Stearns 36X Series Parts List

®

Armature Actuated Brakes

Installation, Service and Parts List for

36X Series Armature Actuated Brakes

P/N 8-078-898-00

effective 10/06/10

Important

Please read these instructions carefully before installing, operating,

or servicing your Stearns brake. Failure to comply with these

instructions could cause injury to personnel and/or damage to

property if the brake is installed or operated incorrectly. For

definition of limited warranty/liability, contact

(414) 272-1100.

OEM’s and subsystem suppliers, please forward these

instructions with your components to the final user.

Caution

Servicing shall be in compliance with applicable local safety 1.

codes including Occupational Safety and Health Act (OSHA). All

wiring and electrical connections must comply with the National

Electric Code (NEC) and local electric codes in effect.

To prevent an electrical hazard, disconnect power source before 2.

working on the brake. If power disconnect point is out of sight,

lock disconnect in the off position and tag to prevent accidental

application of power to system.

To avoid damage to internal power supply, hipot testing should 3.

not exceed 1500 volts for one second. Brake coil leads must be

connected together.

Heat developed during normal operation (135°C) of the brake 4.

may be hot enough to be painful or cause injury. Be careful

when touching exterior surfaces. Allow sufficient time for the

brake to cool before servicing.

After usage, the brake will contain burnt and degraded friction 5.

material dust. This dust should be removed before servicing or

adjusting the brake.

DO NOT blow off dust using an air hose. It is important to

avoid dispersing dust into the air or inhaling it, as this may be

dangerous to your health.

a) Wear a filtered mask or a respirator while removing dust.

b) Use a vacuum cleaner or a soft brush to remove dust from

the brake. When brushing, avoid causing the dust to become

airborne. Collect the dust in a container, such as a bag,

which can be sealed off.

Maximum continuous operating ambient temperature for these 6.

brakes should not exceed 40°C (104° F).

I. Installation

Note 1: Position of hub should allow full engagement of friction

disc without interfering with the movement of the armature. Motor

shaft end float should not exceed .020”. Shaft runout should

be within .002” TIR. Motor mounting surface should be flat

and perpendicular to within .004” of motor shaft.

Note 2: Keep grease and oil from contacting friction surfaces.

Note 3: Hub should be a tight sliding fit. For shrink fit hub,

consult factory.

I. Installation

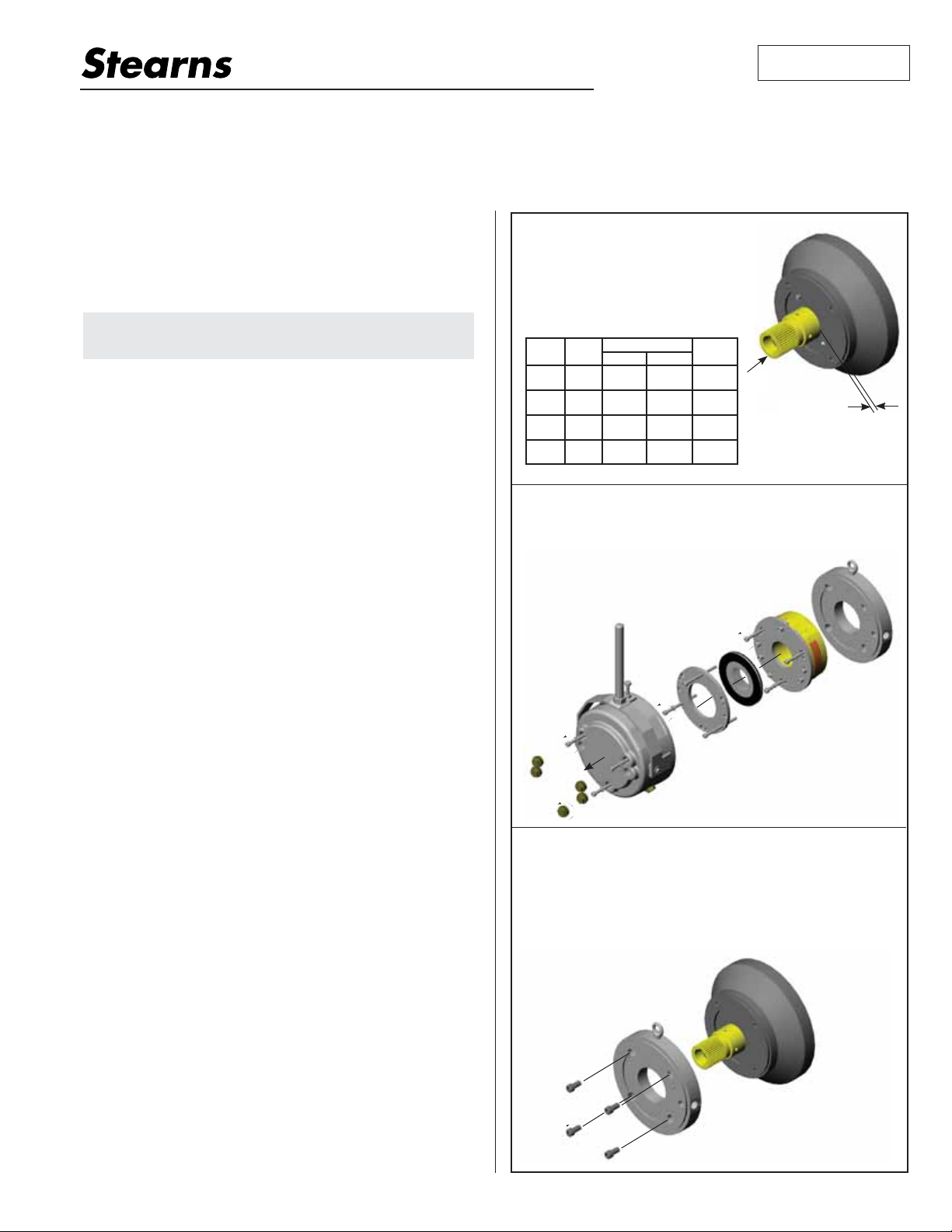

Step 1

Position hub and key on motor shaft (set 1.

screw end toward motor).

Locate hub 1/8” (±1/16”) outward from 2.

the register face.

Tighten set screws per Table A.3.

Table A

Brake

Bolt

Model

Circle

7.25

36X-6

9.00

7.25

36X-7

9.00

9.00

36X-8

11.00

11.00

36X-9

14.00

Step 2

Remove the three access plugs using a 22mm wrench.1.

Remove the three housing bolts using a 6mm hex 2.

wrench, and lift the housing from the brake.

Remove the three pressure plate bolts* and 3.

remove the pressure plate and carrier disc.

Remove the three magbody mounting bolts* 4.

and separate the magbody from the adapter plate.

2.

ccw x 3

1.

ccw x 3

Step 3

Position adapter plate on motor register.1.

Bolt adapter plate to motor register with four mounting bolts. (Not 2.

provided) (1/2-13 x 1.25” for 7.25 and 9.00” BC and 5/8-11 x 1.25”

for 11.00” BC. and 14.00” BC.) Tighten to manufacturers specification

using 3/8” hex wrench for 7.25” and 9.00 BC mounting. Use 1/2” hex

wrench for 11.00” BC and 14.00” BC. mounting.

Note: Verify that the O-ring gasket is in place on the motor side of the

adapter flange.

Bolt Torque

Metric English

32.5Nm 23lb-ft 3/16”

32.5Nm 23lb-ft 3/16”

32.5Nm 23lb-ft 3/16”

76.5Nm 52lb-ft 1/4”

3.

ccw

x 3

2.

1.

Hex

Wrench

4.

ccw

x 3

1.

1/8” Surface

flush to

register.

4.

3.

3.

* Note: Refer to Table B for

proper wrench size.

ccw

2

2.

cw x 4

2.

Installation procedure continued on reverse side.

Installation continued

Installation continued

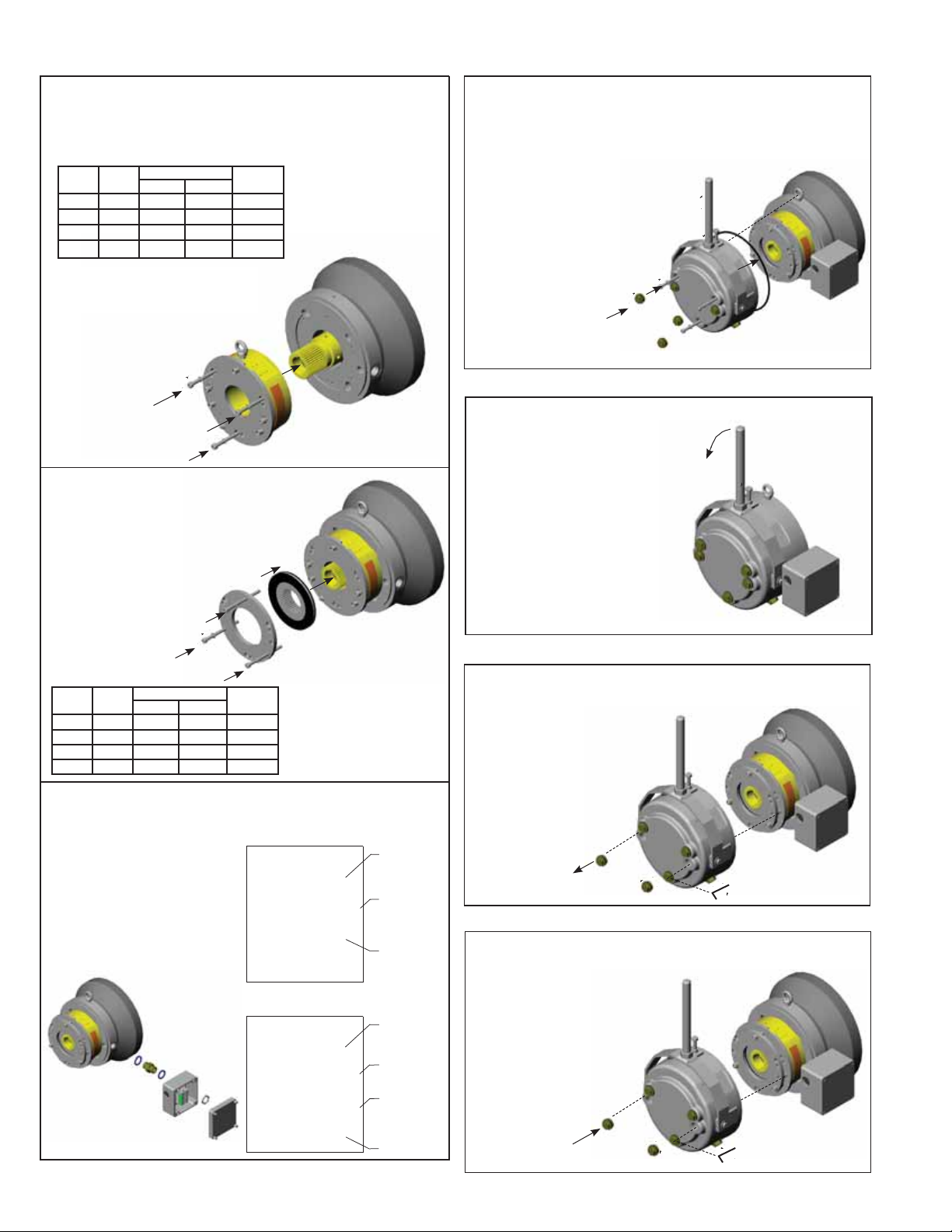

Step 4

Position armature/magbody assembly over hub and on to the adapter.1.

Tighten socket head cap screws per 2. Table B.

Table B

Brake

Bolt

Model

Circle

36X-6 170 38Nm 28 lb-ft 6mm

36X-7 196 38Nm 28 lb-ft 6mm

36X-8 230 68Nm 50 lb-ft 8mm

36X-9 278 68Nm 50 lb-ft 8mm

Bolt Torque

Metric English

Hex

Wrench

Note: Apply dry moly lube, or

anti-seize compound on bolt threads.

1.

2.

cw x 3

Step 5

Slide carrier disc onto the splined hub, with 1.

flat side of disc outward from motor.

Position pressure plate over carrier disc.2.

Tighten socket head cap screws per Table C.3.

Note 1: Apply dry moly

1.

lube, or anti-seize

compound on bolt threads.

Note 2: Verify air-gap as

2.

shown in Table D.

cw x 3

Table C

Brake

Bolt

Model

Circle

36X-6 170 19Nm 14 lb-ft 6mm

36X-7 196 38Nm 28 lb-ft 6mm

36X-8 230 68Nm 50 lb-ft 8mm

36X-9 278 68Nm 50 lb-ft 8mm

Bolt Torque

Metric English

Hex

Wrench

Note: Apply dry moly

lube, or anti-seize

compound on bolt

threads.

Step 6 Leadwire Connection Optional Conduit Box

Loosen NPT plug and four 1.

(4) cover plate screws from

junction box and remove.

Route leadwires into 2.

junction box and connect

conduit to box.

Connect wiring as shown 3.

for either the IP 56 or IP 65

conduit box assembly.

Replace junction box cover 4.

and tighten screws to seal.

5-08-0050-00

IP 56 Assembly

TERM BLOCK = LEADWIRES

1 = H1 YELLOW

2 = H2 YELLOW

Rexnord Corporation

3 = S1 RED-COMMON

8-078-760-00

4 = S2 WHITE - N.C

5 = S3 BLUE - N.O.

6 = B1 BLACK

7 = B2 BLACK

8 = 1 EMPTY

9 = 2 EMPTY

}

}

5-08-0051-00

IP 65 Assembly

TERM BLOCK = LEADWIRES

1 = H1 YELLOW

2 = H2 YELLOW

Rexnord Corporation

3 = L1 RED-COMMON

8-078-760-00

4 = L2 WHITE - N.C

5 = L3 BLUE - N.O.

6 = W1 RED-COMMON

7 = W2 WHITE - N.C

8 = W3 BLUE - N.O.

9 = B1 BLACK

10 = B2 BLACK

}

}

}

}

}

Optional

heater

leads

Optional

brake release

switch leads

Coil

leads

Optional

heater

leads

Optional

brake release

switch leads

Optional

brake wear

switch leads

Coil

leads

CAUTION: Be sure all internal wiring is clear of housing

flange before replacing housing.

Step 7

Slide housing over brake, align the manual release handle with the 1.

lifting lug position on the adapter plate. Verify that the O-ring gasket

is in position in the housing.

Insert the three housing 2.

bolts and tighten to 11 lb-ft

with a 6mm hex wrench.

Ensure that gasket is securely 3.

located on the face of the access

plug. Add a drop of Loctite 242, or

4.

cw

equivalent, to the thread of each

plug and tighten to 28 lb-ft using

a 22mm wrench.

Thread release handle into 4.

place and tighten jam nut

with a 30mm wrench.

3.

Insert and tighten the

stabilizing bolt against

2.

cw x 3

1.

the housing, and tighten

the jam nut using a

13mm wrench.

IIA Manual Release Operation (Deadman)

Loosen jam nut 1/2 turn, and stabilizing 1.

bolt one full turn, using a 13mm wrench.

Pull back on manual release handle.2.

Retighten stabilizing bolt and jam nut

when finished.

2.

1.

ccw

ccw

II Manual Release Engagement (Maintained)

Remove two manual release access 1.

plugs using a 22mm wrench.

Insert 6 mm hex wrench through 2.

housing and pressure plate.

Rotate release bolts cw 180°

at a time, alternating sides each

half turn, until armature is tight

against magnet body.

(You will feel bolts tighten).

1.

ccw x 2

cw

II Manual Release Disengagement (Maintained)

Insert 6mm hex wrench through housing and pressure plate. 1.

Rotate release bolts ccw 180° at a time, alternating sides each

half turn, until bolt head is tight against pressure

plate. (You will feel bolts tighten).

Then turn bolts cw 180°.

Ensure that gasket is 2.

securely located on the face

of the access plug. Add a

drop of Loctite 242, or

equivalent, to the thread

of each plug and tighten

to 28 lb-ft using a

22mm wrench.

1.

cw x 2

ccw

Loading...

Loading...