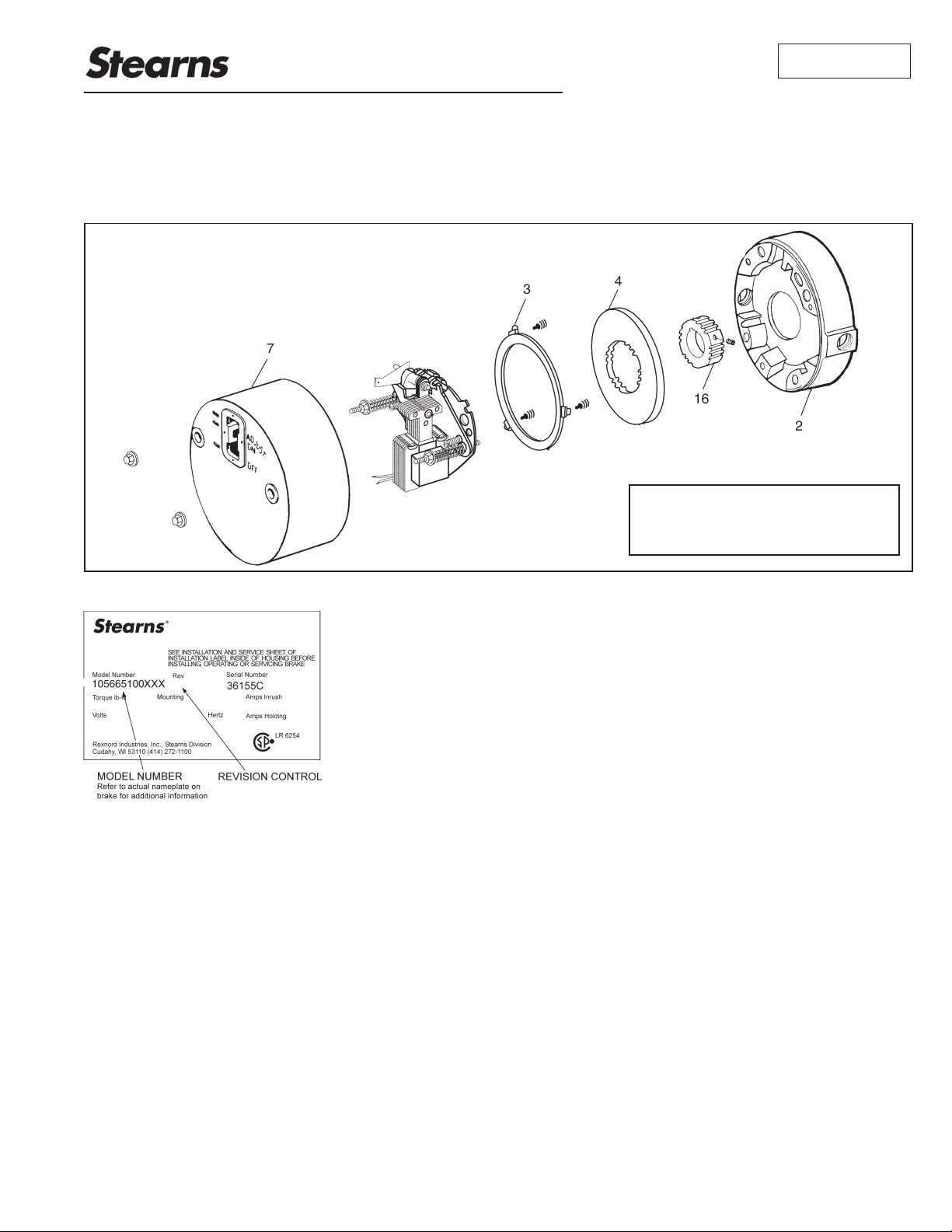

Stearns 1-056-600 Series Parts List

®

Spring-Set Disc Brakes

Parts List

for 1-056-600 Series (rev. A & B)

Manual Adjust Brakes

P/N 8-078-906-06

effective 05/02/14

For Installation and Service Instructions

refer to sheet part number 8-078-905-60.

Instructions and parts list also available at

Tools required for installation and servicing:

3/8” hex wrench 5/16” nut driver

5/16” hex wrench 1/4” screwdriver

3/16” hex wrench 8” adjustable wrench

Typical Nameplate

IMPORTANT

Please read these instructions carefully

before installing, operating, or servicing

your Stearns Brake. Failure to comply

with these instructions could cause

injury to personnel and/or damage

to property if the brake is installed or

operated incorrectly. For definition of

limited warranty/liability, contact Rexnord

Industries, Inc.,

Cudahy, WI

53110, (414) 272-1100.

Caution

1. Installation and servicing must be

made in compliance with all local

safety codes including Occupational

Safety and Health Act (OSHA). All

wiring and electrical connections must

comply with the National Electric

Code (NEC) and local electric codes

in effect.

2. Do not operate the brake in

atmospheres containing explosive

gases or dusts.

3. To prevent an electrical hazard,

disconnect power source before

working on the brake. If power

disconnect point is out of sight, lock

disconnect in the off position and tag

to prevent accidental application of

power.

4. Make certain power source conforms

to the requirements specified on the

brake nameplate.

5. Be careful when touching the

exterior of an operating brake. Allow

sufficient time for brake to cool before

disassembly. Surfaces may be hot

enough to be painful or cause injury.

6. Do not operate brake with housing

removed. All moving parts should be

guarded.

7. Installation and servicing should be

performed only by qualified personnel

familiar with the construction and

operation of the brake.

8. For proper performance and

operation, only genuine Stearns

parts should be used for repairs and

replacements.

9. After usage, the brake interior will

contain burnt and degraded friction

material dust. This dust must be

removed before servicing or adjusting

the brake.

DO NOT BLOW OFF DUST using an air

hose. It is important to avoid dispersing

dust into the air or inhaling it, as this may

be dangerous to your health.

a. Wear a filtered mask or a respirator

while removing dust from the inside of

a brake.

b. Use a vacuum cleaner or a soft brush

to remove dust from the brake. When

brushing, avoid causing the dust to

become airborne. Collect the dust in

a container, such as a bag, which can

be sealed off.

1

Information required when ordering replacement parts:

• Give Part Number of parts or kits needed, Brake Model Number,

and Brake Serial Number. The Brake Model and Serial Number

may identify special brakes not covered by this parts list

• When ordering hubs, specify shaft diameter (hub bore) and

keyway.

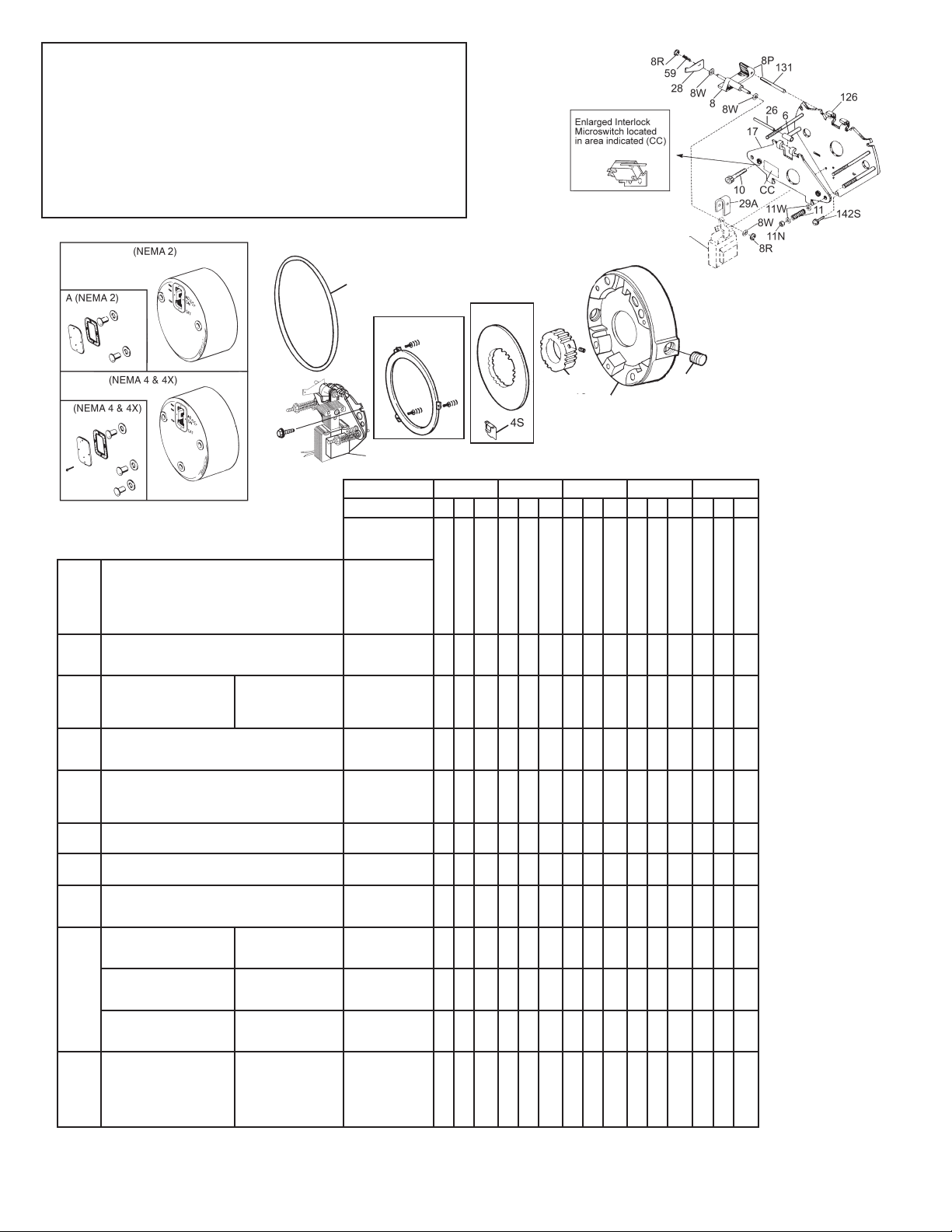

• Enclosure is specified as follows:

• NEMA 2 (formerly referred to as standard)

• NEMA 4 (formerly referred to as DTWP dust-tight waterproof)

7

A (NEMA 4 and 4X)

AA

3 (3A & 3B)

Support Plate

Assembly

Solenoid and

Coil Assembly

4

7

7

Torque (lb-ft) 1.5 and 3 6 10 15 20 and 25

NEMA Enclosure 2 4 4X 2 4 4X 2 4 4X 2 4 4X 2 4 4X

TABLE 1

Components of Standard AC or DC Brake

Item Description

A Hardware kit - NEMA 2

Hardware kit - NEMA 4

Hardware kit - NEMA 4X

AA Plug/Gasket kit

**Close couple

7 Housing ─ NEMA 2

Housing ─ NEMA 4

Housing ─ NEMA 4X

3

Stationary disc kit (1 disc universal

3 disc horizontal)

3A

Stationary disc kit (2 disc universal)

3B

Stationary disc kit (3 disc horizontal)

Not

Vertical spring kit (3 disc) 5-63-0525-00 1 1 1

Shown

44CFriction disc kit

Stabilizing clip (part of 5-66-8462-00)

Disc pack kit ─ 1 disc

DP

Disc pack kit ─ 2 disc

Disc pack kit ─ 3 disc

Hub and set screw assembly

1 & 2 disc (NEMA 2)

Hub and set screw assembly

16

1 disc (NEMA 4 & 4X)

Hub and set screw assembly

3 disc (NEMA 2)

2 and 3 disc (NEMA 4 & 4 X)

Endplate

Endplate

Endplate & seal assembly

2

Endplate & seal assembly

Endplate & seal assembly

Endplate & seal assembly

─ NEMA 4

─ NEMA 4X

─ NEMA 4 3 disc

─ NEMA 4X 3 disc

5/8 bore

7/8 bore

1-1/8 bore

5/8 bore

7/8 bore

1-1/8 bore

5/8 bore

7/8 bore

1-1/8 bore

1 disc (NEMA 2)

2 & 3 disc (NEMA 2)

1 disc (NEMA 4)

2 & 3 disc (NEMA 4)

1 disc (NEMA 4X)

2 & 3 disc (NEMA 4X)

Brake Model

Number

Part Number

5-66-1011-00

5-66-1012-00

5-66-1013-00

5-63-0532-00

5-63-0533-00

5-63-0534-00

5-63-0535-00

8-007-509-20

8-007-509-21

8-007-509-23

5-66-8354-00

5-66-8355-00

5-66-8356-00

5-66-8462-00

5-66-8601-00

5-66-8602-00

5-66-8603-00

5-16-5150-00-01B

5-16-5150-00-01D

5-16-5150-00-01E

5-16-5151-00-01B

5-16-5151-00-01D

5-16-5151-00-01E

5-16-5153-00-01B

5-16-5153-00-01D

5-16-5153-00-01E

8-002-580-01-30F

8-002-582-01-30F

5-02-5043-00

5-02-5044-00

5-02-5045-00

5-02-5046-00

1-056-601-00 & -611-00

1-056-602-00 & -612-00

1-056-604-00 & -614-00

1-056-621-00

1

1

111 111

1212121

111 111

1

1

1

1

1

1

1

1

1

1

1

1

21212

1

1

1

1

1

1

1

1

1

1

1

1

16

2

1-056-622-00

1-056-624-00

1-056-631-00

1-056-632-00

1-056-634-00

1-056-641-00

1

1

1

1

1

1

1

1

111111

2*2*2*2*2*2*3*3*3

111111

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

A

AA

1-056-642-00

1-056-644-00

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1-056-651-00 & -661-00

1-056-652-00 & -662-00

1-056-654-00 & -664-00

1

1

1

1

1

1

1

1

31313

1

*

11 1

1

1

1

1

1

1

1

1

1

1

1

1

* Certain multiple friction disc model numbers require a single stabilizer clip (D1) added to each friction disc. If your particular brake model has this clip

on the discs, as received, it must be replaced whenever the friction disc is replaced. This clip is included as part of the friction disc kit 5-66-8462-00.

** Close coupled brakes are identified by an 8 in the 8th digit. Example: 1-056-XXX-8X.

2

Loading...

Loading...