STIEBEL ELTRON DHC 3-1, DHC 4-3, DHC 4-2, DHC 5-2, DHC 8-2 Operation And Installation

...

OPERATION AND INSTALLATION

OPERACIÓN E INSTALACIÓN

UTILISATION ET INSTALLATION

Tankless Electric Water Heater

Calentador de Agua Instantaneos sin Tanque

Chauffe-Eau Électrique sans Accumulateur

» DHC 3-1

» DHC 3-2

» DHC 4-2

» DHC 4-3

» DHC 5-2

» DHC 6-2

» DHC 8-2

» DHC 9-3

» DHC 10-2

Conforms to ANSI/UL Std. 499

Certified to CAN/CSA Std. E335-1 & E335-2-35

Conforme a ANSI/UL Std. 499

Certificación con CAN/CSA Std. E335-1 & E335-2-35

Conforme à la norme ANSI/UL Std. 499

Certifié à la norme CAN/CSA Std. E335-1 & E335-2-35

Tested and certified by WQA to NSF/ANSI372

for lead free compliance.

Probado y certificado por WQA NSF/ANSI 372 para

el cumplimiento de las regulaciones sin plomo.

Testé et certifié par WQA à la NSF/ANSI 372 pour une

utilisation sans plomb.

2 | DHC WWW.STIEBEL-ELTRON-USA.COM

CONTENTS | OPERATION

OPERATION

1. General information

Note

Read these instructions carefully before using the appliance and familiarize yourself with its functions. Keep

these instructions safe. Pass on the instructions to a new

user if required.

1.1 Safety information

1.1.1 Structure of safety information

KEYWORD Type of risk

Here, possible consequences are listed that may result from not observing the safety information.

Steps to prevent the risk are listed.

1.1.2 Symbols. type of risk

Symbol Type of risk

!

Injury

Electrocution

Burns or scalding

1.1.3 Keywords

KEYWORD Description

DANGER If this information is not observed, it will result in serious

injury or death.

WARNING If this information is not observed, it can result in serious

injury or death.

CAUTION If this information is not observed, it can lead to medium

or minor injury.

OPERATION

1. General information �����������������������������������������2

1.1 Safety information ����������������������������������������������� 2

1.2 Other symbols in this document ������������������������������ 3

2. Safety ���������������������������������������������������������� 3

2.1 Intended use ������������������������������������������������������ 3

2.2 General Information��������������������������������������������� 3

2.3 Safety Precautions ����������������������������������������������� 3

2.4 Test symbols ������������������������������������������������������ 3

3. Register your product ���������������������������������������4

4. General ��������������������������������������������������������4

INSTALLATION

5. Mounting the unit ��������������������������������������������4

6. Water connections �������������������������������������������5

7. Electrical connection �����������������������������������������5

7.1 Terminal block ���������������������������������������������������� 6

8. Commissioning �����������������������������������������������6

8.1 Appliance handover ��������������������������������������������� 6

9. Troubleshooting ����������������������������������������������7

10. Normal maintenance �����������������������������������������8

11. Technical Data ������������������������������������������������8

11.1 Dimensions �������������������������������������������������������� 8

11.2 Wiring diagram �������������������������������������������������� 8

11.3 Temperature increase above ambient water temperature

���������������������������������������������������������������������� 9

11.4 Data table �������������������������������������������������������� 10

12. Spare parts ������������������������������������������������� 11

13. Warranty ���������������������������������������������������� 12

OPERATION

SAFETY

ENGLISH

WWW.STIEBEL-ELTRON-USA.COM DHC | 3

1.2 Other symbols in this document

Note

Notes are bordered by horizontal lines above and below

the text. General information is identified by the symbol

shown on the left.

Read these notes carefully.

Symbol

!

Damage to the appliance and environment

Appliance disposal

This symbol indicates that you have to do something. The ac-

tion you need to take is described step by step.

2. Safety

Observe the following safety information and regulations.

Operate the appliance only when fully installed and with all safety

equipment fitted.

2.1 Intended use

The appliance is intended for heating domestic hot water and can

supply one draw-off point.

Any other use beyond that described shall be deemed inappropriate.

Observation of these instructions is also part of the correct use

of this appliance.

2.2 General Information

This appliance is designed for domestic use. It can be used safely

by untrained persons. The appliance can also be used in a nondomestic environment, e.g. in a small business, as long as it is

used in the same way.

Read this entire manual. Failure to follow all the guides, instructions and rules could cause personal injury or property damage.

Improper installation, adjustment, alteration, service and use of

this appliance can result in serious injury.

This appliance must be installed by a licensed electrician and

plumber. The installation must comply with all national, state and

local plumbing and electric codes. Proper installation is the responsibility of the installer. Failure to comply with the installation

and operating instructions or improper use voids the warranty.

Save these instructions for future reference. Installer should leave

these instructions with the consumer.

If you have any questions regarding the installation, use or operation of this water heater, or if you need any additional installation

manuals, please call our technical service line, see last side.

2.3 Safety Precautions

!

DANGER: Injury

Please read and follow these instructions. Failure to

follow these instructions could result in serious personal injury or death.

!

Damage to the appliance and the environment

The appliance must be installed by a licensed electrician

and plumber. The installation must comply with all national, state and local plumbing and electric codes.

Service of the appliance must be performed by qualified

service TECHNICIANS.

DANGER: Electrocution

Before proceeding with any installation, adjustment.

Alteration, or service of this appliance all circuit

breakers and disconnect switches servicing the appliance must be turned off. Failure to do so could result

in serious personal injury or death.

DANGER: Electrocution

Never remove the appliance‘s cover unless the electricity servicing the appliance is turned off. Failure to

do so could result in personal injury or death.

DANGER: Electrocution

The appliance must be properly grounded. Failure to

electrically ground the product could result in serious

personal injury or death.

DANGER: Burns

Water temperatures over 125°F (52 °C)can cause

severe burns instantly or death from scalding. A hot

water scalding potential exists if the thermostat on

the appliance is set too high. Households with small

children, disabled or elderly persons may require that

the thermostat be set at 113°F (45 °C) or lower to

prevent possible injury from hot water.

WARNING: Injury

Where children or persons with limited physical, sensory or mental capabilities are to be allowed to control this appliance, ensure that this will only happen

under supervision or after appropriate instructions by

a person responsible for their safety. Children should

be supervised to ensure that they never play with the

appliance.

2.4 Test symbols

See type plate on the appliance.

4 | DHC WWW.STIEBEL-ELTRON-USA.COM

INSTALLATION

REGISTER YOUR PRODUCT

3. Register your product

You must register this product within 90 days of purchase on our web site in order to activate the standard

warranty or to be eligible for the extended warranty.

Go to our web site at www.stiebel-eltron-usa.com

and click on register your product.

Before beginning the registration process, we suggest that

you gather the necessary information which will be as

follows:

Type, Example: DHC (from the label that is on the unit)

Number listed after "Nr."

Place of Purchase

Purchase Date

First & Last Name

Email address

Physical Address

Phone Number

Installation Date

IF YOU HAVE ANY QUESTIONS CONCERNING THE REGISTRATION PROCESS OR WARRANTY OPTIONS, PLEASE CONTACT

STIEBEL ELTRON USA DIRECTLY AT (800)-582-8423.

4. General

The DHC tankless water heater differs from conventional storage

type water heaters in several ways. It does not store hot water.

Instead, water is heated instantaneously as it flows through the

unit. The powerful heating elements are activated by a flow switch

as water is drawn from a hot water faucet connected to the DHC.

Due to the absence of stand-by losses, the DHC has greater energy

efficiency than storage type water heaters.

The temperature of the hot water delivered by the DHC depends

on the wattage of the heating element, the temperature of the

incoming cold water, and the water flow rate through the unit.

In order for the DHC to operate properly, it must be carefully

matched to the application.

In case you have questions regarding the way you plan to use the

DHC, please call our technical service line at 800-582-8423 (USA and

Canada). For service outside the U.S. and Canada, please call us at

USA 413-247-3380. You can also e-mail us at info@stiebel-eltron-usa.com or fax us at 413-247-3369.

The DHC can be used for hand washing type applications in the

U.S. and Canada:

- Restroom sinks in commercial/industrial facilities and homes

- Kitchen areas in commercial /industrial facilities and homes

- Cabins

- Special uses in photo developing shops, laboratories etc.

The DHC can also be used for whole apartments and homes in

warm climate zones such as the Caribbean region, Central America and Mexico due to the higher ambient water temperatures.

INSTALLATION

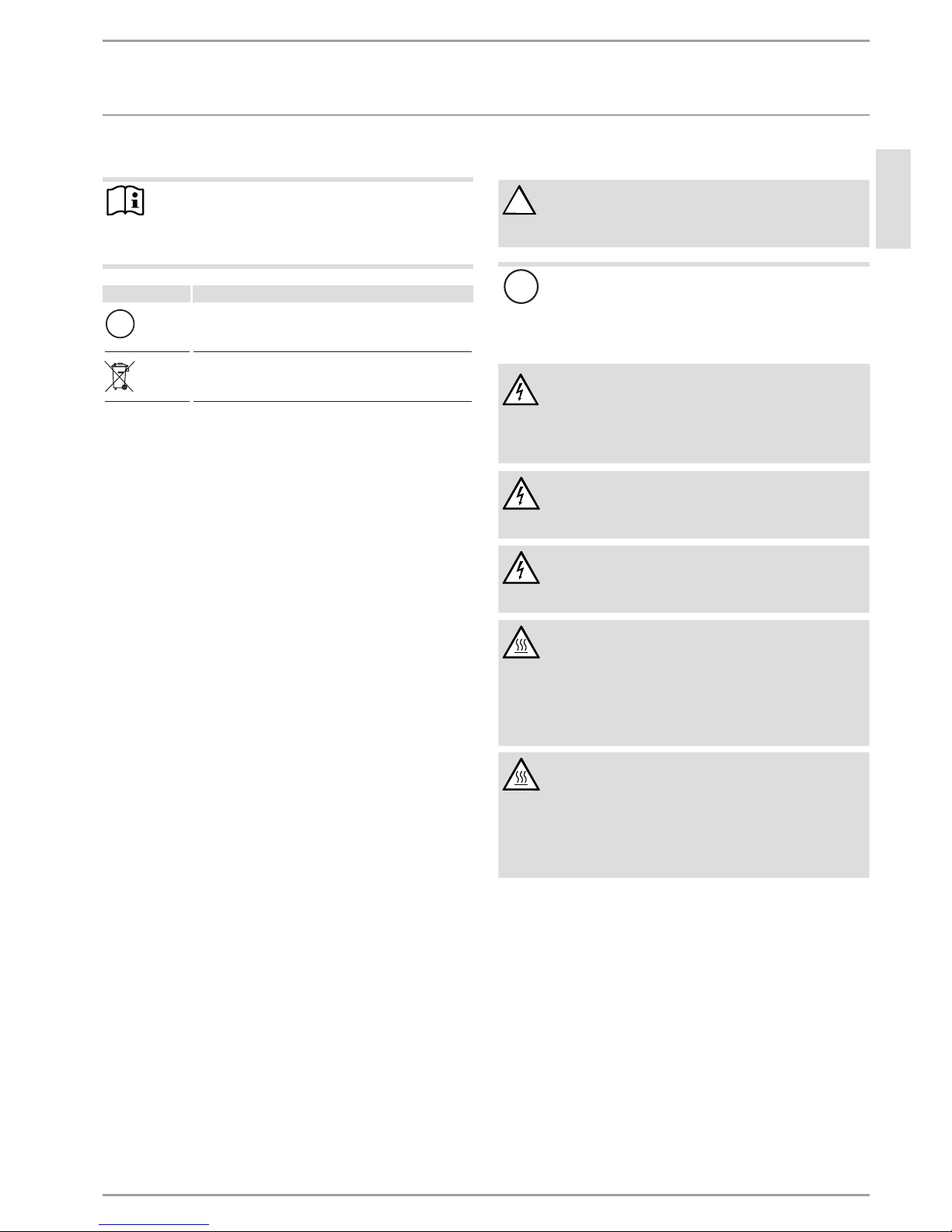

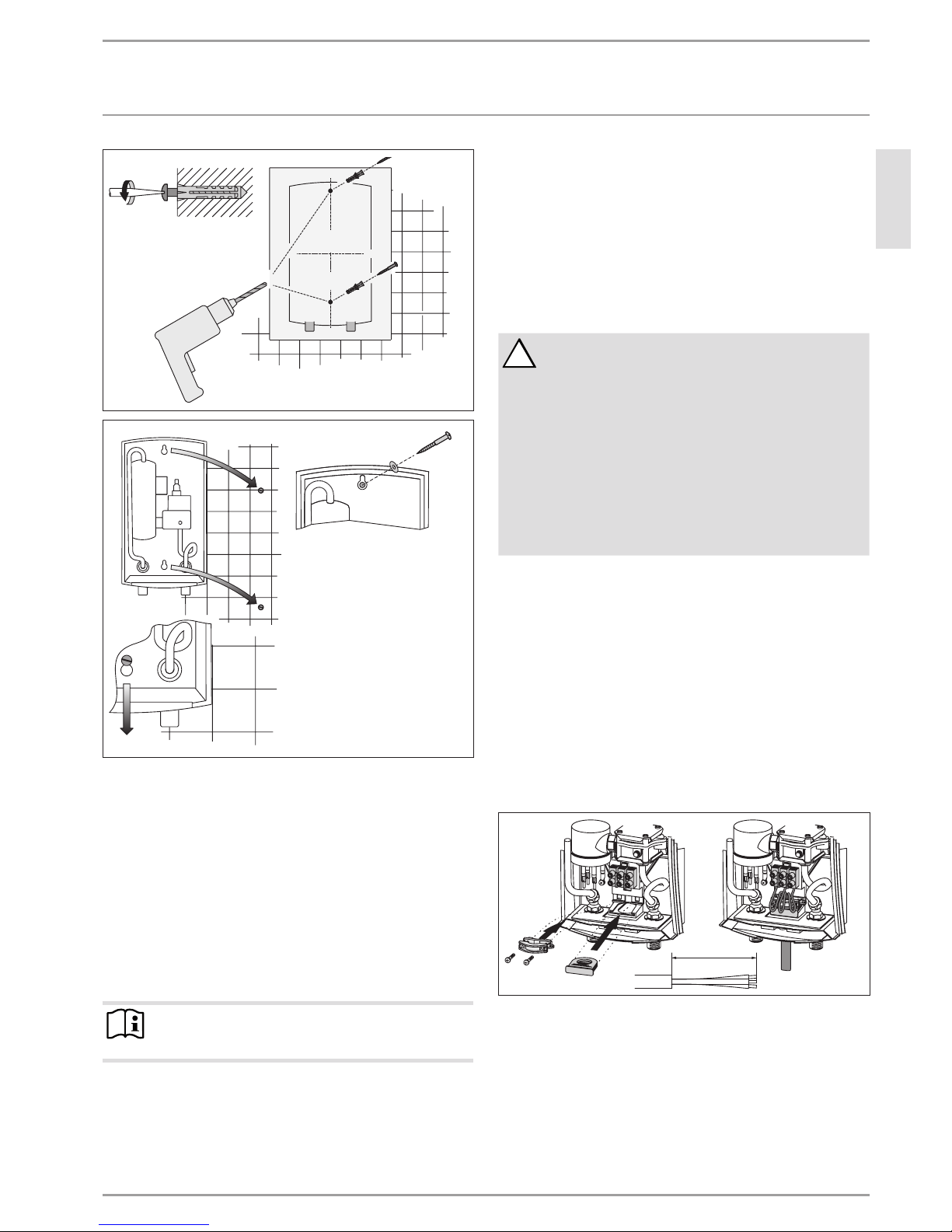

5. Mounting the unit

26�02�02�0330

7

6

1

4

3

2

8

5

1 Electrical junction box

2 Water supply line for faucet installation

3 3/8˝ compression-T

4 Shut-off valve

5 1/2˝ main pipe

6 Sink

7 Cold valve (right)

8 Hot valve (left)

DANGER: Electrocution

The unit must be installed in a vertical position with

the water fittings pointing downward. Do not install

unit where it would routinely be splashed with water.

Electric shock may result.

1. Install DHC as close as possible to the hot water draw-off

point, for example, directly underneath the sink or next to

the shower stall.

2. Install DHC in a frost free area. If frost may occur, remove

unit before freezing temperatures set in.

3. Leave a minimum of 5˝ of clearance on all sides for

servicing.

4. Remove plastic cover.

26�02�02�1360

5. Mount unit securely to wall by putting two screws through

mounting holes. Screws and plastic wall anchors for mounting on masonry or wood are provided.

ENGLISH

WWW.STIEBEL-ELTRON-USA.COM DHC | 5

INSTALLATION

WATER CONNECTIONS

26�02�02�033126�02�02�1355

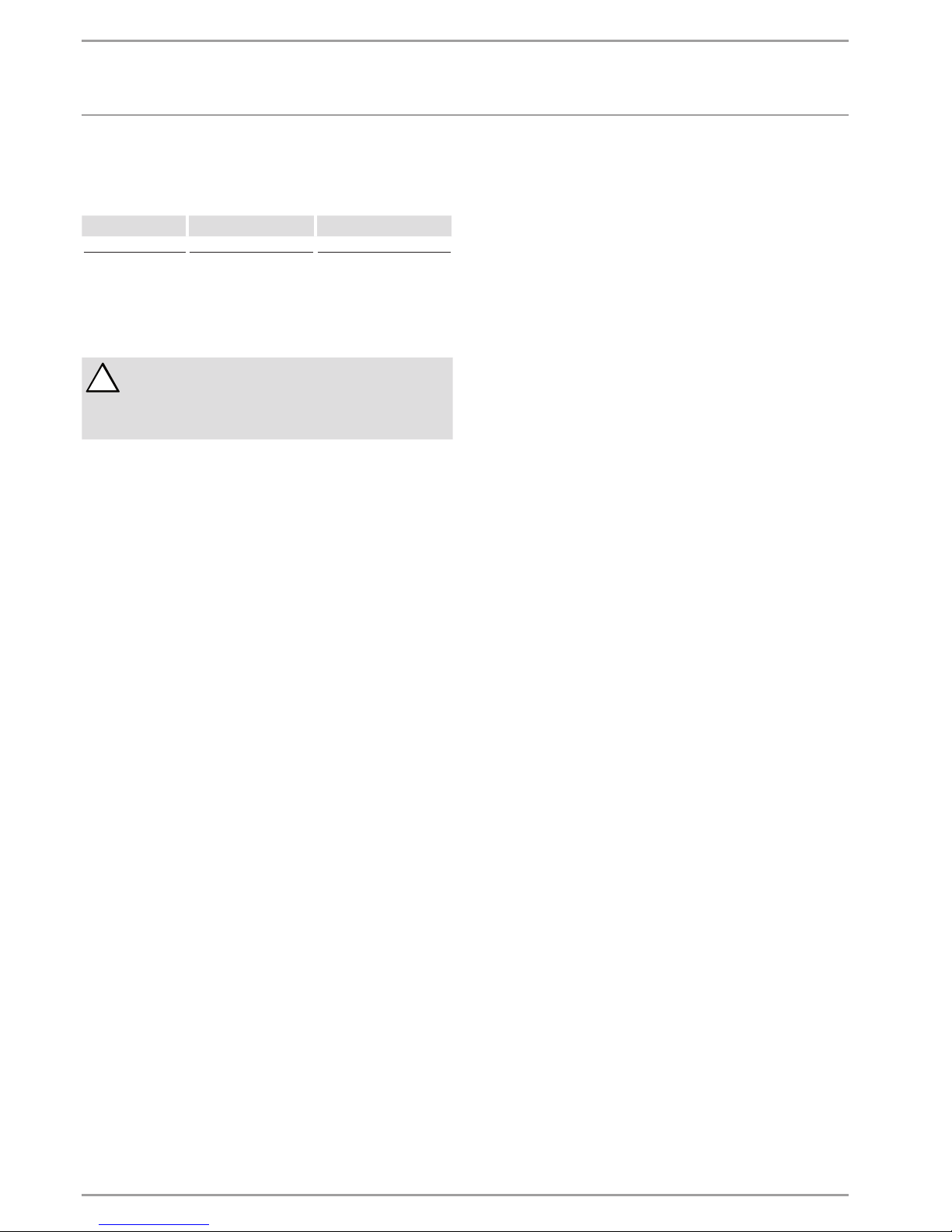

6. Water connections

1. All plumbing work must comply with national and applicable

state and local plumbing codes.

2. A pressure reducing valve must be installed if the cold water

supply pressure exceeds 150 PSI (10 bar).

3. Make certain that the cold water supply line has been flushed

to remove any scale and dirt.

4. Install isolating valve in cold water line as shown in illustration. This allows the unit to be isolated for maintenance

purposes.

5. Cold water connection (inlet) is on the right side of the unit,

hot water connection (outlet) is on the left side of unit.

Note

Excessive heat from soldering on copper pipes near the

DHC may cause damage.

6. Tankless water heaters such as the DHC are not required to

be equipped with a Pressure and Temperature Relief Valve

(PTRV). If the local inspector will not pass the installation

without a PTRV, it should be installed on the hot water outlet

side of unit.

7. In case you are connecting to 1/2˝ water pipe, solder 1/2˝

NPT tapered female adapter by copper on ends of cold and

hot water lines. In case you are connecting to 3/8˝ water

pipe, use a 1/2˝ female pipe thread by 3/8˝ compression

adapter. Braided flexible connectors will work as well.

Connect cold and hot water lines to the unit.

8. When all plumbing work is completed, check for leaks and

take corrective action before proceeding.

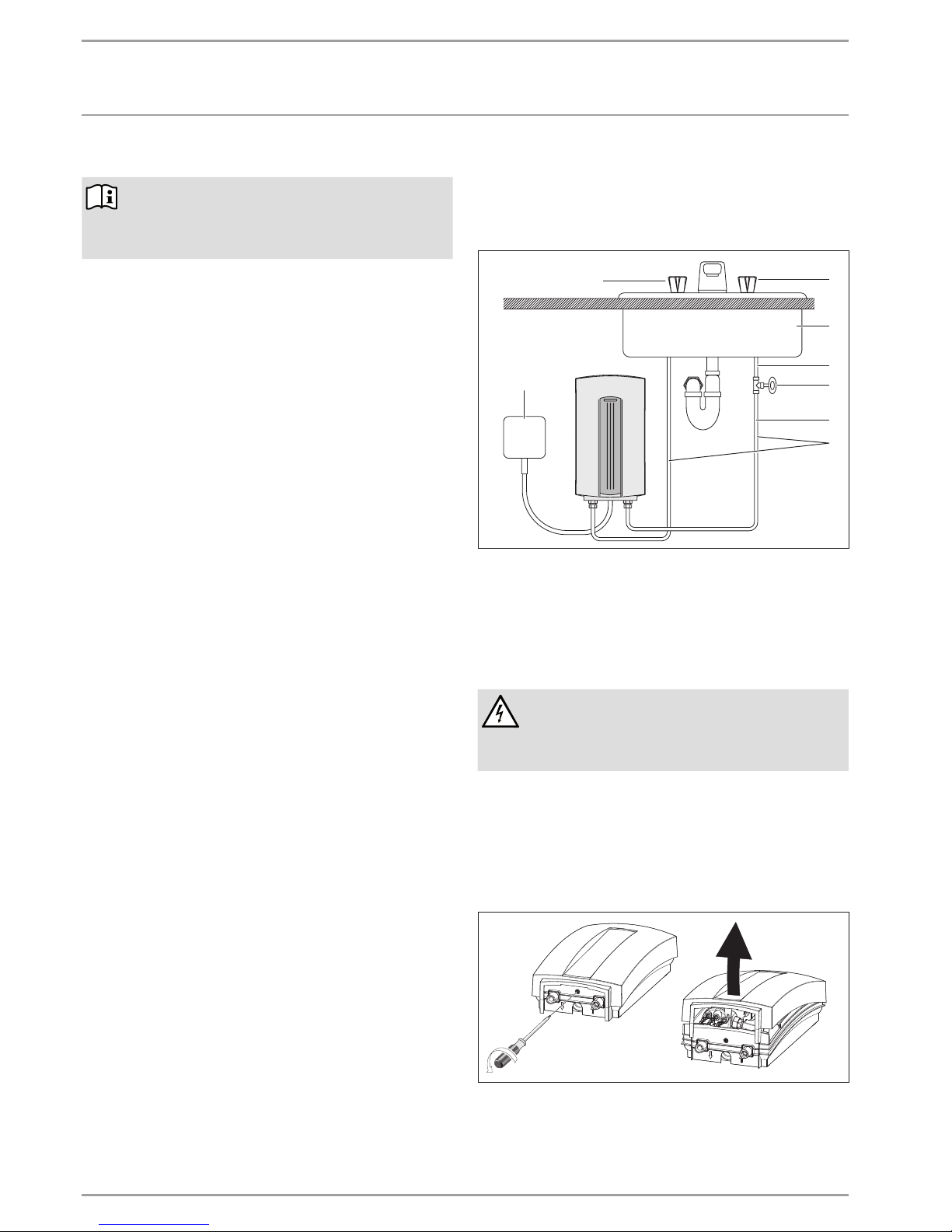

7. Electrical connection

!

WARNING:

Before beginning any work on the electric installation,

be sure that main breaker panel switches are "off"

to avoid any danger of electric shock. All mounting

and plumbing must be completed before proceeding with electrical hook-up. Where required by local,

state or national electrical codes the circuits should be

equipped with a "ground fault interrupter".

The unit must be properly grounded in accordance

with state and local codes, or in absence of such

codes, in accordance with national electric code or the

Canadian electric code. Failure to electrically ground

the product could result in serious personal injury or

death.

1. All electrical work must comply with national and applicable

state and local electrical codes.

2. The DHC should be connected to a properly grounded dedicated branch circuit of proper voltage rating. In installa tions

with several DHC units, each unit requires an independent

circuit. Please refer to the technical data table for the correct

wire and circuit breaker size.

3. The wire must be fed through the rubber seal located between the hot and cold water connections. Then feed wires

through strain relief clamp and tighten clamp down on wire.

The "live" wires must be connected to the slots on the terminal block marked N and L (DHC 3-1 only) or L and L (all other

versions). The ground wire must be connected to slot marked with the ground symbol.

4. Reinstall plastic cover.

4˝ (100 mm)

26�02�02�0469

6 | DHC WWW.STIEBEL-ELTRON-USA.COM

INSTALLATION

COMMISSIONING

7.1 Terminal block

Consult the chart below for the recommended torque amounts on

the terminal block screws.

Screw Size (mm) Min. Torque (N•cm) Min. Torque (lbf•in)

M5 150-2 00 13.3-17.7

Using the proper torque specifications to secure wire to the wiring

block helps to avoid personal loss or property damage.

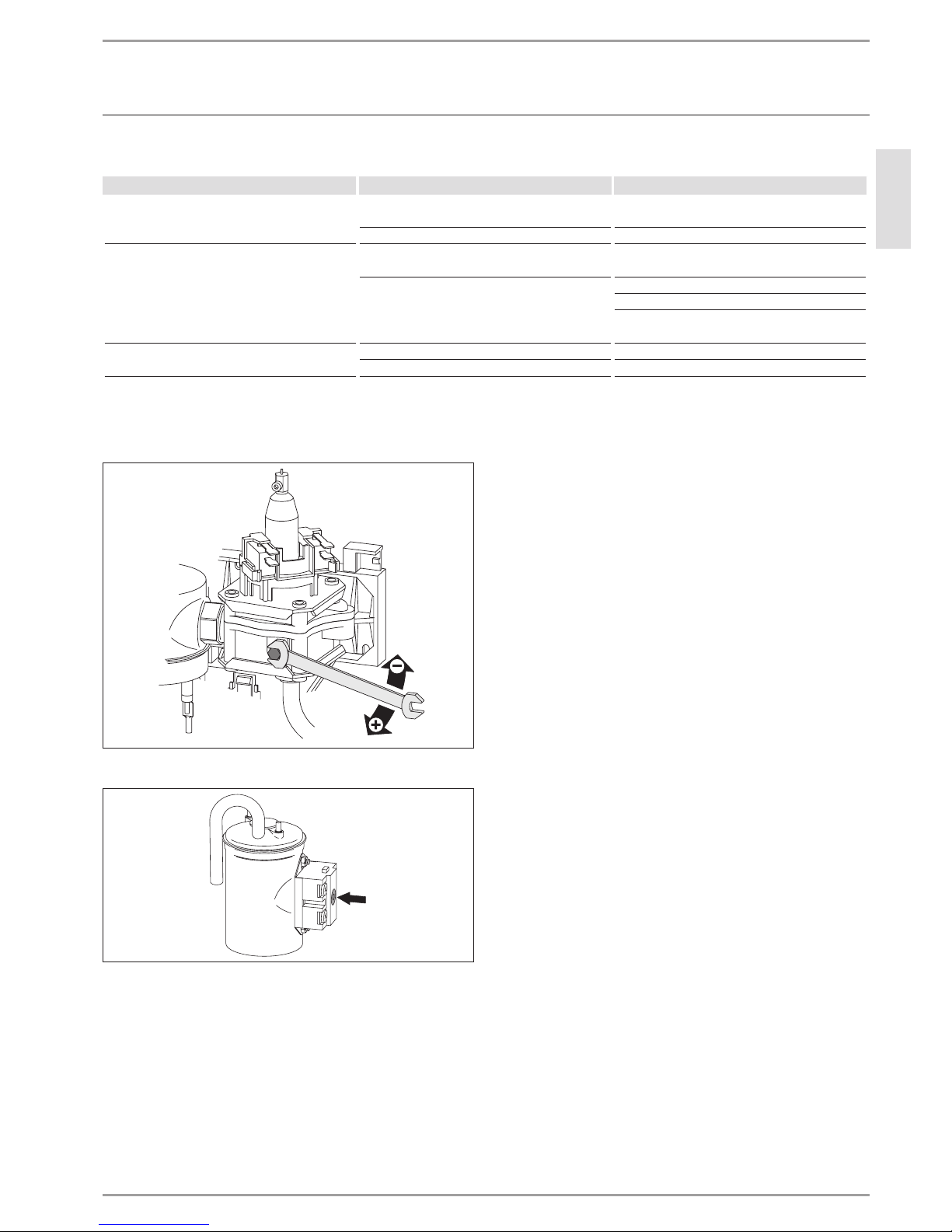

8. Commissioning

!

WARNING:

Open hot water faucet for a few minutes until water

flow is continuous and all air is purged from water

pipes. The unit’s cover must be installed before the

circuit breakers are turned on.

1. Turn on circuit breaker to bring electrical power to the unit.

2. Open hot water faucet to a degree so that water flow is „typical“ i.e. until the water flow is the same as that encountered

during normal use.

3. Wait twenty seconds until temperature has stabilized. Then

check water temperature. If temperature is too low, the

water flow rate needs to be reduced. In order to do this,

turn off the unit’s circuit breaker, remove the cover and turn

the flow adjustment screw shown in illustration clockwise

1/2 turn (180 degrees). Then reinstall plastic cover, turn on

circuit breaker and check water temperature. This procedure

should be repeated until the desired temperature is achieved. In case the water temperature is too high, turn the flow

adjustment screw counter clockwise in the same manner

until the desired temperature is achieved. The arrows in illustration refer to the water temperature.

4. In order to obtain temperature control at a single spout mixer-type faucet, restrict cold water flow to faucet by partially

closing the cold water shut-off valve under the sink until cold

water and hot water flow rates are approximately the same.

8.1 Appliance handover

Explain the functions of the appliance to the user. Draw special

attention to the safety information. Hand the operating and installation instructions to the user.

ENGLISH

WWW.STIEBEL-ELTRON-USA.COM DHC | 7

INSTALLATION

TROUBLESHOOTING

9. Troubleshooting

Symptom Possible cause Solution

No hot water but audible click can be heard when

water is turned on.

circuit breaker off circuit breaker on.

safety thermal cut-out tripped reset thermal cut-out.

No hot water and no audible click can be heard when

water is turned on

water flow too low to activate flow switch clean faucet aerator.

open shut-off valve completely.

open flow adjustment screw.

clean filter screen at DHC unit (see figure “Spare

parts”).

Water not warm enough water flow too high reduce wter flow, close flow agjusment screw.

voltage too low supply correct voltage to unit.

If you are not able to resolve a problem please contact us toll free at 800-582-8423 before removing the unit from the wall.

STIEBEL ELTRON is happy to provide technical assistance. In most instances, we can resolve the problem over the phone.

Open flow adjustment screw

26�02�02�1358

Reset button from safety thermal cut out

26�02�02�1357

8 | DHC WWW.STIEBEL-ELTRON-USA.COM

INSTALLATION

NORMAL MAINTENANCE

10. Normal maintenance

STIEBEL ELTRON DHC tankless heaters are designed for a very long

service life. Actual life expectancy will vary with water quality and

use. The unit itself does not require any regular maintenance.

However, to ensure consistent water flow, it is recommended

to periodically remove scale and dirt that may build up at the

aerator of the faucet or in the shower head. Also, the DHC has

a built in filter screen that should be cleaned from time to time.

In order to do this, turn off the cold water supply at the isolating

valve and remove the ground wire. Twist cold water supply tube

counterclock wise by 90° and pull towards bottom of unit. Clean

screen and put the screen, the cold water supply tube and the

ground wire back into their original position. Please be sure that

the ground wire is reinstalled and that ground screw is securely

tightened after this procedure.

Note:

Other than the filter screen, the DHC does not contain any

parts serviceable by the lay person. In case of malfunction

please contact a licensed plumber or electrician.

11. Technical Data

11.1 Dimensions

b01

c06 c01

c01

c06

38 (1.5")

360 (14.17")

200 (7.88")

100 (3.94")

110 (4.33")

273 (10.75")75 (2.953")

8 (0.315")

D0000021558

b01 electrical supply cable

c01 cold water connection 1/2" NPT

c06 hot water connection 1/2" NPT

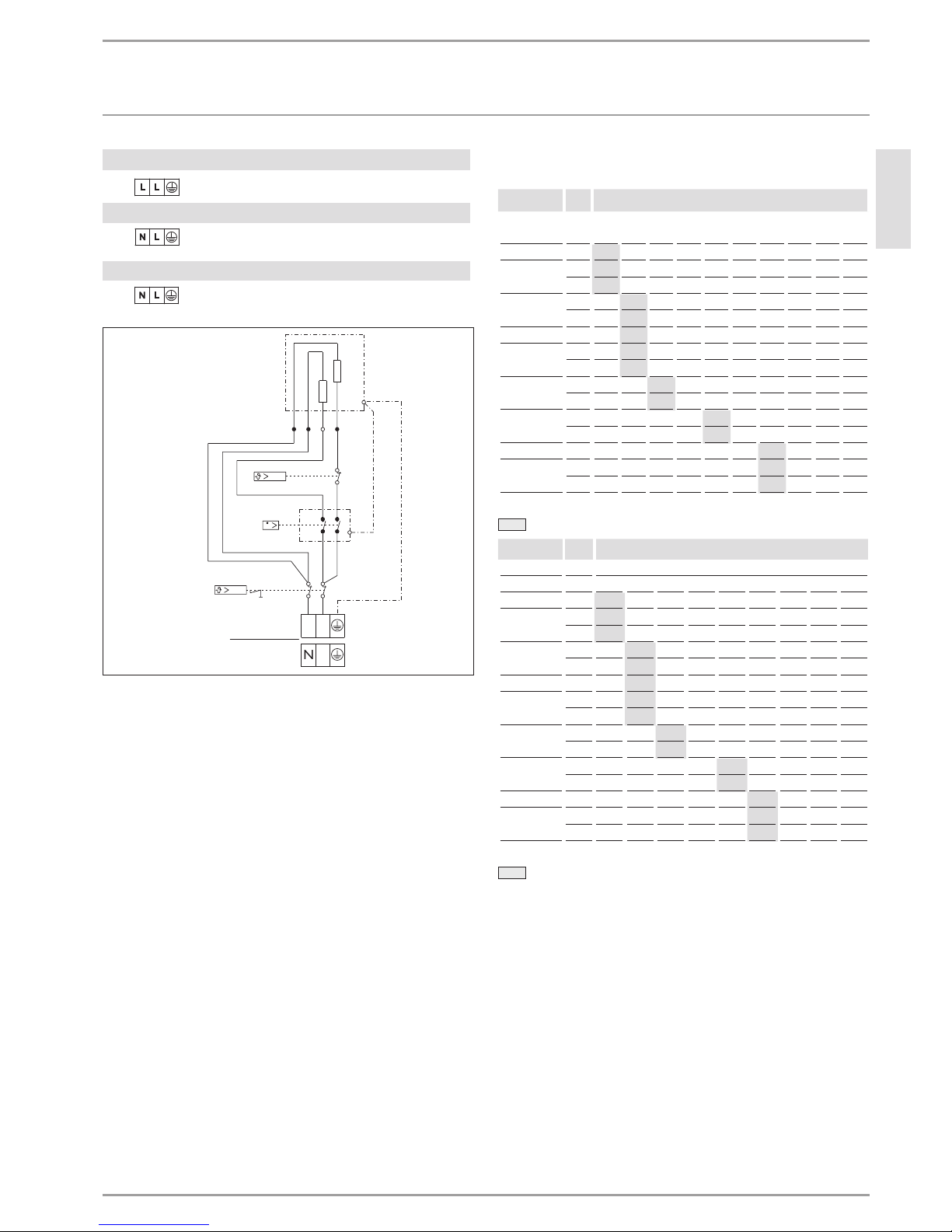

11.2 Wiring diagram

DHC 3-2, DHC 4-2, DHC 5-2

A 2/GRD ~ 208 / 240 V

DHC 4 -3

B 1/N/GRD ~ 277 V

LL

A

V

NL

B

85�02�02�0008

ENGLISH

WWW.STIEBEL-ELTRON-USA.COM DHC | 9

INSTALLATION

TECHNICAL DATA

DHC 6-2, DHC 8-2, DHC 10-2

A 2/GRD ~ 208 / 240 V

DHC 9 -3

B 1/N/GRD ~ 277 V

DHC 3-1

B 1/N/GRD ~ 120 V

V

LL

NL

85�02�02�0009

A

B

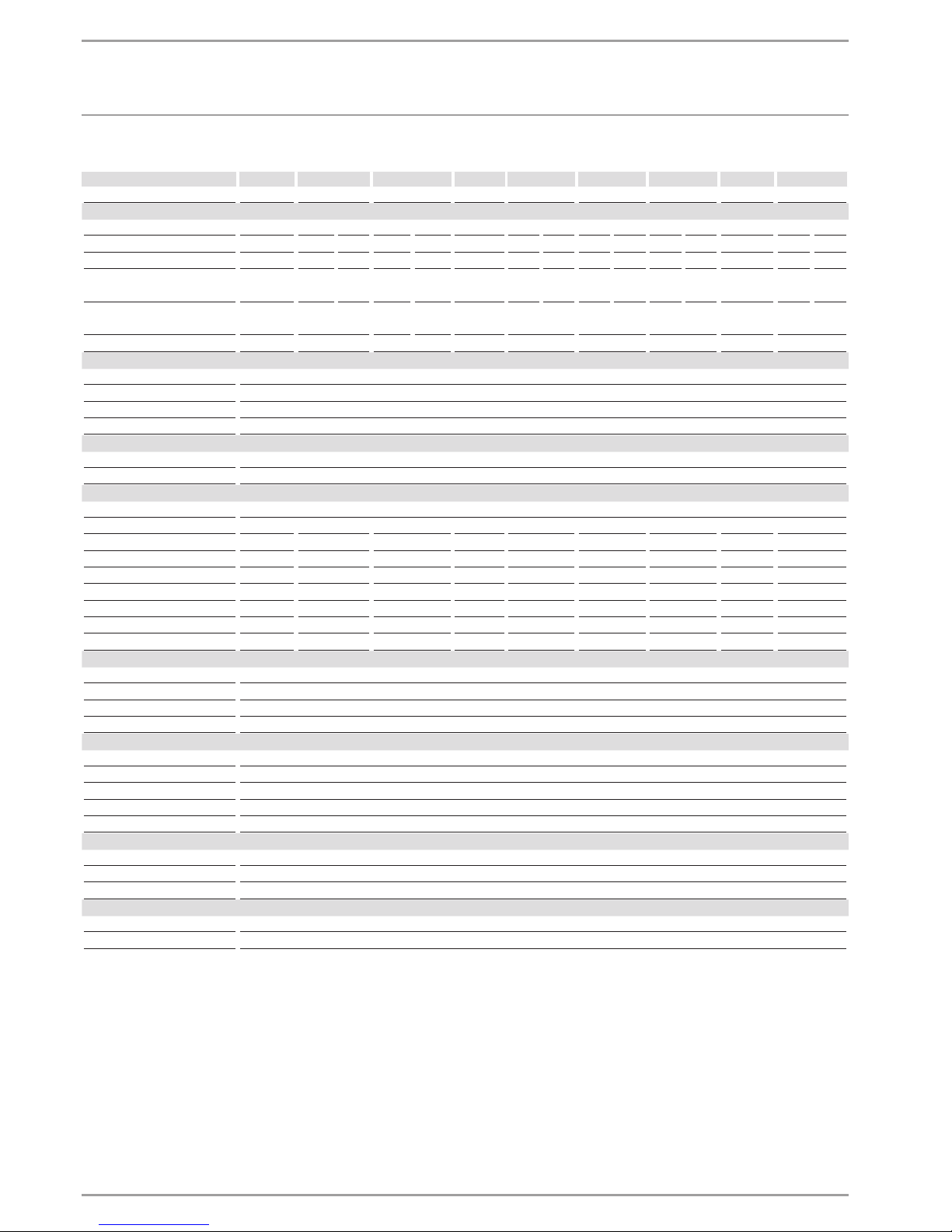

11.3 Temperature increase above ambient water

temperature

[ °F ]

Typ kW GPM (gallon per minute)

0.32 0.42 0.48 0.5 0.69 0.75 0.79 1.0 1.5 2.0

DHC 3-1 3.0 65 49 43 41 30 27 26 20 14 10

DHC 3-2 2.5 54 40 35 34 25 23 21 17 11 9

3.3 71 53 47 45 33 30 28 22 15 11

DHC 4-2 2.9 – 47 41 40 29 26 25 20 13 10

3.8 – 61 54 52 38 35 33 26 17 13

DHC 4-3 4.5 – 73 64 61 45 41 39 31 20 15

DHC 5-2 3.6 – 58 51 49 36 33 31 25 16 12

4.8 – 77 68 65 48 44 41 33 22 16

DHC 6-2 4.5 – – 64 61 45 41 39 31 20 15

6.0 – – 85 82 60 55 52 41 27 20

DHC 8-2 5.4 – – – – 54 49 46 37 25 18

7.2 – – – – 71 65 62 49 33 25

DHC 9-3 9.0 - - - - - - 77 58 41 31

DHC 10-2 7.2 – – - – – – 62 49 33 25

9.6 – – - – – – 82 65 44 33

Min. water flow to activate unit

[ °C ]

Typ / Type kW l/min

1.2 1.6 1.8 2.0 2.6 3.0 4.0 5.0 7.5

DHC 3-1

3.0 36 27 24 22 17 14 11 9 6

DHC 3-2

2.5 30 22 20 18 14 12 9 7 5

3.3 39 30 26 24 18 16 12 9 6

DHC 4-2

2.9 – 26 23 21 16 14 10 8 6

3.8 – 34 30 27 21 18 14 11 7

DHC 4-3

4.5 – 40 36 32 25 22 16 13 9

DHC 5-2

3.6 – 32 29 26 20 17 13 10 7

4.8 – 43 38 34 26 23 17 14 9

DHC 6-2

4.5 – – 36 32 25 22 16 13 9

6.0 – – 48 43 33 29 22 17 11

DHC 8-2

5.4 – – – – 30 26 19 15 10

7.2 – – – – 40 34 26 21 14

DHC 9-3 9.0 - - - - - 43 32 26 17

DHC 10-2

7.2 – – – – – 34 26 21 14

9.6 – – – – – 46 34 28 18

Min. water flow to activate unit

10 | DHC WWW.STIEBEL-ELTRON-USA.COM

INSTALLATION

TECHNICAL DATA

11.4 Data table

DHC 3-1 DHC 3-2 DHC 4-2 DHC 4-3 D HC 5-2 DHC 6-2 DHC 8-2 DHC 9 -3 DHC 10-2

074050 074052 074053 074051 074054 074424 074055 232204 074056

Electrical details

Voltage 120 V 208 V 240 V 208 V 240 V 277 V 208 V 240 V 208 V 240 V 208 V 240 V 277 V 208 V 240 V

Wattage 3.0 kW 2.5 kW 3.5 kW 2.9 kW 3.8 kW 4.5 kW 3.6 kW 4.8 kW 4.5 kW 6.0 kW 5.4 kW 7.2 k W 9 kW 7. 2 k W 9.6 kW

Amperage 25 A 12 A 14 A 14 A 16 A 17 A 18 A 20 A 22 A 25 A 26 A 30 A 32.5 A 35 A 40 A

Min. recommended circuit breaker size

1

25 A 15 A 15 A 15 A 20 A 20 A 20 A 20 A 25 A 25 A 30 A 30 A 35 A 35 A 40 A

Min. recommended wire size

(copper)

2

10 AWG 14 AWG 14 AWG 12 AWG 12 AWG 12 AWG 10 AWG 10 AWG 8 AWG 8 AWG

Power connection 1/N/GRD 2/GRD 2/GRD 2/GRD 2/GRD 2/GRD 2/GRD 2/GRD 2/GRD

Connections

Water connection

3

1/2˝ NPT

Total alkaline earths 2.5 mol/m³

Total hardness (H2O) 14 Degree d

Hardness range 2 (average hardness)

Hydraulic data

Rated capacity 0.5 l

Rated capacity 0.13 gal

Values

Max. permissible inlet temp. 86 °F / 30°C

Min. water flow to activate unit 1.2 l/min 1.2 l/min 1.6 l/min 1.6 l/min 1.6 l/min 1.8 l/min 2.6 l/min 3.0 l/min 3.0 l/min

Min. water flow to activate unit 0.32 GPM 0.32 GPM 0.43 GPM 0.43 GPM 0.43 GPM 0.48 GPM 0.69 GPM 0.8 GPM 0.8 GPM

Pressure drop at flow rate 0.023 MPa 0.023 MPa 0.023 MPa 0.023 MPa 0.023 MPa 0.023 MPa 0.025 MPa 0.03 MPa 0.03 MPa

Pressure drop at flow rate 2.88 PSI 2.88 PSI 2.88 PSI 2.88 PSI 2.88 PSI 2.88 PSI 3.13 PSI 3.75 PSI 3.75 PSI

Flow rate for pressure drop 1.2 l/min 1.2 l/min 1.6 l/min 1.6 l/min 1.6 l/min 1.8 l/min 2.6 l/min 3.0 l/min 3.0 l/min

Flow rate for pressure drop 0.32 GPM 0.32 GPM 0.43 GPM 0.43 GPM 0.43 GPM 0.48 GPM 0.69 GPM 0.8 GPM 0.8 GPM

DHW delivery 1.2 l/min 1.2 l/min 1.6 l/min 1.6 l/min 1.6 l/min 1.8 l/min 2.6 l/min 3.0 l/min 3.0 l/min

DHW delivery 0.32 GPM 0.32 GPM 0.43 GPM 0.43 GPM 0.43 GPM 0.48 GPM 0.69 GPM 0.8 GPM 0.8 GPM

Application limits

Max. permissible pressure 1 MPa

Max. permissible pressure 150 PSI

Test pressure 2 MPa

Test pressure 300 PSI

Versions

IP-Rating IP25

Material of the pressure vessel Copper

Heating system Tubular heater

Cover and back panel Plastic

Color white

Dimensions

Height 14.17 in / 360 mm

Width 7.88 in / 200 mm

Depth 4.33 in / 100 mm

Weights

Weight 2.1 kg

Weight 4.6 lb

ENGLISH

WWW.STIEBEL-ELTRON-USA.COM DHC | 11

INSTALLATION

SPARE PARTS

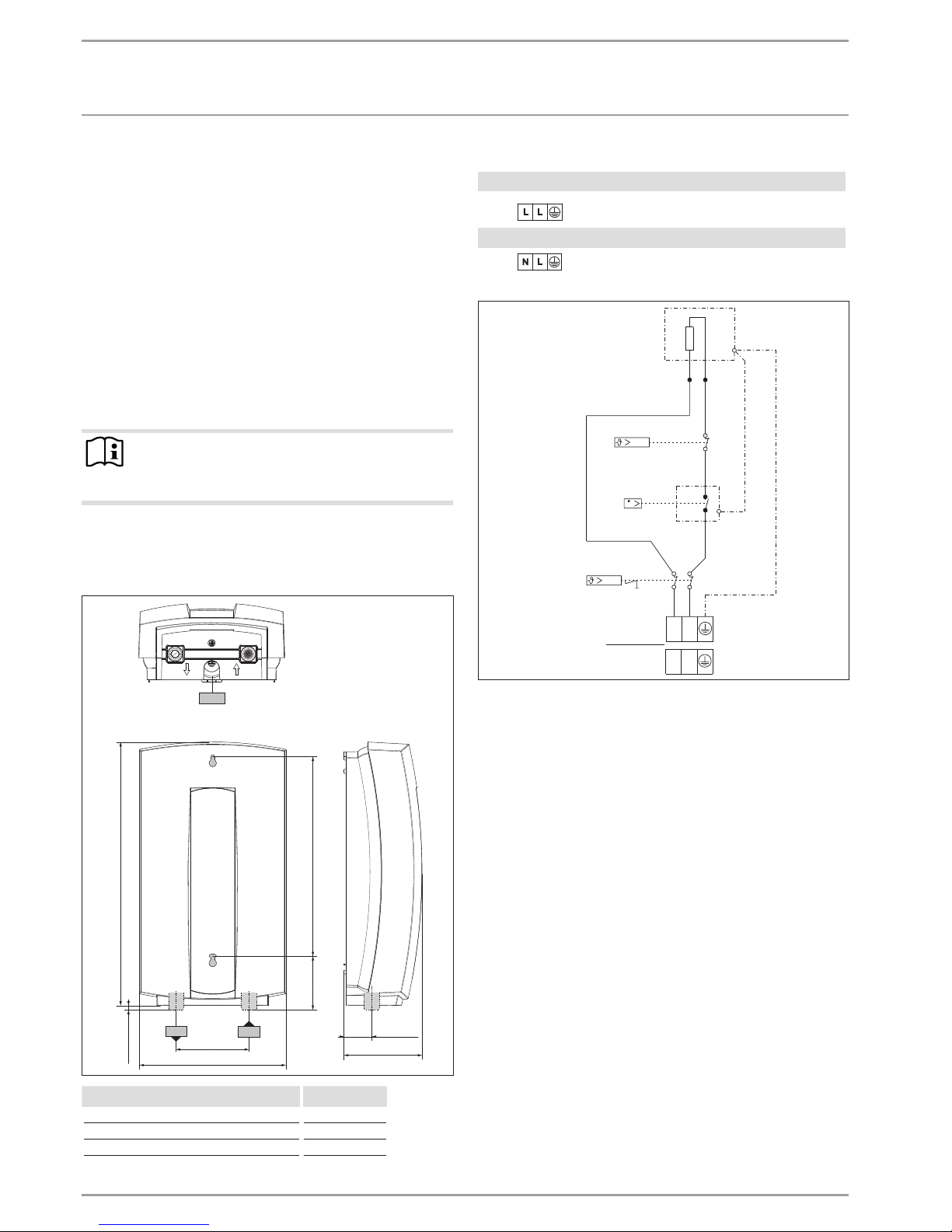

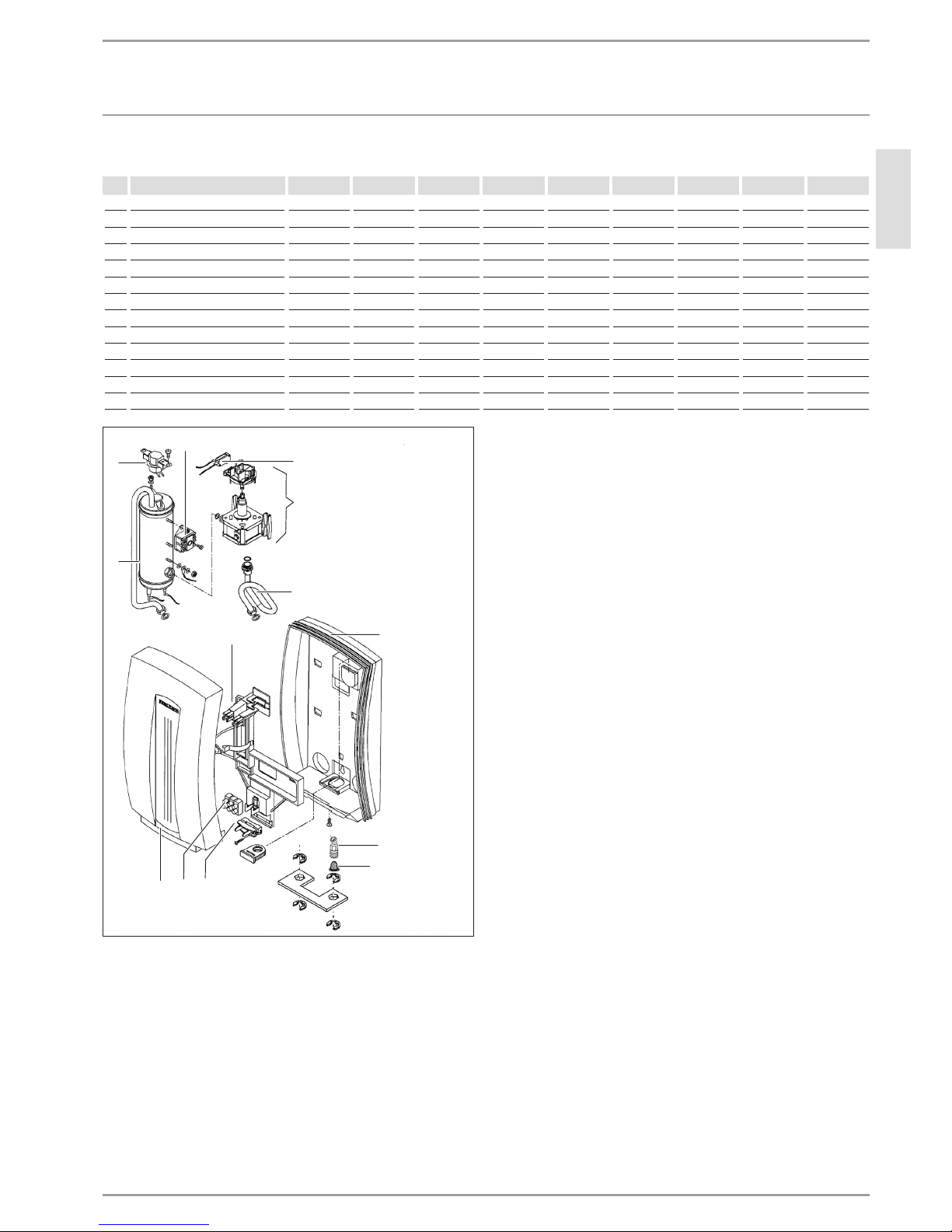

12. Spare parts

No. Spare part DHC 3-1 DHC 3-2 DHC 4-2 DHC 4-3 D HC 5-2 DHC 6-2 DHC 8-2 D HC 9-3 DHC 10-2

1 Heating system 165889 167769 167770 165890 167771 171117 167772 296874 167773

2 Flow switch 165273 165273 162162 162162 162162 171105 162164 162465 162165

3 Thermostat 162472 162472 162472 162472 162472 162472 162472 162472 162472

4 Switch 168026 168026 168026 168026 168026 168026 168026 168026 168026

5 Housing (back) 165891 165891 165891 165891 165891 165891 165891 165891 165891

6 Plumbing connection 170789 170789 170789 170789 170789 170789 170789 170789 170789

7 Housing (front) 165892 165892 165892 165892 165892 165892 165892 165892 165892

8 Safety thermal cut out 162474 162474 162474 162474 162474 162474 162474 162474 162474

9 Wiring block 026010 026010 026010 026010 026010 026010 026010 026010 026010

10 Copper tube 162314 162314 162314 162314 162314 162314 162314 162314 162314

11 Module chassis 162462 162462 162462 162462 162462 162462 162462 162462 162462

12 Wire strain relief clamp 055754 055754 055754 055754 055754 055754 055754 055754 055754

13 Filter screen 275981 275981 275981 275981 275981 275981 275981 275981 275981

D0000043978

4

7

1

3

2

10

5

6

13

9

12

8

11

Loading...

Loading...