Stearns 1-087-3XX Catalog Page

Series 87,300-00 and 87,300-02

(1-087-3XX) Motor Mounted

Division I Hazardous Location

Mounting Face: NEMA 182TC, 184TC,

213TC, 215TC, 254TC, 256TC

8.5” AK, 7.25” AJ

Static Torque: 10 through 105 lb-ft

Enclosure Material: Cast Iron

Release Type: Knob

Modification required for vertical above

mounting. For vertical below, modification

required on 50-105 lb-ft. See SAB

Modification Section..

• Self-Adjusting Design

• Epoxy Encapsulated Coil Construction,

with Class H Insulation

• NC Thermostat

• Spring-Set Electrically Released

• Lead Wire Length: 36 inches

• Maximum Speed: Horizontal 4000 rpm,

Vertical 3000 rpm

• ABS Type Approval Certified.

Brake set and release times in milliseconds,

when brake and motor are switched separately

(for T1/T2 definitions, see page 101):

Static Torque Coil Size T1 T2

10, 15, 25, 50 5 & 6 42 20

35, 75, 105 8 48 20

Hazardous-location brakes are intended essentially for non-cyclic or holding

purposes, but may be used for stopping light inertial loads.

Series 87,300-00

Enclosure Protection: Type 1/IP 40, Type 4/IP 55, or Type 4/IP 57 protection, the brake must be mounted close coupled to the motor end

bell (a motor frame adapter may be included). Hazardous Location NEMA 7, 9.

Mounting Requirements: 1-087-3XX-00 Series Hazardous Location Motor Mounted Brake is recommended for mounting close coupled

(directly) to the motor end bell. If the brake is to be mounted to a motor fan guard, or if a motor frame adapter is incorporated, it is

recommended that Series 1-087-3XX-02 be used, as it provides additional bearing support for the longer shaft that is required. The

acceptability of the brake and motor combination must be determined by Underwriters Laboratories Inc.

Certified: UL Listed, File E-14893 for Class I, Group C and D and Class II, Group F and G.

CSA Certified, File LR-9584 for Class I, Group C and D, and Class II, Group F and G.

BACK TO TABLE OF CONTENTS

Installation and Service Instructions: P/N 8-078-927-03

Parts List: P/N 8-078-917-03 for IP 40 8-078-917-23 for IP 55

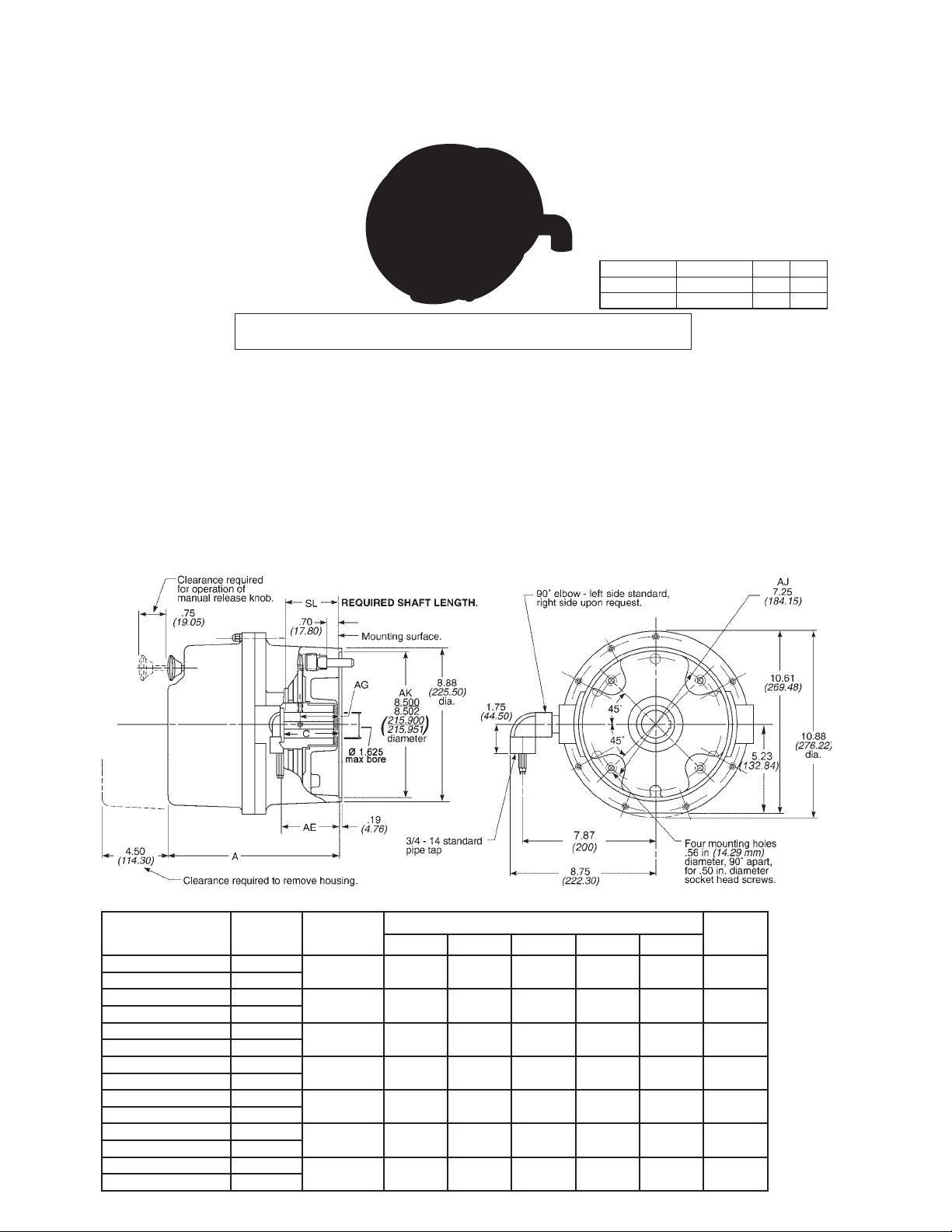

Outline Drawing for IP 40 & 55

Dimensions for estimating only. For installation

purposes request certified prints.

32

Dimensional Data

Model

Number

1-087-311-00-XXX IP 40

1-087-314-00-XXX IP 55

1-087-321-00-XXX IP 40

1-087-324-00-XXX IP 55

1-087-331-00-XXX IP 40

1-087-334-00-XXX IP 55

1-087-341-00-XXX IP 40

1-087-344-00-XXX IP 55

1-087-351-00-XXX IP 40

1-087-354-00-XXX IP 55

1-087-361-00-XXX IP 40

1-087-364-00-XXX

1-087-381-00-XXX IP 40

1-087-384-00-XXX IP 55

Enclosure

IP 55

Nominal

Static Torque

(lb-ft) (Nm)

10

(14)

15

(20)

25

(34)

35

(47)

50

(68)

75

(102)

105

(142)

Dimensions in Inches

(Dimensions in Millimeters)

AAEAGC

9.34

(237.33)

9.34

(237.33)

9.34

(237.33)

9.34

(237.33)

9.34

(237.33)

9.34

(237.33)

10.34

(262.73)

3.22

(81.79)

3.22

(81.79)

3.22

(81.79)

3.22

(81.79)

3.22

(81.79)

3.22

(81.79)

4.22

(107.19)

2.25

(57.2)

2.25

(57.2)

2.25

(57.2)

2.25

(57.2)

2.25

(57.2)

2.25

(57.2)

2.75

(69.9)

2.76

(70.1)

2.76

(70.1)

2.76

(70.1)

2.76

(70.1)

2.76

(70.1)

2.76

(70.1)

3.73

(94.7)

SL

± .05”

2.56

(65.0)

2.56

(65.0)

2.56

(65.0)

2.56

(65.0)

2.56

(65.0)

2.56

(65.0)

3.53

(89.7)

Weight

lbs

(kg)

62

(28.0)

63

(28.6)

63

(28.6)

63

(28.6)

64

(29.0)

65

(29.5)

72

(32.7)

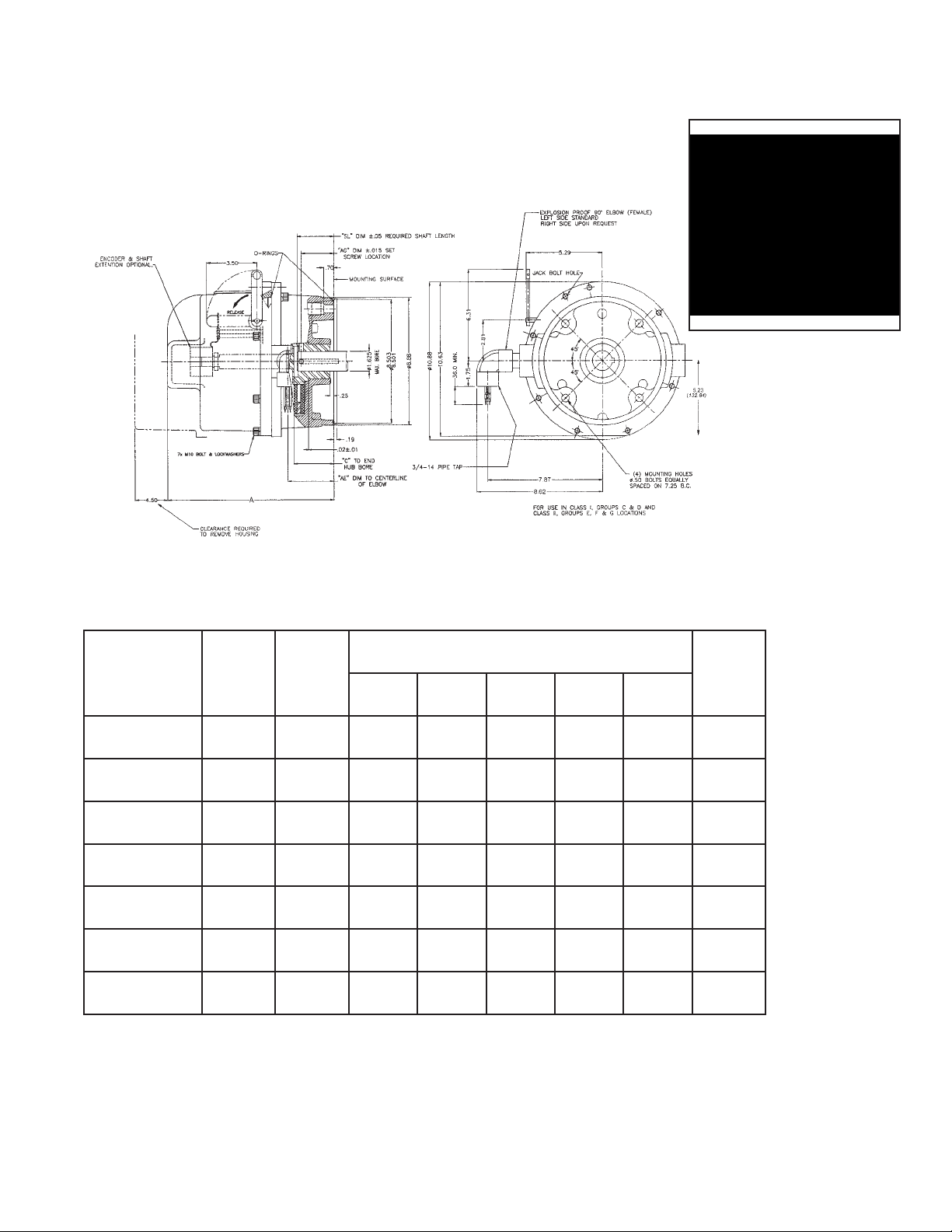

Series 87,300-00

Enclosure Protection: IP 57

Certified: UL Listed, File E-14893 for Class I, Group C and D and Class II, Group E, F and G.

BACK TO T ABLE OF CONTENTS

Dimensional Data

Model Number Enclosure

1-087-318-00-XXX IP 57

1-087-328-00-XXX IP 57

1-087-338-00-XXX IP 57

1-087-348-00-XXX IP 57

1-087-358-00-XXX IP 57

1-087-368-00-XXX IP 57

1-087-388-00-XXX IP 57

Nominal

Static

Torque

lb-ft

(Nm)

10

(14)

15

(20)

25

(34)

35

(47)

50

(68)

75

(102)

105

(142)

Dimensions in Inches

(Dimensions in Millimeters)

A C SL AE G

11.57 2.76 2.56 3.22 2.25

11.57 2.76 2.56 3.22 2.25

11.57 2.76 2.56 3.22 2.25

11.57 2.76 2.56 3.22 2.25

11.57 2.76 2.56 3.22 2.25

11.57 2.76 2.56 3.22 2.25

12.57 3.73 3.53 4.22 2.75

Wt.

Lbs

(kg)**

63

(28.6)

64

(29)

64

(29)

64

(29)

65

(29.5)

66

(30)

73

(33.1)

33

Loading...

Loading...