Page 1

THERMAL PRINTER

TSP200 Series

TECHNICAL MANUAL

[SECOND EDITION]

Page 2

NOTICE

• All rights reserved. Reproduction of any part of this manual in any form whatsoever,

without STAR’s express permission, is strictly forbidden.

• The contents of this manual are subject to change without notice.

• All efforts have been made to ensure the accuracy of the contents of this manual at the time

of printing. However, should any errors be found, STAR would greatly appreciate being

informed of them.

• The above notwithstanding, STAR can assume no responsibility for any errors in this

manual.

© Copyright 1997 Star Micronics Co., LTD.

Page 3

INTRODUCTION

This manual describes the thermal printer TSP200 series.

It is designed for use as a reference for periodic inspections and maintenance procedures to be executed by

service personnel. It is not intended for the general user. Users of this manual should have a basic knowledge

and understanding of the English language.

• This manual is comprised of the following chapters.

Chapter 1 Specifications and Operation

Chapter 2 Theory of Operation

Chapter 3 Parts Replacement and Related Adjustments

Chapter 4 Maintenance and Lubrication

Chapter 5 Parts Lists

• First edition : Mar. 1997

Second edition : Aug. 1999

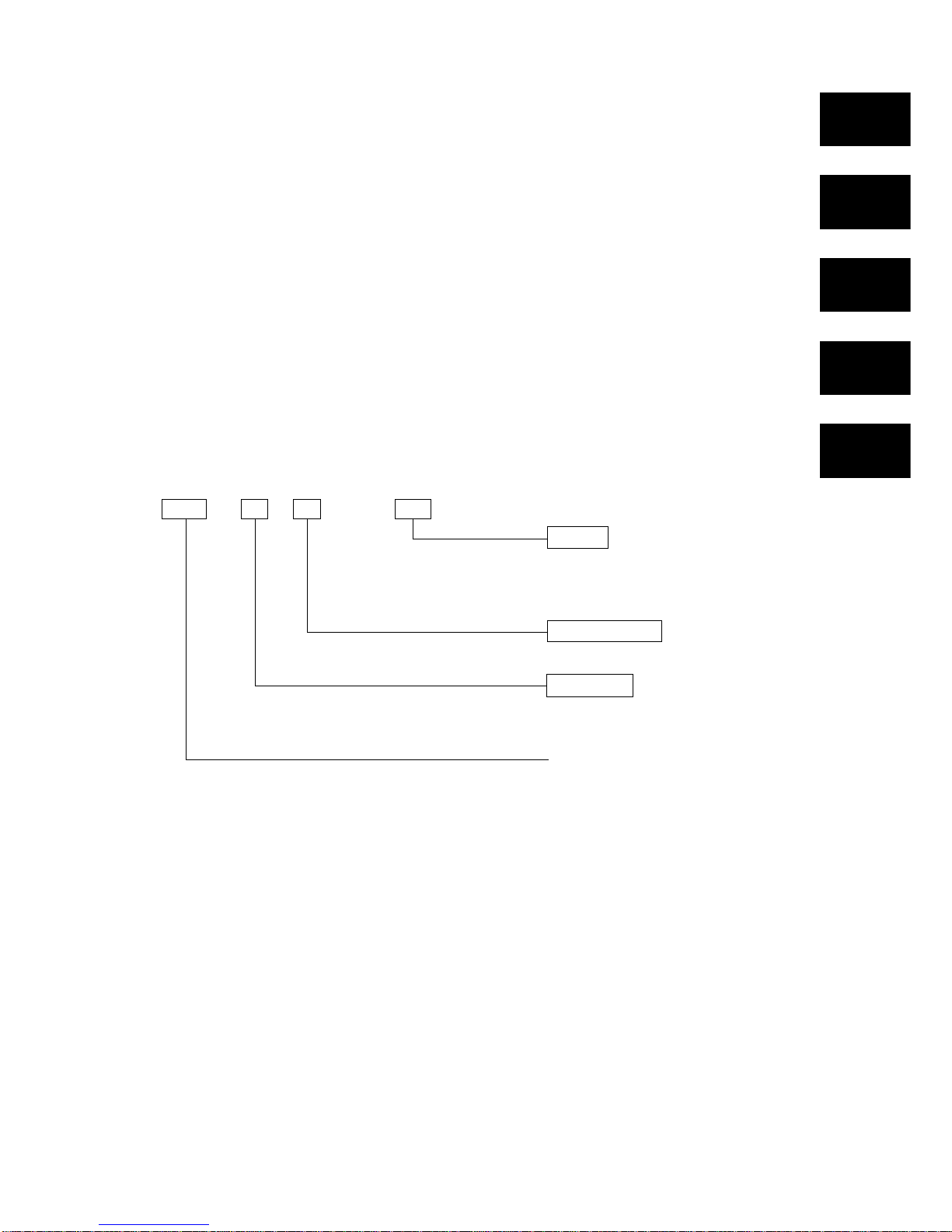

■ Model Name

TSP 2 1 2 — 120

Voltage

24 : 24VDC

120 : 120VAC

230 : 230VAC

Mechanism type

2: 48 columns

Printer type

1: Standard

4: With auto-cutter

TSP200-series thermal printer

5

1

4

3

2

Page 4

Page 5

CHAPTER 1

SPECIFICATIONS AND OPERATION

1. General Specifications..........................................................................................3

2. External Appearance.............................................................................................4

3. DIP-Switch Settings ..............................................................................................5

4. Using the control panel to adjust the sensors, select the head rank, and set

the memory switches............................................................................................

6

5. Running a test print ..............................................................................................8

6. HEX dump mode....................................................................................................8

1

Page 6

– 2 –

SPECIFICATIONS AND OPERATION

Page 7

– 3 –

SPECIFICATIONS AND OPERATION

158mm

193mm

234mm(TSP242-120/230)

239mm(TSP242-24)

158mm

193mm

234mm(TSP212-120/230)

239mm(TSP212-24)

(TSP212) (TSP242)

Fig. 1-1 External Dimensions

1. General Specifications

Printing method Line thermal direct

Resolution 8 dots/mm (H) × 8 dots/mm (V)

Printable width 72 mm

Printing speeds 50 mm/sec (max.)

Printable characters ANK, International

Bar codes JAN, EAN, UPC, Code 39, ITF, Code 128, Code 93, NW-7

Character matrix 12 × 24 dots

Interfaces RS-232C, Parallel

Dimensions TSP212-120/230 : 158(W) × 234(D) × 193(H) mm

TSP242-120/230 : 158(W) × 234(D) × 193(H) mm

TSP212-24 : 158(W) × 239(D) × 193(H) mm

TSP242-24 : 158(W) × 239(D) × 193(H) mm

Weight TSP212-120/230 : 2.8kg

TSP242-120-230 : 3.0kg

TSP212-24 : 1.8kg

TSP242-24 : 2.0kg

AC adapter : 350g

AC cable : 150g

Power AC120V, AC230V, DC24V

Power consumption Max. 43 W Avg. 19W (During continuous printing of ASCII characters)

Operating environment +5˚C ~ +40˚C

25% ~ 85% RH

Storage environment –20˚C ~ +60˚C

10% ~ 90% RH

Automatic paper cutter

Life 300, 000 cuts

Min. cut length 25.4mm (1 inch)

Page 8

– 4 –

SPECIFICATIONS AND OPERATION

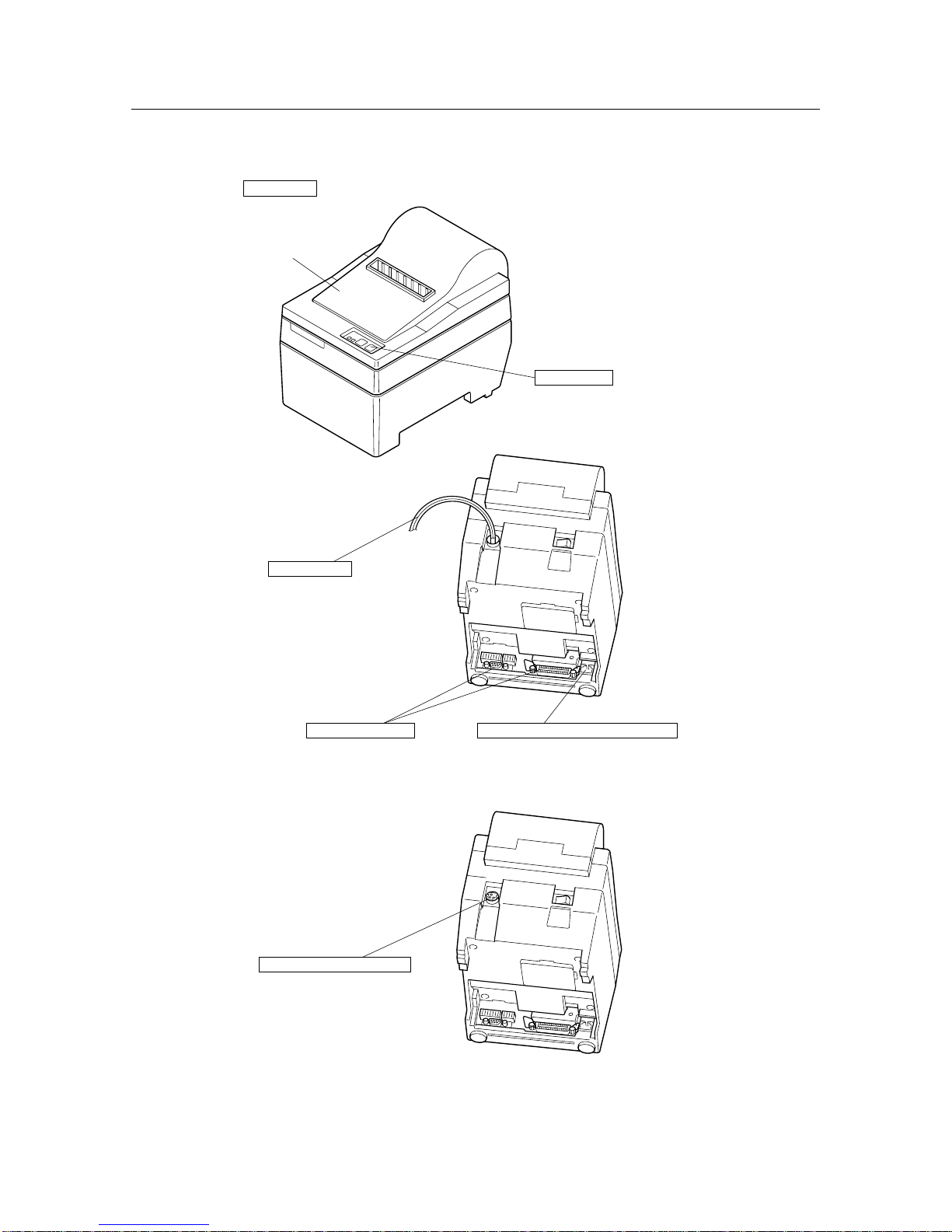

Features two control

switches and two

indicators to indicate

printer status.

Control panel

Plugs into an outlet of

the specified voltage.

Shape of AC power plug

will vary according to

destinations.

AC power cord

Connects the printer

with host computer.

Interface connector

Connects to peripheral units such

as cash drawers, etc.

Do not connect this to a telephone.

Peripheral unit drive circuit connector

Protects the printer from

dust and reduces noise.

Do not open the cover

while printing.

Printer cover

[ TSP200-120/230 ]

2. External Appearance

Fig. 1-2 External Appearance

For connection of the AC adapter.

Never unplug the AC adapter

while the printer is on.

AC adapter cable connector

[ TSP200-24 ]

Page 9

– 5 –

SPECIFICATIONS AND OPERATION

8141

ON

OFF

DIP switch 1

DIP switch

DIP switch 2

Power off

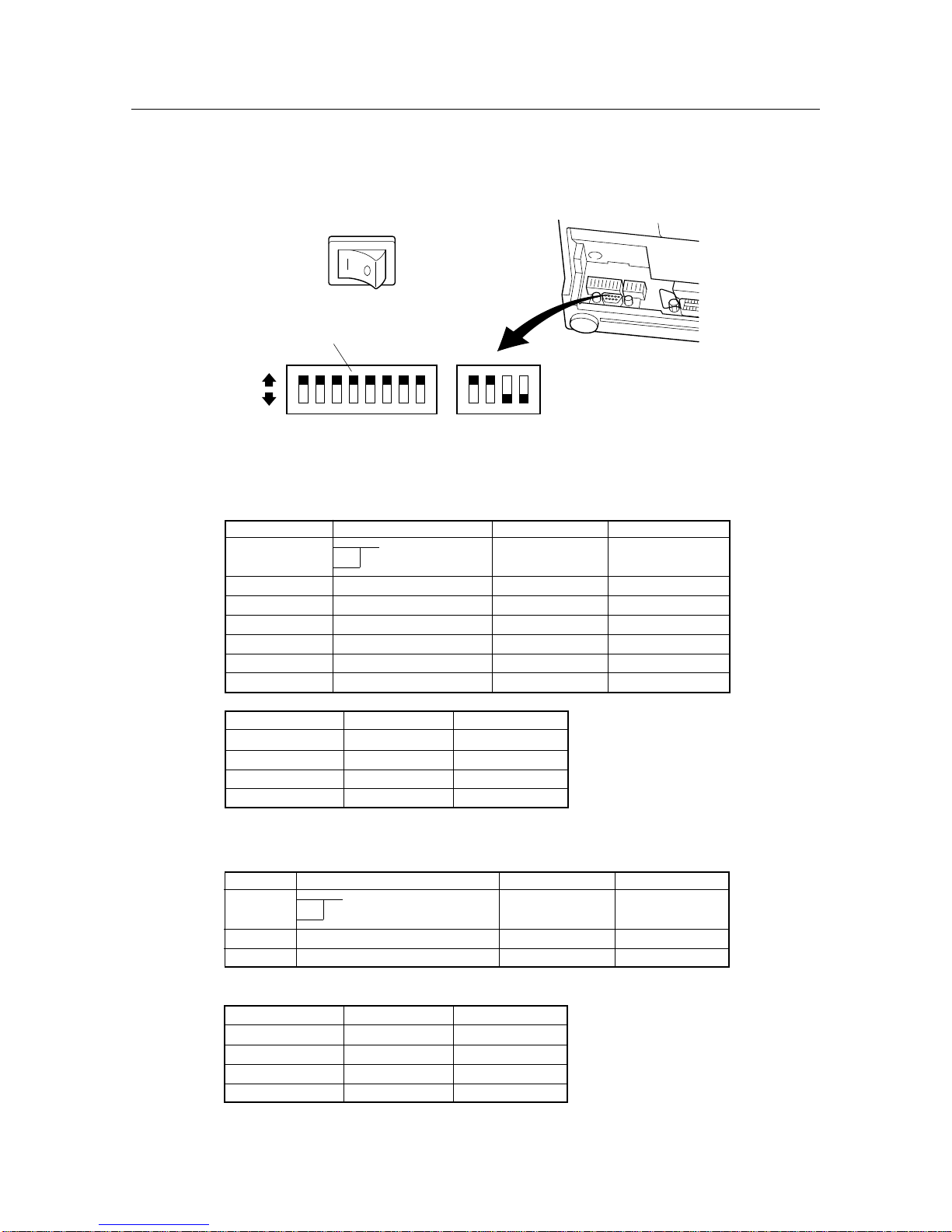

3. DIP-Switch Settings

Be sure to turn the power to both the printer and host computer off before changing the setting of the DIP

switches.

Fig.1-3 DIP switch array

DIP switch #1

The factory settings of DIP switch 1 are all on.

Switch Contents ON OFF

1-1 Baud Rate

1-2

1-3 Data Length 8 bit 7 bit

1-4 Parity Check Disabled Enabled

1-5 Parity Selection Odd Even

1-6 Handshake DTR/DSR XON/XOFF

1-7 Operating Mode Star ESC/POS

1-8 Interface RS232C Parallel

Baud Rate 1-1 1-2

2400BPS OFF OFF

4800BPS ON OFF

9600BPS ON ON

19200BPS OFF ON

DIP Switch #2

Factory settings: 2-1 and 2-2 are on; 2-3 and 2-4 are off.

Switch Contents ON OFF

2-1 Print Density

2-2

2-3 Serial I/F No. 6 Pin Reset Signal Enabled Disabled

2-4 Serial I/F No. 9 Pin Reset Signal Enabled Disabled

Print Density 2-1 2-2

Light OFF OFF

Standard ON ON

Somewhat Heavy ON OFF

Heavy OFF ON

Page 10

– 6 –

SPECIFICATIONS AND OPERATION

Buzzer beeps 1 time.

Press both

switches.

Start

Buzzer beeps twice.

Buzzer beeps 3 times.

Buzzer beeps 4 times.

Buzzer beeps 5 times.

Release within 2 seconds.

Enters "Adjust Paper-Out Sensor" mode.

Release within 2 seconds.

Enters "Adjust Paper-Near-End Sensor"

mode.

Continue to

hold down.

Both switches

Release within 2 seconds.

Enters "Set Head Rank" mode.

Continue to

hold down.

Both switches

Release within 2 seconds.

Resets, then executes test print.

Continue to

hold down.

Both switches.

Release within 2 seconds.

Enters "Set Memory Switches" mode.

Continue to

hold down.

Both switches

Continue to

hold down.

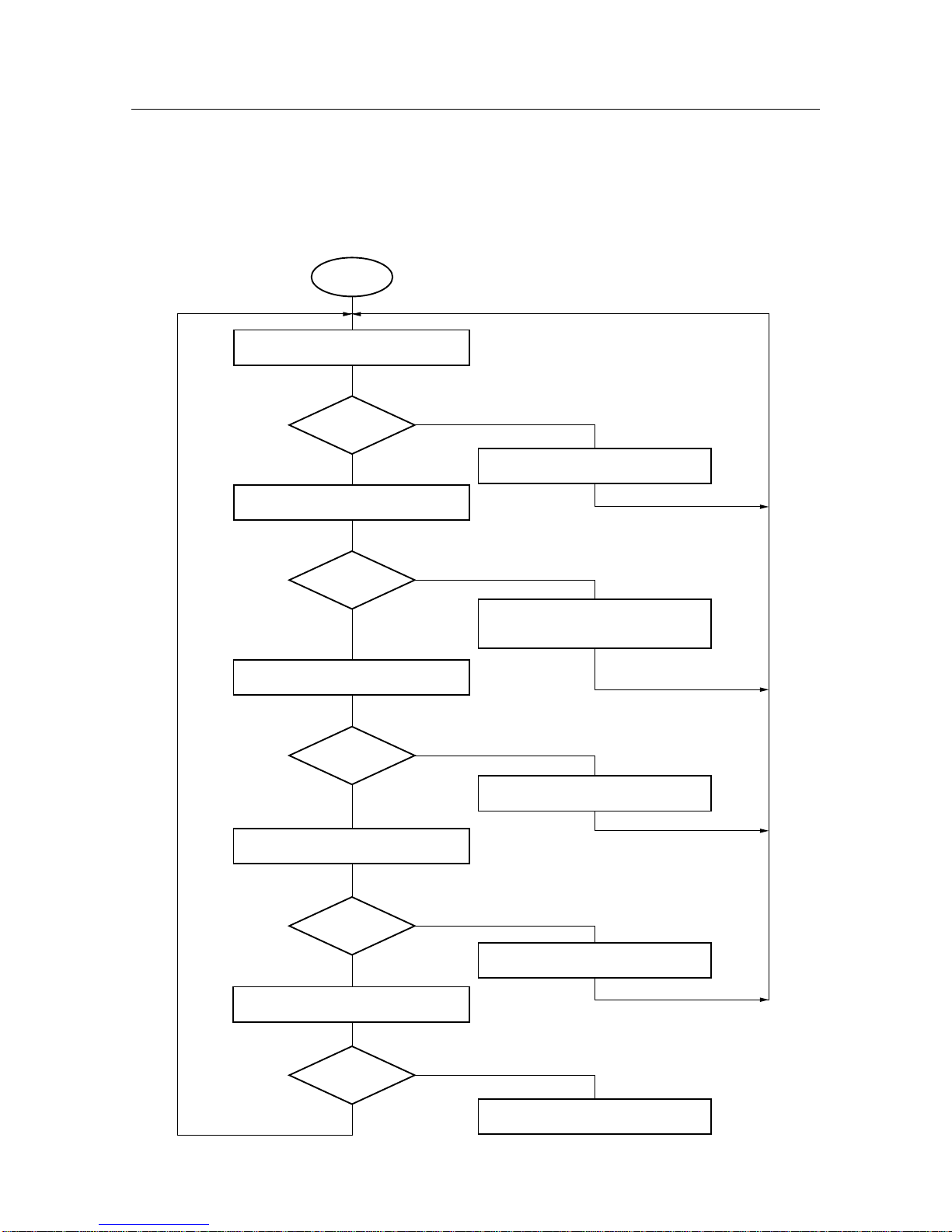

4. Using the control panel to adjust the sensors, select the head rank, and set the

memory switches.

Hold down the FEED and ONLINE switches while setting power on, then continue to hold the switches down for the time

necessary to enter the required mode, as indicated below.

Page 11

– 7 –

SPECIFICATIONS AND OPERATION

(1) “Adjust Paper-Out Sensor” mode.

Adjustment is not necessary if the ONLINE lamp is ON when you enter this mode. If the lamp is OFF, the turn VR1

clockwise until it the lamp comes ON.

To exit this mode, press ONLINE. To move back to the start of the sequence, press both ONLINE and FEED at the same

time.

Please be sure that paper is inserted before entering this mode.

(2) “Adjust Paper-Near-End Sensor” mode

When you enter this mode, the POWER lamp will be lit if the near-end sensor is detecting paper. The lamp will be off

if no paper is detected.

To exit the mode, press ONLINE. To move back to the start of the sequence, press both ONLINE and FEED at the same

time.

(3) “Set Head Rank” mode

When you enter the mode, the ONLINE and POWER lamps will both be OFF. Press the FEED switch as necessary to

select the desired rank. The rank is indicated by the ONLINE and POWER lamp pattern, which changes each time you

press the switch. The change sequence is indicated below. (Note that you can move back to the start of the sequence by

pressing the ONLINE and FEED switches at the same time.)

ONLINE lamp FEED lamp Head Rank

OFF OFF A

OFF ON B

ON OFF C

ON ON C

(4) “Set Memory Switches” mode

1 When you first enter this mode, memory switch 0 is selected. You can change the selection by pressing FEED

as many times as necessary. Specifically, the selection cycle is 0 -> 1 -> 2 -> 3 -> 4 -> 0 -> 1 ->... In other words,

press 0 times to select Switch 0, 1 time to select Switch 1, and so on.

2 Press ONLINE once to confirm your selection. The buzzer beeps one time in response.

3 Set a value for each bit in turn, starting from Bit F and proceeding sequentially to Bit 0. Note that the lamps

indicate each bit’s current value: ONLINE lamp ON means that the current value is “1”, while POWER lamp

ON means that the current value is “1”.

To set to 0: Press FEED. (The buzzer will beep once.)

To set to 1: Press ONLINE. (The buzzer will beep once.)

When you complete setting of Bit 0, the buzzer will beep again.

4 When you have set all bit values and are ready to enter the new value, press the ONLINE switch. The buzzer

beeps once and the value is written to memory.

If you wish to cancel your changes, press the FEED switch instead. The buzzer will beep twice and the process

will return to the beginning of Step (3) above.

5 Press the ONLINE and FEED switches at the same time to move back to the start of the sequence.

Page 12

– 8 –

SPECIFICATIONS AND OPERATION

5. Running a test print

To generate a test print, hold down the FEED switch while setting the power on.

6. HEX dump mode

To enter HEX dump mode, hold down the ONLINE switch while setting the power on, and then release the switch after

the buzzer beeps once.

When this mode is active, all data sent from the host will be printed in HEX form.

Page 13

CHAPTER 2

PRINCIPLES OF OPERATION

This chapter describes the operating principles of the circuitry and printer mechanism.

1. Block Diagram .....................................................................................................11

2. Interface ...............................................................................................................13

2-1. Interface Types ..................................................................................................... 13

2-1-1. RS232 interface ................................................................................................ 13

2-1-2. Parallel interface............................................................................................... 14

2-2. Data Arrangement and Printing........................................................................... 15

2-2-1. Arrangement ..................................................................................................... 15

2-2-2. Thermal printhead ............................................................................................ 15

2-2-3. Head current control ........................................................................................ 16

2-2-4. Head current control ........................................................................................ 18

2-2-5. Head burnout protection ................................................................................. 18

2-3. Feed-Motor Drive Circuit...................................................................................... 19

2-4. Power-On Reset Circuit ....................................................................................... 21

2-5. +5V Line Voltage Detector Circuit ....................................................................... 22

3. Printer Mechanism .............................................................................................. 23

3-1. Thermal Printhead ................................................................................................ 23

3-2. Paper-Feed Mechanism ....................................................................................... 23

3-3. Detectors ............................................................................................................... 24

3-4. Auto-Cutter Drive circuit (on TSP242-24/120/230 only) .................................... 25

2

Page 14

– 10 –

PRINCIPLES OF OPERATION

Page 15

– 11 –

PRINCIPLES OF OPERATION

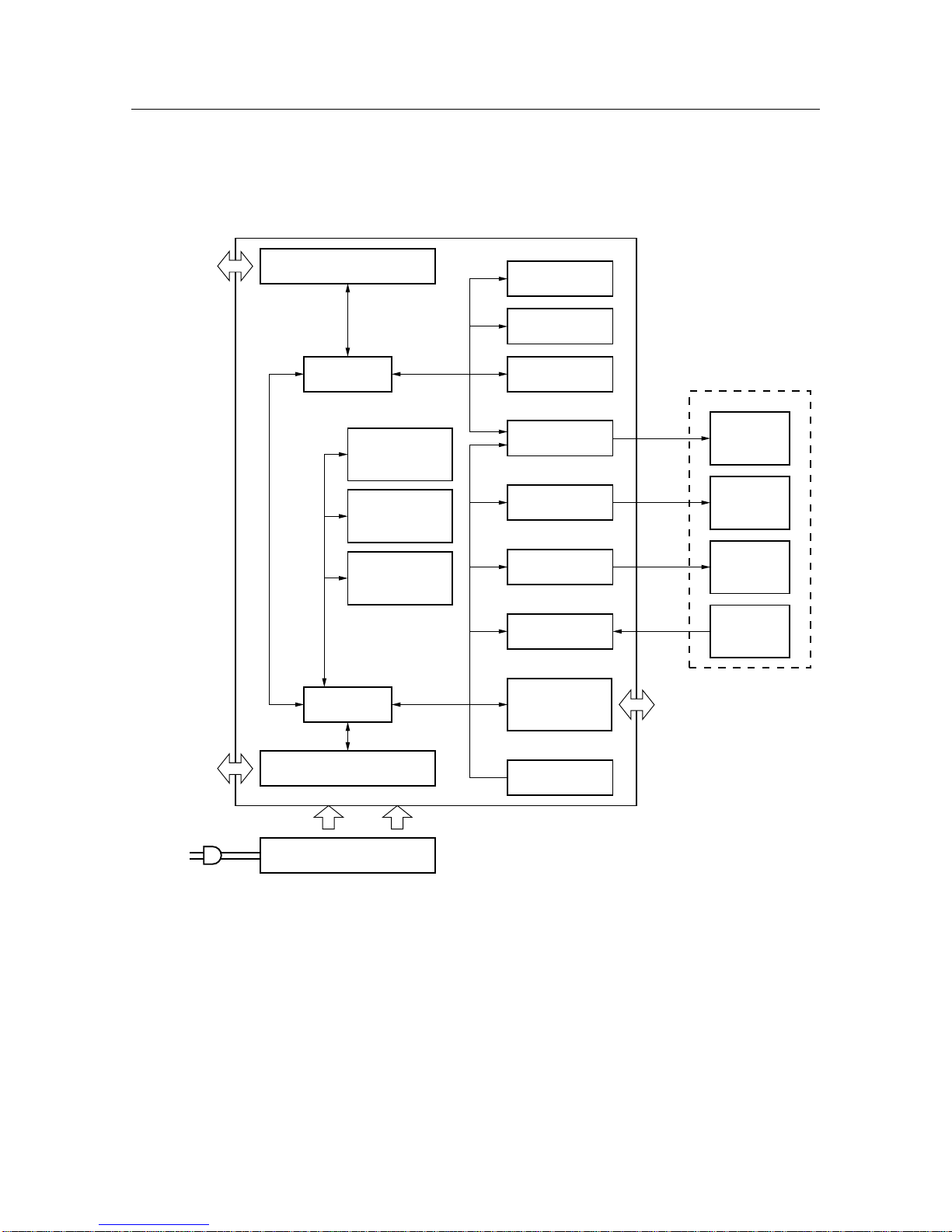

1. Block Diagram

The following diagram illustrates the relation between the main logic board and its peripherals.

Fig. 2-1 Block Diagram

Host computer

Host computer

Parallel I/F

Main Logic Board

RS232C I/F

Gate array

CPU

EEPROM

Head driver

Lamp

Dipswitch

Motor driver

Cutter driver

Sensor circuit

EPROM

256K × 8 bits

PSRAM

128K × 8 bits

Kanji ROM

512K × 8 bits

Peripheral unit

driver

Switch

Thermal

head

Printer mechanism

Paper-feed

motor

Auto-cutter

Sensor

Peripheral unit

5V 24V

Power supply unit

Page 16

– 12 –

PRINCIPLES OF OPERATION

(1) Main Logic Board

The main logic board’s CPU passes data transmitted from the host computer into the local RAM. It then reads the data

from the RAM, arranges it in accordance with the ROM program, and prints the results by issuing appropriate drive signals

to the printer mechanism.

[Block Descriptions]

a. CPU: HD6413002F16

CMOS single-chip computer.

Controls overall printer operation.

b. EPROM: 256K × 8 bits

Stores the CPU control program.

c. PSRAM: 128K × 8 bits

Work area and data buffer.

d. EEPROM: 1024 bits

Stores printer settings. Settings can be changed by software. (Used in place of dip switches.)

e. Interface

Interfaces the main board with the host computer.

Two versions available: RS232C and Centronics.

f. Gate array

Handles signal input, output, and conversions.

g. Drivers

The various drivers convert signals received from the CPU and gate array into drive signals that directly control

the printer mechanism.

(2) Printer Mechanism

Comprised of thermal head, platen, paper-feed motor, auto-cutter, and sensor mechanism.

(3) Power Supply Unit

Converts primary power to DC5V, DC24V.

(4) Peripheral Unit

External device (such as cash drawer) driven by signals issued from the main logic board.

Page 17

– 13 –

PRINCIPLES OF OPERATION

RXD

TXD

DSR

DTR

RTS

FAULT

INIT

CN6

IC10

ADM232LJR

Dipswitch 2-4

IC1 CPU

Dipswitch 2-3

RXD 0

TXD 0

P93

P91

P94

Comparator

TTL

232C

TTL

232C

Comparator

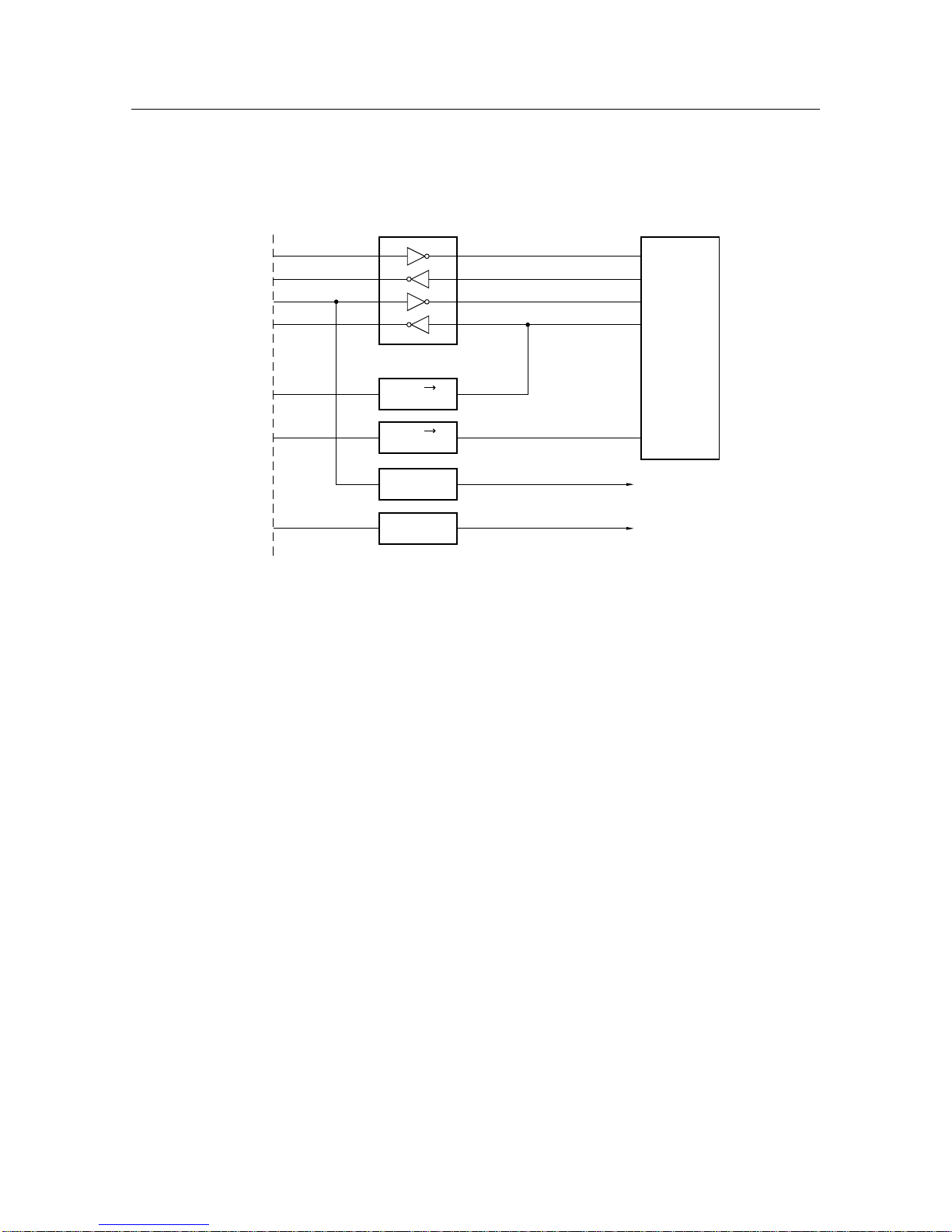

2. Interface

2-1. Interface Types

2-1-1. RS232 interface

Fig. 2-2 Serial Interface

Data flow from host to printer: IC10 receives serial data from the host through RXD, converts the voltage level from

RS232C to TTL, and passes the result to the CPU. The CPU converts the serial data to

parallel form and stores the result into buffer memory.

Data flow from printer to host: The CPU generates the data, converts it into serial form, then passes it to IC10. IC10

converts the level from TTL to RS232C and outputs the result over the TXD line.

Page 18

– 14 –

PRINCIPLES OF OPERATION

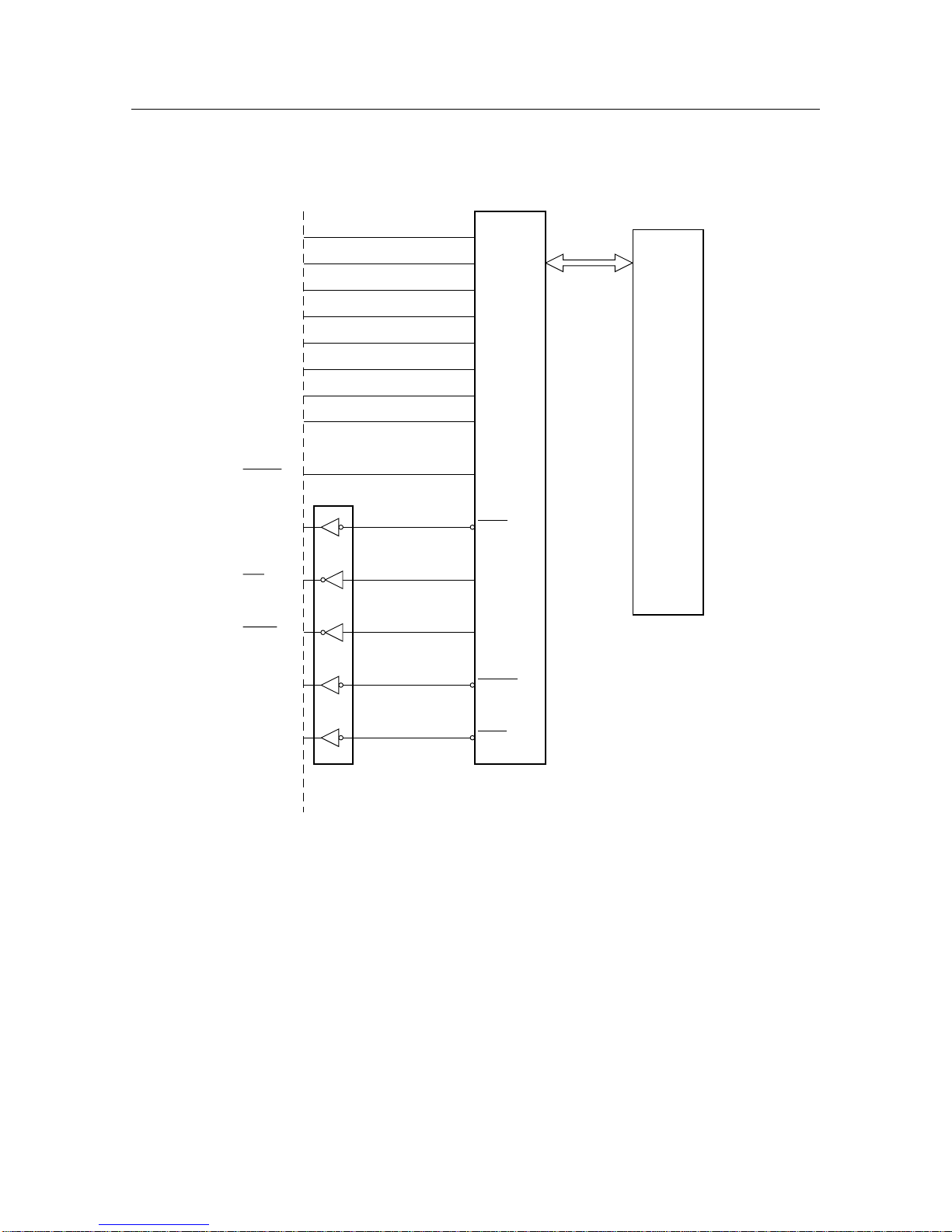

2-1-2. Parallel interface

Fig. 2-3 Parallel interface

When the printer is ready (BUSY is LOW), the host computer transmits eight bits of parallel data (DATA1,...,DATA8)

to CN4. The data passes through the gate array and moves into the CPU.

Printer signals from the CPU (ACK, ERROR, SELECT, PAPER OUT, etc.) pass through the gate array and are output

over the appropriate connector pins.

DATA 1

DATA 2

DARA 3

DATA 4

DATA 5

DARA 6

DATA 7

DATA 8

STROBE

BUSY

ACK

ERROR

SELECT

PAPER OUT

CN4

CPU

IC1

Gate array

IC4

LS05

CD0

CD1

CD2

CD3

CD4

CD5

CD6

CD7

CSTB

BUSY

ACK

ERROR

SELECT

POUT

IC5

Page 19

– 15 –

PRINCIPLES OF OPERATION

2-2. Data Arrangement and Printing

2-2-1. Arrangement

The CPU reads data sequentially from RAM and arranges this data in accordance with program instructions stored in

EPROM. The arranged data is then converted from parallel to serial form. The gate array then outputs the resulting serial

data to the drive controller in the thermal printhead.

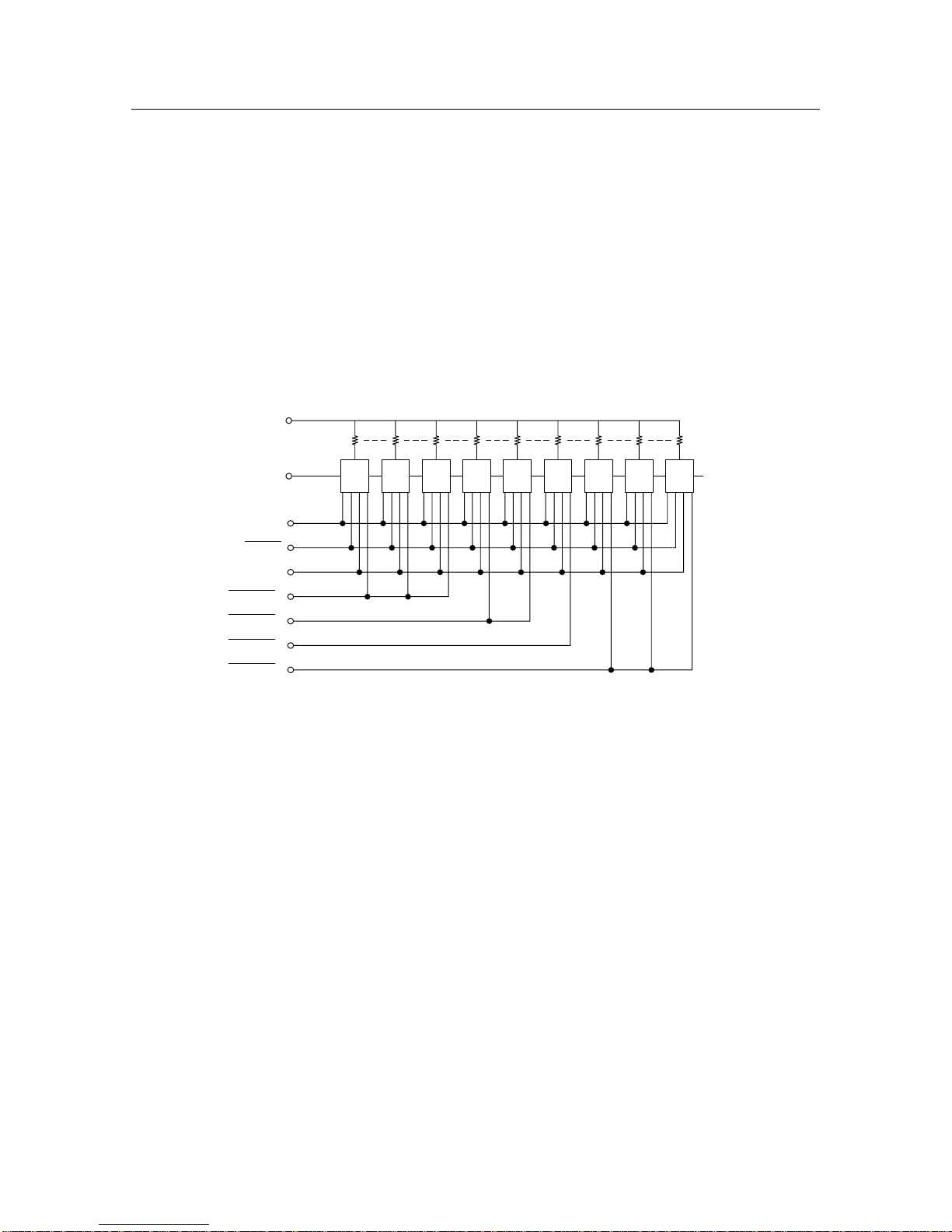

2-2-2. Thermal printhead

The thermal printhead has 576 heat elements. Printing is executed by switching these elements ON and OFF as required.

The printhead contains a built-in dedicated drive controller. The controller consists of shift register, latch circuit, and

driver circuit, as illustrated below. The controller receives serial data (SI) from the gate array in sync with the CLK signal.

It latches this incoming data (by LATCH signal), then outputs the data to the elements in sync with the falling edge of

the STROBE signal. A data value of LOW corresponds to an element value of ON (generating print).

Fig. 2-4 Drive Circuitry of Thermal Printhead

B. E. O

LATCH

CLOCK

STROBE4

STROBE3

STROBE2

STROBE1

V

H

DATE IN

(SI)

SO

R576 R1

1 2 3 4 5 6 7 8 9

Page 20

– 16 –

PRINCIPLES OF OPERATION

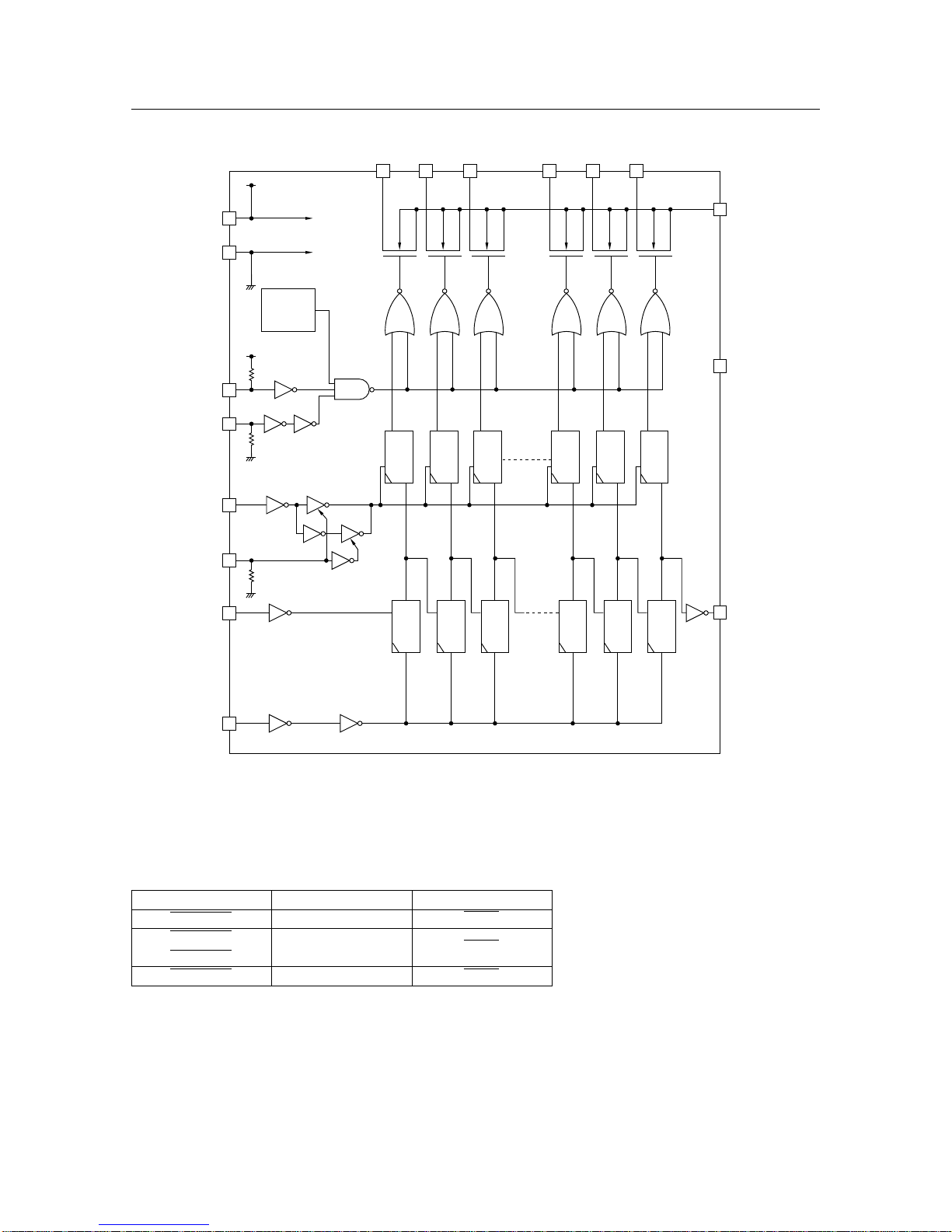

Fig. 2-5 Block Diagram of Drive IC

2-2-3. Head current control

Although the thermal printhead has four different STROBE lines, in fact it uses only three strobe signals to control its 576

elements. Specifically, each signal drives 192 of these elements. The signal/element arrangement is shown below.

Thermal Printhead Elements Strobe Signal

STROBE1 1 – 192 STB1

STROBE2 193 – 256

STB2

STROBE3 257 – 384

STROBE4 385 – 576 STB3

DO1

GND

H

V

DD

SO

DO2

V

DD

GND

L

STB

BEO

D

Q

L

C

Q

D

D

Q

L

C

Q

D

DO3

D

Q

L

C

Q

D

VDD

CHECKER

LAT

SI

CLK

CTL

DO62 DO63

D

Q

L

C

Q

D

D

Q

L

C

Q

D

DO64

D

Q

L

C

Q

D

BUFFER

LATCH

SHIFT

REGISTER

Page 21

– 17 –

PRINCIPLES OF OPERATION

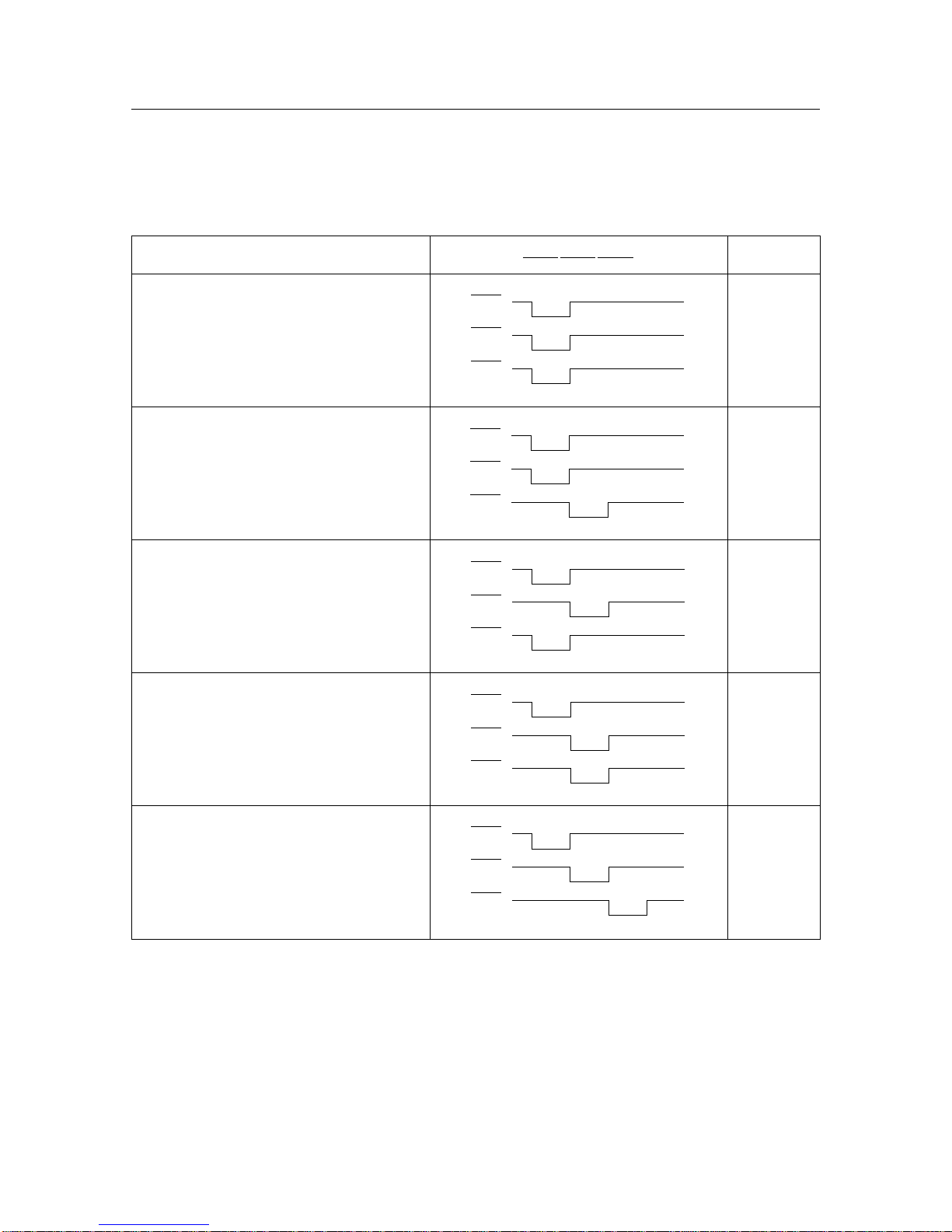

Strobe signals are output in one of five patterns, depending on the number of dot lines that are simultaneously ON.

The following table shows each of the patterns.

Figure 2-7 shows the timing for Pattern (5).

Strobe Signal Output

Pattern

STB1 STB2 STB3

0 STB1+STB2+STB3 384

1

193 STB1+STB2+STB3 384

STB1+STB2 192

2

193 STB1+STB2+STB3 384

STB1+STB3 192

3

193 STB1+STB2+STB3 384

STB2+STB3 192

4

385 STB1+STB2+STB3 576

5

STB1: Number of ON elements in element range 1 to 192.

STB2: Number of ON elements in element range 193 to 384.

STB3: Number of ON elements in element range 385 to 576.

Fig. 2-6 Strobe Signal Output Patterns for Different Print Rates

STB1

STB2

STB3

STB1

STB2

STB3

STB1

STB2

STB3

STB1

STB2

STB3

STB1

STB2

STB3

Number of ON Elements per Dot Line

Page 22

– 18 –

PRINCIPLES OF OPERATION

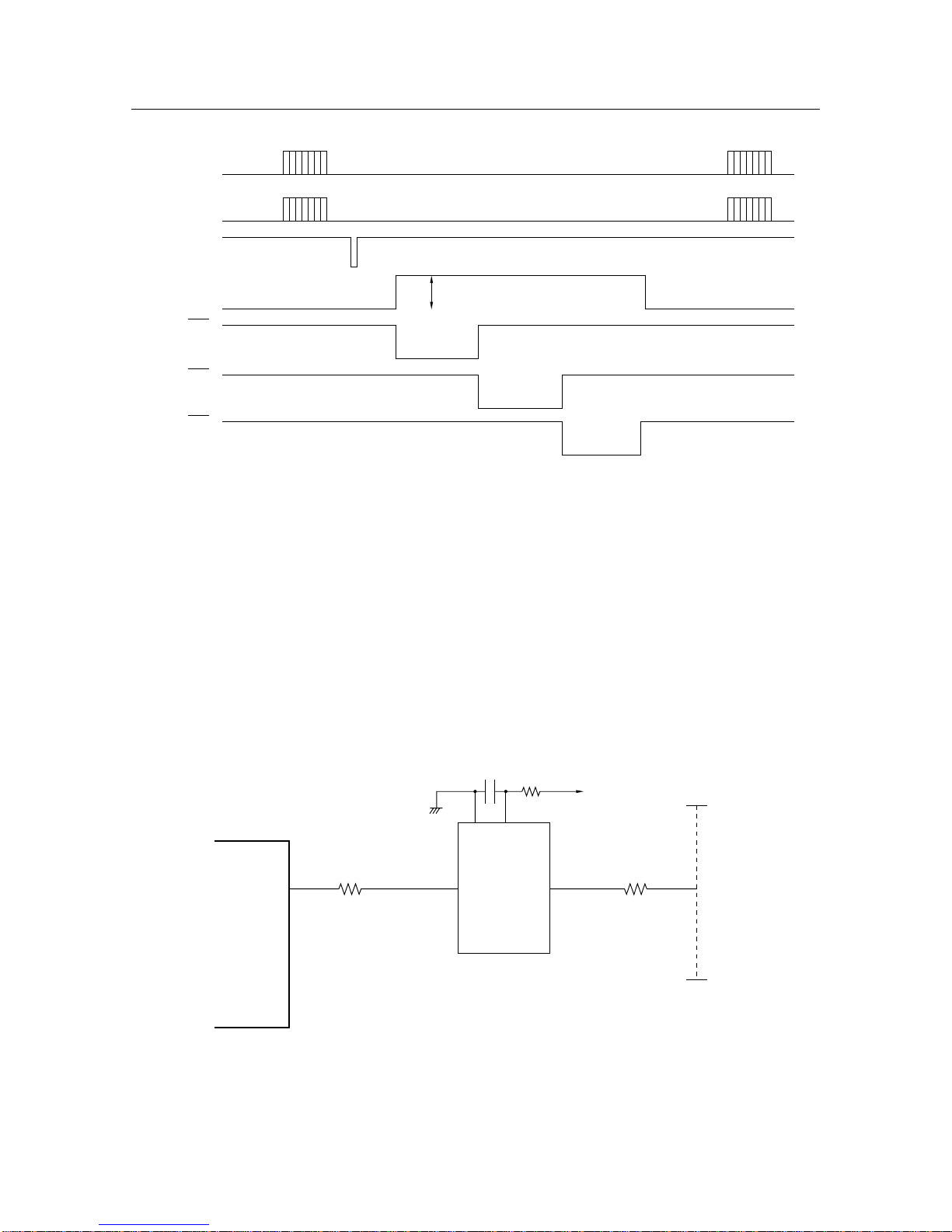

Fig. 2-7 Timing Chart

2-2-4. Head current control

Heat buildup in the thermal printhead can cause print quality to degrade. To maintain uniform quality, the printer varies

the energizing time (time that STROBE remains LOW) in accordance with the head temperature.

The print head’s surface temperature is calculated based on the resistance value of the attached thermistor, and energizing

time is controlled accordingly.

2-2-5. Head burnout protection

Misoperation of the CPU may cause head current to remain on too long, resulting in burn damage to the elements unless

current is shut off by other means. The printer therefore includes a burnout protection circuit that automatically forces

current off at some fixed time tw following current startup. Control is implemented through the head’s BEO terminal,

which is active on HIGH; setting the terminal LOW forces current off regardless of the STROBE state.

Fig. 2-8 Head Burnout Protection Circuit

24V

CLOCK

LATCH

COMMON

STB1

STB2

STB3

SI

HD ON

+5V

tw=(C

EXT

) (R

EXT

)

IC1

CPU

C

EXTREXT

B BEOQ

IC6

CN6

Page 23

– 19 –

PRINCIPLES OF OPERATION

Fig. 2-9 Timing Chart

2-3. Feed-Motor Drive Circuit

The printer uses a 4-phase step motor (phase 1-2 excitation) to implement paper feed. The motor rotates through a certain

angle each time it receives a pulse from the drive circuit. The following diagram illustrates the excitation method. Figure

2-11 shows the feed-motor drive circuit.

Fig. 2-10 Motor Control by Phase 1-2 Excitation

Fig. 2-11 Feed-Motor Drive Circuit

1 2 3 4 5 6 7 8

1

2

3

4

ON

ON

ON

ON

ON

Step

Reverse Feed

Forward Feed

PB4

TP8

TP9

TP10

TP11

1

3

2

4

CN7

1

2

3

6

5

4

+24V

TR5

TA1

DT9

M-GND

IC1

CPU

tw

STB1

STB2

STB3

HD ON

(B)

BEO

(Q)

Trigger Retrigger Retrigger

Page 24

– 20 –

PRINCIPLES OF OPERATION

STB1

STB2

STB3

LF COMMON

T3 T3 T3

STB1

STB2

STB3

LF COMMON

T2 T2 T2

STB1

STB2

STB3

LF COMMON

T1 T1 T1

The feed-motor pulse width varies according to the strobe output pattern (where the output pattern is determined by the

print rate, as described above). The following diagram shows the pulse width for each pattern.

Pattern 1

Pattern 2

Pattern 5

Fig. 2-12 Pulse Width by Pattern

Page 25

– 21 –

PRINCIPLES OF OPERATION

2-4. Power-On Reset Circuit

The power-on reset signal initializes all elements so as to protect against possible operating errors at power-on. The signal

is held for approximately 160ms when power comes on. The reset circuit is shown below.

Fig. 2-13 Power-On Reset Circuit

Fig. 2-13 Power-On Reset Circuit

1 At power-on, voltage detector IC3 (M51953BL) outputs a LOW signal from its OUT terminal. The signal is held

for approximately 160ms by the action of capacitor C9 (0.47µF), in accordance with the following relation:

T = 0.34 × C9 (pF) [µs] = 160ms

2 The LOW signal generates reset of the CPU and gate array, and stops operation of the mechanism drive circuitry.

+5V

IC3

CD

C9

GND

+5V

+5V

+5V

VCC

OUT

D1

IC1 : CPU

Drive circuit

RES

RESO

RESET

+

Gate

array

RESET IC

IC4

CPU

+5V

Page 26

– 22 –

PRINCIPLES OF OPERATION

2-5. +5V Line Voltage Detector Circuit

The voltage-detection IC (IC3 in Fig. 2-13) detects momentary drops or unstable levels in the +5V line voltage. The

following shows an IC3-equivalent circuit.

Fig. 2-14 Equivalent Circuit, Voltage Detection IC

Figure 2-15 shows the IC’s operational timing. The IC asserts a reset signal at its output terminal when the -5V line voltage

falls below 4.25V, thereby resetting the CPU and the gate array.

Fig. 2-15 Operation Timing Chart

1.25V

R1

R2

SµA typ

V

CC

1

GND

3

Cd

4

–

OUT

5

–

+

VCC Voltage

4.25V

0.8V

Output

Voltage

tdtd

t

t

td = 0.34 × Cd (pF) [µs]

Page 27

– 23 –

PRINCIPLES OF OPERATION

3. Printer Mechanism

3-1. Thermal Printhead

The TSP400 printers utilize thermal line printing. The thermal printhead consists of a horizontal line of 576 heat elements.

These elements print one line of dots at a time as the paper passes over the head. The printhead is fixed in position; only

the paper moves.

The printer prints a dot by heating the corresponding heat element. The heated element generates a chemical reaction in

the coloring layer of the thermal paper, resulting in the formation of a visible dot.

Fig. 2-16 Principle of Thermal Printing

3-2. Paper-Feed Mechanism

The paper-feed mechanism is comprised of paper-feed motor, gear train, platen, and thermal printhead. The paper-feed

motor drives the gear train, which in turn rotates the platen. The platen carries the thermal paper past the printhead.

The paper-feed motor is a PM (permanent magnet) type, 4-phase 48-pole step motor. 3 steps feed the paper approximately

0.125mm.

Fig. 2-17 Paper-Feed Machanism

Thermal head

Thermal paper

Printed point

Platen

Heat element

Coloring layer

Gear train

Paper-feed motor

Thermal head

Thermal paper

Platen

Page 28

– 24 –

PRINCIPLES OF OPERATION

3-3. Detectors

1 Paper-Out Detector

The paper-out detector (reflective photosensor) is located at the paper entry slit. The photosensor’s phototransistor

remains ON while paper is present. It goes OFF when paper runs out, generating output of a paper-out signal.

Fig. 2-18 Paper-Out Detector

2 Paper-Near-End Detector

The near-end detector is mounted in the paper-roll holder.

Fig. 2-19 Paper-Near-End Detector

–

+

CN2

P45

+5V

+5V

+5V

4

IC1

CPU

Photosensor

Paper

5

3

P47

IC1

CPU

CN3

+5V

+5V

2

Paper-roll

3

1

Page 29

– 25 –

PRINCIPLES OF OPERATION

3 Head-Up Detector

This detector senses the position of the thermal printhead. The leaf switch closes when the printhead is in contact

with the platen, and opens when the printhead is separated from the platen.

Fig. 2-20 Head-Up Detector

4 Cover-Open Detector

This detector senses whether the upper cover is open or closed. The leaf switch closes when the cover closes,

and opens when the cover opens.

Fig. 2-21 Cover-Open Detector

3-4. Auto-Cutter Drive circuit (on TSP242-24/120/230 only)

The TSP242 includes a guillotine-type cutter. The motor rotation direction determines whether the cutter executes a full

cut or a partial cut. (The partial cut leaves paper attached at one point.)

Note that Memory Switch 2 Bit 8 must be set ON to enable use of the cutter.

Fig. 2-22 Auto-Cutter Drive Circuit

P44

CN7

+5V

2

1

IC1

CPU

Leaf Switch

P46

CN1

+5V

1

2

IC1

CPU

Leaf Switch

CN9

P40

2

3

4

5

6

2

8

4

7

3

9

5

OUT

P42

IC3

IC1

CPU

P41

V

CC

VM

VM

V

CC

Switch

Motor

GND

M-GND

GND

VM

C

C

C

C

E

E

10

1

B

B

B

B

TA2

TH3C10

M

Page 30

– 26 –

PRINCIPLES OF OPERATION

<Full Cut>

<Partial Cut>

Fig. 2-23 Auto-Cutter Timing Chart

P40

P41

Switch

40ms 100ms Brake

H

L

H

L

ON

OFF

< Full Cut >

P41

P40

Switch

40ms 100ms Brake

H

L

H

L

ON

OFF

< Partial Cut >

Page 31

CHAPTER 3

PART REPLACEMENT AND RELATED ADJUSTMENT

This chapter presents printer disassembly and reassembly procedures. Please note the following important

points.

1. Always disconnect the power cord from the AC outlet before beginning work.

2. Except where otherwise indicated, the reassembly procedure is the reverse of the disassembly

procedure.

3. Coat screw heads with locking sealant after completing of reassembly.

4. Refer to Chapter 4 Section 2 for information about lubrication. (Chapter 3 does not include any

lubrication information.)

Note: This printer has no adjustment sites.

1. Upper Case Unit ..................................................................................................29

2. Auto-Cutter Unit ..................................................................................................29

3. Printer Mechanism ..............................................................................................30

4. Near-End-Sensor Unit .........................................................................................30

5. Power Unit............................................................................................................31

6. Main Logic Board ................................................................................................32

7. Fuses ....................................................................................................................32

8. Thermal-head Unit...............................................................................................33

3

Page 32

PARTS REPLACEMENT

– 28 –

Page 33

PARTS REPLACEMENT

– 29 –

3

2

1

1

2

4

6

5

1

3

1. Upper Case Unit

(1) Switch off the power, and unplug the power cord

from the power outlet.

(2) Remove:

• Cover 1

• Four tapping screws 2

• Upper case unit 3

Remove the upper case unit by lifting it up and

off.

2. Auto-Cutter Unit

<Model TSP242-24/120/230 only>

(1) Remove:

• Upper case unit (See 1. above.)

• Two tapping screws 1

• Wire band 2

• Cutter Holder Plates R,L 3, 4

• Cutter Unit 5

• Connector 6

Page 34

PARTS REPLACEMENT

– 30 –

4

5

7

1

2

6

3

5

1

2

3

4

3. Printer Mechanism

<TSP212-24/120/230>

(1) Remove the upper case unit (see 1. above), then

proceed to (2) below.

<TSP242-24/120/230>

(1) Remove the auto-cutter unit. (See 2. above.)

(2) Remove:

• Two screws 1

• Sub-chassis 2

• Guide 3

• Two tapping screws 4

• Three tapping screws 5

• Flat cable 6

• Connector

• Printer mechanism 7

4. Near-End-Sensor Unit

(1) Remove the upper case unit. (See 1. above.)

(2) Remove:

• Two screws 1

• Mechanism sub-chassis 2

• One tapping screw 3

• Connectors 4

• Near-end-sensor unit 5

Page 35

PARTS REPLACEMENT

– 31 –

1

3

5

6

4

2

5. Power Unit (TSP200-120/230)

(1) Remove the upper case unit. (See 1. above.)

(2) Remove the connector cover 1.

(3) Remove the main chassis unit 5 from the lower

casing unit 2.

(4) Remove:

• Two screws 3

• Cord bushing 4

• Connector

• Power unit 6 from main chassis 5

1

3

4

3

6

5

2

Power Unit (TSP200-24)

(1) Remove the upper case unit. (See 1. above.)

(2) Remove the connector cover 1.

(3) Remove the main chassis unit 5 from the lower

casing unit 2.

(4) Remove:

• Three screws 3

• Connector 4

• Power unit 6 from main chassis 5

Page 36

PARTS REPLACEMENT

– 32 –

2

1

7. Fuses (TSP200-120/230)

(1) Remove the main chassis unit from the lower casing

unit. (See 5. above.)

(2) Check the fuses in the power unit.

• Fuse F1 1

• Fuse F2 2

If fuse is blown, replace it with the fuse type

indicated below.

Destination F1 F2

U.S.A. 5TT1A 5TT3A

EC EAWK630mA EAK3.15A

United Kingdom

EAWK630mA 5TT3A

If the replacement fuse also blows out, replace the

power unit or check the main logic board.

6. Main Logic Board

(1) Remove the upper case unit. (See 1. above.)

(2) Remove the connector cover 1.

(3) Remove the main chassis unit 3 from the lower

casing unit 2.

(4) Remove:

• Two tapping screws 4

• Board chassis unit 5

• Two tapping screws 6

• Two screws 7

• Connector

• Main logic board 8

1

4

4

3

7

6

6

7

8

2

5

Page 37

PARTS REPLACEMENT

– 33 –

9

8

4

4

6

6

6

7

7

3

5

4

2

1

2

8. Thermal-head Unit

(1) Remove the printer mechanism. (See 3. above.)

(2) Be sure that the unit is in head-down state (that the

head-lift lever 1 is back).

(3) Press the two head-opening levers 2 and remove the

set cover 3 from the printer mechanism.

(4) Remove:

• Three stop rings 4

• Stay 5

• Three springs 6

• Two screws 7

• Head plate 8

• Thermal head 9

(5) Attach the replacement thermal head. as follows.

(a)Be sure that the unit is in head-open state.

(b)Hold the replacement head in position, and screw

the right end loosely into place with the one of the

screws 7.

(c)Set the unit into head-closed state.

(d)Fit the remaining screw 7 into the left side, and

tighten both of the screws to a torque of 5g-cm.

(6) Caution:

Keep hands clear of the head’s heat elements when

making the replacement.

Fuses (TSP200-24)

(1) Remove the main chassis unit from the lower casing

unit. (See 5. above.)

(2) Check the fuses in the power unit.

• Fuse F1 1

If fuse is blown, replace it with the fuse type

indicated below.

F1

5TT3A

If the replacement fuse also blows out, replace the

power unit or check the main logic board.

1

Page 38

Page 39

CHAPTER 4

MAINTENANCE AND LUBRICATION

1. Maintenance.........................................................................................................35

1-1. Cleaning................................................................................................................. 35

1-2. Checks ................................................................................................................... 35

2. Lubrication........................................................................................................... 36

2-1. Lubricants ............................................................................................................. 36

2-2. Application Method .............................................................................................. 36

2-3. Lubrication Points ................................................................................................ 36

4

Page 40

– 35 –

MAINTENANCE AND LUBRICATION

1. Maintenance

Proper maintenance is necessary to maintain printer performance and forestall potential problems. Please carry out

maintenance as described below.

1-1. Cleaning

(1) Surface dirt

Clear away dirt with a soft cloth. If necessary, apply a small quantity of alcohol to the cloth to improve cleaning

power. NEVER use thinner, trichlene, or ketone solvents, as these can cause damage to plastic components.

When cleaning, take care to avoid damaging or moistening of electronic parts, mechanical parts, and wires.

(2) Internal dust

For best results, use an electric vacuum cleaning device to remove dust from the inside of the printer. Note that such

cleaning may also remove lubrication; when you have finished cleaning, check lubrication levels and apply

lubricant as necessary.

1-2. Checks

There are two types of maintenance checks. Simple “daily checks” can be performed by users during the course of daily

operation. “Periodic checks” must be carried out by qualified service personnel.

(1) Daily checks

• Check whether dirt or other foreign matter has worked its way into the printer, and remove as necessary.

• Check the thermal head for excessive dirt. If the head is very dirty, clean it with a cotton stick or a soft cloth soaked

in alcohol.

(2) Periodic checks

Periodic checks and lubrication should be carried out once every six months or once every million lines of printing.

• Check the integrity of springs.

• Clear dust from areas around the detectors.

MAINTENANCE AND LUBRICATION

Page 41

– 36 –

MAINTENANCE AND LUBRICATION

2. Lubrication

Proper lubrication is essential for maintaining the printer’s performance level and preventing breakdowns or other

problems.

2-1. Lubricants

Choice of lubrication can significantly affect the printer’s performance, longevity, and low-temperature characteristics.

We recommend the following lubricant for this printer.

Type Name Manufacturer

Grease Molykote EM Dow Corning

2-2. Application Method

If you are lubricating parts during disassembly or reassembly, be sure to wash or wipe the parts thoroughly to remove all

dirt and dust prior to lubricating.

Remember that cleaning can remove necessary lubrication. Always lubricate after cleaning, disassembly, or replacement.

2-3. Lubrication Points

Apply lubricants at the following locations.

Lubrication points

Page 42

Page 43

CHAPTER 5

PARTS LIST

HOW TO USE PARTS LIST

(1) DRWG. NO.

This column shows the drawing number of the illustration.

(2) REVISED EDITION MARK

This column shows a revision number.

Parts that have been added in the revised edition are indicated with “#”.

Parts that have been abolished in the revised edition are indicated with “*”.

#1:First edition → Second edition *1:First edition → Second edition

(3) PARTS NO.

Parts numbers must be notified when ordering replacement parts. Parts described as “NPN” have no parts number and are not

in stock, i.e., unavailable.

(4) PARTS NAME

Parts names must be notified when ordering replacement parts.

(5) Q’TY

This column shows the number of the part used as indicated in the figure.

(6) REMARKS

Where differences in specifications exist depending on location/destination.

(7) RANK

Parts marked “S” are service parts. Service parts are recommended to be in stock for maintenance.

1. Printer Assembly.................................38

1-1. Disassembly Drawing.....................38

1-2. Parts List .........................................41

2. Printer Mechanism ..............................43

2-1. Disassembly Drawing.....................43

2-2. Parts List .........................................45

3. Cutter Unit............................................46

3-1. TSP200-120/230 .............................. 46

3-2. TSP200-24 ....................................... 47

4. Wiring Scheme of Printer ...................48

4-1. TSP212/242......................................48

4-2. TSP212-24/242-24 ...........................49

5. Main Logic Board ................................50

5-1. Circuit Diagram ............................... 50

5-2. Component Layout ......................... 56

5-3. Parts List .........................................57

6. Power Supple Unit (120VAC/230VAC)....61

6-1. Circuit Diagram ............................... 61

6-2. Parts List .........................................62

7. Power Supple Unit (24VDC) ...................63

7-1. Circuit Diagram ............................... 63

7-2. Component Layout ......................... 63

7-3. Parts List .........................................63

8. Paper Near-End Sensor ......................64

8-1. Circuit Diagram ............................... 64

8-2. Parts List .........................................64

5

Page 44

– 38 –

1. Printer Assembly

1-1. Disassembly Drawing

1-1-1. TSP212-120/230

17

25

24

22

12

26

7

13

18

29

27

5

34

1

27

4

A

E

C

F

G

B

D

D

B

C

A

F

G

E

35

31

32

19

11

3

10

9

2

6

23

8

33

21

28

20

Page 45

– 39 –

1-1-2. TSP242-120/230

17

25

29

27

5

34

21

1

27

4

13

26

8

A

H

E

C

F

G

B

D

D

B

C

A

F

G

E

18

22

24

12

11

10

9

2

32

7

3

28

6

H

15

23

16

20

14

20

33

19

30

30

Page 46

– 40 –

1-1-3. TSP242-24

27

17

25

25

29

27

5

26

28

1

4

13

26

26

8

A

H

E

C

F

G

B

D

D

B

C

A

F

G

E

18

22

36

36

22

24

12

11

10

9

2

21

32

7

3

6

H

15

23

16

20

14

20

27

19

30

30

26

25

25

34

37

33

20

Page 47

– 41 –

1 37300011 LOWER CASE UNIT SP2 1 S

2 37309010 POWER SUPPLY UNIT SP2-120 US 1 FOR US S

37309030 POWER SUPPLY UNIT SP2-230 EC 1 FOR EC S

37309040 POWER SUPPLY UNIT SP2-240 UK 1 FOR UK S

3 *1 32010011 MAIN CHASSIS SP2 1

#1 32010012 MAIN CHASSIS SP2 1

4 32010030 BOARD CHASSIS P SP2 1

5 37437010 TBD212-24 UNIT TSP2 1 TSP212 S

37437110 TBD242-24 UNIT TSP2 1 TSP242 S

6 30722000 FLAT CABLE 24X105 TSP2 1 S

7 32010050 SUB-CHASSIS TSP2 1

8 37432200 COVER OPEN SWITCH UNIT TSP2 1 S

9 32043500 DETECTOR HOLDER PLATE TSP2 1

10 33020500 NEAR-END DETECTOR COVER TSP2 1

11 37437400 DETECTOR BOARD ASSY TSP2 1 S

12 33900060 ASSIST GUIDE TSP2 1

13 38420000 TMP212A-24 1 TSP212 S

38420100 TMP212B-24 1 TSP242 S

14 37432000 CUTTER 4022-24V UNIT TSP2 1 TSP242 S

15 32043210 CUTTER HOLDER PLATE R TSP2 1 TSP242

16 32043220 CUTTER HOLDER PLATE L TSP2 1 TSP242

17 33020022 COVER SP2 1 TSP212 S

33020060 COVER TSP2 1 TSP242 S

18 37431000 UPPER CASE UNIT TSP2 1 S

19 83911720 CONNECTOR COVER SP312 1

20 04991204 FASTENER T18S 1 TSP212 S

04991204 FASTENER T18S 2 TSP242 S

21 04991220 CORD BUSHING SR-5N-4 1 S

22 00926603 SCREW TAT 2.6-6 CT 2 S

23 00926803 SCREW TAT 2.6-8 PT 1 S

24 01902618 SCREW TAT 2.6-4 3 S

25 01903058 SCREW TAT 3-10 PT 4 S

26 01903059 SCREW TR 3-5 FL 2 S

27 *1 01903064 SCREW TAT 3-5 CT 2 S

#1 01903101 SCREW TAT 3-6 CT-FL 2 S

28 01903026 SCREW TR 3-5 WB 1 S

29 01903069 SCREW TAT 3-5 ST-FL 2 S

30 01903077 SCREW TAT 3-5 CT-FL 2 TSP242 S

31 00930603 SCREW TAT 3-6 PT 2 TSP212 S

32 01903033 SCREW TR 3-12 2 S

33 *1 01903077 SCREW TAT 3-5 CT-FL 1 S

#1 01903101 SCREW TAT 3-6 CT-FL 1 S

34 01914003 SCREW TR 4-10 WS/WF 2 S

35 32970010 TEAR BAR SP2 1 TSP212

- 04991204 FASTENER T18S 1 FOR EC,UK :ACCESSARY

09990723 FERRITE CORE TFC-23-11-14 1 FOR EC,UK :ACCESSARY

30970030 THERMAL ROLL PAPER 76X35D 1 :ACCESSARY

DRWG.NO. REV. PARTS NO. PARTS NAME Q’TY REMARKS RANK

1-2. Parts List

1-2-1. TSP200-120/230

Printer Assembly(TSP200-120/230)

Page 48

– 42 –

DRWG.NO. REV. PARTS NO. PARTS NAME Q’TY REMARKS RANK

1-2-2. TSP200-24

Printer Assembly(TSP200-24)

1 37300011 LOWER CASE UNIT SP2 1 S

2 37439000 POWER SUPPLY UNIT TSP2-24 1 S

3 32010130 MAIN CHASSIS TSP2-24 1

4 32010030 BOARD CHASSIS P SP2 1

5 37437010 TBD212-24 UNIT TSP2 1 TSP212-24 S

37437110 TBD242-24 UNIT TSP2 1 TSP242-24 S

6 30722000 FLAT CABLE 24X105 TSP2 1 S

7 32010050 SUB-CHASSIS TSP2 1

8 37432200 COVER OPEN SWITCH UNIT TSP2 1 S

9 32043500 DETECTOR HOLDER PLATE TSP2 1

10 33020500 NEAR-END DETECTOR COVER TSP2 1

11 37437400 DETECTOR BOARD ASSY TSP2 1 S

12 33900070 ASSIST GUIDE A TSP2 1

13 38420400 TMP212E-24 1 TSP212-24 S

38420300 TMP212D-24 1 TSP242-24 S

14 37432010 CUTTER ACS230 UNIT TSP2 1 TSP242-24 S

15 32043210 CUTTER HOLDER PLATE R TSP2 1 TSP242-24

16 32043220 CUTTER HOLDER PLATE L TSP2 1 TSP242-24

17 33020170 COVER B TSP2 1 TSP212-24 S

33020091 COVER A TSP2 1 TSP242-24 S

18 37431050 UPPER CASE UNIT TSP2-24 1 S

19 83911720 CONNECTOR COVER SP312 1

20 04991204 FASTENER T18S 3 S

21 30781130 ADAPTER SET PS48 US 1 FOR US S

30781140 ADAPTER SET PS48 EC 1 FOR EC S

30781150 ADAPTER SET PS48 UK 1 FOR UK S

30781160 ADAPTER SET PS48 AS 1 FOR AS S

22 00926603 SCREW TAT 2.6-6 CT 2 S

23 00926803 SCREW TAT 2.6-8 PT 1 S

24 01902618 SCREW TAT 2.6-4 3 S

25 01903058 SCREW TAT 3-10 PT 4 S

26 01903059 SCREW TR 3-5 FL 5 S

27 01903101 SCREW TAT 3-6 CT-FL 3 S

28 09990713 FERRITE CORE TFC-16-8-16 1 S

29 01903069 SCREW TAT 3-5 ST-FL 2 S

30 01903077 SCREW TAT 3-5 CT-FL 2 TSP242-24 S

31 00930603 SCREW TAT 3-6 PT 2 TSP212-24 S

32 01903033 SCREW TR 3-12 2 S

33 01903055 SCREW TR 3-8 WS/WF 1 S

34 37430300 HOLDER LEVER UNIT TSP2 1

35 32970010 TEAR BAR SP2 1 TSP212-24

36 33900080 ASSIST SPACER TSP2 2

37 33910150 HOLDER SP24 2

- 30970040 THERMAL ROLL PAPER 80X35D 1 ACCESSARY

09990723 FERRITE CORE TFC-23-11-14 1 ACCESSARY

Page 49

– 43 –

2. Printer Mechanism

2-1. Disassembly Drawing

2-1-1. TSP212

17

20

23

15

22

23

29

29

29

27

27

7

8

23

14

21

19

18

26

26

28

24

9

4

5

12

1

13

25

6

11

10

24

16

30

28

3

3

2

11

13

Page 50

– 44 –

2-1-2. TSP242

15

22

19

18

26

26

28

24

9

4

5

1

13

25

6

11

10

24

16

30

28

3

3

2

11

13

17

20

23

23

29

29

29

27

27

7

8

23

14

21

Page 51

– 45 –

1 37440400 FRAME ASSY TMP2 1

2 33910070 PAPER GUIDE A TMP2 1

3 33900050 SUB-GUIDE TMP2 2 TSP212/242

4 33210020 HOLDER ROLLER TMP2 1

5 30365020 HOLDER ROLLER SHAFT TMP2 1

6 37447000 DETECTOR UNIT TMP2 1 S

7 32025030 SET COVER TMP2 1

8 31360000 STAY TMP2 1

9 30375010 PLATEN TMP2 1 S

10 33490020 HEAD-UP LEVER TMP2 1

11 04310403 OILESS BUSHING F4X6X5 2 S

12 33910080 PAPER GUIDE B TMP2 1 TSP212/212-24

13 32490020 HEAD OPEN LEVER TMP2 2 S

14 33020300 MOTOR COVER TMP2 1

15 33101510 PLATEN GEAR TMP2 1 S

16 33990000 PLATEN KNOB TMP2 1 S

17 30905021 THERMAL HEAD M22E 1 TSP212-24/242-24 S

30905030 THERMAL HEAD RJ072-8S63 1 TSP212/242 S

18 33102230 GEAR 20X43X0.35 TMP2 1 S

19 33102220 GEAR 13X44X0.35 TMP2 1 S

20 32042030 HEAD PLATE TMP2 1

21 37442400 MOTOR ASSY TMP2 1 S

22 04020002 STOP RING SE1.5 1 S

23 04020010 STOP RING SE2.0 3 S

24 04020004 STOP RING SE2.5 2 S

25 01901709 SCREW TAT 1.7-5 CT FL 1 S

26 00820304 SCREW TR 2-3 2 S

27 00626404 SCREW TR 2.6-4 2 S

28 30510300 SPRING E032-035-0109 2 S

29 30520040 SPRING C048-054-0110 3 S

30 82500860 WAVE WASHER 834G 1

DRWG.NO. REV. PARTS NO. PARTS NAME Q’TY REMARKS RANK

2-2. Parts List

Printer Mechanism

Page 52

– 46 –

3. Cutter Unit

3-1. TSP200-120/230

DRWG.NO. REV. PARTS NO. PARTS NAME Q’TY REMARKS RANK

1 04991512 CUTTER 4022-24V 1 S

2 32025040 CUTTER EJECT COVER TSP2 1

3 45049930 POLARITY LABEL QMB-06S 1

4 32045430 CUTTER GUIDE A TSP2 1

5 32045440 CUTTER GUIDE B TSP2 1

6 37433500 CUTTER SUPPORT R ASSY TSP2 1

7 37433510 CUTTER SUPPORT L ASSY TSP2 1

8 00820304 SCREW TR 2-3 6 S

9 00626404 SCREW TR 2.6-4 2 S

4

5

1

3

8

8

7

2

6

9

9

Page 53

– 47 –

3-2. TSP200-24

DRWG.NO. REV. PARTS NO. PARTS NAME Q’TY REMARKS RANK

1 04991516 CUTTER ACS-230STR 1 S

2 30990240 PAPER GUIDE TSP2 1

3 30040020 MOUSE PLATE F2 TSP2 1

4 32045470 CUTTER GUIDE C TSP2 1

5 37433530 CUTTER SUPPORT L ASSY TSP2A 1

6 37433520 CUTTER SUPPORT R ASSY TSP2A 1

7 00926503 SCREW TAT 2.6-5 CT 2 S

8 01902018 SCREW TAT 2-4 4 S

1

5

7

7

2

4

8

8

3

8

6

Page 54

– 48 –

4. Wiring Scheme of Printer

4-1. TSP200-120/230

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

·

30

31

32

33

34

35

36

1

2

3

4

5

6

7

8

9

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

VH

VH

VH

DI

VCC

BEO

GNDH

GNDH

GNDL

CLK

GNDH

GNDH

GNDH

GNDH

DO

TH

TH

VH

VH

1

2

3

4

5

6

CMN

CMN

LF#2

LF#4

LF#3

LF#1

1

2

3

4

5

6

F-GND

EXT1

+24V

+24V

EXT2

CSW

1

2

3

4

+24V

M-GND

+5V

GND

1

2

3

4

5

N/C

HP

GND

CUT

CUT

DATA1

DATA2

DATA3

DATA4

DATA5

DATA6

DATA7

DATA8

BUSY

PE

SELECT

NC

NC

GND

F-GND

VCC

GND

·

GND

GND

NC

NC

SLCT IN

CN4

( 36 PIN )

CENTRONICS CONNECTOR

FOR PARALELL I/F

( 9 PIN )

DSUB CONNECTOR

FOR SERIAL I/F

COVER OPEN SW

HEAD UP SW

PAPER END

SENSOR

PAPER NEAR END SENSOR

MAIN LOGIC BOARD

CN6

CN1

CN2

CN3

F-GND

RXD

TXD

DTR

S-GND

DSR

RTS

INIT

FAULT

1

2

COVER-OP

GND

1

2

3

4

5

GND

HEAD-UP

LED(-)

PE

+5V

1

2

3

PNE

+5V

GND

WHT

BLU

GRN

TR(E)

+5V

GND

CN5

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

VH

VH

VH

DI

VCC

BEO

GNDH

GNDH

GNDL

CLK

GNDH

GNDH

GNDH

GNDH

DO

TH

TH

VH

VH

THERMAL HEAD

CN7

CN9

CN8

CN10

ACK

INIT

ERROR

STROBE

STB4

LAT

STB3

STB2

STB1

STB4

LAT

STB3

STB2

STB1

WHT

WHT

RED

BLK

NC

SENSER

SENSER

MOTOR

MOTOR

AUTO CUTTER

CONNECTOR FOR PERIPHERAL UNIT

PAPER FEED MOTOR

GRN

GRN

RED

WHT

YEL

BLU

CMN

CMN

LF#2

LF#4

LF#3

LF#1

CN1

POWER

SUPPLY

BOARD

+24V

M-GND

+5V

GND

RED

RED

BLU

BLU

Page 55

– 49 –

4-2. TSP200-24

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

·

30

31

32

33

34

35

36

1

2

3

4

5

6

7

8

9

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

VH

VH

VH

DI

VCC

BEO

GNDH

GNDH

GNDL

CLK

GNDH

GNDH

GNDH

GNDH

DO

TH

TH

VH

VH

1

2

3

4

5

6

CMN

CMN

LF#2

LF#4

LF#3

LF#1

1

2

3

4

5

6

F-GND

EXT1

+24V

+24V

EXT2

CSW

1

2

3

4

+24V

M-GND

+5V

GND

1

2

3

4

5

N/C

HP

GND

CUT

CUT

DATA1

DATA2

DATA3

DATA4

DATA5

DATA6

DATA7

DATA8

BUSY

PE

SELECT

NC

NC

GND

F-GND

VCC

GND

·

GND

GND

NC

NC

SLCT IN

CN4

( 36 PIN )

CENTRONICS CONNECTOR

FOR PARALELL I/F

( 9 PIN )

DSUB CONNECTOR

FOR SERIAL I/F

COVER OPEN SW

HEAD UP SW

PAPER END

SENSOR

PAPER NEAR END SENSOR

MAIN LOGIC BOARD

CN6

CN1

CN2

CN3

F-GND

RXD

TXD

DTR

S-GND

DSR

RTS

INIT

FAULT

1

2

COVER-OP

GND

1

2

3

4

5

GND

HEAD-UP

LED(-)

PE

+5V

1

2

3

PNE

+5V

GND

WHT

BLU

GRN

TR(E)

+5V

GND

CN5

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

VH

VH

VH

DI

VCC

BEO

GNDH

GNDH

GNDL

CLK

GNDH

GNDH

GNDH

GNDH

DO

TH

TH

VH

VH

THERMAL HEAD

CN7

CN9

CN8

CN10

ACK

INIT

ERROR

STROBE

STB4

LAT

STB3

STB2

STB1

STB4

LAT

STB3

STB2

STB1

WHT

WHT

RED

BLK

NC

SENSER

SENSER

MOTOR

MOTOR

AUTO CUTTER

CONNECTOR FOR PERIPHERAL UNIT

PAPER FEED MOTOR

GRN

GRN

RED

WHT

YEL

BLU

CMN

CMN

LF#2

LF#4

LF#3

LF#1

CN2

POWER

SUPPLY

BOARD

+24V

M-GND

+5V

GND

RED

RED

BLU

BLU

+24V

GND

N.C.

AC

Adapter

1

2

3

Page 56

– 50 –

5. Main Logic Board

5-1. Circuit Diagram

Main Logic Board (1/6)

Page 57

– 51 –

Main Logic Board (2/6)

Page 58

– 52 –

Main Logic Board (3/6)

Page 59

– 53 –

Main Logic Board (4/6)

Page 60

– 54 –

Main Logic Board (5/6)

Page 61

– 55 –

Main Logic Board (6/6)

Page 62

– 56 –

5-2. Component Layout

Page 63

– 57 –

DRWG.NO. REV. PARTS NO. PARTS NAME Q’TY REMARKS RANK

5-3. Parts List

Main Logic Board

IC1 08251008 CPU HD6413002F-16MHZ 1 S

IC2 08201013 IC-LIN UPC393G2*T1 1 S

IC3 08200109 IC-RESET M51953BL 1

IC4 08240076 GATE ARRAY D65622GF-TSP 1 S

IC5 08210126 TTL IC 74LS05FP*EL 1 S

IC6 08231054 CMOS 74HC123AFP*EL 1

IC7 08222047 EEPROM KM93C46 1

IC8 08222095 EPROM M27C2001-10F1 1 TS2.** S

09110121 IC SOCKET DILB-32P-8J 1

IC9 *1 08221049 PSRAM LC338128M-80 1 S

#1 08221062 PSRAM LC338128M80*ER 1 S

IC10 08200157 IC-I/F ADM232LJR*SOL16 1 S

IC11 08201013 IC-LIN UPC393G2*T1 1 S

IC12 08231042 CMOS 74HC04FP*EL 1 TSP242/242-24

IC13 08231053 CMOS 74HC08AP*EL 1 TSP242/242-24

IC14 08210127 TTL IC 74LS06FP*EL 1 TSP242/242-24

IC15 NOT MOUNTED

IC16 08202011 IC-REG UPC7824 1

IC17-19 NOT MOUNTED

TA1 07650054 TRANSISTOR ARRAY MP4020 1 S

TA2 07650037 TRANSISTOR ARRAY TH3C10 1 TSP242/242-24 S

TR1 07016492 CHIP TRANSISTOR 2SA1649Z* 1 S

TR2 07013381 CHIP TRANSISTOR 2SA1338-67*TA 1 S

TR3 07238754 CHIP TRANSISTOR 2SC3875S-G*AL 1

TR4 07011793 CHIP TRANSISTOR 2SA1179M6-STR 1

TR5 07113591 TRANSISTOR 2SB1359 1 S

TR6-7 07320101 TRANSISTOR 2SD2010 2

TR8 07238754 CHIP TRANSISTOR 2SC3875S-G*AL 1 TSP242/242-24

TR9 07238754 CHIP TRANSISTOR 2SC3875S-G*AL 1

TR10 07011793 CHIP TRANSISTOR 2SA1179M6-STR 1

ZD1 NOT MOUNTED

DSW1 *1 09090034 DIP SWITCH KSS08-1 1

#1 09090068 DIP SWITCH 210B008MS 1

DSW2 *1 09090033 DIP SWITCH KSS04-1 1

#1 09090039 LEAF SWITCH LSA1119H 1

SW1-2 09010055 PUSH SWITCH SKHHLN 2

LED1-2 08300136 LED SLZ-390B 2

XTAL1 09250064 CERA. OSCILLATOR EFO-EX1605X4 1

C1 05751045 CERA. CAPA. CHIP 0.1UF 50V 1

C2-3 05752236 CERA. CAPA. CHIP 0.022UF 50V 2

C4 05751045 CERA. CAPA. CHIP 0.1UF 50V 1

C5 05752236 CERA. CAPA. CHIP 0.022UF 50V 1

C6-8 05751045 CERA. CAPA. CHIP 0.1UF 50V 3

C9 05054745 CHEM. CAPA. 0.47UF 50V 1

C10-11 05751045 CERA. CAPA. CHIP 0.1UF 50V 2

C12 05751025 CERA. CAPA. CHIP 1000PF 50V 1

C13-17 05751045 CERA. CAPA. CHIP 0.1UF 50V 5

C18-22 05051054 CHEM. CAPA. 1UF 50V 5

C23-24 05752236 CERA. CAPA. CHIP 0.022UF 50V 2

C25-26 05751045 CERA. CAPA. CHIP 0.1UF 50V 2

C27 05752236 CERA. CAPA. CHIP 0.022UF 50V 1 TSP242/242-24

C28-31 05751045 CERA. CAPA. CHIP 0.1UF 50V 4 TSP242/242-24

C32 05751045 CERA. CAPA. CHIP 0.1UF 50V 1

C33 05751045 CERA. CAPA. CHIP 0.1UF 50V 1 TSP242/242-24

C34-35 05751045 CERA. CAPA. CHIP 0.1UF 50V 2

Page 64

– 58 –

Main Logic Board

DRWG.NO. REV. PARTS NO. PARTS NAME Q’TY REMARKS RANK

C36-41 NOT MOUNTED

CRA1-3 06542211 RESIS. ARRAY CHIP V8V221J 3

CRA4-8 06544711 RESIS. ARRAY CHIP V8V471J 5

CRA9-10 06542211 RESIS. ARRAY CHIP V8V221J 2

D1-2 08000047 DIODE CHIP DCB010 2

D3 08000068 DIODE CHIP MC2836 1

D4-5 08000059 DIODE CHIP MC2840 2

D6 NOT MOUNTED

D7-9 08000091 DIODE DSM1SD2*A 3

DT1 07603017 DIGITAL TRANSISTOR FN1A4P 1

DT2-4 07603016 DIGITAL TRANSISTOR FA1A4P 3

DT5 07603017 DIGITAL TRANSISTOR FN1A4P 1

DT6 07603016 DIGITAL TRANSISTOR FA1A4P 1

DT7 07603017 DIGITAL TRANSISTOR FN1A4P 1

DT8-9 07603016 DIGITAL TRANSISTOR FA1A4P 2

DT10-11 07603017 DIGITAL TRANSISTOR FN1A4P 2

DT12 07603016 DIGITAL TRANSISTOR FA1A4P 1

DT13 07603017 DIGITAL TRANSISTOR FN1A4P 1 TSP242/242-24

DT14 07603017 DIGITAL TRANSISTOR FN1A4P 1

DT15 07603016 DIGITAL TRANSISTOR FA1A4P 1

DT16 07603017 DIGITAL TRANSISTOR FN1A4P 1

L1-6 09990730 BEADS INDUCTOR BK2125HS601 6

L7 09990725 BEADS INDUCTOR RIB-6-6-C-C8 1

L8-10 09990730 BEADS INDUCTOR BK2125HS601 3

L11-17 06750004 CHIP RESISTOR 0 OHM 1/10W 7

L18-20 09990730 BEADS INDUCTOR BK2125HS601 3

VR1 06451035 RP RESISTOR RH0614C-10K 1

RA1 06584729 RESIS. ARRAY 4.7K-OHM 1/8W 8EL 1

RA2 06581824 RESIS. ARRAY 1.8K-OHM 1/8W 6EL 1

R1-3 06754711 CHIP RESISTOR 470 OHM 1/10W 3

R4-7 06753324 CHIP RESISTOR 3.3 K-OHM 1/10W 4

R8-9 06751031 CHIP RESISTOR 10 K-OHM 1/10W 2

R10-14 06754711 CHIP RESISTOR 470 OHM 1/10W 5

R15-17 06751031 CHIP RESISTOR 10 K-OHM 1/10W 3

R18 06754711 CHIP RESISTOR 470 OHM 1/10W 1

R19-20 06752215 CHIP RESISTOR 220 OHM 1/10W 2

R21 06754711 CHIP RESISTOR 470 OHM 1/10W 1

R22-23 NOT MOUNTED

R24 06751031 CHIP RESISTOR 10 K-OHM 1/10W 1

R25 06754721 CHIP RESISTOR 4.7 K-OHM 1/10W 1

R26 06751031 CHIP RESISTOR 10 K-OHM 1/10W 1

R27 06754721 CHIP RESISTOR 4.7 K-OHM 1/10W 1

R28 06752215 CHIP RESISTOR 220 OHM 1/10W 1

R29 06754721 CHIP RESISTOR 4.7 K-OHM 1/10W 1

R30 06751031 CHIP RESISTOR 10 K-OHM 1/10W 1

R31 06754721 CHIP RESISTOR 4.7 K-OHM 1/10W 1

R32 06751824 CHIP RESISTOR 1.8 K-OHM 1/10W 1

R33 06753334 CHIP RESISTOR 33 K-OHM 1/10W 1

R34 06751031 CHIP RESISTOR 10 K-OHM 1/10W 1

R35-39 06754721 CHIP RESISTOR 4.7 K-OHM 1/10W 5

R40 06751525 CHIP RESISTOR 1.5 K-OHM 1/10W 1

R41 06751021 CHIP RESISTOR 1 K-OHM 1/10W 1

R42 06751031 CHIP RESISTOR 10 K-OHM 1/10W 1

R43 *1 06753314 CHIP RESISTOR 330 OHM 1/10W 1

#1 06751014 CHIP RESISTOR 100 OHM 1/10W 1

R44 06751021 CHIP RESISTOR 1 K-OHM 1/10W 1

Page 65

– 59 –

R45-53 06754721 CHIP RESISTOR 4.7 K-OHM 1/10W 9

R54 06751021 CHIP RESISTOR 1 K-OHM 1/10W 1

R55 06751014 CHIP RESISTOR 100 OHM 1/10W 1

R56-58 06754711 CHIP RESISTOR 470 OHM 1/10W 3

R59 06751031 CHIP RESISTOR 10 K-OHM 1/10W 1

R60-61 06751031 CHIP RESISTOR 10 K-OHM 1/10W 2

R62-63 06754711 CHIP RESISTOR 470 OHM 1/10W 2

R64 06752215 CHIP RESISTOR 220 OHM 1/10W 1

R65-67 06754711 CHIP RESISTOR 470 OHM 1/10W 3

R68-70 NOT MOUNTED

R71 06754711 CHIP RESISTOR 470 OHM 1/10W 1

R72 06753334 CHIP RESISTOR 33 K-OHM 1/10W 1

R73 06754711 CHIP RESISTOR 470 OHM 1/10W 1

R74 06752031 CHIP RESISTOR 20 K-OHM 1/10W 1

R75-76 06751021 CHIP RESISTOR 1 K-OHM 1/10W 2

R77-80 06754711 CHIP RESISTOR 470 OHM 1/10W 4

R81 06751031 CHIP RESISTOR 10 K-OHM 1/10W 1

R82 06753324 CHIP RESISTOR 3.3 K-OHM 1/10W 1

R83 06751021 CHIP RESISTOR 1 K-OHM 1/10W 1

R84 06753334 CHIP RESISTOR 33 K-OHM 1/10W 1

R85-86 06751014 CHIP RESISTOR 100 OHM 1/10W 2

R87-88 06751031 CHIP RESISTOR 10 K-OHM 1/10W 2

R89 06751041 CHIP RESISTOR 100 K-OHM 1/10W 1

R90-91 06751031 CHIP RESISTOR 10 K-OHM 1/10W 2

R92 06751031 CHIP RESISTOR 10 K-OHM 1/10W 1

R93 06753324 CHIP RESISTOR 3.3 K-OHM 1/10W 1

R94-95 06751014 CHIP RESISTOR 100 OHM 1/10W 2

T96-98 06751031 CHIP RESISTOR 10 K-OHM 1/10W 3

R99 06751041 CHIP RESISTOR 100 K-OHM 1/10W 1

R100-101 06751031 CHIP RESISTOR 10 K-OHM 1/10W 2

R102 06752725 CHIP RESISTOR 2.7 K-OHM 1/10W 1

R103-105 06751031 CHIP RESISTOR 10 K-OHM 1/10W 3

R106 06751021 CHIP RESISTOR 1 K-OHM 1/10W 1

R107 06751031 CHIP RESISTOR 10 K-OHM 1/10W 1

R108 06751021 CHIP RESISTOR 1 K-OHM 1/10W 1

R109 06751031 CHIP RESISTOR 10 K-OHM 1/10W 1

R110 06752031 CHIP RESISTOR 20 K-OHM 1/10W 1 TSP242/242-24

R111 06751031 CHIP RESISTOR 10 K-OHM 1/10W 1

R112 06754721 CHIP RESISTOR 4.7 K-OHM 1/10W 1

R113-114 06753324 CHIP RESISTOR 3.3 K-OHM 1/10W 2 TSP242/242-24

R115-116 06751534 CHIP RESISTOR 15 K-OHM 1/10W 2 TSP242/242-24

R117-123 NOT MOUNTED

R124 06751031 CHIP RESISTOR 10 K-OHM 1/10W 1

R125 NOT MOUNTED

R126 06751021 CHIP RESISTOR 1 K-OHM 1/10W 1

R127 06753334 CHIP RESISTOR 33 K-OHM 1/10W 1

R128 06753324 CHIP RESISTOR 3.3 K-OHM 1/10W 1

R129-133 NOT MOUNTED

BZ1 45060201 BUZZER QMB-111P 1

CN1 09100270 CONNECTOR 5483-02A 1

CN2 09100516 CONNECTOR 53014-0510 1

CN3 09100460 CONNECTOR 53014-0310 1

CN4 09100582 CONNECTOR 57GE-40360-751 1

CN5 09100664 CONNECTOR 6216-024-000 1

CN6 09100665 CONNECTOR 17JE-13090-37 1

CN7 09100267 CONNECTOR 5483-06A 1

Main Logic Board

DRWG.NO. REV. PARTS NO. PARTS NAME Q’TY REMARKS RANK

Page 66

– 60 –

CN8 09100567 CONNECTOR 95003-2661 1

CN9 09100038 CONNECTOR 5045-05A 1 TSP242/242-24

CN10 09100317 CONNECTOR 5483-04A 1

CN11 NOT MOUNTED

Main Logic Board

DRWG.NO. REV. PARTS NO. PARTS NAME Q’TY REMARKS RANK

Page 67

– 61 –

6. Power Supple Unit (120VAC/230VAC)

6-1. Circuit Diagram

Page 68

– 62 –

IC1 08202025 IC-REG 7573B 1

DB1 08990227 DIODE STACK D3SB20 1

R1 06214721 RN RESISTOR 4.7 K-OHM 1W 1

R2 06230031 RN RESISTOR 0.33 OHM 3W 1

R3 06230021 RN RESISTOR 0.22 OHM 3W 1

R4 06201022 RN RESISTOR 1 K-OHM 2W 1

C1 05291045 FILM CAPA. 0.1UF 275V 1

C2-3 05192224 CERA. CAPA. 2200PF 400V 2

C4 05054782 CHEM. CAPA. 4700UF 50V 1

C5 05051058 CHEM. CAPA. 1UF 50V 1

C6-7 05152223 CERA. CAPA. 2200PF 50V 2

C8 05043385 CHEM. CAPA. 3300UF 35V 1

C9 05044771 CHEM. CAPA. 470UF 35V 1

SW1 *1 09030026 SEESAW SWITCH T-883S3BBR1-W 1

#1 09030036 SEESAW SWITCH SF-W1P1A03BB 1

L1 09251106 LINE FILTER SU10V-05050 1

L2 09251037 CHOKE COIL NM-1-200 1

L3 09251036 CHOKE COIL NM-16-300 1

F1 09990058 FUSE 5TT1A 250V 1 FOR US S

09990021 FUSE EAWK630MA 250V 1 FOR EC,UK S

F2 09991011 FUSE 5TT3A 250V 1 FOR US,UK S

09990050 FUSE EAK3.15A 250V 1 FOR EC S

FB1 09990706 BEADS INDUCTOR B-01AT 1

CN1 80703850 CABLE UNIT 4X120TT SP300II 1

TRNS1 30780010 TRANSFORMER 120V SP200 US 1 FOR US

30780030 TRANSFORMER 230V SP200 EC 1 FOR EC,UK

- *1 09110090 CORD SET US-PN SP300 1 FOR US

#1 09110158 CORD SET US-PN L=1.8M SP3 1 FOR US

09110129 CORD SET EC-PN SP300II 1 FOR EC

09110067 CORD SET UK-PN LC 1 FOR UK

04991204 FASTENER T18S 1 FOR US

04991204 FASTENER T18S 2 FOR EC,UK

82911071 RADIATION PLATE SP312 1

01903087 SCREW TAT 3-14 2

09990023 FUSE HOLDER UF-0033 4

09990708 FERRITE CORE ESD-R-16C 1 FOR EC,UK

09992307 HEAT-SHRINK TUBE F2-18X30 1 FOR EC,UK

DRWG.NO. REV. PARTS NO. PARTS NAME Q’TY REMARKS RANK

6-2. Parts List

Power Supply Unit(120VAC/230VAC)

Page 69

– 63 –

IC1 08202048 IC-REG SI-8401L 1

ZD1 08020090 ZENER DIODE RD7.5EB1T 1

C1 05043387 CHEM. CAPA. 3300UF 35V 1

C2 NOT USED

C3 05014775 CHEM. CAPA. 470UF 10V 1

SW1 09030036 SEESAW SWITCH SF-W1P1A03BB 1

F1 09991011 FUSE 5TT3A 250V 1

09991024 FUSE HOLDER EYF52BC 2

CN1 09100636 CONNECTOR TCS7960-53-2010 1

CN2 30720080 CABLE UNIT 4X200CC SP23 1

JP1 93930006 JUMPER WIRE STP122 1

- 09991910 S/N SEAL KEI-802 1

7. Power Supple Unit (24VDC)

7-1. Circuit Diagram

7-2. Component Layout

7-3. Parts List

Power Supply Unit(24VDC)

DRWG.NO. REV. PARTS NO. PARTS NAME Q’TY REMARKS RANK

Page 70

– 64 –

8. Paper Near-End Sensor

8-1. Circuit Diagram

8-2. Parts List

DRWG.NO. REV. PARTS NO. PARTS NAME Q’TY REMARKS RANK

TR1 07227853 TRANSISTOR 2SC1740SE 1

PS1 08300082 PHOTO-INTERRUPTER PS6002A-KS 1

R1 06051235 RD RESISTOR 12 K-OHM 1/6W 1

R2 06057514 RD RESISTOR 750 OHM 1/6W 1

R3 06053324 RD RESISTOR 3.3 K-OHM 1/6W 1

C1 05532234 CAPACITOR 0.022UF 25V 1

- 30721241 CABLE UNIT 3X270C TSP2 1

BLU2

WHT1

GRN3

R3

3.3K

PSI

PS6002A

R1

12K

C1

0.022µF

R2

750

TRI

C1740

CN3

Page 71

Page 72

Printed in Japan, 80873016

Distributed by

STAR MICRONICS U.K. LTD.

Star House, Peregrine Business

Park, Gomm Road, High Wycombe,

Bucks, HP13 7DL, U.K.

Tel : 01494-471111

Fax : 01494-473333

OVERSEAS SUBSIDIARY COMPANIES

STAR MICRONICS AMERICA, INC.

70-D Ethel Road West,

Piscataway, NJ 08854 U.S.A

Tel : 732-572-9512

Fax : 732-572-5095

ELECTRONIC PRODUCTS DIVISION

STAR MICRONICS CO., LTD.

536 Nanatsushinya,

Shimizu, Shizuoka, 424-0066 Japan

Tel : 0543-47-0112

Fax : 0543-48-5271

Please access the following URL

http://www.star-micronics.co.jp/service/t_mans_e.htm

for the lastest revision of the manual.

Loading...

Loading...