STIEBEL ELTRON DHB-E 11 SLi electronic, DHB-E 13 SLi electronic, DHB-E 18 SLi 25 A electronic, DHB-E 18/21/24 SLi electronic, DHB-E 27 SLi electronic Operation And Installation

BEDIENUNG UND INSTALLATION

OPERATING AND INSTALLATION

UTILISATION ET INSTALLATION

GEBRUIK EN INSTALLATIE

OBSŁUGA I INSTALACJA

OBSLUHA A INSTALACE

Elektronisch geregelter Durchlauferhitzer | Electronically controlled instantaneous

water heater | Chauffe-eau instantanés à régulation électronique | Elektronisch

geregelde doorstromer | Elektronicznie regulowany przepływowy ogrzewacz wody |

Elektronicky regulovaný průtokový ohřívač

» DHB-E 11 SLi electronic

» DHB-E 13 SLi electronic

» DHB-E 18 SLi 25 A electronic

» DHB-E 18/21/24 SLi electronic

» DHB-E 27 SLi electronic

electronic

°C

45

50

40

55

35

60

30

CONTENTS

SPECIAL INFORMATION

OPERATION

1. General information ��������������������������������������� 20

1.1 Safety instructions ���������������������������������������������� 20

1.2 Other symbols in this documentation ���������������������� 20

1.3 Units of measurement ����������������������������������������� 21

2. Safety �������������������������������������������������������� 21

2.1 Intended use ����������������������������������������������������� 21

2.2 General safety instructions �����������������������������������21

2.3 Test symbols ����������������������������������������������������� 21

3. Appliance description ������������������������������������� 21

4. Operation ��������������������������������������������������� 21

4.1 Recommended settings ��������������������������������������� 22

4.2 Temperature limit / Anti-scalding protection ������������� 22

5. Cleaning, care and maintenance ������������������������� 22

6. Troubleshooting �������������������������������������������� 22

INSTALLATION

7. Safety �������������������������������������������������������� 23

7.1 General safety instructions ����������������������������������� 23

7.2 Instructions, standards and regulations ������������������� 23

8. Appliance description ������������������������������������� 23

8.1 Standard delivery ����������������������������������������������� 23

8.2 Accessories ������������������������������������������������������� 23

9. Preparations ������������������������������������������������ 24

9.1 Installation site �������������������������������������������������� 24

9.2 Water installation ����������������������������������������������� 24

9.3 Appliance with adjustable connected load ���������������� 25

10. Installation �������������������������������������������������� 25

10.1 Standard installation ������������������������������������������� 25

10.2 Completing the installation ����������������������������������� 27

11. Commissioning ��������������������������������������������� 27

11.1 Initial start-up ��������������������������������������������������� 27

11.2 Recommissioning ����������������������������������������������� 28

12. Shutdown ��������������������������������������������������� 28

13. Installation options ���������������������������������������� 28

13.1 Electrical connection from above on unfinished walls �� 28

13.2 Electrical connection on finished walls �������������������� 28

13.3 Large conductor cross-section for electrical

connection from below ���������������������������������������� 28

13.4 Connecting a load shedding relay ��������������������������� 29

13.5 Water installation on finished walls ������������������������29

13.6 Water installation on finished walls with solder/

compression fitting ��������������������������������������������� 29

13.7 Water installation on finished walls; fitting the

appliance cover �������������������������������������������������29

13.8 Fitting the base part of the back panel with threaded

fittings on finished walls �������������������������������������� 29

13.9 Wall mounting bracket when replacing an appliance ��� 30

13.10 Installation with offset tiles ����������������������������������� 30

13.11 Pivoting appliance cover ��������������������������������������30

13.12 Temperature limit / Anti-scalding protection ������������� 30

14. Troubleshooting �������������������������������������������� 31

15. Maintenance ������������������������������������������������ 32

16. Specification ������������������������������������������������ 32

16.1 Dimensions and connections ��������������������������������� 32

16.2 Wiring diagram ������������������������������������������������� 32

16.3 DHW output ������������������������������������������������������ 33

16.4 Application areas/ conversion table ����������������������� 33

16.5 Pressure drop ��������������������������������������������������� 33

16.6 Details on energy consumption ������������������������������ 33

16.7 Data table ��������������������������������������������������������34

GUARANTEE

ENVIRONMENT AND RECYCLING

ENGLISH

www.stiebel-eltron.com DHB-E SLi | 19

SPECIAL INFORMATION

SPECIAL INFORMATION | OPERATION

General information

General information

SPECIAL INFORMATION

- The appliance may be used by children aged 3

and older and persons with reduced physical,

sensory or mental capabilities or a lack of experience and know-how, provided that they are

supervised or they have been instructed on how

to use the appliance safely and have understood

the resulting risks. Children must never play with

the appliance. Children must never clean the appliance or perform user maintenance unless they

are supervised.

- The tap can reach temperatures in excess of

60°C. There is a risk of scalding at outlet temperatures in excess of 43 °C.

- Ensure the appliance can be separated from the

power supply by an isolator that disconnects all

poles with at least 3mm contact separation.

- The specified voltage must match the mains

voltage.

- The appliance must be connected to earth.

- The appliance must be permanently connected to

fixed wiring.

- Secure the appliance as described in chapter “Installation/ Installation”.

- Observe the maximum permissible pressure (see

chapter “Installation/ Specification/ Data table”).

OPERATION

1. General information

The chapters “Special Information” and “Operation” are intended

for both the user and qualified contractors.

The chapter “Installation” is intended for qualified contractors.

Note

Read these instructions carefully before using the appliance and retain them for future reference.

Pass on the instructions to a new user if required.

1.1 Safety instructions

1.1.1 Structure of safety instructions

KEYWORD Type of risk

!

Here, possible consequences are listed that may result

from failure to observe the safety instructions.

Steps to prevent the risk are listed.

1.1.2 Symbols, type of risk

Symbol Type of risk

!

Injury

Electrocution

Burns

(burns, scalding)

- The specific water resistivity of the mains water

supply must not be undershot (see chapter “Installation / Specification / Data table”).

- Drain the appliance as described in chapter “Installation/ Maintenance/ Draining the

appliance”.

1.1.3 Keywords

KEYWORD Meaning

DANGER Failure to observe this information will result in serious

injury or death.

WARNING Failure to observe this information may result in serious

injury or death.

CAUTION Failure to observe this information may result in non-seri-

ous or minor injury.

1.2 Other symbols in this documentation

Note

General information is identified by the adjacent symbol.

Read these texts carefully.

20 | DHB-E SLi www.stiebel-eltron.com

OPERATION

45

Safety

Symbol Meaning

!

This symbol indicates that you have to do something. The ac-

tion you need to take is described step by step.

Material losses

(appliance damage, consequential losses and environmental pollution)

Appliance disposal

1.3 Units of measurement

Note

All measurements are given in mm unless stated otherwise.

2. Safety

2.1 Intended use

This appliance is intended for heating domestic hot water (DHW)

or for reheating preheated water and can supply one or several

draw-off points.

This appliance is intended for domestic use. It can be used safely

by untrained persons. The appliance can also be used in a non-domestic environment, e.g. in a small business, as long as it is used

in the same way.

Any other use beyond that described shall be deemed inappropriate. Observation of these instructions and of instructions for any

accessories used is also part of the correct use of this appliance.

2.2 General safety instructions

CAUTION Burns

During operation, the tap can reach temperatures in excess of 60 °C.

There is a risk of scalding at outlet temperatures in excess of 43°C.

2.3 Test symbols

See type plate on the appliance.

3. Appliance description

The electronically controlled instantaneous water heater maintains a constant outlet temperature up to its output limit, irrespective of the inlet temperature.

The appliance heats the water directly at the draw-off point, as

soon as you turn on the hot water tap. The short pipe runs ensure

that energy and water losses are minimal.

For the start flow rate, see chapter “Installation/ Specification/

Data table, On”.

The DHW output depends on the cold water temperature, the

heating output, the flow rate and the selected set temperature.

Water will not be reheated if the maximum inlet temperature for

reheating is exceeded.

DHW temperature

The DHW outlet temperature can be variably adjusted.

Temperature limit / Anti-scalding protection

The maximum outlet temperature for the appliance can be limited

to 43°C. For this, contact your local heating contractor.

Heating system

The bare wire heating system has a pressure-tested plastic casing.

The heating system is suitable for (both) soft and hard water and

is largely resistant to scale build-up. This heating system ensures

rapid and efficient DHW availability.

Note

The appliance is equipped with an air detector that largely prevents damage to the heating system. If, during operation, air is drawn into the appliance, the appliance

shuts down for one minute, thereby protecting the heating system.

ENGLISH

CAUTION Burns

When operating the appliance with preheated water, e.g.

from a solar thermal system, the DHW temperature may

vary from the selected set temperature.

WARNING Injury

!

The appliance may be used by children aged 3 and older

and persons with reduced physical, sensory or mental

capabilities or a lack of experience and know-how, provided that they are supervised or they have been instructed on how to use the appliance safely and have

understood the resulting risks. Children must never play

with the appliance. Children must never clean the appliance or perform user maintenance unless they are

supervised.

Material losses

!

The user should protect the appliance and its tap against

frost.

www.stiebel-eltron.com DHB-E SLi | 21

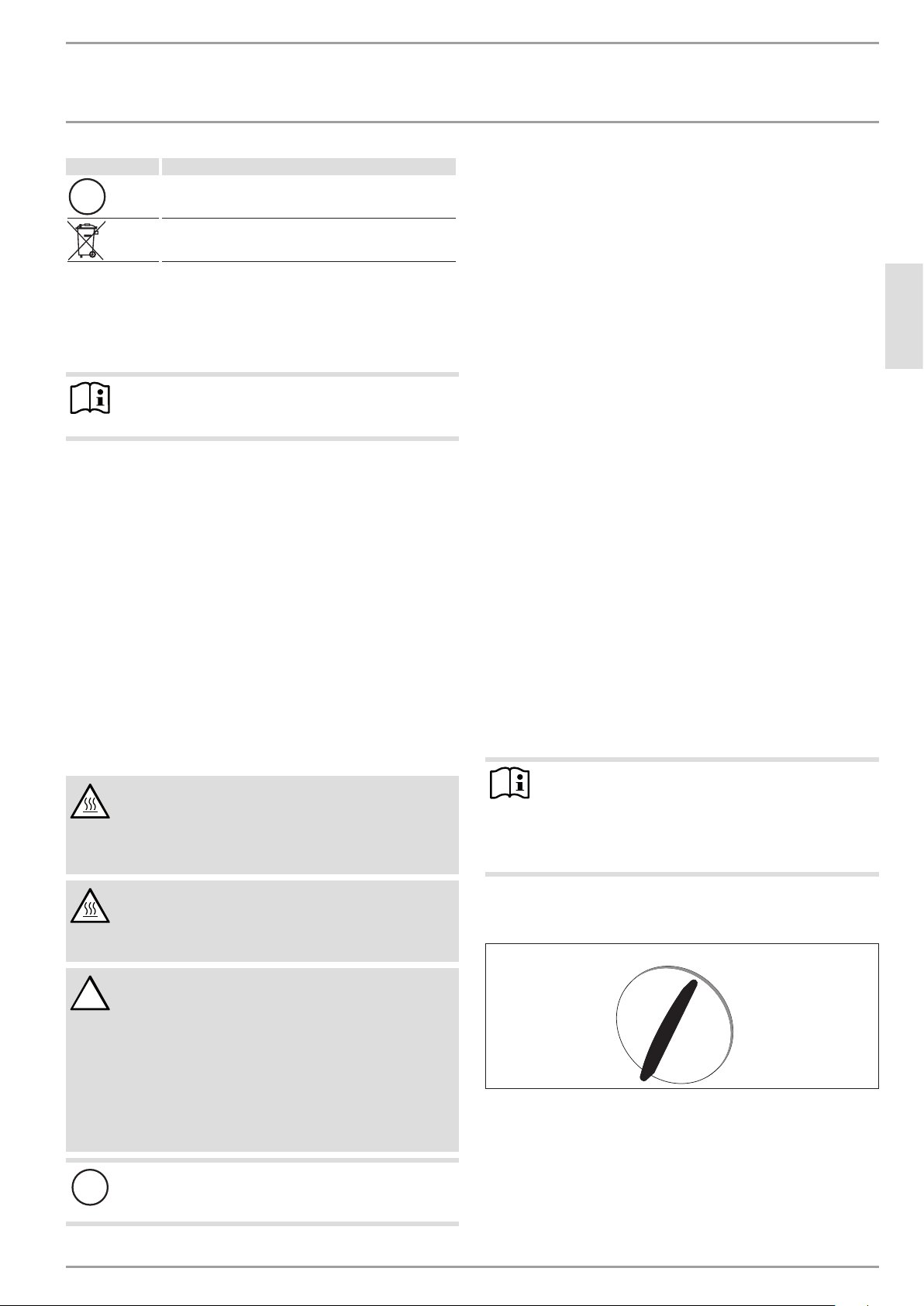

4. Operation

40

35

30

Turn the temperature selector to the required position.

If the outlet temperature fails to reach the required level with the

tap fully open and the temperature selector set to maximum, then

more water is flowing through the appliance than can be heated

by the heating element.

Reduce the flow rate at the tap.

50

55

60

26�02�02�1381

OPERATION

Cleaning, care and maintenance

4.1 Recommended settings

Thermostatic valve

If the appliance is being operated with a thermostatic valve, we

recommend setting the temperature on the appliance to maximum. The required temperature can then be set at the thermostatic valve.

DHB-E ... SL

Following an interruption to the water supply

Material losses

!

To ensure that the bare wire heating system is not damaged following an interruption to the water supply, the

appliance must be restarted taking the following steps.

Disconnect the appliance from the power supply by

removing the fuses/tripping the MCBs.

Open the tap for one minute until the appliance and

its upstream cold water inlet line are free of air.

Switch the mains power back ON again.

4.2 Temperature limit / Anti-scalding protection

The maximum outlet temperature for the appliance can be limited

to 43°C. For this, contact your local heating contractor.

5. Cleaning, care and maintenance

Never use abrasive or corrosive cleaning agents. A damp

cloth is sufficient for cleaning the appliance.

Check the taps regularly. Limescale deposits at the tap out-

lets can be removed using commercially available descaling

agents.

26�02�02�0818

6. Troubleshooting

Problem Cause Remedy

The appliance will not

start despite the DHW

valve being fully open.

When hot water is being

drawn off, cold water

flows for a short period.

Required temperature

>45°C is not achieved.

Cold water inlet tempera-

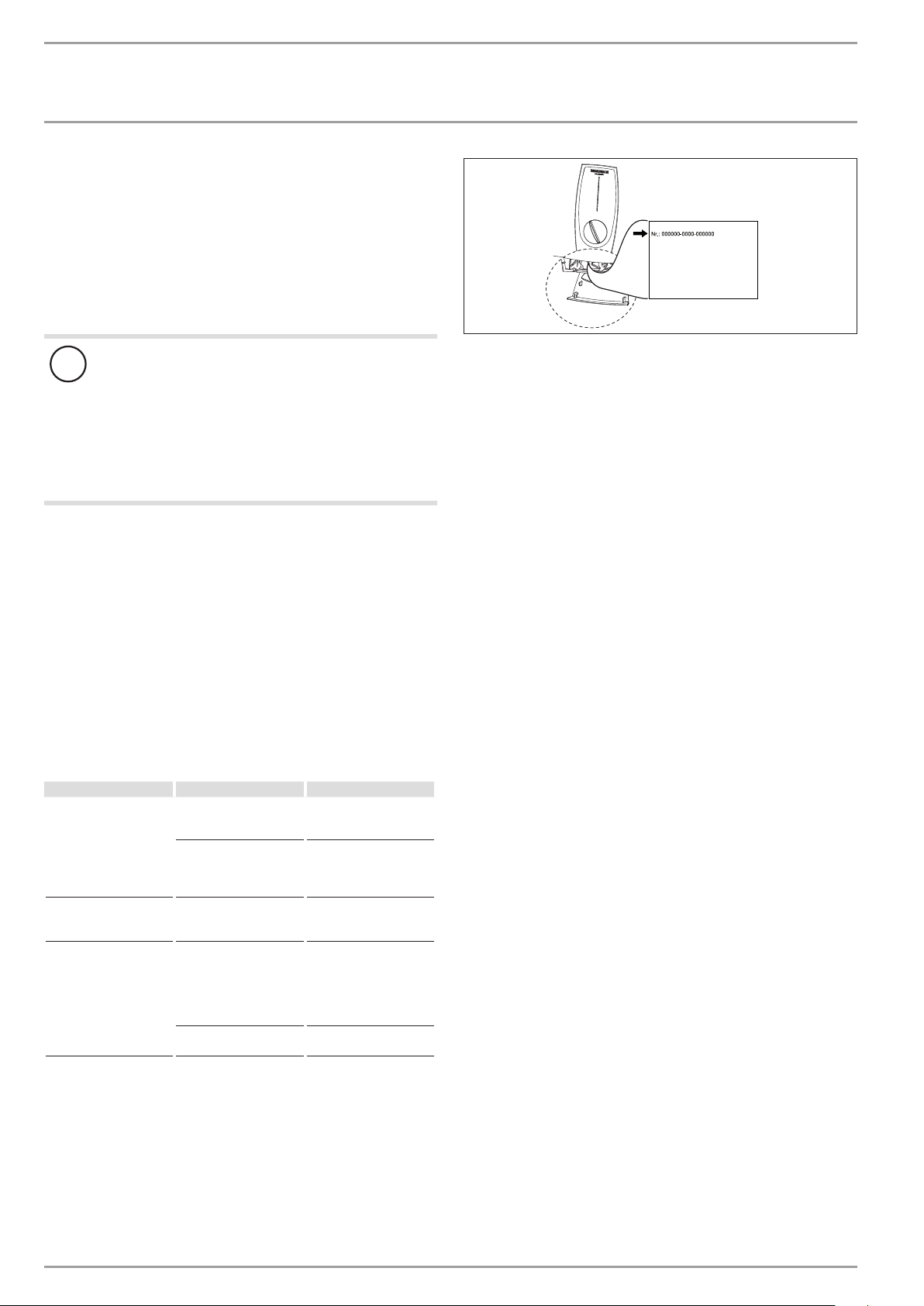

If you cannot remedy the fault, notify your qualified contractor.

To facilitate and speed up your request, provide the number from

the type plate (000000-0000-000000).

There is no power.

The aerator in the tap

or the shower head is

scaled up or contaminated.

The air sensor detects air

in the water and briefly

switches the heater off.

The water supply has

been interrupted.

ture is >45°C.

Check the fuses/MCBs in

your fuse box/distribution panel.

Clean and/or descale the

aerator or shower head.

The appliance restarts

automatically after

1minute.

Vent the appliance and

the cold water supply line

(see chapter "Operation/

Recommended settings/

Following an interruption

to the water supply").

Reduce the cold water

inlet temperature.

22 | DHB-E SLi www.stiebel-eltron.com

INSTALLAT ION

Safety

INSTALLATION

7. Safety

Only a qualified contractor should carry out installation, commissioning, maintenance and repair of the appliance.

7.1 General safety instructions

We guarantee trouble-free function and operational reliability only

if original accessories and spare parts intended for the appliance

are used.

Material losses

!

Observe the maximum permissible inlet temperature

(see chapter "Installation/ Specification/ Data table").

Higher temperatures may damage the appliance. The

inlet temperature can be limited by means of a central

thermostatic valve (see chapter "Installation/ Appliance

description/ Accessories").

7.2 Instructions, standards and regulations

Note

Observe all applicable national and regional regulations

and instructions.

- The IP 25 (hoseproof) rating can only be ensured with a correctly fitted cable grommet.

- The specific electrical resistance of the water must not fall

below that stated on the type plate. In a linked water network, factor in the lowest electrical resistance of the water

(see chapter “Installation/ Specification/ Data table”). Your

water supply utility will advise you of the specific electrical

resistance or conductivity of the water.

8.2 Accessories

Taps/valves

- MEKD mono lever kitchen pressure tap

- MEBD mono lever bath pressure tap

Plug G½A

If you use pressure taps for finished walls other than those recommended in the accessories, please use the plugs.

ENGLISH

Installation set for finished walls

- Solder fitting - copper pipe for soldered connection Ø12mm

- Compression fitting - copper pipe

- Compression fitting - plastic pipe (suitable for Viega: Sanfix-Plus or Sanfix-Fosta)

Universal mounting frame

- Mounting frame with electrical connections

Pipe assembly for undersink appliances

You will need the undersink installation set if you make the water

connections (G⅜A) at the top of the appliance.

Pipe assembly for offset installation

Use this pipe assembly set if you intend to offset the appliance by

90mm downwards from the water connection.

Pipe assembly for replacing a gas water heater

You will need this pipe assembly set if the existing installation

has gas water heater connections (cold water connection on the

left-hand side, DHW connection on the right-hand side).

Pipe assembly DHB water plug-in couplings

Use the water plug-in couplings if the existing installation contains

water plug-in connections from a DHB water heater.

8. Appliance description

8.1 Standard delivery

The following are delivered with the appliance:

- Wall mounting bracket

- Installation template

- 2 twin connectors

- Cold water 3-way ball shut-off valve

- DHW tee

- Flat gaskets

- Strainer

- Flow limiter

- Plastic profile washer

- Plastic connection pieces/ installation aid

- Cap and back panel guides

www.stiebel-eltron.com DHB-E SLi | 23

Load shedding relay (LR 1-A)

The load shedding relay for installation in the distribution board

provides priority control for the instantaneous water heater when

other appliances, such as electric storage heaters, are being operated simultaneously.

ZTA 3/4 – Central thermostatic valve

Thermostatic valve for central premixing, for example when operating an instantaneous water heater with a solar thermal system.

Loading...

Loading...