Page 1

WinType 4000

T

ECHNICAL MANUAL

[ SECOND EDITION ]

LASER PRINTER

Page 2

NOTICE

• All rights reserved. Reproduction of any part of this manual in any

form whatsoever, without STAR’s express permission, is forbidden.

• The contents of this manual are subject to change without notice.

• All efforts have been made to ensure the accuracy of the contents

of this manual at the time of going to press. However, should any

errors be detected, STAR would greatly appreciate being informed of them.

• The above notwithstanding, STAR can assume no responsibility

for any errors in this manual.

Trademark acknowledgments

Windows

: Microsoft Corporation

© Copyright 1996 Star Micronics Co.,Ltd.

Page 3

INTRODUCTION

1

2

3

4

5

6

This manual describes the WinType 4000 laser printer.

It is intended for use as a reference when performing maintenance procedures.

This manual is prepared for use at a technical level and is not for the general user.

This manual is divided into the following sections:

Chapter 1 General Specifications

Specifications, safety information

Chapter 2 Theory of Operation

A description of the principles of the electrical and mechanical systems and their functions

Chapter 3 Parts Replacement and Adjustments

Explanation of disassembly, reassembly, and adjustment procedures

Chapter 4 Maintenance Guide

Contains an overview of steps for recovering from a breakdown, connector layout diagrams, wiring

connections, and other information useful in maintenance operations.

Chapter 5 Troubleshooting

Contains breakdown analysis procedures used when repairing breakdowns.

Chapter 6 Parts List

Illustrations showing disassembly diagrams, part numbers and part names

* In this manual, MCU PWB is the abbreviation for Main Control Unit Printed Wiring Board.

Page 4

Page 5

1

CHAPTER 1

GENERAL SPECIFICATIONS

1. GENERAL SPECIFICATIONS................................................................................3

2. SAFETY INFORMATION........................................................................................6

2-1. Power Supply .......................................................................................................... 6

2-2. Drive Parts............................................................................................................... 6

2-3. Safety Devices ........................................................................................................ 6

2-4. Laser safety............................................................................................................. 7

3. PRINTER COMPONENTS......................................................................................8

Page 6

– 2 –

GENERAL SPECIFICATIONS

Page 7

– 3 –

GENERAL SPECIFICATIONS

1. GENERAL SPECIFICATIONS

Engine

Printing process Electro-photographic

Resolution 300 x 300 dpi (Smoothing off)

600 dpi class (Smoothing on)

Exposure Semi-conductor laser beam scanning

Fixing Thermal fusing using heated rollers

Printing speed

Warm-up time 45 seconds or less after power on at 22°C (72°F)

(115 volts or 220 volts)

Time for first print 20.5 seconds for Letter paper

21.1 seconds for A4 paper

Continuous printing speed Min. 4 pages per minute for Letter or A 4 size paper

Printable area 4mm in from the edge of the paper on all sides

Paper feed

Input tray Capacity: 100 sheets of standard paper, 30 overhead (OHP) trans-

parencies, 30 label sheets or 10 envelopes

Paper weight: From 60 g/m2 (16 lb.) – 135 g/m2 (36 lb.)

Output tray Face down

Capacity: Approximately 50 sheets

Printing materials

Standard paper XEROX 4024 DP 20 lb 8.5" x 11" cut sheet paper (US)

Special printing OHP film: 8.5" x 11" XEROX, PN 3R2780 (US)

materials A4 XEROX, PN 3R91330 (Europe)

Label: 8.5" x 11" XEROX, PN 3R4469 (US)

A4 XEROX, PN 3R97408 (Europe)

Envelope: Com-10 Monroe Brand, Monarch Monroe Brand

Page 8

– 4 –

GENERAL SPECIFICATIONS

Toner cartridge

The toner cartridge consists of an OPC drum, developing roller and blades,

primary charge roller, drum cleaner and high definition black toner.

Toner save mode Off/Dark/Medium/Light

Mode Yield

Off Approx. 4000 pages

Dark Approx. 5000 pages

Medium Approx. 5700 pages

Light Approx. 8000 pages

Mean printing life Starter cartridge: 4000 sheets at 5% paper coverage

Replacement cartridge: 4000 sheets at 5% paper coverage

Power specifications

Input line voltage/ For US Voltage Frequency

frequency Min.: 90V 47Hz

Normal: 100/120V 50/60Hz

Max.: 132V 63Hz

For Europe and Asia/Pacific

Voltage Frequency

Min.: 198V 4 7Hz

Normal: 220/240V 50/60Hz

Max.: 264V 63Hz

Power consumption Maximum power consumption when warming-up and printing is as

follows

100/120V Less than 400W (less than 3A)

220/240V Less than 400W (less than 2A)

Environmental specifications Energy Star Compliant

Temperature, humidity Print engine with toner cartridge:

and altitude Operating: 5 – 35°C (41 – 95°F) at 15 – 85% RH (no conden-

sation)

Non-operating: 20 – 40°C (60 – 104°F) at 5 – 95% RH (no conden-

sation)

0 – 2,500 meters (0 – 8,200 feet)

Print engine without toner cartridge:

Non-operating: 20 – 40°C (60 – 104°F) at 5 – 95% RH (no conden-

sation)

0 – 15,000 meters (0 – 49,200 feet)

Acoustic noise Printing: 48 dB (A) or less

Warm up: 38 dB (A) or less

In accordance with ISO 7779

Dust emission Less than 0.1mg/m

3

concentration: Measured in accordance with Mass Measurements Method

Page 9

– 5 –

GENERAL SPECIFICATIONS

Reliability specifications

MPBF Recommended usage: Average 2,000 pages per month

Maximum 10,000 in any one month

MPBF: 60,000 pages

MTTR Within 30 minutes

Jam ratio 1/1000 using recommended paper

1/100 using special printing materials

Double feed ratio 1/1000 using recommended paper

1/100 using special printing materials

Life 100,000 pages or 5 years

Dimensions 330mm x 235mm x 265mm

(13.0 in. x 9.25 in. x 10.4 in.)

Weight 6.5 kg. (14.3 lbs.) without toner cartridge

7.5 kg. (16.5 lbs.) with toner cartridge

Controller

I/F High speed bi-directional parallel interface

Panel 2 LED lamps (Ready and Error)

Software

Windows Direct (GDI) mode Provides fast, WYSIWYG output from Windows (GDI) mode applica-

tions

PCL mode Provides compatibility with the popular printer languages used in the

LaserJet II series. Both Windows applications and DOS applications

running under Windows can use PCL emulation mode for printing.

PostScript mode Provides compatibility with the sophisticated PostScript language. Both

Windows applications and DOS applications running under Windows can

use PostScript emulation mode for printing.

Paper size

Paper sizes available A4, Letter, Legal, A5, Executive, B5, Com 10, C5, DL, Monarch

in GDI mode

Paper sizes available in A4, Letter, Legal, Executive, Com 10, C5, DL, Monarch

PCL4 emulation

Paper sizes available in A4, Letter, Legal, A5, Executive, B5, Com 10, C5, DL, Monarch

PostScript emulation

Page 10

– 6 –

GENERAL SPECIFICATIONS

2. SAFETY INFORMATION

In order to prevent accidents from occurring while maintenance is being carried out, all warnings and precautions should

be strictly observed while work is being carried out. Never attempt any kind of dangerous procedure when servicing this

machine.

The precautions noted below only cover a few of the situations which could foreseeably occur during maintenance

operations. Please make sure every safety precaution is observed while work is being carried out.

2-1. Power Supply

In order to prevent electrical shock, burns, damage to the equipment and other problems, always make sure the power

supply is turned off and the power supply cable has been unplugged before maintenance work is carried out.

If the power must be left on in order to measure voltage or for other reasons, make sure sufficient precautions are taken

to prevent electrical shock, and follow the procedures laid down in this manual.

2-2. Drive Parts

Inspection of drive section parts such as sprockets and gears should be carried out using a hand crank.

DANGER: Never inspect these parts while the equipment is in operation!

2-3. Safety Devices

Thorough consideration should be given to safety devices designed to prevent accidents (fuses, interlock switches, etc.)

as well as those handled by the user in the course of operating the equipment (covers, panels, etc.), in order to make sure

they fulfill their function as safety equipment.

DANGER: In order to prevent exposure to the laser beam contained in the printer, the following precautions must

always be strictly observed.

Exposure to the laser beam can result in blindness.

• Never open a cover (ROS assembly) that has the label shown in figure 1-3 on it.

• When disassembling and adjusting the equipment, always make sure the power supply has been

turned off first.

• This equipment is provided with a two-stage safety switch function, so that it can be operated even

with the covers removed, by pressing the interlock switch. When using this method of operation, never

short the other switch at the same time (the second switch is pressed when the actuator at the back of

the EP toner cartridge attachment section is pressed).

• When servicing the printer’s optical system, be careful not to place screwdrivers or other reflective

objects in the path of the laser beam.

Be sure to take off accessories, such as watches and rings, before working on the printer. A reflected

beam, though invisible, can permanently damage your eyes.

Because the laser beam is invisible, be especially careful when servicing the optical system.

Figure 1-1 Itnerlock switch location

Itnerlock switch

Page 11

– 7 –

GENERAL SPECIFICATIONS

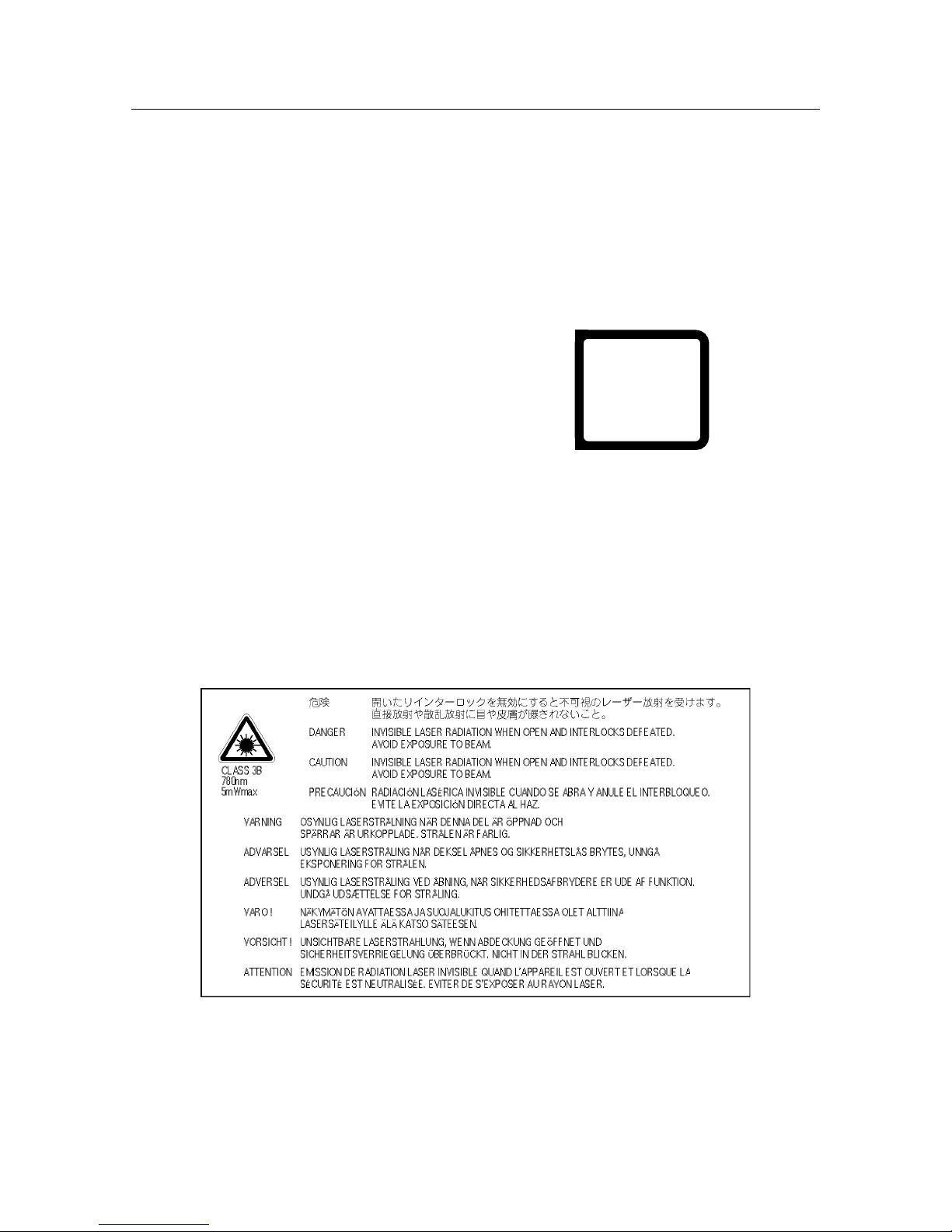

2-4. Laser safety

This printer is certified as a Class 1 laser product. This means that this laser product does not emit harmful laser beams.

This printer emits a Class 3B laser beam, but the beam is entirely enclosed within a protective case and an external cover,

and cannot escape from the printer while the printer is in use.

CLASS 1 LASER PRODUCT.

LUOKAN 1 LASERLAITE.

KLASS 1 LASER APPARAT.

CLASS 3B LASER

WAVE LENGTH 780nm (INVISIBLE)

RATED POWER 5mW

LUOKAN 3B LASER

AALLONPITUUS 780nm (NÄKYMÄTÖN)

TEHO 5mW

Figure 1-3 Caution Label

VARO! Avattaessa ja suojalukitus ohitettaessa olet alttiina näkymättömälle lasersäteilylle. Älä katso

säteeseen.

VARNING! Osynlig laserstrålning när denna del är öppnad och spärren är urkopplad. Betrakta ej strålen.

Laser Klasse 1

Laser de Classe 1

Láser Clase 1

Laser Luokan 1

Laser Klass 1

Figure 1-2 Class 1 Label

Page 12

– 8 –

GENERAL SPECIFICATIONS

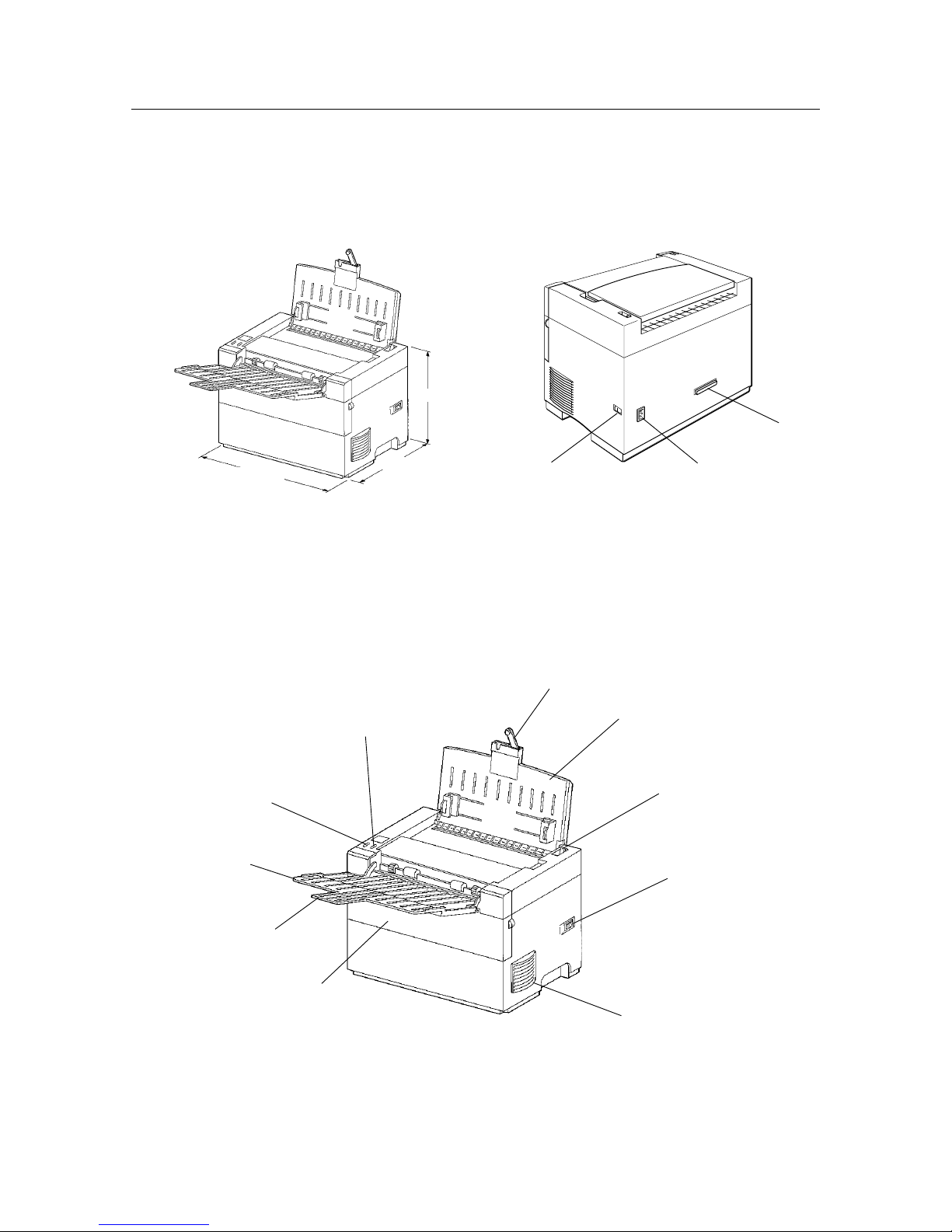

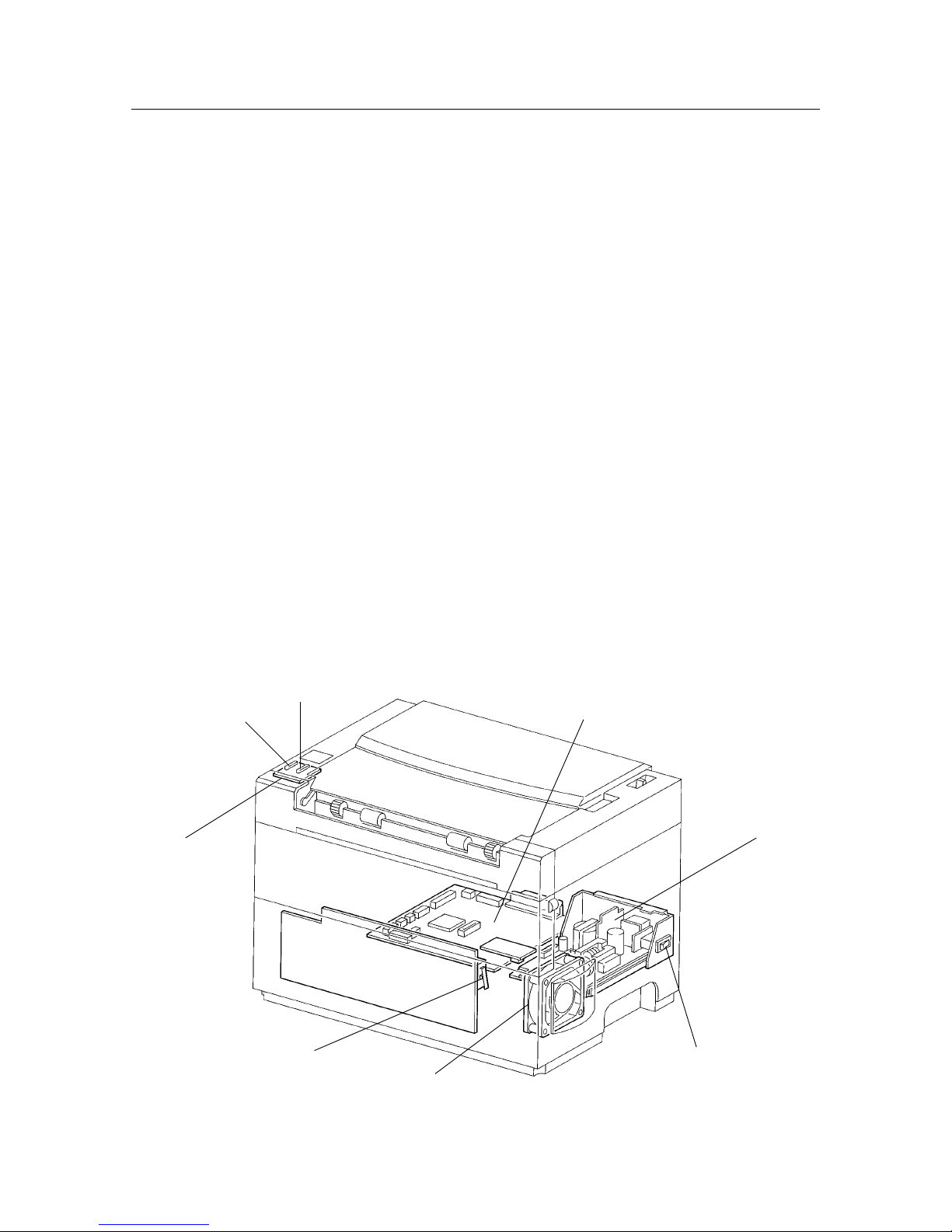

3. PRINTER COMPONENTS

Figure 1-4 External Dimensions Figure 1-5 Rear View

Figure 1-6 Front View

Power release lever

Power switch

Extension bar and

paper support extender

Upper paper tray

330 mm

235 mm

265 mm

Ventillation fan outlet

Front cover

Output paper

extender

Output tray

Ready LED lamp

(Green)

Error LED lamp

(Orange)

Power switch Power card socket

Parallel interface

connector

Page 13

2

CHAPTER 2

THEORY OF OPERATION

1. PRINTING PROCESS...........................................................................................11

2. PAPER TRANSPORTATION ...............................................................................14

3. FUNCTIONS OF THE MAIN PARTS....................................................................15

3.1 Covers.................................................................................................................... 15

3.2 Feeder & Drive ...................................................................................................... 15

3.3 Fuser & Paper Exit................................................................................................ 17

3.4 Photographics & ROS .......................................................................................... 19

3.5 Electrical................................................................................................................ 21

Page 14

– 10 –

THEORY OF OPERATION

Page 15

– 11 –

THEORY OF OPERATION

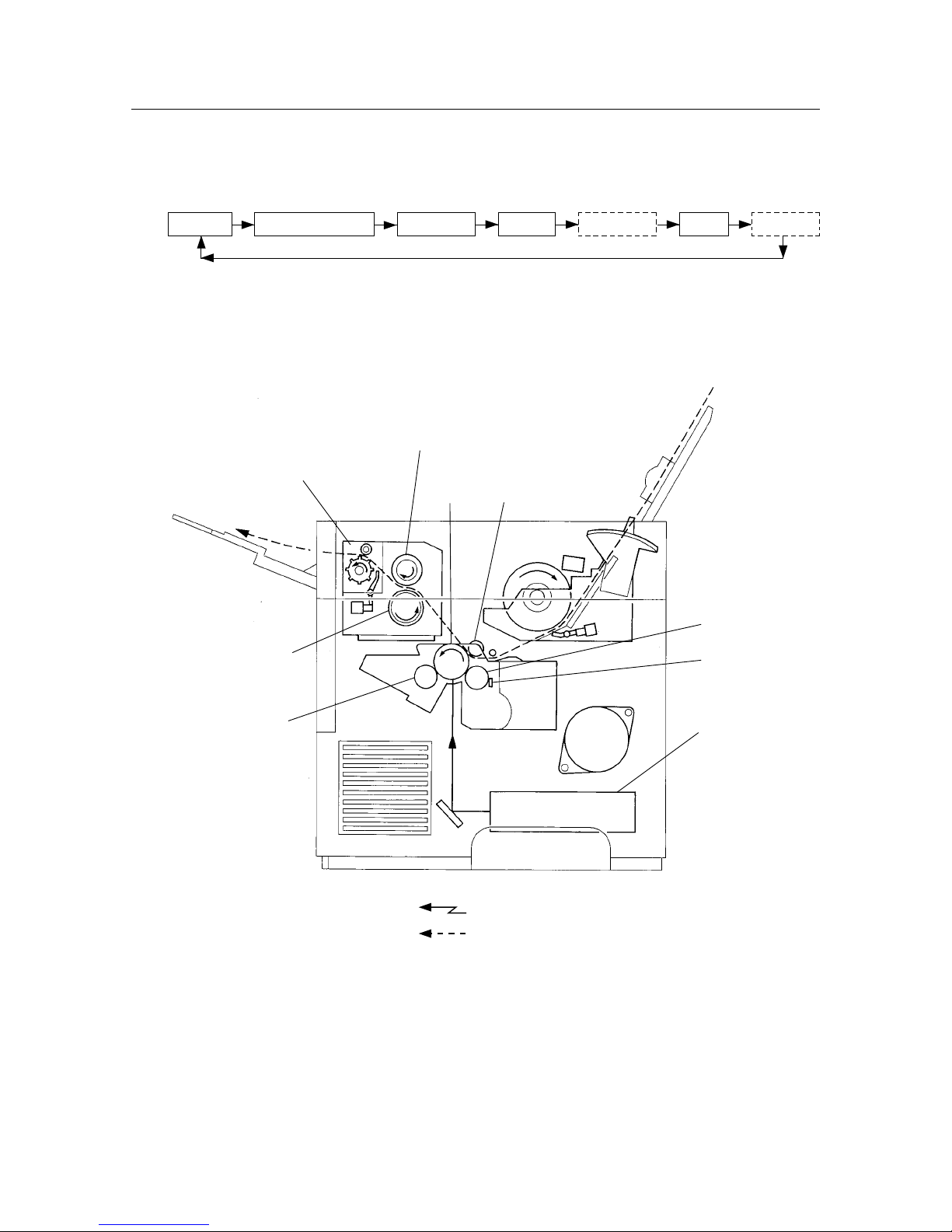

1. PRINTING PROCESS

The printing process for this system consists of the repetition of the following five basic steps:

Charging Scanning exposure Developing FusingTransfer

(Separation)

(Cleaning)

CM blade

Heat roller

Fuser assembly

Pressure roller

BTR

Drum

Magnetic roller

Ros assembly

BCR

Figure 2-1 Printing Process

: Laser beam

: Paper path

Page 16

– 12 –

THEORY OF OPERATION

• Description of the Printing Process

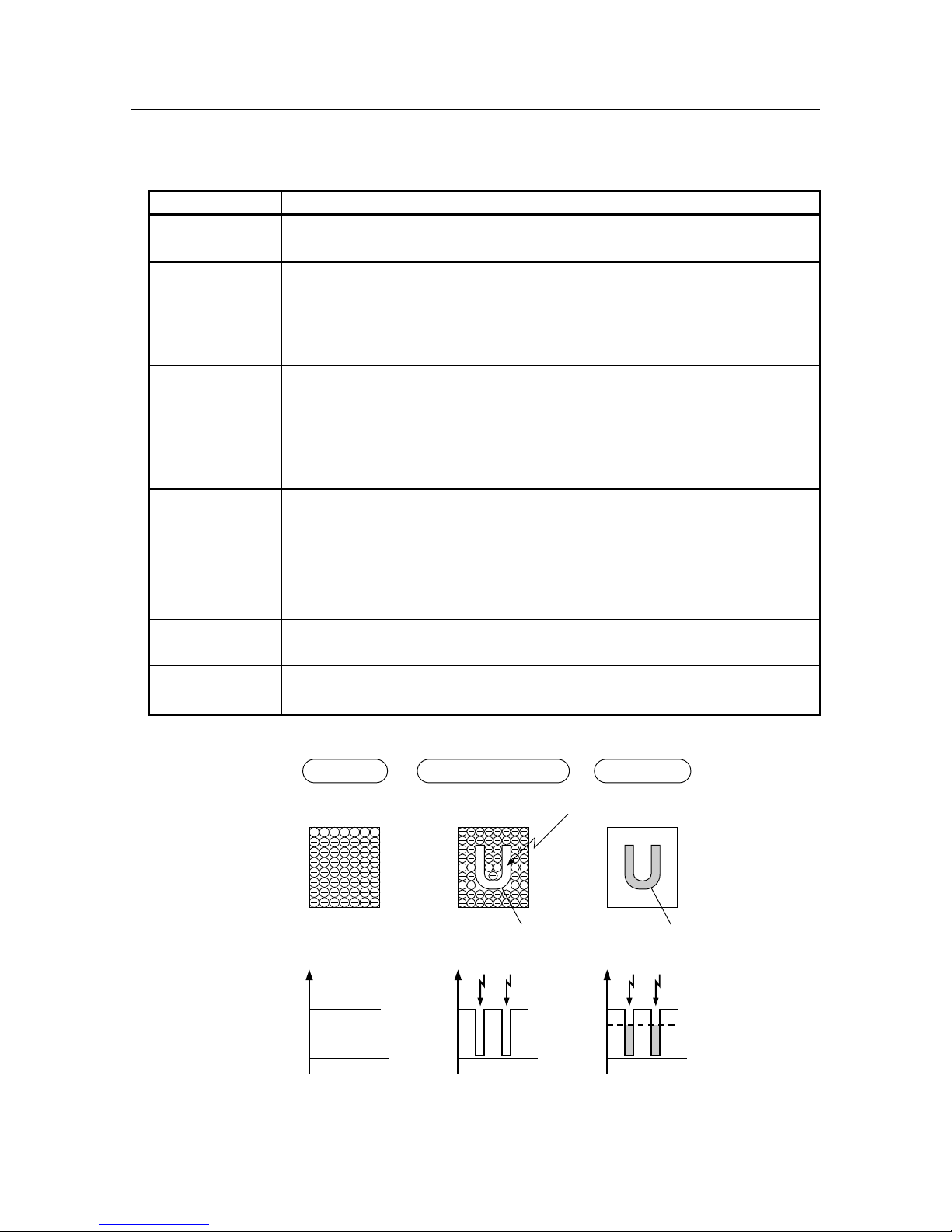

Step Details

Charging

The surface of the rotating drum in the EP toner cartridge is uniformly negatively charged

by the electric charge from the BCR (Bias Charge Roller).

The ROS assembly scans the exposure by converting the image signal from the MCU PWB

into an optical signal (laser beam) and directs the laser beam onto the drum.

Scanning Exposure When an image is present, a laser is emitted and the laser beam is irradiated onto the surface

of the drum causing the irradiated area to be set to a neutral charge, thus enabling an

invisible latent electrostatic image to be formed on the drum’s surface.

The latent electrostatic image on the drum’s surface attracts toner from the surface of the

magnetic roller in the EP toner cartridge, forming a visible image on the surface of the drum.

Developing

The magnet inside the magnetic roller causes the toner, which also has magnetic properties,

to adhere to the roller while the friction between the rotating magnetic roller and the CM

blade (Charge Metal Blade) negatively charges the toner, so that a thin layer of toner is n

the surface of the magnetic roller.

Transfer

A positive charge is applied to the back of the paper by the BTR (Bias Transfer Roller)

causing the toner on the drum’s surface to be transferred to the paper.

Applying a positive charge to the back of the paper causes the paper itself to be positively

charged, so that the paper adheres to the drum

(Separation)

The firmness of the paper causes the paper with the toner affixed to it to be separated from

the drum.

Fusing

The heat from the heat roller heated by the heat rod and the pressure from the pressure roller

causes the toner to be fused to the paper in the fuser assembly.

(Cleaning)

Any residual toner remaining on the drum after the transfer step is scraped off by the

cleaning blade which is in contact with the drum’s surface.

–350V

0

–V

–350V

0

–V

–350V

0

–V

–210V

(Developing bias)

Laser beam

Scanning Exposure DevelopingCharging

Toner image

(Visible image)

Electrostatic latent

image (Invisible image)

Drum’s surface

Voltage

Figure 2-2 Printing Process (Drum’s Surface)

Page 17

– 13 –

THEORY OF OPERATION

Cleaning blade

BCR

AC Bias: 1.6kVp-p

(f=2.4kHz)

DC Bias: –210V

Laser beam

Toner

DC Bias

(+): 250V~2600V

(0.5µA~1.6µA)

(–): –700V

Magnetic roll

AC Bias: 200µA

(f=160Hz)

DC Bias: –350V

Paper

Eliminator

Pressure roll

BTR

Drum

( 30mm)

CM blade

Toner

17.28

Heat roll

17

Transfer

Scanning Exposure

152˚C 140˚C

158˚C 150˚C

Separation

While the lamp

flashes

six times

After the lamp

flashes

the sixth time

Developing

Charging

Heat roll

Figure 2-3 Printing Process (Seven Steps)

Page 18

– 14 –

THEORY OF OPERATION

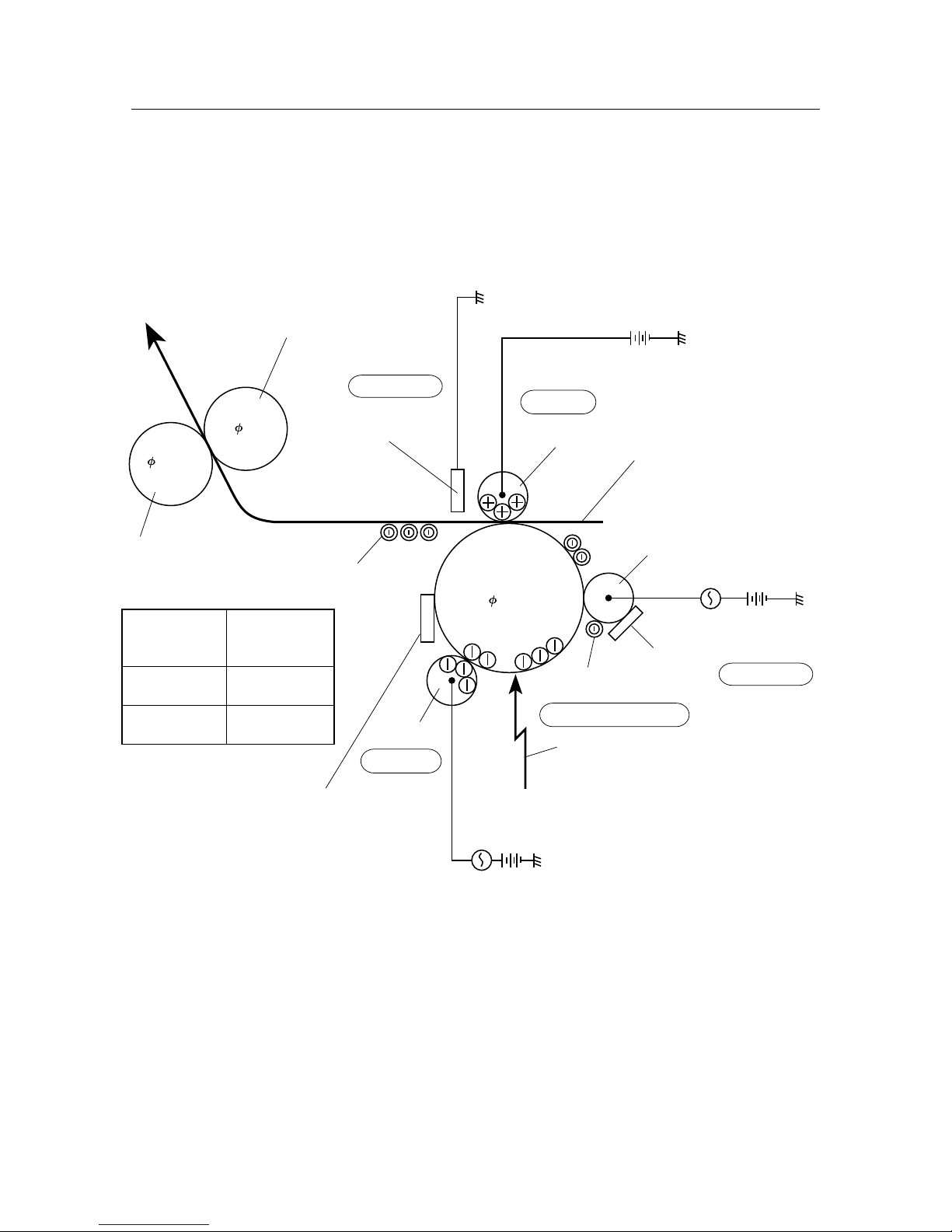

- - -

: Transport path of the paper

Input tray assembly

Feeder assembly

Heat roller

Pinch roller

Exit roller

Delivery tray assembly

Fuser assembly

Pressure roller

Drum

BTR

Feed roller

Figure 2-4 Paper Transportation

2. PAPER TRANSPORTATION

The following diagram shows the order in which paper passes over the rollers.

Paper that is inserted is automatically fed.

Paper is supplied and transported by the feed roller.

Paper is transported by the drum and BTR assembly.

Paper is transported by the heat roller and pressure roller.

Paper is discharged by the exit roller in the fuser assembly and the pinch roller in the

fuser top cover assembly.

Page 19

– 15 –

THEORY OF OPERATION

3. FUNCTIONS OF THE MAIN PARTS

The main parts are briefly described and illustrated as follows. In order to remain consistent with the parts list, parts are

divided into the following five sections based on their type.

1 Covers

2 Feeder & Drive

3 Fuser & Paper Exit

4 Photographics & ROS

5 Electrical

3.1 Covers

This consists of the printer, four covers and two trays.

(Refer to Chapter 6, Parts List)

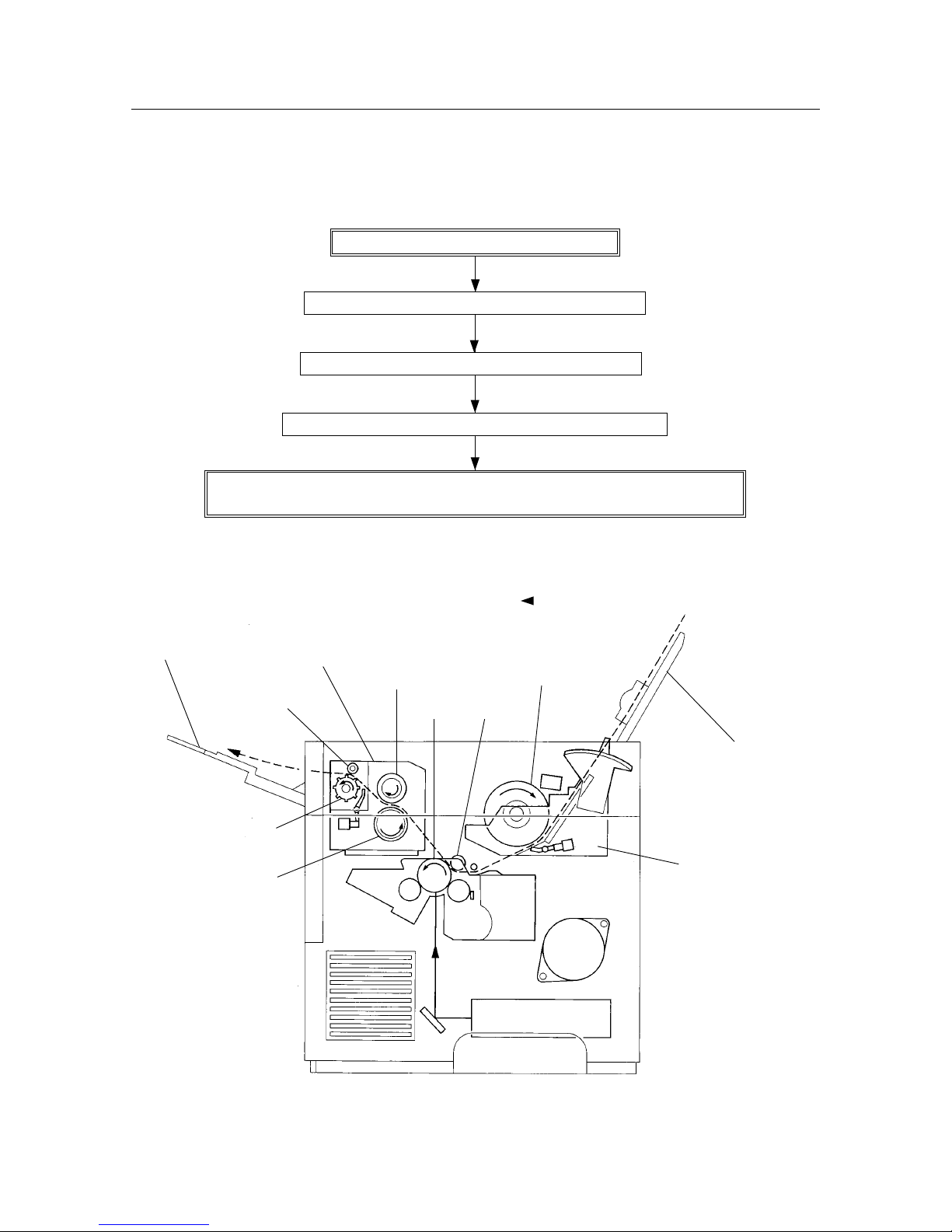

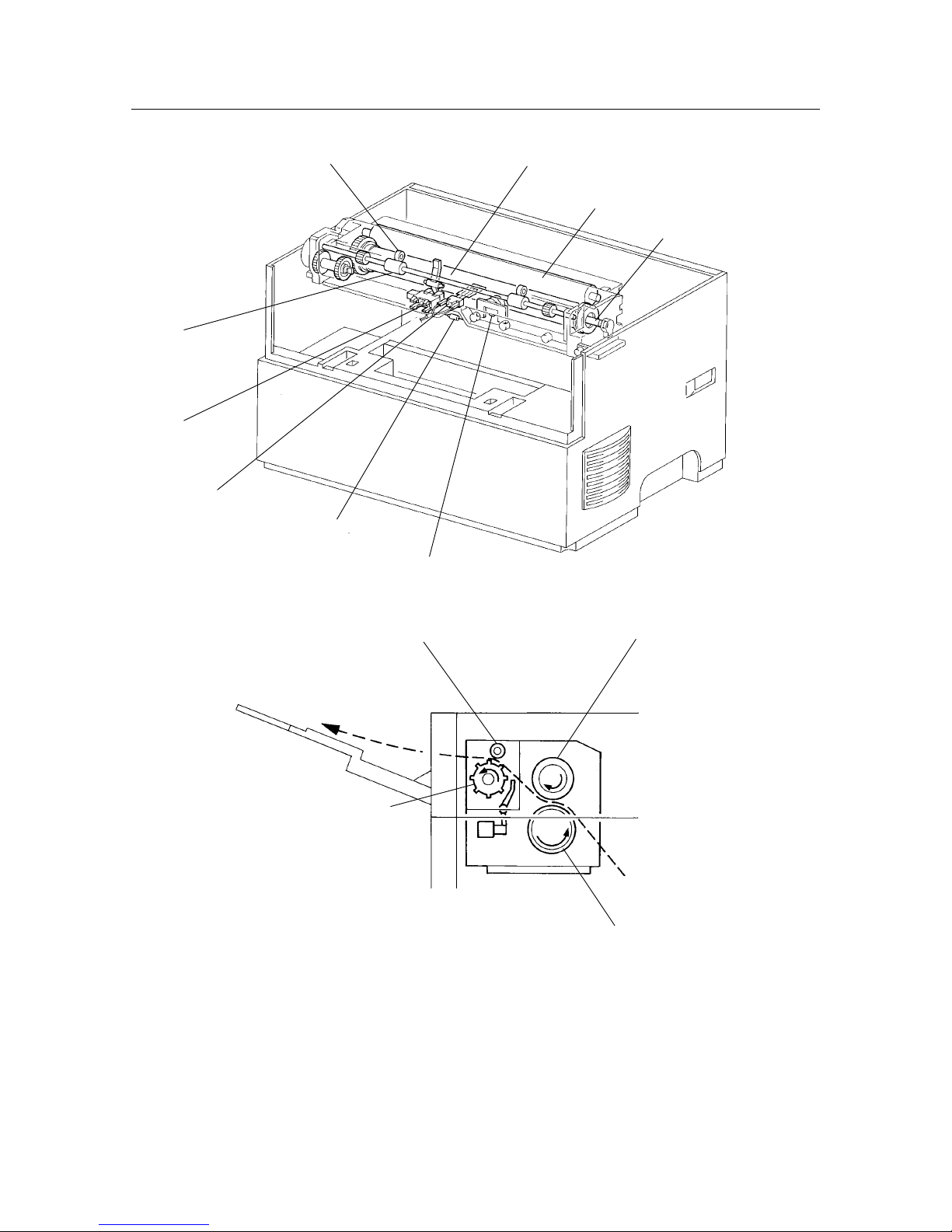

3.2 Feeder & Drive

• Input Tray Assembly

Regular (cut sheet) paper, envelopes can be fed into the printer from this tray.

Slide the left and right paper guides to hold the paper in place.

• Feed Roller Assembly

This assembly consists of the feed roller and the feed clutch. After the spring clutch in the feed clutch has been set by

the movement of the feed solenoid, the feed roller assembly rotates driven by the drive assembly and the feed rollers

feed the paper into the printer from the input tray assembly.

One full rotation of the feed roller assembly causes the spring clutch to be released by the feed solenoid and disables

the drive assembly from transmitting a driving signal.

• Feed Solenoid

The feed solenoid controls the operations (rotation and stop) of the feed roller assembly.

• Pre-regi. Sensor

This sensor detects whether paper is sent by the paper set lever based on changes in the position of the regi. actuator

and sends a signal to the MCU PWB.

• MCU PWB

The MCU PWB controls the regi. solenoid, rotates the feed roller assembly and feeds the paper into the printer with

the paper set lever. After receiving the signal from the regi. sensor, the MCU PWB instructs the EP toner cartridge to

generate the image.

(Refer to section 3.5 Electrical System. Illustrations of the parts described above are shown in Chapter 6, Parts List

PL5.)

• Drive Assembly

The drive assembly consists of the main motor and the gear that transmits the driving force. This assembly transmits

a driving force by rotating the main motor.

Page 20

– 16 –

THEORY OF OPERATION

Feed clutch

Feed solenoid

Feed roller assembly

Paper set lever

Retard pad

Pre-regi. sensor

Figure 2-5 Feeder & Drive

Drive assembly

Main motor

Paper set lever

Input tray assembly

Feed roller

Page 21

– 17 –

THEORY OF OPERATION

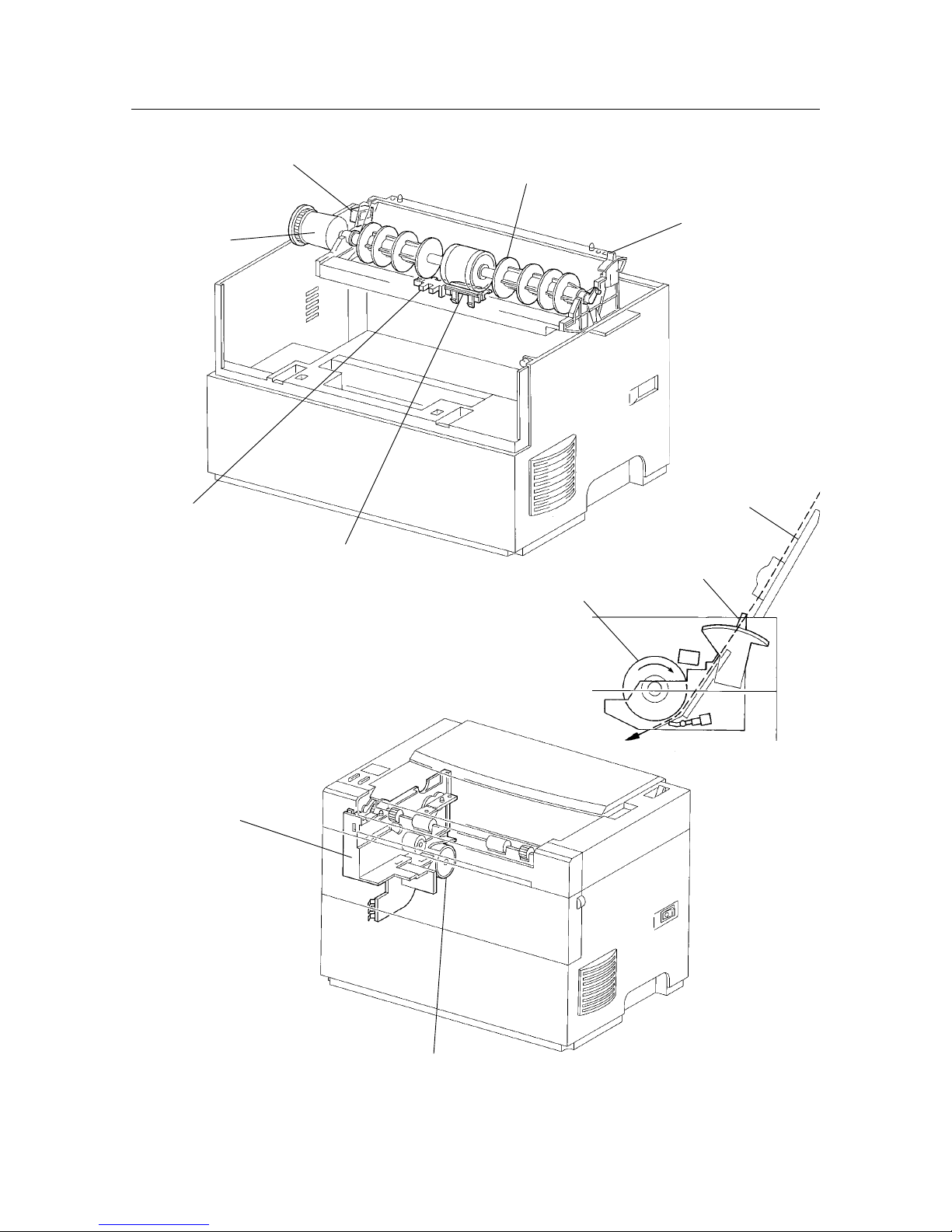

3.3 Fuser & Paper Exit

• Fuser Assembly

The fuser assembly includes the heater rod, heat roller, pressure roller, thermostat, thermistor and exit sensor. This

assembly fixes the toner onto the paper using heat and pressure, then outputs the printed paper.

Parts in the fuser assembly are referred to as fusers.

Heater Rod

The heater rod is a lamp with a heated coil sealed inside it and serves as the heat source inside the heat roller.

Heat Roller

The hollow, metal heat roller is coated on the surface and provides the heat to fuse the toner to the paper.

Pressure Roller

The rubber pressure roller provides the pressure to fuse the toner to the paper.

Thermistor

The thermistor is in contact with the heat roller and responds to its surface temperature.

When the heater rod is ON (a light is on), the thermistor controls the ON/OFF position of the heater rod according

to the temperature detected and prevents excessive increases in the primary temperature.

Thermostat

The thermostat is in series with the power supply in the heater rod. If the thermistor fails to prevent an excessive

increase in the (primary) temperature, the thermostat prevents an excessive increase in the secondary temperature

by opening the point of contact that results when the ambient temperature reaches a set level.

Thermal Fuse

The thermal fuse is in series with the heater rod circuit. If the thermistor fails to prevent the (primary) temperature

from getting too high and the thermostat fails to prevent the (secondary) temperature from getting too high, the

fuse will prevent tertiary overheating by melting when the ambient temperature reaches a set level.

Exit Roller

After fusing the toner onto the paper, the exit roller passes the printed paper out of the printer.

Exit Sensor

The exit sensor detects the state of the printed paper in the exit area in response to changes in the position of the

exit actuator. The exit sensor is turned ON when the presence of the printed paper is detected.

Page 22

– 18 –

THEORY OF OPERATION

Heat roller

Thermostat

Thermal fuse

Thermister

Exit sensor

Exit roller

Pressure roller

Heater rod

Pinch roller

Pinch roller

Pressure roller

Heat roller

Exit roller

Figure 2-6 Fuser & Paper Exit

Page 23

– 19 –

THEORY OF OPERATION

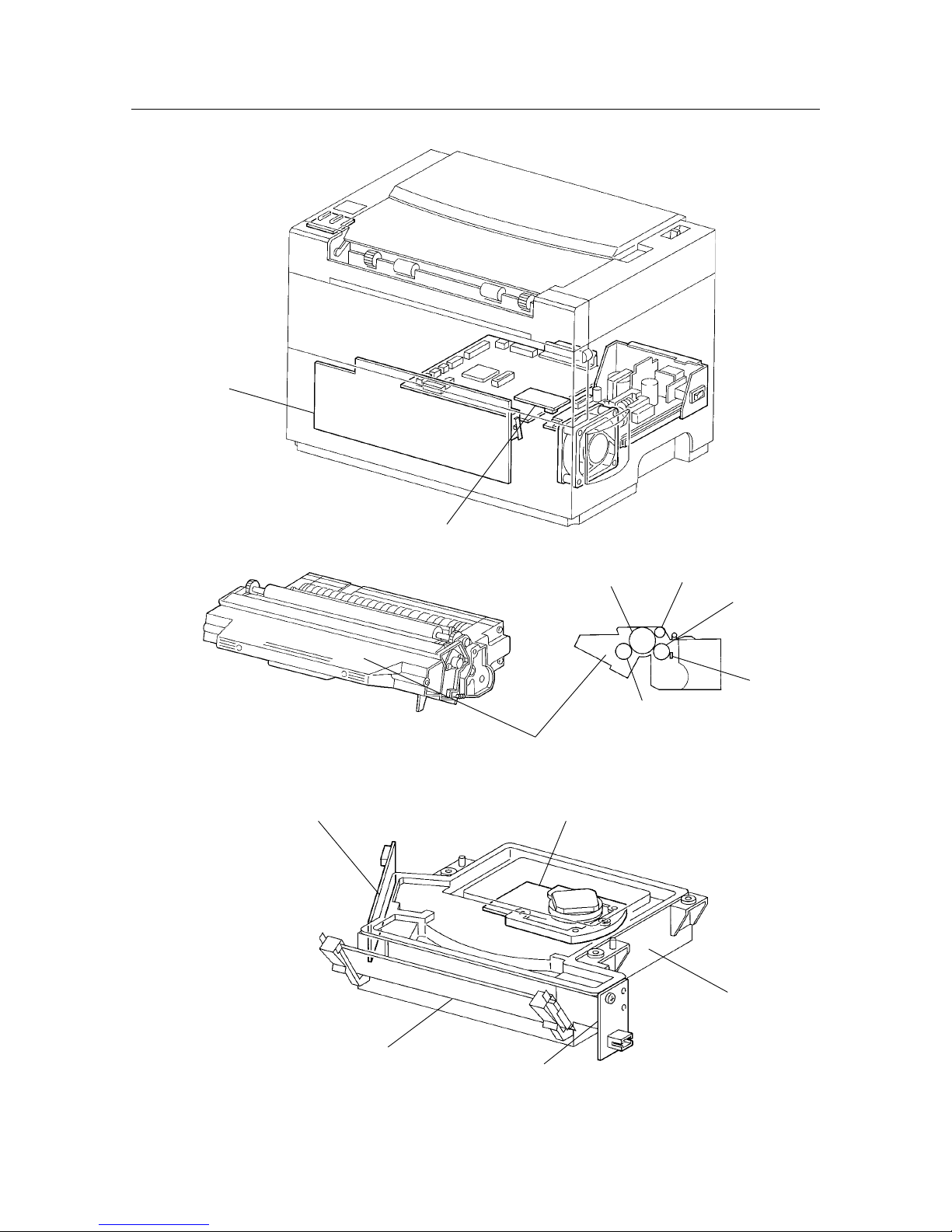

3.4 Photographics & ROS

• HVPS (HVPS: High Voltage Power Supply)

The HVPS supplies voltage/current to the BCR, magnetic roller, BTR and drum during the charging, developing and

transfer steps. It also supplies current to the fan. (The front cover interlock switch is mounted onto the HVPS.)

• ROS Assembly (ROS: Raster Output Scanner)

The ROS assembly consists of the LD assembly, the scanner assembly, the SOS PWB and the mirror. Parts in the ROS

assembly are referred to as ROS items.

LD Assembly (LD: Laser Diode)

The LD assembly converts electrical signals into a laser beam and emits light.

The laser diode output (LD power) is kept constant and transmitted through the monitor’s circuits.

Scanner Assembly

A polygonal mirror with four specular surfaces is mounted on the scanner motor which rotates at a constant speed.

The rotation of the polygonal mirror changes the laser beam’s angle of reflection and causes one surface of the

mirror to scan one line (in the direction of the drum’s axis).

The laser beam reflected by the polygonal mirror is irradiated onto the drum’s surface via the lens and mirror.

SOS PWB (SOS: Start of Scan)

The irradiation of the laser beam onto the SOS sensor causes the laser beam to be converted into an electrical signal

(SOS signal) and allows the initial scanning position of a line to be detected.

• CRU Sensor PWB (CRU: Customer Replaceable Unit)

The CRU sensor consists of a CRU switch which detects the presence of the EP toner cartridge and is turned ON or

OFF in response to the CRU actuator. The CRU switch is in series with the circuit emitting the laser beam and ensures

the safety of the laser beam.

• EP toner cartridge (EP: Electrical Photographics)

The EP toner cartridge consists of the drum, BCR, magnetic roller, CM blade and cleaning blade.

Drum

The drum is constructed of an aluminum cylinder covered with an OPC (organic photo conductor) sensitive material with

photoconductive properties (the ability to retain the electric charge in darkness and set the charge to neutral in light). The drum

produces a printed image based on the potential difference (latent electrostatic image) on its surface.

BCR (BCR: Bias Charge Roller)

The BCR sets the drum’s surface to a uniform electrical charge.

Magnetic Roller

The magnetic roller supplies toner to the drum for developing a latent electrostatic image on the surface of the drum.

BTR (BTR: Bias Transfer Roller)

The BTR applies a positive charge to the back of the paper and transfers the toner from the drum’s surface to the paper.

CM Blade (CM: Charge Metal)

The CM blade not only uniformly controls the amount of toner on the surface of the magnetic roller, but also uses friction to

give the toner its electric charge.

Cleaning Blade

The cleaning blade cleans the surface of the drum by scratching off the residual toner after the transfer step.

Page 24

– 20 –

THEORY OF OPERATION

Mirror

Scanner assemblyLD assembly

ROS assembly

SOS PWB

Magnetic roller

BTR

Drum

BCR

CM blade

EP toner cartridge

HVPS

CRU sensor

Figure 2-7 Photographics & Ros

Page 25

– 21 –

THEORY OF OPERATION

3.5 Electrical

• LED & LED PWB

The condition of the printer is displayed by LEDs (green/orange) and can be confirmed by observing these LEDs.

• LVPS Assembly (LVPS: Low Voltage Power Supply)

The LVPS assembly not only supplies AC power from the power supply to the heater rod in the fuser assembly, but

also generates and supplies a stable low-voltage DC power for use in the logic circuitry, etc.

It includes a main power switch which is used to turn the main power supply to the printer ON or OFF.

• MCU PWB

The MCU PWB controls the whole printing operation.

Its main functions are as follows:

(1) Receive information from the sensors and switches

(2) Control the ROS, fuser and drive assemblies

(3) Control the printing sequence

(4) Distribute low-voltage DC power from the LVPS assembly to each component

• Front Cover Interlock Switch

The interlock switch is a safety switch which completes or breaks the AC power circuit and the low-voltage (24V) DC

power circuit (but not the power supply to the fan) when the front cover assembly is closed or opened (the switch is

pressed or released). (This switch is mounted onto the HVPS.)

• Fan

The fan receives power from the HVPS and draws in air which is used to lower the internal temperature of the system,

thereby preventing it from increasing.

(Refer to section 1.2 Parts List in chapter 6, Parts List.)

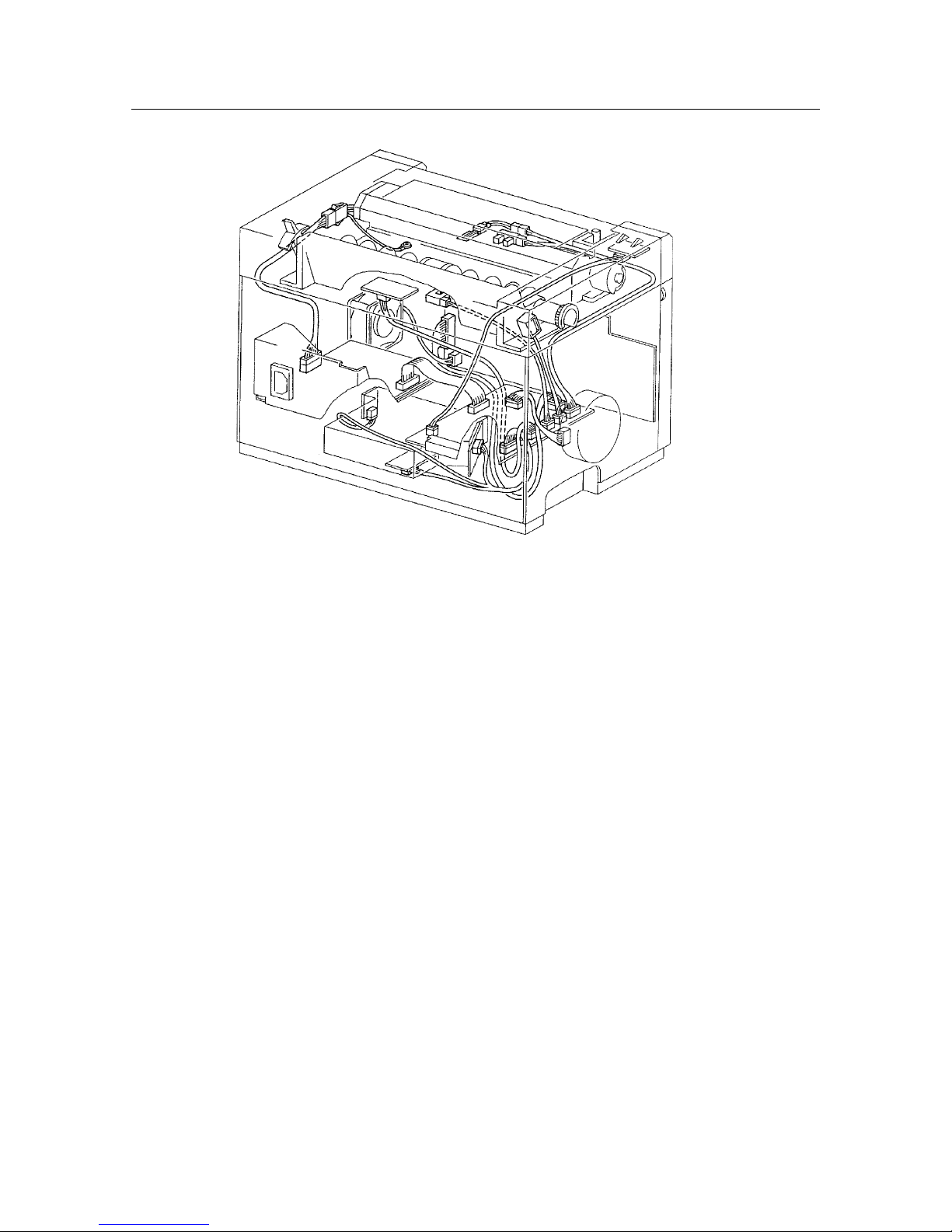

Figure 2-8 Electrical

LVPS assembly

Main power switch

Front cover Interlock switch

LED PCW

MCU PWB

LED (orange)

LED (green)

Fan

Page 26

– 22 –

THEORY OF OPERATION

Figure 2-9 Electrical

Page 27

CHAPTER 3

REPLACEMENT AND ADJUSTMENTS OF PARTS

This chapter explains adjustment, disassembly and reassembly of the printer. The following precautions should be

noted during disassembly and reassembly:

1. Disconnect the printer from the wall outlet before servicing it.

2. Unless otherwise specified, the printer is assembled by reversing the disassembly procedure.

3. Do not operate the printer with any parts removed.

4. When you remove the EPX toner cartridge, be sure to keep the cartridge in its original box. If the box is not

available, cover the cartridge with a cloth or put it in a dark place to prevent light from affecting the drum inside

the cartridge.

3

1. COVERS ..............................................25

1.1 Front Cover .................................... 25

1.2 Top Cover ....................................... 26

1.3 Rear Cover...................................... 27

1.4 Bottom Cover ................................. 28

1.5 Fan .................................................. 29

2. FEEDER & DRIVE ...............................30

2.1 Feeder Assembly ........................... 30

2.2 Feed Roller Assembly ................... 31

2.3 Feed Solenoid ................................ 32

2.4 Paper Set Lever.............................. 33

2.5 Retard Pad...................................... 34

2.6 Pre-Regi. Sensor............................ 35

2.7 Drive Assembly.............................. 36

2.8 Main Motor...................................... 37

3. FUSER .................................................38

3.1 Fuser Assembly ............................. 38

3.2 Pressure Roller .............................. 39

3.3 Heater Rod...................................... 40

3.4 Heat Roller...................................... 42

3.5 Thermostat ..................................... 43

3.6 Thermal Fuse ................................. 44

3.7 Thermistor ...................................... 45

3.8 Exit Sensor ..................................... 46

4. ROS......................................................47

4.1 ROS Assembly ............................... 47

4.2 SOS Sensor Assembly .................. 48

4.3 Laser Diode .................................... 49

4.4 Scanner Assembly......................... 50

4.5 Mirror .............................................. 51

4.6 HVPS ............................................... 52

4.7 Front Cover Interlock Switch

Actuator .......................................... 53

4.8 CRU Sensor PWB & Actuator ....... 54

5. ELECTRICAL SYSTEM....................... 55

5.1 PWB Chassis.................................. 55

5.2 MCU PWB ....................................... 56

5.3 LVPS Assembly ............................. 57

Page 28

– 24 –

REPLACEMENT AND ADJUSTMENT OF PARTS

Page 29

– 25 –

REPLACEMENT AND ADJUSTMENT OF PARTS

Be sure that the power is disconnected!

1. COVERS

1.1 Front Cover

[Disassembly]

Warning: Turn off the power switch and disconnect the power supply cord from the wall outlet.

(1) Grasping the left and right sides of the front cover [1], open it by pulling it down.

(2) Remove the EP toner cartridge and keep it in a safe place.

(3) Pressing down on the center of the printer with one hand, separately unhook the left and right hinges

[2] on the front cover [1] and remove the front cover.

[Assembly]

Reverse the disassembly procedure.

[1]

[2]

Page 30

– 26 –

REPLACEMENT AND ADJUSTMENT OF PARTS

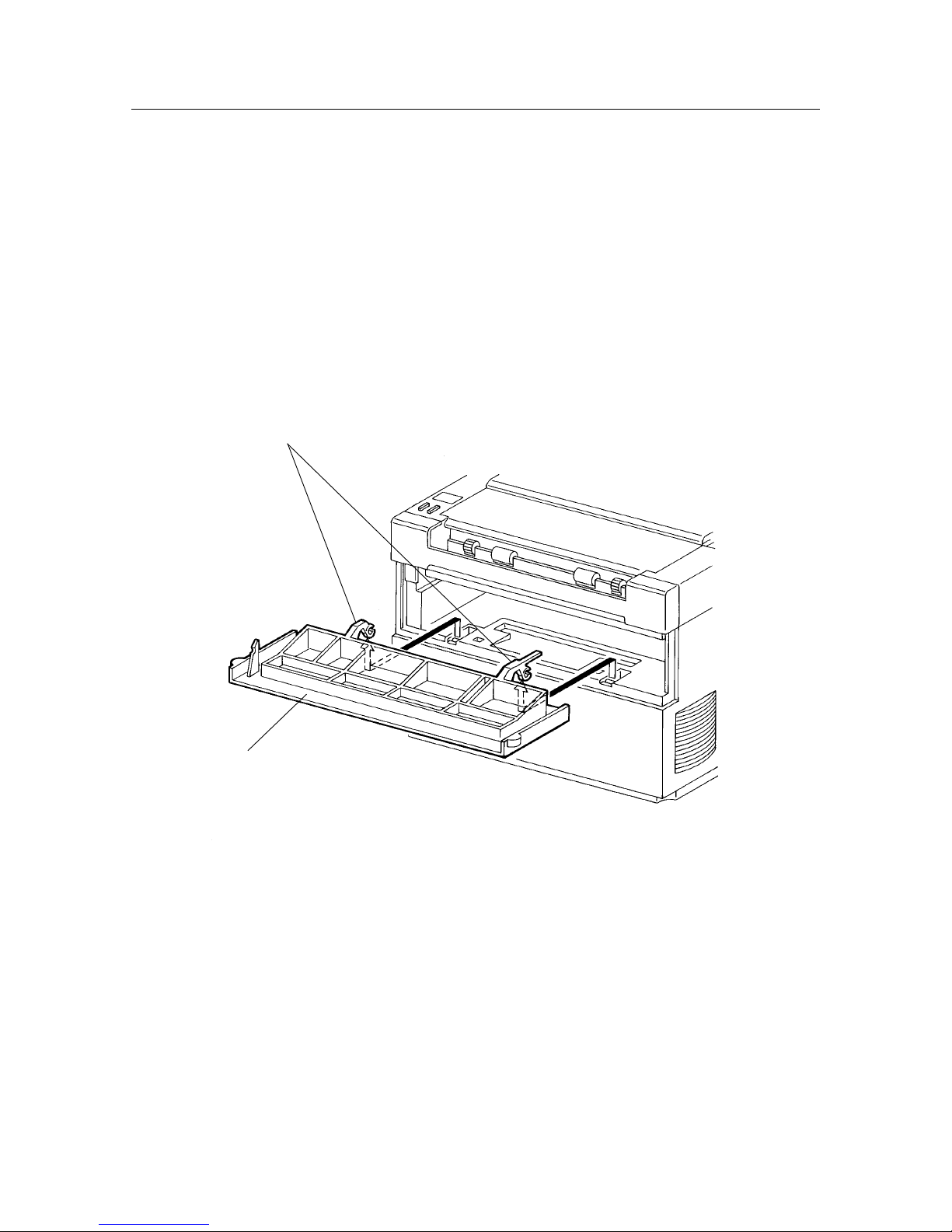

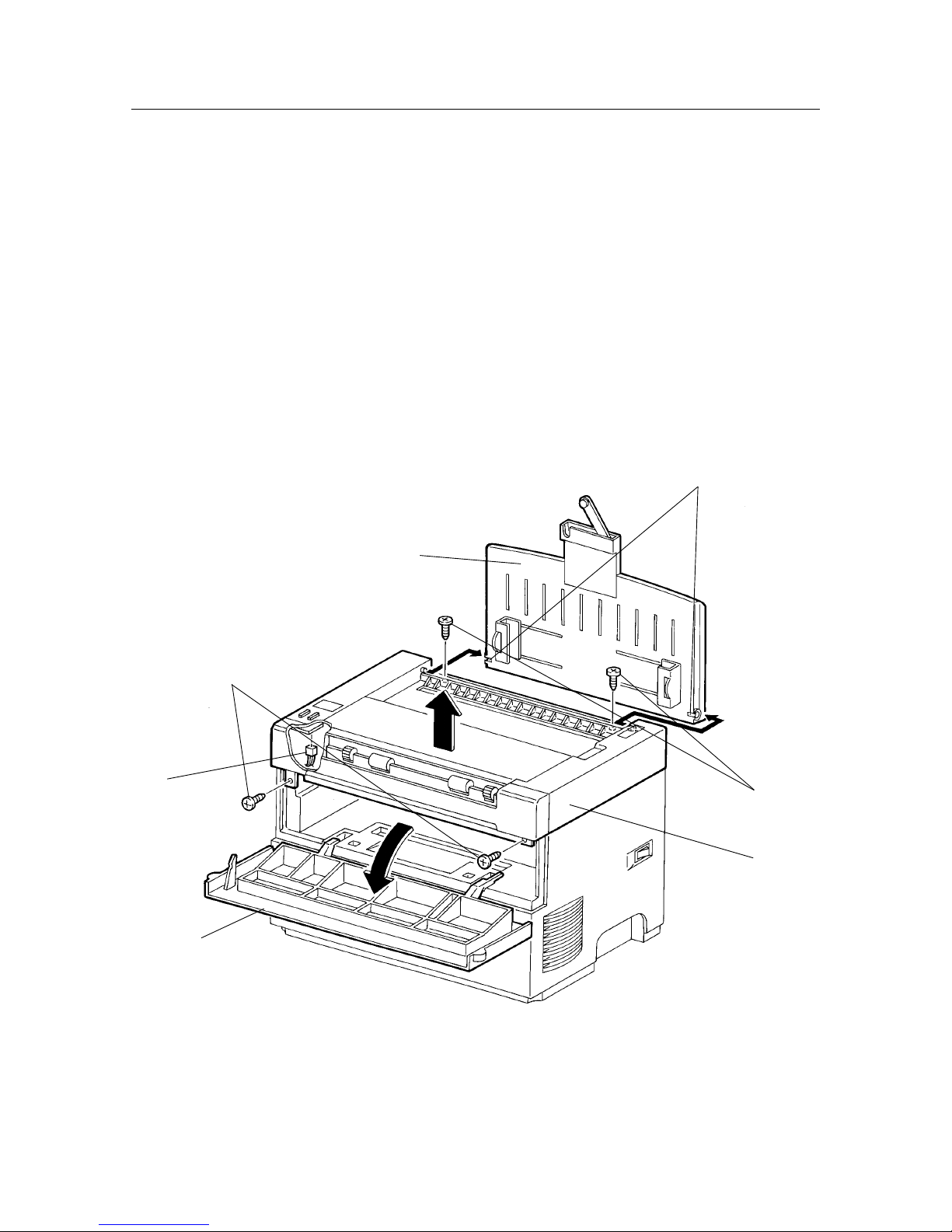

1.2 Top Cover

[Disassembly]

Warning: Turn off the power switch and disconnect the power supply cord from the wall outlet.

(1) Open the front cover [1], remove the EP toner cartridge and keep it in a safe place.

(2) Remove the two screws [2] that can be seen when the front cover is opened.

(3) While pressing down on the center of the printer with one hand, separately unhook the left and right

bosses [3] on the input tray assembly [4] and remove the input tray assembly.

Caution: In order to illustrate the positions of the screws in relation to the input tray assembly, fig.

(4) Remove the two screws [5] revealed when the input tray assembly is removed and raise the top cover

[6] a few centimeters.

(5) Raise the top cover to disconnect PJ321 [7] from the LED PWB.

[Assembly]

Reverse the disassembly procedure.

Caution: When installing the top cover [1] on the printer, be sure that the harness is not pinched between any other

parts.

[1]

[2]

[5]

[6]

[3]

[4]

[7]

Page 31

– 27 –

REPLACEMENT AND ADJUSTMENT OF PARTS

Be sure that the power is disconnected!

1.3 Rear Cover

[Disassembly]

Warning: Turn off the power switch and disconnect the power supply cord from the wall outlet.

Remove the EP toner cartridge and keep it in a safe place.

(1) Disconnect the printer’s power cord from the wall outlet.

(2) Remove the two screws [1] securing the MCU PWB interface connector (PJ31) to the rear cover.

(3) Remove the two screws [2] on the top left and right that are attaching the rear cover to the printer.

(4) Remove the center screw and the two screws [3] on the bottom left and right and remove the rear cover

[4].

[Assembly]

Reverse the disassembly procedure.

[3]

[4]

[2] [1]

Page 32

– 28 –

REPLACEMENT AND ADJUSTMENT OF PARTS

1.4 Bottom Cover

[Disassembly]

Warning: Turn off the power switch and disconnect the power supply cord from the wall outlet.

Remove the EP toner cartridge and keep it in a safe place.

(1) Remove the front cover. (Refer to section 1.1)

Caution: Be careful not to break the front cover interlock actuator when installing the bottom cover while the front

cover is removed.

(2) Turn the printer over onto its top cover. (Turn it upside down.)

(3) Remove the four screws [1] securing the bottom cover and remove the bottom cover [2].

(4) Disconnect CN121 [3] from the laser diode [4] and remove the harness [5] from the bottom cover.

(5) Disconnect PJ152 [6] from the HVPS and remove the bottom cover.

[Assembly]

Reverse the disassembly procedure.

Caution 1: Pass the harness [5] through the bottom cover [2], then connect it to connector CN 121. Do not connect the

harness directly to connector CN 121 [3] without passing it through the bottom cover.

Caution 2: Insert PJ152 from the fan into the HVPS before installing the bottom cover.

[2]

[5]

[6]

[1]

[4]

[3]

Page 33

– 29 –

REPLACEMENT AND ADJUSTMENT OF PARTS

Be sure that the power is disconnected!

1.5 Fan

[Disassembly]

Warning: Turn off the power switch and disconnect the power supply cord from the wall outlet.

Remove the EP toner cartridge and keep it in a safe place.

(1) Remove the bottom cover. (Refer to section 1.4)

(2) Disconnect PJ152 [1] attaching the HVPS to the fan [2].

(3) Inserting a miniature standard screwdriver [3] between the bottom cover [4] and fan [2], unhook the

latch and remove the fan.

[Assembly]

Reverse the disassembly procedure.

[4]

[3]

[2]

[1]

Page 34

– 30 –

REPLACEMENT AND ADJUSTMENT OF PARTS

2. FEEDER & DRIVE

2.1 Feeder Assembly

[Disassembly]

Warning: Turn off the power switch and disconnect the power supply cord from the wall outlet.

Remove the EP toner cartridge and keep it in a safe place.

(1) Remove the top cover. (Refer to section 1.2)

(2) Remove the four screws [1] securing the feeder assembly [2].

(3) Disconnect PJ181 [3] from the pre-regi. sensor.

(4) Remove the rear cover. (Refer to section 1.3)

(5) Disconnect PJ16 [4] from the MUC PWB and remove the feeder assembly [2].

[Assembly]

Reverse the disassembly procedure.

Caution: When installing the feeder assembly [2] on the printer, be sure the harnesses [6] are not pinched between

any other parts.

[2]

[6]

[4]

[3]

[1]

[1]

Page 35

– 31 –

REPLACEMENT AND ADJUSTMENT OF PARTS

Be sure that the power is disconnected!

2.2 Feed Roller Assembly

[Disassembly]

Warning: Turn off the power switch and disconnect the power supply cord from the wall outlet.

Remove the EP toner cartridge and keep it in a safe place.

(1) Remove the following units:

• Top cover (Refer to section 1.2)

• Feeder assembly (Refer to section 2.1)

• Spring [1].

• Feed roller assembly [2]

Pressing down on the feeder frame [3] of the feeder assembly, separately unhook the left and right

ends of the feed roller assembly [2] and remove it.

[Assembly]

Reverse the disassembly procedure.

[2]

[1]

[3]

Page 36

– 32 –

REPLACEMENT AND ADJUSTMENT OF PARTS

2.3 Feed Solenoid

[Disassembly]

Warning: Turn off the power switch and disconnect the power supply cord from the wall outlet.

Remove the EP toner cartridge and keep it in a safe place.

(1) Remove the following units:

• Top cover (Refer to section 1.2)

• Feeder assembly (Refer to section 2.1)

• Screw [1]

• Feeder solenoid [2]

• Feed roller assembly [3]

[Assembly]

Reverse the disassembly procedure.

Caution: When installing the feed solenoid [2] on the feeder assembly, align the hole in the stabilizing boss [4] on

the feeder frame [5] with the hole on the feed solenoid. Tighten the screw while pressing down on the back

of the feed solenoid.

[2]

[1]

[5]

[4]

[3]

Page 37

– 33 –

REPLACEMENT AND ADJUSTMENT OF PARTS

Be sure that the power is disconnected!

2.4 Paper Set Lever

[Disassembly]

Warning: Turn off the power switch and disconnect the power supply cord from the wall outlet.

Remove the EP toner cartridge and keep it in a safe place.

(1) Remove the following units:

• Top cover (Refer to section 1.2)

• Feeder assembly (Refer to section 2.1)

• Spring [1]

• Paper set lever [2]

[Assembly]

Reverse the disassembly procedure.

[1]

[2]

Page 38

– 34 –

REPLACEMENT AND ADJUSTMENT OF PARTS

2.5 Retard Pad

[Disassembly]

Warning: Turn off the power switch and disconnect the power supply cord from the wall outlet.

Remove the EP toner cartridge and keep it in a safe place.

(1) Remove the following units:

• Top cover (Refer to section 1.2)

• Feed roller assembly (Refer to section 2.2)

• Retard pad [1]

Press together the retard pad clips [2] on the back of the feeder frame [3] and remove the retard pad.

Caution: When removing the retard pad [1], do not to lose the spring [4] that is installed behind it.

[Assembly]

Reverse the disassembly procedure.

[2]

[4]

[3]

[1]

Page 39

– 35 –

REPLACEMENT AND ADJUSTMENT OF PARTS

Be sure that the power is disconnected!

2.6 Pre-Regi. Sensor

[Disassembly]

Warning: Turn off the power switch and disconnect the power supply cord from the wall outlet.

Remove the EP toner cartridge and keep it in a safe place.

(1) Remove the following units:

• Top cover (Refer to section 1.2)

• Feeder assembly (Refer to section 2.1)

• Pre-regi. sensor [1]

Unhook the pre-regi. sensor clips [2] on the back of the feeder frame and remove the pre-regi.

sensor [1].

[Assembly]

Reverse the disassembly procedure.

[2]

[1]

Page 40

– 36 –

REPLACEMENT AND ADJUSTMENT OF PARTS

2.7 Drive Assembly

[Disassembly]

Warning: Turn off the power switch and disconnect the power supply cord from the wall outlet.

Remove the EP toner cartridge and keep it in a safe place.

(1) Remove the following units:

• Feeder assembly (Refer to section 2.1)

• Fuser assembly (Refer to section 3.1)

• Rear cover (Refer to section 1.3)

• PJ14 [1]

Remove the three screws [2] securing the drive assembly and, while lifting the rear of the drive

assembly [3], remove it.

[Assembly]

Reverse the disassembly procedure.

Caution: Remove the bottom cover (refer to section 1.4) and be sure the HVPS terminal [4] on the drive assembly

[3] is securely connected to the HVPS.

[4]

[1]

[3]

[2]

Page 41

– 37 –

REPLACEMENT AND ADJUSTMENT OF PARTS

Be sure that the power is disconnected!

2.8 Main Motor

[Disassembly]

Warning: Turn off the power switch and disconnect the power supply cord from the wall outlet.

Remove the EP toner cartridge and keep it in a safe place.

(1) Remove the following units:

• Top cover assembly (Refer to section 1.2)

• Feeder assembly (Refer to section 2.1)

• Fuser assembly (Refer to section 3.1)

• Drive assembly (Refer to section 2.7)

• Two screws [1]

• Main motor [2]

[Assembly]

Reverse the disassembly procedure.

Note: Since the holes [3] attaching the main motor [2] to the drive assembly determine the position in which it is

installed, it is not necessary to adjust the backlash.

Caution: Install the main motor with the harness [4] facing towards the rear.

[2]

[4]

[3]

[1]

Page 42

– 38 –

REPLACEMENT AND ADJUSTMENT OF PARTS

3. FUSER

3.1 Fuser Assembly

[Disassembly]

Warning: Turn off the power switch and disconnect the power supply cord from the wall outlet.

Remove the EP toner cartridge and keep it in a safe place.

Caution: Be very careful not to get burnt when working on the fuser since it becomes hot while the printer is being

operated.

(1) Remove the following units:

• Top cover (Refer to section 1.2)

• PJ114 [1]

• PJ131 [2]

• PJ132 [3]

• Screws [4]

• Fuser assembly [5]

Remove the two screws [4] securing the fuser and while lifting the rear of the fuser assembly [5],

remove it from the frame.

[Assembly]

Reverse the disassembly procedure.

Caution: When installing the fuser assembly [5] on the printer, be sure the harnesses are not pinched between any other

parts.

[1]

[4]

[5]

[2]

[3]

Page 43

– 39 –

REPLACEMENT AND ADJUSTMENT OF PARTS

Be sure that the power is disconnected!

3.2 Pressure Roller

[Disassembly]

Warning: Turn off the power switch and disconnect the power supply cord from the wall outlet.

Remove the EP toner cartridge and keep it in a safe place.

Caution: Be careful not to get burnt when working on the fuser since it becomes very hot while the printer is being

operated.

(1) Remove the following units:

• Fuser assembly (Refer to section 3.1)

• Screw [1]

• Two screws [2]

• Fuser cover [3]

Lift the fuser cover from the fuser assembly [4].

• Pressure roller [5]

Turn over the fuser cover [3], remove the two screws [6] securing the inlet chute and remove

the pressure roller [5].

[Assembly]

Reverse the disassembly procedure.

Caution 1: When installing PJ114, be sure the green ground wire [7] and the diodes are installed correctly. (The diodes

should be installed with the cathode marks in the correct position.)

Caution 2: The ground plate on the inlet chute [8] should be in contact with the pressure roller shaft [5] (silver-colored

section).

[6]

[5]

[3]

[4]

[2]

[3]

[1]

[7]

[2]

[8]

Cathode marks

Page 44

– 40 –

REPLACEMENT AND ADJUSTMENT OF PARTS

3.3 Heater Rod

[Disassembly]

Warning: Turn off the power switch and disconnect the power supply cord from the wall outlet.

Remove the EP toner cartridge and keep it in a safe place.

Caution 1: Be careful not to get burnt when working on the fuser since it becomes very hot while the printer is being

operated.

(1) Remove the following units:

• Fuser assembly (Refer to section 3.1)

• Screw [1]

• Two screws [2]

• Fuser cover [3]

• Two screws [4]

• Fuser right housing [5]

• Screw [6]

• Two screws [7]

• Fuser left housing [8]

• Pinch roller [9]

[4]

[6]

[2]

[3]

[5]

[9]

[1]

[2]

[7]

[8]

Page 45

– 41 –

REPLACEMENT AND ADJUSTMENT OF PARTS

Be sure that the power is disconnected!

(2) Remove the following units:

• Two screws [10]

• Paper guide [11]

Caution 2: Do not to lose the spring [12] that is placed over the screws.

• Screw [13]

(3) Pull out the heater rod [14] from the heat roller [15].

Caution 3: Do not touch the glass surface of the heater rod [14] since oil from your hands may damage

it.

[Assembly]

Reverse the disassembly procedure.

Caution: When installing PJ114 [17], be sure the green ground wire [16] and the diodes are installed correctly. (The

diodes should be installed with the cathode marks in the correct position.)

[10]

[10]

[12]

[12]

[11]

[14]

[15]

[13]

[16]

[17]

Page 46

– 42 –

REPLACEMENT AND ADJUSTMENT OF PARTS

3.4 Heat Roller

[Disassembly]

Warning: Turn off the power switch and disconnect the power supply cord from the wall outlet.

Remove the EP toner cartridge and keep it in a safe place.

Caution: Be careful not to get burnt when working on the fuser since it becomes very hot while the printer is being

operated.

(1) Remove the following units:

• Fuser assembly (Refer to section 3.1)

• Pressure roller (Refer to section 3.2)

• Heater rod (Refer to section 3.3)

• Heat roller [1] (Refer to section 3.3)

Sliding the right and left ends of the H/R bearing [2] in the direction of the arrow, remove the heat

roller [1].

[Assembly]

Reverse the disassembly procedure.

Caution: There is only one correct way to install the gear [3]. Insert the tab [4] on the gear into the notch [5] on the

heat roller. (Do not install the gear in any other manner.)

[3]

[5]

[2]

[2]

[1]

[1]

[2]

[4]

Page 47

– 43 –

REPLACEMENT AND ADJUSTMENT OF PARTS

Be sure that the power is disconnected!

3.5 Thermostat

[Disassembly]

Warning: Turn off the power switch and disconnect the power supply cord from the wall outlet.

Remove the EP toner cartridge and keep it in a safe place.

Caution: Be careful not to get burnt when working on the fuser since it becomes very hot while the printer is being

operated.

(1) Remove the following units:

• Fuser (Refer to section 3.1)

• Pressure roller (Refer to section 3.2)

• Heater rod (Refer to section 3.3)

• Heat roller (Refer to section 3.4)

• Electrical frame [1]

Pull out the exit sensor actuator [2], remove the two screws [3] on the electrical frame used to attach

the thermostat and thermistor and detach it [1] from the fuser frame [4].

• Two screws [5]

• Thermostat [6]

[Assembly]

Reverse the disassembly procedure.

[1]

[5]

[6]

[2]

[3]

[4]

Page 48

– 44 –

REPLACEMENT AND ADJUSTMENT OF PARTS

3.6 Thermal Fuse

[Disassembly]

Warning: Turn off the power switch and disconnect the power supply cord from the wall outlet.

Remove the EP toner cartridge and keep it in a safe place.

Caution: Be careful not to get burnt when working on the fuser since it becomes very hot while the printer is being

operated.

(1) Remove the following units:

• Fuser (Refer to section 3.1)

• Pressure roller (Refer to section 3.2)

• Heater rod (Refer to section 3.3)

• Heat roller (Refer to section 3.4)

• Electrical frame [1]

Pull out the exit sensor actuator [2], remove the two screws [3] on the electrical frame used to attach

the thermostat and thermistor and detach it [1] from the fuser frame [4].

(2) Loosen the screw [5] securing the thermostat and the screw [6] securing the plate and remove the

thermal fuse [7].

[Assembly]

Reverse the disassembly procedure.

[4]

[7]

[6]

[5]

[2]

[3]

[1]

Page 49

– 45 –

REPLACEMENT AND ADJUSTMENT OF PARTS

Be sure that the power is disconnected!

3.7 Thermistor

[Disassembly]

Warning: Turn off the power switch and disconnect the power supply cord from the wall outlet.

Remove the EP toner cartridge and keep it in a safe place.

Caution: Be careful not to get burnt when working on the fuser since it becomes very hot while the printer is being

operated.

(1) Remove the following units:

• Fuser (Refer to section 3.1)

• Pressure roller (Refer to section 3.2)

• Heater rod (Refer to section 3.3)

• Heat roller (Refer to section 3.4)

• Electrical frame (Refer to section 3.5)

Pull out the exit sensor actuator, remove the two screws on the electrical frame used to attach the

thermostat and thermistor and detach it from the fuser frame.

• Screw [1]

• Thermistor [2]

[Assembly]

Reverse the disassembly procedure.

Caution: Install the thermistor [2] so that it is touching with the back of the heat roller.

[1]

[2]

Page 50

– 46 –

REPLACEMENT AND ADJUSTMENT OF PARTS

3.8 Exit Sensor

[Disassembly]

Warning: Turn off the power switch and disconnect the power supply cord from the wall outlet.

Remove the EP toner cartridge and keep it in a safe place.

Caution: Be careful not to get burnt when working on the fuser since it becomes very hot while the printer is being

operated.

(1) Remove the following units:

• Fuser (Refer to section 3.1)

• Pressure roller (Refer to section 3.2)

• Heater rod (Refer to section 3.3)

• Heat roller (Refer to section 3.4)

• Electrical frame (Refer to section 3.5)

Pull out the exit sensor actuator, remove the two screws on the electrical frame used to attach the

thermostat and thermistor and detach it from the fuser frame.

(2) Press together the exit sensor [1] clips [2] and remove it from the fuser frame [3].

[Assembly]

Reverse the disassembly procedure.

[3]

[2]

[3]

[1]

Page 51

– 47 –

REPLACEMENT AND ADJUSTMENT OF PARTS

Be sure that the power is disconnected!

4. ROS

4.1 ROS Assembly

[Disassembly]

Warning: Turn off the power switch and disconnect the power supply cord from the wall outlet.

Remove the EP toner cartridge and keep it in a safe place.

The ROS must not be running while it is being handled.

(1) Turn the printer over onto its top cover. (Turn it upside down.)

(2) Remove the bottom cover. (Refer to section 1.4)

(3) Disconnect CN122 [1] from the scanner assembly [2].

(4) Disconnect CN121 [3] from the laser diode [4].

(5) Disconnect CN123 [5] from the SOS sensor assembly [6].

(6) Remove the three screws [7] securing the ROS assembly and remove the ROS assembly [8].

[Assembly]

Reverse the disassembly procedure.

Caution: When installing the ROS assembly on the printer, align the holes in the stabilizing bosses and ROS assembly

before inserting the screws.

[8]

[2]

[7]

[4]

[3]

[6]

[5]

[1]

Page 52

– 48 –

REPLACEMENT AND ADJUSTMENT OF PARTS

4.2 SOS Sensor Assembly

[Disassembly]

Warning: Turn off the power switch and disconnect the power supply cord from the wall outlet.

Remove the EP toner cartridge and keep it in a safe place.

The ROS must not be running while it is being handled.

(1) Turn the printer over onto its top cover. (Turn it upside down.)

(2) Remove the following units:

• Bottom cover (Refer to section 1.4)

• ROS assembly (Refer to section 4.1)

• Screw [1]

• SOS sensor assembly [2]

[Assembly]

Reverse the disassembly procedure.

[2]

[1]

Page 53

– 49 –

REPLACEMENT AND ADJUSTMENT OF PARTS

Be sure that the power is disconnected!

4.3 Laser Diode

[Disassembly]

Warning: Turn off the power switch and disconnect the power supply cord from the wall outlet.

Remove the EP toner cartridge and keep it in a safe place.

The ROS must not be running while it is being handled.

(1) Turn the printer over onto its top cover. (Turn it upside down.)

(2) Remove the following units:

• Bottom cover (Refer to section 1.4)

• ROS assembly (Refer to section 4.1)

• Two screws [1]

• Laser diode [2]

Caution: The two (gold) screws covered with red paint must not be removed. If they are removed and the printer is

operated, the direction of the laser beam will change, affecting the picture quality considerably.

[Assembly]

Reverse the disassembly procedure.

[1]

[2]

Page 54

– 50 –

REPLACEMENT AND ADJUSTMENT OF PARTS

4.4 Scanner Assembly

[Disassembly]

Warning: Turn off the power switch and disconnect the power supply cord from the wall outlet.

Remove the EP toner cartridge and keep it in a safe place.

The ROS must not be running when it is being handled.

(1) Turn the printer over onto its top cover. (Turn it upside down.)

(2) Remove the bottom cover. (Refer to section 1.4)

(3) Disconnect CN122 [1] from the scanner assembly [2].

(4) Remove the three screws [3] securing the scanner assembly to the ROS assembly and remove the

scanner assembly [2].

Note: When removing the scanner assembly [2] only, it is not necessary to remove the ROS assembly [4] from the

printer as well.

[Assembly]

Reverse the disassembly procedure.

Caution: When installing the scanner assembly [2] onto the ROS assembly [4], align the holes in the stabilizing bosses

on the ROS assembly and scanner assembly before inserting the screws [3].

[2]

[1]

[4]

[3]

[5]

Page 55

– 51 –

REPLACEMENT AND ADJUSTMENT OF PARTS

Be sure that the power is disconnected!

4.5 Mirror

[Disassembly]

Warning: Turn off the power switch and disconnect the power supply cord from the wall outlet.

Remove the EP toner cartridge and keep it in a safe place.

The ROS must not be running while it is being handled.

(1) Turn the printer over onto its top cover. (Turn it upside down.)

(2) Remove the bottom cover. (Refer to section 1.4)

(3) Disconnect CN122 [1] from the scanner [2].

(4) Disconnect CN121 [3] from the laser diode [4].

(5) Disconnect CN123 [5] from the SOS sensor [6].

(6) Remove the three screws [7] securing the ROS assembly.

[Assembly]

Reverse the disassembly procedure.

Caution: Do not scratch or touch the front surface of the mirror with your hand; also, be sure to use the mirror clips

[9] to install it on the ROS assembly.

[2]

[1]

[4]

[3]

[6]

[5]

[7]

Page 56

– 52 –

REPLACEMENT AND ADJUSTMENT OF PARTS

4.6 HVPS

[Disassembly]

Warning: Turn off the power switch and disconnect the power supply cord from the wall outlet.

Remove the EP toner cartridge and keep it in a safe place.

(1) Remove the following units:

• Front cover (Refer to section 1.1)

• Bottom cover (Refer to section 1.4)

(2) Turn the printer onto its front. (Turn it sideways so that the front of the printer is pointing downwards.)

(3) Disconnect PJ151 [1] from the HVPS [2].

(4) Inserting a miniature standard screwdriver [3] into the small hinge hole [4] on the front cover, unhook

the latch supporting the HVPS and remove the HVPS [2].

Caution: If, while the HVPS is being removed, it catches on the drive assembly, carefully remove it without damaging

the contacts.

Note: The HVPS is supported by the latch mentioned above in (4) and the slot on the bottom cover.

[Assembly]

Reverse the disassembly procedure.

Caution: If, while the HVPS is being installed, it catches on the drive assembly, use a ruler or any other flat object

to guide in the HVPS without damaging any contacts.

[1]

[2]

[3]

[4]

Page 57

– 53 –

REPLACEMENT AND ADJUSTMENT OF PARTS

Be sure that the power is disconnected!

4.7 Front Cover Interlock Switch Actuator

[Disassembly]

Warning: Turn off the power switch and disconnect the power supply cord from the wall outlet.

Remove the EP toner cartridge and keep it in a safe place.

(1) Remove the bottom cover. (Refer to section 1.4)

(2) Turn the printer onto its front. (Turn it sideways so that the front of the printer is pointing downwards.)

(3) Remove the screw [1] securing the front cover interlock switch actuator [2] and remove the actuator.

[Assembly]

Reverse the disassembly procedure.

[1]

[2]

Page 58

– 54 –

REPLACEMENT AND ADJUSTMENT OF PARTS

4.8 CRU Sensor PWB & Actuator

[Disassembly]

Warning: Turn off the power switch and disconnect the power supply cord from the wall outlet.

Remove the EP toner cartridge and keep it in a safe place.

(1) Turn the printer onto its front. (Turn it sideways so that the front of the printer is pointing downwards.)

(2) Remove the following units:

• Bottom cover (Refer to section 1.4)

• Two screws [1]

• CRU sensor actuator cap [2]

• CRU sensor actuator [3]

• PJ171 [4]

• Two screws [5]

• CRU sensor PWB [6]

[Assembly]

Reverse the disassembly procedure.

[3]

[2]

[6]

[4]

[1]

[5]

Page 59

– 55 –

REPLACEMENT AND ADJUSTMENT OF PARTS

Be sure that the power is disconnected!

5. ELECTRICAL

5.1 PWB Chassis (including the MCU PWB and LVPS)

[Disassembly]

Warning: Turn off the power switch and disconnect the power supply cord from the wall outlet.

Remove the EP toner cartridge and keep it in a safe place.

(1) Remove the rear cover. (Refer to section 1.3)

(2) Disconnect all the harnesses except PJ11 [1] from the MCU PWB [2] and PJ111 [3] from the LVPS [4].

(3) Remove the three screws [5] securing the PWB chassis and remove the PWB chassis [6].

[Assembly]

Reverse the disassembly procedure.

Caution: Be sure that all the harnesses are firmly connected.

Page 60

– 56 –

REPLACEMENT AND ADJUSTMENT OF PARTS

5.2 MCU PWB

[Disassembly]

Warning: Turn off the power switch and disconnect the power supply cord from the wall outlet.

Remove the EP toner cartridge and keep it in a safe place.

(1) Remove the following units:

• Rear cover (Refer to section 1.3)

• PWB chassis (Refer to section 5.1)

(2) Disconnect PJ11 [1].

To disconnect PJ11, press down on the white, plastic sliding lock [2] to unlock it and pull out the harness.

(3) Remove the two screws [3] securing the MCU PWB [4] to the PWB chassis and remove the MCU PWB.

[Assembly]

Reverse the disassembly procedure.

Caution 1: Be sure that all the harnesses are firmly connected.

Caution 2: To install and lock PJ11, insert the harness and push the white, plastic sliding lock upwards until it stops.

Page 61

– 57 –

REPLACEMENT AND ADJUSTMENT OF PARTS

Be sure that the power is disconnected!

5.3 LVPS Assembly

[Disassembly]

Warning: Turn off the power switch and disconnect the power supply cord from the wall outlet.

Remove the EP toner cartridge and keep it in a safe place.

(1) Remove the following units:

• Rear cover (Refer to section 1.3)

• PWB chassis (Refer to section 5.1)

(2) Disconnect PJ11 [1].

To disconnect PJ11, press down on the white, plastic sliding lock [2] to unlock it and pull out the harness.

(3) Remove the three screws [4] securing the LVPS assembly [3] to the PWB chassis and remove the LVPS

assembly.

Caution: There are four screws securing the LVPS to the LVPS frame, but it is not necessary to remove these screws

in order to remove the LVPS assembly.

[Assembly]

Reverse the disassembly procedure.

Page 62

– 58 –

REPLACEMENT AND ADJUSTMENT OF PARTS

Page 63

MAINTENANCE GUIDE

1.

DESCRIPTION OF THE DIAGNOSTIC

TOOL............................................................. 61

1.1 Making Connections........................ 61

1.2 General Diagram .............................. 61

1.3 Operating Mode ............................... 61

1.4 On-line Mode .................................... 62

1.4.1 Function ....................................... 62

1.4.2 Entering On-line Mode ................ 62

1.5 User Settings Mode ......................... 62

1.5.1 Function ....................................... 62

1.5.2 Entering User Settings Mode ..... 62

1.5.3 Print Density Adjustment ............ 62

1.5.4 Input Tray Paper Setting............. 63

1.6 Test Print Mode................................ 63

1.6.1 Function ....................................... 63

1.6.2 Entering Test Print Mode............ 64

1.6.3 Operation...................................... 64

1.6.4 Simple Test Print Mode............... 64

1.7 Diagnosis Mode ............................... 65

1.7.1 Summary ...................................... 65

1.7.2 Different Types of Diagnosis

Mode Operation ........................... 65

1.7.3 Entering Diagnosis Mode ........... 65

1.7.4 List of Diagnosis Codes.............. 66

1.7.5 Diagnosis Code Selection .......... 67

1.7.6 Input Test ..................................... 67

1.7.7 Output Tests ................................ 68

1.7.8 Counter......................................... 71

1.8 Non-volatile Settings Mode............. 71

1.8.1 Function ....................................... 71

1.8.2 Entering the Non-volatile

Settings Mode .............................. 71

1.8.3 List of Non-volatile Codes .......... 73

1.8.4 Non-volatile Code Selection....... 75

1.8.5 Setting the Data ........................... 75

CHAPTER 4

2. ERROR/STATUS ...................................76

2.1 List of Error/Status Codes .............. 76

2.2 Error/Status Code Search and

2.3 Error/Status Code Display .............. 81

3. CONTROLLERS ....................................82

3.1 Paper Size Controller ...................... 82

3.2 ROS Controller................................. 83

3.2.1 Scanner Motor Operation ........... 83

3.2.2 ROS Warm Up.............................. 83

3.2.3 Standard ROS Values.................. 83

3.3 Fuser Controller............................... 84

3.3.1 Setting the Fuser Controller....... 84

3.3.2 ON/OFF Controller for the

3.3.3 Fuser Warm up ............................ 84

3.3.4 List of Fuser Temperatures ........ 84

3.3.5 List of Temperature Codes......... 85

3.4 Erase Cycle ...................................... 86

3.5 Paper Feed Regulation Time .......... 87

4. ARRANGEMENT OF

THE CONNECTORS [P/J]..................... 89

4.1 P/J Schematic Diagram ................... 89

4.2 List of P/J Connectors..................... 90

5. WIRING DIAGRAM CONNECTIONS ....91

5.1 Wiring Diagram of General

5.2 Wiring Diagram of Connections

5.2.1 Operation...................................... 92

5.2.2 Symbols used in the wiring dia-

6. PRINTING ALIGNMENT......................105

Operation .......................................... 78

4

Heater Rod ................................... 84

Connections ..................................... 91

Between Parts .................................. 92

gram for the part connection...... 93

Page 64

MAINTENANCE GUIDE

– 60 –

Page 65

MAINTENANCE GUIDE

1. DESCRIPTION OF THE DIAGNOSTIC TOOL

A diagnostic tool must be used in order to keep this printer in good working condition. When the diagnostic tool

is connected to this printer, it can be used to set the control codes and to diagnose any problem.

1.1 Making Connections

Connect the diagnostic tool to connector P/J31 on the MCU PWB of the printer using a harness.

Caution: Remove the rear cover (refer to chapter 3, section 1.3) when connecting the harness to P/J31 on the

MCU PWB on the printer.

LVPS

Rear of the printer

P/J31

MCU PWB

Harness

Diagnostic tool

1.2 General Diagram

The console consists of an LCD (liquid crystal display) with two rows of 16 characters each and two input key switches.

LCD

KEY 1 KEY 0

1.3 Operating Mode

This printer is able to operate in the five following modes:

• On-line Mode

• User Settings Mode

• Test Print Mode

• Diagnosis Mode

• Non-volatile Settings Mode

Caution: It is not possible to change from one mode to another while the power is ON. To cancel one mode and

start another, you must turn the power switch OFF.

– 61 –

Page 66

MAINTENANCE GUIDE

1.4 On-line Mode

1.4.1 Function

This mode allows you to print using commands from MCU PWB. In addition, this diagnostic tool will only respond

when the message “RDY” (READY) is displayed.

1.4.2 Entering On-line Mode

The printer enters this mode when the power is first turned ON.

Message [1] is shown on the LCD while the printer is warming up. After it has finished warming up, message [2]

will be displayed.

The counter showing the number of pages that have been printed, shown as “000058”, increases by one each time

a page is printed. “00 00 00 00” shown on the display does not mean anything and should be ignored.

WA I T 0 0

000058

[1]

1

00 00 00

RDY

000058

[2]

2

00 00 00 00

The main motor runs while the printer is warming up.

Note: The printer continues to warm up until it is operating normally and is able to begin printing.

1.5 User Settings Mode

1.5.1 Function

This mode allows you to set values in the non-volatile memory for the character density and paper size codes for

the input tray. The density of the characters can be set to any value between 0 and 4.

1.5.2 Entering User Settings Mode

This mode is entered by pressing KEY 1 while turning the power switch ON and then holding KEY 1 down for longer

than three seconds. The LCD will display the following message.

DEN I TY T

LIGHT<01

S

UN I NG

34>DARK

*

“DENSITY TUNING” is displayed on the top row indicating that the print density adjustment mode is now on display.

The “*” on the bottom row shows the current setting (2) for the character density. This value is also assigned to

non-volatile memory code 2. (Refer to 1.8.3 List of Non-volatile Codes.)

1.5.3 Print Density Adjustment

[1] After entering user settings mode, the density

value increases by one each time KEY 0 is

pressed, and this value is stored in the nonvolatile memory simultaneously.

DEN I TY T

LIGHT<01

S DEN I TY T

2

*

UN I NG

4>DARK

– 62 –

[2] If the density setting is set at its maximum (4)

and KEY 0 is pressed, the setting will return to

its minimum (0).

S

LIGHT<

*

UN I NG

1

234>DARK

Page 67

MAINTENANCE GUIDE

1.5.4 Input Tray Paper Setting

If KEY 1 is pressed in user settings mode while the print density value is being displayed, the current input tray

setting for the type of paper will be displayed as shown below.

FRONT TRAY S IZE

MONARCH

This setting is also assigned to non-volatile memory code A. (Refer to 1.8.3 List of Non-volatile Codes.)

[1] If KEY 0 is pressed, the type of paper can be

changed and this setting is entered in the non-

[2] If KEY 1 is pressed, the density value will be

displayed.

volatile memory at the same time.

FRONT TRAY S IZE

LEGAL- 13˝

DENSI TY

LIGHT<

*

TUNI NG

1

234>DARK

Caution: Since the printer’s paper setting is controlled by the host, the printer’s and host’s paper settings will

always be the same. If the printer’s setting is changed and is no longer the same as the host’s setting,

the printer’s setting will automatically change to match the host’s setting.

1.6 Test Print Mode

1.6.1 Function

This mode enables the printer’s built-in test pattern (self-test pattern) to be printed at maximum speed.

The self-test pattern is shown below.

Direction the paper is fed through the printer

Approx. 4mm

Approx. 4mm Approx. 4mm

127dots

(Paper)

About 127dots

1dot

1dot

About 1dot

* 1 The straight lines perpendicular to the direction that the paper is fed into the printer

A black line with a width of one dot is printed at 128 dots.

(However, the straight line at the bottom of the page is not printed 128 dots from the previous line.)

* 2 The straight lines in the direction that the paper is fed into the printer

A black line with a width of about one dot is printed at about 128 dots.

(However, the straight line at the right of the page is not printed 128 dots from the previous line.)

• About 1 dot: Since the horizontal and vertical widths of the dot is converted in the clock of the MCU PWB’s

circuit, the actual distance between the lines is not 127 dots.

About 127dots

Approx. 4mm

About 1dot About 1dot

1dot

Resolution (DPI) 300

Width (mm) Approx. 24.8

– 63 –

Page 68

MAINTENANCE GUIDE

1.6.2 Entering Test Print Mode

This mode is entered by pressing KEY 1 while turning the power switch ON and then releasing KEY 1 within three

seconds. The LCD will display the following message.

Caution: The printer will enter user settings mode if KEY 1 is held down for more than three seconds.

After entering test print mode, message [1] is shown on the LCD while the printer is warming up. Message [2] is

displayed when the printer is ready to print.

WA I T 0 0

000058

[1]

1

00 00 00

TEST

RDY

000058

00

[2]

2

00 00 00

TEST

“TEST” is shown on the bottom row of display when the printer enters test print mode. The number of test patterns

printed (“000058”) increases by one each time a test pattern is printed. “00000000” shown on the display on the

display does not mean anything and should be ignored.

Note 1: When test print mode is entered, the scanner motor in the ROS assembly begins running and continues

running at a fixed speed.

Note 2: The number of test patterns printed is displayed as a decimal number. After “999999” test patterns

have been printed, the display returns to “000000”.

1.6.3 Operation

1) After the printer is ready to print (when display [2] is shown), the printer will begin printing when KEY 0 is pressed

and will continue printing test patterns until it is stopped.

2) If KEY 0 is pressed while the test patterns are being printed, the printer will stop printing the test patterns after the

test pattern currently being printed has been generated.

3) If KEY 0 is pressed while the test patterns are not being printed, the printer will begin printing them and will continue

printing test patterns until it is stopped.

Warning: Print only after the covers have been properly installed.

1.6.4 Simple Test Print Mode

The printer is able to print the test print pattern (self-test pattern) without using the diagnostic tool.

Printing Procedure

1) Remove the rear cover. (Refer to Sec. 1.3 in Chapter 3, Replacement and Adjustment of Parts.)

2) Insert the EP cartridge and turn the power switch ON.

3) After the printer has finished warming up, connect PIN 1 and PIN 2 on the MCU PWB plug (P31).

Note: It is best to short circuit these pins using a screwdriver.

4) The printer will print one test pattern.

To print test patterns continuously, keep the pins (PIN 1 and PIN 2) on the MCU PWB plug (P31) connected.

– 64 –

Page 69

MAINTENANCE GUIDE

1.7 Diagnosis Mode

1.7.1 Summary

This mode displays the counter, which counts the number of pages which are stored in the non-volatile memory

and which will be printed, checks (using the input test) that the sensors and switches are functioning properly and

checks the operation and function (using the output test) of each component (main motor, HVPS, etc.).

1.7.2 Different Types of Diagnosis Mode Operation

The diagnosis mode is able to perform the following three functions:

• Counter Display

• Input Test

• Output Test

(The output test is further divided into each output component.)

1.7.3 Entering Diagnosis Mode

This mode is entered by pressing KEY 0 while turning the power switch ON.

The LCD will display the following message when diagnosis mode has been entered.

PRI NT CO

SELECT IN

UNTER

GDG30

Diagnosis code

When diagnosis mode has been entered, the top row will display the type of the diagnosis code chosen and “DG”

will be displayed in the bottom row followed by a two digit number representing the diagnosis code.

Note: If a paper jam occurs when the power supply is turned ON, diagnosis mode can still be entered.

However, diagnosis mode cannot be entered if an incorrect value is entered in ROM CHECK or RAM

CHECK when the power supply is turned ON.

– 65 –

Page 70

MAINTENANCE GUIDE

1.7.4 List of Diagnosis Codes

Diagnosis LCD Display

Code (Top Row)

Counter 30 PRINT COUNTER Displays the number of pages to be printed.

Input Test 02 SENSOR CHECK

07 FUSER TEMP. SET

08 FUSER TEMP.

80 SOLENOID TRAY0

90 MOTOR MAIN Operates the main motor in the drive assembly.

91 HVPS (C.ROLL AC)

Output

Test

92 HVPS (C.ROLL DC)

Shows whether or not the switches and sensors are

operating properly.

Displays a temperature code corresponding to the

temperature set in the fuser controller.

Displays a temperature code corresponding to the

present temperature of the fuser.

Operates the feed solenoid in the input tray (for 0.5

seconds only).

The HVPS applies an AC voltage to the charge roller

(CR).

The HVPS applies a DC voltage to the charge roller

(CR).

Operation

93 HVPS (DEV.BIAS)

94 HVPS (T.ROLL –)

95 HVPS (T.ROLL +)

00 EXIT DIAG. Turns OFF the output test.

00 SIZE SENSOR The main function does not operate.

00 CHECK SUM Displays the SUM of the ROM.

Caution 1: Diagnosis code 00 (“EXIT DIAG.”) can only be used to stop diagnosing in output test mode; it cannot

be used to initiate diagnosis mode.

Caution 2 : Only the diagnosis codes that are described above can be executed.

The HVPS applies a –DC/AC voltage to the magnetic

roller (DB).

The HVPS applies a –DC voltage to the bias transfer

roller (TR(–)).

The HVPS applies a +DC voltage to the bias transfer

roller (TR(+)).

– 66 –

Page 71

MAINTENANCE GUIDE

1.7.5 Diagnosis Code Selection

When diagnosis mode is entered, diagnosis code 30 is the first code displayed.

Each time KEY 1 is pressed, the diagnosis code changes according to the order shown in section 1.7.4 List of Diagnosis Codes.

DG 30

DG 02

DG 07

DG 08

DG 80

DG 90

DG 91

KEY1 ON

KEY1 ON

KEY1 ON

KEY1 ON

KEY1 ON

KEY1 ON

KEY1 ON

KEY1 ON

DG 00

KEY1 ON

DG 00

KEY1 ON

DG 00

KEY1 ON

DG 95

KEY1 ON

DG 94

KEY1 ON

DG 93

KEY1 ON

DG 92

Caution: When diagnosis code 02 (input test mode) is being executed, KEY 0 cannot be used to choose another

diagnosis code since it has another function under diagnosis code 02.

When a diagnosis code other than code 02 (input test mode) is being executed, another diagnosis code

can be chosen by pressing KEY 0.

1.7.6 Input Test (Diagnosis Code 02 (“SENSOR CHECK”))

(1) Function

Each time a sensor or switch is turned ON, the (two-digit, decimal number) number on the bottom right of the LCD

is increased by one.

This number allows you to verify that the switch and sensors are functioning properly.

(2) Operation

After entering diagnosis mode and choosing diagnosis code 02 with KEY 1, press KEY 0 to begin the check to

determine whether the switch and sensors are operating correctly.