Page 1

COMMERCIAL

STORAGE TANKS

State Large Volume Jacketed and Insulated Storage Tanks

Sizes From 140 to 1,000 Gallons – ASME code steel tanks are

constructed of code material. For extremely severe or special

applications, ASME code tanks are available in stainless steel or

silicon bronze. Larger sizes, consult factory representative.

ASME Code Construction – All tanks are constructed to the

requirements of the ASME. ASME code tanks are available in 100,

125, 150 and 160 psi working pressures (125 psi working pressure standard). Consult factory for ASME code tanks with greater or lesser

working pressures, with special configurations or materials.

Insulation – Entire tank is surrounded with high density fiber glass

insulation to reduce costly heat loss; non-sagging and vermin-proof. To

meet or exceed thermal efficiency and/or standby loss requirements of the

U.S. Department of Energy and current edition of ASHRAE/IESNA 90.1.

ASME

U

(OPTIONAL)

CRN

MEETS OR EXCEEDS THE THE THERMAL EFFICIENCY

AND/OR STANDBY LOSS REQUIREMENTS OF THE

U.S. DEPARTMENT OF ENERGY AND CURRENT EDITION

OF ASHRAE/IESNA 90.1

Limited Warranty Outlines

– Glass-Lined, Cement, Epoxy: If the tank should leak any time

during the first five years, under the terms of the warranty, State

Water Heaters will repair or replace the tank; installation, labor and

handling extra.

– Black Steel: If the tank should leak on installation, under the terms

of the warranty, State Water Heaters will repair or replace the tank;

installation, labor and handling extra.

– NOTE: This Outline Is NO

consult the written warranty or State Water Heaters. Warranty does

not apply to product installed outside of the United States of

America or its territorial possessions and Canada.

T A Warranty. For complete information,

Cabinet – Heavy gauge steel with high quality powder coat paint

provides additional insulating qualities for greater energy savings.

Linings and Coatings – Each lining and coating has particular

capabilities and limitations. Please consult the factory for

recommendations on the uses of linings for specific applications.

Thorough investigation on the service life of steel tanks with

protective coatings or linings has led to the recommendations of the

following linings:

– Glass-lined – These are normally stocked tanks for water storage

up to 180°F, with glass lining to prevent corrosion and addition of

rust to water. The glass lining was developed over many years of

ceramic research for a wide variety of conditions.

– Cement – A special formulation of cement provides excellent

corrosion protection. Available on 200 gallon and larger sizes. A

manhole or handhole is included for application of cement lining.

– Epoxy – The application of specially formulated epoxy makes this

lining suitable for cold or hot water storage. A manhole or handhole

is included for application of epoxy lining. Available on 200 gallon

and larger sizes.

Cathodic Protection – Glass-lined, cement and epoxy tanks are

furnished with anodes designed for maximum protection.

Accessories – Tanks will be supplied with the fittings located as

indicated on the drawings unless specified otherwise. A manhole or

handhole is included on cement or epoxy tanks. A manhole or

handhole is optional on glass-lined tanks.

For more information on State® contact:

State Water Heaters

500 Tennessee Waltz Parkway, Ashland City, TN 37015

800.365.0024 Toll-free USA

www.statewaterheaters.com

STMSS00107 June 2011R Page 1 of 2 ©2011 State Industries, Inc.

Page 2

COMMERCIAL

STORAGE TANKS

State Large Volume Jacketed and Insulated Storage Tanks

Suggested Specifications

Jacketed insulated ASME storage tank shall be State Water Heaters model_____________________. Capacity to

be ______ gallons with enclosed insulation of sufficient thickness to meet or exceed thermal efficiency and/or

standby loss requirements of the U.S. Department of Energy and current edition of ASHRAE/IESNA 90.1. Tank(s)

shall be constructed and stamped according to ASME specifications for _____ psi working pressure. Optional

(11″x 15x 15 x 15 manhole,4″x 6″ handhole, or [2] 2″ threaded) inspection opening(s) shall be supplied, if

required. The tank to be constructed of carbon steel and shall be lined with ________ (glass, epoxy or cement).

Tanks shall be equipped with the number and size of magnesium anode rod(s) sufficient to provide adequate

protection for the tank lining. Tank(s) shall be ___________ (vertical or horizontal design).

CAUTION

All openings are shipped unplugged and unused. Openings must be plugged at time of installation except as noted.

E-NPT

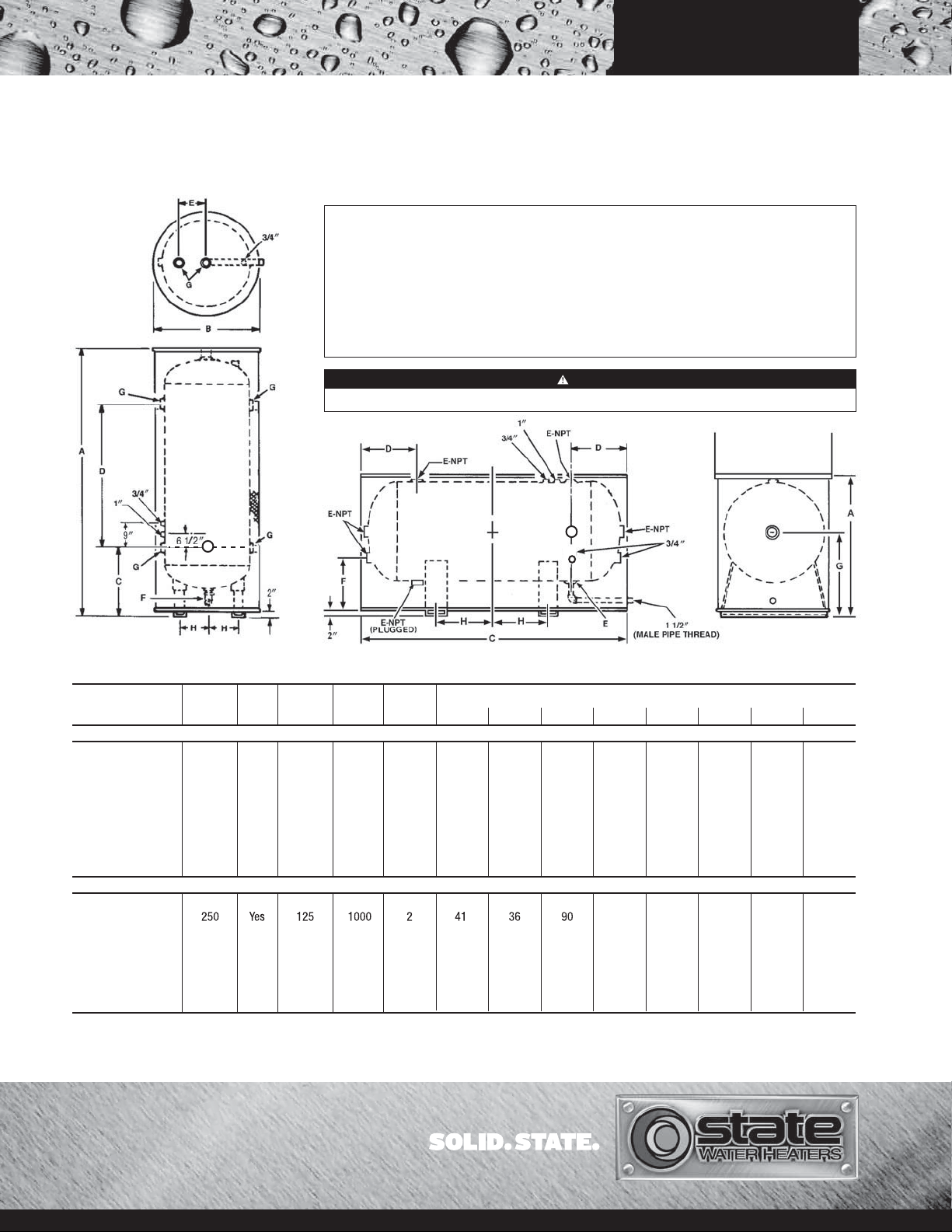

PVG 01400 OVTA125 thru PVG 10000 OVTA125

Model Gallon ASME Working to

Vertical

PVG 01400 OVTA125 140 Yes 125 516 1 87 30 211⁄2 51 8 11⁄2 21⁄2 63⁄8

PVG 02000 OVTA125 200 Yes 125 612 1 83 36 22 45 10 11⁄2 21⁄2 73⁄4

PVG 02500 OVTA125 250 Yes 125 900 1 93 36 22 58 10 11⁄2 21⁄2 73⁄4

PVG 03500 OVTA125 350 Yes 125 1080 1 97 42 241⁄2 54 14 11⁄2 21⁄2 91⁄2

PVG 04000 OVTA125 400 Yes 125 1282 1 105 42 241⁄2 61 14 11⁄2 21⁄2 91⁄2

PVG 05000 OVTA125 500 Yes 125 1369 1 100 48 27 52 16 11⁄2 311

PVG 05000 OVSA125 500 Yes 125 1526 1 84 54 273⁄4 331⁄4 18 11⁄2 312

PVG 07500 OVTA125 750 Yes 125 2395 1 116 54 273⁄4 651⁄2 18 11⁄2 312

PVG 10000 OVTA125 1000 Yes 125 3320 1 150 54 273⁄4 971⁄2 18 11⁄2 312

Horizontal

PVG 02000 OHTA125 200 Yes 125 790 2 41 36 77 16 21⁄2 11 23 16

PVG 02500 OHTA125

PVG 03500 OHTA125 350 Yes 125 1370 2 47 42 93 171⁄2 21⁄2 10 26 221⁄2

PVG 04000 OHTA125 400 Yes 125 1476 2 47 42 99 171⁄2 21⁄2 10 26 26

PVG 05000 OHTA125 500 Yes 125 1448 2 53 48 94 21 3 11 29 191⁄2

PVG 05000 OHSA125 500 Yes 125 1540 2 59 54 79 223⁄4 3123211

PVG 07500 OHTA125 750 Yes 125 2575 2 59 54 111 223⁄4 3123227

PVG 10000 OHTA125 1000 Yes 125 3260 2 59 54 143 223⁄4 3113243

Inspection openings, i.e., handholes and manholes, are optional and are to be included with glass lined tanks only when specified.

Other tanks to 66″ diameter and 3500 gallon are available on special order.

All openings Female Pipe Thread except as noted. “F” opening Male Pipe Thread on models “PVG 01400 OVTA125” thru “PVG 10000 OVTA125”.

Optional on “PVG 02000 OHTA125” thru “PVG 10000 OHTA125” models: handhole or 11″ x 16″ manholes, additional openings & heating coils.

Figure 1

Nominal Standard

Capacity

Pressure

Approx.

Ship. Wt.

Refer

Figure A B C D E F G H

In keeping with our policy of continuous product improvement, specifications are subject to change without prior notice.

PVG 02000 OHTA125 thru PVG 10000 OHTA125

Figure 2

Dimensions In Inches

16

2

5

⁄16

3

⁄4

3

⁄4

3

⁄4

1

⁄

2

11 23 16

For more information on State® contact:

State Water Heaters

500 Tennessee Waltz Parkway, Ashland City, TN 37015

800.365.0024 Toll-free USA

www.statewaterheaters.com

STMSS00107 June 2011R Page 2 of 2 ©2011 State Industries, Inc.

Loading...

Loading...