Page 1

THERMAL PRINTER

TUP400 Series

TECHNICAL MANUAL

[ SECOND EDITION ]

Page 2

NOTICE

• All rights reserved. Reproduction of any part of this manual in any form whatsoever, without

STAR’s express permission is forbidden.

• The contents of this manual are subject to change without notice.

• All efforts have been made to ensure the accuracy of the contents of this manual at the time of going

to press. However, should any errors be detected, STAR would greatly appreciate being informed

of them.

• The above notwithstanding, STAR can assume no responsibility for any errors in this manual.

© Copyright 1997 Star Micronics Co.,Ltd.

Page 3

• First edition : Aug.1997

• Second edition : Jun. 1998 Add interface board Ver. 2

Model Name

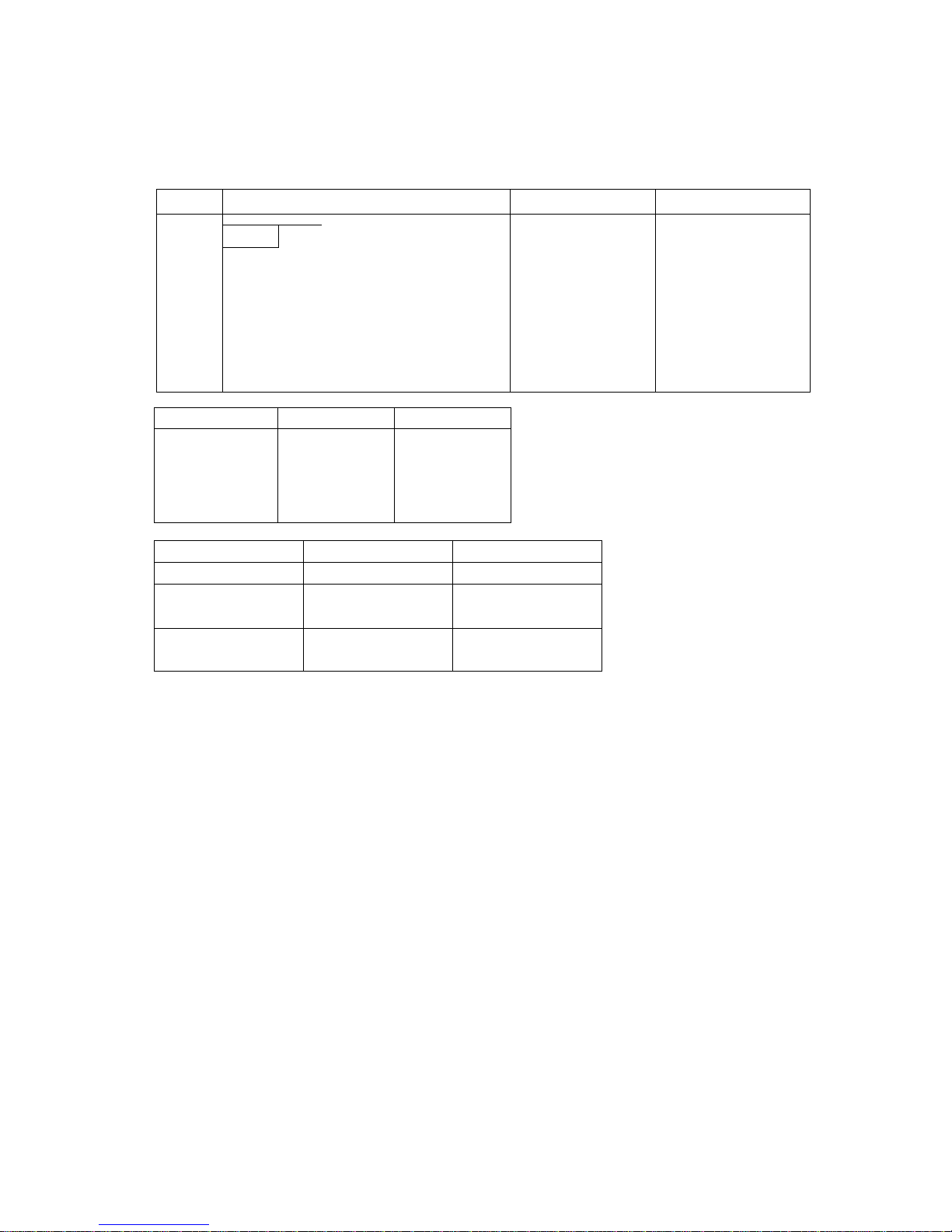

TUP 4 5 2 V2 D — 24 NL

No Transparent Laser

Voltage

24 : 24 VDC

Interface

D: RS232C

C: Parallel

K: RS422A

Board type

None:Ver.1

V2:Ver.2

Mechanism type

2: 40 columns

Printer type

5: Guilotine Type Full Cutter

8: Guillotine Type Full Cutter + Presenter

TUP400-series thermal printer

INTRODUCTION

This manual was created as a reference for maintenance of the Thermal Printer TUP400 Series for

personnel who are responsible for periodic inspections or troubleshooting of that equipment. This manual

was written for maintenance personnel, and was not intended to be used by the general operator.

This manual is organized into the following chapters.

Chapter 1 Specifications and Operation

Chapter 2 Theory of Operation

Chapter 3 Parts Replacement and Related Adjustments

Chapter 4 Maintenance and Lubrication

Chapter 5 Parts Lists

1

5

4

3

2

Page 4

This page was intentionally left blank.

Page 5

CHAPTER 1

SPECIFICATIONS AND OPERATION

1. General Specifications ....................................................................................... 6

2. External Appearance .......................................................................................... 7

3. DIP-Switch Settings ............................................................................................8

4. Print-Density Adjustment ................................................................................. 11

5. Sensor Adjustment ...........................................................................................12

6. HEX Dump Mode/Test Print.............................................................................. 13

7. Changing the Interface Board..........................................................................14

1

Page 6

– 6 –

1. General Specifications

Printing method Line thermal direct

Resolution 8 dots/mm (H) × 8 dots/mm (V)

Printable width 50 mm in Line Mode; 80 mm in Page Mode

Printing speeds 2 Inches/sec and 1 Inch/sec

Printable characters Page mode: ANK, International, Slash zero

Line mode: ANK, International, Special, Block graphics, IBM special,

IBM block graphics, Chinese characters, Slash zero

NOTE: ANK is comprised of ASCII characters and Japanese katakana characters.

Character matrixes Page mode

Small 8×16

Standard 16×24

Wide 24×32

OCR-B 16×24

Chinese chara. 24×24

Line mode

IBM block graphic 12×24 or 12×32

Chinese chara. 24×24 (12×24)

All others 12×24

Bar Codes JAN, EAN, UPC, Code39, ITF, Code93, Code128, NW-7

Paper

Recommended brands TF50KS-E, TF62KS-E (Nippon Paper Industries)

KP50-HEAEX (New Oji Paper Co., Ltd.)

Width 82.5 mm(3.25 inches)

Thickness General thermal paper 60 to 85 µm

Roll diameters External 203 mm max. (8 Inch), Internal 32 mm (1.26 Inch)

Interface RS232C, RS422A, or Parallel

MCBF 5,000,000 Lines

Head longevity 100 Km or 1.0 x 108 pulses(excludes damaged caused by dirt or foreign objects.)

(Missing dots is Max. 5%. However, there will be no missing dots up to 50Km.

This is the point where the thermal body resistor value varies more than 15% of the

initial value when continuously printing up to 12.5% of the printing rate.)

Cutter longevity 300,000 cuts (One piece max. paper thickness: 85 µm.)

Power supply DC 24 V ±7%

Power consumption Max. 120 W

Operating environment Temperature 5°C to 40°C

Humidity 25% to 80% (No condensation)

Storage environment Temperature -20°C to 60°C

Humidity 10% to 90% (No condensation)

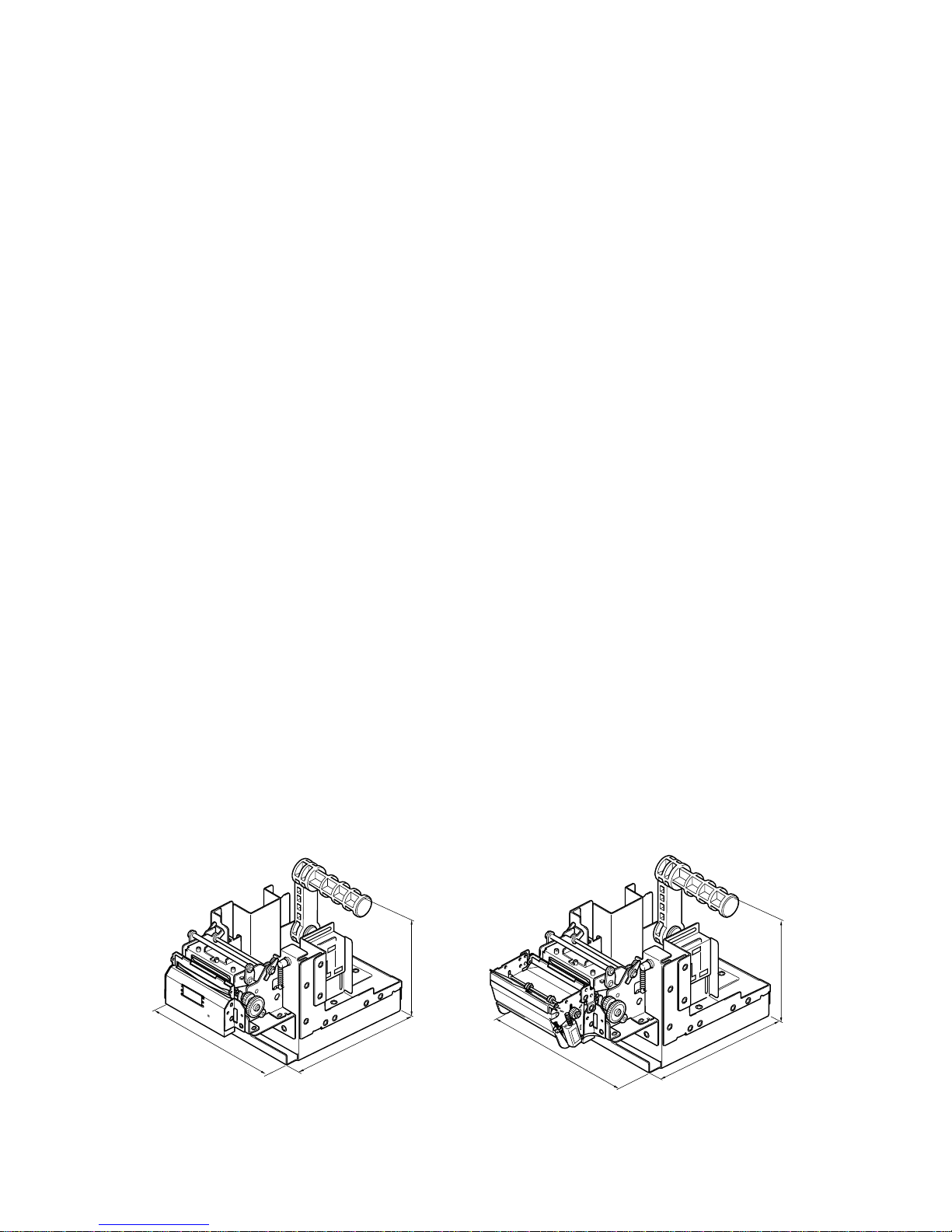

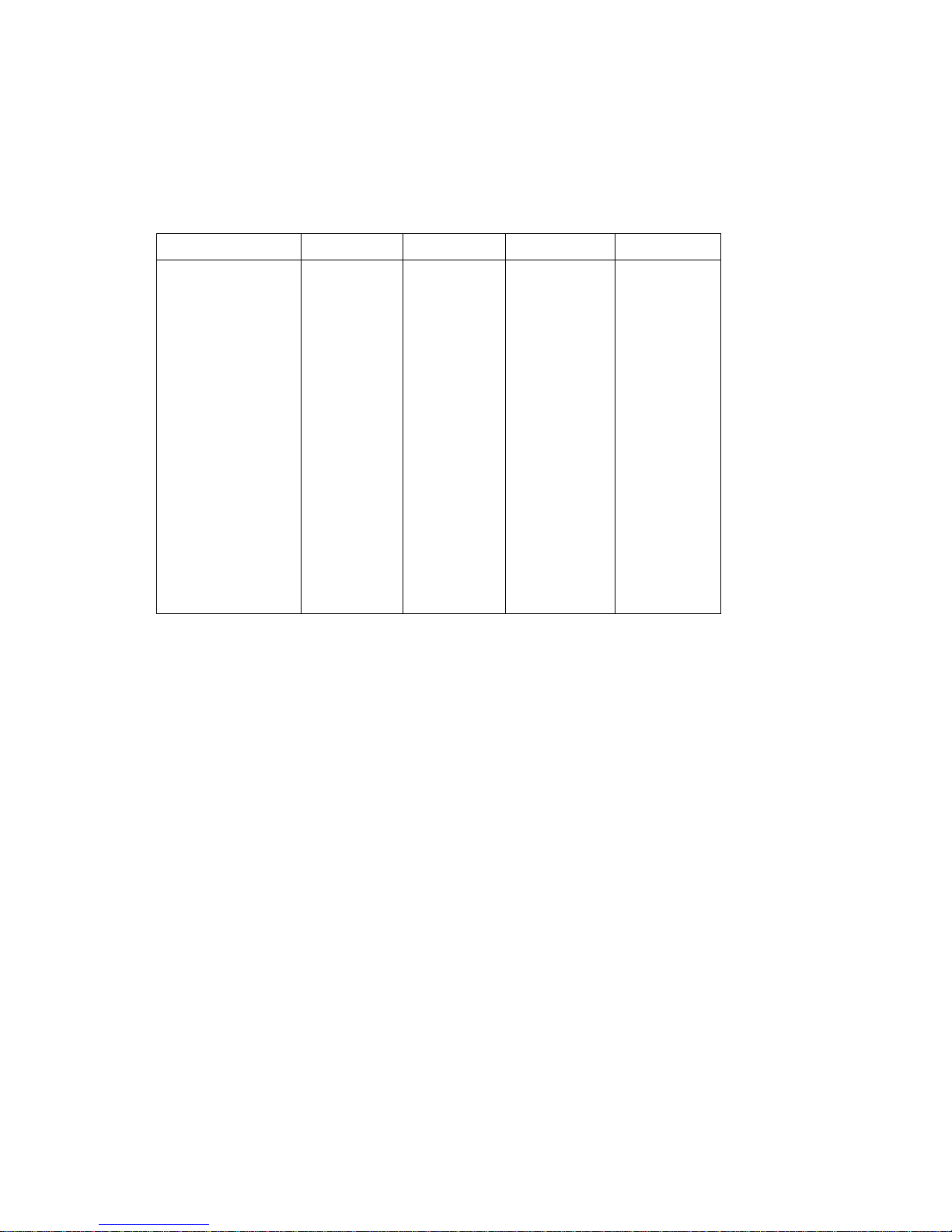

Fig. 1-1 External Dimensions

164mm

164mm

299mm

254mm

356mm

Approximately 3.3kg

Approximately 3.1kg

254mm

TUP452

TUP482

0

-1

Page 7

– 7 –

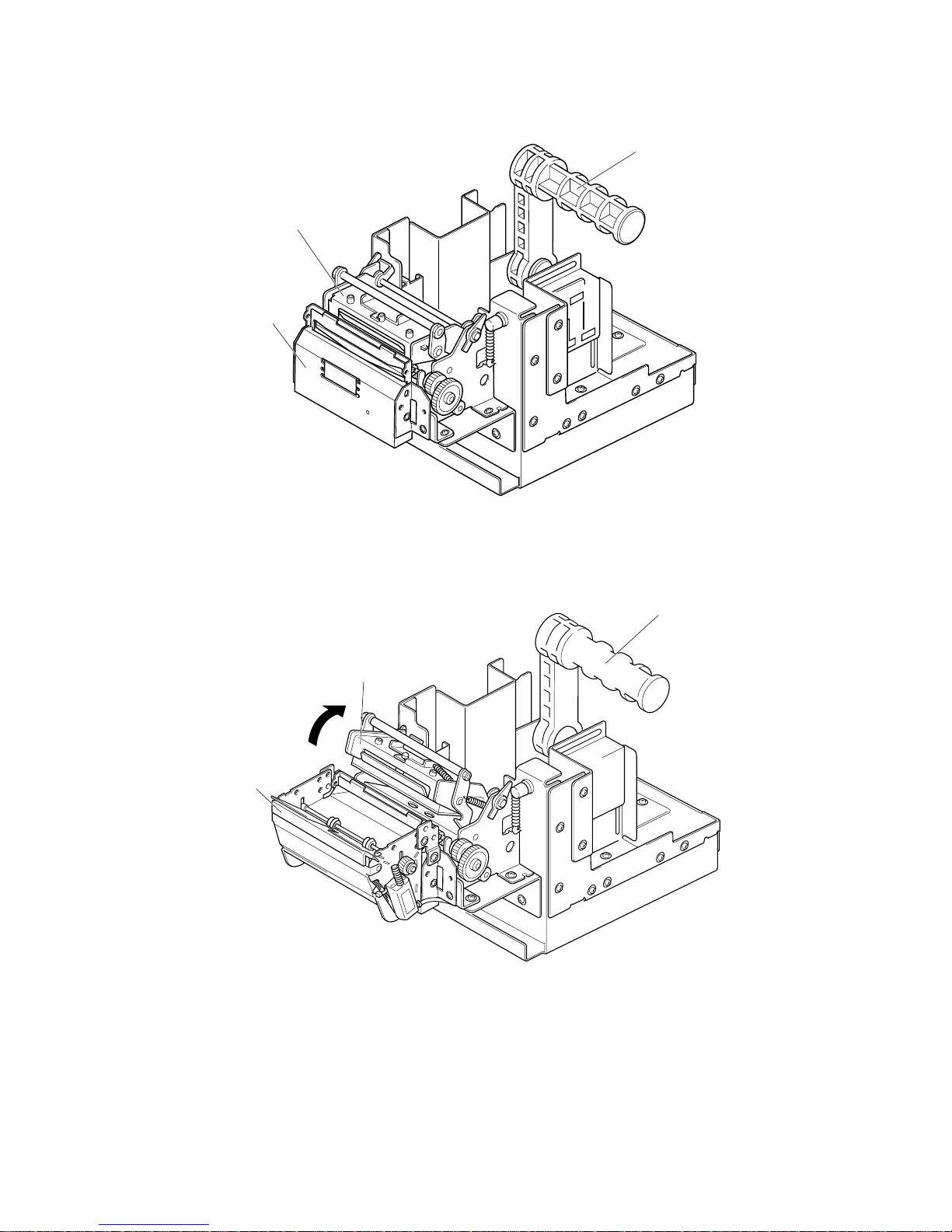

Fig. 1-2-b Internal Configuration (TUP482)

Arm

Printer head

Presenter

Fig. 1-2-a Internal Configuration (TUP452)

2. External Appearance

Printer head

Arm

Cutter

Page 8

– 8 –

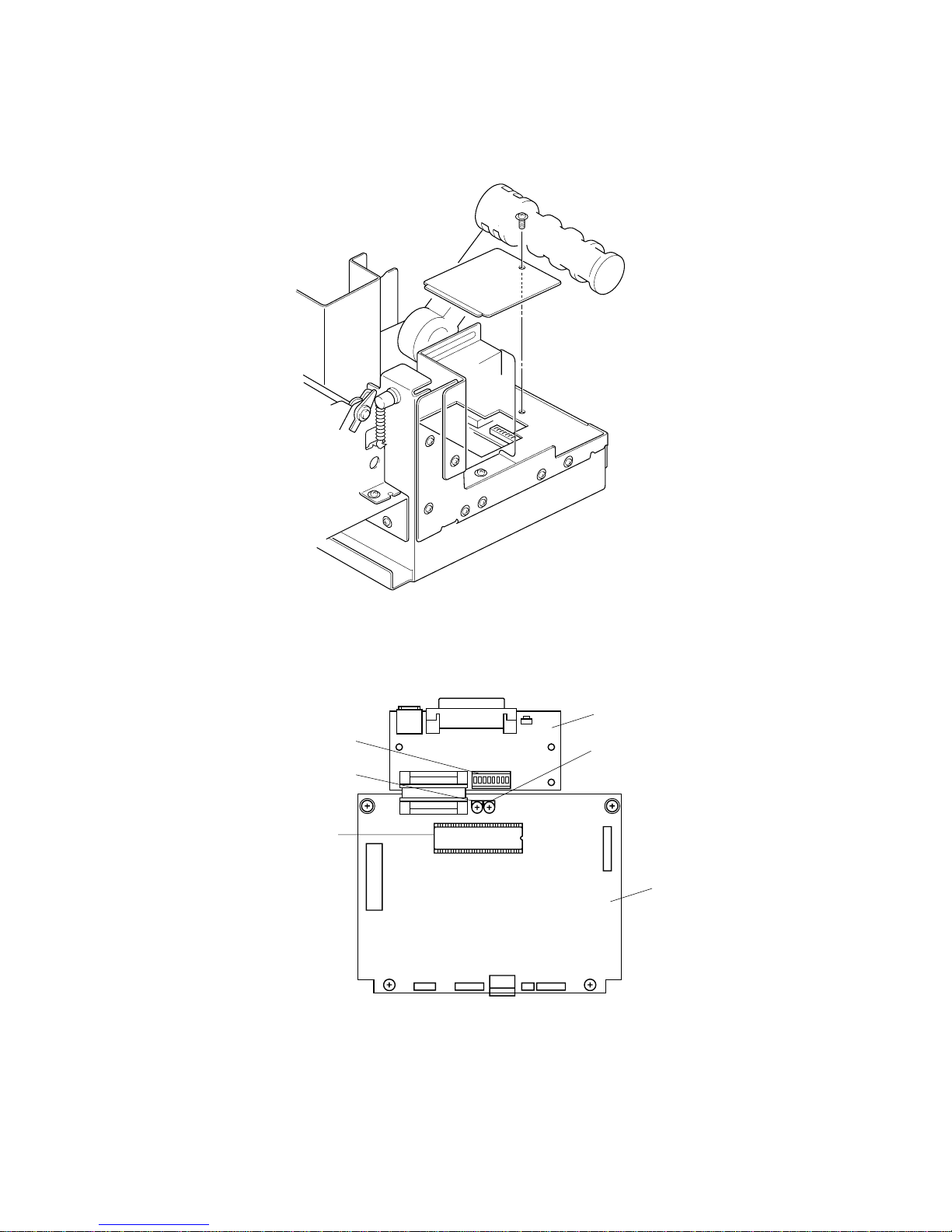

3. DIP-Switch Settings

DIP switches are located on the interface board and they differ according to the type of interface.

(1) Setting the DIP Switches

1. Turn the power supply OFF.

2. Remove the screw holding the ROM cover in place. (The screw is located at the base of the paper-roll holder.)

3. Remove the ROM cover to expose the main and interface PCBs

4. Set the DIP-switches on the interface board.

Fig. 1-3 DIP-Switch Settings

DIP Switches

VP4 (Black Mark Sensor)

EPROM

Main Logic Board

VP3 (Paper End Sensor)

Interface Board (RS-232C)

Fig. 1-4 Main Interface Board

Page 9

– 9 –

2. DIP-switch values

(1) RS-232C interface

This board has a single 8-bit DIP switch.

Switch Setting ON OFF

1-1 Baud

1-2

1-3 Handshake DTR XON/XOFF

1-4 Data 8 bits 7 bits

1-5 Parity No parity Enabled

1-6 Parity Odd Even

1-7 DC1/DC3 Disabled Enabled

1-8 Power ON

Baud 1-1 1-2

2400BPS OFF OFF

4800BPS OFF ON

9600BPS ON ON

19200BPS ON OFF

Mode 1-8 ON Power On

DC1/DC3 Disabled Disabled Printer selected

DC1/DC3 Disabled ON Printer selected

OFF Printer de-selected

Addressable ON Printer de-selected

OFF Printer selected

*1 The old type is selected.

Page 10

– 10 –

(2) RS-422A interface

This board had two DIP switches: one 8-bit switch and one 4-bit switch.

DIP switch #1 (8 bits):

Identical to the DIP switch on the RS-232C. (Bit 1-7 is disabled.)

DIP switch #2 (4 bits):

SW2-1 SW2-2 SW3-3 SW2-4

DC1,3 off ON ON ON ON

Address #1 OFF ON ON ON

#2 ON OFF ON ON

#3 OFF OFF ON ON

#4 ON ON OFF ON

#5 OFF ON OFF ON

#6 ON OFF OFF ON

#7 OFF OFF OFF ON

#8 ON ON ON OFF

#9 OFF ON ON OFF

#10 ON OFF ON OFF

#11 OFF OFF ON OFF

#12 ON ON OFF OFF

#13 OFF ON OFF OFF

#14 ON OFF OFF OFF

DC1,3 mode on OFF OFF OFF OFF

* DIP-SW #2 overrides the DIP-SW #1 DC1/3 setting (bit 1-7).

* DIP-SW #2 factory setting: All ON

(3) Parallel (Centronics) interface

The parallel-interface board has no DIP switches.

Page 11

– 11 –

4. Print-Density Adjustment

Adjust the print density in accordance with the sensitivity of the paper being used.

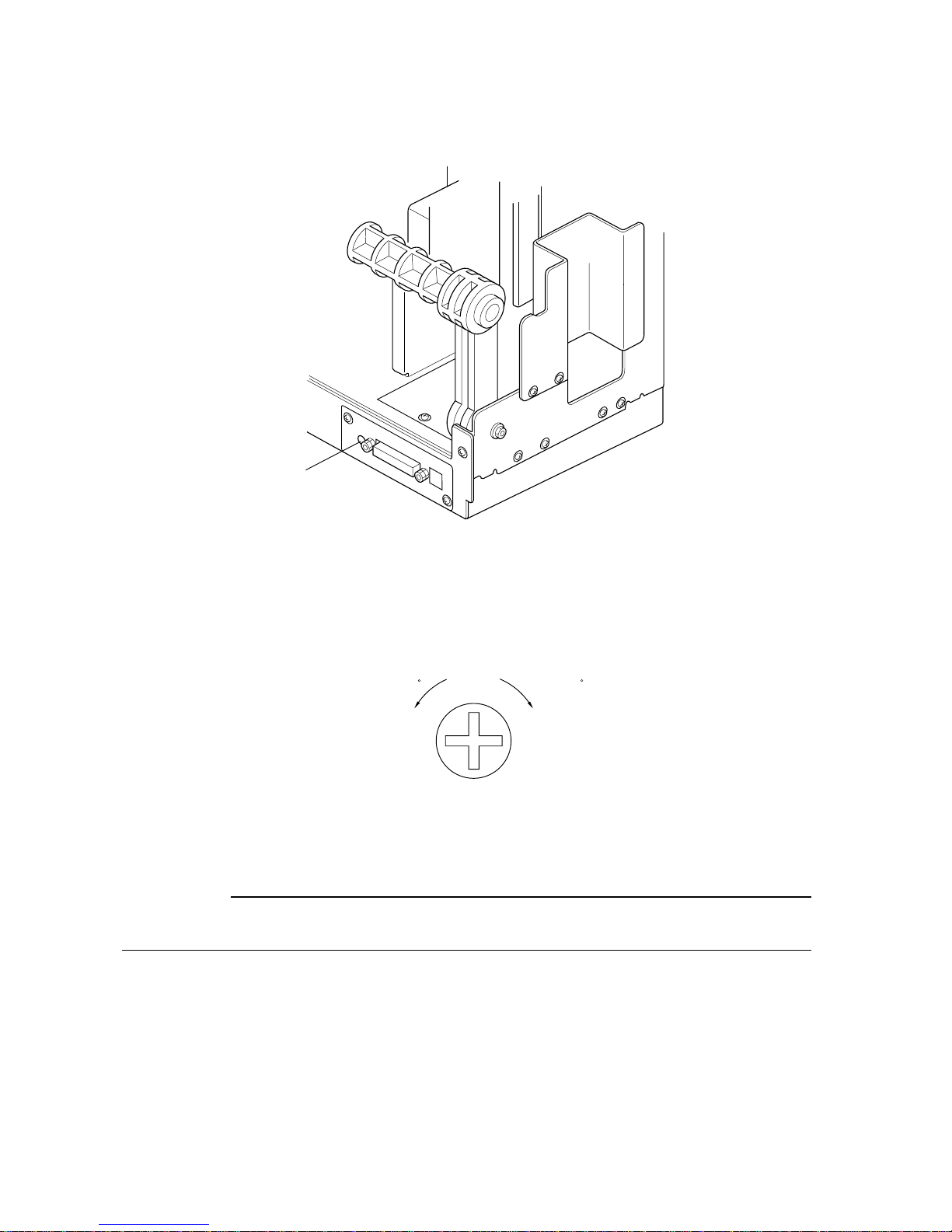

Fig. 1-5 Print-Density Adjustment

1. The variable resistor is located to the left of the interface connector on the back side of the printer.

2. Use a phillips screw driver to rotate the variable resistor to adjust the print density. The variable resistor will

rotate approximately 180°.

If you are not getting a good print on the thermal paper with the density set to its maximum at 2 Inch/sec print

speed, set the print speed to 1 Inch sec.

CAUTION

Avoid setting density too high for sensitive paper types. Excessive dark values may cause the paper

to swell which will degrade the quality of the image.

Variable Resistor

Approx. 90

Light Dark

Approx. 90

Page 12

– 12 –

5. Sensor Adjustment

You must adjust the paper sensor for the paper quality and the black mark print.

Fig. 1-6 Sensor Adjustment

1) Remove the screw on the underside of the paper-roll holder and remove the ROM cover.

2) Turn ON the power supply while holding down the push switch on the Near-end Sensor Board.

Remove the push-switch within 3 seconds after the "HU" LED on the Near-end Sensor Board lights.

CAUTION

If you continue holding the push switch for more than 3 seconds, the "PE" LED will light and you will not

be able to make any adjustments.

3) Black Mark Sensor

• Insert a piece of paper into the mechanism’s sensor area. Set it anywhere but the book mark area.

• Rotate the variable resistor VR4 on the main logic board until the "HU" LED on the Near-end Board lights.

Paper End Sensor

• Insert a piece of paper into the mechanism’s sensor area. Set it anywhere but the book mark area.

• Rotate the variable resistor VR3 on the main logic board until the "PE" LED on the Near-end Board lights.

4) After the LED lights, press the RESUME switch.

VR4

EPROM

Main Logic Board

VR3

Interface Board

Page 13

– 13 –

6. HEX Dump Mode/Test Print

You can enter the HEX Dump Mode and run Test Prints by turning ON the power supply while pressing the RESUME

switch. The HEX Dump mode prints the data sent from the host computer in HEX data format.

1) Turn ON the power supply while pressing the RESUME switch.

2) Release the RESUME switch using the following timing to set each mode.

Releasing at a: HEX Dump Mode

Releasing at b: Test Print

2 Sec

a

b

HU Lights

PE Lights

Near-end Sensor Board LED

Page 14

– 14 –

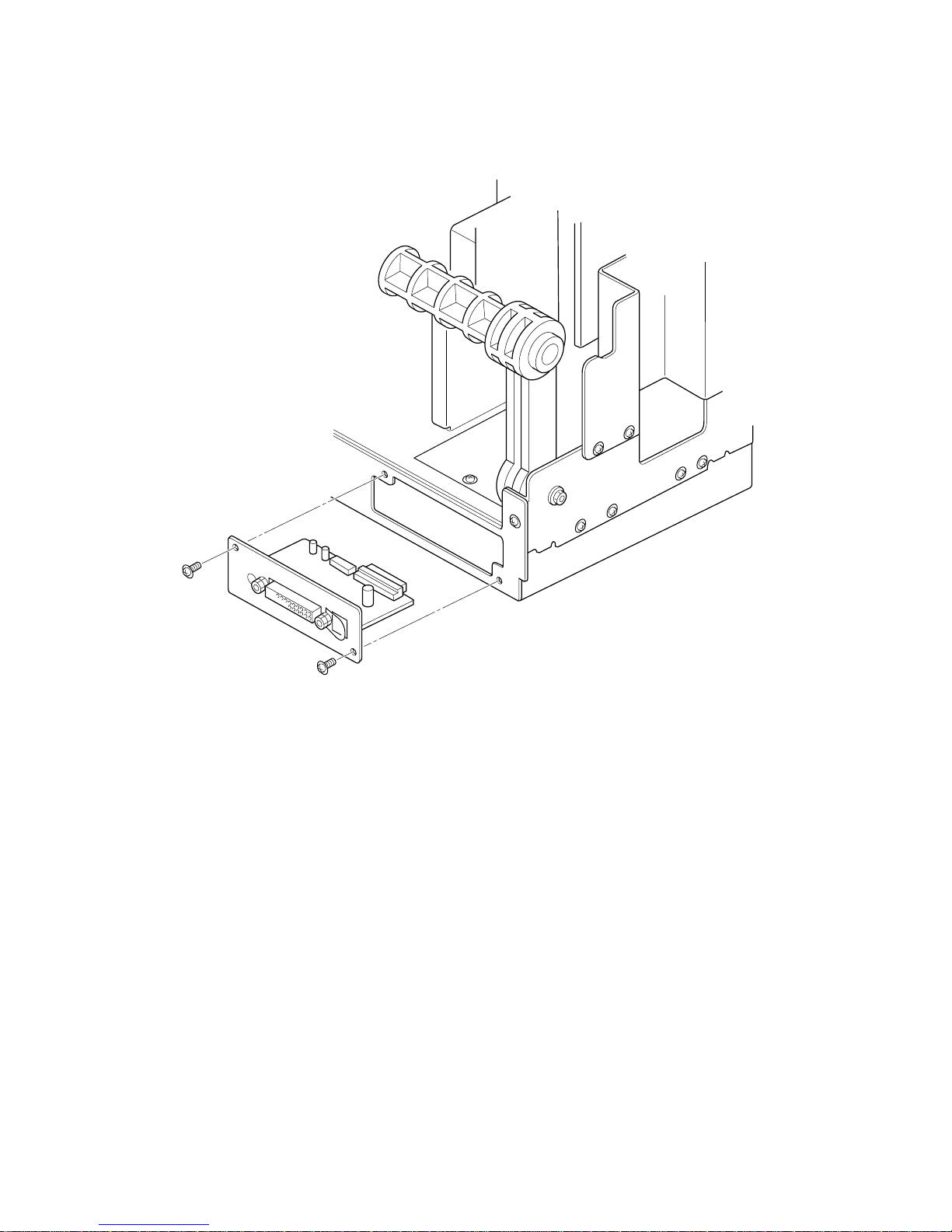

7. Changing the Interface Board

You can change the printer’s interface by replacing the interface board.

Fig. 1-7 Changing the Interface Board

1. Turn the power supply OFF.

2. Remove the 2 Interface Board Screws.

3. Remove the Interface Board.

4. Insert the new Interface Board by pushing it along the guides.

Push until the connector is completely inserted.

5. Attach the 2 screws to attach the Interface Board to the printer.

(Note)

The printer will automatically recognize the new Interface Board when it has been changed.

Page 15

CHAPTER 2

THEORY OF OPERATION

This chapter describes the operating principles of the circuitry and printer mechanism.

1. Block Diagram ................................................................................................... 16

2. Main Logic Board ..............................................................................................18

2-1. Data I/O Circuitry .................................................................................................. 18

2-1-2.RS-422A Interface............................................................................................ 19

2-1-3. Parallel Interface.......................................................................................... 20

2-2. Editing and Printing ............................................................................................. 21

2-2-1. Editing .......................................................................................................... 21

2-2-2. Thermal Head............................................................................................... 21

2-2-3. Head Current Control .................................................................................. 22

2-3. Feed-Motor Drive Circuit...................................................................................... 23

2-4. Power-On Reset Circuit ....................................................................................... 24

2-5. +5V Line Voltage Detector Circuit....................................................................... 25

3. Printer Mechanism ............................................................................................26

3-1. Thermal Head........................................................................................................ 26

3-2. Paper-Feed Mechanism ....................................................................................... 26

3-3. Sensor ................................................................................................................... 27

2

Page 16

– 16 –

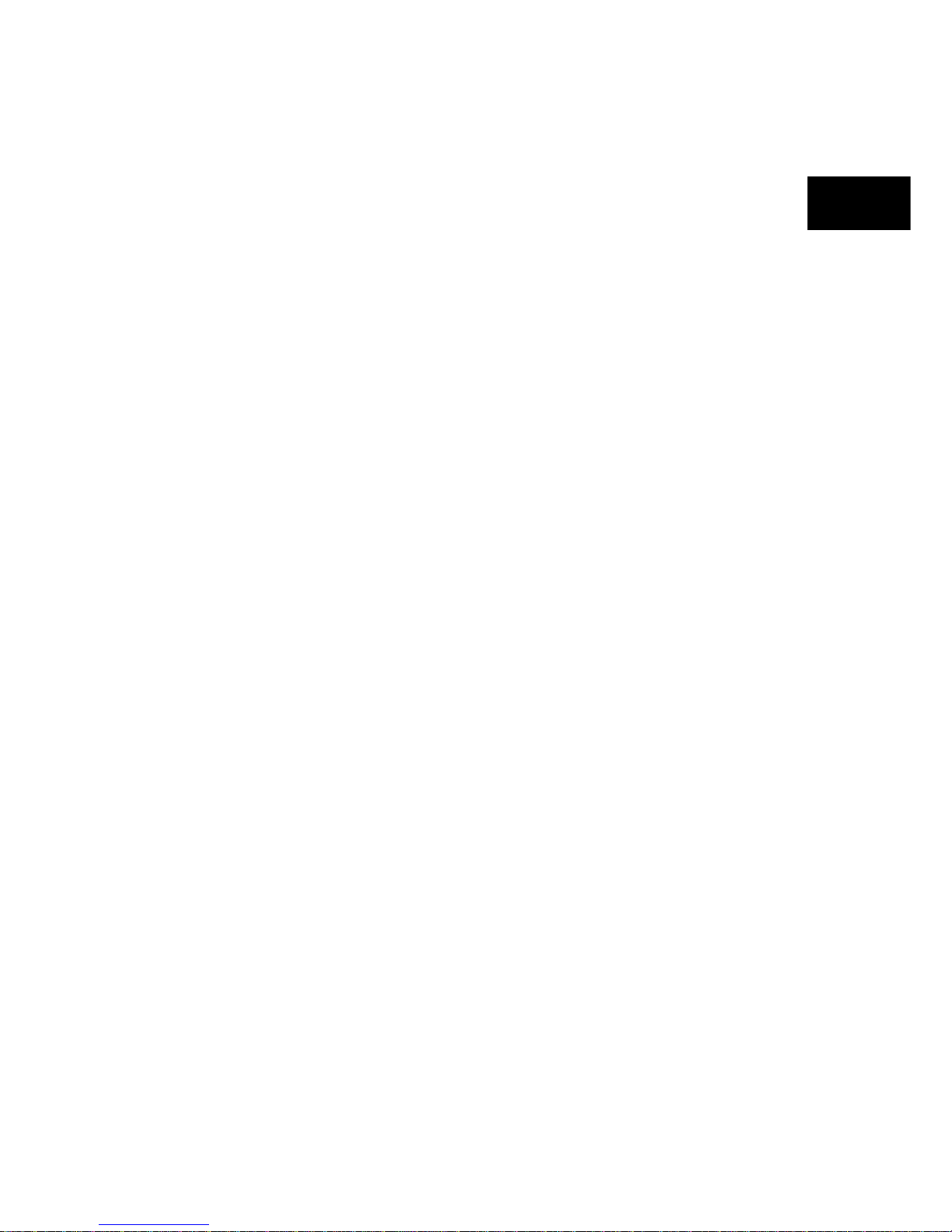

1. Block Diagram

The following is the block diagram for this printer.

(16)

(16)

(8)

(8)

(16)

24V

Data (Host Computer)

Near-end

Sensor Board

RESUME

Switch

Main Logic Board

Gate Array

CPU

DC-DC Coverter

Power Supply Unit

EPROM

128 k x 16 Bit (Ver. 1

)

250 k x 16 Bit (Ver. 2

)

PS-RAM

128 x 16 BitPS-RAM

S-RAM

8K x 8 BitS-RAM

Chinese Char. ROM

256 k x 16 Bit (Ver. 1

)

512 k x 16 Bit (Ver. 2

)

EEPROM

Head Driver

Motor Driver

Cutter Driver

Sensor Circuit

Presenter

Driver

Thermal

Head

Print Mechanism

Paper

Feed

Motor

Cutter

Sensor

Presenter

Interface Board

RS-232C, RS-422A, Parallel

Fig. 2-1 Block Diagram

Page 17

– 17 –

(1) Main Logic Board

The interface board relays data from the host computer to the main logic board. The main logic board’s CPU

temporarily stores the data into local RAM.

It then reads out the data, edits it according to the control program stored in the board’s ROM, and prints the results

by issuing the appropriate drive signals to the printer mechanism.

[Block Description]

a. CPU: HD641300F, CMOS single-chip computer

Controls overall printer operation.

b. EPROM

Contains the program and character fonts (other than Chinese characters) for CPU control.

c. PS-RAM: 128 K × 16 bits

Used as the work area and data buffer

d. S-RAM 8 K × 8 bits

Saves format data and externally defined characters.

e. EEPROM: 1024 bits

Stores printer settings. Settings can be changed by software. (Used in place of dip-switches.)

f. Gate array

Executes various types of signal processing.

g. Drivers

The various drivers convert signals received from the CPU and gate array into the drive signals that directly control

the printer mechanism.

h. DC-DC converter

Converts 24V to 5V.

(2) Interface board

Interfaces the main board with the host computer.

There are three versions, each for a different interface type: RS-232C, RS-422A, or Centronics parallel.

(3) Near-end sensor board

a. Checks the amount of paper remaining on the paper roll.

b. Used to adjust the sensor.

c. Displays errors using the LED.

(4) RESUME Switch

a. Used to set paper.

b. Used in HEX Dump output and test prints.

(5) Printer Mechanism

The printer mechanism is composed of the thermal head, paper feed motor, cutter sensors and presenter (only on the

TUP482.)

Page 18

– 18 –

2. Main Logic Board

2-1. Data I/O Circuitry

The main logic board relays data back and forth to the host computer via the interface board.

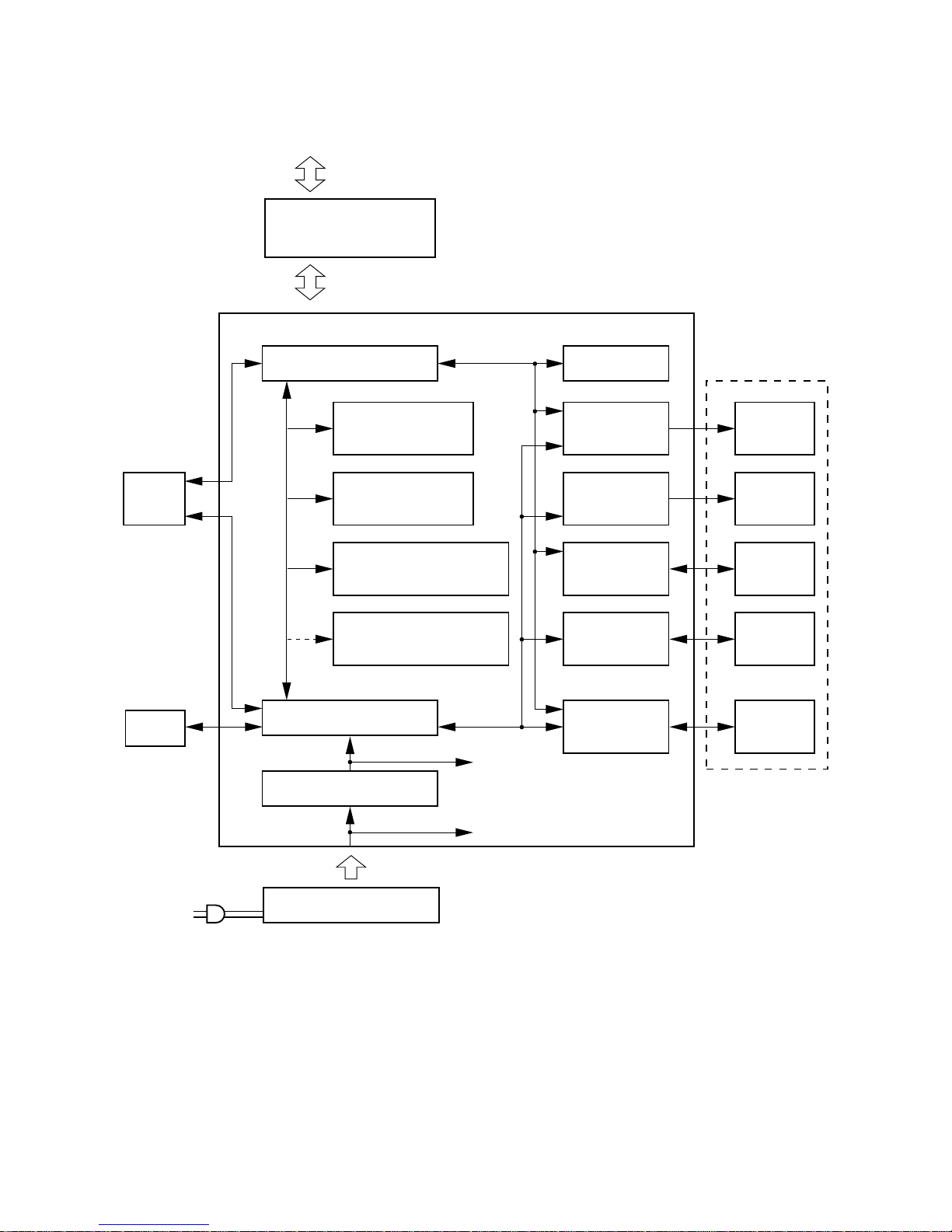

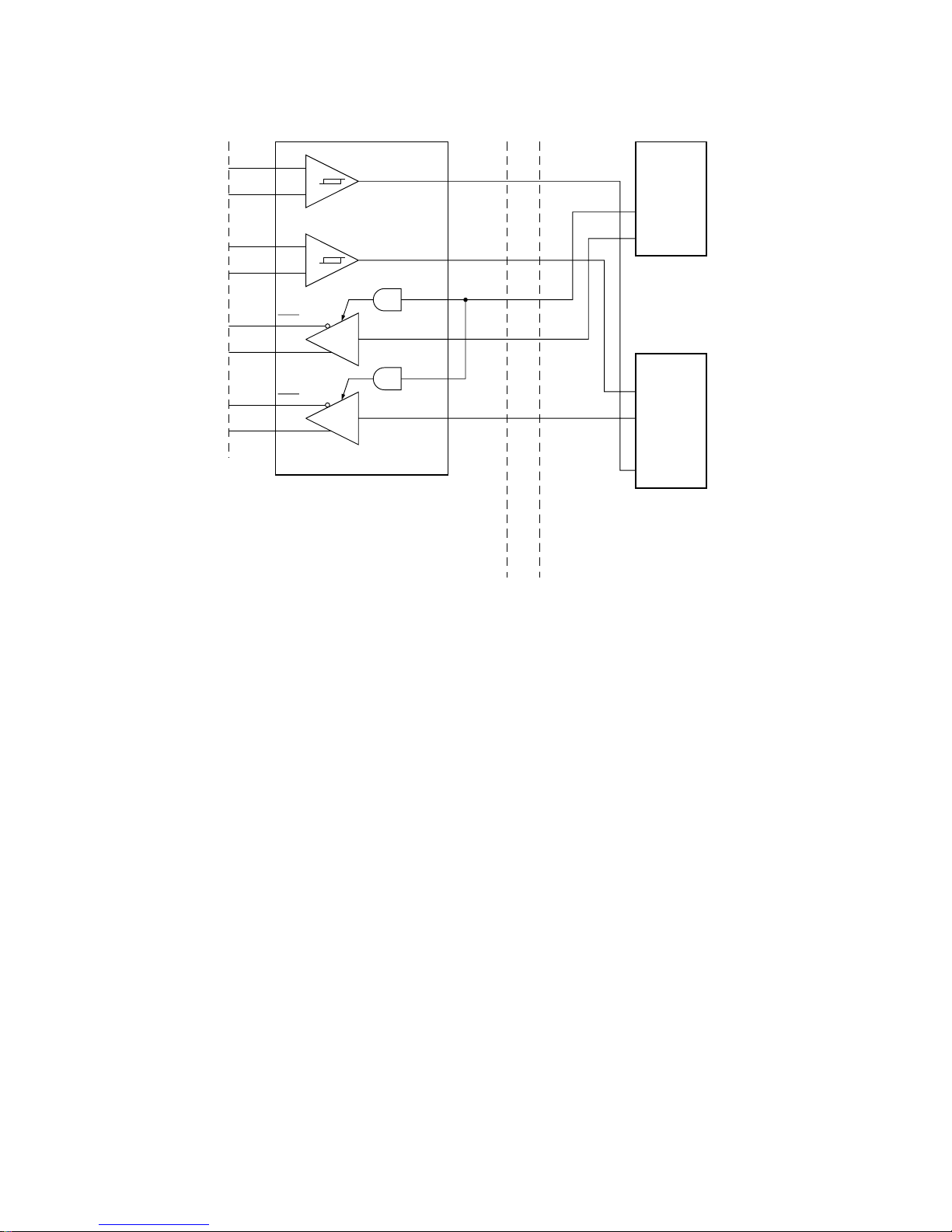

2-1-1. RS-232C Interface

Fig. 2-2 RS-232C Interface

Data from host to printer passes through the IC1 on the interface board from the RXD terminal and is input to the CPU on

the main logic board.

IC1 converts the RS-232C and TTL voltage levels.

The CPU converts the input serial data to parallel data and stores that data in the memory buffer memory. It also converts

the internal parallel data to serial data and outputs that to the IC1.

The CTS line is hardware-connected, but the connection is not recognized by software. (The printer does not monitor the

signal.)

D2O

D1O

R1I

R2I

D2I

D1I

R1O

R2O

B12

B14

A15

B15

ACKDTR

R-CH

TXD

RXD

CTS

TXD0

RXD0

RXD1

CN3 CN1

IC1

CN9

IC10

IC5

Gate

Array

CPU

HD151232FP

RS-232C Interface Board Main Logic Board

B12

B14

A15

B15

Page 19

– 19 –

2-1-2. RS-422A Interface

Fig. 2-3 RS-422A Interface

Data flow from host to printer passes from the RD terminal to the IC1 on the interface board and is input to the CPU.

The IC1 converts the RS-422A and TTL voltage levels.

The CPU converts the input serial data to parallel data and stores that data in the memory buffer memory. It also converts

the internal parallel data to serial data and outputs that to the IC1.

D2O

D1O

D2EN

D2I

D1EN

D1I

ERROR

ACK

RD (+)

RD (–)

CS (+)

CS (–)

RS (–)

RS (+)

SD (–)

SD (+)

CN3 CN1

IC1

+

–

+

–

Gate

Array

CN9 IC10

R2I

+

R2I

–

R1I

+

R1I

–

D2O

D2O

D1O

D1O

RXD0

TXD0

RXD1

CPU

IC5

A15

B15

A10

B12

B14

A15

B15

A10

B12

B14

MC34051

RS-422A Interface Board Main Logic Board

Page 20

– 20 –

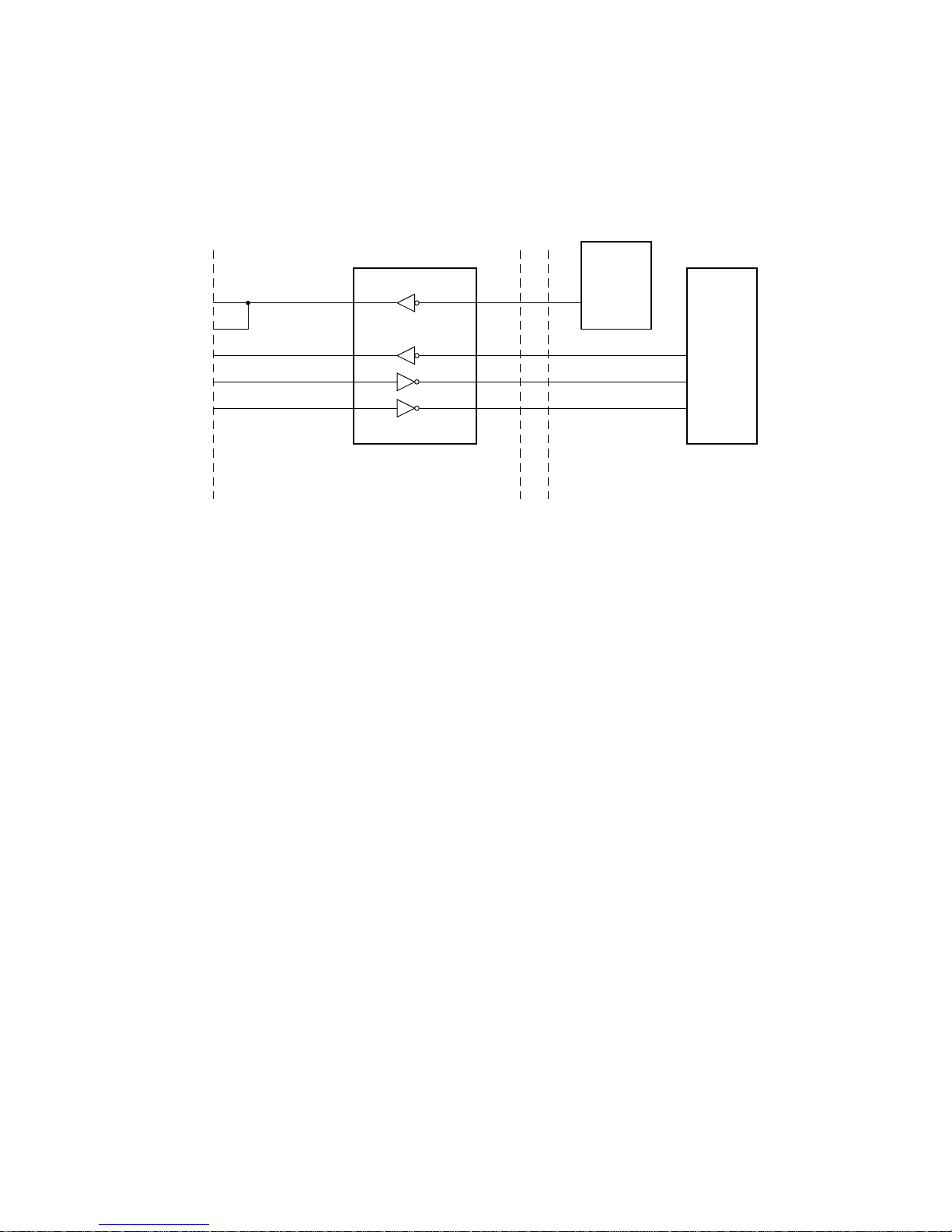

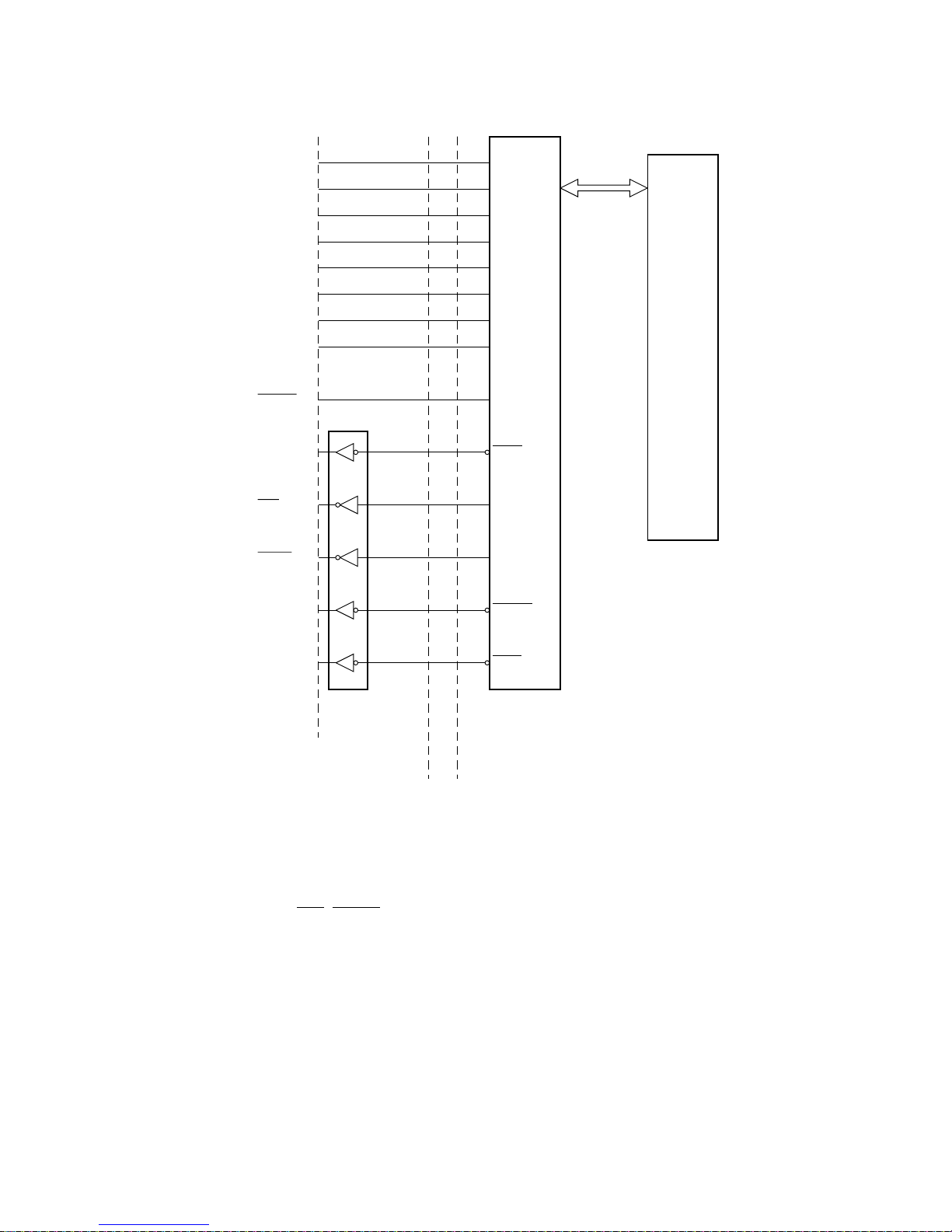

2-1-3. Parallel Interface

Fig. 2-4 Parallel Interface

The host computer sends eight bits of data for DATA 1 - 8 to the CN3 connector when the BUSY signal is LOW (printer

is ready).

The data passes through the interface board and gate array, then moves into the CPU.

Printer signals from the CPU (ACK, ERROR, SELECTED, PAPER OUT, etc.) pass through the gate array and are output

the appropriate connector pins.

DATA 1

DATA 2

DARA 3

DATA 4

DATA 5

DARA 6

DATA 7

DATA 8

STROBE

BUSY

ACK

ERROR

SELECTED

PAPER OUT

A4

B4

A5

B5

A6

B6

A7

B7

A13

A12

B12

A10

A11

B11

CN3

CPU

CN1

IC5

CN9

A4

B4

A5

B5

A6

B6

A7

B7

A13

A12

B12

A10

A11

B11

Gate Array

IC10

LS05

IC1

CD0

CD1

CD2

CD3

CD4

CD5

CD6

CD7

CSTB

BUSY

ACK

ERROR

SELECT

POUT

Parallel Interface Board Main Logic Board

Page 21

– 21 –

2-2. Editing and Printing

2-2-1. Editing

The CPU reads data sequentially from RAM and edits it in accordance with program instructions stored in EPROM. The

edited data undergoes parallel-to-serial conversion in the gate array, and is then output to the thermal head’s drive

controller.

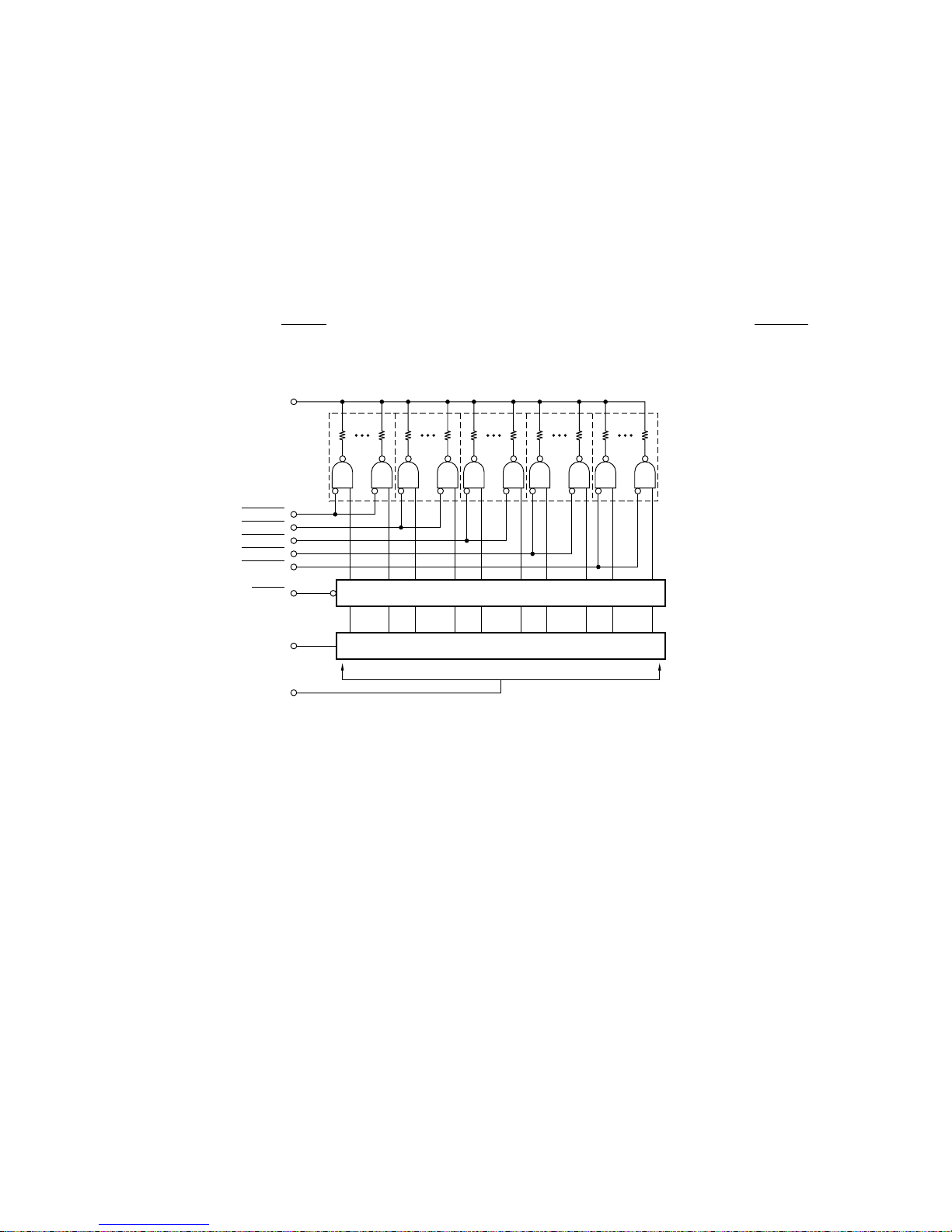

2-2-2. Thermal Head

The thermal head contains 640 heat elements. Printing is carried out by switching these elements ON or OFF as required.

(Note that Line Mode supports 600-dot printing only. Heat elements numbered 1 to 20 and 621 to 640 are always off.

(Off data is always being transmitted.)) The thermal head has a built-in dedicated drive controller. The controller consists

of a shift register, a latch circuit, and a driver circuit, as illustrated below.

The drive controller receives serial data (SI) from the drive control board in sync with the CLOCK signal. The controller

latches the incoming data (LATCH), then outputs it to the heat elements in sync with the trailing edge of the STROBE

signals. A data value of LOW corresponds to a heat-element value of ON.

Fig. 2-5 Thermal-Head Drive Circuit

STROBE5

STROBE4

STROBE3

STROBE2

STROBE1

LATCH

SI

CLOCK

COM

Latch

Shift Resistor

Page 22

– 22 –

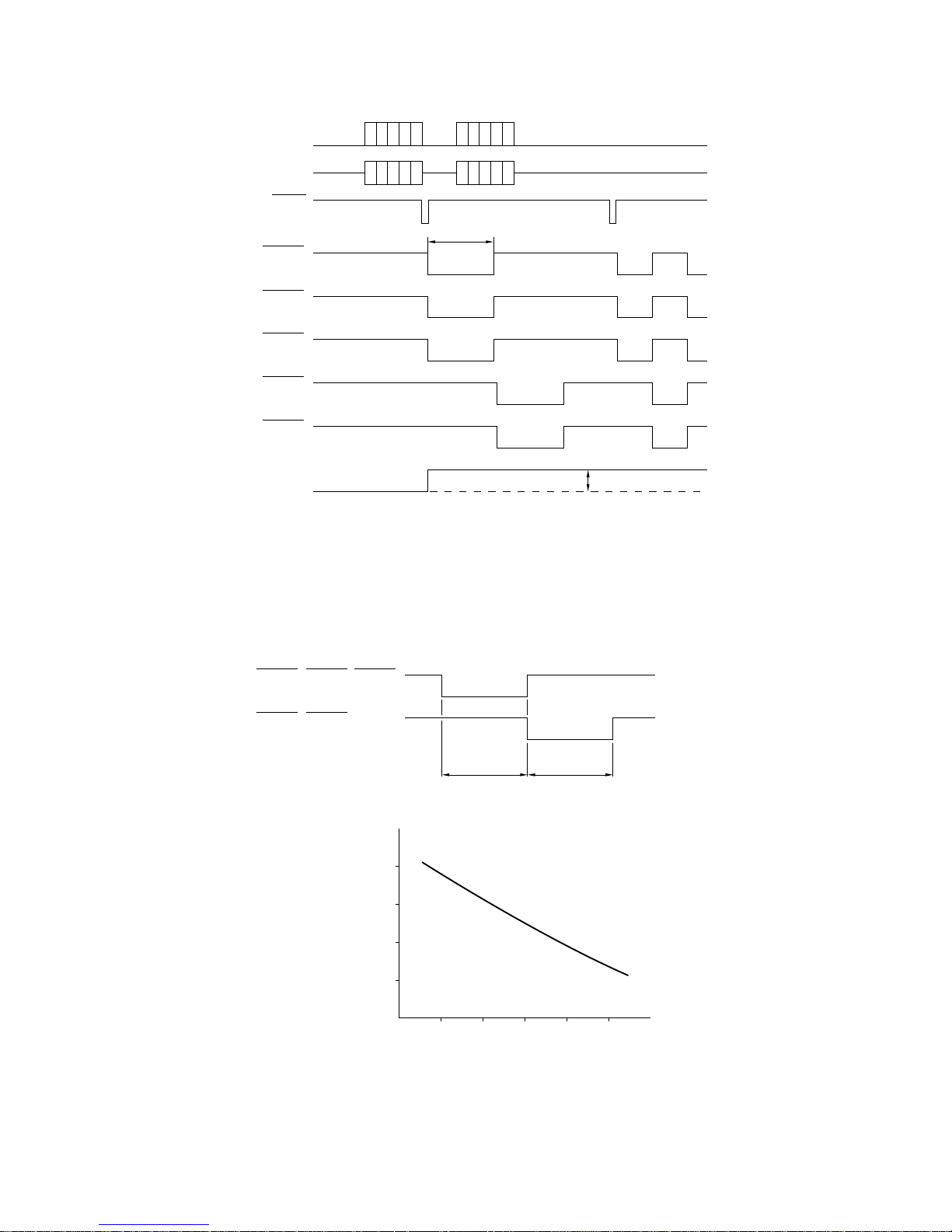

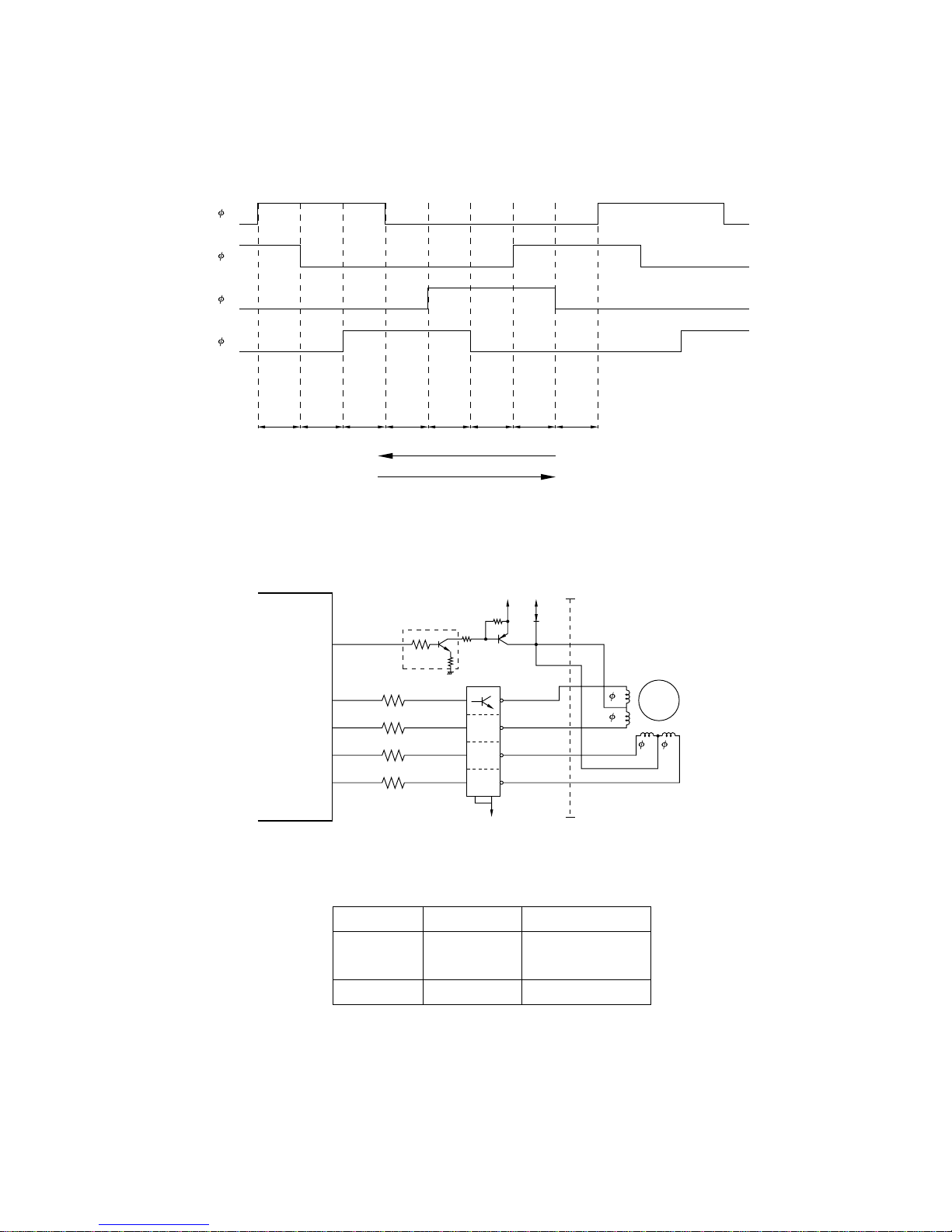

Fig.2-6 Timing Chart

2-2-3. Head Current Control

Heat buildup in the head during operation can cause print quality to degrade. To maintain uniform printing quality, the

printer varies the energizing time (time that STROBE remains LOW) in accordance with the head temperature.

The thermal head’s surface temperature is calculated based on the resistance value of an attached thermistor. Energizing

time is reduced at higher temperatures, as indicated in the Figure 2-6.

Fig. 2-7 Head Energizing Control

24V

t

CLOCK

SI

LATCH

STROBE1

STROBE2

STROBE3

STROBE4

STROBE5

COMMON

STROBE1, STROBE2, STROBE3

STROBE4, STROBE5,

t t

10 20 30 40 50

300

400

500

Head Energizing Time t (µsec)

Thermistor Temp. °C

600

Page 23

– 23 –

2-3. Feed-Motor Drive Circuit

This printer employs a paper feed motor and a stepping motor. The motor rotates through a certain angle each time it

receives a pulse from the drive circuit. This printer employs a 4-phase stepping motor and controls the paper feed motor

with a phase 1-2 excitation method. The following diagram illustrates the phase 1-2 excitation method. Diagram 2-8

shows the feed-motor drive circuit.

Fig. 2-8 Motor Control by Phase 1-2 Excitation

Fig. 2-9 Feed-Motor Drive Circuit

Voltage to the motor is controlled to produced the required action, as follows.

Mode Voltage Action

Operating VM (+24V) Drives the motor

VL (+5V)

Idle VL (+5V) Holds the motor

Voltage is controlled by PA4 pin of the CPU, which goes HIGH or LOW to switch transistors DQ2 and Q2 ON and OFF.

When Q2 is ON, the paper feed motor receives VM (+24V). When Q2 is OFF, VL (+5V) is supplied to the motor via

diode D1.

1 2 3 4 5 6 7 8

1

2

3

4

ON

ON

ON

ON

ON

Step

Reverse Feed

Forward Feed

PA4

PA0

PA2

PA3

PA1

1

2

3

4

CN4

1

2

4

5

6

3

M

+5V+24V

Q2

D1

TA1

B

DQ2

M-GND

E

IC5

CPU

Paper Feed Motor

Page 24

– 24 –

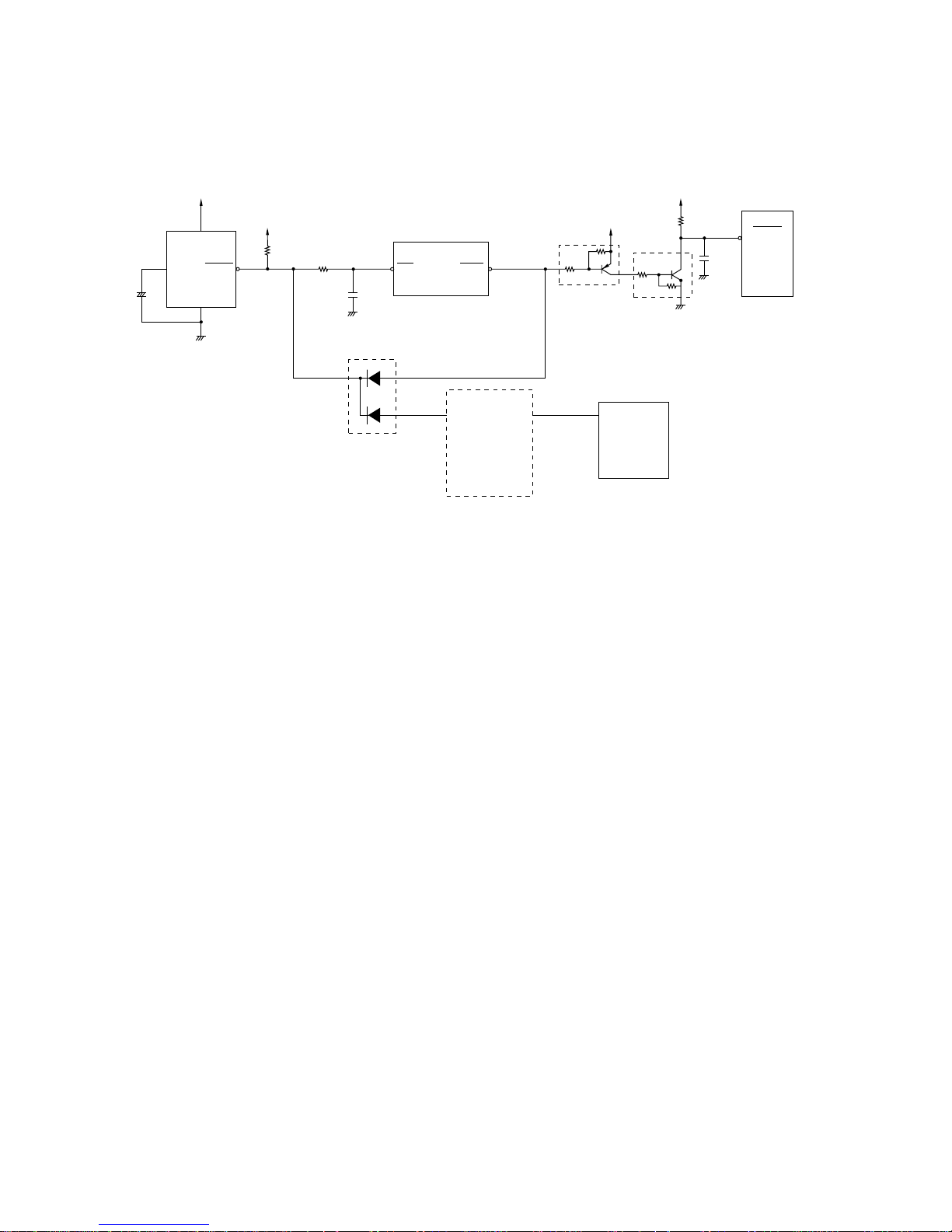

2-4. Power-On Reset Circuit

Immediately following power-on the printer executes a power-on reset, initializing all circuit elements. The power-on

reset serves as protection against operational errors. The power-on RESET signal is maintained for approximately 160ms.

The reset circuit is illustrated below.

Fig. 2-10 Power-On Reset Circuit

(1) At power on, voltage-detector circuit IC4 (M51953BL) outputs a LOW signal from its OUT terminal.

The following formula is used by capacitor C2 (0.47µF).

T = 0.34 × C2 (pF) [µs] = 160ms

(2) The LOW signal resets the CPU and the mechanism drive circuits.

(3) The LOW signal sets S-RAM into backup status.

+5V

IC4

CD

C2

GND

+5V

+5V

+5V

VCC

RESET

DD3

IC5 : CPU

RES

RESO

RESET

VCC

S-RAM

+

Gate

Array

IC1

RESET IC

IC10

Protection

Circuit

CPU

Page 25

– 25 –

2-5. +5V Line Voltage Detector Circuit

The voltage-detection IC detects momentary drops or unstable levels in the +5V line voltage.

The following illustrates the equivalence circuit of the voltage detector IC (Fig. 2-9 IC4).

Fig. 2-11 Equivalence Circuit for Voltage Detecting IC

The following operation timing chart shows control is performed by the voltage detector IC output. If the +5V line voltage

falls below 4.25V, the IC produces a reset signal from its OUT terminal, resetting the CPU and the gate array.

Fig. 2-12 Operation Timing Chart

1.25V

R1

R2

SµA typ

V

CC

1

GND

3

Cd

4

–

OUT

5

–

+

VCC Voltage

4.25V

0.8V

Output

Voltage

tdtd

t

t

td = 0.34 × Cd (pF) [µs]

Page 26

– 26 –

3. Printer Mechanism

3-1. Thermal Head

TSP400 series printers employ thermal line printing. The thermal head consists of a horizontal line of 640 heat elements.

These elements print one line of dots at a time as the paper passes over the head. The head is fixed in position; only the paper

moves.

The printer prints a dot by heating the corresponding heat element. The heated element causes a chemical reaction in the

coloring layer of the thermal paper, resulting in the formation of a visible dot.

Fig. 2-13 Principle of Thermal Printing

3-2. Paper-Feed Mechanism

The paper-feed mechanism is comprised of the paper-feed motor, gear train, platen, and thermal head. The paper-feed motor

drives the gear train, which in turn rotates the platen. The platen carries the thermal paper past the thermal head.

The paper-feed motor is a PM (permanent magnet) type, 4-phase 48-pole stepping motor. A single step feeds the paper

approximately 0.125mm.

Fig. 2-14 Paper-Feed Mechanism

Thermal Printing Head

Heat Element

Coloring Layer

Thermal Paper

Printed Point

Platen Roller

Gear Train

Paper-feed Motor

Platen Roller

Thermal Paper

Thermal Head

Page 27

– 27 –

3-3. Sensor

(1) Paper-Out Sensor

The paper-out sensor is located at the paper entry slit. The detector consists of a reflective photosensor. The

photosensor’s phototransistor remains ON while paper is present. It goes OFF when paper runs out, generating

output of a paper-out signal.

(2) Black-Mark Sensor

This detector senses black marks indicating print start positions. The detector is useful only with specially marked

paper. Like the paper-out detector, the black-mark detector consists of a reflective photosensor. The photosensor’s

phototransistor goes OFF when a black mark appears.

Fig. 2-15 Paper-Out Detector Fig. 2-16 Black-Mark Detector

(3) Paper Near-end Sensor

The Paper Near-end Sensor detects the amount of paper remaining on the roll. When the roll paper no longer exists

at the set position, the reflective photosensor turns OFF and outputs a no paper signal.

Fig. 2-17 Paper Near-end Sensor

GND

+5V

R

R

GND

+5V

R

R

Paper

(Reflective Photosensor)

Detection Signal

Paper

Black Mark

(Reflective Photosensor)

Detection Signal

GND

+5V

R

R

Paper

(Reflective Photosensor)

Detection Signal

Page 28

– 28 –

(4) Head-Up Detector

This detector consists of a leaf switch indicating whether the head is closed (in contact with the platen) or open

(separated from the platen). The leaf switch is closed when the head is closed; it opens when the head is opened.

Fig. 2-18 Head-Up Detector

GND

Detection Signal

Leaf Switch

R

+5V

Page 29

CHAPTER 3

PARTS REPLACEMENT AND RELATED ADJUSTMENTS

This chapter describes disassembly and reassembly procedures.

Please take note of the following.

1. ALWAYS disconnect the power cord from the AC outlet before beginning a disassembly or reassembly

procedure.

2. Except where otherwise stated, the reassembly procedure is the reverse of the disassembly procedure.

3. Coat screw heads with locking sealant after completion of reassembly.

4. Refer to Chapter 4 Section 2 for important information about lubrication requirements.

Note:The printer has no adjustable parts.

1. Presenter (TUP482) ........................................................................................... 30

2. Cutter.................................................................................................................. 30

3. Printer Mechanism ............................................................................................31

4. Main Logic Board ..............................................................................................31

5. Print Head Unit .................................................................................................. 32

6. Feed Motor Assembly ....................................................................................... 32

7. Sensor Unit ........................................................................................................ 33

3

Page 30

– 30 –

1. Presenter (TUP482)

(1) Disconnect the power cord from the AC outlet.

(2) Remove:

• Screws 4 pcs. [1]

• Presenter Holder L and R [2]

• Presenter [3]

Refer to Step 4 to remove the connector which is

connected to the main logic board from the

Presenter.

2. Cutter

(2) Remove:

• The presenter in Step 1.

• Screws 5 pcs. [1]

• Cutter Holder L and R [2]

• Cutter [3]

Refer to Step 4 to remove the connector which is

connected to the main logic board from the Cutter.

[2]

[3]

[1]

[2]

[1]

[2]

[1]

[3]

[1]

[2]

Page 31

– 31 –

3. Printer Mechanism

(1) Remove the power supply connector.

(2) Remove:

• Screws 4 pcs. [1]

• Connector [2]

Cut the wire band in four places.

• Printer Mechanism [3]

Refer to Step 4 to remove the connector which is

connected to the main logic board from the printer

mechanims.

4. Main Logic Board

(1) Remove the power supply connector.

(2) Remove:

• Four screws [1]

• Wiring band

• Connectors

• Screws 4 pcs. [2]

• Main Logic Board [3]

When removing the wiring band, check which one is

the lead wire.

[1]

[2]

[3]

[1]

[2]

[1]

[3]

Page 32

– 32 –

5. Print Head Unit

(1) Pull the pressure stay [1] forward to open the head

frame unit [2].

(2) Slide the head clamp [3] in the direction indicated by

the arrow. Remove the print head unit [4].

(3) Remove the head connector [5].

Note :Be careful to avoid damaging the heat elements when

installing the replacement unit.

6. Feed Motor Assembly

(1) Remove:

• Printer mechanism (See 3. above.)

• Wiring band holding the lead wire.

• Screws 2 pcs. [1]

• Feed motor [2]

[2]

[1]

[4]

[5]

[2]

[1]

[3]

Page 33

– 33 –

[3]

[2]

[1]

[4]

7. Sensor Unit

Old Type

(1) Remove:

• Printer mechanism (See 3. above.)

• Two wire band screws holding the lead wire [1].

• Screws 2 pcs. [1]

• Transmit sensor [2]

• Screw 1 pc. [3]

• Head-up sensor [4]

Note:There are two types of transmit sensors.

One is for the old type and the other is for the new type.

New Type

[3]

[2]

[1]

[4]

Page 34

This page was intentionally left blank.

Page 35

4

CHAPTER 4

MAINTENANCE AND LUBRICATION

This chapter explains printer maintenance and lubrication.

1. Maintenance ...................................................................................................... 36

1-1. Cleaning ................................................................................................................ 36

1-2. Checks................................................................................................................... 36

2. Lubrication......................................................................................................... 37

2-1. Lubricants ............................................................................................................. 37

2-2. Application Method .............................................................................................. 37

2-3. Lubrication Points................................................................................................ 37

Page 36

– 36 –

1. Maintenance

Proper maintenance is necessary to maintain printer performance and forestall potential problems. Please carry out

maintenance as described below.

1-1. Cleaning

(1) Surface dirt

Clear away dirt with a soft cloth. If necessary, apply a small quantity of alcohol to the cloth to improve cleaning

power. NEVER use thinner, trichlene, or ketone solvents, as these can cause damage to plastic components.

When cleaning, take care to avoid damaging or moistening of electronic parts, mechanical parts, and wires.

(2) Internal dust

For best results, use an electric vacuum cleaning device to remove dust from the inside of the printer. Note that such

cleaning may also remove lubrication; when you have finished cleaning, check lubrication levels and apply

lubricant as necessary.

1-2. Checks

There are two types of maintenance checks. Simple “daily checks” can be performed by users during the course of daily

operation. “Periodic checks” must be carried out by qualified service personnel.

(1) Daily checks

• Check whether dirt or other foreign matter has worked its way into the printer, and remove as necessary.

• Check the thermal head for excessive dirt. If the head is very dirty, clean it with a cotton stick or a soft cloth

soaked in alcohol.

(2) Periodic checks

Periodic checks and lubrication should be carried out once every six months or once every million lines of printing.

• Check the integrity of springs.

• Clear dust from areas around the detectors.

Page 37

– 37 –

2. Lubrication

Proper lubrication is essential for maintaining the printer’s performance level and preventing breakdowns or other problems.

2-1. Lubricants

Choice of lubrication can significantly affect the printer’s performance, longevity, and low-temperature characteristics. We

recommend the following lubricant for the TSP400 series.

Type Name Manufacturer

Grease Molykote EM Dow Corning

2-2. Application Method

If you are lubricating parts during disassembly or reassembly, be sure to wash or wipe the parts thoroughly to remove all

dirt and dust prior to lubricating.

Remember that cleaning can remove necessary lubrication. Always lubricate after cleaning, disassembly, or replacement.

2-3. Lubrication Points

Apply lubricants at the following locations. (Refer to Diagram 4-1.)

No. Location

[1] Contact area of pressure bar and pressure pin

[2] Contact area of gear 15×50×0.5 and gear shaft

[3] Contact area of gear 58×0.5 and gear shaft

[4] Contact area of gear 15×50×0.5 and PF motor gear

[5] Contact area of gear 58×0.5 and platen gear

[6] Contact area of head stay and head base frame

[7] Contact area of head clamp and clamp pin

[8] Contact area of head clamp and head stay R

Page 38

– 38 –

B

A

C

D

D

A

B

C

C

[5]

[2]

[4]

[3]

[1]

[6]

[6]

[7]

[8]

[1]

Fig. 4-1 Lubrication Points

Page 39

5

CHAPTER 5

PARTS LIST

HOW TO USE PARTS LIST

(1) DRWG. NO.

This column shows the drawing number of the illustration.

(2) REVISED EDITION MARK

This column shows a revision number.

Part that have been added in the revised edition are indicated with "#"

Part that have been abolished in the revised edition are indicated with "*"

#1:First edition → Second edition *1:First edition → Second edition

(3) PARTS NO.

Parts numbers must be notified when ordering replacement parts. Parts described as "NPN" have no parts number

and are not in stock, unavailable.

(4) PARTS NAME

Parts names must be notified when ordering replacement parts.

(5) Q’TY

This column shows the number of the part used as indicated in the figure.

(6) REMARKS

This column is used for general comments. It also indicates EPROM seal numbers. A"*" within a seal number

indicates the version number.

(7) RANK

Parts marked “S” are service parts. Service parts are recommended to be in stock for maintenance.

9. RS-422A Interface Board.................69

9-1. Circuit Diagram.........................69

9-2. Component Layout...................70

9-3. Parts List ...................................70

10. Parallel Interface Board (Ver. 1) .....71

10-1.Circuit Diagram........................71

10-2.Parts List ..................................72

11. Parallel Interface Board (Ver. 2) .....73

11-1.Circuit Diagram........................73

11-2.Component Layout..................74

11-3.Parts List ..................................74

12. Near-End Sensor Board ..................75

12-1.Circuit Diagram........................75

12-2.Parts List ..................................75

13. Paper-End Sensor Board ................76

13-1.Circuit Diagram........................76

13-2.Parts List ..................................76

14. Transit Board ...................................77

14-1.Circuit Diagram........................77

14-2.Parts List ..................................77

15. Presenter Sensor Board..................78

15-1.Circuit Diagram........................78

15-2.Parts List ..................................78

1. Printer Assembly .............................40

1-1. Disassembly Drawing ..............40

1-2. Parts List ...................................41

2. Printer Mechanism...........................42

2-1. Disassembly Drawing ..............42

2-2. Parts List ...................................43

3. Presenter-Assembly ........................44

3-1. Disassembly Drawing ..............44

3-2. Parts List ...................................45

4. Wiring Scheme of printer ................46

4-1. RS232 Interface Type ...............46

4-2. RS-422A Interface Type ...........47

4-3. Parallel Interface Type .............48

5. Main Logic Board (Ver.1) ................49

5-1. Circuit Diagram.........................49

5-2. Parts List ...................................53

6. Main-Logic Board (Ver.2) ................56

6-1. Circuit Diagram.........................56

6-2. Component Layout...................61

6-3. Parts List ...................................62

7. RS-232C Interface Board (Ver. 1) ...65

7-1. Circuit Diagram.........................65

7-2. Parts List ...................................66

8. RS-232C Interface Board (Ver. 2) ...67

8-1. Circuit Diagram.........................67

8-2. Component Layout...................68

8-3. Component Layout...................68

Page 40

– 40 –

1. Printer Assembly

1-1. Disassembly Drawing

17

13

30

16

15

13

38

16

12

33

29

14

34

18

18

19

3736

B

20

21

A

F

K

E

G

H

C

D

L

C

K

J

E

F

G

H

D

I

I

J

22

25

32

A

1

4

2

2

31

23

24

5

6

11

9

2

B

10

28

2

26

3

35

39

7

27

L

27

8

Page 41

– 41 –

1 01903059 SCREW TR 3-5 FL 3 S

2 *1 01903077 SCREW TAT 3-5 CT-FL 41 S

#1 01903101 SCREW TAT 3-6 CT-FL 41 S

3 30721610 CUTTER CABLE UNIT TUP4 1 TUP452,TUP482VER.1

4 32000050 FRAME R TUP4 1

5 32002211 BOTTOM FRAME TUP4 1

6 32005120 PAPER FRAME L TUP4 1

7 32041130 SNOUT HOLDER L TUP4 1 TUP482

8 32041140 SNOUT HOLDER R TUP4 1 TUP482

9 02040402 FLANGED NUT NHW4 1 S

10 31303211 ARM SHAFT TUP4 1

11 32000060 FRAME L TUP4 1

12 37427400 TRANSIT BOARD UNIT TUP4 1 S

13 30510510 SPRING E050-035-0235 2 S

14 32003211 FRONT FRAME TUP4 1

15 32005020 CUSHION FRAME L TUP4 1

16 33390010 CUSHION SHAFT TUP4 2

17 83390020 ROLL PAPER SHAFT SP312 1

18 37422500 PUSH SWITCH UNIT TUP4 1

19 04991401 SCREW DBLC-J25SAF 2 RS232,RS422 S

20 32003020 REAR PLATE TUP4 1

21 37407800 RS232C IF BOARD UNIT TSP4 1 RS232 VER.1

#1 37427620 INTERFACE BOARD R232 UNIT T4V2 1 RS232 VER.2

37407810 RS422 IF BOARD UNIT TSP4 1 RS422

37407820 PARALLEL IF BOARD UNIT TSP4 1 PARALLEL VER.1

#1 37427610 INTERFACE BOARD PARA UNIT T4V2 1 PARALLEL VER.2

22 37420310 PAPER FRAME R UNIT TUP4 1

23 37420510 COVER FRAME UNIT TUP4 1

24 37427000 MAIN LOGIC BOARD UNIT TUP4 1 VER.1 S

37427030 MAIN LOGIC BOARD UNIT T4V2 1 VER.2 S

25 37427300 NE BOARD UNIT TUP4 1 S

26 38405400 TMP452W-24N 1 S

27 01903090 SCREW TAT 3-8 CT-FL 2 TUP482 S

28 33490210 ARM TUP4 1

29 32005311 MECHANISM FRAME TUP4 1

30 32005010 CUSHION FRAME R TUP4 1

31 82020361 ROM COVER SP312 1

32 30093010 ESD GUARD SHEET TUP4 1

33 09990713 FERRITE CORE TFC-16-8-16 1

34 30721650 POWER CABLE UNIT TUP4 1

35 38511201 PR112-24 1 TUP482

36 32021010 SERIAL IF PLATE TSP4 1 RS232,RS422

32021110 PARALLEL IF PLATE TSP4 1 PARALLEL

37 #1 30091010 TENSION SHEET TSP2 1

38 #1 30992010 DISCHARGE BRUSH T4V2 1 TUP482 VER.2

39 #1 30992020 DISCHARGE SHEET T4V2 1 TUP482 VER.2

DRWG.NO. REV. PARTS NO. PARTS NAME Q’TY REMARKS RANK

Printer Assembly

1-2. Parts List

Page 42

– 42 –

2. Printer Mechanism

2-1. Disassembly Drawing

13-6

13-14

13-12

13-10

13-5

13-11

13-3

13

13-9

13-12

28

16

16

14

13-9

19

13-2

13-1

13-6

13-10

13-14

13-12

15

15

13-7

13-13

13-8

13-7

13-13

13-15

9

7

4

11

1-2

1-3

28

6

1

11

28

6

5

17

3

18

10

22

1-4

1-1

13-12

24

12

19

23

23

25

21

21

8

21

26

21

2

2

20

27

B

A

D

C

D

C

B

A

(New Type)

(Old Type)

2-1

Page 43

– 43 –

1 NPN FRAME ASSY TMP4 1

1-1 37412300 PF MOTOR ASSY TMP4 1 S

1-2 87340390 HEAD DETECTOR ASSY BMP8 1 S

1-3 00920503 SCREW TAT 2-5 CT 1 S

1-4 00930403 SCREW TAT 3-4 CT 2 S

2 37417000 REFLECT SENSOR BD UNIT TMP4 1 OLD TYPE S

37417020 TRANSMIT SENSOR BD UNIT B TMP4 1 NEW TYPE S

2-1 30721010 CABLE UNIT TMP4 1 S

3 83100460 IDLER GEAR 15X50X0.5 1 S

4 31375211 PLATEN TMP4 1 S

5 33102210 GEAR 28X0.5 TMP4 1 S

6 80203041 DRIVE SHAFT BEARING MP300 2 S

7 33910060 PAPER GUIDE C TMP4 1 S

8 04991509 CUTTER AC310-24-LN 1

9 *1 33910030 PAPER GUIDE B TMP4 1 S

#1 33910031 PAPER GUIDE B TMP4 1 S

10 33903010 FRICTION PLATE TMP4 1 S

11 33490010 HEAD POSITION LEVER TSP4 2

12 37419000 HEAD UNIT TMP4 1 S

13 NPN HEAD FRAME UNIT TMP4 1

13-1 81360850 PAPER GUIDE ROLLER BMP4 1

13-2 *1 81370920 HEAD UNIT HOLDER SHAFT BMP4 1

#1 31303010 HEAD UNIT HOLDER SHAFT TMP4 1

13-3 82902330 HEAD CLAMP BMP4 1

13-4 81370910 PRESSURE STAY BMP4 1

13-5 09991391 HEAT-SHRINK TUBE A-6.0 GRN 1

13-6 82401370 PRESSURE LEVER BMP4 2

13-7 82401360 HEAD STOPPER LEVER BMP4 2

13-8 80994252 GUARD SHEET BMP4 1

13-9 04310401 OILESS BUSHING F4X7X3 2

13-10 80511070 SPRING E040-040-0159 2 S

13-11 80510840 SPRING E055-060-0180 1 S

13-12 04020015 STOP RING SE3.0 4 S

13-13 04020016 STOP RING SE4.0 2 S

13-14 02040301 FLANGED NUT NHW3 2 S

13-15 09991372 HEAT-SHRINK TUBE 4.0 1 S

14 80705031 CABLE UNIT 26X290CC BMP4 1

15 30510410 SPRING E065-070-0238 2 S

16 30520210 SPRING C075-080-0165 2 S

17 04012003 ROLL PIN SP2.0X8 1 S

18 04020010 STOP RING SE2.0 1 S

19 04991204 FASTENER T18S 8 S

20 00630404 SCREW TR 3-4 2 S

21 01903077 SCREW TAT 3-5 CT-FL 5 S

22 01914035 SCREW TAT 4-10 PT-FL 1 S

23 00820304 SCREW TR 2-3 2 S

24 01903090 SCREW TAT 3-8 CT-FL 1 S

25 32041110 CUTTER HOLDER L TSP4 1

26 32041120 CUTTER HOLDER R TSP4 1

27 32045220 GUIDE B AC3 1

28 04020016 STOP RING SE4.0 5 S

DRWG.NO. REV. PARTS NO. PARTS NAME Q’TY REMARKS RANK

Printer Mechanism

2-2. Parts List

Page 44

– 44 –

3. Presenter-Assembly

3-1. Disassembly Drawing

10

2

11

2-1

2-3

2-4

2-2

2-5

2-6

6

7

12

1

8

13

11

6

5

4

3

3-1

9

4-1

Page 45

– 45 –

1 37517000 DETECTOR BOARD UNIT PR1 1 S

2 37514010 SLIP GEAR UNIT PR1 1 S

2-1 33120210 SLIP WHEEL PR1 1

2-2 33101410 SLIP GEAR PR1 1

2-3 32012010 SLIP PLATE PR1 1

2-4 30520510 SPRING C111-080-0090 1

2-5 04020017 STOP RING SE5.0 1

2-6 02206002 PLAIN WASHER WF6X13X1.0 1

3 37513010 PAPER FEED ROLLER UNIT PR1 1

3-1 04300781 O-RING 7.8X1.9JIS3P8 1 S

4 37512010 PAPER FEED MOTOR UNIT PR1 1

4-1 33140020 WORM GEAR PR1 1 S

5 37510010 FRAME UNIT PR1 1

6 33215010 PF ROLLER BEARING PR1 2

7 32025010 UPPER COVER PR1 1

8 30045040 GUIDE D PR1 1 S

9 30045011 GUIDE A PR1 1 S

10 04033001 PUSH RIVET P3035B 2

11 04020010 STOP RING SE2.0 2 S

12 00930609 SCREW TAT 3-6 CT 1 S

13 00820304 SCREW TR 2-3 2 S

DRWG.NO. REV. PARTS NO. PARTS NAME Q’TY REMARKS RANK

Presenter-Assembly

3-2. Parts List

<Note 1> If DRWG. NO. 10 is removed, it should be replaced with new ones.

Page 46

– 46 –

4. Wiring Scheme of Printer

4-1. RS232 Interface Type

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10

A11

A12

A13

A14

A15

A16

A17

A18

A19

A20

B1

B2

B3

B4

B5

B6

B7

B8

B9

B10

B11

B12

B13

B14

B15

B16

B17

B18

B19

B20

1

2

3

4

5

6

CN2

CN3

RS232C I/F BOARD

F-GND

TXD

RXD

RTS

CTS

NC

GND

NC

NC

NC

RCH

NC

GND

FAULT

MP-TXD

MP-DTR

NC

NC

NC

DTR

NC

NC

NC

NC

NC

NC

NC

VVR

DIN1

DIN3

DIN5

DIN7

GND

Vcc(+5V)

NC

NC

NC

DIEN

GND

RXD

NC

ID2

GND

PEXT1

VEXT

NC

NC

GND

DIN2

DIN4

DIN6

DIN8

GND

Vcc(+5V)

NC

FAULT

DTR

GND

TXD

CTS

ID1

GND

PSWIN

PEXT2

VEXT

DIN9

DIN11

VVR

DIN1

DIN3

DIN5

DIN7

GND

Vcc(+5V)

ERR

SLCT

BUSY

STB

GND

RXD

ID0

ID2

GND

PEXT1

VEXT

DIN10

DIN12

GND

DIN2

DIN4

DIN6

DIN8

GND

Vcc(+5)

NMI

PE

ACK

GND

TXD

CTS

ID1

GND

PSWIN

PEXT2

VEXT

1

2

3

4

5

6

7

1

2

1

2

3

4

5

6

1

2

3

4

1

2

3

GND

PE

MARK

Vcc(+5)

LABLE

GND

LED

HUP DTCT

HUP DTCT

LFCMN

LFCMN

LFø1

LFø3

LFø4

LFø2

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

1

2

3

4

1

2

3

4

5

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

COM(+24V)

COM(+24V)

COM(+24V)

GND

GND

GND

SI

SO

CLK

GND

LAT

GND

STB5

V

DD(+5V)

STB3

STB4

STB1

STB2

TM1

TM2

GND

GND

GND

COM(+24V)

COM(+24V)

COM(+24V)

CUTSW

CUTSW

M(–)

M(+)

VP(+24V)

VP(+24V)

NC

P-GND

P-GND

F-GND

PEXT1

VEXT

VEXT

PEXT2

PSW

1

2

3

4

5

Vcc(+5V)

PEXT1

VP(+24V)

PSWIN

GND

CUTTER UNIT

CN1

CONTROL BOARD PRINTER MECHANISM

CN9 CN1 CN1

CN1

MARK

DETECTOR

PAPER OUT

DETECTOR

HADE UP DETECTOR

PAPER FEED MOTOR

ø1

ø3

ø2 ø4

M

THERMAL HEAD

M

CN2

CN4

CN6

CN5

CN3

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10

A11

A12

A13

A14

A15

A16

A17

A18

A19

A20

B1

B2

B3

B4

B5

B6

B7

B8

B9

B10

B11

B12

B13

B14

B15

B16

B17

B18

B19

B20

CONNECTED BOARD

CN5

1

2

3

4

5

6

7

GND

PE

MARK

Vcc(+5)

LABLE

GND

LED

CN4

1

2

3

4

5

6

7

8

HUP DTCT

HUP DTCT

LFCMN

LFCMN

LFø1

LFø3

LFø4

LFø2

1

2

3

4

5

6

CN1

1

2

CN2

1

2

3

4

5

6

7

CN3

PRESENTER

1

2

3

4

5

CN1

CN8

NEAR-END DETECTOR

1

2

3

4

5

6

7

8

9

CN1

GND

COPEN

PF-SW

OL-SW

PSW1

PSW2

PSW

OL-LED

PO-LED

1

2

3

4

5

6

7

8

9

10

11

12

CN7

GND

COPEN

PF-SW

OL-SW

PSW1

PSW2

PSW

OL-LED

PO-LED

HU-LED

ER-LED

Vcc(+5V)

RESUME SWITCH

1

2

3

4

[CN2]

(TUP482 only)

GND

PE

MARK

Vcc(+5)

LABLE

GND

LED

HUP DTCT

HUP DTCT

LFCMN

LFCMN

LFø1

LFø3

LFø4

LFø2

Page 47

– 47 –

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10

A11

A12

A13

A14

A15

A16

A17

A18

A19

A20

B1

B2

B3

B4

B5

B6

B7

B8

B9

B10

B11

B12

B13

B14

B15

B16

B17

B18

B19

B20

DIN9

DIN11

VVR

DIN1

DIN3

DIN5

DIN7

GND

Vcc(+5V)

ERR

SLCT

BUSY

STB

GND

RXD

ID0

ID2

GND

PEXT1

VEXT

DIN10

DIN12

GND

DIN2

DIN4

DIN6

DIN8

GND

Vcc(+5)

NMI

PE

ACK

GND

TXD

CTS

ID1

GND

PSWIN

PEXT2

VEXT

1

2

3

4

5

6

7

1

2

1

2

3

4

5

6

1

2

3

4

1

2

3

GND

PE

MARK

Vcc(+5)

LABLE

GND

LED

HUP DTCT

HUP DTCT

LFCMN

LFCMN

LFø1

LFø3

LFø4

LFø2

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

1

2

3

4

1

2

3

4

5

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

COM(+24V)

COM(+24V)

COM(+24V)

GND

GND

GND

SI

SO

CLK

GND

LAT

GND

STB5

V

DD(+5V)

STB3

STB4

STB1

STB2

TM1

TM2

GND

GND

GND

COM(+24V)

COM(+24V)

COM(+24V)

CUTSW

CUTSW

M(–)

M(+)

VP(+24V)

VP(+24V)

NC

P-GND

P-GND

1

2

3

4

5

Vcc(+5V)

PEXT1

VP(+24V)

PSWIN

GND

CUTTER UNIT

CONTROL BOARD PRINTER MECHANISM

CN9 CN1 CN1

CN1

MARK

DETECTOR

PAPER OUT

DETECTOR

HADE UP DETECTOR

PAPER FEED MOTOR

ø1

ø3

ø2 ø4

M

THERMAL HEAD

M

CN2

CN4

CN6

CN5

CN3

CONNECTED BOARD

CN5

1

2

3

4

5

6

7

GND

PE

MARK

Vcc(+5)

LABLE

GND

LED

CN4

1

2

3

4

5

6

7

8

HUP DTCT

HUP DTCT

LFCMN

LFCMN

LFø1

LFø3

LFø4

LFø2

1

2

3

4

5

6

CN1

1

2

CN2

1

2

3

4

5

6

7

CN3

PRESENTER

1

2

3

4

5

CN1

CN8

NEAR-END DETECTOR

1

2

3

4

5

6

7

8

9

CN1

GND

COPEN

PF-SW

OL-SW

PSW1

PSW2

PSW

OL-LED

PO-LED

1

2

3

4

5

6

7

8

9

10

11

12

CN7

GND

COPEN

PF-SW

OL-SW

PSW1

PSW2

PSW

OL-LED

PO-LED

HU-LED

ER-LED

Vcc(+5V)

RESUME SWITCH

1

2

3

4

[CN2]

(TUP482 only)

GND

PE

MARK

Vcc(+5)

LABLE

GND

LED

HUP DTCT

HUP DTCT

LFCMN

LFCMN

LFø1

LFø3

LFø4

LFø2

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

1

2

3

4

5

6

CN2

CN3

RS422A I/F BOARD

F-GND

NC

NC

NC

NC

NC

GND

NC

SD(+)

SD(–)

NC

NC

GND

FAULT

NC

NC

RD(+)

RD(–)

CS(+)

NC

NC

NC

CS(–)

RS(+)

RS(–)

DIN9

DIN11

VVR

DIN1

DIN3

DIN5

DIN7

GND

Vcc(+5V)

DOEN

NC

NC

DIEN

GND

RD

ID0

ID2

GND

PEXT1

VEXT

DIN10

DIN12

GND

DIN2

DIN4

DIN6

DIN8

GND

Vcc(+5V)

NC

FAULT

RS

GND

SD

CS

ID1

GND

PSWIN

PEXT2

VEXT

F-GND

PEXT1

VEXT

VEXT

PEXT2

PSW

CN1

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10

A11

A12

A13

A14

A15

A16

A17

A18

A19

A20

B1

B2

B3

B4

B5

B6

B7

B8

B9

B10

B11

B12

B13

B14

B15

B16

B17

B18

B19

B20

4-2. RS422A Interface Type

Page 48

– 48 –

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10

A11

A12

A13

A14

A15

A16

A17

A18

A19

A20

B1

B2

B3

B4

B5

B6

B7

B8

B9

B10

B11

B12

B13

B14

B15

B16

B17

B18

B19

B20

DIN9

DIN11

VVR

DIN1

DIN3

DIN5

DIN7

GND

Vcc(+5V)

ERR

SLCT

BUSY

STB

GND

RXD

ID0

ID2

GND

PEXT1

VEXT

DIN10

DIN12

GND

DIN2

DIN4

DIN6

DIN8

GND

Vcc(+5)

NMI

PE

ACK

GND

TXD

CTS

ID1

GND

PSWIN

PEXT2

VEXT

1

2

3

4

5

6

7

1

2

1

2

3

4

5

6

1

2

3

4

1

2

3

GND

PE

MARK

Vcc(+5)

LABLE

GND

LED

HUP DTCT

HUP DTCT

LFCMN

LFCMN

LFø1

LFø3

LFø4

LFø2

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

1

2

3

4

1

2

3

4

5

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

COM(+24V)

COM(+24V)

COM(+24V)

GND

GND

GND

SI

SO

CLK

GND

LAT

GND

STB5

V

DD(+5V)

STB3

STB4

STB1

STB2

TM1

TM2

GND

GND

GND

COM(+24V)

COM(+24V)

COM(+24V)

CUTSW

CUTSW

M(–)

M(+)

VP(+24V)

VP(+24V)

NC

P-GND

P-GND

1

2

3

4

5

Vcc(+5V)

PEXT1

VP(+24V)

PSWIN

GND

CUTTER UNIT

CONTROL BOARD PRINTER MECHANISM

CN9 CN1 CN1

CN1

MARK

DETECTOR

PAPER OUT

DETECTOR

HADE UP DETECTOR

PAPER FEED MOTOR

ø1

ø3

ø2 ø4

M

THERMAL HEAD

M

CN2

CN4

CN6

CN5

CN3

CONNECTED BOARD

CN5

1

2

3

4

5

6

7

GND

PE

MARK

Vcc(+5)

LABLE

GND

LED

CN4

1

2

3

4

5

6

7

8

HUP DTCT

HUP DTCT

LFCMN

LFCMN

LFø1

LFø3

LFø4

LFø2

1

2

3

4

5

6

CN1

1

2

CN2

1

2

3

4

5

6

7

CN3

PRESENTER

1

2

3

4

5

CN1

CN8

NEAR-END DETECTOR

1

2

3

4

5

6

7

8

9

CN1

GND

COPEN

PF-SW

OL-SW

PSW1

PSW2

PSW

OL-LED

PO-LED

1

2

3

4

5

6

7

8

9

10

11

12

CN7

GND

COPEN

PF-SW

OL-SW

PSW1

PSW2

PSW

OL-LED

PO-LED

HU-LED

ER-LED

Vcc(+5V)

RESUME SWITCH

1

2

3

4

[CN2]

(TUP482 only)

GND

PE

MARK

Vcc(+5)

LABLE

GND

LED

HUP DTCT

HUP DTCT

LFCMN

LFCMN

LFø1

LFø3

LFø4

LFø2

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

1

2

3

4

5

6

CN2

CN3

PARALLEL I/F BOARD

STROBE

DATA 1

DATA 2

DATA 3

DATA 4

DATA 5

DATA 6

DATA 7

DATA 8

ACK

BUSY

PE

SLCT

NC

NC

GND

F-GND

Vcc(+5V)

RETURN-GND

RETURN-GND

RETURN-GND

RETURN-GND

RETURN-GND

RETURN-GND

RETURN-GND

RETURN-GND

RETURN-GND

RETURN-GND

RETURN-GND

RETURN-GND

INIT

ERROR

EXT-GND

CPL

NC

SLCT-IN

NC

NC

VVR

DIN1

DIN3

DIN5

DIN7

GND

Vcc(+5V)

ERROR

SLCT

BUSY

STB

GND

NC

ID0

NC

GND

PEXT1

VEXT

NC

NC

GND

DIN2

DIN4

DIN6

DIN8

GND

Vcc(+5V)

INIT

PE

ACK

GND

NC

NC

ID1

GND

PSWIN

PEXT2

VEXT

F-GND

PEXT1

VEXT

VEXT

PEXT2

PSW

CN1

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10

A11

A12

A13

A14

A15

A16

A17

A18

A19

A20

B1

B2

B3

B4

B5

B6

B7

B8

B9

B10

B11

B12

B13

B14

B15

B16

B17

B18

B19

B20

4-3. Parallel Interface Type

Page 49

– 49 –

5. Main Logic Board (Ver.1)

5-1. Circuit Diagram

2

3

1

[VR2]

4.7K

VCC

2

3

1

[VR1]

47K

VCC

[R135]

220

[R101]

220

CN1

53014-0710

7654321

LABEL

MARK

PE

VCC

VP

CN8

53014-0510

<FOR PRESENTER>

12345

VEXT

ZD2

RD4. 7JSB1

R25

10K

R120

10K

C134

0.1U

Q4

A1649

R119

10K

VP

Q5

A1388

R17

10K

R124

10K

DQ5

FA1A4P

VH

VCC

8

5

IC8

VCC

GND

CSSKDI

DO

123

4

93C46

R18

33

C9

33P

C126

33P

C127

100P

C8

33P

R19

10K

VCC

DQ6

FA1A4P

DQ7

FN1A4P

VCC

323130292827262524232221201918

17

123456789

1011131415415756555254165160636162

59

47

I/O1

I/O2

I/O3

I/O4

IN5

IN6

IN7

IN8

HDPWR

IN9

IN10

IN11

IN12

IN13

IN14

IN15

IN16

CD0

CD1

CD2

CD3

CD4

CD5

CD6

CD7

CSTB

ACK

BUSY

ERROR

SELECT

POUT

HDONRDWRCERESET

CLK

INTCDT

INTSDT

RAMCS

PSOE

PSCE0

PSCE1

RFSH

UPD65622GF-TSP

SDATA

SCLK

HISTIN

LATCH

STB4

STB3

STB2

STB1

CUTON

CUTSW

OUT1

OUT2

OUT3

OUT4

A0A1A2

A3

A15

A17

D0D1D2D3D4D5D6

D7

VCC

VCC

TEST

PSSEL

GND

GND

GND

GND

4950464842434445403938373635696867666564797877767574737034728058123353

71

A0A1A2A3A15

A17D8D9

D10

D11

D12

D13

D14

D15

R21

R20

R23

R22

33 × 4

C129 C131

C128 C130

33P × 4

FL4

TU02M

VCC

2

31

C135

0.1U

VCC

JPB2

JPA2

5P8128 :

5P832 :

Standard

JPB2=Cut, JPA2=Short

R130

4.7K

R131

4.7K

VCC

R129

4.7K

R134

4.7K

CN7

53014-1210

121110

987654321

VCC

ER-LED

HU-LED

PO-LED

OL-LED

PSW

PSW2

PSW1

OL-SW

PF-SW

COPEN

GND

DQ3

FA1A4P

R161K1/2W

DQ4

FN1A4P

VP

Q1

D2010Q3B1359

CN5

5483-04A-RED

432

1

VCC

1

RA1

10K × 4

2435

C123 C120

C121

100P × 3

VH

COM

COM

GNDSICLK

/LAT

/STB5

/STB3

/STB1

TH1

GND

GND

COM

135791113151719212325

246

8

101214161820222426

COM

GND

GNDSOGND

GND

VDD

/STB4

/STB2

TH2

GND

COM

COM

CN6

5332-265G1

(AOI : J080-85523)

VH

VCC

C122

100P

THERMAL HEAD BLOCK

R128

20K

R127

1K

VCC

CN9

PHEC40R-R111

COMMUNICATION I/F BLOCK

EXPANDED I/O BLOCK

IC10

B

C

A

<Note 1> The unit of resistor and resistor array is "Ω", and no indication of wattage means 1/6W, 1/8 respectively.

<Note 2> The unit of capacitor and capacitor array is "F", and no indication of Voltage means 50V.

<Note 3> The coimponents in the parentheses are not installed in the board.

<Note 4> ★-Not mounted on old type

Page 50

– 50 –

B

VCC

VCC

VCCVB

VCC

VCC

VCC

D0D1D2D3D4D5D6D7D8D9D10

D11

D12

D13

D14

D15

191817161514131210

9876543

2

201130

O0O1O2O3O4O5O6O7O8O9O10

O11

O12

O13

O14

O15CEOE

GND

GND

IC11

A0A1A2A3A4A5A6A7A8

A9

A10

A11

A12

A13

A14

A15

A16

A17

VPP

VCC

2122232425262728293132333435363738

39140

A1A2A3A4A5A6A7A8A9

A10

A11

A12

A13

A14

A15

A16

A17

A18

C133

33P

C12

33P

(AM27C4096)

AM27C2048

(AM27C1024)

C137

0.1U

FL5

TU02M

13

2

D8D9D10

D11

D12

D13

D14

D15

13141517181920

211292422

16

D0D1D2D3D4D5D6D7RFSH

R/WOECE1

IC6

A0A1A2A3A4A5A6A7A8

A9

A10

A11

A12

A13

A14

A15

A16

CE2

121110

98765

272623

25428331232

30

A1A2A3A4A5A6A7A8A9

A10

A11

A12

A13

A14

A15

A16

A17

LH5P8128N

(LH5P832N)

C110

0.1U

FL1

TU02M

13

2

C5

33P

C3

33P

VB

R102

10K

C100

33P

D8D9D10

D11

D12

D13

D14

D15

1112131516171819272220

28

D0D1D2D3D4D5D6D7WEOECE

VCC

A0A1A2A3A4A5A6A7A8

A9

A10

A11

A12

A13

A14

10

9876543

252421

23226

1

A0A1A2A3A4A5A6A7A8A9A10

A11

A12

A14

JPB1

JPA1

A13

(HM62256ALFP)

HM6264LFP

6264:

62256:

Standard

JPA1=Cut, JPB1=Short

D0D1D2D3D4D5D6D7D8D9D10

D11

D12

D13

D14

D15

141618202325272915171921242628301113321231

O0O1O2O3O4O5O6O7O8O9O10

O11

O12

O13

O14

O15/A-1CEOE

W/B

GND

GND

IC9

A0A1A2A3A4A5A6A7A8

A9

A10

A11

A12

A13

A14

A15

A16

A17

A18

A19

VCC

10

9876543

414039383736353433

2

1

42

22

A1A2A3A4A5A6A7A8A9

A10

A11

A12

A13

A14

A15

A16

A17

A18

A19

A20

(UPD23C16000)

(UPD23C8000)

UPD23C4000A

D0D1D2D3D4D5D6

D7

1314151718192021129242216

D0D1D2D3D4D5D6D7RFSH

R/WOECE1

A0A1A2A3A4A5A6A7A8

A9

A10

A11

A12

A13

A14

A15

A16

CE2

121110

98765

272623

25428331232

30

A1A2A3A4A5A6A7A8A9

A10

A11

A12

A13

A14

A15

A16

A17

LH5P8128N

(LH5P832N)

C111

0.1U

FL2

TU02M

1

2

3

C4

33P

IC7

CN9

PHEC40R-R111

A1A2A3A4A5A6A7A8A9

A10

A11

A12

A13

A14

A15

A16

A17

A18

A19

A20

B1B2B3B4B5B6B7B8B9

B10

B11

B12

B13

B14

B15

B16

B17

B18

B19

B20

VCC

VEXT VEXT

VCC

VCC

R29

1K

R28

4.7K

COMMUNICATION I/F BLOCK

MEMORY BLOCK

IC1

A

D

Page 51

– 51 –

VP

DQ2

FA1A4P

D1

EG01YV0

VCC

R15

10K

R103

10K

Q2

B1359

FEED

MOTOR

CN4

5483-06A

12345

6

TA1

MP4020

1B2B3B

4B

1C2C3C

4C

EE

1

0

1

246

8

357

9

R3R2R104

R105

3.3K × 4

X1

CST9.83MT

1

3

2

R122

3.3K

C118

0.1U

10K × 2

VCC

R9

R6

33 × 9

R10R8R7R5R4

R12

R13

R14

R123

33P × 9

C105

C103

C104 C102 C106 C108

C101 C107 C119

C11

0.1U

FL3

TU02M

VCC

31

2

C125

0.1U

VCC

D0D1D2D3D4D5D6D7D8D9D10

D11

D12

D13

D14

D15

2021222324257574718182

83

100

101

102

103

104

807978777270696867

661448476851026355399947327282930313233343637383940414243

IC5

P90/TXD0

P91/TXD1

P92/RXD0

P93/RXD1

P94/SCK0/IREQ4

P95/SCK1/IREQ5

XTAL

EXTAL

RES

MD0

MD1

MD2

P80/RFSH/IRQ0

P81/CS3/IRQ1

P82/CS2/IRQ2

P83/CS1/IRQ3

P84/CS0

LWR

HWRRDAS

NMI

STBY

CLK

P62/BACK

P61/BREQ

P60/WAIT

VCC

VCC

AVCC

VCC

VREF

VSS

VSS

VSS

VSS

VSS

AVSS

VSS

P40/D0

P41/D1

P42/D2

P43/D3

P44/D4

P45/D5

P46/D6

P47/D7D8D9

D10

D11

D12

D13

D14

D15

HD6413003F10T

RESO

PA7/TP7/TIOCB2

PA6/TP6/TIOCA2

PA5/TP5/TIOCB1

PA4/TP4/TIOCA1

PA3/TP3/TIOCB0/

PA2/TP2/TIOCA0/

PA1/TP1/TEND1/T

PA0/TP0/TEND0/T

PB0/TP8/TIOCA3

PB1/TP9/TIOCB3

PB2/TP10/TIOCA4

PB3/TP11/TIOCB4

PB4/TP12/TIOCXA

PB5/TP13/TIOCXB

PB6/TP14/DREQ0

PB7/TP15/DREQ1/

P70/AN0

P71/AN1

P72/AN2

P73/AN3

P74/AN4

P75/AN5

P76/AN6

P77/AN7

PC0

PC1

PC2/TEND2/CS4

PC3/DREQ2/CS5

PC4/TEND3/CS6

PC5/DREQ3/CS7

PC6/IRQ6

PC7/IRQ7

A0A1A2A3A4A5A6A7A8

A9

A10

A11

A12

A13

A14

A15

A16

A17

A18

A19

P54/A20

P55/A21

P56/A22

P57/A23

19

112

111

110

109

108

107

106

1052345678986878889909192931112131415161718454647484950515254555657585960616263646595969798

DA0

DA1

DA2

DA3

DA4

A0A1A2A3A4A5A6A7A8A9

A10

A11

A12

A13

A14

A15

A16

A17

A18

A19

A20

FEED MOTOR BLOCK

PERIPHERAL/BUZZER BLOCK

R11

1K

R100

10K

VCC

CN2

5483-02A

2

1

HEAD UP

DETECTOR

SENSERS BLOCK

VCC

R118

33

C117

33P

VCC

VCC

VCC

VCC

R136

1K

LABEL

MARK

PE

VR3

4.7K

3

1

2

R31

2.7K

R27

10K

–

+

3

1

2

C14

0.1U

R26

4.7K

IC12-D

13

1011UPC339C

67UPC339C

VR4

4.7K

R137

1K

VCC

R33

2.7K

R32

4.7K

C13

0.1U

IC12-B

VCC

1

R30

4.7K

VCC

–

+

–

+

VCC

3

5

4

IC12-A

2

UPC339C

1–2

R114

20K

DA4

[

R115

]

10K

[

R113

]

20K

DA3

[

R111

]

10K

[

R112

]

20K

DA2

[

R108

]

10K

[

R110

]

20K

DA1

[

R107

]

10K

[

R109

]

20K

DA0

[

R106

]

20K

8

9

–

+

14

IC12-C

UPC339C

R116

4.7K

[

C15

]

0.1U

VCC

VP

[

DD1

]

VCC

[

DQ8

]

*

FN1A4P

[

R132

]*

1K

VCC

DQ9

FN1A4P

R133

1K

Q9

D2010

[

Q8

]*

D2010

VP

D2

1SR139-100

[

IC3

]

UPC7824HF

VI VO

G

N

D

[

C114

]

0.1U

[

C113

]

0.1U

D4

1SR139-100

[

D3

]

*

1SR139-100

VCC

BZ

+

[

BZ1

]

QMB111P

[

R1

]

330

[

DQ1

]

FA1A4P

DCB010

A

D

C

Page 52

– 52 –

D

D

8

D

9

D

1

0

D

1

1

D

1

2

D

1

3

D

1

4

D

1

5

23498765

1

CA3

220P × 8

D

0

D

1

D

2

D

3

D

4

D

5

D

6

D

7

23498765

1

CA4

220P × 8

A

2

0

A

1

7

A

1

5

A

1

3

A

1

1

A

9

23456789

1

CA2

220P × 8

A

1

9

A

1

8

A

1

6

A

1

4

A

1

2

A

1

0

A

8

23456789

1

CA1

220P × 8

A

0

A

1

A

2

A

3

A

4

A

5