Page 1

Bedienung und installation

operating and installation

utilisation et installation

geBruik en installatie

3-Wege-umschaltventil | 3-Way sWitching valve | soupape d’inversion à 3 voies | drieWeg-omschakelklep

» huv 1

» huv 2

» huv 65

» huv 80

Page 2

OPERATION

!

!

GENERAL INFORMATION

1. General information

This accessory installation guide is aimed at specialist technicians.

For installing the heat pump or similar items, see the additional

operating and installation instructions.

Please read

Read these instructions carefully before use and keep

them in a safe place. If you pass on the equipment to

another user, give them the instructions as well.

1.1 Explanation of symbols

Symbols in the documentation:

This documentation contains symbols and highlights. These have

the following meanings:

Beware of injury

Indication of possible risk of injury to the technician or

user, and possible damage to the device.

Beware of electrocution

Beware of burns and scalding

Beware of damage

Indicates a potentially dangerous situation which might

occur while installing or operating the device and could

damage the device or cause environmental or financial

harm.

Please read

Read these instructions carefully before use and keep

them in a safe place. If you pass on the equipment to

another user, give them the instructions as well.

2. Safety

2.2 Safety instructions

Observe the following safety instructions and regulations.

Heat pump systems and accessories may only be installed by a

recognised specialised company.

The qualified technician is responsible for observing all applicable

regulations during installation and commissioning.

Only operate the device when it is fully installed with all its safety

equipment.

Beware of electrocution

Switch off the power supply immediately if cables are

damaged. Make sure it is secured against being switched

on again unintentionally.

Beware of electrocution

Make sure all cable entries are fitted with the appropriate protection class.

Beware of burns and scalding

Before working on the system, let the pipes on the relevant section cool down as necessary and reduce the

system pressure to ambient pressure.

Beware of injury

The appliance may be used by children aged 8 and up

and persons with reduced physical, sensory or mental

capabilities or a lack of experience provided that they

are supervised or they have been instructed on how to

use the appliance safely and have understood the resulting risks. Children must never play with the appliance.

Children must never clean the appliance or perform user

maintenance unless they are supervised.

Beware of damage

The 3-way switching valve is designed for use in STIEBEL

ELTRON or Tecalor heat pump systems and may not be

used for applications outside the stated range, particularly in aircraft or other means of transport.

2.1 Proper use

The 3-way switching valve distributes and regulates the flow in

STIEBEL ELTRON or Tecalor heat pump systems. Any different or

extended use is considered improper, especially use with other

media to be heated. Proper use also includes observing the installation instructions. Only use the device for the purpose stated by

the manufacturer and do not make any modifications to it.

This appliance is designed for domestic use. It can be used safely

by untrained persons. The appliance can also be used in a nondomestic environment, e.g. in a small business, as long as it is

used in the same way.

10 | HUV 1/2/65/80

3. Device description

3.1 Overview of models and combination options

Model Order no.

HUV 1 247420

HUV 2 223391

HUV 65 227425

HUV 80 227426

3.2 Scope of delivery

- 3-way switching valve

- Servo drive

- 3 x counter screws G1

- 3 x counter screws G2

The servo drive is delivered already fitted to the 3-way switching

valve.

1

/2” x 1” (HUV 1 only)

3

/4“ x 2“ (HUV 2 only)

Page 3

OPERATION

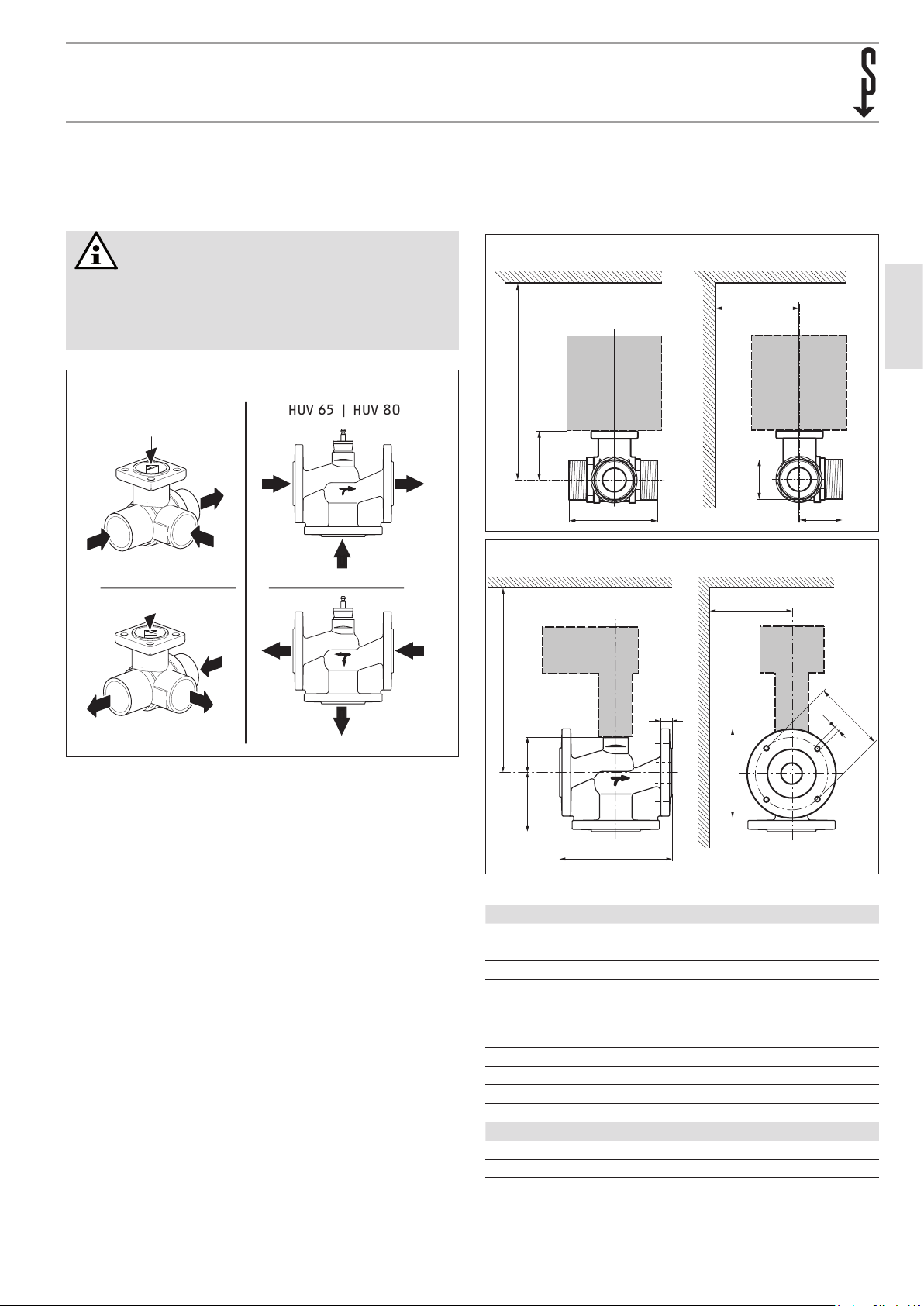

HUV 65 | HUV 80

min. X

DEVICE DESCRIPTION

3.3 Function

The 3-way switching valve is controlled using a servo or

lift drive.

Note

As well as the flow direction A – AB and B – AB which

is marked with an arrow on the housing, the opposite

direction AB – A and AB – B is also permitted in STIEBEL

ELTRON or Tecalor heat pump systems.

Flow direction

HUV 1 | HUV 2

A

AB

A

B

B

AB

3.4 Dimensions, distances and connections

3.4.1 3-way switching valves

Dimensions and flanges for HUV 1 | 2

min. Y

min. X

H

D

L

Dimensions and flanges for HUV 65 | 80

min. Y

ENGLISH

B

C26_03_01_0995

A

AB

A

B

B

AB

HUV 1 | HUV 2 only: The servo drive is constantly regulated by a

control system and moves the ball of the 3-way switching valve,

that acts as a restrictor, to the position specified by the actuator

signal. The valve opens by turning clockwise and closes by turning

anticlockwise (factory setting).

HUV 65 | HUV 80 only: The lift drives are regulated by a 3-point

control system and move the closing element, which acts as a

mixer, to the opening position defined by the actuator signal.

C

C26_03_01_0998

HB

D

L

Dimensions HUV 1 HUV 2 HUV 65 HUV 80

L mm84.5 131,5 290 310

H mm46 56 100 110

B mm47.5 71.5 120 130

D DN 25

C mm– – 16 18

K mm– – 130 150

d mm– – 4 x 14 4 x 18

25 mm

(1 inch)

1

/

G1

2

DN 50

50 mm

(2 inches)

G23/

4

DN 65

160 mm

d

DN 80

190 mm

K

C26_03_01_0996

HUV 1/2/65/80 | 11

Distances*

X mm240 240 515 515

Y mm90 90 100 100

* Distances in relation to the centre of the valve

Page 4

OPERATION

25 103

HUV 1 | HUV 2

!

!

INSTALLATION

3.4.2 Servo drives

Dimensions HUV 1 | 2

(33)* (117)*

R65

Dimensions HUV 65 | 80

193

45

* Values in brackets are for HUV 1.

(177)*

134

160

150

98

84

(86)*

71

(93)*

4. Installation

4.1 Installation position

The 3-way switching valves can be installed either vertically or

horizontally.

Beware of damage

!

The 3-way switching valves may not be installed suspended, i.e. with the tappet facing down.

Permissible installation positions

90° 90°

C26_03_01_0997

4.2 Hydraulic connection

Beware of damage

The conditions in VDI 2035 regarding water quality must

be complied with. So that the 3-way switching valve controls the flow for a long time, we recommend the use of

contamination filters.

Beware of damage

Make sure the ball is correctly positioned in

the 3-way switching valve (note the mark on

the spindle).

D0000038083

Note

As well as the flow direction A – AB and B – AB which

is marked with an arrow on the housing, the opposite

direction AB – A and AB – B is also permitted in STIEBEL

ELTRON or Tecalor heat pump systems.

C26_03_01_0998

12 | HUV 1/2/65/80

A

A

AB

B

AB

B

A

B

A

B

AB

AB

26_03_01_0999

Page 5

INSTALLATION

!

!

MAINTENANCE

4.3 Electrical connection

Beware of electrocution

Always switch off the power supply before installation.

Make sure it is secured against being switched on again

unintentionally.

4.3.1 HUV 1 | HUV 2

Connection diagram (open/closed control)

L1

N

1

2 3

Y2

Beware of damage

Only the factory-set open/close setting may be used in

STIEBEL ELTRON or Tecalor heat pump systems.

The 3-way diverter valve is factory-set to flow direction B - AB.

To change the flow direction to A - AB, change the covered rotary

selector from Y2 to Y1.

4.3.2 HUV 65 | HUV 80

Connection diagram (open/closed control)

N L

1 2 3

a a

bb

1 blue

2 brown

3 white

5. Maintenance

26_03_01_1784

The 3-way switching valves with integrated servo drive require no

maintenance. They do not contain any parts that can be replaced

or repaired by the user.

Beware of electrocution

Always switch off the power supply before maintenance.

Make sure it is secured against being switched on again

unintentionally.

a

b

ENGLISH

D0000043142

Beware of burns and scalding

Let the pipes on the relevant section cool down as necessary and reduce the system pressure to ambient pressure.

Beware of damage

Switch off the pumps for the relevant pipe section and

close the associated shut-off valves.

The system may only be started up again once the 3-way switching

valves with integrated servo drive have been correctly fitted and

the pipes correctly filled.

26_03_01_1783

HUV 1/2/65/80 | 13

Page 6

INSTALLATION

TECHNICAL DATA

6. Technical data

HUV 1 HUV 2 HUV 65 HUV 80

227420 223391 227425 227426

Sound data

Sound power level dB(A) 35 45 45 35

Application limits

Max. permissible pressure MPa 276 276 60 60

Hydraulic data

Flow capacity m3/h 26 49 58 90

Differential pressure Δp

Closing pressure Δp

Electrical data

Rated voltage V 230 230 230 230

Frequency Hz 50/60 50/60 50/60 50/60

Power consumption, operational W 1.5 2.5 2 2

Power consumption, idle W 0.4 0.4 1 1

Power consumption, sizing VA 4.5 4.5

Versions

Power cable * * * *

Power cable length approx. mm 1000 1000 1000 1000

Operating mode parallel parallel parallel parallel

Safety category II, double insulated II, double insulated II, double insulated II, double insulated

IP rating IP54 IP54 IP54 IP54

Dimensions

Length mm 84.5 131.5 290 310

Weights

Weight kg 1.65 4.8 16.3 22.5

Values

Permissible medium H2O H2O H2O H2O

Permissible medium 2 H2O glycol S H2O glycol S H2O glycol S H2O glycol S

Maximum mixing ratio % 50 50 50 50

Permissible additive medium glycol glycol glycol glycol

Max. operating temperature °C 100 100 100 100

Flow rate, control path A-AB (VDi 2173) n(gL) 3.9 3.9 3 3

Flow rate, bypass B-BA (linear) kvs * 0.7 kvs * 0.7

Leakage rate bypass B-AB kvs * 0.01 kvs * 0.01 kvs * 0.01 kvs * 0.01

Leakage rate, control path A-AB (B0.1 Din 3230) air bubble tight air bubble tight

Pivoting bracket ° 90 90

Angle of rotation, working area ° 15...90 15...90

Connecting cable, cable cross-section mm

Torque Nm min. 5 min. 20

Runtime 90s / 90° 90s / 90° 7.5 s/mm (18mm) 7.5 s/mm (18mm)

Ambient temperature °C 0...50 0...50 0...50 0...50

Permissible relative humidity (non-condensing) % 95 95 95 95

max

s

kPa 100 350 140 80

kPa 1000 1400 140 80

2

3 x 0.75 3 x 0.75

14 | HUV 1/2/65/80

Page 7

Warranty | EnvironmEnt and rEcycling

Warranty

The warranty conditions of our German companies do not

apply to appliances acquired outside of Germany. In countries

where our subsidiaries sell our products, it is increasingly the

case that warranties can only be issued by those subsidiaries.

Such warranties are only granted if the subsidiary has issued

its own terms of warranty. No other warranty will be granted.

We shall not provide any warranty for appliances acquired in

countries where we have no subsidiary to sell our products.

This will not aect warranties issued by any importers.

Environment and recycling

We would ask you to help protect the environment. After use,

dispose of the various materials in accordance with national

regulations.

ENGLISH

HUV 1/2/65/80 | 15

Page 8

STIEBEL ELTRON GmbH & Co. KG

Dr.-Stiebel-Str. 33 | 37603 Holzminden

Tel. 05531 702-0 | Fax 05531 702-480

info@stiebel-eltron.de

www.stiebel-eltron.de

tecalor GmbH

Fürstenberger Str. 77 | 37603 Holzminden

Tel. 05531 99068-700 | Fax 05531 99068-712

info@tecalor.de

www.tecalor.de

4<AMHCMN=ifdahi>

Irrtum und technische Änderungen vorbehalten! | Subject to errors and technical changes! | Sous réserve d‘erreurs et de modifications techniques! | Onder voorbehoud

van vergissingen en technische wijzigingen! | Salvo error o modificación técnica! | Rätt till misstag och tekniska ändringar förbehålls! | Excepto erro ou alteração técnica |

Zastrzeżone zmiany techniczne i ewentualne błędy | Omyly a technické změny jsou vyhrazeny! | A muszaki változtatások és tévedések jogát fenntar tjuk! | Отсутствие ошибок

не гарантируется. Возможны технические изменения. | Chyby a technické zmeny sú vyhradené! Stand 8843

A 285307-37449-8938

Loading...

Loading...