Page 1

THERMAL UNIT PRINTER MECHANISM

TUP492-24

SPECIFICATION

AND

OPERATION MANUAL

Page 2

NOTICE

• All rights reserved. Reproduction of any part of this manual in any form whatsoever, without

STAR’s express permission is forbidden.

• The contents of this manual are subject to change without notice.

• All efforts have been made to ensure the accuracy of the contents of this manual at the time of

going to press. However, should any errors be detected, STAR would greatly appreciate being

informed of them.

• The above notwithstanding, STAR can assume no responsibility for any errors in this manual.

Copyright 1998 Star Micronics Co., LTD.

– 0 –

Page 3

CONTENTS

1. GENERAL DESCRIPTION ..........................................................................................................1

2. CONSTRUCTION ..........................................................................................................................2

2.1 Configuration .......................................................................................................................2

2.2 Principle of Operation..........................................................................................................2

3. GENERAL SPECIFICATIONS

4. PAPER ROLL SPECIFICATIONS

5. PRINTER SETTINGS

5.1 Switches and Buttons...........................................................................................................7

5.2 Setting the DIP Switches......................................................................................................8

5.3 Setting the EEPROM .........................................................................................................10

6. DISPLAYS AND FUNCTIONS

6.1 LEDs ..................................................................................................................................12

6.2 RESUME Button................................................................................................................12

6.3 Power Switch and Button Combinations ...........................................................................12

6.4 Sensor Adjusting Mode......................................................................................................13

6.5 Near-End Sensor ................................................................................................................13

6.6 Error Messages...................................................................................................................14

6.7 Near-End Sensor Position ..................................................................................................16

7. INTERFACE

7.1 Serial Interface (RS-232C or RS-422A) ............................................................................17

7.2 Parallel Interface ...............................................................................................................19

8. CUTTER

9. PRESENTER

10. CHARACTERS

10.1 Character Set......................................................................................................................22

10.2 Characters and Sizes...........................................................................................................22

11. POWER REQUIREMENTS

12. NOISE

13. STANDARDS

14. RELIABILITY

15. INSTALLING THE PAPER ROLL

16. INSTALLATION

17. MAINTENANCE

.............................................................................................................................................25

14.1 During operation ................................................................................................................26

14.2 During storage....................................................................................................................26

14.3 Allowable Static Electricity Level ....................................................................................27

14.4 Vibration Test.....................................................................................................................27

14.5 Drop Test ...........................................................................................................................27

14.6 Life Test .............................................................................................................................28

16.1 Installation precautions ......................................................................................................32

16.2 Other precautions ...............................................................................................................32

.................................................................................................................................17

.......................................................................................................................................20

.................................................................................................................................21

.............................................................................................................................22

.................................................................................................................................25

..............................................................................................................................26

....................................................................................................................7

..........................................................................................................................31

..........................................................................................................................36

....................................................................................................4

..............................................................................................5

...................................................................................................12

........................................................................................................23

............................................................................................29

Page 4

1. GENERAL DESCRIPT

The TUP492-24 printer is a line thermal printer and is used in various electronic equipment, such as

game machines, ATMs and information kiosks. TUP492-24 is equipped with a presenter which discharge and collect paper.

These printers feature the following:

1. High-speed printing: 2 in./sec (50 mm/sec)

2. High resolution: 8 dots/mm vertically, 8 dots/mm horizontally (approx. 200 dpi)

3. Silent operation

4. Paper roll size: max. 8-inch diameter

5. Choice of three types of interfaces (optional)

6. Presenter function

Display of Model Name

TUP4 9 2 D 24 NL

—

Equipped with no translucent sensor

Power supply voltage : DC 24 V

Interface

D: RS-232C

C: Parallel

K: RS-422A

Mechanism type

2: 40 digits

Printer type

9: Equipped with a guillotine-type full cutter and presenter

(discharge and collect)

TUP400 series thermal printer

– 1 –

Page 5

2. CONSTRUCTION

2.1 Configuration

The unit printer mechanism is constructed of the following components:

Unit printer mechanism Thermal printer Sensor

Thermal head

Drive Gear

Platen

MotorPresenter

Cutter (guillotine-type full cutter)

2.2 Principle of Operation

2.2.1 Drive and paper feed

The rotation of the stepping motor is transmitted to the gear, which turns the platen. The rotation of the platen generates friction between it, the thermal paper and the thermal head, therefore causing the paper to be fed.

2.2.2 Printer

Color appears on the thermal paper as the temperature of the thermal head’s heat-generating

element increases.

2.2.3 Presenter

The edge of the thermal paper stops just before the presenter’s ejector, the continuous feed of

the thermal paper creates a loop and after printing is finished, the paper is cut. Then, the paper is

fed out by the roller in front of the ejector (The DC motor rotates the roller). Detecting the paper

bottom end, the roller stops its rotation.

Frame Control and interface boards

Near-end sensor

When the fixed period of time passes, or the collection command is sent, the presenter collects

the paper.

– 2 –

Page 6

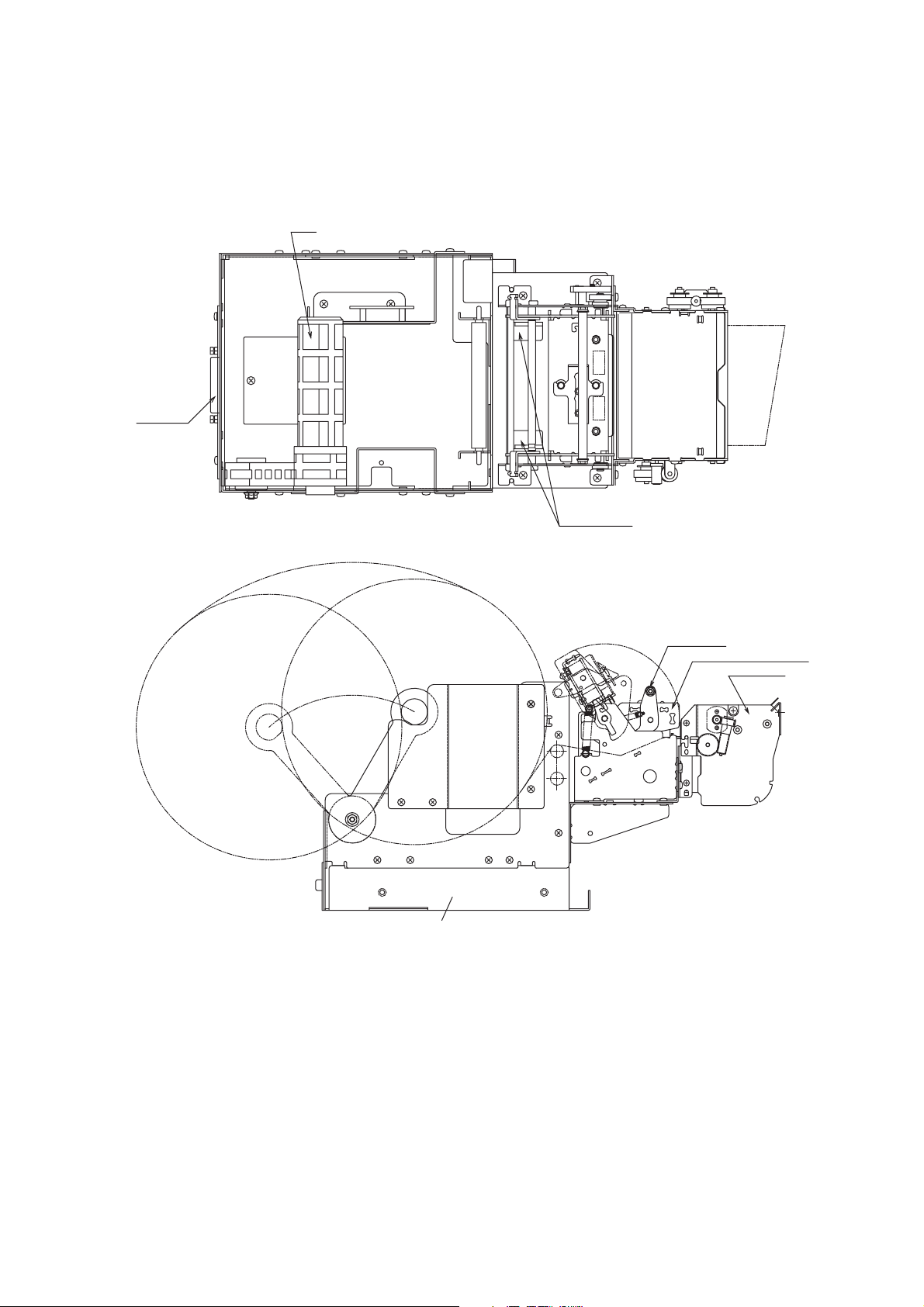

Exterior Vie w

Inter face

Arm

Paper guide

Head stay

Thermal mechanism

B

A

Frame (Inside is the main PCB and interface PCB)

Presenter

– 3 –

Page 7

3. GENERAL SPECIFICATIONS

Item Specification

Printing method Line thermal direct printing

Printing speed 50 mm/sec, 25 mm/sec

Printing area 80 mm wide (page mode), 75 mm wide (line mode)

Resolution 8 dot/mm (horizontal)

8 dot/mm (vertical)

Paper width 82.55 mm (3.25 in.)

Paper roll diameter Outer: max. 203 mm (approx. 8 in.)

Inner: 32 mm (approx. 1.26 in.)

+1

0

Characters ASCII

International character set

Katakana (Japanese syllabary)

Bar code

0

-2

Paper detection Paper-out detection using a reflecting photo sensor

Black mark detection using a reflecting photo sensor

Paper near-end detection using a reflecting photo sensor

Interface Serial (RS-232C or RS-422A (optional))

Parallel

Data buffer Approx. 8 KB

Auto cutter Guillotine-type full cutter

Power supply voltage DC 24 V ± 7%

Environment Temperature 5˚C to 40˚C

Relative humidity 25% to 80% (no condensation)

External dimensions 173 mm (W) × 355 mm (D) × 175 mm (H)

(without paper roll inserted)

173 mm (W) × 382 mm (D) × 254 mm (H)

(with 8-in. paper roll inserted)

Weight Approx. 3.45 kg

– 4 –

Page 8

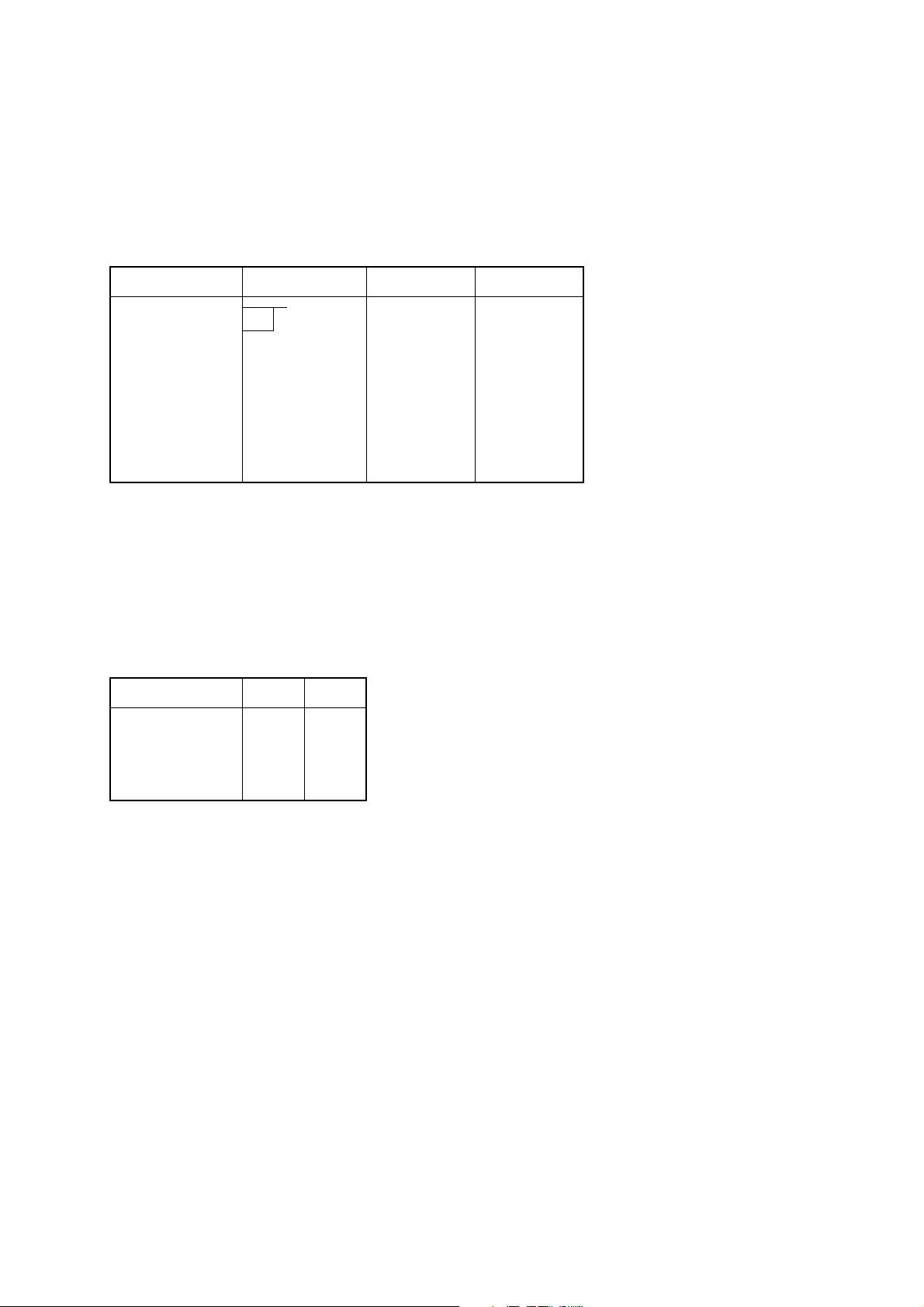

4. PAPER ROLL SPECIFICATIONS

Item Specification

Paper type Normal heat-sensitive paper

Paper width 82.55 mm (3.25 in.)

Paper thickness 60 to 100 µ m

Core diameter Inner: 32 mm

Paper type Nippon Seishi TF50KS-E

0

–1

+1

0

Outer: 35 mm

+1

0

TF62KS-E

Shin Oji Seishi KF-730

Printing area

82.55 mm

275 mm

80 mm

Printing area

(Page mode)

3.775 mm

Black mark Printing density Macbeth valve 1.2 or higher

Printing position

26 mm

82.55 mm

75 mm

Printing area

(Line mode)

Paper feed

Max. 36 mm

Printing side Back (opposite to the printed side)

Size Width: 10 to 20 mm

(center of the paper must be avoided)

Length: 3 to 10 mm

Reference position The end of the black mark should be positioned at

the front in the paper feed direction.

– 5 –

Page 9

Notes)

Use paper that is rolled inward.

●

●

Do not affix the end of the paper to the paper roller.

●

Paper jams may occur depending on the paper quality used and the pattern printed.

If the machine is turned off and left for a long time with paper caught in the thermal head, the

●

paper should be removed and inserted again.

●

Keep this machine on a level surface.

The roller may leave short marks in the end of the paper.

●

– 6 –

Page 10

5.PRINTER SETTINGS

5.1Switches and Buttons

The DIP switches and memory switches (EEPROM) are used to make the printer’s settings. In addition, the sensor adjusting button and RESUME button, which are not used for making printer settings,

are installed.

The sensor adjusting button is located on the paper-out and near-end sensor’s PCB (N.EPCB), and is

mainly used for adjusting the photo sensors, therefore, it is not used by the general user. The RESUME

button is located on the casing (near the LF motor), and is used to bring the printer back on line after it

goes off line (e.g. paper-out). For more details about the RESUME button, refer to “6. DISPLAYS

AND FUNCTIONS”.

The DIP switches are mounted to the interface’s PCB and can be changed by operating them from the

hole used for replacing the EPROM or by removing the interface’s PCB.

The number of DIP switches differs according to the type of interface.

Centronics: 1(4-bit)

RS-232C: 2 (10-bit and 4-bit)

RS-422A: 2 (8-bit and 4-bit)

The EEPROM is 1 word by 16 bits. The EEPROM is mounted on the main unit’s PCB and can be

changed with the commands.

– 7 –

Page 11

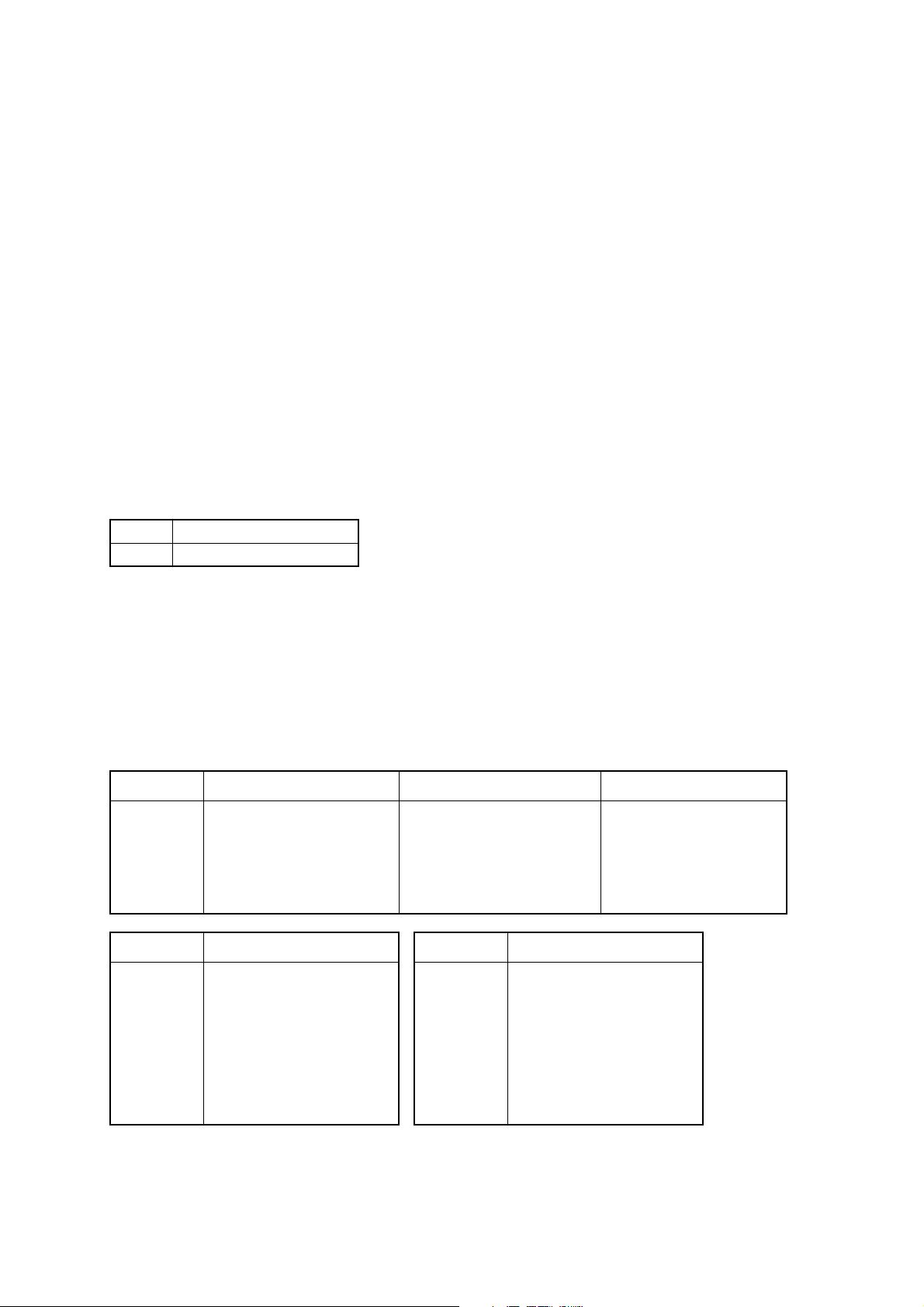

5.2 Setting the DIP Switches

All of the DIP switches have been set to ON at the time of shipping.

5.2.1 Serial Interface

a) DIP switch 1 (for both RS-232C and RS-422A)

Switch position Function ON OFF

1-1 Baud rate

1-2

1-3 Handshaking DTR XON/XOFF

1-4 Data length 8 bits 7 bits

1-5 Parity Disabled Enabled

1-6 Parity Odd Even

1-7 DC1, 3 (*1) Disabled Enabled

1-8 Power on (*2)

*1 Only for the RS-232C (This setting is made with DIP switch 2 on the RS-422A.)

*2 For the power on function

1-8 ON 1-8 OFF

When DC1, 3 is disabled Select Select

When DC1, 3 is enabled Select Deselect

When addressable Deselect Select

Baud rate 1-1 1-2

2400BPS OFF OFF

4800BPS OFF ON

9600BPS ON ON

19200BPS ON OFF

– 8 –

Page 12

b) DIP switch 2 (only for the RS-422A)

SW 2-1 SW 2-2 SW 2-3 SW 2-4

DC1, 3 disabled ON ON ON ON

Address #1 OFF ON ON ON

#2 ON OFF ON ON

#3 OFF OFF ON ON

#4 ON ON OFF ON

#5 OFF ON OFF ON

#6 ON OFF OFF ON

#7 OFF OFF OFF ON

#8 ON ON ON OFF

#9OFFONONOFF

#10 ON OFF ON OFF

#11 OFF OFF ON OFF

#12 ON ON OFF OFF

#13 OFF ON OFF OFF

#14 ON OFF OFF OFF

DC1, 3 mode OFF OFF OFF OFF

5.2.2 Parallel Interface

Switch position Function ON OFF

1-1 Mode

1-2

1-3 Not used

1-4 Not used

Mode 1-1 1-2

Compatibility mode ON ON

Nibble mode (without negotiation, without termination) OFF ON

Byte mode (without negotiation, without termination) ON OFF

Not used OFF OFF

– 9 –

Page 13

5.3 Setting the EEPROM

The following command from the host computer is used to make the EEPROM settings.

a) EEPROM settings command

<ESC> #N, n1 n2 n3 n4 <LF> <NUL>

N: Memory switch no.

n1 n2 n3 n4: Setting data

For more details, refer to “Programmer’s Manual”.

b) Memory switch 0

N = 0

n1: Always 0

n2: Always 0

n3: Always 0

n4: Mode select

0 Page mode (Default)

1 Line mode

c) Memory switch 1

N = 1

n1: Sensor select

n2: Start-position detect

n3: Zero style

n4: International character set

Parameter Setting 0 (Default) 1

n1 Sensor select Reflective sensor

Transmissive sensor

(Black mark)

n2 Start-position detect OFF ON

n3 Zero style Normal zero Slashed zero

n4 International character set See below

n4 Country n4 Country

0 USA 7 Spain #1

1 France 8 Japan

2 Germany 9 Norway

3 UK A Denmark #2

4 Denmark #1 B Spain #2

5 Sweden C Latin America

6 Italy

– 10 –

Page 14

d) Memory switch 2

N = 2

n1: Always 0

n2: Always 1

n3: Always 0

n4: Printing speed

0 50 mm/sec. (Default)

1 25 mm/sec.

e) Memory switch 3

N = 3

n1: Always 0

n2: Character table

0 Normal (Default)

1 Katakana

2IBM

3IBM

n3: Print column

0 40 column (Default)

1 50 column

n4:

0 <CR> Disabled Paper feed 4 mm (Default)

1 <CR> Disabled Paper feed 3 mm (Default)

2 Same as <LF> Paper feed 4 mm

3 Same as <LF> Paper feed 3 mm

f) Memory switch B

N = B

n1: Always 0

n2: Presenter

0 Not installed (TUP452)

1 Installed (TUP482)

n3: Always 0

n4: Always 1

– 11 –

Page 15

↓

↓

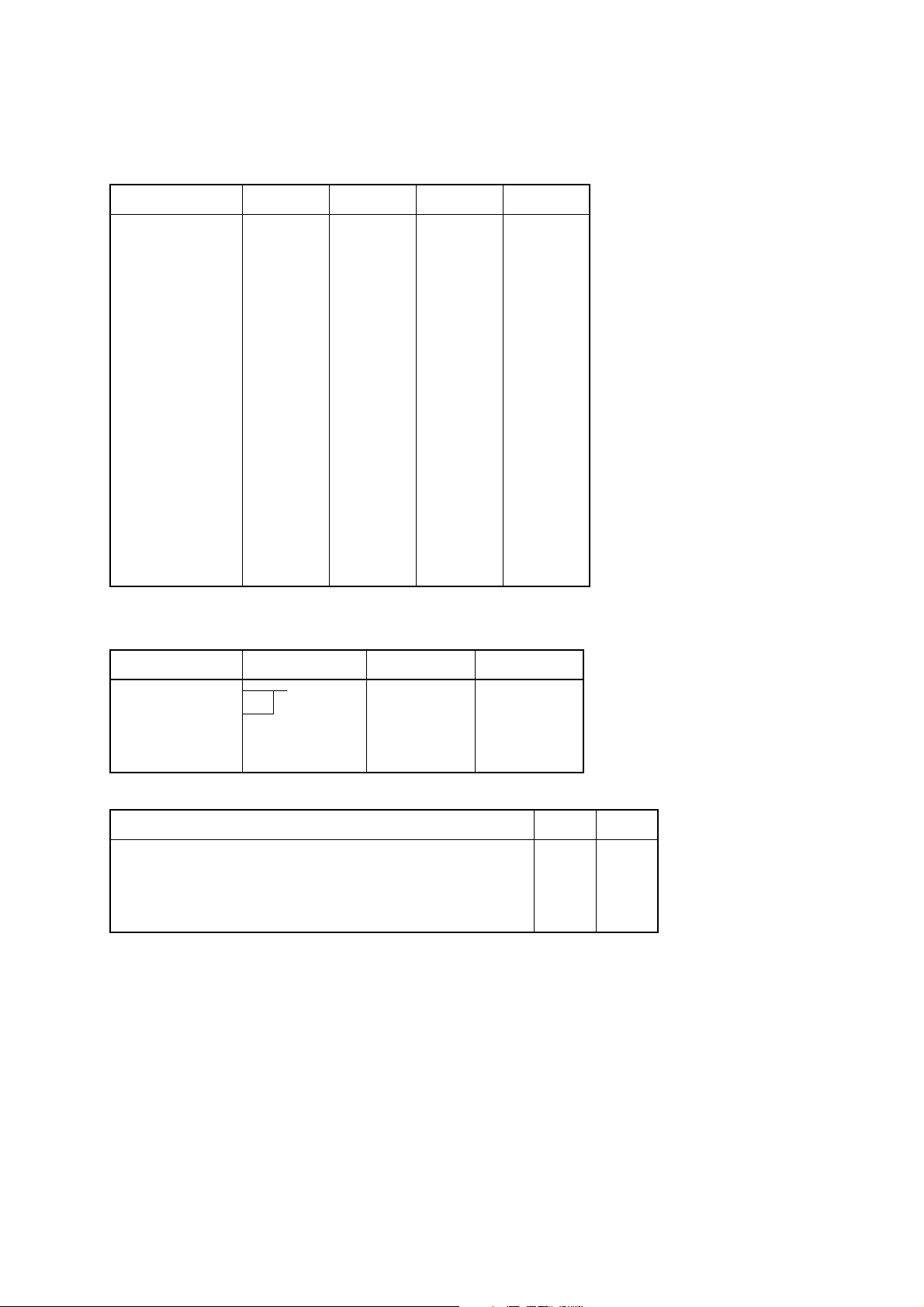

6. DISPLAYS AND FUNCTIONS

The LEDs and RESUME button are mounted on the NEPCB.

6.1 LEDs

LED Function

HU

PE

ERR

6.2 RESUME Button

When no paper is inserted, insert more paper, then press this button to automatically feed the specified

length of paper (approx. 80 mm when the presenter is installed or approx. 30 mm when it is not). After

the paper is cut, the printer will go back on line.

6.3 Power Switch and Button Combinations

The following settings can be made by pressing either the RESUME button or the sensor adjusting b utton at the same time that the power switch is turned on.

<RESUME button and power switch>

Buzzer LED Function

One beep HU lights up

Two beeps PE lights up

Lights up when errors occur

(For more details, refer to “6.6 Error Messages”.)

2 sec.

Release the RESUME button to execute a HEX dump.

[*1]

Release the RESUME button to execute a test print. [*2]

[*1] The HEX dump mode remains valid until the power is turned off.

[*2] The printer continues the test print until the power is turned off.

<Sensor adjusting button and power switch>

Buzzer LED Function

One beep HU lights up

2 sec.

[*3] Do not continue pressing the sensor adjusting button for more than two seconds.

Note) The Line and Page modes cannot be chosen with the panel buttons; these modes can only be

chosen with commands.

Release the sensor adjusting button to start sensor

adjusting mode. [*3]

– 12 –

Page 16

6.4 Sensor Adjusting Mode

a) Reflecting sensor (black mark sensor)

●

Insert the paper in front of the sensor mechanism so that a black mark is not positioned in front of

the sensor.

●

Adjust the reflecting sensor controller VR4 on the PCB until the HU LED lights up.

b) Paper-out sensor

Insert the paper in front of the sensor mechanism so that a black mark is not positioned in front of

●

the sensor.

Adjust the paper-out sensor controller VR3 on the PCB until the PE LED lights up.

●

6.5 Near-End Sensor

Selecting the open frame setting with memory switch B enables near-end sensors A and B. It is possible to determine the state of near-end sensors A and B by outputting the <EOT> command to the

printer. (This is only possible when a serial interface is used.) Refer to “Programmer’s Manual”.

– 13 –

Page 17

6.6 Error Messages

It is possible to determine the type of error occurring by observing the printing results and which LED

lights up.

a) Recoverable errors

The printer goes off line when these errors occur.

To resume operation, remove the cause of the error, then press the RESUME button.

Error Cause

LED

ERR HU PE

Head up error The head is raised. On

Paper-out error No paper is inserted. On

Label size error The paper size differs from the measured size. On

b) Unrecoverable errors

The printer goes off line when these errors occur.

Operation of the printer will be resumed by pressing the resume button after the cause of the unrecoverable error is removed.

LED

Error Cause

ERR HU PE

Command error There is an error in the command. On

Cutting error The paper is not cut properly. On On

Transmission error *1 There is an abnormality in the received data. On On

Paper jam error *2 The paper is not fed up to the sensor. On On On

*1 Valid only with the serial interface

*2 If the paper is jamed inside the presenter

1

Paper Jam, Case 1: Removing paper from inside the presenter.

(Procedure)

1) If there is a paper jam at the Open/Close plate, lower

the Open/Close plate if it is in the up position. (If it is

in the down position, leave it down.)

2) Remove the jammed paper from the space below the

presenter unit.

Note) When lowering the Open/Close plate, be careful

not to bend the PET film unit.

– 14 –

Page 18

2

Paper Jam, Case 2: Removing paper from near the cutter.

(Procedure)

1) When paper is jammed inside the cutter , if it cannot be

removed by the procedure in Case 1, take out the

screws on both sides of the presenter, as shown in the

figure.

2) Slide the presenter along the * part in the figure, separating the presenter and the cutter, then remove the

jammed paper.

3) After removing the jammed paper, slide the presenter

back, following the procedure in 2) in reverse order,

then fasten it in its original position using the screws.

Note) When fitting the presenter with the cutter in 3)

above, be careful not to get the two wires sho wn in

the figure caught between the presenter and cutter.

c) Other errors

Data errors (<ESC> “PC” command: defines character and bar code data)

●

A data error will occur if an invalid character or bar code type is selected or if the print result

extends outside the print area. When a data error occurs, all commands become invalid (character

strings and bar codes are not printed). Howev er, the printer will not go off line and the LEDs will

not light up.

– 15 –

Page 19

6.7 Near-End Sensor Position

<Technical Specifications>

The near-end sensors can be moved a maximum of 5 mm to the right or left by moving the near-end

sensor PCB.

Slightly loosen the three screws (without removing them) used to install the PCB, then move the PCB

to the desired position. After making sure that the PCB fits properly (i.e. it is not loose), tighten the

three screws. (Do not break the PCB.)

Near-end sensor NEA

Near-end sensor NEB

Near-end sensor PCB

Screw

Square hole

Side frame

Can be moved a maximum

of 5 mm to the right and left

* The near-end sensors are mounted on the back of the PCB.

– 16 –

Slot

Page 20

7. INTERFACE

Three interface types are available: parallel, serial RS-232C or serial RS-422A. Any of these interfaces

can be used by installing the corresponding PCB.

7.1 Serial Interface (RS-232C or RS-422A)

RS-232C

Item Specification

Data transfer method Asynchronous serial interface

Data transfer rate 2400, 4800, 9600, 19200

Start bit: 1

Data bit: 7 or 8

Odd, even or no parity

Stop bit: 1

Signal polarity Mark = logic “1” (–3 V to –15 V)

Space = logic “0” (+3 V to +15V)

Connector Pin Assignment (D-SUB 25 pin)

Pin No. Signal Name IN/OUT Function

1 F-GND — Frame ground

2 TXD OUT Transmit data

3 RXD IN Receive data

4 RTS OUT Send request signal. There is a space when the printer is

ready to receive.

5 CTS IN There is a space when the host computer is ready to

send. However, this signal is not checked by the printer.

6 N/C Not used

7 S-GND Signal ground

8 ~ 10 N/C Not used

11 RCH OUT There is a space when the printer is ready to receive.

Same as pin 20.

12 N/C Not used

13 S-GND Signal ground

14 FAULT OUT There is a mark when an error is occurring in the printer.

15 Multi-TXD OUT Send data for multi printer

16 Multi-DTX IN Receive data for multi printer

17 ~ 19 N/C Not used

20 DTR Data terminal ready signal. There is a space when the

printer is ready to receive.

21 ~ 25 N/C Not used

– 17 –

Page 21

RS-422A

Item Specification

Data transfer method Asynchronous serial interface

Data transfer rate 2400, 4800, 9600, 19200

Start bit: 1

Data bit: 7 or 8

Odd, even or no parity

Stop bit: 1

Signal polarity Mark = logic “1” (–)

Space = logic “0” (+)

Connector Pin Assignment

Pin No. Signal Name IN/OUT Function

1 F-GND Frame ground

2 ~ 6 N/C Not used

7 S-GND Signal ground

8 N/C Not used

9 SD (+) OUT Send data

10 SD (–) OUT Send data

11 ~ 12 N/C Not used

13 S-GND Signal ground

14 ~ 16 N/C Not used

17 RD (+) IN Receive data

18 RD (–) IN Receive data

19 CS (+) IN There is a space when the host computer is ready to

send. However, this signal is not checked by the printer.

20 ~ 22 N/C Not used

23 CS (–) IN There is a space when the host computer is ready to

send. However, this signal is not checked by the printer.

24 RS (+) OUT Send request signal. There is a space when the printer is

ready to receive.

25 RS (–) OUT Send request signal. There is a space when the printer is

ready to receive.

– 18 –

Page 22

7.2 Parallel Interface

Item Specification

Method Centronics

Data transfer rate 1000 to 6000 cps

Synchronization method External supply strobe pulse

Handshaking By A

CK and BUSY signals

Logic level TTL-compatible

Connector Pin Assignment

Pin No. Signal Name IN/OUT Function

1 STR

OBE IN Normally HIGH. Data reading starts after this signal

becomes LOW.

2 ~ 9 DATA 1 ~ 8 IN Data. HIGH for “1”, LOW for “0”.

10 A

CK OUT Turned ON when data acquisition is complete.

11 BUSY OUT Reception of data is possible when this signal is LOW;

reception is not possible when HIGH.

12 PAPER OUT OUT Becomes HIGH when no paper is inserted.

13 SELECTED OUT Becomes HIGH when the printer goes on line.

14 ~ 15 N/C Not used

16 SIGNAL GND Signal ground

17 CHASSIS

Printer frame ground

GND

18 +5 V +5 V for external equipment (50 mA max.)

19 ~ 30 TWISTED

Return signal for various signals

P AIR RETURN

31 RESET

32 ERR

OR OUT Becomes LOW when the printer cannot function.

IN Initializes the printer when LOW.

33 EXT GND Ground terminal for external equipment

34 ~ 35 N/C Not used

36 — Always HIGH

– 19 –

Page 23

8. CUTTER

Item Specification

Method Guillotine-type full cutting

Drive method DC motor

Installation Attached to the mechanism with screws

Supply Thickness of one sheet of paper: 60 to 100 µ m

Minimum cutting length 25.4 mm (no presenter)

80 mm (equipped with presenter)

Life (standard paper) 300,000 times

Paper debris must be removed.

Error An error occurs if the cutter has not returned to the home position within

the specified time.

Notes) If the cutter is not located at the home position when an error has occurred, it can be returned

to the home position by removing the cause of the error and turning the power off, then on

again.

The cutter can also be returned to the home position by turning off the power, inserting a

screwdriver into the hole on the side of the cutter, then rotating the motor until the cutter is

returned to the position which is believed to be the home position.

– 20 –

Page 24

9. PRESENTER

Item Specification

Possible sheet length Approx. 80 mm (min.)

Approx. 300 mm (max.)

Operation sequence

(viewed from the

operator’s side)

a. The paper is not ejected during printing.

b. The cutter cuts the end of the paper after printing is completed.

c. The presenter’s roller rotates for 5 seconds, which causes the sheet to

be ejected from the exit. The sheet stops when the end leaves the

roller.

d. The next printing step starts when the sheet is removed by the opera-

tor.

e. If the sheet is not removed within 5 seconds, the roll begins to rotate.

If the status end request (EOT) is sent from the host computer while

the sheet is remains at the exit, the host computer will return to status

E5.

– 21 –

Page 25

10. CHARACTERS

10.1 Character Set

ASCII

Katakana (Japanese syllabary)

International character set

10.2 Characters and Sizes

(Width and length of 1 dot = 0.125 mm (1/8 mm))

1. Page mode

Character face Print size (length × width)

Small characters 16 × 8 dots

Standard characters 24 × 16 dots

Bold characters 32 × 24 dots

OCR-B 24 × 16 dots

Full-size Kanji 24 × 24 dots

2. Line mode

Character face Print size (length × width)

IBM Block 24 × 12 or 32 × 12 dots

Other ANK 24 × 12 dots

Full-size Kanji 24 × 24 dots

Half-size Kanji 24 × 12 dots

– 22 –

Page 26

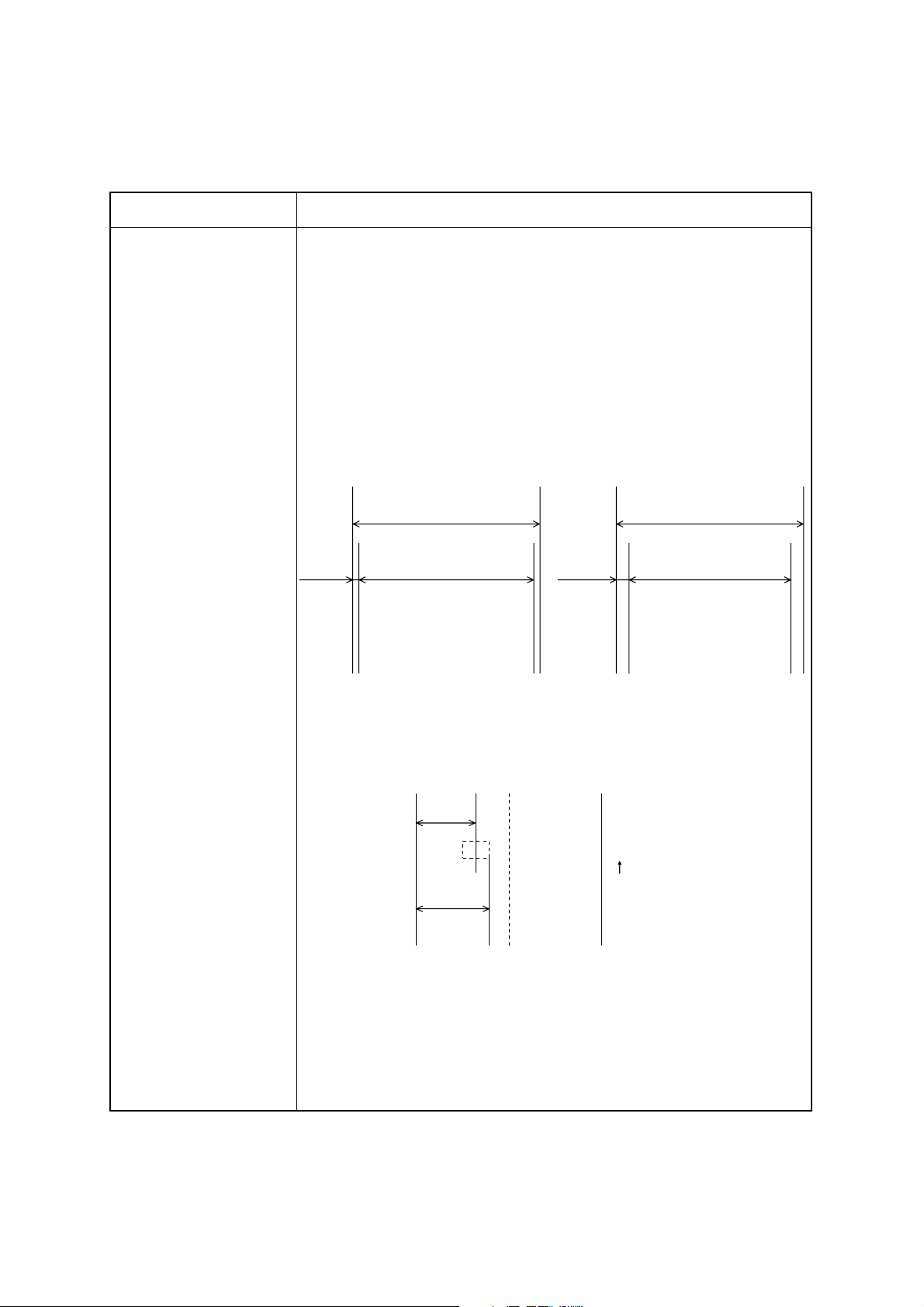

11. POWER REQUIREMENTS

The input voltage shall be DC 24 V ± 7% (rated 2.5 A, less than 6 A/15 sec.). The current used when

solid printing is performed is shown below.

Block 1 (384 dots)

12A

8A

T T

0.5A 0.5A

Cycle 2.5ms

12A

Block 2 (256 dots)

8A

T T

Item Specification

T (weld time) approx. 550 ms (25˚C, standard density)

Max. 800 ms depending on the conditions

Current (during solid

printing)

Item Specification

Recommended power

supply

Peak current: 12 A max.

Average current: 6.6 A max.

12 × 0.8 + 8 × 0.8 + 0.5 × (2.5 – 0.8 × 2)

2.5

For 100 or 120 V Star Micronics Power Supply Unit SLS-060P-50

(Part number: 87393030)

For 230 V Star Micronics Power Supply Unit SLS060PH-50A

(Part number: 87393090)

– 23 –

Page 27

Power connector

1

2

3

4

JST. VHR-4N

UL1007 AWG18

Recommended power – unit junction cable

Unit junction connector

AMP 1-480425-0

Unit power cable

1: 24V

2: 24V

3: GND

4: GND

1

2

3

4

AMP 1-480426-0

– 24 –

Page 28

12. NOISE

Item Specification

Measurement standard = ANSI 1.29 (DIN45, ISO7779)

Average sound pressure at 1 m 50 dB or less

13. STANDARDS

Safety standards

1. UL (RU)

2. CSA

– 25 –

Page 29

14. RELIABILITY

14.1 During operation

Temperature: 5˚ ~ 40˚C

Humidity: 25% RH ~ 80% RH (no condensation)

Operating temperature and humidity ranges

% RELATIVE HUMIDITY

100

90

80

70

60

50

40

30

20

10

-20-100 1020304050607080

°C ENVIRONMENTAL

TEMPERATURE

Notes) When the environmental temperature is too high, the thermal head temperature sensor is acti-

vated and the printer stops operating.

14.2 During storage

Temperature: –20˚C ~ 60˚C

Humidity: 10% RH ~ 90% RH (no condensation)

– 26 –

Page 30

14.3 Allowable Static Electricity Level

Quality control

test specifications

±

±

±

Direct discharge Element allowable level

(self-printing)

8 kV (*1)

No fracturing of elements allowed ± 15 kV

Indirect discharge Element allowable level

(self-printing)

Checker connection allowable le vel

(continuous printing)

15 kV

3 kV (*2)

Direct discharge error: ≤ 5% (*1) ±10 kV test is also performed.

Indirect discharge error: 0% (*2) ±5 kV test is also performed.

Notes)

●

Use SLS-060P-50 (Sanken) as the power source.

The reference data is shown in the table above; this data may differ depending on the instal-

●

lation conditions.

14.4 Vibration Test

Item Specification

Frequency 7 ~ 100 ~ 7 Hz (sweeping: 2.5 minutes)

Amplitude 15.3 ~ 0.07 mm

Gravity 1.5 G (constant)

Vibration direction and

time

1 hour in each direction: X, Y and Z

Total of 3 hours

Packing As small as possible

14.5 Drop Test

Item Specification

Drop height 80 cm

Drop sequence One corner, three edges and six surfaces

Packing As small as possible

– 27 –

Page 31

14.6 Life T est

MCBF

Item Specification

No. of printed lines 5 million lines (excluding the thermal head life)

Auto cutter 300,000 cutting operations (One sheet of paper should be less than 85 µm.)

Thermal head 5 × 10

7

pulses or a printing distance of 30 km

Notes)

● The thermal head life given above is applicable for cases when standard paper is used.

● Printing continuously at a print ratio of less than 12.5% increases the resistance of the ther-

mal head’s heat-generating element by more than 15% of the initial value.

● Excluding damages caused by dust, foreign objects etc.

● Missing dot ratio maximum of 0.5% over 50 km.

– 28 –

Page 32

15. INSTALLING THE PAPER ROLL

OPEN

Lever

Arm

Cutter’s guide

Paper roll

• Remove the arm from the frame

and install the paper roll.

• Make sure that the end of

the paper is sharply cut.

Pass the paper over the damper shaft, pass it under the thermal head, then insert the paper between cutter guides. Double check that the paper is inserted into the cutter by looking into the small wholes on

the upper cutter guide. Feed the paper until the end enters the presenter’s roller.

– 29 –

Page 33

PRESS

Firmly press the areas indicated with crosshatches

on the thermal head until the lever is reset.

Carefully place the paper roll on the frame, then wind the roll to remove any slack in the paper. (Incorrectly installing the paper roll may bend the frame or cause a paper jam.)

RESUM

E

Press the RESUME button.

– 30 –

Page 34

16. INSTALLATION

Installation procedure

Install the printer using four M4 bolts as shown in the illustration below. (Refer to the diagram of the

“Installation Hole Dimensions”.)

Unit printer

Metal base

M4

– 31 –

Page 35

16.1 Installation precautions

1. Install the printer on a level surface. (Consult with a representati v e when installing the printer at an

angle.)

2. Be sure that there is plenty of space around the printer. (Refer to the diagram of the “External

Dimensions”.)

3. Since the thermal head is very hot, carefully examine where the printer is installed. (When a fan is

used to provide ventilation, be very careful of dust since it can damage the thermal head.)

4. Although this printer is made of plated steel sheets, the ends are not plated.

16.2 Other precautions

1. Correctly insert the paper before printing.

2. Do not use or store this printer in a dusty or oily environment or in a place containing a large

amount of iron.

3. Remove any dust, paper particles, etc. using either a soft brush or a cloth dampened in alcohol.

4. Do not apply a strong force to the printer. Otherwise, the frame may bend causing the printer to

malfunction.

5. The printer should only be used in the specified environmental conditions (temperature, humidity,

etc.) and not subject to sudden environmental changes. When sudden environmental changes

occur, the printer should be kept in the new environment for approximately 30 minutes before it is

used.

6. Do not use the printer if condensation has formed on it.

– 32 –

Page 36

5

74

6

204 146

349

2.8

82.5(PAPER WIDE)

73.3

10319

148

164.2

External Dimensions

– 33 –

(Unit: mm)

Page 37

120˚

45˚

266

253

204

199

175

162

159

151

80

19

72.4

382

max ø203

±0.15

13.7

±0.1

19

123.8

+0.03

2-3.7

493

0

– 34 –

(Unit: mm)

Page 38

Installation Hole Dimensions

Using four M4 bolts, install the printer from the bottom as shown in the illustration below.

Front

16

72.4115±0.1

4-M4

Back

130±0.1

View A (rear surface)

(Unit: mm)

– 35 –

Page 39

17. MAINTENANCE

Regular maintenance is very important since minute debris of thermosensible paper sticking to the

platen may cause slipping of the paper feeder. Maintenance should be made as follows:

Maintenance Timing:

Generally, TUP series should be maintained every time after using 8 rolls of 8 inch ø Star Standard

Spec paper roll, or 6 month.

Maintenance Procedures:

1. Make sure that the power supply is turned off before starting the maintenance procedures.

2. Wipe and rub the platen gently with a dry soft cloth to remove all debris stuck on the platen surface. (Turn the platen around to remove debris from all the surface.)

Take enough care not to touch the gears and the cutter guide when wiping the platen to avoid any

*

bodily injury.

Avoid wiping a same spot of the platen continuously, otherwise it may cause deformation of the

*

platen.

Wash your hands thoroughly before touching the platen.

*

Platen

Cutter guide

Dry soft cloth

– 36 –

Page 40

3. Remove the dirt from the thermal head using a cotton bud or soft cloth dipped in alcohol.

4. Remove all dirt, dust or paper debris, etc. adhering to the sensors (particularly the reflector type

sensors) of the thermal mechanism and the presenter.

Note) For the presenter’s paper sensor, take out the screws in the presenter cover on the side as

shown in the figure below, remove the cover, then remove the dust from above. Also, after

maintenance, return the presenter cover to its original position and fasten it with the screws

which were taken out before.

Presenter Cover

Screw

Paper sensor

– 37 –

Page 41

HEAD OFFICE

ELECTRONIC PRODUCTS DIVISION

STAR MICRONICS CO., LTD.

536 Nanatsushinya, Shimizu,

Shizuoka, 424-0066 JAPAN

Tel : 0543-47-0112

Fax: 0543-48-5271

Please access the following URL

http://www.star-micronics.co.jp/service/sp_sup_e.htm

for the lastest revision of the manual.

OVERSEAS SUBSIDIARY COMPANIES

STAR MICRONICS AMERICA, INC.

70-D Ethel Road West,

Piscataway, NJ 08854 U.S.A.

Tel : 732-572-9512

Fax: 732-572-5095

Distributed by

STAR MICRONICS U.K. LTD

Star House, Peregrine Business

Park, Gomm Road, High Wycombe,

Bucks, HP13 7DL, U.K.

Tel : 01494-471111

Fax: 01494-473333

Printed in Japan, 80874275

Loading...

Loading...