Page 1

INSTALLATION INSTRUCTIONS & PARTS LIST

OIL FIRED UNIT HEATERS

MODELS: QVOF (50, 84, 100, 140, 180, 250)

ATTENTION: READ THIS MANUAL AND ALL LABELS ATTACHED TO THE UNIT CAREFULLY BEFORE

ATTEMPTING TO INSTALL, OPERATE OR SERVICE THESE UNITS! CHECK UNIT DATA PLATE FOR ELECTRICAL

SPECIFICATIONS AND MAKE CERTAIN THAT THESE AGREE WITH THOSE AT POINT OF INSTALLATION. RECORD

THE UNIT MODEL AND SERIAL No.(s) IN THE SPACE PROVIDED. RETAIN FOR FUTURE REFERENCE.

IIOF-1

Model No.

Serial No.

FOR YOUR SAFETY

The use and storage of gasoline or other flammable vapors and liquids in open containers in

the vicinity of this appliance is hazardous.

WARNING: Improper installation, adjustment, alteration, service or maintenance can

cause property damage, injury or death. Read the installation, operating and

maintenance instructions thoroughly before installing or servicing this equipment.

WARNING: Install, operate and maintain unit in accordance with manufacturer's

instructions to avoid exposure to fuel substances or substances from incomplete

combustion which can cause death or serious illness. The state of California has

determined that these substances may cause cancer, birth defects, or other

reproductive harm.

INSTALLER'S RESPONSIBILITY

Installer Please Note: This equipment has been test fired and inspected. It has been

shipped free from defects from our factory. However, during shipment and installation,

problems such as loose wires, leaks or loose fasteners may occur. It is the installer's

responsibility to inspect and correct any problems that may be found.

RECEIVING INSTRUCTIONS

Inspect shipment immediately when received to determine if any damage has occurred to the

unit during shipment. After the unit has been uncrated, check for any visible damage to the

unit. If any damage is found, the consignee should sign the bill of lading indicating such

damage and immediately file claim for damage with the transportation company.

HVAC EQUIPMENT

260 NORTH ELM STREET/WESTFIELD, MA 01085

TEL: (413) 564-5540 FAX: (413) 562-5311

Page 2

Sterling oil powered Unit Heaters are shipped in a heavy

duty reinforced corrugated shipping crate. Upon receiving

your unit, a careful inspection of this crate should be

made to ascertain if there is any damage either external

or concealed.

The thermostat should be mounted away from the blower

air stream on an inside wall or partition approximately 5

feet above the floor.

3 – FUEL OIL PIPING

All Unit Heaters come completely assembled and wired.

GENERAL INFORMATION

Oil Fired Unit heaters are designed to be suspended.

However, they can be installed on approved fire-resistive

slabs or supports having no combustible material against

the underside of the unit. Other clearances to

combustible sources should be not less than 6″ from

sides and top and 18″ from flue pipe in any direction.

When suspending the unit from a ceiling, an allowance

of 18″ from the top of the unit should be made to

accommodate a barometric draft regulator.

Unit Heaters should not be subjected to negative

pressures (drafts) created by room or building exhaust

fans. Sufficient air for combustion is an important

consideration.

Special attention must be given to those installations,

such as service stations and warehouses, where the

units have short stacks since the draft may not be

adequate.

When the vertical distance from the fuel supply tanks to

the fuel unit on the burner is more than 15 feet, or

when a multiple installation is required, the fuel system

should include a boost pump. See Figure 2.

INSTALLATION PROCEDURE

1 – HANGING OF UNIT

Welded to the top of the heat exchanger at each corner

is a 3/4″ pipe coupling which will accommodate a

standard 3/4″ pipe nipple. There are many ways the

suspension of a unit can be accomplished. However,

care should be taken to be sure the supporting beams

or girders are of ample strength to support the weight

of the unit. It is good practice to distribute the weight

over several girders rather than depending on one.

2 – WIRING

As this is a prewired unit, all controls, with the exception

of the thermostat are mounted and wired. 115 volt

service to utility box on unit heater is required. Unit

should be fused independent of other fixtures,

equipment, etc. There is a service switch on the unit.

An additional switch should be provided at the room or

building entrance.

a) Gravity Systems

Gravity systems where fuel supply is on the same level

as unit, require one line from tank to burner. This should

be 1/2″ or 3/8″ O.D. tubing or 3/8″ iron pipe according

to local codes. There should be a hard seat globe valve

at tank. A Main line oil filter should be installed

immediately after valve. Another valve, either hard seat

globe or heat responsive, should be installed at burner.

Local codes must be adhered to.

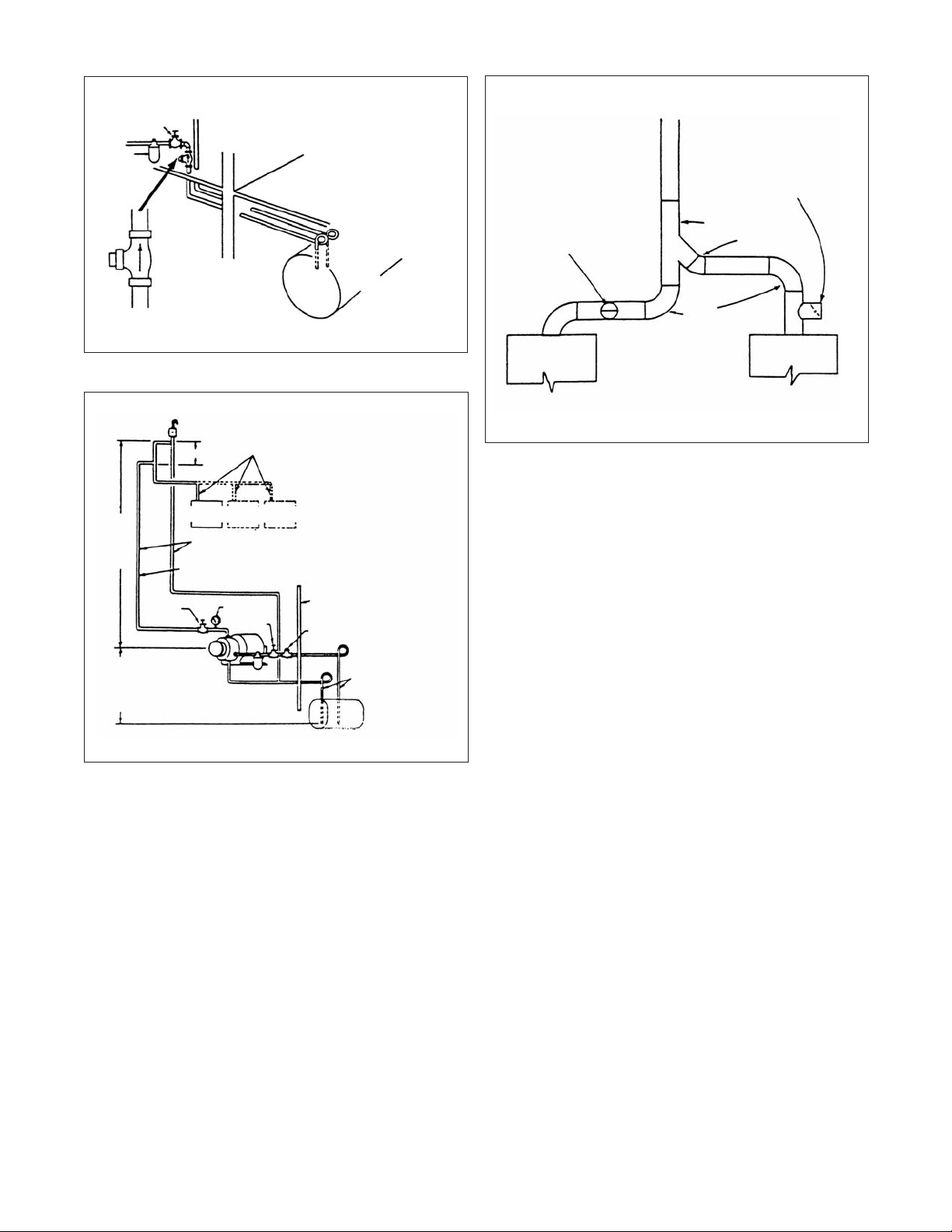

b) Lift Systems

Lift systems where fuel supply tank is below unit, require

a two-pipe system. See Figure 1.

Suction and return lines should originate no less than

2″ nor more than 4″ from bottom of fuel tank. If code

permits, 1/2″ O.D. soft tubing should be used. A doubletapped bushing should be used in tapping of tank with

a slip connector so that both lines are continuous from

bottom of tank to inside of building.

A good quality ball check valve should be in the suction

line immediately inside of building.

Care should be exercised in installing lines in tank so

that they do not curl up inside of tank.

Lines should continue to burner either as copper tubing

or black pipe, depending on local codes, and should be

run straight and direct, eliminating need for bends or

elbows as much as possible. Lines should be securely

fastened to eliminate vibration and/or sagging.

Be sure bypass plug is installed in proper place, tightly

secured. See instruction sheet attached to pump for

more detail. On all connections, use oil resistant joint

compound. Either hard seat globe valve or heat

responsive valve (Firomatic or equal), depending on

code, should be installed in suction line as close to

pump as practicable.

A boost pump should be used on multiple unit heater

installations, or where an installation has more than a

15 foot lift (measured from the suction line in fuel tank

to the fuel unit on the burner). See Figure 2

2

Page 3

Figure 1 - Fuel Oil Piping.

Figure 3

VALVE

FILTER

GROUND LEVEL

CHECK VALVE

(ENLARGED)

BURNED

FUEL OIL

TANK

Figure 2 - Piping Overhead System

VACUUM BREAKER

35 FT. MAX.

PRESSURE HEAD

(OPTIONAL)

15 FT. MAX.

SUCTION LIFT

VALVE

LINE PRESSURE

NOT TO EXCEED 6 PSI

2 – 4 FT.

FURNACE

FURNACE

NO. 1

NO. 2

1/2" O.D. COPPER TUBING

SUPPLY LINE

COMPOUND

GAUGE

VALVE

PUMP

FILTER

RETURN LINE

FURNACE

NO. 3

WALL

CHECK VALVE

INLET

LINE

RETURN LINE

SUCTION AND

RETURN LINE

CLEARANCE FROM

BOTTOM OF TANK

MINIMUM 2"

MAXIMUM4"

1/2" O.D. COPPER TUBING

SUCTION AND RETURN

LINE CLEARANCE FROM

BOTTOM OF TANK

TANK

MINIMUM 2"

MAXIMUM 4"

TO ROOF

BAROMETRIC

DRAFT

REGULATOR

BAROMETRIC

DRAFT

REGULATOR

"Y"

45° L

90°

UNIT 1 UNIT 1

4 – FLUE CONNECTIONS

Connect flue pipe to chimney. If chimney is masonry

type, be sure base is clean of debris and that opening

through tile is at least as large as flue pipe (see

specification sheet).

Chimney, either masonry or pre-fab, should be in

accordance with local requirements. The flue gas exit

of a chimney shall be at least 3 feet above the highest

point where the chimney passes through the roof of a

building, and at least 2 feet higher than any portion of a

building within 10 feet of the chimney. Chimney should

not be connected to an open fireplace, but could serve

two heating units.

NOTE: When two units are connected to a common

chimney, they should be connected as shown in

Figure 3.

Barometric draft regulator should be installed in flue

pipe, Regulator should be installed in run of flue pipe,

either horizontal or vertical. It is poor practice to install

in a tee that is substituted for an elbow as this has a

tendency to puff odors out of regulator on starts.

Special attention must be given to those installations

such as service stations and warehouses where units

are suspended at ceiling level. Because of the height

restrictions on the chimney, draft is not adequate.

Available for these installations is a draft inducer and

prover at additional cost.

3

Page 4

5 – FAN AND LIMIT CONTROL SETTING

A good rule to follow is to use lowest limit setting that

will assure enough heat and use lowest fan settings

that will not circulate cool air before fan stops.

The recommended setting is: Limit 200 degrees, fan on

130 degrees; fan off 90 degrees.

6 – STARTING AND TESTING OF UNIT

Before starting burner, it is advisable to remove nozzle

assembly and check nozzle size (see nozzle

specifications label on unit) and setting of electrodes.

Put 5 to 10 drops of good quality SAE 20 motor oil

(Havoline) in the oil cups at each end of the motor.

Repeat oiling of motor at the start and mid-point of

each heating season.

7 – TO PRIME FUEL UNIT

Place a can under valve of fuel unit and open bleed

valve one-quarter turn. Make certain all fuel oil valves

to burner are open. Push reset on primary control. Turn

on switch to burner. Operate burner until a good stream

of fuel, free from bubbles and foam, flows from bleed

valve. Close bleed valve and combustion should occur.

If primary goes “safety” before fuel unit is completely

purged, wait approximately four minutes, RESET

PRIMARY CONTROL AND CONTINUE PRIMING

UNTIL COMBUSTION IS ESTABLISHED.

8 – FINAL ADJUSTING AND TESTING

Punch or drill a hole in flue pipe as close to unit as

possible large enough to accommodate the probes of

the instruments (1/4″).

The burner is equipped with a cadmium sulfide flame

detector that is located in the base plate of ignition

transformer and is accessible by moving the transformer

to a position normally required for the removal of the

ignition assembly. If new installation, make sure fuel

tank has been filled. Insert a fuse in fuse block. Set

thermostat a minimum of 2 degrees above room

temperature.

It is important that the installation be checked for safety

shutdown in the event a malfunction of equipment

occurs. There are several ways this can be

accomplished. We recommend on of the following:

a. Before opening oil valve and priming fuel unit, turn

on switch. Burner should, but because of no fuel,

combustion will not be established. Burner should

operate the prescribed time, depending on the primary

control, and then go off on “safety”. If burner does

not start, check reset of primary, thermal cutout on

burner motor, or fuse.

b. After priming fuel unit (see following paragraph) and

establishing combustion, disconnect motor lead from

orange wire of primary and turn switch on. Primary

control should be energized and remain so the

prescribed time, depending on primary, and then go

on “safety”. After completion of test reconnect motor

lead to orange wire.

Using the draft gauge, adjust barometric draft regulator

to establish a maximum of minus .04 inches of draft in

flue pipe. It is desirable to operate with minimum draft

required to remove products of combustion; however,

unit should not operate with draft in flue pipe below

minus .02 inches. Failure to obtain these readings

indicate a need for a draft inducer.

Using the Smoke Tester, adjust “fine” air shutter of

burner (see burner specifications sheet) to effect a 0+

reading on smoke scale. If this is not possible, open

bulk air band to No. 1 setting on scale on burner housing

and reset “fined” adjustment. Continue the procedure

until recommended reading is obtained remembering

final adjustment should be made with fine tuning air

shutter.

Using the CO2 Tester, analyze the flue gas. CO2 should

be a minimum of 8 percent. Determine the gross stack

temperature using the Stack Thermometer. Net stack

temperature (flue gas temperature minus room

temperature) should be less than 600 degrees F.

If the recommended CO2 or smoke readings cannot be

obtained, check the fuel nozzle pressure, and flue draft.

Recheck fuel nozzle for proper type (refer to nozzle

specification label on unit).

Installation is now complete. Fill out warranty card and

mail to register your warranty.

4

Page 5

RECOMMENDED

OIL SUPPLY SYSTEMS

Figure 4 - Pressurized System

MANIFOLD AIR BLEED – HIGHEST POINT IN LINE

BOOSTER PUMP

SETTING PRESSURE AND BLEEDING

FIGURES 4 AND 5

1. Stop all burner pumps.

2. Start boost pump manually

3. Set boost pump pressure so that gauge in first burner

manifold reads not more than 10 P.S.I.

4. Bleed air from first burner pump by loosening unused

inlet plug; bleed other units downstream the same

way.

5. Bleed manifold by loosening pipe cap (Figure 4).

6. For automatic operation, place switch on OFF.

Boost Pump Maximum Inlet Line (Ft.)

For Figures 4 & 5

Height 0-7′ 10′ 13′ 15′

30 GPH 100′ 80′ 63′ 52′

50 GPH 60′ 53′ 41′ 34′

Operation is extremely simple. Pressure developed by

oil burner fuel unit closes low-voltage switch connected

to it. This causes switch relay to energize boost pump

motor, which starts and stop automatically with burner.

For initial start-up, switch relay may be held “in”

manually. Or a manual ON/OFF switch can be

connected across low-voltage wires leading from switch

relay to pressure switch. With manual switch in “ON”

position, boost pump runs continuously.

NOTE: Check all burners for normal start and fuel

units for stable atomizing pressure. Then open boost

pump switch for automatic operation upon burner

demand.

Systems in Figures 4 and 5 will be in constant operation

when low-voltage switches are not used.

NOTE: Installations in figures 4 and 5 can be either

Intermittent or Constant operation.

CAUTION: When 2′ riser cannot be maintained, use

pressurized system in Figure 4.

Manifold and feeder lines must be run in a horizontal

plane and elevated above fuel unit intakes. At furnace

locations, extend feeder lines downward to fuel unit

intakes.

1/2" O.D. TUBING – INTAKE LINE

"h"

15 FT.

MAX

TANK

30 GPH 300′ 800′ 2500′

50 GPH 175′ 350′ 1500′

Figure 5 - Loop System

MAX INTAKE GAUGE

PRESSURE AT FIRST

BURNER 6 PSI

1/2" O.D. TUBING

SHUTOFF VALVE

INLET

1/2" O.D. TUBING

AUXILIARY FILTER

15 FT.

MAX LIFT

MANIFOLD LINE

35 FT.

MAX

RETURN 1/2" O.D. TUBING

TANK

NO. 1

SUSPENDED FURNACES

MAX INTAKE PRESSURE

AT BURNER 6 PSI

COMPOUND

GAUGE

NO. 1 NO. 2

SUSPENDED FURNACES

35 FT.

MAX

1/2" O.D. TUBING

PIPE CAP

MANIFOLD LINE

FEEDER

LINES

1/2" O.D. TUBING

SHUT OFF VALVE

AUXILIARY FILTER

BOOST PUMP

AND MOTOR SET

FURNACE

NO. 3 ETC.

Maximum Horizontal Line

Boost 1/2″ 1/2″ 3/4″

Pump Tube Pipe Pipe

VENT

RISER

FEEDER

LINES

NO. 1

BOOST PUMP ASSEMBLY

OIL

SAFETY VALVES

1 1/4" PIPE

Install in accordance with National Board of Fire

Underwriters and local ordinances where applicable.

Maximum Horizontal Line

Boost 1/2″ 1/2″ 3/4″

Pump Tube Pipe Pipe

30 GPH 300′ 800′ 2500′

50 GPH 175′ 350′ 1500′

5

Page 6

RECOMMENDED

OIL SUPPLY SYSTEMS

2 PIPE SYSTEM

WIRING

Figure 7

Separated suction oil line must be used for second unit.

Return oil lines can be twinned together.

Correct line size for two pipe installation 1/2″ O.D. tubing.

Figure 6

RETURN LINE

B

SUCTION LINE

OIL TANK

SEE TABLE A

BLACK

TO THERMOSTAT

TERMINALS ON

PRIMARY CONTROL

THERMOSTAT

TWO WIRE

CABLE

PRIMARY

CONTROL

AND IGNITION

TRANSFORMER

LINE

FAN

BURNER

MOTOR

BLACK

TOGGLE

SWITCH

ORANGE

WHITE

BLUE

PRIMARY

CONTACT

JUNCTION BOX

JUNCTION BOX

THERMOSTAT

BLACK

CAD

CELL

BURNER SERVICE

SWITCH

JUMPER

IN PLACE

FAN SIDE

LIMIT SIDE

WIRING

CABLE

COMBINATION

CONTROL

FUSER 9A

WHITE

BLOWER

MOTOR

TYPICAL

ENTRANCE

SWITCH

TYPICAL

FUSED SWITCH

ENTRANCE

9A CM

Maximum allowable length of either intake or return line

in feet, including horizontal and vertical run.

Maximum line lengths shown above are calculated for

No. 2 oil at 60° and 3450 RPM pump speed.

Table A

“Lift” Installation Values

Distance “B” Single Two

Lift Stage Stage

0′ 100′ 100′

1′ 100′ 100′

2′ 100′ 100′

3′ 100′ 100′

4′ 100′ 100′

5′ 100′ 100′

6′ 100′ 100′

7′ 99′ 100′

8′ 83′ 100′

9′ 68′ 100′

10′ 52′ 100′

11′ 42′ 100′

12′ 25′ 100′

13′ — 100′

14′ — 100′

15′ — 100′

Figure 8 - Intermittent Operation

CONNECT PRESSURE

SWITCH TO FUEL UNIT

GAGE PORT

1/8 NIPPLE OF LENGTH TO

CLEAR STRAINER COVER

1/8 TEE

1/8 PIPE PLUG

PRESSURE SWITCH

NORMALLY OPEN

CLOSED –

CONTINUOUS OPERATION

OPEN –

OPERATES ONLY UPON

BURNER DEMAND

LOW VOLTAGE

TWO CONDUCTOR WIRE

SWITCH RELAY

LINE

VOLTAGE

POWER

SUPPLY

MANUAL

BOOST PUMP

SWITCH

TO BOOST

PUMP

MOTOR

6

Page 7

NOTES:

7

Page 8

HVAC EQUIPMENT

260 NORTH ELM STREET/WESTFIELD, MA 01085

TEL: (413) 564-5540 FAX: (413) 562-5311

Loading...

Loading...