Steelcase V.I.A. FEIJA2V User Manual

CAUTION

CRUSH HAZARD!

FAILURE TO PROPERLY SECURE

V.I.A. TO THE BUILDING COULD

RESULT IN PERSONAL INJURY.

Read the entire Assembly Directions

before beginning installation.

Building construction varies greatly. The

Building’s Engineer of Record is responsible

for the design of building floors, ceilings

and walls which V.I.A. attaches to and must

verify the adequancy of the mounting

even if provided by Steelcase.

The building owner or designated agent is

responsible for verifying that the

installation is in compliance with all local

codes and regulations.

V.I.A.™ - Frames & Structure

Non-Seismic Applications*

The building’s Engineer of Record must be

*

consulted to determine if there are any

seismic requirements.

If you have a problem, question, or request, call

your local dealer, or Steelcase Line 1 at

888.STEELCASE (888.783.3522)

for immediate action by people who want to help you.

(Outside the U.S.A., Canada, Mexico, Puerto Rico,

and the U.S. Virgin Islands, call: 1.616.247.2500)

Or visit our website: www.steelcase.com

©

2017 Steelcase Inc.

Grand Rapids, MI 49501

U.S.A.

Printed in U.S.A.

By Steelcase Inc. Grand Rapids, MI 49501-1967

www.steelcase.com/patents

Model: FEIJA2V

Ship Date: 10/09/13 Athens

Order No.: 05207605-001160

Barcode: 1PN8Z952O

Assembled By: F529602

Finishes 6249

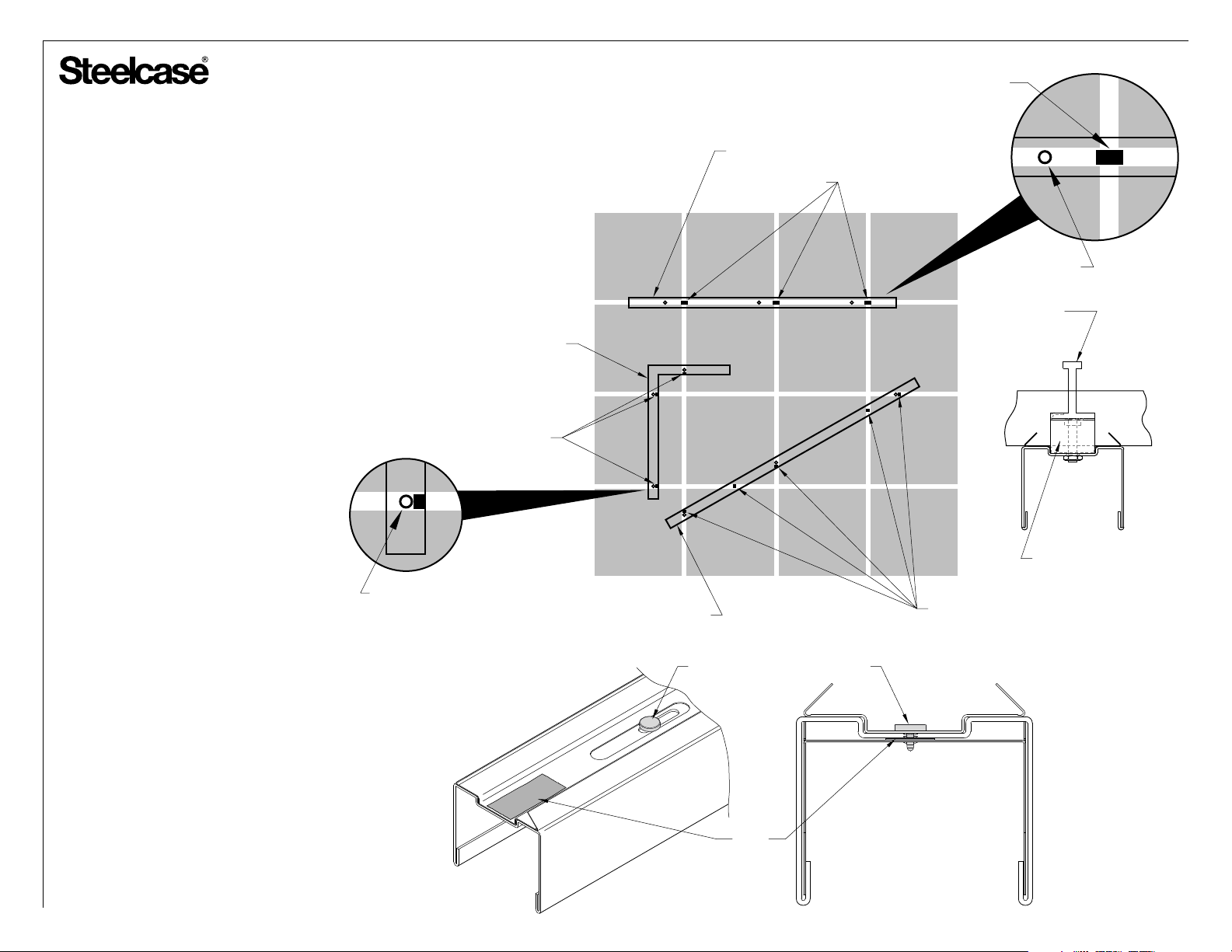

Installation Reference Identification (IRID) Label example shown above.

Many V.I.A. Products have specific locations within the floor plan layout.

These products will be identified with an Installation Reference Identification Label.

The Installation Reference ID Label number will indicate the location of the product

within the floor plan layout. Detailed information can be found on the label

including style/model number, finish, Plan dimensions, Measured dimensions etc....

J0DEF

PH: 108.000 MH: 105.618

Page 1 of 38

939502326 Rev G

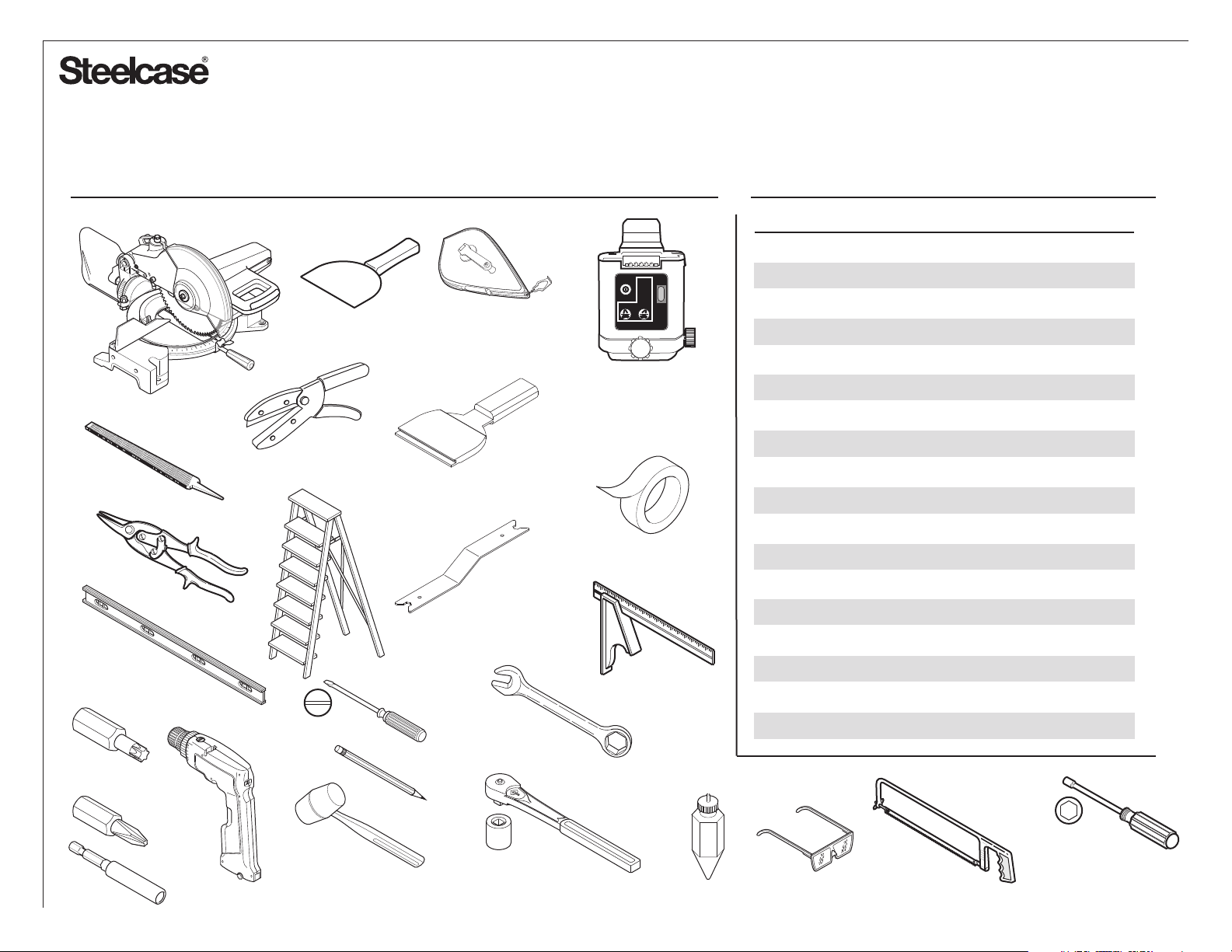

Tools Table of Contents

FRAMING LEVEL

PUTTY

KNIFE

HEAVY DUTY

UTILITY SHEAR

CHALK LINE

w/ WHITE CHALK

BASE TRIM

INSTALLATION TOOL

GLIDE

ADJUSTMENT

TOOL

LASERTRANSIT

ROTATE

POWER

SLOW

FAST

LASERTRANSIT

TIP: A 5-point alignment

self leveling laser is the

best tool to plumb, level

& square the product.

2" WIDE

MASKING TAPE

Topic Page

Layout Drawings & General Information

Installing Ceiling Channels

Installing Ceiling Track

Where to start Installing Structure

Floor Guide

Vertical Post Assembly Features

Installing Full Height Vertical Post Assembly

Junction Assemblies

Floor Track Features & Installation

Structural Horizontal Installation

Intermediate Horizontal Installation

Partial Height Vertical Post Installation

Base Trim Installation

Base Trim Removal Process

Acoustic Block Installation

Assembling a Junction Kit to a Junction

Assembling a Mini End to a Junction

3-4

5-8

9-18

19

20

21-22

23

24-25

26

27

28

29

30-33

34

34

35

36

T30

P2

LARGE & SMALL

DEAD BLOW HAMMER

8mm & 10mm

8mm & 10mm

PLUMB BOB

Changing Acoustic Seals

O

RAYB

32-TOOTH BLADE

HACKSAW

37-38

7/16” & 1/2”

Page 2 of 38

939502326 Rev G

®

A

119-1/4"

CL to outside of FE

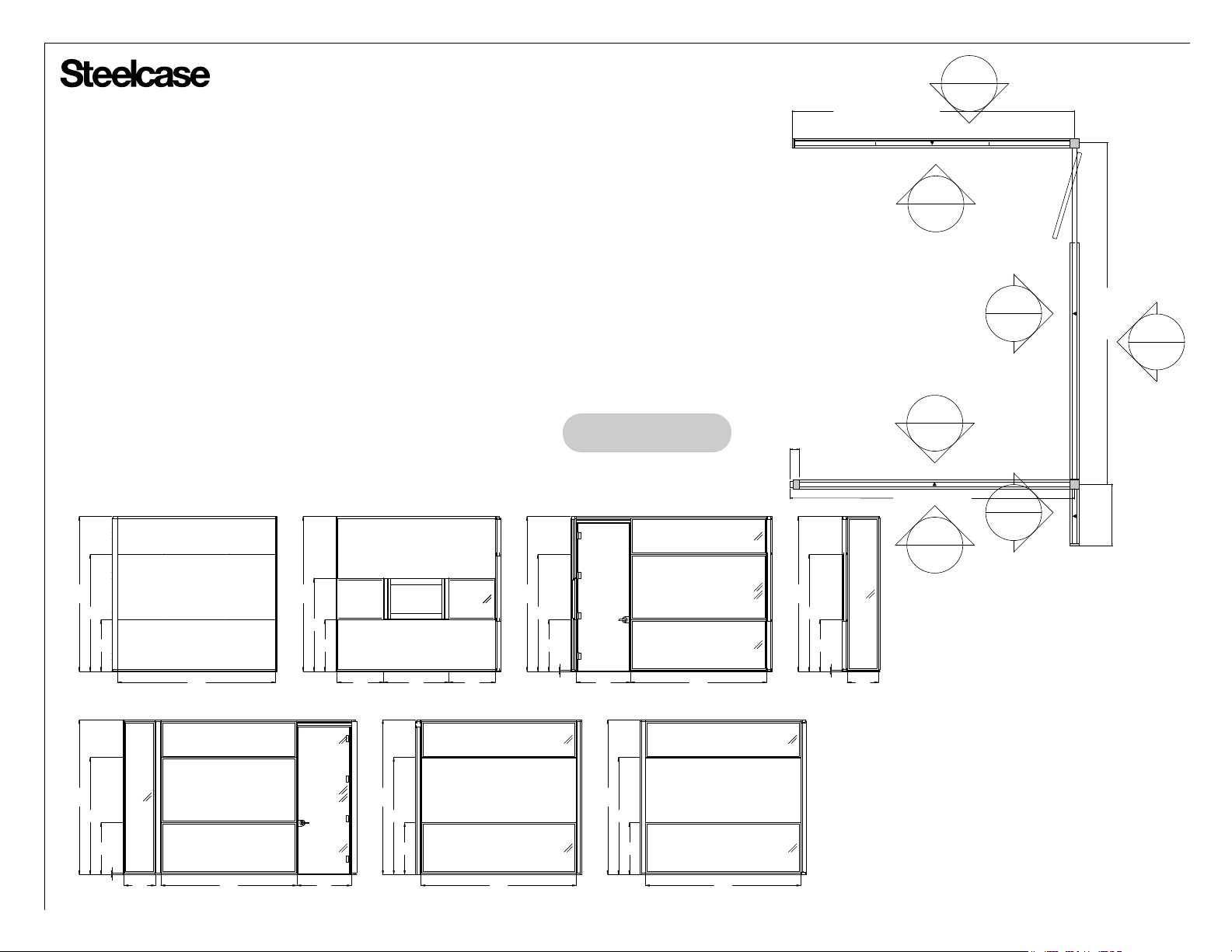

V.I.A. structures - Layout Drawings

Layout drawings give dimensions and details to help

installers determine location of product.

Ceiling track locations are taken from the centerline

dimensions on the plan view.

Locations of vertical components are found on the

plan view designated with individual IRID labels.

Locations of horizontal components are found in the

elevation views designated with individual IRID

labels.

Separate elevations are supplied for Structure, Skin

& Electrical components.

Automatic Elevations

114"

Ceiling Height

86"

38"

4242

SB12D

4242

S1362

4242

116"

Elevation A

114"

Ceiling Height

69"

38"

5F94

7360

6582

BE4C8

5F94

34" 48" 34"

Elevation B

B

Factory components are shipped with one

acoustic seal color applied. Elevation views

will indicate if a acoustic seal color changes.

See pages 37-38 for instructions on how to

replace acoustic seals.

C

144-1/8"

CL to CL

E

F

Example only

6500

S81F3

6582

BE4C8

S846AS4EC2

114"

Ceiling Height

86"

38"

1"

Elevation C

D30E6

40" 100"

3-3/4"

114"

Ceiling Height

86"

L696F

38"

1"

23"

Elevation D

CL to ME 120"

G

D

26"

CL to outside FE

114"

Ceiling Height

86"

6500

G2381

38"

1"

23" 100" 40"

GD660

G8EBA

GF791

Elevation E

114"

Ceiling Height

86"

38"

7241

Elevation F

G58C9

3062

C5175

114"

114"

Ceiling Height

86"

38"

Elevation G

WB6A0

G6207

114"

Page 3 of 38

939502326 Rev G

®

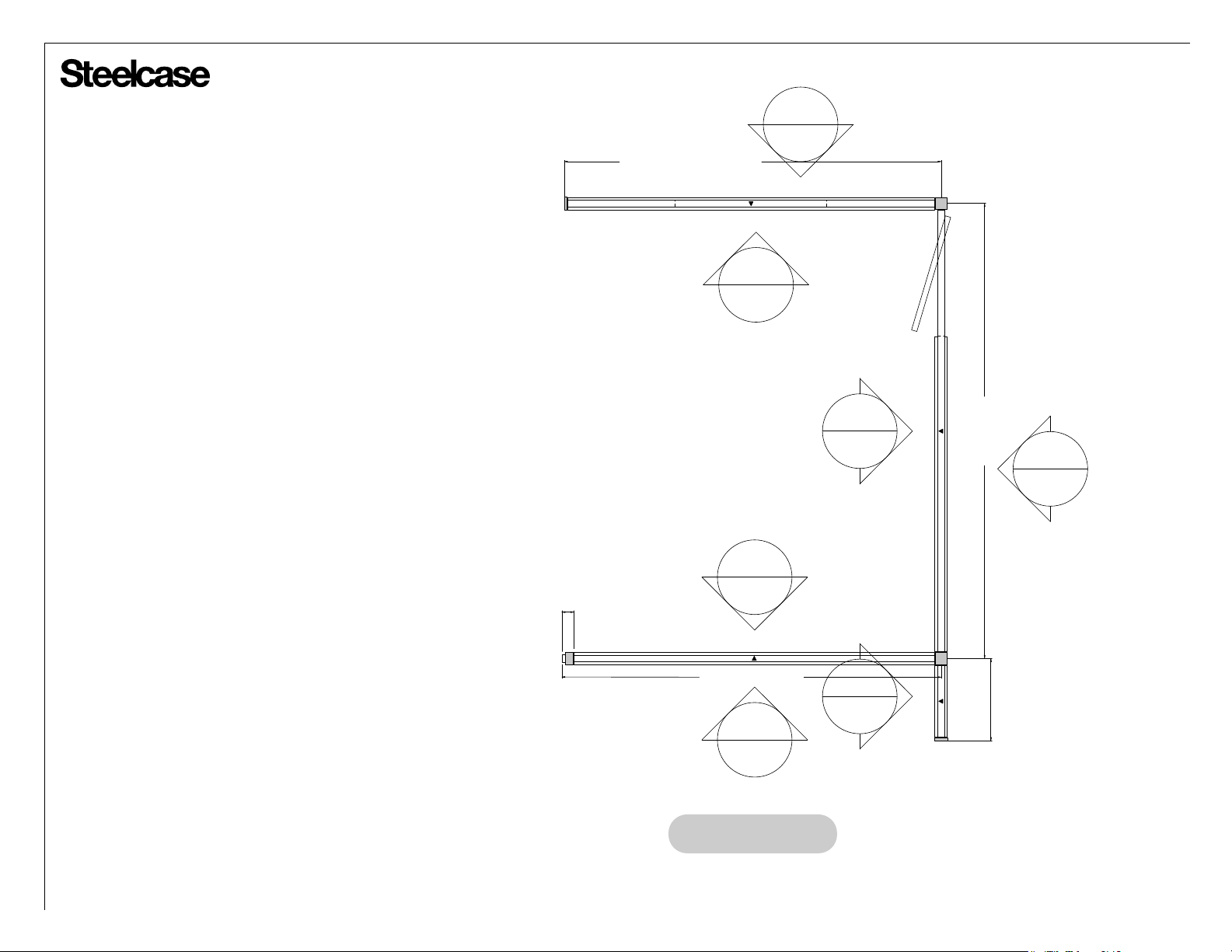

V.I.A. structures - General information

Use the centerline dimensions from the layout

drawing plan view to determine location of ceiling

track centerlines. Several methods can be used to

mark lines on the ceiling, including laser transit,

pencil marks on tape, chalk lines.

See pages 9 through 18 for additional ceiling track

information to determine cutting lengths for common

ceiling track conditions.

Transfer the ceiling centerline to the floor by means

of laser transits or plumb bob.

Make sure that the tape or lines are not visible after

install is complete.

119-1/4"

CL to outside of FE

B

A

C

144-1/8"

CL to CL

E

For the best results use a 5-point alignment self

leveling laser to transfer lines, plumb, level and square

+

to within 1/32 of an inch. The most accurate

feature to reference, while leveling, is the vertical

post system hole shown on page 21 & throughout

various V.I.A. assembly directions.

_

F

3-3/4"

CL to ME 120"

D

26"

G

CL to outside FE

Example only

Page 4 of 38

939502326 Rev G

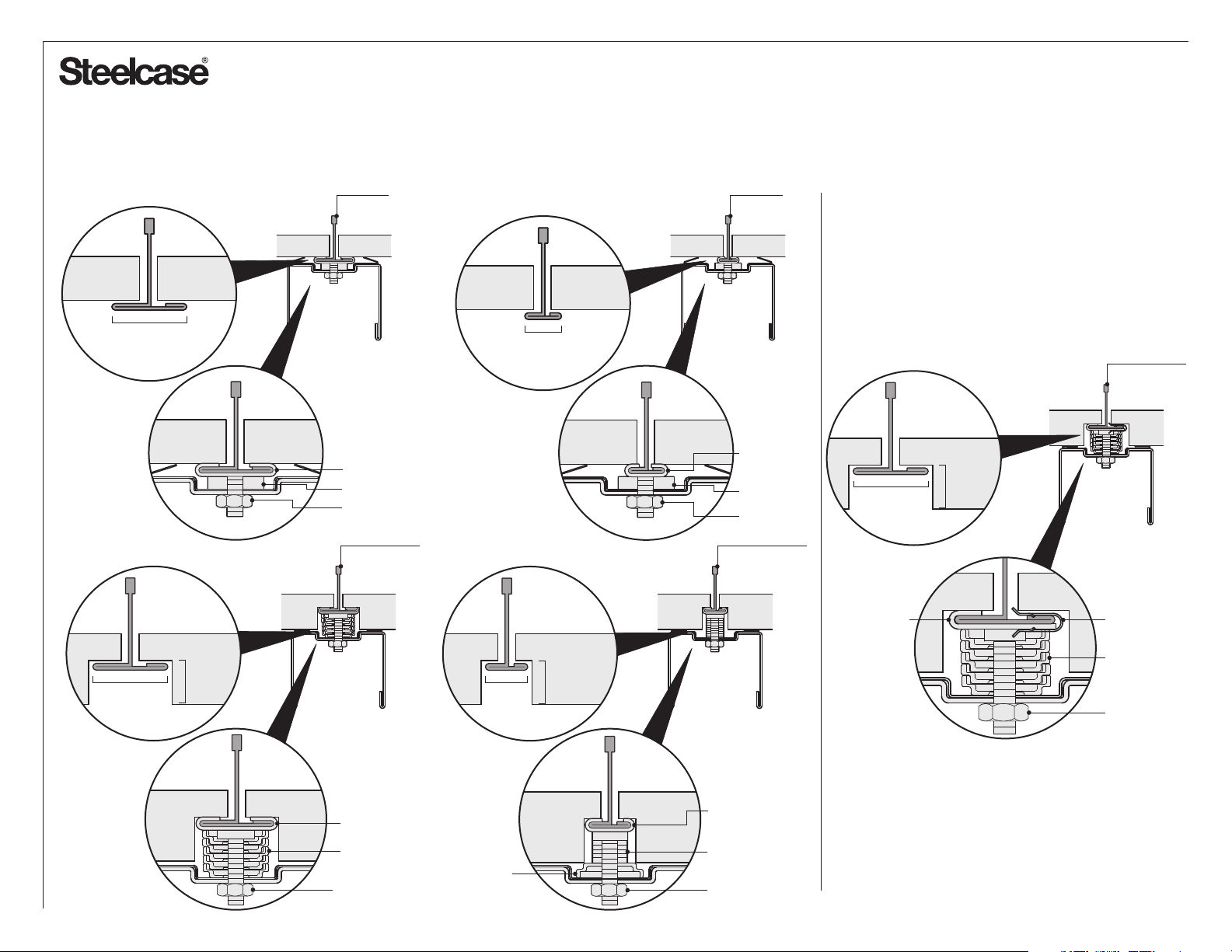

Channel Mounting Options*

The building’s designated design professional (Architect or Engineer) must verify that the ceiling grid is

*

adequate to support lateral loads imposed by V.I.A. Local codes may require independent bracing.

Exposed Tee Grids - V.I.A. Fastener Kits

1" nominal

(24mm)

1" nominal

(24mm)

1

/4",

3

/8", 1/2",

5

/8"

or

Exposed

T-clip

1/4-20 Caddy Clip Assembly

Nylon Washer

1/4-20 Hex Nut

1" Tegular Tee

9

9

/16"

nominal

(14mm)

/16" (14mm)

1

/4",

5

or

Exposed

T-clip

Exposed Tee Grids - V.I.A. Fastener Kit

Tinnerman Clip Style (Recessed Version)

1" Tegular Tee

1/4-20 Caddy

Clip Assembly

Nylon Washer

1/4-20 Hex Nut

9

/16" Tegular Tee

16"

/

1" nominal

(24mm)

#10-24 Ceiling

Clip Assembly

1

/4",

3

/8", 1/2",

5

or

/8"

Tinnerman Clip

Stack Spacers

#10-24 Hex Nut

#10-24 Caddy Clip Assembly

Stack Spacers

1 Stack Spacer

#10-24 Hex Nut

1/4-20 Caddy Clip

Assembly

Nylon Washers

1/4-20 Hex Nut

Page 5 of 38

939502326 Rev G

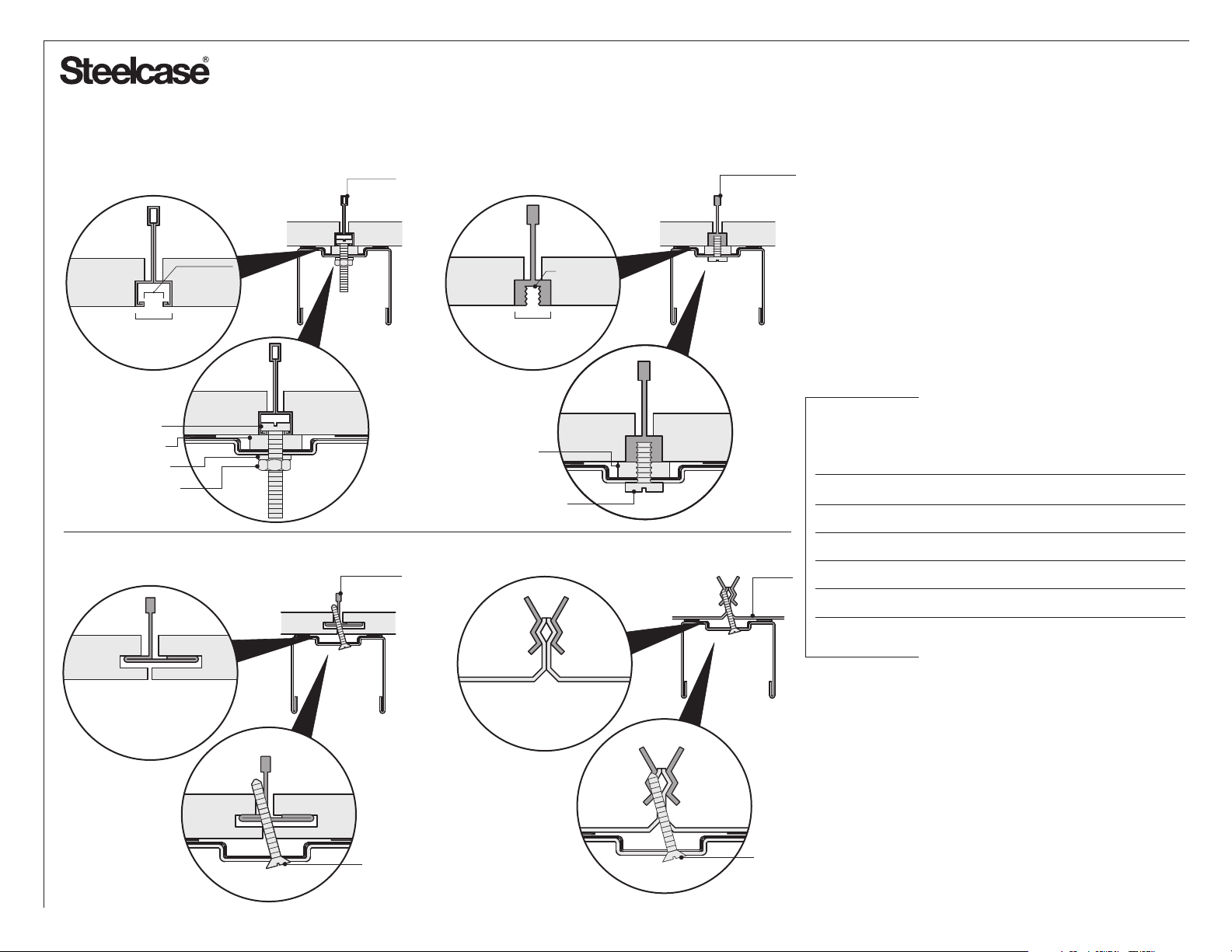

Channel Mounting Options (Continued)*

The building’s designated design professional (Architect or Engineer) must verify that the ceiling grid is

*

adequate to support lateral loads imposed by V.I.A. Local codes may require independent bracing.

Bolt and Screw Grids - V.I.A. Fastener Kits

9

/16" (14mm)

1/4-20 Donn Bolt

Nylon Washer

Nylon Washer

1/4-20 Hex Nut

slot widths

1

/8" or 1/4"

Fineline

channel

5

-18

/16

thread

9

/16" (14mm)

Nylon Washer

5/16-18 Screw

Concealed Grids - Field-Purchased Generic Fasteners

Concealed

spline

Fluted runner

Metal

ceiling

The following hardware is NOT supplied with the

product, but is commonly used for attachment

for common building construction.

NOTE: Mounting hardware must be specified/verified

by the designated design professional or approved by

the AHJ.

For these and other types of ceilings, the following

fasteners can be sourced locally by the installer:

Concealed spline

Drywall

Plaster

Concrete

Metal Pan

#7-17 x 1-5/8" Bugle Head Self-Drilling Screws

#14 - 1" Phillips Head SMS with plastic anchor

1/4-20 Toggle Bolt

Tapcon Anchor x 2"

#7-17 x 1" Bugle Head Self-Drilling Screws

Generic Sheet Metal Screw

Generic Sheet Metal Screw

Page 6 of 38

939502326 Rev G

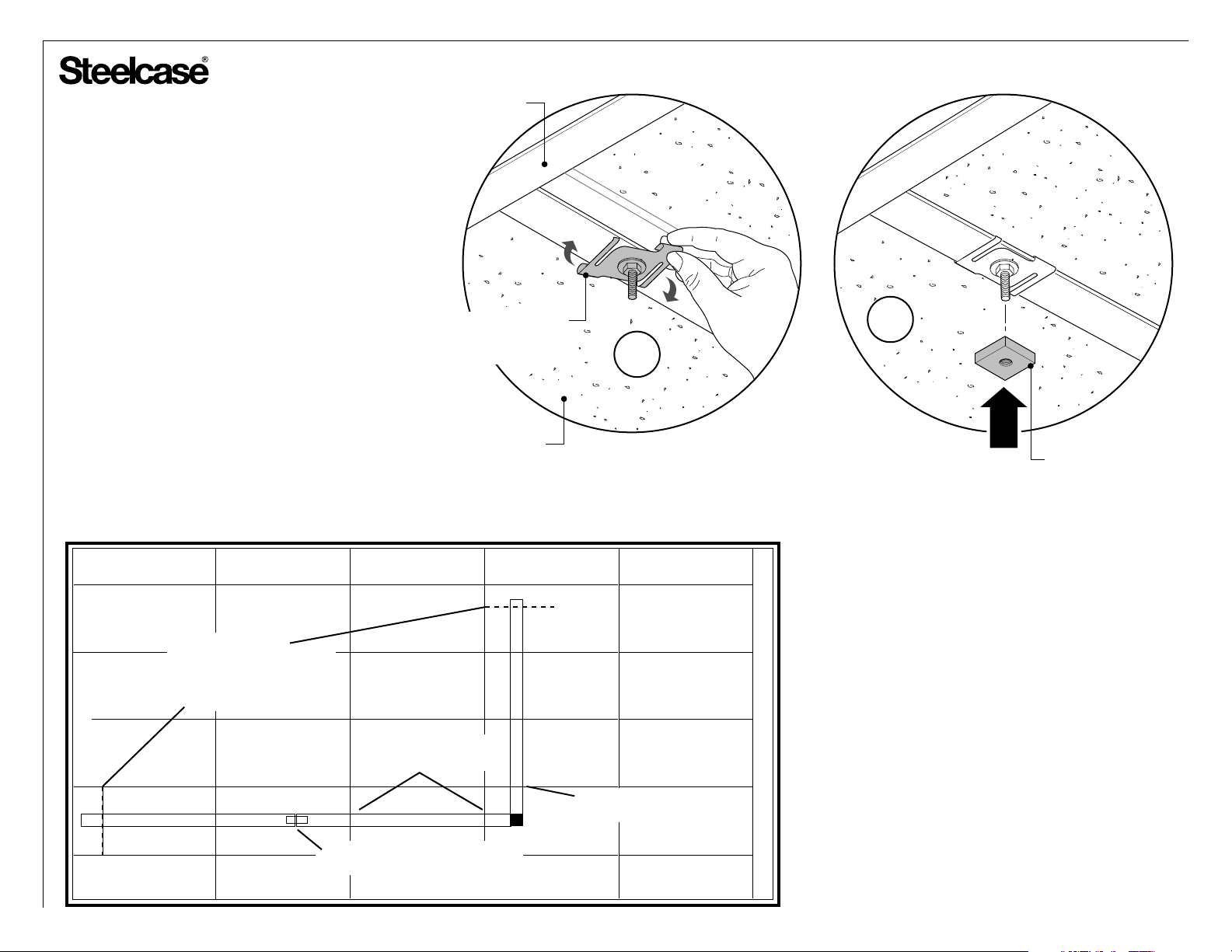

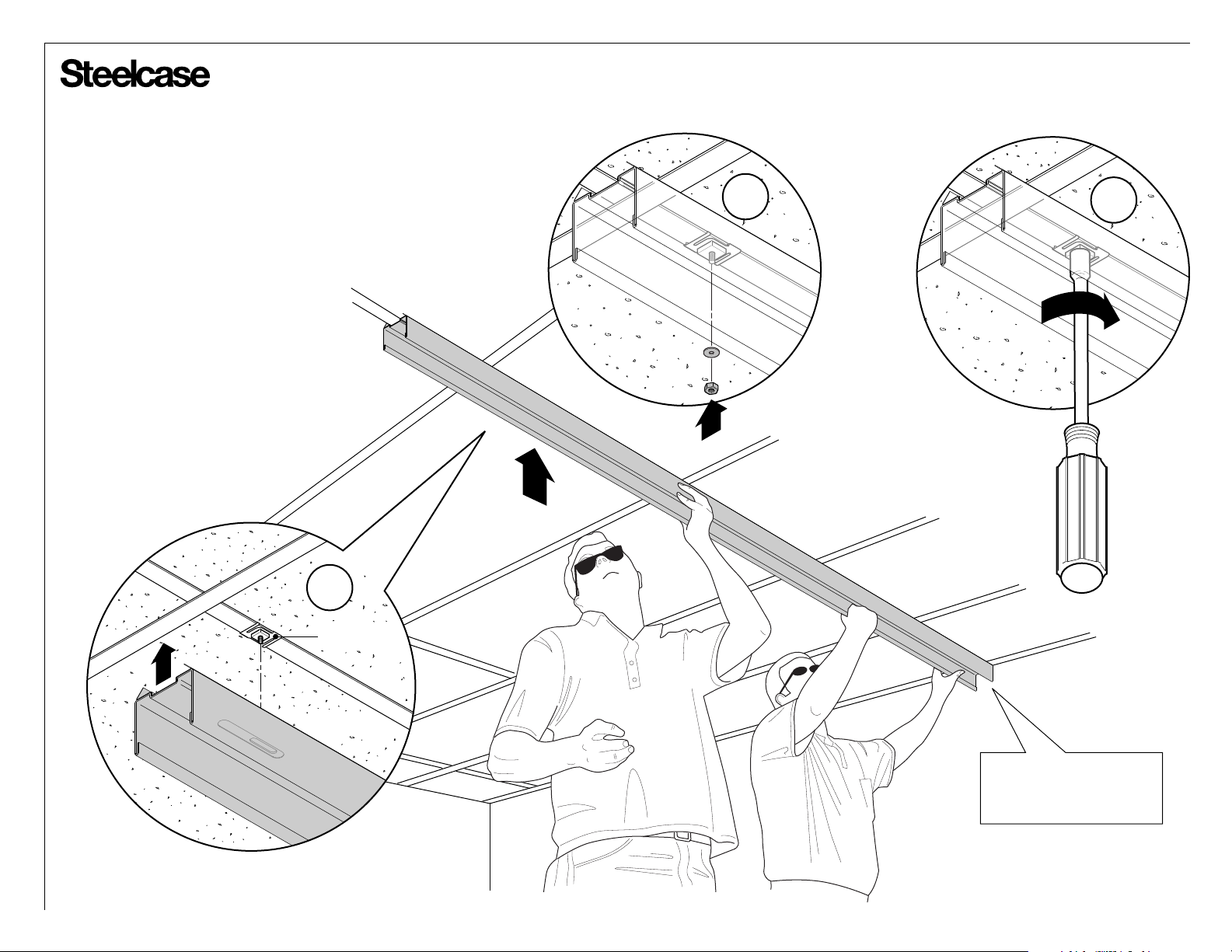

Installing Ceiling Channels

1. Attach the ceiling track to your ceiling in

compliance with local building codes and

common local practice as directed by the

lead installer. See 'channel mounting options'

for typical handling of common ceiling

conditions.

Connections should be made at least every

four feet for normal duty and at least every

two feet for heavy duty and along straight

runs, and within eight inches of the end of

any run. Each off-module connection or

junction should also have a connection

within eight inches of the joint.

CEILING GRID

1” EXPOSED CLIP SHOWN

(ONE OF SEVERAL

TYPES OF CLIPS)

CEILING TILE

1b

1a

SPACER

(ONE OF SEVERAL

TYPES OF SPACERS)

connect within 8" of

any end-of-run; this

may require building

a spanning structure above

the ceiling

X

4 feet maximum spacing

between junctions for normal

duty

XX

splice together ceiling joints

(supplied - one per ceiling channel)

X

X

X

X

X

connect within 8" of

any junction

NOTE: At this time consider electrical or

communications routing that would need to

be accommodated through the ceiling track.

Field cutting of track may be required.

Page 7 of 38

939502326 Rev G

CUT A SEAL PIECE BIG ENOUGH TO BLOCK

SOUND AND LIGHT IN BOTH DIRECTIONS

Installing Sound & Light Seal for

Tegular Ceiling

NOTE: Cut and place pieces of seal

anywhere that sound or light can travel

through the tegular grid.

Applications

CEILING TRACK PERPENDICULAR TO GRIDS

CEILING CLIP

SEAL

CEILING TRACK DIAGONALLY ACROSS GRIDS

CEILING TRACK INLINE WITH GRID

SEAL

CEILING

CLIP

TEGULAR

CEILING GRID

SEAL TO ONE SIDE

OF CEILING CLIP

AND WASHER STACK

SEAL

Installing Ceiling Channels

The Christmas Tree fasteners and tape serve

only as a shipping and assembly aid. They are

not required after the ceiling track is installed.

Move or remove them as needed to accommodate

the ceiling track clips.

If the channel is cut, it may be helpful to add a

piece of tape to one end. This maintains alignment

between the seal and steel channel while attaching

the channel to the ceiling.

CHRISTMAS TREE FASTENER

TAPE

Page 8 of 38

939502326 Rev G

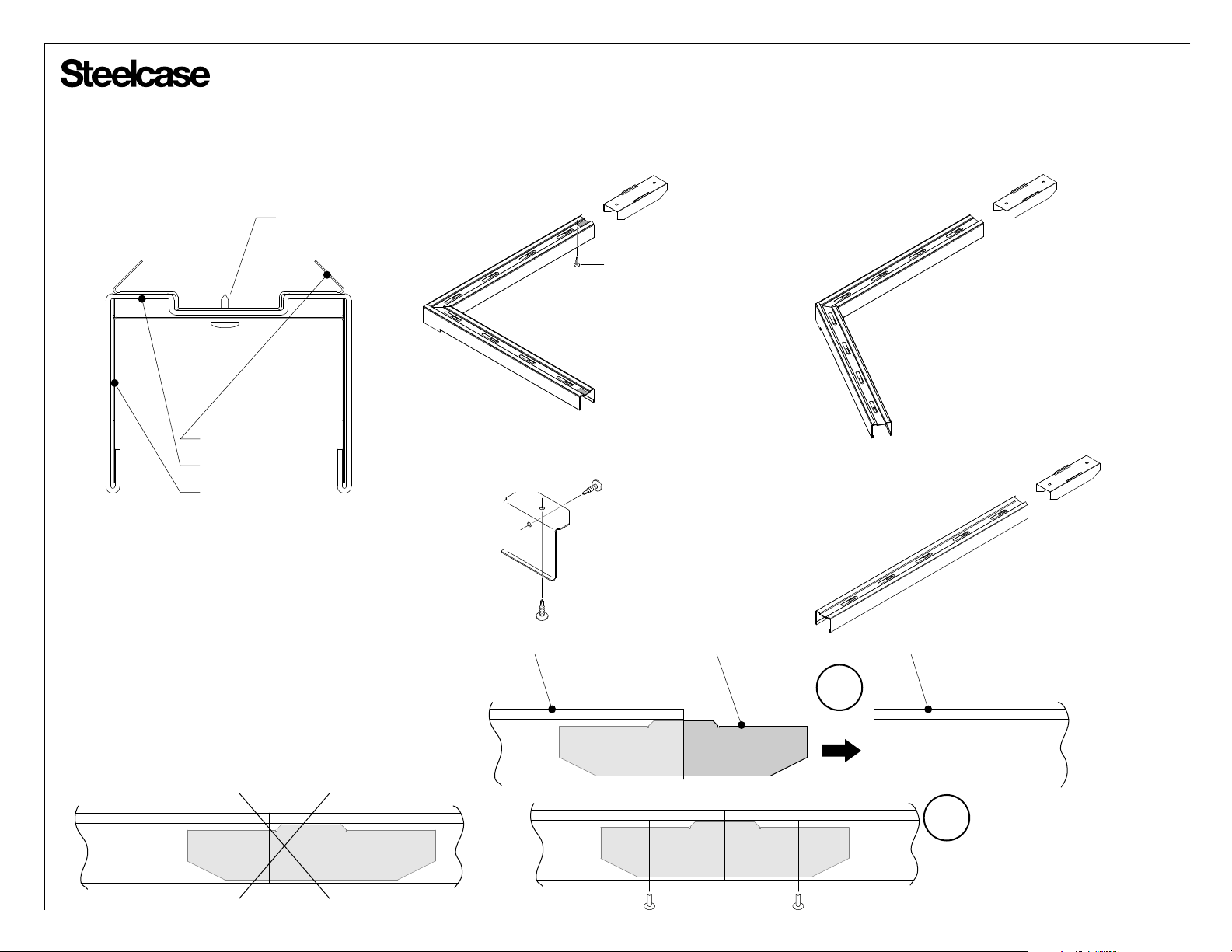

®

CEILING TRACK

INSTALLATION

SEAL

CEILING TRACK

SPLICE

SELF DRILLING

SCREWS

SPLICE

SELF DRILLING SCREW

90o CEILING TRACK (SHOWN)

120o CEILING TRACK

135o CEILING TRACK

NOTE: Specifiable angle ceiling track will have an

installation reference ID label placed on it and has a

specific location in the floor plan.

SPLICE

SPECIFIABLE ANGLE

CEILING TRACK

SPLICE

Each ceiling track comes with one (1) splice.

1.

When installing ceiling track butt joints, center the

splice as shown.

2. A feature of the straight ceiling track is the

center hole spacing matches most ceiling grids.

3. Two self tapping screws are provided to secure

the splice connection after the ceiling track

is installed.

WRONG

CEILING TRACK

BRACKET WITH

TWO (2) #6-20 x 3/8”

SELF DRILLING

SCREWS

CEILING TRACK CEILING TRACK

SPLICE

STRAIGHT

CEILING TRACK

1

3

TWO (2) #6-20 x 3/8”

SELF DRILLING

SCREWS

Page 9 of 38

939502326 Rev G

®

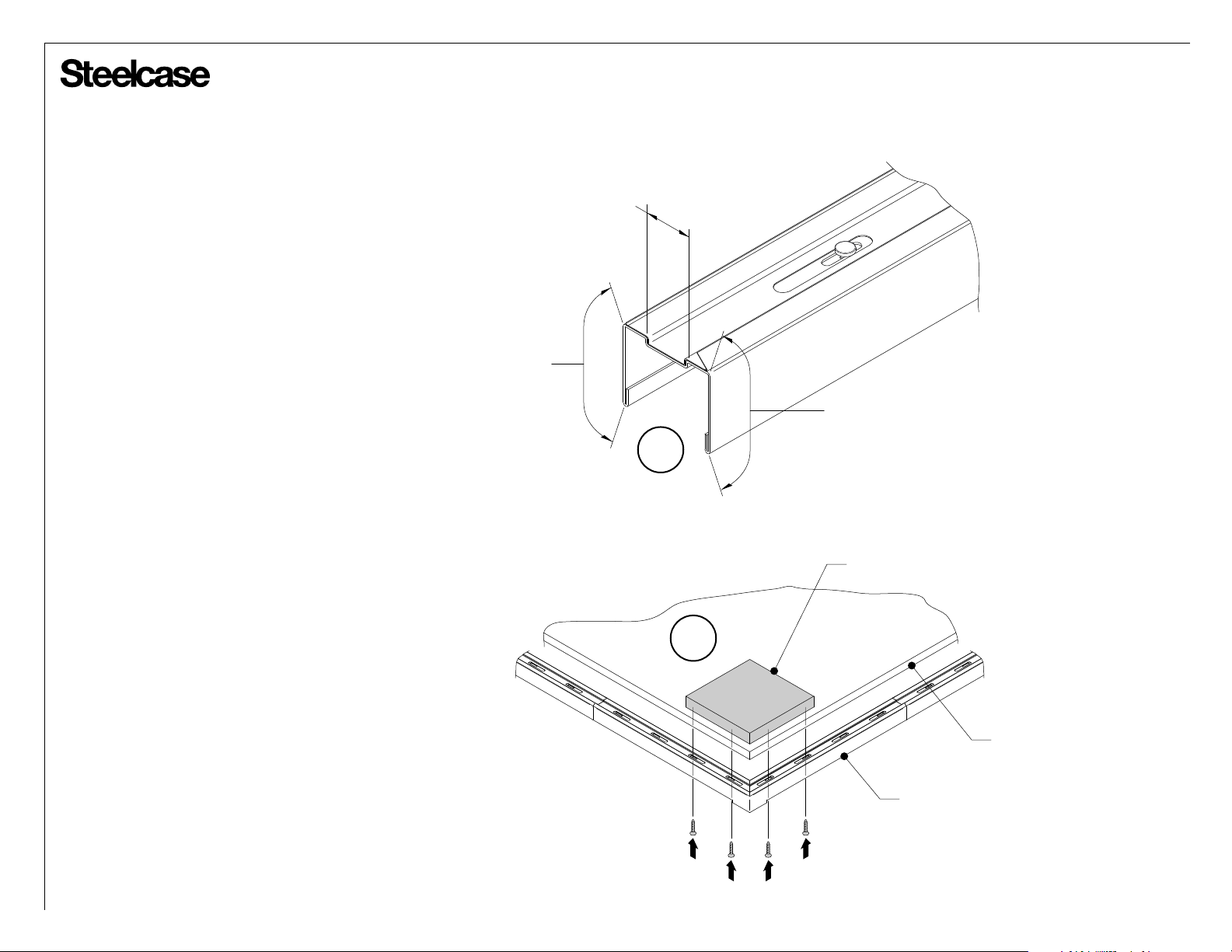

CEILING TRACK

INSTALLATION (cont.)

TIP: Before cutting the ceiling track, consider

locations of pre-punched holes to minimize the

need for additional holes.

3. Use a saw to cut ceiling track when required.

Remove all burrs with a file. Square cuts will

insure best appearence. When routing power or

communication, sheet metal shears can be

used to cut a hole in the top of the ceiling track.

Avoid cutting the side of the ceiling track

because these cuts will be visible.

4. To create a tight fit when a corner ceiling

track lacks structure, a wood block can be

installed above the ceiling tile for reinforcement.

NO

CUTS

AREA

CUT

AREA

NO

CUTS

AREA

3

WOOD BLOCK

4

CEILING TILE

CORNER

CEILING TRACK

Page 10 of 38

939502326 Rev G

®

CEILING TRACK

INSTALLATION (cont.)

Refer to ceiling clip mounting for

5.

information on available ceiling fastener

types and locations (Showing typical

ceiling fastener for general installation

purposes).

6. Take care to insure that the ceiling

track seal seats consistently.

6

CADDY CLIP

5a

5b

Install ceiling track flush

against building wall if

floor plan indicates.

Page 11 of 38

939502326 Rev G

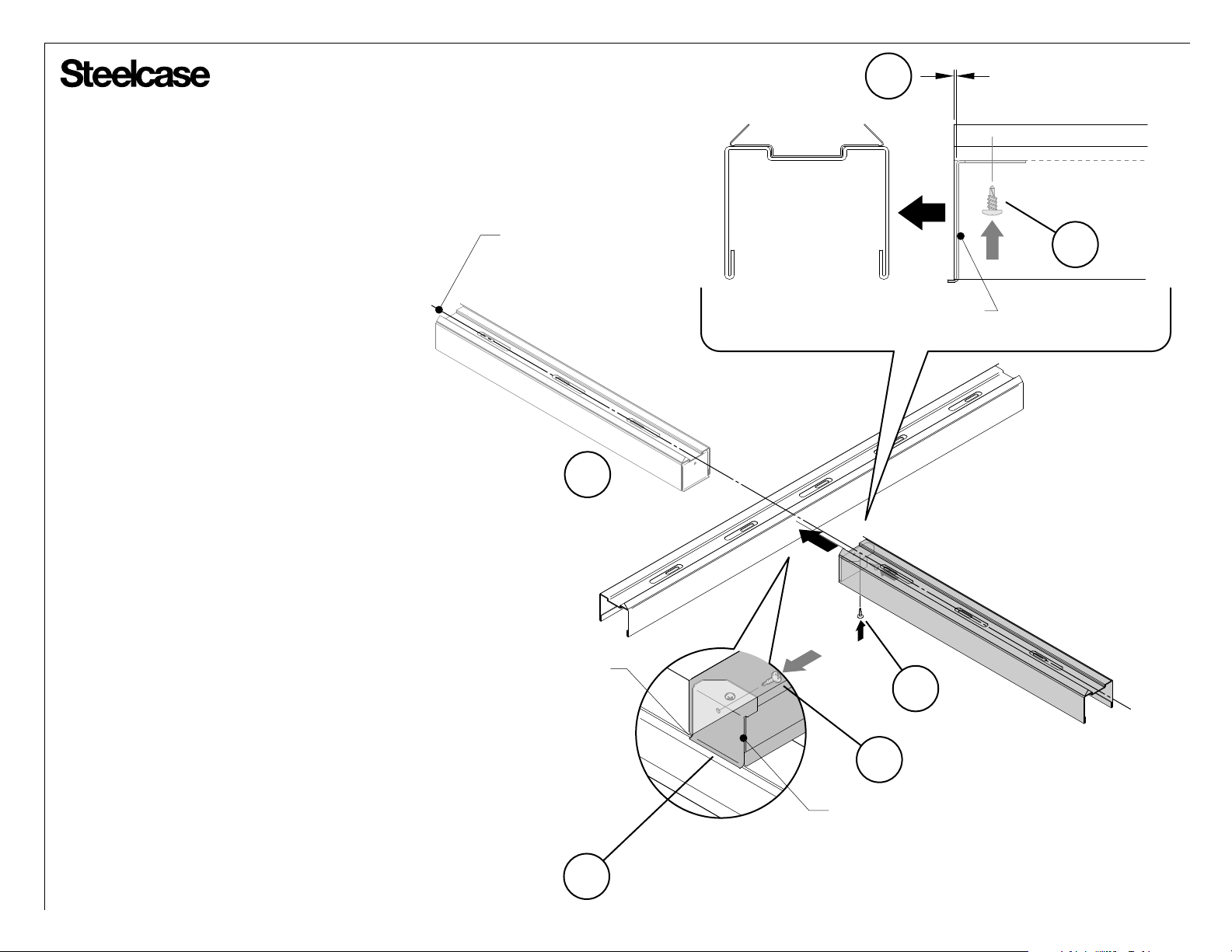

®

CEILING TRACK

INSTALLATION (cont.)

7a

1/16” BACK

When a ‘T’ intersection is required,

7.

attach the ceiling track bracket to 1/16”

back from end of ceiling track as shown

(7a) and attach with self-drilling screw

to the ceiling track (7b). Aligning to the

centerline of the floor plan, hook ceiling

track bracket (7c) to the other ceiling

track and attach with self-drilling screw

as shown (7d).

Repeat the process on the other side if

an ‘X’ intersection is required (7e).

FLOOR PLAN

CENTERLINE

7e

HOOK TO

CEILING TRACK

7b

CEILING TRACK

BRACKET

7b

7c

7d

CEILING TRACK

BRACKET

Page 12 of 38

939502326 Rev G

Loading...

Loading...