Steelcase Convene Assembly Manual

Steelcase, Inc.

Grand Rapids, MI 49501

U.S.A.

1-888-783-3522

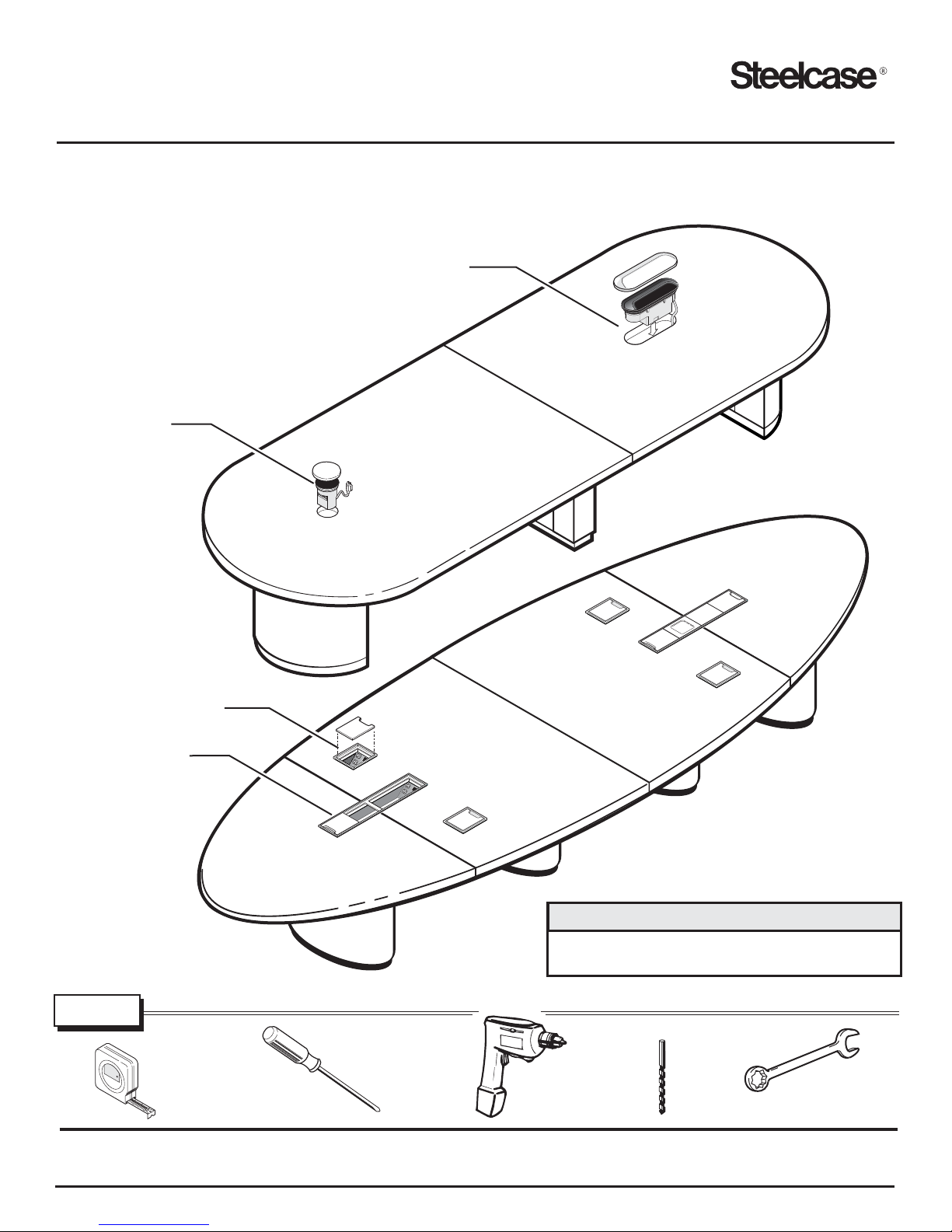

Convene - Sectional Table Top Assembly

RACETRACK TOP WITH ROUND

AND OVAL POWER PORTS

ROUND

POWER PORT

and Table Base Installation

OVAL

POWER PORT

POWER UNIT

POWER CHANNEL

TOOLS

4

7

8

0

8

6

4

8

9

Lufkin

R

3m/10'

Tape Measure

Assembly Directions

Screw Driver

Printed in U.S.A.

OVAL TOP WITH

POWER UNIT/CHANNEL

IMPORTANT NOTE

Install Power Unit/Power Channel before base.

(See Assembly Direction N9501956)

Power Driver

w/square tip

1/8"

Drill Bit

7/16” Wrench

Page1of11

N9501959 Rev. F

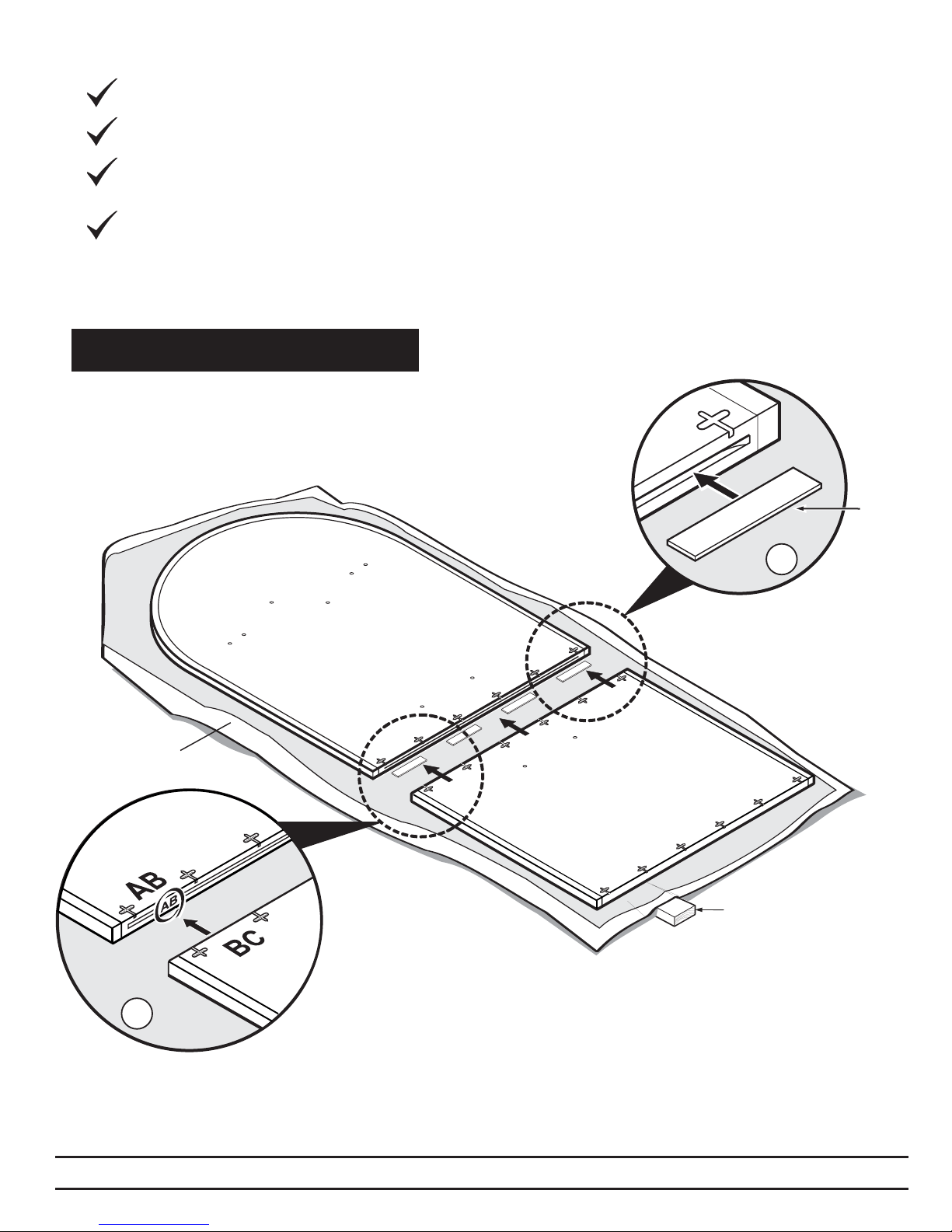

Setup

Check content of order to ensure all parts are accounted for

and components match.

Make sure you have the tools identified on front cover.

Install optional Power Unit/Power Channel to tops before

installing bases. (See Assembly Direction N9501956)

Ensure adequate work space is available for performing this

assembly and that table top surfaces are protected with clean

padded material such as shipping blankets.

Sectional Top Assembly

1.

To ensure a uniform finish match, align

table top sections referring to match

marks on inside edge of top sections.

SPACER

PACKING

BLANKET

1.

2.

SHIM

TIP: Shims can be made

from the packing material

to elevate one edge of table

top and will allow for a finger

hold when assembly is

complete and top is

ready to upright.

Insert spacers into machine slot along top edge,

2.

spacing them equally along length.

Push table top sections together and check alignment.

N9501959 REV. F

DO NOT GLUE.

Steelcase

Page2of11

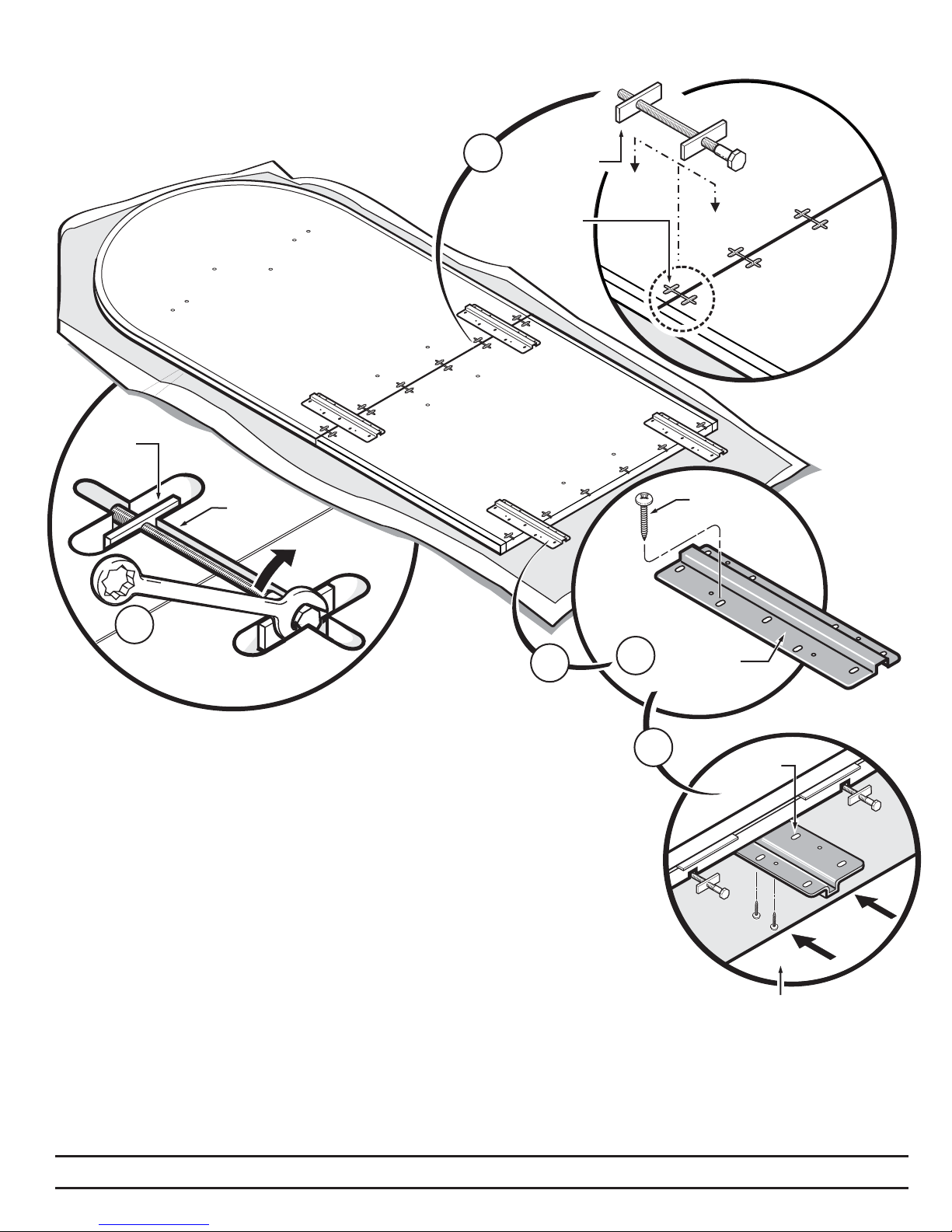

Put ‘T’ bolt connectors in each of the

3.

machined ‘T’ bolt slots. Tighten

bolts finger tight.

‘T’ BOLT

‘T’ BOLT

SLOT

3.

‘T’ BOLT

‘T’ BOLT

SLOT

#10 x 7/8”

SCREW

4.

7/16” WRENCH

4.

Using a 7/16” wrench, tighten ‘T’ bolts

5.

starting with bolts located closest to the

center of top and work outward. Continue

to repeat this process until all bolts are tight.

Attach hanger brackets (2) per section with

5.

#10 X 7/8” screws, (9) per bracket. Evenly

space brackets to the outside edge of top.

Do not cover T-Bolt slots or table base locations.

NOTE: When assembling tops having three or more sections,

completely assemble two sections separately. Attach hanger brackets

to one of the completed sections (see figure B), then upright assembled

sections to complete assembly.

A

HANGER

BRACKET

B

HANGER

BRACKET

TOP SHOWN IN

UPRIGHT POSITION

N9501959 REV. F

Steelcase

Page3of11

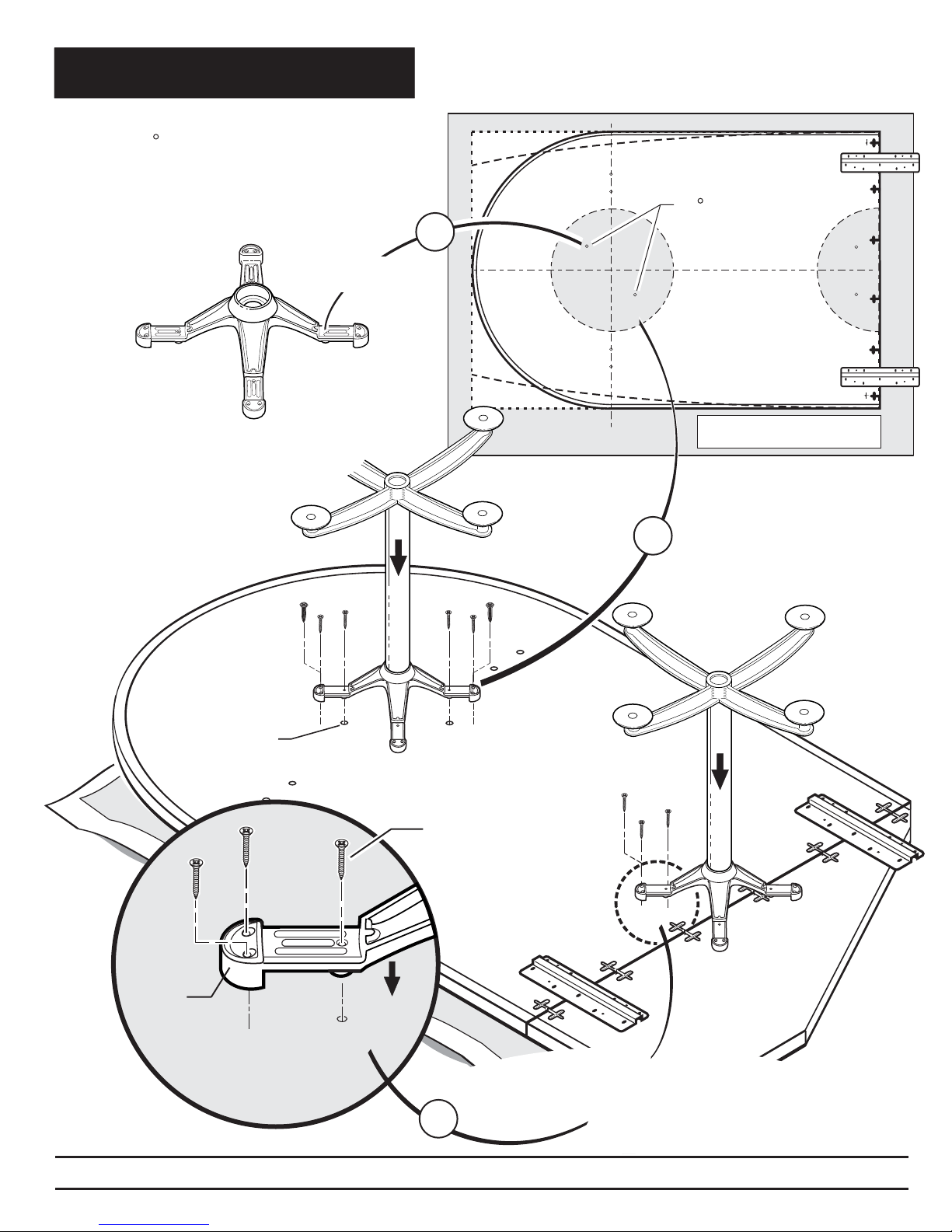

Positioning And Attachment Of

Table Bases With Spider Bracket

Locate 45 hole pattern on bottom

1.

of table top, then position spider

bracket base as shown.

Align pilot holes with

this hole in bracket.

SPIDER BRACKET

2.

Install (2) screws into pilot

holes, then drill pilot holes

for the other (10) screws.

45 hole pattern

1.

TWO PIECE RACETRACK TOP

(LOOKING DOWN AT BOTTOM)

Install screws into

these pilot holes.

2.

#10 x 1-3/4”

SPIDER

BRACKET

N9501959 REV. F

3.

Steelcase

3.

Secure table base with screws

(#10 X 1- 3/4”, 3 per foot).

Page4of11

Loading...

Loading...