Page 1

Revised March 2011

©2011 State Industries

Page 2

PUMP

TA N KS

™

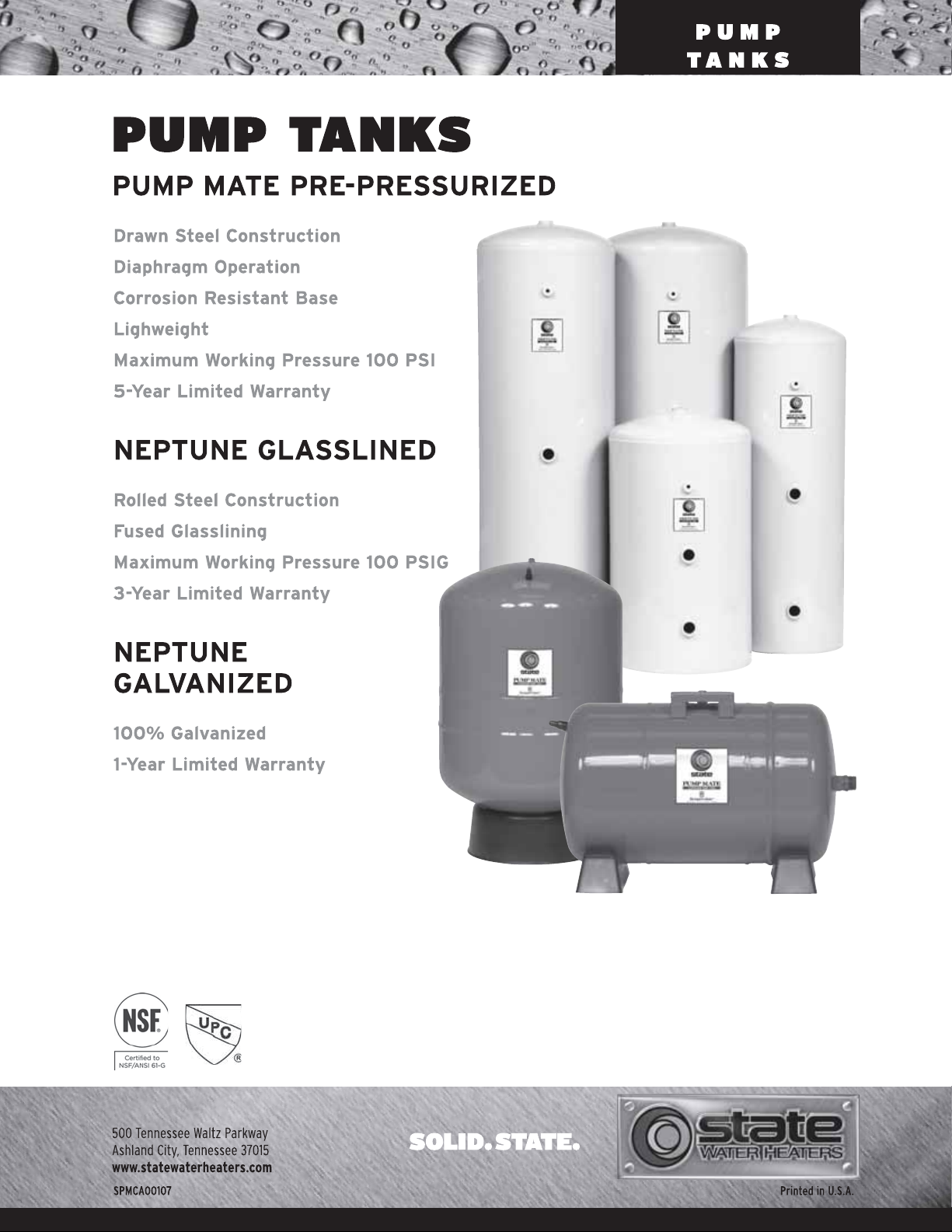

PUMP MATE

PRE-PRESSURIZED DIAPHRAGM OPERATION

5-YEAR LIMITED WARRANTY

State Industries Pump Mate tanks are designed for installation flexibility and years of trouble-free service. Smooth,

dependable diaphragm design and operation provides precise

control of system operation cycles. Free-standing and in-line

vertical tanks are available, as well as horizontal tanks with

universal pump mounting bracket. Every State Pump Mate

tank is made in the U.S.A.

Higher Drawdown Than

Competition!

Convenient Air Charge Valve.

Butyl Diaphragm ensures

permanent separation of air

and water. Steel retaining

ring “seals” diaphragm

directly to tank shell.

The industry's most popular “standard” tank sizes are

44-gallon. Pump Mate offers 52-gallon tanks in the same

price range. So, a 52-gallon Pump Mate delivers 12%

higher drawdown than the industry standard. A 52-gallon

Pump Mate delivers 18% higher drawdown than standard!

In-Line Tanks

SPMDI Series tanks, available in 2, 4.6,

7.3 and 14-gallon sizes, are designed to

be supported by system piping (See

Typical Installations, page 4).

2-coat polymer water-side

lining, bonded to shell,

proven protection

against rust.

Rotating corrosion-resistant base

assures stability. Rotates for

easy alignment to connection.

Slotted and notched for proper

airflow, reduced condensation.

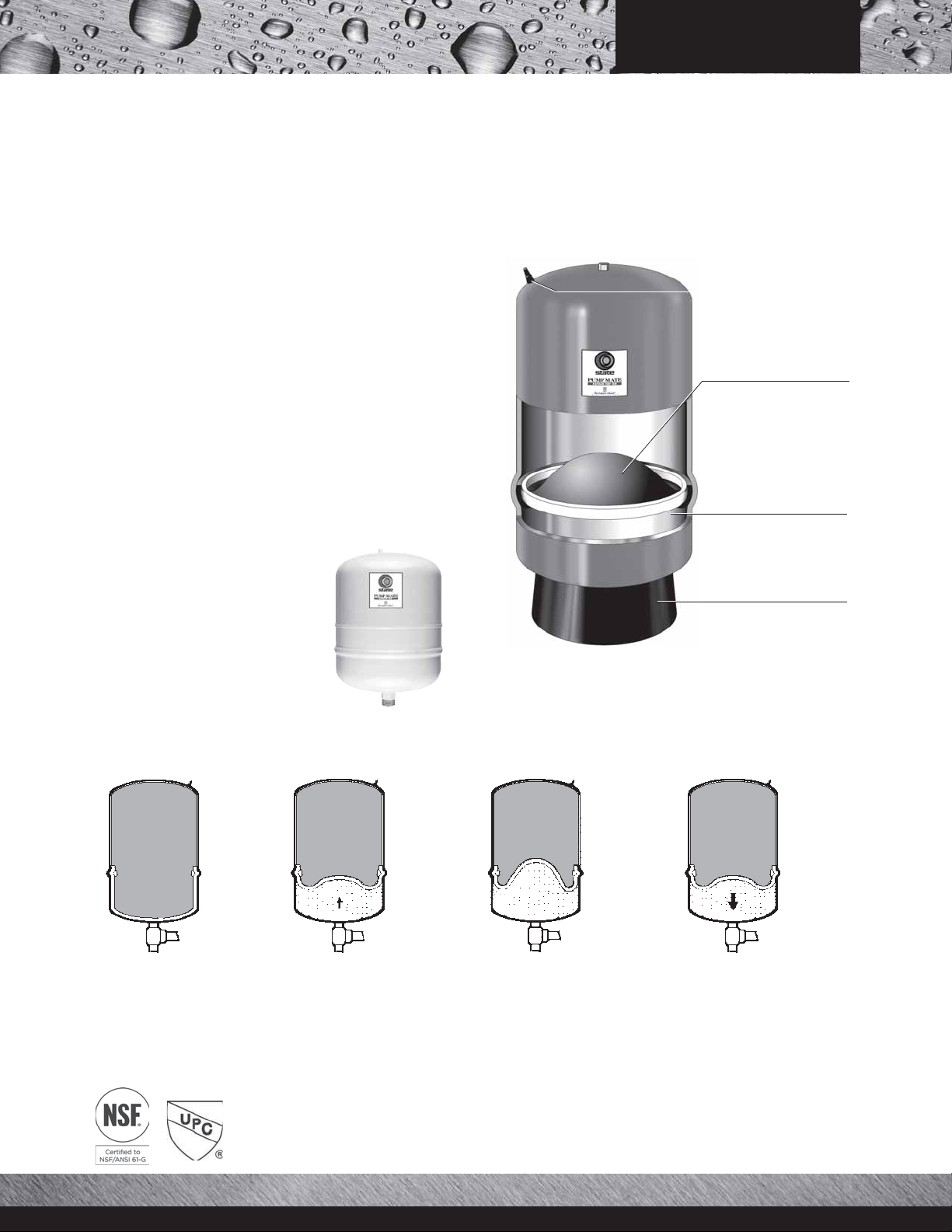

PRE-PRESSURIZED PUMP TANK OPERATION CYCLES

38 PSI

50 PSI

28 PSI

40 PSI

Start-up Cycle*

Diaphragm is pressed against

the bottom of the chamber.

* Based on 30-50 PSI operating system.

2

Fill Cycle*

Water is pumped into the reservoir, which forces the diaphragm

upward into the air chamber.

Hold Cycle*

Pump-cutoff pressure is attained.

Diaphragm reaches its uppermost

position. Reservoir is now filled to

its rated capacity.

Delivery Cycle*

Pump remains shut off while air

pressure in top chamber forces

diaphragm downward, delivering

water to syste m.

Page 3

PUMP

TA N KS

™

PUMP MATE

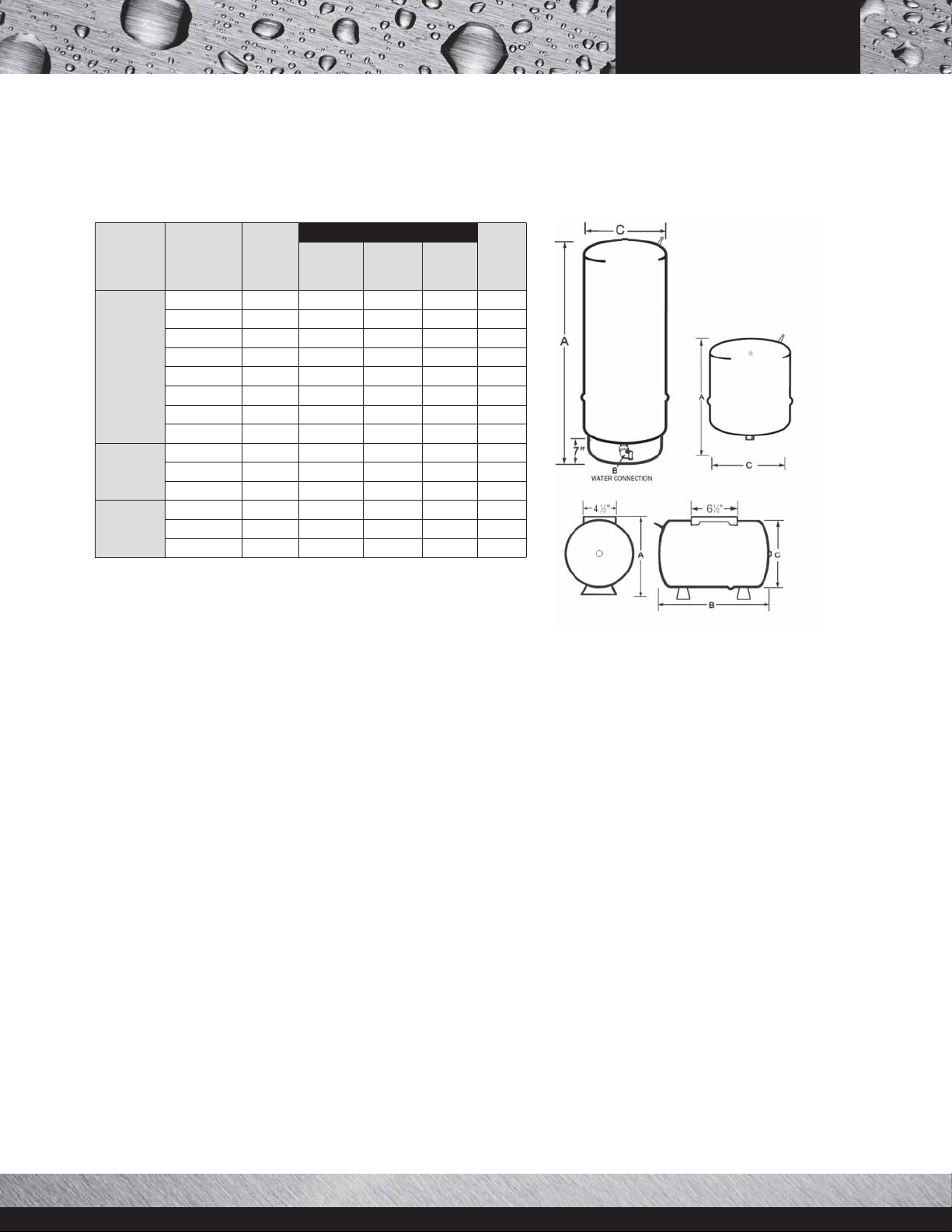

PRE-PRESSURIZED DIMENSIONS AND WEIGHTS

Dimensions in Inches

SPMD

Series

Free

Standing

SPMDI

Series

In-Line

SPMDH

Series

Horizontal

Model Number

SPMD-14

SPMD-20

SPMD-31

SPMD-36S

SPMD-52

SPMD-86

SPMD-96

SPMD-119

SPMDI-2

SPMDI-5

SPMDI-7

SPMDH-7

SPMDH-14

SPMDH-20

Vol um e

(Gallons)

14.0

20.0

31.0

36.0

52.0

86 59

96.0

119.5

2.0

4.6

7. 3

7. 3

14.0

20.0

“A”

Overall

Height

243⁄

323⁄

451⁄

325⁄

385⁄

633⁄

611⁄

103⁄

143⁄

211⁄

127⁄

173⁄

173⁄

4

4

2

8

8

8

4

16

4

16

8

8

8

“B” To

Center of

Water Inlet

21⁄

21⁄

21⁄

21⁄

21⁄

21⁄

21⁄

21⁄

—

—

—

211⁄

213⁄

271⁄

SPMD-14, SPMD-20, SPMD-36S connection 1" Female.

SPMD-52, SPMD-86, SPMD-96, SPMD-119 connection 1-1⁄4" Female.

SPMDI connection3⁄4" Male. • SPMDI-14 1" male.

SPMDH-7 connection3⁄4" Male. * SPMDH-14, SPMDH-20 connection 1" Male.

4

4

4

4

4

4

4

4

16

4

8

Diameter

153⁄

153⁄

153⁄

233⁄

233⁄

233⁄

81⁄

153⁄8251⁄

153⁄

Weight

“C”

(Lbs.)

8

8

8

20

8

105

8

8

26 160

4

11 9

11 12

11

8

25

30

40

45

77

111

5

16

2

30

3

Page 4

PUMP TANK SIZING

PUMP

TANKS

Free-Standing

Chart 1- PMD Series Free-Standing Tank Selection Chart

Selection

Charts

The charts below allow you

to easily select the right

free-standing tank for standard size pumps between

2-1/2 and 30 gallons in

capacity and for 20-40 PSI,

30-50 PSI and 40-60 PSI

pressure ranges. Minimum

run times shown (from

start-up) are 1 minute, 11/2 minutes and 2 minutes. For example, for a system that delivers 10 gpm at

30-50 PSI, with a minimumruntimeof1

minute, Chart 1 indicates

that the proper tank is the

SPMD-36S.

If proper tank

selection can-

Pump

GPM

1

2.5 SPMD-14 SPMD-14 SPMD-14 SPMD-14 SPMD-14 SPMD-20 SPMD-14 SPMD-20 SPMD-20

5 SPMD-14 SPMD-20 SPMD-36S SPMD-20 SPMD-36S SPMD-36S SPMD-20 SPMD-36S SPMD-52

7 SPMD-20 SPMD-36S SPMD-52 SPMD-36S SPMD-36S SPMD-52 SPMD-36S SPMD-52 SPMD-86

10 SPMD-36S SPMD-52 SPMD-86 SPMD-36S SPMD-52 SPMD-86 SPMD-52 SPMD-86 SPMD-86

12 SPMD-36S SPMD-52 SPMD-86 SPMD-52 SPMD-86 SPMD-86 SPMD-52 SPMD-86 SPMD-96

15 SPMD-52 SPMD-86 SPMD-86 SPMD-52 SPMD-86 SPMD-119 SPMD-86 SPMD-96 SPMD-119

20 SPMD-86 SPMD-86 SPMD-119 SPMD-86 SPMD-119 [2]SPMD-86 SPMD-86 SPMD-119 [2]SPMD-86

25 SPMD-86 SPMD-119 [2]SPMD-86 SPMD-86 [2]SPMD-86 [2]SPMD-86 SPMD-96 [2]SPMD-86 [2]SPMD-96

30 SPMD-86 [2]SPMD-86 [2]SPMD-86 SPMD-119 [2]SPMD-86 [2]SPMD-119 SPMD-119 [2]SPMD-96 [2]SPMD-119

Chart 2- Drawdown Volume Multiplier (Approximate)

Pump

Shut-Off

Pressure

10 20 30 40 50 60 70 80

Psi

20 0.26

30 0.41 0.22

40 0.37 0.18

50 0.46 0.31 0.15

60 0.40 0.27 0.13

70 0.47 0.35 0.24 0.12

not be made

using Chart 1,

follow this procedure .

First find the “drawdown multiplier” by matching the

pump start-up and shut-off pressures on Chart 2. For

example, the multiplier for a 30-50 PSI pressure range

is .31. Next, insert the pump GPM capacity and

desired minimum run time into this formula:

PUMP GPM x Min. Run Time

Multiplier

To assume dependable Drawdown Volumes, and in

keeping with present industry practice, Drawdowns

are based on Boyles Law.

For example, using a 10 GPM pump, a one-minute

minimum run time, and a 30-50 PSI pressure range,

the formula is as follows:

10 x 1

.31

32.25 Minimum Tank Volume

=

Then, using Chart 3, select the tank that has a minimum volume that meets or exceeds your minimum

volume requirement, and supplies adequate drawdown at the required pressure range. Minimum drawdown equals Pump GPM x Minimum Run Time.

Therefore, in the above example, select the SPMD36S 36-gallon tank. It provides adequate drawdown at

30-50 PSI.

Minimum Tank

=

Volume Required

System Pressure Ranges-PSI

20-40

1-1/2

Minimum Run Times (Minutes)

2 1

30-50 40-60

1-1/2

2 1

1-1/2

Chart 3- Drawdown in Gallons

Pump Start-Up Pressure-PSI

Model No.

SPMDI-2 2.0 0.7 0.6 —

SPMDI-5 4.6 1.7 1.4 —

SPMDI-7 7.3 2.7 2.3 —

SPMD-14 14.0 5.2 4.3 3.8

SPMD-20 20.0 7.4 6.2 5.4

SPMD-31 31 11.4 9.6 8.4

SPMD-36S 36.0 13.3 11.2 9.7

SPMD-52 52.0 19.2 16.1 14.0

11.012.023.024.008

SPMD-86 86.0 31.8 26.7 23.2

SPMD-96 96.0 35.5 29.8 25.9

01.091.092.083.084.009

SPMD-119 119.5 44.2 37.0 32.3

71.062.053.044.0001

Vol . i n

Gallons

20-40 30-50 40-60

Rule of Thumb Sys tem Sizing

The following water requirements figures are based on averages accepted by

the industry. They represent typical household and farm animal water use

requirements. Generally speaking, a reliable daily average water requirement is

100 gallons per day per person.

Average home water requirements based on

Average daily farm animal

requirements

Gallons/Day

Horse, Mule, Steer 12

Cow-Dry 15

Cow-Milking 35

Hog 4

Sheep 2

Chicken/100 6

Turkey/100 20

Average household water requirements (GPM) using industry-accepted 7-minute peak

demand cycle

No. of

Bathrooms

1 Sink, Toilet, Lavatory Tub/Shower 7

2

11⁄

Same as Above but with Automatic Washer 10

2

2-21⁄

Same as Above but with Automatic Dishwasher 14

3-4 Same as Above 17

industry-accepted 7-minute peak demand cycle

Unit

Kitchen sink 5 3

Toilet 4 5

Lavatory 4 2

Tub or Shower 5 35

Auto Wash Machine 5 35

Dishwasher 2 14

Garden Hose (1⁄2") 3

Lawn Sprinkler 3-7

Water Softener 7

Type of Water Using Fixtures Installed

Flow Rate

GPM

Requirement

Gallons

Depends

upon

{

cycle time

GPM

Required

2

4

Page 5

PUMP

TANKS

TYPICAL INSTALLATIONS

F or multiple installations, manifold size is critical. If you have questions about sizes call our

Technical Engineering Services Department at 1-800-36 5-002 4.

Free-Standing Series*

The standard installation, utilizing front entry, with gauge, relief

valve and pressure switch installed in

front

of tank.

Free-Standing Series With

Pump Mounted On Tank*

The pump can be mounted on tank using a universal

mounting base. The pump and base can be strapped to

the tank in the horizontal position, or mounted to the

tank in a vertical position.

In-Line Series*

The In-Line Series is designed to be supported by

system piping, either directly above the pump, or in

a convenient place in the piping system as close to

the pump as possible.

Universal Mounting Bracket

Standard on SPMDH

models.

* When pump and tank are in different locations, the pressure switch should be at the tank location.Orcompensating adjustment must be made for pressure loss due

to head of water, i.e., one PSI for every two feet of elevation.

5

Page 6

™

NEPTUNE

GLASSLINED

Rolled Steel Construction

Fused Glasslining

Maximum working pressure 100 PSIG

3-Year limited warranty

PUMP

TANKS

“Glasslining,” a porcelain protective coating

to a steel tank interior, is the plumbing

industry’s most time-tested system protection. State Neptune Glasslined Pump Tanks

feature rolled-steel construction. State Water

Heaters is one of the world’s largest producers of glasslined tanks, and every Neptune

Tank is made in the U.S.A.

Other Neptune features include a 1-1/4"

NPT spud on top for motor mount or retention tank connections, a 1/4" switch or

gauge tapping on the air side of the tank, and

full-size 1-1/4" connections at all needed

locations.

G Series Glasslined Pump Tanks

Model

Number

G-42-T 42 51-1/4 26 16 12 3 6 77

G-42-S 42 35-7/8 17 20 8 3 6 79

G-82 82 62-1/4 33 20 12 3 6 120

G-120 120 63 33 24 12 3 6 160

G-220 220 62 33 36 12 3 6 640

1-1/4" NPT Spud in head for alternate motor mount or retention tank connection.

All tapping 1-1/4" Water Connections.

1/4 " pressure switch tapping on all models.

Volume

(Gallons)

A B C D E F

Dimensions in Inches

(Pounds)

Weight

A STANDARD RETENTION SYSTEM

Typical Installation of Retention Tank

With Chemical Feed Pump

Pump-type

Chlorinator

Chlorine

Suction Line

Water

Pump

Chlorine

Solution

Container

6

Pump

Delivery

Line

Page 7

™

NEPTUNE

GALVANIZED

Horizontal or Vertical Tanks

Maximum working pressure 75 PSIG

NSF Certified

1-Year limited warranty

Sizes 12 to 120 Gallons - Free Standing

Model

Number

Z-1 2 12 26-1⁄2 24 12 5 13 27

Z-21 21 27 24 16 5 13 45

Z-32 32 38 3⁄4 36 16 8 17 52

ZT-42 42 51 48 16 12 26 71

ZS-42 42 33 3⁄4 30 20 8 17 71

Z-8 2 82 63 60 20 12 33 114

Z-1 20 120 64 1⁄2 60 24 12 33 154

Volume

(Gallons)

A B C D E

Dimensions in Inches

(Pounds)

Weight

PUMP

TANKS

Fre e

Standing

30-Gallon - Horizontal

Model

Volume

Number

(Gallons)

Z-30 H 30 16 29-1/2 34-1/2 5-1/4 14 1 3/8 65

A B C E F

Dimensions in Inches

G H

(Pounds)

Sizes 220 to 900 Gallons - Galvanized

Model

Number

Z-220 220 78 66 30 6 32 6 2-1/2 2 2 303

Z-31 5 315 79-1/2 66 36 6 32 7 2-1/2 2 2 416

Z-4 80 480 87 72 42 6 32 7-1 /2 2-1/2 2 3 640

Volume

(Gallons)

Models: ZU-525, ZU-900

A B C D E

Dimensions in Inches

G J K L

Model

Number

ZU-525 525 128 114 36 6 56 2-1/2 2-1/2 4 2" NPT 685

ZU-900 900 159 144 42 14 77 4 4 9 3" NPT 1040

1" NPT Spud in head for alternate motor mount or retention tank connection.

All tapping 1-1⁄4" Water Connections.

1⁄4" pressure switch tapping on all models.

Volume

(Gallons)

A B C D E

(Pounds)

Weight

Weight

Dimensions in Inches

F G H J

Horizontal

Models: Z-220, Z-315, Z-480

Weight

(Pounds)

7

Page 8

Revised March 2011

©2011 State Industries

Loading...

Loading...