Page 1

Page 2

F

SERVICE MANUAL

028/038

FOREWORD

This Service Manual covers model

028 chain saws up to machine

number

5561640

as well as later

machines unless technical information

bulletins have been issued

in

the meantime with updated

repair procedures.

Models

038

have substantially the

same constructional features as

model 028 chain saws" This Service

Manual can therefore be used

for the 038 chain saws as

well.

In

the event of faults it is quite pos-,

sible

that a single malfunction may

have several causes. It is, there-

fore,

advisable to consult the

"troubleshooting charts" when

tracing

faults"

We

also recommend

that you make use of the

exploded

views

in

the illustrated parts lists

while

carrying out repair work.

This service

manual and all techni-

cal information bulletins are

in-

tended exclusively for the use

of

STIHL servicing staff and dealers

and must not be passed on to third

parties.

STI

H

L®

Andreas Stihl

Postfach 1760

Repair

work

is made considerably

easier if the chain saw is mounted

on

assembly stand 59108503100.

The saw is

easily attached to the

stand by means

of

the two stud

bolts and collar

nuts

for bar mount-

ing"

While

on the assembly stand, the

chain saw can be

swivelled into any

required position to suit the repair

in

question" This not only has the

advantage of keeping the component

in

the best

position

for

the re-

pair, but

also leaves both hands

free for the work, and

thus

repre-

sents a considerable time-saving.

0-7050

Waiblingen

SPECIAL TOOL

MANUAL

1

Our

special tool manual illustrates

and lists the part numbers of all

available

machine-related tools as

well as general purpose tools for all

machines.

The

special tool manual is available

in various languages and can be

ordered

by

quoting the appropriate

part number

listed hereunder.

German

English

French

Spanish

Yugoslav

Swedish

Italian

Portuguese

0455

901

0023

04559010123

0455

901

0223

0455

901

0323

0455

901

0423

0455901 0523

0455

901

0723

0455

901

1223

Page 3

p

2

CONTENTS

1 .

Specifications

4 4

..

Ignition System 26 4

.. 5 ..

1

Checking on breaker-

4.1

Construction 26

controlled ignition

45

4

..

2

Operation 26 4.5.2

Adjustment on

breaker-

2

..

Clutch, Chain Drive 4 .

.2

..

1

General information

26

controlled ignition

45

and Chain Brake

7

4.2.2

Breaker-controlled

4

.. 5 ..

3

Checking on

electronic

2.1

Construction magneto ignition 27 ignition

47

and operation

7

4 .

.2

..

3 Bosch

transistor-controlled

4.6 Magneto edge

gap

48

2

..

1.1

Clutch and chain sprocket 7

magneto ignition 28

2

..

1.2

Chain brake

8

4.2.4

SEM

thyristor-controlled

2.2

Troubleshooting chart

8

magneto ignition

29

2.3

Disassembly

and repair

9

4

..

2.4..1

Charging the storage 5

..

Rewind Starter

49

2

..

3.1

Clutch

9

capacitor

29

5

..

1

Construction

2.3

.

.2

Chain brake

12

4.2

..

4.2Triggering the

thyristor

29 and operation

49

2.4

Assembly

13

4 . .2.4..3 Ignition 30 5.2 Troubleshooting chart

49

2.4.1 Chain brake

13 4

..

3

Troubleshooting chart

31

5.3 Disassembly

50

2.4 .

.2

Clutch

14

4.3.1

Breaker-controlled

5.4 Replacing the

starter

ignition system

31

rope

50

4

..

3 .

.2

Electronic ignition

5.5

Replacing the rewind

3

..

Engine 15 system 32 spring

51

3.1

Construction 15 4.4 Function and repair 5

..

6 Tensioning the rewind

3.2 Troubleshooting chart

15

of components 33 spring

51

3

..

3 Exposing the

cylinder

16

4.4..1

Spark

plug

33

5.7

Replacing starter rope

3.4 Disassembly of cylinder 4.4..2 Ignition lead

34 guide bush

52

and piston 16

4

..

4.3

Short-circuit

wire/ground

5

..

8 Routine maintenance

52

3.5

Assembly

of piston wire 35

and

cylinder

17

4.4.4

Short-circuit

contact

36

3

..

6 Disassembly of crankcase 4.4.5 Flywheel

37

-

removal

of

crankshaft 19 4

..

4.6 Armature

(Bosch)/ignition

6

..

AV Handle System

53

3

.

.7

Installing the

Crankshaft

module (SEM)

39

6

..

1

Construction

-

assembly

of crankcase21 4.4..6

..

1 Resistance

test

on

and operation

53

3.8 Leakage testing

primary winding

39 6

.

.2

Repair

53

the

crankcase

23 4.4..6.2Resistance

test

on

3

..

8.1

Pressure test 23

secondary

winding

39

3

. .8.2 Vacuum

test

25

4.4..6

..

3 Ignition coil

tester

40

3.8

..

3

Replacing the oil seals 25 4.4..6.4 Disassembly 7

..

Master Control

55

and

assembly

40

7.1

Construction

4.4.7

Condenser

41

and operation

55

4.4.8

Contact

set

42

7

.

.2

Disassembly

4.4..9

Trigger plate

44

and

assembly

55

4

..

5 Ignition timing 44

Page 4

8"

Electric Handle Heating

System

56

8,,1

Construction

and operation

56

8.2

Troubleshooting

56

8,,3

Disassembly

and assembly

58

8.3.1

Switch

58

8,,3,,2

Heating element

in pistol grip

58

8.3.3

Handlebar

58

8,,3..4

Generator

59

9"

Chain Lubrication

60

9.1

Construction and

operation of oil pump

60

9,,2

Troubleshooting chart

61

9,,3

Oil

tank/tank

vent

62

9..4

Repair

of

pickup body

and valve

62

9.5

Disassembly and repair

of

oil pump

63

1O"

Fuel System

64

1

0,,1

Construction and

operation

of

carburetor

64

10"1,, 1 Operation of fuel pump

64

1 0.1,.2 Operation of carburetor

64

10,,2

10,,3

10..4

10.5

10,,6

10,,6,,1

Troubleshooting chart

66

Leakage test

on carburetor

68

Disassembly

of

carburetor

68

Repair

of

carburetor

69

Carburetor adjustment

71

Notes for fine adjustment

of

carburetor

71

3

10.7

Fuel line and tank vent

71

10.8

Air filter and choke

72

Page 5

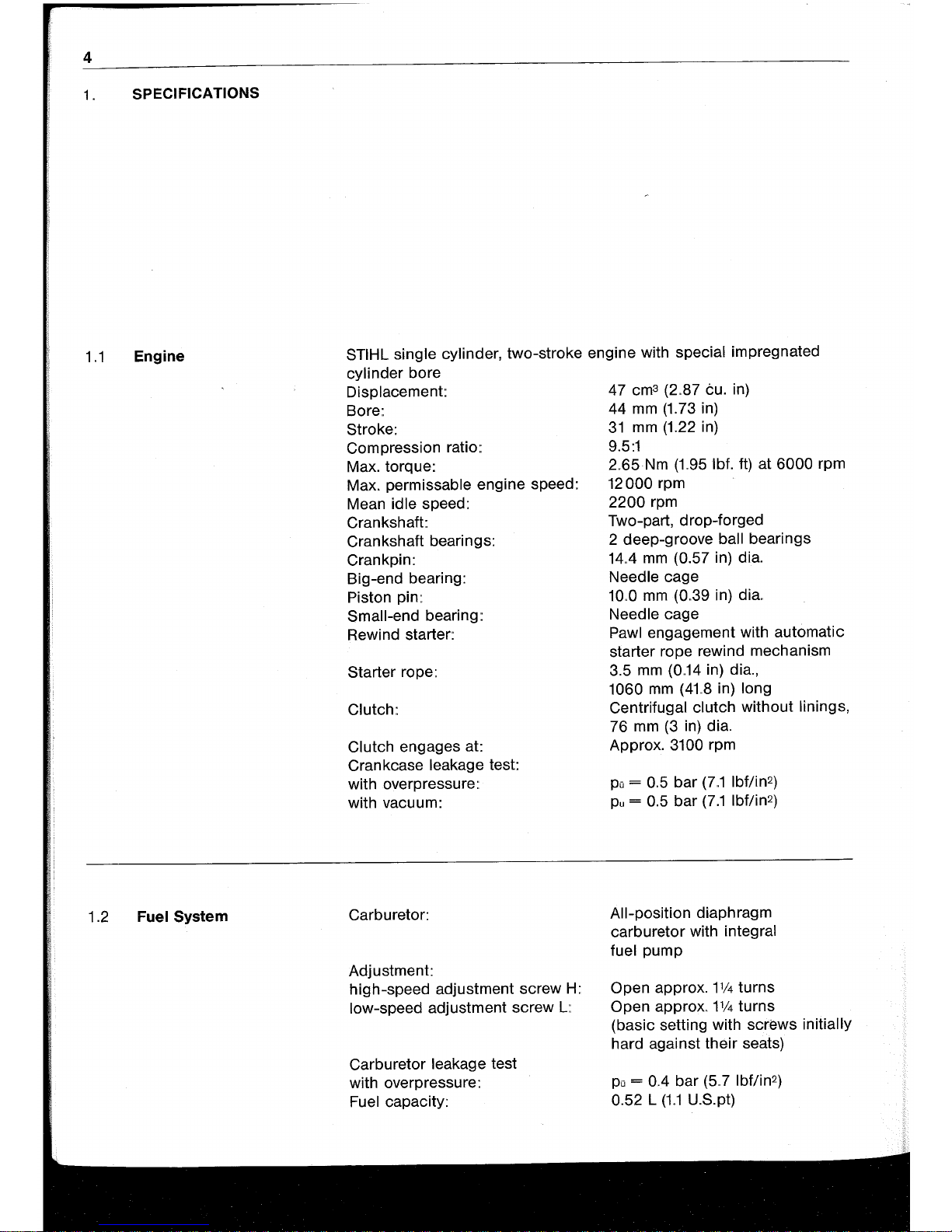

4

1. SPECIFICATIONS

1.1

Engine

1.2

Fuel System

STIHL single cylinder, two-stroke engine with special impregnated

cylinder bore

Displacement:

Bore:.

Stroke:

Compression

ratio::

Max. torque:

Max.

permissable engine speed:

Mean

idle speed:

Crankshaft:

Crankshaft bearings:

Crankpin:

Big-end bearing:

Piston pin:

Small-end bearing:

Rewind starter:

Starter rope:

Clutch:

Clutch

engages at:

Crankcase

leakage test:

with overpressure::

with vacu u

m:

Carburetor:

Adjustment:

high-speed adjustment screw

H:

low-speed adjustment screw

L:

Carburetor leakage test

with overpressure:

Fuel capacity:

47 cm3 (2

..

87 tu. in)

44

mm

(1.73 in)

31

mm

(1.22 in)

9.5:1

2

..

65

Nm

(1..95

Ibf. ft) at

6000

rpm

12000

rpm

2200

rpm

Two-part, drop-forged

2 deep-groove ball bearings

14..4

mm

(0.57 in) dia.

Needle cage

10

..

0

mm

(0

..

39 in) dia.

Needle

cage

Pawl engagement with automatic

starter rope rewind mechanism

3.5

mm

(0

..

14

in) dia.,

1060

mm

(41.8 in) long

Centrifugal

clutch without linings,

76

mm

(3

in) dia.

Approx.

3100 rpm

po

= 0

..

5 bar

(7

..

1 Ibf/in2)

pu

= 0.5 bar

(7.1

Ibflin2)

All-position

diaphragm

carburetor with

integral

fuel

pump

Open approx.

11/4

turns

Open approx

..

1114

turns

(basic setting with screws

initially

hard against their seats)

po

= 0.4 bar

(5

..

7 Ibflin2)

0.52 L

(1..1

U.S.pt)

Page 6

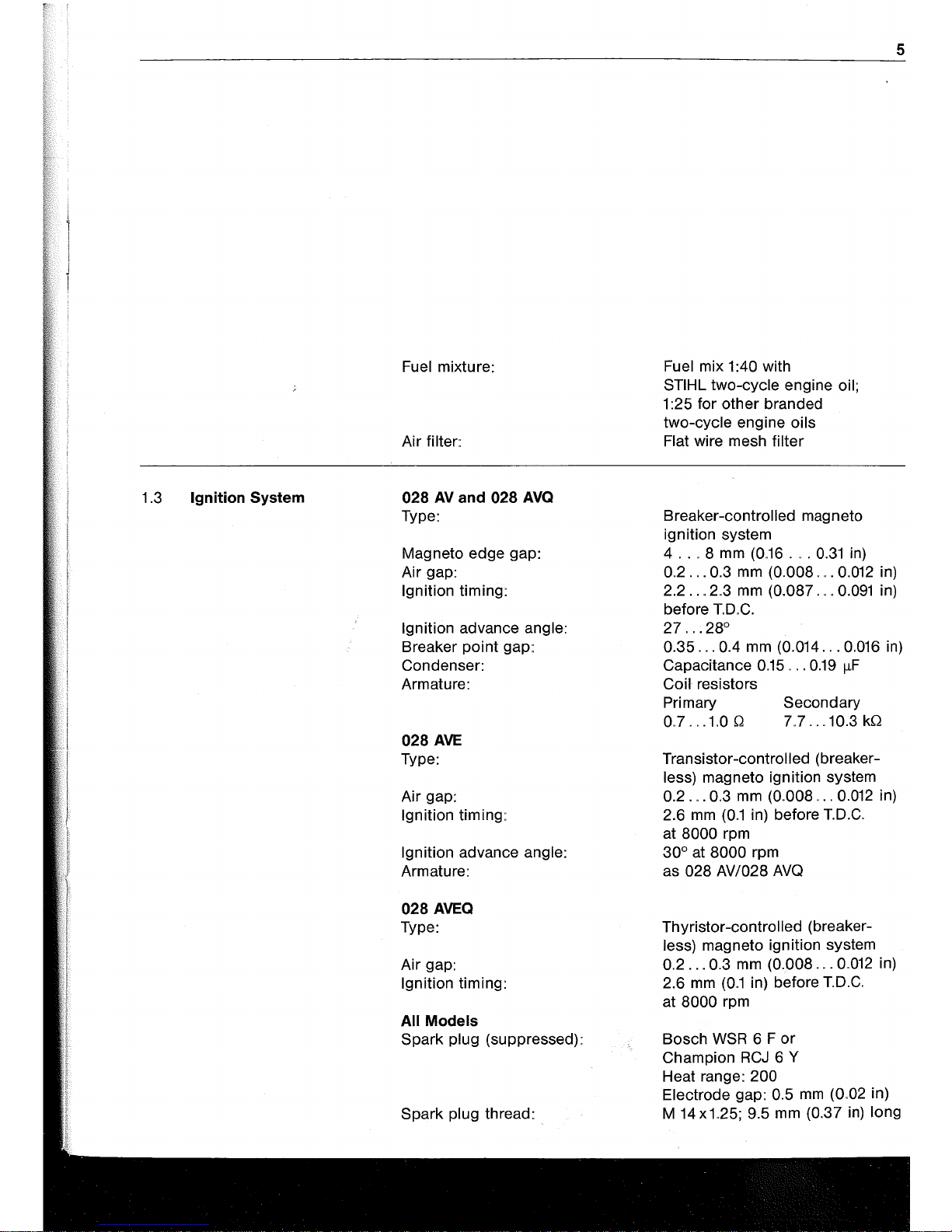

1.3

Ignition System

Fuel mixture:

Air

filter::

028

AV

and

028

AVQ

Type:

Magneto edge gap:

Air gap:

Ignition timing:

Ignition advance angle:

Breaker point

gap::

Condenser:

Armature:

028

AVE

Type:

Air gap:

Ignition timing::

Ignition advance angle:

Armature:

028

AVEQ

Type:

Air gap:

Ignition timing:

All Models

Spark plug (suppressed):

Spark

plug thread:

Fuel mix 1 :40 with

STIHL two-cycle engine oil;

1 :25 for other branded

two-cycle engine oils

Flat

wire mesh filter

Breaker-controlled magneto

ignition system

4

..

" 8

mm

(0,,16

. " .

0.31

in)

0,,2

...

0.3

mm

(0.008" " .

0.012

in)

2.2

..

,,2,,3

mm

(0.087" ,

,,0.091

in)

before

T..D"C.

27"".28°

5

0.35

...

0.4

mm

(0.014. , .0.016 in)

Capacitance

0.15" " .

0.19

IlF

Coil

resistors

Primary

0..7

...

1,,00

Secondary

7..7

...

10.3

kQ

Transistor-controlled (breaker-

less) magneto ignition system

0.2.

" .

0,,3

mm

(0,,008,. ,

0.012

in)

2.6

mm

(0,,1

in) before

T.D.C"

at 8000 rpm

30° at 8000 rpm

as

028 AV/028

AVQ

Thyristor-controlled (breaker-

less) magneto ignition system

0,,2

...

0.3

mm

(0.008

...

0,,012

in)

2.6

mm

(0,,1

in) before

T.D.C"

at 8000 rpm

Bosch

WSR

6 F

or

Champion

RCJ

6 Y

Heat range: 200

Electrode

gap::

0.5

mm

(0,,02

in)

M 14x1..25; 9.5

mm

(0.37

in)

long

Page 7

6

1.4

Tightening Torques

Crankshaft nut

(ignition side) M

8 x

1:

30

Nm (22 Ibf. ft)

Hub/spider

(output side):,

50

Nm

(37 Ibf.

ft)

M 5 socket head screws:

8 Nm (6

Ibf..

ft)

M

5 cheese-head screws:

5 Nm

(3,,7

Ibf. ft)

M

4 cheese-head screws:,

2.5

Nm

(1.8

Ibf..

ft)

M 5 nuts:

5 Nm (3.7

Ibf..

ft)

Spark plug:

25

Nm

(18,,4

Ibf..

ft)

Important: The M 5 x 12 screws on the front handguard and the

M 4 x 8 screws on the spider are fitted with LOCTITE.

1.5

Cutting Attachment

Guide

bars:,

STIHL Duromatic guide bars

with stellite-tipped bar

nose;

STIHL Rollomatic

guide bars

with sprocket nose. Both types

with corrosion resistant finish

and induction hardened track

Bar lengths:

Duromatic

40

and 45 cm

(16

and

18

in)

Rollomatic 32, 37, 40 and 45 cm

(13,14.6,16 and

18

in)

Chain:,

0.325" (8,,25

mm)

pitch

Chain sprocket::

7 -tooth for 0.325" chain

Chain

speed:,

16.4

m/s

(53.8 ft/sec) at

8500

rpm

Chain

lubrication:,

Speed-controlled

oil pump

with

lift plunger, operative

only when chairi is running

Oil delivery rate:

8 cm

3

/min

(0,,49

cu. in/m in)

at

6000

rpm

Oil tank capacity:,

0.3 L

(0,,63

U"S"pt)

1.6

Weights

Model:

AV/AVE

AVQ/AVEQ

Dry weight with

32

cm

bar and

chain:,

6,,5

kg (14.3

Ib)

6,,6

kg (14.5 Ib)

1,,7

Special Accessories

STIHL rescue kit

028

11189005000

Gasket set 028

11180071050

Page 8

2.

CLUTCH,

CHAIN DRIVE AND

CHAIN BRAKE

2

..

1 Construction and

Operation

2

.. 1 ..

1 Clutch and Chain Sprocket

The transmission of

power

from the

engine to the

saw

chain is effected

via a centrifugal clutch

..

O~

"Quick-

stop"

models, the centrifugal clutch

incorporates an isolating clutch

which

isactuated

by the chain brake.

On the Quickstop version the hub

screwed to the crankshaft is the

clutch element which absorbs the

torque and acceleration of the

crankshaft.. It is essential that the

hub is always tightened down to the

specified torque

..

The clutch

spider

is supported on the hub

by

a needle

sleeve and located axially with a

circlip

..

The driving plate is located

on

thethree

lugs of the clutch

spider

and can move axially while remaining in

constant

mesh with the

spider

..

The flat spring between the

spider and driving plate presses the

driving plate against the release

plate; this means

that

the internal

teeth of the driving plate are always

in mesh with the teeth of the hub

when the chain brake is released,

and thus provides positive

transmission of engine torque to the

clutch

spider

..

When the chain brake

is actuated, the release plate

dis-

engages the driving plate from the

hUb

..

The clutch

spider

and hub can

then rotate independently.

On the standard version the clutch

spider assumes the function of the

hub and must therefore always be

tightened to the specified torque

..

Chain

brake

engaged

The centrifugal clutch has three

clutch shoes

without

linings

..

The

clutch drum and chain sprocket are

separate components. The

spur

gear

which drives the oil pump is a

ring-gear,

positively

mounted to the

hub of the clutch drum

..

The chain

sprocket has two

integrally cast lugs

which engage in corresponding recesses on the drum hub

..

As the lugs

have odd sizes, the chain sprocket

can only be fitted in one position

..

When the engine is running at idle

speed the clutch shoes are also in

the idle position, because the

ten-

sion of the clutch spring is

greater

than the centrifugal force

..

As engine

speed increases, centrifugal force

presses the clutch shoes outwards

against the clutch drum and thus

transmit engine torque

positively

via

the chain

sprocket

to the saw

chain

..

The preload and strength of the

clutch spring are designed so

that

7

Chain

brake

released

the clutch shoes begin to make

con-

tact with the clutch drum at an en-

gine speed of approx

..

3100 rpm

(engagement speed)

..

The clutch

engages fully above this speed

..

The

correct idle setting on the

carbure-

tor

is therefore essential in

order

to

insure that the clutch engagement

speed is not reached when

the

en-

gine is idling

..

Page 9

8

2,,1,,2

Chain Brake

The chain brake is a

spring-loaded

band brake without linings" Its main

components are the brake band,

tension spring, handguard and release plate - which operates the

isolating clutch"

The chain brake is actuated by

means of the handguard which can

be used to release and engage the

brake"

2.2

Troubleshooting Chart

Fault

Saw chain turns at idle speed

The chain brake is

released (reset)

by pulling the handguard back

against the handlebar"

This

move-

ment is transmitted

via

a lever

system which preloads the tension

spring and

disengages

the brake

band. At the same time the release

plate moves back and

allows the

driving plate to engage in the teeth

of the hub"

The

brake lever, which is

connected to the tension spring,

brake band and release plate, is

locked in the idle position by the

relay lever.

Cause

Engine idle speed too high

Clutch spring stretched or fatigued,

spring hooks broken

Excessive chain

sprocket

wear

Incorrect chain tension

Chain stops in

mid-cut

even with Isolating clutch worn

engine at maximum speed Isolating clutch

disengages

Flat spring broken

during cutting

Isolating clutch does not re-engage Engine idle speed too high

after releasing chain brake

Flat spring broken

Saw chain does not stop

imme-

Tension spring broken

diately when chain brake is engaged

The chain brake is actuated by

mo-

ving the handguard

towards

the

bar

nose" This movement unlatches

the

brake lever and causes

the

brake

band to be clamped around

the

clutch drum by the force

of

the

preloaded brake spring" The release

plate simultaneously

disengages

the driving plate from the hub and

interrupts the flow of power between

the crankshaft and the centrifugal

clutch"

Clutch drum and

saw

chain

are brought to a

standstill within a

fraction of a second even if the

engine continues running at high

speed"

Remedy

Readjust at idle speed

adjustment

screw

Renew clutch spring

Tension saw chain properly

Renew hub and driving plate

Renew flat spring

Readjust at idle speed adjustment

screw

Renew flat spring

Renew tension spring

Page 10

2,,3

Disassembly and Repair

2,,3,,1

Clutch

Top:

Chain

brake

released

Bottom:

Pressing

out

the

retaining

washer

First remove chain sprocket cover

and cutting attachment..

The chain brake

must

be released

before removing the chain

sprocket

Use a screwdriver, about 5 mm

wide, to press the retaining

washer

out of the annular groove in the

crankshaft.

The

thrust

washer,

chain sprocket and needle sleeve

can now be pulled off the

cranks-

haft

Top:

Removing

the

side

plate

Center:

Releasing

the

cover

Bottom:

Ring-gear

removed

9

Top:

Removing

the

spur

gear

Bottom:

Clutch

drum

and

needle

sleeve

removed

Remove the inner side plate -

se-

cured with a single M 4 x 12

cheesehead screw" Unscrew the five

M 4 x

12

cheese-head

screws and

take off the cover" Now remove ring

gear

from clutch drum hub and the

spur

gear

(with worm) from the oil

pump shaft by turning it clockwise.

Pull clutch drum and needle sleeve

off

the

crankshaft

Page 11

10

Top:

Removing

the

circlip

Bottom:

Clutch,

flat

spring

and

needle

sleeve

removed

Disassembly differs on the

Quick-

stop and standard versions from this

stage onwards.

On the Quickstop version, first remove

the

circlip which locates the

clutch spider on the hub

..

The

clutch

with flat spring and needle sleeve

can now be pulled

off

the hub

..

If the

hub has to be removed, first remove

the driving

plate and block the

crankshaft..

To

do this, unscrew

Top:

Driving

plate

removed

Center:

Locking

screw

11071911200

Bottom:

Locking

screw

inserted

Top:

Special

socket

11188931300

Bottom:

Unscrewing

the

hub

spark

plug and fit locking

screw

11071911200 in the spark plug hole

and tighten down by hand

..

Use

spe-

cial socket 11188931300 to

unscrew

the hub. Remove

washer

from

behind hub

..

Page 12

Unscrewing

the

clutch

spider

The

crankshaft

must

also be blocked with locking screw11071911200

in

order

to remove the clutch

spider

on the standard version,

Use'

a

19

mm cranked ring wrench to un-

screw the

clutch

spider

and then re-

move the dished cover

plate"

Caution: The hub and clutch spider

have

left-hand threads - unscrew

them

clockwise.

Wash all parts of the clutch, including the needle cages, in clean

gasoline

and

blowout

with com-

pressed

air

if available" Also clean

crankshaft

stub"

Always replace damaged

or

worn

parts,

Top:

Removing

cover

plate

Bottom:

Clutch

spring

in

spring

recess

Use the following procedure to replace the clutch spring, clutch shoes

or spider:

First unscrew the

cover

plate from

the

spider

(Quickstop only) and then

remove the

clutch shoes"

Toassembletheclutch,

first position

the

clutch spring in the spring recess

of one

clutch shoe, so

thatthe

spring

11

Pressing

clutch

spring

into

position

hooks are

in

the

center

of the clutch

shoe" Now fit the three olutch shoes

on the arms of

the

spider

so

that

the

spring recesses face

away

from the

triangular plate on the spider" Grip

the

clutch spring with both

thumbs

and push it into

the

spring recesses

of the other two

clutch shoes.

Refit the cover

plate on the

Quick-

stop clutch" The three M 4 x 8

cheese-head

screws

must

be secu-

red with

LOCTITE"

Page 13

12

2.3,,2 Chain Brake

Detaching

the

tension

spring

The clutch drum must be removed

before the brake band can be disassembled"

To

do this, engage the

chain brake and detach the tension

spring" Remove retaining washer

from brake

lever's

pivot pin and

carefully withdraw the brake lever"

Collect

the washers and helical

spring on the brake

band's

pivot pin"

The other end of the brake band can

now be prised out

of

its seat in the

crankcase"

Take out the

clutch before removing

the

release plate" Remove the re-

taining washers, washers and

heli-

cal

springs from the guide pins and

take the

release plate out of the

crankcase"

Unscrew the handguard (the cheese-head screws

will be difficult to

remove because they are fitted with

LOCTITE) and then take out the

actuating

lever, relay lever and tor-

sion spring"

Top:

Removing retaining

washer

Center

and

Bottom:

Unscrewing

the

handguard

The spring guide pins in the crankcase must be

replaced if they are

damaged"

These screw pins

must

be bonded

in position to prevent them

loose-

ning in operation"

To

do this, use a

suitable solution (trichlorethlene,

diluted

nitro or similar) to

complete-

ly degrease the threads

in

the crank-

case and on the pins

themselves,

Then coat the threads of the screw

pins with a

little adhesive -

101,

part

number

0786

111

1101,

(LOCTITE

242) - and screw them into the

crankcase, Tighten to a torque of

4,,9

Nm (0.5 kpm).

It is essential to use a suitable

screwdriver with a tip which fits

snugly in the slot of the pin in order

to avoid damaging the pin materiaL

A 1 x 6.5 screwdriver in accordance

with

DIN 5265 is recommended for

this purpose"

Page 14

2..4 Assembly

24..1 Chain brake

Top:

Torsion

spring

and relay

lever

in

position

Bottom:

Actuating

lever

fitted

First fit the relay lever, actuating

lever and handguard. The ends

of

the torsion spring

must

engage in

the

hole in the crankcase and the

actuating

lever

..

The

M 5 x12

cheesehead screws must be secured with

LOCTITE.

Now fit release plate in crankcase

so

that

its slots locate

overthe

guide

pins

..

Fit washer, helical spring,

wa-

sher

and retaining

washer

on the

guide pins in

that

order

..

Locate bent

Seat

for

brake

band

end of brake band in its seat in the

crankcase and insert pivot pin of

brake

lever in the loop of the brake

band

..

Fit washer, helical spring and

washer on the pivot pin

of

the brake

lever

..

Push lever onto pivot pin and

locate pin in slot of release plate at

the same time. Now secure brake

lever with retaining

washer

and attach the tension spring using the

special assembly tool.

Top:

Brake

band and

brake

lever

in position

Center:

Special

assembly

tool

11178900900

Bottom:

Attaching

the tension

spring

13

Page 15

14

2..4.2 Clutch

Top:

Tightening

the

hub

with a

torque

wrench

First degrease the threads on the

crankshaft and hub (Quickstop)

or

clutch

spider

(standard) with a

suit-

able solution (trichlorethlene,

dilu-

ted nitro

or

similar)"

The initial

assembly

operations are

different on the

Quickstop

and stan-

dard versions

..

On the Quickstop version, fit the

flange

washer

on the crankshaft,

screw

hub

counter-clockwise

onto

the crankshaft and tighten to a

tor-

que

of

49.0

Nm (5

..

0 kpm) using the

special socket

11188931300

and a

torque wrench"

It is essential to observe the specified torque as the hub may otherwise

loosen during operation.

Engage the driving plate on the teeth

of the hub" The chain brake

must

be

in the

released condition during this

operation, Fit

flat spring on lugs

of

clutch spider; the raised spring tabs

Bottom:

Flat

spring

fitted on

spider

lugs

mustfaceawayfromtheclutch.

Now

push

clutch

together

with greased

needle sleeve onto the hub and turn

backwards and forwards until the

clutch

spider

lugs engage in the

driving plate.. Fit circlip to secure

clutch.

On

the standard version, fit cover

plate on the crankshaft so that the

raised outer

diameter

faces away

from the crankcase"

Screw

spider

of

clutch assembly

counter-clockwise

onto

the

crankshaft and tighten to a

torque

of

49.0 Nm (5.0 kpm) using

a torque wrench with a

19

mm socket.

It is essential to observe the specifiedtorqueasthespidermayotherwise

loosen

in

operation.

The

assembly

procedure is now the

same for both versions"

Lubricate

needle sleeve of clutch

drum with antifriction grease and fit

it on the crankshaft..

Push clutch drum onto crankshaft

and

needle sleeve and then fit spur

gear

onto oil pump shaft. Slip ring

gear

onto

hub of clutch drum.

Finish

off

by fitting cover and chain

sprocket; remove the

locking screw,

fit and tighten down the

spark

plug"

Page 16

3"

ENGINE

3

..

1 Construction

Series 028 chain saws are powered

by an

air-cooled, single cylinder

two-stroke

engine

..

The crankcase is a

two-part

pres-

sure die-casting made of a

special

magnesium alloy.. The

two-part

drop-forged crankshaft is supported

in two

deep-groove

ball bearings

..

Two oil seals, in the crankcase

atthe

ignition side and in the ball bearing

3.2

Troubleshooting Chart

Fault

Engine does not start easily,

stalls

at idle speed, but operates

normally at full throttle

Engine

does

not

deliver

full power

or

runs erratically

Engine overheating

at the other side,

hermetically seal

the crank chamber.

The connecting rod,

also

drop-forged, is supported on needle cages

both on the crankpin and the piston

pin.

Once the needle cage and the

connecting rod have been fitted, the

two

halves of the crankshaft are

pressed together to form a torsionally rigid assembly and then

First check

fuel supply, carburetor,

air

filter and ignition system before

looking for faults on the engine

..

Cause

Oil seals in crankcase

leaking

Elbow

connector leaking

Crankcase damaged (cracks)

Secondary

air

seepage into engine

through

poorly mounted

or

faulty elbow connector

Piston rings leaking

or

broken

Insufficient cylinder cooling

..

Air inlet opening in fan housing

blocked

or

cooling fins

on

cylinder plugged

15

machine finished

..

For this reason a

replacement crankshaft can only

be

supplied

complete with connec-

ting rod and needle sleeve.

Cylinder and piston are made of a

special aluminum alloy" The cylinder bore is impregnated in a special

process

..

Remedy

Replace oil seals

Seal

or

replace elbow connector

Replace crankshaft

Mount

elbow connector correctly

or

replace

Replace

piston rings

Thoroughly clean all cooling

air

openings

Page 17

16

3,,3

Exposing the Cylinder

Top:

Removing

the

shroud

Bottom:

Unscrewing

the

muffler

First remove carburetor box cover,

unscrew spark

plug and take off the

shroud and

two-part

muffler"

The cooling fins of the cylinder are

now

easily accessible and can be

cleaned thoroughly" Check for

da-

mage (cracks, broken cooling fins,

etc),

3.4

Disassembly of Cylinder

and Piston

Removing

the

cylinder

base

screws

Drain fuel and oil tanks, Remove the

carburetor (see

10.4) and unscrew

the four cylinder base screws" Carefully pull the cylinder off the piston

and press the

elbow connector for-

wards and

,out of the tank housing"

Before removing the piston it must

be decided

whether

or not the

crankshaft is to be removed,

Le. the

wooden

block used to lock the

crankshaft

- to facilitate removal of

the

flywheel and hub (Quickstop)

or

clutch spider (standard) - must be

fitted be1ween the crankcase and

the piston"

To

remove the piston, first take out

the two wire retainers and press the

piston pin out

of

the piston and nee-

dle cage by means of drift

11108934700.

If the piston pin is stuck as a result

of carbonization, tap it out lightly

with a hammer and the drift. It is

Top:

Removing

the

wire

retainers

Bottom:

Pushing

out

the

piston

pin

essential to counterhold the piston

to insure that no

jolts are transmitted

to the connecting

rod"

Remove the

piston"

Page 18

3..5 Reassembly of Piston

and Cylinder

Arrow

and"

A"

point

towards

exhaust

port

If the

cylinder

has to be replaced the

new

cylinder

must always be installed with a matching piston" Replacement cylinders are only supplied

complete with piston"

If only the piston is to be renewed,

every replacement piston (marked

"B")

can be used with any cylinder"

Before installing the piston, lubricate the needle cage with oil and

insert it in the connec!ing

rod"

Posi-

tion piston on connecting rod

sothat

the stamped markings (arrow and A)

point

towards

the cylinder exhaust

port (towards tip of guide bar)" Now

fit piston pin in piston and

connec-

ting rod (needle cage)"

To

do this,

push

assembly

drift

through piston

bore and connecting rod to align

both bores concentrically" Fit piston

pin on spigot of assembly drift and

slide into piston" Gently move piston

to and fro to ease insertion

of

piston

pin,

Fitting

the

piston

pin

The piston pin must move freely in

its bore. Never use force during

assembly.

Insert the two wire retainers and

make sure

that

they

are properly

seated,

Mounting of the cylinder is best

car-

ried out using the wooden

assembly

block and

the

ring

compressor

1113

893 4900 or clamping strap

00008932600"

The

elbow

connector

must

be fitted

if a new cylinder is used"

To

insure

a perfect seal, coat the inside

of

the

elbow

connector's

neck

with

sea-

ling paste 0783

810

1101"

Fit

elbow

connector

on the intake stub so that

it faces upwards (towards

cylinder

head) and the moulding seam is

vertical (parallel with

cylindercenter

line)" Then secure elbow

connector

17

Top:

Wooden

assembly

block,

ring

compressor

and

clamping

strap

Bottom:

Elbow

connector

in

position

with hose clamp, making

sure

that

the clamp is

correctly

seated and

does not

distortthe

elbow

connector

when tightened down.

Page 19

a

18

Top:

Piston on

wooden

assembly

block

Bottom:

Piston rings

correctly

positioned

Fit new

cylinder

gasket

on the

crankcase. Lubricate piston and piston

rings with

oil. Place wooden block

on the crankcase so

that

piston is

resting on

it..

Position each piston ring so that the

radii at

the

ring gaps locate against

their

respective fixing pins in the

piston grooves.

Fitting

the

cylinder

Insert the

four

M 5 x

16

socket head

screws in the

cylinder mounting

holes

..

Using the ring

compressor

or

clamping strap,

compress

the piston

rings

while making sure

they

are

correctly positioned.. Fit

cylinder

over

the piston with the exhaust port

facing in the direction of the

guide

bar

tip

..

During this process make

sure

that

the cylinder is properly

aligned, Le.

the

outer

edges of the

cooling fins must be exactly parallel

with the outer edge of the crankcase

atthe

sprocket side

..

Ifthis

alignment

is not carried out,

the

piston rings

may

break

..

The ring

compressor

is

pushed downwards as the piston

rings

move into the cylinder

..

Re-

move wooden

assembly

block and

ring compressor..

Push flange of

elbow

connector

through the bore

in the

tank

housing (do not use a

sharp

tool

forthis

purpose) and align

the cylinder

gasket

and cylinder

..

Tighten down the

four

cylinder

base

screws to a

torque

of 7 .. 8 Nm

(0 .

.8

kpm) in a diagonal pattern..

Tightening

cylinder

base

screws

with

torque

wrench

Insert sleeve in

elbow

connector

and then refit

carburetor

(see 1004),

muffler, shroud, spark plug and

car-

buretor box cover

..

Page 20

BUYNOW

ThenInstantDownload

theCompleteManual

Thankyouverymuch!

Loading...

Loading...