Page 1

Page 2

Congratulationsl

You

are

the

owner

of a

precision-manufactured

STlHL

chain

saw

designed

to

give

you

long

and

dependable

service.

To

receive

maximum

performance

and

satisfaction

from

your

STlHL

chain

saw,

it

is

important

that

you

read

and

understand

the

maintenance

and

safety

precautions

before

using

your

saw.

Contact

your

STlHL

Dealer

or

the

SllHL

Distributor

for

your

area

if

you

do

not

understand

any

of

the

instructions

or

warnings

in

this

Manual.

This

Manual

contains

warnings

regarding

your

saw,

operating

and

safety

instructions for all

STlHL

090

series

power

saws.

Warning I

Because a chain

saw

is a high-speed

wood-cutting

tool,

some

special

safety

precautions

must

be

observed

as

with

any

other

power

saw

to

reduce

the

risk of

personal

acci-

dents.

Careless

or

improper

use

may

cause

serious

or

even

fatal

injury.

It

is

important

that

you

fully

understand

'the

contents

of

this

Manual

and

that

you

allow

only

persons

who

understand

this

Manual

to

operate

your

chain

saw.

Pay

special

attention

to

the

safety

precautions

and

cutting

techniques

outlined

on

pages 4 to

19.

STIHL!s

philosophy

Is

to

continually

improve

all

of its pro-

ducts.

As

a

result,

engineering

changes

and

improvements

are

made

from

time-to-time.

Written

notices

relating

to

such

changes

are

sent

to

STIHL

Dealers.

If the

operating

characteristics

of

the

appearance

of your

saw

differs

from

those

described

in

this

Manual,

please

contact

your

local

STlHL

Dealer

for

updated

information

and

assistance.

0458

166

0121.

MO,7S.AO.1:

Printed In

West

Germany

x

8nHL

090,

090

AY,

090

G

Instruction Manual/Owner's Manuals, .

Sharpening and Maintenance

of

Saw Chains

Contents

Parts of

the

Chain

Saw

Satety

Precautions

-

The

Operator

-The

Saw

-

The

Use

of

the

Saw

-

Maintaining

and

Storing

the

Saw

Mounting

Guide

Bar

and

Chain

Fuel

Chain

Oil

Helpers

Handle

Starting

011

Quantity

Control

Cutting

Attachment

Air

Filter

Carburetor

.

Replacing

the

Chain

Sprocket

Gear

Lubricant

090 G

Rewind

Starter

Maintenance

Chart

Specifications

Sharpening

and

Maintenance

of

Saw

Chain

STIHL~

C

1990

Andreas

Stlhl,

Walblingen

Andreas Stihl

D-7050 W8lblingen

2

4

4

6

6

19

20

22

22

23

24

27

28

30

31

32

33

34

36

37

39

1

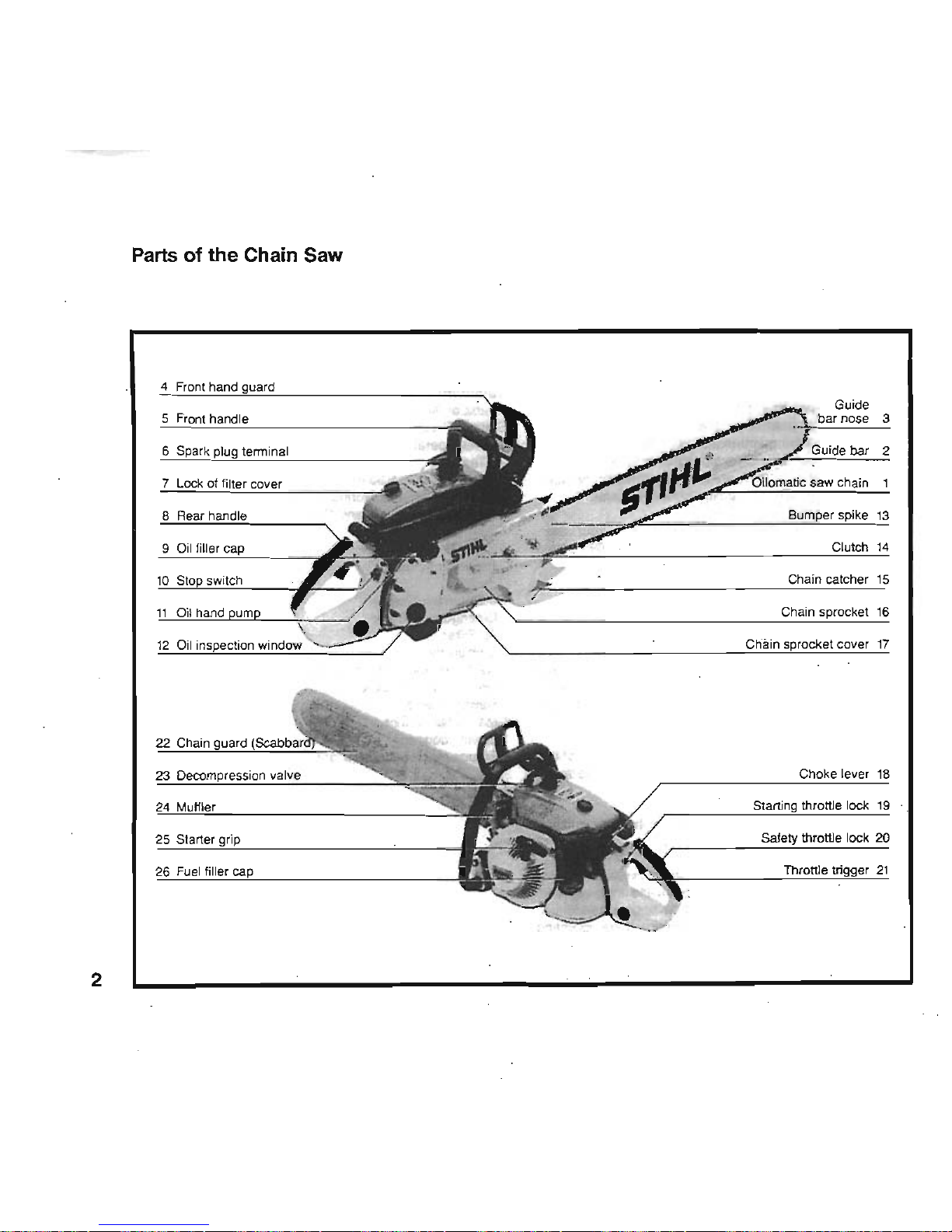

Page 3

Parts

of

the

Chain Saw

4 Front hand

Guide

5

Front handle

bar nose

3

6

tenninal

Guide

bar

2

of filter cover

Bumper spike

13

9 Clutch

l'

O'lain catcher 15

Oil

hand

Chain

16

12

Oil

22 Chain

23

Choke lever

18

throttle lock

19

25 Slarter throttle lock

20

2

Page 4

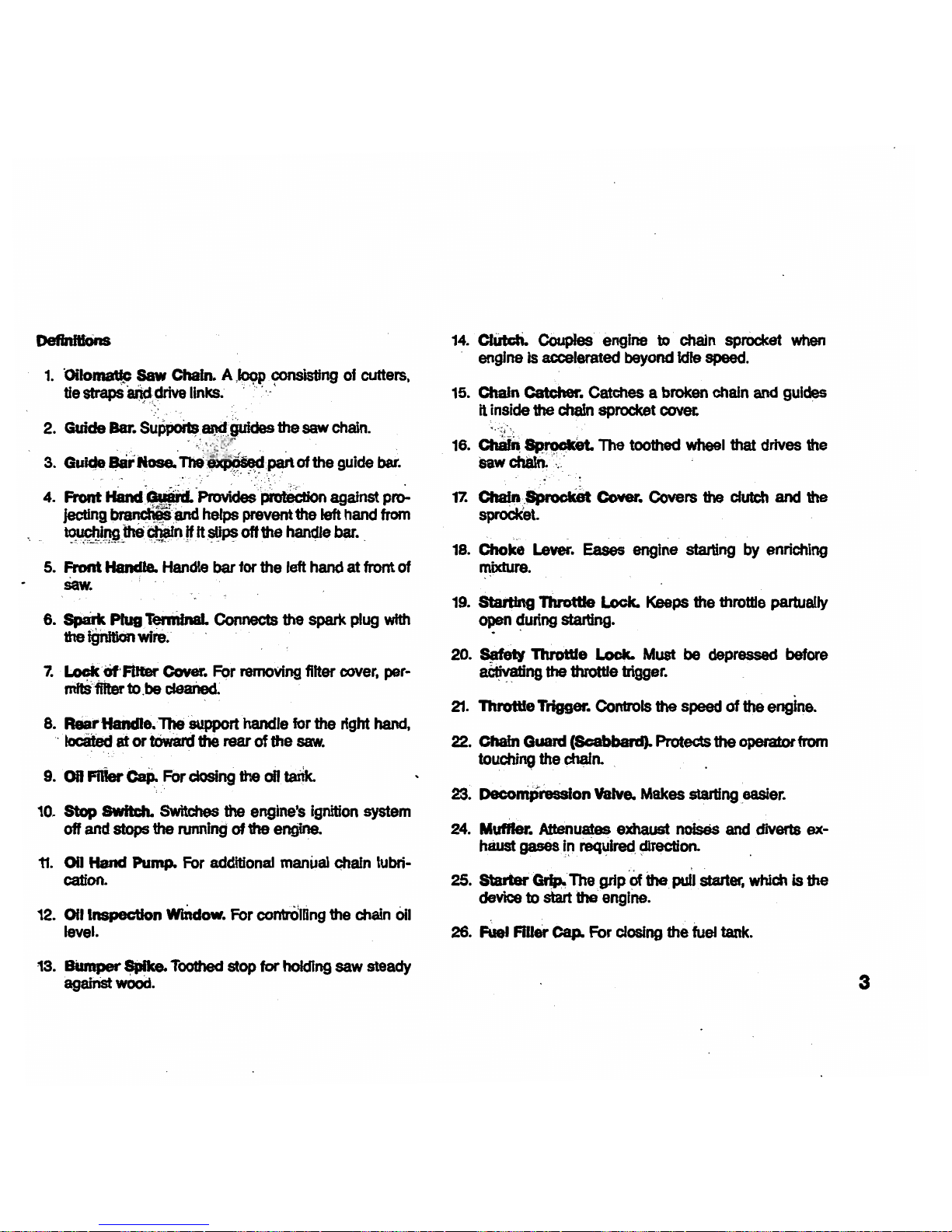

Defil1llfOns

1.

Oilo~

Saw

Chain. A

J09P

~

of

cutters.

tie straps

~drive

links. . ','

~,.-

2. Guide Bar.

Su_~:ijuJdes

the

saw

chain.

.

";.,:

)"'~:

~:/r~

3. Gu

..

~rNose.:~~,paitoftheguidebar.

4.

~

~auarii.-~.::\~

afnst

ro..

~

.,."

PI,

ag P

jecting

~fInd

helps prevent the left

hand

from

touchi

ttcEt

Ch8tn

if

It

slips off

the

handle bar •

•

0<

,.:,._.,..J!~t

",,-of

.. ' ',',

',,,,,

, ,

5.

Front Handle.

Handle

bar

for

the left

hand

at front

of

saw.

6.

Sp;idc

Plug

TemdnaL Connects the spark

plug

with

1he

i9nHiOn

Wire.

7.

Lock'or-Filter

Cover. For

remoVing

filter cover, per-

rnitS1Uter

to.be

cIearied.:

8.

,

Rear'Handle-The

Support

handJe

for the right hand,

. Iocited at

or

tOward

the

rear

of

the

saw.

9.

Oil

Fftier

~For

closing

the

011

tank.

10.

Stop

Switch. Switches

the

engine's

ignition

system

off

and

stops the

running

of

the

engine.

11.

Oil Hand Pump.

For

additional

manual

c::;haln

lubri-

cation..

12.

011

Inspection

WIiu:Iow.

For

contrO'mng

the

chain

011

level.

13. BUmper

~

Toothed

stop

for

holding

saw

steady

againSt

wood.

14.

ClUtch.

C()upJes

engine

to

chain sprocket

when

engine

is accelerated beyond Idle

speed.

15.

Chain

Catcher. Catches a broken chain

and

guides

It inside

the

chain

sprocket COVet

""~~~~\'

16.

cta8fr.

8prf;K=ket.

The toothed wheel that drives the

sawctUll~

.

17.

Chain.Sprock8t

Cover. Covers the clutch and the

sproClCet.

18.

Choke

Lever.

Eases engine starting

by

enriching

~ixlure.

19.

Startfng Throttle Lock.

Keeps

the throttle partualJy

~n

~ring

starting.

20.

~

Throttle

Look.

Must

be

depressed before

~

the

throttle

trigger.

21.

Throttle

TrIgger. Controls

the

speed of the

engine.

22. ChaIn Guard (Scabbard). Protects

the

operator

from

touchil1$1

the

chain.

23. Decompfession Valve. Makes starting easier.

24.

Muffler.

Attenuates

exhaust noises

and

diverts ex-

haust

gases

i~,

req~lreQ

~on.

25.

Starter

~'The,

grip

Of

the,

pull

,starter.

which is

the

device

to

start the engine.

26.

Fuel

FlUer

Cap.

For

closing

the

fuel tank.

3

Page 5

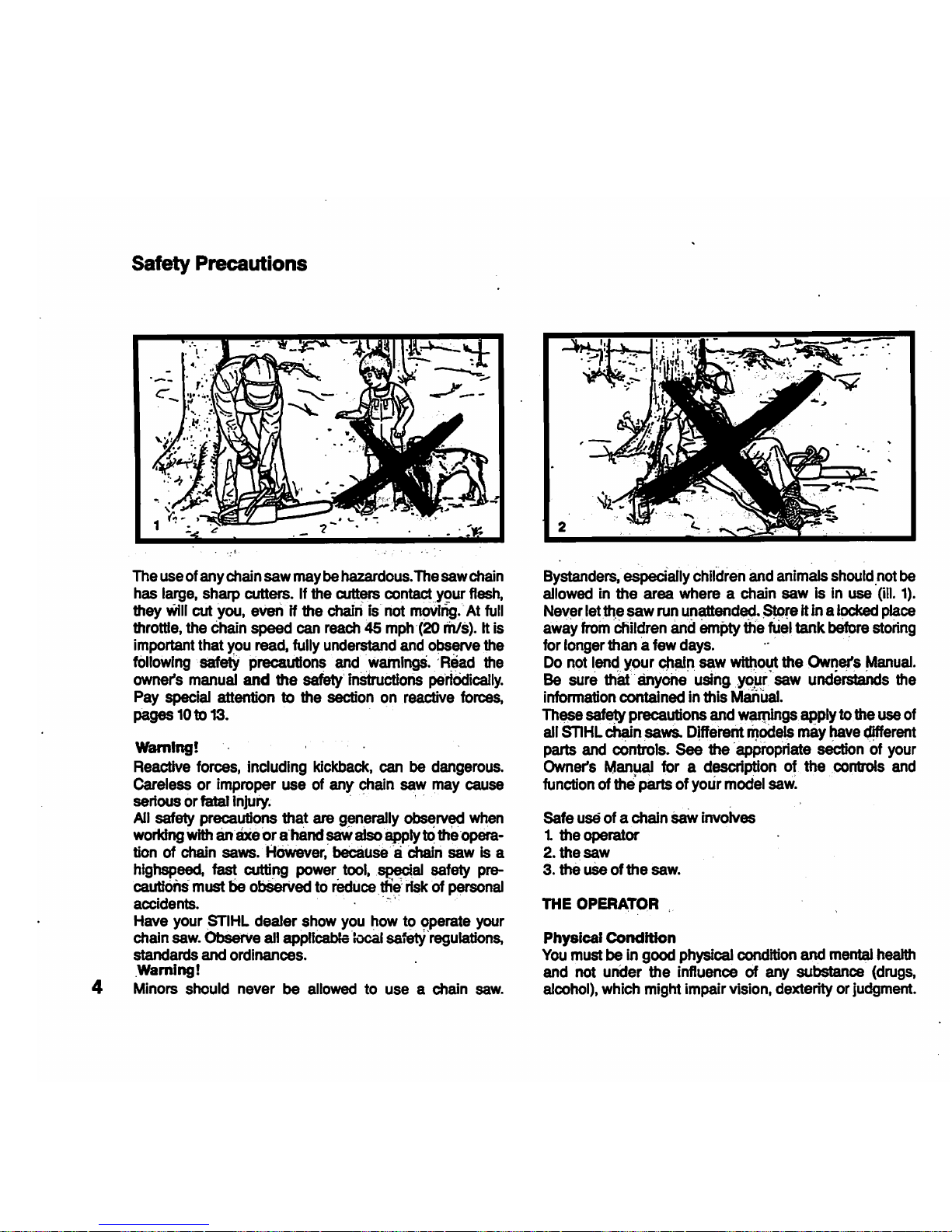

Safety Precautions

The

use

of any chain saw may

be

hazardous.

The

saw

chain

has

large,

sharp cutters. If the cutters contact your

flesh,

they

will

cut

you,

ewn

H the

chain,

is not

m9VIns.'

At

full

throttle,

the chain

speed

can

reach

45

mph

'(20

ri1Is).

It is

important that

you

read,

fully

understand

and

observe the

following .

safetY

precautions

and

.

warningS.

;Read

the

owner's

manual and the safety'

inStructions

periOdically.

Pay

special attention to the section

on

reactive

forces,

pages

10

to 13.

Warning!

Reactive

forces,

including

kickback,

can

be

dangerous.

Careless or improper use of any chain

saw

may

cause

serious or fatallnjuiy. . ' , .

All

safety precautions that are generally

observed

when

working with Bnaxeor a'hand

saW

aisoapply

~

the'opefa-

lion

of

chain

saws.

HOWever;

beCause

'8

Chain

saw

is a

hlghspeed,

fast cutting power

tool,~a1

safety

pre-

cautions

must be

obSerVed

to

reduce

,tti~~

risk of

personal

accidents. . -.

Have

your

,STIHL

dealer

show

you

how

to operate

your

chain

saw.

ObserVe

all

appllCabra'~

safetY

'regulations,

standards

and

ordinances.

,Warning!

4 Minors should never

be

allowed

to

use a chain

saw.

2

Bystanders,

espedally children

and

anim~s

should

.not

be

allowed in the area where a chain saw is

in

use

(ill.

1).

Never letlt\e saw

run

unattended.

$.Ore

it in a

locked

place

away

from

'Children

and

empty

the fuel

tank

before

stonng

for longer than a few

days.

. .

Do

not

lend

Y'0ur

chain saw without the Owner's

Manual.

Be

sure

that

'anyone'

'using

,yO~'saw

understands

the

information contained in this Manual.

These

safety precautions

and

waqlings apply

to

the

use

of

all

STlHL

~n

saws.

Different

~odc$

may

have

~erent

parts

and

controls. See the 'appropriate section of your

Owner's

Manual for a description of the controls

and

function of

the'

p8rts

of your model

saw.

Safe

use

of a chain

SaW

involves

t the operator

2. the saw

3. the

uSe

of the

saw.

THE

OPERATOR

Physical

Condition

You

must

be

in good physical condition and

mental

health

and

not under the influence of

any

substance

(drugs,

alcohol),

which might impair vision, dexterity

or

judgment.

Page 6

Do

not

operate a chain saw when

you

are fatigued

(UI.

2).

Be

alert

.:.. H you

'get tired while

operating

yOlir ctiain

saw,

take.

a

~r~ak.

tiredness

may

result

,in

.1oSs~f

co~.

Working

vVith

aity,chaiO

saw.

can

De

'Strenu()us.

If

you

have

any . conditiOn

tfiat

inight

..

be

aggravated by 'strenuous

work.

check

with

your doctor

befOre

operating a chain

saw.

~!

PtoIonged.~

ofcl1ain saws (or other

m~ines)

exposing

the

operator to vibrations may produce Whitefinger dis-

ease

(Raynaud's phenomenon). This phenomenon redu-

ces

the hand's ability to

feel.

and regulate temperature,

produces

numbness andburriing sensations

and

may

•

cause

nerve

and

circulation damage

and

tissue necrosis.

MinySTIHL

models

are'

available with

an

anti-vibration

system

designed to reduce engine 'vibration.

An

anti-

vibration system is recommended for those using chain

saws

on

a regular or sustained basis.

Heated

handles help to reduce the risk of Whit8finger

disease and

are

recommended for cold weather

use.

Most

STlHL

Powerheads

are available with heated handles.

Anti-vibration

sYstems

and

he~ecI

handles do not gua-

rantee

that

you

will not,sustain Whitefinger

d"lS8ase~

There-

fore continual

and

regular users'should 'monitor clOsely

. their

use

of chain saws

and

their physical condition.

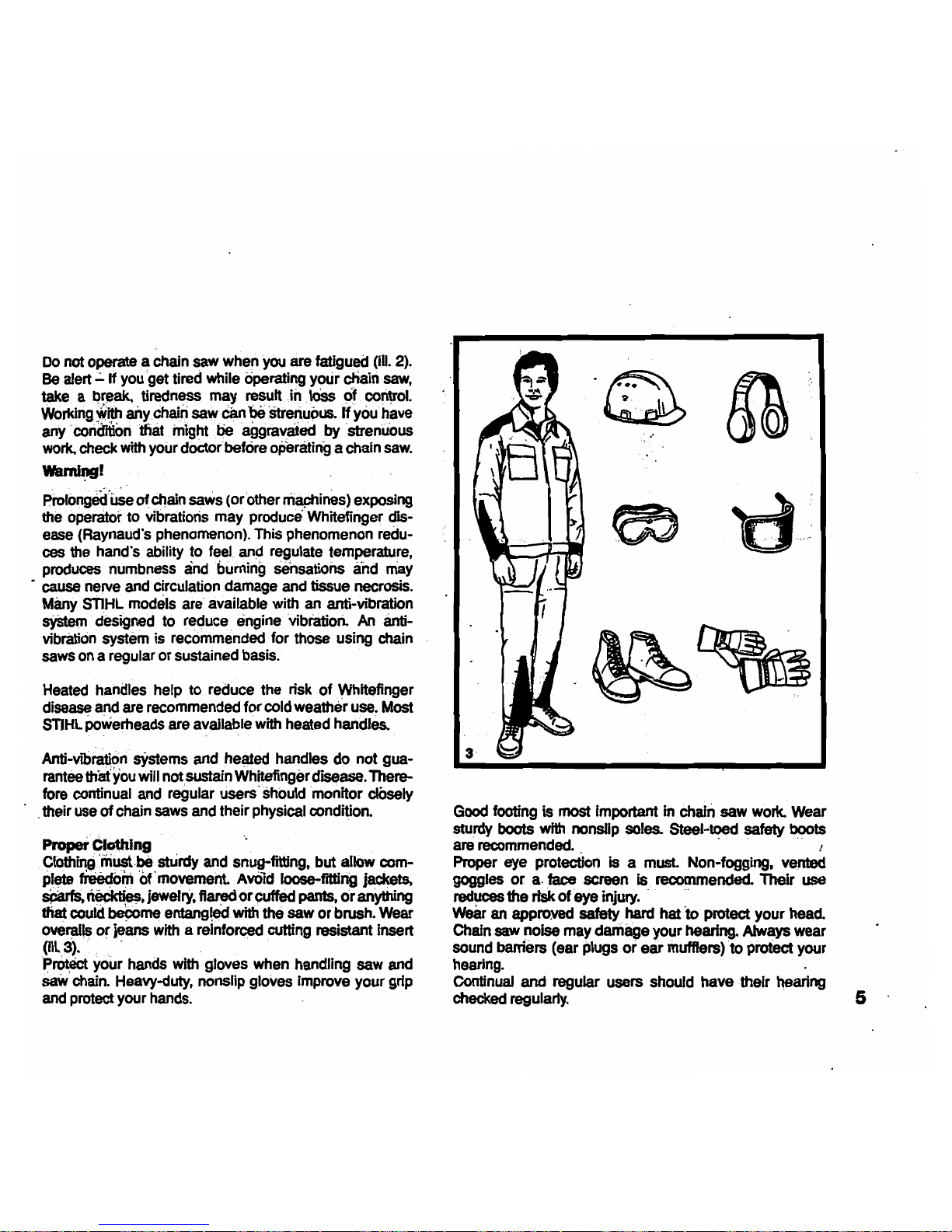

Proper Clothing .

'.

CIOthil1Q

'musfbe stUrdy

and

snug-fitting. but allow

c0m-

plete

fieedom

of'

movement.

AvOId

Ioose-fitting jackets,

~

~.jeweirY.

~

or~

pants,

or

anYthing

that could

become

entangled

with the

saw

or brush. Wear

ove~~

o~

jeans

with'

a reinforced

cutting

resistant insert

(Ill

3). , . .

p.

your hands with gloves when handling saw

and

saW

chain.

Heavy-duty, nonslip gloves improve your grip

and

protect your

hands.

Good

footing is most Important

in

chain

saw work.

Wear

sturdy boots

with

nonslip soles. Steel-toed safety boots

are

recommended.

. ,"

>.

Proper

eye

protection

Is

a must. Non-fogging, vented

goggles or a.face screen

is recommended. Their use

reduces the risk of eye

injury.

" "

Wear

an

approved safety

hard

hat

to

protect your

head.

Chain

saw

noise may darriage your hearing. Always wear

sound barriers (ear plugs

or

ear muffters)

to

protect your

hearing.

Continual

and regular users should have ·their hearing

checked

regularty.

5

Page 7

4

THE

SAW

Parts

of

the

chain

saw;

Illustrations

and

definitions

of the

parts

see

pages

2 and

31

~I

NevermodHy a

chain

saw

in

any

way.

Only

attachments

supplied

by

STlHL

or expressly

appro~,!)y

STlHL

,for

use

with

the

specific

STlHL

saw

modelS

,are.

authorized.

Although

certain

unauthorized

attachmentsaie

useable

with

the

STlHL

powerhead.

their

use

may,

in

fact,

.be

extremely dangerous. '

THE

USE

OF

THE SAW

TranSporting the

chain

saw

W8ming!

AJW8yS

Stop

the

enQtne

before'pUtting a chain

saw

down or

carryi~

~. ~ ~

.chain'

sti~;with

~'

engine

running

is extteinely

dangerous.

'A'CCidentaJ

acceleration

of the

engine

eancsuse

the

chain to

rotate.

Avoid

touchmg

the

hotmUffter.' .

.~

.

6

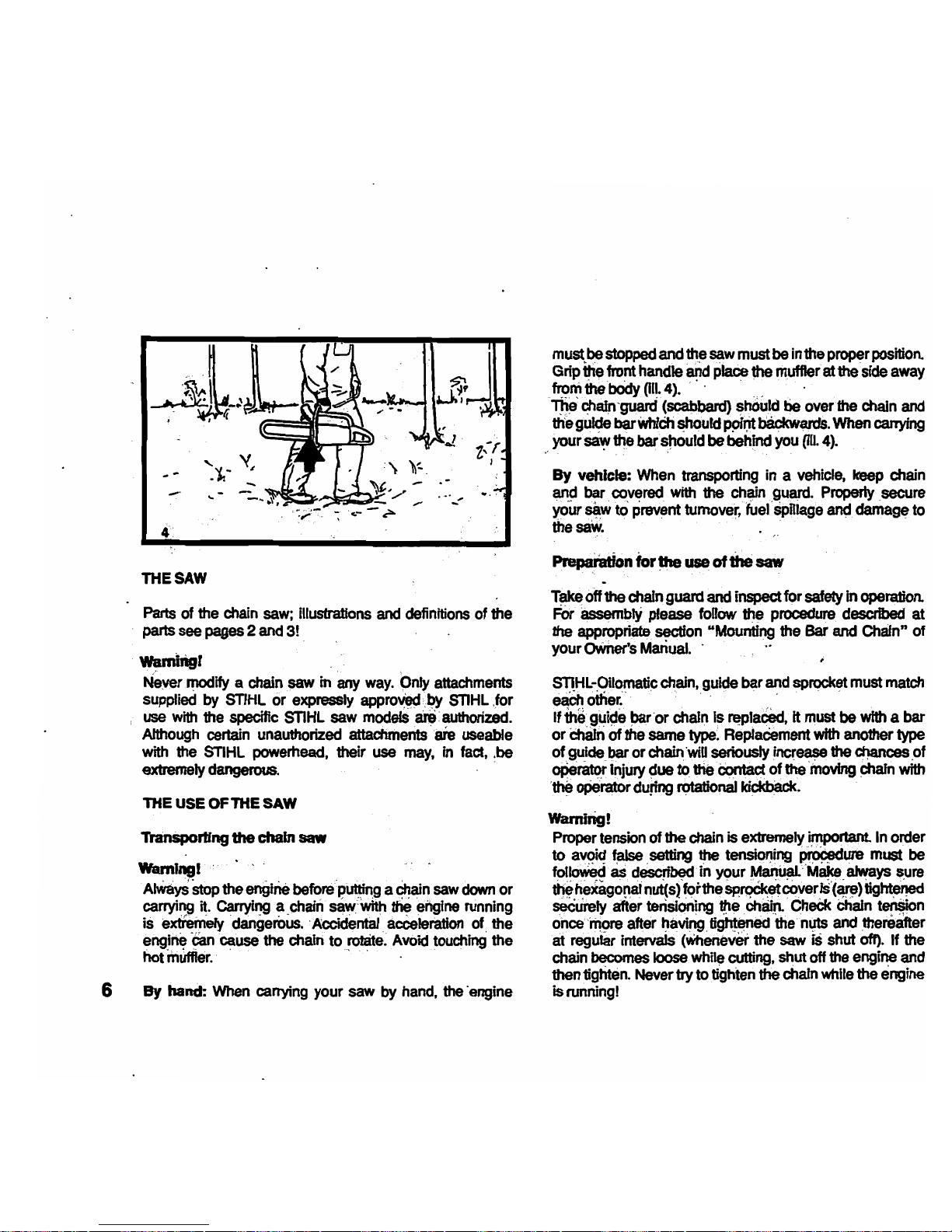

By

hand:

When

carrying

your

saw

by

hand,

the

'engine

must

be

stopped

and

the

saw

must

be

in

the

proper

position.

Grip

~e

front

handle

and

place

the muffler at the

'side

away

from

the

body

(i1l.4).

" .

1tl8'

c;hafn

-guard

(scabbard)

~Uld

tie

over

the

chain

and

the

gu~

barWhfCh

~rd

P9fljt

b8ckwards.

When

carrying

your

~

~

barsttould be behind

you

(i1l.4).

By

vehicle: When transporting in a

vehicle,

keep

chain

EiI19

bar,

~v~red

with the

ch~n.guard.,

Properly

,secure

your

saw

to

prevent

turnover,

fuel

SpHlage

and

damage

to

the

saW.

" .

Prepaf8tion

forihe

use

of

the

saw

T~

off the

chain

guard

and

inspect for safety in

operation.

For

assemblY

please

foUow

~

procedure described at

the

appropriate

section "Mounting

the

Bar

and

Chafn" of

your owner's

Manual.

'

STlHb-Oilornatic

chain,

guide

bar

and

sprocket

must

match

eaCh

other:'

' " .

."

If

the,

g~i48

~r

'or chain Is

~1aC8dt

it

must

be

with

a bar

or

Ch8In

of the

same

type.

ReplaCement

with

another

type

of

guide bar or

chain

'wiD

seriously

increase

the

00,ances

,of

ope~

iF.ljury

~ue

t()

the

Contact

of

the

'moving

chain

with

.~

operator

during

n;rtational

kicIcb8ck.

W8rnirig!

Proper

tension

of

the

chain is extremely important. In order

to

av~

~

.setting the

tensiol1ing

~we

must

'be

fot~

as,

d~

in

Y9ur

~"'M~,~ys

~re

~h,e*agoraarn~s>'fotthesp~coveriS(~)~

seCuteJy

after

tensioning,

~e

.chaffL

CheCk

Chain

t~n

once'~

after

t:taving.

tigtlte.ned

the

n~

and thereafter

at

regular

intervals

(Whenever

the

saw

is

shut

off).

If

the

chain

becomes loose while cutting,

shut

off the

engine

and

then

tighten.

Never try to tighten the chain

while

the engine

is

runningl

Page 8

5

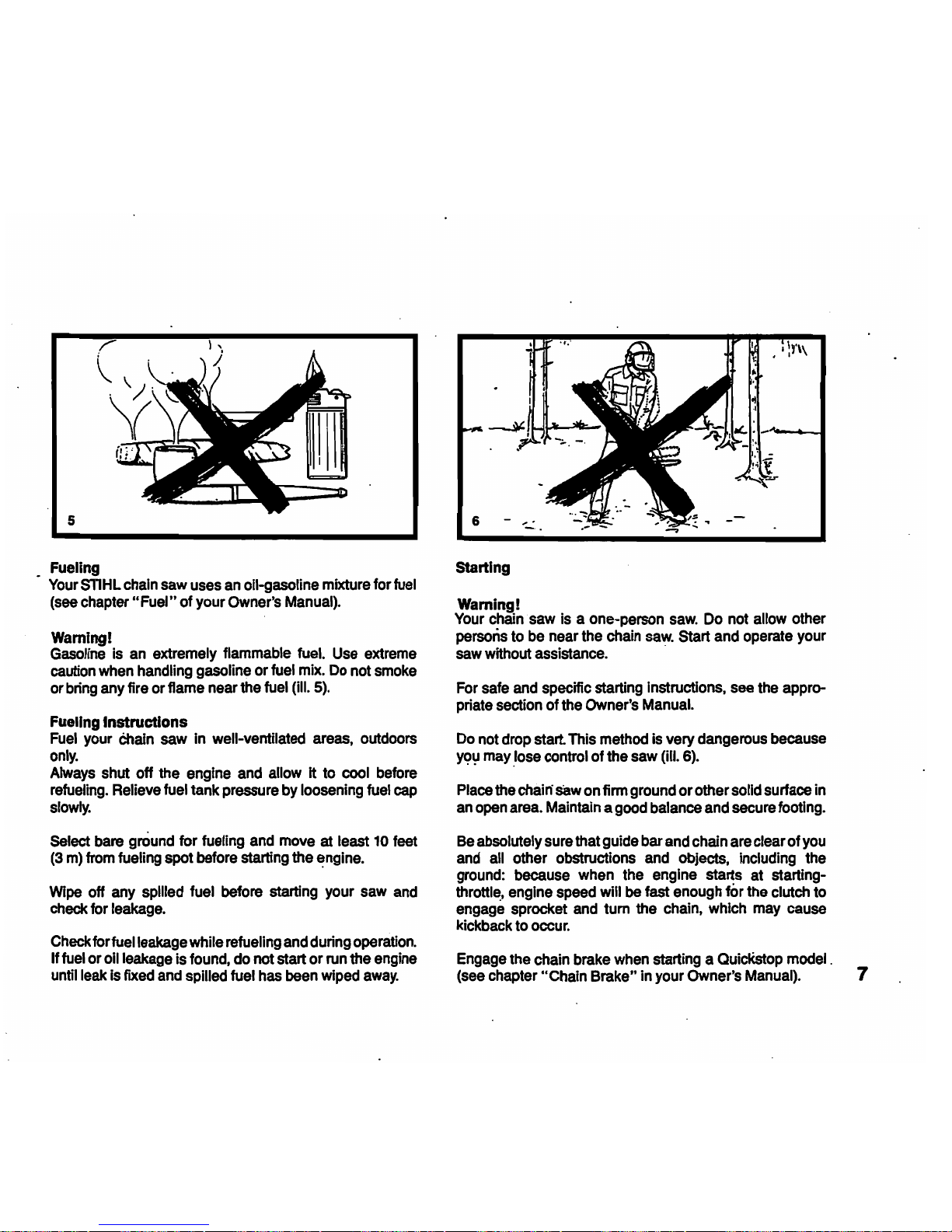

Fueling

-

Your

STlHL

chain

saw

uses

an

oll-gasoline mixture for

fuel

(see chapter"

Fuel

n of your

Owner's

Manual).

Warning!

Gasoline

is

an

extremely

flammable

fuel.

Use

extreme

caution

when

handling

gasoline or

fuel

mix.

Do

not

smoke

or

bring

any

fire

or

flame near the

fuel

(ill. 5).

Fueling

Instructions

Fuel

your

Chain

saw

in well-ventilated

areas,

outdoors

only.

Always

shut off the

engine

and

allow

It to

cool

before

refueling.

Relieve

fuel

tank

pressure

by

loosening

fuel

cap

slowly.

Select

bare

ground

for fueling

and

move

at

least

10

feet

(3

m)

from

fueling spot before starting the

~ngine.

Wipe

off

any

spilled

fuel

before

starting your

saw

and

check

for

leakage.

Check

for

fuel

leakage

while

refueling

and

during

operation.

If

fuel

or

011

leakage

is

found,

do not start or

run

the

engine

until

leak

is

fixed

and

spilled fuel

has

been

wiped

away.

6

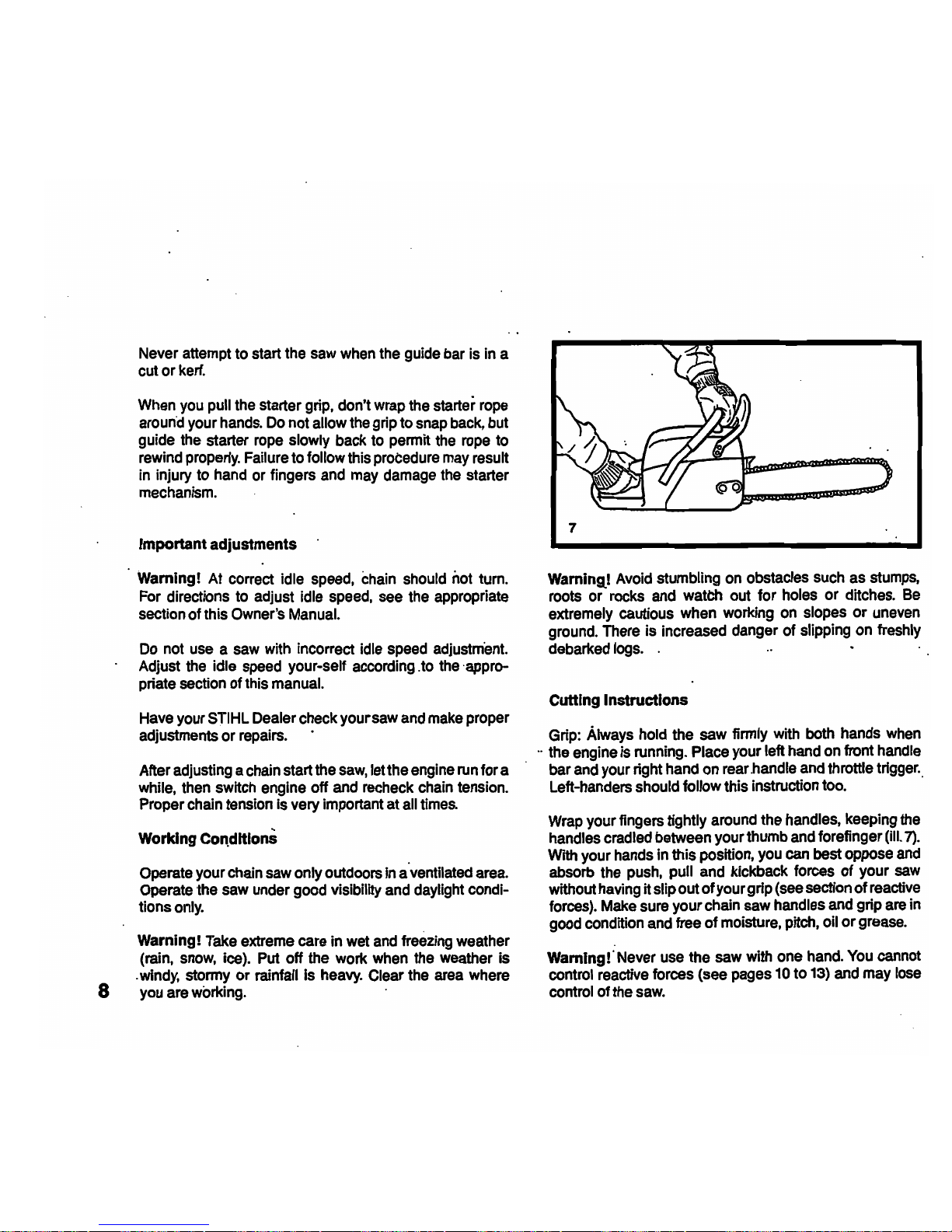

Starting

Wamlng!

Your

chain

saw

is

a one-person

saw.

Do

not

allow

other

persons

to

be

near

the

chain

saw.

Start

and

operate

your

saw

without

assistance.

.

For

safe

and

specific starting Instructions.

see

the

appro-

priate

section

of the

Owner's

Manual.

Do

not

drop

start.

This

method

is

very dangerous

because

YC?':I

maY.lose

control of the

saw

(ill. 6).

Place

the

chain

saw

on

finn

ground

or other solid surface

in

an

open

area.

Maintain a good

balance

and

secure

footing.

Be absolutely

sure

that guide bar

and

chain are clear of

you

and

all

other obstructions

and

objects,

including

the

ground:

because

when

the

engine starts

at

starting-

throttl~,

engine

speed

will be fast

enough

fOr

the

clutch to

engage

sprocket

and

tum the

chain,

which

may

cause

kickback

to

occur.

Engage

the

chain

brake

when

starting a

QuiclCstop

model.

(see

chapter

"Chain Brake"

in

your Owner's

Manual).

7

Page 9

8

Never attempt to start the

saw

when

the guide

bar

is

in

a

cut or

kerf.

When

you

pull

the

starter grip, don't

wrap

the starter

rope

around

your

hands.

Do

not allow

the

grip to

snap

back,

but

guide

the

starter

rope

slowly back to permit

the

rope

to

rewind

properly.

Failure

to follow this

probedure

may

result

in

injury to

hand

or

fingers

and

may

damage

the

starter

mechanism.

Important adjustments

Warning!

At

correct idle

speed,

chain

should

not

turn.

For

directions

to

adjust idle

speed,

see

the appropriate

section of this Owner's

Manual.

Do

not

use a saw

with incorrect idle

speed

adjustment.

Adjust

the

idle

speed

your

..

self according. to the' appro-

priate section of this

manual.

Have

your

STIHL

Dealer check your

saw

and

make

proper

adjustments or

repairs.

.

After adjusting a chain start the

saw,

letthe

engine

run

for a

while,

then

switch engine off

and

recheck

chain

tension.

Proper

chain

tension

Is

very important at

all

times.

Working COl\dltlons

Operate your

chain

saw

only outdoors in aventilated area.

Operate the saw under good visibility

and

daylight condi-

tionsonly.

Warning!

Take

extreme care in

wet

and

freezing

weather

(rain,

snow,

ice).

Put

off the work

when

the weather is

.

windy,

stormy or rainfall is

heavy.

Clear the

area

where

you

are working.

7

Warning,!

Avoid

stumbling

on

obstacles

such

as

stumps,

roots or

rocks

and

watCh

out for holes or ditches.

Be

extremely cautious when working

on

slopes or

uneven

ground.

There

is increased danger of slipping on freshly

debarked

logs.

.

Cutting Instructions

Grip:

Always

hold the saw firmly

with

both hands

when

..

the

engine

is

running. Place your left hand on front

handle

bar

and

your right hand

on

rear

,handle

and

throttle trigger

..

Left-handers should follow this instruction

too.

Wrap

your fingers tightly

around

the handles, keeping

the

handles cradled between your thumb

and

forefinger

(ill.

7),

With your

hands

in this position,

you

can

best oppose

and

absorb the

push,

pull

and

kickback forces of your

saw

without

having

it slip out

of

your grip

(see

section of

reactive

forces).

Make

sure your chain

saw

handles

and

grip

are

in

good

condition

and

free of moisture, pitch, oil or

grease.

Wamlngl'Never

use

the

saw

with one

hand.

You

cannot

control reactive forces (see pages

10

to

13)

and

may

lose

control of the

saw.

Page 10

warning!

Do

not

operate

your

chain

saw

with

starting

throttle.

Cutting

with

starting throttle

does

not

permit

the

operator

proper

control

of the

saw

or

chain

speed.

Wamingl

Never

touch a rotating

chain

with

your

hand or

any

part

of your

body.

Wamlngl

Do

not

cut

any

material

other

than

wood

or

wooden

objects.

Use

your

chain

saw

for

cutting

only.

It is

not

designed

for

prying

or

shoveling

away

limbs,

roots

or

other

objects.

When

sawing,

make

sure

that

the

saw

chain

does

not

touch

any

foreign

materials

such

as

rocks,

nails

and

the

like

(ill.

8).

Such

objects

may

be flung

off,

damage

the

saw

chain

or

cause

the

saw

to

kick

back.

In

order

to

keep

control

of your

saw,

always

maintain

a

firm

foothold.

Never

work

on a ladder,

In a tree

or

on

any

other

insecure

support.

Never use the

saw

above

shoulder

height

(ill.

9).

Position

the

chain

saw

in

such

a way that your

body

is clear

of

the

cutting

attachment

whenever the

engine

is

running.

Stand

to

the

left of cut while

bucking

(see

ill.

10).

Don't

put

pressure

on

the

saw

when

reaching

the

end

of a

cut.

The

pressure

may

cause the bar

and

rotating

chain

to

pop

out of the

cut

or

kerf,

go

out of

control

and

strike

the

operator or

some

other object. If the rotating

chain

strikes

some

other object a reactive force (see

pages

10to

13)

may

cause

the

chain

to

strike the

operator.·

9

Page 11

10

Reactive

forces

during

the

cut,

including

kickba-*

WARNING!

Reactive forces, that

may

occur during

any

cut are kick-

back,

pushback

andpull-in.

Reactive forces

·can

··be

dangerous!

In

any chain

saw,

the powerful force

used

to

cut

wood

can

be

reversed

(and

work against the operator).

If the rotating chain is suddenly stopped

by

contact

with

any solid object like a log or branch or is pinched, the

reactive forces Instantly

oCcUr.

These reactive forces

may

result

in

loss of control which

may,

in

tum, cause serious

or

fatal injury.

Anunderstaiidin~i

of the

cauSes

of

these

reactfveforces

may

help you

aVoid

loss of control.

The

most

common

reactive forces are

':"ldckback,

-pushback,

-pull-in.

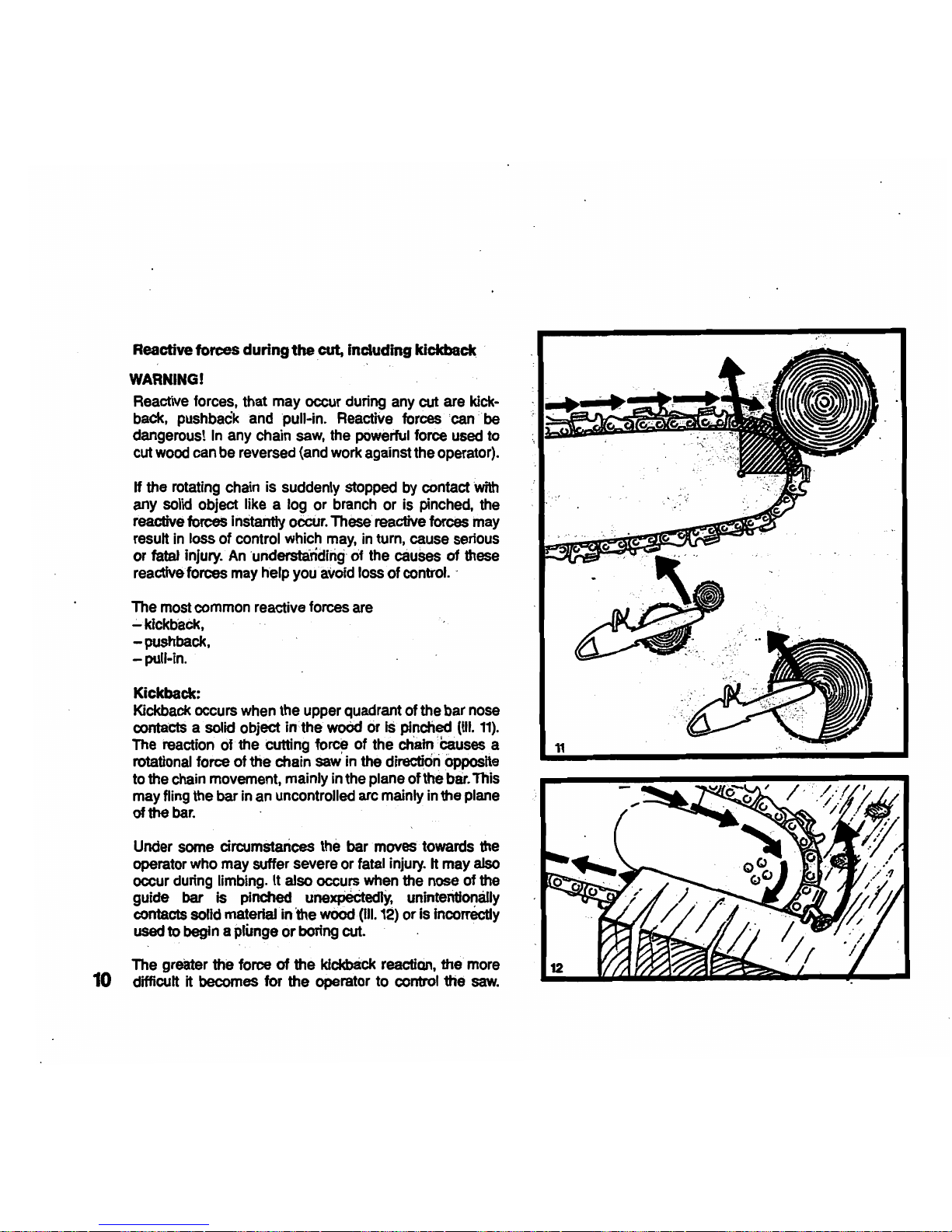

Kickback:

Kickback occurs

when

the upper quadrant of the bar

nose

contaCts

a solid object

in·

the

woOd

Or

is pinched

(III.

11).

The

reaction of the cutting force of the chain 'causes a

rotational

force of the chain saw'in the directidn

Opposite

to the

chain

movement, mainly in the plane

of

the

bar.

This

may

fling

the bar

in

an

uncontrolled arc mainly

in

the plane

of the

bar.

Under

some

circumstances the bar

·moves

towards the

operator

who

may

suffer severe or fatal

injury.

It may also

occur during limbing. It also occurs

when

the nose of

the

guide bar is pinched

unexPeCtecDY,

unintentionally

contacts

sorld

material

in

the wood (ill.

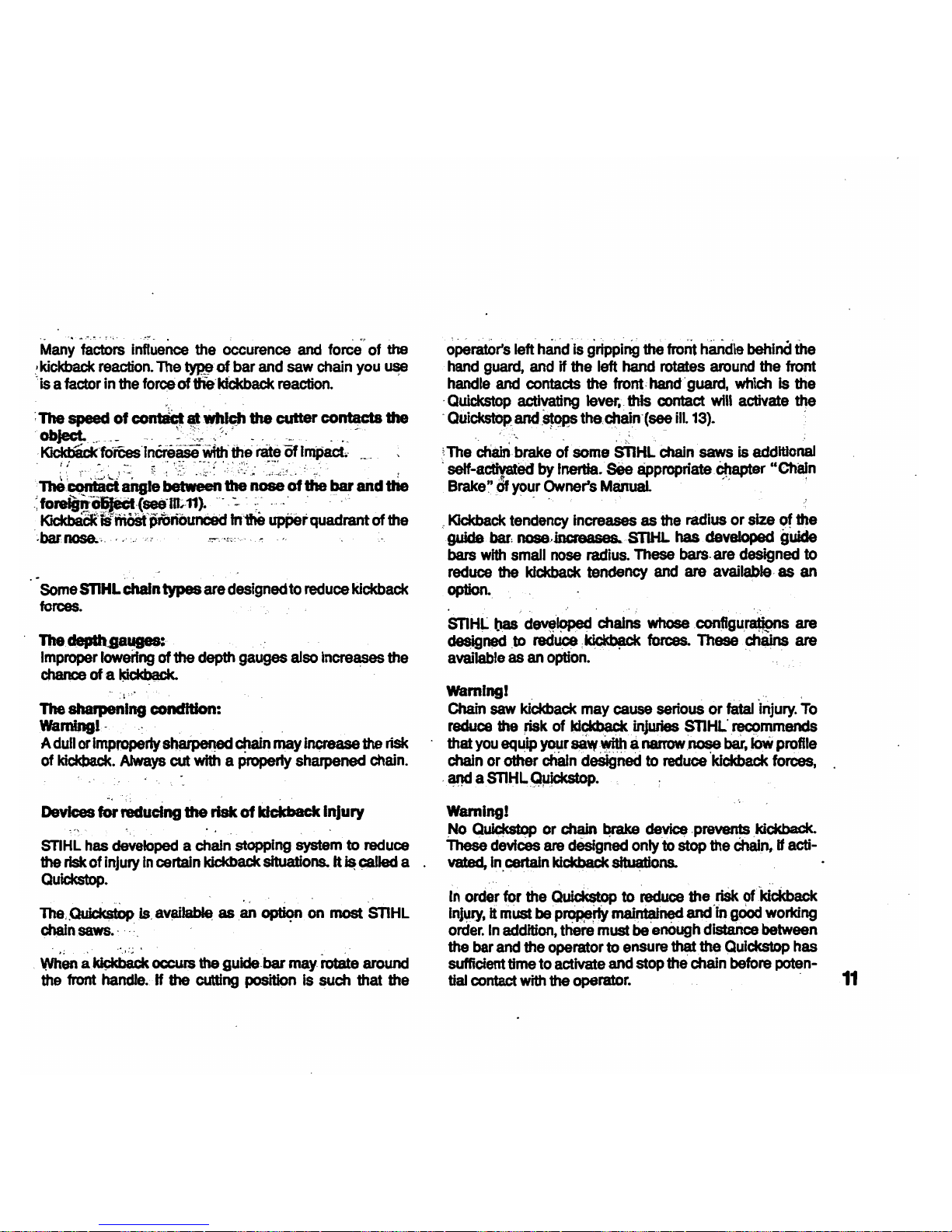

12)

or is Incorrectly

used

to begin a plunge or

bOring

cut.

The greater

the

force

of

the kfckb8ck reaction, the

more

difficult it becomes for the operator to controf the

saw.

Page 12

.

...

..-

~

.

Many

factors influence the occurence

and

force of the

!kickback

reaction.

The

~

of

bar

and

saw chain you

~

~

is a factor in the force of

ttie-klCkback

reaction.

;

The

speed

of

~

~wh"

the

cutter

contacts

the

object.

.,'

_

~"

<.~,

),' -

'_'.

".

-

,Kickoaclfforces'Inereuewlth

the

raleOf

Impact·

il

>

\::..:

_"M~:

','

,'i-

~

''''-''f

~_ct~~

u.;

~ose

of

the

b,ar

and

the

~fo.~·{see-IIt-11).'.-

':

,.:

'

".'

KickbaCltVmosfproriOunc:ed

'"1M

upper

quadrant of the

~bar

ROSa,

,,'.'

SOme

STlHL

chain types are designed to reduce kickback

forces.

The.cJeptb.aauges:'

Improper

lowering

of

the

depth gauges also

Incre~

the

chanceofa~

:1

The

sharpening

condition:

warning!

Adun

orimproperty sharpen.ed

~

may Increase the

risk

of

kickback.

Always cut

with

a property sharpened chain .

",

Devices

for

reducing

the

risk

of

Idckback

Injury

STlHL

has

developed a chain stopping system to reduce

the

risk

of injury

In

certain kickback sItuations.Jt ~ called a

Quickstop.

""

.,

The,

,Quickstopis,

av-.i~

as

an

optiQn on most STIHL

chain.saws.

' .

Wti.

a~

oc:curs

the

guide.bar

may

iotate

around

the

front

handle. H

the

cutting position

Is

such that

the

operatOr's

left

hand

is

gripping

the

froI1t

hBrldle

behind

the

hand

guard,

and

if the left hand rotates around the front

handle and contacts the front:

hanef

guard, which is the

,Quickstop activating

lever,.

this contact

will

activate the

. Quickslop

and,~

the;chaln'(~

ill 13). '

\

The

~.brake

of

some

STlHL

chain

saws

is additional

.

self-activated

by

fnertia.·

see

appropriate.

ct1apler

"ChaIn

Brake"dt

yo~r

<?wner's

ManuaL

' , ,

,

Kickback

tendency increases as

the

radius or size

of

the

guide

bar,

noseAncreaseLSTIHL has

developed

guide

bars

with

small

nose

radius.

These

bars. are designed to

reduce

the

kfckback

tendency

and

are available, as

an

option.

STlHL

taas~

d~~

chains

whoseconftgu,r~

are

~ned.to

reduce.~

forces. These.

chains

are

available

as

an

option.

.

Warning!

Chain

saw

kickback

may cause serious or fatal

'injury.

To

reduce the

risk

of

kickback

injuries snHL'recommends

that

you

equip

your

saw·With

a narrow),ose

bal,

lOW

profile

chain

or

oth8r

chatn

deSIgned

to

reduce

'kickback

forces,

..

~aS11HL~.

Warning I

~o

Qulcksk;Jp

or

ch~

~

de~

.prev&n!SkIckback.

These

devices

are

designed only to stop the chain.

if

acti-

vated,

in.

certain kickback

situations.

In

~r

for the

Quickstep

to

reduce

the

riSk

of

'kiCkback

inj~,

it

mUst

be

P"'~

mai~

anei'ln

gOod

working

order.

In

addition,

there

must be

enough

distance between

the

bar

and

the operator to ensure that

the

Quickstop has

sufficient time to activate

and

stop the chain before poten-

tial contact

with

the

operator. '

11

Page 13

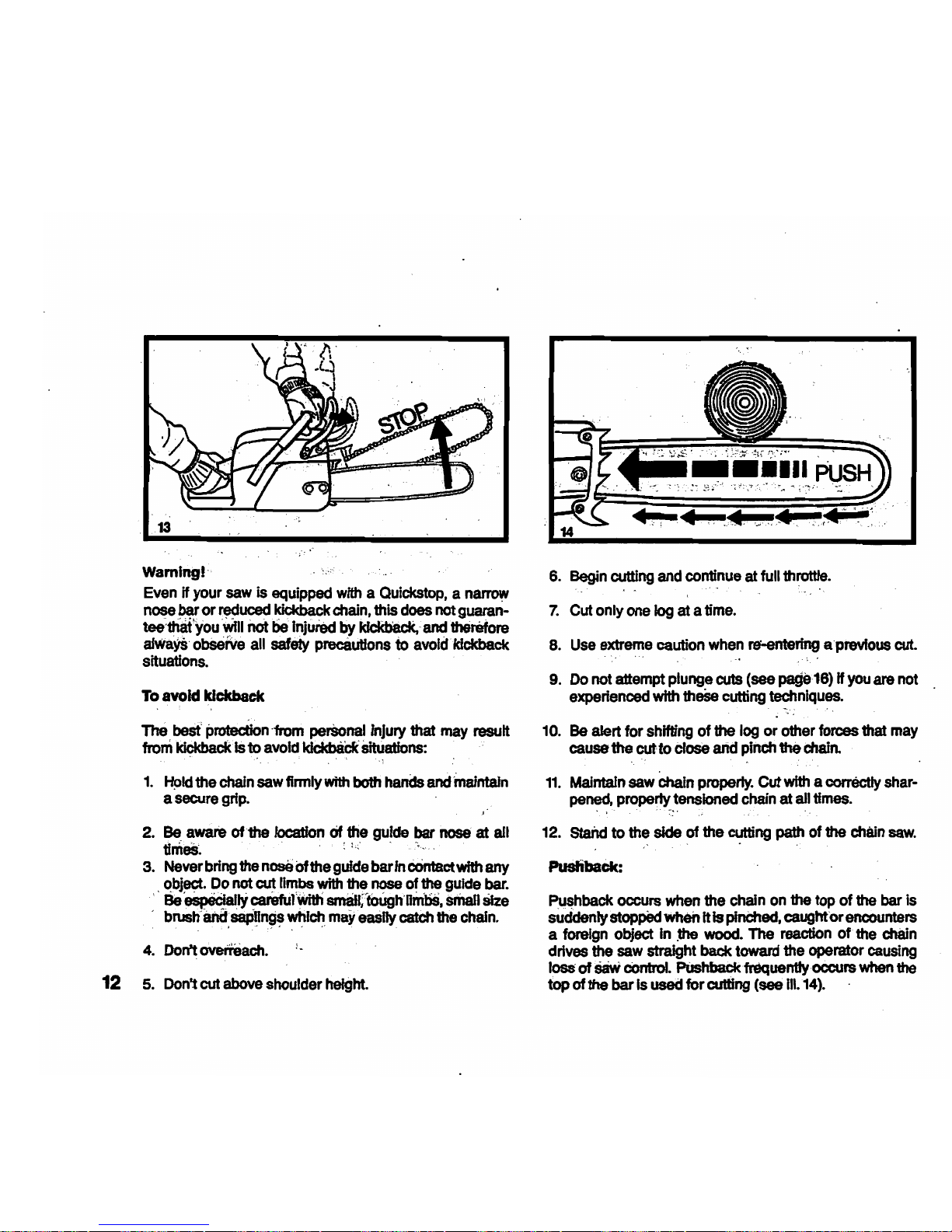

13

Warning!-

Even

if your

saw

is

equipped

with a

Quickstop, a n8J'l'OVl

nos.e

_~

or

~uced

kickback

chain,

this

does

not guaran-

tee'th8t'you

'!III

not

be

Injuied by

kfcftback,~and

therefore

always-

observe

aU

safety

prec8utlons

to

avoldldckback

situations.

To avoid kickback

The

best'

protection

-from

perSonal

injury that

may

result

from

kickback·

Is

to

avoid

I<k:kb8Ck

Situations:

. ,

'~

1.

~kI

the

chain

saw

firmly

with

both hands andlnalntain

a

secure

grip.

2.

Be

aware

of1he

location

Of

the

guide bar

nose

at

aU

timeS.

-':'

3. Never bring the nose

Of

the guide

bar

In

COntactwfth

any

.

~bject.

Do

not

cut limbs

with

the nose of the guide bar.

.

Be'~DIhi

car8fulWhti

smalftb'

h'nmbS.

sman

SIze

~.'.1

..

ug

, brustf

antf'saplIngs

which

may

eaSily

catch the

chain.

.

~.-

,,'

."

~',

.

4.

Don't

overi8ach.

i_

12

5. Don't cut above shoulder height.

6.

Begin

cutting and continue

at

fuU

throttle.

7.

Cut

only

one

log

at

a

time.

8.

Use

extreme

caution

when

re-entering

a-previous

cut.

, • > ~

9.

Do

not attempt plunge cuts (see

page

18) if

you

are not

experienced

with

theSe

cutting

techniques.

10.

Be

alert for shifting

of

the

log

or other forces that

may

cause

the cutto

close

arid

pinch

the chain.

11.

Maintain saw chain properly. Cut

with

a correctly shar-

pened,

properly tensioned chain at

all

times.

12. Statid

to

the side

of

the cutting path of the

ch8Jn

saw.

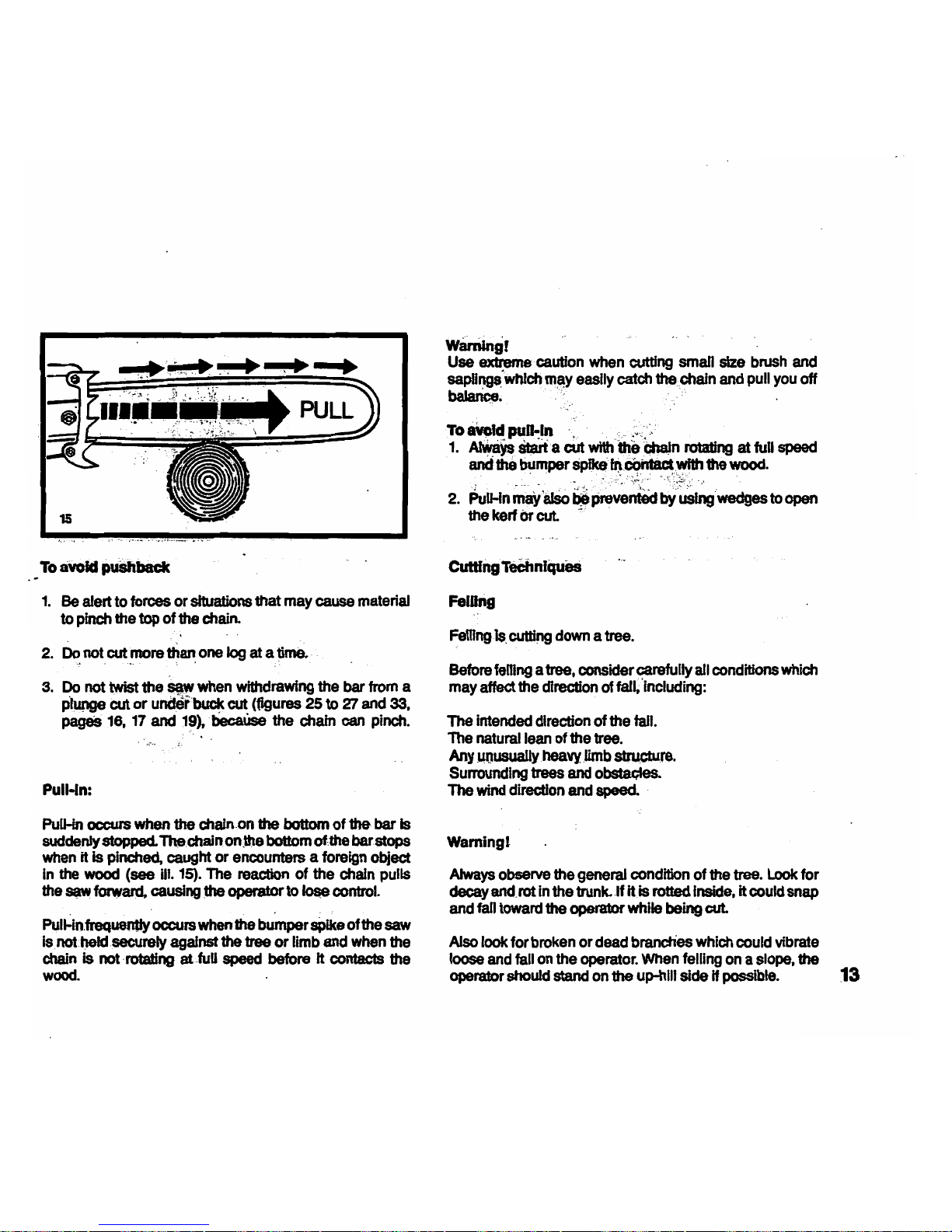

Pusliback:

~hback

occurs

when

the

chain

on

the

top

of

the

bar

is

suddenly stopped

when

Ills

pInChed.

caughforencounters

a foreign object in

..

wood.

The

reaction

of

the

chain

drives the

saw

straight back toward the operator

causing

loss

of

saw

cOntrol.

PUshback frequenttyoccws

when

the

top of the bar

Is

used

for cutting (see

111.14).

Page 14

_ '

To

8VoIcI

puShback

1.

Be

alert to forces or situations

that

may

cause

material

to

pinch the

top

of

the

chain.

2.

rlc?

notcut~reth~

one

log at a time. ' ,

3.

Do

not twist the •

when

withdrawing the

bar

from

a

plupge

cut

or

und8r~

cut (figures 25

to

'Zl

and

33,

pageS

16, 17 and 19),'

becaUse

the chain

can

pinch.

'. ,

Pull-ln:

PuU-ln

occurs

when

the

chain

,on

the bottom of the

bar

Is

suddenly

stopped.

The,chain

on~8

bottom oUhe bar stops

when

it

is

pinched, caught or encounters a foreign object

In

the

wood

(see

HI.

15).

The reaction of the chain pulls

the

S(lW forward, causing

Ute

operator to

Iotle

control.

Pull-4n.frequently

occurs

when

the

buR.per

sPIke

of the

saw

Isnot.I)eId,secureIy against

the

tree or limb

and

when

the

chain

is not'rotating atJuU

speed

before It contacts the

wood.

WBmlngf

Use extreme . caution

when

cutting small size

brush

and

sapOF.'9$.'

whfch

m~y

easily catch the.chafn

and

pull

you

off

balance.

'.

To

aVoId

pu~1n

','

... ' _",,','

1.

~

St$rt'a

cut

with

'the

Ci1aJn

rotating at

full

speed

and

the

bumper

SpIk8'~,COhtactwlth

1he

wood.

2.

PuU-in~8ISo~pre~~~:~~:_toopen

the

kerf

Or

cut.

-' '

Femng

is,

cuttll'I9

down a tree.

Before

femng

a tree, consider carefully

afl

conditions

which

may

affect the direction of fall/including:

The

intended direction

of

the fall.

The

natural

lean

of the tree.

Any

MOusuallyheavylimb

atru.cture.

Surrounding

trees

and

obstaQles.

The

wind

direction and speed.

Warnlngt

Always

observe the general condition of the tree.

Look

for

decay and,rot

in

the trunk-If

iUs

rotted inside, it could snap

and

faD

toward the operator while being cut.

Also look for

broken

or

dead

brandies

which

could vibrate

loose

and

fall

on

the

operator.

When

felling

on a slope.

the

operator

should

stand

on

the

up-hiIJ

side

H possible.

13

Page 15

When felling in the vicinity of roads, railways and power

lines, etc

..

take extra precautions (see ill.

16).

Inform the

police,

u1ifity

company

or

railway au1hority before begin-

ning

to

cu1

.

When felling, maintaJn a distance of

at

least·

2'h

tree

lengths

from

the nearest person (see ill.

17).

Note:

14

The noise of your engine may drown any warning call.

Felling

Instructions:

Firs1

clear the tree base and work area from interfering

limbs end brush and clean its lower portion

with

an

axe

(ill.

18).

.

Then, establish. a path of escape and remove all obstacles.

This path should be opposite to the planned'dlrection of the

fall

of

the tree end at a

4S.

angle (ill. 19). An alternate

path must also be selected. Place all tools and equipment

a safe distance away from the tree,

bu1

not

on

the escape

path.

Page 16

20

H

ttle.~,,~

large

~

~

cut

Into

the

largest

. -.

~utbeSSes

vertically;

first,

(hori,zontally

next)

and

remove

(Hl20~

,,;

~

d8t8rmiil8,

the

placement

of

the.feUIng

note."

(Ul2t).

1J1e'~

~

~

,poper:tY

,placed

determ1r)es

the

directioh

In

whJchthe

treewiiUaLIt

Is

made perpendicular

to

the

nne

Of

f8n

&net

shOUld

be.

close

to

the

groUnd

as

possible. Cut the

felling

notch

to a dePth

of

abOut

one-fifth

to one-fourth of the trunk diameter (Ill 22). It should be

In

no

~

higher than it is

deep.

Make the felling notch

very carefully.

Begin

the

felUng

cut slightly higher than the

feDing

notch

and.

ora

the

opppsite side of

tIMI

tn!e

(ill.

.22).

Then

cut

ho~l)I~h:toward$

~

~,n,g

notch. Apply the

chab1

saw

with its

spikes

dlrecdy

t;MlhIndthe

~

portion

of

wood and cut toward the notch (ill

23~

Leave

approx-

imately

'ho

.o1.the

~

dlam_~

~n.c;ul

This is

the

hln.ge

(III.

23}.'Ofi'i1ot

Cut

thrOugh

the

hinge

_use

you

Could

lose control

of

the direction

of

the

faIL

Drive wedges into

the

felfll'l9.

~t ~ ~

to

COI1tmI

the

direction

oftha

ftdl.W~es

should be ofw9Qd.

Ught

alloy

or

plastic-

never

~'~

Which

can

~

kIckback,and

~

tothechala

22

Hinge

---i~

Felling

notch

-*

Hinge......,........,H

Felling

notch

15

Page 17

16

24

A'iways

keep

to

the

side of the

f8Jling

tree.

When

the tree

starts

to

fall,

shut off

the

engine.

WIthdraw

the bar

and

walk

away

on

the pre-planned escape

path.

Watch

out for

failing

limbs.

Warning! :

Be

extremely careful with partially fallen trees

which

are

poorly

supported.

When

the tree

h~;or

19r

~

other

reason

does

not

fall'

completelY,

set"the

saw

asfde'and

pull

the tree

down

with

a cabIe·wlnch,btockand tackle or tJactor.lf you

try

to

cut

it

down

with

your

saw,

you

may

be

injured.

Sectioning Method

warning!

.

Felling

a tree that has a diameter greater than the

length

of

the

guide bar

requl~

use

of either the

sectioning

or

plunge-cut

method.

These methods' are

extremely

dangerous

because they

InvolVe

the

use

of the

nose

of

the

guide

bar

and

can

result

In

kickback. Only

property

trained professionals should attempt· these techniqueS.

25

Forthe

tteeHOriing

methOd

(HI.

24)

make

the first cut

with

the

guide bar fanning

tn

toWard

the·

hinge. Then,usmgthe

bumper spike

as a pivot, reposition the

saw

for the next

cut.

Avoid

reposftioning the

saw

more

than

necessary.

When

r8poSltiori!rig

fci

the

11Et~

~

ic8ep

'the guide

~r

.i¥!Iy

engaged

in the

kerr

to keep

the

fettlng

cut

strafght

If

the

saW

begins

to

pinCh.

inSert

a

w8dge

to

open the

cut.

On

the

~

cut.

dO

not

cut

the

hinge.'

Plunge-Cut

~

Tmber

haVIng

a diameter

more

than

tWice

the

!ength

Of

the

gUKJe

bar

reqUires

the use of the

plunge-(x.it

method

before

making

th.e

f8lHngcUt . .

First.

cUt

a large. wide

nOtch.

Make a plunge-

cut

In

the

center of the

notCh.

. . .

The-

plunge

cut

is

made

with

the guide' ~ nose.

BegIn

the

plunge.

cUt

by

'applylitg

the

lower

portiOn

of

the

guide

bei

nose

to

the

tree

at

an

angle

(ill.

25)~

Cut until

the

dePth

of the kerf

Is

about the

same

as

the width

of

the guide

bar

Page 18

26"

28

~

.

\A)

~

29

(m.

26).

Next,

align

the saw

In

the direction

In

which the

recess

is to

be

cut."

.

WIth

the

ssw-

at

fulithrotUe, insert

th8

guide bar

in

the

trunk

(II!.

27).

Enlarge

the

plunge

cut as

shown

In

illustration (ill.

28).

warning

I

There

is

an

extreme

danger

of

kickback

at

ttris point.

Extra

caution

must

be

taken

to

maintain

control

of1he

saw.

To

make

the

felting cut,

..

follow the· sectlonfng

rnettiod

described previously (ill.

29).

H you

are

inexperienced with a

chain

saw prunge-cutting

should

not

be

attempted.

Seek

the help

of

a professional.

Umbing

Umbing . is

removing

the

branches

from

a fallen tree.

WBmIngl

There is an

extreme

danger

of

kickback during the limbing

operation.

Do

not work with the hose

of

the

bar.

Be

extre-

mely cautious

and

avoid contacting the

log

or other limbs

with

the

nose

of

the guide bar.

00

not stand

on

a log while Ilmblng it - you may slip or the

log

may

roll.

17

Po

Page 19

18

Start

Umbing

by

leaving

the

lower

limb$

to

support

the

log

off

the

ground

(ill. 30).

Always

cut

f~

the

top of the

limb.

Do

not

underbuckfreely hanging limbs

•.

A pinch

may

result

or

the

limb

may

fall,

causing

loss

of

control.

If a

pinch

occurs,

stop. the

engine

and

remove

the

saw,

by

lifting the

limb.

warning!

Be

extremely

cautious

when cutting

limbs

under tension.

The

limb

could

spring back toward

the

operator and

cause

loss of control of

the

saw

or injury

to

the

operator.

Bucking

Bucking

is

cutting a

log

into

sections.

Warnings!

1.

When bucking,

do

not

stand

on

the

log.

Make

sure

the

log

will

not

ron

down-hill. If

on a slope,

stand

on

the

up-

hill

side

of

the

109

(see

Ill.

31).

Watch

out

for

rolling

logs.

2.

Cut

only one

log

at a time.

3.

Shattered

wood

should be cut

very

carefully.

Sharp.

slivers of

wood

may

be

caught

and

flung

in

the

direction

of

the operator of

the

saw.

4.

When

cutting

small

iOgS~

Use

8SaWhorae-(iD.

32).

NeVer

permit another

person

to

hold

the

log.

Never

hold

the

log

with

your

leg

or.foot.

5.

Logs

under straln,'require

sPecial

attention to

prevent

the saw

trpm

pinch1n.g

•.

The

fifst cut·is

made

on

the

compression

side to relieve the stresS

on

the

log

(see

III.

33~

34).

The

bucking

cut is

thEm

made

as

shown.

If the

saw

pinches,

stop

the

engine

and

remove

it

from

the

log.

6.

Only

properly trained professionals

should

work

in

an

area

where

the

logs,

limbs

Bn.d

roots

are

tangled

(i.e. a

Page 20

1.

Refoeving

cut

33

. 2. Cross art

34

blowdown area, ill. 35). Worldng

in

blowdown areas

is

extremely hazardous.

7.

Drag the logs into a clear area before cutting. Pull out

exposed and cleared logs

first.

Maintenance BDd Repair

Never operate a chain saw that is damaged, improperly

adjusted

Of

not completely or securely assembled. Follow

the maintenance and repair.instructions

in

the appropriate

section of your

Owne~s

Manual.

warning!

Always stop the engine and make sure that the chain is

stoppe.d

before doing any maintenance or repair

wor!<

or

cleaning the saw.

Do

not attempt any maintenance or

repair

wor!<

not described in your

Own~s

Manual. Have

such work performed at your STlHL service shop orily.

MAINTAINING

AND

STORING

THE

SAW

Keep the chain, bar and sprocket clean and lubricated;

replace worn sprockets or chains.

Keep the chain sharp.

You

can spot a dull chain when

easy-to-cut wood beccmes hard to cut and bum marks

appear

on

the wood.

Keep the chain at proper tension. Tighten all nuts, bolts

and

screws

except

the

carburetor

adjustment

screws

after

each

use.

Keep

spar!<

plug

and

wire connection tight and clean.

Store saws

In

a high or locked place, away from children.

19

Page 21

20

Mounting Guide

Bar

and Chain

Top:

Backing off tensioning

nut

Bottom:

Locating

the

guide

bar

The guide bar and Oilomatic chain are supplied separately

for safety reasons.

To

mount them, first unscrew the coliar nuts

(1)

from the

stud bolts (2) and take off the sprocket cover (3).

Now back off the chain tensioning

nU1

(4)

- below the stud

bolts

(2

) - by tuming the tensioning screw (5) counter-

clockwise to the end of

Its thread.

Top: FJtting

the Ollomalic chain

Bottom: Cutting

edges

face

the

bar

nose

Locate slot

of

guide bar over the stud bolts (2)

so

that the

lug of the tensioning

nU1

(4) engages in the lower fixing

hole (6).

Starting at the chain sprocket, place the Oilomatic chain

on

the guide bar so thal cutting edges on the top

of

the bar are

facing

the

bar nose

(7).

Fit chain sprocket cover (3) on the

stud bolts

(2)

and tighten coliar nuts

(1)

temporarily by

hand. .

Page 22

Top

: Tensioni

ng

the Oilomatic chain

Bottom

:

TIght

en

collar

nuts

secu

rely

Now tension

the

Ollomatic chain by

tumlng

the tensioning

screw (5) ctockwise. making sure

that

the drive link tangs

are lined

up

with

the bottom groove

of

the

bar

. Hold the

bar

nose (7) up

tum

tension screw (5) until

the

Oilomatlc chain ·

is

pmperly

seated

on

the

underside

01

the

bar

. While stili

holding

the

bar nose

uP.

tighten

the

collar

nuts

(1)

securely.

Ch

ecking chal

n

te

nsi

on

The Otlomatic chain

Is

correctly tensioned when is

fits

snugly on the underside

01

the bar

1;,"1

can stili

be

pulled

easily around

the

bar

.

21

Page 23

22

Fuel

Fuel

tank

cap open

You

two-stroke engine is powered by a mixture of gasoline

and engine

011.

Only

regular

gasoline

may

be

used.

Never use high

octane gasoline as it contains benzol which would per-

manently damage the carburetor diaphragms.

Only use STIHL two-cycle engine oil or

other

branded two-

cycle engine oils for mixing. The mix ratio

Is

1: 40

(1

part oil

to

40

parts regular gasoline) with STlHL two-cycle engine

oil

or

1: 25

for

other

branded engine oils.

Important:

Always

shake

mixture

In

fuel

can

vigorously

before

fueling.

-

Chain Oil

Oil

filler

cap

open

The

service

I~e

of

the

cutting attachment (Oilomatic chain

andguide

bar) depends on'good lubrication and the quality

of

the

lubricating

011.

Never

use

waste

011

for

this

pUrPosel

Always use

the

chain lubricating oll.approved by STIHL

and

appointed dealers.

If

special chain lubricating oil is not available, one of the

high-duty, Single grade engine oils listed below may be

used

In

an

emergency,

d~nding

on the outside tempe-

rature.

Outside temperature + 1 O'C

...

+40"C: SAE

30

Outside temperature +

10'C

...

-10·C:

SAE

20

Outside temperature

-10·C

...

--30OC:

SAE

20

W or

SAE

10 W

Always top up with chain

011

when you refuel. Carefully

clean the area around the filler caps before opening and

make sure that no dirt falls

inlo

the

tank

while you are

refueling.

Page 24

Helpers Handle

Knocking out blanking plug

,--------~~~-~

For safety reasons and

to

Improve cutting accuracy ~ is

.. advisable

to

use

the

helpers handle

(1109

660

2500) n your

saw

is equipped with a 105 em

(42

In)

or

longer cutting

attachment.

With

the

handle fitted a second man can safely

assist

the

saw

operator in handling

the

saw.

When the helpers handle Is being

used

the

non-cutting

side

of

the

saw

chain

must

always be covered

by

a guard

rail which matches

the

bar

length.

To

assemblethe helpers handle, first

knockoutthe

blanking

plug (3) In

the

slot

(1)

at

the

bar

nose

(2).

Then

tum

the

clamp nut (5) (star knob) counterclockwise to rotate

the

head

of

the

clamp bott (4)

so

that

it

fits through the slot

(1)

in

the

bar.

The

head

of

the

clamp bon (4) is turned through

90" when

the

clamp nut (5) (star knob) Is tightened and

thus secures

the

helpers

handle

(6) against

the

guide

bar

(2).

To

attach

the

guard rail (7), first ffl

the

mountfng

hardware

to

the

CI8J1kcase

and

the

helpers

handle

and then place

the

guard rail

In

posiIJon.

Top:

TIghtening

the

clamp

nut

Center:

Mounting

hardware

fitted

on

bumper

spike

Bottom:

Guard

rail

in

posttion

___

6

'-'-

____

1

23

Page 25

Starting

Stop

switcl1

away

from

"STOP "

"

To start the engine, place

Ihe

chain

saw

on the ground,

make

sure you have a finn foothold and

the

saw chain is

clear

of

all obstacles and

the

ground. Bystanders must

be

kepI well clear

of

the

general

work

area

of

the

saw.

Starting

procedure

1.

Move

stop switch

(1)

away

from "

STOP".

2.

If

the engine is cold, move choke lever (2) to

"Choke

".

If

the

engine

is

wann

or

has only

been

stopped for a

brief

period, move choke

lever

(2)

away

from"

Choke".

3.

Set

throttle trigger (3)

10

starting throt1le position by.

pressing the

safety throWe lock (4), throttle trigger (3)

and

starting throttle lock (5) In

thai

order.

Le\go

ofthrotUe

trigger (3) first

and then

the

starting throtUe lock (5).

If

you have an O9OAVfirsI squeeze

the

throttle trigger (3)

and

press In

the

starting throtUe lock (5) . LeI goofthrotUe

24 trigger (3) first and then the starting throtUe lock (5).

Top

: Choke lever

In

" Choke" position (cold start)

Center: Choke lever away

from"

Choke" position (warm start)

Bottom: Starting throttle position

Page 26

Pressing

the

decompression

valve

4.

Hold

the saw firmly

on

the ground with your left hand

around the handlebar (6) and put the toe of your right

foot into the rear handle and press down.

5.

Press the decompression valve (7) with the

th

umb

of

your left hand. Pull the starter grip (8) slowly with your

right hand until you feel the starter engage and then

give

~

a brisk strong pull.

The starter rope should not be pulled out more than

70

em

(27 in) as there is otherwise a risk of it breaking.

Do

not allow starter grip (8) to snap back. Guide it back

vertically so that the starter rope can rewind correctly.

6.

As

soon as the engine is running, release the decom-

pression valve

(7) and immediately disengage the start-

ing

throttle lock

(5)

by briefly squeezing the throttle

trigger so that the engine can settle down

to

idle speed.

7.

To

stop the engine, flick the stop switch (2) to the

"STOP"

position.

Top:

51.rting

Center:

Idle

position

Bottom:

S10p

switch

In

"STOP"

position

*"

__

8

•

,

25

Page 27

;

other

points to

beobserved:~~·l~

..

,

~

engine:

The choke lever:is

mectianl~

"

&)ritJ

i~<

the

.·

~

retor's choke valve. The:

dlOki

:V8(Vltis

Closi,cfWhen

the

choke lever

is

00

..

chOke

t"skfWiiQ'n

the ,

CilOke

lever

is

moveda~ay,

from

.~

~;~:~,,~;

::~

~:,

;,

·',Yi~

:,

:;:,~~".:~

:,

:.::~1}

:

; . ,

~

-"'. I

I,'

~en

'

Starti~

a-cold fihglne

on~~p

~~'~~:~ve~

in

the " Choke

II

poSition

until the

engine

~bj$~:ftie.

Then

open

choke fully -

chOICe

rever'away

·

~tCfWk8"

-

ev,en

if the ,engine

stops

and

you

have ·to,·repeat:,thestartfng

prcx:edur~l.the

choke

lever

~.~iJl#:l~··.~·~

pqsition.

. the combustion chamber

wllfftOQd8hd

'

_II'''~ri8/

.

~~

.~'::

: :·tt:~;~;·";

~::,:.:51>'··:

··:~;:

~(

~

If

you

moved

tile

choke lever

8Wlly!

·

frOJtli]hj

~

~QiQke

..

position

after

~~j~Qgtnefired

B!td~

"

~a~~~((:~

·

~ot

run

after

sevEDI'"

, H

is:alMQAU'~

:In~

SUCb

a

_t" o

.

~

.. " . : ••

~t

.

-·'

~"'

~ '.':~

'

-'1":~

~

:-'.

·'·

,,;,"'

~'·

""

:

C8$~.

re_'~,1ty9fUh!'~P!qg~~~~~s

tionch~bY)~~gtht

..

~;~~~

~

~~n

. the

starter:WiIti:the

"

ric'".

"StiU'remoYed '8rid:,1Iuf"8lO

~~11ii"

,·

':

~~

;~

~;sTbpT~~~.

~!p

,i

;

y~q~

"

,

~,~:~

,

mOv8:~'~e

lever

~froril

uChQk~~~f-

,

__

n

"e

qlneJfi(cold, -

and

set the '

throttle

triggerJp,:1I18SJ8rt1ng

:';

tt1roUle'po$ition.

."'·:

,~'

/.: :

,:~,~~::

~~;+t:~~

:'

I~

the"choke slightly after

..

~:g:,:mq

v~~r

t.Ocenterposition.Alloweng,

.

ne

"

to

wsnntyp'fo

r:j

1)rlet:P8rfod,

at

haIt.;;tfli'ottIe.

Then

move

choke

1eY8t'8Wi-fioRj

~ChOke"

and

diSen

' the start-

(n9th~

",.

~.bck

"

' ,

:,,

'

..

:

'>

.

~:

.

"

",

,'

',~./

i>

r.j:;.

.

:

:->~..

.

:~>.~':.~:

"

:-:"

..

A,

f)ew

engin8

::

o.~

·

W_~

been

run

until

~~~~~k

is

dry

will

not

start

fI!St~8fter

fueling becauS"1hecar-

buretor's

dlaphragm

~

pqtiJp

only

deDvers

sufft~J~el

26 after the engine

haS

b88atUmed

over, several

timeS:

, '"

Page 28

Oil quantity control

Top:

1 = Adjusting screw

2 =

Counter

nut

Bottom: Loosening

the

counter

nut

At

the factory the chain oil supply of the oil pump is adjusted

to

the standard cutting lengths

of

53

em

(20.9 in.) bar for

090, 090

AV,

90

em

(35.4 In.)

bar

for

090 G. When using

longer guide bars

rt

is possible to adjust the

011

quantity

according to the bar length used by means of the provided

adjustmem screw.

Before readjusting the oil quanttty remove

Mer

cover and

fllter, flrst, however, close choke shutter (posrtion

"0")

so

that no dirt can drop Imo the carburetor.

.

Top:

. Adjusting

the

oil quantity

Bottom:

Countering

The adjusting screw for regulating the oil quantity is located

althe

rear-wall of the

011

tank and is coumered with a hexa-

gonal nut. Hold adjusting screw

wlth fork wrench SW

10

and loosen counter nut wrth second wrench . .

When tuming the adjusting screw to the left - counter

clockwise - more

011

Is supplied and when tuming to the

right less

011

is supplied. Tuming the adjusting screw '/3 of

a tum corresponds approx. to the necessary change of oil

supply which is needed for the next longer bar length.

27

Page 29

Cutting Attachment

, O

Ulntet

borings

2

Gente,ring

borings

The cutting attachment

of

a chain saw consists of the guide

bar; saw chain and chain

sprocket

GuJdebar

The nose and underside

of

the guide

bar

are subject

to

a

particularly high rate

of

wear

. To avoid one-sided wear, tum

the bar around every

time

you resharpen or replace the

chain. Regular cleaning

of

the

011

Inlet holes and guide

bar

groove is also important. The

bar

can be examined for signs

of wear

at the same

time.

A minimum

bar

groove depth

of

7 mm (0.28 in)

must

be

maintained in order to prevent the drive

Unks

fouling the

bottom of the groove (the heels

of

the culler and tie strap

would no longer locate on the guide bar track

).

This depth should be measured

at

the point where the

bat

is

stressed

mOst

,

I.

e.

the

bar

noee or:

D'..!romatic

bars

and

the area where most

of

the cuttiilg is done

on

RoliomaUc

bars. The guide bar must be replaced.

1f

the minimum depth

28 cannot be maintained.

On Roliomatic guide bars the bearing

01

the nose sprocket

must also

be

lubricated at regulated intervals with the

appropriate grease

gun.

Lubricate at least once druly under

normal operating conditions. Only use a high grade grease

for refilling the grease gun. e.g. refill lUbe

0781120

1111

.

To lubricate, place chain saw on its side so that the bar

nose is firmly supported. Clean the grease hole and pump

in grease while slowly pulling saw chain around

bar

(sprocket rotates) so

thai

bearing is uniformly filled. When

grease emerges

at

the hole on the other

sid!>

of the bar or

around

!be

nose. sprocket, repeat the procedure on the

other side.

The sprocket nose bearing should

be

greased more often

ff

the

cutting

attachment is used

in

damp conditions, e.g.

working

in

snow. AfII!r finishing cutting work the sprocket

nose should be .thoroughly greased from both sides

to

force moisture

out

of the bearing and prevent corrosion.

Chain

lubrication

Never operate the chain

saw

without proper chain lubrica-

tion. Check operation

of

chain lubrication and level in 011

tank before starting work.

Hold chain saw with mounted cutting attachment over a

light background. Take care, the Ollomatic chain must not

touch the ground.

i.

e. keep H at least

20

em (8 in) clear of

the ground. Run the engine with haH-throttle position.

ff

an

increasing patch

of

oil can be seen, chain lubrication

is

operating correctly.

Page 30

Checking

chain

lubrication

Wom

chain

sprocket

Breaking

In

OHomatic

chain

Every new chain

has

to be broken

In

for about 2 to 3 mInu-

tes. Ample chain lubrication is essential during this period.

After breaking

in

, stop

the

engine, check chain tension and

adjust if necessary.

Correct

chain

tension

The Ollomatic chain must always be slackened off after

finishing cutting

work

A chain properly tensioned when

~

is warm would, when the temperature drops, be subjected

to such great contnaction stresses that

~

would break and

also damage the crankshaft and bearings.

The Oilomatic chain must, therefore, always be tensio

ned-

w~

the engine switched off - before you start cutting.

Chain tension is correct

In

the cold condition when the

chain fits snugly

on

the underside of the bar and can still

be moved along the bar

by

hand. Extreme care must be

!eken as ·the cutting edges are very sharp.

When the chaln saw Is operated at extremely low outside

temperatures a correctfy cold-tensioned Ollorpatic chain

will begin to sag noticeabl)i"as H warms up to

noimal

operat-

ing temperature. The chaln must then be retensioned.

However, the chain must be slackened off again

immedia-

tely after shutting down the saw. This Is necessary to avoid

contraction

stress which would occur as

the

chain cools

down to ambient temperature.

A new chain must be retensloned more frequently than a

used one util h has stretched fully.

Chain

sprocket

The stress and strain

on

the chain sprocket are particularly

high.

~

the

wear

mar1<s

on the teeth are very pronounced

(about

0.5

mm/O.D2

In

deep), the sprocket should be re-

pl8ced. A

wom

sprocket reduces the service life

of

the saw

chain. The chain sprocket should be replaced as a matter

of routine whh every secOnd Oilomatic chain.

n Is

best

to

use two chains alternately

w~

one sprocket. 29

Page 31

, =

Oil

filler

cap

2 =

Manual

oiler

3 = Oil

inspection

window

Alter adjusting hold adjusting screw with a fork wrench

and counter hexagonal nut again wi

th

second wrench.

Thereafter assemble air finer and filter cover again.

In extreme cases (failure of automatic oil pump, heavy

frost etc.) the use of the hand oiler assures sufficient chain

lubrication.

Also during longer cutting periods with longer cutting

lengths the chain

is additionally supplied with lubricating

all by activating the manual oller. Moreover, before

starting

we

recommend to supply

add~lonal

lubricating oil to bar

and chain by activating the manuai olier should the saw

s~

idle at freezing temperatures for a longer period. Thus the

cutting attachment is protected against excessive wear.