en paralelo a la

marca de servicio (véase la flecha)

– al hacerlo, no hacer retroceder el

punto más alto del limitador

de profundidad

564BA020 KN

: Colocar el calibre de limado sobre la

cadena – el punto más alto del

limitador de profundidad tiene que

estar enrasado con el calibre de

limado

Los limitadores de profundidad

demasiado bajos aumentan la

tendencia al rebote de la motosierra

564BA026 KN

: Untar con regularidad la pieza

de guía con aceite

Girar un poco la lima en intervalos

regulares, a fin de evitar un

desgaste unilateral.

564BA025 KN

Oil

564BA024 KN

47FG 2

Page 26

español

Componentes importantes

1

2

3

4

5

6

1 = Tornillo de ajuste

2 = Pieza de guía

3 = Bastidor de limado

4 = Barra de tope

5 = Tuerca

6 = Lima de afilar

7 = Palanca tensora

7

564BA021 KN

8 = Tuerca moleteada

9 = To pe

10= Caballete de afilado

8

9

11= Placa giratoria

12= Tuerca de retención

13= Tuerca de mariposa

14= Tornillo

48

10

12

11

13

14

564BA022 KN

FG 2

Page 27

0458 564 7721

MF

Loading...

Loading...