Page 1

Sensor-Gartenlampe

Bedienungsanleitung

D

Operating Instructions

GB

Mode d’emploi

F

Gebruiksaanwijzing

NL

Istruzioni per l’uso

I

Instrucciones de montaje

E

103577605 08/2011_B Technische Änderungen vorbehalten.

Page 2

Leuchtenfuß mit Rohr

so weit über die Zuleitung zurückziehen, bis

die angezeichneten

Befestigungslöcher

sichtbar werden, dann

die Befestigungslöcher

bohren und den Fuß

mit drei Sechskantschrauben am Boden

befestigen.

10. Den Leuchtenkörper

wieder in das Rohr

stecken und ausrichten,

wie in Punkt 6 beschrieben. Über die abgemantelten Netzleiter ist nun

der beigelegte Schutzschlauch zu ziehen. Die

Leitung samt Schutzschlauch werden jetzt in

der Zugentlastung geklemmt.

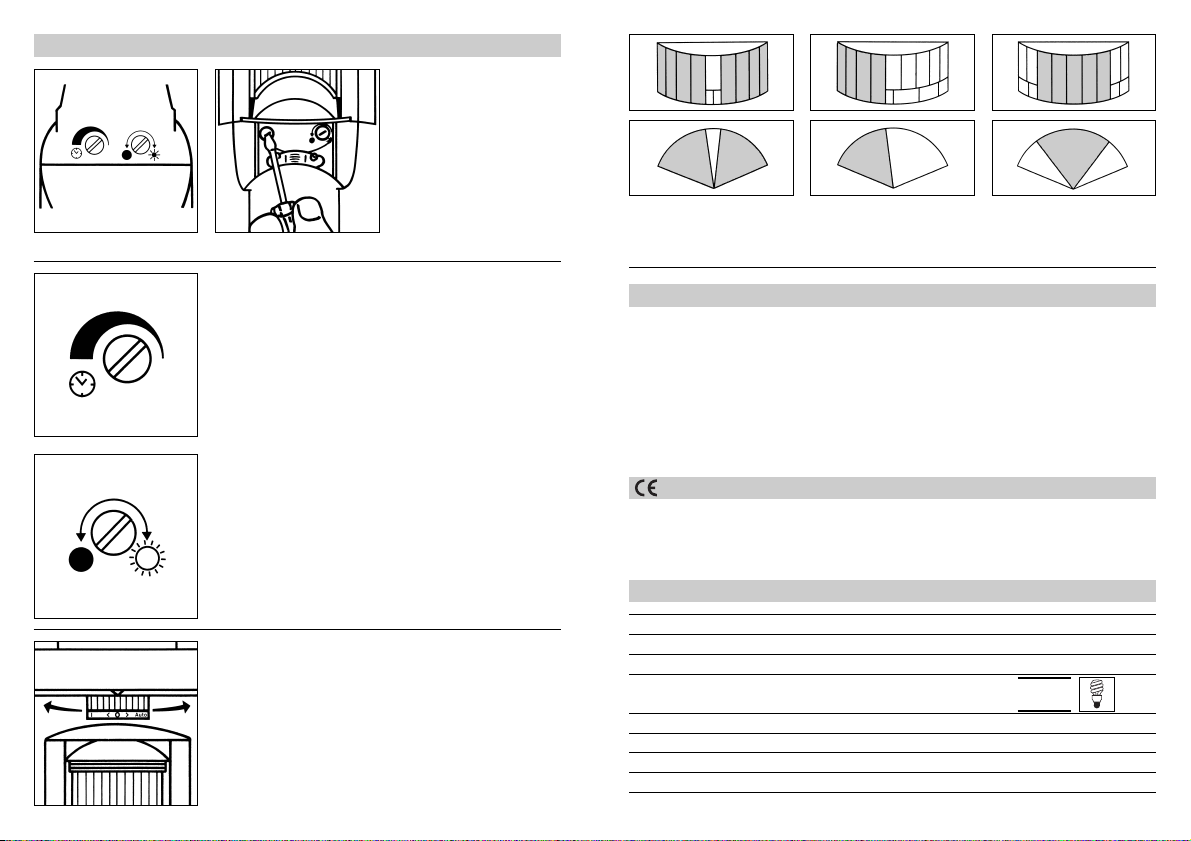

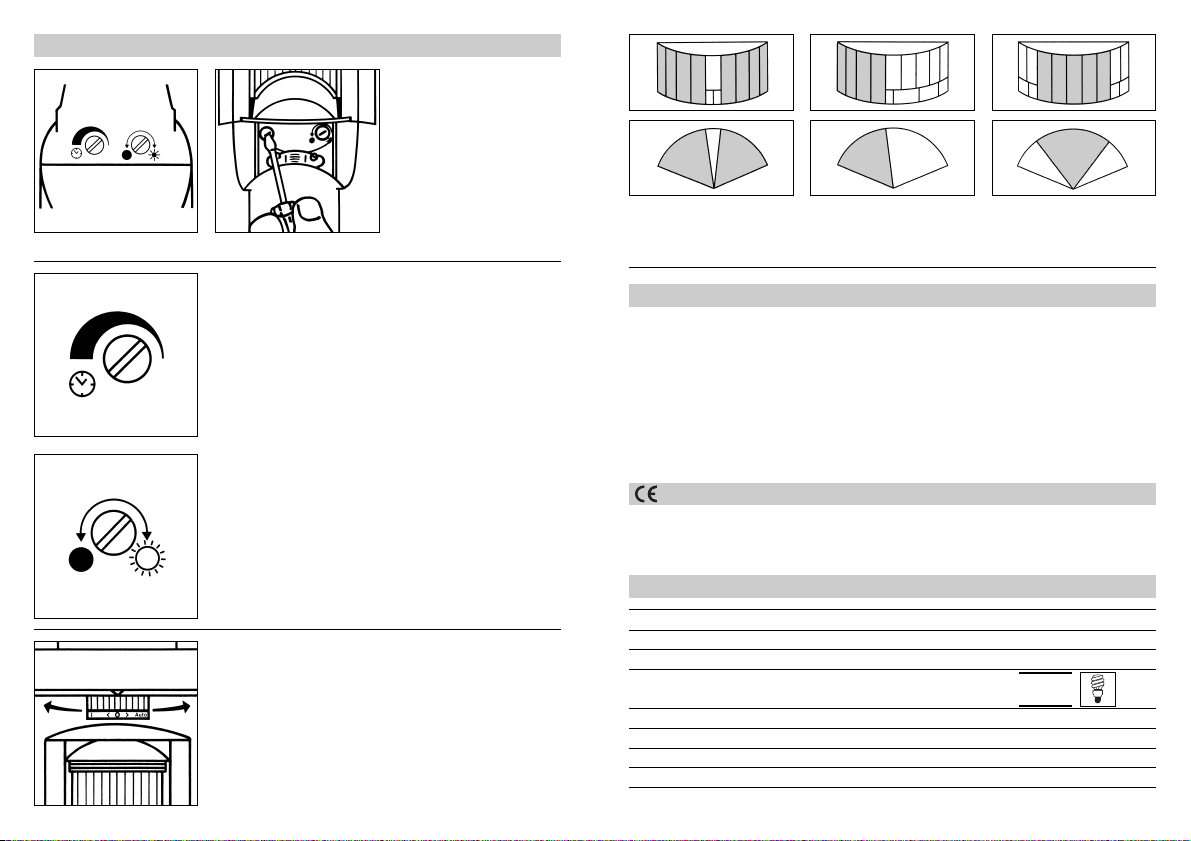

11. Auf eine M3,5 x 10Schraube eine Mutter

drehen. Den Leuchtenkörper leicht anheben und die Schraube

(1) in den Längsschlitz

legen. Sensor in die

gewünschte Position

drehen (Feineinstellung).

Schraube (1) festziehen.

12. Den Schutzschlauch mit

den Leitern durch eines

der vorgesehenen

Löcher in den Anschlussraum zur Lüsterklemme führen.

13. Anschluss der Netz-

zuleitung

Die Netzzuleitung

besteht aus einem

3-poligen Kabel.

L = Stromführender Leiter (schwarz oder braun)

N = Nullleiter (blau)

PE = Schutzleiter

(gelb/grün).

Im Zweifelsfall müssen

Sie die Kabel mit einem

Spannungsprüfer identifizieren; anschließend

wieder spannungsfrei

schalten. Der Erdleiter

(gelb/grün) braucht nicht

angeschlossen zu werden, da die Leuchte

doppelt-schutzisoliert

ist (Schutzklasse II). Den

Erdleiter einfach umbiegen und isolieren. Den

L-Leiter in die Klemme

mit der schwarzen Leitung montieren. Den

N-Leiter in die Klemme

mit der blauen Leitung

montieren.

14. Schiebekappe (Anschlussraumabdeckung)

hochschieben, ausrichten, einrasten und mit

der beiliegenden

Schraube 2,2 x 9,5 festziehen.

15. Glühlampe (max.

100 Watt) einschrauben.

16. Plexiglaskuppel aufsetzen und mit den beiliegenden drei Schrauben

M4 x 12 mm befestigen.

Wichtig: Ein Vertauschen

der Anschlüsse führt im

Gerät oder in Ihrem Sicherungskasten später zum

Kurzschluss. In diesem Fall

müssen nochmals die einzelnen Kabel identifiziert

werden.

3

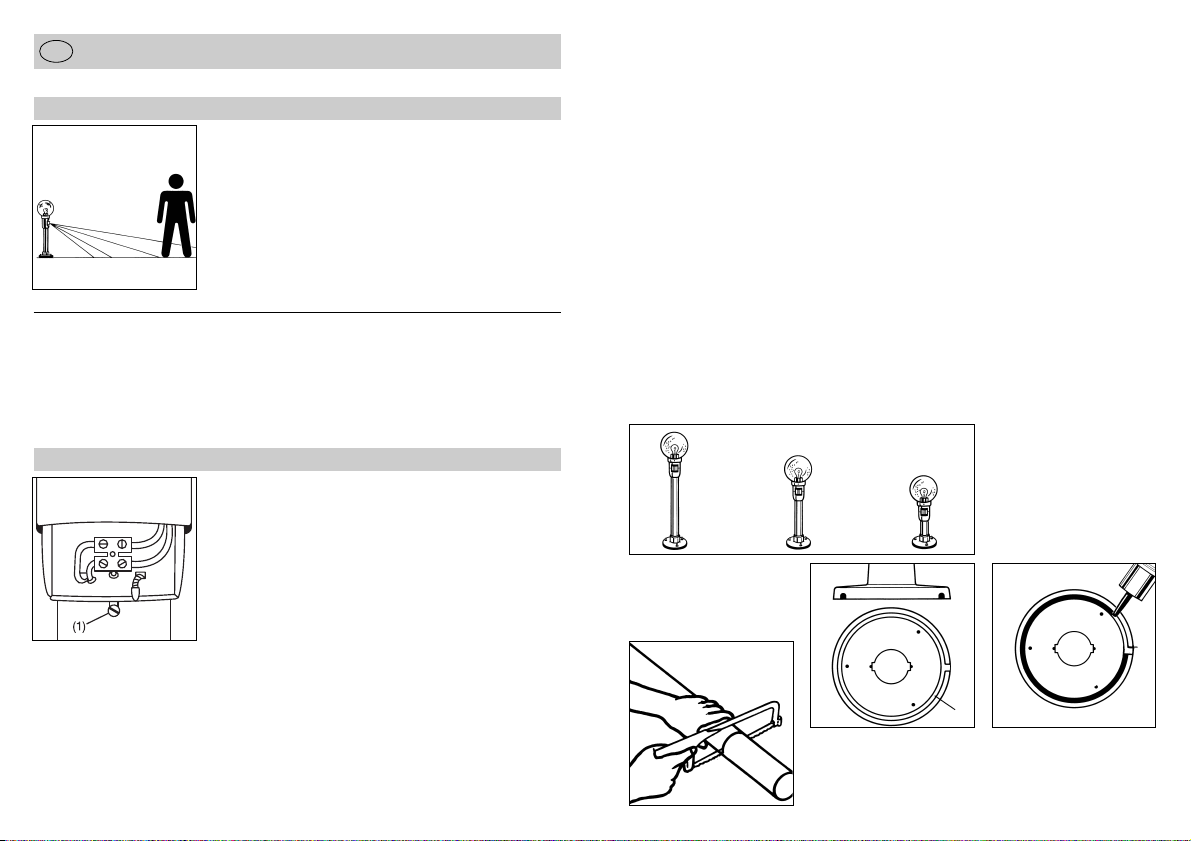

Durch Kürzen des Standrohres ist es möglich, die

Lampenhöhe individuell zu

bestimmen.

Achtung: Niemals die Aussparung abschneiden

Bei Bedarf können Sie die

Nut der Fußplatte (2) mit

Silikon ausfüllen, um somit

Befestigungsboden und

Fußplatte miteinander zu

verbinden und abzudichten.

Achtung: seitliche Wasserabflussöffnung (3) nicht mit

Silikon ausfüllen.

Bedienungsanleitung

D

Die Einschaltdauer des

Verbrauchers ist stufenlos

einstellbar (von ca. 10 Sek.

bis ca. 15 Min.). Nach Ablauf der eingestellten Zeit

wird bei jeder Bewegung im

Erfassungsbereich die eingestellte Zeit neu aktiviert.

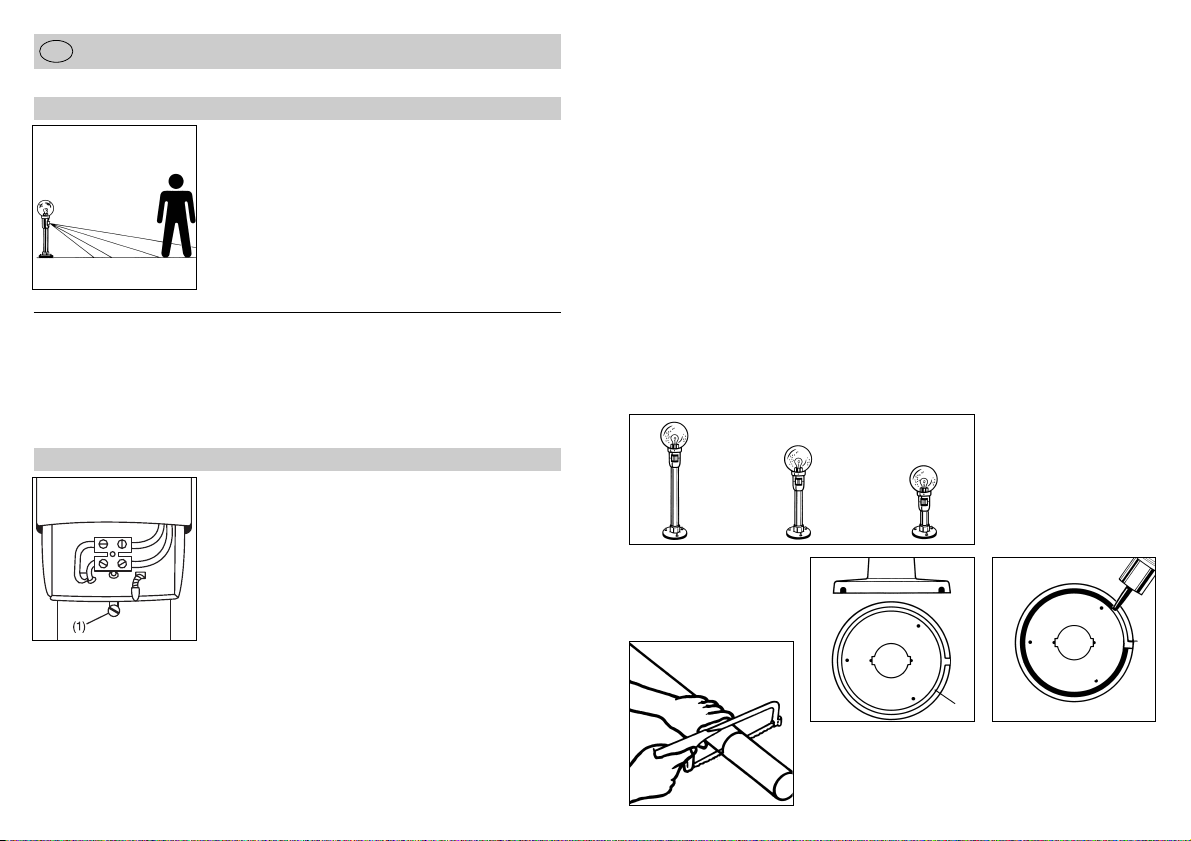

Die sicherste Bewegungserfassung haben Sie, wenn

das Gerät in einem kleinen

Winkel zur Gehrichtung

montiert bzw. ausgerichtet

wirrd und keine Hindernisse

(wie z.B. Bäume, Mauern

etc.) die Sicht behindern.

Der integrierte Dämmerungsschalter (LDR) ist

ebenfalls stufenlos einstellbar (von ca. 2 Lux bis ca.

2000 Lux).

2 Lux = Nachtbetrieb,

2000 Lux = Tagbetrieb.

Das Prinzip

2

Der eingebaute pyroelektrische Infrarot-Detektor

erfasst die unsichtbare

Wärmestrahlung von sich

bewegenden Körpern

(Menschen, Tieren, etc.).

Diese so erfasste Wärmestrahlung wird elektronisch

umgesetzt und schaltet die

Lampe. Durch Hindernisse,

wie z.B. Mauern oder

Glasscheiben, wird keine

Wärmestrahlung erkannt,

es erfolgt also auch keine

Schaltung.

Installation

Achtung: Die Montage

bedeutet Netzanschluss.

230 Volt bedeutet Lebensgefahr. Bei der Installation

der Garten-Sensorlampe

handelt es sich um eine

Arbeit an der Netzspannung; sie muss daher fachgerecht nach VDE 0100

ausgeführt werden. Daher

vor Beginn der Arbeiten den

Strom abschalten und

Spannungsfreiheit mit

einem Spannungsprüfer

überprüfen.

01. Das Rohr so in den

Leuchtenfuß stecken,

dass die kleine Aussparung nach oben zeigt.

Dann mit 4 Schrauben

(3 x 16) von unten festschrauben.

02. Die Zuleitung von unten

durch das Rohr schieben. Wichtig: Die Zuleitung muss mindestens

13 cm länger sein als

das Rohr. Die Zuleitung

muss doppelt-schutzisoliert bis in das Leuchtenoberteil hineingeführt

werden.

03. Schiebekappe (Anschlussraumabdeckung)

von dem Leuchtenkörper abziehen und über

das Rohr nach unten

schieben.

04. Äußere Zuleitung ca.

10 cm abisolieren.

05. Den Leuchtenkörper in

das Rohr stecken, dabei

die Zuleitung durch die

vorgesehene Öffnung

führen.

06. Den Leuchtenkörper so

drehen, dass sich die

Lüsterklemme über dem

Langschlitz im Rohr befindet.

07. Die so vorgefertigte

komplette Lampe mit

Sensor so drehen, dass

der Sensor ungefähr in

die gewünschte Richtung zeigt (Grobeinstellung).

08. Die Befestigungslöcher

vom Fuß auf den Boden

übertragen bzw. anzeichnen.

09. Den Leuchtenkörper

wieder aus dem Rohr

entfernen und den

2–12 m

von 100 cm – 50 cm

(2)

(3)

Page 3

5

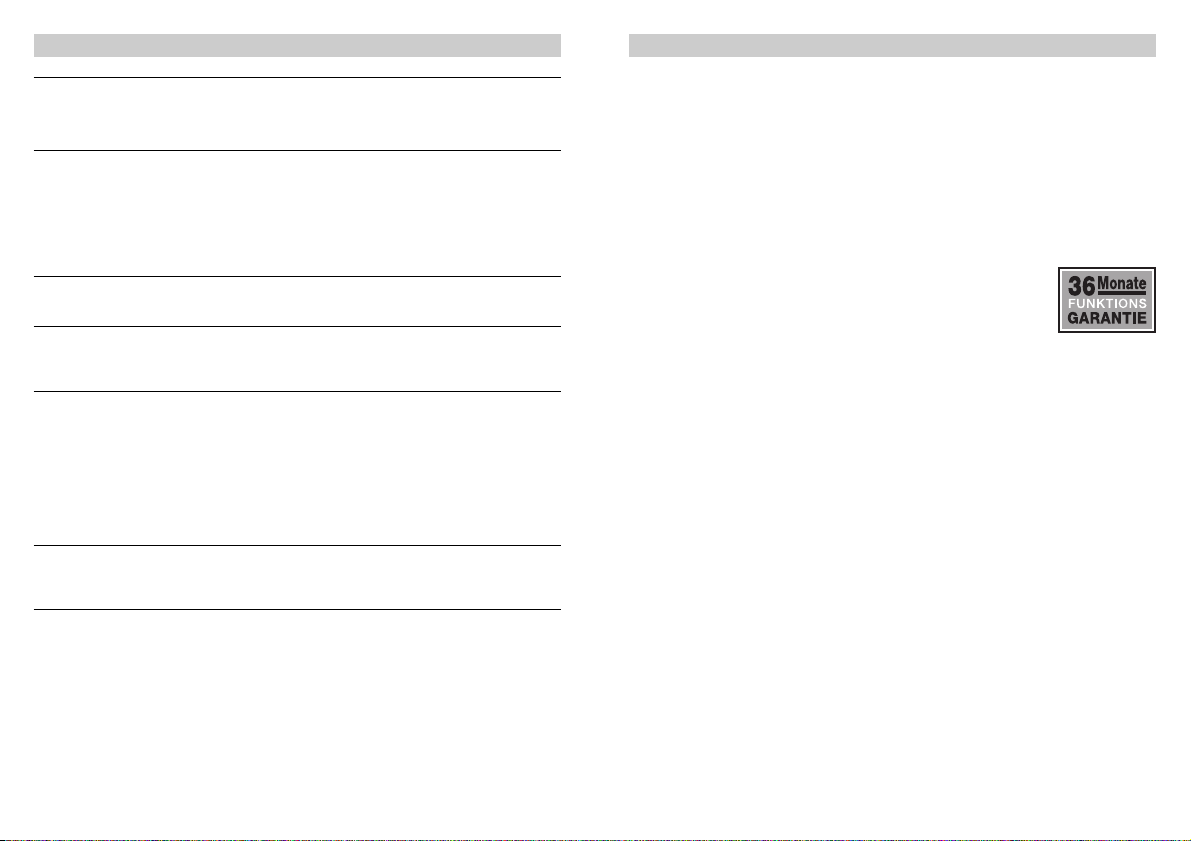

Je nach Bedarf kann der

Erfassungsbereich optimal

eingestellt werden. Mit den

beigelegten Abdeckungen

können Sie den Erfassungsbereich des Sensors zusätzlich bestimmen. Linsensegmente können abge-

deckt werden, um somit

Fehlschaltungen durch z.B.

Autos, Passanten auszuschließen.

Soll der Verbraucher unabhängig von einer Wärmequelle im Erfassungsbereich

eingeschaltet werden, wird

der hausinterne Netzschalter einmal kurz betätigt. So

wird der Verbraucher für die

eingestellte Zeit aktiv.

Witterungseinflüsse sowie

starke elektromagnetische

Felder können die Funktion

der Gartenlampe beeinträchtigen. Bei starken

Windböen, Schnee, Regen,

Hagel kann es zu einer

Fehlschaltung kommen, da

die plötzlichen Temperaturschwankungen nicht von

Wärmequellen unterschieden werden können.

Die Fresnellinse (Erfassungslinse) kann bei Verschmutzung mit einem

feuchten Tuch (ohne Reinigungsmittel) gesäubert

werden.

Betrieb

Dieses Produkt erfüllt die

- Niederspannungrichtlinie 2006/95/EG

- EMV-Richtlinie 2004/108/EG

Konformitätserklärung

Montage: Netzanschluss 220–240 V

Erfassungswinkel des Sensors: 180° horizontal, 8° vertikal

Schwenkbereich des Sensors: 55° horizontal, 35° vertikal

Schaltzeit, einstellbar: 10 Sek. – 15 Min.

Reichweite: 12 m frontal, 10 m seitlich

Erfassungsfläche: ca. 240 m

2

Leistung der Glühlampe: max. 100 Watt

Schutzart: IP 44

Technische Daten

Funktion

4

Nachdem die SensorLampe

angeschlossen ist, kann

diese eingeschaltet werden.

Zwei Einstellmöglichkeiten

stehen nun auf der Unterseite des Gerätes zur Verfügung.

Achtung! Schiebekappe

nach unten ziehen und Sensorkopf nach oben schwenken. Mit einem kleinen

Schraubendreher von unten

Zeit- und Dämmerungseinstellung vornehmen.

A) Ausschaltverzögerung

(Zeiteinstellung)

Die gewünschte Leuchtdauer des Betriebsmittels

kann auf der Unterseite des

Gerätes stufenlos von ca.

10 Sek. bis max. 15 Min.

eingestellt werden. Stellschraube Rechtsanschlag

bedeutet kürzeste Zeit, ca.

10 Sek. Stellschraube

Linksanschlag bedeutet

längste Zeit, ca. 15 Min.

(Bei Auslieferung ist das

Gerät werkseitig auf kürzeste Zeit eingestellt). Bei der

Einstellung des Gerätes für

den Erfassungsbereich und

für den Funktionstest wird

empfohlen, die kürzeste Zeit

einzustellen.

B) Dämmerungseinstellung (Ansprechschwelle)

Die gewünschte Ansprechschwelle des Gerätes kann

ebenfalls auf der Unterseite

stufenlos von ca. 2 Lux bis

2000 Lux eingestellt werden.

Stellschraube Rechtsanschlag bedeutet Tageslichtbetrieb ca. 2000 Lux. Stellschraube Linksanschlag bedeutet Dämmerungsbetrieb

ca. 2 Lux. (Bei Auslieferung

ist das Gerät werkseitig auf

Tageslichtbetrieb eingestellt.)

Bei der Einstellung des

Gerätes für den Erfassungsbereich und für den Funktionstest bei Tageslicht

muss die Stellschraube auf

Rechtsanschlag stehen.

Drei Schalter-Funktionen

stehen zur Auswahl und

können am Gerät über dem

Sensor eingestellt werden.

Schalter nach links schieben. Schalterstellung (I):

Lampe leuchtet im Dauerbetrieb.

Schalterstellung (0)

Lampe ist ausgeschaltet.

Schalter nach rechts schieben. Schalterstellung (Auto):

Lampe schaltet im Sensorbetrieb.

Tipp!

min.

5 Min.

Page 4

7

Dieses Steinel-Produkt ist

mit größter Sorgfalt hergestellt, funktions- und sicherheitsgeprüft nach geltenden

Vorschriften und anschließend einer Stichprobenkontrolle unterzogen.

Steinel übernimmt die

Garantie für einwandfreie

Beschaffenheit und Funktion.

Die Garantiefrist beträgt

36 Monate und beginnt

mit dem Tag des Verkaufs

an den Verbraucher. Wir

beseitigen Mängel, die auf

Material- oder Fabrikationsfehlern beruhen, die Garantieleistung erfolgt durch

Instandsetzung oder

Austausch mangelhafter

Teile nach unserer Wahl.

Eine Garantieleistung entfällt für Schäden an Verschleißteilen sowie für

Schäden und Mängel,

die durch unsachgemäße

Behandlung, Wartung oder

durch Verwenden von

Fremdteilen auftreten.

Weitergehende Folgeschäden an fremden Gegenständen sind ausgeschlossen.

Die Garantie wird nur gewährt, wenn das unzerlegte

Gerät mit kurzer Fehlerbeschreibung, Kassenbon

oder Rechnung (Kaufdatum

und Händlerstempel), gut

verpackt, an die zutreffende

Servicestation eingesandt

wird.

Reparaturservice:

Nach Ablauf der Garantie-

zeit oder Mängeln ohne

Garantieanspruch repariert

unser Werkservice. Bitte

das Produkt gut verpackt

an die nächste Servicestation senden.

Funktionsgarantie

6

Störung Ursache Abhilfe

Sensor-Gartenlampe

ohne Spannung

Haussicherung defekt,

nicht eingeschaltet,

Leitung unterbrochen

Kurzschluss

neue Haussicherung,

Netzschalter einschalten,

Leitung überprüfen mit

Spannungsprüfer

Anschlüsse überprüfen

Sensor-Gartenlampe

schaltet nicht ein

bei Tagesbetrieb

Dämmerungseinstellung

steht auf Nachtbetrieb

Leuchtmittel defekt

Netzschalter AUS

Haussicherung defekt

Erfassungsbereich nicht

gezielt

neu einstellen

Glühlampe austauschen

einschalten

neue Haussicherung,

evtl. Anschluss prüfen

neu justieren

Sensor-Gartenlampe

schaltet nicht aus

dauernde Bewegung im

Erfassungsbereich

Bereich kontrollieren und

evtl. neu justieren, bzw.

abdecken

Sensor-Gartenlampe

schaltet immer EIN/AUS

Tiere bewegen sich im

Erfassungsbereich

Sensor höher schwenken

bzw. gezielt abdecken,

Bereich umstellen bzw.

abdecken

Sensor-Gartenlampe

schaltet unerwünscht ein

Wind bewegt Bäume und

Sträucher im Erfassungsbereich

Erfassung von Autos auf

der Straße

plötzliche Temperatur-

veränderungen durch

Witterung (Wind, Regen,

Schnee) oder Abluft aus

Ventilatoren, offenen

Fenstern

Bereich umstellen, bzw.

abdecken

Bereich umstellen,

Sensor abschwenken

Bereich verändern,

Montageort verlegen

Sensor-Gartenlampe

Reichweiteveränderung

andere Umgebungstem-

peraturen

bei Kälte Sensorreichwei-

te durch Abschwenken

verkürzen

bei Wärme höher stellen

Betriebsstörungen

Page 5

holes. Now drill mounting holes and secure

base to mounting surface using three hexagon head cap screws.

10. Insert the light enclosure

back into the tube and

align as described in

point 6. Now fit the protective sleeve provided

over the stripped mains

conductor. The conductor, including protective

sleeve, must now be

clamped in the cable

grip.

11. Fit a nut onto an M3.5 x

10 screw. Slightly raise

top section of lamp and

insert screw (1) into slot.

Turn sensor to chosen

position (fine adjustment). Tighten screw

12. Thread the protective

sleeve with the conductors through one of the

holes provided in the

terminal compartment

and take it to the terminal block.

13. Connecting mains

power supply lead

The mains power supply

lead is a 3-core cable.

L = phase conductor

(black or brown)

N = neutral conductor

(blue)

PE = protective earth

conductor (green/yellow)

If you are in any doubt,

you must identify the

cables using a voltage

tester; then disconnect

power supply again. The

earth conductor (yellow/green) does not

need to be connected

because lamp is doubly

insulated (Class II).

Simply bend the earth

conductor back and insulate. Fit L conductor

into terminal with black

lead. Fit the N conductor

into terminal with blue

lead.

14. Push up slide cap (terminal compartment),

align, clip into place and

secure in place using

2.2 x 9.5 screw provided.

15. Screw in light bulb

(100 watts max.).

16. Mount polycarbonate

globe and secure in

place with the three M4

x 12 screws provided.

Important: Getting the cable connections crossed will

later on produce a short

circuit in the unit or in your

fuse box. In this case, you

must once again identify

the individual wires and

connect them correctly.

9

The tubular stem tube

may be shortened to adjust

the lamp height to suit your

requirements.

Attention: never cut off the

notch.

If you wish, you can fill the

groove in the base plate (2)

with silicone to attach and

seal the base plate to the

mounting surface.

Attention: Be careful not to

fill silicone into the water

drainage opening (3) at the

side.

Operating Instructions

GB

The on time can be continuously adjusted (from approx. 10 sec. to approx.

15 min.). After the selected

time elapses, any movement in the detection zone

will re-activate the timer.

The most reliable way of

detecting motion is to install

the light in such a way that

the sensor is aimed more

or less across the direction

in which a person would

walk and by ensuring that

no obstacles (such as trees,

walls etc.) obstruct the line

of sensor vision.

The integrated photoelectric

lighting controller (LDR) is

also continuously adjustable (from approx. 2 lux to

approx. 2000 lux).

2 lux = night-time operation

2000 lux = daytime operation

Operating Principle

8

The built-in pyro-electric

infrared detector senses the

invisible heat radiated by

moving objects (people,

animals, etc.). Detected in

this way, the heat is converted electronically into a signal that switches the light

on. Heat is not detected

through obstacles, such as

walls or panes of glass.

Heat radiation of this type

will, therefore, not activate

the light.

Installation

Attention: Installation invol-

ves connecting the unit to

the mains power supply.

Mains voltage of 230 V can

be lethal. To install the Garden SensorLamp, you must

work with mains voltage;

this work must therefore be

carried out professionally in

accordance with the applicable wiring regulations and

electrical operating condi-

tions. Therefore disconnect

the power supply prior to

commencing work and check

that the circuit is dead using

a voltage detector.

01. Insert tubular stem into

lamp base so that the

small notch faces upwards. Afterwards,

fasten from below using

4 screws (3 x 16).

02. Route power supply

lead from below through

tubular stem. Impor-

tant: Power supply lead

must be at least 13 cm

longer than tubular

stem. Power supply

lead must be doubly insulated into top section

of lamp.

03. Pull slide cap (terminal

compartment cover)

from lamp and slide

down over tubular stem.

04. Strip about 10 cm of

insulation off end of

power supply lead.

05. Insert top section of

lamp into tubular stem,

routing power supply

lead through opening

provided.

06. Turn top section so that

terminal block is positioned above the slot in

the tubular stem.

07. Pre-assembled in this

way, turn lamp and sensor so that sensor

points more or less in

chosen direction (rough

adjustment).

08. Transfer position of ba-

se mounting holes onto

mounting surface.

09. Remove top section of

lamp from tubular stem

again. Ease back lamp

base and tubular stem

over power supply lead

so as to reveal mounting

2–12 m

from 100 cm to 50 cm

(2)

(3)

Page 6

11

The detection zone can be

optimised to suit requirements. Using the shrouds

provided with the lamp, you

can also adjust the sensor's

detection zone. Lens segments can be covered so as

to prevent the light from

being triggered inadvertently, for example, by cars or

passers-by.

If you want the light to come on independently of a

heat source, switch on the

indoor power switch momentarily. This will activate

the light for the period

selected.

Weather as well as strong

electromagnetic fields can

affect operation of the Garden Lamp. Strong gusts of

wind, snow, rain or hail may

cause switching errors because the unit cannot

distinguish sudden change

in temperature from heat

sources.

The Fresnel lens (detection

lens) can be wiped clean

with a damp cloth (not

using detergent) if it gets

dirty.

Operation

This product complies with

- Low Voltage Directive 2006/95/EC

- EMC Directive 2004/108/EC

Declaration of conformity

Technical Specifications

Functions

10

Once the SensorLamp has

been connected, it can be

switched on. Two setting

controls are provided on the

bottom of the unit.

Attention: Pull down slide

cap and tilt up sensor head.

Use a small screwdriver

from below to set timer and

light threshold.

A) Switch-off delay (time

setting)

At the bottom of the unit

you can set the light to

come on for any period between approx. 10 sec. and

a maximum of 15 min. The

shortest period, approx. 10

sec., is selected by turning

the control fully clockwise.

The longest period, 15 min.,

is selected by turning the

control fully anticlockwise.

(The unit leaves the factory

set to the shortest time). It

is recommended to select

the shortest time for adjusting the detection zone

and for performing the walk

test.

B) Light level setting

(threshold)

The desired light threshold

can also be adjusted continuously from about 2 lux to

2,000 lux on the bottom of

the unit. Turn control fully

clockwise to select daylight

operation at about 2,000

lux. Turned fully anticlockwise, control is set to duskto-dawn operation at about

2 lux (on leaving factory,

light is set to daytime

operation).

The control must be turned

fully clockwise when adjusting the detection zone

and performing the walk

test in daylight.

Three switch setting capabilities are provided on the

unit above the sensor.

Slide switch to left; switch

position (I): Lamp is switched on all the time.

Switch position (0)

Lamp is switched off.

Slide switch to right; switch

position (Auto): Lamp controlled in sensor mode.

Mains power supply: 220–240 V mains connection

Sensor angle of coverage: 180° horizontal, 8° vertical

Sensor swivel range: 55° horizontal, 35° vertical

"ON" time, adjustable: 10 sec. – 15 min.

Reach: 12 m in front, 10 m at sides

Detection area: approx. 240 m

2

Light bulb output: 100 watt max.

Enclosure: IP 44

Tip!

at

least

5 min.

Page 7

13

This STEINEL product has

been manufactured with

great care, tested for proper

operation and safety in accordance with applicable

regulations and then subjected to random sample

inspection. STEINEL guarantees that it is in perfect

condition and proper working order. The warranty

period is 36 months, starting from the date of sale

to the consumer.

We will remedy defects caused by material flaws or

manufacturing faults. The

warranty will be met by

repair or replacement of

defective parts at our own

discretion. The warranty

does not cover damage

to wear parts, nor does it

cover damage or defects

caused by improper treatment, maintenance or the

use of non-genuine parts.

Further consequential damage to other objects shall

be excluded.

Claims under the warranty

will only be accepted if the

product is sent fully assembled and well packed complete with a brief description of the fault as well as a

receipt or invoice (date of

purchase and dealer's

stamp) to the appropriate

Service Centre.

Repair Service:

Our Customer Service

Department will repair faults

not covered by warranty or

after the warranty period.

Please send the product

well packed to your nearest

Service Centre.

Functional Guarantee

12

Malfunction Cause Remedy

Garden SensorLamp without power

House fuse faulty, not

switched on, break in

wiring

Short-circuit

Renew house fuse,

switch on mains power

switch, check wiring with

voltage tester

Check connections

Garden SensorLamp will

not switch on

Twilight control set to

night-time mode during

daytime operation

Bulb faulty

Power switch OFF

House fuse faulty

Detection zone not pro-

perly targeted

Adjust setting

Change bulb

Switch on

Renew house fuse, check

connection if necessary

Re-adjust

Garden SensorLamp will

not switch off

Continuous movement in

the detection zone

Check detection zone

and re-adjust if necessary, or attach shrouds

Garden SensorLamp keeps

switching ON/OFF

Animals moving in detec-

tion zone

Tilt sensor up or use

shrouds to target more

precisely

Garden SensorLamp switches on when it should not

Wind moving trees or

bushes in detection zone

Cars in street being

detected

Sudden temperature

changes due to weather

(wind, rain, snow) or air

expelled from ventilators,

open windows

Change detection zone or

attach shrouds

Change detection zone,

tilt sensor down

Adjust detection zone,

change site of installation

Reach of Garden SensorLamp changes

Differing ambient tem-

peratures

In cold weather, shorten

sensor reach by tilting

down

Tilt up in warm weather

Troubleshooting

Page 8

trous marqués au sol

soient visibles. Percer

les trous de fixation et

fixer le pied au sol avec

des vis six pans.

10. Replacer le bloc d'éclairage dans le tube et l'aligner, comme décrit au

point 6. Enfiler ensuite

sur les conducteurs

dénudés la gaine protectrice fournie. Puis

bloquer la ligne et sa

gaine protectrice dans

la décharge de traction.

11. Visser un écrou sur une

vis M3,5 x 10. Soulever

légèrement le bloc

d’éclairage et poser la

vis (1) dans la fente

oblongue. Régler le détecteur dans la position

souhaitée en le faisant

pivoter (réglage de précision). Serrer la vis (1).

12. Amener la gaine protectrice et les conducteurs

au domino de raccorde-

ment en passant par

un des perçages prévus

dans l'espace de

raccordement.

13. Branchement du câble

secteur

Le câble secteur est

composé d’un câble à

3 conducteurs :

L = phase

(noir ou marron)

N = neutre (bleu)

PE = terre (vert/jaune)

En cas de doute, il faut

identifier les câbles

avec un testeur de tension puis les remettre

hors tension. Il n’est

pas nécessaire de raccorder le conducteur de

terre (jaune/vert) car la

lampe a une isolation

double (classe II). Il suffit de replier le conducteur de terre et de l’isoler. Raccorder le conducteur de phase à la

borne du conducteur

noir. Raccorder le conducteur de neutre à la

borne du conducteur

bleu.

14. Remonter la plaque

coulissante (cache-bornes), l’ajuster, l’enclencher et la fixer avec la

vis 2,2 x 9,5 fournie.

15. Visser une ampoule à

incandescence (max.

100 watts).

16. Poser le globe en plexiglas et le fixer avec les

deux vis M4 x 12 mm

fournies.

Attention: une inversion

des branchements entraînera plus tard un court-circuit

dans l’appareil ou dans le

boîtier à fusibles. Dans ce

cas, il faut à nouveau identifier les câbles.

15

On peut modifier la hauteur du luminaire en coupant le tube.

Attention: ne jamais

découper l’évidement.

Si nécessaire, vous pouvez

remplir de silicone la rainure

de la plaque d’assise (2)

afin de fixer ensemble le

fond de fixation et la plaque

d’assise et de les étanchéifier.

Attention: ne pas remplir

de silicone le trou latéral

d’évacuation de l’eau (3).

Mode d’emploi

F

La durée de commutation

de l’appareil raccordé est

réglable en continu (d’environ 10 s à 15 min). Après

écoulement de la durée

réglée, chaque mouvement

réactive la temporisation

réglée. La détection des

mouvements est la plus

fiable quand l’appareil est

placé perpendiculairement

au sens de passage et

qu’aucun obstacle (arbre,

mur, etc.) n’obstrue le

champ de visée.

L’interrupteur crépusculaire

(LDR) intégré est également

réglable en continu (d’environ 2 lux à 2000 lux).

2 lux = mode nocturne,

2000 lux = mode diurne.

Le principe

14

Le détecteur infrarouge pyroélectrique intégré détecte

le rayonnement de chaleur

invisible émis par les corps

en mouvement (personnes,

animaux, etc.). Ce rayonnement de chaleur capté est

ensuite traité par un systè-

me électronique qui met en

marche la lampe. Les

obstacles comme les murs

ou les vitres s’opposent à la

détection du rayonnement

de chaleur et empêchent

toute commutation.

Installation

Attention: le montage com-

prend le raccordement au

secteur. La tension de 230 V

peut être mortelle. L’installation du luminaire de jardin

à détecteur implique une

intervention sur le réseau

électrique et doit donc être

effectuée correctement et

conformément à la norme

NF C-15100. Avant de commencer le travail, il faut

donc couper le courant et

s’assurer de l’absence de

courant à l’aide d’un testeur

de tension.

01. Enfoncer le tube dans le

pied du luminaire afin

que le petit évidement

soit orienté vers le haut.

Le fixer ensuite par dessous avec 4 vis (3 x 16).

02. Passer le câble dans le

tube en l’introduisant

par le bas. Attention: le

câble doit être plus long

que le tube d’au moins

13 cm. Le câble doit

avoir une isolation

double jusque sur la

section introduite dans

la partie supérieure du

luminaire.

03. Retirer la plaque coulis-

sante (cache-bornes) du

bloc d’éclairage et la

faire glisser vers le bas

sur le tube.

04. Retirer la gaine du câble

sur une longueur d’environ 10 cm.

05. Enfoncer le bloc d’éclai-

rage dans le tube en faisant passer le câble

dans l’ouverture prévue.

06. Faire pivoter le bloc

d’éclairage afin que le

domino se trouve audessus de la fente

oblongue du tube.

07. Faire pivoter le luminaire

ainsi préassemblé afin

que le détecteur soit à

peu près orienté dans la

direction souhaitée

(réglage approximatif).

08. Marquer au sol l’empla-

cement des trous pour

la fixation du pied.

09. Retirer le bloc d’éclaira-

ge du tube et faire remonter le tube sur le

câble jusqu’à ce que les

emplacements des

2–12 m

100 cm – 50 cm

(2)

(3)

Page 9

17

Vous pouvez optimiser la

portée en fonction de vos

besoins. Vous pouvez

également régler la zone de

détection à l’aide des caches fournis et masquer

des segments de lentille

afin d’éviter des déclenche-

ments intempestifs causés

p. ex. par des voitures, des

passants, etc.

Si l’appareil raccordé doit

être mis sous tension indépendamment de la présence d’une source de chaleur

dans la zone de détection, il

faut actionner une fois rapidement l’interrupteur monté

sur le réseau domestique.

Ceci active l’appareil raccordé pour la durée réglée.

Les intempéries et les

champs électroma-

gnétiques intenses peuvent

nuire au bon fonctionnement du luminaire de jardin

à détecteur.

Les rafales de vent violentes, la neige, la pluie, la

grêle peuvent entraîner un

déclenchement intempestif

car le détecteur ne peut pas

distinguer les brusques variations de température des

sources de chaleur.

Si la lentille de Fresnel (lentille de détection) se salit,

vous pouvez la nettoyer

avec un chiffon humide (ne

pas utiliser de détergent).

Fonctionnement

Ce produit est conforme à

- la directive basse tension 2006/95/CE

- la directive compatibilité électromagnétique 2004/108/CE

Déclaration de conformité

Caractéristiques techniques

16

Après avoir branché le luminaire à détecteur, vous pouvez le mettre en service.

Deux possibilités de réglage

sont disponibles sur la face

inférieure de l’appareil.

Attention ! Tirez vers le bas

la plaque coulissante et faites pivoter la tête du détecteur vers le haut. Vous pouvez maintenant accéder par

le bas avec un petit tournevis aux réglages de temporisation de l’extinction et de

crépuscularité.

A) Temporisation de l’extinction (minuterie)

La durée d’éclairage souhaitée est réglable en continu d’environ 10 s à 15 min

maxi à l’aide de la vis située

sous l’appareil. La temporisation est à son minimum

(env. 10 s) quand la vis de

réglage est en butée à droite, à son maximum (env.

15 min) quand la vis est en

butée à gauche.

(L’appareil est livré réglé sur

la temporisation la plus

courte.) Il est conseillé de

régler l’appareil sur la temporisation la plus courte

pour régler la zone de détection et procéder au test

de fonctionnement.

B) Réglage crépusculaire

(seuil de réaction)

Le seuil de réaction du détecteur est également réglable en continu d’env. 2 à

2000 lux à l’aide de la vis

située sous l’appareil.

Lorsque la vis de réglage

est en butée à droite, l’appareil est en fonctionnement diurne, soit env. 2000

lux. Lorsque la vis de réglage est en butée à gauche,

l’appareil est en fonctionnement crépusculaire, soit

env. 2 lux. (L’appareil est

livré réglé en mode diurne.)

Lors du réglage de la zone

de détection et du test de

fonctionnement en plein

jour, la vis de réglage doit

être en butée à droite.

On dispose de trois modes

de fonctionnement réglables à l’aide du commutateur situé au-dessus du

détecteur.

Commutateur à gauche :

position (I) = la lampe

fonctionne en mode

éclairage permanent.

Commutateur en position

(0) : la lampe est éteinte.

Commutateur à droite :

position (Auto) = la lampe

est en fonctionnement par

détecteur.

Fonction

Montage: Tension 230–240 V

Angle de détection: 180° horizontalement, 8° verticalement

Orientabilité du détecteur: 55° horizontalement, 35° verticalement

Temporisation réglable: 10 s – 15 min

Portée: frontale : 12 m, latérale : 10 m

Surface de détection: env. 240 m

2

Puissance de l’ampoule: 100 watts maximum

Indice de protection: IP 44

Tip!

min.

5 min.

Page 10

19

Ce produit STEINEL a été

fabriqué avec le plus grand

soin. Son fonctionnement

et sa sécurité ont été contrôlés suivant des procédures fiables et il a été soumis

à un contrôle final par sondage. Steinel garantit un

état et un fonctionnement

irréprochables. La durée de

garantie est de 36 mois et

débute au jour de la vente

au consommateur. Nous

remédions aux défauts provenant d'un vice de matière

ou de construction. La garantie sera assurée à notre

discrétion par réparation

ou échange des pièces

défectueuses. La garantie

ne s'applique ni aux pièces

d'usure, ni aux dommages

et défauts dus à une utilisation ou maintenance incorrectes, ou à l'utilisation de

pièces non homologuées

par le fabricant. Les dommages consécutifs causés

à d'autres objets sont

exclus de la garantie.

La garantie ne s'applique

que si l'appareil non démonté est retourné à la station de service après-vente

la plus proche, dans un emballage adéquat, accompagné d'une courte description de la panne, d'une facture ou d'un ticket de caisse

portant la date d'achat et le

cachet du vendeur.

Service de réparation:

Le service après-vente de

notre usine effectue également les réparations non

couvertes par la garantie ou

survenant après l'expiration

de celle-ci. Veuillez envoyer

le produit correctement emballé à la station de service

après-vente la plus proche.

Garantie de fonctionnement

18

Problème Cause Remède

Le luminaire de jardin à

détecteur n’est pas sous

tension

Fusible de la maison dé-

fectueux, appareil hors

circuit, câble coupé

Court-circuit

Changer le fusible de la

maison, mettre l’interrupteur en circuit, vérifier le

câble à l’aide d’un testeur

de tension

Vérifier le branchement

Le luminaire de jardin à

détecteur ne s’allume pas

Pendant la journée, le

réglage de crépuscularité

est en position nocturne

Ampoule défectueuse

Interrupteur en position

ARRÊT

Fusible de la maison

défectueux

Réglage incorrect de la

zone de détection

Régler à nouveau

Changer l’ampoule

Mettre en circuit

Changer le fusible de la

maison, éventuellement

vérifier le branchement

Régler à nouveau

Le luminaire de jardin à

détecteur ne s’éteint pas

Mouvement continu dans

la zone de détection

Contrôler la zone de dé-

tection, éventuellement la

régler à nouveau ou la

masquer

Le luminaire de jardin à

détecteur s’allume et

s’éteint en permanence

Des animaux se dépla-

cent dans la zone de détection

Orienter le détecteur plus

vers le haut ou le masquer, modifier la zone ou

la masquer

Le luminaire de jardin à

détecteur s’allume de façon

intempestive

Le vent agite les arbres et

les arbustes dans la zone

de détection

Détection de voitures

passant sur la chaussée

Variations subites de

température dues aux intempéries (vent, pluie,

neige) ou à des courants

d’air provenant de ventilateurs ou de fenêtres ouvertes

Modifier la zone ou la

masquer

Modifier la zone, orienter

le détecteur plus vers le

bas

Modifier la zone, monter

l’appareil à un autre endroit

Changement de portée du

luminaire de jardin à détecteur

Autres températures am-

biantes

Par temps froid, réduire la

portée en orientant le

détecteur plus vers le bas

Par temps chaud, le

remonter

Dysfonctionnements

Page 11

penvoet met buis zover

over de stroomtoevoerkabel omhoog schuiven tot

de aangegeven bevestigingsgaten zichtbaar worden. Dan de bevestigingsgaten boren en de voet

met drie zeskantschroeven op de bodem bevestigen.

10. Steek de lamp weer in de

buis en lijn hem uit zoals

beschreven onder punt 6.

Trek vervolgens de bijgevoegde beschermende

slang over de gestripte

draden. De leiding met

bescherming wordt nu in

de snoerontlastingsklem

geklemd.

11. Een moer op een M3,5 x

10-schroef draaien. Het

sensorhuis iets optillen en

de schroef (1) in de lengtekerf leggen. De sensor

in de gewenste richting

draaien (fijninstelling).

Schroef (1) stevig aandraaien.

12. De beschermende slang

met de draden door een

van de aanwezige gaten

in de aansluitkamer naar

het kroonsteentje voeren.

13. Aansluiting van de

stroomtoevoerkabel

De stroomtoevoerkabel

bestaat uit een 3-polige

kabel.

L = stroomdraad

(zwart of bruin)

N = nuldraad (blauw)

PE = aardedraad

(geel/groen)

In geval van twijfel moet

u de kabels met een

spanningstester identificeren; daarna de kabel

weer spanningsloos

schakelen. De aardedraad (geel/groen) hoeft

niet te worden aange-sloten, omdat de lamp dubbel-randgeaard is (veiligheidsklasse II). De aardedraad eenvoudig ombuigen en isoleren. De fase

in de klem met de zwarte

kabel monteren. De nuldraad in de klem met de

blauwe kabel monteren.

14. De verschuifbare beschermkap (bedekking

van de aansluitingsruimte)

omhoog schuiven, richten, laten inklikken en met

de bijgevoegde schroef

2,2 x 9,5 vastzetten.

15. Gloeilamp (max.

100 Watt) indraaien.

16. De plexiglazen bol erop

zetten en met de drie bijgevoegde schroeven M4

x 12 mm vastzetten.

Belangrijk: Verwisseling van

de aansluitingen leidt in het

apparaat of in uw meterkast

later tot kortsluiting. In dit geval moeten de afzonderlijke

kabels nogmaals geïdentificeerd worden.

21

Door inkorten van de buis

kan de lamphoogte individueel worden aangepast.

Let op: Nooit de uitsparing

afknippen.

Indien nodig kunt u de groef

in de voetplaat (2) met siliconen opvullen om zo de

bevestigingsbodem en de

voetplaat met elkaar te ver-

binden en af te dichten.

Let op: de zijdelingse afvoeropening voor water (3)

niet met siliconen opvullen.

Gebruiksaanwijzing

NL

De inschakeltijd van de

lamp is traploos instelbaar

(van ca. 10 sec. tot ca.

15 min.). Bij iedere beweging binnen het registratiebereik wordt na afloop van

de ingestelde tijd de lamp

opnieuw geactiveerd.

De beste bewegingsregistratie heeft u, als de lamp

in een kleine hoek t.o.v. de

looprichting gemonteerd,

resp. gericht wordt en het

zicht van de sensor niet

(bijv. door bomen, muren

etc.) belemmerd wordt.

De geïntegreerde schemerschakelaar (LDR) is

eveneens traploos instelbaar (van ca. 2 lux tot ca.

2000 lux).

2 lux = nachtstand,

2000 lux = daglichtstand.

Het principe

20

De ingebouwde pyro-elektrische infrarood-sensor

registreert de onzichtbare

warmtestraling van zich bewegende mensen, dieren

etc. Deze zo geregistreerde

warmtestraling wordt elektronisch omgezet en scha-

kelt de lamp aan. Door belemmeringen, zoals bijv.

muren of ramen, wordt de

warmtestraling niet herkend, er volgt dus ook geen

schakeling.

Installatie

Let op: Montage is netaan-

sluiting. 230 Volt is levensgevaarlijk. Bij de installatie van

de sensor-tuinlamp werkt u

met netspanning: dit moet

dus vakkundig volgens NL:

NEN 1010; B: (AREI) NBN 15101 worden uitgevoerd. Daarom eerst de stroom uitschakelen en op spanningsloos

heid testen met een spanningstester.

01. De buis in de lampenvoet

steken, zodat de kleine

uiitsparing naar boven

wijst. Dan van onderen

met 4 schroeven (3 x 16)

vastschroeven.

02. De stroomdraad van on-

deren door de buis leiden.

Belangrijk: De stroomtoevoerkabel moet minstens 13 cm langer zijn

dan de buis. De stroomtoevoerkabel moet dubbel-randgeaard tot in het

bovenste lampengedeelte

worden geleid.

03. De verschuifbare be-

schermkap (bedekking

van de aansluitingsruimte)

van het sensorhuis afhalen en over de buis naar

beneden schuiven.

04. Buitenste stroomtoe-

voerkabel ca. 10 cm

afstrippen.

05. Het sensorhuis in de

buis steken, daarbij de

stroomtoevoerkabel

door de hiervoor bestemde opening leiden.

06. Het sensorhuis draaien,

zodat het kroonsteentje

boven de lengtekerf in de

buis staat.

07. De aldus voorbereide

complete lamp met

sensor zo draaien, dat

de sensor ongeveer in

de gewenste richting

wijst (grove instelling).

08. De bevestigingsgaten

van de voet op de

bodem overbrengen,

resp. aftekenen.

09. Het sensorhuis weer uit

de buis halen en de lam-

2–12 m

van 100 cm – 50 cm

(2)

(3)

Page 12

23

Het registratiebereik kan afhankelijk van de wensen

optimaal worden ingesteld.

Met de meegeleverde af-

dekplaatjes kunt u het registratiebereik van de sensor

nauwkeurig afstellen. Lenssegmenten kunnen worden

afgedekt om foutieve schakelingen door bijv. auto’s,

voorbijgangers uit te sluiten.

Als de lamp onafhankelijk

van een warmtebron binnen

het registratiebereik ingeschakeld moet worden, dan

wordt de netschakelaar binnenshuis eenmaal kort ingedrukt. Dan wordt de lamp

gedurende de ingestelde

tijd actief. Weersomstandigheden en sterke elektromagnetische velden kunnen

de functie van de tuinlamp

beïnvloeden. Bij sterke

windvlagen, sneeuw, regen

of hagel kan een foutieve

schakeling plaatsvinden,

omdat het plotselinge temperatuurverschil niet van

warmtebronnen onderscheiden kan worden. De

Fresnel-lens (registratielens)

kan bij vervuiling met een

vochtige doek (zonder reinigingsmiddel) worden

schoongemaakt.

Werking

Dit product voldoet aan de

- laagspanningsrichtlijn 2006/95/EG

- EMC-richtlijn 2004/108/EG

Verklaring CE-richtlijnen

Montage: spanning 220–240 V

Registratiehoek van de sensor: 180° horizontaal, 8° verticaal

Zwenkbereik van de sensor: 55° horizontaal, 35° verticaal

Schakeltijd, instelbaar: 10 sec. – 15 min.

Reikwijdte: 12 m frontaal, 10 m zijdelings

Registratieoppervlak: ca. 240 m

2

Vermogen van de gloeilamp: max. 100 Watt

Bescherming: IP 44

Technische gegevens

Functies

22

Na aansluiting kan de sensorlamp worden ingeschakeld. Twee instelmogelijkheden staan nu aan de onderzijde van het apparaat ter

beschikking.

Let op! Beschermkap naar

beneden schuiven en de

sensorkop naar boven

draaien. Met een kleine

schroevendraaier aan de

onderzijde tijds- en schemerinstelling regelen.

A) Uitschakelvertraging

(tijdsinstelling)

De gewenste inschakelduur

van de lamp kan aan de onderzijde van het apparaat

traploos van ca. 10 sec. tot

max. 15 min. worden ingesteld. Stelschroef naar de

rechter aanslag betekent de

kortste tijd, ca. 10 sec. Stelschroef naar de linker aanslag betekent langste tijd, ca.

15 min. (Bij levering is het

apparaat bedrijfsklaar op de

kortste tijd ingesteld.) Voor

het instellen van het apparaat op het registratiebereik

en voor de functietest adviseren wij u de kortste tijd in

te stellen.

B) Schemerinstelling

(drempelwaarde)

De gewenste drempelwaarde van het apparaat kan

ook aan de onderzijde traploos van ca. 2 lux tot

2000 lux worden ingesteld.

Stelschroef naar de rechter

aanslag betekent daglichtstand, ca. 2000 lux.

Stelschroef naar de linker

aanslag betekent schemerstand, ca. 2 lux. (Bij levering

is het apparaat bedrijfsklaar

op de daglichtstand ingesteld). Voor het instellen van

het apparaat op het registratiebereik en voor de functietest bij daglicht moet de

stelschroef tegen de rechter

aanslag staan.

Drie schakelstanden zijn

mogelijk en kunnen aan het

apparaat boven de sensor

worden ingesteld.

Schakelaar naar links schuiven: schakelstand (I), lamp

brandt continu.

Schakelstand (0): lamp is

uitgeschakeld.

Schakelaar naar rechts

schuiven: schakelstand

(Auto), lamp ingesteld

op sensorregistratie bij

duisternis.

Tip!

min.

5 min.

Page 13

25

Dit STEINEL-product is met

grote zorgvuldigheid gefabriceerd, getest op goede

werking en veiligheid volgens de geldende voorschriften, en aansluitend

steekproefsgewijs gecontroleerd. Steinel verleent

garantie op de storingvrije

toestand en werking. De

garantietermijn bedraagt

36 maanden en gaat in op

de datum van aanschaf

door de klant. Alle klachten

die berusten op materiaalof fabricagefouten, worden

door ons opgelost. De garantie bestaat uit reparatie

of vernieuwen van de defecte onderdelen, door ons

te beoordelen. Garantie vervalt bij schade aan onderdelen, die aan slijtage onderhevig zijn en bij schade

of gebreken, die door ondeskundig gebruik of onderhoud ontstaan, alsmede

bij gebruik van vreemde

onderdelen. Schade aan

andere voorwerpen is uitgesloten van garantie.

De garantie wordt alleen

verleend als het niet-gedemonteerde apparaat met

korte foutbeschrijving,

kassabon of rekening (aankoopdatum en winkeliersstempel), goed verpakt aan

het desbetreffende serviceadres wordt gestuurd.

Reparatie-service:

Na afloop van de garantietermijn of bij schade die niet

onder de garantie valt, kan

ook door ons gerepareerd

worden. Gelieve het product

goed verpakt aan het dichtstbijzijnde serviceadres op

te sturen.

Functiegarantie

24

Storing Oorzaak Oplossing

Sensor-tuinlamp zonder

spanning

zekering in meterkast de-

fect, niet ingeschakeld,

leiding onderbroken

kortsluiting

nieuwe zekering in meter-

kast, netschakelaar inschakelen, leiding testen

met spanningstester

aansluitingen controleren

Sensor-tuinlamp schakelt

niet aan

bij daglicht, schemerin-

stelling staat op nacht

gloeilamp defect

netschakelaar UIT

zekering in meterkast

defect

registratiebereik niet

gericht ingesteld

opnieuw instellen

gloeilamp verwisselen

inschakelen

nieuwe zekering in meter-

kast, evt. aansluitingen

controleren

opnieuw instellen

Sensor-tuinlamp schakelt

niet uit

permanente beweging in

het registratiebereik

bereik controleren en evt.

opnieuw instellen of

afschermen

Sensor-tuinlamp schakelt

steeds AAN/UIT

bewegende dieren binnen

het registratiebereik

sensor omhoog draaien,

resp. gericht afschermen,

bereik veranderen of

afschermen

Sensor-tuinlamp schakelt

ongewenst aan

wind beweegt bomen en

struiken binnen het

registratiebereik

registratie van auto's op

straat

plotselinge verandering

van temperatuur door

weersomstandigheden

(wind, regen, sneeuw) of

luchtafvoer van ventilatoren of open ramen

bereik veranderen of

afschermen

bereik veranderen, sensor

wegdraaien

bereik veranderen, andere

montageplaats kiezen

Sensor-tuinlamp reikwijdteverandering

andere omgevingstem-

peraturen

bij kou sensorreikwijdte

door omlaag zwenken

verkorten

bij warmte sensor hoger

instellen

Storingen

Page 14

il tubo fino al punto in cui

diventano visibili i fori di

fissaggio, poi praticate

i fori di fissaggio e con

tre viti a testa esagonale

fissate lo zoccolo al

pavimento.

10. Infilate nuovamente il

corpo della lampada nel

tubo e orientatelo, come

descritto al punto 6.

Attraverso i conduttori

di rete pelati dovete far

passare ora il tubo flessibile di protezione fornito

in dotazione. Il conduttore

viene ora bloccato assieme al tubo flessibile di

protezione nello scarico

di trazione.

11. Avvitate un dado su una

vite M3,5 x 10. Sollevate

poi leggermente il corpo

luminoso ed inserite la

vite (1) nella fessura. Girate il sensore nella posizione desiderata (regolazione di precisione). Stringete la vite (1).

12. Fate passare il tubo flessibile di protezione con i

fili attraverso uno dei fori

predisposti portandolo

nel vano di collegamento

con il morsetto.

13. Allacciamento al cavo

di rete

Il cavo di collegamento a

rete ha 3 fili.

L = filo di fase (nero o

marrone)

N = filo neutro (blu)

PE = conduttore di terra

(verde/giallo)

Se avete dei dubbi controllate i cavi con un indicatore di tensione; poi

disinserite nuovamente

la tensione. Non occorre

collegare il conduttore

di terra (giallo/verde), poiché la lampada è dotata

di un doppio isolamento

protettivo (protezione

Classe II). Piegate semplicemente il conduttore

di terra e isolatelo. Fissate il filo di fase L nel

morsetto con filo nero.

Fissate il filo neutro nel

morsetto con filo blu.

14. Spingete verso l'alto il

coperchio (coperchietto

della cassetta collegamenti), mettetelo nella

giusta posizione, fatelo

inserire a scatto e fissatelo con la vite in dotazione

2,2 x 9,5.

15. Avvitate una lampadina

(max 100 watt).

16. Infilate sopra la calotta

in plexiglas e fissatela

con le tre viti M4 x 12 mm

in dotazione.

Importante: Se scambiate

tra di loro i punti di allacciamento dei fili, potete provocare un corto circuito nell'apparecchio oppure nella scatola dei fusibili. In tal caso dovete allora individuare di nuovo i singoli fili.

27

Accorciando il tubo di

sostegno si può regolare

l'altezza della lampada.

Attenzione: Non tagliare

mai la cavità.

Se necessario potete riempire con silicone la scanalatura della piastra di zoccolo

(2), per fissare la piastra di

zoccolo sul pavimento con

interposto tratto di isolamento. Attenzione: Non

riempite di silicone l'apertura laterale per lo scarico

dell'acqua (3).

Istruzioni per l'uso

I

Il tempo di inserimento

dell'utilizzatore è regolabile

in continuo (da circa 10 sec.

a circa 15 min). Una volta

decorso il tempo di inserimento impostato, dopo

ogni rilevamento di movimento nel campo di rilevazione viene nuovamente

attivato il tempo impostato.

Il modo più sicuro per rilevare i movimenti si ha quando l'apparecchio viene

montato angolato rispetto

alla direzione di movimento,

senza che sull'area da controllare ci siano ostacoli (come p. es. alberi, mura ecc.)

che potrebbero impedire i

rilevamenti del sensore.

Anche l'incorporato interruttore crepuscolare (LDR) si

può regolare in continuo (da

circa 2 a circa 2000 lux).

2 lux = funzionamento

notturno,

2000 lux = funzionamento

diurno.

Il principio

26

Il rilevatore di movimento

piroelettrico a raggi infrarossi registra le radiazioni termiche invisibili provenienti

da corpi in movimento (uomini, animali, ecc.). Le radiazioni registrate vengono

elaborate elettronicamente

e provocano l'accensione

automatica della lampada .

Non vengono rilevate radiazioni termiche attraverso

ostacoli come p. es. mura o

lastre di vetro, ed in tal caso

non si ha nessuno scatto di

commutazione.

Installazione

Attenzione: Quando si instal-

la l'apparecchio, questo viene allacciato alla rete elettrica. 230 volt. Installando la

lampada a sensore da giardino intervenite sulla tensione

di rete; questo lavoro deve

venire eseguito a regola d'arte, in base alle Norme VDE

0100. Perciò prima di tutto

disinserite la corrente e con

un indicatore di tensione

accertatevi che non ci sia

presenza di tensione.

01. Inserite il tubo nello

zoccolo della lampada in

modo tale che la piccola

cavità sia rivolta verso

l’alto. Poi fissatelo in

basso con 4 viti (3 x 16).

02. Dal di sotto spingete il

conduttore di alimentazione attraverso il tubo,

Importante: Il conduttore

di alimentazione deve essere di almeno 13 cm più

lungo del tubo. Il cavo

elettrico, con doppio

isolamento protettivo,

deve venir spinto fino

nella parte superiore

della lampada.

03. Sfilate il coperchio

(coperchietto della cassetta collegamenti) dal

corpo della lampada e

spingetelo verso il basso

lungo il tubo.

04. Togliete dal cavo esterno

circa 10 cm di isolamento.

05. Inserite il corpo della lam-

pada nel tubo, facendo

passare il cavo di alimentazione attraverso il foro

appositamente eseguito.

06. Girate il corpo della lam-

pada fino a posizionare il

morsetto sopra la fessure del tubo.

07. Girate ora assieme la

lampada così premontata

ed il sensore fino al punto

in cui il sensore viene a

trovarsi rivolto all'incirca

nella direzione desiderata

(regolazione all'incirca).

08. Riportate o segnate i

fori di fissaggio dallo

zoccolo sul terreno o sul

pavimento.

09. Staccate nuovamente il

corpo della lampada dal

tubo e ritraete assieme

dal cavo la lampada con

2–12 m

Da 100 cm a 50 cm

(2)

(3)

Page 15

29

A seconda della necessità è

possibile impostare il campo di rilevamento in modo

ottimale. Con le elementi di

schermatura in dotazione

potete definire il campo di

rilevamento del sensore con

maggiore precisione. Si

possono coprire determinati

segmenti di lente per evitare

scatti non desiderati, provocati, p. es. da automobili o

passanti.

Se l'utilizzatore deve essere

attivato indipendentemente

dalla presenza di una sorgente di calore nell'ambito

del suo campo di rilevamento, basta azionare brevemente l'interruttore interno di casa. Allora l'utilizzatore rimane attivato per il

tempo impostato.

Influssi atmosferici e forti

campi magnetici possono

pregiudicare il buon funzionamento della lampada da

giardino. In caso di forti raffiche di vento, molta neve,

pioggia o grandine l'illuminazione può venire attivata

erroneamente, poiché l'apparecchio non è in grado di

fare una distinzione tra improvvisi sbalzi di temperatura e l'apparire di fonti di radiazioni termiche. Quando

la lente Fresnel (lente di rilevamento) risulta imbrattata

si può pulire con uno straccio umido (senza impiego di

detergenti).

Questo prodotto è conforme alle seguenti direttive:

- Direttiva sulla bassa tensione 2006/95/CE

- Direttiva sulla compatibilità elettromagnetica 2004/108/CE

Dichiarazione di conformità CE

Dati tecnici

28

Potete accendere la lampada dopo averla allacciata a

rete. Sul lato inferiore dell'apparecchio potete regolare

la lampada su uno di due tipi di funzionamento.

Attenzione! Sfilate verso il

basso la schermatura scorrevole e orientate verso l'alto la testa del sensore. Con

un piccolo cacciavite eseguite dal di sotto la regolazione dello spegnimento ritardato e della luce crepuscolare.

A) Ritardo di disinserimento (Impostazione del

tempo)

Sul lato inferiore dell'apparecchio la durata di accensione della lampada può venire regolata in modo continuo da circa 10 sec fino ad

un massimo di 15 min. Vite

di regolazione sulla battuta

di arresto destra significa

tempo più breve, circa

10 sec. Vite di regolazione

sulla battuta di arresto sinistra significa tempo più lungo, circa 15 min. (In fabbrica viene eseguita una regolazione sul tempo più breve.)

Quando impostate il campo

di rilevamento e quando

eseguite il test di funzionamento è consiqliabile impostare il tempo più breve.

B) Regolazione di luce

crepuscolare (Soglia di

reazione)

La soglia di reazione desiderata si può impostare in

continuo da circa 2 lux fino

a 2000 lux sul lato inferiore

dell'apparecchio.

Vite di regolazione sulla battuta di arresto destra significa funzionamento a luce

diurna, circa 2000 lux. Vite

di regolazione sulla battuta

di arresto sinistra significa

funzionamento crepuscolare, circa 2 lux. (In fabbrica

viene eseguita una regolazione su funzionamento a

luce diurna.) Quando impostate il campo di rilevamento e quando eseguite il

test di funzionamento con

luce diurna bisogna impostare la vite di regolazione sulla battuta di arresto

destra.

Sono disponibili tre funzioni

di commutatore, che possono essere impostate tramite il sensore.

Spingete il commutatore

verso sinistra.

Posizione (I): la lampada

rimane continuamente

accesa.

Posizione (0): la lampada è

spenta.

Spingete il commutatore

verso destra.

Posizione (Auto): la lampada si commuta su funzionamento con sensore

Funzioni

Funzionamento

Montaggio: Collegamento a 220-240 V

Angolo di rilevazione del sensore: 180° orizzontale, 8° verticale

Campo di orientamento del sensore: 55° orizzontale, 35° verticale

Tempo di accensione, regolabile: 10 sec – 15 min

Raggio d'azione: 12 m frontalmente, 10 m lateralmente

Superficie di rilevamento: circa 240 m

2

Potenza della lampada: max 100 watt

Classe di protezione: IP 44

Consiglio!

min.

5 min.

Page 16

31

Questo prodotto STEINEL

viene prodotto con la massima cura, con controlli di

funzionamento e del grado

di sicurezza in con-formità

alle norme vigenti in materia; vengono poi effettuati

collaudi con prove di campionamento. La Steinel si

assume la garanzia per una

perfetta costruzione ed un

perfetto funzionamento.

La garanzia si estende a 36

mesi ed inizia il giorno d'acquisto da parte dell'utilizzatore finale. Noi eliminiamo

anomalie dovute a difetti del

materiale o ad errori di fabbricazione, la prestazione

della garanzia avviene a nostra discrezione sottoforma

di riparazione o sostituzione

dei pezzi difettosi. La garanzia non viene prestata in caso di danni a pezzi soggetti

ad usura nonché di anomalie e danni dovuti ad un trattamento o una manutenzione inadeguati o all'impiego

di pezzi di altri costruttori .

Sono esclusi dal diritto di

garanzia gli ulteriori danni

conseguenti su oggetti

estranei. La garanzia viene

prestata solo se l'apparecchio viene inviato al

centro di assistenza competente non smontato, ben

imballato e accompagnato

da una breve descrizione

del difetto e dallo scontrino

di cassa o dalla fattura

(con l'indicazione della

data dell'acquisto e timbro

del rivenditore).

Centro assistenza tecnica:

Con periodo di garanzia

scaduto e nel caso di difetti

che non danno diritto a

prestazioni di garanzia, il

nostro centro di assistenza

esegue le relative riparazioni. Inviate il prodotto ben

imballato, al più vicino

centro di assistenza.

Garanzia sulle funzioni

30

Disturbo Causa Rimedi

La lampada a sensore da

giardino è senza tensione

Difetto del fusibile princi-

pale di casa, disinserimento, interruzione di

conduzione

Corto circuito

Cambiate il fusibile princi-

pale di casa, inserite l'interruttore principale, controllate il conduttore con

un indicatore di tensione

Controllate gli allaccia-

menti

La lampada a sensore da

giardino non si accende

Nel funzionamento di gior-

no l'impostazione di crepuscolo è regolata su funzionamento di notte.

Difetto della lampadina

ad incandescenza

Interruttore principale su

OFF

Difetto del fusibile princi-

pale di casa

Campo di rilevamento non

impostato con direzione

giusta

Eseguite una nuova im-

postazione

Cambiate la lampadina

ad incandescenza

Accendete l'apparecchio

Cambiate il fusibile princi-

pale di casa, eventualmente controllate

l'allacciamento

Eseguite una nuova rego-

lazione

La lampada a sensore non

si spegne

Movimento continuo sul

campo di rilevamento

Controllate il campo di

rilevamento, eseguite

eventualmente una nuova

regolazione o modificate

l'applicazione degli elementi di schermatura

La lampada a sensore

commuta in continuazione

(ON/OFF)

Animali in movimento sul

campo di rilevamento

Orientate il sensore più in

alto o eseguite una più

precisa schermatura del

sensore, modificate o

schermate il campo di

rilevazione

La lampada a sensore

commuta in continuazione

(ON/OFF)

Il vento muove alberi e

cespugli sul campo di

rilevazione

Vengono rilevate automo-

bili sulla strada

Improvvisi sbalzi di tem-

peratura dovuti a condizioni atmosferiche (vento,

pioggia, neve) o causati

da aria di scarico di ventilatori o da aria proveniente da finestre aperte

Modificate o schermate il

campo di rilevamento

Modificate il campo di

rilevamento, orientate

altrimenti il sensore

Regolate altrimenti il

campo di rilevamento,

cambiate il punto di montaggio

Cambiamenti del raggio

d'azione della lampada a

sensore da giardino

Altre temperature

ambientali

Nel caso di basse tempe-

rature accorciate il raggio

d'azione del sensore orientandolo verso il basso

Nel caso di elevate tem-

perature orientate il sensore verso l'alto.

Disturbi di funzionamento

Page 17

pie con el tubo por el cable de alimentación hasta

que puedan verse los orificios de sujeción marcados. A continuación taladre los orificios de sujeción y atornille al suelo el

pie de la Lámpara Sensor

con tres tornillos de cabeza hexagonal.

10.Insertar de nuevo el cuer-

po luminoso en el tubo y

alinearlo conforme a lo

descrito en el punto 6. Por

encima del conductor de

red pelado sin aislamiento, se ha de colocar la

manguera de protección

adjunta. La línea asi como

el tubo de protección son

fijados en la descarga de

tracción.

11.Aplique una tuerca en un

tornillo M3,5 x 10. Levante

ligeramente la lámpara e

introduzca el tornillo (1) en

el taladro longitudinal. Gire

el sensor a la posición deseada (ajuste de precisión)

y apriete el tornillo (1).

12.Pasar la manguera de

protección con los conductores a través de uno

de los orificios previstos al

recinto de conexión de la

regleta.

13.Conexión a la red

El cable de alimentación

consta de tres conductores.

L = fase (negro o marrón)

N = neutro (azul)

PE = toma de tierra

(amarillo/verde)

En caso de duda debe

identificar los conductores

con un comprobador de

tensión; a continuación

debe desconectarse de

nuevo la tensión. Debido

a que la lámpara lleva doble aislamiento de protección (clase de protección

II), no es necesario conectar la toma de tierra (amarillo/verde); simplemente

dóblela y aíslela. Monte la

fase L en el borne con el

conductor negro. Monte el

neutro en el borne con el

conductor azul.

14.Suba la cubierta corrediza

(cubierta del espacio de

las conexiones), alinéela,

enclávela y fíjela con el

tornillo 2,2 x 9,5 adjunto.

15.Enrosque la bombilla

(máx. 100 W).

16.Coloque el globo de plexi-

glás y sujételo con los

tres tornillos M4 x 12 mm

adjuntos.

Importante: Si se efectúan

mal las conexiones se producirá luego un cortocircuito

en el aparato o en la caja de

fusibles. En este caso hay

que identificar cada uno de

los cables y montarlos de

nuevo.

33

Acortando el tubo puede

obtenerse la altura de Lámpara Sensor deseada.

Atención: No corte nunca

la entalladura.

En caso necesario puede

rellenar con silicona la ranura de la base (2) para estanqueizar la unión de la misma al suelo.

Atención: No rellene con

silicona el orificio lateral de

desagüe (3).

Instrucciones de montaje

E

El período de alumbrado de

la lámpara puede regularse

continuamente (de aprox.

10 seg. hasta aprox.

15 min.). Una vez transcurrido el período de alumbrado

regulado, con cada movimiento registrado en el

campo de detección se activa de nuevo el período de

alumbrado seleccionado.

La detección de movimientos más segura se consigue

montando u orientando el

aparato lateralmente con

relación al sentido del movimiento y evitando todo tipo

de objetos que obstaculcen

la visión del sensor (tales

como árboles, muros etc.).

El interruptor crepuscular

integrado (LDR) también

puede regularse continuamente (entre 2 y aprox.

2000 Lux).

2 Lux = funcionamiento

nocturno,

2000 Lux = funcionamiento

a la luz del día.

El concepto

32

El detector piroeléctrico

infrarrojo integrado registra

la radiación térmica invisible

de cuerpos en movimiento

(personas, animales etc.).

Esta radiación térmica

registrada se transforma

electrónicamente, encendiendo la lámpara.

Obstáculos tales como paredes o cristales impiden la

detección de una radiación

térmica y por consiguiente

no se produce tampoco el

encendido.

Instalación

Atención: El montaje signifi-

ca conexión a la red eléctrica. 230 V representan peligro

de muerte. La instalación de

la Lámpara Sensor de jardín

es un trabajo en la red eléctrica, por lo que debe realizarse

profesionalmente según las

normas VDE 0100. Por eso,

desconecte primero la

corriente y compruebe la

ausencia de tensión con un

comprobador de tensión.

1. Introduzca el tubo en el

pie de la Lámpara Sensor

de forma que la pequeña

entalladura mire hacia arriba. A continuación, fíjelo

desde abajo con 4 tornillos (3 x 16).

2. Introduzca el cable de

alimentación en el tubo

desde abajo. Importante:

El cable de alimentación

tiene que ser como mínimo 13 cm más largo que

el tubo. El cable de alimentación debe introducirse hasta la parte superior de la Lámpara Sensor

con doble aislamiento de

protección.

3. Retire la cubierta corrediza

(cubierta del espacio de

las conexiones) de la lámpara y desplácela por el

tubo hacia abajo.

4. Desaísle el cable de

alimentación exterior

aprox. 10 cm.

5. Introduzca la lámpara en

el tubo e inserte el cable

de alimentación por la

abertura existente.

6. Gire la lámpara de tal modo que la regleta divisible

se halle sobre el taladro

longitudinal del tubo.

7. Gire la lámpara completa

con el sensor en este

estado de montaje,

de tal modo que el

sensor está orientado

en la dirección deseada

(ajuste aproximado).

8. Marque en el suelo los

orificios del pie de la

Lámpara Sensor utilizando éste como plantilla.

9. Saque de nuevo la lámpara del tubo y retire el

2–12 m

de 100 cm a 50 cm

(2)

(3)

Page 18

35

El campo de detección puede regularse óptimamente

según necesidad. Con las

cubiertas adjuntas puede

regularse adicionalmente el

campo de detección del

sensor, cubriendo segmentos de lente para evitar que

la Lámpara Sensor se encienda inoportunamente

por el movimiento de automóviles o transeúntes.

Para conectar el aparato independientemente de una

fuente de calor en el campo

de detección, accione brevemente una vez el interruptor interno de la casa.

De ese modo se activa el

aparato para el período de

tiempo ajustado.

Las condiciones atmosféricas así como los campos

electromagnéticos potentes

pueden afectar al funcionamiento de la Lámpara

Sensor de jardín. Fuertes

ráfagas de viento, la nieve,

la lluvia y el granizo pueden

provocar un funcionamiento

erróneo al no poder diferenciar entre cambios de temperatura repentinos y fuentes térmicas.

La lente Fresnel (lente de

detección) puede limpiarse

con un paño húmedo (sin

detergente) cuando esté

sucia.

Funcionamiento

Este producto cumple con la

- Directiva de baja tensión 2006/95/CE

- Directiva CEM 2004/108/CE

Declaración de conformidad

Datos técnicos

Funciones

34

Una vez realizada la conexión, puede ponerse en funcionamiento la Lámpara

Sensor. El aparato ofrece

dos posibilidades de ajuste

en su cara inferior.

¡Atención!: Desplace la cubierta corrediza hacia abajo

y gire hacia arriba el cabezal del sensor. Realice la

temporización y la regulación crepuscular desde

abajo con un destornillador

pequeño.

A) Temporización

En la parte inferior del aparato puede usted regular

continuamente el período

de alumbrado de la lámpara

desde aprox. 10 seg. hasta

15 min. como máximo. El

tornillo de ajuste en el tope

derecho significa el tiempo

mínimo de aprox. 10 seg. El

tornillo de ajuste en el tope

izquierdo significa el tiempo

máximo de aprox. 15 min.

(El aparato viene ajustado

de fábrica para el período

de alumbrado mínimo). En

la regulación del campo de

detección y para la prueba

de funcionamiento se recomienda ajustar el tiempo

mínimo.

B) Graduación crepuscular (Punto de reacción)

El punto de reacción deseado también se puede regular continuamente en la

parte inferior del aparato,

desde 2 Lux hasta

2000 Lux.

El tornillo de ajuste en el tope derecho significa funcionamiento a la luz del día a

aprox. 2000 Lux. El tornillo

de ajuste en el tope izquier-

do significa funcionamiento

crepuscular a aprox. 2 Lux.

(El aparato viene ajustado

de fábrica para funcionamiento a la luz del día.)

En la regulación del campo

de detección y para la prueba de funcionamiento a la

luz del día debe hallarse el

tornillo de ajuste en el tope

derecho.

Se pueden seleccionar tres

funciones desplazando el

interruptor situado encima

del sensor.

Posición del interruptor a la

izquierda (I): La lámpara se

enciende en funcionamiento

permanente.

Posición del interruptor (0):

La lámpara está desconectada.

Posición del interruptor a la

derecha (Auto): La lámpara

se enciende en funcionamiento por sensor.

Montaje: tensión de alimentación 220–240 V

Ángulo de detección del sensor: 180° horizontal, 8° vertical

Girabilidad del sensor: 55° horizontal, 35° vertical

Temporización regulable: 10 seg. – 15 min.

Alcance: 12 m frontal, 10 m lateral

Área de detección: aprox. 240 m

2

Potencia de la bombilla: máx. 100 W

Clase de protección: IP 44

Tip!

mín.

5 min.

Page 19

37

Este producto STEINEL ha

sido elaborado con el máximo esmero, habiendo pasado los controles de funcionamiento y seguridad previstos por las disposiciones

vigentes, así como un control adicional de muestreo

al azar. Steinel garantiza el

perfecto estado y funcionamiento. El período de garantía es de 36 meses comenzando el día de la venta

al consumidor. Reparamos

defectos por vicios de

material o de fabricación,

la garantía se aplicará a

base de la reparación o el

cambio de piezas defectuosas, según nuestro criterio.

La prestación de garantía

queda anulada para daños

producidos en piezas de

desgaste, daños y defectos

originados por uso o mantenimiento inadecuados y

los causados por el uso de

piezas de otros fabricantes.

Quedan excluidos de la

garantía los daños consecuenciales causados en

objetos ajenos.

Sólo se concede la garantía

si se envía el aparato sin

desarmar con una breve

descripción del fallo, ticket

de caja o factura (con fecha

de compra y sello del

comercio), bien empaquetado, al centro de servicio

correspondiente.

Servicio de reparación:

Una vez transcurrido el período de garantía o en caso

de defectos no cubiertos

por la misma, las reparaciones las lleva a cabo nuestro

departamento técnico. Rogamos envíen el producto

bien embalado a la dirección indicada.

Garantía de funcionamiento

36

Fallo Causa Remedio

La Lámpara Sensor de

jardín no tiene tensión

fusible interno de la casa

defectuoso, sin conectar,

línea interrumpida

cortocircuito

cambiar fusible interno de

la casa, conectar el interruptor, comprobar la línea

con comprobador de

tensión

comprobar las conexiones

La Lámpara Sensor de

jardín no se enciende

en funcionamiento a la luz

del día, regulación crepuscular ajustada para funcionamiento nocturno

bombilla defectuosa

interruptor desconectado

fusible interno de la casa

defectuoso

campo de detección sin

ajuste selectivo

volver a regular

cambiar bombilla

conectar

cambiar fusible interno de

la casa, dado el caso

comprobar conexiones

graduar de nuevo

La Lámpara Sensor de

jardín no se apaga

movimiento permanente

en el campo de detección

volver a controlar el cam-

po de detección y dado

el caso graduar de nuevo

o cubrir partes del sensor

La Lámpara Sensor de

jardín se enciende y apaga

continuamente

hay animales en movi-

miento en el campo de

detección

girar el sensor a un plano