Page 1

SOM 7 SI

Installation,

Configuration

and Troubleshooting

Manual

Thanks for buying this product.

Read this manual carefully to get the best perfomance from this unit.

*49004470*

49004470

SOM 7 SI

manual

Page 2

SOM 7 SI

US

Contents

Imprint

Safety regulations ................................................................2

Technical data and overview of functions ........................3

1. Installation .............................................................4

1.1 Mounting .................................................................................. 4

1.2 Electrical Connection ........................................................... 4

1.2.1

1.2.2 Standard Solar System .......................................................... 5

1.2.3 Solar System with Heat Exchange .....................................6

1.2.4 Solar System with After-Heating ........................................ 6

1.2.5 Solar System with Layered Tank Charge ........................... 7

1.2.6 2 Tank Solar System with Valve Logic ................................ 7

1.2.7 2 Tank Solar System with Pump Logic ............................... 8

1.2.8 Solar System with East-West Collectors ......................... 8

1.2.9 Solar System with After-Heating by Solid Fuel Boiler ... 9

1.2.10 Solar system with heating circuit return flow incr..........9

2. Opearation and function ....................................10

Data communication / Bus ............................................. 5

2.1 Adjustment buttons ............................................................ 10

2.2 System monitoring display ................................................. 10

2.2.1 Channel indication ...............................................................10

2.2.2 Tool bar .................................................................................. 10

2.2.3 System screen ....................................................................... 11

2.3 Blinking codes ....................................................................... 11

2.3.1 System-Screen Blinking codes ........................................... 11

2.3.2 LED blinking codes .............................................................. 11

3. Primary commissioning ......................................12

4. Control parameter and display channels ..........13

4.1 Channel overview ................................................................13

4.1.1-6 Indication channels ..............................................................15

4.1.6-21 Adjustment channels ........................................................... 16

4.2 Recommended Settings .....................................21

5. Troubleshooting Tips

6. Warranty..............................................................28

...........................................23

Safety regulations:

Please read the following information carefully before

installing and operating the controller. When configuring the

controller please change the default settings as illustrated

in section 4.2. This will avoid damage to the solar system

by common problems such as overheating. Installing the

controller using the default settings without making

any adjustments to the configuration parameters

is likely to result in an overheating condition of the

solar system at some point. Please also note that

changing the system scheme (Arr 1 - 9) will reset all

settings to the defaults. Please ensure that the mounting

is in accordance to local, state and federal regulations.

CU 72060171 01

UL 60730-1A:2002

CSA E60730.1:2002

C

Reprinting / copying

This installation manual in its entirety is copyrighted.

Another use outside the copyright requires the approval

of STIEBEL-ELTRON Inc. This especially applies for copies,

translations, micro films and the storage into electronic

systems.

Editor: STIEBEL-ELTRON Inc.

Important notice:

Your own calculations and plans under consideration of

the current norms and DIN-directions should primarily

be basis for your projects. We don´t offer a guarantee

for the completeness of the drawings and texts of this

manual - they only represent some examples. They can

only be used at your own risk. No liability is assumed

for incorrect, incomplete or false information and the

resulting damages.

.

| 2

© 08042 som_7_si.monen.indd

Page 3

© 08042 som_7_si.monen.indd

3 |

SOM 7 SI

!

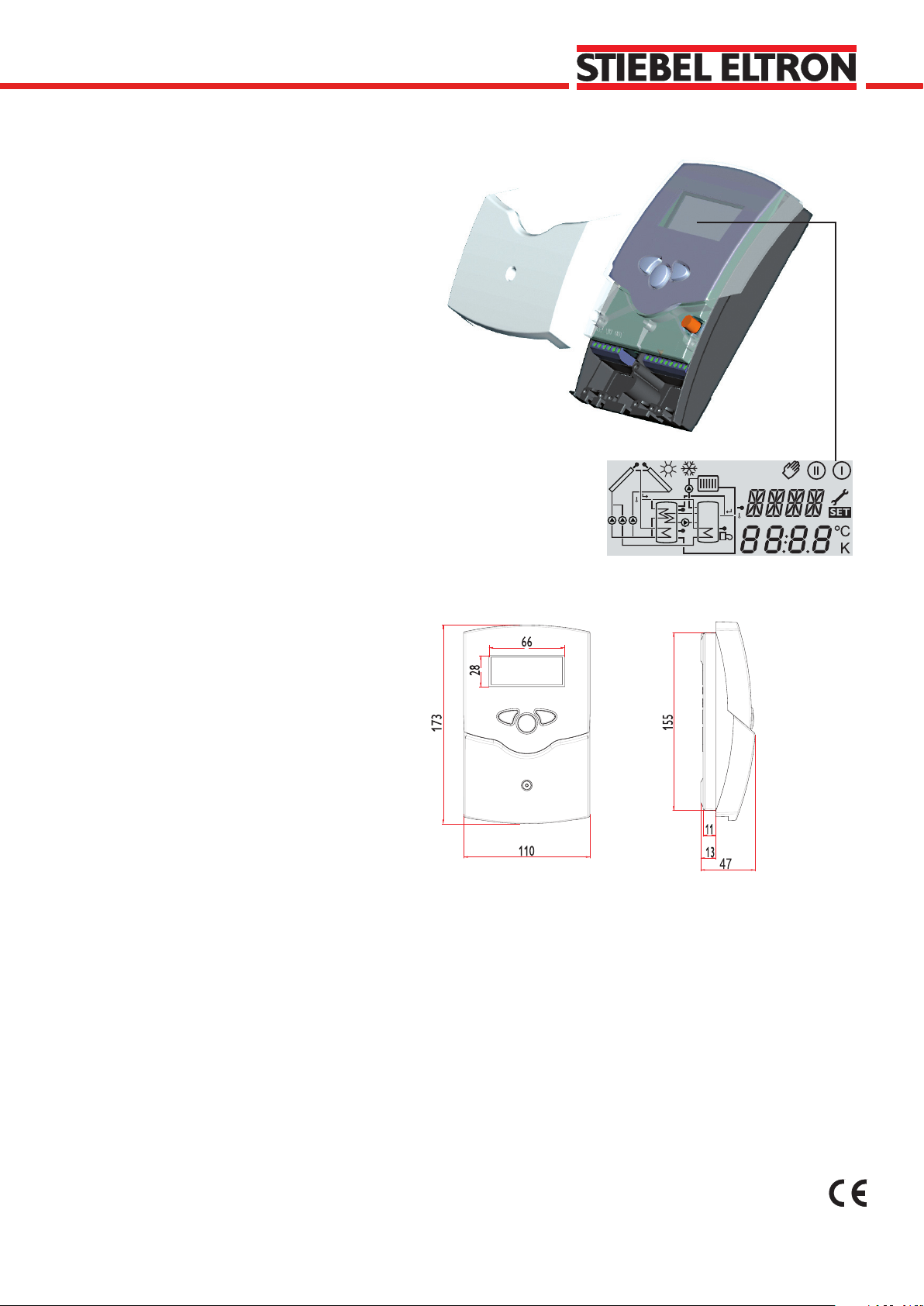

• SystemMonitoringDisplay

• Upto4TemperatureSensors,

Pt1000

• 9SelectableSystemSchemes

• EnergyProductionMeasurement

• VBus

• FunctionControl

• ThermostatFunctionwithTime

• ServiceCenterSoftware

• User-FriendlyOperation

• Compact,EasytoInstallHousing

®

Control

Connectivity

Scope of delivery:

1 x SOM 7 SI

1 x accessory bag

1 x spare fuse T4A

2 x screws and dowels

4 x strain relief and screws

Additionally enclosed in the full kit:

4 x sensor FKP6

Technical data

Housing:

plastic, PC-ABS and PMMA

Protection type: IP 20 / DIN 40050

Ambient temp.: 32 ... 104 °F

Size: 172 x 110 x 46 mm

Mounting: wall mounting, mounting

into patch-panels is possible

Display: System screen for system visualisation, 16-segment display,

7-segment display, 8 symbols for system

status and operating control lamp

Operation: by 3 pushbuttons in the

front of the housing

Functions: Differential temperature

controller with optional add-on system

functions. Func ti on con trol according

to BAW-standards, operating hours

counter for solar pump, tube collector

special function, thermostat function

and heat quantity balancing.

Inputs: for 4 temperature sensors

Pt1000

Bus:VBus

Power supply:

120 VAC

Total power supply:

4 (2) A 120VAC

®

Outputs: 2 electromechanical relays

Page 4

SOM 7 SI

© 08042 som_7_si.monen.indd

| 4

12

S1 S2 S3

3456

Temp. Sensor Pt1000

LNR1NR2N

201918171615

S4

78

141312

DE - 45527 Hattingen

DeltaSol BS Plus

2 (1) A 1152V~

(1) A 115V~

R1

R2

T4A

115V~

CU 72060171 01

UL 60730-1A:2002

CSA E60730.1:2002

VBus

910

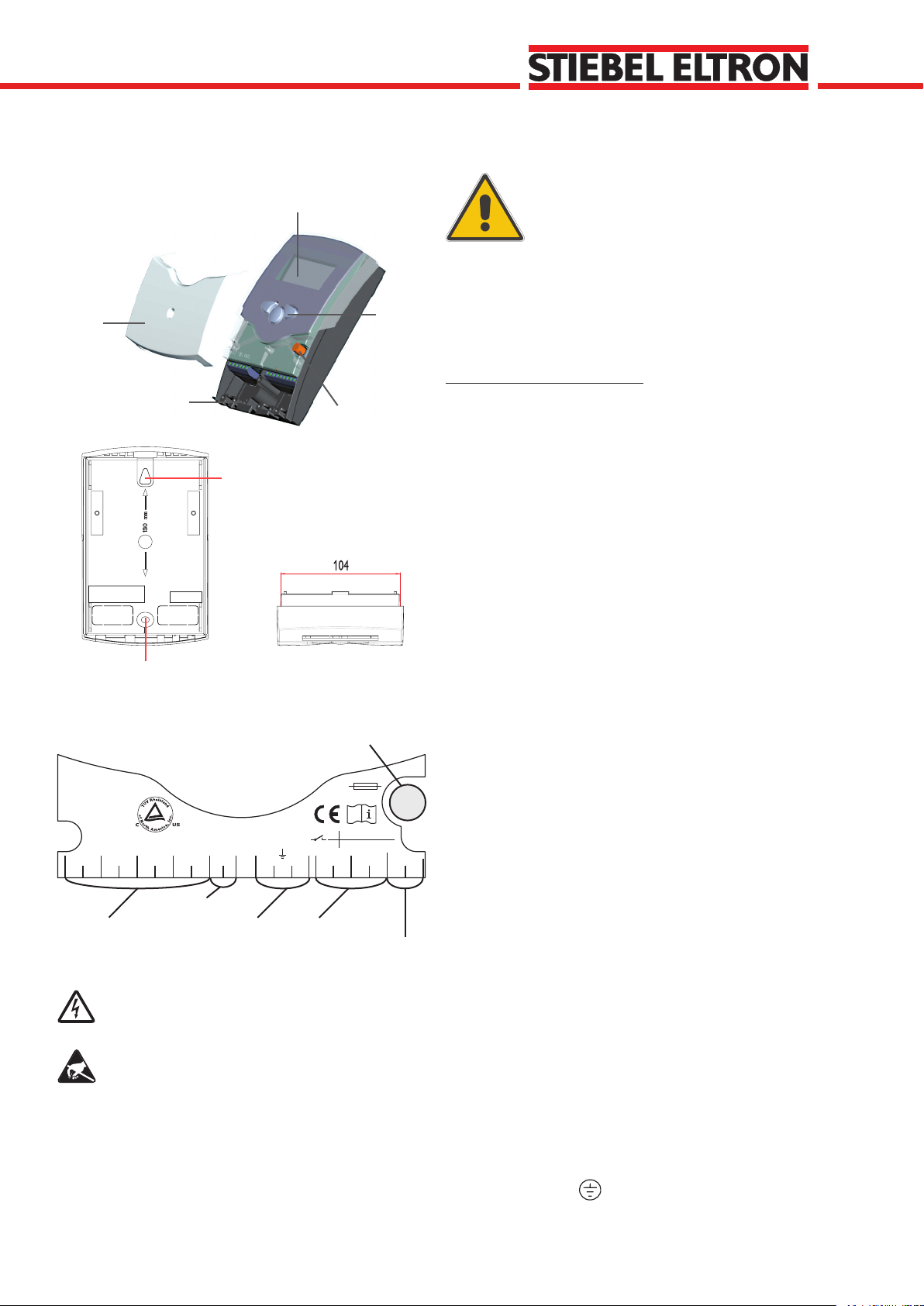

1. Installation

1.1 Mounting

cover

cable conduits with strain

relief

fastening

display

can fuse 4A

pushbutton

Warning!

Switch-off power supply before

opening the housing.

The unit is designed for indoor installation only. It is not

suitable for installation in hazardous locations and should not

be sited near to any electromagnetic field. The controller

must installed in accordance with all electrical regulations.

These regulations vary from region to region. Please contact

the appropriate agency in your area if unclear on this.

Wall Mounting Instructions

1. Unscrew the cross-recessed screw of the cover and

remove it from the housing.

2. Mark the upper fastening point on the wall and mount

the enclosed dowel and screw.

3. Hang up the housing at the upper fastening point and

mark the lower fastening point on the wall. The distance

between the 2 mounting holes is 130 mm.

4. Fasten the housing at its lower point..

1.2 Electrical connection

fixing

fuse

®

VBus

ground clamp

consumer clampsSensor clamp

net clamps

Dangerous voltage on contact!

Electrostatic discharge can lead to damages of electronic components!

The power supply to the controller must only be made by

an external power supply switch and the line voltage must

be 120 VAC (50/60 Hz). Flexible lines are to be fixed at the

housing by enclosed strain relief supports and screws.

The controller is equipped with 2 standard relays, to which

the consumers (pumps, valves etc.) can be connected:

• Relay 1

18 = conductor R1

17 = neutral conductor N

13 = ground clamp

• Relay 2

16 = conductor R2

15 = neutral conductor N

14 = ground clamp

The temperature sensors (S1 up to S4) will be

connected to the following terminals independently of the

polarity:

1 / 2 = Sensor 1 (e.g. Sensor collector 1)

3 / 4 = Sensor 2 (e.g. Sensor tank 1)

5 / 6 = Sensor 3 (e.g. Sensor collector 2)

7 / 8 = Sensor 4 (e.g. Sensor tank 2)

The power supply is effected to the clamps:

19 = Neutral Conductor N

20 = Line Conductor L

12 = Ground Clamp

Page 5

© 08042 som_7_si.monen.indd

5 |

SOM 7 SI

LNR1NR2N

201918171615

S4

7 8

141312

2 (1) A 1152V~

(1) A 115 V~

R1

R2

T4A

115 V~

CU 72060171 01

UL 60730-1A:2002

CSA E60730.1:2002

VBus

910

1.2.1 Datacommunication/Bus

VBus

connection clamps

The controller comes with a VBus® for data communication

and energy supply of external modules. The connection

is effected with optional polarity at the clamps marked

with„VBus®. Via this data bus you can install one or more

VBus® modules.

• Energy Production Measurement Module WMZ-M1

• Large Display GA3

• Data Logger, DL1

• Data Teleindication, DFA2

The controller can also be connected to a PC with the

help of a RS-COM adapter. With the Service Center

Software (RCS) the controller parameters can be changed,

measurements can be read out, processed and visualised.

The software enables an easy function control and

adjustment of the system.

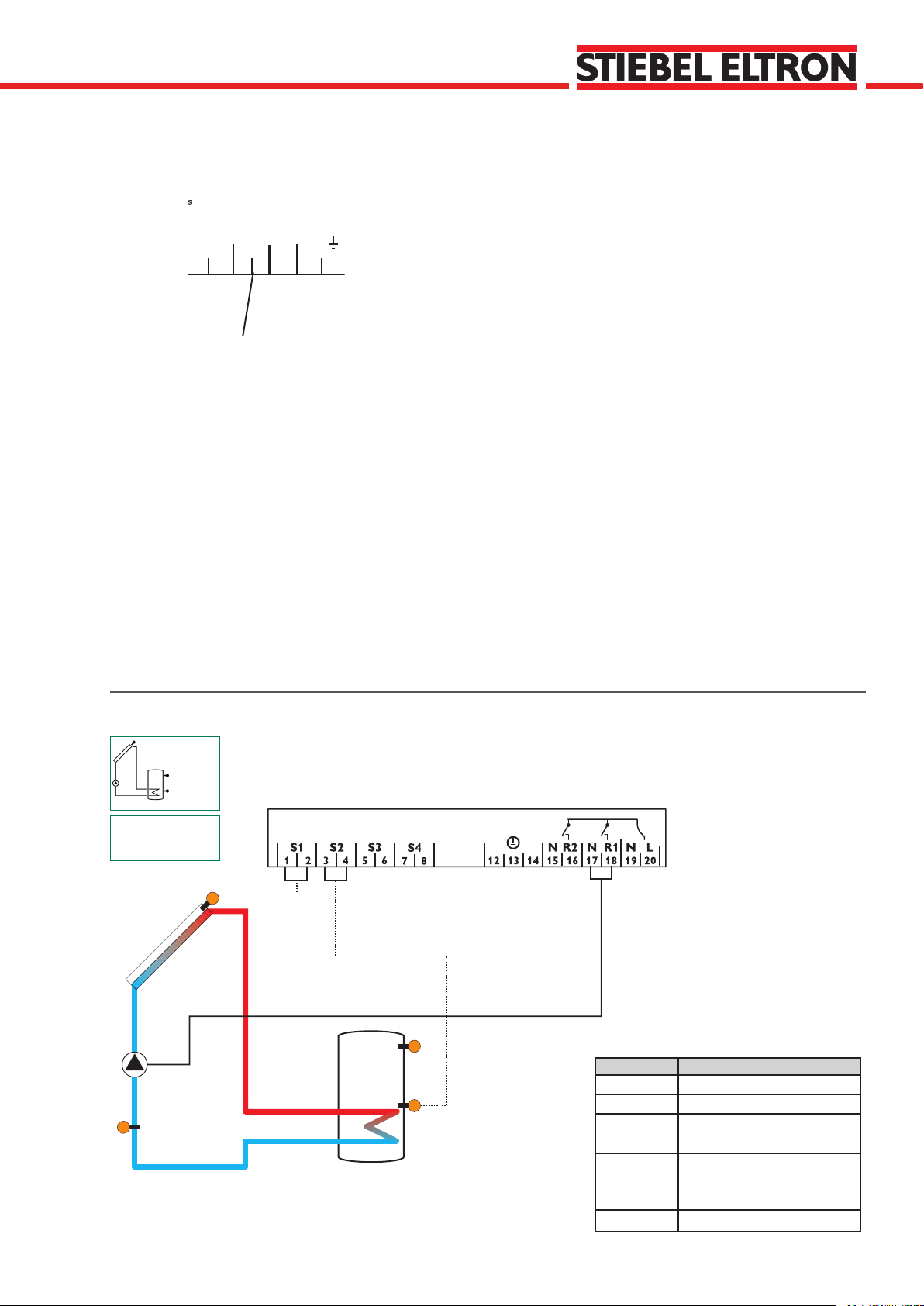

1.2.2 Allocation of Clamps for System 1 Standard Solar System with 1 tank, 1 pump and 2

Arr 1

R1

S4 / TRF

S1

sensors. Sensor S4 / TRF can optionally be used for Energy

Production Measurement.

S3

Symbol Specification

S1 Collector Sensor

S2 Lower Tank Sensor

S2

S3 Upper Tank Sensor

(optional)

S4 / TRF Sensor for Energy

Production Measurement

(optional)

R1 Solar Pump

Page 6

SOM 7 SI

© 08042 som_7_si.monen.indd

| 6

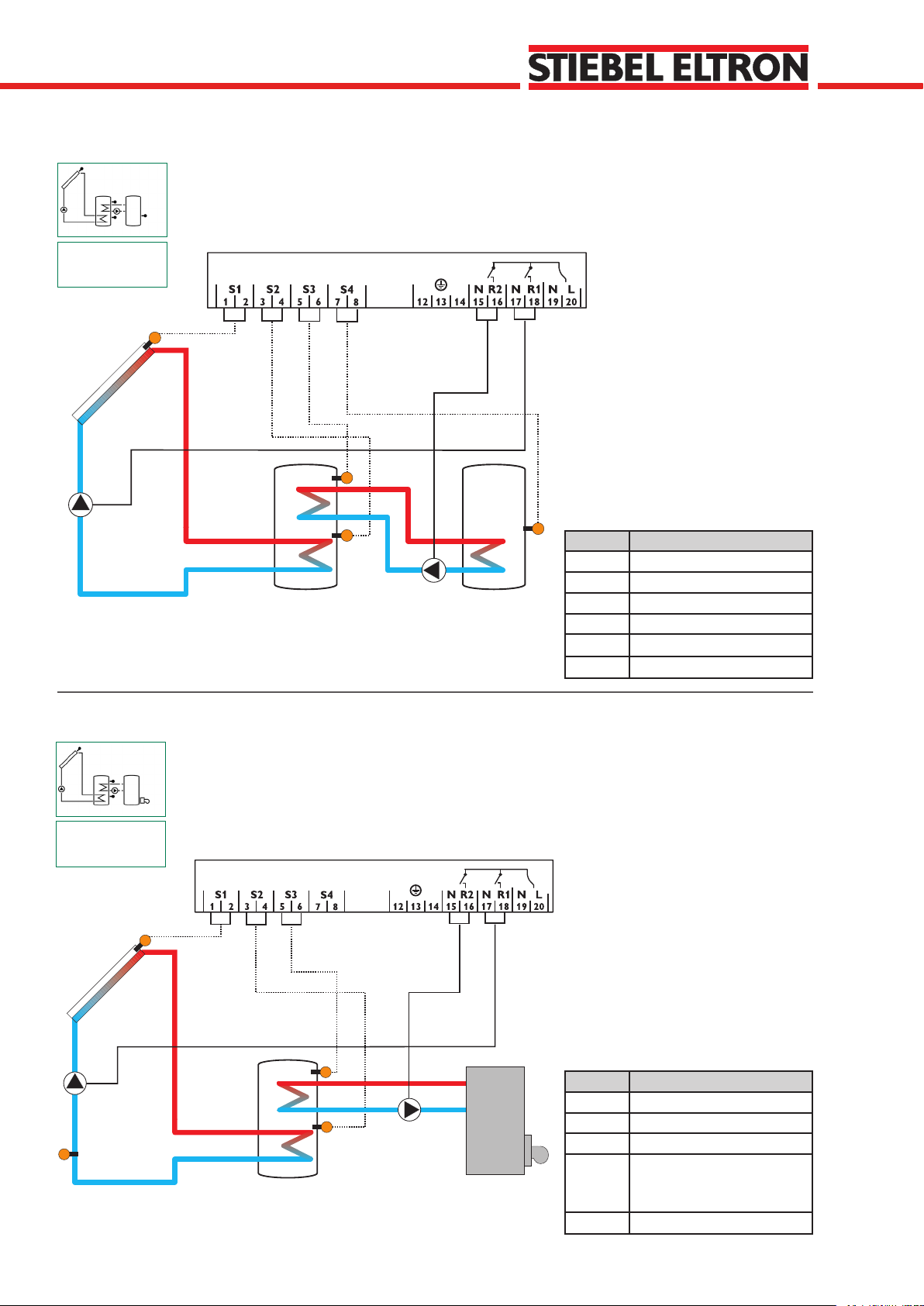

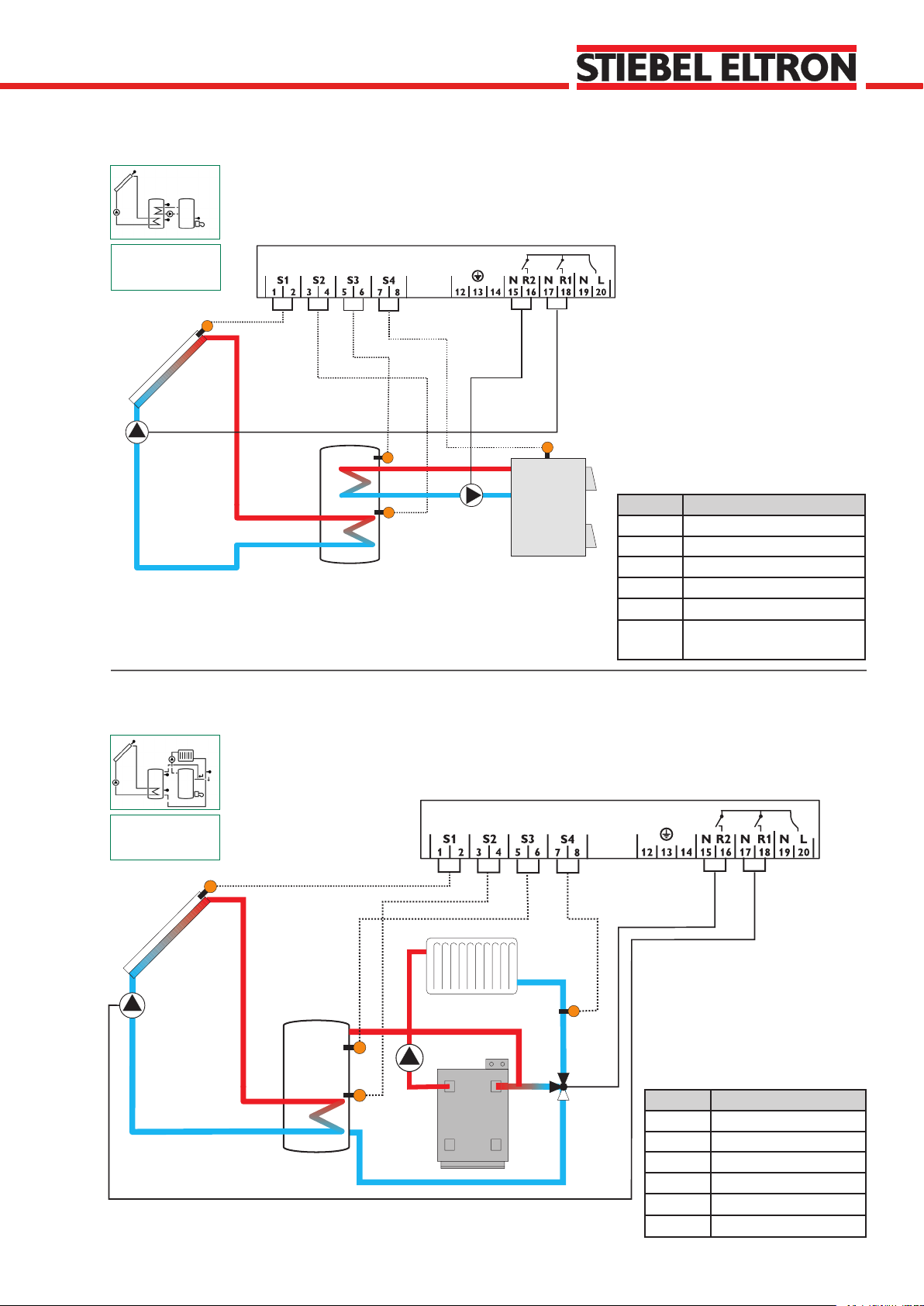

1.2.3 Allocation of Clamps for System 2

Arr 2

S1

R1

Tank 1

S2

S3

SolarSystemwith HeatExchangewith an existing

tank. With 1 tank, 4 sensors and 2 pumps.

Tank 2

S4

Symbol Specification

S1 Collector Sensor

R2

S2 Lower Tank Sensor

S3 Upper Tank Sensor

S4 Tank 2 Sensor

R1 Solar Pump

R2 Pump for Heat Exchange

1.2.4 Allocation of Clamps for System 3 SolarSystemwithAfter-Heatingwith 1 tank, 3 sensors

and after-heating thermostatic control options. Sensor

S4/TRF can optionally be used for Energy Production

Measurement.

Arr 3

S1

R1

S4 / TRF

S2

S3

R2

Symbol Specification

S1 Collector Sensor

S2 Lower Tank Sensor

S3 Upper Tank Sensor

S4 / TRF Sensor for Energy

Production Measurement

(Optional)

R1 Solar Pump

Page 7

© 08042 som_7_si.monen.indd

7 |

SOM 7 SI

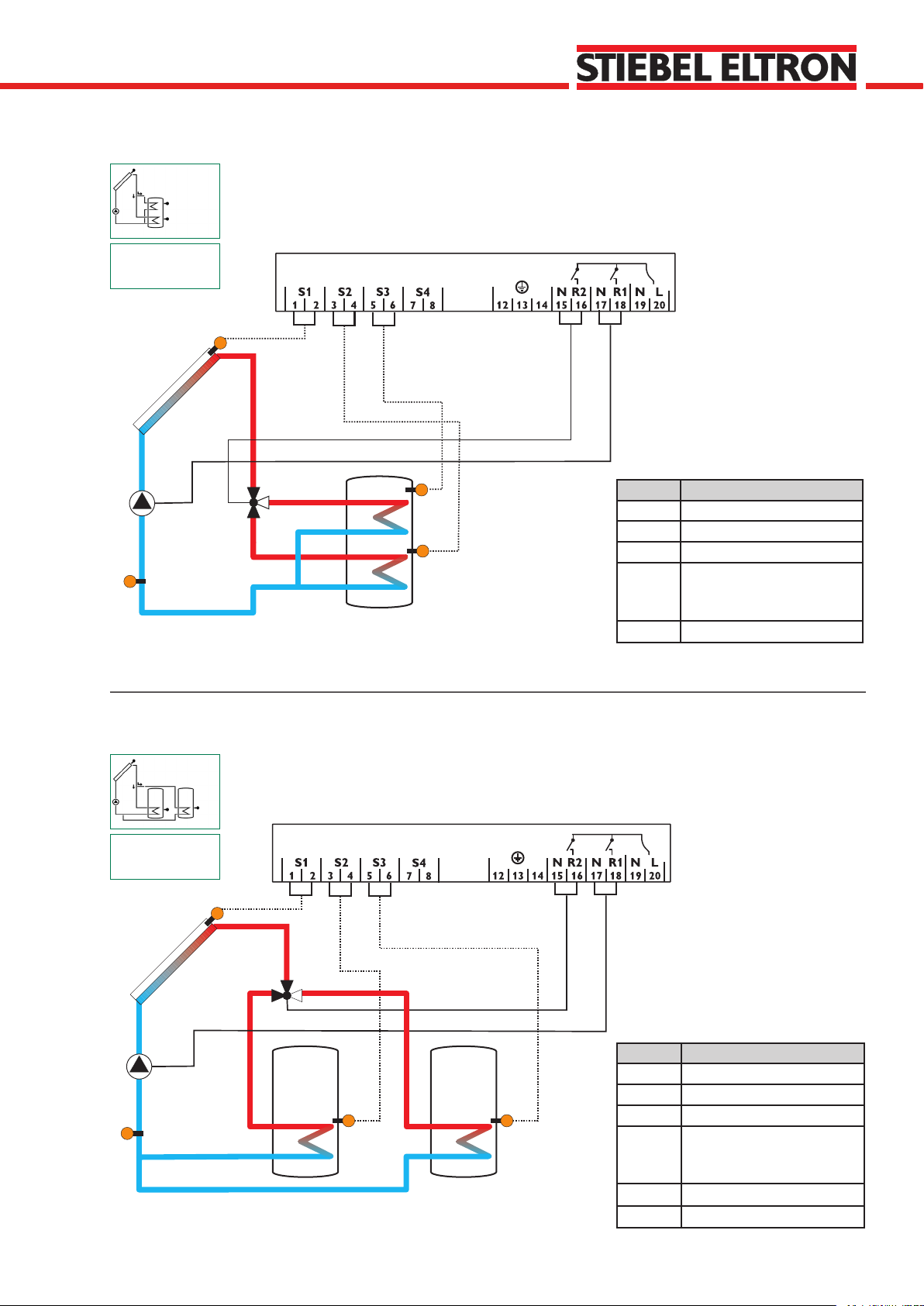

1.2.5 Allocation of clamps for system 4

Arr 4

S1

R1

R2

S4 / TRF

S3

S2

Solar System with Layered Tank Charge with 1 tank,

3 sensors, 1 solar pump and a 3-way-valve for layered tank

charge. Sensor S4 / TRF can optionally be used for heat

quantity balancing.

Symbol Specification

S1 Collector Sensor

S2 Lower Tank Sensor

S3 Upper Tank Sensor

S4 / TRF Sensor for Energy

Production Measurement

(Optional)

R1 Solar Pump

1.2.6 Allocation of clamps for system 5

Arr 5

S1

R2

R1

Tank 1 Tank 2

S2 S3

S4 / TRF

2Tank SolarSystemwithValveLogic: with 2 tanks,

3 sensors, 1 solar pump and 1 3-way-valve. Sensor S4/

TR F can optionally b e used fo r Ener gy Produc tion

Measurement

Symbol Specification

S1 Collector sensor

S2 Tank 1 Sensor

S3 Tank 2 Sensor

S4 / TRF Sensor for Energy

Production Measurement

(optional)

R1 Solar Pump

R2 3-Way Valve

Page 8

SOM 7 SI

© 08042 som_7_si.monen.indd

| 8

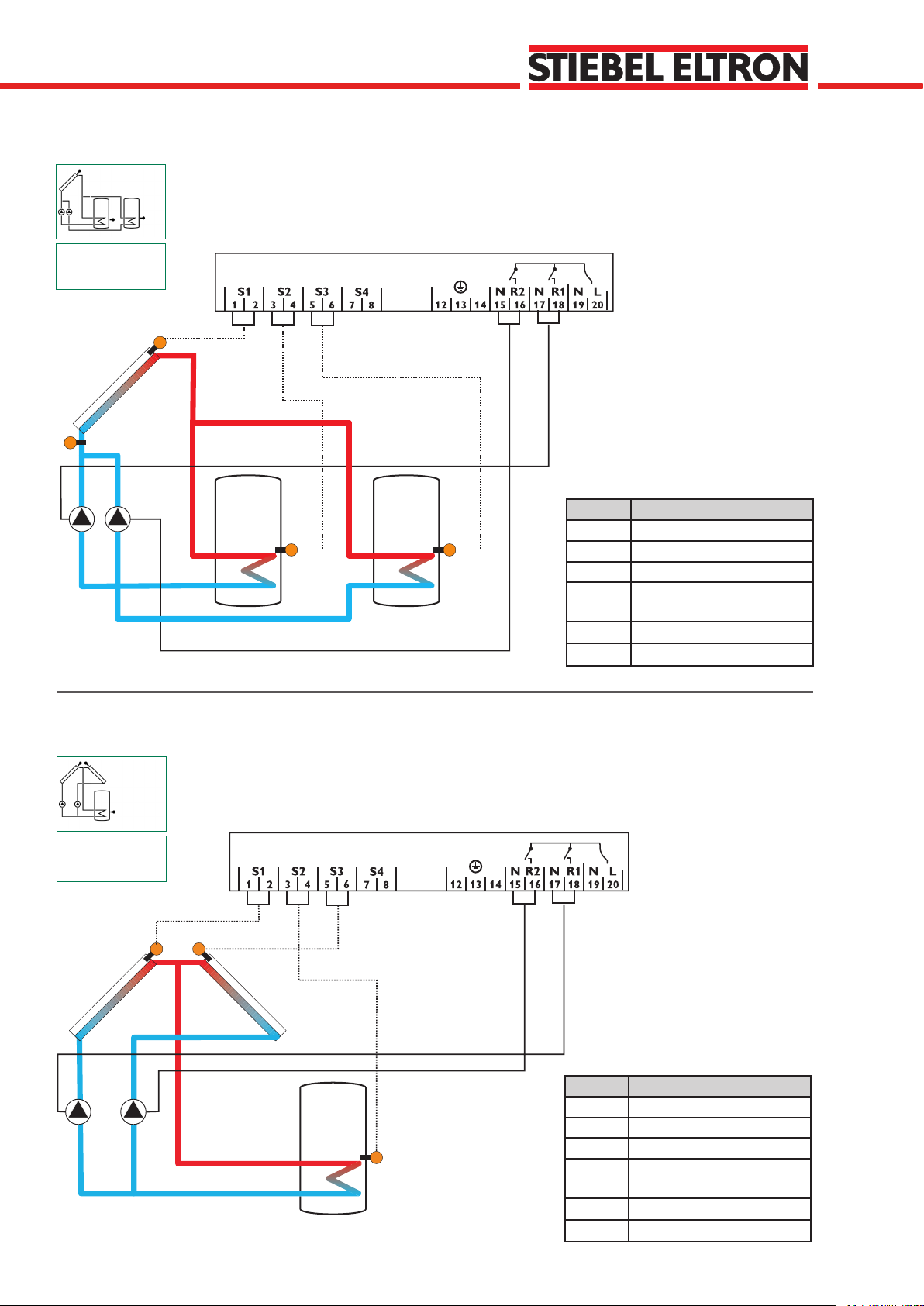

1.2.6 Allocation of Clamps for System 6

Arr 6

S1

S4

Tank 1 Tank 2

R1

R2

S2

2 Tank Solar System with Pump Logic with 2 tanks, 3

sensors and 2 solar pumps.

Symbol Specification

S3

S1 Collector Sensor

S2 Tank Sensor 1

S3 Tank Sensor 2

S4 Measuring Sensor

(optinal)

R1 Solar Pump 1

R2 Solar Pump 2

1.2.7Allocation of Clamps for System 7 Solar System with East-West Collectors, 1 tank,

3 sensors and 2 solar pumps. This system is appropriate

for any system with multiple collector banks with differing

output power.

Arr 7

S3

S2

Symbol Specification

S1 Collector Sensor

S2 Tank Sensor 1

S3 Collector Sensor 2

S4 Measuring Sensor

(optinal)

R1 Collector 1 Solar Pump

R2 Collector 2 Solar Pump

R1

S1

R2

Page 9

© 08042 som_7_si.monen.indd

9|

SOM 7 SI

1.2.8 Allocation of Clamps for System 8

Arr 8

S1

R1

S2

S3

SolarSystemwithAfter-HeatingbySolidFuelBoiler

with 1 tank, 4 sensors, 1 solar pump and 1 pump for afterheating.

S4

R2

Symbol Specification

S1 Collector Sensor

S2 Lower Tank Sensor

S3 Upper Tank Sensor

S4 Tank for Solid Fuel Boiler

R1 Solar Pump

R2 Pump for Solid

Fuel Boiler

1.2.9 Allocationofclampsforsystem9

Arr 9

S1

R1

S3

S2

SolarSystem andHeatingCircuitReverseRaising

with 1 tank, 4 sensors, 1 solar pump and 1 3-way-valve for

heating circuit reverse raising.

S4

R2

Symbol Specification

S1 Collector Sensor

S2 Lower Tank Sensor

S3 Upper Tank Sensor

S4 Heating Circuit Return

R1 Solar Pump

R2 3-Way-Valve

Page 10

SOM 7 SI

© 08042 som_7_si.monen.indd

| 10

!

2. Opeartion and function

2.1 Pushbuttons for adjustment

backward

2

1

3

(selection / adjustment mode)

SET

2.2 System monitoring display

forward

The controller is operated by the 3 keys below the display.

To enter the configuration mode toggle through the display

parameters by pressing and releasing key 1 until this no

longer causes the display to change. At this point press and

hold key 1 until the configuration parameters are displayed

(about 5 seconds), then quickly release the key to avoid toggling to the end of the parameter list. The first parameter in

the list is DT O. To change the setting of a given parameter,

follow the steps below.

1. Toggle to the parameter using keys 1 and/or 2. The

abbreviation for the parameter is displayed on the right

side of the screen, with the setting directly below, and the

set icon solid (not blinking) on the extreme right.

2. Press key 3. The set icon begins blinking signifying that

the parameter may now be adjusted.

3. Quickly use keys 1 and/or 2 to change the setting to

that which is required.

4. Press key 3 again. The set icon stops blinking signifying

that the new value has been stored.

The system display consists of an indication channel, a tool

bar, and the system screen. These are detailed below.

Monitoring-Display

2.2.1 Indication Channel

Indication channel

2.2.2 Tool bar

Toolbar only illustrated above

The indication channel consists of two lines. The upper

line is an alphanumeric 16-segment display, in which an

abbreviation of the current setting or reading is shown. In

the lower 7-segment display, the value of said reading or

setting is shown.

The additional symbols of the tool bar indicate the current

system status.

Symbol standard blinking

relay 1 active

relay 2 active

maximum tank limitation

active / maximum tank

temperature exceeded

antifreeze- function activated

+

+

collector cooling function or

reccoling function active

collector minimum limitation

or antifreeze function active

collector security shutdown or

tank securtiy shutdown active

sensor defect

manual operation active

an adjustment channel is

changed SET-mode

Page 11

© 08042 som_7_si.monen.indd

11 |

SOM 7 SI

2.2.3 System screen

System Screen only

The system screen (active system scheme) shows the

schemes selected on the controller. It consists of several

system component symbols, which are - depending on the

current status of the system - either flashing, permanently

shown or hidden.

Collector 1

Valve

Pumps

Sensors

Tank heat-exchanger

Collectors

with collector sensor

Tanks 1 and 2

with heat-exchanger

Collector 2

Tank

upper sensor tank

Heating circuit

Valve

Sensor

Additional symbol for

operation of the burner

Tank 2 or afterheating (with

an additional symbol)

Temperature sensor

Heatingcircuit

Pump

3-way-valve

The flow direction or the

current breaking capacity

is always shown.

Afterheating

with burner symbol

2.3 Blinkingcodes

2.3.1 System screen blinking codes

• Pumps are blinking during starting phase

• Sensors are blinking when their value is being displayed in

the indication channel.

• Sensors are quickly blinking in case of sensor defect.

Burner symbol is blinking if after-heating is activated•

2.3.2LEDblinkingcodes

Constantly green: Normal operation

Red/green blinking: Power-up phase

Manual operation

Red blinking: Sensor defect

(sensor symbol is quickly blinking)

Page 12

SOM 7 SI

© 08042 som_7_si.monen.indd

| 12

3. Primary commissioning

Forprimarycommissioningthesystemschemehastobeselectedrst

1. After AC power is supplied to the unit it goes through

its power up tests during which the control lamp is blinking

operating control lamp

backward

2

(selection / adjustment mode)

3

SET

1

forward

red and green. After this the unit is ready for configuration.

The unit‘s default system scheme is Arr. 1.

2. Clock time adjustment in channel TIME. By pressing the

button once you can adjust hours, pressing it

once again the minutes.The time can be adjusted by buttons

1 and 2 and saved by pressing the button.

3. - select adjustment channel Arr

- change into -mode (see 2.1)

- adjustment are saved by pressing button

Now the controller is ready for operation and should enable

an optimum operation of the solar system with the factory

settings.

Arr 1 Arr 2

Arr 3 Arr 4

Arr 5 Arr 6

Arr 7 Arr 8

Arr 9

System survey:

Arr 1 : Standard Solar System

Arr 2 : Solar System with Heat Exchange

Arr 3 : Solar System with After-Heating

Arr 4 : Solar System with Tank Charge in Layers

Arr 5 : 2-Tank Solar System with Valve Logic

Arr 6 : 2-Tank Solar System with Pump Logic

Arr 7 : Solar System with 2 Collectors and 1 Tank

Arr 8 : Solar System with After-Heating by Solid Hot Fuel

Boiler

Arr 9 : Solar System with Heating Circuit Reverse Raising

Page 13

© 08042 som_7_si.monen.indd

13 |

SOM 7 SI

4. Control parameter and indication channels

4.1 Channel-overview

Legend:

x

Corresponding channel is available.

x*

Corresponding channel is available if the appropriate option

is activated.

Please note:

S3 and S4 are only indicated in case of sensors connected

Corresponding channel is only available if the option Energy

Production Measurement is activated (OHQM).

Corresponding channel is only available if the option Energy

Production Measurement is deactivated (OHQM).

MEDT

The channel antifreeze content (MED%) is only shown

if the antifreeze is not water or Tyfocor LS / G-LS

(MEDT0or 3).Adjustments concerning the antifreeze

content will only make sense if the antifreeze is used in the

solar circuit.

Channnel

COL x x x x x x x x Temperature collector 1 15

COL 1 x Temperature collector 1 15

TST x x Temperature tank 1 15

TSTU x x x x Temperature tank 1 below 15

TST1 x x x Temperature tank 1 below 15

TSTO x x x x x Temperature tank 1 at the top 15

TST2 x x x Temperature tank 2 below 15

TFSB x Temperature solid hot fuel boiler 15

TRET x Temperature heating circuit 15

COL2 x Temperature collector 2 15

S3 x Temperature sensor 3 15

TRF

S4

hP x x x x Operating hours relay 1 16

h P1 x x x x x Operating hours relay 1 16

h P2 x x x x x Operating hours relay 2 16

kWh

MWh

time x Time 15

Arr 1-9 System 12

DT O x x x x x x Switch-on temperature diff 17

DT1O x x x Switch-on temperature diff 1 17

DT F x x x x x x Switch-off temperature diff 1 17

DT1F x x x Switch-off temperature difference 17

S MX x x x x x x Maximum temperature tank 1 17

S1 MX x x x Maximum temperature tank 1 17

DT2O x x x Switch-on temperature difference 2 17

DT2F x x x Switch-off temperature difference 2 17

S2MX x x x Maximum temperature tank 2 17

EM x x x x x x x x emergency temperature collector 1 18

EM1 x emergency temperature collector 1 18

1 2 3 4 5 6 7 8 9

Arr

Specification Page

Temperature return sensor 15

x x Temperature sensor 4 15

Heat quantity kWh 16

Heat quantity MWh 16

Page 14

SOM 7 SI

© 08042 som_7_si.monen.indd

| 14

Channel

OCX x x x x x x x x option collector cooling collector 1 18

OCX1 x option collector cooling collector 1 18

CMX x* x* x* x* x* x* x* x* maximum temperature collector 1 18

CMX1 x* maximum temperature collector 1 18

OKN x x x x x x x x option minimum limitation collector 1 18

OKN1 x option minimum limitation collector 1 18

CMN x* x* x* x* x* x* x* x* minimun temperature collector 1 18

CMN1 x* minimun temperature collector 1 18

OCF x x x x x x x x option antifreeze collector 1 18

OCF1 x option antifreeze collector 1 18

CFR x* x* x* x* x* x* x* x* antifreeze temperature collector 1 18

CFR1 x* antifreeze temperature collector 1 18

EM2 x emergency temperature collector 2 18

OCX2 x option collector cooling collector 2 18

KMX2 x* maximum temperature collector 2 18

OCN2 x option miminum limitation collector 2 18

CMN2 x* minium temperature collector 2 18

OCF2 x option antifreeze collector 2 18

CFR2 x* antifreeze temperature collector 2 18

PRIO x x x priority 19

tST x x x stop time 19

tRUN x x x Ciruclation time 19

OREC x x x x x x x x x option reccoling 19

O TC x x x x x x x x x option tube collector 19

DT3O x x switch-on temperature difference 3 17

DT3F x x switch-off temperature difference 3 17

MX3O x x switch-on treshold for maximum temp. 17

MX3F x x switch-off treshold for maximum temp. 17

MN3O x x switch-on treshold for minimum temp. 17

MN3F x x switch-off treshold for minimum temp. 17

AH O x switch-on temp. for thermostat 1 20

AH F x switch-off temp. for thermostat 1 20

OHQM x x x x option WMZ 16

FMAX

MEDT

MED% MEDT MEDT MEDT MEDT antifreeze content 16

t1 on x Switch on time 1 thermostat 20

t1 off x Switch off time 1 thermostat 20

t2 on x Switch on time 2 thermostat 20

t2 off x Switch off time 2 thermostat 20

t3 on x Switch on time 3 thermostat 20

t3 off x Switch off time 3 thermostat 20

HND1 x x x x x x x x x manual operation relay 1 20

HND2 x x x x x x x x x manual operation relay 2 20

LANG x x x x x x x x x Language 20

UNIT x x x x x x x x x Change over °FAH / °CEL 20

PROG XX.XX program number

VERS X.XX version number

1 2 3 4 5 6 7 8 9

Arr

Specification Page

maximum flow 16

antifreeze type 16

Page 15

© 08042 som_7_si.monen.indd

15 |

SOM 7 SI

4.1.1 Collector Temperatures

COL, COL1, COL2:

Collector Temperature

display range: -40 → +480°F

4.1.2 Tank Temperatures

TST, TSTL, TSTU,

TST1, TST2:

Tank Temperatures

Display range: -40 →+480 °F

4.1.3 Sensor 3 and Sensor 4 Temperatures

S3, S4:

S3, S4:

Sensor Temperatures

Display range: -40 →+480 °F

Shows the current collector temperature.

• COL : collector temperature (1-collector-system)

• COL1 : collector 1 temperature

• COL2 : collector 2 temperature

Shows the current tank temperature.

• TST : tank temperature (1-tank-system)

• TSTL : tank temperature, lower

• TSTU : tank temperature, upper

• TST1 : tank 1 temperature

• TST2 : tank 2 temperature

Shows the current temperature of the corresponding additional sensor (without control function).

• S3 : sensor 3 temperature

• S4 : sensor 4 temperature

Please note:

S3 and S4 are only shown if the temperature sensors are

connected.

4.1.4 Other Temperatures

TFSB,TRET,TRF:

O t h e r M e a s u r e d

Temperatures

Display range: -40 →+480 °F

4.1.5 Time

Shows the current temperature of the corresponding

sensor.

• TFSB : solid fuel boiler temperature

• TRET : heating reverse raising temperature

• TRF : return flow temperature

This channel stores and displays the current time in 24

hour format. To change the stored time, press the key 3 for

2 seconds. This causes the icon to blink and the hour

may be adjusted using keys 1 and 2. To adjust the minutes

press key 3 again. The icon continues to blink, but keys

1 and 2 now cause the minutes to change. Pressing key 3

again causes the displayed value to be stored.

Page 16

SOM 7 SI

© 08042 som_7_si.monen.indd

| 16

4.1.6 Operating hours counter

h P / h P1 / h P2:

Operating Hours Counter

Indication channel

4.1.7 Energy Production Measurement

OHQM: Energy Production

Measurement. Adjustment

range: OFF/ON

Factory setting: OFF

FMAX:

Volumetric flow rate in l/min

Adjustment range 0 - 20

in steps of 0.1

Factory setting 6.0

The operating hours counter adds up the solar operating

hours of the respective relay (h P / h P1 / hP2). The total

amount of hours which the relay has been active is shown

on the display.

The operating hours total can be reset. As soon as the operating hours channel is selected, the symbol is displayed

solid. To reset the operating hours press and hold the middle

key (key 3) for approximately 5 seconds. The set symbol

blinks. Press key 3 again and the operating hours counter

is reset to 0.

In order to interrupt the RESET-procedure, don’t press

any button for about 5 seconds. The controller returns

automatically into the display mode.

A measurement of the system’s energy production is possible in conjunction with a flowmeter and an additional

sensor which measures the heat exchanger’s return temperature. Activate this option by changing the value of

OHQMto “on”.

Adjust this setting to the maximum flow rate of the system

in liters per minute. This is necessary in order to calculate

the system‘s actual energy output. Some controllers have

an additional parameter, FMXG, which is the flow rate in

gallons per minute.

MEDT: Type of antifreeze

Adjustment range 0 - 3

Factory setting 1

MED%: Concentration of

antifreeze in (Vol-) %

MED% is blinded out by

MEDT 0 and 3.

Adjustment range 20 - 70

Factory setting 45

kWh/MWh:Energy production in kWh / MWh

Display channel

Type of antifreeze:

0 : water

1 : propylene glycol

2 : ethylene glycol

3 : Tyfocor® LS / G-LS

The energy produced by the system is measured by the

calculation of the volume of heat exchanger fluid moved

through the system and a comparison of the temperature

of the fluid leaving the collector (S1) with that of the fluid

exiting the storage tank‘s heat exchanger (S4). It is shown

in kWh in one channel and MWh in another.

The total energy produced can be reset. As soon as one of

the display channels of the heat quantity is selected, the sym-

bol is displayed solid. To reset the total energy produced

press and hold the middle key (key 3) for approximately 5

seconds. The set symbol blinks. Press key 3 again and the

total energy produced is reset to 0..

In order to interrupt the RESET-procedure, no button

should be pressed for about 5 seconds. The controller returns automatically into indication mode.

Page 17

© 08042 som_7_si.monen.indd

17 |

SOM 7 SI

4.1.8∆T-regulation

DTO/ DT1O/ DT2O/

DT3O:

Switch-on temperature

differential

Adjustment range

2.0 - 40.0 °F

Factory setting 12.0

DTF/ DT1F/ DT2F/DT3F:

Switch-off temperature

differential

Adjustment range

1.0 - 38.0 °F

Factory setting 8.0 °F

Please note: Switch-on temperature difference DT O must

be at least 2 °F higher than the switch-off tempe raturedifference DT F.

4.1.9MaximumTankTemperature

Primarily the controller works in the same way as a standard

differential controller. If the switch-on difference (DTO/

DT1O/DT2O/DT3O) is sensed, the pump is activated.

If the adjusted switch-off temperature is measured (DTF/

DT1F/DT2F/DT3F), the controller switches-off.

SMX/ S1MX/S2MX:

Maximum storage tank temp.

Adjustment range: 40 - 205 °F

Factory setting 140 °F

4.1.10 ∆T-controller (solid fuel boiler and heat exchange)

MaximumTemperatureLimitation

MX3O/MX3F:

Maximum temperature limitation

Adjustment range

MX3O 137 - 205°F

MX3F30 - 136°F

Factorysettings

MX3O 140°F

MX3F 136°F

Minimum Temperature Limitation

MN3O/MN3F:

Minimum Temperature

Limitation

Adjustment range

Arr 2

MN3O 30 - 49°F

MN3F 41 - 195°F

Arr 8

MN3O 30 - 149°F

MN3F 141 - 195°F

Factorysettings

Arr 2

MN3O 40°F | MN3F 50°F

Arr 8

MN3O 140°F |MN3F 150°F

If the adjusted maximum temperature is exceeded, a further

loading of the store is stopped so that a damaging overheating

can be avoided. If the maximum store temperature is

exceeded, the symbol is displayed.

Please note: The controller is equipped with a securityswitch-off of the storage tank, which will not allow further

loading of the tank if it reaches 205 °F.

The Maximum Temperature Limitation regulates the

temperatures at which the second differential switch-on

temperature (DT3O) will operate. This feature is only

available if Arr 2 or Arr 8 is selected (for solid fuel boilers

or heat exchange regulation).

If the relavent sensor measures a temperature greater than

MX3O, relay 2 is disabled. Relay 2 will not be enabled

again until a temperature less than MX3F is reached.

Reference sensor:

S3 by Arr 8 (TSTU)

S4 by Arr 2 (TST2)

The Minimum Temperature Limitation also works in

co njunction with the second di ffe rential swi tch-on

temperature (DT3O). If the relavent sensor measures

a temperature less than MN3O, relay 2 will be disabled.

Relay 2 will not be enabled again until a temperature greater

than MN3F is measured. by the relavent sensor.

Reference sensor:

S4 by Arr 8 (TFSB)

S3 by Arr 2 (TSTU)

Page 18

SOM 7 SI

© 08042 som_7_si.monen.indd

| 18

4.1.11 Collector Emergency Shutdown

Temperature

EM / EM1 / EM2:

Collector Emergency

Shutdown Temperature

Adjustment range

230 - 400 °F,

Factory setting 285 °F

4.1.12 SystemCoolingFunctions.

OCX/ OCX1/OCX2:

System Cooling

Adjustment range OFF/ON

Factory setting OFF

If the collector emergency shutdown temperature (EM/

EM1/EM2) is reached, the solar pump (R1/R2) is deactivated

in order to avoid damaging the solar components. The default

setting is 285°F. If the system is in emergency shutdown

mode the symbol is flashing. The system will not exit this

mode until the temperature measured is 30°F lower than

the value of this setting.

The system cooling function is used to prevent the system‘s

heat exchanger fluid from overheating. This in turn prevents

the degradation of the fluid‘s corrosion inhibitors avoiding

damage to the system components. If the system cooling

function is activated the symbol is flashing.

CMX/ CMX1/CMX2:

Maximum Collector

Temperature

Adjustment range:

210 - 380 °F

Factory setting 250 °F

4.1.13 Minimum Collector Temperature Limit

OCN / OCN1 / OCN2:

Collector Minimum

Temperature Limitation

Adjustment range OFF/ON

CMN / CMN1 / CMN2:

Collector Minimum

Temperature

Adjustment range 50 - 195°F

Factory setting 50°F

If the maximum collector temperature (CMX/CMX1/

CMX2) is reached the maximum storage tank temperature

(SMX/S1MX/S2MX) is overridden and the system‘s

circulator pump is turned on, cooling the system‘s HX fluid

using the water in the storage tank. This will continue until

either the collector temperature is measured to be at least

9°F lower than the setting of “CMX/CMX1/CMX2”, the

tank reaches it’s 205°F security-switch-off temperature, or

the collector reaches its collector emergency shutdown

temperature. The last two instances should not occur if the

system is sized and configured properly.

The minimum collector temperature is a temperature which

must be exceeded in order for the solar pump (R1/R2) to

be switched-on. The minimum temperature setting is used to

avoid starting-up the solar pump (or solid fuel boiler charging

pumps) when the temperature of the heat exchanger fluid

is too low. If the minimum temperature feature is activated

the symbol is shown on the display (blinking).

4.1.14 AntifreezeFunction

OCF/ OCF1/OCF2:

Antifreeze Function

Adjustment range OFF/ON

Factory setting OFF

CFR/CFR1/ CFR2:

Antifreeze Temperature

Adjustment range 15 - 50°F

Factory setting 40°F

The antifreeze function activates the loading circuit between

collector and tank if the antifreeze temperature is reached

in order to protect the heat exchanger fluid against freezing

or “thickening“. If the antifreeze temperature is exceeded

by 2°F, the loading circuit will be deactivated.

Please note:

As there is only a limited heat quantity of the tank available

for this function, the antifreeze function should only be used

in regions with few days of temperatures around freezing

point.

Page 19

© 08042 som_7_si.monen.indd

19|

SOM 7 SI

4.1.15 Oscillating Charge

RespectiveAdjustmentValues:

Factorysetting Adjustmentrange

Priority [PRIO] (1 / Arr 5,6) (2 / Arr 4) 0-2

OscillatingBreakTime[tST] 2 min. 1-30 min.

Oscillating Charge Time [tRUN] 15 min. 1-30 min.

SOM 7 SI Priority Logic

Tank Priority:

OscillatingBreakTime/OscillatingChargeTime/

Collector Rising Temperature

The above oscillating charge parameters are only available

in multi-tank or layered charge systems (Arr 4, 5 and

6). If Tank Priority is set to 0, the tanks which show a

temperature difference towards the collector are loaded in

numerical order (tank 1 or tank 2). Usually only one tank

is loaded at this point. For Arr= 5, 6 parallel loading is also

possible.

The controller checks the tanks regarding loading facilities

(switch-on difference). If the priority tank cannot be loaded,

the lower-ranking tank is checked. If the lower-ranking tank

can be charged this is effected by the so-called “oscilating

charge time” (tRUN).When the oscillating charge time is

over the loading is stopped. The controller regulates the

increase of the collector temperature. If it increases by the

collector rising temperature (∆T-Col 4°F, fixed software

value), the expired break time is again reset to zero and the

oscillating break time starts again. If the switch-on conditions

of the priority tank are not reached, the loading of the

lower-ranking tank is continued. If the priority switch has

reached its maximum temperature, the oscillating charge is

not effected.

This setting is designed to be used in conjunction with the

4.1.16 Recooling function

OREC:

Recooling Option

adjustment range

OFF / ON

Factory setting: OFF

4.1.17 Tube collector special function

O TC:

Tube Collector Function

Adjustment range:

OFF / ON

Factory setting: OFF

System Cooling Function, which overrides the maximum

store temperature (SMX,S1MX,S2MX) when used.

This function will cool the tank back down to its maximum

temperature when the collector temperature becomes

low enough to facilitate such. This prevents a cumulative

overheating condition if the cooling function needs to be

used multiple days in a row. In order to utilize this function

with tube collectors, a heat rejection loop (heat dump) is

necessary.

If the controller measures an increase of 4 °F compared to

the collector temperature which was last stored, the solar

pump is switched-on for about 30 seconds. After the solar

pump is deactivated the current collector temperature is

stored as new reference value. If the measured temperature

(new reference value) is again exceeded by 4 °F, the solar

pump again switches-on for 30 seconds. If the switch-on

differential is reached during any of these processes the

controller automatically switches over to solar charging.

If the collector temperature drops by 4 °F while the system

fluid is stagnant, the switch-on value for the special tube

collector function will be recalculated.

Page 20

SOM 7 SI

© 08042 som_7_si.monen.indd

| 20

4.1.18ThermostatFunction(Arr = 3)

Afterheating

AHO:

Thermostat

Switch-on Tem perature

Adjustment range 30 - 205°F

Factory setting 105°F

AHF:

Thermostat

Switch-off Tem pe rature

Adjustment range 30 - 205°F

Factory setting 115°F

use of surplus energy

The thermostat function is independent from the solar loop’s

differential switching temperatures and can be used either

to control a backup heating source such as a boiler, or to

send some of the tank’s excess thermal energy to a heating

loop or heat dump. Whis one it does is dependent upon the

settings AHOandAHF.

• If AHO< AHF

The thermostat function is used to add heat to the

tank using a back up heating source.

• If AHO > AHF

The thermostat function is used to remove the tank’s

excess thermal energy.

Symbol will be shown on the display if the second

relay output is activated.

t1 E, t2 E, t3 E:

Thermostat switch-on time

Adjustment range:

00:00 - 23:45

Factory setting: 00:00

4.1.19 OperatingMode

HND1/HND2:

Operating Mode

Adjustment range:

OFF, AUTO, ON

Factory setting: AUTO

4.1.20 Language

LANGUAGE

Language Setting

Adjustment range:

dE, En, It, Fr

Factory setting: En

t1 A, t2 A, t3 A:

Thermostat switch-off time

Adjustment range:

00:00 - 23:45

Factory setting: 00:00

In order to block the thermostat function for a certain time

span, there are 3 time frames t1, t2 and t3. If, for example,

the function should be activated only between 6:00 and

9:00, t1 E should be set to 6:00 and t1 A should be set for

9:00. If all of the thermostat time functions are set to 00:00,

the themostat function will be in continuous operation.

(factory setting).

For control and service work the operating mode of the

controller can be manually adjusted by selecting the adjustment value HAND, in which the following settings are

available.

• HND1/HND2

Operating mode

OFF : relay off (blinking) +

AUTO : relay in automatic operation

ON : relay on (blinking) +

The menu language can be adjusted in this channel.

• dE : German

• En : English

• It : Italian

• Fr : French

4.1.21 UnitsforTemperatureDisplay

UNIT:

Temperature Display Units

Adjustment range:

FAH, CEL

Factory setting: FAH

The menu unit can be adjusted:

• °FAH

• °CEL

Page 21

© 08042 som_7_si.monen.indd

21 |

SOM 7 SI

4.2 Recommended Settings for any System Scheme

Below is a list of important settings which must be changed from their default value no matter what system

scheme (Arr. 1 - Arr. 9) is being used. Any time the system scheme is changed these values need to be

reset to the below values. If this is not done there is a very good chance that the system will overheat and

thus be in need of time consuming and possibly costly repairs.

Display

Code

EM

OCX

CMX

OREC

Below is a list of the recommended switch-on and switch-off settings for the controller. These options are

available on all 9 system schemes. These settings also need to be reset to the below values whenever the

system scheme (Arr. 1 - Arr. 9) is changed. Advanced users may want to set these differently depending on

the circumstances.

Parameter Name

and Reference

Collector Emergency

Shutdown Temperature

(p. 18)

System Cooling

Function (p. 18)

Maximum Collector

Temperature (p. 18)

Recooling Function

(p. 19)

RecommendedSettingandExplanation

(All temperatures in °F)

310° This prevents the HX fluid directly behind that in the

sensor well from causing the system to go into emergency

shutdown mode as soon as the cooling function is activated.

On Failure to change this option to ‘on’ will likely result in

overheating of the system at some point.

230° Having a relatively large ΔT between CMX and EM

prevents the HX fluid directly behind that in the sensor well

from causing the system to go into emergency shutdown mode

as soon as the cooling function is activated.

On This prevents a cumulative overheating of the system by

ensuring a relatively high Δt between the tank temperature and

and the security switch-off of the tank (205°).

Display

Code

DT O

DT F

Parameter Name

and Reference

Switch on Temperature

Difference (p. 17)

Switch off Temperature

Difference (p. 17)

RecommendedSettingandExplanation

(All temperatures in °F)

15° Setting this too low can cause the circulator to cycle on and

off too frequently.

5° Too high of a ΔT between DT O and DT F can cause the

circulator to switch on and off too frequently.

Page 22

SOM 7 SI

© 08042 som_7_si.monen.indd

| 22

4.2.1RecommendedSettingsforStandardDHWSystem(Arr.1)

Display

Code

DT O

DT F

S MX

EM

OCX

CMX

OCN

Parameter Name

and Reference

Switch on Temperature

Difference (p. 17)

Switch off Temperature

Difference (p. 17)

Maximum Store

Temperature (p. 17)

Collector Emergency

Shutdown Temperature

(p. 18)

System Cooling

Function (p. 18)

Maximum Collector

Temperature (p. 18)

Minimum Collector

Temperature (p. 18)

RecommendedSettingandExplanation

(All temperatures in °F)

15° Setting this too low can cause the circulator to cycle on and

off too frequently.

5° Too high of a ΔT between DT O and DT F can cause the

circulator to switch on and off too frequently.

140° This will prevent the temperature at the top of the tank

from getting hot enough to cause the T & P valve to release.

This will also allow the cooling function to operate effectively.

310° This prevents the HX fluid directly behind that in the

sensor well from causing the system to go into emergency

shutdown mode as soon as the cooling function is activated.

On Failure to change this option to ‘on’ will likely result in

overheating of the system at some point.

230° Having a relatively large ΔT between CMX and EM

prevents the HX fluid directly behind that in the sensor well

from causing the system to go into emergency shutdown mode

as soon as the cooling function is activated.

Off The ΔT between DT O and DT F achieves the requisite

effect for most situations.

OCF

OREC

O TC

OHQM

HND1

LANG

UNIT

Please note that advanced users may desire to adjust certain parameters differently depending

on the circumstances. These suggested settings are merely a manner in which to congure the

unit that will avoid damage to the system from overheating. Installing the SOM 7 with the default

settings will likely result in an overheating condition of the solar system.

Antifreeze Option

(p. 18)

Recooling Function

(p. 19)

Tube Collector

Function (p. 19)

Energy Production

Measurement (p. 16)

Circulator Pump

Operating Mode (p. 20)

Language (p. 20)

Units for Temperature

Display (p. 20)

Off Unless the system is located in a region which rarely

experiences temperatures near freezing, and a very low glycol

to water percentage is being used.

On This prevents a cumulative overheating of the system by

ensuring a relatively high Δt between the tank temperature and

and the security switch-off of the tank (205°).

Off Unless the system is utilizing tube collectors.

Off Unless the installer has installed a sensor in position S4 and

wishes to utilize this function.

Auto This is the normal operating mode. The other two

modes are for testing, charging, etc.

En (English) For most applications in North America this is

appropriate, with some exceptions.

FAHFor most applications in North America this is

appropriate, but it is purely a matter of preference.

Page 23

© 08042 som_7_si.monen.indd

23 |

SOM 7 SI

4.2.2RecommendedSettingsforStandardDHWSystemwithBoilerBackup(Arr.3)

Display

Code

DT O

DT F

S MX

EM

OCX

CMX

OCN

Parameter Name

and Reference

Switch on Temperature

Difference (p. 17)

Switch off Temperature

Difference (p. 17)

Maximum Store

Temperature (p. 17)

Collector Emergency

Shutdown Temperature

(p. 18)

System Cooling

Function (p. 18)

Maximum Collector

Temperature (p. 18)

Minimum Collector

Temperature (p. 18)

RecommendedSettingandExplanation

(All temperatures in °F)

15° Setting this too low can cause the circulator to cycle on and

off too frequently.

5° Too high of a ΔT between DT O and DT F can cause the

circulator to switch on and off too frequently.

140° This will prevent the temperature at the top of the tank

from getting hot enough to cause the T & P valve to release.

This will also allow the cooling function to operate effectively.

310° This prevents the HX fluid directly behind that in the

sensor well from causing the system to go into emergency

shutdown mode as soon as the cooling function is activated.

On Failure to change this option to ‘on’ will likely result in

overheating of the system at some point.

230° Having a relatively large ΔT between CMX and EM

prevents the HX fluid directly behind that in the sensor well

from causing the system to go into emergency shutdown mode

as soon as the cooling function is activated.

Off The ΔT between DT O and DT F achieves the requisite

effect for most situations.

OCF

OREC

O TC

AH O

AH O

t1 0-t3 F

OHQM

HND1

Antifreeze Option

(p. 18)

Recooling Function

(p. 19)

Tube Collector

Function (p. 19)

Thermostat Switch-On

Temperature (p. 20)

Thermostat Switch-Off

Temperature (p. 20)

Thermostat Switching

Times (p. 20)

Energy Production

Measurement (p. 16)

Solar Pump Operating

Mode (p. 20)

Off Unless the system is located in a region which rarely

experiences temperatures near freezing, and a very low glycol

to water percentage is being used.

On This prevents a cumulative overheating of the system by

ensuring a relatively high Δt between the tank temperature and

and the security switch-off of the tank (205°).

Off Unless the system is utilizing tube collectors.

115 Or whatever temperature the user wants the boiler to

begin heating the tank water via the upper heat exchanger.

125 Or whatever temperature the user wants the boiler to

stop heating the tank water via the upper heat exchanger.

00:00 Unless there are certain times in the day when the boiler

loop should not switch on.

Off Unless the installer has installed a sensor in position S4 and

wishes to utilize this function.

Auto This is the normal operating mode. The other two

modes are for testing, charging, etc.

HND2

LANG

Boiler Loop Operating

Mode (p. 20)

Language (p. 20)

Auto This is the normal operating mode. The other two

modes are for testing, charging, etc.

En (English) For most applications in North America this is

appropriate, with some exceptions.

Page 24

SOM 7 SI

© 08042 som_7_si.monen.indd

| 24

R

W

Ta co

S R 501

(T ypic al Wiring)

N

H

6

N/O

5

B oiler C ontrol

B oard

Thermostat

Input

S OM 7

15

16

Display

Code

UNIT

Parameter Name

and Reference

Units for Temperature

Display (p. 20)

RecommendedSettingandExplanation

(All temperatures in °F)

FAHFor most applications in North America this is

appropriate, but it is purely a matter of preference.

Please note that advanced users may desire to adjust certain parameters differently depending

on the circumstances. These suggested settings are merely a manner in which to congure the

unit that will avoid damage to the system from overheating. Installing the SOM 7 with the default

settings will likely result in an overheating condition of the solar system.

4.2.2.1SOM7WiringDiagramforConnectiontoColdStartBoiler

In order to interface the SOM 7 with the boiler control board of a typical boiler (which does

not heat up the boiler water unless a zone calls for heat) it is necessary to incorporate a

relay circuit. Below is a wiring diagram in which a commonly used single zone controller in

conjunction with a SOM 7 is controlling such a boiler.

Page 25

© 08042 som_7_si.monen.indd

25 |

SOM 7 SI

12

S1 S2 S3

3456

Temp. Sensor Pt1000

LNR1NR2N

201918171615

S4

78

141312

DE - 45527 Hattingen

DeltaSol BS Plus

2 (1) A 1152V~

(1) A 115V~

R1

R2

T4A

115V~

CU 72060171 01

UL 60730-1A:2002

CSA E60730.1:2002

VBus

910

5. Troublesooting Tips

If a malfunction occurs, it will be indicated on the display of

the controller:

°F Ω °F Ω

14 961 131 1213

23 980 140 1232

32 1000 149 1252

41 1019 158 1271

50 1039 167 1290

59 1058 176 1309

68 1078 185 1328

77 1097 194 1347

86 1117 203 1366

95 1136 212 1385

104 1155 221 1404

113 1175 230 1423

122 1194 239 1442

Resistance values of the

Pt1000-sensors

Warning symbol

Operating control lamp

Symptom Possible Cause and Remedies List

Operating control lamp flashes red. The

symbol is displayed and the symbol is flashing.

The indication channel of the relevent sensor

displays 888.8 instead of the temperature.

SOM unit is sensing an open circuit condition.

Measure the resistance between the two terminals to which 1.

the relevent sensor is attached. If it measures infinite resistance continue to step 2. If it measures a resistance within

range of the above chart, call for service.

Disconnect the sensor wire from the terminals and measure 2.

the resistance between the two wires. If it still measures infinite resistance continue to step 3. If it measures a resistance

within range of the above chart, there is a problem with the

connection from the sensor wire to the terminal.

This problem lies either with the sensor or the wire/connec-3.

tions. In order to determine whether the problem lies with

the sensor itself, the sensor must be disconnected from any

extension wire and its resistance must be measured. If, when

the sensor is disconnected, the resistance is measured to be

within the values of the resistance chart the problem is with

the extension wire/connections.

Page 26

SOM 7 SI

© 08042 som_7_si.monen.indd

| 26

Symptom Possible Cause and Remedies List

Operating control lamp flashes red. The

symbol is displayed and the symbol is flashing.

The indication channel of the relevent sensor

displays -88.8 instead of the temperature.

Operating control lamp is off and screen is blank. SOM unit’s control board is not receiving power.

Collector is much hotter than the storage tank,

but the system’s circulator is not on.

SOM unit is sensing a short circuit condition.

Measure the resistance between the two terminals to which 1.

the relevant sensor is attached. If it measures a resistance

close to zero continue to step 2. If it measures a resistance

within range of the above chart, call for service.

Disconnect the sensor wire from the terminals and measure 2.

the resistance between the two wires. If it still measures a

resistance close to zero continue to step 3. If it measures a

resistance within range of the above chart, there is a problem

with the connection from the sensor wire to the terminal.

This problem lies either with the sensor or the wire/connec-3.

tions. In order to determine whether the problem lies with

the sensor itself, the sensor and its 4’ wire which was factory

installed must be disconnected from any extension wire and

its resistance must be measured. If, when the sensor is disconnected, the resistance is measured to be within the values of

the resistance chart the problem is with the extension wire/

connections.

HAZARDOUSVOLTAGEPRESENT!

Measure the voltage between terminals 19 and 20. If the volt-1.

age is close to the nominal voltage of 120 VAC, continue to

step 2. If the voltage is not correct, the problem lies with the

power supply to the unit.

Remove the unit’s can fuse and measure its resistance. If the 2.

resistance is close to zero, call for service. If infinite resistance

is measured, replace the fuse.

Compare the tank’s present temperature with its maximum 1.

setting (SMX). If the storage tank is within 4 degrees of this

setting the circulator pump will not turn on even if the switch

on temperature has been reached unless the System Cooling

Function (OCX) is turned on and the Maximum Collector

Temperature (CMX) has been reached.

Check to see if the 2. symbol is blinking. If this is the case the

system is in Emergency Shutdown Mode. Either the collector

sensor measured a temperature equal to or greater than the

Collector Emergency Shutdown Temperature (step 3), or the

store sensor measured a temperature of at least 205 °F (step

4).

If the system has reached the Collector Emergency Shut-3.

down Temperature, the controller’s configuration needs to be

checked. Is the cooling function (OCX) set to on? Is there

a sufficiently large ΔT between the Maximum Collector

Temperature (CMX) and the Collector Emergency Shutdown

Temperature (EM)? To get the system to exit emergency

shutdown mode the EM setting must be at least 30 °F greater

than the measured collector temperature.

If the storage tank has reached its emergency shutdown tem-4.

perature (205 °F), the circulator will not turn on unless the

store sensor measures a temperature of 201 °F or less. This

parameter is not adjustable.

Page 27

© 08042 som_7_si.monen.indd

27 |

SOM 7 SI

Symptom Possible Cause and Remedies List

LED is blinking red and green. Check the Circulator Pump Operating Mode, HNDx. This 1.

Tank temperature cools excessively overnight. Make sure that the check valve between the upper port of 1.

Circulator pump is running, collector is much

hotter than store, but the tank fails to heat up.

should be set to “auto”. If it is set to either “on” or “off” the

unit will flash red and green, the symbol will flash and the

symbol will be displayed.

If the unit is in its power up mode this condition is normal.2.

the lower heat exchanger and the output of the solar array is

installed and functioning properly.

Check all configuration settings (see section 4.2).2.

Make sure that all system components are properly insulated.3.

Make sure that the controller is actually powering the circula-1.

tor. Is the symbol displayed in the tool bar? If not, check all

configuration settings (see section 4.2). Otherwise continue to

step 2.

HAZARDOUSVOLTAGEPRESENT!

Check for 120 VAC between terminals 17 and 18. If the 2.

symbol is displayed and there is not 120 VAC between these

two terminals, call for service.

Check the system’s flow meter. Is the system getting the 3.

proper voumetric flow rate required by the collectors? If not,

try adjusting the system’s flow adjustment valve (if present).

If the system is getting no flow even though the circulator is 4.

running there is either an obstruction in the collector loop, or

there is air in the system. If the system recently experienced

an overheating condition, the problem is most likely the latter

and the system needs to be purged. There is also a possibility

that the circulator pump itself is defective.

Page 28

SOM 7 SI

6. Warranty

WARRANTY

RESIDENTIAL & COMMERCIAL WARRANTY: STIEBEL ELTRON WARRANTS TO THE ORIGINAL OWNER THAT THE

SOM 7 CONTROLLER WILL BE FREE FROM DEFECTS IN WORKMANSHIP AND MATERIALS FOR A PERIOD OF TWO

(2) YEARS FROM THE DATE OF PURCHASE. SHOULD THE PART(S) PROVE TO BE DEFECTIVE UNDER NORMAL USE

DURING THIS PERIOD, STIEBEL ELTRON, INC. WILL BE RESPONSIBLE FOR REPLACEMENT OF THE DETECTIVE PART(S)

ONLY. STIEBEL ELTRON, INC. IS NOT RESPONSIBLE FOR LABOR CHARGES TO REMOVE AND/OR REPLACE THE DEFECTIVE PART(S), OR ANY INCIDENTIAL OR CONSEQUENTIAL EXPENSES.

SHOULD THE OWNER WISH TO RETURN THE SOM 7 CONTROLLER FOR REPAIR, THE OWNER MUST FIRST SECURE

WRITTEN AUTHORIZATION FROM STIEBEL ELTRON, INC. THE OWNER SHALL BE REQUIRED TO SHOW PROOF

OF PURCHASE DATE, AND TO PAY ALL TRANSPORTATION COSTS TO RETURN THE DEFECTIVE PART(S) OR SOM

7 CONTROLLER. WARRANTY IS VOID IF SOM 7 CONTROLLER HAS BEEN INSTALLED OR USED IMPROPERLY OR IF

DESIGN HAS BEEN ALTERED IN ANY WAY.

Stiebel Eltron, Inc.

17 West Street

USA - West Hatfield, MA 01088

Phone: (413) 247-3380

Fax: (413) 247-3369

info@stiebel-eltron-usa.com

Distributed by:

Comments:

The design and the specifications can be changed without advance notice.

The illustrations can differ from the production model.

| 28

© 08042 som_7_si.monen.indd

Loading...

Loading...