Page 1

Thermal Printer

TSP400

Series

TUP400

Programmer’s Manual

Page 2

Page 3

TABLE OF CONTENTS

1. OUTLINE............................................................................................1

2. Memory Switch and DIP Switch.........................................................3

2-1. Memory Switch............................................................................3

3. Display panel and functions ................................................................4

3-1. LED.............................................................................................. 4

3-2. Switches .......................................................................................4

3-3. Power switch and ON LINE/FEED switch combinations ...........4

3-4. Sensor adjustment mode ..............................................................5

4. SERIAL INTERFACE .......................................................................... 6

4-1. Interface Specifications................................................................6

4-2. Interface Circuit ...........................................................................7

4-2-1. RS-232C Interface .............................................................7

4-2-2. RS-422A Interface.............................................................7

4-3. Connectors and Signal Names .....................................................8

4-3-1. RS-232C Interface .............................................................8

4-3-2. RS-422A Interface.............................................................9

4-4. Interface Connections ................................................................ 10

4-5. Data Protocol..............................................................................11

4-5-1. DTR/DSR mode ..............................................................11

4-5-2. X-ON/X-OFF mode.........................................................13

4-5-3. STX-ETX mode...............................................................14

4-6. Error Status ...............................................................................16

5. PARALLEL INTERFACE..................................................................18

5-1. Interface Specifications..............................................................18

5-2. Interface Timing.........................................................................18

5-3. Connectors and Signal Names ...................................................19

6. PERIPHERAL UNIT DRIVE CIRCUIT ............................................21

6-1. Errors..........................................................................................23

7. CONTROL CODES/PAGE MODE.................................................... 24

8. CONTROL CODES/LINE MODE .....................................................61

8-1. Line Mode Command Summary................................................61

8-2. Command Specification .............................................................65

9. CHARACTER CODE TABLES.......................................................99

10. Automatic Cutter .............................................................................108

11. Presenter’s memory switch settings ................................................ 109

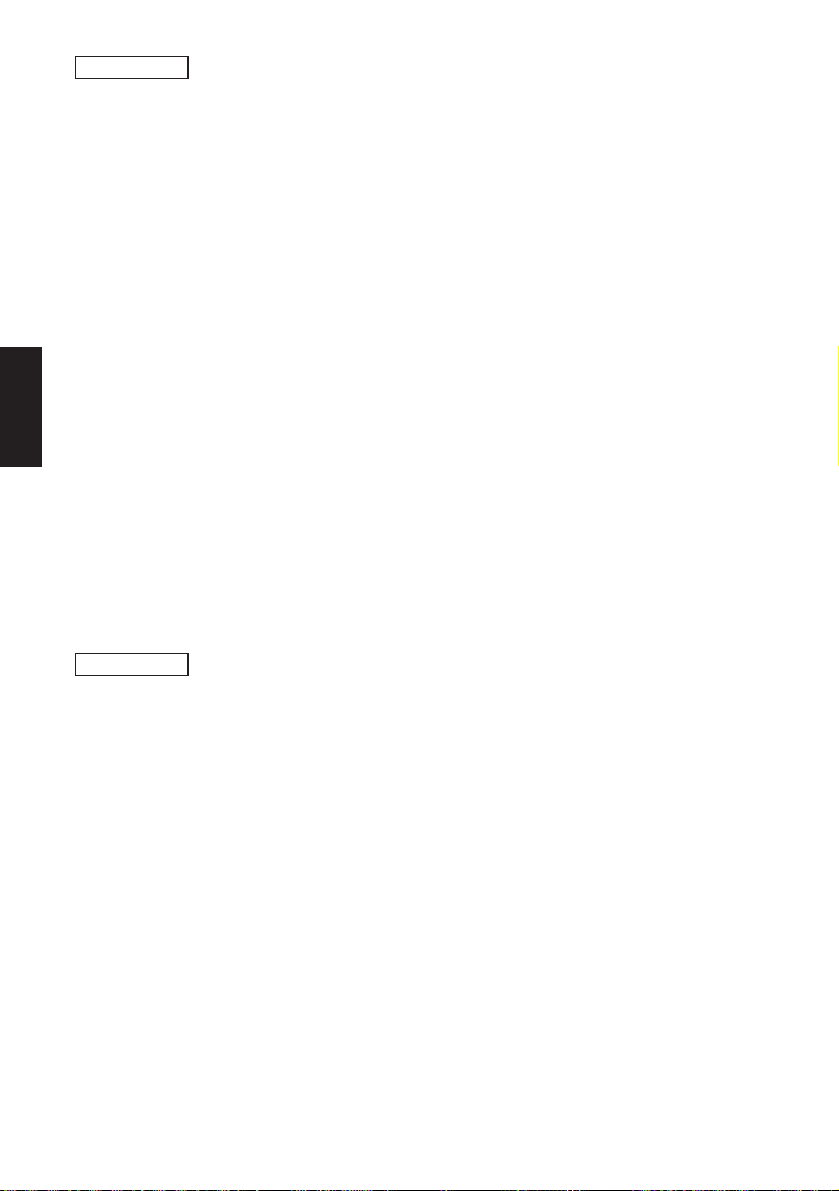

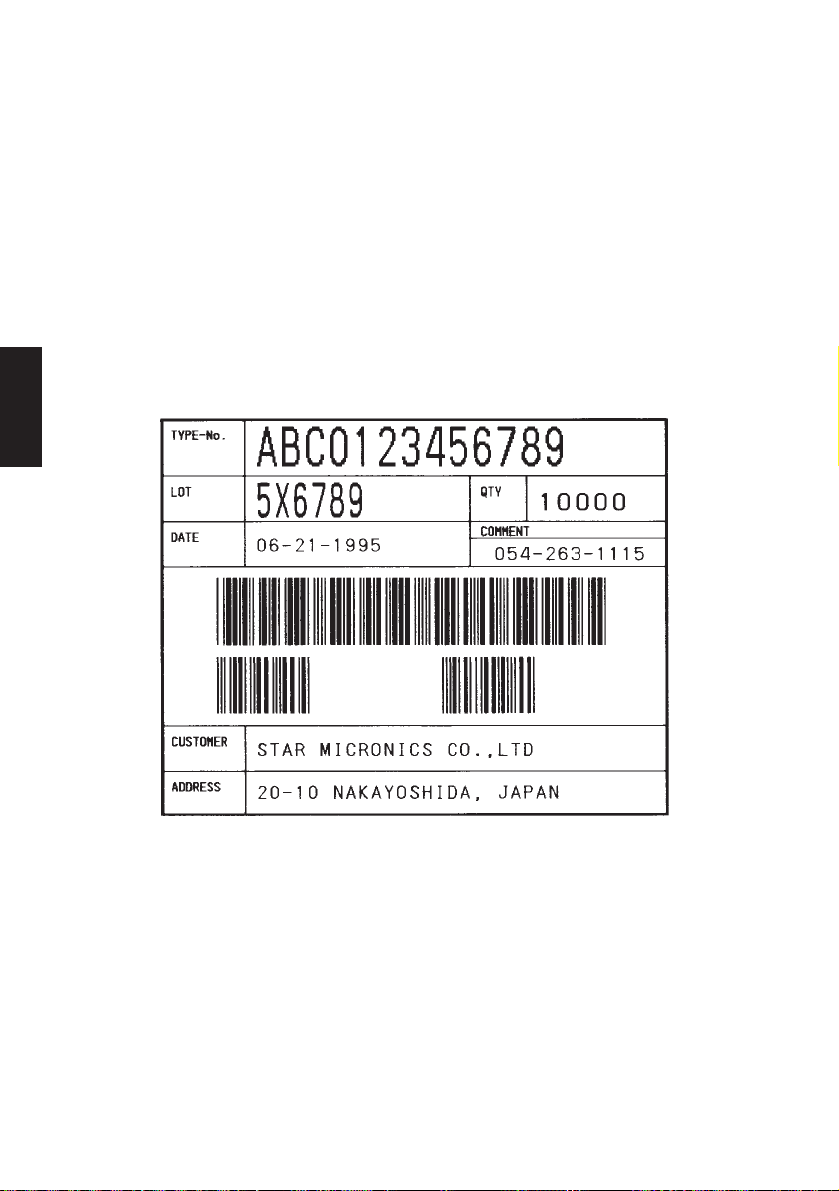

12. TSP LABEL ....................................................................................110

Page 4

1. OUTLINE

The TSP400 series is ideal for printing text, bar code and graphics.

The TSP400 series has the following features:

1. extremely quiet and fast printing (50 mm/sec.) using the direct line thermal

printing method

2. a straight paper path, which prevents paper jams and is ideal for label printing

3. support for many bar code types

(UPC, JAN/EAN-8, JAN/EAN-13, CODE 39, IFT 2 OF 5, CODE 128, CODE

93, NW-7)

4. a black mark sensor that detects the top of the page

5. a transmissive sensor that detects the gap between labels (no black mark is

necessary)

6. a large-diameter (115 mm) roll

7. a wide selection of interchangeable interfaces (RS232C, Centronics Parallel,

RS422A)

8. an installed heavy-duty and reliable cutter (TSP442 only)

9. enclosed utility software (TSPLABEL) that makes it easier to design and print

bar code labels

10.a memory switch that enables a wide selection of printer default settings and

easy setup using the enclosed utility software (TSPSETUP)

The printer has two different software modes which can be selected using the

memory switch. In order to enable changed memory switch settings, turn the

printer OFF and ON again or send printer reset command (<ESC>“?”) to the

printer.

(Factory setting: Page Mode)

Page Mode:

Code <ESC> “#0,0000” <LF> <NUL>

Hex 1B 23 30 2C 30 30 30 30 0A 00

Ideal for bar code label, graphics and text data printing.

Can locate and rotate bar code and text. Accepts a non-compressed BMP file so

that the printer can import and print a BMP file which is scanned or edited in

Windows applications.

– 1 –

Page 5

Line Mode:

Code <ESC> “#0,0001” <LF> <NUL>

Hex 1B 23 30 2C 30 30 30 31 0A 00

This mode is compatible with Star Receipt printers, such as the SP300 and SP200

series.

For improvement purposes, the descriptions and specifications in this manual are

subject to change without notice.

– 2 –

Page 6

2. MEMORY SWITCH AND DIP SWITCH

Functional settings are made using the printer’s EEPROM memory switches and

the DIP switches located on the interface board.

2-1. Memory Switch

Each memory switch is a 16-bit word stored in EEPROM.

The printer is shipped with the factory setting which is made in accordance with

its product type.

For the detailed functions and the settings of the Memory switches, please refer

to "Chapter 7 and 8".

The factory settings are shown in the table below.

hctiwsyromoM214PST244PST284PUT

0#000000000000

1#000000000000

2#000000000000

3#000000000000

B#--1010

2-2. DIP Switch

For the detailed functions and the settings of theDIP switches, please refer to

"Installation manual".

– 3 –

Page 7

3. DISPLAY PANEL AND FUNCTIONS

3-1. LED

LED Function

POWER Lights up when the printer is turned on

HEAD UP

NO PAPER Lights up when an error occurs (Refer to 6-1 Errors.)

ERROR

ON LINE Lights up when the printer is on line; goes off when the printer

is off line; lights up when the head temperature is too high

3-2. Switches

Switch Function

ON LINE Switches between on line and off line

FEED Enable starting position: Feeds the paper to the next starting

position

Disable starting position: Feeds the paper while pressed

3-3. Power switch and ON LINE/FEED switch combinations

The following can be set when the power switch is turned on.

1) Power + FEED switches

1 short beep … Test print

HEAD UP LED lights up

2) Power + ON LINE switches

Approx. 2 sec. Approx. 2 sec.

1 short beep … 2 short beeps … 3 short beeps …

abc

HEAD UP LED NO PAPER LED ERROR LED

lights up lights up lights up

Pause at a: HEX dump

Pause at b: sensor selection

Press ON LINE 1 short beep Reflecting sensor

Press FEED 2 short beeps Transmissive sensor

– 4 –

Page 8

Pause at c: command mode selection

Press ON LINE 1 short beep Page mode

Press FEED 2 short beeps Line mode

3) Power + ON LINE + FEED switches

Approx. Approx. Approx. Approx.

2 sec. 2 sec. 2 sec. 2 sec.

1 short beep … 2 short beeps … 3 short beeps … 1 long beep … …

abcde

HEAD UP NO PAPER ERROR LEDs flash All LEDs

LED LED LED successively light up

lights up lights up lights up lights up

Pause at a: RAM backup cleared

Pause at b: feed function selection

Press ON LINE 1 short beep Disable starting position

Press FEED 2 short beeps Enable starting position

Pause at c: sensor adjustment mode

Pause at d: no operation

Pause at e: clearing of all memory switches and test print

3-4. Sensor adjustment mode

a) Reflecting sensor (black mark sensor)

• Insert the paper in front of the sensor mechanism so that the sensor is not

positioned at a black mark.

• Turn the reflecting sensor adjustment controller VR4 on the PCB until the

HEAD UP LED lights up.

b) No paper sensor

• Insert the paper in front of the sensor mechanism so that the sensor is not

positioned at a black mark.

• Turn the reflecting sensor adjustment controller VR3 on the PCB until the NO

PAPER LED lights up.

c) Transmissive sensor

• Insert only the label’s base paper in front of the sensor mechanism.

• Turn the reflecting sensor adjustment controllers VR1 and VR2 on the PCB

until the ERROR LED lights up.

• VR1 is used for coarse adjustment and VR2 is used for fine adjustment.

– 5 –

Page 9

4. SERIAL INTERFACE

4-1. Interface Specifications

Transmission type.................Asynchronous serial interface

Baud rate (bps) .....................2400, 4800, 9600, or 19200

(Selected by DIP switch)

Word format

Start bit: ......................1

Data bits: ....................7 or 8 (Selected by DIP switch)

Parity: .........................Odd, Even, or None

(Selected by DIP switch)

Stop bit: ......................1

Signal polarities

RS-232C .....................Mark = Logic “1” (–3V to –15V)

Space = Logic “0” (+3V to +15V)

RS-422A.....................Mark = Logic “1” (“A” negative with respect to

“B” by at least 0.2V: A B – 0.2V)

Space = Logic “0” (“A” positive with respect to

“B” by at least 0.2V: A B + 0.2V)

Handshaking .........................DTR or XON/XOFF mode (Selected by DIP

switch)

SERIAL

Mark [1]

Space [0]

b0 b1 b2 b3 b4 b5 b6 (b7)

ABCD

A: Start bit

B: Data bits

C: Vertical parity bit

D: Stop bit

– 6 –

Page 10

4-2. Interface Circuit

4-2-1. RS-232C Interface

SERIAL

Input (RXD, CTS)

Printer Host computer

Output (DTR, FAULT, TXD, RCH, RTS)

Printer Host computer

75188 or equivalent

4-2-2. RS-422A Interface

Input (RD, RS)

Printer Host computer

A

B

Output (SD, CS)

Printer Host computer

A

B

– 7 –

Page 11

4-3. Connectors and Signal Names

13 1

25

14

4-3-1. RS-232C Interface

Pin no Signal name

1 F-GND – Frame ground

2 TXD OUT Outgoing data

3 RXD IN Incoming data

4 RTS OUT Request To Send: The printer sets this signal

5 CTS IN The host sets this signal to “SPACE” when it

6 N/C Not used

7 S-GND – Signal ground

8 N/C Not used

9 ~ 10 N/C Not used

11 RCH OUT The printer sets this signal to “SPACE” when

12 N/C Not used

13 S-GND – Signal ground.

14 FAULT OUT The printer sets this signal to “MARK” to

15

16

Multi-Printer TXD

Multi-Printer DTR

17 ~ 19 N/C Not used

20 DTR OUT Data Terminal Ready: The printer sets this

21 ~ 22 N/C Not used

23 ~ 25 N/C Not used

Direction

Function

to “SPACE” when it is ready to send.

is ready to send. NOTE: The printer does not

monitor this signal.

it is ready to receive. This pin outputs the

same signal as pin 20, to which it is connected.

indicate an error condition (machine error, no

paper, etc.).

OUT Diode gate TXD

OUT Diode gate DTR

signal to “SPACE” when it is ready to re-

ceive.

SERIAL

– 8 –

Page 12

4-3-2. RS-422A Interface

SERIAL

Pin no Signal name

9 SD(+) OUT

10 SD(–) OUT

17 RD(+) IN

18 RD(–) IN

19 CS(+) IN

23 CS(–) IN

24 RS(+) OUT

25 RS(–) OUT

Direction

Function

These pins carry data from the printer.

These pins carry data to the printer.

The host sets this signal to “SPACE” when it

is ready to send.

NOTE: The printer does not monitor this

signal.

The host sets this signal to “SPACE” when it

is ready to receive.

NOTE: The printer does not monitor this

signal.

The printer sets this signal to “SPACE” when

it is ready to receive.

The printer sets this signal to “SPACE” when

it is ready to receive.

– 9 –

Page 13

4-4. Interface Connections

Refer to the host computer’s interface specifications for details of how to connect

the interface. The following illustrations show typical connection configurations.

[RS-232C]

[RS-422A]

Printer #n

RD

SD

Printer side IBM PC side

F-GND

TXD

RXD

RTS

CTS

S-GND

FAULT

DTR

1

2

3

4

5

7

14

20

Printer side Host side

17

18

9

10

Twisted pair cable

SERIAL

F-GND

1

TXD

2

RXD

3

RTS

4

CTS

5

DSR

6

S-GND

7

DCD

8

DTR

20

SD

RD

Printer #n+1

RD

SD

17

18

9

10

– 10 –

Page 14

4-5. Data Protocol

4-5-1. DTR/DSR mode

SERIAL

This mode is accessed when the DIP switch 1-3 is set to ON.

Signals are controlled using the DTR line as a BUSY flag.

RXD

DTR

Printing

Power ON

Data Data Data

Buffer full Buffer empty

Immediately after power on (provided that no error occurs), the printer sets DTR

to “SPACE” to indicate that it is ready to receive data. When the host detects that

DTR is in “SPACE” condition, it begins sending text data over the RXD line.

When the printer’s remaining buffer space falls to 256 bytes or less, the printer

sets DTR to “MARK.” The host responds by halting the data transfer. However,

note that the printer remains capable of receiving data until the buffer becomes

full.

Available buffer space increases as the printer prints the buffered data. When the

printer has cleared all but the last 256 bytes of data, it sets DTR back to “SPACE”

to indicate that it is ready to receive more data.

Data buffer full Nearly full

256 bytes

remaining

DTR

“MARK”

Nearly empty Empty

256 bytes

DTR

“SPACE”

– 11 –

Page 15

■ Error Condition

Upon detecting an error, the printer immediately sets DTR to “MARK” and goes

offline. If the error was caused by a paper-out condition, you can clear it by

loading new paper and then pressing the ON LINE switch.

When paper is out

RXD

OFF LINE ON LINE

DTR

Printing

SERIAL

PAPER OUT signal

Power ON

Paper out

Press the ON LINE switch after

loading paper.

– 12 –

Page 16

4-5-2. X-ON/X-OFF mode

This mode is accessed when DIP switch 1-3 is set to OFF.

SERIAL

X–OFF

X–ON X–OFF X–OFF X–ON X–OFF X–OFF

TXD

X–OFF

X–ON

RXD

Printing

PAPER OUT

signal

ON LINE

indicator

ON

OFF

Power ON Load paper and press

Data Data Data

Paper out

the ON LINE switch.

Immediately after power on (provided that no error occurs), the printer informs

the host that it is ready to receive data by outputting the X-ON signal (control code

DC1; value = 11H) over the TXD line. If necessary the printer repeats the signal

every three seconds until the host begins sending text data over the RXD line.

When the printer’s remaining buffer space falls to 256 bytes or less, the printer

begins to output X-OFF signals (DC3, 13H) over the TXD line. The host

responds by halting the data transfer. Note that the printer remains capable of

receiving data until the buffer becomes full.

Available buffer space increases as the printer prints the buffered data. When the

printer has cleared all but the last 256 bytes of data, it again outputs the X-ON

signal.

Data buffer full Nearly full

256 bytes

remaining

Printer outputs

X-OFF.

– 13 –

Nearly empty Empty

256 bytes

Pinter outputs

X-ON.

Page 17

4-5-3.STX-ETX mode

This mode is accessed from whichever DTR mode or XON/XOFF mode.

To set this mode, the data buffer must be empty.

The host computer sends an ENQ code to the printer and acknowledges the printer

status. Then, the host computer checks if the printer buffer is empty. After the host

computer detects that the buffer is empty, a STX code and data are transmitted.

After 1 block of data is transmitted, the host computer sends an ENQ code to the

printer and then receives the printer status and check byte (horizontal parity for

the printer).

At this point, the host computer performs a status and horizontal parity check.

When the host computer determines that there was no error, it transmits an ETX

code which serves as text end code. After the printer receives the ETX code, data

in the data buffer is printed out. If an error occurs, a CAN code is transmitted by

the host computer. (In this instance, the data which was previously sent to the

buffer is cleared, thus, the host computer must retransmit the same data to the

printer.)

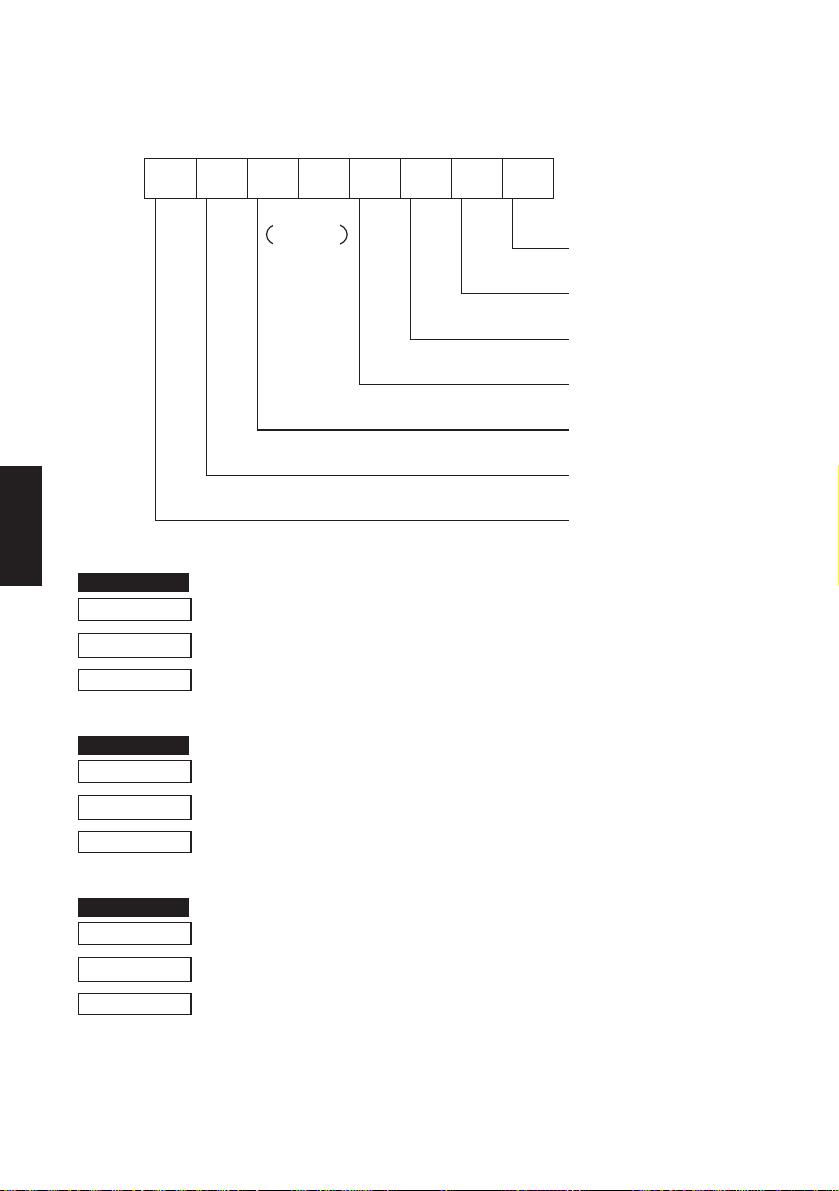

A flowchart of this operation is shown on the next page.

SERIAL

– 14 –

Page 18

SERIAL

Starts the

STX-ETX mode.

Sends an ENQ signal.

Sends ENQ

Receives status byte.

NO

Is the data buffer

empty?

YES

Sends STX signal

Is an odd parity

check?

YES

(FF) H is set for the text

byte.

Acquires the exclusive OR of the content

of the text byte and the data to sent, then

it is used as the content of the test byte.

NO

The test byte is set at (0)H.

Receives status signal.

Receives a check byte.

Is the status an

error?

Horizontal

parity check

Ends the

STX-ETX mode.

NO

Check byte =

test byte?

YES

Sends ETX

(Printing)

YES

NO

Sends CAN

Transmits the data to

the printer.

NO

Is this the last data in

a block?

YES

Check byte:

Horizotal parity of the printer.

Test byte:

Horrizontal parity of the host

computer.

– 15 –

Is there a data block in

the STX-ETX mode?

YES

NO

RET

Page 19

4-6. Error Status

Page Mode

During Label-Mode operation, the printer sends the following statuses to the host.

Data Meaning

<SOH> <STX> “F” “I” <ETX> <EOT> <CR> <LF> Printing finished

<SOH> <STX> “O” “F” <ETX> <EOT> <CR> <LF> Printer is offline

<SOH> <STX> “P” “R” <ETX> <EOT> <CR> <LF> Printing in progress

<SOH> <STX> “R” “E” <ETX> <EOT> <CR> <LF> Ready

<SOH> <STX> “E” “1” <ETX> <EOT> <CR> <LF> System error

<SOH> <STX> “E” “2” <ETX> <EOT> <CR> <LF> Head up

<SOH> <STX> “E” “3” <ETX> <EOT> <CR> <LF> No paper

The printer outputs the “Printing in progress” status only upon receipt of a status

request command. The printer issues the “Printing finished” status when printing

finishes, but never in response to a status request command. All other statuses are

issued both when the event occurs and upon request.

A “system error” indicates one of the following: 1 cutter error, 2 communication error, or 3 command error.

TUP400 Only

Data Meaning

<SOH> <STX> “NA” <ETX> <EOT> <CR> <LF> Inside near-end

<SOH> <STX> “NB” <ETX> <EOT> <CR> <LF> Outside near-end

<SOH> <STX> “E3” <ETX> <EOT> <CR> <LF> No paper

<SOH> <STX> “E5” <ETX> <EOT> <CR> <LF>

<SOH> <STX> “E6” <ETX> <EOT> <CR> <LF>

<SOH> <STX> “E0” <ETX> <EOT> <CR> <LF> None of the above

Paper was fed from presenter

Presenter paper jam error

SERIAL

– 16 –

Page 20

Line Mode

b7 b6 b5 b4 b3 b2 b1 b0

SERIAL

0

Constantly

set at “0” Vertical Parity error

1 : error

Framing error

1 : error

Mechanical error

(Head up, Cutter error)

1 : error

Paper empty

1 : empty

Buffer empty

1 : empty

Buffer overflow

1 : overflow

Compulsion switch

High level

(Switch is set to ON)

■ Compulsion switch

When pin 6 of the peripheral unit drive circuit connector is set “high”, status bit

7 becomes “1”.

TUP400 Only

b7 b6 b5 b4 b3 b2 b1 b0

0

Constantly

set at “0”

– 17 –

01

Constantly

set at “1”

Constantly

set at “0”

Inside near-end sensor

1: Near-end

Paper empty

1 : empty

Outside near-end sensor

1: Near-end

Presenter paper jam error

1: Paper jam error

Presenter no paper sensor

1: Paper is installed.

Page 21

5. PARALLEL INTERFACE

5-1. Interface Specifications

1 Interface: Conforms with Centronics parallel interface standard

2 Data transfer speed: 1000 ~ 6000 CPS

3 Synchronization: External strobe pulse

4 Handshaking: Using ACK and BUSY

5 Logic level: TTL-level compatible

5-2. Interface Timing

A C K

DATA

STROBE

BUSY

PARALLEL

Approx. 9ms

TTT

T: At least 0.5ms

– 18 –

Page 22

Signal Name Sample Circuit

4.7k

DATA 1

~

W

74LS-equivalent

DATA 8

Input

PARALLEL

STROBE

BUSY

Output

ACK

5-3. Connectors and Signal Names

(18) (1)

(36) (19)

(Printer Side)

1kW

1.8kW

100W

1000pF

74LS-equivalent

74LS-equivalent

Conforms to Amphenol

connector 57-30360

Figure 5-1. Parallel Interface Connector

– 19 –

Page 23

Pin no Signal name

1 STROBE IN Strobe pulse for data read. Usually HIGH;

Direction

Function

goes LOW to trigger data read.

2-9 DATA 1~8 IN Parallel data lines for eight-bit data. HIGH

is “1”; LOW is “0”.

10 ACK OUT Printer outputs this pulse for approxi-

mately 9µs to indicate that data read is

completed. Printer becomes ready to

receive new data at the moment the ACK

pulse ends.

11 BUSY OUT DC-level signal indicating printer’s cur-

rent status. LOW indicates that printer is

ready to receive the next data; HIGH

indicates that printer is unable to receive.

The printer holds this signal “HIGH”

during any of the following conditions.

1 While data entry is in progress

2 While printer is offline

3 While error condition exists

12 PAPER OUT OUT DC-level signal indicating whether printer

has paper. The signal stays LOW while paper

is present; it goes HIGH to indicate that paper

has run out.

13 SELECTED OUT DC-level signal; stays HIGH while printer is

online.

14-15 N/C Not used

16 SIGNAL GND Signal ground

17

18 +5V Outputs +5V (Max. 50mA)

19-30 TWISTED Return pins for various signals. Each pin is

31 RESET IN LOW level causes printer to reset its control

32 ERROR OUT Goes LOW to indicate that printer is unable to

33 EXT GND Ground terminal for external connection

34-35 N/C Not used

36 – – Fixed “HIGH” at printer side

CHASSIS GND

PAIR RETURN

Printer-frame ground

connected to the corresponding signal line by

twisted pair line.

circuitry and return to its initial state.

print.

PARALLEL

– 20 –

Page 24

6. PERIPHERAL UNIT DRIVE CIRCUIT

A drive circuit for driving peripheral units (such as cash drawers) is featured on

the main logic board of this printer. A modular connector for driving peripheral

units is featured on the output side on the drive circuit. When using this circuit,

connect the cable for the peripheral unit. (Cables must be prepared by the user.)

Note that Page Mode does not support external-device drive commands. Drive

commands are available only in Line Mode.

Use cables which meet the following specifications.

1. Use the modular plug as shown in Figure 1.

2. Separate ground wire is required for Europe only.

3. Use if the printer is to be used in Europe, the noise filter and the cable should

be separate, as shown in Figure 2.

CAUTION: DO NOT connect any other plug to the peripheral unit connector.

Modular plug MOLEX 90075-0007,

AMP641337 or JAPAN BURNDY B-66-4

16

Shield

Wire lead

Separated Ground wire

connected to shield (Europe only).

Figure 6-1. Cable specifications for peripheral unit.

Distance within 5cm.

Noise filter

( Ferrite-ring enclosed

to printer package. )

Ground wire

1 turn

Figure 6-2. Separate ground wire and noise filter are required for Europe.

– 21 –

Page 25

■ Drive circuit

The recommended drive circuit is shown.

[Drive output 24V, max. 1.0 A]

F.G

M-GND

M-GND

TR3

TR1

TR2

+5V

+24V

R2

D1

7824

D2

R1

1

2

3

4

5

6

With shield

L1

L2

Peripheral

unit 2

Frame

ground

Peripheral

unit 1

R3

4.7kΩ

1/4W

Compulsion

switch

NOTES:

1. Peripheral units #1 and #2 cannot be driven simultaneously.

When driving a device continuously, do not use drive duty above 20%.

2. Compulsion switch status is available as status data.

3. Resistance for coils L1 and L2 is not less than 24 ohms.

4. Absolute maximum ratings for diodes D1 and D2 (at Ta=25˚C):

Average rectified current Io = 1A

Maximum forward surge current (60Hz,1-cycle sine wave) I

FSM=40A

5. Absolute maximum rating for transistors TR1 and TR2 (at Ta = 25˚C):

Collector current Ic = 2A

– 22 –

Page 26

6-1. Errors

The various types of errors can be identified by the buzzer’s sound and the lit

LEDs or the test print result.

Buzzer: The circled numbers refer to the type of buzzer sound.

LED: The circle (

a) Recoverable errors

The printer goes off line (ON LINE LED goes off) when these errors occur.

After the cause of the error is removed, operation of the printer should return after

the ON LINE switch is pressed.

) indicates that the LED is lit up.

Error Cause Buzzer

Head up error The head is up. 2

No paper error Paper is not installed. 3

Label size error

The paper size differs from

the set size.

4

ERROR

LED

HEAD UP

NO PAPER

b) Unrecoverable errors

The printer goes off line (ON LINE LED goes off) when these errors occur.

Operation of the printer cannot be returned after the cause of the error is removed.

Error Cause Buzzer

Command There is an error in the

error *1 command.

Cutting error The paper was not cut

properly.

Transmission There is an abnormality in

error *2 the received data.

*1 Only in page mode

*2 Only with the serial interface

If a framing error or a vertical parity error occurs in Line Mode, “?” is printed.

5

5

5

ERROR

LED

HEAD UP

NO PAPER

c) Other errors (only in page mode)

• Data errors (<ESC> “PC” command: defines character and bar code data)

A data error will occur if an invalid character or bar code type is selected or

if the print result extends outside the print area. When a data error occurs, all

commands become invalid (character strings and bar codes cannot be printed).

However, the printer will not go off line and the LEDs will not light up.

– 23 –

Page 27

7. CONTROL CODES/PAGE MODE

7-1. General Flow for Programming the Page Mode ................................... 25

7-2. Command Summary.............................................................................. 26

7-3. Command Specification ........................................................................ 28

7-4. Appendix: How to set various bar codes............................................... 50

7-5. Sample Program .................................................................................... 58

PAGE MODE

– 24 –

Page 28

7-1. General Flow for Programming the Page Mode

START

PAGE MODE

Set Memory Switches

(if necessary)

Clear Format (if necessary)

Define Print Area (page length)

Define Ruled Line

Format Define Character String Format

Define Bar Code Format

Enable Cutter (if installed)

Set Character String Data

Set Bar Code Data

Copy BMP graphic file

Print Label

<ESC> "#"

<ESC> "C"

<ESC> "D"

<ESC> "L"

<ESC> "PC"

<ESC> "PB"

<ESC> "B"

<ESC> "RC"

<ESC> "RB"

<ESC> "H"

<ESC> "I"

Yes

Yes

Re-print same label?

No

Change character and/or bar code data and print?

Use same format settings

No

END

– 25 –

Page 29

7-2. Command Summary

The printer has the following control commands. Each control code starts with

<ESC> code and ends with <LF> <NUL> codes, except for the Request status

command <ENQ> and the Call Download Character command <ESC> “G”.

Format Definition

Control codes

<ESC> “C”<LF> <NUL>

<ESC> “D n1n2n3n4” <LF>

<NUL>

<ESC> “L n1n2 ; x1x2x3x4

, y1y2y3y4, x5x6x7x8

, y5y6y7y8, d, w” <LF>

<NUL>

<ESC> “E n1n2” <LF> <NUL>

<ESC> “PC n1n2 ; x1x2x3x4

, y1y2y3y4, w, h,

c, r1r2, d1d2” <LF> <NUL>

<ESC> “PB n1n2 ; x1x2x3x4

, y1y2y3y4, w, b,

m, h1h2h3h4” <LF> <NUL>

<ESC> “Y d1d2” <LF> <NUL>

Print Data Settings

Control codes

<ESC> “RC n1n2 ; a1.....an”

<LF> <NUL>

<ESC> “RB n1n2 ; a1.....an”

<LF> <NUL>

<ESC> “Q ; x1x2x3x4,

y1y2y3y4, |1|2|3|4,

w1w2w3, n11n12n13

n.…n1k <LF>.…nm1nm2

.…nmk” <LF> <NUL>

<ESC> “H m x1x2x3x4,

y1y2y3y4, (BMP file data)

,” <LF> <NUL>

<ESC> “G n1n2, n3n4” <ESC>

“0”

<ESC> “X” <LF> <NUL>

Hexadecimal codes

1B 43 0A 00

1B 44 n1n2n3n4 0A

00

1B 4C n1n2 3B x1x2x3x4

2C y1y2y3y4 2C x5x6x7x8

2C y5y6y7y8 2C d 2C w 0A

00

1B 45 n1n2 0A 00

1B 50 43 n1n2 3B x1x2x3x4

2C y1y2y3y4 2C w 2C h 2C

c 2C r1r2 2C d1d2 0A 00

1B 50 42 n1n2 3B x1x2x3x4

2C y1y2y3y4 2C w 2C b 2C

m 2C h1h2h3h4 0A 00

1B 59 d1d2 0A 00

Hexadecimal codes

1B 52 43 n1n2 3B a1a2.…an

0A 00

1B 52 42 n1n2 3B a1a2.…an

0A 00

1B 51 3B x1x2x3x4 2C

y1y2y3y4 2C|1|2|3|4 2C

w1w2w3 2C n11n12n13

n.…n1k <LF>.…nm1nm2

.…nmk” 0A 00

1B 48 m x1x2x3x4 2C

y1y2y3y4 2C (BMP file data)

2C 0A 00

1B 47 n1n2 2C n3n4 1B 30

1B 58 0A 00

Function

Clear format

Define print area

Define ruled line format

Cancel ruled line format

Define character string format

Define bar code format

Define character pitch

Function

Set character string data

Set bar code data

Store dot graphic data into image

memory

Copy BMP file to printer

Call download character

Clear image data

Pages

28

28

30

31

32

34

36

Pages

37

38

38

40

42

42

PAGE MODE

– 26 –

Page 30

Other commands

Control codes

<ESC> “I” <LF> <NUL>

<ESC> “T d n1n2” <LF> <NUL>

<ESC> “B d n1n2” <LF>

<NUL>

<ESC> “# N, n1n2n3n4” <LF>

<NUL>

<ESC> “?” <LF> <NUL>

<ENQ>

<ESC> “N n1n2” <LF> <NUL>

PAGE MODE

<ESC> “F n1n2 ; d1.....d48”

<LF> <NUL>

<ESC> “Z n” <LF> <NUL>

TUP400 only

Control codes

<EOT>

Hexadecimal codes

1B 49 0A 00

1B 54 d n1n2 0A 00

1B 42 d n1n2 0A

00

1B 23 N 2C n1n2n3n4 0A

00

1B 3F 0A 00

05

1B 4E n1n2 0A 00

1B 46 n1n2 3B d1.…d48

0A 00

1B 5A n 0A 00

Hexadecimal codes

04

Function

Print Label

Set Feed Length after Printing

Enable cutter

Set Memory Switch

Reset printer

Request status

Select international character set

Register download character

Select “zero”style

Function

Request status

Pages

43

43

44

44

46

46

47

48

48

Pages

49

– 27 –

Page 31

7-3. Command Specification

Format Definition

FUNCTION

CODE <ESC> “C” <LF><NUL>

HEX

REMARKS

EXAMPLE

Clear format

1B 43 0A 00

When the printer receives this command, all defined format and

image data are cleared.

The format defined by the following commands will be cleared by

<ESC> “C”.

<ESC> “D” <ESC> “L” <ESC> “PC” <ESC> “PB”

<ESC> “Y” <ESC> “RC” <ESC> “RB” <ESC> “Q”

<ESC> “H” <ESC> “G” <ESC> “T” <ESC> “B”

LPRINT CHR$(&H1B);”C”;CHR$(&H0A);CHR$(&H00);

FUNCTION

CODE <ESC> “D n1n2n3n4” <LF> <NUL>

HEX

REMARKS

Define print area

1B 44 n1n2n3n4 0A 00

This command defines the print area(page length) according to the

value of n1n2n3n4 in 1/10 mm unit.

When start position detect is OFF(memory switch #1 n2=0,

Default), defined print area is same as page length.

When start position detect is ON(memory switch #1 n2=1), page

length is automatically detected and set by either black mark

(when reflective sensor is selected) or a gap between each label

(when transmissive sensor is selected). So size of print area is

different from actual page length in this case.

n1n2n3n4 :Print area 0080 to 3000 (8 mm to 300 mm)

PAGE MODE

– 28 –

Page 32

Note :When a value greater than the size of the label is set,

two or more labels are assumed to be one label.

For example, when 50 mm is set for a label whose

pitch is 40 mm, one print pattern is printed using two

labels.

PAGE MODE

EXAMPLE

ABCD

EFG

ABCD

EFG

40 mm

ABCD

EFG

ABCD

EFG

50 mm

Define print area 254 mm (10 inches)

LPRINT CHR$(&H1B);“D2540”;CHR$(&H0A);CHR$(&H00);

– 29 –

Page 33

FUNCTION

CODE

HEX

REMARKS

Define ruled line format

<ESC> “L n1n2 ; x1x2x3x4 , y1y2y3y4 , x5x6x7x8 ,

y5y6y7y8 , d , w” <LF> <NUL>

1B 4C n1n2 3B x1x2x3x42Cy1y2y3y4 2Cx5x6x7x82C

y5y6y7y82C d 2C w 0A 00

This command defines ruled line format.

n1n2 :Line number(00 to 63)

x1x2x3x4 :Position of the starting point in the X direction (0000

to 0800 × 0.1 mm)

y1y2y3y4 :Position of the starting point in the Y direction (0000

to 0300 × 0.1 mm)

x5x6x7x8 :Position of the ending point in the X direction (0000

to 0800 × 0.1 mm)

y5y6y7y8 :Position of the ending point in the Y direction (0000

to 0300 × 0.1 mm)

These four parameters work in 1/10 mm unit, and should be given

with four digit numbers.

d :Line direction d=0 : Horizontal line

d=1 : Vertical line

When d=0, then y1y2y3y4 = y5y6y7y8. When d=1,

then x1x2x3x4 = x5x6x7x8.

PAGE MODE

EXAMPLE

w :Line width 1 to 9 dots

Note: a) This command is used to define lines for label fram-

ing.

b) Up to 64 lines can be defined.

c) Lines must be vertical or horizontal (no diagonal

line).

d) The width of one dot is about 0.125 mm, and so four

dots make 0.5 mm width.

Line number: 00

Position of the starting point (X,Y) direction: (3.3)mm

Position of the ending point (X,Y) direction: (72.3)mm

Line direction :Horizontal line, Line width 5 dots (0.625 mm)

LPRINT CHR$(&H1B);“L00;0030,0030,0720,0030,0,5”;

CHR$(&H0A); CHR$(&H00);

– 30 –

Page 34

FUNCTION

CODE

HEX

REMARKS

EXAMPLE

PAGE MODE

Cancel ruled line format

<ESC> “E n1n2” <LF><NUL>

1B 45 n1n2 0A 00

This command cancels the line previously defined by<ESC> “L

n1n2”.

n1n2 :Line number (00 to 63)

Cancel the line 00 which is previously defined.

LPRINT CHR$(&H1B);“E00”;CHR$(&H0A);CHR$(&H00);

– 31 –

Page 35

FUNCTION

CODE

HEX

REMARKS

Define character string format

<ESC> “P C n1n2 ; x1x2x3x4 , y1y2y3y4

, w , h , c , r1r2 ,

d1d2” <LF> <NUL>

1B 50 43 n1n2 3B x1x2x3x4 2C y1y2y3y4

2C w 2C h 2C c 2C r1r2 2C

d1d2 0A 00

This command defines start position and type of character string.

n1n2 :Character string number(00 to 99)

x1x2x3x4 :Print start position in the X direction (0000 to 0800 ×

0.1 mm)

y1y2y3y4 :Print start position in the Y direction (0000 to 3000 ×

0.1 mm)

w :Character width magnification (1 to 6)

h :Character height magnification (1 to 6)

c :Character type (1to 5)

1: Small size character (8×16 dots)

2: Standard size character (16×24 dots)

3: Reserved

4: Boldface character (24×32 dots)

5: OCR-B(16×24 dots)

r1 : Character rotation direction (0 to 3)

0123

0 degree 90 degrees

180 degrees 270 degrees

PAGE MODE

r2 : Character string rotation direction (0 to 3)

0123

0 degree 90 degrees

180 degrees 270 degrees

d1d2 :Space between characters (00 to 63 dots)

Note: a) “d1d2” can be left out. When “d1d2” is left out, a

space between characters is defined by <ESC> “Y”.

Default value is “00”.

b) Up to 100 character strings can be defined.

c) If “;” or “,” is missing, printer goes into an error

condition.

– 32 –

Page 36

Character rotation and character string rotation

1) Charcter rotation only(no character string rotaion)

Start position

A

BC

A

r1=0(0˚)

r2=0(0˚)

r1=1(90˚)

r2=0( 0˚)

2) Charcter string rotation only(no character rotaion)

BC

A

PAGE MODE

Start position

r1=0(0˚)

r2=0(0˚)

3) Charcter string rotation and character rotation

A

BC

EXAMPLE

A

Start position

r1=0(0˚)

r2=0(0˚)

Character number : 00 print start position (X,Y) = (10.20) mm,

character width magnification : 2,

height magnification : 1, standard size character, character and

character string rotation : 0 degree. 10 dots character space.

BC

r1=1(90˚)

r2=1(90˚)

B

A

B

C

r1=0( 0˚)

r2=1(90˚)

C

C

r1=0( 0˚)

r2=2(180˚)

BC

Start position

r1=2(180˚)

r2=2(180˚)

r1=2(180˚)

r2=0( 0˚)

Start position

BA

A

C

BA

r1=3(270˚)

r2=0( 0˚)

A

C

B

A

r1=0( 0˚)

r2=3(270˚)

BC

A

r1=3(270˚)

r2=3(270˚)

B

C

LPRINT CHR$(&H1B);“PC00;0100,0200,2,1,2,00,10”;

CHR$(&H0A);CHR$(&H00);

10 mm

1 mm

ABCDEF

20 mm

– 33 –

Page 37

FUNCTION

CODE

HEX

Define bar code format

<ESC> “P B n1n2 ; x1x2x3x4 ,

y1y2y3y4 , w , b , m ,

h1h2h3h4”<LF><NUL>

1B 50 42 n1n2 3B x1x2x3x4 2C

y1y2y3y4 2C w 2C b 2C m 2C

h1h2h3h4 0A 00

REMARKS

This command defines start position and type of bar code string.

n1n2 :Bar code string number (00 to 31)

x1x2x3x4 :Print start position in the X direction (0000 to 0800 ×

0.1 mm)

y1y2y3y4 :Print start position in the Y direction (0000 to 3000 ×

0.1 mm)

w :Mode (See Appendix for details)

b :Bar code type (1 to 7)

1: CODE 39

2: INTERLEAVED 2 OF 5 (ITF)

3: CODE 93

4: UPC-A

5: JAN/EAN-8

6: JAN/EAN-13

7: CODE 128

8: NW-7

m :Bar code rotation direction (0 to 3) (clockwise)

0123

0 degree 90 degrees

180 degrees 270 degrees

h1h2h3h4 :Bar code height (0000 to 2999 × 0.1 mm)

Note: a) When a bar code is rotated, its dimensions may not

conform to ANSI specifications. Make sure that the

printed bar code is compatible with the scanner or

scanners to be utilized.

b) Up to 32 bar codes can be defined.

c) If “;” or “,” is missing, printer goes into an error

condition.

PAGE MODE

– 34 –

Page 38

Bar code rotation

PAGE MODE

EXAMPLE

Start position

m=1

90˚

m=2

m=0

0˚

180˚

LPRINT CHR$(&H1B);“PB00;0100,0150,2,1,0,0100”;

CHR$(&H0A);CHR$(&H00);

1 mm

15 mm

10 mm

10 mm

Bar code string number : 00

Print start position (X,Y)= 10

mm, 15 mm

Mode: 2

Bar code type : CODE 39

Bar code rotation : 0 degree

Bar code height : 10 mm

Start position

m=3

270˚

– 35 –

Page 39

FUNCTION

CODE

HEX

REMARKS

Define character pitch

<ESC> “Y d1d2” <LF><NUL>

1B 59 d1d2 0A 00

This command defines dot space between characters.

d1d2 :Indicates dot space (00 to 63)

Note: a) The command is used to define dot space between

characters.

b) When changing the inter character space, a new value

must be placed in front of the <ESC> “PC” com-

mand.

c) Default value is 00.

d) Pitch for each kind of character is as shown below.

e) Up to 64 dot space can be defined.

(unit: mm)(default)

d1d2

Small size

character

Standard size

character

Boldface

character

00 dot 01 dot 02 dots 03 dots 04 dots 05 dots 06 dots 07 dots

1 1.125 1.25 1.375 1.5 1.625 1.75 1.875

2 2.125 2.25 2.375 2.5 2.625 2.75 2.875

3 3.125 3.25 3.375 3.5 3.625 3.75 3.875

PAGE MODE

EXAMPLE

Increase 0.125 mm per 1 dot. (d1d2=10 , then 1(or 2 or 3)+0.125 ×

10 mm)

Use standard size character and character pitch is 4.0 mm. d1d2=16

(=(4-2)/0.125)

LPRINT CHR$(&H1B);“Y16”;CHR$(&H0A);CHR$(&H00);

– 36 –

Page 40

Print Data Settings

FUNCTION

CODE

HEX

REMARKS

PAGE MODE

Set character string data

<ESC> “R C n1n2 ; a1a2.…an” <LF><NUL>

1B 52 43 n1n2 3Ba1a2.…an 0A 00

This command sets character strings defined by the <ESC>

“PC”.

n1n2 :Two digit reference number of character string whose

print position and type are previously defined with

<ESC> “PC”.

a1a2.…an :Character string data (up to 100 characters)

Note: a) The same reference numbers used by the format

definition command <ESC> “PC” is used.

b) To print data, the Print Label command (<ESC> “I”)

must be sent.

c) This command, along with the Print Label command

(<ESC> “I”), allows reprinting of labels where only

the character string data changes.

d) If “;” is missing, printer goes into an error condition.

EXAMPLE

(1) Defined character string number : 03, Print data is “STAR

MICRONICS”

LPRINT CHR$(&H1B);“RC03;STAR

MICRONICS”;CHR$(&H0A);CHR$(&H00);

(2) Change data of character string number 03 to“TSP400 Ther-

mal” and reprint.

LPRINT CHR$(&H1B);“RC03;TSP400 Thermal”;

CHR$(&H0A);CHR$(&H00);

LPRINT CHR$(&H1B);“l”;CHR$(&H0A);CHR$(&H00);

– 37 –

Page 41

FUNCTION

CODE

HEX

REMARKS

Set bar code data

<ESC> “R B n1n2 ; a1a2.…an”<LF> <NUL>

1B 52 42 n1n2 3B a1a2.…an 0A 00

This command defines the bar code data to be printed.

n1n2 : Two digits reference number of defined bar code

whose print position and type are previously defined

with <ESC>“PB”.

a1a2.…an :Bar code data to be encoded and printed.

Note: a) Start character of CODE 39 is automatically inserted.

b) Check word of JAN, EAN, or UPC is automatically

calculated and inserted.

c) When data length does not meet the specifications of

JAN, EAN, or UPC, data length is automatically

modified.

d) CODE 128 conforms to EAN-128; the start code,

check word, and stop code of CODE 128 are automatically inserted.

e) Start, stop and check characters of CODE 93 are

automatically inserted.

f) Start and stop characters of Interleaved 2 of 5 are

automatically inserted.

g) When the number of digits of lnterleaved 2 of 5 is an

odd number, “0” is automatically inserted as the

highest digit.

h) If “;” is missing, printer goes into an error condition.

PAGE MODE

EXAMPLE

FUNCTION

CODE

HEX

Defined bar code number: 00, print data: 12345678901

LPRINT CHR$(&H1B);“RB00;12345678901”;CHR$(&H0A);

CHR$(&H00);

Store dot graphic data into image memory

<ESC> “Q ; x1x2x3x4 , y1y2y3y4 , |1|2|3|4

, w1w2w3 , n11n12n13n.…n1k

<LF>.…nm1nm2.…nmk” <LF> <NUL>

1B 51 3B x1x2x3x4 2C y1y2y3y4 2C |1|2|3|4

2C w1w2w3 2C n11n12n13n.…n1k

<LF>.…nm1nm2.…nmk” 0A 00

– 38 –

Page 42

REMARKS

PAGE MODE

This command stores graphic data into image memory.

x1x2x3x4 :Print start position in the X direction. (0000 to 0800 ×

0.1 mm)

y1y2y3y4 :Print start position in the Y direction. (0000 to 3000 ×

0.1 mm)

|1|2|3|4 :Defines the length (Y direction) of the graphic area.

(0001 to 2400 dots)

w1w2w3 :Defines the width (X direction) of the graphic area.

(010 to 080 dots)

n11.…nmk:n11 represents data in the 1st line. Each line ends with

<LF>.

Data (X direction) appears in the same way as bit

image data. n21 represents data in the 2nd line.

Note: a) This command can be used any number of times.

b) Size of graphic data is set in 1 mm units (byte units

(8 bits/bytes)) in the X direction and 0.125 mm units

(dot units) in the Y direction.

c) <ESC> “X” cancels data that was set using the

command.

d) If “;” or “,” is missing, printer goes into an error

condition.

EXAMPLE

Position of starting point (X,Y) direction : (30,40) mm

Size of image data (X,Y) direction : (3,3) mm, (|1|2|3|4 = 3 × 8 =

0024 bytes, w1w2w3 = 3 × 1 = 003 dots)

LPRINT CHR$(&H1B);”Q;0300,0400,0024,003,”;

CHR$(&H01);CHR$(&H02);CHR$(&H03);CHR$(&H0A);

CHR$(&H01);CHR$(&H02);CHR$(&H03);CHR$(&H0A);

CHR$(&H01);CHR$(&H02);CHR$(&H03);CHR$(&H0A);

CHR$(&H01);CHR$(&H02);CHR$(&H03);CHR$(&H0A);

CHR$(&H01);CHR$(&H02);CHR$(&H03);CHR$(&H0A);

CHR$(&H01);CHR$(&H02);CHR$(&H03);CHR$(&H0A);

CHR$(&H01);CHR$(&H02);CHR$(&H03);CHR$(&H0A);

CHR$(&H01);CHR$(&H02);CHR$(&H03);CHR$(&H0A);

CHR$(&H01);CHR$(&H02);CHR$(&H03);CHR$(&H0A);

CHR$(&H01);CHR$(&H02);CHR$(&H03);CHR$(&H0A);

CHR$(&H01);CHR$(&H02);CHR$(&H03);CHR$(&H0A);

CHR$(&H01);CHR$(&H02);CHR$(&H03);CHR$(&H0A);

CHR$(&H01);CHR$(&H02);CHR$(&H03);CHR$(&H0A);

CHR$(&H01);CHR$(&H02);CHR$(&H03);CHR$(&H0A);

– 39 –

Page 43

CHR$(&H01);CHR$(&H02);CHR$(&H03);CHR$(&H0A);

CHR$(&H01);CHR$(&H02);CHR$(&H03);CHR$(&H0A);

CHR$(&H01);CHR$(&H02);CHR$(&H03);CHR$(&H0A);

CHR$(&H01);CHR$(&H02);CHR$(&H03);CHR$(&H0A);

CHR$(&H01);CHR$(&H02);CHR$(&H03);CHR$(&H0A);

CHR$(&H01);CHR$(&H02);CHR$(&H03);CHR$(&H0A);

CHR$(&H01);CHR$(&H02);CHR$(&H03);CHR$(&H0A);

CHR$(&H01);CHR$(&H02);CHR$(&H03);CHR$(&H0A);

CHR$(&H01);CHR$(&H02);CHR$(&H03);CHR$(&H0A);

CHR$(&H01);CHR$(&H02);CHR$(&H03);CHR$(&H0A);

CHR$(&H00);

FUNCTION

CODE

HEX

REMARKS

Copy BMP file to printer

<ESC> “H m x1x2x3x4 , y1y2y3y4 ,

(BMP file data) ,” <LF> <NUL>

1B 48 m x1x2x3x4 2C y1y2y3y4 2C

(BMP file data) 2C 0A 00

This command copies BMP file to the printer(Image buffer). BMP

file can be scanned by scanner and edited by a program such as the

PAINT BRUSH in the WINDOWS. The printer can accept noncompressed monochrome BMP file only.

BMP file contains white pixel (dots). There are two mode in this

command depending on how to handle these white pixels when

there are black pixels already set in the area to be printed on.

m : Mode “;” 3B(hex) “OR” mode : White pixels (area) of

BMP file do not erase black pixels previously set.

“:” 3A(hex) “OVERWRITE” : White pixels (area) of

BMP file erase(overwrite) black pixels previously set.

BMP graphic file

ABCDEFGHIJK

ABCDEFGHIJK

ABCDEFGHIJK

ABCDEFGHIJK

ABCDEFGHIJK

ABCDEFGHIJK

ABCDEFGHIJK

ABCDEFGHIJK

ABCDEFGHIJK

ABCDEFGHIJK

ABCDEFGHIJK

ABCDEFGHIJK

OR mode:

OVERWRITE mode:

Data previously set Print out result

ABCDEFGHIJK

ABCDEFGHIJK

ABCDEFGHIJK

ABCDEFGHIJK

ABCDEFGHIJK

ABCDEFGHIJK

ABCDEFGHIJK

ABCDEFGHIJK

ABCDEFGHIJK

ABCDEFGHIJK

ABCDEFGHIJK

ABCDEFGHIJK

PAGE MODE

– 40 –

Page 44

x1x2x3x4 :Print start position in the X direction

y1y2y3y4 :Print start position in the Y direction

BMP file data :Command accepts BMP non-compressed mono-

chrome graphic file as binary file.

Note : Printer will result in an error on the following condi-

tions:

a) Error in command format structure

b) If either start position or image data is located out of

print area.

PAGE MODE

c) If a BMP file does not meet command specification.

(Printer can only accept non-compressed, monochrome BMP file)

Contents of BMP file

Please refer the following as contents of standard BMP graphic file. Pleas note

that only some of data apply to the Printer. All other data will be ignored. The

printer can accept non-compressed, monochrome BMP file only.

BIT MAP FILE HEADER (Total 14 byte)

2 byte bf Type Type of file Always “BM”. Error for

4 byte bf Size File Size Ignored

2 byte bf Received 1 Reserved Ignored

2 byte bf Received 2 Reserved Ignored

4 byte bf off bits Off set byte for Bit Map data Read Bit Map data from off-

other letter

set

BIT MAP INFO HEADER (Total 40 byte or more)

4 byte bi Size Size of Bit Map Info Header Used as size of Bit Map

Info Header

4 byte bi Width Width of Bit Map Used as width of graphic.

4 byte bi Height Width of Bit Map Used as height of graphic.

2 byte bi Planes Number of Planes(Always 1) Always “1”. Error for other

number

2 byte bi Bit Count Number of bit per pixel Always “1”(Monochrome).

Error for other number

4 byte Type of compression Always “0”. Error for other

number

4 byte bi Size Image Size of image Ignored

4 byte

4 byte

4 byte bi Cir Used Number of color index Ignored

4 byte bi Cir Important Number of important color index Ignored

4 byte bi Unknown Unknown Ignored

bi X Pels Per Meter

bi Y Pels Per Meter

Horizontal resolution Ignored

Vertical resolution Ignored

– 41 –

Page 45

RGB QUAD (Total 4 byte)

1 byte rgb Blue Brightness of Blue Ignored

1 byte rgb Green Brightness of Green Ignored

1 byte rgb Red Brightness of Red Ignored

1 byte rgb Reserved Reserved Ignored

EXAMPLE

FUNCTION

CODE

HEX

REMARKS

EXAMPLE

FUNCTION

CODE

HEX

REMARKS

EXAMPLE

Please see a sample program “SAMPLE2.BAS” written in QBASIC

at the end of this booklet.

Call download character

<ESC> “G n1n2 , n3n4 ” <ESC> “0”

1B 47 n1n2 2C n3n4 1B 30

This command calls download character.

n1n2,n3n4 :Reference numbers of defined download characters(00

to 31).

Note : Only standard size characters (16 (W) × 24 (H) dots) can

be defined as download characters.

Character number “00” is “ABC” and “DEF” and between those

character, print download character number : 00,01

LPRINT CHR$(&H1B);“RC00;ABC”;CHR$(&H1B);

“G00,01”;CHR$(&H1B);“0”;“DEF”;CHR$(&H0A);CHR$(&H00);

Clear image data

<ESC> “X” <LF><NUL>

1B 58 0A 00

When the printer receives this command, the defined image data

are cleared.

The following commands will be cleared by<ESC> “X”

<ESC> “RC”<ESC> “RB”<ESC> “Q”<ESC> “H”<ESC> “G”

Note: a) Image print area specified by <ESC> “D” is

cleared.

b) The defined format is not cleared.

c) To change the format, use <ESC> “C”.

d) This command clears data for rewriting, allowing the

existing format to be used.

LPRINT CHR$(&H1B);“X”;CHR$(&H0A);CHR$(&H00);

– 42 –

PAGE MODE

Page 46

Other commands

FUNCTION

CODE

HEX

REMARKS

Print Label

<ESC> “I” <LF><NUL>

1B 49 0A 00

This command print out one label according to the previously

defined format and data.

EXAMPLE

LPRINT CHR$(&H1B);“I”;CHR$(&H0A);CHR$(&H00);

FUNCTION

PAGE MODE

CODE

HEX

REMARKS

EXAMPLE

Set Feed Length after Printing

<ESC> “T d n1n2” <LF><NUL>

1B 54 d n1n2 0A 00

This command sets paper feed length after printing. Paper feed is

executed only the printer receives<ESC> “I” command.

This command is designed to adjust distance between print head

and paper tear off bar(applicable only for TSP412)

Feed paper will be feed back again for same length right before

next printing starts.

d : “+” or “-” indicates the direction of the paper feed

length from the tear bar.

“+” indicates a forward feed, and “-” indicates a

reverse feed.

n1n2 :Indicates the value to move with 1/10 mm unit. (00 to

50)

Note: a) If parameters (d and n1n2) are omitted, then paper

feed is to the default position.

b) Feeds paper to the tear bar and stops until next

<ESC> “I” command, then reverse feeds and prints.

Feed paper length from tear bar: +2.5 mm

LPRINT CHR$(&H1B);“T+25”;CHR$(&H0A);CHR$(&H00);

– 43 –

Page 47

FUNCTION

CODE

HEX

REMARKS

Enable cutter(applicable only for TSP442)

<ESC> “B d n1n2” <LF><NUL>

1B 42 d n1n2 0A 00

This command defines cut position and enables cutter. This

command does not energize cutter.

Cutter will be operated only when receiving<ESC> “I” command.

d :“+” or “-” indicates the direction of the cut position

from the normal position.

“+” indicates a forward feed, and “-” indicates a

reverse feed from the normal cut position.

n1n2 :Indicates the value to move in 1/10 mm unit.(00 to 50)

Note: a) If these parameters (d and n1n2) are omitted, then the

cut position is set at the default position.

b) Default cut position , or normal position, is at the

bottom edge of the print area.

c) This command is only applicable when cutter is

installed. (model TSP442 only)

PAGE MODE

EXAMPLE

FUNCTION

CODE

HEX

REMARKS

+ 2.5 mm from the edge of print area.

LPRINT CHR$(&H1B);“B+25”;CHR$(&H0A);CHR$(&H00);

Set Memory Switch

<ESC> “# N , n1n2n3n4”<LF> <NUL>

1B 23 N 2C n1n2n3n4 0A 00

Set the memory switch. In order to enable changed memory switch

settings, turn the printer OFF and ON again or send printer reset

command (<ESC>“?”) to the printer. Changed memory switch

settings are stored in EEPROM and these setting will be stored as

long as the time when they are changed again.

N :Memory switch number (1 or 2)

n1n2n3n4 :Mode settings (For details see below)

1) Use N=1 to set printer conditions. Parameters are as follows.

n1 :Sensor select

n2 :Start-position detect

n3 :Zero style

n4 :International character set

– 44 –

Page 48

Parameter

n1

n2

n3

n4

Setting

Sensor select

Start-position detect

Zero style

International character set

(Default)

0

Reflective sensor

(Black mark)

OFF

Normal zero

1

Transmissive sensor

ON

Slashed zero

See below

PAGE MODE

n4 Country

0 USA

1 France

2 Germany

n4 Country

C Latin America

n4 Country

3UK

4 Denmark #1

5 Sweden

n4 Country

6 Itary

7 Spain #1

8 Japan

2) Use N=2 to set option-related settings. Parameters are as

follows.

n1 :Always “0” (TSP400)

n2 :Cutter installed status

n3 :Always “0”

n4 :Printing speed

n Setting 0 1

n2 Cutter Invalid(TSP412) Valid(TSP442)

n4 Printing speed

50 mm/sec(Default)

EXAMPLE 1

LPRINT CHR$(&H1B);“#1,010A”;CHR$(&H0A); CHR$(&H00);

LPRINT CHR$(&H1B);“#2,0100";CHR$(&H0A); CHR$(&H00);

n4 Country

9 Norway

A Denmark #2

B Spain #2

25 mm/sec

LPRINT CHR$(&H1B);“?”;CHR$(&H0A); CHR$(&H00);

Sensor : Reflective sensor

Start position detect : ON

Zero style : Normal Zero

International character set : Denmark #2

Cutter : Valid

Printing speed : 50 mm/sec

– 45 –

Page 49

EXAMPLE 2

LPRINT CHR$(&H1B);“#1,1111”;CHR$(&H0A);CHR$(&H00);

LPRINT CHR$(&H1B);“?”;CHR$(&H0A);CHR$(&H00);

Sensor : Transmissive sensor

Start position detect : ON

Zero style : Slashed zero

International character set : France

EXAMPLE 3

LPRINT CHR$(&H1B);“#2,0001”;CHR$(&H0A);CHR$(&H00);

LPRINT CHR$(&H1B);“?”;CHR$(&H0A);CHR$(&H00);

Cutter : Invalid

Printing speed : 25 mm/sec

Note: In order to enable the changed memory switch setting,

turn the printer OFF and ON again or send the printer

reset command (<ESC>“?”) to the printer.

PAGE MODE

FUNCTION

CODE <ESC> ? <LF><NUL>

HEX

REMARKS

Reset printer

1B 3F 0A 00

Resets the printer and prints self-test. This command will also set

memory switch conditions without the need to turn the printer

power OFF and ON again.

EXAMPLE

FUNCTION

CODE <ENQ>

HEX

REMARKS

LPRINT CHR$(&H1B);“?”;CHR$(&H0A);CHR$(&H00);

Request status

05

When the printer receives this command, the printer sends back a

status byte for the current printer condition immediately to the

host.

Note: Printer conditions are reported by the following status

bytes:

– 46 –

Page 50

<SOH> <STX> “FI” <ETX> <EOT> <CR> <LF> 01 02 46 49 03 04 0D 0A Printing fin-

<SOH> <STX> “OF” <ETX> <EOT> <CR> <LF> 01 02 4F 46 03 04 0D 0A Printer off-line

<SOH> <STX> “PR” <ETX> <EOT> <CR> <LF> 01 02 50 52 03 04 0D 0A Printing in

<SOH> <STX> “RE” <ETX> <EOT> <CR> <LF> 01 02 52 45 03 04 0D 0A Ready

<SOH> <STX> “E1” <ETX> <EOT> <CR> <LF> 01 02 45 31 03 04 0D 0A System error

<SOH> <STX> “E2” <ETX> <EOT> <CR> <LF> 01 02 45 32 03 04 0D 0A Head up

<SOH> <STX> “E3” <ETX> <EOT> <CR> <LF> 01 02 45 33 03 04 0D 0A Paper empty

PAGE MODE

Data HEX Condition

ished

progress

Note: When more than one printer condition exists, the printer

sends each status byte separated by a comma.

Head up, and paper empty: <SOH> <STX> “E2”,“E3”

<ETX> <EOT> <CR> <LF>

EXAMPLE

LPRINT CHR$(&H05);

If the printer is in a condition of “Head up, paper empty” then the

printer returns the following codes to the host.

CODE <SOH> <STX> “E2” , “E3” <ETX> <EOT> <CR> <LF>

HEX 01 02 45 32 2B 45 33 03 04 0D 0A

FUNCTION

Select international character set

CODE <ESC> “N n1n2” <LF><NUL>

HEX

REMARKS

1B 4E n1n2 0A 00

This command defines temporary change of the international

character set.

For permanent change of the international character set, change

memory switch settings by using<ESC> “#”.

n1n2

Country

00 U.S.A

01 France

02 Germany

n1n2

Country

12 Latin America

n1n2

Country

03 UK

04 Denmark #1

05 Sweden

n1n2

06 Itary

07 Spain #1

08 Japan

Country

n1n2

Country

09 Norway

10 Denmark #2

11 Spain #2

EXAMPLE

Select Spain #2 Character set.

LPRINT CHR$(&H1B);“N11”;CHR$(&H0A);CHR$(&H00);

– 47 –

Page 51

FUNCTION

CODE

HEX

REMARKS

Register download character

<ESC> “F n1n2 ; d1.…d48”<LF><NUL>

1B 46 n1n2 3Bd1.…d480A 00

This command defines one download character.

n1n2 :Download character reference number.(00 to 31).

d1.…d48 :Character bit map data.

Note: a) Only standard size character (16 (W) × 24 (H) dots)

can be defined as download characters.

b) Data consists of 48 bytes (2 bytes × 24) and defined

in the same way as bit image data:

c) If “;” is missing, printer goes into an error condition.

MSB LSB MSB LSB

d1

d3

d5

d7

d9

d2

d4

d6

d7

d10

PAGE MODE

d45

d47

EXAMPLE

In this example data d1,d2,d3,.…

LPRINT

CHR$(&H1B);“F00”;CHR$(&H21);CHR$(&HC0);CHR$(&H32);

CHR$(&H20).…;CHR$(&H0A);CHR$(&H00)

FUNCTION

CODE <ESC> “Z n” <LF><NUL>

HEX

REMARKS

Select “zero” style

1B 5A n 0A 00

This command selects zero style, normal zero slashed zero.

n=0 : Select normal zero.

n=1 : Select slashed zero.

EXAMPLE

Select normal zero.

LPRINT CHR$(&H1B);“Z0”;CHR$(&H0A);CHR$(&H00);

d46

d48

– 48 –

Page 52

TUP400 Only

FUNCTION

CODE

HEX

REMARKS

PAGE MODE

<SOH> <STX> “NA” <ETX> <EOT> <CR> <LF> 01 02 4E 41 03 04 0D 0A Inside near-

<SOH> <STX> “NB” <ETX> <EOT> <CR> <LF> 01 02 4E 42 03 04 0D 0A Outside near-

<SOH> <STX> “E3” <ETX> <EOT> <CR> <LF> 01 02 45 35 03 04 0D 0A Page Empty

<SOH> <STX> “E5” <ETX> <EOT> <CR> <LF> 01 02 45 35 03 04 0D 0A Paper was fed

<SOH> <STX> “E6” <ETX> <EOT> <CR> <LF> 01 02 45 36 03 04 0D 0A Presenter paper

<SOH> <STX> “E0” <ETX> <EOT> <CR> <LF> 01 02 45 30 03 04 0D 0A None of the

Request status

<EOT>

04

When the printer receives this command, the printer sends back a

status byte for the current printer condition immediately to the

host.

Note: Printer conditions are reported by the following status

bytes:

Data HEX Condition

end

end

from presenter

jam error

above

Note: When more than one printer condition exists, the printer

sends each status byte separated by a comma.

Inside near-end, Outside near-end: <SOH> <STX>

“NA”,“NB” <ETX> <EOT> <CR> <LF>

EXAMPLE

LPRINT CHR$(&H04);

If the printer is in a condition of “Inside near-end, Outside nearend” then the printer returns the following codes to the host.

CODE <SOH> <STX> “NA” , “NB” <ETX> <EOT> <CR> <LF>

HEX 01 02 4E 41 2B 4E 42 03 04 0D 0A

– 49 –

Page 53

7-4. Appendix

How to set various bar codes

Refer to the industry standards reference material for the features and applications of each bar code symbology.

This section of this document covers the proper commands to select the bar code

symbology required.

(1) CODE 39

CODE 39 can represent numeric characters from 0 to 9 and alphabetical

characters A to Z. Width of each bar of bar code depends on the mode.

The number of dots for each element of the bar code in each mode is shown as

below. The number of dots depends on whether the print direction is horizontal

or vertical.

1) Length of each element in each mode

a) Horizontal printing

Item

Width of narrow

elements

Width of wide

elements

Ratio

Inter-character

space

Length of one

character (mm)

Mode 1Mode 2 Mode 3 Mode 4 Mode 5 Mode 6 Mode 7 Mode 8 Mode 9

2 dots 3 dots 4 dots 2 dots 3 dots 4 dots 2 dots 3 dots 4 dots

6 dots 9 dots 12 dots 5 dots 8 dots 10 dots 4 dots 6 dots 8 dots

1 : 3 1 : 3 1 : 3 1 : 2.5 1 : 2.7 1 : 2.5 1 : 2 1 : 2 1 : 2

2 dots 3 dots 4 dots 2 dots 3 dots 4 dots 2 dots 3 dots 4 dots

4 6 8 3.625 5.625 7.25 3.25 4.875 6.5

b) Vertical printing

In vertical printing, one dot is added to each white bar which is horizontally

printed. (This is because the width of black bars is made wider due to the

change of printing characteristics caused by heating of the printing head. As

a result, the number of dots for white bars and for black bars are different

even when white and black bars have the same narrow-element width.

Length of each element is as shown below.

Item

Length of one

character (mm)

Mode 1Mode 2 Mode 3 Mode 4 Mode 5 Mode 6 Mode 7 Mode 8 Mode 9

4.625 6.625 8.625 4.25 6.25 7.875 3.875 5.5 7.125

PAGE MODE

– 50 –

Page 54

2) REQUIREMENTS

a) The Start code and the Stop code of CODE 39 are automatically added.

b) The position defined by the control command locates the bar code symbols.

It is necessary to provide space for a quiet zone for bar code symbol.

3) ANSI and AIM specifications (for reference only)

a) Width of narrow elements:

Minimum 0.0075 inch (0.191 mm)

b) Ratio of narrow-element width to width-element width:

PAGE MODE

1 : 2.2 (the width of narrow elements is 0.508 mm or smaller)

1 : 2 (the width of narrow elements is 0.508 mm or greater)

c) Inter-element space:

Minimum is the same as the narrow-element width.

Maximum is three times the narrow-element width or 1.524 mm, whichever

is greater.

d) Bar height:

For hand scanners, the minimum is 0.25 inch (6.35 mm) or 15% of the bar

code-length, whichever is greater.

For non-hand scanners, the minimum is 0.8 inch (20.3 mm) or 25% of the

bar code-length, whichever is greater.

e) Quiet zone:

Minimum is ten times the narrow-element width or 0.10 inch (2.54 mm),

whichever is greater.

For hand scanners, the minimum is 0.25 inch (6.35 mm) or greater.

EXAMPLE Bar code string number 11 ,starting position of bar code (X,Y)

= 10 mm, 10 mm, use Mode 2 of CODE39, Bar code height

10mm data:ABCDEFG, bar code rotation direction 0 degree.

LPRINT CHR$(&H1B);“PB11;0100;0100,2,1,0,0100”;

CHR$(&H0A);CHR$(&H00);

LPRINT CHR$(&H1B);“RB11;ABCDEFG”;CHR$(&H0A);

CHR$(&H00);

– 51 –

Page 55

(2) Interleaved 2 of 5 (ITF)

This code can represent numeric characters from 0 to 9. This code can be used for

an application that requires higher character density.

JIS and EAN specify that this code be used for printing on corrugated boxes.

1) Width of narrow elements and length of two characters

a) Horizontal printing

Item

Width of narrow

elements

Width of wide

element

Ratio

Length of one

character (mm)

Mode 1Mode 2 Mode 3 Mode 4 Mode 5 Mode 6 Mode 7 Mode 8 Mode 9

2 dots 4 dots 6 dots 2 dots 4 dots 6 dots 2 dots 3 dots 4 dots

5 dots 10 dots 15 dots 4 dots 8 dots 12 dots 6 dots 9 dots 12 dots

1 : 2.5 1 : 2.5 1 : 2.5 1 : 2 1 : 2 1 : 2 1 : 3 1 : 3 1 : 3

4 8 12 3.5 7 10.5 4.5 6.75 9

b) Vertical printing

Item

Length of two

character (mm)

Mode 1Mode 2 Mode 3 Mode 4 Mode 5 Mode 6 Mode 7 Mode 8 Mode 9

4.625 8.625 12.625 4.125 7.625 11.125 5.125 7.375 9.625

2) REQUIREMENTS

a) When this code is used, the start and stop patterns are automatically

inserted.

b) When the number of digits for bar code data is an odd number, the printer

automatically adds “0” in the highest digit position.

c) Details conform to the AIM, USS-12/5, ANSI, and JIS X 0502 specifica-

tions

PAGE MODE

EXAMPLE Bar code string number 25, starting position of bar code (X, Y)

= 5 mm, 10 mm, use Mode 1 of ITF, Bar code height 10 mm

Data: 0123456, bar code rotation direction 0 degree

LPRINT CHR$(&H1B);“PB25;0050,0100,1,2,0,0100”;

CHR$(&H0A); CHR$(&H00);

LPRINT CHR$(&H1B);“RB25;0123456”; CHR$(&H0A);

CHR$(&H00);

– 52 –

Page 56

(3) CODE 93

1) Each mode and module width

a) Horizontal printing

Item

Module width

Width of one

character (mm)

Mode 1Mode 2 Mode 3

2 dots 3 dots 4 dots

2.25 3.375 4.5

Note: The start and stop bars are not included.

PAGE MODE

b) Vertical printing

Module width

Width of one

character (mm)

2) REQUIREMENTS

a) The start and stop patterns are automatically inserted.

b) The check characters are automatically inserted.

c) 2-character set codes are same as CODE 128. (Expect FNC1-4, and START

A-C)

EXAMPLE Bar code number 00, starting position of bar code (X, Y) = 40

Item

Mode 1Mode 2 Mode 3

2 dots 3 dots 4 dots

2.625 3.75 4.875

mm, 16 mm Mode 2 of CODE 93, Bar code rotation: 0 degree.

Bar code height 10 mm, Data “ABCDefg”

LPRINT CHR$(&H1B);“PB00;0400,0160,2,3,0,0100”;

CHR$(&H0A);CHR$ (&H00);

LPRINT CHR$(&H1B);“RB00;ABCDefg”;

CHR$(&H0A);CHR$ (&H00);

– 53 –

Page 57

(4) UPC (5) JAN/EAN-8 (6) JAN/EAN-13

These codes are common commodity codes, mainly used for miscellaneous

goods or groceries sold at supermarkets.

1) Each mode and bar code width

a) Horizontal printing

Item

Module width

Bar code width

JAN/EAN-8

JAN/EAN-13, UPC

Mode 1 Mode 2 Mode 3

2 dots 3 dots 4 dots

16.75 mm 25.125 mm 33.5 mm

23.75 mm 36.625 mm 47.5 mm

Note: Right and left guard bars are included, white spaces are not included.

b) Vertical printing

Item

Module width

Bar code width

JAN/EAN-8

JAN/EAN-13, UPC

Mode 1 Mode 2 Mode 3

2 dots 3 dots 4 dots

13.375 mm 27.75 mm 36.125 mm

27.624 mm 39.5 mm 51.375 mm

Note: Right and left guard bars are included, white spaces are not included.

2) REQUIREMENTS

a) JAN/EAN-8

Must consist of a 7 or 8 numeric digits, otherwise, the command is ignored.

The check digit is automatically added using modules 10/3 weight.

When the calculated value and the value in the 8th digit differ, the former

value has precedence over the latter values.

b) JAN/EAN-13

Must consist of a 12 or 13 numeric digits; otherwise, the command is

ignored. The check digit is automatically added using modules 10/3 weight.

When the calculated value and the value in the 13th digit differ, the former

value has precedence over the latter values.

c) UPC-A Must consist of a 11 or 12 numeric digits, otherwise, the command

is ignored. The check digit is automatically added using modules 10/3

weight.

When the calculated value and the value in the 12th digit differ, the former

value has precedence over the latter values.

– 54 –

PAGE MODE

Page 58

EXAMPLE Bar code string number 10, starting position of bar code (X, Y)

= 5 mm, 10 mm, use Mode 1 of EAN-13, Bar code height 10 mm

data:246801357956, bar code rotation direction 0 degree

LPRINT CHR$(&H1B);“PB10;0050,0100,1,6,0,0100”;

CHR$(&H0A);CHR$(&H00);

LPRINT CHR$(&H1B);“RB10;246801357956”;

CHR$(&H0A);CHR$(&H00);

(7) CODE 128

This code can represent 128 ASCII characters.

PAGE MODE

1) Each mode and module width

a) Horizontal printing Note: The start and stop bars are not included.

Item

Module width

Width of one

character

Mode 1 Mode 2 Mode 3

2 dots 3 dots 4 dots

2.75 mm 4.125 mm 5.5 mm

b) Vertical printing

Item

Module width

Width of one

character

Mode 1 Mode 2 Mode 3

2 dots 3 dots 4 dots

3.125 mm 4.5 mm 6.5 mm

2) REQUIREMENTS

%(25 H) is sent as data %0(25H 35H). Control codes 00H to 1FH and 7FH are

sent as data % followed by 40H to 5FH and 35 H. For example, control code 7FH

is sent as data %5 (25H 35H). Function codes are sent as data % followed by 1

to 4 (31H to 34H). The start code is sent as data % followed by 6 to 8(36H to 38H).

Although CODE 128 data requires START CODE, the printer automatically adds

START CODE. Please omit START CODE when sending data to the printer.

– 55 –

Page 59

3) 2-character set codes

Control codes

Code HEX Format HEX

NUL 00H %@ 25H 40H

SOH 01H %A 25H 41H

STX 02H %B 25H 42H

ETX 03H %C 25H 43H

EOT 04H %D 25H 44H

ENQ 05H %E 25H 45H

ACK 06H %F 25H 46H

BEL 07H %G 25H 47H

BS 08H %H 25H 48H

HT 09H %I 25H 49H

LF 0AH %J 25H 4AH

VT 0BH %K 25H 4BH

FF 0CH %L 25H 4CH

CR 0DH %M 25H 4DH

SO 0EH %N 25H 4EH

SI 0FH %O 25H 4FH

DLE 10H %P 25H 50H

DC1 11H %Q 25H 51H

DC2 12H %R 25H 52H

DC3 13H %S 25H 53H

DC4 14H %T 25H 54H

NAK 15H %U 25H 55H

SYN 16H %V 25H 56H

ETB 17H %W 25H 57H

CAN 18H %X 25H 58H

EM 19H %Y 25H 59H

SUB 1AH %Z 25H 5AH

ESC 1BH %[ 25H 5BH

FS 1CH %× 25H 5CH

GS 1DH %] 25H 5DH

RS 1EH %^ 25H 5EH

US 1FH % 25H 5FH

DEL 7FH %5 25H 35H

Special code

Code HEX Format HEX

% 25H %0 25H 30H

Function codes

Code HEX Format HEX

FNC1 %1 25H 31H

FNC2 %2 25H 32H

FNC3 %3 25H 33H

FNC4 %4 25H 34H

Start codes

Code HEX Format HEX

START A

START B

START C

%6 25H 36H

%7 25H 37H

%8 25H 38 H

EXAMPLE Bar code string number 00, starting position of bar code (X, Y)

= 15 mm, 5 mm, use Mode 1 of CODE128, Bar code height 15

mm, data: 1213477657, and CR (carriage return)

LPRINT CHR$(&H1B);“PB00;0150,0050,1,7,0150”;

CHR$(&H0A);CHR$(&H00);

LPRINT CHR$(&H1B);“RB00;1213477657%M”;

CHR$(&H0A);CHR$(&H00);

– 56 –

PAGE MODE

Page 60

(8) NW-7

NW-7 bar code can represent numeric characters 0 to 9 and special characters

such as - , $ , : , / , . , + with one of character from A to D as Start or Stop code

in NW-7.

1) Width of character in each mode

Width of each bar code character varies since number of narrow bars and wide

bars are different in each character.

Normal character

(number of narrow element : 5 , number of wide element : 2)

0 to 9 , $ , -

PAGE MODE

Wide character

(number of narrow element : 4 , number of wide element : 3)

: , / , . , + , A to D

Length of each bar code character includes a space between characters.

a) Horizontal direction print

Item

Width of narrow

elements

Width of wide

element

Ratio

Space between

characters

Length of

each character

(Normal)(mm)

(Wide)(mm)

Mode 1Mode 2 Mode 3 Mode 4 Mode 5 Mode 6 Mode 7 Mode 8 Mode 9

2 dots 3 dots 4 dots 2 dots 3 dots 4 dots 2 dots 3 dots 4 dots

6 dots 9 dots 12 dots 5 dots 8 dots 10 dots 4 dots 6 dots 8 dots

1 : 3 1 : 3 1 : 3 1 : 2.5 1 : 2.7 1 : 2.5 1 : 2 1 : 2 1 : 2

2 dots 3 dots 4 dots 2 dots 3 dots 4 dots 2 dots 3 dots 4 dots

3 4.5 6 2.75 4.25 5.5 2.5 3.75 5

3.5 5.25 7 3.125 5.125 6.25 2.75 4.125 5.5

b) Vertical direction print

Item

Length of

each character

(Normal)(mm)

(Wide)(mm)

Mode 1Mode 2 Mode 3 Mode 4 Mode 5 Mode 6 Mode 7 Mode 8 Mode 9

3.5 5 6.5 3.25 4.75 6 3 4.25 5.5

4 5.75 7.5 3.625 5.625 6.75 3.25 4.625 6

– 57 –

Page 61

7-5. Sample Program

==SAMPLE PROGRAM==

’This sample program (SAMPLE1.BAS) is included in a floppy disk comes with the

TSP400 printer.

’——<< SAMPLE1.BAS >>——

E$=CHR$(27): LN$ = CHR$(10) + CHR$(0): A$ = DATE$

OPEN “COM1:9600,N,8,1,CS0,DS0”FOR RANDOM AS #1 :’For Serial I/F COM1: