Page 1

OPERATION AND INSTALLATION

OPERACIÓN E INSTALACIÓN

UTILISATION ET INSTALLATION

ELECTRONICALLY CONTROLLED INSTANTANEOUS WATER HEATER | CALENTADOR INSTANTÁNEO

CON CONTROLADO ELECTRÓNICA | CHAUFFE-EAU INSTANTANÉ À GESTION ÉLECTRONIQUE

»DHC-E 8/10

»DHC-E 12

The DHC-E series is

tested and certifi ed

by WQA against NSF/

ANSI 372 for lead free

compliance.

STIEBEL ELTRON, Inc.

17 West Street | West Hatfi eld, MA 01088

Tel. 413-247-3380 | Fax 413-247-3369

Email info@stiebel-eltron-usa.com

www.stiebel-eltron-usa.com

Page 2

CONTENTS | OPERATION

OPERATION

1. General information _________________________________________2

1.1 Safety information _______________________________________________ 2

1.2 Other symbols in this document ______________________________ 3

2. Safety __________________________________________________________3

2.1 Intended use ______________________________________________________ 3

2.2 General Information_____________________________________________ 3

2.3 Safety Precautions _______________________________________________ 3

2.4 Test symbols ______________________________________________________ 3

3. General ________________________________________________________4

4. Troubleshooting ______________________________________________4

OPERATION

1. General information

Note

Read these instructions carefully before using the appliance and familiarize yourself with its functions. Keep

these instructions safe. Pass on the instructions to a new

user if required.

INSTALLATION

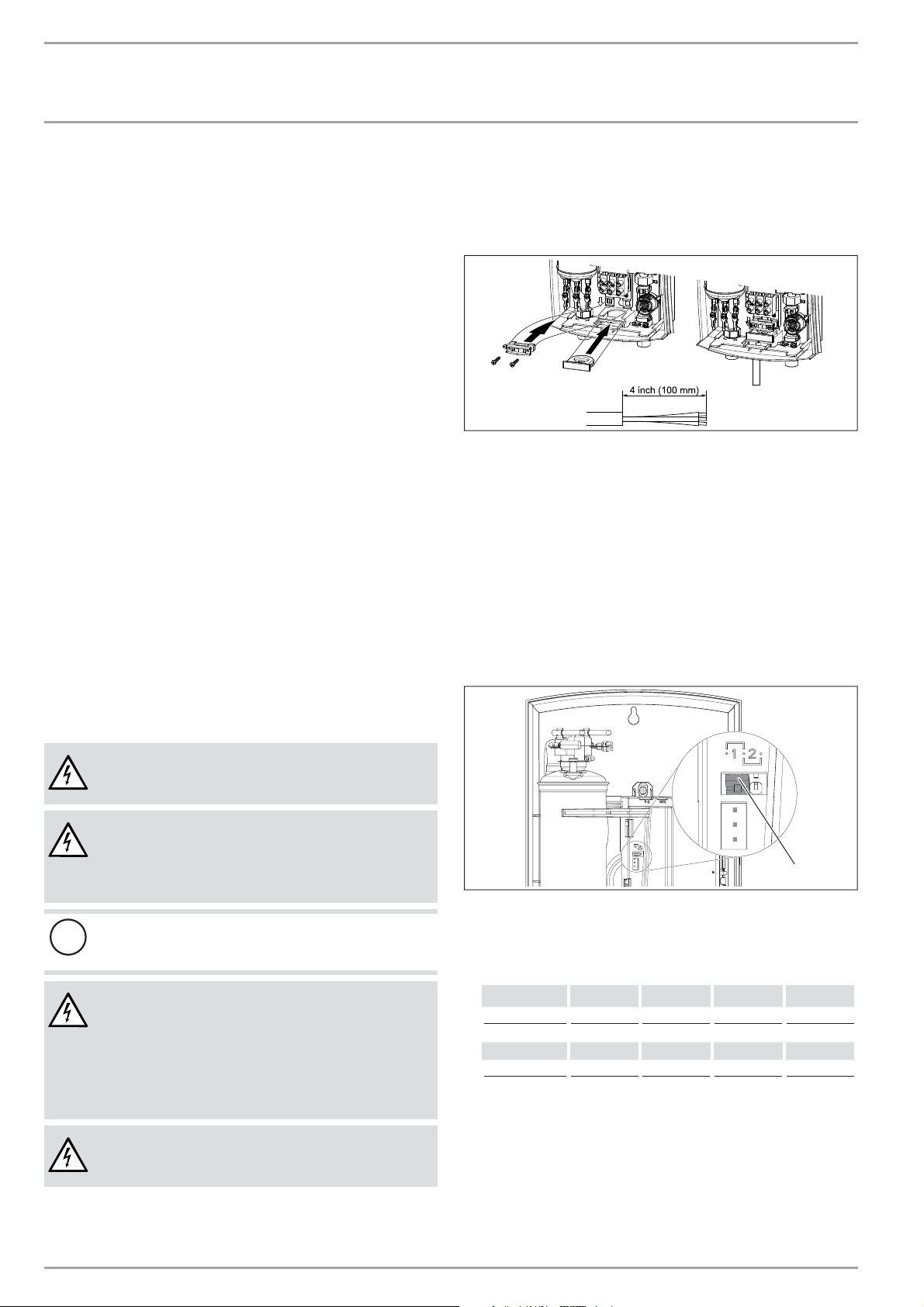

5. Mounting the appliance _____________________________________5

5.1 Application ________________________________________________________ 5

5.2 Mounting __________________________________________________________ 5

5.3 Water connections _______________________________________________ 5

6. Electrical connection _________________________________________6

6.1 DHC-E 8/10 - Appliance with output power options ______ 6

6.2 Temperature setting/anti-scalding protection ____________ 7

7. Commissioning _______________________________________________7

7.1 Appliance handover _____________________________________________ 7

8. Troubleshooting ______________________________________________7

8.1 Display options LED diagnostic „traffi c lights“ _____________ 7

8.2 Fault table _________________________________________________________ 7

9. Normal maintenance _________________________________________7

10. Technical Data ________________________________________________8

10.1 Dimensioned drawing __________________________________________ 8

10.2 Wiring diagram __________________________________________________ 8

10.3 Maximum temperature increase above ambient water

temperature ______________________________________________________ 9

10.4 Data table ________________________________________________________ 10

11. Spare parts _________________________________________________ 10

WARRANTY | ENVIRONMENT AND RECYCLING

1.1 Safety information

1.1.1 Structure of safety information

KEYWORD Type of risk

Here, possible consequences are listed that may result from not observing the safety information.

Steps to prevent the risk are listed.

1.1.2 Symbols. type of risk

Symbol Type of risk

Injury

!

Electrocution

Burns or scalding

1.1.3 Keywords

KEYWORD Description

DANGER If this information is not observed, it will result in serious

injury or death.

WARNING If this information is not observed, it can result in serious

injury or death.

CAUTION If this information is not observed, it can lead to medium

or minor injury.

2 | DHC-E WWW.STIEBEL-ELTRON-USA.COM

Page 3

OPERATION

SAFETY

1.2 Other symbols in this document

Note

Notes are bordered by horizontal lines above and below

the text. General information is identifi ed by the symbol

shown on the left.

Read these notes carefully.

Symbol

Damage to the appliance and environment

!

Appliance disposal

This symbol indicates that you have to do something. The ac-

tion you need to take is described step by step.

2. Safety

Observe the following safety information and regulations.

Operate the appliance only when fully installed and with all safety

equipment fi tted.

2.1 Intended use

The appliance is intended for heating domestic hot water and can

supply several draw-off points.

Any other use beyond that described shall be deemed inappropriate.

Observation of these instructions is also part of the correct use

of this appliance.

2.2 General Information

Read this entire manual. Failure to follow all the guides, instructions and rules could cause personal injury or property damage.

Improper installation, adjustment, alteration, service and use of

this appliance can result in serious injury.

Damage to the appliance and the environment

!

The appliance must be installed by a licensed electrician

and plumber. The installation must comply with all national, state and local plumbing and electric codes.

Service of the appliance must be performed by qualifi ed

service TECHNICIANS.

DANGER Electrocution

Before proceeding with any installation, adjustment. alteration, or service of this appliance all circuit breakers

and disconnect switches servicing the appliance must

be turned off. Failure to do so could result in serious

personal injury or death.

DANGER Electrocution

Never remove the appliance‘s cover unless the electricity

servicing the appliance is turned off. Failure to do so

could result in personal injury or death.

DANGER Electrocution

The appliance must be properly grounded. Failure to

electrically ground the product could result in serious

personal injury or death.

DANGER Burns

Water temperatures over 125°F (52 °C)can cause severe

burns instantly or death from scalding. A hot water scalding potential exists if the thermostat on the appliance

is set too high. Households with small children, disabled

or elderly persons may require that the thermostat be

set at 113°F (45 °C) or lower to prevent possible injury

from hot water.

WARNING Injury

!

Where children or persons with limited physical, sensory

or mental capabilities are to be allowed to control this

appliance, ensure that this will only happen under supervision or after appropriate instructions by a person

responsible for their safety.

Children should be supervised to ensure that they never

play with the appliance.

2.4 Test symbols

ENGLISH

This appliance must be installed by a licensed electrician and

plumber. The installation must comply with all national, state and

local plumbing and electric codes. Proper installation is the responsibility of the installer. Failure to comply with the installation

and operating instructions or improper use voids the warranty.

Save these instructions for future reference. Installer should leave

these instructions with the consumer.

If you have any questions regarding the installation, use or operation of this water heater, or if you need any additional installation

manuals, please call our technical service line, see last side.

See type plate on the appliance.

2.3 Safety Precautions

DANGER Injury

!

Please read and follow these instructions.

Failure to follow these instructions could result in serioius personal injury or death.

WWW.STIEBEL-ELTRON-USA.COM DHC-E | 3

Page 4

OPERATION

GENERAL

3. General

The tankless water heater differs from conventional storage type

water heaters in several ways. It does not store hot water. Instead,

water is heated instantaneously as it fl ows through the appliance.

Due to the absence of stand-by losses, the appliance offers greater

energy effi ciency than storage type water heaters.

The input of heat into the water is electronically controlled. The

appliance will deliver any water temperature between 86°F (30

°C) and 140 °F (60 °C). Please set the desired temperature using

the knob on the front cover.

Note

For reasons of appliance effi ciency and durability (scaling), the optimum temperature setting lies between 86°F

(30°C) and 120°F (50°C).

In case the “Power” light is fl ashing while the appliance operates,

the water fl ow rate exceeds the heating capacity of the appliance. Reduce the hot water fl ow rate in order to let the appliance

achieve the set point temperature. The maximum temperature is

electronically limited to 140 °F (60 °C). In case you have questions

regarding the way you plan to use the appliance, please call our

technical service line, see last side.

4. Troubleshooting

Symptom Possible Cause Solution

No hot water not enough flow rate to

activate appliance

Water not hot enough water flow too high reduce water flow rate until

clean faucet aerator or shower

head

light on front cover stops

blinking

26_02_02_1086

If you cannot remedy the fault, notify the contractor who installed

the appliance. To facilitate and speed up your enquir y, please provide the serial number from the type plate (000000-0000-000000).

4 | DHC-E WWW.STIEBEL-ELTRON-USA.COM

Page 5

INSTALLATION

MOUNTING THE APPLIANCE

INSTALLATION

5. Mounting the appliance

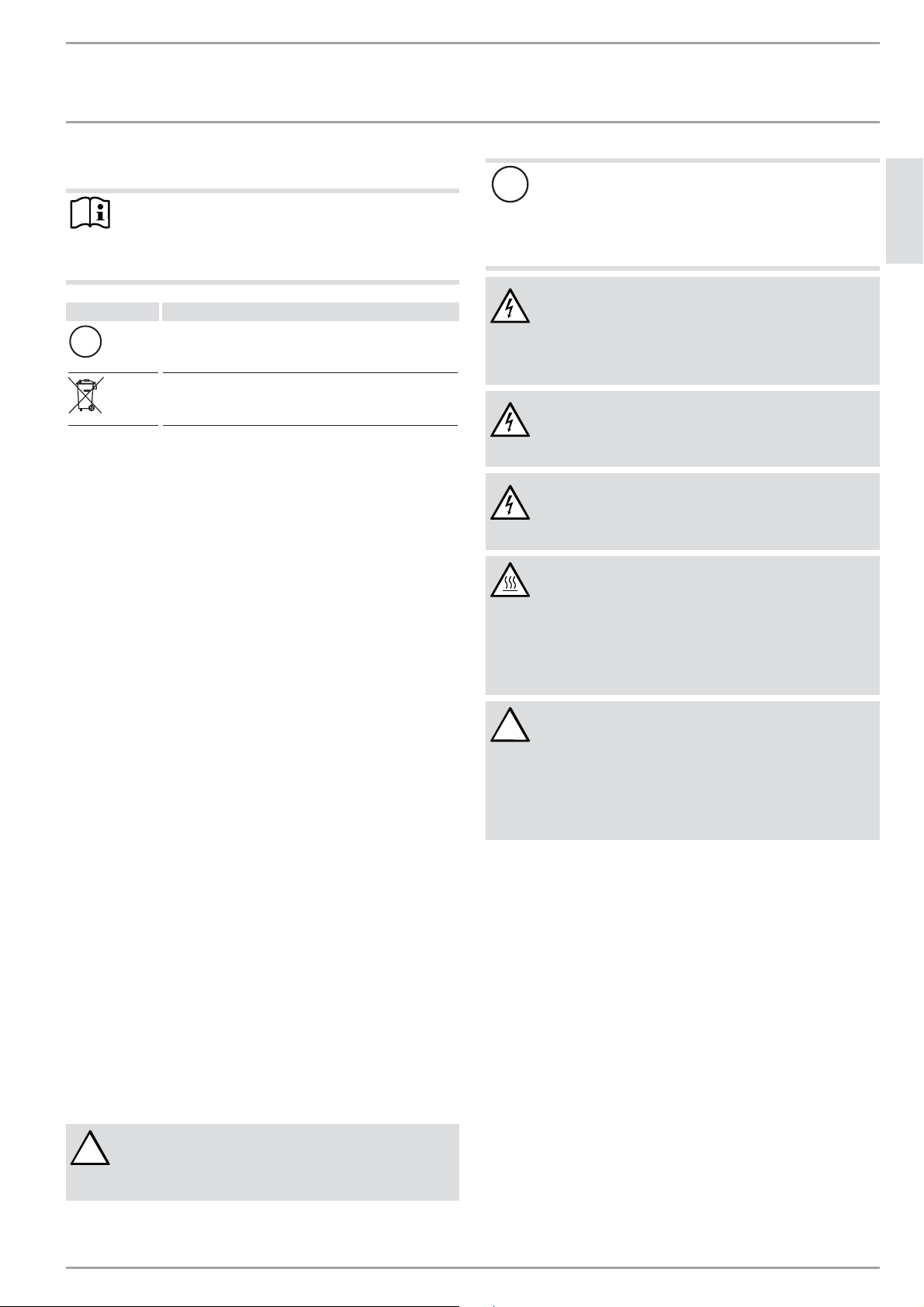

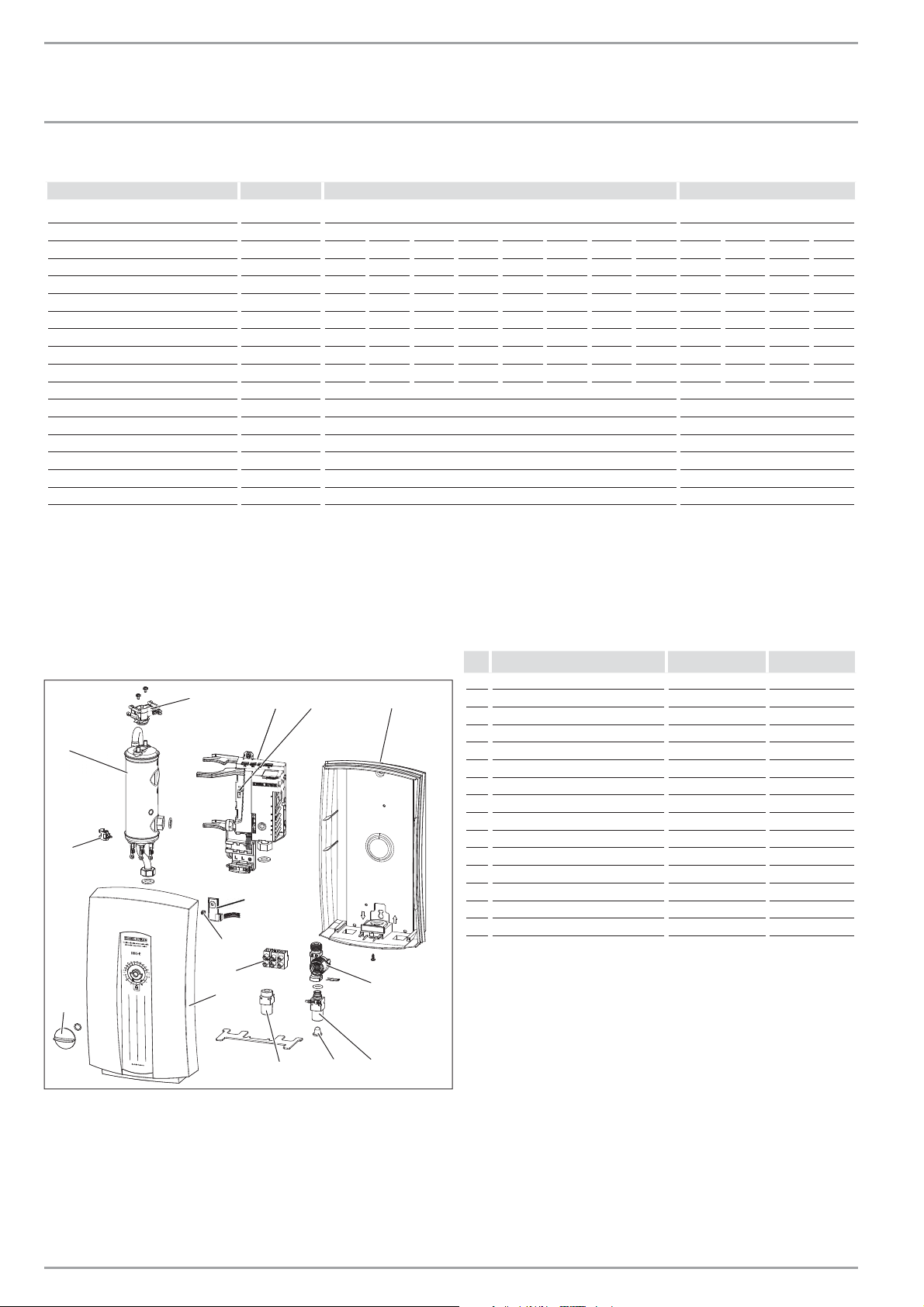

5.1 Application

ENGLISH

One appliance can be used for the following applications:

one or multiple hand washing sinks

one kitchen sink

cabins with fl ow restriction at shower head.

A combination of two appliance can be used for whole apartment

and house applications. Please contact STIEBEL ELTRON for special

installation instructions.

All areas with a ground water temperature likely to exceed 65°F

(18°C) year round:

Whole apartment or house

CAUTION Electrocution

Unit must be installed in a vertical position with the

water fi ttings pointing downward. In this position the

unit is splashproof, so that no water can soak in.

12

3

7

4

5

6

26_02_02_1083

Remove plastic cover.

26_02_02_033126_02_02_1090

26_02_02_1082

1

7

1 Hot valve (left)

2 Cold valve (right)

3 Sink

4 1/2“ main pipe

5 Water supply line for faucet installation

6 Shut-off valve

7 Electrical junction box

2

3

4

5

6

5.2 Mounting

Install appliance as close as possible to the main hot water

draw-off points.

Install appliance in a frost free area. If frost may occur, re-

move appliance before freezing temperatures set in.

Leave a minimum of 5“ of clearance on all sides for servicing.

26_02_02_1081

Screw the screws into the wall and hang the appliance.

Screws and plastic wall anchors for mounting on masonry or

wood are provided.

Secure the screws.

5.3 Water connections

Damage to the appliance and the environment

!

Excessive heat from soldering on copper pipes near the

DHC may cause damage.

WWW.STIEBEL-ELTRON-USA.COM DHC-E | 5

Page 6

INSTALLATION

ELECTRICAL CONNECTION

All plumbing work must comply with national and applicable

state and local plumbing codes.

Notice for Australia / New Zealand:

The installation shall comply with AS/NZS 3500.4.

A pressure reducing valve must be installed if the cold water

supply pressure exceeds 150 PSI (10 bar).

Make certain that the cold water supply line has been fl ushed

to remove any scale and dirt.

Install isolating valve in cold water line as shown in illustra-

tion “Mounting the appliance”. This allows the appliance to

be isolated for maintenance purposes.

Cold water connection (inlet) is on the right side of the ap-

pliance, hot water connection (outlet) is on the left side of

appliance.

Tankless water heaters such as the DHC-E are not required to

be equipped with a Pressure and Temperature Relief Valve

(P&T). If the local inspector will not pass the installation

without a P&T, it should be installed on the hot water outlet

side of appliance.

The appliance is designed for connection to copper tubing,

PEX tubing or a braided stainless steel hose with a ½“ NPT

female tapered thread. If soldering near the appliance is necessary, please direct the fl ame away from the plastic housing

of the appliance in order to avoid damage.

When all plumbing work is completed, check for leaks and

take corrective action before proceeding.

The appliance should be connected to a properly grounded

dedicated branch circuit of proper voltage rating. In installations with several appliances, each appliance requires an

independent circuit. Please refer to the technical data table

for the correct wire and circuit breaker size.

26_02_02_1084

The wire must be fed through the rubber seal located be-

tween the hot and cold water connections. Then feed wires

through strain relief clamp and tighten clamp down on wire.

The „live“ wires must be connected to the slots on the terminal block marked L and L (L and N). The ground wire must

be connected to slot marked with the ground symbol. Strain

relief clamp with screws and rubber seal are provided.

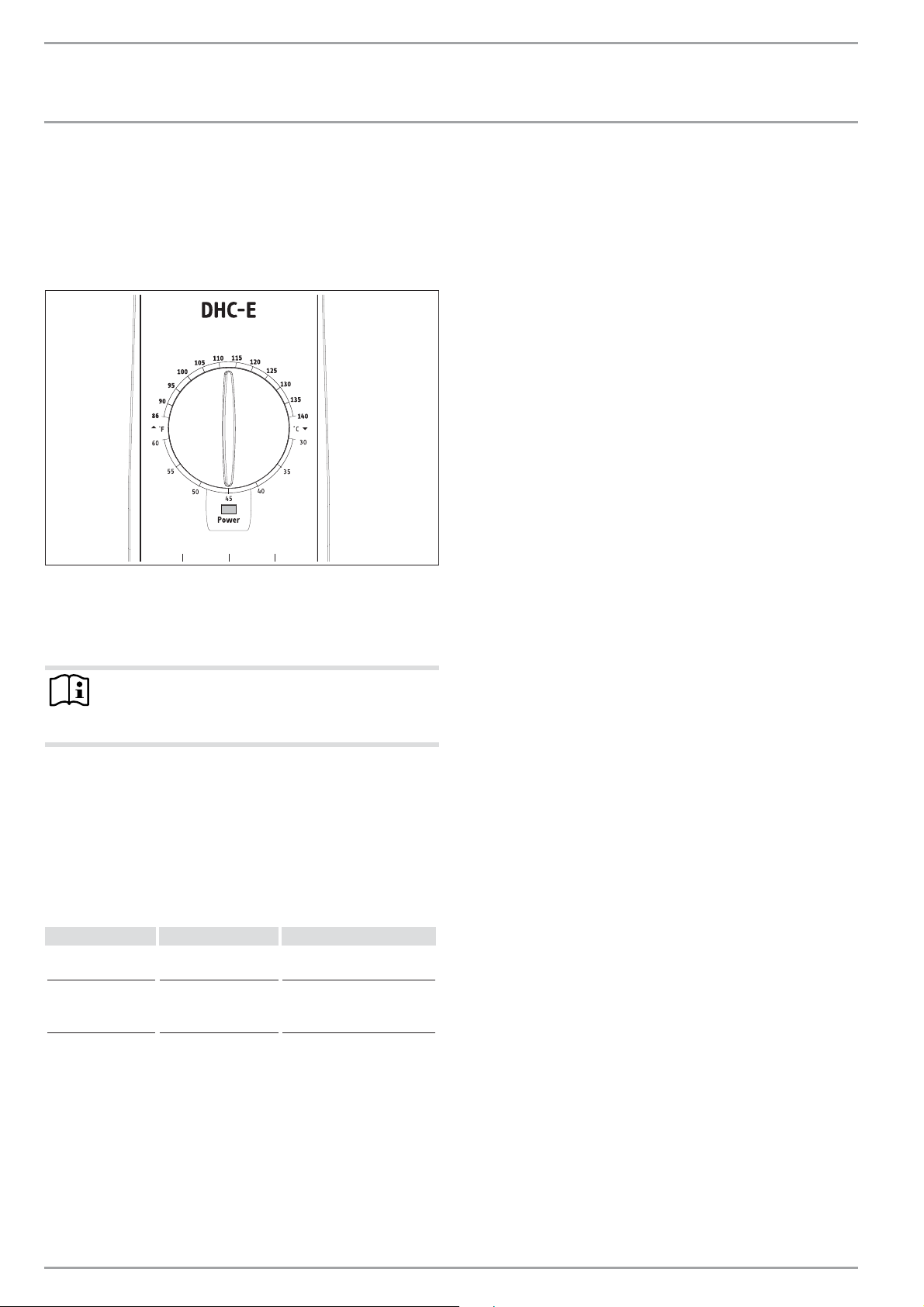

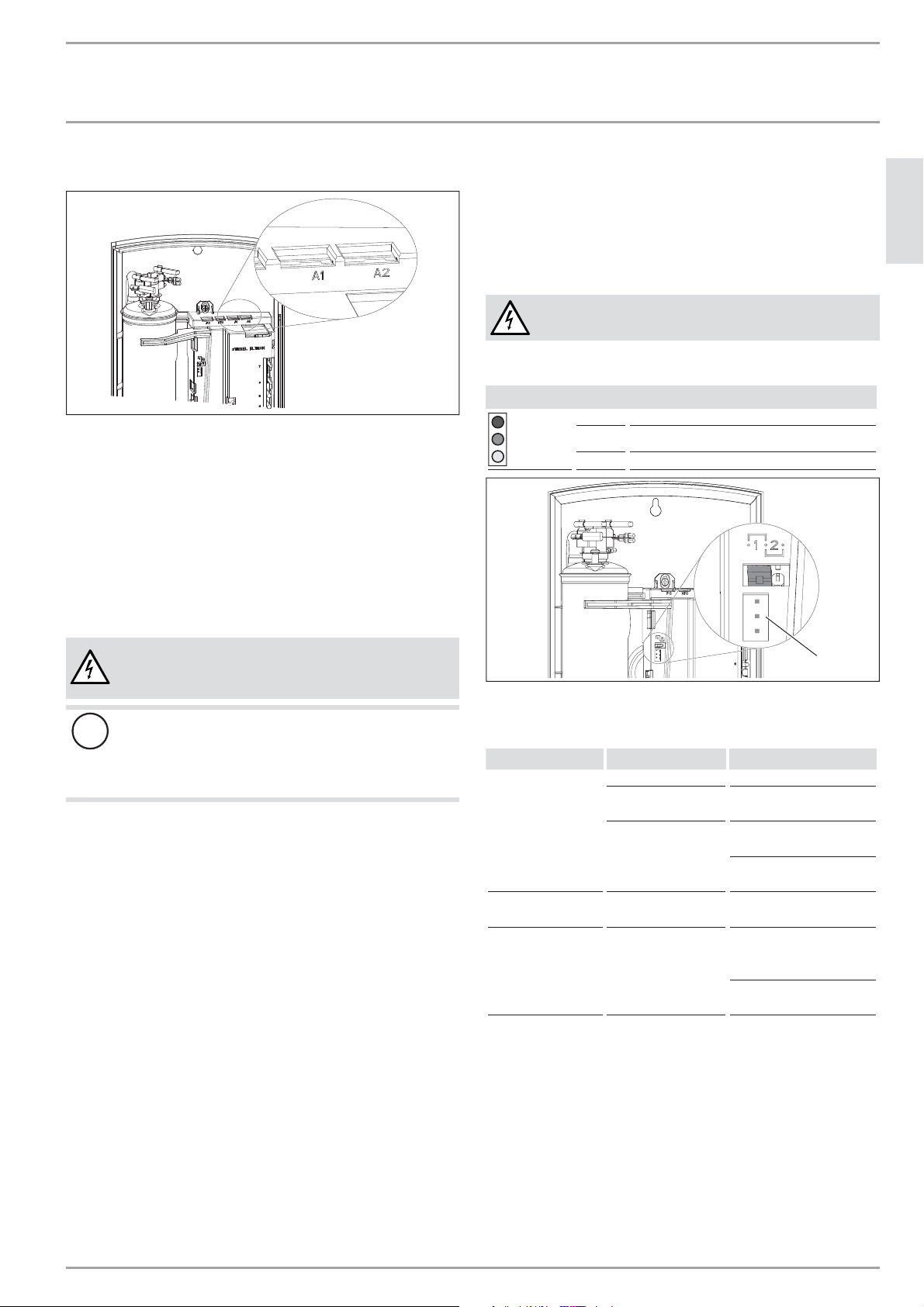

6.1 DHC-E 8/10 - Appliance with output power options

For the DHC-E 8/10 instantaneous water heater, the output power

is adjustable in 2 stages. In its delivered condition the appliance

is set to 7.2 kW@240 V.

6. Electrical connection

DANGER Electrocution

Carry out all electrical connection and installation work

in accordance with relevant regulations.

DANGER Electrocution

Only use a permanent connection to the power supply.

The appliance must be able to be separated from the

power supply by an isolator that disconnects all poles

with at least 3mm contact separation.

Damage to the appliance and the environment

!

Observe the type plate. The specifi ed voltage must match

the mains voltage.

DANGER Electrocution

Before beginning any work on the electric installation, be sure that main breaker panel switch is „off“ to

avoid any danger of electric shock. All mounting and

plumbing must be completed before proceeding with

electrical hook-up. Where required by local, state or

national electrical codes the circuit should be equipped

with a „ground fault interrupter“.

DANGER Electrocution

As with any electric appliance. failure to electrically

ground appliance may result in serious injury or death.

1

1 coding plug

If the appliance should be installed with a different output power,

take the following steps:

Insert the coding plug to the desired performance.

Stage 1 208 V 220 V 230 V 240 V

5,4 kW 6,0 kW 6,6 kW 7,2 kW

Stage 2 208 V 220 V 230 V 240 V

7,2 kW 8,1 kW 8,8 kW 9,6 kW

Mark the selected output power and voltage on the type plate

with a permanent marker.

26_02_02_1088

6 | DHC-E WWW.STIEBEL-ELTRON-USA.COM

Page 7

INSTALLATION

COMMISSIONING

6.2 Temperature setting/anti-scalding protection

Connect the lead of the electronic temperature control to po-

sition „A1“ in order to get the maximum outlet temperature

of 140°F (60°C).

The maximum temperature can be limited to 109°F (43°C):

Connect the lead of the electronic temperature control to po-

sition „A2“.

Reinstall the plastic cover.

7. Commissioning

7.1 Appliance handover

Explain the functions of the appliance to the user. Draw special

attention to the safety information. Hand the operating and installation instructions to the user.

8. Troubleshooting

Danger of electrocution

To test the appliance, it must be supplied with power.

8.1 Display options LED diagnostic „traffi c lights“

Display options

26_02_02_1089

red illuminates in case of faults

yellow illuminates when the appliance is heating water

green flashing: The appliance is supplied with power

ENGLISH

DANGER Electrocution

Commissioning must onl y be carried out by an authorised

contractor in accordance with safety regulations.

Damage to the appliance and the environment

!

Open hot water faucet for a few minutes until water fl ow

is continuous and all air is purged from water pipes. The

appliance’s plastic cover must be installed before the circuit breaker is turned on.

Turn on circuit breaker to bring electrical power to the

appliance.

Turn the temperature selector clockwise and anti-clockwise,

to calibrate the temperatur selector.

Adjust the water temperature to the desired level using the

knob on the front cover of the appliance.

Turn on hot water and wait twenty seconds until temperature

has stabilized.

Check the water temperature with your hand and make sure

that it does not feel too hot. Reduce temperature if this is

necessary. A setting of 108°F - 116°F (42 - 47°C) is recommended for most applications.

Explain to the user how the appliance works and familiarise

him or her with its use.

Advise the user about possible hazards (hot water tempera-

ture up to 140°F (60°C). Hand over these instructions, to be

kept for future reference.

A setting of 108°F - 116°F (42 - 47 °C) is recommended for

most applications.

1

1 LED diagnostic „traffi c lights“

8.2 Fault table

Symptom Possible Cause Solution

No hot water

clean faucet aerator or

Not enough hot water filter screen clogged clean filter screen at appli-

Water not hot enough water flow too high

supply correct voltage to

If you are not able to resolve a problem please contact us,

see last side, before removing the appliance from the wall.

STIEBEL ELTRON is happy to provide technical assistance. In

most instances, we can resolve the problem over the phone.

circuit breaker off

safety thermal cut-out

tripped

not enough flow rate to

activate appliance

turn circuit breaker on

reset thermal cut-out

clean filter screen at appliance

shower head

ance

reduce water flow rate until

light on front cover stops

blinking

appliance

9. Normal maintenance

STIEBEL ELTRON tankless water heaters are designed for a very

long service life. Actual life expectancy will vary with water quality and use. The appliance itself does not require any regular

maintenance.

26_02_02_1088

WWW.STIEBEL-ELTRON-USA.COM DHC-E | 7

Page 8

INSTALLATION

TECHNICAL DATA

However, to ensure consistent water fl ow, it is recommended to

periodically remove scale and dirt that may build up at the aerator of the faucet(s), the fi lter screen in the appliance, or in the

shower head.

10. Technical Data

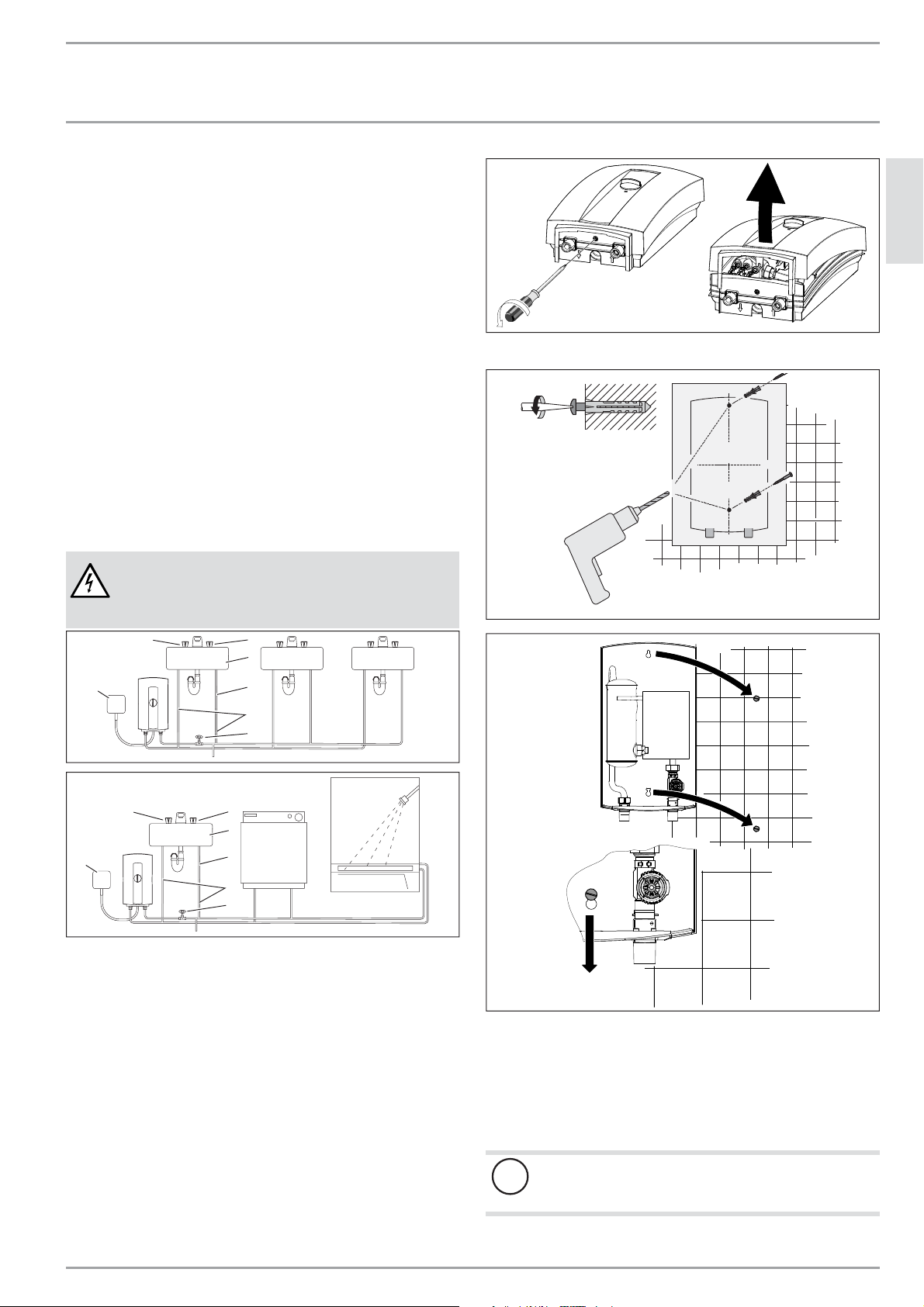

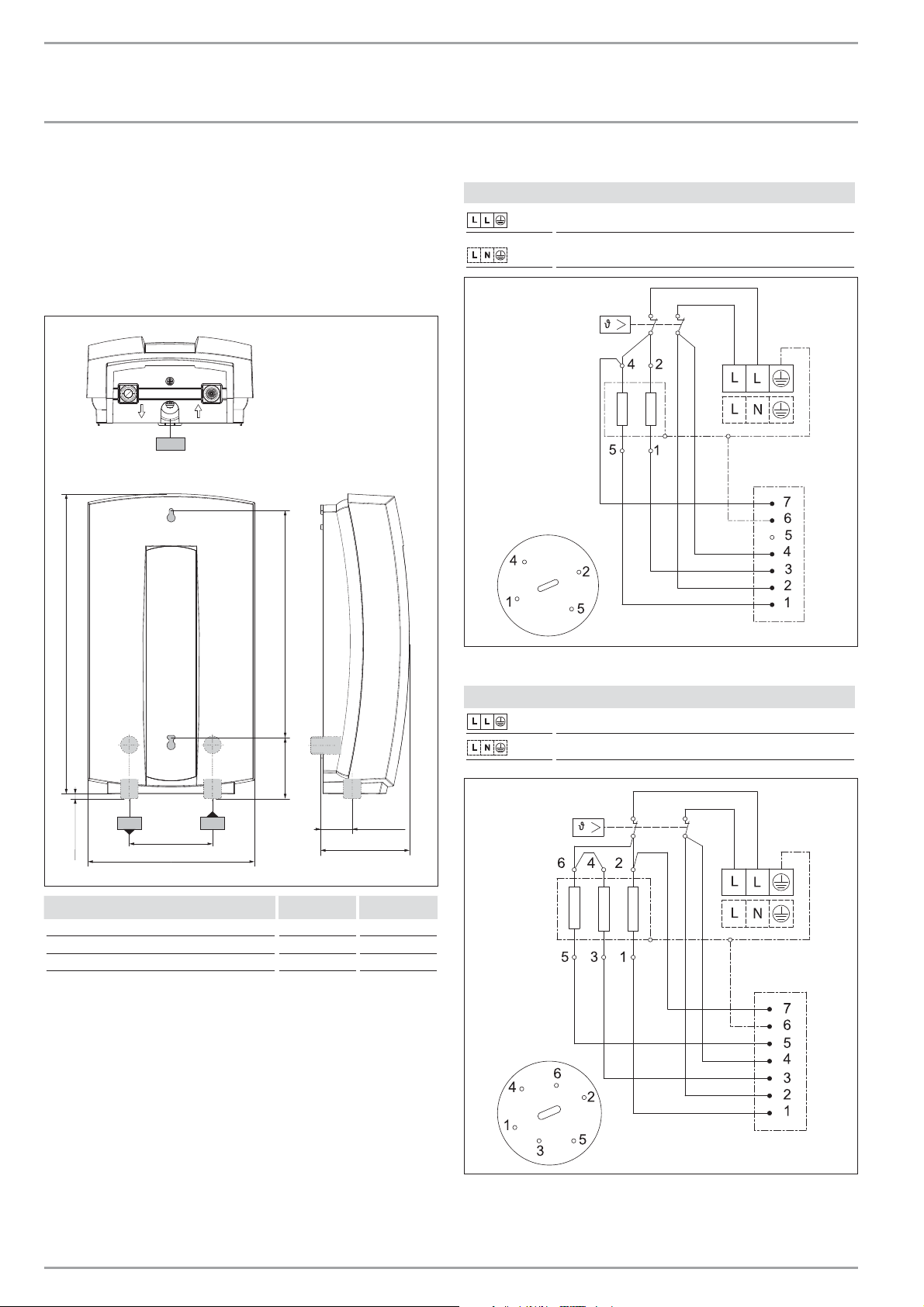

10.1 Dimensioned drawing

b01

10.2 Wiring diagram

DHC-E 8/10

2/GRD ~ 208 / 240 V

1/N/PE ~ 220 / 230 / 240 V

360 (14.17")

c06

c06 c01

100 (3.94")

8 (0.315")

b01 Electrical cable entry

c01 cold water inlet "NPT 1/2

c06 hot water outlet "NPT 1/2

200 (7.88")

c01

273 (10.75")75 (2.953")

38 (1.5")

110 (4.33")

85_02_03_0001

DHC-E 12

2/GRD ~ 208 / 240 V

1/N/PE ~ 220 / 230 / 240 V

D0000017762

8 | DHC-E WWW.STIEBEL-ELTRON-USA.COM

85_02_03_0002

Page 9

INSTALLATION

TECHNICAL DATA

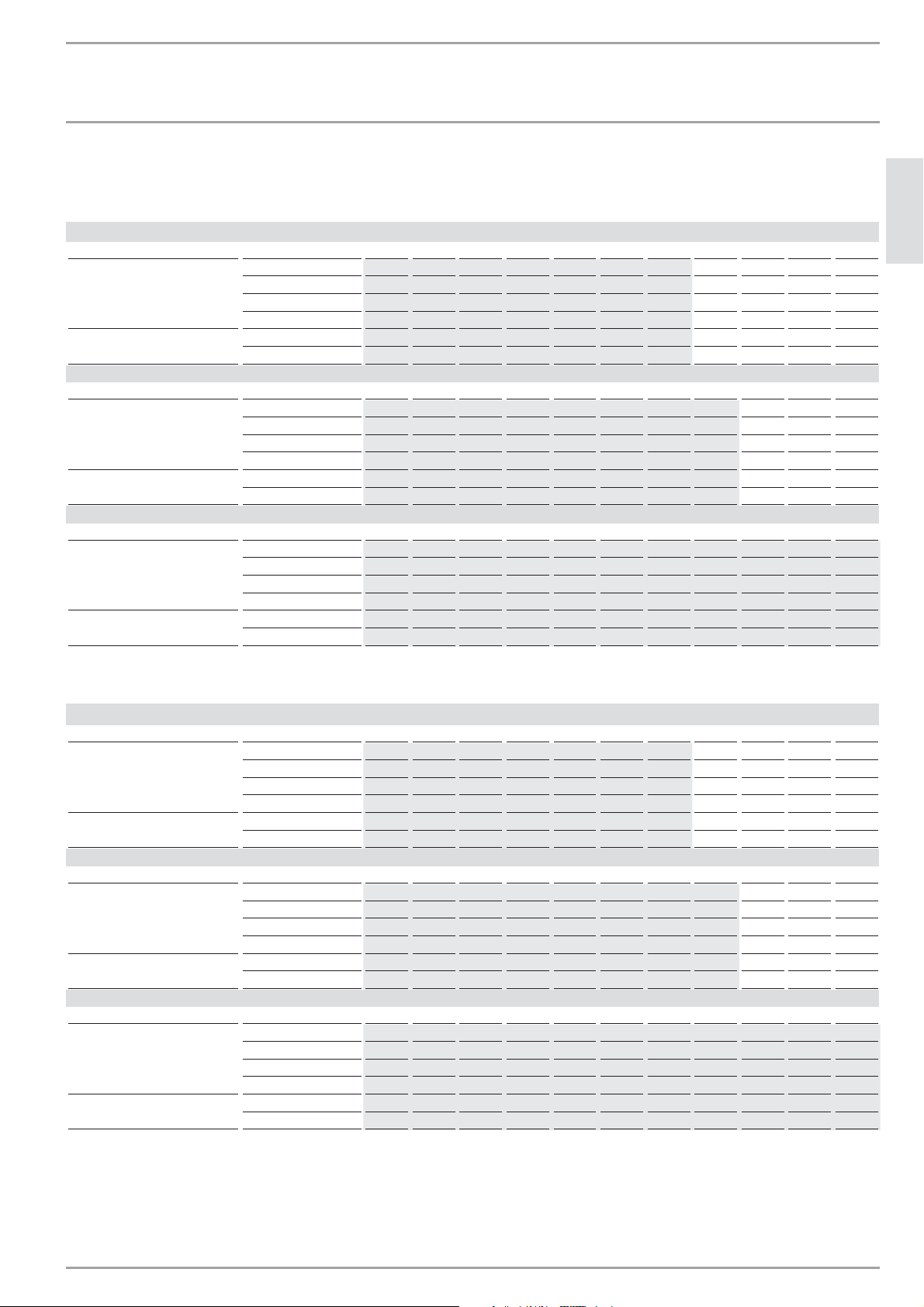

10.3 Maximum temperature increase above ambient water temperature

Warm water fl ow rate [ GPM ]

Warm water outlet temperature 104 °F

Cold water inlet temperature °F 39 50 59 68 77 86 95 104 113 122 131

DHC-E 8/10

9.6 kW @ 240 V 1.01 1.21 1.45 1.82 2.42 3.63 6.61 - - - DHC-E 12

12 kW @ 240 V 1.26 1.51 1.82 2.27 3.03 4.31 6.61 - - - -

Warm water outlet temperature 113 °F

Cold water inlet temperature °F 39 50 59 68 77 86 95 104 113 122 131

DHC-E 8/10

9.6 kW @ 240 V 0.89 1.04 1.21 1.45 1.82 2.42 3.63 6.61 - - DHC-E 12

12 kW @ 240 V 1.11 1.30 1.51 1.82 2.27 2.88 4.31 6.61 - - -

Warm water outlet temperature 140 °F

Cold water inlet temperature °F 39 50 59 68 77 86 95 104 113 122 131

DHC-E 8/10

9.6 kW @ 240 V 0.65 0.73 0.81 0.91 1.04 1.21 1.45 1.82 2.42 3.63 6.61

DHC-E 12

12 kW @ 240 V 0.81 0.91 1.01 1.14 1.30 1.44 1.73 2.16 2.88 4.31 6.61

5.4 kW @ 208 V 0.57 0.68 0.82 1.02 1.36 2.04 4.09 - - - -

7.2 kW @ 240 V 0.76 0.91 1.09 1.36 1.82 2.72 5.45 - - - -

7.2 kW @ 208 V 0.76 0.91 1.09 1.36 1.82 2.72 5.45 - - - -

9 kW @ 208 V 0.95 1.14 1.36 1.70 2.27 3.23 6.47 - - - -

5.4 kW @ 208 V 0.50 0.58 0.68 0.82 1.02 1.36 2.04 4.09 - - -

7.2 kW @ 240 V 0.66 0.78 0.91 1.09 1.36 1.82 2.72 5.45 - - -

7.2 kW @ 208 V 0.66 0.78 0.91 1.09 1.36 1.82 2.72 5.45 - - -

9 kW @ 208 V 0.83 0.97 1.14 1.36 1.70 2.16 3.23 6.47 - - -

5.4 kW @ 208 V 0.36 0.41 0.45 0.51 0.58 0.68 0.82 1.02 1.36 2.04 4.09

7.2 kW @ 240 V 0.49 0.54 0.61 0.68 0.78 0.91 1.09 1.36 1.82 2.72 5.45

7.2 kW @ 208 V 0.49 0.54 0.61 0.68 0.78 0.91 1.09 1.36 1.82 2.72 5.45

9 kW @ 208 V 0.61 0.68 0.76 0.85 0.97 1.08 1.29 1.62 2.16 3.23 6.47

ENGLISH

Warm water fl ow rate [ l/min ]

Warm water outlet temperature 40 °C

Cold water inlet temperature °C 4 10 15 20 25 30 35 40 45 50 55

DHC-E 8/10

9.6 kW @ 240 V 3.82 4.58 5.50 6.87 9.16 13.75 25.00 - - - DHC-E 12

12 kW @ 240 V 4.77 5.73 6.87 8.59 11.46 16.32 25.00 - - - -

Warm water outlet temperature 45 °C

Cold water inlet temperature °C 4 10 1 20 25 30 35 40 45 50 55

DHC-E 8/10

9.6 kW @ 240 V 3.35 3.93 4.58 5.50 6.87 9.16 13.75 25.00 - - DHC-E 12

12 kW @ 240 V 4.19 4.91 5.73 6.87 8.59 10.88 16.32 25.00 - - -

Warm water outlet temperature 60 °C

Cold water inlet temperature °C 4 10 15 20 25 30 35 40 45 50 55

DHC-E 8/10

9.6 kW @ 240 V 2.45 2.75 3.05 3.44 3.93 4.58 5.50 6.87 9.16 13.75 25.00

DHC-E 12

12 kW @ 240 V 3.07 3.44 3.82 4.30 4.91 5.44 6.53 8.16 10.88 16.32 25.00

5.4 kW @ 208 V 2.15 2.58 3.09 3.87 5.16 7.73 15.47 - - - -

7.2 kW @ 240 V 2.86 3.44 4.12 5.16 6.87 10.31 20.62 - - - -

7.2 kW @ 208 V 2.86 3.44 4.12 5.16 6.87 10.31 20.62 - - - -

9 kW @ 208 V 3.58 4.30 5.16 6.44 8.59 12.24 24.49 - - - -

5.4 kW @ 208 V 1.89 2.21 2.58 3.09 3.87 5.16 7.73 15.47 - - -

7.2 kW @ 240 V 2.51 2.95 3.44 4.12 5.16 6.87 10.31 20.62 - - -

7.2 kW @ 208 V 2.51 2.95 3.44 4.12 5.16 6.87 10.31 20.62 - - -

9 kW @ 208 V 3.14 3.68 4.30 5.16 6.44 8.16 12.24 24.49 - - -

5.4 kW @ 208 V 1.38 1.55 1.72 1.93 2.21 2.58 3.09 3.87 5.16 7.73 15.47

7.2 kW @ 240 V 1.84 2.06 2.29 2.58 2.95 3.44 4.12 5.16 6.87 10.31 20.62

7.2 kW @ 208 V 1.84 2.06 2.29 2.58 2.95 3.44 4.12 5.16 6.87 10.31 20.62

9 kW @ 208 V 2.30 2.58 2.86 3.22 3.68 4.08 4.90 6.12 8.16 12.24 24.49

WWW.STIEBEL-ELTRON-USA.COM DHC-E | 9

Page 10

INSTALLATION

SPARE PARTS

10.4 Data table

DHC-E 8/10 DHC-E 12

Part number 224201 230628

Phase 1 1 1 1 1 1 1 1 1 1 1 1

Voltage V 208 220 230 240 208 220 230 240 208 220 230 240

Frequency Hz 50 / 60 50 / 60 50 / 60 50 / 60 50 / 60 50 / 60 50 / 60 50 / 60 50 / 60 50 / 60 50 / 60 50 / 60

Coding plug Position 1 1 1 1 2 2 2 2 - - - Output power kW 5.4 6.0 6.6 7.2 7.2 8.1 8.8 9.6 9 10 11 12

Ampere A 28 30 31 32 35 37 39 40 44 46 48 50

Min. required circuit breaker size A 30 40 40 40 50 50 50 50 60 60 60 60

Recommended wire size AWG COPPER 10 - - 8 8 - - 8 6 - - 6

Recommended wire size mm² COPPER - 6 6 - - 10 10 - - 10 10 Protection level according to IP 24 IP 24

Min. water flow to activate appliance GPM / l/min 0.37 / 1.4 0.37 / 1.4

Nominal water volume GAL / l 0.13 / 0.5 0.13 / 0.5

Working pressure max. PSI / bar / MPa 150 / 10 / 1 150 / 10 / 1

Tested to pressure PSI / bar / MPa 300 / 20 / 2 300 / 20 / 2

Weight lbs. / kg 5.9 / 2.7 5.9 / 2.7

Water connections “ NPT 1/2 1/2

Suitable for supply with up to 131 °F / 55 °C

Tankless water heaters are considered a non-continuous load

Conductors should be sized to maintain a voltage drop of less than

3 % under load

11. Spare parts

1

15

14

2

12

11

10

35

4

13

6

No. No. Spare par t DHC-E 8/10 DHC-E 12

1 Heating system 292575 292576

2 Safety thermal cut out 286369 286369

3 Electronic control appliance 291851 291852

4 Coding plug 283455 --5 Back panel 292578 292578

6 Flow sensor DFE 286461 286461

7 Cold water connection 291699 291699

8 Filter screen 252430 252430

9 Hot water connection 278634 278634

10 Plastic cover 292577 292577

11 Wiring block 279998 279998

12 Axis connection plug 254312 254312

13 Electronic temperature control 286359 286359

14 Temperature adjustment knob 254307 254307

15 Outlet temperature sensor 280677 280677

987

26_02_02_1091

10 | DHC-E WWW.STIEBEL-ELTRON-USA.COM

Page 11

WARRANTY | ENVIRONMENT AND RECYCLING

12. Warranty

Residential & commercial warranty: Stiebel Eltron, Inc. warrants to the original owner that the DHC-E tankless

electric water heater will be free from defects in workmanship and materials for a period of three (3) years from

the date of purchase, and free from leak age for a period of seven (7) years from the date of purchase. Should

the part(s) prove to be defective under normal use during this period, Stiebel Eltron, Inc. will be responsible for

replacement of the defective part(s) only. Stiebel Eltron, Inc. is not responsible for labor charges to remove and/

or replace the defective part(s), or any incidential or consequential expenses.

Should the owner wish to return the tankless electric water heater for repair, the owner must fi rst secure written

authorization from Stiebel Eltron, Inc. The owner shall be required to show proof of purchase date, and to pay

all transportation costs to return the defective part(s) or tankless electric water heater for repair or replacement.

Warranty is void if water heater has been installed or used improperly or if design has been altered in any way.

Make any warranty claim in the country where you purchased

the appliance. In such cases, please contact our representation

or the importer.

Our warranty applies only if:

— These installation instructions have been observed

— Exclusively accessories designated for this appliance have been

used

— All required steps up to and including commissioning have be

carried out by a qualified contractor

— Maintenance as specified has been carried out

— Exclusively our spare parts have been used for repairs

ENGLISH

Environment and recycling

Please help us protect the environment. Dispose of the appliance

and its packaging in accordance with national regulations.

WWW.STIEBEL-ELTRON-USA.COM DHC-E | 11

Page 12

ÍNDICE|OPERACIÓN

INDICACIONES GENERALES

OPERACIÓN

1. Indicaciones generales ____________________________________ 12

1.1 Indicaciones para el cableado: _______________________________ 12

1.2 Otras marcas presentes en este documento ______________ 13

2. Seguridad ___________________________________________________ 13

2.1 Uso previsto ______________________________________________________13

2.2 Información general ___________________________________________13

2.3 Medidas de seguridad _________________________________________13

2.4 Sello de certifi cación ___________________________________________ 13

3. Descripción del equipo ___________________________________ 14

4. Solución de problemas ____________________________________ 14

OPERACIÓN

1. Indicaciones generales

Indicación

Lea atentamente estas instrucciones antes de utilizar el

aparato y familiarícese con sus funciones. Conserve este

manual en un lugar seguro. Si entregara este aparato a

otros usuarios no olvide incluir el manual.

INSTALACIÓN

5. Descripción del equipo ____________________________________ 15

6. Montaje _____________________________________________________ 15

6.1 Conexión de agua_______________________________________________ 16

6.2 Conexión eléctrica ______________________________________________ 16

6.3 Ajuste de temperatura/protección antiescaldamiento _ 17

7. Puesta en marcha __________________________________________ 17

8. Localización y reparación de fallos_______________________ 17

8.1 Posibilidades de indicación de los LED de diagnóstico __ 17

8.2 Tabla de averías _________________________________________________ 17

9. Mantenimiento _____________________________________________ 18

10. Especifi caciones técnicas __________________________________ 18

10.1 Plano dimensional ______________________________________________ 18

10.2 Diagrama eléctrico _____________________________________________18

10.3 Posibles caudales para distintas temperaturas de entrada y de salida ____________________________________________________ 19

10.4 Tabla de especifi caciones _____________________________________20

11. Piezas de recambio ________________________________________ 20

GARANTÍA | MEDIO AMBIENTE Y RECICLAJE

1.1 Indicaciones para el cableado:

1.1.1 Estructura de las indicaciones de seguridad

ADVERTENCIA de tipo de peligro

Aquí aparecen las posibles consecuencias del desobedecimiento de las indicaciones de seguridad.

Se indican las medidas necesarias para evitar

estos peligros.

1.1.2 Símbolos, tipo de peligro

Símbolo Tipo de peligro

Lesión

!

Electrocución

Quemadura o escaldamiento

1.1.3 Palabras clave

PALABRA CLAVE Descripción

PELIGRO El desobedecimiento de esta información conlleva

graves lesiones o la muerte

ADVERTENCIA El desobedecimiento de esta información puede con-

llevar graves lesiones o la muerte

ATENCIÓN El desobedecimiento de esta información puede con-

llevar lesiones de mediana gravedad o lesiones leves

12 | DHC-E WWW.STIEBEL-ELTRON.COM

Page 13

OPERACIÓN

SEGURIDAD

1.2 Otras marcas presentes en este documento

Indicación

La indicación está limitada por líneas horizontales sobre

y bajo el texto. La información general se señaliza mediante el símbolo que se muestra a la izquierda.

Lea atentamente las indicaciones.

Símbolo

Daños en el aparato y al medio ambiente

!

Eliminación del aparato

Este símbolo indica que debe usted hacer algo. Lo que debe

hacer se describe en pasos individuales.

2. Seguridad

Observe las siguientes indicaciones y normas de seguridad.

El equipo sólo debe utilizarse después de haber sido instalado

completamente y con todos los dispositivos de seguridad.

2.1 Uso previsto

El aparato está previsto para el calentamiento del agua potable y

puede abastecer varios puntos de extracción.

El uso fuera de las especifi caciones descritas se considera indebido.

Además, el obedecimiento de las presentes instrucciones forma

parte del uso previsto de este aparato.

2.2 Información general

Lea el manual íntegramente. El desobedecimiento de las normas,

instrucciones y reglamentos puede causar lesiones físicas a personas y/o daños materiales. La instalación, ajuste, modifi cación y

mantenimiento incorrectos del presente aparato puede conducir

a lesiones físicas considerables.

Este aparato debe ser instalado por un técnico autorizado. La instalación debe cumplir toda la normativa nacional, regional y local.

El técnico especializado es responsable de la correcta instalación.

El desobedecimiento de las instrucciones de instalación y operación o el uso indebido conducen a la anulación de la garantía.

Daños en el aparato y al medio ambiente

!

Este aparato debe ser instalado por un técnico autorizado. La instalación debe cumplir toda la normativa nacional, regional y local.

El mantenimiento del aparato debe ser realizado por técnicos autorizados.

PELIGRO Electrocución

Antes de llevar a cabo cualquier tarea de instalación,

ajuste, modifi cación o mantenimiento de este aparato

deben desconectarse todos los interruptores de potencia

y seccionadores de alimentación eléctrica del aparato. El

desobedecimiento de estas indicaciones puede conllevar

graves lesiones o la muerte.

PELIGRO Electrocución

Sólo podrá retirar la cubierta del aparato si se ha interrumpido la alimentación eléctrica del aparato. El desobedecimiento de estas indicaciones puede conllevar

lesiones físicas o la muerte.

PELIGRO Electrocución

El aparato debe conectarse a tierra adecuadamente. Si

no se conecta a tierra el producto pueden producirse

graves lesiones físicas o incluso la muerte.

PELIGRO Quemaduras

Las temperaturas del agua que superen los 125 °F (52 °C)

pueden causar quemaduras graves repentinas o incluso

la muerte por escaldamiento. El peligro de escaldamiento con agua caliente existe si el termostato del aparato

presenta un ajuste demasiado alto. En hogares con niños

pequeños, personas discapacitadas o personas mayores

puede ser necesario ajustar el termostato a 113 °F (45 °C)

o menos para evitar lesiones físicas por agua caliente.

ADVERTENCIA Peligro de lesiones

!

Si niños o personas con discapacitación física, sensorial o

mentalmente, operan el aparato debe asegurarse de que

dicha operación se realice después de haber recibido la

instrucción adecuada por una persona a su cargo.

En el caso de los niños debe procurar que no jueguen

con el aparato.

2.4 Sello de certifi cación

Consulte la placa de especifi caciones del aparato.

ESPAÑOL

Guarde el presente manual para futuras consultas. El técnico especializado debe entregar este manual al usuario.

En caso de cualquier consulta relativa a la instalación, uso u operación del presente calentador o, si fuera preciso en relación a

cualquier otro manual de instalación, diríjase al teléfono de servicio técnico (véase última página).

2.3 Medidas de seguridad

PELIGRO de lesiones

!

Lea y obedezca las siguientes instrucciones.

El desobedecimiento de esta información puede conllevar graves lesiones o la muerte.

WWW.STIEBEL-ELTRON.COM DHC-E | 13

Page 14

OPERACIÓN

DESCRIPCIÓN DEL EQUIPO

3. Descripción del equipo

El calentador instantáneo DHC-E se distingue de los acumuladores

de agua convencionales en varios aspectos. No acumula agua caliente. En lugar de ello, el agua se calienta de inmediato mientras

fl uye a través del aparato. Debido a la ausencia de pérdidas de

calor en modo standby, el DHC-E ofrece un rendimiento energético

superior a un acumulador de agua caliente.

El calentamiento del agua se controla electrónicamente. El DHC-E

puede suministrar agua a una temperatura de 86 °F (30 °C) a 140 °F

(60 °C). La temperatura deseada puede ajustarse mediante el regulador de temperatura.

Indicación

Por razones de efi ciencia y vida útil (calcifi cación) del

aparato, el rango de ajuste óptimo de la temperatura

está entre 30°C (86°F) y 50°C (120°F).

Si durante el funcionamiento del aparato parpadea la luz “power”

(alimentación), el caudal del agua es superior a lo que puede

calentar la potencia calefactora del aparato. En ese caso, reduzca

el caudal para que el aparato pueda proporcionar la temperatura

ajustada. La temperatura máxima está limitada electrónicamente a 140 °F. Si tuviera cualquier pregunta adicional sobre el uso

previsto del DHC-E, diríjase al teléfono de nuestro servicio técnico

(véase última página).

4. Solución de problemas

Problema Causa Solución

No hay agua caliente El caudal de agua no es

suficiente para la acti-

vación del aparato

El agua no está suficientemente caliente

El caudal de agua es

demasiado alto

Limpiar el regulador de chorro

o el cabezal de la ducha

Reducir el caudal hasta que la

luz de la cubierta frontal deje

de parpadear

26_02_02_1086

Si no puede solucionar la causa llame al instalador. Para poder

ayudarle mejor y con mayor agilidad, indique el número de la

placa de especifi caciones (000000-0000-000000).

14 | DHC-E WWW.STIEBEL-ELTRON.COM

Page 15

INSTALACIÓN

DESCRIPCIÓN DEL EQUIPO

INSTALACIÓN

5. Descripción del equipo

El DHC-E puede utilizarse para los siguientes usos:

- Uno o varios lavabos de manos

- Un fregadero de cocina

- Ducha con límite de fl ujo en el cabezal de la ducha

Para llevar a cabo el suministro completo de agua caliente de

un piso o de una vivienda unifamiliar, en algunos países puede

bastar una combinación de dos aparatos DHC-E. Para este caso

de utilización especial, recibirá más información previa consulta

a STIEBEL ELTRON.

En regiones con una elevada temperatura de entrada de agua

fría, durante todo el año por encima de los 65 °F (18 °C), el aparato puede ser adecuado para abastecer todo el piso o vivienda

unifamiliar.

ATENCIÓN Peligro de electrocución

El aparato debe instalarse en vertical con las conexiones

de agua hacia abajo. En esta posición de instalación, las

salpicaduras de agua no pueden penetrar en el aparato.

El montaje del equipo sólo debe realizarse en habitaciones

resguardadas de la escarcha. Guarde el aparato desmontado

resguardado de la escarcha, ya que hay agua residual su interior que puede congelarse y causar daños en el aparato.

Debe dejarse un espacio libre mínimo de 125 mm a cada

lado para la realización de las tareas de mantenimiento.

ESPAÑOL

26_02_02_1083

Retirar la carcasa de plástico.

12

3

7

1

7

1 Válvula de agua caliente (izquierda)

2 Válvula de agua fría (a la derecha)

3 Lavabos

4 Tubería de alimentación de agua fría 1/2”

5 Tubería de agua para instalar el grifo de agua

6 Válvula de cierre

7 Toma de corriente

4

5

6

2

3

4

5

6

26_02_02_0331

26_02_02_1082

26_02_02_1081

6. Montaje

Colocar el DHC-E lo más cerca posible del punto de extrac-

ción de agua caliente.

WWW.STIEBEL-ELTRON.COM DHC-E | 15

Atornille los tornillos y enganche el aparato. Los tornillos y

tacos de plástico para colocar el aparato a la pared de mampostería o de madera vienen incluidos.

Fije los tornillos.

26_02_02_1090

Page 16

INSTALACIÓN

MONTAJE

6.1 Conexión de agua

Daños en el aparato y al medio ambiente

!

Si se genera demasiado calor al soldar los tubos de cobre

cerca del DHC pueden producirse daños en el aparato.

En todos los trabajos debe observarse la normativa nacional

y regional vigente.

A una presión superior a 1 MPa del suministro de agua fría

debe instalar una válvula reductora de presión.

Lave el tubo de alimentación de agua fría a fondo para elimi-

nar los restos de cal y suciedad.

En el tubo de alimentación de agua fría debe montar una

válvula de cierre, véase ilustración “Montaje”. Así, el aparato

puede cerrarse con fi nes de mantenimiento.

Conexiones en el equipo:

- Agua fría (entrada) a la derecha

- Agua caliente (salida) a la izquierda

En este aparato no es necesario una válvula de seguridad en

la tubería de agua caliente.

En algunas regiones es necesario, dependiendo de la normativa vigente, montar una válvula de seguridad. Esta debería

instalarse a la salida de agua caliente del aparato.

El acumulador de pared es apto para la conexión a sistemas

de tuberías de plástico. Si fuera necesario realizar trabajos

de soldadura cerca del aparato, procure que la llama no

cause daños.

Al fi nalizar todos los trabajos, examine el aparato para de-

tectar posibles fugas.

6.2 Conexión eléctrica

PELIGRO Electrocución

Como en cualquier aparato eléctrico, si no se lleva a

cabo la conexión a tierra del aparato pueden causarse

lesiones graves o la muerte.

Conecte el aparato conforme a la normativa vigente, tenien-

do en cuenta la conexión a tierra y el circuito eléctrico propio

con la tensión adecuada. En instalaciones con varios equipos

DHC-E es necesario un circuito eléctrico para cada aparato.

La sección transversal del cable de alimentación y el fusible

vienen indicados en las “Especifi caciones técnicas”.

Pase la junta de goma sobre el cable de alimentación y

monte el cable de alimentación con la abrazadera de descarga de tracción. La abrazadera de descarga de tracción, los

tornillos y la junta de goma vienen incluidos en el suministro.

Conecte el cable de alimentación con L y L (L y N) al terminal

de conexión eléctrica y conecte los hilos de conexión a tierra

al tornillo marcado con el símbolo de conexión a tierra.

6.2.1 DHC-E 8/10 – Selección de potencia

En el calentador instantáneo DHC-E 8/10 puede seleccionarse la

potencia en dos etapas. El aparato viene de fábrica con el ajuste

7,2 kW a 240 V.

26_02_02_1084

PELIGRO Electrocución

Tenga presentes todos los reglamentos y disposiciones

nacionales y regionales.

PELIGRO Electrocución

La conexión a la red eléctrica sólo está permitida estableciendo una conexión fi ja. El aparato debe poder desconectarse omnipolarmente de la red eléctrica al menos

durante un intervalo de 3 mm.

Daños en el aparato y al medio ambiente

!

Observe la información de la placa de especifi caciones

técnicas. La tensión indicada debe coincidir con la tensión

de la red local.

PELIGRO Electrocución

Antes de trabajar en la instalación eléctrica, asegúrese

de que los fusibles de suministro eléctrico están apagados para evitar electrocuciones. Antes de la conexión

a la red es necesario llevar a cabo todos los pasos de

montaje. Si la normativa nacional o regional así lo requiriera, es necesario equipar el circuito eléctrico con un

“interruptor de protección de fallas a tierra”.

1

1 Enchufe de codifi cación

Si es necesario instalar una potencia distinta para el equipo de-

berá seguir los pasos que se indican a continuación:

Inserte el enchufe codifi cador a la potencia deseada.

Nivel 1 208 V 220 V 230 V 240 V

5,4 kW 6,0 kW 6,6 kW 7,2 kW

Nivel 2 208 V 220 V 230 V 240 V

7,2 kW 8,1 kW 8,8 kW 9,6 kW

Marcar una cruz con un rotulador sobre la potencia seleccio-

nada en la placa de especifi caciones técnicas.

26_02_02_1088

16 | DHC-E WWW.STIEBEL-ELTRON.COM

Page 17

INSTALACIÓN

PUESTA EN MARCHA

6.3 Ajuste de temperatura/protección antiescaldamiento

Inserte el cable del regulador de temperatura electrónico en

la posición “A1“ y así obtendrá la temperatura del agua caliente más alta, de 140 °F (60 °C).

La temperatura máxima puede limitarse a 109 °F (43 °C):

Inserte el cable del regulador de temperatura electrónico en

la posición “A2”.

Monte la tapa de plástico.

8. Localización y reparación de fallos

PELIGRO Electrocución

Para poder comprobar el aparato, éste debe estar conectado a la red de alimentación eléctrica.

8.1 Posibilidades de indicación de los LED de diagnóstico

Visualización

Rojo se ilumina en caso de fallo

Amarillo se ilumina si el aparato calienta agua

Verde parpadea: el aparato recibe suministro eléctrico

26_02_02_1089

ESPAÑOL

1

26_02_02_1088

7. Puesta en marcha

PELIGRO Electrocución

La puesta en marcha sólo puede ser realizada por un técnico autorizado, observando la normativa de seguridad.

Daños en el aparato y al medio ambiente

!

Abra el grifo de agua caliente durante algunos minutos,

hasta que el agua fl uya con uniformidad y las tuberías de

agua caliente no contengan más aire. La tapa de plástico

del aparato debe estar montada antes de conectar los

fusibles.

Conecte los fusibles para suministrar alimentación al

aparato.

Gire el selector de temperatura a derechas y a izquierdas

para calibrar el selector de temperatura.

Mediante el botón del regulador de temperatura puede ajus-

tar la temperatura deseada.

Gire el grifo de agua caliente durante algunos segundos

hasta que la temperatura se estabilice.

Compruebe la temperatura del agua con la mano para ase-

gurarse de que el agua no esté demasiado caliente. Reduzca

la temperatura si fuera necesario. Para la mayoría de las

aplicaciones se recomienda un ajuste de 108 °F - 116 °F (42 °C

- 47 °C).

1 Semáforo de diagnóstico LED

8.2 Tabla de averías

Problema Causa Solución

No hay agua caliente

Limpiar el regulador de cho-

No hay suficiente espacio en la memoria.

El agua no está suficientemente caliente

Suministrar la tensión ade-

Si el problema no puede solucionarse, diríjase a nosotros

(véase última página) antes de retirar el aparato de la pared.

STIEBELELTRON le proporcionará asistencia técnica con

mucho gusto. En la mayoría de los casos, el problema puede

solucionarse mediante una consulta telefónica.

Fusibles apagados

Limitador de temperatura de seguridad

activado

El caudal de agua no es

suficiente para la activación del aparato

Filtro obstruido Limpiar el filtro del aparato

El caudal de agua es

demasiado alto

Conectar fusibles

Solucionar el fallo y presionar el limitador de temperatura de seguridad

Limpiar el filtro del aparato

rro o el cabezal de la ducha

Reducir el caudal hasta que

la luz de la cubierta frontal

deje de parpadear

cuada al aparato

Explique al usuario el funcionamiento del aparato e instrúya-

lo acerca del uso del mismo.

Explique al usuario los posibles peligros (temperatura del

agua caliente hasta 140 °F [60 °C]).

WWW.STIEBEL-ELTRON.COM DHC-E | 17

Page 18

INSTALACIÓN

MANTENIMIENTO

9. Mantenimiento

Los aparatos de STIEBELELTRON están previstos para una larga

vida útil. La esperanza real de vida útil depende de la calidad

del agua y del uso. El propio aparato no requiere mantenimiento

periódico.

Recomendamos eliminar periódicamente la cal y la suciedad que

pueda acumularse en el regulador de chorro del grifo o en el

cabezal de la ducha.

10. Especifi caciones técnicas

10.1 Plano dimensional

b01

10.2 Diagrama eléctrico

DHC-E 8/10

2/GRD ~ 208 / 240 V

1/N/PE ~ 220 / 230 / 240 V

360 (14.17")

c06

c06 c01

100 (3.94")

8 (0.315")

b01 Tendido de cableado eléctr. I

c01 Alimentación del agua fría "NPT 1/2

c06 Salida de agua caliente "NPT 1/2

200 (7.88")

c01

273 (10.75")75 (2.953")

38 (1.5")

110 (4.33")

85_02_03_0001

DHC-E 12

2/GRD ~ 208 / 240 V

1/N/PE ~ 220 / 230 / 240 V

D0000017762

18 | DHC-E WWW.STIEBEL-ELTRON.COM

85_02_03_0002

Page 19

INSTALACIÓN

ESPECIFICACIONES TÉCNICAS

10.3 Posibles caudales para distintas temperaturas de entrada y de salida

Caudal de agua fría [ GPM ]

Temperatura de salida del agua caliente 104 °F

Temperatura de entrada de agua fría °F 39 50 59 68 77 86 95 104 113 122 131

DHC-E 8/10

9.6 kW a 240 V 1.01 1.21 1.45 1.82 2.42 3.63 6.61 - - - DHC-E 12

12 kW a 240 V 1.26 1.51 1.82 2.27 3.03 4.31 6.61 - - - -

Temperatura de salida del agua caliente 113 °F

Temperatura de entrada de agua fría °F 39 50 59 68 77 86 95 104 113 122 131

DHC-E 8/10

9.6 kW a 240 V 0.89 1.04 1.21 1.45 1.82 2.42 3.63 6.61 - - DHC-E 12

12 kW a 240 V 1.11 1.30 1.51 1.82 2.27 2.88 4.31 6.61 - - -

5.4 kW a 208 V 0.57 0.68 0.82 1.02 1.36 2.04 4.09 - - - -

7.2 kW a 240 V 0.76 0.91 1.09 1.36 1.82 2.72 5.45 - - - -

7.2 kW a 208 V 0.76 0.91 1.09 1.36 1.82 2.72 5.45 - - - -

9 kW a 208 V 0.95 1.14 1.36 1.70 2.27 3.23 6.47 - - - -

5.4 kW a 208 V 0.50 0.58 0.68 0.82 1.02 1.36 2.04 4.09 - - -

7.2 kW a 240 V 0.66 0.78 0.91 1.09 1.36 1.82 2.72 5.45 - - -

7.2 kW a 208 V 0.66 0.78 0.91 1.09 1.36 1.82 2.72 5.45 - - -

9 kW a 208 V 0.83 0.97 1.14 1.36 1.70 2.16 3.23 6.47 - - -

ESPAÑOL

Temperatura de salida del agua caliente 140 °F

Temperatura de entrada de agua fría °F 39 50 59 68 77 86 95 104 113 122 131

DHC-E 8/10

9.6 kW a 240 V 0.65 0.73 0.81 0.91 1.04 1.21 1.45 1.82 2.42 3.63 6.61

DHC-E 12

12 kW a 240 V 0.81 0.91 1.01 1.14 1.30 1.44 1.73 2.16 2.88 4.31 6.61

5.4 kW a 208 V 0.36 0.41 0.45 0.51 0.58 0.68 0.82 1.02 1.36 2.04 4.09

7.2 kW a 240 V 0.49 0.54 0.61 0.68 0.78 0.91 1.09 1.36 1.82 2.72 5.45

7.2 kW a 208 V 0.49 0.54 0.61 0.68 0.78 0.91 1.09 1.36 1.82 2.72 5.45

9 kW a 208 V 0.61 0.68 0.76 0.85 0.97 1.08 1.29 1.62 2.16 3.23 6.47

Caudal de agua caliente [l/min]

Temperatura de salida del agua caliente 40 °C

Temperatura de entrada de agua fría °C 4 10 15 20 25 30 35 40 45 50 55

DHC-E 8/10

9.6 kW a 240 V 3.82 4.58 5.50 6.87 9.16 13.75 25.00 - - - DHC-E 12

12 kW a 240 V 4.77 5.73 6.87 8.59 11.46 16.32 25.00 - - - -

Temperatura de salida del agua caliente 45 °C

Temperatura de entrada de agua fría °C 4 10 1 20 25 30 35 40 45 50 55

DHC-E 8/10

9.6 kW a 240 V 3.35 3.93 4.58 5.50 6.87 9.16 13.75 25.00 - - DHC-E 12

12 kW a 240 V 4.19 4.91 5.73 6.87 8.59 10.88 16.32 25.00 - - -

5.4 kW a 208 V 2.15 2.58 3.09 3.87 5.16 7.73 15.47 - - - -

7.2 kW a 240 V 2.86 3.44 4.12 5.16 6.87 10.31 20.62 - - - -

7.2 kW a 208 V 2.86 3.44 4.12 5.16 6.87 10.31 20.62 - - - -

9 kW a 208 V 3.58 4.30 5.16 6.44 8.59 12.24 24.49 - - - -

5.4 kW a 208 V 1.89 2.21 2.58 3.09 3.87 5.16 7.73 15.47 - - -

7.2 kW a 240 V 2.51 2.95 3.44 4.12 5.16 6.87 10.31 20.62 - - -

7.2 kW a 208 V 2.51 2.95 3.44 4.12 5.16 6.87 10.31 20.62 - - -

9 kW a 208 V 3.14 3.68 4.30 5.16 6.44 8.16 12.24 24.49 - - -

Temperatura de salida del agua caliente 60 °C

Temperatura de entrada de agua fría °C 4 10 15 20 25 30 35 40 45 50 55

DHC-E 8/10

9.6 kW a 240 V 2.45 2.75 3.05 3.44 3.93 4.58 5.50 6.87 9.16 13.75 25.00

DHC-E 12

12 kW a 240 V 3.07 3.44 3.82 4.30 4.91 5.44 6.53 8.16 10.88 16.32 25.00

5.4 kW a 208 V 1.38 1.55 1.72 1.93 2.21 2.58 3.09 3.87 5.16 7.73 15.47

7.2 kW a 240 V 1.84 2.06 2.29 2.58 2.95 3.44 4.12 5.16 6.87 10.31 20.62

7.2 kW a 208 V 1.84 2.06 2.29 2.58 2.95 3.44 4.12 5.16 6.87 10.31 20.62

9 kW a 208 V 2.30 2.58 2.86 3.22 3.68 4.08 4.90 6.12 8.16 12.24 24.49

WWW.STIEBEL-ELTRON.COM DHC-E | 19

Page 20

INSTALACIÓN

PIEZAS DE RECAMBIO

10.4 Tabla de especifi caciones

DHC-E 8/10 DHC-E 12

224201 230628

Fase 1 1 1 1 1 1 1 1 1 1 1 1

Tensión V 208 220 230 240 208 220 230 240 208 220 230 240

Frecuencia Hz 50 / 60 50 / 60 50 / 60 50 / 60 50 / 60 50 / 60 50 / 60 50 / 60 50 / 60 50 / 60 50 / 60 50 / 60

Enchufe de codificación Posición 1 1 1 1 2 2 2 2 - - - Potencia de funcionamiento kW 5,4 6,0 6,6 7,2 7,2 8,1 8,8 9,6 9 10 11 12

Corriente nominal A 28 30 31 32 35 37 39 40 44 46 48 50

Protección mín. por fusible A 30 40 40 40 50 50 50 50 60 60 60 60

Sección transversal recomendada AWG Cobre 10 - - 8 8 - - 8 6 - - 6

Sección transversal recomendada mm² Cobre - 6 6 - - 10 10 - - 10 10 Tipo de protección según IP 24 IP 24

Caudal ON GPM / l/min 0,37 / 1,4 0,37 / 1,4

Capacidad nominal GAL / l 0,13 / 0,5 0,13 / 0,5

Presión máx. admisible PSI / bar / MPa 150 / 10 / 1 150 / 10 / 1

Presión de ensayo PSI / bar / MPa 300 / 20 / 2 300 / 20 / 2

Peso lbs Kg 5,9 / 2,7 5,9 / 2,7

Conexión de agua “ NPT 1/2 1/2

Apto para temperaturas de admisión de hasta 131 °F ( 55 °C )

Calentador instantáneo no admisible para el funcionamiento

constante

Los cables deben dimensionarse de forma que sean capaces

de mantener un descenso de tensión de menos del 3% bajo

carga

11. Piezas de recambio

1

15

14

2

12

11

10

35

4

13

6

Nº Piezas de recambio DHC-E 8/10 DHC-E 12

1 Sistema de calefacción 292275 292276

2 Limitador de temperatura de seguridad 286369 286369

3 Grupo electrónico 291851 291852

4 Enchufe de codificación 283455 283455

5 Pared posterior de la carcasa 292578 292578

6 Caudalímetro (DFE) 286461 286461

7 Racor de conexión del agua fría 291699 291699

8 Filtro 252430 252430

9 Racor de conexión del agua caliente 278634 278634

10 Tapa de la carcasa 292577 292577

11 Terminal de conexión eléctrica 279998 279998

12 Eje de quita y pon 254312 254312

13 Pletina (transmisor de valor de referencia) 286359 286359

14 Botón del regulador de temperatura 254307 254307

15 Sensor de temperatura (NTC) 280677 280677

987

26_02_02_1091

20 | DHC-E WWW.STIEBEL-ELTRON.COM

Page 21

GARANTÍA | MEDIO AMBIENTE Y RECICLAJE

12. Garantía

Garantía para uso particular y comercial: Stiebel Eltron garantiza la mano de obra y las piezas de los calentadores eléctricos sin

tanque DHC-E, por un periodo de tres (3) años a partir de la fecha de compra y libre de fugas por un periodo de siete (7) años a

partir de la fecha de compra. En caso que alguna parte o partes se dañen durante este periodo, Stiebel Eltron se responsabiliza a

cambiar la parte(s) defectuosa(s) únicamente. Stiebel Eltron no se hace responsable de los gastos de mano de obra en los que se

incurra para quitar y/o reemplazar la(s) parte(s) defectuosa(s), o cualquier gasto accidental o como consecuencia del problema.

En caso que el propietario desee regresar el calentador de agua eléctrico sin tanque para que sea reparado, el propietario debe

obtener una autorización por escrito de Stiebel Eltron. Y estar preparado para probar la fecha de adquisición, así como, pagar por

todos los costos de transportación para regresar la(s) parte(s) defectuosa(s) o el calentador de agua para reparación o reemplazo.

La garantía será anulada si el calentador de agua ha sido instalado o usado inadecuadamente o si el diseño ha sido alterado de

cualquier manera.

Para los aparatos adquiridos fuera de Alemania no son aplicables las condiciones de garantía de nuestras sociedades alemanas. Además, en los países en los que alguna de nuestras

liales comercialice nuestros productos, la garantía sólo será

otorgada por dicha lial. Este tipo de garantía únicamente se

otorgará si la lial hubiera publicado unas condiciones de garantía propias. No se otorgará ninguna garantía adicional.

No otorgamos ninguna garantía para aquellos aparatos adquiridos en países en los que ninguna de nuestras liales comercialicen nuestros productos. Cualquier garantía asegurada por

el importador permanecerá inalterada.

Medio ambiente y reciclado

Colabore para proteger nuestro medio ambiente. Elimine los

materiales después de su uso conforme a la normativa nacional

vigente.

ESPAÑOL

WWW.STIEBEL-ELTRON.COM DHC-E | 21

Page 22

TABLE DES MATIÈRES | UTILISATION

REMARQUES GÉNÉRALES

UTILISATION

1. Remarques générales _____________________________________ 22

1.1 Informations relatives à la sécurité _________________________22

1.2 Autres repérages utilisés dans ce document ______________23

2. Sécurité _____________________________________________________ 23

2.1 Utilisation conforme ___________________________________________23

2.2 Informations générales ________________________________________ 23

2.3 Précautions de sécurité________________________________________ 23

2.4 Label de conformité ____________________________________________ 23

3. Description de l’appareil _________________________________ 24

4. Comment remédier à un problème _______________________ 24

UTILISATION

1. Remarques générales

Remarque

Lisez attentivement cette notice avant d‘utiliser l‘appareil

et familiarisez-vous avec ses fonctions. Conservez la notice dans un endroit sûr. Remettez cette notice au nouvel

utilisateur le cas échéant.

INSTALLATION

5. Description de l’appareil __________________________________ 25

6. Montage _____________________________________________________ 25

6.1 Raccordement hydraulique ___________________________________ 26

6.2 Raccordement électrique _____________________________________ 26

6.3 Réglage de la température/protection anti-ébouillantement ______________________________________________________________27

7. Mise en service _____________________________________________ 27

8. Comment remédier aux défauts __________________________ 27

8.1 Possibilités d’affi chage des DEL de diagnostic ___________27

8.2 Tableau des pannes ____________________________________________27

9. Maintenance ________________________________________________ 27

10. DONNÉES TECHNIQUES ____________________________________ 28

10.1 Plan de cotes ____________________________________________________ 28

10.2 Schéma des connexions _______________________________________28

10.3 Débits possibles pour différentes températures d’entrée

et de sortie _______________________________________________________29

10.4 Tableau de données ____________________________________________ 30

11. Pièces de rechange ________________________________________ 30

GARANTIE | ENVIRONNEMENT ET RECYCLAGE

1.1 Informations relatives à la sécurité

1.1.1 Structure des consignes de sécurité

MOT-CLÉ Nature du danger

Ici s’affi chent les conséquences possibles de la nonobservation des prescriptions de sécurité.

Les mesures permettant d’éviter ces dangers

sont également indiquées.

1.1.2 Symboles, nature du danger

Symbole Nature du danger

Blessure

!

Électrocution

Brûlures ou ébouillantements

1.1.3 Mots-clés

MOT-CLÉ Description

DANGER La non-observation de ces informations entraîne des bles-

sures graves, voire la mort.

AVERTISSEMENT La non-observation de ces informations peut entraîner des

blessures graves, voire la mort.

ATTENT ION La non-observation de ces informations peut entraîner des

blessures moyennement graves ou légères.

22 | DHC-E WWW.STIEBEL-ELTRON.COM

Page 23

UTILISATION

SÉCURITÉ

1.2 Autres repérages utilisés dans ce document

Remarque

Les remarques sont délimitées par des lignes horizontales

au-dessus et en dessous du texte. Les remarques d’ordre

général sont caractérisées par le symbole représenté ici

à gauche.

Lisez attentivement ces remarques.

Symbole

Dommages sur l’appareil et sur l’environnement

!

Recyclage de l’appareil

Ce symbole indique ce que vous devez faire. Ce que vous

devez faire est décrit étape par étape.

2. Sécurité

Respectez les consignes suivantes et les prescriptions de sécurité.

N’utilisez cet appareil que s’il est complètement installé et doté

de tous les dispositifs de sécurité.

2.3 Précautions de sécurité

DANGER Blessure

!

Lisez et respectez la présente notice.

Le non-observation de cette notice peut entraîner des

blessures très graves, voire la mort.

Dommages sur l’appareil et sur l’environnement

!

L’appareil doit être installé par un installateur agréé.

L’installation doit satisfaire à toutes les prescriptions

nationales, régionales et locales.

La maintenance de l’appareil doit être effectuée par un

installateur qualifi é.

DANGER Électrocution

Avant d’effecteur les travaux d’installation, de paramétrage, de modifi cation ou de maintenance sur cet

appareil, coupez tous les disjoncteurs et sectionneurs

de l’alimentation électrique de l’appareil. La non-observation de ces consignes peut entraîner des blessures

très graves, voire la mort.

DANGER Électrocution

Ne retirez le capot de l’appareil qu’une fois l’alimentation électrique de l’appareil coupée. La non-observation

de cette consigne peut entraîner des blessures, voire la

mort.

FRANÇAIS

2.1 Utilisation conforme

L’appareil est destiné au chauffage de l’eau sanitaire et peut alimenter plusieurs points de soutirage.

Toute utilisation dépassant ces spécifi cations est considérée

comme non conforme.

Le respect de la présente notice faite également partie de l’utilisation conforme de cet appareil.

2.2 Informations générales

Lisez la notice en sa totalité. La non-observation de toutes les

directives, notices et réglementations peut entraîner des blessures corporelles et/ou des dégâts matériels. Une installation, un

paramétrage, une modifi cation ou une maintenance effectué(e) de

manière incorrecte sur cet appareil peut entraîner des blessures

très importantes.

Cet appareil doit être installé par un installateur agréé. L’installation doit satisfaire à toutes les prescriptions nationales, régionales

et locales. L’installateur est responsable de la réalisation correcte

de l’installation. La non-observation de la notice d’installation et

d’emploi ou toute installation non-conforme invalide la garantie.

Conservez la présente notice pour consultation ultérieure. L’installateur doit remettre cette notice à l’utilisateur.

DANGER Électrocution

L’appareil doit être relié correctement à la terre. L’absence de liaison à la terre du produit peut entraîner des

blessures très graves, voire la mort.

DANGER Brûlures

L’eau à des températures supérieures à 52°C (125°F)

peut entraîner des brûlures immédiates graves, voire la

mort par ébouillantement. Le danger d’ébouillantement

par eau brûlante existe lorsque le thermostat de l’appareil est sur un réglage trop élevé. Dans les foyers avec

des enfants en bas âge, des personnes handicapées ou

âgées, il peut être nécessaire de régler le thermostat sur

45°C (113°F) ou moins pour éviter les blessures dues

à l’eau chaude.

AVERTISSEMENT Risque de blessures

!

Si des enfants ou des personnes aux capacités physiques,

sensorielles ou mentales réduites sont autorisées à utiliser cet appareil, il convient de s’assurer qu’ils l’utilisent

uniquement quand ils sont supervisés ou s’ils ont été

instruits par la personne responsable de leur sécurité.

Veillez à ce que les enfants ne jouent pas avec l’appareil.

2.4 Label de conformité

Voir la plaque signalétique de l’appareil.

En cas de questions à propos de l’installation, de l’utilisation et de

l’exploitation de ce préparateur d’eau chaude sanitaire, ou bien

si vous avez besoin de manuels d’installation supplémentaires,

merci de contacter le numéro de téléphone de l’assistance technique (voir la dernière page).

WWW.STIEBEL-ELTRON.COM DHC-E | 23

Page 24

UTILISATION

DESCRIPTION DE L’APPAREIL

3. Description de l’appareil

Le chauffe-eau instantané DHC-E se distingue des ballons d’eau

chaude sanitaire conventionnels à plusieurs points de vue. Il ne

stocke pas l’eau chaude. Au lieu de cela, l’eau est immédiatement

chauffée quand elle circule dans l’appareil. En raison de la disparition des déperditions calorifi ques en mode stand-by, le DHC-E

présente une effi cacité énergétique supérieure à celle d’un ballon

d’eau chaude sanitaire.

Le chauffage de l’eau est commandé par un système électronique.

Le DHC-E peut fournir de l’eau à des températures entre 30°C

(86°F) et 60°C (140°F). Pour régler la température souhaitée,

utilisez le bouton de thermostat.

Remarque

Pour des raisons d‘effi cience et de durée de vie (entartrage), la plage de réglage optimale de la température

se situe entre 30°C (86°F) et 50°C (120°F).

Si le voyant «Power» clignote pendant que l’appareil fonctionne,

cela signifi e que le débit volumétrique de l’eau est supérieur à

ce que la puissance chauffage de l’appareil peut chauffer. Dans

ce cas, réduisez le débit volumétrique pour que l’appareil puisse

fournir de l’eau à la température paramétrée. La température

maximale est limitée à 60°C (140°F) par le système électronique.

Si vous avez des questions sur l’utilisation que vous prévoyez pour

le DHC-E, merci de contacter le numéro de téléphone de notre

assistance technique (voir la dernière page).

4. Comment remédier à un problème

Problème Cause Remède

Pas d’eau chaude

sanitaire

L’eau n’est pas assez

chaude.

Le débit volumétrique

en eau est insuffisant

pour activer l’appareil.

Le débit volumétrique

en eau est trop élevé.

Nettoyez le régulateur de jet

ou la pomme de douche.

Réduire le débit volumétrique

en eau jusqu’à ce que le

voyant sur le capot avant ne

clignote plus.

26_02_02_1086

Appelez un installateur si vous ne réussissez pas à éliminer la

cause. Donnez-lui le numéro indiqué sur la plaque signalétique

pour qu’il puisse vous aider plus rapidement et plus effi cacement

(000000-0000-000000).

24 | DHC-E WWW.STIEBEL-ELTRON.COM

Page 25

INSTALLATION

DESCRIPTION DE L’APPAREIL

INSTALLATION

5. Description de l’appareil

Un DHC-E peut être utilisé pour les applications suivantes:

- un ou plusieurs lavabos

- un évier de cuisine

- une douche avec un dispositif limiteur de débit sur la pomme

de douche

Pour alimenter un appartement ou une maison en eau chaude

sanitaire, une combinaison de deux DHC-E peut suffi re dans certains pays. Sur demande, STIEBEL ELETRON vous fournira des

informations supplémentaires pour cette application spécifi que.

Pour les régions où la température d’admission de l’eau froide est

élevée, à savoir supérieure à 18°C (65 °F) toute l’année, l’appareil

peut également convenir pour un appartement entier ou toute

une maison entière.

ATTENTION Électrocution

L’appareil doit être installé à la verticale avec les raccordements hydrauliques vers le bas. Dans cette position de montage, l’eau projetée ne peut pas entrer dans

l’appareil.

L’appareil doit être monté uniquement dans un local hors

gel. Stockez un appareil démonté en le protégeant du gel, car

il reste de l’eau à l’intérieur, qui pourrait geler et causer des

dommages.

Prévoyez un espace libre d’au moins 125 mm sur tous les

côtés pour les travaux de maintenance.

Retirez le boîtier en matière synthétique.

26_02_02_1083

FRANÇAIS

12

3

7

1

7

1 Robinet d’eau chaude (à gauche)

2 Robinet d’eau froide (à droite)

3 Lavabo

4 Conduite d’eau froide 1/2»

5 Conduite d’eau pour l’installation du robinet

6 Robinet d’arrêt

7 Raccordement électrique

4

5

6

2

3

4

5

6

6. Montage

Installez le DHC-E le plus près possible du point de soutirage

d’eau chaude.

26_02_02_0331

26_02_02_1082

26_02_02_1081

26_02_02_1090

Vissez les vis et suspendez l’appareil. Les vis et les chevilles

en matière synthétique pour le montage sur maçonnerie ou

bois sont fournies à la livraison.

Bloquez les vis.

WWW.STIEBEL-ELTRON.COM DHC-E | 25

Page 26

INSTALLATION

MONTAGE

6.1 Raccordement hydraulique

Dommages sur l’appareil et sur l’environnement

!

L’appareil peut être endommagé par une chaleur trop

élevée lors du brasage de tubes en cuivre à proximité

du DHC.

Pour tous les travaux, vous devez respecter les prescriptions

nationales et régionales respectives et applicables.

Si la pression de l’alimentation en eau froide est supérieure

à 1 MPa, vous devez installer un réducteur de pression.

Rincez soigneusement la conduite d’eau froide pour évacuer

tous les restes de tartre et les saletés.

Vous devez monter une vanne d’arrêt sur la conduite d’eau

froide, voir la fi gure Montage. Cette vanne permet de couper

l’appareil du réseau pour les travaux de maintenance.

Raccordements sur l’appareil:

- Eau froide (entrée) à droite

- Eau chaude sanitaire (sortie) à gauche

Sur cet appareil, il n’est pas obligatoire d’installer une sou-

pape de sécurité sur la conduite d’eau chaude sanitaire.

Dans certaines régions, les prescriptions exigent d’installer

une soupape de sécurité. Dans ce cas, elle doit être installée

au niveau de la sortie d’eau chaude sanitaire de l’appareil.

Le DHC-E convient pour être raccordé à des tubes en cuivre,

en matière synthétique ou en inox. Si des travaux de brasage

sont nécessaires à proximité de l’appareil, vous devez veiller

à ce que les fl ammes ne provoquent aucun dégât.

Une fois tous les travaux terminés, vérifi ez l’étanchéité de

l’appareil.

DANGER Électrocution

Comme pour tous les appareils électriques, l’absence de

liaison à la terre de l’appareil peut entraîner de graves

blessures, voire la mort.

Raccordez l’appareil correctement en veillant à la mise à

la terre et à ce que le circuit électrique présente la tension

correcte. Dans le cas d’installations avec plusieurs DHC-E,

chaque appareil doit disposer de son propre circuit électrique. La section de la conduite d’alimentation et la protection électrique fi gure dans la section Données techniques.

Enfi lez le joint d’étanchéité en caoutchouc par-dessus la

conduite de raccordement et montez celle-ci à l’aide d’un

collier anti-traction. Le collier anti-traction, les vis et le joint

d’étanchéité en caoutchouc sont fournis à la livraison.

Raccordez les conducteurs L et L (L et N) au bornier de rac-

cordement secteur. Raccordez le conducteur de terre à la vis

portant le symbole de mise à la terre.

6.2.1 DHC-E 8/10 – Sélection de la puissance

Sur le chauffe-eau instantané DHC-E 8/10, la puissance peut être

sélectionnée sur deux niveaux. À sa sortie d’usine, l’appareil est

réglé sur 7,2 kW en 240 V.

26_02_02_1084

6.2 Raccordement électrique

DANGER Électrocution

Tenez compte de la législation et des prescriptions nationales et locales.

DANGER Électrocution

Le raccordement au secteur doit être réalisé exclusivement en connexion fi xe. L‘appareil doit pouvoir être

déconnecté du secteur par un dispositif de coupure multipolaire ayant une ouverture minimale des contacts de

3mm.

Dommages sur l’appareil et sur l’environnement

!

Tenez compte des indications sur la plaque signalétique.

La tension qui y est indiquée doit correspondre à la tension du secteur.

DANGER Électrocution

Avant d’effectuer des travaux sur l’installation électrique, assurez-vous que les fusibles de l’alimentation

électrique ont été coupés afi n d’éviter toute électrocution.

Avant le raccordement au secteur, toutes les opérations

de montage doivent être terminées. Si les dispositions

nationales ou régionales l’exigent, le circuit électrique

doit être équipé d’un «disjoncteur différentiel».

1

1 Codeur

Si l’appareil doit être installé avec une autre puissance, procédez

comme suit:

Positionnez le codeur sur la puissance souhaitée.

Niveau 1 208 V 220 V 230 V 240 V

5,4kW 6,0kW 6,6kW 7,2kW

Niveau 2 208 V 220 V 230 V 240 V

7,2kW 8,1kW 8,8kW 9,6kW

Marquez la puissance souhaitée et la tension sur la plaque

signalétique à l’aide d’un feutre indélébile.

26_02_02_1088

26 | DHC-E WWW.STIEBEL-ELTRON.COM

Page 27

INSTALLATION

MISE EN SERVICE

6.3 Réglage de la température/protection antiébouillantement

Enfi chez le câble de la régulation de température électro-

nique sur la position A1 pour obtenir la température d’eau

chaude sanitaire maximale de 60°C (140°F).

La température maximale peut être limitée à 43°C (109°F) par

le système électronique:

enfi chez le câble de la régulation de température électro-

nique sur la position A2.

Mettez en place le capot plastique.

7. Mise en service

DANGER Électrocution

La mise en service doit être réalisée uniquement par un

installateur agréé dans le respect des prescriptions de

sécurité.

Dommages sur l’appareil et sur l’environnement

!

Ouvrez le robinet d’eau chaude sanitaire pendant

quelques minutes jusqu’à ce que l’eau s’écoule régulièrement et que la conduite d’eau ne contienne plus

d’air. Avant de mettre sous tension, le capot plastique

de l’appareil doit être en place.

Activez les fusibles pour alimenter l’appareil en courant.

Tournez le thermostat dans le sens horaire et anti-horaire

pour l’étalonner.

Le bouton du thermostat vous permet de régler la tempéra-

ture souhaitée.

Ouvrez le robinet d’eau chaude pendant quelques secondes

jusqu’à ce que la température se stabilise.

Vérifi ez la température de l’eau en mettant la main sous le

jet d’eau pour vous assurer qu’elle n’est pas trop chaude.

Si nécessaire, réduisez la température. Une température de

42°C à 47°C (108°F à 116 °F) est recommandée pour la plupart des applications.

Expliquez le fonctionnement à l’utilisateur et familiarisez-le

avec l’emploi de l’appareil.

Attirez l’attention de l’utilisateur sur les dangers possibles

(température de l’eau chaude sanitaire pouvant atteindre

60°C [140°F]).

8. Comment remédier aux défauts

DANGER Électrocution

Pour pouvoir tester l’appareil, il doit être alimenté électriquement.

8.1 Possibilités d’affi chage des DEL de diagnostic

Affichage

rouge s’allume en cas de défaut.

jaune s’allume lorsque l’appareil chauffe de l’eau.

vert clignote: l’alimentation électrique de l’appareil

est activée.

26_02_02_1089

1 DEL de diagnostic

8.2 Tableau des pannes

Problème Cause Remède

Pas d’eau chaude

sanitaire

Nettoyez le régulateur de jet

Pas assez d’eau

chaude.

L’eau n’est pas assez

chaude.

Alimentez l’appareil avec la

Si ces mesures ne permettent pas de supprimer le problème,

contactez-nous (voir la dernière page) avant de décrocher

l’appareil du mur. STIEBEL ELTRON se tient à votre disposition pour une assistance technique. Dans la plupart des cas,

le problème peut être résolu par téléphone.

Fusibles coupés

Thermostat limiteur de

sécurité déclenché

Le débit volumétrique

en eau est insuffisant

pour activer l’appareil.

Le filtre est obstrué. Nettoyez le filtre de l’appa-

Le débit volumétrique

en eau est trop élevé.

Activez les fusibles.

Supprimez le défaut et

appuyez sur le thermostat

limiteur de sécurité.

Nettoyez le filtre de l’appareil.

ou la pomme de douche.

reil.

Réduire le débit volumétrique en eau jusqu’à ce que

le voyant sur le capot avant

ne clignote plus.

tension correcte.

9. Maintenance

Les appareils de STIEBEL ELTRON sont conçus pour durer. Leur

durée de vie effective dépend de la qualité de l’eau et de l’utilisation. L’appareil lui-même n’exige aucun entretien particulier.

FRANÇAIS

1

26_02_02_1088

WWW.STIEBEL-ELTRON.COM DHC-E | 27

Page 28

INSTALLATION

DONNÉES TECHNIQUES

Nous recommandons de supprimer régulièrement le tartre et les

saletés qui peuvent s’accumuler dans le régulateur de jet du robinet ou sur la pomme de douche.

10. DONNÉES TECHNIQUES

10.1 Plan de cotes

b01

10.2 Schéma des connexions

DHC-E 8/10

2/GRD ~ 208 / 240 V

1/N/PE ~ 220 / 230 / 240 V

360 (14.17")

c06

c06 c01

100 (3.94")

8 (0.315")