Stero ER-64 User Manual

Project:___________________________________________ Item No.___________________________________________ Quantity___________________

STERO ER-64

RACK CONVEYOR SERIES

The STERO ER-64 provides recirculating, heated wash and rinse tanks followed by a fresh water rinse creating a high volume, low water consuming washer in a 64" footprint.

STANDARD FEATURES

●270 racks per hour

●Rinse 2.02 gpm /.49 gallons per rack

●Automatic fill maintains proper tank levels

●Automatic start, rack activated switch starts conveyor and pumps

●Automatic shut down stops operation during idle periods

●2 HP wash and rinse motor each recirculating

225 gpm

●Single point drain connection

●2 large inspection doors

●Center-fed wash and rinse manifolds

●Stainless steel front enclosure panel protects motors and controls from moisture

●Door safety switches prevents operation if door is open

●Stainless steel drain valves and poppets, foot activated

●Kit 55, included prv, shock arrestor and pressure gauge in final rinse line

●Bell-type stainless steel skimmer acts as overflow and removes fats and oils from the wash tank

OPTIONS & ACCESSORIES

The full rack width washing pattern with our 225 gallons per minute pump powers this dishwashing workhorse. Rinsing and sanitizing is controlled by STERO’s exclusive rack activated final rinse which guarantees accurate, trouble-free cleaning.

Easy to operate, accessibility to components for maintenance and a basic design that produces clean dishes… that is the STERO ER-64 conveyor.

Right to Left / Left to Right Operation

Vent Cowls

Rinse Booster Electric or Steam

Circuit Breakers

Optional Cabinet-Style Doors

Automatic Dwell Conveyor

Table Limit Switch

Correctional Package

Voltage

208V 220V 480V 60cy 3ph

International options available, consult factory

ST50411 (07/15) |

Page 1 of 4 |

STERO ER-64

RACK CONVEYOR SERIES

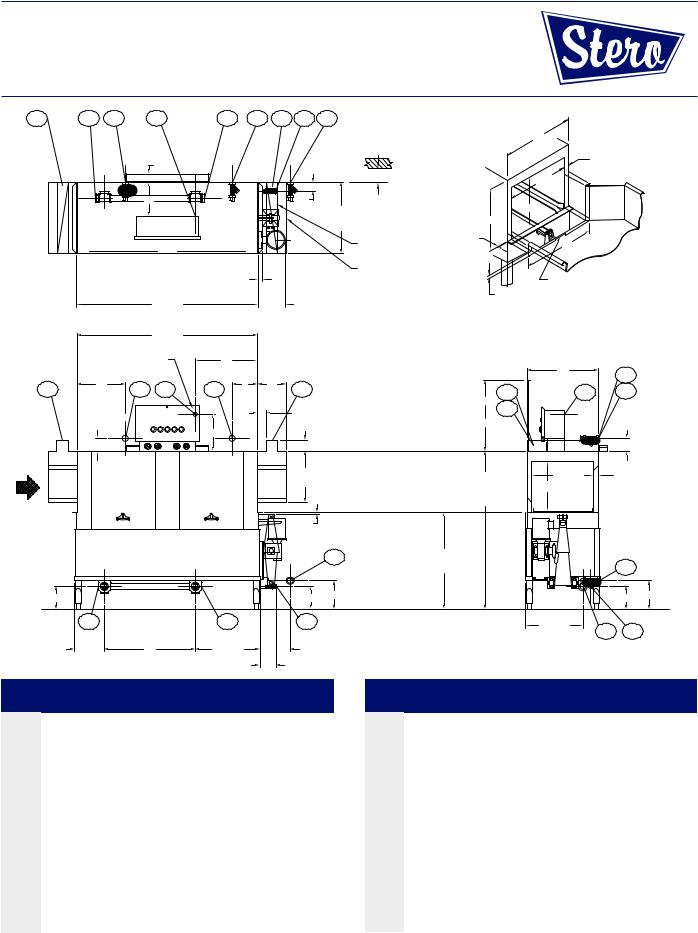

VL |

DM1 WM |

EM |

|

DM2 WH |

VU SR |

SS |

|

|

|

|

|

|

|

|

5" RECOMMENDED CLEARANCE |

|

|

|

|

|

|

|

4" MINIMUM TO WALL |

|

|

3 |

|

|

|

|

|

|

|

ELECTRICAL CHANNEL |

|

|

|

|

5 |

|

|

|

|

|

|

|

|

|

|

12 |

|

|

|

3 |

|

|

|

|

|

|

|

|

25 |

|

|

ELEC. BOX |

|

|

|

|

OVER |

|

|

|

|

|

|

HOOD |

|

|

|

W/CONTROLS |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

24 7/8"x 3 7/8" |

|

|

|

|

|

|

|

VENT I.D. (TYP) |

|

|

|

|

|

|

|

VENT COWLS |

|

|

|

TABLE LIP |

|

|

OPTIONAL MUST |

|

|

|

|

1 1/2 |

|

BE SPECIFIED |

||

|

|

|

(TYP) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

63 7/8 |

|

|

|

9 1/2 |

CLEARANCE |

|

|

TANK I.D. |

|

|

|

|

TO MOTOR |

|

TABLE WIDTH TO |

|

25 |

SUIT INSTALLATION, |

|

RECOM. MINIMUM 30" |

||

HOOD |

||

OVER |

|

|

|

1 5/8 |

|

|

(TYP) |

|

21 3/4 |

|

|

17 1/2 |

|

|

21 1/2 |

|

|

3/16 |

25 |

|

TABLE |

O.D. |

|

GAP |

||

|

||

1/2"x 3" CUTOUT TO CLEAR |

||

1" TURNDOWN |

CONVEYOR PAWL BAR |

|

SYMMETRICAL TO HOOD |

||

INTO MACHINE |

DRIVE END ONLY |

|

SUGGESTED TABLE CONNECTION

|

|

OVER HOOD |

|

|

63 1/2 |

|

|

ELEC. BOX K.O. |

|

|

APPROX. AS SHOWN, |

|

|

CONN. POINTS WITHIN |

VL |

17 |

WM EM |

|

||

|

|

16 |

|

4 1/2 |

|

DRAIN |

OSED |

|

L |

|

|

C |

O P E |

O |

8 |

|

|

F-F |

|

|

|

DM 1 |

|

10 1/2 |

|

32 |

OSED

P E

|

|

|

|

|

|

|

|

NOTE: RIGHT HAND-AS SHOWN |

|

|

|

|

|

|

|

|

|

|

LEFT HAND-OPPOSITE AS SHOWN |

|

|

|

|

VENT |

|

|

|

|

|

|

|

|

|

22 |

COWL |

|

|

|

|

|

OVER HOOD |

|

|

|

|

(TYP) |

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

25 |

WH |

|

|

|

|

|

|

|

|

|

|

||

|

9 |

10 |

|

|

|

|

|

|

|

|

WH |

VU |

|

|

|

VL |

|

EM |

WM |

||

|

|

|

HEIGHT FOR |

29 |

|

|||||

|

|

|

|

|

DOOR REMOVAL |

VU |

|

|

||

|

|

|

3 1/16 |

(TYP) |

|

|

|

|||

|

|

|

INSPECTION DOOR |

|

|

|

||||

|

|

|

|

|

25 |

|

|

|

|

|

13 |

|

|

|

|

IN RAISED POSITION |

|

|

|

|

|

|

|

|

VENT |

|

|

|

|

|

|

|

|

|

|

4 |

|

|

|

|

|

4 1/2 |

|

|

|

|

HEIGHT |

|

|

|

|

|

||

|

|

|

|

(TYP) |

|

|

|

|

|

|

|

|

|

18 |

|

|

55 1/2 |

|

|

21 3/4 |

1 5/8 |

|

|

|

(TYP) |

NOMINAL |

|

17 1/2 |

|

|

||

|

|

|

|

|

|

CLEAR. |

|

|||

|

|

|

|

|

MACHINE |

|

|

|

||

|

|

|

|

|

|

|

THRU |

|

||

|

|

|

|

|

|

HEIGHT |

|

|

|

|

|

|

|

|

|

|

|

|

MACHINE |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3/4 |

|

|

|

|

|

|

|

|

|

34 |

+1 |

|

|

|

|

|

SS |

-0 |

|

|

|

|

|

|

TABLE |

|

SS |

|

||

|

|

|

HEIGHT |

|

|

||

|

8 |

10 |

|

|

|

8 |

10 |

|

|

|

|

|

|

||

|

|

|

|

|

|

|

F-F |

DM |

SR |

|

|

20 1/4 |

DM |

SR |

|

|

2 |

|

|

|

|

||

22 3/4 |

10 5/8 |

|

|

|

1&2 |

|

|

|

|

|

|

|

|

||

|

5 5/8 |

|

|

|

|

|

|

|

ELECTRIC TANK HEAT |

|

|

|

STEAM TANK HEAT |

||

PTS. |

SIZE |

|

DESCRIPTION |

|

PTS. |

SIZE |

DESCRIPTION |

DM |

2" NPT (F) |

DRAIN, MACHINE WASTE: LEAVE UNUSED PORTS |

|

DM |

2" NPT (F) |

DRAIN, MACHINE WASTE: LEAVE UNUSED PORTS |

|

PLUGGED |

|

PLUGGED |

|||||

|

|

|

|

|

|||

WM |

3/4" NPT (F) |

WATER SUPPLY: 140° MIN. TANK FILL |

|

WM |

3/4" NPT (F) |

WATER SUPPLY: 140° MIN. TANK FILL |

|

WH |

3/4" NPT (F) |

WATER SUPPLY: 180°F. MIN. @ 20 PSI FLOW PRES . |

|

WH |

3/4" NPT (F) |

WATER SUPPLY: 180°F. MIN. @ 20 PSI FLOW PRES . |

|

|

|

|

CONSUMPTION = 121 GALS./HR. |

|

|

|

CONSUMPTION = 121 GALS./HR. |

|

|

1. |

WASH PUMP MOTOR...........2 HP |

|

SS |

1" NPT (F) |

STEAM SUPPLY: 15-40 PSI CONSUMPTION @ 20 PSI |

|

|

2. |

RINSE PUMP MOTOR...........2 HP |

|

TANK HEAT: 140 LBS./HR. |

||

|

|

3. |

CONVEYOR MOTOR..........1/4 HP |

|

SR |

3/4" NPT (F) |

STEAM RETURN: |

|

|

4. |

WASH TANK HEAT............10 KW |

|

|||

EM |

ELECTRICAL |

5. |

RINSE TANK HEAT.............15 KW |

|

|

|

ONE (3) WIRE FEEDER SIZED FOR: |

|

|

|

|

|

1. WASH PUMP MOTOR...........2 HP |

||

REQ. |

TOTAL LOAD @ 208V-3PH = 83.6 AMPS |

|

EM |

|

|||

|

|

TOTAL LOAD @ 480V-3PH = 37.9 AMPS |

|

ELECTRICAL |

2. RINSE PUMP MOTOR...........2 HP |

||

|

|

SINGLE POINT CONNECTIONS REQUIRE MOUNTED |

|

|

REQ. |

3. CONVEYOR MOTOR..........1/4 HP |

|

|

|

|

|

|

TOTAL LOAD @ 208V-3PH = 14.1 AMPS |

||

|

|

CIRCUIT BREAKERS. MULTIPLE FEEDERS REQUIRED |

|

|

|

||

|

|

OTHERWISE. |

|

|

|

TOTAL LOAD @ 480V-3PH = 7.7 AMPS |

|

VL |

NOTED |

VENT, LOAD END: RECOM. MIN. DRAW = 200 CFM |

|

VL |

NOTED |

VENT, LOAD END: RECOM. MIN. DRAW = 200 CFM |

|

VU |

NOTED |

VENT, UNLOAD END: RECOM. MIN. DRAW = 400 CFM |

|

VU |

NOTED |

VENT, UNLOAD END: RECOM. MIN. DRAW = 400 CFM |

|

|

ER-64 L-R |

STANDARD 208V./230V./480V.-3PH.-60HZ. AVAILABLE |

|

|

|

|

|

|

Page 2 of 4 |

|

ST50411 (07/15) |

Loading...

Loading...