STIEBEL ELTRON FCR 28/180 Si, FCR 28/120 Si, FCR 28/270 Si, FSR 28/90, FCR 28/360 Si Operation & Installation

...Page 1

BEDIENUNG UND INSTALLATION

OPERATION AND INSTALLATION

UTILISATION ET INSTALLATION

BEDIENING EN INSTALLATIE

Heizansch | Flanged immersion heater | Corps de chauffe | Verwarmingsens

» FCR 28/120 Si

» FCR 28/180 Si

» FCR 28/270 Si

» FCR 28/360 Si

» FSR 28/ 90

» FSR 28/ 180

Page 2

12 | FCR 28 Si www.stiebel-eltron.com

CONTENTS | OPERATION

General information

OPERATION

1. General information ��������������������������������������� 12

1.1 Safety instructions ���������������������������������������������� 12

1.2 Other symbols in this documentation ���������������������� 13

1.3 Units of measurement ����������������������������������������� 13

2. Safety �������������������������������������������������������� 13

2.1 Intended use ����������������������������������������������������� 13

2.2 General safety instructions �����������������������������������13

2.3 CE designation ��������������������������������������������������13

2.4 Test symbols ����������������������������������������������������� 13

3. Appliance description ������������������������������������� 13

4. Settings ����������������������������������������������������� 14

5. Cleaning, care and maintenance ������������������������� 14

6. Troubleshooting �������������������������������������������� 14

INSTALLATION

7. Safety �������������������������������������������������������� 15

7.1 General safety instructions ����������������������������������� 15

7.2 Instructions, standards and regulations ������������������� 15

7.3 Water connection and safety assembly �������������������� 15

8. Appliance description ������������������������������������� 15

8.1 Standard delivery ����������������������������������������������� 15

8.2 Accessories ������������������������������������������������������� 15

9. Installation �������������������������������������������������� 15

9.1 Power connection ���������������������������������������������� 16

10. Commissioning ��������������������������������������������� 16

10.1 Commissioning �������������������������������������������������� 16

10.2 Recommissioning ����������������������������������������������� 16

11. Settings ����������������������������������������������������� 17

11.1 Limiting the temperature selection ������������������������� 17

12. Troubleshooting �������������������������������������������� 17

13. Maintenance ������������������������������������������������ 17

13.1 Checking the safety assembly �������������������������������� 17

13.2 Descaling the flanged immersion heater ������������������17

13.3 Replacing the heating elements and protective pipe���� 17

14. Specification ������������������������������������������������ 18

14.1 Dimensions, immersion depths and connections �������� 18

14.2 Wiring diagrams and connections �������������������������� 18

14.3 Data table �������������������������������������������������������� 20

GUARANTEE

ENVIRONMENT AND RECYCLING

OPERATION

1. General information

The chapter "Operation" is intended for appliance users and qualified contractors.

The chapter "Installation" is intended for qualified contractors.

Note

Read these instructions carefully before using the appliance and retain them for future reference.

Pass on the instructions to a new user if required.

1.1 Safety instructions

1.1.1 Structure of safety instructions

!

KEYWORD Type of risk

Here, possible consequences are listed that may result

from failure to observe the safety instructions.

Steps to prevent the risk are listed.

1.1.2 Symbols, type of risk

Symbol Type of risk

Injury

Electrocution

Burns

(burns, scalding)

1.1.3 Keywords

KEYWORD Meaning

DANGER Failure to observe this information will result in serious

injury or death.

WARNING Failure to observe this information may result in serious

injury or death.

CAUTION Failure to observe this information may result in non-

serious or minor injury.

!

Page 3

OPERATION

Safety

www.stiebel-eltron.com FCR 28 Si | 13

ENGLISH

1.2 Other symbols in this documentation

Note

General information is identified by the symbol shown

on the left.

Read these texts carefully.

Symbol Meaning

Material losses

(Appliance and consequential losses, environmental pollution)

Appliance disposal

This symbol indicates that you have to do something. The ac-

tion you need to take is described step by step.

1.3 Units of measurement

Note

All measurements are given in mm unless stated otherwise.

2. Safety

2.1 Intended use

The appliance is intended for installation in cylinders in a sealed

unvented heating or DHW heating system.

This appliance is designed for domestic use. It can be used safely

by untrained persons. The appliance can also be used in a nondomestic environment, e.g. in a small business, as long as it is

used in the same way.

Any other use beyond that described shall be deemed inappropriate. Observation of these instructions and of instructions for any

accessories used is also part of the correct use of this appliance.

Using the appliance for heating fluids other than water or water

supplemented with chemicals, such as brine, is also deemed inappropriate.

2.2 General safety instructions

WARNING Electrocution

Never spray the appliance with water or other liquids.

WARNING Burns

There is a risk of scalding at outlet temperatures in excess of 43 °C.

!

WARNING Injury

The appliance may be used by children aged 8 and up

and persons with reduced physical, sensory or mental

capabilities or a lack of experience provided that they

are supervised or they have been instructed on how to

use the appliance safely and have understood the resulting risks. Children must never play with the appliance.

Children must never clean the appliance or perform user

maintenance unless they are supervised.

!

Material losses

Condensate can drip from the appliance.

Never store objects below the appliance.

Note

The appliance is under pressure.

During the heat-up process, expansion water will drip

from the safety valve.

If water continues to drip when heating is complet-

ed, please inform your heating contractor.

2.3 CE designation

The CE designation shows that the appliance meets all essential

requirements according to the:

- Electromagnetic Compatibility Directive

- Low Voltage Directive

2.4 Test symbols

See type plate on the appliance.

3. Appliance description

The appliance electrically heats DHW and heating water.The

temperature of the water is set by a qualified contractor via the

temperature selector. Once the selected temperature has been

reached, the appliance switches off and restarts automatically

when required.

The appliance is also protected against frost on the temperature

setting "cold" as long as the power supply is guaranteed. The

appliance switches on in good time and heats the water. The tap

and the mains water supply line are not protected against frost

by the appliance.

!

Page 4

OPERATION

Settings

14 | FCR 28 Si www.stiebel-eltron.com

4. Settings

The temperature can be freely selected by the qualified contractor

(see chapter "Installation / Settings").

Factory setting: 60°C

5. Cleaning, care and maintenance

Have the electrical safety of the appliance regularly checked

by an electrician.

Scaling

Almost every type of water will deposit lime at high tempera-

tures. Limescale will settle inside the appliance and affect its

function and service life. The heating elements must therefore be descaled from time to time. A qualified contractor

who is aware of the local water quality will tell you when the

next service is due.

Check the taps/valves regularly. You can remove limescale

deposits at the tap outlets using commercially available descaling agents.

Regularly activate the safety valve to prevent it from becom-

ing blocked e.g. by limescale deposits.

6. Troubleshooting

Fault Cause Remedy

The water does not heat

up.

There is no power. Check the fuses/MCBs in

your fuse box.

The temperature is incor-

rectly adjusted.

Check the temperature

setting.

The flow rate is low. The aerator in the taps or

shower heads is dirty or

scaled-up.

Clean or descale the

aerator or shower head.

Water drips from the

safety assembly after

heating has stopped.

The valve seat is contaminated.

Depressurise and isolate

the appliance from the

power supply. Request

your qualified contractor

to attend.

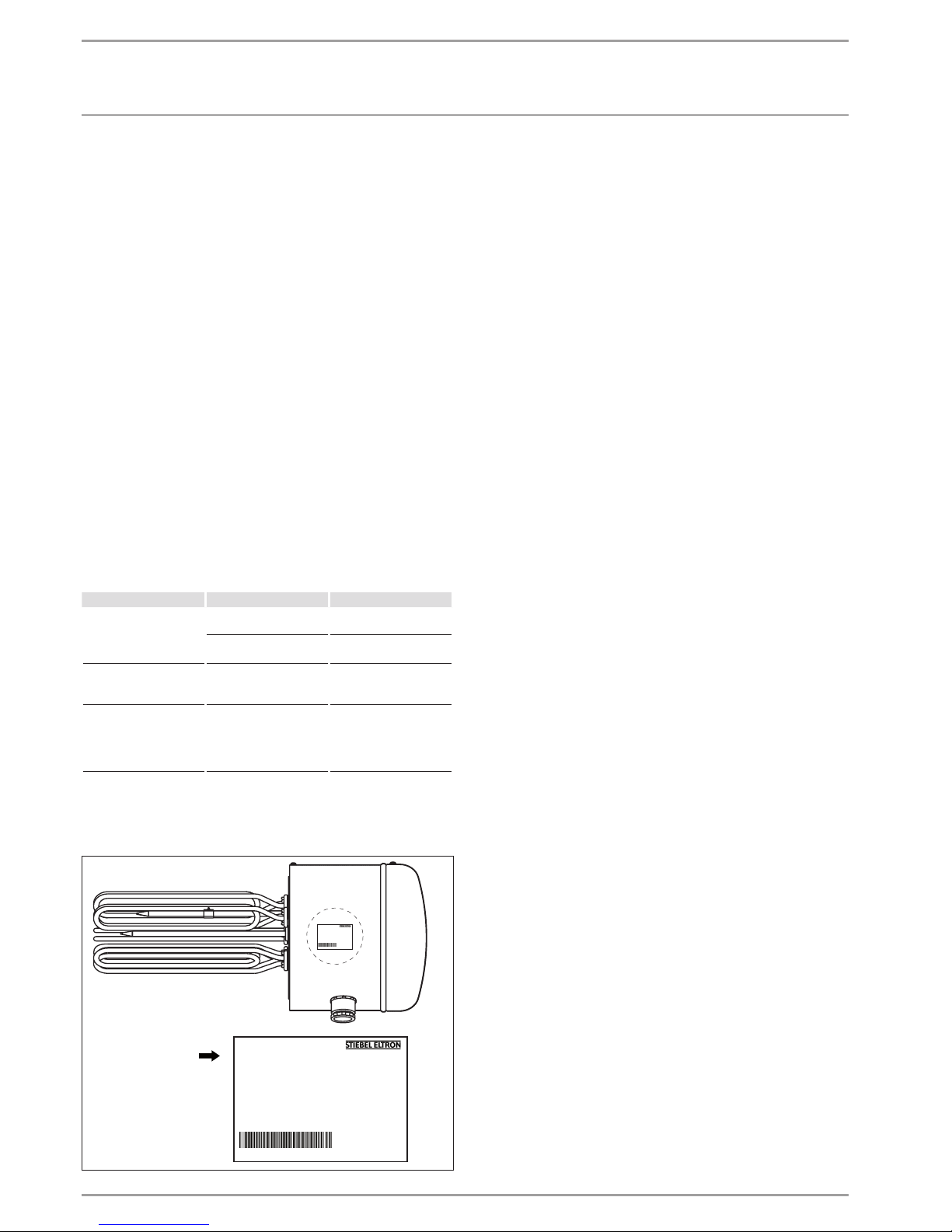

If you cannot remedy the fault, notify your heating contractor. To

facilitate and speed up your enquiry, please provide the serial

number from the type plate (no. 000000-0000-000000):

FCR Nr.: 000000 - 0000 - 000000

Made in Germany

FCR Nr.: 000000 - 0000 - 000000

Made in Germany

26�02�79�0076

Page 5

www.stiebel-eltron.com FCR 28 Si | 15

ENGLISH

INSTALLATION

Safety

INSTALLATION

7. Safety

Only a qualified contractor should carry out installation, commissioning, maintenance and repair of the appliance.

7.1 General safety instructions

We guarantee trouble-free function and operational reliability

only if the original accessories and spare parts intended for the

appliance are used.

7.2 Instructions, standards and regulations

Note

Observe all applicable national and regional regulations

and instructions.

7.3 Water connection and safety assembly

Note

Carry out all water connection and installation work in

accordance with regulations.

The cylinder must be connected with water inlet and outlet pipes

made from metal. Other metal parts of the cylinder that can be

touched and that are in contact with water must be permanently

and reliably connected with the earth conductor.

The max. permissible pressure must not be exceeded (see chapter

"Specification/ Data table").

Install a type-tested safety valve in the cold water supply

line. For this bear in mind that, depending on the static pressure, you may also need a pressure reducing valve.

Size the drain so that water can drain off unimpeded when

the safety valve is fully opened.

Fit the discharge pipe of the safety valve with a constant

downward slope and in a room free from the risk of frost.

The safety valve discharge aperture must remain open to the

atmosphere.

8. Appliance description

8.1 Standard delivery

Delivered with the appliance:

- 12 screws M14x35

- Cable entries (supplied as loose parts depending on the appliance type)

8.2 Accessories

Required accessories

Depending on the static pressure, safety assemblies and pressure

reducing valves are available. These type-tested safety assemblies

protect the appliance against unacceptable excess pressure.

Further accessories

A mating flange is available as an accessory.

9. Installation

Note

For the installation of the appliance, the cylinder must

be fitted with a mating flange (see chapter "Appliance

description / Accessories").

Note

The control panel must not be thermally insulated to prevent any excessively high temperatures from occurring

inside the control panel.

The condensate aperture in the flanged control panel

must remain open while the cylinder is thermally insulated so that any condensate that occurs can drip off freely.

Observe the required torque values during installation (see

chapter "Specification / Data table").

Always install the appliance horizontally with the cable en-

tries facing downwards.

Always install the appliance with heating elements and a

protective pipe arranged in parallel. For this, use the screws

supplied. Realign the components where necessary.

Page 6

16 | FCR 28 Si www.stiebel-eltron.com

INSTALLATION

Commissioning

9.1 Power connection

WARNING Electrocution

Carry out all electrical connection and installation work

in accordance with relevant regulations.

WARNING Electrocution

The connection to the power supply is only permissible

as a permanent connection in conjunction with the removable cable entry. Ensure that the appliance can be

separated from the power supply by an isolator that disconnects all poles with at least 3mm contact separation.

WARNING Electrocution

Ensure that the appliance is earthed.

!

Material losses

Observe the type plate. The specified voltage must match

the mains voltage.

Undo the screws at the bottom of the control panel cover and

remove the cover.

100

200

26�02�79�0049

Select a cable of the cross-sectional area suited to the load

of the appliance. Prepare the power cable, ensuring that the

earth conductor is longer than the other conductors.

Feed the power cable through the cable entry into the control

panel.

Connect the required load in accordance with the wiring

diagrams (see chapter "Specification/ Wiring diagrams and

connections").

Fit the control panel cover.

!

Material losses

Contactors for thermostats or high limit safety cut-outs

must be installed outside the control panel of the flanged

immersion heater. The contactors must be switched independently of one another by the thermostats and the high

limit safety cut-out respectively (see chapter "Specification/ Wiring diagrams and connections").

If the appliance is operated with power-OFF control, you must

install the power-OFF contact between the contactors or upstream

of the contactor.

Required contactor breaking capacity:

Sizing in accordance with the connected load (see chapter

"Specification/ Data table") for l

e

/ AC-1 / 70°C (thermal constant current with a resistive load at an ambient temperature of

up to 70°C).

Label the contactors according to their function.

If required, mark any live components inside the control

panel that are supplied with power from outside.

Once connected, check that the contactors are functioning

properly.

10. Commissioning

10.1 Commissioning

Fill the system with water.

!

Material losses

Boiling dry destroys the thermostat, which must then

be replaced. The high limit safety cut-out must be reset.

!

Material losses

If an indirect coil is installed in the same cylinder, limit

the maximum temperature for this appliance to the maximum temperature for the flanged immersion heater. This

prevents the high limit safety cut-out of the flanged immersion heater from responding.

Appliance handover

Explain the appliance function to users and familiarise them

with its operation.

Make users aware of potential dangers.

Hand over these instructions.

10.2 Recommissioning

See chapter "Commissioning".

Page 7

www.stiebel-eltron.com FCR 28 Si | 17

ENGLISH

INSTALLATION

Settings

11. Settings

Temperature

85°C

60°C

35°C

26�02�79� 0028

The temperature can be freely adjusted.

Factory setting 60°C (the temperature selector clicks into

place at this setting).

11.1 Limiting the temperature selection

Appliance type with external temperature selector

You can adjust the temperature selection limitation beneath the

temperature selector.

Factory setting: 60°C

Set the temperature selector to "cold" and isolate the appli-

ance from the power supply.

Remove the temperature selector and the control panel

cover.

Loosen the two screws from the outside and pull the thermo-

stat down to remove.

Once you have removed the limiter disc from the thermostat

axis, the maximum temperature can be reached.

Tighten the thermostat screws again and replace the tem-

perature selector and control panel cover.

12. Troubleshooting

Fault Cause Remedy

The water does not

heat up.

The high limit safety cutout has responded because

the controller is faulty.

Replace the thermostat and

press the high limit safety

cut-out reset button.

The high limit safety cutout has responded because

the temperature has fallen

below -15°C.

Press the reset button.

A heating element is faulty. Replace the heating ele-

ment or flanged immersion

heater.

The high limit safety cutout has responded because

an indirect coil in the same

cylinder is set too high.

Limit the maximum temperature of the indirect

coil.

The safety valve drips

when the heating is

switched off.

The valve seat is contaminated.

Clean the valve seat.

1

26�02�79�0015

1 High limit safety cut-out reset button

13. Maintenance

WARNING Electrocution

Before any work on the appliance, disconnect all poles

from the power supply.

13.1 Checking the safety assembly

Check the safety assembly regularly.

13.2 Descaling the flanged immersion heater

Descale the flanged immersion heater only after it has been

removed.

13.3 Replacing the heating elements and protective

pipe

When installing heating elements or a protective pipe, en-

sure that the components are electrically isolated from the

flange.

Page 8

18 | FCR 28 Si www.stiebel-eltron.com

INSTALLATION

Specication

14. Specification

14.1 Dimensions, immersion depths and connections

FCR 28/120 Si | FCR 28/180 Si | FCR 28/270 Si |

FSR 28/90 | FSR 28/180

325

280

225

D0000020344

1 2

FCR 28/360 Si

280

450

225

D0000020345

1 2

1 Entry electrical cables PG 13.5

2 Entry electrical cables PG 21

Mating flange

245

Ø 219

Ø 205

83

14

280

26�02�79�0013

14.2 Wiring diagrams and connections

FCR 28/120 Si, part number 075140

FCR 28/180 Si, part number 075131

12, 18 kW, 3/PE ~ 400 V

5

L3L2

L1

4

85�02�79�0001

4

5

3

1

2

1 Heating element

12 kW connected load: 6 x 2 kW

18 kW connected load: 6 x 3 kW

2 High limit safety cut-out

3 Thermostat

4 Contactor, installed by the heating contractor

5 Power-OFF contact, installed by the heating contractor

Page 9

www.stiebel-eltron.com FCR 28 Si | 19

ENGLISH

INSTALLATION

Specication

FCR 28/270 Si, part number 075141

FCR 28/360 Si, part number 075124

FSR 28/90, part number 004817

FSR 28/180, part number 004785

9, 18, 27, 36 kW, 3/PE ~ 400 V

6

5

4

L3L2

L1

4

5

3

1

2

85�02�79� 0002

1 Heating element

9 kW connected load: 9 x 1 kW

18 kW connected load: 9 x 2 kW

27 kW connected load: 9 x 3 kW

36 kW connected load: 9 x 4 kW

2 Thermostat

3 High limit safety cut-out

4 Contactor, installed by the heating contractor

5 Power-OFF contact, installed by the heating contractor

!

Material losses

When connecting the contactors, please observe chapter

"Installation / Power connection".

Page 10

20 | FCR 28 Si www.stiebel-eltron.com

INSTALLATION | GUARANTEE | ENVIRONMENT AND RECYCLING

14.3 Data table

FCR 28/120 Si FCR 28/180 Si FCR 28/270 Si FCR 28/360 Si FSR 28/ 90 FSR 28/180

075140 075131 075141 075124 004817 004785

Electrical data

Connected load ~ 400 V kW 12 18 27 36 9 18

Connected load ~ 380 V kW 10.8 16.4 24.4 32.6 8.2 16.4

Rated voltage V 400 400 400 400 400 400

Phases 3/PE 3/PE 3/PE 3/PE 3/PE 3/PE

Frequency Hz 50/60 50/60 50/60 50/60 50/60 50/60

Single circuit operating mode X X X X X

Application limits

Temperature setting range °C 35-85 35-85 35-85 35-85 35-85 35-85

Max. permissible pressure MPa 1 1 1 1 1.0 1.0

Minimum cylinder diameter mm 450 450 450 550 550 550

Minimum cylinder volume l 200 200 200 300 300 300

Versions

IP rating IP24 IP24 IP24 IP24 IP24 IP24

Dimensions

External flange diameter mm 280 280 280 280 280 280

Immersion depth mm 325 325 325 450 450 450

Torque Nm 80 80 80 80 80 80

Weights

Weight kg 13 13 14.8 17.7 15 15

Guarantee

The guarantee conditions of our German companies do not

apply to appliances acquired outside of Germany. In countries

where our subsidiaries sell our products a guarantee can only

be issued by those subsidiaries. Such guarantee is only granted if the subsidiary has issued its own terms of guarantee. No

other guarantee will be granted.

We shall not provide any guarantee for appliances acquired in

countries where we have no subsidiary to sell our products.

This will not aect warranties issued by any importers.

Environment and recycling

We would ask you to help protect the environment. After use,

dispose of the various materials in accordance with national

regulations.

ENVIRONMENT AND RECYCLING

Page 11

Deutschland

STIEBEL ELTRON GmbH & Co. KG

Dr.-Stiebel-Straße 33 | 37603 Holzminden

Tel. 05531 702-0 | Fax 05531 702-480

info@stiebel-eltron.de

www.stiebel-eltron.de

Verkauf Tel. 05531 702-110 | Fax 05531 702-95108 | info-center@stiebel-eltron.de

Kundendienst Tel. 05531 702-111 | Fax 05531 702-95890 | kundendienst@stiebel-eltron.de

Ersatzteilverkauf Tel. 05531 702-120 | Fax 05531 702-95335 | ersatzteile@stiebel-eltron.de

Irrtum und technische Änderungen vorbehalten! | Subject to errors and technical changes! | Sous réserve

d‘erreurs et de modifications techniques! | Onder voorbehoud van ver

g

issingen en technische wijzigingen! |

Salvo error o modificación técnica! | Excepto erro ou alteração técnica | Zastrzeżone zmian

y

techniczne i

ewentualne błędy | Omyly a technické změny jsou vyhrazeny! | A muszaki változtatások és tévedések jogát

fenntartjuk! |

Отсутствие ошибок не гарантируется. Возможны технические изменения.

| Chyby a

technické zmeny sú vyhradené! Stand 9046

Australia

STIEBEL ELTRON Australia Pty. Ltd.

6 Prohasky Street | Port Melbourne VIC 3207

Tel. 03 9645-1833 | Fax 03 9645-4366

info@stiebel.com.au

www.stiebel.com.au

Austria

STIEBEL ELTRON Ges.m.b.H.

Eferdinger Str. 73 | 4600 Wels

Tel. 07242 47367-0 | Fax 07242 47367-42

info@stiebel-eltron.at

www.stiebel-eltron.at

Belgium

STIEBEL ELTRON bvba/sprl

't Hofveld 6 - D1 | 1702 Groot-Bijgaarden

Tel. 02 42322-22 | Fax 02 42322-12

info@stiebel-eltron.be

www.stiebel-eltron.be

China

STIEBEL ELTRON (Guangzhou) Electric

Appliance Co., Ltd.

Rm 102, F1, Yingbin-Yihao Mansion, No. 1

Yingbin Road

Panyu District | 511431 Guangzhou

Tel. 020 39162209 | Fax 020 39162203

info@stiebeleltron.cn

www.stiebeleltron.cn

Czech Republic

STIEBEL ELTRON spol. s r.o.

K Hájům 946 | 155 00 Praha 5 - Stodůlky

Tel. 251116-111 | Fax 235512-122

info@stiebel-eltron.cz

www.stiebel-eltron.cz

Finland

STIEBEL ELTRON OY

Kapinakuja 1 | 04600 Mäntsälä

Tel. 020 720-9988

info@stiebel-eltron.fi

www.stiebel-eltron.fi

France

STIEBEL ELTRON SAS

7-9, rue des Selliers

B.P 85107 | 57073 Metz-Cédex 3

Tel. 0387 7438-88 | Fax 0387 7468-26

info@stiebel-eltron.fr

www.stiebel-eltron.fr

Hungary

STIEBEL ELTRON Kft.

Gyár u. 2 | 2040 Budaörs

Tel. 01 250-6055 | Fax 01 368-8097

info@stiebel-eltron.hu

www.stiebel-eltron.hu

Japan

NIHON STIEBEL Co. Ltd.

Kowa Kawasaki Nishiguchi Building 8F

66-2 Horikawa-Cho

Saiwai-Ku | 212-0013 Kawasaki

Tel. 044 540-3200 | Fax 044 540-3210

info@nihonstiebel.co.jp

www.nihonstiebel.co.jp

Netherlands

STIEBEL ELTRON Nederland B.V.

Daviottenweg 36 | 5222 BH 's-Hertogenbosch

Tel. 073 623-0000 | Fax 073 623-1141

info@stiebel-eltron.nl

www.stiebel-eltron.nl

Poland

STIEBEL ELTRON Polska Sp. z O.O.

ul. Działkowa 2 | 02-234 Warszawa

Tel. 022 60920-30 | Fax 022 60920-29

biuro@stiebel-eltron.pl

www.stiebel-eltron.pl

Russia

STIEBEL ELTRON LLC RUSSIA

Urzhumskaya street 4,

building 2 | 129343 Moscow

Tel. 0495 7753889 | Fax 0495 7753887

info@stiebel-eltron.ru

www.stiebel-eltron.ru

Slovakia

TATRAMAT - ohrievače vody s.r.o.

Hlavná 1 | 058 01 Poprad

Tel. 052 7127-125 | Fax 052 7127-148

info@stiebel-eltron.sk

www.stiebel-eltron.sk

Switzerland

STIEBEL ELTRON AG

Industrie West

Gass 8 | 5242 Lupfig

Tel. 056 4640-500 | Fax 056 4640-501

info@stiebel-eltron.ch

www.stiebel-eltron.ch

Thailand

STIEBEL ELTRON Asia Ltd.

469 Moo 2 Tambol Klong-Jik

Amphur Bangpa-In | 13160 Ayutthaya

Tel. 035 220088 | Fax 035 221188

info@stiebeleltronasia.com

www.stiebeleltronasia.com

United Kingdom and Ireland

STIEBEL ELTRON UK Ltd.

Unit 12 Stadium Court

Stadium Road | CH62 3RP Bromborough

Tel. 0151 346-2300 | Fax 0151 334-2913

info@stiebel-eltron.co.uk

www.stiebel-eltron.co.uk

United States of America

STIEBEL ELTRON, Inc.

17 West Street | 01088 West Hatfield MA

Tel. 0413 247-3380 | Fax 0413 247-3369

info@stiebel-eltron-usa.com

www.stiebel-eltron-usa.com

A 296668-38920-9063

4<AMHCMN=jgggig>

Loading...

Loading...