Page 1

OPERATION AND INSTALLATION

UTILISATION ET INSTALLATION

OPERACIÓN E INSTALACIÓN

TANKLESS ELECTRIC WATER HEATER | CHAUFFE-EAU ÉLECTRIQUE SANS ACCUMULATEUR |

CALENTADOR DE AGUA INSTANTANEOS SIN TANQUE

» DHC 3-1

» DHC 3-2

» DHC 4-2

» DHC 4-3

» DHC 5-2

» DHC 6-2

» DHC 8-2

» DHC 9-3

» DHC 10-2

84335

The DHC series is tested and

certified by WQA against

NSF/ANSI 372 for lead free

compliance.

Page 2

CONTENTS | OPERATION

OPERATION

1. General information �����������������������������������������2

1.1 Safety information ����������������������������������������������� 2

1.2 Other symbols in this document ������������������������������ 2

2. Safety ���������������������������������������������������������� 2

2.1 Intended use ������������������������������������������������������ 3

2.2 General Information��������������������������������������������� 3

2.3 Safety Precautions ����������������������������������������������� 3

2.4 Test symbols ������������������������������������������������������ 3

3. General ��������������������������������������������������������3

INSTALLATION

4. Mounting the unit ��������������������������������������������4

5. Water connections �������������������������������������������4

6. Electrical connection �����������������������������������������5

7. Putting the water heater into operation ������������������� 5

8. Normal maintenance ����������������������������������������� 5

9. Technical Data ������������������������������������������������6

9.1 Wiring diagram �������������������������������������������������� 6

9.2 Data table ��������������������������������������������������������� 7

10. Temperature increase above ambient water

temperature ��������������������������������������������������8

11. Troubleshooting ����������������������������������������������9

12. Spare parts ������������������������������������������������� 10

WARRANTY | ENVIRONMENT AND RECYCLING

1.1 Safety information

1.1.1 Structure of safety information

KEYWORD Type of risk

Here, possible consequences are listed that may result from not observing the safety information.

Steps to prevent the risk are listed.

1.1.2 Symbols. type of risk

Symbol Type of risk

Injury

!

1.1.3 Keywords

KEYWORD Description

DANGER If this information is not observed, it will result in serious

WARNING If this information is not observed, it can result in serious

CAUTION If this information is not observed, it can lead to medium

Electrocution

Burns or scalding

injury or death.

injury or death.

or minor injury.

OPERATION

1. General information

Note

Read these instructions carefully before using the appliance and familiarize yourself with its functions. Keep

these instructions safe. Pass on the instructions to a new

user if required.

1.2 Other symbols in this document

Note

Notes are bordered by horizontal lines above and below

the text. General information is identified by the symbol

shown on the left.

Read these notes carefully.

Symbol

Damage to the appliance and environment

!

This symbol indicates that you have to do something. The ac-

tion you need to take is described step by step.

Appliance disposal

2. Safety

Observe the following safety information and regulations.

Operate the appliance only when fully installed and with all safety

equipment fitted.

2 | DHC WWW.STIEBEL-ELTRON.COM

Page 3

OPERATION

GENERAL

2.1 Intended use

The appliance is intended for heating domestic hot water and can

supply one draw-off point.

Any other use beyond that described shall be deemed inappropriate.

Observation of these instructions is also part of the correct use

of this appliance.

2.2 General Information

This appliance is designed for domestic use. It can be used safely

by untrained persons. The appliance can also be used in a nondomestic environment, e.g. in a small business, as long as it is

used in the same way.

Read this entire manual. Failure to follow all the guides, instructions and rules could cause personal injury or property damage.

Improper installation, adjustment, alteration, service and use of

this appliance can result in serious injury.

This appliance must be installed by a licensed electrician and

plumber. The installation must comply with all national, state and

local plumbing and electric codes. Proper installation is the responsibility of the installer. Failure to comply with the installation

and operating instructions or improper use voids the warranty.

Save these instructions for future reference. Installer should leave

these instructions with the consumer.

If you have any questions regarding the installation, use or operation of this water heater, or if you need any additional installation

manuals, please call our technical service line, see last side.

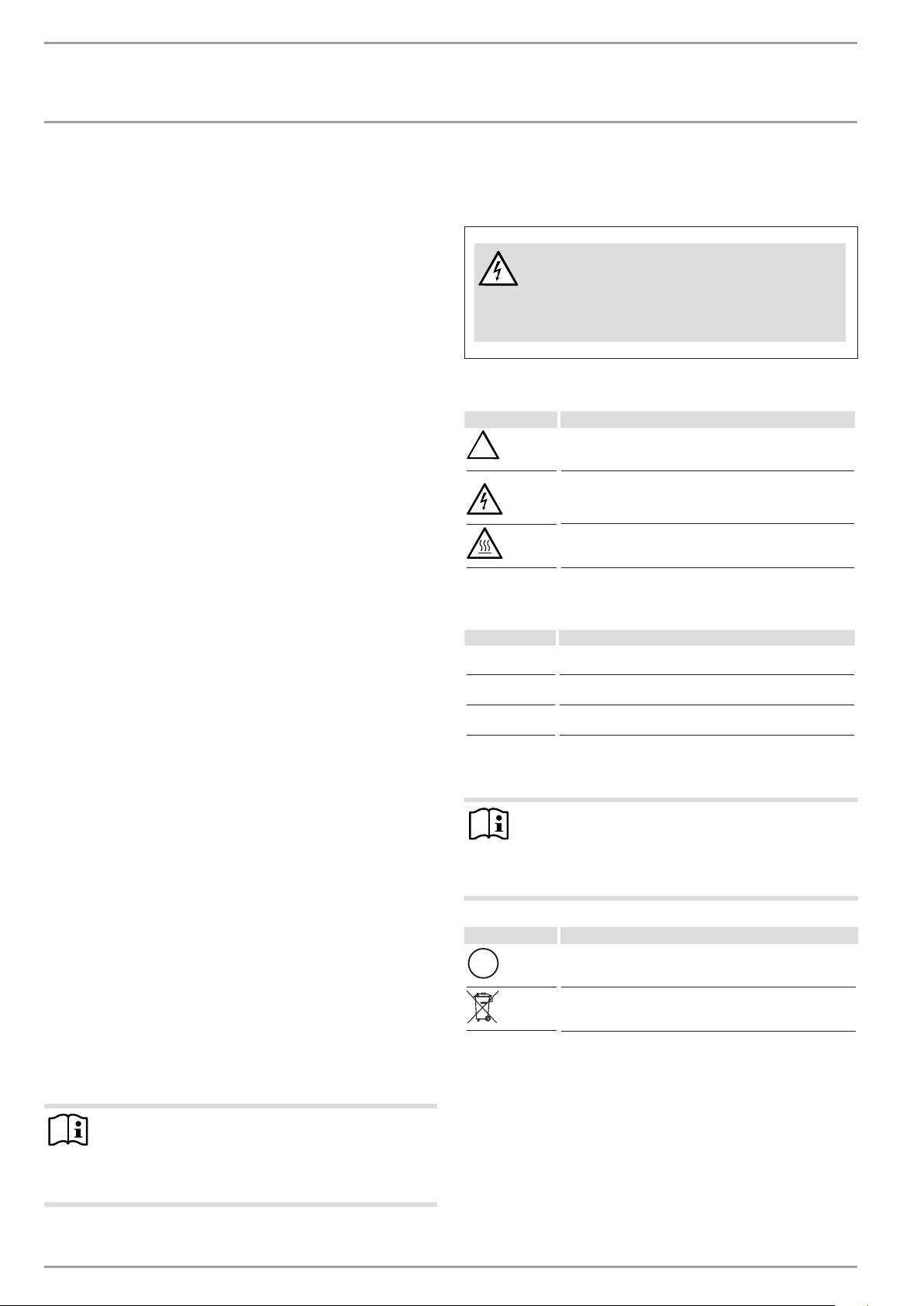

2.3 Safety Precautions

DANGER Injury

!

Please read and follow these instructions.

Failure to follow these instructions could result in serioius personal injury or death.

Damage to the appliance and the environment

!

The appliance must be installed by a licensed electrician and plumber. The installation must comply with all

national, state and local plumbing and electric codes.

Service of the appliance must be performed by qualified

service TECHNICIANS.

DANGER Electrocution

Before proceeding with any installation, adjustment. alteration, or service of this appliance all circuit breakers

and disconnect switches servicing the appliance must

be turned off. Failure to do so could result in serious

personal injury or death.

DANGER Electrocution

Never remove the appliance‘s cover unless the electricity servicing the appliance is turned off. Failure to do so

could result in personal injury or death.

DANGER Electrocution

The appliance must be properly grounded. Failure to

electrically ground the product could result in serious

personal injury or death.

DANGER Burns

Water temperatures over 125°F (52 °C)can cause severe

burns instantly or death from scalding.

WARNING Injury

!

The appliance may be used by children aged 8 and up

and persons with reduced physical, sensory or mental

capabilities or a lack of experience provided that they

are supervised or they have been instructed on how to

use the appliance safely and have understood the resulting risks. Children must never play with the appliance.

Children must never clean the appliance or perform user

maintenance unless they are supervised.

2.4 Test symbols

See type plate on the appliance.

3. General

The DHC tankless water heater differs from conventional storage

type water heaters in several ways. It does not store hot water.

Instead, water is heated instantaneously as it flows through the

unit. The powerful heating elements are activated by a flow switch

as water is drawn from a hot water faucet connected to the DHC.

Due to the absence of stand-by losses, the DHC has greater energy

efficiency than storage type water heaters.

The temperature of the hot water delivered by the DHC depends

on the wattage of the heating element, the temperature of the

incoming cold water, and the water flow rate through the unit.

In order for the DHC to operate properly, it must be carefully

matched to the application.

In case you have questions regarding the way you plan to use the

DHC, please call our technical service line at 800-582-8423 (USA and

Canada). For service outside the U.S. and Canada, please call us at

USA 413-247-3380. You can also e-mail us at info@stiebel-eltronusa.com or fax us at 413-247-3369.

The DHC can be used for hand washing type applications in the

U.S. and Canada:

- Restroom sinks in commercial/industrial facilities and homes

- Kitchen areas in commercial /industrial facilities and homes

- Cabins

- Special uses in photo developing shops, laboratories etc.

The DHC can also be used for whole apartments and homes in

warm climate zones such as the Caribbean region, Central America and Mexico due to the higher ambient water temperatures.

ENGLISH

WWW.STIEBEL-ELTRON.COM DHC | 3

Page 4

INSTALLATION

MOUNTING THE UNIT

INSTALLATION

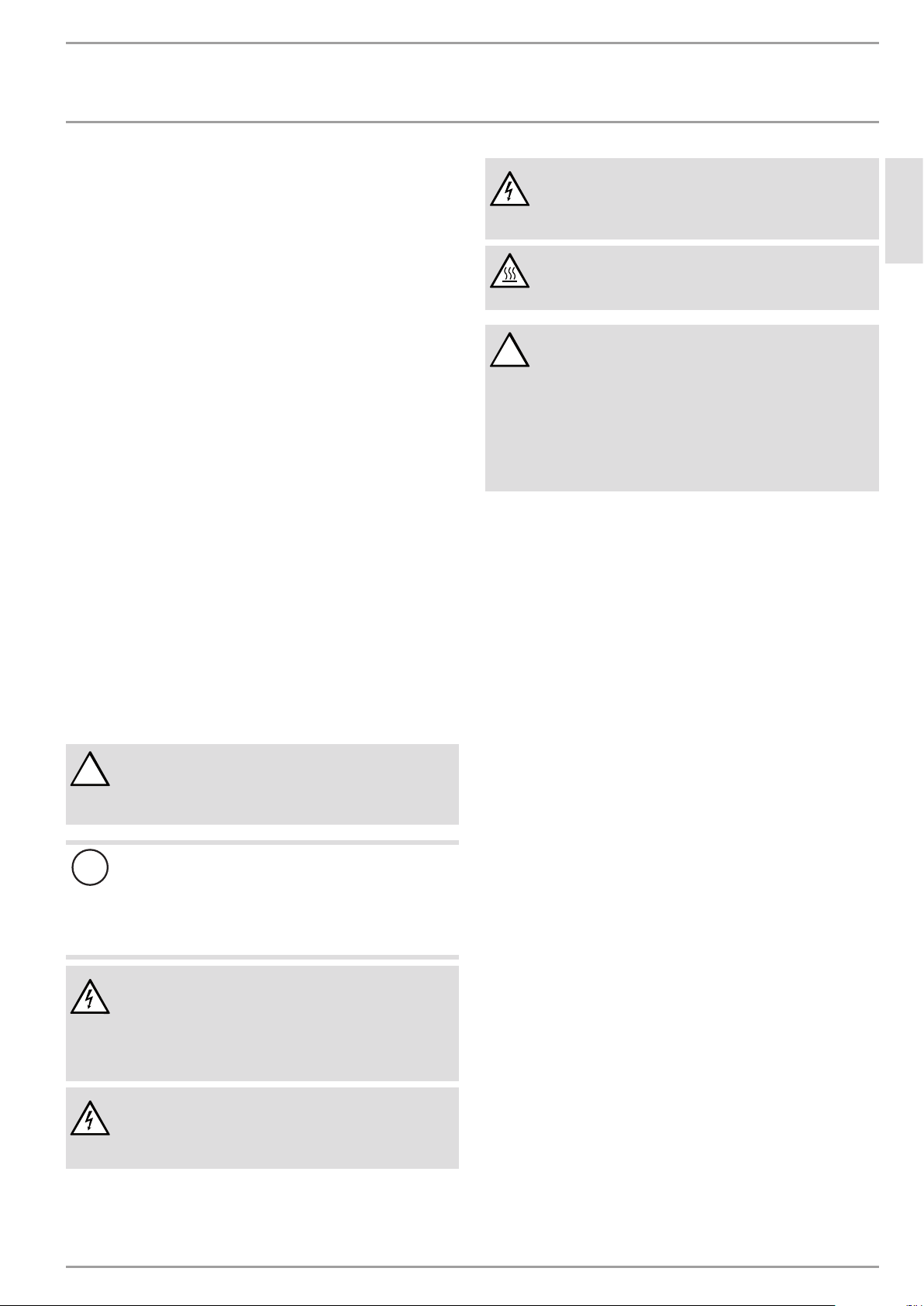

4. Mounting the unit

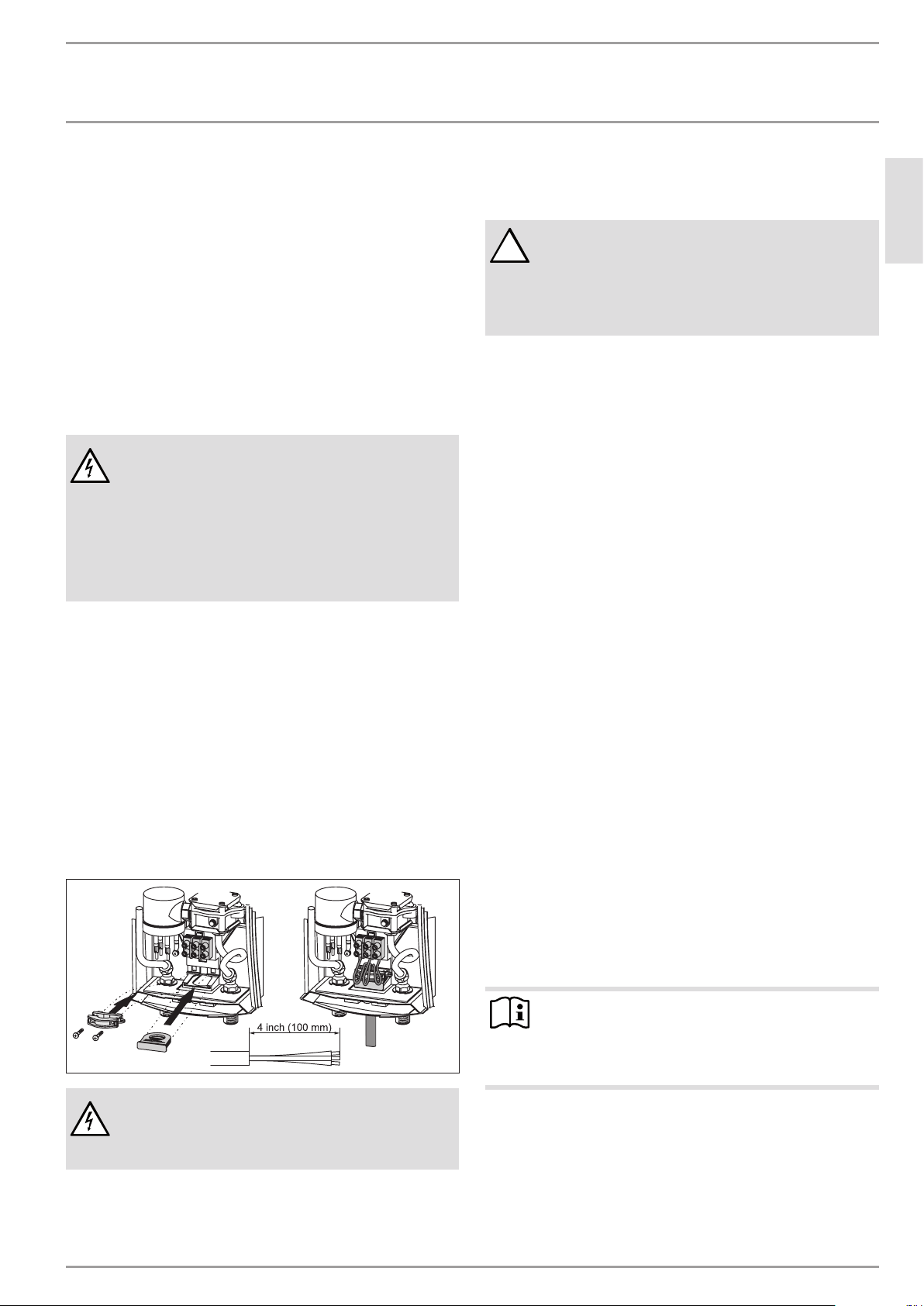

5. Mount unit securely to wall by putting two screws through

mounting holes. Screws and plastic wall anchors for mounting on masonry or wood are provided.

8

1

1 Electrical junction box

2 Water supply line for faucet installation

3 3/8“ compression-T

4 Shut-off valve

5 1/2“ main pipe

6 Sink

7 Cold valve (right)

8 Hot valve (left)

7

6

5

4

3

2

26�02�02�0330

26�02�02�033126�02�02�1355

DANGER Electrocution

UNIT MUST BE INSTALLED IN A VERTICAL POSITION WITH

THE WATER FITTINGS POINTING DOWNWARD. DO NOT

INSTALL UNIT WHERE IT WOULD ROUTINELY BE SPLASHED

WITH WATER. ELECTRIC SHOCK MAY RESULT.

1. Install DHC as close as possible to the hot water draw-off

point, for example, directly underneath the sink or next to

the shower stall.

2. Install DHC in a frost free area. If frost may occur, remove

unit before freezing temperatures set in.

3. Leave a minimum of 5“ of clearance on all sides for

servicing.

4. Remove plastic cover.

5. Water connections

1. All plumbing work must comply with national and applicable

state and local plumbing codes.

2. A pressure reducing valve must be installed if the cold water

supply pressure exceeds 150 PSI (10 bar).

3. Make certain that the cold water supply line has been flushed

to remove any scale and dirt.

4. Install isolating valve in cold water line as shown in illustration. This allows the unit to be isolated for maintenance

purposes.

5. Cold water connection (inlet) is on the right side of the unit,

hot water connection (outlet) is on the left side of unit.

Note

26�02�02�1360

EXCESSIVE HEAT FROM SOLDERING ON COPPER PIPES

NEAR THE DHC MAY CAUSE DAMAGE.

4 | DHC WWW.STIEBEL-ELTRON.COM

Page 5

INSTALLATION

ELECTRICAL CONNECTION

6. Tankless water heaters such as the DHC are not required to

be equipped with a Pressure and Temperature Relief Valve

(PTRV). If the local inspector will not pass the installation

without a PTRV, it should be installed on the hot water outlet

side of unit.

7. In case you are connecting to 1/2“ water pipe, solder 1/2“

NPT tapered female adapter by copper on ends of cold and

hot water lines. In case you are connecting to 3/8“ water

pipe, use a 1/2“ female pipe thread by 3/8“ compression

adapter. Braided flexible connectors will work as well. Connect cold and hot water lines to the unit.

8. When all plumbing work is completed, check for leaks and

take corrective action before proceeding.

6. Electrical connection

DANGER Electrocution

BEFORE BEGINNING ANY WORK ON THE ELECTRIC INSTALLATION, BE SURE THAT MAIN BREAKER PANEL

SWITCH IS „OFF“ TO AVOID ANY DANGER OF ELECTRIC SHOCK. ALL MOUNTING AND PLUMBING MUST

BE COMPLETED BEFORE PROCEEDING WITH ELECTRICAL HOOK-UP. WHERE REQUIRED BY LOCAL, STATE OR

NATIONAL ELECTRICAL CODES THE CIRCUIT SHOULD BE

EQUIPPED WITH A „GROUND FAULT INTERRUPTER“.

1. All electrical work must comply with national and applicable

state and local electrical codes.

2. The DHC should be connected to a properly grounded dedicated branch circuit of proper voltage rating. In installa tions

with several DHC units, each unit requires an independent

circuit. Please refer to the technical data table for the correct

wire and circuit breaker size.

3. The wire must be fed through the rubber seal located between the hot and cold water connections. Then feed wires

through strain relief clamp and tighten clamp down on wire.

The „live“ wires must be connected to the slots on the terminal block marked N and L (DHC 3-1 only) or L and L (all

other versions). The ground wire must be connected to slot

marked with the ground symbol.

4. Reinstall plastic cover.

7. Putting the water heater into

operation

WARNING

!

OPEN HOT WATER FAUCET FOR A FEW MINUTES UNTIL

WATER FLOW IS CONTINUOUS AND ALL AIR IS PURGED

FROM WATER PIPES. THE UNIT’S PLASTIC COVER MUST

BE INSTALLED BEFORE THE CIRCUIT BREAKER IS TURNED

ON.

1. Turn on circuit breaker to bring electrical power to the unit.

2. Open hot water faucet to a degree so that water flow is „typi-

cal“ i.e. until the water flow is the same as that encountered

during normal use.

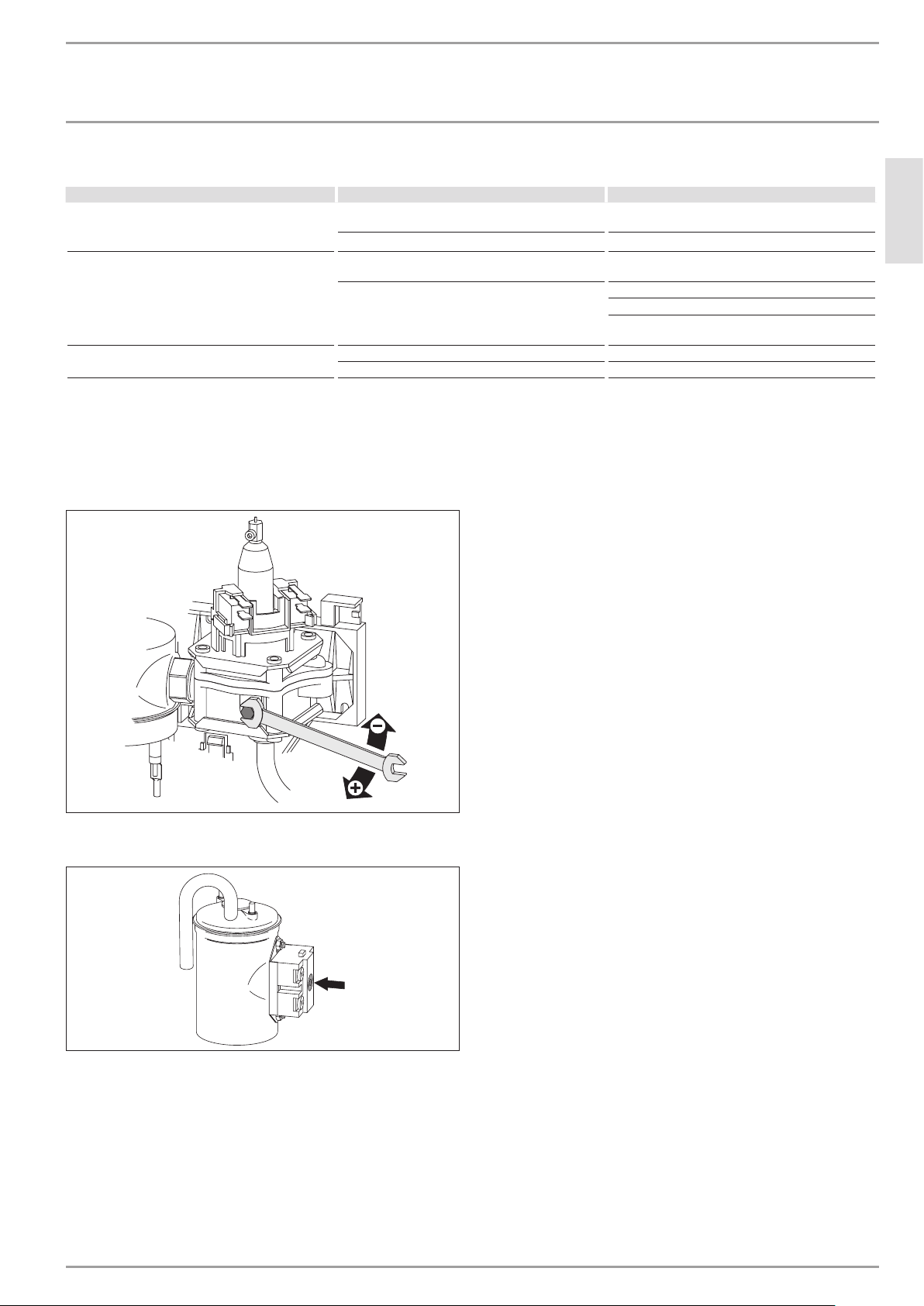

3. Wait twenty seconds until temperature has stabilized. Then

check water temperature. If temperature is too low, the

water flow rate needs to be reduced. In order to do this,

turn off the unit’s circuit breaker, remove the cover and turn

the flow adjustment screw shown in illustration clockwise

1/2 turn (180 degrees). Then reinstall plastic cover, turn

on circuit breaker and check water temperature. This procedure should be repeated until the desired temperature is

achieved. In case the water temperature is too high, turn the

flow adjustment screw counter clockwise in the same manner until the desired temperature is achieved. The arrows in

illustration refer to the water temperature.

4. In order to obtain temperature control at a single spout mix-

er-type faucet, restrict cold water flow to faucet by partially

closing the cold water shut-off valve under the sink until cold

water and hot water flow rates are approximately the same.

8. Normal maintenance

STIEBEL ELTRON DHC tankless heaters are designed for a very long

service life. Actual life expectancy will vary with water quality and

use. The unit itself does not require any regular maintenance.

However, to ensure consistent water flow, it is recommended

to periodically remove scale and dirt that may build up at the

aerator of the faucet or in the shower head. Also, the DHC has

a built in filter screen that should be cleaned from time to time.

In order to do this, turn off the cold water supply at the isolating

valve and remove the ground wire. Twist cold water supply tube

counterclock wise by 90° and pull towards bottom of unit. Clean

screen and put the screen, the cold water supply tube and the

ground wire back into their original position. Please be sure that

the ground wire is reinstalled and that ground screw is securely

tightened after this procedure.

ENGLISH

Note

OTHER THAN THE FILTER SCREEN, THE DHC DOES NOT

CONTAIN ANY PARTS SERVICEABLE BY THE LAY PERSON.

26�02�02�0469

DANGER Electrocution

AS WITH ANY ELECTRIC APPLIANCE, FAILURE TO ELECTRICALLY GROUND UNIT MAY RESULT IN SERIOUS INJURY

OR DEATH.

WWW.STIEBEL-ELTRON.COM DHC | 5

IN CASE OF MALFUNCTION PLEASE CONTACT A LICENSED

PLUMBER OR ELECTRICIAN.

Page 6

INSTALLATION

TECHNICAL DATA

9. Technical Data

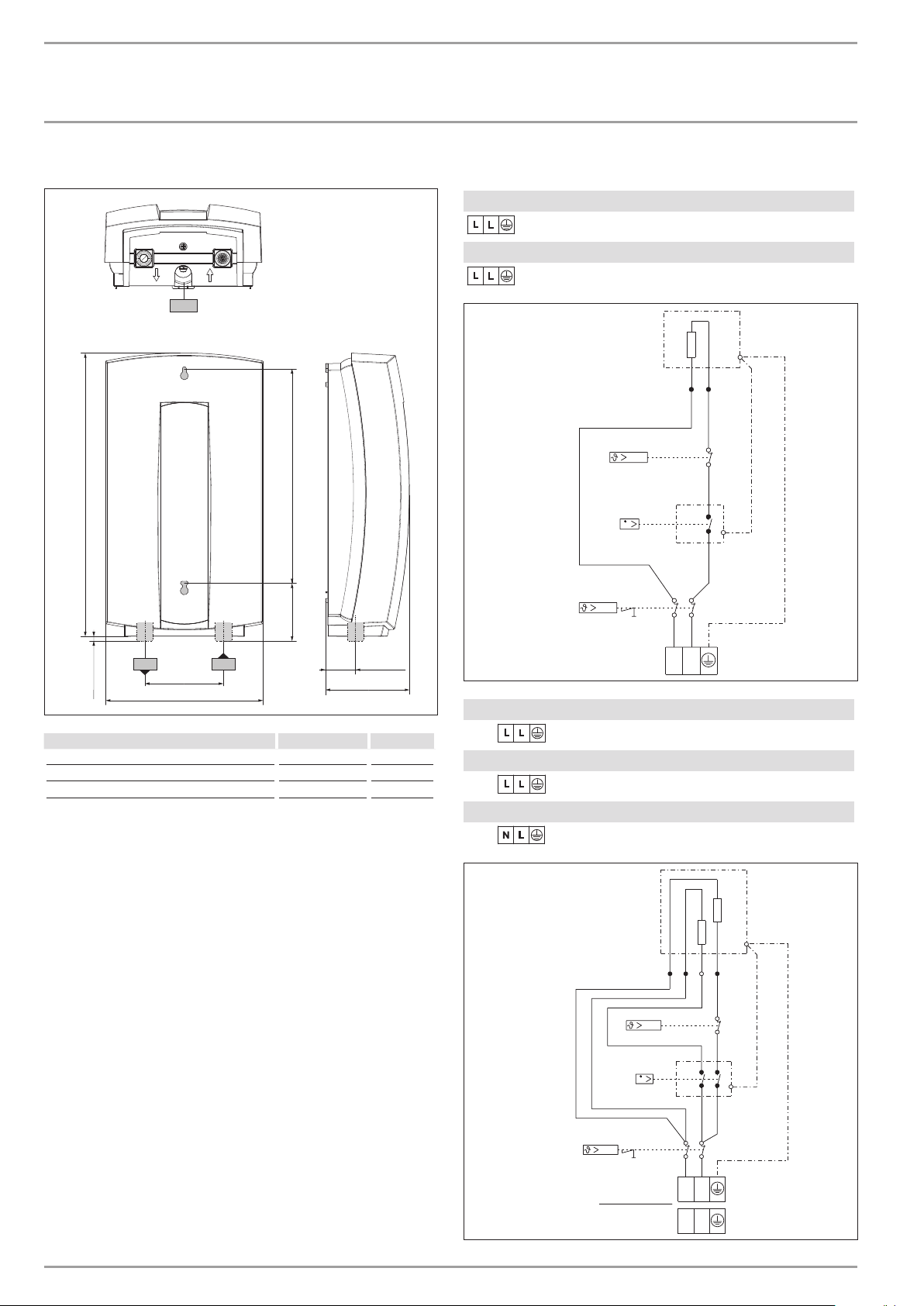

b01

360 (14.17")

9.1 Wiring diagram

DHC 3-2, DHC 4-2, DHC 5-2

2/GRD ~ 208 / 240 V

DHC 4 -3

2/GRD ~ 277 V

273 (10.75")75 (2.953")

V

c06

c06 c01

8 (0.315")

b01 electrical supply cable

c01 cold water connection " NPT 1/2

c06 hot water connection " NPT 1/2

100 (3.94")

200 (7.88")

c01

38 (1.5")

110 (4.33")

D0000021558

DHC 6-2, DHC 8-2, DHC 10-2

A

DHC 9 -3

A

DHC 3-1

B

2/GRD ~ 208 / 240 V

2/GRD ~ 277 V

1/N/GRD ~ 120 V

V

LL

85�02�02�0008

A

B

LL

NL

6 | DHC WWW.STIEBEL-ELTRON.COM

85�02�02�0009

Page 7

INSTALLATION

TECHNICAL DATA

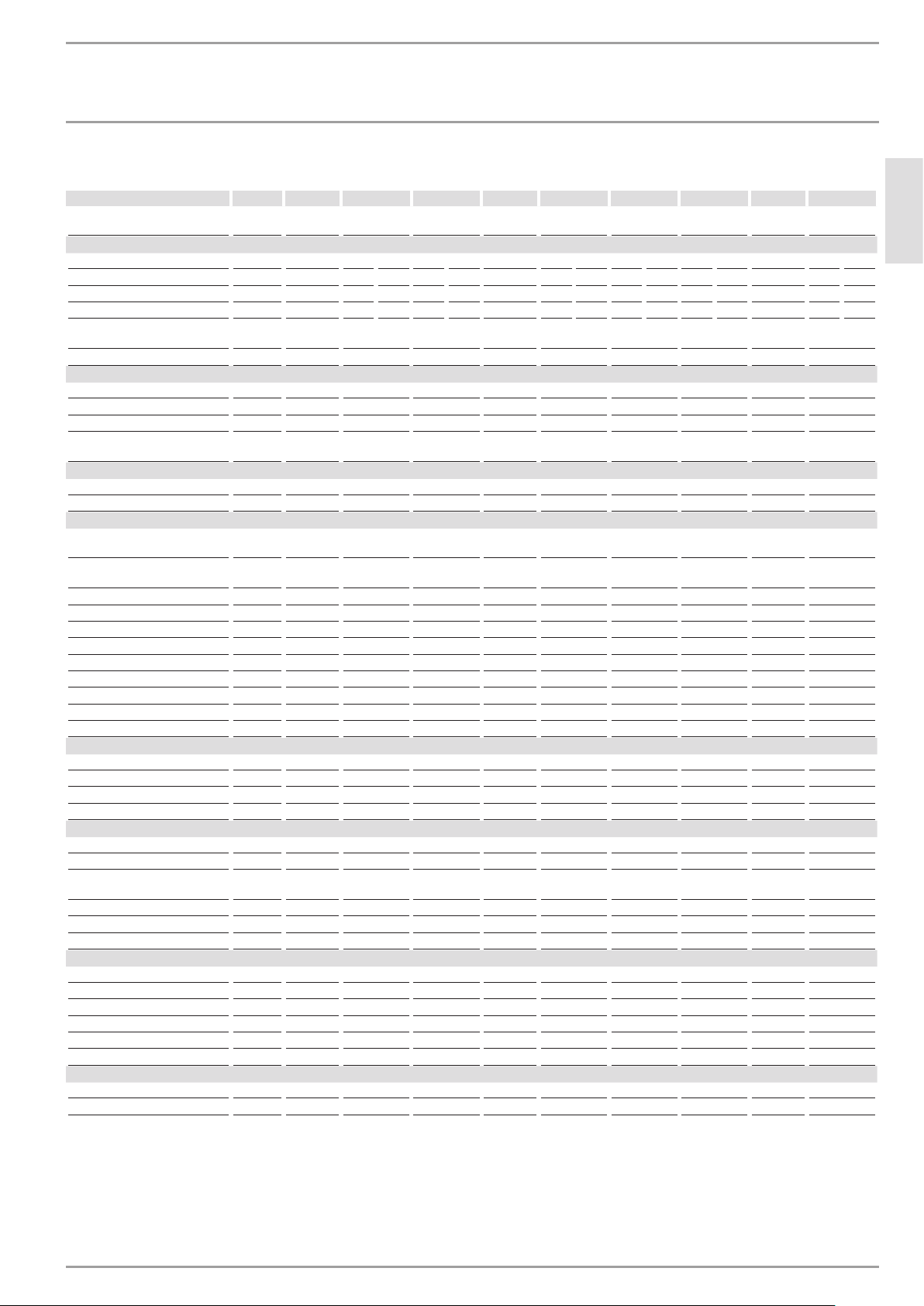

9.2 Data table

DHC 3-1 DHC 3-2 DHC 4-2 DHC 4-3 DHC 5-2 DHC 6-2 DHC 8-2 DHC 9-3 DHC 10-2

074050

Electrical details

Voltage V 120 208 240 208 240 277 208 240 208 240 208 240 277 208 240

Wattage kW 3.0 2.5 3.5 2.9 3.8 4.5 3.6 4.8 4.5 6.0 5.4 7.2 9 7. 2 9.6

Ampere A 25 12 14 14 16 17 18 20 22 25 26 30 32.5 35 40

Min. required circuit breker size A 30 15 20 20 20 20 30 30 30 30 30 40 40 50 50

Required wire size AWG

Copper

Power connection 1/N/GRD 2/GRD 2/GRD 2/GRD 2/GRD 2/GRD 2/GRD 2/GRD 2/GRD

Connections

Water connection 1/2“ NPT 1/2“ NPT 1/2“ NPT 1/2“ NPT 1/2“ NPT 1/2“ NPT 1/2“ NPT 1/2“ NPT 1/2“ NPT

Total alkaline earths mol/m³ 2.5 2.5 2.5 2.5 2.5 2.5 2.5 2.5 2.5

Total hardness (H2O) Degree d 14 14 14 14 14 14 14 14 14

Hardness range 2 (average

Hydraulic data

Rated capacity l 0.5 0.5 0.5 0.5 0.5 0.5 0.5 0.5 0.5

Rated capacity gal 0.13 0.13 0.13 0.13 0.13 0.13 0.13 0.13 0.13

Values

Max. permissible inlet tem-

perature

Max. permissible inlet tem-

perature

ON l/min 1.2 1.2 1.6 1.6 1.6 1.8 2.6 3.0 3.0

ON GPM 0.32 0.32 0.43 0.43 0.43 0.48 0.69 0.8 0.8

Pressure drop at flow rate MPa 0.023 0.023 0.023 0.023 0.023 0.023 0.025 0.03 0.03

Pressure drop at flow rate PSI 2.88 2.88 2.88 2.88 2.88 2.88 3.13 3.75 3.75

Flow rate for pressure drop l/min 1.2 1.2 1.6 1.6 1.6 1.8 2.6 3.0 3.0

Flow rate for pressure drop GPM 0.32 0.32 0.43 0.43 0.43 0.48 0.69 0.8 0.8

DHW delivery l/min 1.2 1.2 1.6 1.6 1.6 1.8 2.6 3.0 3.0

DHW delivery GPM 0.32 0.32 0.43 0.43 0.43 0.48 0.69 0.8 0.8

Δϑ if presented K 36 30 34 40 43 48 30 43 34

Application limits

Max. permissible pressure MPa 1 1 1 1 1 1 1 1 1

Max. permissible pressure PSI 150 150 150 150 150 150 150 150 150

Test pressure MPa 2 2 2 2 2 2 2 2 2

Test pressure PSI 300 300 300 300 300 300 300 300 300

Versions

IP-Rating IP25 IP25 IP25 IP25 IP25 IP25 IP25 IP25 IP25

Material of the pressure vessel Copper Copper Copper Copper Copper Copper Copper Copper Copper

Heating system Tubular

Cap and back panel Plastic Plastic Plastic Plastic Plastic Plastic Plastic Plastic Plastic

Colour white white white white white white white white white

Colour white white white white white white white white white

Dimensions

Height mm 360 360 360 360 360 360 360 360 360

Height in 14.17 14.17 14.17 14.17 14.17 14.17 14.17 14.17 14.17

Width mm 200 200 200 200 200 200 200 200 200

Width in 7.88 7.88 7.88 7.8 8 7.88 7.88 7.88 7.8 8 7.88

Depth mm 100 100 100 100 100 100 100 100 100

Depth in 4.33 4.33 4.33 4.33 4.33 4.33 4.33 4.33 4.33

Weights

Weight kg 2.1 2.1 2.1 2.1 2.1 2.4 2.4 2.4 2.4

Weight lb 4.6 4.6 4.6 4.6 4.6 4.6 4.6 4.6 4.6

234452

10 12 12 12 10 10 8 8 8

hardness)

°C 30 30 30 30 30 30 30 30 30

°F 86 86 86 86 86 86 86 86 86

heater

074052 074053 074051 074054 074424

2 (average

hardness)

Tubular

heater

2 (average

hardness)

Tubular

heater

2 (average

hardness)

Tubular

heater

2 (average

hardness)

Tubular

heater

2 (average

hardness)

234453

Tubular

heater

074055

234454

2 (average

hardness)

Tubular

heater

232204 074056

2 (average

hardness)

Tubular

heater

2 (average

hardness)

234455

Tubular

heater

ENGLISH

- Suitable for supply with cold water

- Tankless water heaters are considered a non-continuous load

- Conductors should be sized to maintain a voltage drop of less

than 3 % under load

WWW.STIEBEL-ELTRON.COM DHC | 7

Page 8

INSTALLATION

TEMPERATURE INCREASE ABOVE AMBIENT WATER TEMPERATURE

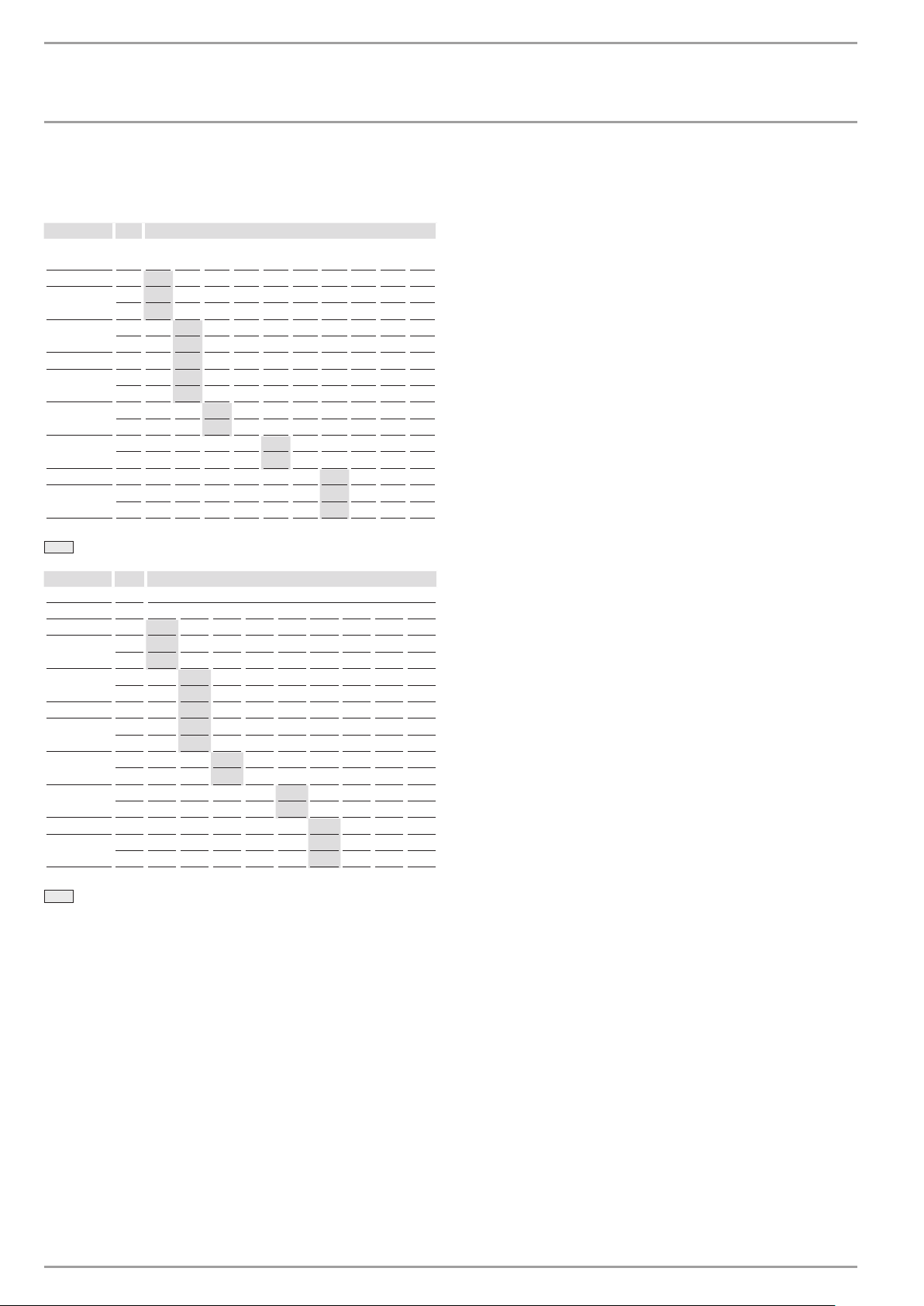

10. Temperature increase above

ambient water temperature

[ °F ]

Typ kW GPM (gallon per minute)

0.32 0.42 0.48 0.5 0.69 0.75 0.79 1.0 1.5 2.0

DHC 3-1 3.0 65 49 43 41 30 27 26 20 14 10

DHC 3-2

3.3 71 53 47 45 33 30 28 22 15 11

DHC 4-2

3.8 – 61 54 52 38 35 33 26 17 13

DHC 4-3 4.5 – 73 64 61 45 41 39 31 20 15

DHC 5-2

4.8 – 77 68 65 48 44 41 33 22 16

DHC 6-2

6.0 – – 85 82 60 55 52 41 27 20

DHC 8-2

7.2 – – – – 71 65 62 49 33 25

DHC 9-3 9.0 - - - - - - 77 58 41 31

DHC 10-2

9.6 – – - – – – 82 65 44 33

2.5 54 40 35 34 25 23 21 17 11 9

2.9 – 47 41 40 29 26 25 20 13 10

3.6 – 58 51 49 36 33 31 25 16 12

4.5 – – 64 61 45 41 39 31 20 15

5.4 – – – – 54 49 46 37 25 18

7.2 – – - – – – 62 49 33 25

Min. water flow to activate unit

[ °C ]

Typ / Type kW l/min

1.2 1.6 1.8 2.0 2.6 3.0 4.0 5.0 7.5

DHC 3-1

DHC 3-2

3.3 39 30 26 24 18 16 12 9 6

DHC 4-2

3.8 – 34 30 27 21 18 14 11 7

DHC 4-3

DHC 5-2

4.8 – 43 38 34 26 23 17 14 9

DHC 6-2

6.0 – – 48 43 33 29 22 17 11

DHC 8-2

7. 2 – – – – 40 34 26 21 14

DHC 9-3 9.0 - - - - - 43 32 26 17

DHC 10-2

9.6 – – – – – 46 34 28 18

3.0 36 27 24 22 17 14 11 9 6

2.5 30 22 20 18 14 12 9 7 5

2.9 – 26 23 21 16 14 10 8 6

4.5 – 40 36 32 25 22 16 13 9

3.6 – 32 29 26 20 17 13 10 7

4.5 – – 36 32 25 22 16 13 9

5.4 – – – – 30 26 19 15 10

7.2 – – – – – 34 26 21 14

Min. water flow to activate unit

8 | DHC WWW.STIEBEL-ELTRON.COM

Page 9

INSTALLATION

TROUBLESHOOTING

11. Troubleshooting

Symptom Possible cause Solution

No hot water but audible click can be heard when

water is turned on

safety thermal cut-out tripped reset thermal cut-out.

No hot water and no audible click can be heard when

water is turned on

clean filter screen at DHC unit (see figure “Spare

Water not warm enough

voltage too low supply correct voltage to unit.

If you are not able to resolve a problem please contact us toll

free at 800-582-8423 before removing the unit from the wall.

STIEBEL ELTRON is happy to provide technical assistance. In most

instances, we can resolve the problem over the phone.

Open flow adjustment screw

circuit breaker off circuit breaker on.

water flow too low to activate flow switch clean faucet aerator.

open shut-off valve completely.

open flow adjustment screw.

parts”).

water flow too high reduce wter flow, close flow agjusment screw.

ENGLISH

Reset button from safety thermal cut out

26�02�02�1358

26�02�02�1357

WWW.STIEBEL-ELTRON.COM DHC | 9

Page 10

INSTALLATION

4

7

1

3

9

12

8

SPARE PARTS

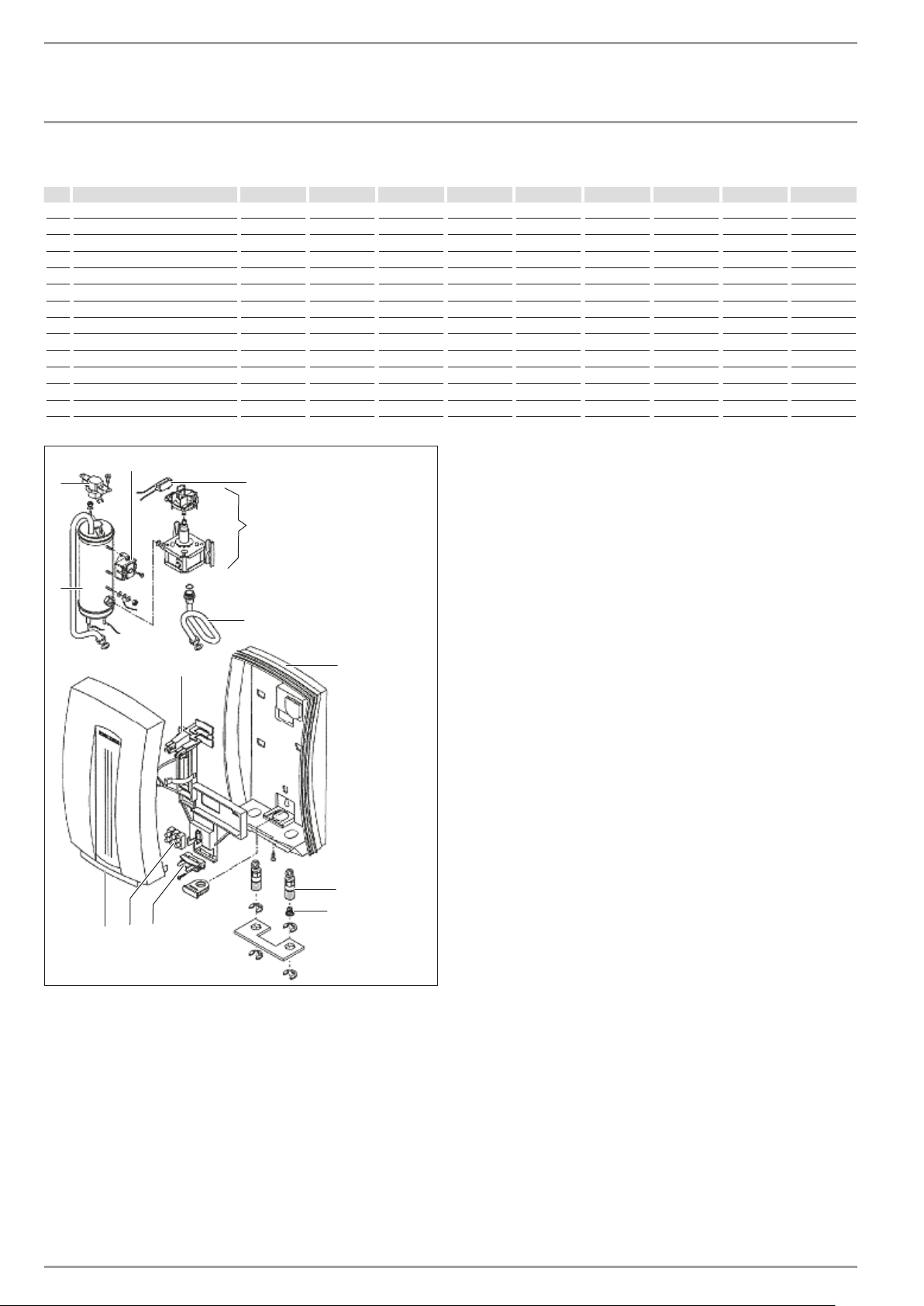

12. Spare parts

No. Spare part DHC 3-1 DHC 3-2 DHC 4-2 DHC 4 -3 DHC 5-2 DHC 6-2 DHC 8-2 DHC 9 -3 DHC 10-2

1 Heating system 165889 167769 167770 165890 167771 171117 167772 296874 167773

2 Flow switch 165273 165273 162162 162162 162162 171105 162164 162465 162165

3 Thermostat 162472 162472 162472 162472 162472 162472 162472 162472 162472

4 Switch 168026 168026 168026 168026 168026 168026 168026 168026 168026

5 Housing (back) 165891 165891 165891 165891 165891 165891 165891 165891 165891

6 Plumbing connection 165893 165893 165893 165893 165893 165893 165893 165893 165893

7 Housing (front) 165892 165892 165892 165892 165892 165892 165892 165892 165892

8 Safety thermal cut out 162474 162474 162474 162474 162474 162474 162474 162474 162474

9 Wiring block 026010 026010 026010 026010 026010 026010 026010 026010 026010

10 Copper tube 162314 162314 162314 162314 162314 162314 162314 162314 162314

11 Module chassis 162462 162462 162462 162462 162462 162462 162462 162462 162462

12 Wire strain relief clamp 055754 055754 055754 055754 055754 055754 055754 055754 055754

13 Filter screen 252430 252430 252430 252430 252430 252430 252430 252430 252430

11

2

10

5

6

13

D0000043978

10 | DHC WWW.STIEBEL-ELTRON.COM

Page 11

WARRANTY | ENVIRONMENT AND RECYCLING

DATE OF PURCHASE. SHOULD THE PART(S) PROVE TO BE DEFECTIVE UNDER NORMAL USE DURING THIS PERIOD, STIEBEL ELTRON,

INC. WILL BE RESPONSIBLE FOR REPLACEMENT OF THE DEFECTIVE PART(S) ONLY. STIEBEL ELTRON, INC. IS NOT RESPONSIBLE FOR

Guarantee

The warranty conditions of our German companies do not

apply to appliances acquired outside of Germany. In countries

where our subsidiaries sell our products, it is increasingly the

case that warranties can only be issued by those subsidiaries.

Such warranties are only granted if the subsidiary has issued

its own terms of warranty. No other warranty will be granted.

We shall not provide any warranty for appliances acquired in

countries where we have no subsidiary to sell our products.

This will not aect warranties issued by any importers.

Environment and recycling

We would ask you to help protect the environment.

dispose of the various materials in accordance with national

regulations.

WARRANTY

RESIDENTIAL & COMMERCIAL WARRANTY: STIEBEL ELTRON WARRANTS TO THE ORIGINAL OWNER THAT THE INSTANTANEOUS

WATER HEATER WILL BE FREE FROM DEFECTS IN WORKMANSHIP AND MATERIALS FOR A PERIOD OF THREE YEARS FROM THE

LABOR CHARGES TO REMOVE AND/OR REPLACE THE DEFECTIVE PART(S), OR ANY INCIDENTIAL OR CONSEQUENTIAL EXPENSES.

SHOULD THE OWNER WISH TO RETURN THE INSTANTANEOUS WATER HEATER FOR REPAIR, THE OWNER MUST FIRST SECURE

WRITTEN AUTHORIZATION FROM STIEBEL ELTRON, INC. THE OWNER SHALL BE REQUIRED TO SHOW PROOF OF PURCHASE DATE,

AND TO PAY ALL TRANSPORTATION COSTS TO RETURN THE DEFECTIVE PART(S) OR INSTANTANEOUS WATER HEATER FOR REPAIR

OR REPLACEMENT. WARRANTY IS VOID IF WATER HEATER HAS BEEN INSTALLED OR USED IMPROPERLY OR IF DESIGN HAS BEEN

ALTERED IN ANY WAY.

STIEBEL ELTRON, INC.

17 West Street

West Hatfield, MA 01088, USA

PHONE: 800-582-8423 or 413-247-3380

FAX: 413-247-3369

E-Mail info@stiebel-eltron-usa.com

www.stiebel-eltron-usa.com

ENGLISH

After use,

WWW.STIEBEL-ELTRON.COM DHC | 11

Page 12

TABLE DES MATIÈRES | UTILISATION

REMARQUES GÉNÉRALES

UTILISATION

1. Remarques générales ������������������������������������� 12

1.1 Informations relatives à la sécurité ������������������������� 12

1.2 Autres repérages utilisés dans ce document �������������� 12

2. Sécurité ����������������������������������������������������� 12

2.1 Utilisation conforme ������������������������������������������� 12

2.2 Informations générales ���������������������������������������� 13

2.3 Précautions de sécurité���������������������������������������� 13

2.4 Label de conformité �������������������������������������������� 13

INSTALLATION

3. Montage de l’appareil ������������������������������������� 14

4. Raccordements d’eau �������������������������������������� 15

5. Raccordement électrique ���������������������������������� 15

6. Mise en œuvre du chauffe-eau �������������������������� 15

7. Maintenance normale ������������������������������������� 16

8. Caractéristiques techniques ������������������������������ 16

8.1 Wiring diagram ������������������������������������������������� 16

8.2 Tableau de données �������������������������������������������� 17

9. Elévation de température au delà de la température

ambiante de l’eau ������������������������������������������ 18

10. Dépannage �������������������������������������������������� 19

11. Pièces de rechange ���������������������������������������� 20

GARANTIE | ENVIRONNEMENT ET RECYCLAGE

1.1.2 Symboles, nature du danger

Symbole Nature du danger

Blessure

!

1.1.3 Mots-clés

MOT- CLÉ Description

DANGER La non-observation de ces informations entraîne des bles-

AVERTISSEMENT La non-observation de ces informations peut entraîner des

ATTENTION La non-observation de ces informations peut entraîner des

Électrocution

Brûlures ou ébouillantements

sures graves, voire la mort.

blessures graves, voire la mort.

blessures moyennement graves ou légères.

1.2 Autres repérages utilisés dans ce document

Remarque

Les remarques sont délimitées par des lignes horizontales

au-dessus et en dessous du texte. Les remarques d’ordre

général sont caractérisées par le symbole représenté ici

à gauche.

Lisez attentivement ces remarques.

UTILISATION

1. Remarques générales

Remarque

Lisez attentivement cette notice avant d‘utiliser l‘appareil

et familiarisez-vous avec ses fonctions. Conservez la notice dans un endroit sûr. Remettez cette notice au nouvel

utilisateur le cas échéant.

1.1 Informations relatives à la sécurité

1.1.1 Structure des consignes de sécurité

MOT-CLÉ Nature du danger

Ici s’affichent les conséquences possibles de la

non-observation des prescriptions de sécurité.

Les mesures permettant d’éviter ces dangers

sont également indiquées.

Symbole

Dommages sur l’appareil et sur l’environnement

!

Ce symbole indique ce que vous devez faire. Ce que vous

devez faire est décrit étape par étape.

Recyclage de l’appareil

2. Sécurité

Respectez les consignes suivantes et les prescriptions de sécurité.

N’utilisez cet appareil que s’il est complètement installé et doté

de tous les dispositifs de sécurité.

2.1 Utilisation conforme

L’appareil est destiné au chauffage de l’eau sanitaire et peut un

point de soutirage.

Toute utilisation dépassant ces spécifications est considérée

comme non conforme.

Le respect de la présente notice faite également partie de l’utilisation conforme de cet appareil.

12 | DHC WWW.STIEBEL-ELTRON.COM

Page 13

UTILISATION

SÉCURITÉ

2.2 Informations générales

L’appareil est destiné à une utilisation domestique. Il peut être

utilisé par des personnes qui ne disposent pas de connaissances

techniques particulières. L’appareil peut également être utilisé

dans un environnement non domestique, p. ex. dans des petites

entreprises, à condition que son utilisation soit du même ordre.

Lisez la notice en sa totalité. La non-observation de toutes les

directives, notices et réglementations peut entraîner des blessures

corporelles et/ou des dégâts matériels. Une installation, un paramétrage, une modification ou une maintenance effectué(e) de

manière incorrecte sur cet appareil peut entraîner des blessures

très importantes.

Cet appareil doit être installé par un installateur agréé. L’installation doit satisfaire à toutes les prescriptions nationales, régionales

et locales. L’installateur est responsable de la réalisation correcte

de l’installation. La non-observation de la notice d’installation et

d’emploi ou toute installation non-conforme invalide la garantie.

Conservez la présente notice pour consultation ultérieure. L’installateur doit remettre cette notice à l’utilisateur.

En cas de questions à propos de l’installation, de l’utilisation et de

l’exploitation de ce préparateur d’eau chaude sanitaire, ou bien

si vous avez besoin de manuels d’installation supplémentaires,

merci de contacter le numéro de téléphone de l’assistance technique (voir la dernière page).

2.3 Précautions de sécurité

DANGER Blessure

!

Lisez et respectez la présente notice.

Le non-observation de cette notice peut entraîner des

blessures très graves, voire la mort.

Dommages sur l’appareil et sur l’environnement

!

L’appareil doit être installé par un installateur agréé.

L’installation doit satisfaire à toutes les prescriptions

nationales, régionales et locales.

La maintenance de l’appareil doit être effectuée par un

installateur qualifié.

DANGER Électrocution

Avant d’effecteur les travaux d’installation, de paramétrage, de modification ou de maintenance sur cet appareil, coupez tous les disjoncteurs et sectionneurs de

l’alimentation électrique de l’appareil. La non-observation de ces consignes peut entraîner des blessures très

graves, voire la mort.

DANGER Électrocution

Ne retirez le capot de l’appareil qu’une fois l’alimentation électrique de l’appareil coupée. La non-observation

de cette consigne peut entraîner des blessures, voire la

mort.

DANGER Électrocution

L’appareil doit être relié correctement à la terre. L’absence de liaison à la terre du produit peut entraîner des

blessures très graves, voire la mort.

DANGER Brûlures

L’eau à des températures supérieures à 52°C (125°F)

peut entraîner des brûlures immédiates graves, voire la

mort par ébouillantement.

AVERTISSEMENT Blessure

!

L’appareil peut être utilisé par les enfants de 8 ans et

plus ainsi que par les personnes aux facultés physiques,

sensorielles ou mentales limitées ou manquant d’expérience et de connaissances, si elles sont supervisées ou

si elles ont reçu les instructions d’usage de l’appareil

et des risques pouvant résulter de son utilisation. Les

enfants ne doivent pas jouer avec l’appareil. Les opérations de maintenance, de nettoyage à effectuer par

l’utilisateur ne doivent pas être réalisées par des enfants

sans surveillance.

2.4 Label de conformité

Voir la plaque signalétique de l’appareil.

Le chauffe-eau DHC sans accumulateur diffère à plusieurs égards

des chauffe-eau conventionnels à ballon d’eau chaude. Il ne

stocke pas d’eau chaude. En fait, l’eau est chauffée instantanément lorsqu’elle passe dans l’appareil. Les puissants éléments

chauffants sont activés par un commutateur de débit lorsque l’eau

est tirée d’un robinet d’eau chaude relié au DHC. Comme il n’y

a pas de perte due à la réserve d’eau, le DHC a une plus grande

efficacité énergétique que les chauffe-eau à accumulation.

La température de l’eau chaude fournie par le DHC dépend de

la puissance de l’élément chauffant, de la température de l’eau

froide d’arrivée et du débit de l’eau à travers l’appareil. Afin que

le DHC fonctionne correctement, il doit répondre exactement à

son application.

Au cas où vous auriez des questions sur la manière dont vous

prévoyez d’utiliser le DHC, n’hésitez pas à appeler notre service

technique au n°800-582-8423 (USA et Canada). Pour le service

après-vente dans les autres pays, appelez nous au n°413-2473380 aux USA, vous pouvez aussi nous envoyer un e-mail à

l’adresse info@stiebel-eltron-usa.com ou nous envoyer un fax

au n°suivant: 413-247-3369.

Le DHC peut être utilisé pour se laver les mains, aux USA et au

Canada:

- Lavabos dans les toilettes de locaux commerciaux / industriels et d’habitations

- Cuisines dans les locaux commerciaux / industriels et les

habitations

- Cabines

- Usages spéciaux dans les magasins de développement de

photos, les laboratoires, etc.

Le DHC peut aussi être utilisé pour des appartements entiers et des

habitations dans des zones à climat chaud comme dans la région

des caraïbes, l’Amérique Centrale et le Mexique en raison des

températures d’eau ambiante plus élevées.

FRANÇAIS

WWW.STIEBEL-ELTRON.COM DHC | 13

Page 14

INSTALLATION

MONTAGE DE L’APPAREIL

INSTALLATION

3. Montage de l’appareil

8

1

1 Boîte de raccordement électrique

2 Conduite d’alimentation en eau pour installation à robinet

3 T de réduction 3/8‘’

4 Vanne de fermeture

5 Tuyau principal ½’’

6 Evier

7 Robinet d’eau (droit)

8 Robinet d’eau (gauche)

7

5. Fixer solidement l’appareil en faisant coulisser les trous de

6

5

4

3

2

26�02�02�0330

montage sur les deux vis préalablement fixées au mur. Les

vis et les chevilles en plastique pour montage sur maçonnerie ou bois sont fournies.

26�02�02�1360

26�02�02�033126�02�02�1355

DANGER Électrocution

L’APPAREIL DOIT ETRE INSTALLE EN POSITION VERTICALE

AVEC LES SORTIES D’EAU DIRIGEES VERS LE BAS. NE

PAS INSTALLER L’APPAREIL A UN ENDROIT OU IL SERAIT

REGULIERE MENT ECLABOUSSE. UN CHOC ELECTRIQUE

POURRAIT EN RESULTER.

1. Installer le DHC aussi près que possible du point de tirage

d’eau chaude, par exemple directement en dessous de

l’évier ou juste à côté de la cabine de douche.

2. Installer le DHC dans une zone non exposée au gel. En cas

de risque de gel, enlever l’appareil avant l’apparition des

températures négatives.

3. Laisser un minimum de 5‘’ d’espace libre sur tous les côtés

pour la maintenance.

4. Enlever le cache en plastique.

14 | DHC WWW.STIEBEL-ELTRON.COM

Page 15

INSTALLATION

RACCORDEMENTS D’EAU

4. Raccordements d’eau

1. Tout le travail de plomberie doit répondre aux normes de

plomberie nationales et locales applicables.

2. Une vanne de réduction de pression doit être installée si

la pression d’alimentation d’eau froide dépasse 150 PSI

(10bar).

3. Assurez-vous que la conduite d’alimentation d’eau froide a

été purgée pour enlever tout dépôt ou saleté.

4. Installer une vanne d’isolation dans la conduite d’eau froide

comme le montre l’illustration. Cela permet à l’appareil

d’être isolé pour des opérations de maintenance.

5. Le raccordement d’eau froide (entrée) est situé du côté droit

de l’appareil, le raccordement d’eau chaude (sortie) est situé

du côté gauche de l’appareil.

Remarque

UNE CHALEUR EXCESSIVE DE SOUDAGE SUR LES TUYAUX

DE CUIVRE A PROXIMITE DU DHC PEUT CAUSER DES DEGATS.

6. Les chauffe-eau sans accumulateur tels que le DHC n’ont pas

besoin d’être équipés d’une vanne de décharge de température et de pression. Si l’inspecteur local n’agrée pas l’installation sans cette vanne, la vanne devra être installée du côté

de la sortie d’eau chaude de l’appareil.

7. Si vous faites un branchement à un tuyau d’eau d’½’’, soudez un adaptateur femelle conique de ½’’ NPT avec du cuivre

aux extrémités des conduites d’eau froide et d’eau chaude.

Si vous faites un branchement à un tuyau d’eau de 3/8‘’, utilisez un tuyau femelle d’1/2‘’ fileté avec un adaptateur de réduction de 3/8‘’. Les raccords flexibles tressés conviendront

également. Connectez les conduites d’eau froide et d’eau

chaude à l’appareil.

8. Lorsque tout le travail de plomberie est terminé, chercher

les fuites et prendre une action corrective avant d’aller plus

loin.

5. Raccordement électrique

DANGER Électrocution

AVANT DE COMMENCER TOUTE OPERATION SUR L’INSTALLATION ELECTRIQUE, S’ASSURER QUE L’INTERRUPTEUR

DU DISJONCTEUR PRINCIPAL EST EN POSITION ”ARRET”

POUR EVITER TOUT RISQUE D’ELECTROCUTION. TOUTES

OPERATIONS DE MONTAGE ET DE PLOMBERIE DOIVENT

ETRE TERMINEES AVANT DE PROCEDER A L’ASSEMBLAGE

ELECTRIQUE. SI LES NORMES ELECTRIQUES LOCALES OU

NATIONALES L’EXIGENT, LE CIRCUIT DOIT ETRE EQUIPE

D’UN ”INTERRUPTEUR DE TERRE”.

1. Toutes les opérations électriques doivent répondre aux

normes électriques nationales et locales applicables.

2. Le DHC doit être relié à un circuit de branchement dédié,

correctement mis à la terre et d’une tension adéquate. Dans

les installations ayant plusieurs DHC, chaque unité a besoin

d’un circuit indépendant. Se référer au tableau de caractéristiques techniques pour la bonne taille des câbles et du

coupe-circuit.

3. Le câble doit être alimenté à travers le joint de caoutchouc

situé entre les branchements de l’eau chaude et de l’eau

froide. Ensuite, faire passer le câble à travers le collier de

serrage et resserrer le collier sur le câble. Les extrémités dénudées des câbles doivent être insérées dans les fentes sur le

bloc terminal marqué N et L (pour le DHC 3-1 seulement) ou L

et L (pour toutes les autres versions). Le conducteur de terre

doit être inséré dans la fente identifiée par le symbole de la

terre.

4. Réinstaller le cache en plastique.

DANGER Électrocution

COMME AVEC N’IMPORTE QUEL APPAREIL ELECTRIQUE,

L’ABSENCE DE MISE A LA TERRE PEUT ENTRAINER LA

MORT

6. Mise en œuvre du chauffe-eau

ATTENTION

!

OUVRIR LE ROBINET D’EAU CHAUDE QUELQUES MINUTES

AVANT QUE LE DEBIT D’EAU SOIT CONTINU ET QUE TOUT

L’AIR SOIT PURGE DES CANALISATIONS D’EAU. LE CACHE

EN PLASTIQUE DE L’APPAREIL DOIT ETRE INSTALLE AVANT

QUE LE DISJONCTEUR SOIT MIS EN POSITION DE MARCHE.

1. Mettre le disjoncteur en position de ”marche” pour amener

l’électricité à l’appareil.

2. Ouvrir le robinet d’eau chaude à un degré tel que l’écoulement d’eau soit ”typique” c’est-à-dire avant que l’écoulement

d’eau soit le même que celui qu’on rencontre en utilisation

normale.

3. Attendre vingt secondes jusqu’à ce que la température soit

stabilisée. Ensuite, vérifier la température de l’eau. Si la

température est trop basse, le débit d’eau doit être réduit.

Pour ce faire, fermer le disjoncteur de l’appareil, enlever le

cache et tourner la vis de réglage de débit, montrée dans

l’illustration, d’un ½ tour (à 180 degrés) dans le sens horaire. Ensuite, réinstaller le cache en plastique, remettre le

disjoncteur en position ”marche” et vérifier la température

de l’eau. Cette procédure doit être répétée jusqu’à ce que la

température désirée soit atteinte. Au cas où la température

de l’eau est trop élevée, tourner de la même manière la vis

de réglage de débit dans le sens anti-horaire jusqu’à ce que

la température désirée soit atteinte. Les flèches dans l’illustration se réfèrent à la température de l’eau.

4. Afin d’obtenir le contrôle de la température sur un robinet

unique de type mitigeur, limiter le débit d’eau froide au robinet en fermant partiellement la vanne de fermeture d’eau

froide sous l’évier jusqu’à ce que les débits d’eau froide et

d’eau chaude soient approximativement les mêmes.

FRANÇAIS

26�02�02�0469

WWW.STIEBEL-ELTRON.COM DHC | 15

Page 16

INSTALLATION

MAINTENANCE NORMALE

7. Maintenance normale

Les chauffe-eau DHC de STIEBEL ELTRON sont conçus pour une très

longue durée de vie. La durée de vie réelle escomptée va varier

avec la qualité et l’utilisation de l’eau. L’appareil lui-même ne

nécessite pas de maintenance régulière. Cependant, pour assurer

un écoulement d’eau homogène, il est recommandé d’enlever

périodiquement les dépôts et saletés qui peuvent se constituer

sur l’évent du robinet ou dans la pomme de douche. Le DHC a

aussi un écran de filtrage intégré qui doit être nettoyé de temps en

temps. Pour ce faire, fermer l’alimentation d’eau froide à la vanne

d’isolation et enlever le conducteur de mise à la terre. Tourner le

tube d’alimentation d’eau froide dans le sens anti-horaire à 90° et

tirer vers le fond de l’appareil. Nettoyer le filtre et remettre dans

leur position d’origine le filtre, le tube d’alimentation d’eau froide

et le conducteur de mise à la terre. S’assurer que le conducteur

de mise à la terre est réinstallé et que la vis de mise à la terre est

bien serrée après cette procédure.

Remarque

MIS A PART LE FILTRE, LE DHC NE CONTIENT AUCUNE

PIECE NECESSITANT UN ENTRETIEN PATICULIER. EN CAS

DE MAUVAIS FONCTIONNEMENT, CONTACTER UN PLOMBIER OU UN ELECTRICIEN PROFESSIONNEL.

8.1 Wiring diagram

DHC 3-2, DHC 4-2, DHC 5-2

2/GRD ~ 208 / 240 V

DHC 4 -3

2/GRD ~ 277 V

V

8. Caractéristiques techniques

b01

360 (14.17")

273 (10.75")75 (2.953")

DHC 6-2, DHC 8-2, DHC 10-2

A

DHC 9 -3

A

DHC 3-1

B

2/GRD ~ 208 / 240 V

2/GRD ~ 277 V

1/N/GRD ~ 120 V

LL

85�02�02�0008

V

c06

c06 c01

8 (0.315")

b01 Câble d’alimentation secteur

c01 Raccord d’eau froide " NPT 1/2

c06 Raccord d’eau chaude sanitaire " NPT 1/2

100 (3.94")

200 (7.88")

c01

38 (1.5")

110 (4.33")

D0000021558

A

B

LL

NL

16 | DHC WWW.STIEBEL-ELTRON.COM

85�02�02�0009

Page 17

INSTALLATION

CARACTÉRISTIQUES TECHNIQUES

8.2 Tableau de données

DHC 3-1 DHC 3-2 DHC 4-2 DHC 4-3 DHC 5-2 DHC 6 -2 DHC 8-2 D HC 9-3 DHC 10-2

074050

Données électriques

Voltage V 120 208 240 208 240 277 208 240 208 240 208 240 277 208 240

Puissance kW 3.0 2.5 3.5 2.9 3.8 4.5 3.6 4.8 4.5 6.0 5.4 7.2 9 7.2 9.6

Intensité A 25 12 14 14 16 17 18 20 22 25 26 30 32.5 35 40

Taille minimale nécessaire du

disjoncteur

Sect. de condcteur recommndée

Copper

Raccord électrique 1/N/GRD 2/GRD 2/GRD 2/GRD 2/GRD 2/GRD 2/GRD 2/GRD 2/GRD

Raccordements

Raccord hydraulique 1/2“ NPT 1/2“ NPT 1/2“ NPT 1/2“ NPT 1/2“ NPT 1/2“ NPT 1/2“ NPT 1/2“ NPT 1/2“ NPT

Total des métaux alcalino-terreux mol/m³ 2.5 2.5 2.5 2.5 2.5 2.5 2.5 2.5 2.5

Dureté de l´eau (H2O) Degré d 14 14 14 14 14 14 14 14 14

Niveau de dureté 2 (dureté

Données hydrauliques

Capacité nominale l 0.5 0.5 0.5 0.5 0.5 0.5 0.5 0.5 0.5

Capacité nominale gal 0.13 0.13 0.13 0.13 0.13 0.13 0.13 0.13 0.13

Valeurs

Température d‘arrivée max. admis-

sible

Température d‘arrivée max. admis-

sible

Marche l/min 1.2 1.2 1.6 1.6 1.6 1.8 2.6 3.0 3.0

Marche GPM 0.32 0.32 0.43 0.43 0.43 0.48 0.69 0.8 0.8

Pertes de charge avec débit volu-

métrique

Pertes de charge avec débit volu-

métrique

Débit volumétrique pour pertes de

pression

Débit volumétrique pour pertes de

pression

Volume eau chaude sanitaire dis-

ponible

Volume eau chaude sanitaire dis-

ponible

Δϑ pour offre K 36 30 34 40 43 48 30 43 34

Limites d‘utilisation

Pression maxi. admissible MPa 1 1 1 1 1 1 1 1 1

Pression maxi. admissible PSI 150 150 150 150 150 150 150 150 150

Pression d‘essai MPa 2 2 2 2 2 2 2 2 2

Pression d‘essai PSI 300 300 300 300 300 300 300 300 300

Fabrication

Indice de protection (IP) IP25 IP25 IP25 IP25 IP25 IP25 IP25 IP25 IP25

Matériau du réservoir à pression cuivre cuivre cuivre cuivre cuivre cuivre cuivre cuivre cuivre

Système de chauffage

Cache et panneau arrière plastique plastique plastique plastique plastique plastique plastique plastique plastique

Couleur blanc blanc blanc blanc blanc blanc blanc blanc blanc

Couleur blanc blanc blanc blanc blanc blanc blanc blanc blanc

Dimensions

Hauteur mm 360 360 360 360 360 360 360 360 360

Hauteur in 14.17 14.17 14.17 14.17 14.17 14.17 14.17 14.17 14.17

Largeur mm 200 200 200 200 200 200 200 200 200

Largeur in 7. 88 7. 88 7.88 7.8 8 7.88 7.88 7.88 7. 88 7.88

Profondeur mm 100 100 100 100 100 100 100 100 100

Profondeur in 4.33 4.33 4.33 4.33 4.33 4.33 4.33 4.33 4.33

Poids

Poids kg 2.1 2.1 2.1 2.1 2.1 2.4 2.4 2.4 2.4

Poids lb 4.6 4.6 4.6 4.6 4.6 4.6 4.6 4.6 4.6

234452

A 30 15 20 20 20 20 30 30 30 30 30 40 40 50 50

AWG

°C 30 30 30 30 30 30 30 30 30

°F 86 86 86 86 86 86 86 86 86

MPa 0.023 0.023 0.023 0.023 0.023 0.023 0.025 0.03 0.03

PSI 2.88 2.88 2.88 2.88 2.88 2.88 3.13 3.75 3.75

l/min 1.2 1.2 1.6 1.6 1.6 1.8 2.6 3.0 3.0

GPM 0.32 0.32 0.43 0.43 0.43 0.48 0.69 0.8 0.8

l/min 1.2 1.2 1.6 1.6 1.6 1.8 2.6 3.0 3.0

GPM 0.32 0.32 0.43 0.43 0.43 0.48 0.69 0.8 0.8

Corps de

10 12 12 12 10 10 8 8 8

moyenne)

chauffe

tubulaire

074052 074053 074051 074054 074424

2 (dureté

moyenne)

Corps de

chauffe tu-

bulaire

2 (dureté

moyenne)

Corps de

chauffe tu-

bulaire

2 (dureté

moyenne)

Corps de

chauffe

tubulaire

2 (dureté

moyenne)

Corps de

chauffe tu-

bulaire

chauffe tu-

234453

2 (dureté

moyenne)

Corps de

bulaire

074055

234454

2 (dureté

moyenne)

Corps de

chauffe tu-

bulaire

232204 074056

2 (dureté

moyenne)

Corps de

chauffe

tubulaire

2 (dureté

moyenne)

Corps de

chauffe tu-

234455

bulaire

FRANÇAIS

- Convenant pour l’alimentation en eau froide

WWW.STIEBEL-ELTRON.COM DHC | 17

Page 18

INSTALLATION

ELÉVATION DE TEMPÉRATURE AU DELÀ DE LA TEMPÉRATURE AMBIANTE DE L’EAU

- Les chauffe-eau sans accumulateur sont considérés comme

charge non continue

- Les conducteurs doivent être calibrés pour maintenir une

chute de tension de moins de 3% sous charge

9. Elévation de température au delà

de la température ambiante de

l’eau

[ °F ]

Typ / Type kW GPM ( galones per minute )

0.32 0.42 0.48 0.5 0.69 0.75 0.79 1.0 1.5 2.0

DHC 3-1 3.0 65 49 43 41 30 27 26 20 14 10

DHC 3-2

3.3 71 53 47 45 33 30 28 22 15 11

DHC 4-2

3.8 – 61 54 52 38 35 33 26 17 13

DHC 4-3 4.5 – 73 64 61 45 41 39 31 20 15

DHC 5-2

4.8 – 77 68 65 48 44 41 33 22 16

DHC 6-2

6.0 – – 85 82 60 55 52 41 27 20

DHC 8-2

7.2 – – – – 71 65 62 49 33 25

DHC 9-3 9.0 - - - - - - 77 58 41 31

DHC 10-2

9.6 – – - – – – 82 65 44 33

2.5 54 40 35 34 25 23 21 17 11 9

2.9 – 47 41 40 29 26 25 20 13 10

3.6 – 58 51 49 36 33 31 25 16 12

4.5 – – 64 61 45 41 39 31 20 15

5.4 – – – – 54 49 46 37 25 18

7.2 – – - – – – 62 49 33 25

Débit d’eau minimum pour activer l’appareil

[ °C ]

Typ / Type kW l/min

1.2 1.6 1.8 2.0 2.6 3.0 4.0 5.0 7.5

DHC 3-1

DHC 3-2

3.3 39 30 26 24 18 16 12 9 6

DHC 4-2

3.8 – 34 30 27 21 18 14 11 7

DHC 4-3

DHC 5-2

4.8 – 43 38 34 26 23 17 14 9

DHC 6-2

6.0 – – 48 43 33 29 22 17 11

DHC 8-2

7. 2 – – – – 40 34 26 21 14

DHC 9-3 9.0 - - - - - 43 32 26 17

DHC 10-2

9.6 – – – – – 46 34 28 18

3.0 36 27 24 22 17 14 11 9 6

2.5 30 22 20 18 14 12 9 7 5

2.9 – 26 23 21 16 14 10 8 6

4.5 – 40 36 32 25 22 16 13 9

3.6 – 32 29 26 20 17 13 10 7

4.5 – – 36 32 25 22 16 13 9

5.4 – – – – 30 26 19 15 10

7.2 – – – – – 34 26 21 14

Débit d’eau minimum pour activer l’appareil

18 | DHC WWW.STIEBEL-ELTRON.COM

Page 19

INSTALLATION

DÉPANNAGE

10. Dépannage

Symptôme Causse possible Solution

Pas d’eau chaude mais on entend un cliquetis quand

l’eau est ouverte

le disjoncteur de sécurité s’est déclenché réarmer le disjoncteur.

Pas d’eau chaude et on n’entend pas de cliquetis

quand l’eau est ouverte

nettoyer le filtre sur l’appareil DHC.

L’eau n’est pas assez chaude

tension trop basse fournir la tension correcte à l’appareil.

Si vous n’arrivez pas à résoudre un problème, contacter nous en

appelant le numéro gratuit 800-582-8423 avant d’enlever l’appareil du mur. STIEBEL ELTRON est heureuse de vous fournir son

assistance technique. Dans la plupart des cas, il s’agit d’un problème que nous pouvons résoudre par téléphone.

Réglage du débit

disjoncteur fermé mettre le disjoncteur en marche.

l’écoulement d’eau est trop bas pour activer le commutateur de débit

écoulement d’eau trop haut réduire l’écoulement d’eau, fermer la vis de réglage

nettoyer l’évent du robinet.

ouvrir complètement la vanne de fermeture.

ouvrir la vis de réglage de débit.

de l’écoulement.

FRANÇAIS

Bouton de réarmement du disjoncteur de sécurité

26�02�02�1358

26�02�02�1357

WWW.STIEBEL-ELTRON.COM DHC | 19

Page 20

INSTALLATION

4

7

1

3

9

12

8

PIÈCES DE RECHANGE

11. Pièces de rechange

N° de pièce de rechange DHC 3-1 D HC 3-2 DHC 4-2 DH C 4-3 DHC 5-2 DHC 6-2 D HC 8-2 DHC 9-3 DHC 10-2

1 Système de chauffage 165889 167769 167770 165890 167771 171117 167772 296874 167773

2 Commutateur de débit 165273 165273 162162 162162 162162 171105 162164 162465 162165

3 Thermostat 162472 162472 162472 162472 162472 162472 162472 162472 162472

4 Commutateur 168026 168026 168026 168026 168026 168026 168026 168026 168026

5 Carter (arrière) 165891 165891 165891 165891 165891 165891 165891 165891 165891

6 Branchement de plomberie 165893 165893 165893 165893 165893 165893 165893 165893 165893

7 Carter (avant) 165892 165892 165892 165892 165892 165892 165892 165892 165892

8 Disjoncteur thermique de sécurité 162474 162474 162474 162474 162474 162474 162474 162474 162474

9 Bloc de câblage 026010 026010 026010 026010 026010 026010 026010 026010 026010

10 Tube de cuivre 162314 162314 162314 162314 162314 162314 162314 162314 162314

11 Châssis du module 162462 162462 162462 162462 162462 162462 162462 162462 162462

12 Collier de serrage 055754 055754 055754 055754 055754 055754 055754 055754 055754

13 Filtre 252430 252430 252430 252430 252430 252430 252430 252430 252430

11

2

10

5

6

13

D0000043978

20 | DHC WWW.STIEBEL-ELTRON.COM

Page 21

GARANTIE | ENVIRONNEMENT ET RECYCLAGE

Eltron, Inc. n’est responsable que du remplacement de la ou des pièces défectueuses. STIEBEL ELTRON, INC. n’est pas responsable

Si le propriétaire souhaite renvoyer le chauffe-eau instantané électrique pour réparation, il doit d’abord obtenir l’autorisation écrite

de Stiebel Eltron, Inc. Le propriétaire sera tenu de produire la preuve de la date d’achat et de supporter tous les frais de transport

La garantie ne couvre pas les installations ou utilisations incorrectes du chauffe-eau ni les modifications de conception éventuelles.

GARANTIE

Garantie applicable aux utilisateurs privés et commerciaux: STIEBEL ELTRON garantit au propriétaire initial que le chauffe-eau

instantané électrique TEMPRA est exempt de défauts de fabrication et de matériaux pendant une période de trois ans à compter

de la date d’achat. En cas de défaut avéré d’une ou plusieurs pièces lors d’une utilisation normale durant cette période, Stiebel

des frais de main-d’œuvre découlant de la dépose et/ou du remplacement de la ou des pièces défectueuses ni des éventuels

frais accessoires ou indirects.

inhérents au renvoi de la ou des pièces défectueuses ou du chauffe-eau instantané électrique pour réparation ou remplacement.

STIEBEL ELTRON, INC.

17 West Street

West Hatfield, MA 01088, USA

PHONE: 800-582-8423 or 413-247-3380

FAX: 413-247-3369

E-Mail info@stiebel-eltron-usa.com

www.stiebel-eltron-usa.com

-

FRANÇAIS

WWW.STIEBEL-ELTRON.COM DHC | 21

Page 22

ÍNDICE|OPERACIÓN

INDICACIONES GENERALES

OPERACIÓN

1. Indicaciones generales ������������������������������������ 22

1.1 Indicaciones para el cableado: �������������������������������22

1.2 Otras marcas presentes en este documento �������������� 22

2. Seguridad ��������������������������������������������������� 22

2.1 Uso previsto ������������������������������������������������������ 22

2.2 Información general ������������������������������������������� 22

2.3 Medidas de seguridad ����������������������������������������� 23

2.4 Sello de certificación ������������������������������������������� 23

3. General ������������������������������������������������������ 23

INSTALACIÓN

4. Instalación física ������������������������������������������� 24

5. Conexión de agua ������������������������������������������ 25

6. Conexión ���������������������������������������������������� 25

7. Operacion de la unidad ������������������������������������ 25

8. Mantenimiento ��������������������������������������������� 26

9. Datos técnicos ���������������������������������������������� 26

9.1 Diagrama eléctrico ��������������������������������������������� 26

9.2 Tabla de especificaciones ������������������������������������� 27

10. Aumento de temperatura del agua ���������������������� 28

11. Resolución de incidencias (troubleshooting) ������������ 28

12. Repuestos ��������������������������������������������������� 29

1.1.2 Símbolos, tipo de peligro

Símbolo Tipo de peligro

Lesión

!

1.1.3 Palabras clave

PALABRA CLAVE Descripción

PELIGRO El desobedecimiento de esta información conlleva

ADVERTENCIA El desobedecimiento de esta información puede con-

ATENCIÓN El desobedecimiento de esta información puede con-

Electrocución

Quemadura o escaldamiento

graves lesiones o la muerte

llevar graves lesiones o la muerte

llevar lesiones de mediana gravedad o lesiones leves

1.2 Otras marcas presentes en este documento

Indicación

La indicación está limitada por líneas horizontales sobre

y bajo el texto. La información general se señaliza mediante el símbolo que se muestra a la izquierda.

Lea atentamente las indicaciones.

GARANTÍA | | MEDIO AMBIENTE Y RECICLADO

OPERACIÓN

1. Indicaciones generales

Indicación

Lea atentamente estas instrucciones antes de utilizar el

aparato y familiarícese con sus funciones. Conserve este

manual en un lugar seguro. Si entregara este aparato a

otros usuarios no olvide incluir el manual.

1.1 Indicaciones para el cableado:

1.1.1 Estructura de las indicaciones de seguridad

ADVERTENCIA de tipo de peligro

Aquí aparecen las posibles consecuencias del desobedecimiento de las indicaciones de seguridad.

Se indican las medidas necesarias para evitar

estos peligros.

Símbolo

Daños en el aparato y al medio ambiente

!

Este símbolo indica que debe usted hacer algo. Lo que debe

hacer se describe en pasos individuales.

Eliminación del aparato

2. Seguridad

Observe las siguientes indicaciones y normas de seguridad.

El equipo sólo debe utilizarse después de haber sido instalado

completamente y con todos los dispositivos de seguridad.

2.1 Uso previsto

El aparato está previsto para el calentamiento del agua potable y

puede abastecer una punto de extracción.

El uso fuera de las especificaciones descritas se considera indebido.

Además, el obedecimiento de las presentes instrucciones forma

parte del uso previsto de este aparato.

22 | DHC WWW.STIEBEL-ELTRON.COM

Page 23

OPERACIÓN

GENERAL

2.2 Información general

El aparato está previsto para utilizarse en un ámbito doméstico.

Personas no instruidas lo pueden manejar de forma segura. El

aparato puede utilizarse igualmente en ámbitos que no sean domésticos, como en pequeñas empresas, siempre que se maneje

del mismo modo.

Lea el manual íntegramente. El desobedecimiento de las normas,

instrucciones y reglamentos puede causar lesiones físicas a personas y/o daños materiales. La instalación, ajuste, modificación y

mantenimiento incorrectos del presente aparato puede conducir

a lesiones físicas considerables.

Este aparato debe ser instalado por un técnico autorizado. La instalación debe cumplir toda la normativa nacional, regional y local.

El técnico especializado es responsable de la correcta instalación.

El desobedecimiento de las instrucciones de instalación y operación o el uso indebido conducen a la anulación de la garantía.

Guarde el presente manual para futuras consultas. El técnico especializado debe entregar este manual al usuario.

En caso de cualquier consulta relativa a la instalación, uso u operación del presente calentador o, si fuera preciso en relación a

cualquier otro manual de instalación, diríjase al teléfono de servicio técnico (véase última página).

2.3 Medidas de seguridad

PELIGRO de lesiones

!

Lea y obedezca las siguientes instrucciones.

El desobedecimiento de esta información puede conllevar graves lesiones o la muerte.

Daños en el aparato y al medio ambiente

!

Este aparato debe ser instalado por un técnico autorizado. La instalación debe cumplir toda la normativa nacional, regional y local.

El mantenimiento del aparato debe ser realizado por técnicos autorizados.

PELIGRO Electrocución

Antes de llevar a cabo cualquier tarea de instalación,

ajuste, modificación o mantenimiento de este aparato

deben desconectarse todos los interruptores de potencia

y seccionadores de alimentación eléctrica del aparato. El

desobedecimiento de estas indicaciones puede conllevar

graves lesiones o la muerte.

PELIGRO Quemaduras

Las temperaturas del agua que superen los 125 °F (52 °C)

pueden causar quemaduras graves repentinas o incluso

la muerte por escaldamiento.

ADVERTENCIA Lesiones

!

El aparato puede ser utilizado por niños a partir de 8

años, así como personas con capacidades físicas, sensoriales o mentales limitadas, o con falta de experiencia y

conocimientos, solo bajo la vigilancia de otra persona o

si antes han recibido instrucciones sobre el uso seguro

del aparato y han comprendido los peligros que pueden

derivarse. No deje que los niños jueguen con el aparato. Las tareas de limpieza y mantenimiento propias del

usuario no deben ser realizadas por niños sin vigilancia.

2.4 Sello de certificación

Consulte la placa de especificaciones del aparato.

3. General

Los calentadores de agua DHC difieren de los calentadores de tanque en muchas maneras. Este calentador no almacena agua caliente. Al contario, calienta el agua instantáneamente cuando esta

fluye a través de la unidad. El poderoso elemento que calienta,

es activado solamente cuando se abre una llave de agua caliente

la cual esta conectada al sistema alimentado por el calentador.

Usos

Los calentadores eléctricos DHC son ideales para el uso en casas,

apartamentos o cabañas en áreas de un clima subtropical y tropical como el Caribe, muchas partes de México, Centro América

y América del Sur.

Los modelos DHC ocupan muy poco espacio, son fáciles de instalar

y proveen agua caliente continua y sin limite. Se pueden usar con

sistemas eléctricos bien sea de 60 Hz o de 50 Hz.

La unidad se activa solo cuando hay demanda para agua caliente,

evitando así, consumo y gasto innecesario de energía eléctrica

y de agua.

Los importantes ahorros en el consumo de electricidad que ofrecen los modelos DHC pueden llegar hasta un 50 % cuando se comparan con el consumo de los calentadores eléctricos tipo ”tanque”.

ESPAÑOL

PELIGRO Electrocución

Sólo podrá retirar la cubierta del aparato si se ha interrumpido la alimentación eléctrica del aparato. El desobedecimiento de estas indicaciones puede conllevar

lesiones físicas o la muerte.

PELIGRO Electrocución

El aparato debe conectarse a tierra adecuadamente. Si

no se conecta a tierra el producto pueden producirse

graves lesiones físicas o incluso la muerte.

WWW.STIEBEL-ELTRON.COM DHC | 23

Page 24

INSTALACIÓN

INSTALACIÓN FÍSICA

INSTALACIÓN

4. Instalación física

8

1

1 caja eléctrica

2 linea de agua

3 entrada a válvula T-3/8”

4 válvula de servicio

5 reducido a ½”

6 lavamanos

7 válvula de agua fría

8 válvula de agua caliente

7

5. Conexión de agua de suplido (entrada) es al lado derecho de

6

5

4

3

2

26�02�02�0330

la unidad. La conexión de agua caliente (salida) debe ser al

lado izquierdo de la unidad.

26�02�02�1360

26�02�02�033126�02�02�1355

PELIGRO Electrocución

LA UNIDAD DEBE INSTALARSE EN POSICIÓN VERTICAL

CON LAS CONEXIÓNES DE AGUA EN LA PARTE DE ABAJO.

NO INSTALE LA UNIDAD DONDE PUEDA MOJARSE, ESTO

PODRÍA OCASIONAR UNA DESCARGA ELÉCTRICA.

1. Todo trabajo de plomería debe cumplir con los códigos de

plomería. Nacional y/o Local.

2. Una válvula reductora de presión debe ser instalada si la

línea de suplido de agua exede una presión de 150 PSI.

3. Asegúrese de dejar correr el agua por la línea de suplido

antes de cualquier conexión para eliminar cualquier depósito

o sucio en la mísma.

4. Instalar válvula de servicio en línea de suplido de agua . Esto

permite aislar la unidad para propósitos de mantenimiento.

24 | DHC WWW.STIEBEL-ELTRON.COM

Page 25

INSTALACIÓN

CONEXIÓN DE AGUA

5. Conexión de agua

1. Todo trabajo de plomería debe cumplir con los códigos de

plomería. Nacional y/o Local.

2. Una válvula reductora de presión debe ser instalada si la

línea de suplido de agua exede una presión de 150 PSI.

3. Asegúrese de dejar correr el agua por la línea de suplido

antes de cualquier conexión para eliminar cualquier depósito

o sucio en la mísma.

4. Instalar válvula de servicio en línea de suplido de agua. Esto

permite aislar la unidad para propósitos de mantenimiento.

5. Conexión de agua de suplido (entrada) es al lado derecho de

la unidad. La conexión de agua caliente (salida) debe ser al

lado izquierdo de la unidad.

Nota

CALOR EXESIVO DE LAS SOLDADURAS EN LAS LINEAS DE

COBRE PUEDE CAUSAR DAÑOS AL CALENTADOR.

6. El calentador de agua DHC no requiere una válvula de alivio

por presión y temperarura (PTRV). Si el inspector la requiere

se debe instalarla después de la salida de agua caliente de la

unidad.

7. Conectar uniones de ½ (media) pulgada NPT a sus respectivas líneas de agua fría o caliente. Proveer reductores cuando

estos sean necesarios sin el código de plomería Nacional y/o

Local.

8. Cuando finalice el trabajo de plomería verifique si hay goteos

y corrija estos antes de proceder.

6. Conexión

PELIGRO Electrocución

ANTES DE COMENZAR LA INSTALACION ELECTRICA ASEGURESE DE QUE EL INTERRUPTOR TERMOMAGNETICO

PRINCIPAL DEL PANEL ELECTRICO ESTE APAGADO PARA

EVITAR POSIBLE DESCARGA ELECTRICA.

NOTA: TODA INSTALACION ELECTRICA Y DE PLOMERIA

DEBE COMPLETARSE ANTES DE ENCENDER EL INTERRUPTOR TERMOMAGNETICO PRINCIPAL. EL CIRCUITO DEBE

SER EQUIPADO CON UN INTERRUPTOR DE CONEXIÓN A

TIERRA („GROUND FAULT INTERRUPTER“) CUANDO SEA

REQUERIDO POR EL CODIGO ELECTRICO NACIONAL Y/O

LOCAL.

1. Todo trabajo eléctrico debe cumplir con las dispociciones

del Colegio de Peritos Electricistas y Códigos Nacionales y/o

Locales.

2. La unidad DHC debe tener su circuito independiente utilizando tres alambres de cobre de tamaño apropiado y protegido

por un interruptor termomagnético (breaker) correctamente

seleccionado. Para instalar varias unidades DHC se requiere

un circuito independiente para cada una.

3. La cableria debe entrar a la unidad a través del sello de

goma localizado en la parte inferior de la mísma entre las

conexiónes de agua fría y caliente. Alimente los cables a través de la abrazadera localizada dentro de la unidad y ajuste

esta firmemente contra los cables. Los cables vivos deben

ser conectados en los terminales N y L para los modelos

DHC3-1. El DHC 3-2 y en todos los demás modelos los cables

vivos deben ser conectadas en los terminales L y L (Favor ver

diagramas eléctrico).

4. Reinstalar cubierta plástica. El cable de conexión a tierra

„ground“ debe ser conectado al terminal marcado con el

simbolo de tierra.

PELIGRO Electrocución

COMO CUALQUIER OTRO APARATO ELECTRICO EL NO CONECTARLO A TIERRA PUEDE RESULTAR EN UNA DESCARGA ELECTRICA, GRAVE LESION Y/O INCLUSO OCASIONAR

MUERTE.

7. Operacion de la unidad

ADVERTENCIA

!

ABRA LA LLAVE DE AGUA CALIENTE POR VARIOS MINUTOS HASTA QUE EL FLUJO DE AGUA SEA CONTINUO Y

TODO EL AIRE HAYA SALIDO DE LA TUBERIA.

LA COBERTURA PLASTICA DE LA UNIDAD DEBE SER INSTALADA ANTES DE ENCENDER EL „BREAKER“ DEL CIRCUITO.

1. Encender el „breaker“ del circuito para proveer corriente a la

unidad. Abrir la llave de agua caliente a un punto típico, o

sea, hasta que el flujo de agua sea igual al de uso normal.

Espere 60 segundos hasta que la temperatura se estabilize.

2. Probar temperatura del agua, si la temperatura es muy baja,

el flujo de agua debe ser reducido. Para reducir el flujo apague el „ „breaker“ de circuito, remueva cobertura plástica

y dele media vuelta (180 grados) en dirección manecillas del

reloj („clockwise“) al tornillo de ajuste de flujo.

3. Reinstale cobertura plástica, encienda el „breaker“ y verifique la temperatura del agua nuevamente. Este procedimiento debe repetirse hasta que se obtenga la temperatura

de agua deseada. Por lo contrario, si la temperatura de

agua es muy alta ajuste el tornillo de flujo, en contra de las

manecillas del reloj (counterclockwise) de la misma manera

hasta obtener la temperatura deseada.

4. Para obtener control de temperatura con una llave tipo

mezcladora, restrinja el flujo de agua fría a la mezcladora

cerrando parcialmente la llave de paso de dicha mezcladora

hasta tanto el flujo de agua fría y caliente sean aproximadamente iguales.

26�02�02�0469

ESPAÑOL

WWW.STIEBEL-ELTRON.COM DHC | 25

Page 26

INSTALACIÓN

MANTENIMIENTO

8. Mantenimiento

Los calentadores de agua Stiebel Eltron DHC estan diseñados para

una larga y duradera vida de servicio. La vida util del equipo

depende de la calidad de agua y del uso. La unidad, de por

si, no requiere de ningún tipo de mantenimiento. Sin embargo,

para asegurar el flujo de agua se recomienda que se remuevan

los depósitos que puedan acumularse en el filtro („aerator“) del

lavamanos o en las duchas.

Nota

EN CASO DE MAL FUNCIONMENTO DEL EQUIPO FAVOR

SOLICITAR LOS SERVICIOS DE UN PLOMERO O ELECTRICISTA CERTIFICADO. POR FAVOR NO INTENTE REPARARLO

USTED MISMO.

9. Datos técnicos

b01

9.1 Diagrama eléctrico

DHC 3-2, DHC 4-2, DHC 5-2

2/GRD ~ 208 / 240 V

DHC 4 -3

2/GRD ~ 277 V

V

360 (14.17")

c06

c06 c01

8 (0.315")

b01 Cable de alimentación

c01 Conexión de agua fría " NPT 1/2

c06 Conexión de agua caliente " NPT 1/2

100 (3.94")

200 (7.88")

c01

273 (10.75")75 (2.953")

38 (1.5")

110 (4.33")

DHC 6-2, DHC 8-2, DHC 10-2

A

DHC 9 -3

A

DHC 3-1

B

D0000021558

2/GRD ~ 208 / 240 V

2/GRD ~ 277 V

1/N/GRD ~ 120 V

V

LL

85�02�02�0008

A

B

LL

NL

26 | DHC WWW.STIEBEL-ELTRON.COM

85�02�02�0009

Page 27

INSTALACIÓN

DATOS TÉCNICOS

9.2 Tabla de especificaciones

DHC 3-1 DHC 3-2 DHC 4-2 DH C 4 -3 DHC 5-2 DHC 6-2 DHC 8-2 DHC 9-3 DHC 10-2

074050

Especificaciones eléctricas

Voltaje V 120 208 240 208 240 277 208 240 208 240 208 240 277 208 240

Potencia de funcionamiento kW 3.0 2.5 3.5 2.9 3.8 4.5 3.6 4.8 4.5 6.0 5.4 7.2 9 7.2 9.6

Corriente nominal AMPS A 25 12 14 14 16 17 18 20 22 25 26 30 32.5 35 40

Tamaño Mínimo Requerido del

Interruptor Auto. „Breaker“

Tamaño de cable requerido AWG

Conexionado eléctrico 1/N/GRD 2/GRD 2/GRD 2/GRD 2/GRD 2/GRD 2/GRD 2/GRD 2/GRD

Conexiones

Conexión para agua 1/2“ NPT 1/2“ NPT 1/2“ NPT 1/2“ NPT 1/2“ NPT 1/2“ NPT 1/2“ NPT 1/2“ NPT 1/2“ NPT

Cantidad total de alcalinoté-

rreos

Dureza general (H2O) Grado d 14 14 14 14 14 14 14 14 14

Rango de dureza

Datos del sistema hidráulico

Contenido nominal l 0.5 0.5 0.5 0.5 0.5 0.5 0.5 0.5 0.5

Contenido nominal gal 0.13 0.13 0.13 0.13 0.13 0.13 0.13 0.13 0.13

Valores

Temperatura de admisión

máxima admisible

Temperatura de admisión

máxima admisible

Encendido (ON) l/min 1.2 1.2 1.6 1.6 1.6 1.8 2.6 3.0 3.0

Encendido (ON) GPM 0.32 0.32 0.43 0.43 0.43 0.48 0.69 0.8 0.8

Pérdida de carga para caudal

volumétrico

Pérdida de carga para caudal

volumétrico

Caudal para pérdida de presión l/min 1.2 1.2 1.6 1.6 1.6 1.8 2.6 3.0 3.0

Caudal para pérdida de presión GPM 0.32 0.32 0.43 0.43 0.43 0.48 0.69 0.8 0.8

Representación del ACS l/min 1.2 1.2 1.6 1.6 1.6 1.8 2.6 3.0 3.0

Representación del ACS GPM 0.32 0.32 0.43 0.43 0.43 0.48 0.69 0.8 0.8

Δϑ en representación K 36 30 34 40 43 48 30 43 34

Límites de utilización

Presión máxima admisible MPa 1 1 1 1 1 1 1 1 1

Presión máxima admisible PSI 150 150 150 150 150 150 150 150 150

Presión de prueba MPa 2 2 2 2 2 2 2 2 2

Presión de prueba PSI 300 300 300 300 300 300 300 300 300

Modelos

Tipo de protección (IP) IP25 IP25 IP25 IP25 IP25 IP25 IP25 IP25 IP25

Material del depósito a presión Cobre Cobre Cobre Cobre Cobre Cobre Cobre Cobre Cobre

Sistema de calefacción Radiador

Cubierta y pared trasera Plástico Plástico Plástico Plástico Plástico Plástico Plástico Plástico Plástico

Color blanco blanco blanco blanco blanco blanco blanco blanco blanco

Color blanco blanco blanco blanco blanco blanco blanco blanco blanco

Dimensiones

Altura mm 360 360 360 360 360 360 360 360 360

Altura pulg 14.17 14.17 14.17 14.17 14.17 14.17 14.17 14.17 14.17

Anchura mm 200 200 200 200 200 200 200 200 200

Anchura pulg 7.88 7.88 7. 88 7.88 7.88 7.88 7.8 8 7. 88 7. 88

Profundidad mm 100 100 100 100 100 100 100 100 100

Profundidad pulg 4.33 4.33 4.33 4.33 4.33 4.33 4.33 4.33 4.33

Pesos

Peso kg 2.1 2.1 2.1 2.1 2.1 2.4 2.4 2.4 2.4

Peso lb 4.33 4.6 4.6 4.6 4.6 4.6 4.6 4.6 4.6

Copper

mol/m³ 2.5 2.5 2.5 2.5 2.5 2.5 2.5 2.5 2.5

MPa 0.023 0.023 0.023 0.023 0.023 0.023 0.025 0.03 0.03

234452

A 30 15 20 20 20 20 30 30 30 30 30 40 40 50 50

10 12 12 12 10 10 8 8 8

2 (mode-

radamente

dura)

°C 30 30 30 30 30 30 30 30 30

°F 86 86 86 86 86 86 86 86 86

PSI 2.88 2.88 2.88 2.88 2.88 2.88 3.13 3.75 3.75

de tubos

074052 074053 074051 074054 074424

2 (mode-

radamente

dura)

Radiador de

tubos

2 (mode-

radamente

dura)

Radiador de

tubos

2 (mode-

radamente

dura)

Radiador

de tubos

2 (mode-

radamente

dura)

Radiador de

tubos

234453

2 (mode-

radamente

dura)

Radiador de

tubos

074055

234454

2 (mode-

radamente

dura)

Radiador de

tubos

232204 074056

2 (mode-

radamente

Radiador

de tubos

radamente

dura)

Radiador de

234455

2 (mode-

dura)

tubos

ESPAÑOL

- Apropiado para el suministro de agua fría

- Calentador instantáneo no admisible para el funcionamiento

constante

- Los cables deben dimensionarse de forma que sean capaces

de mantener un descenso de tensión de menos del 3% bajo

carga.

WWW.STIEBEL-ELTRON.COM DHC | 27

Page 28

INSTALACIÓN

AUMENTO DE TEMPERATURA DEL AGUA

10. Aumento de temperatura del agua

°F

Typ / Type kW GPM (galones por minuto)

0.32 0.42 0.48 0.5 0.69 0.75 0.79 1.0 1.5 2.0

DHC 3-1 3.0 65 49 43 41 30 27 26 20 14 10

DHC 3-2

3.3 71 53 47 45 33 30 28 22 15 11

DHC 4-2

3.8 – 61 54 52 38 35 33 26 17 13

DHC 4-3 4.5 – 73 64 61 45 41 39 31 20 15

DHC 5-2

4.8 – 77 68 65 48 44 41 33 22 16

DHC 6-2

6.0 – – 85 82 60 55 52 41 27 20

DHC 8-2

7.2 – – – – 71 65 62 49 33 25

DHC 9-3 9.0 - - - - - - 77 58 41 31

DHC 10-2

9.6 – – - – – – 82 65 44 33

2.5 54 40 35 34 25 23 21 17 11 9

2.9 – 47 41 40 29 26 25 20 13 10

3.6 – 58 51 49 36 33 31 25 16 12

4.5 – – 64 61 45 41 39 31 20 15

5.4 – – – – 54 49 46 37 25 18

7.2 – – - – – – 62 49 33 25

Typ / Type kW l/min

DHC 3-1

DHC 3-2

3.3 39 30 26 24 18 16 12 9 6

DHC 4-2

3.8 – 34 30 27 21 18 14 11 7

DHC 4-3

DHC 5-2

4.8 – 43 38 34 26 23 17 14 9

DHC 6-2

6.0 – – 48 43 33 29 22 17 11

DHC 8-2

7. 2 – – – – 40 34 26 21 14