STIEBEL ELTRON SOM 7 PLUS Operation And Installation

OPERATION AND INSTALLATION

SOLAR CONTROLLER

» SOM 7 PLUS

!

ATTENTION: INSTALLING THE CONTROLLER WITH THE

DEFAULT SETTINGS IS NOT RECOMMENDED. IN

ORDER TO PREVENT OVERHEATING OF THE SYSTEM

HEAT EXCHANGER FLUID OR DOMESTIC HOT WATER

THE SETTINGS “OCC” AND “OSTC” SHOULD BE SET

TO “ON” AND THE SETTING “EM” SHOULD BE RAISED

TO 290 °F.

2

Safety advice:

Please read the following information carefully before

installing and operating the controller. In this way damage

to the solar system caused by wrong installation will be

avoided. Please make sure that the mounting is adapted to

the characteristics of the building, that the local regulations

are respected and is conform with the technical rules.

Description of symbols

Signal words describe the danger that may occur, when it is

not avoided.

Warning means that injury, possibly life-threatening injury,

can occur.

Attention means that damage to the appliance can occur.

Information about the product

Proper usage

The solar controller is designed for use in solar thermal

and heating systems in compliance with the technical data

specified in these instructions.

Improper use excludes all liability claims.

Note

Strong elec tromagnetic f ields can impair the

function of the controller.

Î Make sure the controller as well as the system

are not exposed to strong electromagnetic

fields.

WARNING! Warnings are indicated with a warning

triangle!

They contain information on how to

avoid the danger described.

Note

Notes are indicated with an i nformat ion

symbol.

Subject to technical change. Errors excepted.

Please pay attention to the following safety advice in order to

avoid danger and damage to people and property.

Instructions:

Attention should be paid to

• valid national and local standards and regulations

• respective valid standards and directives

Equipment to be installed and used in accordance with the

rules of the National Electrical Code (NEC) or with Canadian

Electrical Code (CEC), Part I.

These instructions are exclusively addressed to authorized

skilled personnel.

• Only qualified electricians should carry out installation

and maintenance work.

• Initial installation should be carried out by qualified personnel

Î Arrows indicate instruction steps that should be carried

out.

General

Contents

General .............................................................................2

Overview ...........................................................................3

1. Installation ..................................................................4

1.1 Mounting ..................................................................... 4

1.2 Electrical connection ....................................................4

1.3 Data communication/ Bus ............................................5

1.4 Terminal allocation in the different system layouts ....... 6

System layout 1 ............................................................ 6

System layout 2 ............................................................ 8

System-specific functions .......................................... 10

System layout 3 .......................................................... 12

System-specific functions .......................................... 14

System layout 4 .......................................................... 16

System layout 5 .......................................................... 18

System layout 6 .......................................................... 20

System layout 7 .......................................................... 22

System layout 8 .......................................................... 24

System-specific functions .......................................... 26

System layout 9 .......................................................... 28

System layout 10 ........................................................ 30

2. Operation and function ..............................................32

2.1 Push buttons .............................................................. 32

2.2 System monitoring display ......................................... 32

2.3 Flashing codes ........................................................... 33

3. Commissioning........................................................... 34

4. Channel overview ...................................................... 37

4.1 Display channels ........................................................ 37

4.2 Adjustment channels .................................................. 39

5. Troubleshooting ......................................................... 47

5.1 Various ...................................................................... 48

3

!

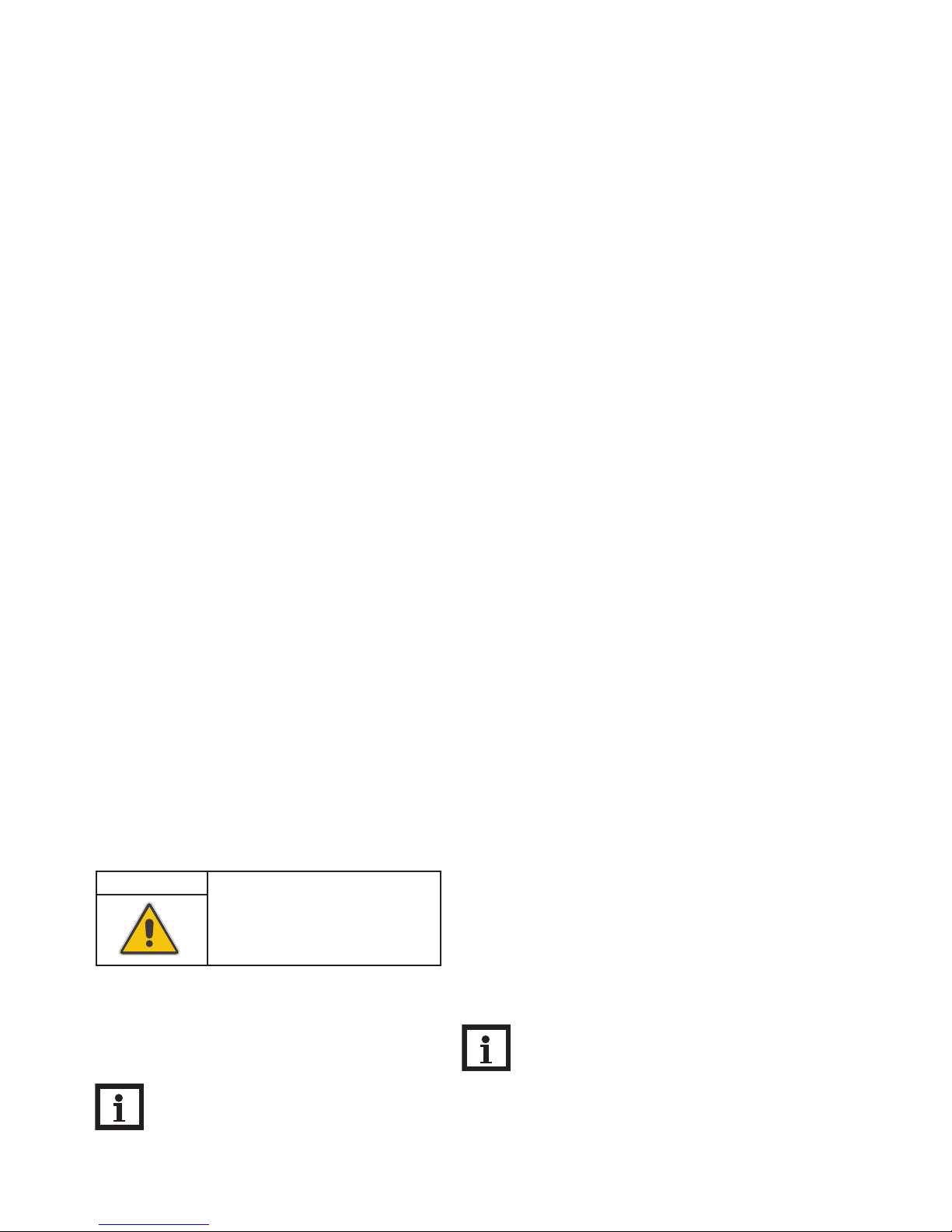

• System-monitoring-display

• Up to 4 Pt1000 temperature sensors

• 2 semiconductor relays for pump speed control

• 10 basic system layouts to choose from

• Energy metering

• VBus

®

• Function control

• Thermostat function (time controlled)

• Control of the system by ServiceCenter

software possible

• User-friendly operation

• Housing with outstanding design

• Extra-low power consumption

2.6"

66 mm

4.3"

110 mm

6.8"

172 mm

1.1"

28 mm

0.4" / 11 mm

1.9" / 47 mm

0.5" / 13 mm

6.1"

155 mm

Included with the SOM 7 plus:

1 × SOM 7 plus

1 × accessory bag

1 × spare fuse T4A

2 × screws and wall plugs

4 × strain relief and screws

1 × manual

Additionally enclosed in the full kit:

4 × sensor PT 1000

1 x heat conducting paste

Technical data

Housing: plastic, PC-ABS and PMMA

Protection type: IP 20 / EN 60529

Ambient temp.:

32 ... 104 °F

[0 ... 40 °C]

Size:

6.8" × 4.3" × 1.9"

172 × 110 × 46 mm

Mounting: wall mounting, mounting into

patch-panels is possible

Display: System screen for syste m

visualization, 16 -segment disp lay,

7-segment display, 8 symbols for system

status and operating control lamp

Operation: by 3 push buttons at the front

of the housing

Functions: Differential temperature

controller with optional add-on system

functions. Func ti on con trol, operating

hours counter for solar pump, evacuated

tube collector function, pump speed

control, thermostat function, drainback

and booster option, and energy metering.

Inputs:

for 4 Pt1000 temperature sensors

Outputs: 2 semiconductor relays

Bus: VBus

®

Power supply:

100 ... 240 V~

Standby power consumption:

< 1 W

Switching capacities:

R1: 1 (1) A 100 ... 240 V~

(semiconductor relay)

R2: 1 (1) A 100 ... 240 V~

(semiconductor relay)

Overview

4

display

push button

fuse 4A

cable conduits with strain

relief

cover

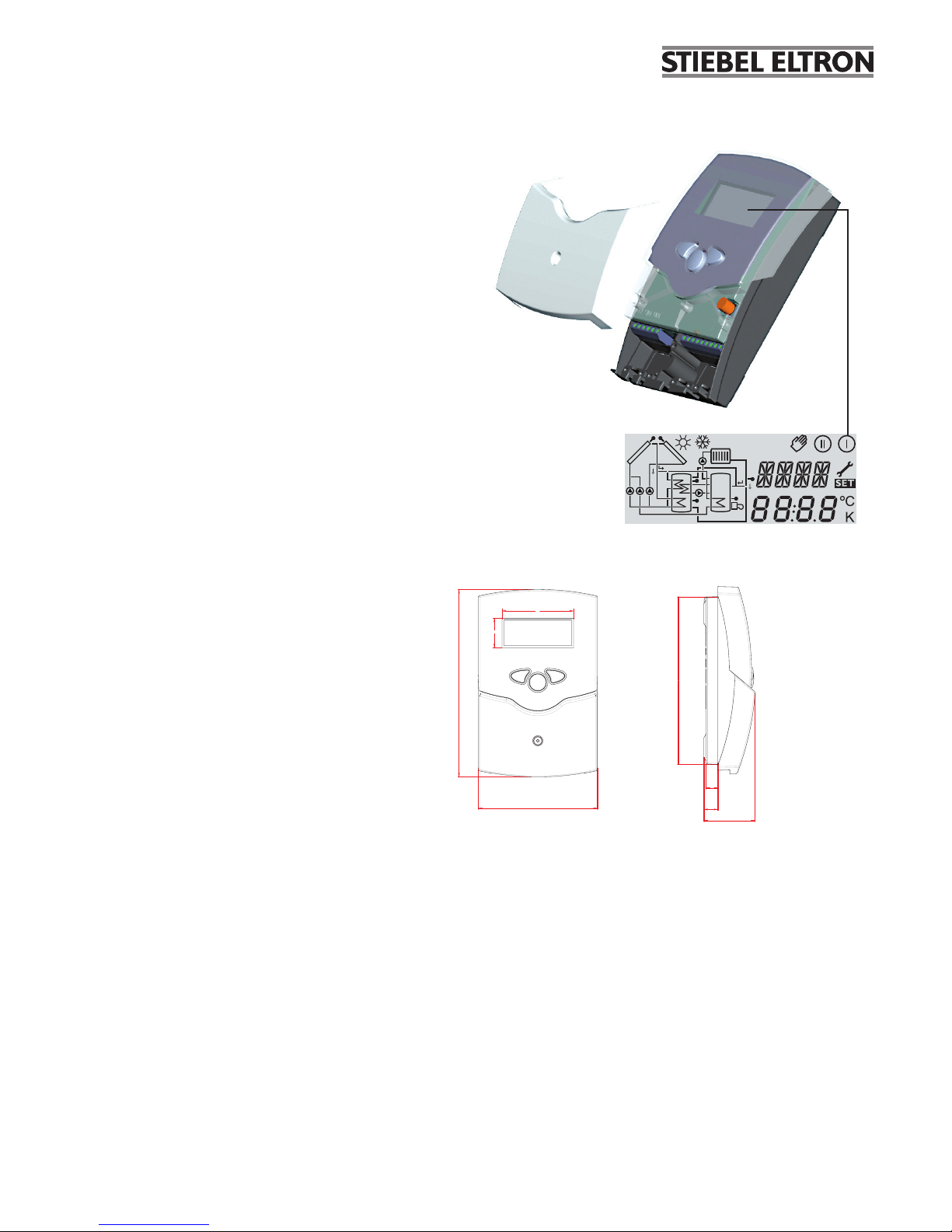

1.1 Mounting

The unit must only be installed

• in a dry interior location

• in a non-hazardous location

• away from electromagnetic fields

The controller must additionally be supplied from a doublepole switch with contact gap of at least 0.12".

Route sensor cables and power supply cables separately.

Î Unscrew the cross-head screw from the cover and remove

it along with the cover from the housing

Î Mark the upper fastening point on the wall and drill

Î Fasten the enclosed wall plug and screw leaving the head

protruding

Î Hang the housing from the upper fastening point and

mark the lower fastening point through the hole in the

terminal box (centers 5.1")

Î Drill and insert the lower wall plug

Î Fasten the housing to the wall with lower fastening screw

and tighten

Î Complete wiring connections in accordance with terminal

allocations, see chap. 1.2 “Electrical connection”

Î Place the cover back onto the housing

Î Fasten the cover by means of the cross-head screw

1. Installation

.

„

upper fastening

lower fastening

VBus

®

1.2 Electrical connection

power supply terminals

fuse

load terminalssensor terminal

ground terminal

Note:

The minimum pump speed must be set to 100% when

auxiliary relays or valves are connected.

WARNING! Electric shock!

Opening the housing will expose live

parts!

Î Switch off power supply and disconnect

the device from power supply before

opening the housing!

ATTENTION! ESD damage!

Electro static dis charge can lead to

damage to electronic components!

Î Take c are to dischar ge properly

before touching the inside of the

device. To do so, touch a grounded

surface such as a radiator or tap!

5

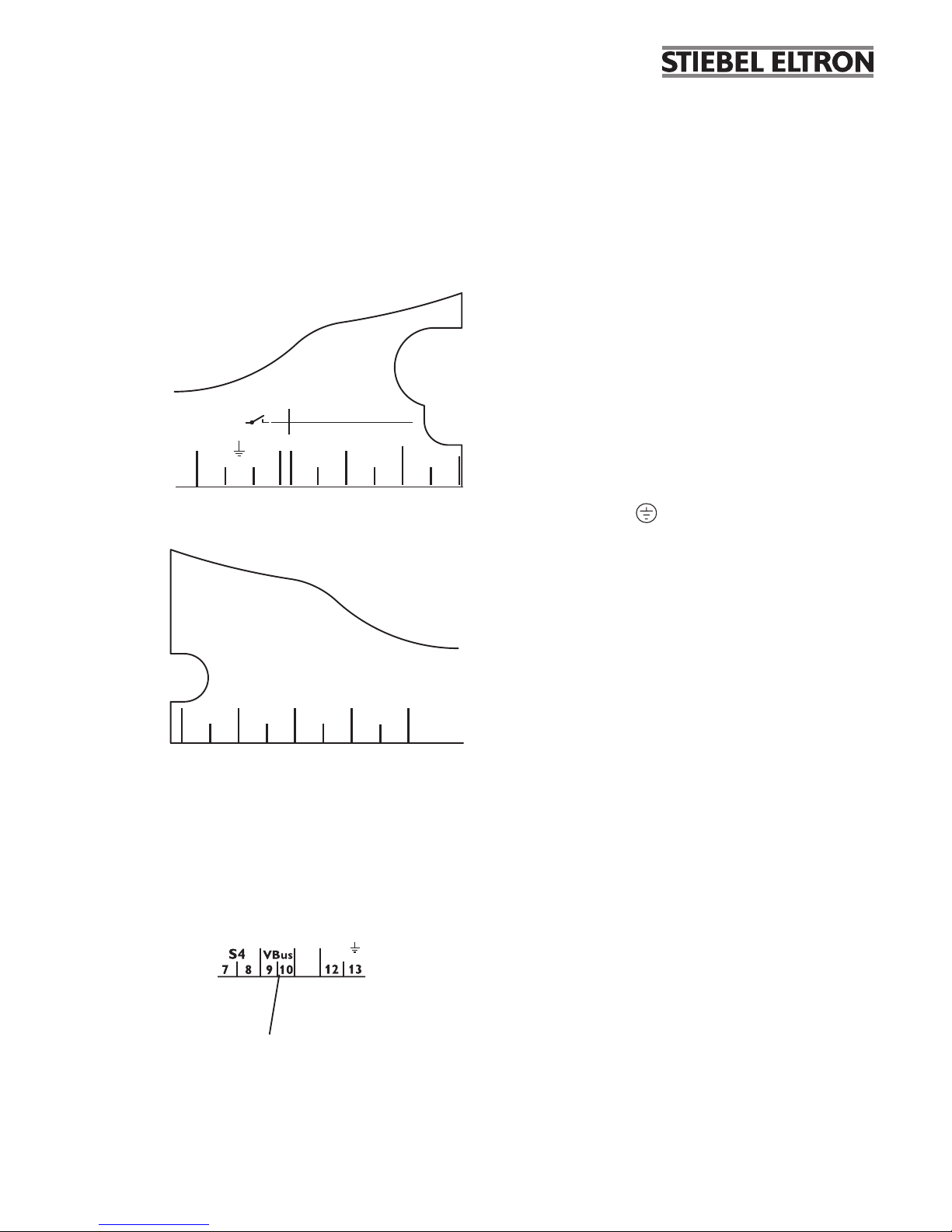

1.3 Data communication/ Bus

The controller is equipped with a VBus® for data transfer with

and energy supply to external modules. The connection is

carried out at the terminals marked “VBus” (either polarity).

One or more VBus® modules can be connected via this data

bus.

By means of an interface adapter, the controller can be

connected to a PC or a computer network.

VBus

®

connection terminals

Connecting the device to the power supply must always be

the last step of the installation!

The power supply to the controller must be carried out via

an external power switch (last step!). The supply voltage

must be 100 ... 240 V~ (50 ... 60 Hz). Flexible cables must be

attached to the housing with the enclosed strain relief and

the corresponding screws.

The controller is equipped with two semiconductor relays,

to which loads such as pumps, valves etc. can be connected:

• Relay 1

18 = conductor R1

17 = neutral conductor N

13 = ground conductor

• Relay 2

16 = conductor R2

15 = neutral conductor N

14 = ground conductor

The power supply is to be carried out at the terminals:

19 = neutral conductor N

20 = conductor L

12 = ground terminal

The temperature sensors (S1 up to S4) are to be connected

to the following terminals with either polarity:

1 / 2 = Sensor 1 (e.g. Sensor collector 1)

3 / 4 = Sensor 2 (e.g. Sensor tank 1)

5 / 6 = Sensor 3 (e.g. Sensor tank top)

7 / 8 = Sensor 4 (e.g. Sensor return)

All Pt1000 temperature sensors are equipped with a platinum

measuring element in their tip. The electrical resistance of the

measuring element changes in relation to the temperature

(see table in chap. 5).

LNR1NR2N

201918171615141312

1 (1) A (1100 ... 240) V~

(1) A (100 ... 240)V~

R1

R2

1 2

S1 S2 S3

3 4 5 6

Temp. Sensor

Pt1000

S4

7 8

Sensor terminals S1 ... S4

Grounding and load terminals

6

S1

S2

S4 / TR

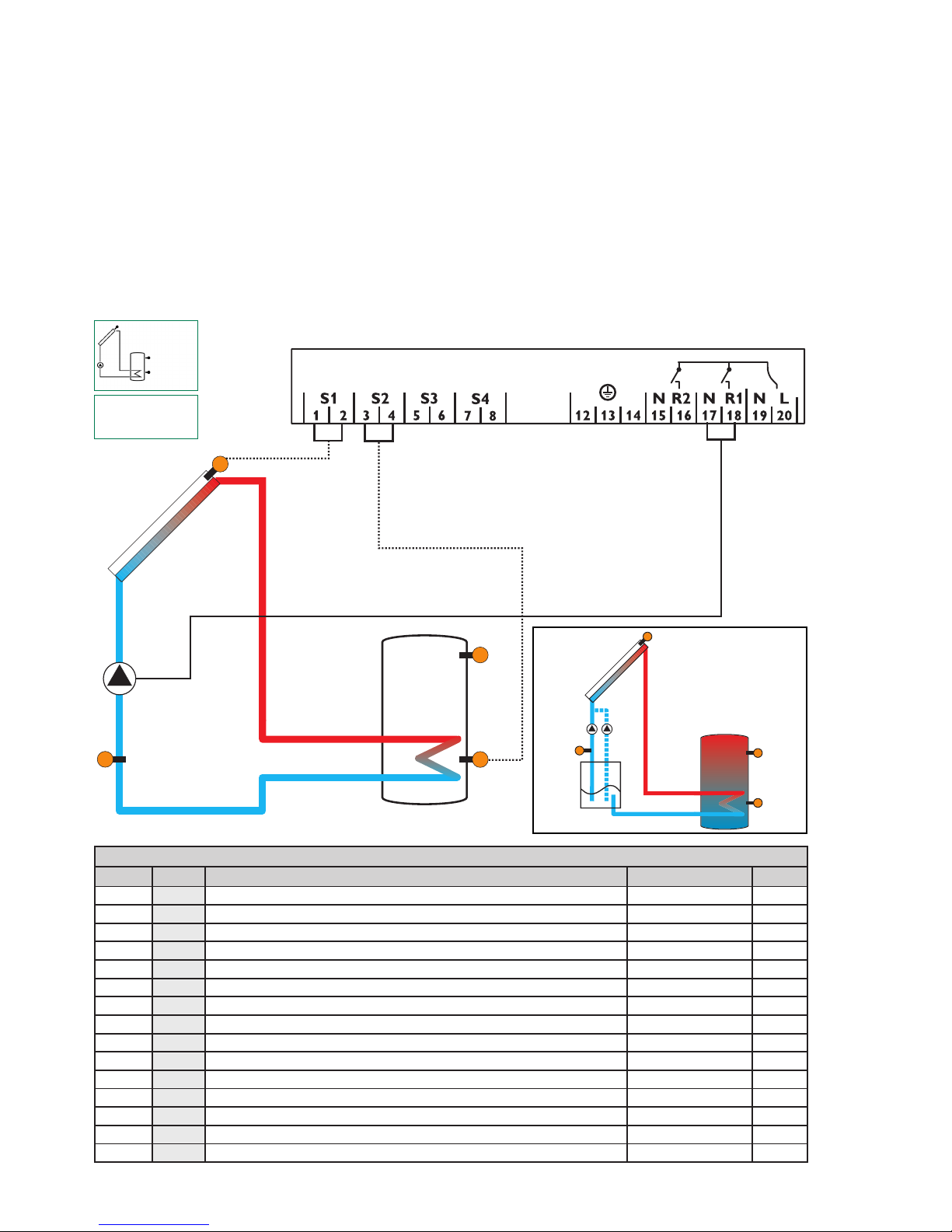

System layout 1

The controller calculates the temperature difference between

collector sensor S1 and tank sensor S2. If the difference is

larger than or identical to the adjusted switch-on temperature

difference (DT O), the solar pump will be operated by relay 1,

and the tank will be loaded until the switch-off temperature

difference (DT F) or the maximum tank temperature (S MX)

is reached.

R1

Arr 1

S3

1.4 Terminal allocation in the different system layouts

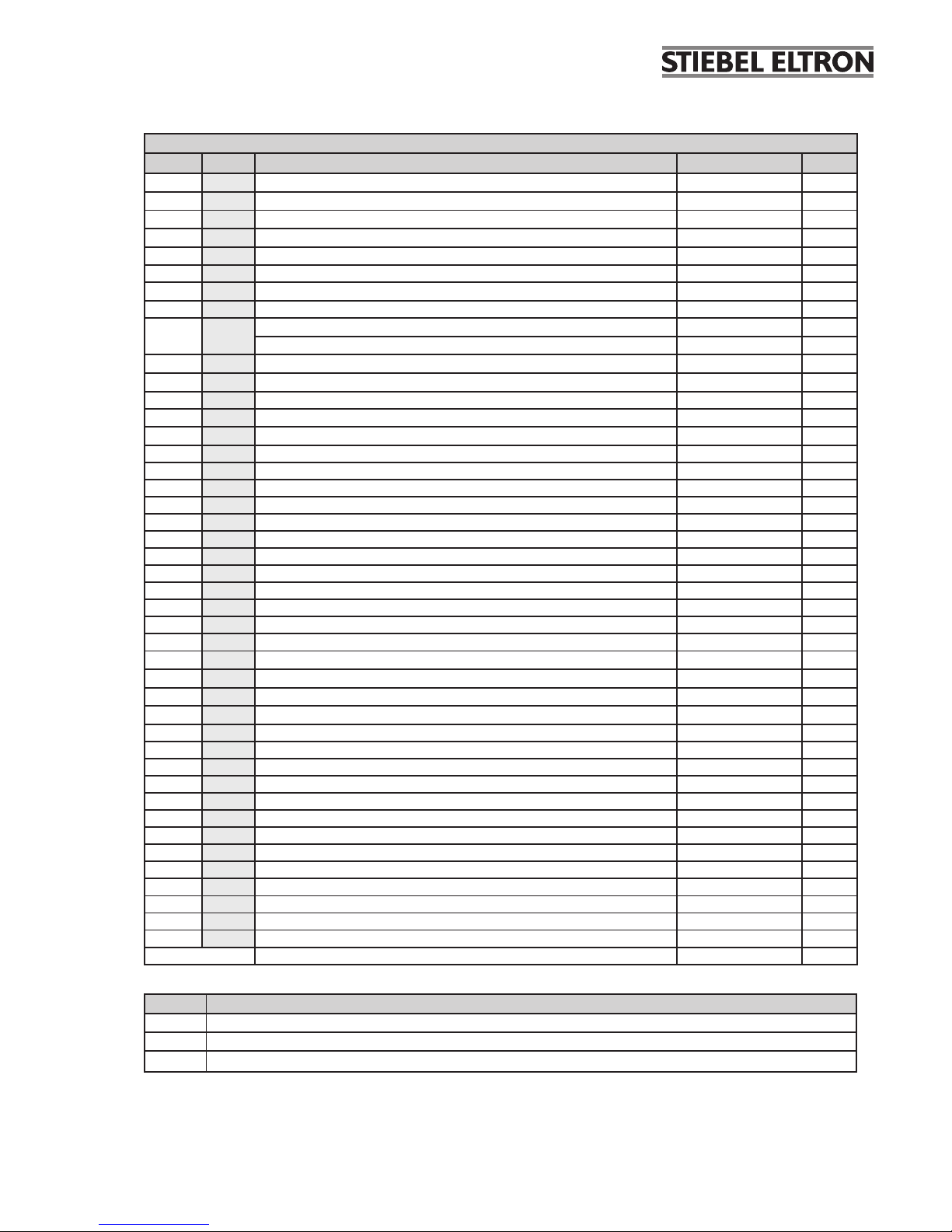

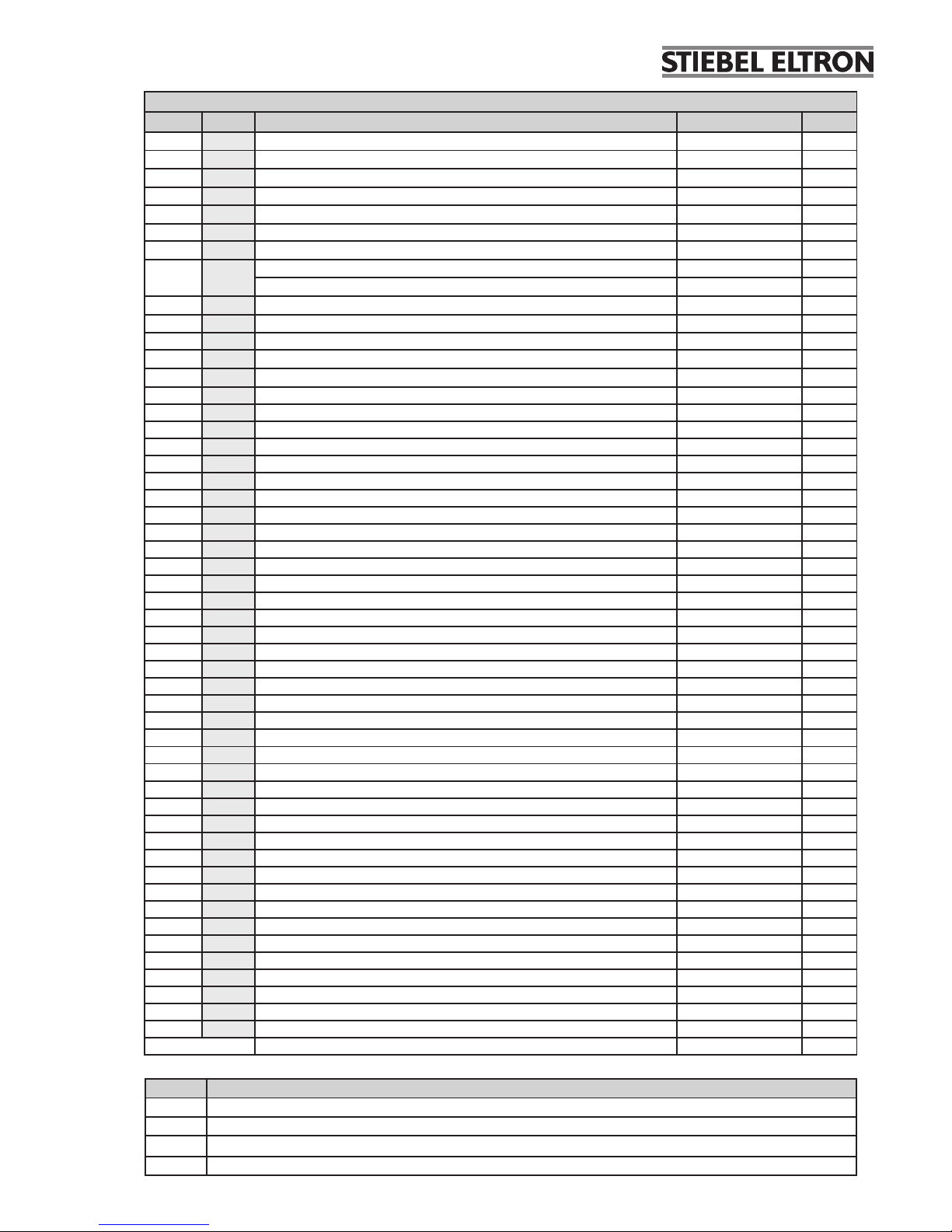

Display Channels

Channel Description Terminal Page

INIT

x*

ODB initialization active - 37

FLL

x*

ODB filling time active - 37

STAB

x*

ODB stabilization in progress - 37

COL x Temperature collector S1 37

TST x Temperature tank S2 37

S3 x Temperature sensor 3 S3 37

S4 x Temperature sensor 4 S4 37

TR x* Temperature return sensor S4 37

n % x Pump speed R1 R1 38

hP x Operating hours R1 R1 38

hP1 x* Operating hours R1 (if OBST is activated) R1 38

hP2 x* Operating hours R2 (if OBST is activated) R2 38

kWh x* Heat quantity kWh - 38

MWh x* Heat quantity MWh - 38

TIME x Time - 34

Sen s ors S3 and S4 can option ally be co n n ected for

measurement purposes.

If energy metering (OHQM) is activated, sensor S4 has to be

connected as return sensor.

If the drainback option (ODB) is activated, relay 2 can be used

to operate a booster pump by activating the booster function

(OBST).

S1

S3

S2

S4/TR

R1 R2

exemplary

Drainback system layout

(with booster pump)

7

Legend:

Symbol Specification

x Channel is available

x* Channel is available if the corresponding option is activated.

s* System-specific channel, only available if the corresponding option is activated

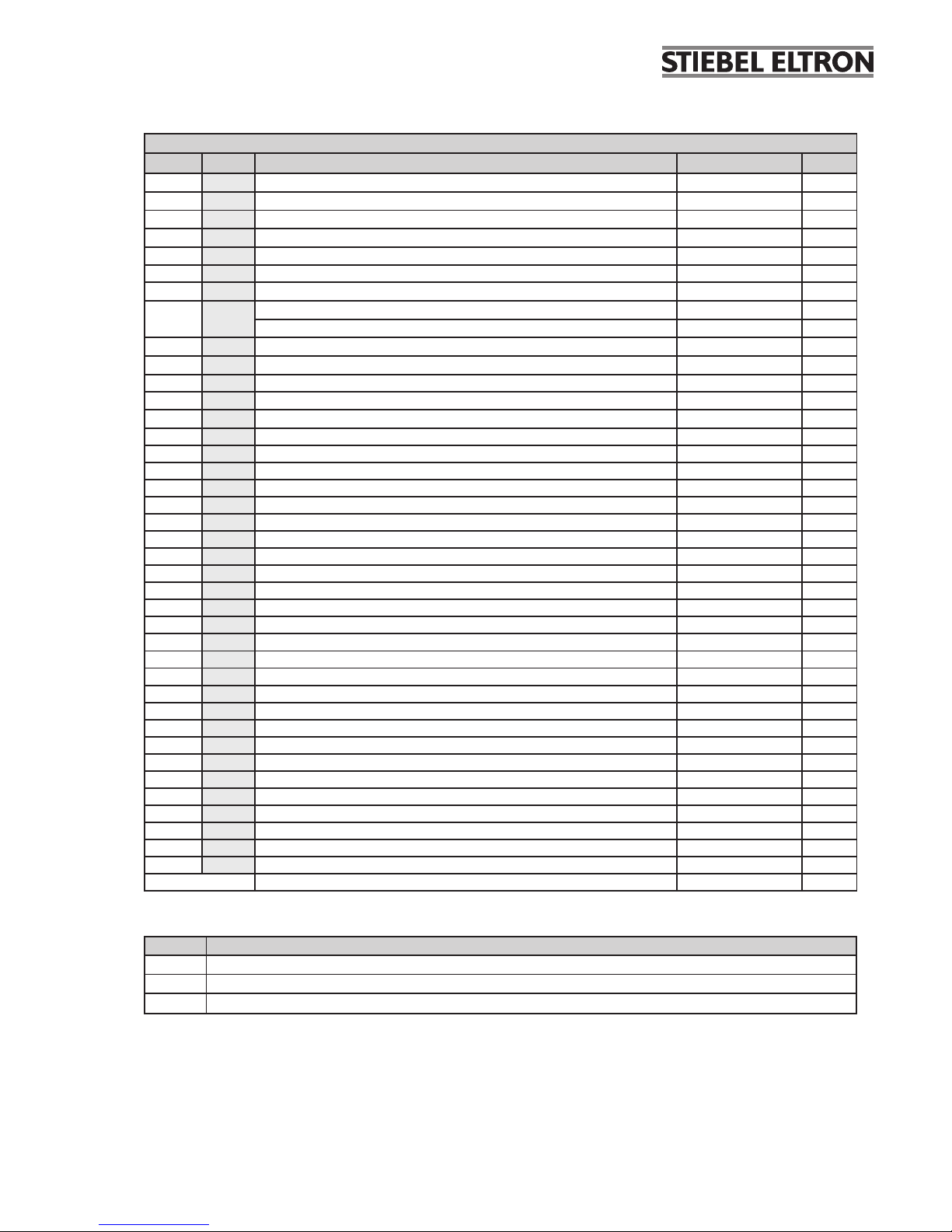

Adjustment Channels

Channel Description Factory setting Page

Arr x System 1 39

DT O x Switch-on temperature difference 12.0 °Ra [6.0 K] 39

DT F x Switch-off temperature difference 8.0 °Ra [4.0 K] 39

DT S x Nominal temperature difference 20.0 °Ra [10.0 K] 39

RIS x Rise control R1 4 °Ra [2 K] 39

nMN x Minimum pump speed 30 % 39

S MX x Maximum tank temperature 140 °F [60 °C] 40

EM x

Emergency temperature collector 270 °F [130 °C] 40

Emergency temperature collector if ODB is activated: 200 °F [95 °C] 40

OCC x Option collector cooling

OFF 41

CMX x* Maximum collector temperature

230 °F [110 °C] 41

OSYC x Option system cooling OFF 41

DTCO x* Cooling switch-on temperature difference

40.0 °Ra [20.0 K]

41

DTCF x* Cooling switch-off temperature difference

30.0 °Ra [15.0 K]

41

OSTC x Option tank cooling OFF 42

OHOL x* Option holiday cooling OFF 42

THOL x* Holiday cooling temperature 110 °F [40 °C] 42

OCN x Option minimum limitation OFF 42

CMN x* Minimum collector temperature 50 °F [10 °C] 42

OCF x Option antifreeze OFF 42

CFR x* Antifreeze temperature 40.0 °F [4.0 °C] 42

O TC x Option tube collector OFF 44

TCST x* OTC starting time 07:00 44

TCEN x* OTC ending time 19:00 44

TCRU x* OTC runtime 30 s 44

TCIN x* OTC standstill interval 30 min 44

OHQM x Option energy metering OFF 44

FMAX x* Maximum flow 6.0 l 44

MEDT x* Antifreeze type 1 44

MED% x* Antifreeze concentration (only if MEDT = propylene or ethylene) 45 % 44

ODB x Drainback option OFF 45

tDTO x* ODB switch-on condition - time period 60 s 45

tFLL x* ODB filling time 5.0 min 45

tSTB x* ODB stabilization time 2.0 min 45

OBST s* Option booster function OFF 45

MAN1 x Manual operation R1 Auto 46

MAN2 x Manual operation R2 Auto 46

LANG x Language En 46

UNIT x Temperature unit °C 46

RESE x Reset - back to factory defaults 46

W0050100 Version number

8

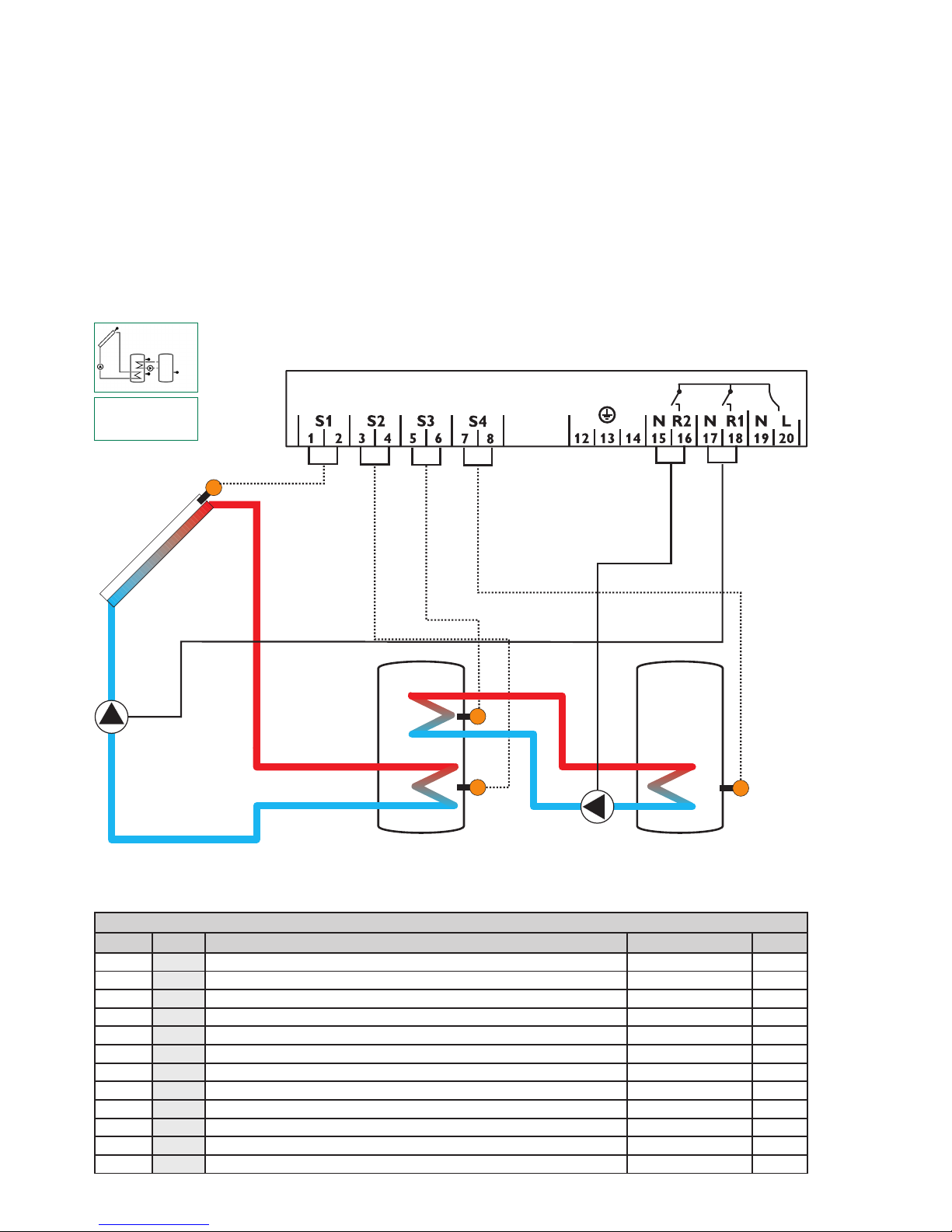

S1

S3

S4

R1

R2

S2

System layout 2

The controller calculates the temperature difference between

collector sensor S1 and tank sensor S2. If the difference is

larger than or identical to the adjusted switch-on temperature

difference (DT O), the solar pump will be operated by relay 1,

and the tank will be loaded until the switch-off temperature

difference (DT F) or the maximum tank temperature (S MX)

is reached.

Arr 2

Tank 1

Tank 2

Display Channels

Channel Description Terminal Page

INIT

x*

ODB initialization active - 37

FLL

x*

ODB filling time active - 37

STAB

x*

ODB stabilization in progress - 37

COL x Temperature collector S1 37

TST1 x Temperature tank 1 bottom S2 37

TSTT x Temperature tank 1 at the top S3 37

TST2 x Temperature tank 2 bottom S4 37

n1 % x Pump speed R1 R1 38

n2 % x Pump speed R2 R2 38

h P1 x Operating hours R1 R1 38

h P2 x Operating hours R2 R2 38

TIME x Time - 34

Heat exchange from tank 1 to tank 2 will be operated by relay

2, if the temperature difference between sensors S3 and S4 is

larger than or identical to the adjusted switch-on temperature

difference (DT3O), until the adjusted minimum (MN3O) and

maximum (MX3O) temperature thresholds of the respective

tanks are reached.

9

Legend:

Adjustment Channels

Channel Description Factory setting Page

Arr x System 2 39

DT O x Switch-on temperature difference 12.0 °Ra [6.0 K] 39

DT F x Switch-off temperature difference 8.0 °Ra [4.0 K] 39

DT S x Nominal temperature difference 20.0 °Ra [10.0 K] 39

RIS x Rise control R1 4 °Ra [2 K] 39

n1MN x Minimum pump speed R1 30 % 39

S MX x Maximum tank temperature 140 °F [60 °C] 40

n2MN s Minimum pump speed R2 30 % 10

EM x

Emergency temperature collector 270 °F [130 °C] 40

Emergency temperature collector if ODB is activated: 200 °F [95 °C] 40

OCC x Option collector cooling

OFF 41

CMX x* Maximum collector temperature

230 °F [110 °C] 41

OSYC x Option system cooling OFF 41

DTCO x* Cooling switch-on temperature difference

40.0 °Ra [20.0 K]

41

DTCF x* Cooling switch-off temperature difference

30.0 °Ra [15.0 K]

41

OSTC x Option tank cooling OFF 42

OHOL x* Option holiday cooling OFF 42

THOL x* Holiday cooling temperature 110 °F [40 °C] 42

OCN x Option minimum limitation OFF 42

CMN x* Minimum collector temperature 50 °F [10 °C] 42

OCF x Option antifreeze OFF 42

CFR x* Antifreeze temperature 40.0 °F [4.0 °C] 42

O TC x Option tube collector OFF 44

TCST x* OTC starting time 07:00 44

TCEN x* OTC ending time 19:00 44

TCRU x* OTC runtime 30 s 44

TCIN x* OTC standstill interval 30 min 44

DT3O s Switch-on temperature difference 3

12.0 °Ra [6.0 K] 10

DT3F s Switch-off temperature difference 3

8.0 °Ra [4.0 K] 10

DT3S s Nominal temperature difference 3

20.0 °Ra [10.0 K] 10

RIS3 s Rise control R2

4 °Ra [2 K] 10

MX3O s Switch-on treshold for maximum temperature 140.0 °F [60.0 °C] 11

MX3F s Switch-off treshold for maximum temperature 136.0 °F [58.0 °C] 11

MN3O s Switch-on treshold for minimum temperature 40.0 °F [5.0 °C] 11

MN3F s Switch-off treshold for minimum temperature 50.0 °F [10.0 °C] 11

ODB x Drainback option OFF 45

tDTO x* ODB switch-on condition - time period 60 s 45

tFLL x* ODB filling time 5.0 min 45

tSTB x* ODB stabilization time 2.0 min 45

MAN1 x Manual operation R1 Auto 46

MAN2 x Manual operation R2 Auto 46

LANG x Language En 46

UNIT x Temperature unit °C 46

RESE x Reset - back to factory defaults 46

W0050100 Version number

Symbol Specification

x Channel is available

x* Channel is available if the corresponding option is activated.

s Channel is specifically available in this system layout

10

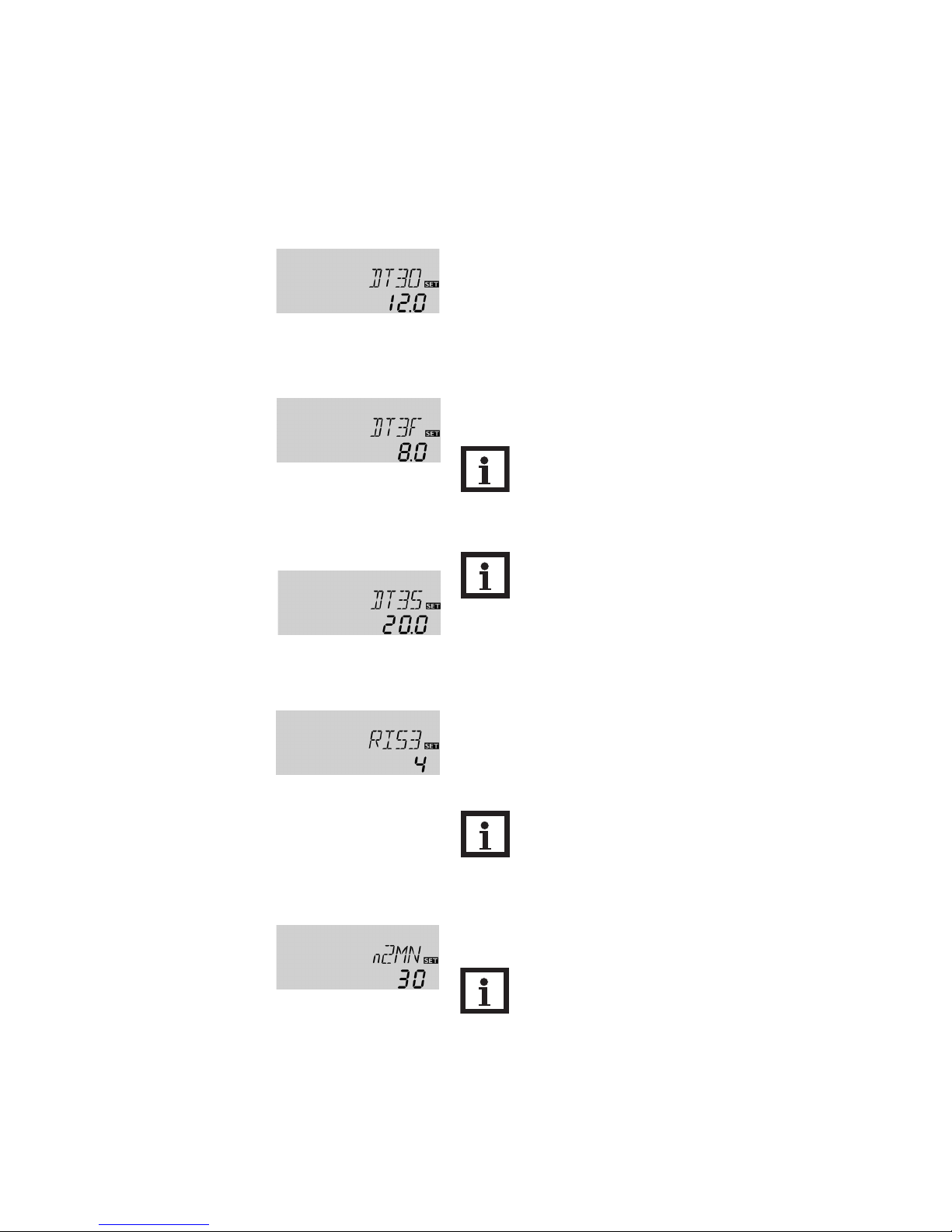

∆T control for the heat exchange between 2 tanks

DT3O:

Switch-on temperature diff.

Adjustment range: 2.0 ... 40.0°Ra

[1.0 ... 20.0 K]

in steps of 1 °Ra [0.5 K]

Factory setting: 12.0°Ra

[6.0 K]

DT3F:

Switch-off temperature diff.

Adjustment range: 1.0 ... 39.0°Ra

[0.5 ... 19.5 K]

in steps of 1 °Ra [0.5 K]

Factory setting: 8.0°Ra

[4.0 K]

Reference sensors for this function are S3 and S4.

Insystem layout 2 thecontroller isequipped with an additional differential control for heat exchange between

two tanks. The basic differential function is adjusted using

the switch-on (DT3O) and switch-off (DT3F) temperature

differences.

When the temp erature difference exce eds the sw itchon temperature difference, relay 2 switches on. If the

temperature difference then falls below the adjusted switchoff temperature difference, relay 2 switches off.

Note:

The switch-on temperature difference must be

at least 1 °Ra [0.5 K] higher than the switch-off

tempe rature difference.

DT3S:

Nominal temperature difference

Adjustment range: 3.0 ... 60.0 °Ra

[1.5 ... 30.0 K]

in steps of 1 °Ra [0.5 K]

Factory setting: 20.0 °Ra

[10.0 K]

RIS3:

Rise

Adjustment range:

2 ... 40 °Ra [1 ... 20 K]

in steps of 2 °Ra [1 K]

Factory setting: 4 °Ra [2 K]

Pump speed control

A relative minimum pump speed can be allocated to the

output R2 via the adjustment channel n2MN.

n2MN:

Pump speed control

Adjustment range: 30 ... 100

in steps of 5 %

Factory setting: 30

Note:

When loads which are not speed-controlled (e.g.

valves) are used, the value must be set to 100% in

order to deactivate pump speed control.

Minimum pump speed

When the switch-on temperature difference is reached, the

pump is activated at full speed for 10 seconds. Then, the speed

is reduced to the minimum pump speed value (n2MN).

If the temperature difference reaches the adjusted nominal

temperature difference (DT3S), the pump speed increases by one

step (10%). If the difference increases by the adjustable rise value,

the pump speed increases by 10% respectively until the maximum

pump speed of 100% is reached. The response of the controller

can be adapted via the parameter RIS3.

Note:

The nominal temperature difference must be

at least 1 °Ra [0.5 K] higher than the switch-on

tempe rature difference.

Note:

For pump speed control of the heat exchange

pump, the operation mode of relay 2 (MAN2) must

be set to Auto.

System-specific functions

The following adjustments are used for the specific function

in system layout 2.

11

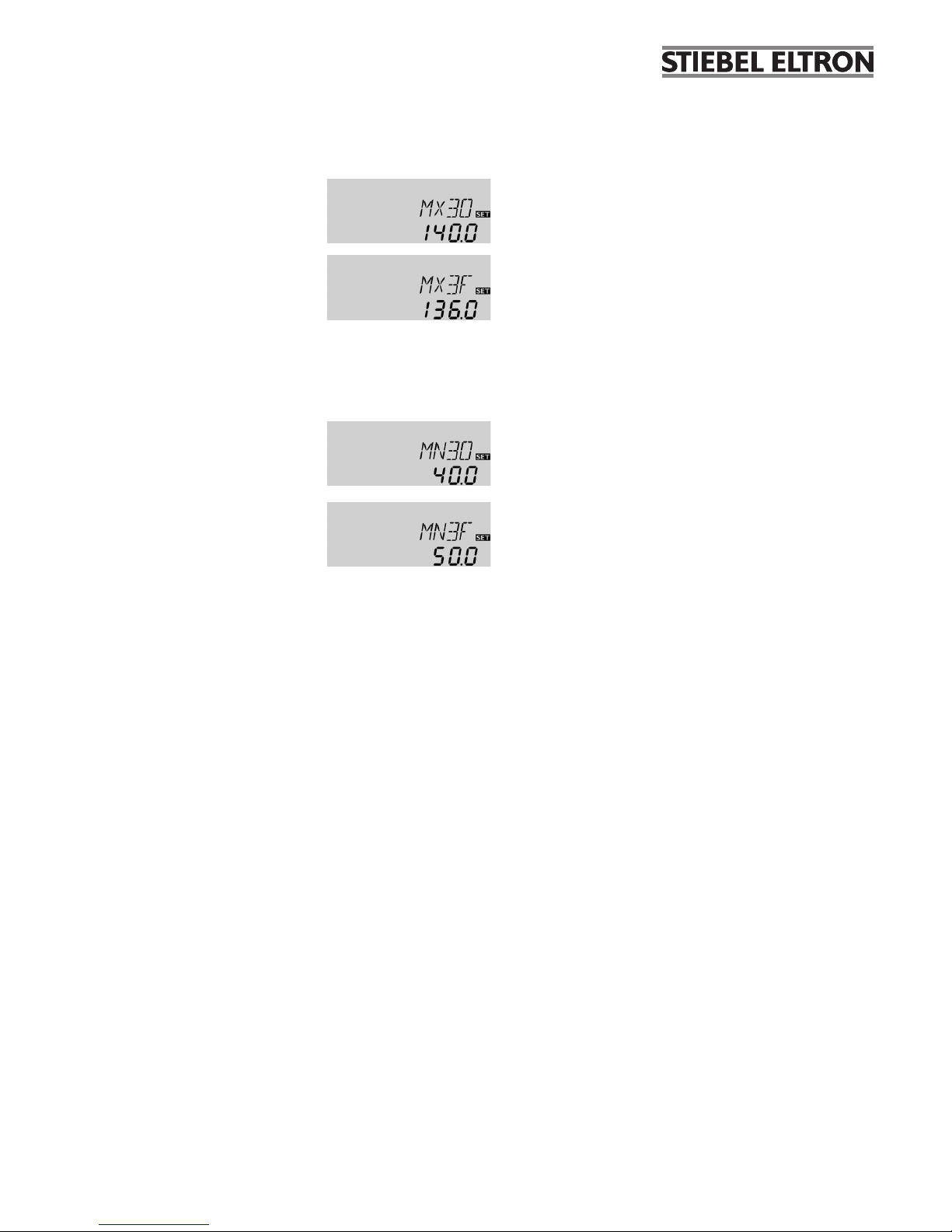

Maximum temperature limitation

MX3O / MX3F:

Maximum temperature limitation

Adjustment range:

30.0 ... 200.0°F

[0.0 ... 95.0 °C]

in steps of 1 °Ra [0.5 K]

Factory setting:

MX3O: 140.0°F [60.0 °C]

MX3F: 136.0°F [58.0 °C]

Minimum temperature limitation

MN3O / MN3F:

Minimum temperature limitation

Adjustment range:

30.0 ... 190.0°F

[0.0 ... 90.0 °C]

in steps of 1 °Ra [0.5 K]

Factory setting (Arr = 2 only):

MN3O: 40.0°F [5.0 °C]

MN3F: 50.0°F [10.0 °C]

Minimum and maximum temperature limits can be set for

the heat exchange function.

The maximum temperature limitation uses sensor 4 as

reference sensor.

The maximum temperature limitation function provides a

maximum tem perature setting, usually to reduce scald risk

in a storage tank. If MX3O is exceeded, relay2 is switched off

until the temperature at sensor 4 falls below MX3F.

The minimum temperature limitation uses sensor 3 as

reference sensor.

The minimum temperature limitation function provides a

minimum tem perature setting for the heat source in system

layout 2. If the temperature at sensor 3 falls below MN3O,

relay2 is switched of f until the temperature at sensor 3

exceeds MN3F.

Both switch-on and switch-off temperature differences

DT3O and DT3F are valid for the maximum and minimum

temperature limitation.

12

R2

S1

S2

R1

S3

S4 / TR

System layout 3

The controller calculates the temperature difference between

collector sensor S1 and tank sensor S2. If the difference is

larger than or identical to the adjusted switch-on temperature

difference (DT O), the solar pump will be operated by relay 1,

and the tank will be loaded until the switch-off temperature

difference (DT F) or the maximum tank temperature (S MX)

is reached.

Sensor S3 is used for a thermostatic function, which operates

Arr 3

Display Channels

Channel Description Terminal Page

INIT

x*

ODB initialization active - 37

FLL

x*

ODB filling time active - 37

STAB

x*

ODB stabilization in progress - 37

COL x Temperature collector S1 37

TSTB x Temperature tank 1 bottom S2 37

TSTT x Temperature tank 1 at the top S3 37

TDIS

s*

Thermal disinfection temperature S3 37

S4 x Temperature sensor 4 S4 37

TR x* Temperature return sensor S4 37

n1 % x Pump speed R1 R1 38

h P1 x Operating hours R1 R1 38

h P2 x Operating hours R2 R2 38

kWh

x*

Heat quantity kWh - 38

MWh

x*

Heat quantity MWh - 38

CDIS

s*

Countdown of monitoring period - 38

SDIS

s*

Starting time display - 38

DDIS

s*

Heating period display - 38

TIME x Time - 34

relay 2 for backup heating or heat dump purposes, when

the adjusted thermostat switch-on temperature (AHO) is

reached. This function can optionally be combined with up

to three adjustable time frames.

Sensor S3 can also be optionally used as a reference sensor

for the thermal disinfection function OTD.

Sensor S4 can optionally be connected for measurement

purposes. If energy metering (OHQM) is activated, sensor S4

has to be connected as return sensor.

13

Adjustment Channels

Channel Description Factory setting Page

Arr x System 3 39

DT O x Switch-on temperature difference 12.0 °Ra [6.0 K] 39

DT F x Switch-off temperature difference 8.0 °Ra [4.0 K] 39

DT S x Nominal temperature difference 20.0 °Ra [10.0 K] 39

RIS x Rise control R1 4 °Ra [2 K] 39

n1MN x Minimum pump speed R1 30 % 39

S MX x Maximum tank temperature 140 °F [60 °C] 40

EM x

Emergency temperature collector 270 °F [130 °C] 40

Emergency temperature collector if ODB is activated: 200 °F [95 °C] 40

OCC x Option collector cooling

OFF 41

CMX x* Maximum collector temperature

230 °F [110 °C] 41

OSYC x Option system cooling OFF 41

DTCO x* Cooling switch-on temperature difference

40.0 °Ra [20.0 K]

41

DTCF x* Cooling switch-off temperature difference

30.0 °Ra [15.0 K]

41

OSTC x Option tank cooling OFF 42

OHOL x* Option holiday cooling OFF 42

THOL x* Holiday cooling temperature 110 °F [40 °C] 42

OCN x Option minimum limitation OFF 42

CMN x* Minimum collector temperature 50 °F [10 °C] 42

OCF x Option antifreeze OFF 42

CFR x* Antifreeze temperature 40.0 °F [4.0 °C] 42

O TC x Option tube collector OFF 44

TCST x* OTC starting time 07:00 44

TCEN x* OTC ending time 19:00 44

TCRU x* OTC runtime 30 s 44

TCIN x* OTC standstill interval 30 min 44

OHQM x Option energy metering OFF 44

FMAX x* Maximum flow 6.0 l 44

MEDT x* Antifreeze type 1 44

MED% x* Antifreeze concentration 45 % 44

AH O s Switch-on temp. for thermostat 1 110 °F [40 °C] 14

AH F s Switch-off temp. for thermostat 1 120 °F [45 °C] 14

t1 O s Switch-on time 1 thermostat 00:00 14

t1 F s Switch-off time 1 thermostat 00:00 14

t2 O s Switch-on time 2 thermostat 00:00 14

t2 F s Switch-off time 2 thermostat 00:00 14

t3 O s Switch-on time 3 thermostat 00:00 14

t3 F s Switch-off time 3 thermostat 00:00 14

ODB x Drainback option OFF 45

tDTO x* ODB switch-on condition - time period 60 s 45

tFLL x* ODB filling time 5.0 min 45

tSTB x* ODB stabilization time 2.0 min 45

OTD s Option thermal disinfection OFF 15

PDIS s* Monitoring period 01:00 15

DDIS s* Heating period 01:00 15

TDIS s* Disinfection temperature 140 °F [60 °C] 15

SDIS s* Starting time 00:00 15

MAN1 x Manual operation R1 Auto 46

MAN2 x Manual operation R2 Auto 46

LANG x Language En 46

UNIT x Temperature unit °C 46

RESE x Reset - back to factory defaults 46

W0050100 Version number

Legend:

Symbol Specification

x Channel is available

x* Channel is available if the corresponding option is activated.

s Channel is specifically available in this system layout

s* System-specific channel, only available if the corresponding option is activated

14

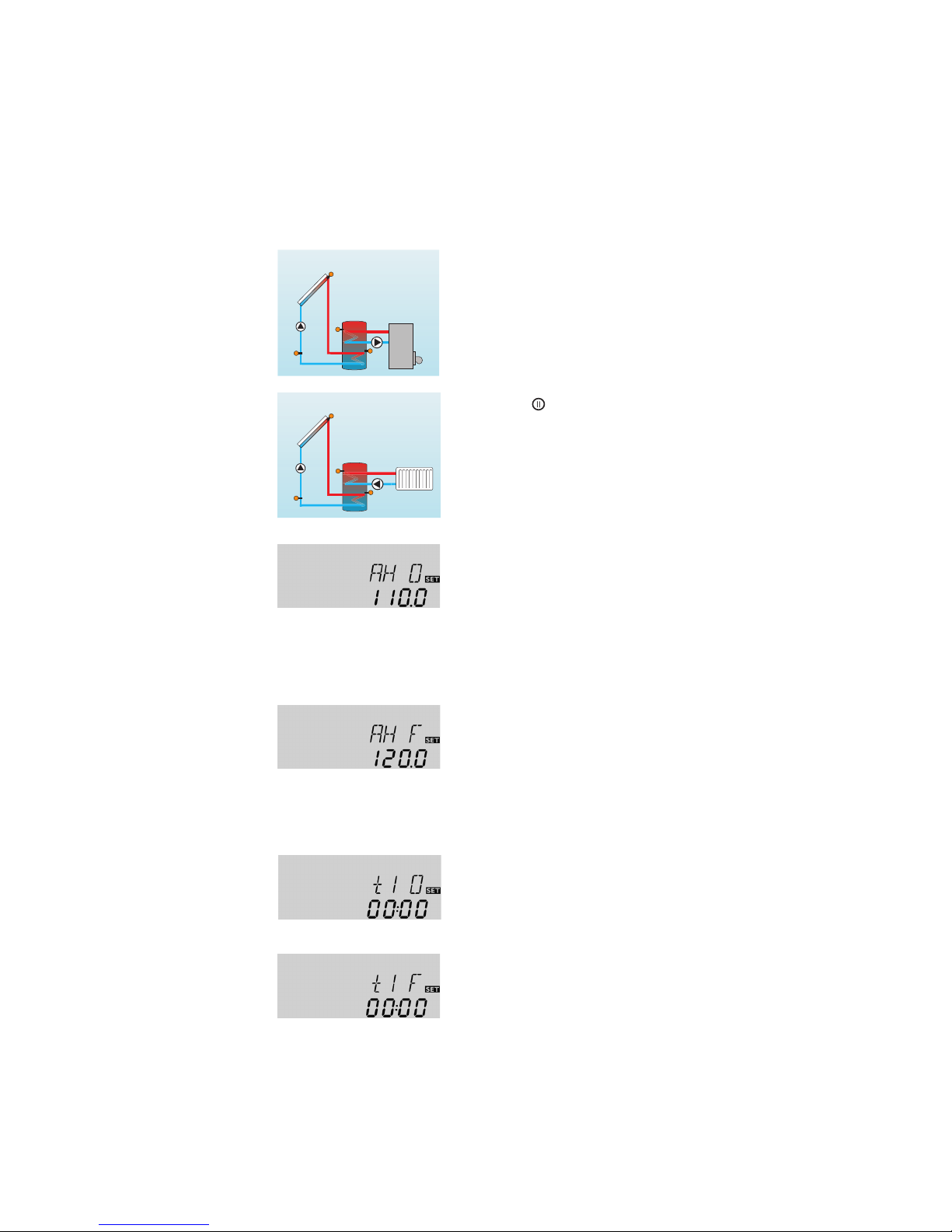

The thermostat function works independently from the solar

operation and can be used for using surplus energy or for

backup heating.

• AH O < AH F

thermostat function for backup heating

• AH O > AH F

thermostat function for using surplus energy

The symbol

will be shown on the display if the second

relay output is activated.

Thermostat function

Backup heating

AH O:

Thermostat switch-on tem p.

Adjustment range:

30.0 ... 200.0 °F

[0.0 ... 95.0 °C]

in steps of 1.0 °Ra [0.5 K]

Factory setting:

110.0°F [40.0 °C]

AH F:

Thermostat switch-off tem p.

Adjustment range:

30.0 ... 200.0 °F

[0.0 ... 95.0 °C]

in steps of 1.0 °Ra [0.5 K]

Factory setting:

120.0 °F [45.0 °C]

t1 O, t2 O, t3 O:

Thermostat switch-on time

Adjustment range:

00:00 ... 23:45

Factory setting: 00:00

t1 F, t2 F, t3 F:

Thermostat switch-off time

Adjustment range:

00:00 ... 23:45

Factory setting: 00:00

In order to block the thermostat function for a certain period,

there are three time frames t1 ... t3. If the function should be

active between 6:00 and 9:00, set t1 O to 6:00 and t1 F to 9:00.

If all time frames are set to 00:00 o’clock, the thermostat

function is continuously activated (factory setting).

Use of surplus energy

Reference sensor for the thermostat function is S3!

System-specific functions

The following functions are exclusively available in system

layout 3. The corresponding channels will not be available in

any other system layout.

15

When a starting time for thermal disinfection with starting

delay is adjusted in SDIS, the thermal disinfection will be

delayed until that time, even after the CDIS has counted down

to 00:00. If CDIS ends, for example, at 12:00 o‘clock, and SDIS

has been set to 18:30, relay 2 will be operated with a delay of

6.5 hours at 18:30 instead of 12:00.

During the waiting time, SDIS is displayed with the adjusted

starting time (flashing).

If, during the waiting time, the temperature at S3 exceeds TDIS

for the adjusted heating period DDIS, thermal disinfection is

considered complete and a new monitoring period begins.

If the starting time is adjusted to 00:00 (factory setting), the

delay function is inactive.

Upon delivery, OTD is deactivated. The adjustment values PDIS,

TDIS, DDIS and SDIS are displayed after the option has been

activated. After the thermal disinfection function has been

completed, the values will be “hidden” and the monitoring

period will be displayed.

SDIS

Starting time

Adjustment range:

00:00 ... 24:00 (o‘clock)

Factory setting: 00:00

Thermal disinfection with starting delay

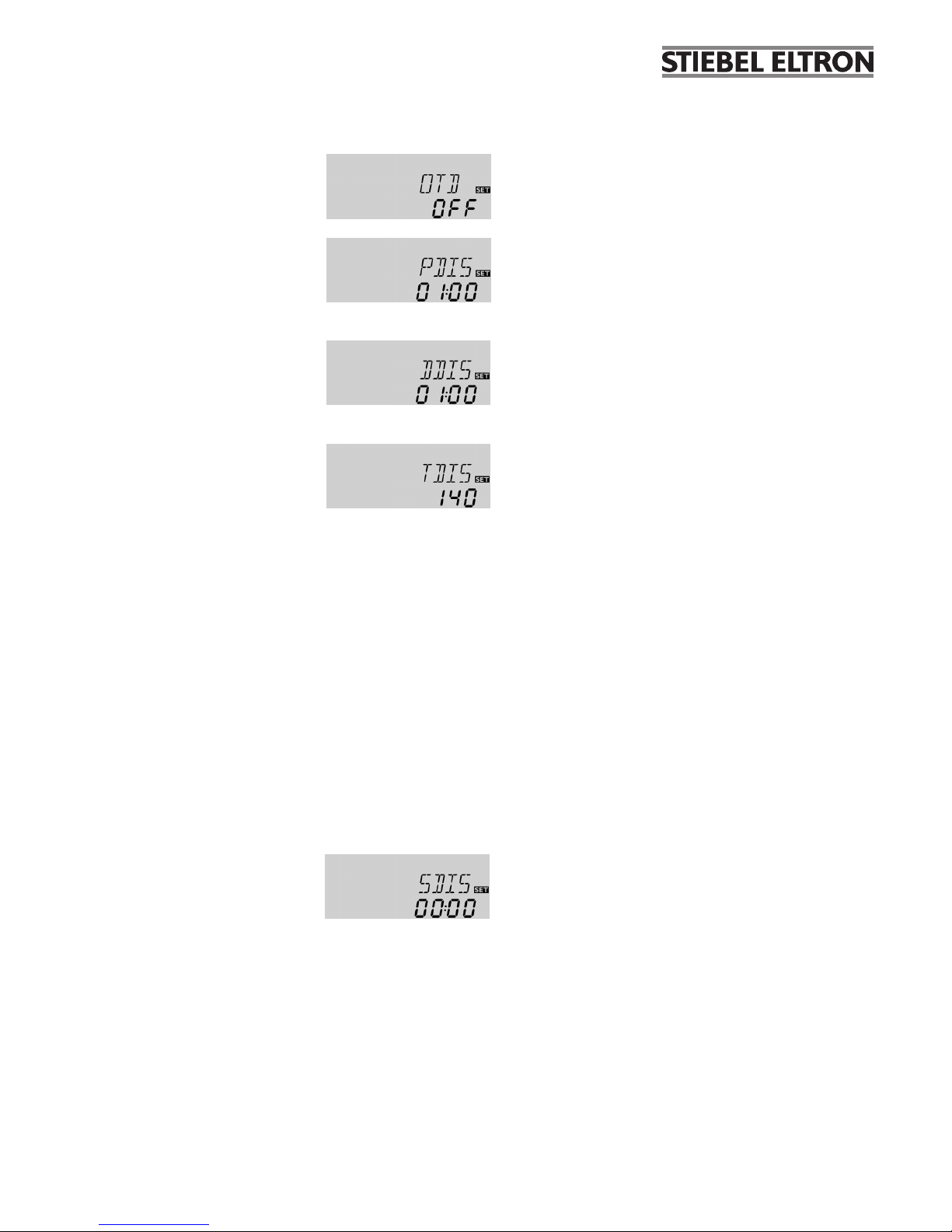

Option: Thermal disinfection of the upper DHW zone (OTD)

TDIS

Disinfection temperature

Adjustment range:

30 ... 200 °F

[0 ... 95 °C]

in steps of 2 °F [2 °C]

Factory setting:

140 °F [60 °C]

DDIS

Heating period

Adjustment range:

00:00 ... 23:59 (hh:mm)

Factory setting: 01:00

For thermal disinfection, the temperature in the upper DHW

tank zone has to be monitored. This protection is ensured

when, during the monitoring period (PDIS), the disinfection

temperature (TDIS) is continuously exceeded for the entire

heating period (DDIS). S3 is used as the reference sensor and

displayed as TSTT.

PDIS:

Monitoring period

Adjustment range:

0 ... 30:0 ... 24 h (dd:hh)

Factory setting: 01:00

This function is used for protecting the upper tank zone against

Legionella by activating the backup heating.

Reference sensor for the thermal disinfection is S3!

Î To activate the function, select “On” in the OTD channel.

OTD:

Thermal disinfection function

Adjustment range: ON / OFF

Factory setting: OFF

Due to the flexible control logic, the exact time of thermal

disinfection is not predictable. In order to set a fixed time

for the disinfection to be run, the starting delay SDIS must

be employed:

If OTD is activated, PDIS will start as soon as the temperature

at S3 falls below TDIS. The display channel CDIS appears,

counting backwards the remaining time of PDIS. If, during

the monitoring period, the temperature at S3 exceeds TDIS

continuously for the duration of DDIS, thermal disinfection is

considered complete and a new monitoring period begins.

If CDIS counts down to 00:00, relay 2 will be operated in order

to use the backup heating for thermal disinfection. CDIS will

then be replaced with a display channel DDIS showing the

adjusted heating period. DDIS will start counting down the

heating period as soon as TDIS is exceeded at S3. As long as

DDIS is active, the temperature at S3 will be displayed as TDIS

instead of TSTT.

If, during DDIS, the temperature at S3 exceeds TDIS by more

than 10°Ra [5K], relay 2 is switched off until the temperature

falls below TDIS+4°Ra [2K].

If, during DDIS, the temperature at S3 falls below TDIS, the

heating period will restart. DDIS can only be completed when

TDIS is exceeded without interruption.

16

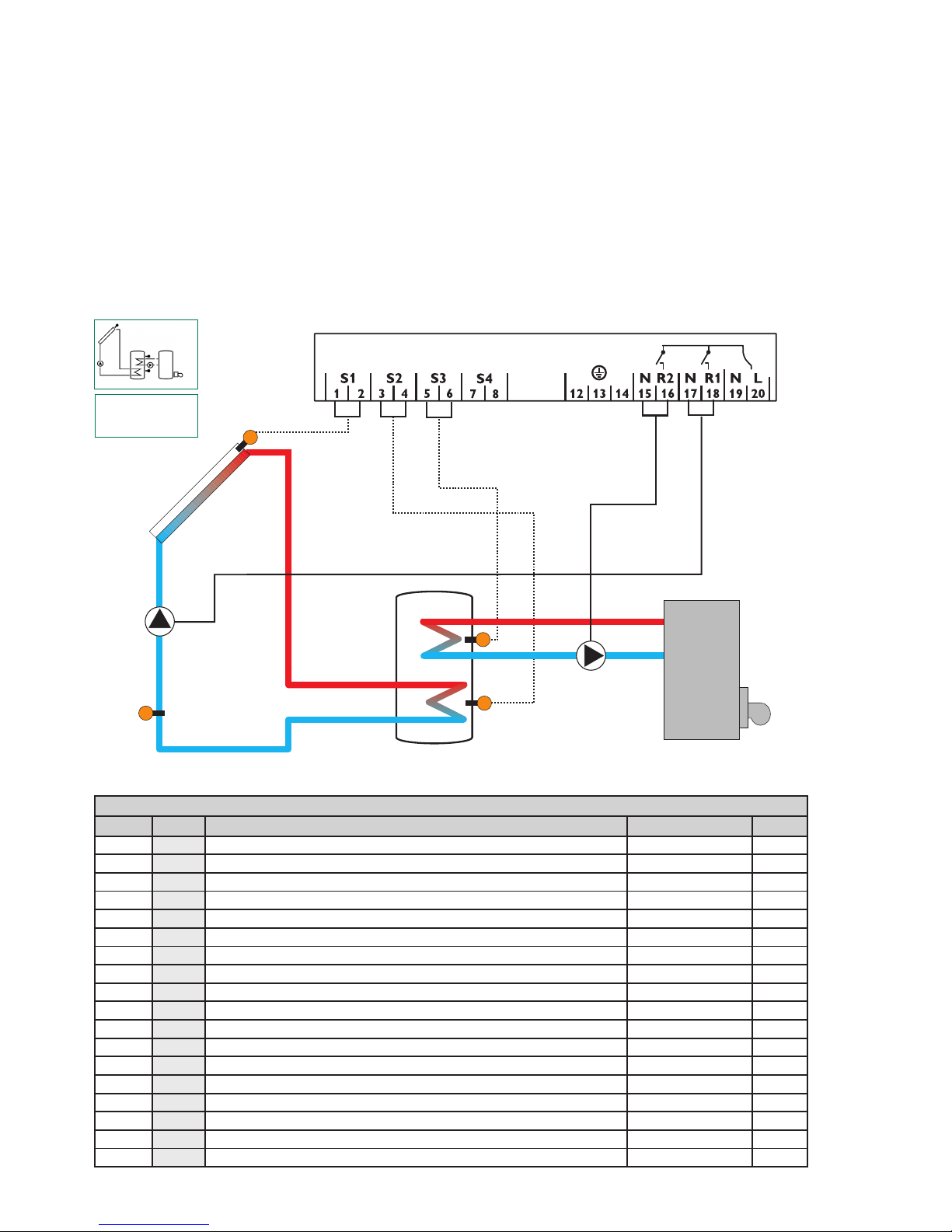

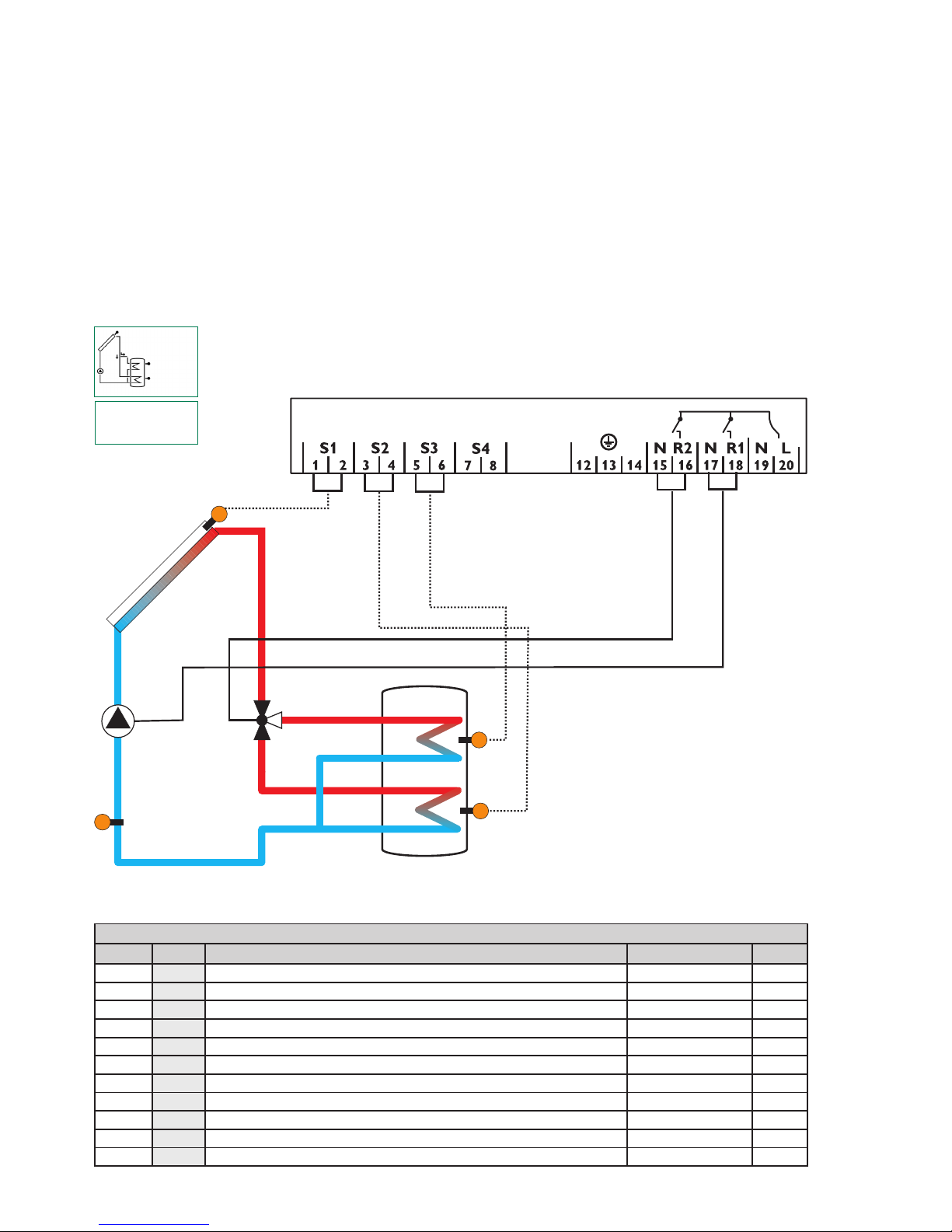

System layout 4

S2

R1

S3

R2

S1

The controller calculates the temperature differences between

collector sensor S1 and tank sensors S2 and S3. If the

differences are larger than or identical to the adjusted switchon temperature differences (DT1O / DT2O), the solar pump will

be operated by relay 1, and the respective tank zone will be

loaded until the switch-off temperature differences (DT1F /

DT2F) or the maximum tank temperatures (S1MX / S2MX) are

S4 / TR

Arr 4

Display Channels

Channel Description Terminal Page

COL x Temperature collector S1 37

TSTB x Temperature tank 1 bottom S2 37

TSTT x Temperature tank 1 at the top S3 37

S4 x Temperature sensor 4 S4 37

TR x* Temperature return sensor S4 37

n % x Pump speed relay R1 38

hP1 x Operating hours R1 R1 38

hP2 x Operating hours R2 R2 38

kWh

x*

Heat quantity kWh - 38

MWh

x*

Heat quantity MWh - 38

TIME x Time - 34

reached. The priority logic causes priority loading of the upper

zone of the tank, if possible. The 3-way-valve will be operated

by relay 2 then.

Sensor S4 can optionally be connected for measurement

purposes.

If energy metering (OHQM) is activated, sensor S4 has to be

connected as return sensor.

Loading...

Loading...