STIEBEL ELTRON HydroShark 115NG, HydroShark 115LP, HydroShark 115 Installation Manual And Owner's Manual

Page 1

OPERATION AND INSTALLATION

UTILISATION ET INSTALLATION

Non-Condensing Gas Micro-boiler

»HydroShark 115NG

»HydroShark 115LP

Conforms to ANSI Z21.10.3/CSA 4.3

Conforme à la norme ANSI Z21.10.3/CSA 4.3

Page 2

HydroShark 115 Gas Micro Boiler

Installation Manual and Owner’s Guide

The HydroShark 115 Gas Micro Boiler

is a compact and powerful residential unit

with a versatile BTU modulating range.

Featuring

• Effi ciency: 83 %

• Wall Hung

• Flow Activated: .75 GPM

• Copper Heat Exchanger

• Temperature Range: 99°-167° F*

• Freeze Protection

• Power Vent

• CAT III Stainless Steel Venting

*Max Water Temp of 167° F at 2.4 GPM

Models:

HydroShark 115NG

HydroShark 115LP

Do not return. Damages or repairs call

800.805.5384

If the information in these instructions is

not followed exactly, a fi re or explosion

may result causing property damage,

personal injury or death.

-Do not store or use gasoline or other fl ammable

vapors and liquids in the vicinity of this or any

other appliance.

-WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance

• Do not touch any electric switch, do not use

any phone in your building.

• Immediately call your gas supplier from a

neighbor’s phone. Follow the gas supplier’s

instructions.

• If you cannot reach your gas supplier, call the

fi re department.

-Installation and service must be performed by

a qualifi ed installer, service agency or the gas

supplier.

2 | HYDROSHARK 115 WWW.HYDRO-SHARK.COM

Page 3

CONTENTS

Installation Manual

SPECIFICATIONS..........................................................................................................4

INTRODUCTIONS..........................................................................................................5

SAFETY GUIDELINES...................................................................................................6

INSTALLATION...............................................................................................................7

General................................................................................................................7

Clearances...........................................................................................................9

Included accessories............................................................................................9

High-altitude installations....................................................................................10

Venting instructions.............................................................................................11

Gas supply and gas pipe sizing..........................................................................17

Water connections..............................................................................................19

Electrical connections.........................................................................................20

APPLICATIONS..................................................................................................22

INITIAL OPERATION..........................................................................................24

OWNER’S GUIDE

OPERATING SAFETY...................................................................................................26

NORMAL OPERATION.................................................................................................28

General..............................................................................................................28

Temperature Settings.........................................................................................29

Flow....................................................................................................................30

Freeze protection system...................................................................................30

Maintenance and service...................................................................................31

Unit draining and fi lter cleaning..........................................................................31

TROUBLESHOOTING..................................................................................................32

General...............................................................................................................32

Error codes.........................................................................................................34

COMPONENTS DIAGRAM...........................................................................................37

PARTS LIST...................................................................................................................39

OUTPUT TEMPERATURE CHART...............................................................................41

WWW.HYDRO-SHARK.COM HYDROSHARK 115| 3

Page 4

Installation Manual

CONGRATULATIONS

Congratulations and thank you for choosing our micro boiler. Before use, we

recommend that you read through this installation manual carefully. Keep

this manual for future reference.

If you need an additional manual, contact the manufacturer or your local

distributor. When you call, please tell us the product name and the serial

number of your unit written on the rating plate of the boiler.

4 | HYDROSHARK 115 WWW.HYDRO-SHARK.COM

Page 5

SPECIFICATIONS

Model

Natural Gas Input

(OperaƟng Range)

Propane Input

(OperaƟng Range)

Gas ConnecƟon ¾” NPT

Water ConnecƟŽŶƐ

Water Pressure

Natural Gas

Inlet Pressure

Propane

Inlet Pressure

Manifold

Pressure**

Weight 33 lbs.

Dimensions

Natural

Propane 2.5” WC

HydroShark 115

Min: 19,500 Btu/h

Max: 140,000 Btu/h

Min: 19,500 Btu/h

Max: 140,000 Btu/h

¾” NPT

15 - 150 psi*

Min. 5.0” WC

Max. 10.5” WC

Min. 8.0” WC

Max. 14.0” WC

2.0” WC

H20.5” x W13.8” x D6.7”

IgniƟon

Supply

Electric

OperaƟon

Standby

Freeze-

ConsumpƟon

ProtecƟon

Electric IgniƟon

120 VAC / 60 Hz

73.1 W / 0.61 A

6.2 W / 0.05 A

111 W / 0.93 A

*18-25 PSI is recommended for maximum fl ow (Space Heating)

**The Manifold Pressure is the factory setting and generally should not need adjustment.

NOTE:

• Check the rating plate to ensure this product matches your specifi cations.

• The manufacture reserves the right to discontinue, or change at any time, specifi cations, or

designs without notice and without incurring obligation.

*When using boiler in-conjunction with HydroShark DHW Integrator Panel, system pressure may be much higher on your

domestic water side. Your space heating side should still refl ect the recommended 18-25 PSI for system pressure.

WWW.HYDRO-SHARK.COM HYDROSHARK 115| 5

Page 6

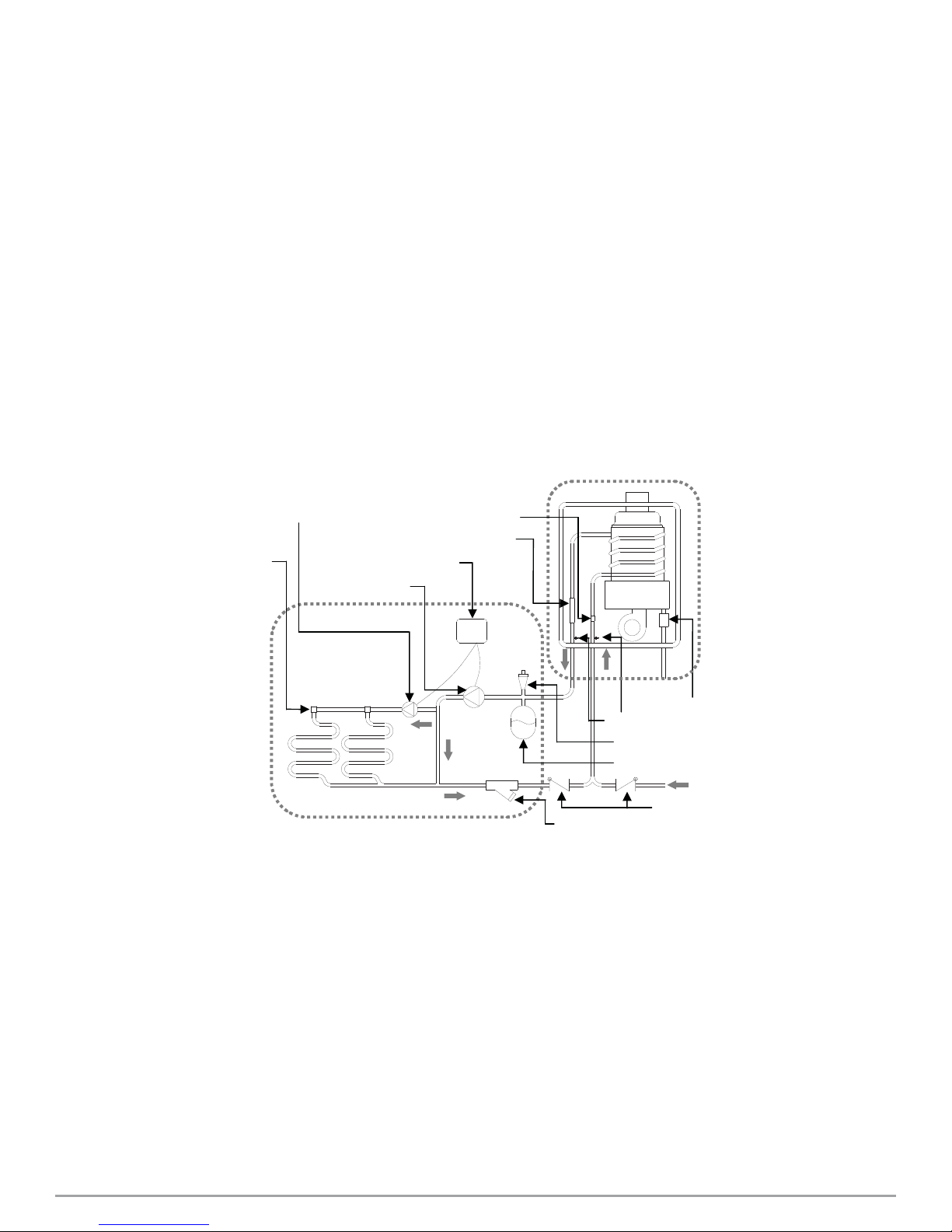

INTRODUCTION

• This manual provides information necessary for the installation, operation, and maintenance of the

boiler.

• The model description is listed on the rating plate which is attached to the side panel of the boiler.

• Please read all instructions completely before installing this product.

• If you have any problems or questions regarding this equipment, consult the manufacturer or its

local representative.

• This equipment is a micro boiler designed to effi ciently supply endless hot water for your needs.

(Radiant Heating, or Domestic Water used in-conjunction with Radiant Heating) See DHW Integrator Panel for more information on integrating domestic water with your radiant heating system.

• These boilers are only to be installed indoors.

• The principle behind micro boilers is easy:

HydroShark 115

Secondary pump

Radiant heĂƟng

Water control valve

Pump controller

Primary pump

HeaƟng panel “Integrator”

Flow sensor

Burner

GAS

Gas valve

Thermistor

Air vent

Expansion tank

Water supply

Check valve

Strainer

*This diagram illustrates micro boiler design concepts only and does not accurately represent the

boilers physical description.

1. Your thermostat indicates a need for heat and turns on the circulator pump(s).

2. Water fl ows through the boiler.

3. The fl ow sensor detects the water fl ow.

4. The computer initiates the fan motor and sends a signal to the igniter to create an ignition spark.

5. The gas ignites and fl ames appear within the burner chamber.

6. Water circulates through the heat exchanger and then gets hot.

7. Using thermistors to measure temperatures throughout the micro-boiler, the computer modulates

the gas and water valves to ensure proper output water temperature.

8. When your room reaches desired temperature the pumps turn off and the boiler shuts down.

6 | HYDROSHARK 115 WWW.HYDRO-SHARK.COM

Page 7

SAFETY GUIDELINES

SAFETY DEFINITION

Indicates an imminently hazardous situation which, if not avoided, will result in

DANGER

WARNING

CAUTION

1. Follow all local codes , or in the absence of local codes, follow the current edition of the National

Fuel Gas Code: ANSI Z223.1/NFPA 54 in the USA or B149.1 Natural Gas, Propane Installation

Code in Canada.

2. Properly ground the unit in accordance with all local codes or in the absence of local codes, with

the National Electrical Codes: ANSI/NFPA 70 in the USA or CSA standard C22.1 Canadian Electrical Code Part 1 in Canada.

3. Carefully plan where you intend to install the micro boiler. Please ensure:

•Your micro boiler will have enough combustible air and proper ventilation

•Locate your micro boiler where water leakage will not damage surrounding areas.

4. Check the rating plate for the correct Gas Type, Gas Pressure, Water Pressure and Electric

Rating.

5. *If this unit does not match your requirements, do not install and consult with the manufacture.

6. If any problem should occur, turn off the unit and unplug the zone controls for the space heating

and/or DHW Integrator Panel system zone controls and turn off the gas. Then call a trained technician or the Gas Company or the manufacture.

death or serious injury.

Indicates an imminently hazardous situation which, if not avoided, could result in

death or serious injury.

Indicates an imminently hazardous situation which, if not avoided, could result in

minor or moderate injury.

GENERAL

• Water temperature over 125°F (52°C) can cause severe burns instantly or

death from scalding. The water temperature is set at 120°F (50°C) from the

factory to minimize any scalding risk. If using micro boiler with HydroShark

DHW Integrator Panel, always check the water temperature. Always verify

WARNING

WWW.HYDRO-SHARK.COM HYDROSHARK 115| 7

emitter water delivery temperature requirements to avoid damage.

• Do not store or use gasoline or other fl ammables, vapors, or liquids in the

vicinity of this appliance.

• Do not reverse the fl uid and/or gas connections as this will damage the gas

valves and can cause sever injury or death.

• Do not use this appliance if any part has been in contact with or been immersed in water. Immediately call a licensed plumber, a licensed gas fi tter, or

a professional service technician to inspect and/or service the unit if necessary.

• Do not disconnect the electrical supply if the ambient temperature will drop

below freezing. The freeze protection system only works if the unit has electrical power. The warranty will not be covered if the heat exchanger is damaged

due to freezing.

Page 8

INSTALLATION

GENERAL

1. Follow all local codes, or in the absence of local codes, follow the current edition of the National

Fuel Gas Code: ANSI Z223.1/NFPA 54 in the USA or B149.1 Natural Gas, Propane Installation

Code in Canada.

2. All gas micro boilers require careful and correct installation to ensure safe and effi cient operation.

This manual must be followed exactly. Read the “Safety Guidelines” section.

3. The manifold gas pressure is preset at the factory. It is computer controlled and should not need

adjustment.

4. Maintain proper space for servicing. Install the unit so that it can be connected or removed easily.

Refer to the “Clearances” section for proper clearance.

5. The micro boiler must be installed in a location where the proper amount of combustible air will be

available to it at all times without obstructions.

6. The electrical connections requires a means of disconnections, to terminate power to the micro

boiler for servicing and safety purposes.

7. Do not install the unit where the exhaust vent is pointing into any opening in the building or where

the noise may disturb your neighbors. Make sure the vent termination meets the required distance

by local code from any doorway or opening to prevent exhaust from entering a building.

8. Particles from fl our, aerosols, and other contaminants may clog the air vent, build up and reduce

the functions of the rotating fan, cause improper burning of the gas, or cause damage to the micro

boiler. Regularly ensure that the area around the unit is dust or debris free. Regular maintenance

is recommended for these types of environment.

9. If you will be installing the micro boiler in a contaminated area with a high level of dust, sand ,

fl our, aerosols or other contaminates/chemicals, they can become airborne and enter and build up

within the fan and burner causing damage to the micro boiler.

10. For the HydroShark 115:

• This unit may be converted to a direct-vent appliance by installing a direct-vent conversion kit.

(TK-TV10) which will bring in all required combustible air from outside the building. When installing

the direct-vent conversion kit, please follow all instructions included with the kit.

• If the boiler is used as a direct vent appliance, the unit requires 3” combustible air supply pipe. The

intake pipe must be sealed airtight. Air supply pope can be made of ABS, PVC, galvanized steel,

corrugated aluminum , corrugated stainless steel or Category III stainless steel.

• Terminating the venting through a sidewall is recommended for the direct-vent system.

• Running the exhaust vent and the intake pipe parallel is recommended.

• Terminate the exhaust and intake on the same wall / surface is recommended. Terminating the

same pressure zone allows for pressure balancing, which prevents nuisance shutdowns.

8 | HYDROSHARK 115 WWW.HYDRO-SHARK.COM

Page 9

WARNING

• Installation and service must be performed by a qualifi ed installer (for

example, a licensed plumber or gas fi tter, otherwise the warranty will be

void.

• The installer (licensed professional) is responsible for the correct installation for the micro boiler and for compliance with all national, state /

provincial, and local codes.

• The manufacturer does not recommend installing the micro boiler in a

pit or location where gas and water can accumulate.

• Do not have the vent terminal pointing toward any operating window, door, or

opening into a building.

• Do not install next to any source of airborne debris, such as clothes dryer, that

can cause debris to be trapped inside the combustion chamber, unless the

system is direct vented.

• The manufacturer does not recommend installing the micro boiler in an

attic due to safety issues. If you install the micro boiler in an attic:

-Keep the area around the micro boiler clean. When dust collects on the

fl ame sensor, the micro boiler will shut down on an error code.

-Place the unit for easy access for service and maintenance.

-A drain pan, or other means of protection against water damage, is to be

installed under the micro boiler in case of leaks.

-Make sure the unit will have enough combustion air and proper ventilation.

NOTICE

• The warranty will not cover damage cause by water quality.

-Only distilled water or distilled water/glycol mixtures can be used with this

micro boiler, unless when used in-conjunction with Stiebel Eltron DHW Integrator Panel system. Do not introduce pool or spa water, or any chemically treated

water into the micro boiler.

-Water hardness levels must not exceed 7 grains per gallon (120 ppm) for

single family applications or more than 4 grains per gallon (70 ppm) for all other

types of applications/ Water hardness leads to scale formation and may aff ect

/ damage the micro boiler. Hard water scaling must be avoided or controlled by

proper water treatment.

-Water pH levels must be between 6.5 and 8.5.

-Well water must be treated.

• Do no install the micro boiler where water, debris, or fl ammable vapors may

get into the fl ue terminal.

• Although the micro boiler is designed to operate with minimal sound, the

manufacturer does not recommend installing the unit on a wall adjacent

to a bedroom, or a room that is intended for quiet study or meditation,

etc.

• Locate your boiler close to a drain where water leakage will not do damage to

surrounding areas. As with any water heating appliance, the potential for leakage at some time in the life of the product does exist. The manufacturer will

not be responsible for any water damage that may occur. If you install a drain

pan under the unit, ensure that it will not restrict the combustion air fl ow.

WWW.HYDRO-SHARK.COM HYDROSHARK 115| 9

Page 10

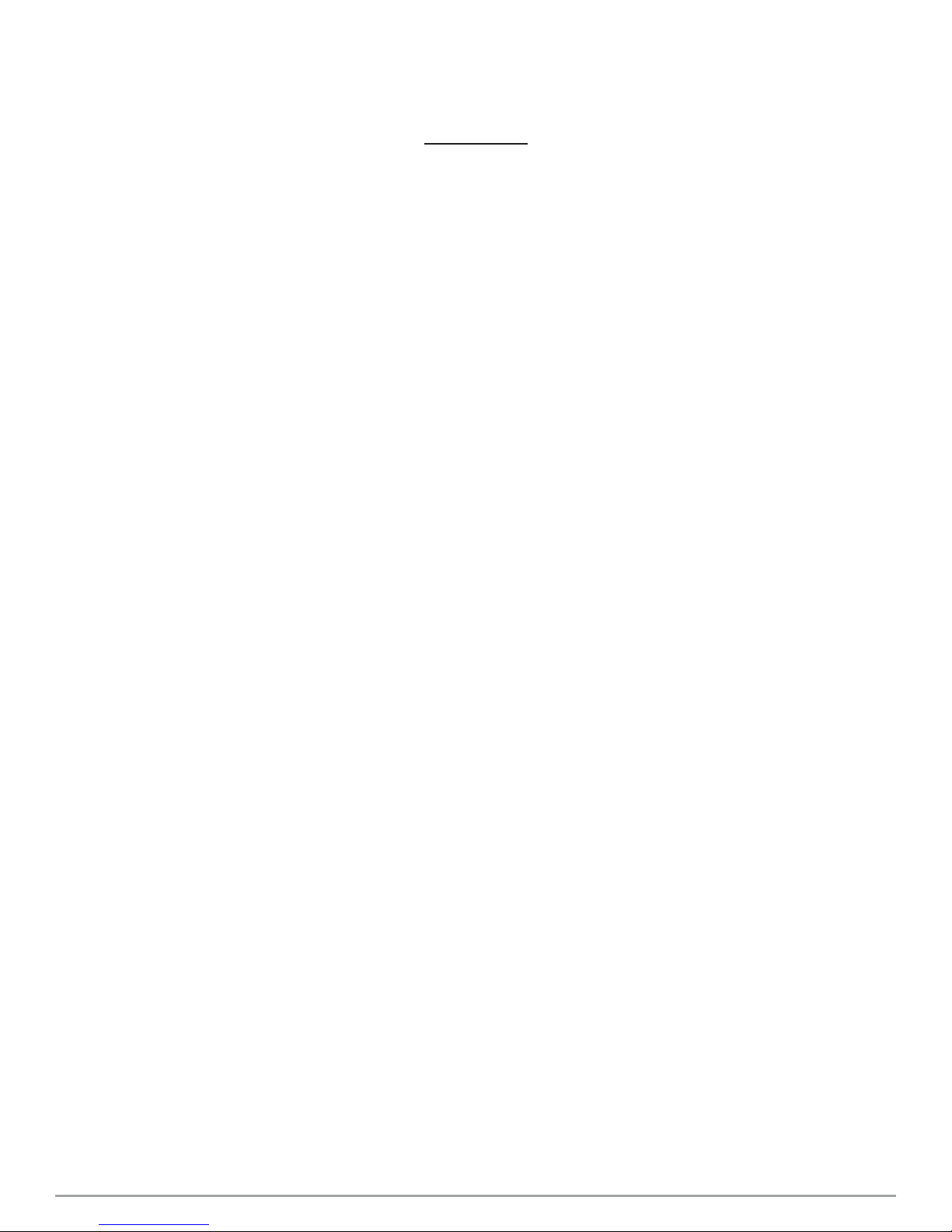

CLEARANCES

Maintain all clearances

around the micro boiler.

Failure to do so could cre-

WARNING

ate a fi re hazard, potentially

leading to death, serious

injury, and/or property damage.

Model Top BoƩom Front Back Sides

12” HydroShark 115* 12” 24” 1” 2 “

*Standard indoor installĂƟŽns and direct-vent indoor instalůĂƟŽns have the same clearances.

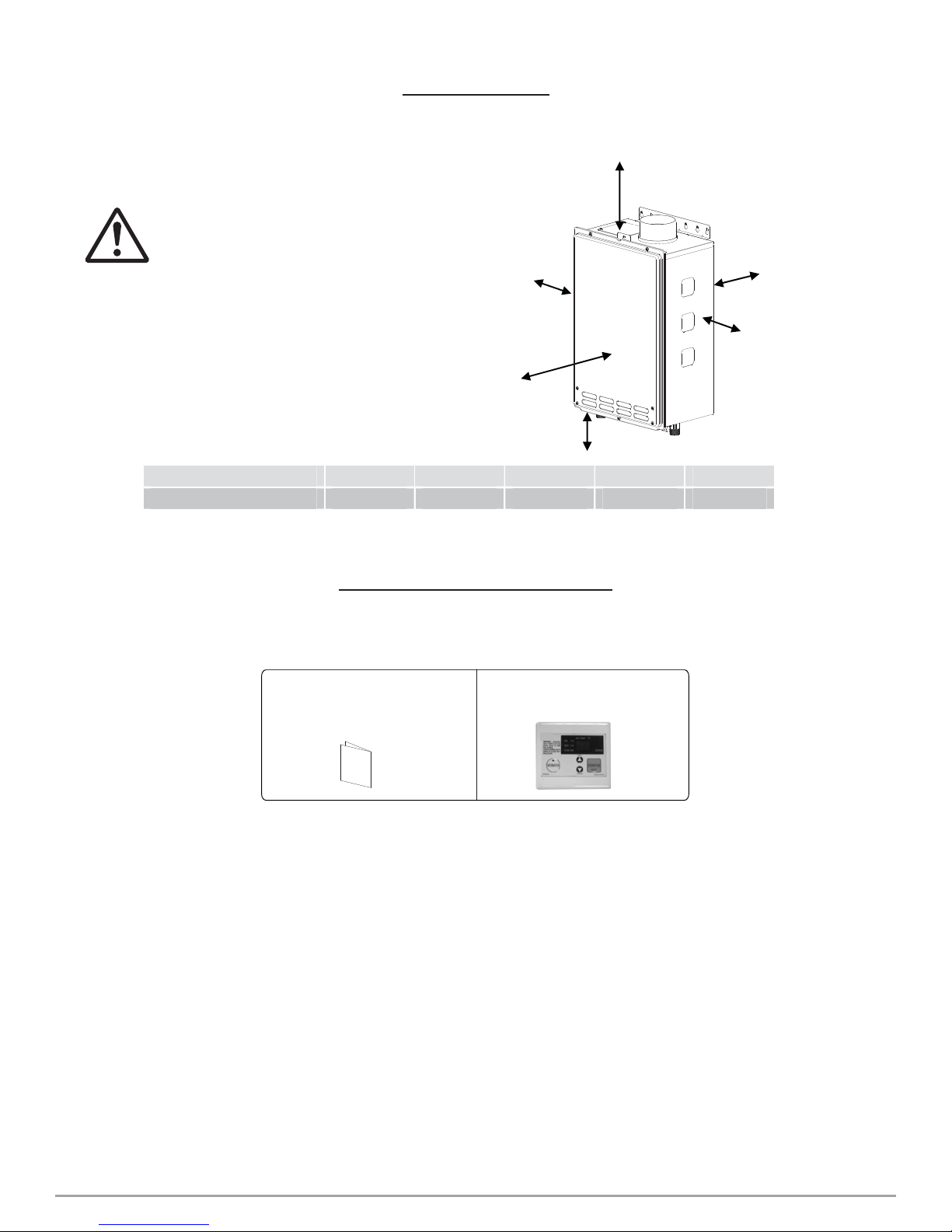

INCLUDED ACCESSORIES

Check that these items below are included with the micro boiler.

Side

Front

BoƩom

Top

Back

Side

1. InstallaƟon Manual and

Owner’s Guide

Qty: 1

2.

Remote controller

900766605 (TK-RE02)

Qty: 1

10 | HYDROSHARK 115 WWW.HYDRO-SHARK.COM

Page 11

HIGH-ALTITUDE INSTALLATIONS

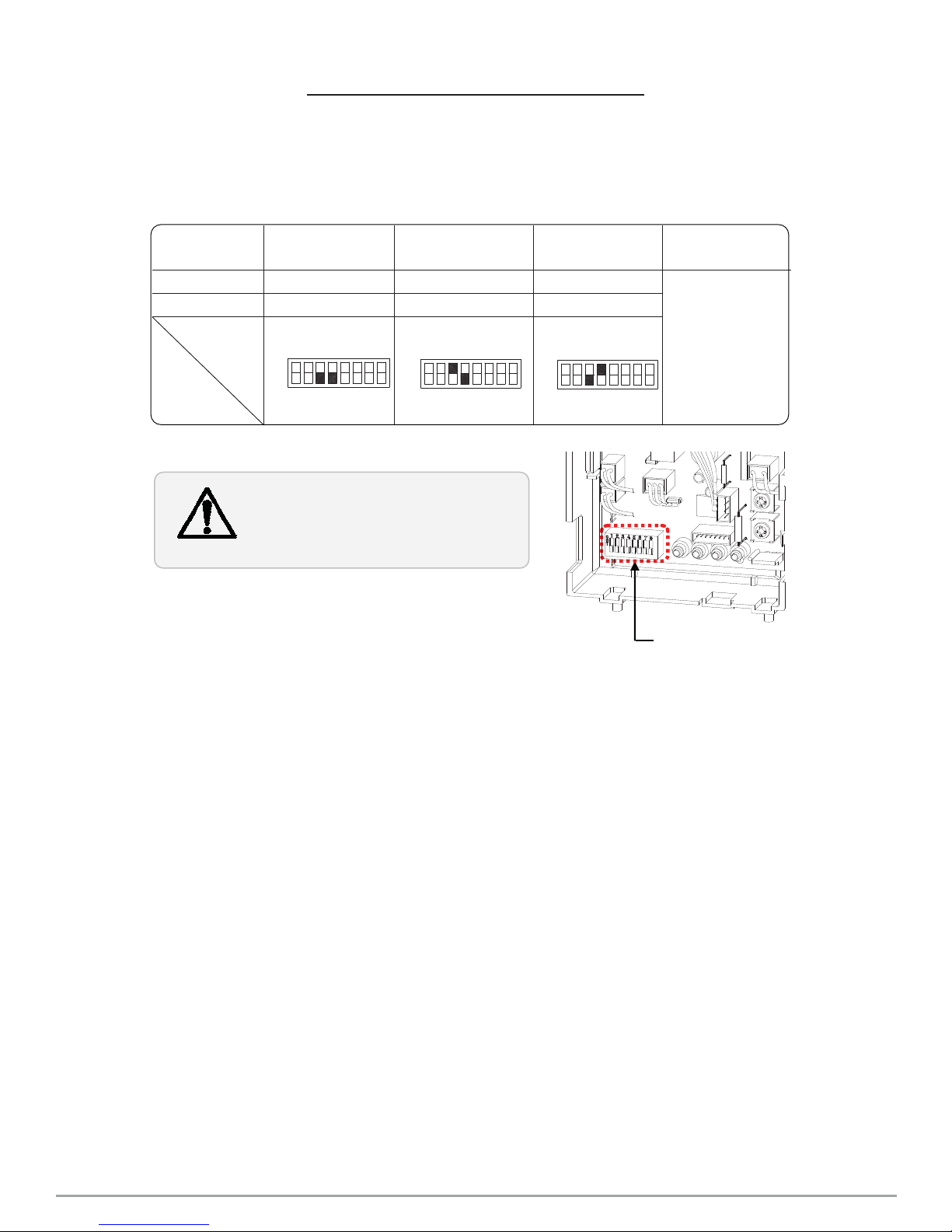

Check the elevation where your micro boiler is installed. Set DIPswitches shown in the table

below depending on the altitude.

AůƟƚƵĚĞ

Swiƚch NŽ.3

WARNING

0 ƚŽ 2,000 Ō

(DEFAULT)

OFF

OFF

࣭

࣮

࣯

ࣰ

ࣱ

ࣲ

2,000 ƚŽ 4,000 Ō

ࣳ

ࣴ

࣭

࣮

ON

OFF

࣯

ࣰ

ࣱ

ࣲ

Th Ğ ĚĂƌk sqƵĂƌĞs ŝŶĚŝĐĂƚĞ ƚhĞ

ĚiƌĞcƟŽn ƚhĞ ĚiƉƐǁŝƚĐŚĞƐ ƐŚŽƵůĚ

bĞ sĞƚ ƚŽ

4,000 ƚŽ 6,000 Ō

ࣳ

ࣴ

࣭

OFF

࣮

OvĞr 6,000 Ō

ON Swiƚch NŽ.4

ࣳ

࣯

ࣰ

ࣴ

ࣱ

ࣲ

DipswiƚĐhĞs

WWW.HYDRO-SHARK.COM HYDROSHARK 115| 11

Page 12

VENTING INSTRUCTIONS

GENERAL

• Improper venting of this appliance can result in excessive levels of carbon

monoxide which can result in severe personal injury or death.

DANGER

CAUTION

This appliance must be vented in accordance with the section” Venting of Equipment” of the current

edition of the National Fuel Gas Code: ANSI Z223.1/NFPA 54 in the United States and/or Section 8 of

the B149.1 Natural Gas and Propane Installation Code in Canada, as well as applicable local building

codes. The manufacturer recommends NovaVENT or Z-Vent Category III, single wall, stainless steel

venting.

The boiler can obtain its combustion air from the space that it is installed in or it can be direct vented

using the direct vent conversion kit (TK-TV10). Ensure the location has suffi cient, clean combustion

air.

General rules for venting micro boilers are:

• Improper installation can cause nausea or asphyxiation, severe injury or death

from carbon monoxide and fl ue gases poisoning. Improper installation will

void product warranty.

When installing the vent system, all applicable national and local codes must be

followed. If you install thimbles, fi re stops or other protective devices and they

penetrate any combustible or noncombustible construction, be sure to follow all

applicable national and local codes.

• Place the micro boiler as close as possible to the vent termination.

• The vent collar of the micro boiler must be fastened directly to an unobstructed vent pipe.

• Do not weld the vent pipe to the micro boiler’s vent collar.

• Do not cut the vent collar of the unit.

• The vent must be easily removable from the top of the boiler for normal service and inspection of

the unit.

• The micro boiler vent must not be connected to any other gas appliance or vent stack except an

approved common venting system.

• Avoid using an oversized vent pope or using extremely long runs of the pope unless it is part of an

approved common vent system.

• For rooftop venting, a rain cap or other from of termination that prevents rain water from entering

into the micro boiler must be installed.

• Do not terminate vent into chimney. If the vent must go through the chimney, the vent must run all

the way through the chimney with approved vent pipe.

General rules for vent terminations:

• Avoid locating the micro boiler vent termination near any air intake devices. These fans can pick

up the exhaust fl ue products from the micro boiler and return them to the building. This can create

a health hazard.

• Locate the vent termination so that it cannot be blocked by any debris, at any time. Most codes require that the termination be at least 12 in. (305 mm) above grade, but the installer may determine

if it should be higher depending on the job site condition and applicable codes.

• A proper sidewall termination is recommended when the micro boiler is vented through a sidewall.

• Be sure to check the clearance form the exhaust termination to the air inlet or opening in the vent

termination clearances section.

12 | HYDROSHARK 115 WWW.HYDRO-SHARK.COM

Page 13

NOTICE

WARNING

Combustion Air Supply

• The guidelines in this section apply to installations within the United Sates. All

U.S. installation must conform to the National Fuel Gas Code, ANSI Z223.1/

NFPA 54 (current edition) and local codes.

• Canadian requirements diff er from the guidelines in this section. In Canada,

follow the requirements of B149.1 (Natural Gas and Propane Installation Code,

current edition) as well as local and provincial codes. Contact your local code

enforcement agency for direction.

This micro boiler requires an adequate source of clean air for combustion and

ventilation. Without suffi cient air, your boiler may not operate properly and may emit

excessive and abnormal amounts of carbon monoxide which may result in carbon

monoxide poisoning or death.

Before installing the boiler, you must determine the amount of air needed to supply this boiler and an

other gas appliances in the same area and provide adequate air for combustion and ventilation. Consult a qualifi ed person if you’re unsure of the proper way to supply air to your boiler.

Check for Chemicals:

Air for combustion and ventilation must be clean and free of corrosive chemicals. If corrosive chemicals, such as sulfur, fl ouring, or chlorine are present, the boiler must be direct vented. Failure due to

these corrosive chemicals is not covered by the warranty.

WARNING!

In all cases, ensure that corrosive chemicals are not present at the air intake. Presence of such

chemicals at the air intake could result in death, personal injury, or property damage. Examples of

locations that require outside air due to chemicals include:

• Beauty salons

• Photo processing labs

• Indoor pools

• Laundry, hobby, or craft rooms

• Chemical storage areas

Products such as aerosol sprays, detergents, bleaches, cleaning solvents, gasoline, air fresheners,

paint, varnish removers, and refrigerants should not be stored or used near the micro boiler.

WWW.HYDRO-SHARK.COM HYDROSHARK 115| 13

Page 14

Exhaust Venting

This is a Category III appliance and must be vented accordingly. The vent system must be sealed

airtight. All seams and joints without gaskets must be sealed with high heat resistant silicone sealant

or UL listed aluminum adhesive tape having a minimum temperature rating of 350° F. For best results,

a vent system should be as short and straight as possible.

• This boiler is a Category III appliance and must be vented accordingly with any 4” vent approved

for use with Category III or Special BH type gas vent.

• Follow the vent pipe manufacturer’s instructions when installing vent pipe.

• Do not common vent this appliance with any other vented appliance. (Do not terminate vent

into a chimney. if the vent must go through the chimney, the vent must run all the way through the

chimney with Category III approved or Special BH vent pipe.)

• When the horizontal vent run exceeds 5 ft. (1.5 m), support the vent run at 3 ft. (0.9 m) intervals

with overhead hangers.

• When th event run exceeds 5 ft. (1.5 m), a condensate drain is recommended. It should be installed as close to the boiler as possible.

• The maximum length of exhaust vent piping must not exceed 50 ft. (15.2 m) (deducting 5 ft. (1.5

m) for each elbow used in the venting system.) Do not use more than 5 elbows.

Diameter Max. No. of Elbow Max. VerƟcal and Horizontal (Total) Vent Length

4” 5 50 Ō.

*For each elbow added, deduct 5 Ō. from max. Vent length.

No. of Elbows

0 50 Ō

1 45 Ō

2 40 Ō

5 25 Ō

Max. sĞƌƟĐĂů or Horizontal Length

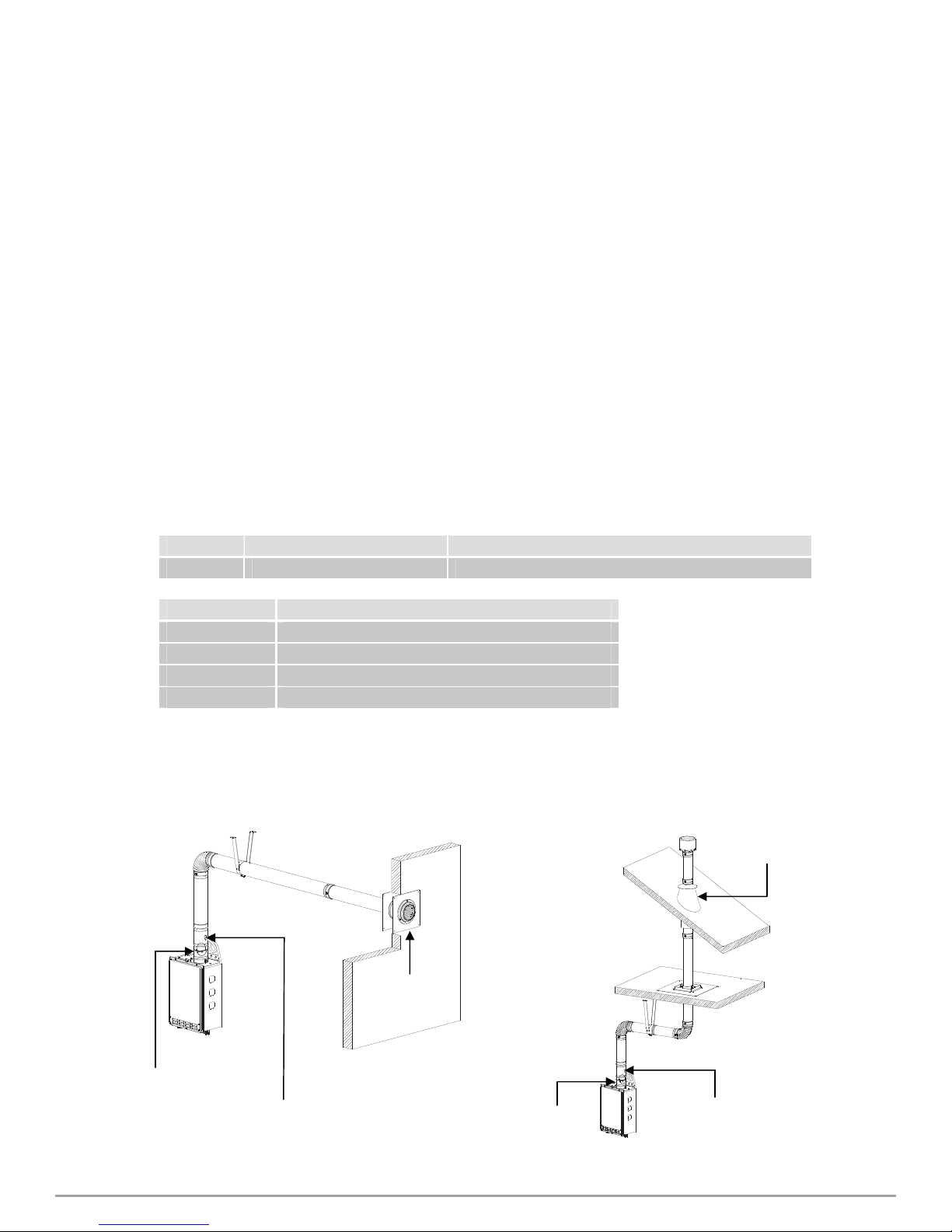

Horizontal InstallaƟŽŶ Diagram

BackŇow Preventer*

VerƟcal CondensaƟon Drain**

Venting Illustrations

Wall

Sidewall Vent

Terminator

BackŇow Preventer *

VerƟcal InstallaƟon Diagram

Rain Cap

Roof Flashing

Roof

sĞƌƟĐĂů CondensaƟon

Drain**

14 | HYDROSHARK 115 WWW.HYDRO-SHARK.COM

Page 15

Venting Illustrations

Horizontal InstallaƟŽŶ Diagram

(With direct-ǀĞŶƟŶŐͿ

BackŇow

Preventer *

sĞƌƟĐĂů CondensaƟon Drain**

See the picture below for detailed connecƟon

instrucƟons to the Direct-Vent Conversion Kit.

Wall

Sidewall

Vent

Terminator

sĞƌƟĐal InstĂůůĂƟŽŶ Diagram

(With direct-venƟŶŐͿ

Rain Cap

Roof

BackŇow

Preventer *

VerƟcal

CondensaƟŽn

Drain**

Roof Flashing

Fire stop

*BackŇow Preventer (Recommended for freezing weather condiƟons: 36°F and below)

**VerƟcal CondensaƟon Drain must be installed accordance with local codes.

Horizontal /ŶƐƚĂůůĂƟŽŶ Diagram

With Direct-Vent Concentric

InstallaƟon Di agram of Direct-Vent

Conversion Kit

TerminaƟŽn

Wall

Plate of Direct-Vent Conversion Kit

Direct-vent

Concentric

TerminaƟon

Intake port of

Direct-Vent

Conversion Kit

WWW.HYDRO-SHARK.COM HYDROSHARK 115| 15

Page 16

Vent Termination Clearances

Canada U.S.A

Direct vent and

other than Direct

Vent

Clearance above grade, veranda, porch, deck,

A 1 foot 1 foot

or balcony.

Clearance to window or door that may be

B

opened.

Clearance to permanently closed window

C * *

VerƟcal clearance to veŶƟůĂted soĸt located

above the vent terminator within a horizontal

D

distance of 2 feet (61cm) from the center line

of the terminator.

E * * *

Clearance to unvenƟlated soĸt

Clearance to outside corner

F

Clearance to inside corner

G

Clearance to each side of center line extended

H

above meter/regulator assembly

Clearance to service regulator vent outlet.

I

Clearance to non-mechanical air supply inlet

J

to building or the combusƟon air inlet to any

other appůŝĐĂƟon.

Clearance to mechanical air supply inlet.

K

Clearance above paved sidewalk or paved

L

driveway located on public property.

Clearance under veranda, porch deck, or

M

balcony.

*For clearances not spĞĐŝĮĞĚ in ANSI Z223.1 / NFPA 54 or CAN/CSA-B149.1, please use clearances in accordance with

local installaƟon codes and the requirements of the gas supplier.

3 feet 1 foot

* * *

** *

** *

3 feet 1 foot

6 feet 3 feet

Direct vent

* 3 feet *

*3 feet

* 7 feet 7 feet

* * 1 foot

Other than Direct Vent

4 feet from below or side

opening. 1 foot from

4 feet from below or side

opening. 1 foot from

1 foot

above opening.

*

*

above opening.

3 feet

16 | HYDROSHARK 115 WWW.HYDRO-SHARK.COM

Page 17

Please follow all local and naƟŽnal codes in regards to proper terminaƟŽŶ clearances.

In the absence of such codes, the following clearances can be used as guidelines. Local

CAUTION

codes supersede these guidelines.

For sidewall terminaƟons

2Ō.

1Ō.

1Ō.

Inside

corner

Exhaust terminaƟŽŶ

For ŵƵůƟƉle sidewall exhaust

terminaƟons (e.g. mulƟ-unit

systems), an exhaust terminaƟŽŶ

must be at least 1 Ō. away from

another exhaust teƌŵŝŶĂƟŽŶ An

exhaust terminaƟon must also be

at least 2 Ō away from an inside

corner (if the adjacent wall is less

than 2 Ō. of length, the minimum

required distance away from the

inside corner will be equal to the

length of that adjacent wall).

ϯŌ.

ϯŌ.

3Ō.

Air supply inlet

For direct-vent sidewall

terminĂƟŽŶƐ that use two

separate penetraƟŽns for the

intake and exhaust, distance

the intake and exhaust

terminĂƟŽŶƐ at least 3 Ō away

from each other, no maƩer the

orientaƟon.

2Ō.

ϭŌ.

1Ō.

Inside

corner

Direct vent ƚĞƌŵŝŶĂƟŽŶ

For ŵƵůƟƉle-unit, direct-vent sidewall

terminaƟons that combine the intake

and exhaust into a single penetraƟon,

space each direct-vent terŵŝŶĂƟŽŶ at

least 1 Ō. away from each other, no

maƩer the orientaƟon. A direct-vent

terminaƟon must also be at least 2 Ō.

away from an inside corner (if the

adjacent wall is less than 2 Ō. of

length, the minimum required

distance away from the inside corner

will be equal to the length of that

adjacent wall).

2Ō.

Exhaust

terminaƟon

Exhaust and/or direct-vent

sidewall terminaƟŽŶƐ should

be at least 2 Ō away from an

opposite surface/wall. Do

not place the terminaƟon

directly in front of an

opening into a building.

For roŽŌŽƉ terminaƟons

A

A

ϮŌ.

A

A

A

Air intake

Exhaust terŵŝŶĂƟon

A: In accordance with local codes

Exhaust

terminaƟon

Air intake

For ŵƵůƟƉle-unit rooŌŽƉ teƌŵŝŶĂƟons (whether for standard indoor or

direct-vent installĂƟons) space all exhaust and intake terminaƟons in

accordance with local codes. An exhaust terminaƟon must be spaced from

a wall or surface in accordance with local codes as well. In the absence of

such a code, an exhaust terminaƟŽŶ must be a horizontal distance of at

least 2 Ō. away from a wall or surface.

WWW.HYDRO-SHARK.COM HYDROSHARK 115| 17

Page 18

GAS SUPPLY AND GAS PIPING SIZE

• Check that the type of gas matches the rating plate fi rst.

• Ensure that any and all gas regulators are operating properly and

providing gas pressures withing the specifi ed range shown below.

CAUTION

• The minimum and maximum inlet gas pressures are:

Excess gas inlet pressure may cause serious accidents.

• Conversion of this unit from natural gas to propane or vice versa will void all

warranty. Contact your local distributor to get the correct unit for your gas

type. The manufacturer is not liable for nay property and/or personal

damage resulting from gas conversions.

Gas type

Natural Gas Min. 5.0” WC – Max. 10.5” WC

Propane Min. 8.0” WC – Max. 14.0” WC

Inlet gas pressure

• Inlet gas pressures that fall outside the range of values listed above may adversely aff ect the performance of the micro boiler. These pressures are measured when the micro boiler is in full operation.

• Inlet gas pressure must not exceed the above maximum values; gas pressure above the specifi ed

range will cause dangerous operating conditions a damages to the unit.

• Until testing of the main gas line supply pressure is completed, ensure the gas line to the micro

boiler is disconnected to avoid any further damage.

Gas connections

1. Install a manual gas shutoff valve between the micro boiler and the gas supply.

2. When the gas connections are completed, it is necessary to perform a gas leak test either by

applying soapy water to all gas fi ttings and observing for bubble or by using a gas leak detection

device.

• The micro boiler and its individual shutoff valve must be disconnected from the gas supply piping system during any pressure testing of that system at the test pressures in excess of 1/2 psi

(3.5kPa).

• The micro boiler must be isolated from the gas supply piping system by closing its individual

manual shutoff valve during any pressure testing of the gas supply piping system at test pressures

equal to or less than 1/2 psi (3.5 kPa).

3. Always purge the gas line of any debris and/or water before connecting to the gas inlet.

Size the gas pipe appropriately to supply the necessary volume of gas required for

NOTICE

the micro boiler using ANSI Z223.1/NFPA 54 in the USA of B149.1 in Canada or

local codes. Otherwise, fl ow capabilities and output temperatures will be limited.

18 | HYDROSHARK 115 WWW.HYDRO-SHARK.COM

Page 19

Natural Gas Supply Piping

Maximum delivery Capacity of Cubic Feet of Gas per Hour of IPS Pipe carrying Natural Gas with 0.60

Specifi c Gravity Based on Pressure Drop of 0.5”W.C.

Based on Energy Content of 1,000 BTU/Cubic ft.: The micro boiler requires 140 Cubic ft./hr.

Unit: Cubic Feet per Hour

Pipe Size

Diameter 10’ 20’ 30’ 40’ 50’ 60’ 70’ 80’ 90’ 100’ 125’ 150’ 200’

¾” 363 249 200 171 152 138 127 118 111 104 93 84 72

1” 684 470 377 323 286 259 239 222 208 197 174 158 135

1 ¼” 1,404 965 775 663 588 532 490 456 428 404 358 324 278

1 ½” 2,103 1,445 1,161 993 880 798 734 683 641 605 536 486 416

2” 4,050 2,784 2,235 1,913 1,696 1,536 1,413 1,315 1,234 1,165 1,033 936 801

Length

Propane (LP) Supply Piping

Maximum Capacity of Propane (LP) Based on 11” W.C. supply pressure at 0.5” W.C. pressure drop.

Unit: kBTU per Hour

Pipe Size

Diameter

10’ 20’ 30’ 40’ 50’ 60’ 70’ 80’ 90’ 100’ 125’ 150’ 200’

¾” 567 393 315 267 237 217 196 185 173 162 146 132 112

1” 1,071 732 590 504 448 409 378 346 322 307 275 252 213

1 ¼” 2,205 1,496 1,212 1,039 913 834 771 724 677 630 567 511 440

1 ½” 3,307 2,299 1,858 1,559 1,417 1,275 1,181 1,086 1,023 976 866 787 675

2” 6,221 4,331 3,465 2,992 2,646 2,394 2,205 2,047 1,921 1,811 1,606 1,496 1,260

For more informaƟŽn, please see the below.

Length

Based on Energy Content of 1,000 BTU/Cubic ft.

Divide each appliance’s BTU/h requirement by 1,000 BTU/ft³ to get the

appliances ft³/h requirement.

Take into account the distance the appliance is from the

gas meter, look in the above gas chart to properly size

the line.

For sections of the gas line supplying gas to more than

one appliance (Ex. Point A to Point B), add up the cubic

ft. per hour requirements of the appliances that are

being supplied by that section, and size to the farthest

appliance.

For Example: The section from A to B supplies gas

to the furnace, range and dryer. Adding up the BTU/h

requirements and dividing by 1,000 yields a cubic ft. per

hour requirements of 220 cubic ft. of gas per hour. The

5’ Le

ngth

1-1/4” Pipe Size

5’ Length

1-1/4” Pipe Size

Gas Meter

farthest appliance is the range, which is 50 ft. away form

the meter. Looking at the above chart, and under column

of 50 ft., Section A to B needs to be 1” in order to supply 220 cubic ft.

Micro

Boiler

199,000BTU

10’ Length

3/4” Pipe Size

A

10’ Length

1” Pipe Size

Gas Sizing Example

(Natural Gas)

15’ Length

B

1” Pipe Size

10’ Length

3/4” Pipe Size

Furnace

120,000BTU

Dryer

35,000BTU

10’ Length

15’ Length

C

Range

65,000BTU

WWW.HYDRO-SHARK.COM HYDROSHARK 115| 19

Page 20

Measuring inlet gas pressure

1. Turn off all electric power to the micro boiler if service is to be performed.

2. Turn the manual gas valve located on the outside of the unit clockwise to

the off position.

WARNING

3. Failure to follow these steps could lead to a fi re or explosion, resulting in

personal injury or death.

The micro boiler cannot perform properly without suffi cient inlet gas pressures. Below are instructions

on how to check the inlet gas pressure.

THIS IS ONLY TO BE DONE BY A LICENSED PROFESSIONAL.

1. Shut off the manual gas valve on the gas supply line.

2. Remove the screw for the pressure port located on the

gas inlet of the micro boiler shown in the diagram on the

right.

3. Connect the manometer to the pressure port.

4. Re-open the manual gas valve. Check to see that there

are no gas leaks.

5. Check in inlet gas pressure. When the micro boiler is on

maximum and minimum burn, the manometer should

read from 5.0” W.C. to 10.5” W.C. (1.24 to 2.61 kPa) for

Natural Gas, from 8.0” to 14.0” W.C. (1.99 to 3.48 kPa)

for Propane.

Pressure port

WATER CONNECTIONS

Do not use the micro boiler if any part has been under water. Immediately

contact a qualifi ed installer or licensed professional to inspect the boiler to

WARNING

NOTICE

determine if it needs to be replaced.

Do not reverse the hot outlet and cold inlet connections to the micro boiler.

This will not properly activate the micro boiler.

All pipes, pipe fi ttings, valves and other components, including soldering materials, must be suitable

for potable water systems (when using DHW Integrator Panel), or distilled water or distilled water/glycol mix.

1. A manual shutoff valve must be installed on the cold

water inlet to the micro boiler between the main water

supply line and the micro boiler.

2. In addition, a manual shutoff valve is also recommended on the hot water outlet of the unit. If the micro boiler

is installed within, or subjected to, a closed loop system

As Close as

Possible

(recommended), a thermal expansion tank or code

approved device to handle the thermal expansion must

be installed.

3. Before installing the micro boiler, fl ush the water line

Pressure

Relief Valve

Hot

outlet

Cold

inlet

Gas

inlet

to remove all debris, and after installation is complete,

purge the air from the line. Failure to do so may cause

damage to the boiler.

20 | HYDROSHARK 115 WWW.HYDRO-SHARK.COM

Page 21

Pressure relief valve

The micro boiler has a high-temperature shutoff switch built in as a standard safety feature (called a

Hi-Limit switch) therefore a “pressure only” relief valve is required.

• This unit does not come with an approved pressure relief valve.

• An approved pressure relief valve must be installed on the hot water outlet.

• The pressure relieve vale must conform to ANSI Z21.22 or Can 1-4.4 and installation must follow

local codes.

• The discharge capacity must be at least 140,000 BTU/h.

• The pressure relief valve needs to be rated for a maximum of 150 psi (1 MPa).

• The discharge piping for the pressure relief valve must be directed so that the hot water cannot

splash on anyone or on nearby equipment.

• Attach the discharge tube to the pressure relief valve and run the end of the tube to within 6

in.(152 mm) from the fl oor. This discharge tube must allow free and complete drainage without any

restrictions.

• If the pressure relive valve installed on the micro boiler discharges periodically, this may be due to

a defective thermal expansion tank or defective pressure relief valve.

• The pressure relief valve must be manually operated periodically to check for correct operation.

• No valve must be placed between the relief valve and the micro boiler.

WARNING

ELECTRICAL CONNECTIONS

• Follow the electrical code requirements of the local authority having jurisdiction. In the absence of such requirements, follow the current edition of the National Electrical Code ANSI/NFPA 70 in the U.S. or the current edition of CSA

C22.1 Canadian Electrical Code Part 1 in Canada.

• When servicing or replacing parts with the micro boiler, label all wires prior to

disconnection to facilitate an easy and error-free reconnection. Wiring errors

can cause improper and dangerous operation. Verify proper operation after

servicing.

• Failure to observe these warnings could result in personal injury or loss of life.

This unit comes with a power plug instead of a junction box.

WWW.HYDRO-SHARK.COM HYDROSHARK 115| 21

Page 22

REMOTE CONTROLLER CONNECTIONS

<How to connect the remote controller to the micro boiler>

1. Disconnect power supply from the micro boiler.

2. Take Žī the micro boiler front cover.

3. Locate the remote controller terminal, pictured below (located around the lower right-hand

side of the computer board).

4. Open the plasƟĐ cover of the remote controller, and then aƩach the two fork terminals to

connector base of the backside the remote controller with two screws. Make sure the

terminals are Įrmly Įxed.

5. Pull the remote’s wires through the hole at the boƩom of the water heater’s casing.

6. Properly ĂƩĂĐŚ the remote’s wires to the remote controller terminal on the computer board.

(No polarity)

*Do NOT jump or short-circuit the wires or computer will be damaged.

7. Replace Front Cover securely.

8. Wires used for the remote controller connecƟon must be:

Minimum 18AWG wire (No polarity)

Maximum 400 feet long

*For detailed ĐŽŶŶĞĐƟŽŶ instrucƟons to the remote controller, refer to the instrucƟons that are

packaged with the remote controller.

Remote controller terminal inside micro boiler

Connect to these

terminals

Front of remote

9007666005

(TK-RE02)

Connect other end to these terminals

Back of remote

22 | HYDROSHARK 115 WWW.HYDRO-SHARK.COM

Page 23

APPLICATIONS

Space Heating Applications

• In order to purge air in water pipes within a closed loop system, an air vent,

air separator, and expansion tank should be installed in the system. (Hydro-

Shark pre-built space heating panels incorporate all of these features).

WARNING

HydroShark per-plumbed panels help make space heating easy and reliable. These panels are professionally engineered and use proven Primary/Secondary hydronic practices. Call Tech Support

(800.805.5384) for assistance.

• Water temperature over 125° F (52° C) can cause sever burns instantly of

death from scalding.

• Chemicals such as diluted Glycol can be used for radiant fl oor, Hydro/fan

coil air or Baseboard heating only. The diluted solution of glycol must contain

between 25% and 55% of Glycol. Be aware that in a closed loop system, low

pressure in the heat exchanger can cause low-temperature boiling, resulting

in excessive noise and damage to the micro boiler. Consult with the glycol

maker for specifi cations prior to use.

HydroShark Pre-Built Space Heating Panels

Sample:

Master Panel Single:

For more information on HydroShark pre-plumbed panels and zoning options for this boiler please

visit www.hydro-shark.com or call 800.805.5384

WWW.HYDRO-SHARK.COM HYDROSHARK 115| 23

Page 24

Dual-purpose hot water heating

(Domestic and Space Heating)

Insert a HydroShark DHW Integrator Panel to provide potable heated water and Hydronic Heating

(with space heating panel(s)) with one heat source.

The HydroShark DHW Integrator Panel integrates with a wide variety of boilers and delivers “Priority”

potable heated water with no storage tank and hydronic space heating in a small reliable package.

Follow all local codes, or in the absence of local codes, follow the most recent

NOTICE

edition of the National Standard Code, ANSI Z21.10.3.

For more information on HydroShark DHW Integrator Panels and integrating space heating and domestic water for this boiler please visit www.hydro-shark.com or call 800.805.5384.

24 | HYDROSHARK 115 WWW.HYDRO-SHARK.COM

Page 25

INITIAL OPERATION

• Check the Gas and Water Connections for leaks before fi ring the unit for the fi rst time.

• Open the main gas supply valve to the unit using only your had to avoid and spark. Never use

tools. If the knob will not sure by had, do not try to force it; call a qualifi ed service technician.

Forced repair may result in a fi re or explosion due to gas leaks.

• Be sure to check for the presence of leaking gas toward the bottom of the unit because some gases are heavier than air and may settle towards the fl oor.

• Check the Gas Pressure.

• Do not try to light the burner manually. It is equipped with an electric ignition device which automatically lights the burner.

• Check for proper venting and combustible air to the micro boiler.

• Purge the gas and water lines to remove any air pockets.

• Do not use this micro boiler if any part has been under water. Immediately call a qualifi ed installer

or service technician to inspect the micro boiler to determine if it needs replacement.

IF YOU SMELL GAS:

• Do not try to start the micro boiler.

• Do no touch any electric switches; do not use any phone in your building.

• Immediately call your gas supplier from a neighbor’s phone. Follow the gas

WARNING

supplier’s instructions.

• If you cannot reach your gas supplier, call the fi re department.

WWW.HYDRO-SHARK.COM HYDROSHARK 115| 25

Page 26

Owner’s Guide

CONGRATULATIONS

Congratulations and thank you for choosing our micro boiler. Before

use, we recommend that you read through this owner’s guide carefully.

Keep this manual for future reference.

If you need an additional manual, contact the manufacturer or your local

distributor. When you call, please tell us the product name and the serial

number of your unit written on the rating plate of the boiler.

26 | HYDROSHARK 115 WWW.HYDRO-SHARK.COM

Page 27

OPERATING SAFETY

FOR YOUR SAFETY READ BEFORE OPERATING

WARNING: If you do not follow these instructions exactly, a fi re or explosion may result

causing property damage, personal injury or loss of life.

1. The micro boiler does not have a pilot. It is equipped with an ignition device that automatically

lights the burner. Do NOT try to light the burner by hand.

2. Before operating smell all around the micro boiler area for evidence of leaking gas. Be sure to

smell next to the fl oor because some gas is heavier than air and will settle on the fl oor.

WHAT TO DO IF YOU SMELL GAS:

• Do not try to light any appliance.

• Do not touch any electric switch; do not use any phone in your building.

• Immediately call your gas supplier from a neighbor’s phone.

• Follow the gas suppliers instructions. If gas supplier cannot be reached, call fi re dept.

3. Use only your hand to turn the gas shutoff valve. Never use tools. If the valve will not turn by hand,

don’t try to repair it, call a qualifi ed service technician. Force or attempted repair may result in a

fi re or explosion.

4. Do not use this micro boiler if any part has been under water. Immediately call a qualifi ed service

technician to inspect the micro boiler and to replace the unit if needed.

OPERATING INSTRUCTIONS

1. STOP! Read the safety information above or in the Owner’s Manual.

2. Turn off all electric power to the micro boiler.

3. Do not attempt to light the burner by hand.

4. Turn the manual as valve located on the outside of the unit clockwise to the OFF position.

5. Wait fi ve (5) minutes to clear out any gas. If you then smell gas, STOP! Follow “B” in the safety

information above on this label. If you don’t smell gas, go to next step.

6. Turn the manual gas valve located on the outside of the unit counterclockwise to the ON position.

7. Turn on all electrical power to the micro boiler.

8. If the micro boiler will not operate, follow the instructions “To turn off Gas to appliance” and call

your service technician or gas supplier.

TO TURN OFF GAS TO APPLIANCE

1. Turn off all electric power to the micro boiler if service is to be performed.

2. Turn the manual gas valve located on the outside of the unit clockwise to the OFF position.

WWW.HYDRO-SHARK.COM HYDROSHARK 115| 27

Page 28

DANGER

Vapors from fl ammable liquids will explode and catch fi re causing death or sever burns.

Do not use or store fl ammable products such as gasoline, solvents or adhesives in the same

room or area near the micro boiler.

Flammable Vapors

Read and follow micro boiler warnings and instructions. If the owner’s manual is missing,

contact the manufacturer.

Keep fl ammable products: Vapors:

1. Far away from boiler.

2. In approved containers.

3. Tightly closed and out of reach of children.

4. Micro boiler has a main burner, which may

come on at any time and will ignite fl am-

1. Cannot be seen.

2. Are heavier than air.

3. Go a long way on the fl oor.

4. Can be carried form other rooms to the

main burner by air currents.

mable vapors.

DANGER

When using micro boiler with DHW Integrator Panel for Domestic Hot Water:

1. Water temperature over 125° F can cause severe burns instantly or death from scalds.

2. Children, disabled and elderly are at highest risk of being scalded

3. Feel water before bathing or showering.

4. Temperate limiting valves are available on the DHW Integrator Panel(s). Adjust these mixing

valves accordingly.

5. The outlet temperature of the micro boiler is set at 120° F (50° C). If you require water temperatures below this setting, follow the instruction manual.

6. Test the boiler before bathing or showering. Do not leave children or an infi rm person unsupervised.

28 | HYDROSHARK 115 WWW.HYDRO-SHARK.COM

Page 29

NORMAL OPERATION

TEMPERATURE CONTROLLER AND REMOVE CONTROLLER

The illustration below shows an example of the controllers. The exact display may diff er from examples.

GENERAL

• Water temperatures over 125° F (52° C) can cause sever burns instantly or

death from scalding.

WARNING

NOTICE

• The outlet hot water temperature of the boiler is factory set at 120° F.

• Flow rate to active micro boiler: 0.75 gallon per minute at the default set

temperature

• Flow rate to keep the micro boiler running: 0.4 gallon per minute.

OPERATION

<Set temperature>

1. Turn on the 120 VAC power supply to the micro boiler.

2. Press the "OPERATION" buƩon on the remote in order to turn the remote controller on. It shows the

set temperature on its display as shown the picture to the below.

3. Press the "HOT" bu

4. You can set the temperature from 99°F (38°C) to 167°F (75°C).

<Exterior view of the remote controller>

"INFOMATION" BuƩon

<The temperature opƟons>

99 100

Ʃon or the "COLD" ďƵƩon to set the temperature seƫng of the unit.

"HOT" BuƩon

"OPERATION" BuƩon

"COLD" BuƩon

102 104 106 108 110 111 113 115 117 122 131 140 158 167

Temperature above 122°F (50°C) can cause severe burns or death from

scalding. Children, disabled

CAUTION

WWW.HYDRO-SHARK.COM HYDROSHARK 115| 29

and the elderly are at high risk of being injured.

Page 30

TEMPERATURE SETTINGS

Set Temperature

-Without remote controller-

There are 4 temperatures that you can select from by changing the dipswitch seƫngs on the

computer board without the remote controller. See the table below.

Temperatures available

113°F 122°F 131°F 140°F

For detailed dipswitch seƫngs for each temperature see below.

The temperature has been preset at the factory to 120°F (50°C).

If temperatures other than the ones listed above are required, the remote controller can

provide several more temperature opƟons.

-Dipswitch seƫngs for each temperature on the computer board-

Temperature Seƫngs

࣭

ࣿࣥ

࣭࣭࣯

ࣰࣱࣤ

WARNING

࣮

ࣳ

࣯

ࣴ

ࣱ

ࣰ

ࣲ

࣭࣮࣮

ࣱࣤ࣬ ࣿࣥ

ࣽ

Turn oī the power supply to the

micro boiler before changing the

dipswitch seƫŶŐƐ

Only change the switches with the

dark squares. The dark squares

indicate which direĐƟŽŶ the

dipswitch should be set to.

࣭

࣮

ࣳ

࣯

ࣴ

ࣰ

ࣱ

ࣲ

࣭࣯࣭

ࣱࣱࣤ

ࣿࣥ

࣭

࣮

ࣳ

࣯

ࣴ

ࣱ

ࣰ

ࣲ

ࣰ࣭࣬

ࣲࣤ࣬

ࣿࣥ

࣭

࣮

ࣳ

࣯

ࣴ

ࣰ

ࣱ

ࣲ

Dipswitches

30 | HYDROSHARK 115 WWW.HYDRO-SHARK.COM

Page 31

FLOW

• The fl ow rate through the micro boiler is limited to a maximum of 6.6 GPM (38 L/min).

• The temperature setting, along with the supply temperature of the water will determine the fl ow

rate output of the unit.

FREEZE PROTECTION SYSTEM

• This unit comes equipped with heating blocks to protect it against damages associated with freezing.

• For this freeze protection system to operate, there has to be electrical power to the unit. Damage

to the heat exchanger caused by freezing temperates due to a power loss is not covered under

warranty. In cases where power losses can occur, consider the use of a backup power supply.

• The freeze protection system will activate when the surrounding and/or outside temperature drop

below 36.5°F (2.5° C).

• It is the installer’s responsibility to be aware of freezing issues and take all preventive measures.

The manufacture will not be responsible for any damage to the heat exchanger as a result of

freezing.

• In any area subject to freezing temperatures, freezing issues can occur if cold air enters through

the venting into the heat exchanger by either negative pressures within the installation location or

by strong outside wind. The manufacturer highly recommends the use of a back fl ow preventer

(sold separately) to minimize the amount of cold air entering through the exhaust venting when the

micro boiler is off .

• It is the installer’s responsibility to be aware of freezing issues and take all preventive measures.

The manufacture will not be responsible for any damage to the heat exchanger as a result of

freezing.

• If you will not be using your boiler for a long period of time:

1. Completely drain the water out of the unit.

2. Disconnect power to your boiler.

This will keep your unit from freezing and being damaged.

Only pipes within the micro boiler are protected by the freeze protection system.

Any water pipes (hot or cold) located outside the unit will no be protected. Properly

CAUTION

WWW.HYDRO-SHARK.COM HYDROSHARK 115| 31

protect and insulate these pipes from freezing.

Page 32

MAINTENANCE AND SERVICE

Turn off the electrical power supply and close the manual gas shutoff valve

and the manual water control valve before servicing.

WARNING

• Be sure that all openings for combustion and ventilation air are not blocked.

• The venting system should be checked annually for any leaks, corrosion, blockages or damage.

• The burner should be checked annually for dust, lint, grease or dirt.

• Keep the area around the micro boiler clear. Remove any combustible materials, gasoline or any

fl ammable vapors and liquids.

• In accordance with all local codes and common safety practices, water discharged from the pressure relief valve can cause severe burns instantly from scalding. DO NOT touch the pressure relief

valve.

• If the relief valve discharges periodically, it may be due to thermal expansion in a closed water

supply system. Contact the water supplier or local plumbing inspector on how to correct this situation.

• Visual check of burner fl ames (see below) through the burner window in the burner assembly located at the middle of the micro boiler.

Flame

blowing up

Red or Yellow

The manufacturer recommends having the unit checked once a year or as necessary by a licensed

technician. If repairs are needed, any repairs should be done by a licensed technician.

UNIT DRAINING

1. Close the manual gas shutoff valve.

2. Turn off power to the unit and wait a couple of

seconds.

Turn on again.

3. Wait 30 seconds, and then turn off power to

the unit, yet again.

4. Close the water shut off valve.

5. Have a bucket or pan to catch the water from

the unit’s drain plugs. Unscrew the two drain

plugs (large and small) to drain all the water

out of the unit.

6. Wait a few minutes to ensure all water has

completely drained from the unit.

Drain Plug

(Large)

Drain Plug

(Small)

Gas Valve

Water Valve

32 | HYDROSHARK 115 WWW.HYDRO-SHARK.COM

Page 33

TROUBLESHOOTING

PROBLEM SOLUTIONS

General

It takes long ƟŵĞ to get

hot water at the

Įdžtures.

The water is not hot

enough.

The water is too hot.

The hot water is not

available when a Įdžture

is opened.

•

The Ɵŵe it takes to deliver hot water froŵ the ŵŝĐƌŽ boiler to

your Įdžtures depends on the length of piping between the two.

The longer the ĚŝƐƚĂŶĐĞ or the bigger the pipes, the longer it will

•

take to get hot water.

•

Žŵpare the Ňow and teŵperature.

•

CheĐŬ Đƌoss plƵŵbing between ĐŽůĚ water lines and hot water

lines.

•

Is the gas supply valve fully open?

•

Is the gas line sized properly?

•

Is the gas supply pressure enough?

•

Is the set teŵperature set too low?

•

Is the set teŵperature set too high?

Make sure the unit has 120 VAC / 60 Hz power supply.

•

If you are using the reŵote ĐŽntroller, is the power buƩon turned

•

on?

•

Is the gas supply valve fully open?

•

Is the water supply valve fully open?

•

Is the hot water ĮdžƚƵre suĸĐiently open to draw at least 0.5 GPM

through the ŵŝĐƌŽ boiler?

•

Is the unit frozen?

•

Is there enough gas in the tank / ĐLJlinder? (For Propane ŵŽĚels)

The hot water turns

Đold and stays Đold.

-TEMPERATURE and AMOUNT OF HOT WATER-

FluĐtuaƟon in hot water

teŵperature.

WWW.HYDRO-SHARK.COM HYDROSHARK 115| 33

•

Is the ŇŽw rate enough to keep the ŵŝĐƌŽ boiler running?

Does the ƌĞĐŝƌĐƵůĂƟŽŶ line have enough ĐŚeĐk valves?

•

Is the gas supply valve fully open?

•

Are the Įdžtures ĐůĞĂŶ of debris and obstruĐƟons?

•

CheĐŬ if the Ňow rate is too low.

•

Is the gas line sized properly?

•

Is the supply gas pressure ƐƵĸĐŝent?

•

CheĐŬ for Đƌoss ĐonneĐƟon between Đold water lines and hot

•

water lines.

Page 34

Troubleshooting (Cont’d)

PROBLEM SOLUTIONS

Unit does not ignite when

water goes through the unit.

The fan motor is sƟůů

spinning aŌer operaƟon has

stopped.

- Micro Boiler -

Unit sounds abnormaů ǁŚŝůe

in opeƌĂƟon

Remote controůůer does not

dispůĂLJ anything when the

power buƩon is turned on.

An ERROR code is diƐƉůayed.

(OPTIONAL)-

-Remote controller-

Is the ŇŽǁ rate over 0.5 GPM?

Check for reverse connecƟŽŶ and cross coŶŶĞĐƟon.

If you use the remote contrŽůůer, is the power buƩon

turned on?

Check if the ŝŶůĞƚ temperature is too high.

This is normaů AŌer opeƌĂƟon has stopped, the fan motor

keeps running from 15 to 70 seconds in order to re-ignite

quickůy, as weůů as purge aůů the exhaust gas out of the Ňue.

Contact Hydro-Shark at 800-805-5384.

Make sure the unit is suppůŝed with power.

Make sure the connecƟŽn to the unit is correct.

ZĞĨĞƌƚŽĨĂƵůƚĂŶĂůLJƐŝƐĐŽĚĞƐƚŽĚĞƚĞƌŵŝŶĞƚŚĞƉƌŽďůĞŵ

34 | HYDROSHARK 115 WWW.HYDRO-SHARK.COM

Page 35

ERROR CODES

• The units are self-diagnostic for safety and convenience when troubleshooting.

• If there is a problem with the installation or the unit, the error code will be displayed on the temperature controller and remote controller.

• Consult with the table on the following pages for the description of each error code.

Red LED

Error code on the computer board

Error code on the remote

controller 9007666005 (TK-RE02)

Single unit installations

Example: if your unit has the “321” error code (which signifi es an inlet thermistor failure)

• Indicator on the temperature

controller or remote controller: “321” will be displayed on the screen in its entirety.

• Green LED on the computer board: The green LED on the computer board will be

blinking two times.

WWW.HYDRO-SHARK.COM HYDROSHARK 115| 35

Page 36

Fault Analysis of Error Codes

If the error code is displayed on the computer board of the micro boiler or remote controller and/or

temperature controller, please check the following. After checking, Consult with the manufacturer.

One

Time

Five

Times

Three

Times

Three

Times

Two

Times

Two

Times

Remote Red LED

03

10

11

12

31

32

39

MalfuncƟon

descripƟon

Incorrect dipswitch

seƫng

Warning for the

“991” error code

IgniƟon failure

Loss of ŇĂme

Outlet thermistor

failure

Inlet thermistor

failure

Air –fuel RaƟŽ Rod

failure

Diagnosis

Check the dipswitch seƫngs on the PCB. (Part #701)

•

Check the gas type of the micro boiler.

•

Check if there is any blockage in the intake air and/or

•

exhaust.

If the micro boiler is installed as a direct-vent system,

•

check whether there is enough distance between the

intake air terminal and the exhaust terminal.

Check the alƟtude/elevĂƟon of area of where the

•

micro boiler installed.

Check if there is grease and/or dirt in the burner (Part

•

#101) and the fan motor (Part #103), especially if the

micro boiler has been installed in a contaminated

area.

Check if the Hi-limit switch (Part #412) is properly

•

funcƟŽning.

•

Check for connecƟŽŶbreakage of wires (Part #413,

708, 709, 710, 712), burn marks on the computer

board (Part #701), and/or soot on the Ňame rod (Part

#108).

Check if there is a buzzing spark igniƟon sound coming

•

from the burner (Part #101) when micro boiler

prepares for combƵƐƟŽŶ

Listen for the double “clunk” sound coming from gas

•

valve assembly (Part #102) when micro boiler goes

into combusƟŽŶ.

Check if there is leaking from heat exchanger. (Part

•

#401)

Check if the Hi-limit switch (Part #412) is properly

•

funcƟŽning.

Check for connecƟŽŶbreakage of wires (Part #413,

•

708, 709, 710, 712), burn marks on the computer

board (Part #701), and/or soot on the Ňame rod (Part

#108).

Check if there is leaking from heat exchanger. (Part

•

#401)

•

••

Check for connecƟŽŶ/breakage of wires and/or debris

on thermistor. (Part #407, 408)

Check for connecƟon/breakage of wires (Part #709)

•

and/or soot on the AFR rod. (Part #108)

36 | HYDROSHARK 115 WWW.HYDRO-SHARK.COM

Page 37

Fault Analysis of Error Codes cont’d

Red LED Remote

Six

51

Times

Six

55

Times

Four 61

Times

One

70

Time

72 Six Times

N/A 74

Five

99

Times

MalfuncƟon

descripƟon

Abnormal Gas

Solenoid Valve

Abnormal Main

Gas Valve

Fan Motor Fault

Computer board

Fault

False Flame

DetecƟŽn

MiscommuniĐĂƟŽn

between Micro

boiler and remote

controller

Imperfect

coŵďƵƐƟŽŶ

Diagnosis

•

Check for connecƟon/breakage of wires (Part #708)

and/or burn marks on the computer board (Part

#701).

Check for connecƟŽŶbreakage of wires (Part #708)

•

and/or burn marks on the computer board (Part

#701).

Check for connecƟŽŶbreakage of wires, dust buildup

•

in the fan motor (Part #103) and/or burn marks on the

computer board (Part #701).

Check for frozen/corrosion of connectors (Part #103).

•

Check for connecƟon/breakage of wires (Part #714)

•

and/or burn marks on the computer board (Part

#701).

•

Check the power supply of the micro boiler.

•

For indoor models, check if condensate drain is

installed on the vent collar of the micro boiler.

•

Check if there is leaking from heat exchanger (Part

#401).

Check the model type of the remote controller.

•

Inspect the connecƟons between the micro boiler

•

and remote controller.

•

Check the power supply of the micro boiler.

Check the gas type of the micro boiler.

•

Inspect the environment around the micro boiler.

•

Determine how long the unit has been installed.

•

Check the alƟtude/elevĂƟon of the area of where the

•

micro boiler installed.

Check if there is any blockage in the intake air and/or

•

exhaust.

If the micro boiler is installed as a direct-vent system,

•

check whether there is enough distance between the

intake air terminal and the exhaust terminal.

••

Check if there is grease and/or dirt in the burner (Part

•

# 101) and the fan motor (Part # 104), especially if the

micro boiler has been installed in a contaminated

area.

WWW.HYDRO-SHARK.COM HYDROSHARK 115| 37

Page 38

COMPONENTS DIAGRAM

Case assembly

࣬࣬ࣳ

࣮࣬࣬

ࣱ࣭࣬

ࣱ࣬࣬

࣯࣬࣬

ࣱ࣮࣬

࣮ࣳ࣬

ࣱ࣮࣬

࣮࣭ࣳ

ࣱ࣮࣬

ࣰࣳ࣬

ࣱ࣮࣬

ࣰ࣬࣬

࣭࣬࣬

Temperature

remote controller

࣮ࣳ࣬

Water way assembly

ࣰࣲ࣬

ࣰࣱࣲ

ࣰࣱࣳ

ࣰࣰ࣬

ࣾ

ࣰ࣮࣬

ࣰࣲ࣭

ࣰࣱࣴ

ࣰࣲ࣯

ࣰ࣭࣯

࣮࣮ࣳ

ࣰࣱ࣯

Computer board

Assembly

࣭ࣳ࣬

ࣳ࣬ࣴ

࣭࣯࣬

38 | HYDROSHARK 115 WWW.HYDRO-SHARK.COM

࣭ࣳ࣬

ࣰࣰ࣭࣬ࣳ࣬ࣴࣳࣵ

ࣰࣱ࣮

ࣲ࣯࣬

ࣰ࣭࣮

ࣰࣱ࣬

ࣰࣰ࣭

ࣰࣰࣱ

ࣰ࣬ࣳ

ࣰࣱ࣬

ࣱ࣮࣬

ࣰࣱ࣭

ࣰࣲ࣬

Water inlet seĐƟŽŶ

ࣰ࣭࣬

ࣰࣱࣲ

ࣿ

ࣳ࣬ࣳ

ࣳ࣬ࣵ

ࣰ࣭ࣳ

ࣰࣰ࣮࣮࣬࣬

ࣰࣲ࣬

ࣰ࣬ࣵ

ࣰࣰ࣭

ࣾ

ࣰࣱࣱ

ࣰ࣭࣬

ࣰࣰࣱ

ࣰ࣬ࣴ

ࣿ

ࣰࣲ࣬

ࣰࣱ࣭

Water Žutlet seĐƟŽŶ

Page 39

Burner assembly

Burner assembly

ࣰࣳ࣬

ࣱࣳ࣬

ࣱ࣯࣬

࣭࣮࣭

ࣲ࣭࣭࣬࣬ࣳ

࣭࣬ࣵ

ࣱ࣯࣬

࣭࣭࣯

ࣰ࣭࣭

࣭࣭࣮

ࣱ࣭࣬

ࣰ࣭࣬

ࣰ࣭࣬

ࣱ࣬ࣵ

ࣱ࣮࣬

ࣱ࣬ࣵ

࣭࣯࣬

࣭࣭࣭࣭࣬࣬

࣭࣭࣬

ࣱࣲ࣬

ࣵࣵ࣬ࣳ࣬ࣳ

࣭࣭࣭࣭࣭࣭

ࣲࣳ࣬

࣯ࣳ࣬

ࣱ࣯࣬

࣭࣬ࣴ

࣭࣮ࣳ

ࣱ࣯࣬

࣭ࣳ࣬

ࣱ࣯࣬

ࣱ࣯࣬

࣭࣮࣬

ࣱ࣯࣬

࣭࣮ࣳ

ࣱ࣯࣬

ࣲ࣬ࣳ

࣭࣭ࣳ

ࣱࣱ࣬

ࣰ࣭ࣳ

ࣱ࣭࣬

ࣲ࣭࣬

ࣲ࣮࣬

ࣱࣱ࣬

ࣳ࣬ࣴ

Manifold

assembly

࣭࣮࣬

࣭࣭ࣵ

ࣱ࣭࣭

࣭࣭ࣴ

ࣱ࣮࣬

ࣱ࣬ࣴ

࣭࣯ࣳ

ࣱ࣭࣭

WWW.HYDRO-SHARK.COM HYDROSHARK 115| 39

Page 40

PARTS LIST

Item# Part# DescripƟon

001

002

003

004

005

006

007

050

051

052

053

055

056

058

059

061

062

063

064

065

066

067

101

102

103

104

105 Burner gasket

106

107

108

109

110

111

112

113

114

115

118

119

120

121

150

151

Screw M4×12 (W/Washer)

Screw M4×10 (W/Washer)

Pan screw M4x12 (W/Washer)

Tap Ɵght screw M4x12 FEZN

Manifold with gas valve assembly LP

Manifold with gas valve assembly NA

Case assembly

Front cover

Air blockage plate

Bracket

:ƵŶĐƟon box

JuncƟon box inner plate

Back guard panel

Screw M4×10 (Coated)

Screw M4x10

Hex head screw M4x8

Screw M4x10

Screw M3x10

Pan screw M4x10

Screw M3x6

Screw M4x6

Pan screw M4x8

Nylon clamp

Wire clamp 60

Burner assembly

Fan motor

Burner holder gasket

Burner window

Rod holder gasket

Flame rod

Igniter rod

Rod holder

Rod cap

Burner damper

Manifold gasket A

Manifold gasket B

Fan damper 319143-160

Gas inlet

Gas inlet ring

Igniter plate

Surge box plate

O-ring P18 NBR (Black)

O-ring P20 NBR (Black)

319143-159

319143-163

319143-150

319143-184

319143-014

319143-128

319143-338

319143-025

319143-325

319143-026

319143-060

319143-063

319143-372

319143-327

319143-061

319143-201

319143-062

319143-087

319143-328

319143-059

319143-143

319143-048

319143-161

319143-169

319143-165

319143-347

319143-341

319143-031

319143-033

319143-034

319143-339

319143-373

319143-340

319143-038

319143-170

319143-044

319143-045

319143-050

319143-049

319143-051

319143-213

319143-350

319143-057

40 | HYDROSHARK 115 WWW.HYDRO-SHARK.COM

Page 41

Item# Part# DescripƟon

401

402

404

405

407

408

409

410

412

413

414

415

450

451

452

453

454

455

456

457

458

460

461

463

701

702

703

704

705

706

707

708

709

710

711

712

713

714

719

720

721

722

Heat exchanger assembly

Flow adjustment valve/Flow sensor

Water inlet

Inlet drain plug

Inlet thermistor

Outlet thermistor

Water outlet

Outlet drain plug

Hi-Limit switch

Overheat-cut-oī fuse

Heater

Inlet heater

Pipe heater ĮdžŝŶŐ plate

Heater ĮdžŝŶŐ plate 16

Fuse Įxing plate 18

Fuse Įxing plate 14

O-ring P4 FKM

O-ring P6 FKM

O-ring P14 FKM

O-ring P15 FKM

O-ring P16 FKM

Fastener “14-22”

Fastener “16A”

Silicon ring

Computer board

Transformer

Surge box

AC120V wire

Transformer wire

AC120V Power ON-OFF switch

Switch wire

Gas valve wire

Flame rod wire

EH-IG wire

Igniter

High voltage igniter cable

Freeze protecƟŽŶ thermostat

ProporƟonal gas valve wire

Computer board cover

Rubber grommet

Cable strap

319143-162

319143-167

319143-193

319143-197

319143-214

319143-218

319143-194

319143-199

319143-228

319143-149

319143-200

319143-078

319143-088

319143-125

319143-066

319143-146

319143-082

319143-080

319143-100

319143-091

319143-083

319143-105

319143-226

319143-065

319143-164

319143-182

319143-168

319143-427

319143-155

319143-141

319143-154

319143-207

319143-171

319143-209

319143-052

319143-039

319143-185

319143-220

319143-212

319143-426

319143-425

319143-352Temperature remote controller

WWW.HYDRO-SHARK.COM HYDROSHARK 115| 41

Page 42

OUTPUT TEMPERATURE CHART

Chart is based on properly sizes gas line

Output Temperature vs. GPM (Max. 6.6 GPM) with Various Inlet Water Temperature

7.0

6.0

5.0

4.0

3.0

2.0

1.0

0.0

Out Put Hot Water GPM

40 F

50 F

60 F

70 F

3.8 3.5 3.3 3.1 2.9 2.7 2.5 2.4 2.3 1.92.1

4.6 4.2 3.8 3.5 3.3 3.1 2.9 2.7 2.5 2.12.3

5.7 5.1 4.6 4.2 3.8 3.5 3.3 3.1 2.9 2.32.5

6.6 6.6 5.7 5.1 4.6 4.2 3.8 3.5 3.3 2.52.9 2.4

105100 110 120115 125 135130 140 150 160 165

40 F 50 F

60 F 70 F

1.8

2.0

2.2

42 | HYDROSHARK 115 WWW.HYDRO-SHARK.COM

Page 43

NOTES:

WWW.HYDRO-SHARK.COM HYDROSHARK 115| 43

Page 44

STIEBEL ELTRON, Inc.

17 West Street | West Hatfield MA 01088

Tel. 800-805-5384

hydroshark@stiebel-eltron-usa.com

www.hydro-shark.com

4<AMHCMO=bgibea>

Subject to errors and technical changes! |

Sous réserve d‘erreurs et de modifi cations techniques!

Subject to errors and technical changes!

331125-40419-9328

Loading...

Loading...