Page 1

THERMAL PRINTER

TSP200-24

USERS MANUAL

MODE D’EMPLOI

BEDIENUNGSANLEITUNG

MANUALE DI ISTRUZIONI

Page 2

Federal Communications Commission

Radio Frequency Interference

Statement

This equipment has been tested and found to comply with the limits for a Class A digital

device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference when the equipment is operated in a

commercial environment. This equipment generates, uses and can radiate radio frequency

energy and, if not installed and used in accordance with the instruction manual, may cause

harmful interference to radio communications. Operation of this equipment in a residential

area is likely to cause harmful interference in which case the user will be required to corect

the interference at his own expense.

For compliance with the Federal Noise Interference Standard, this equipment requires a shielded

cable.

This statement will be applied only for the printers marketed in U.S.A.

Statement of

The Canadian Department of Communications

Radio Interference Regulations

This digital apparatus does not exceed the Class A limits for radio noise emissions from

digital apparatus set out in the Radio Interference Regulations of the Canadian Department

of Communications.

Le présent appareil numérique n’émet pas de bruits radioélectiques dépassant les limites

applicables aux appareils numériques de la classe A prescrites dans le Règlement sur le brouillage

radioélectrique édicté par le ministère des Communications du Canada.

The above statement applies only to printers marketed in Canada.

CE

Manufacturer’s Declaration of Conformity

EC Council Directive 89/336/EEC of 3 May 1989

This product, has been designed and manufactured in accordance with the International Standards EN 50081-1/01.92 and

EN 50082-1/01.92, following the provisions of the Electro Magnetic Compatibility Directive of the European Communities as of May 1989.

EC Council Directive 73/23/EEC and 93/68/EEC of 22 July 1993

This product, has been designed and manufactured in accordance with the International Standards EN 60950, following

the provisions of the Low Voltage Directive of the European Communities as of July 1993.

The above statement applies only to printers marketed in EU.

Trademark acknowledgments

TSP200-24: Star Micronics Co. Ltd.

ESC/POS: Seiko Epson Corporation

Notice

• All rights reserved. Reproduction of any part of this manual in any form whatsoever, without STAR’s express

permission, is strictly forbidden.

• The contents of this manual are subject to change without notice.

• All efforts have been made to ensure the accuracy of the contents of this manual at the time of printing. However,

should any errors be found, STAR would greatly appreciate being informed of them.

• The above notwithstanding, STAR can assume no responsibility for any errors in this manual.

© Copyright 1999 Star Micronics Co., Ltd.

Page 3

Table of Contents

1. Unpacking and Inspection .....................................................................1

1-1. Unpacking ....................................................................................1

1-2. Locating the Printer......................................................................1

2. Parts Identification and Nomenclature ..................................................2

3. Printer Connection.................................................................................3

3-1. Interface Cable .............................................................................3

3-2. Ferrite Core (

3-3. Optional AC Adapter ...................................................................7

4. Near-End Sensor....................................................................................8

5. Loading Paper........................................................................................9

5-1. Loading Paper ..............................................................................9

5-2. Refilling the Paper Supply .........................................................13

5-3. 76mm Width Support.................................................................14

5-4. Clearing Paper Jams...................................................................16

6. Control Panel .......................................................................................17

6-1. Power ON...................................................................................17

6-2. Combined Control Panel Operations .........................................18

6-3. Errors..........................................................................................20

6-4. Buzzer Indicators (Star Mode Only) .......................................... 21

7. Cautions ............................................................................................... 22

7-1. Operating Cautions ....................................................................22

7-2. Safety Cautions ..........................................................................22

Europe only)...............................................................5

ENGLISH

8. Command summary.............................................................................23

8-1. Star Mode................................................................................... 23

8-2. ESC/POS Mode..........................................................................27

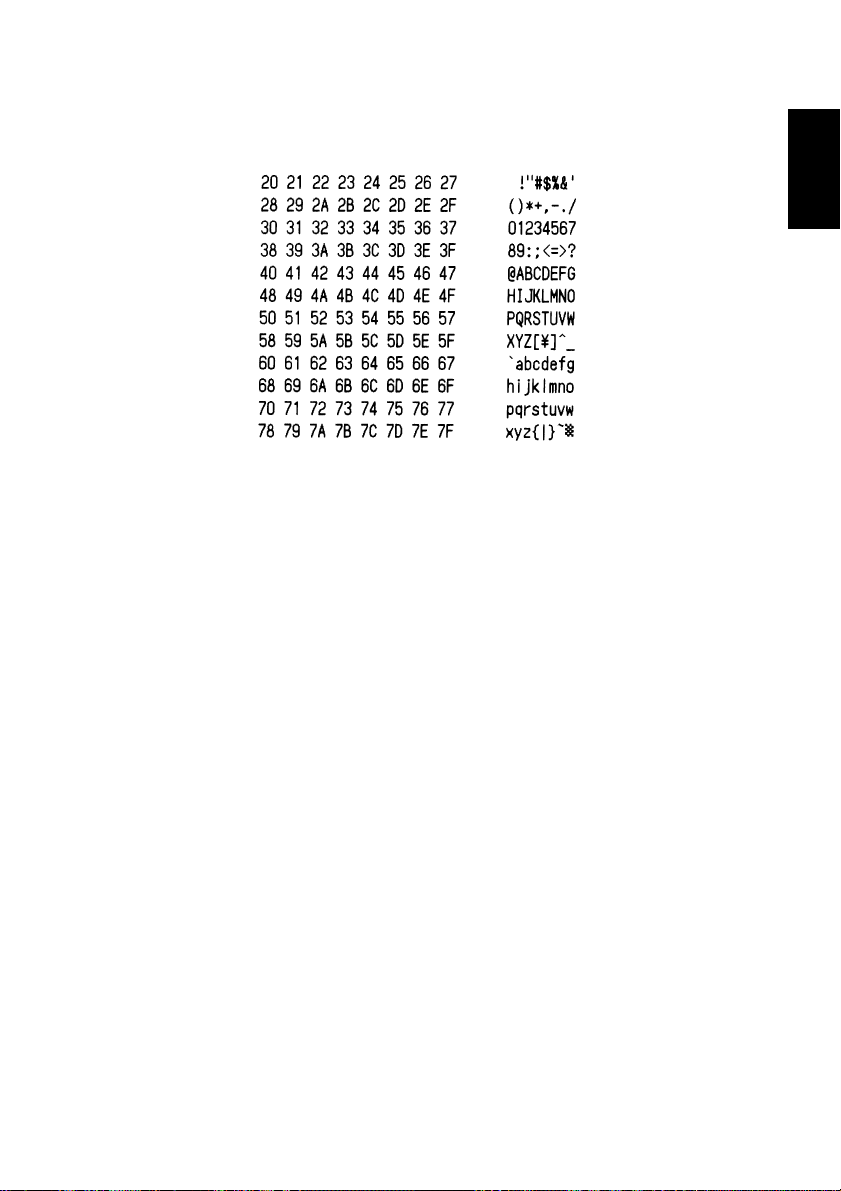

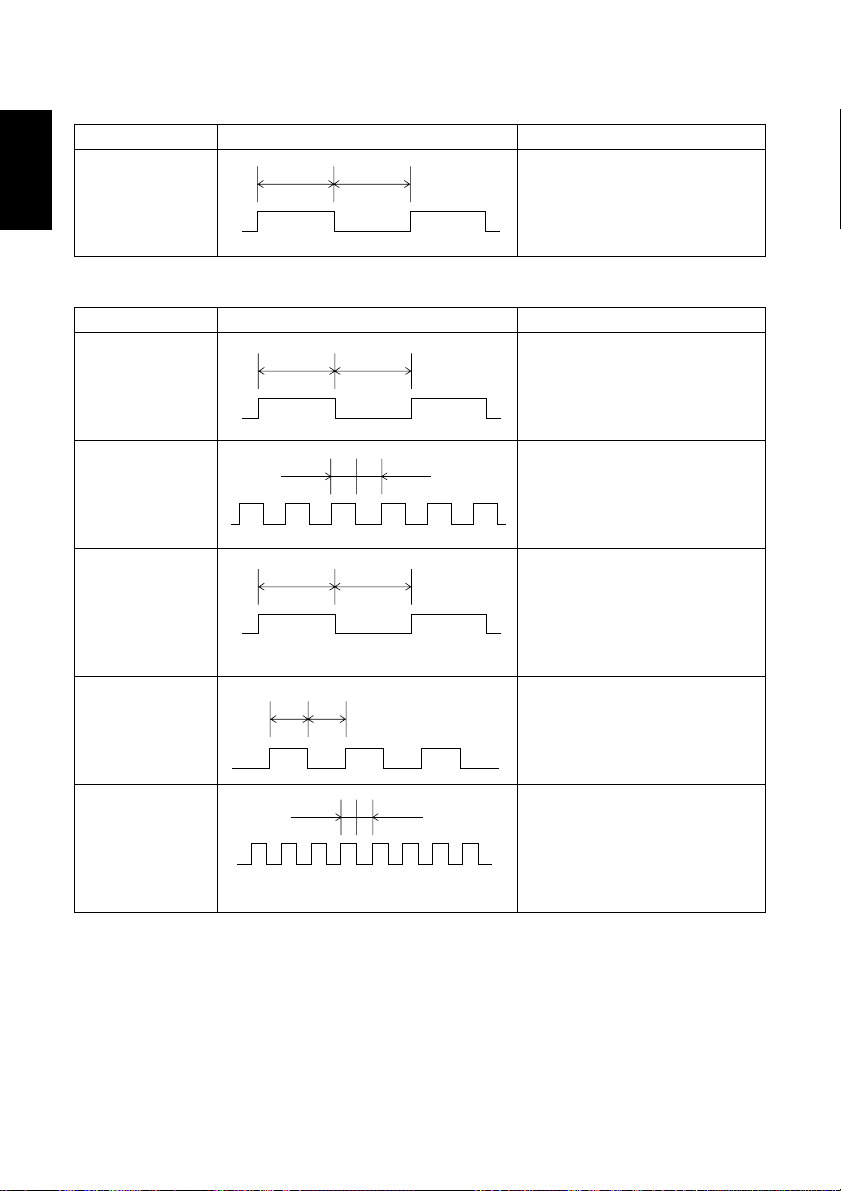

Appendix ............................................................................................... 119

Appendix A: General Specifications ............................................... 119

Appendix B: DIP Switch Setting.....................................................123

Appendix C: Interface .....................................................................125

Appendix D: Peripheral Unit Drive Circuit ....................................130

Appendix E: Cleaning .....................................................................132

Page 4

Page 5

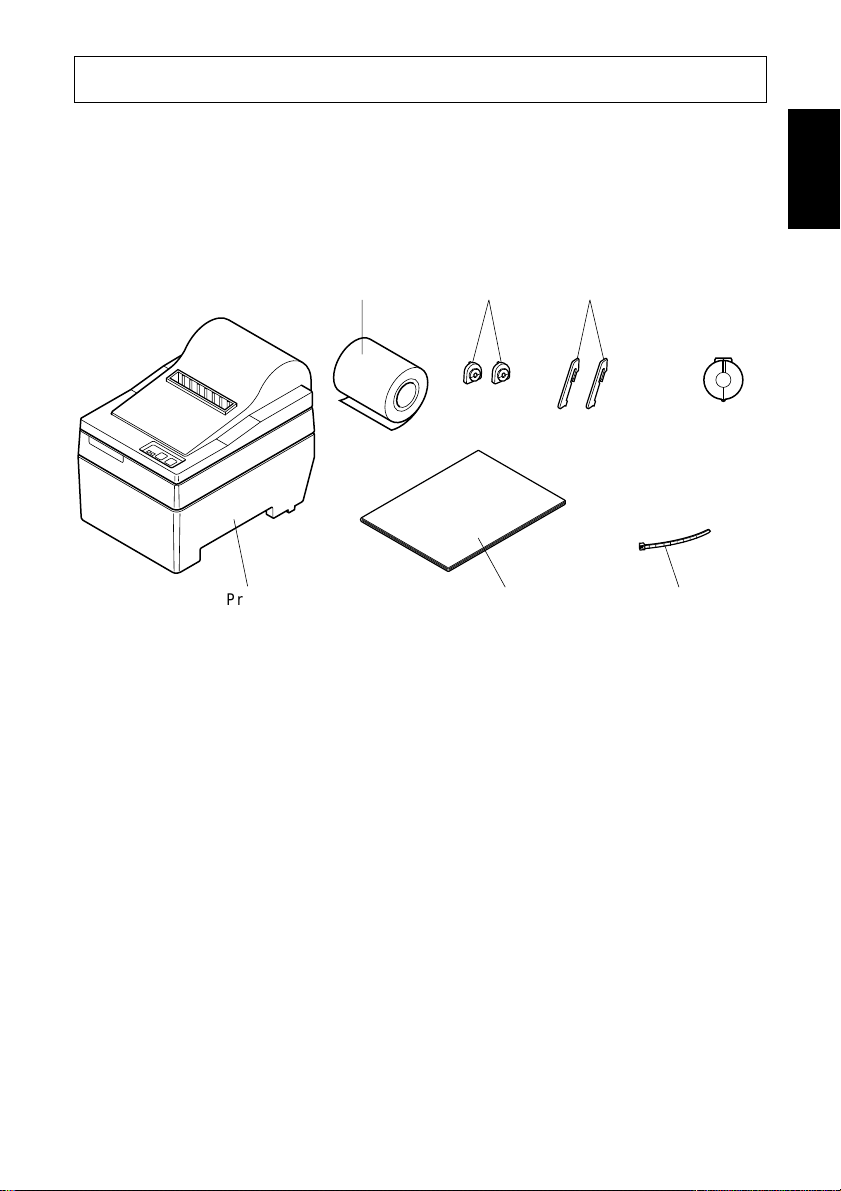

1. Unpacking and Inspection

1-1. Unpacking

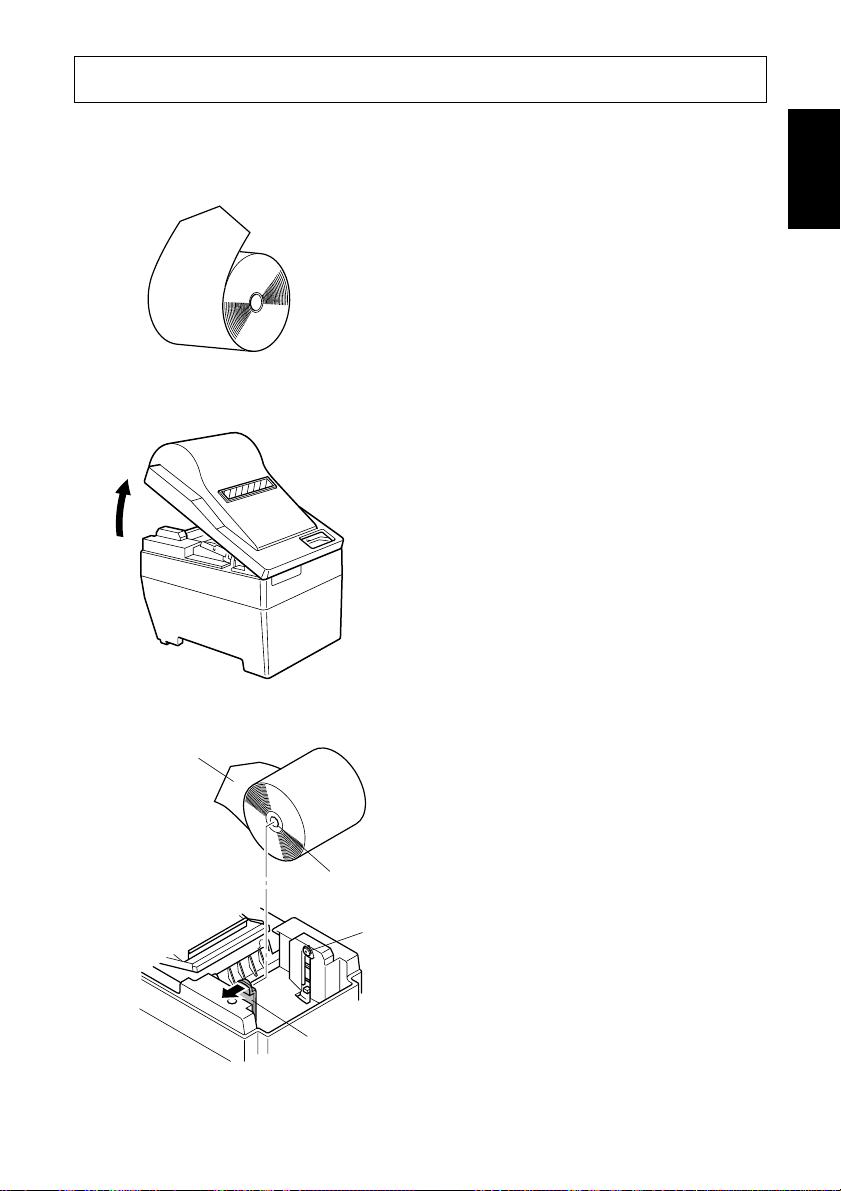

Check each item in the box against Figure 1-1 to make sure that you have

everything.

If any of these items are missing, contact your supplier.

ENGLISH

Printer

Sample paper roll

Fig. 1-1

76mm holders

User's manual

support spacers

Ferrite core

for peripheral

unit cable

(E.U. only)

Fastener

(E.U. only)

1-2. Locating the printer

Before you start setting up your printer, make sure that you have a suitable place

in which to locate it. By “a suitable place”, we mean:

• Close to an easily accessible socket-outlet.

• A firm, level surface which is fairly vibration-free

• Away from excessive heat (such as direct sunlight, heaters, etc)

• Away from excessive humidity

• Away from excessive dust

• With access to a steady power supply that is not subject to power surges. For

example, do not connect the printer to the same circuit as a large, noiseproducing appliance such as a refrigerator or an air conditioner.

NOTE:Make sure that the line voltage is the voltage specified on the printer’s

identification plate.

– 1 –

Page 6

ENGLISH

Protects the printer from

dust and reduces noise.

Do not open the cover

while printing.

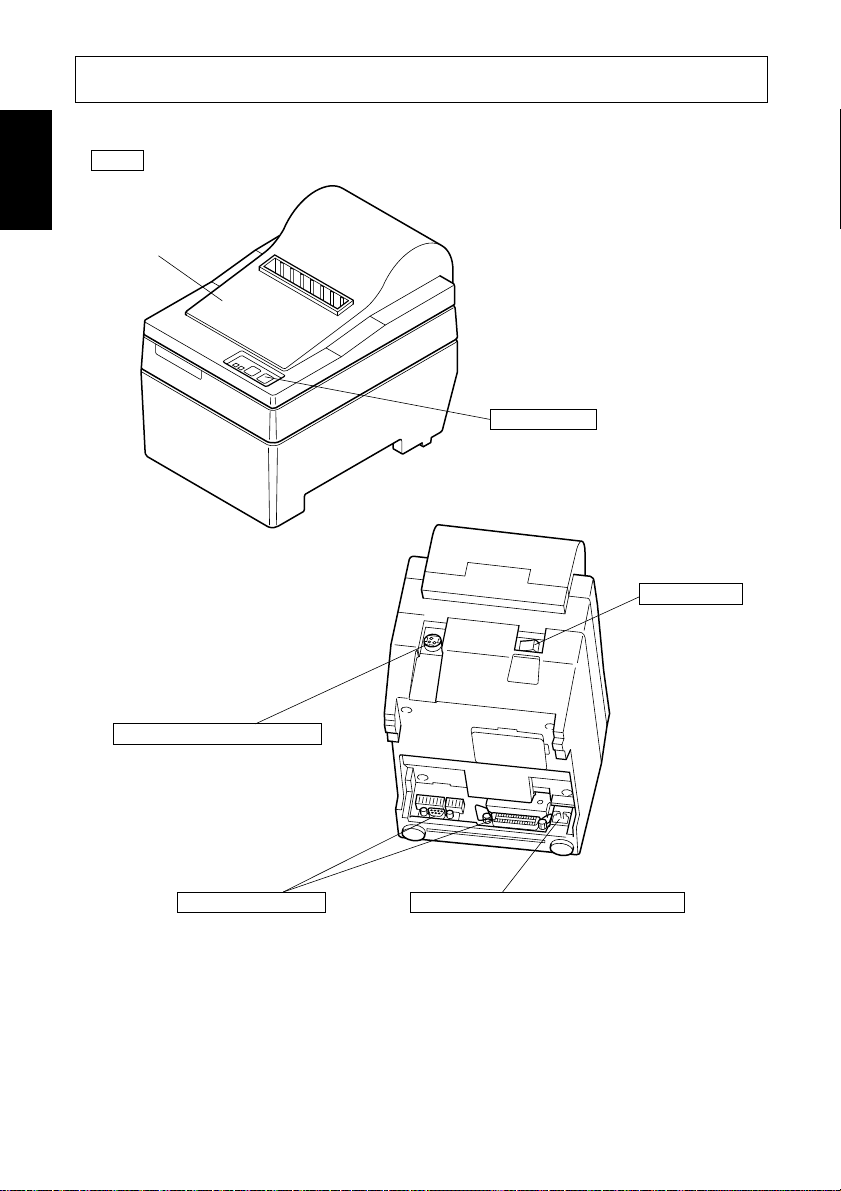

2. Parts Identification and Nomenclature

Cover

Control panel

Features two control

switches and two

indicators to indicate

printer status.

Power switch

Turns printer

power on and off.

AC adapter cable connector

For connection of the AC adapter.

Never unplug the AC adapter

while the printer is on.

Interface connector

Connects the printer

with host computer.

Fig. 2-1 External view of the printer

Peripheral unit drive circuit connector

Connects to peripheral units such

as cash drawers, etc.

Do not connect this to a telephone.

– 2 –

Page 7

3. Printer Connection

Please prepare the following before making connections to the printer. Always

have the power switch in the off position when making any connections.

• Interface cable

• Ferrite core (E.U. only)

• Optional AC adapter

ENGLISH

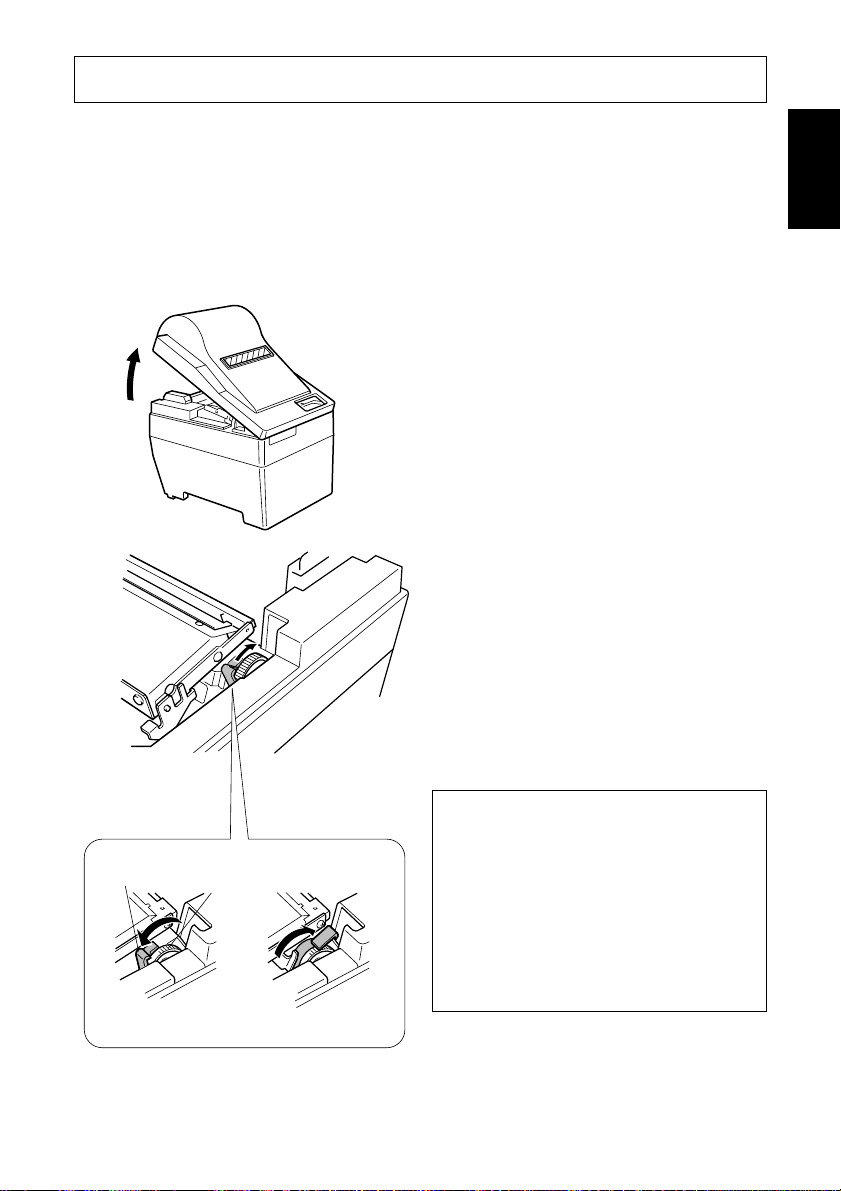

3-1. Interface Cable

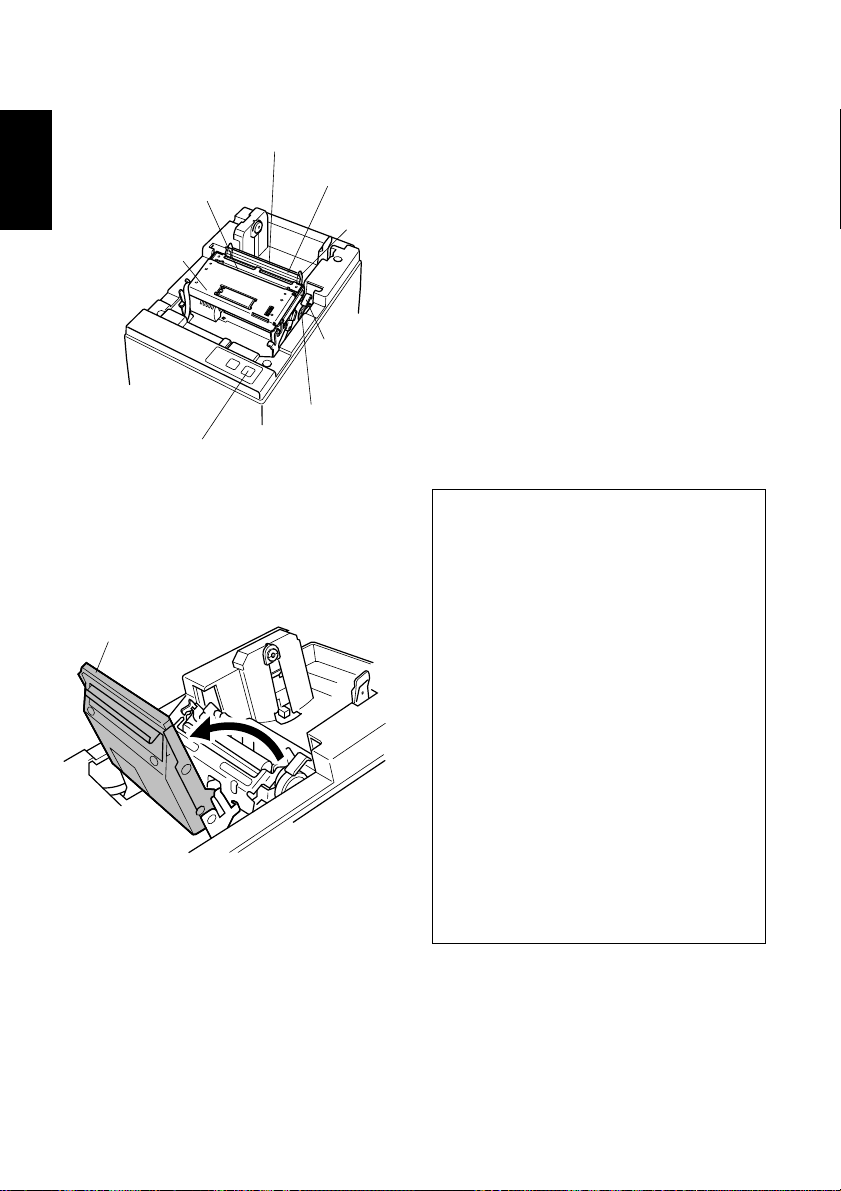

Head-up

lever

[Head-up position]

Feed knob

[Head-closed position]

1 Open the cover

2 Push the head up lever (green) to the

rear.

Caution

If the printer is to be shipped, or if it

is to be stored for an extended period

of time, always pull the head up lever

forward so that the printer head is in

the up position. This will protect the

thermal head and prevent deformation of the platen.

3 Close the cover.

– 3 –

Page 8

ENGLISH

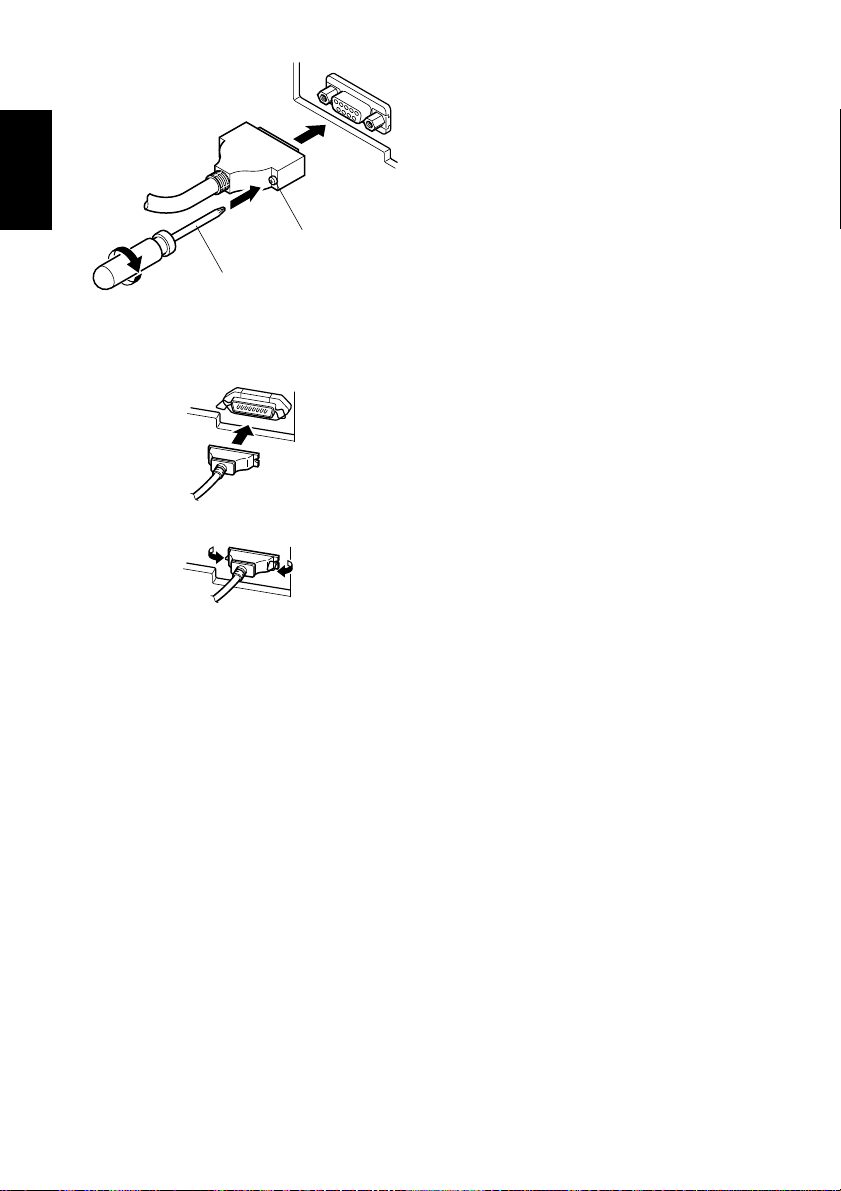

4 Plug the printer-side connector of

the interface cable into the printer

interface connector and use screws

to secure the serial interface connector or a hook bracket to secure

the parallel interface connector.

Screws

Screwdriver

– 4 –

Page 9

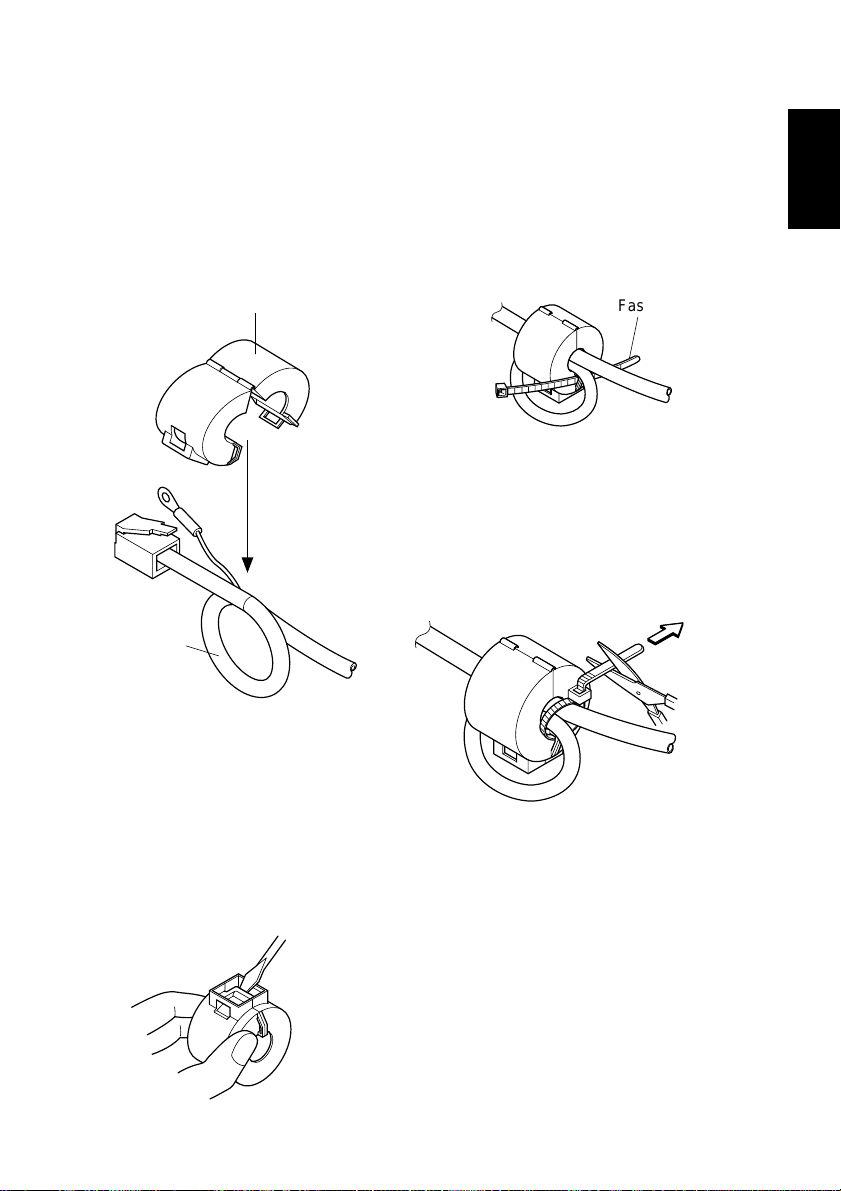

3-2. Ferrite Core (Europe only)

Fastener

NOTE:Take special care when following the procedures listed below.

■ A ferrite core noise filter for the

peripheral unit cable comes packed

with the printer.

■ The ferrite core is normally packed

so it is opened, as shown in Fig. 3-1.

Ferrite core (28mm diameter)

• Pass the fastener through the ferrite

core.

Fig. 3-3

ENGLISH

One loop

Fig. 3-1

If you find that the ferrite core is not

opened: Use a pointed object to pry

the plastic lock of the ferrite core

apart, as shown in Fig. 3-2. When

opening it, take care not to damage

the ferrite core or the plastic lock.

Fig. 3-2

Pull and cut

• Pass the fastener around the cable

and lock it.

Cut off the excess with a pair of scissors.

Fig. 3-4

– 5 –

Page 10

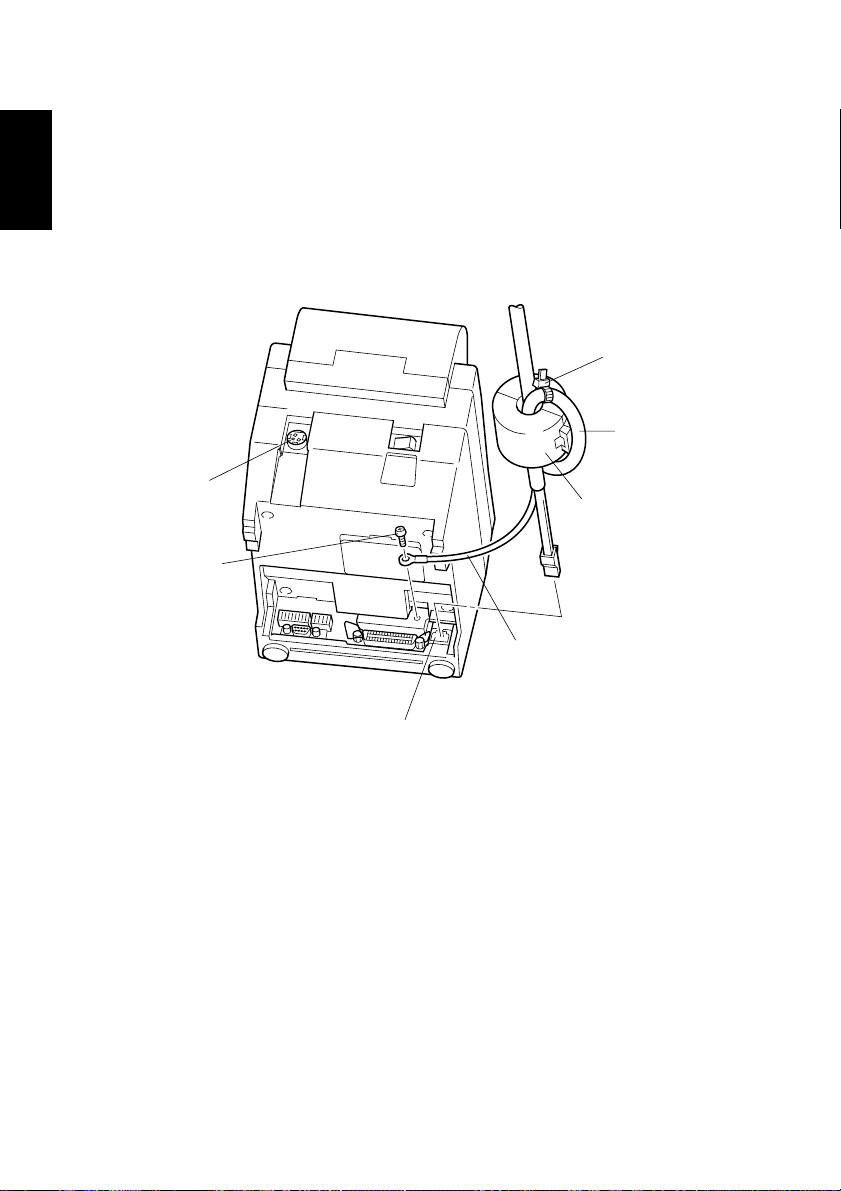

■ Clamp the ferrite core onto the peripheral unit cable, looping the cable as

shown in Fig. 3-1.

ENGLISH

• When installing the ferrite core be careful not to damage the cable.

• The ferrite core should be anchored firmly in place with the fastener that

comes with it, as shown in Fig. 3-3 and Fig. 3-4.

• Do not forget to loop the cable.

Fastener

One loop

Connector

Ferrite core

Screw M3×4

Peripheral unit drive

circuit connector

Fig. 3-5

– 6 –

Separate ground wire

Page 11

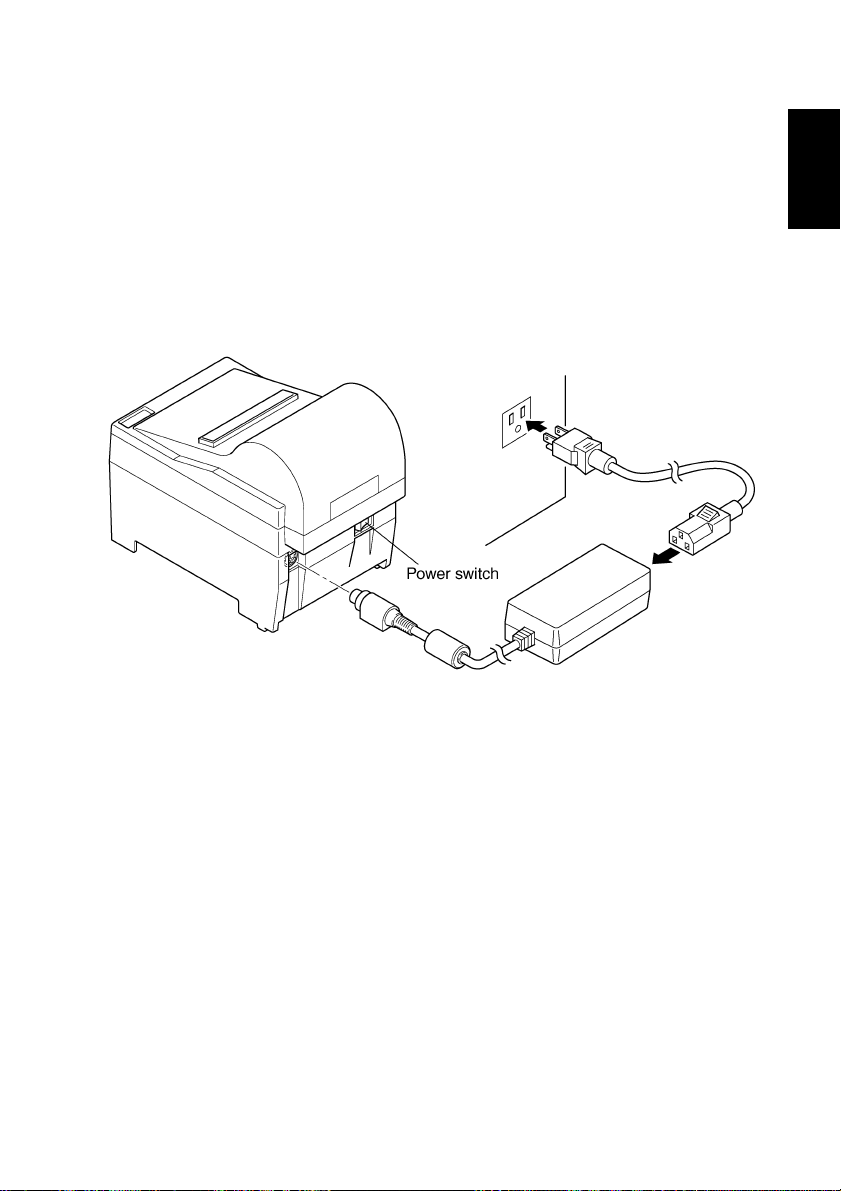

3-3. Optional AC Adapter

NOTE:Before connecting/disconnecting the AC adapter, make sure that power

to the printer and all the devices connected to the printer is turned off.

Also make sure the power cable plug is disconnected from the AC outlet.

1 Connect the AC adapter to the power cable.

Note: Use only the standard AC adapter and power cable.

2 Connect the AC adapter to the connector on the printer.

3 Insert the power cable plug into an AC outlet.

Fig. 3-6

ENGLISH

– 7 –

Page 12

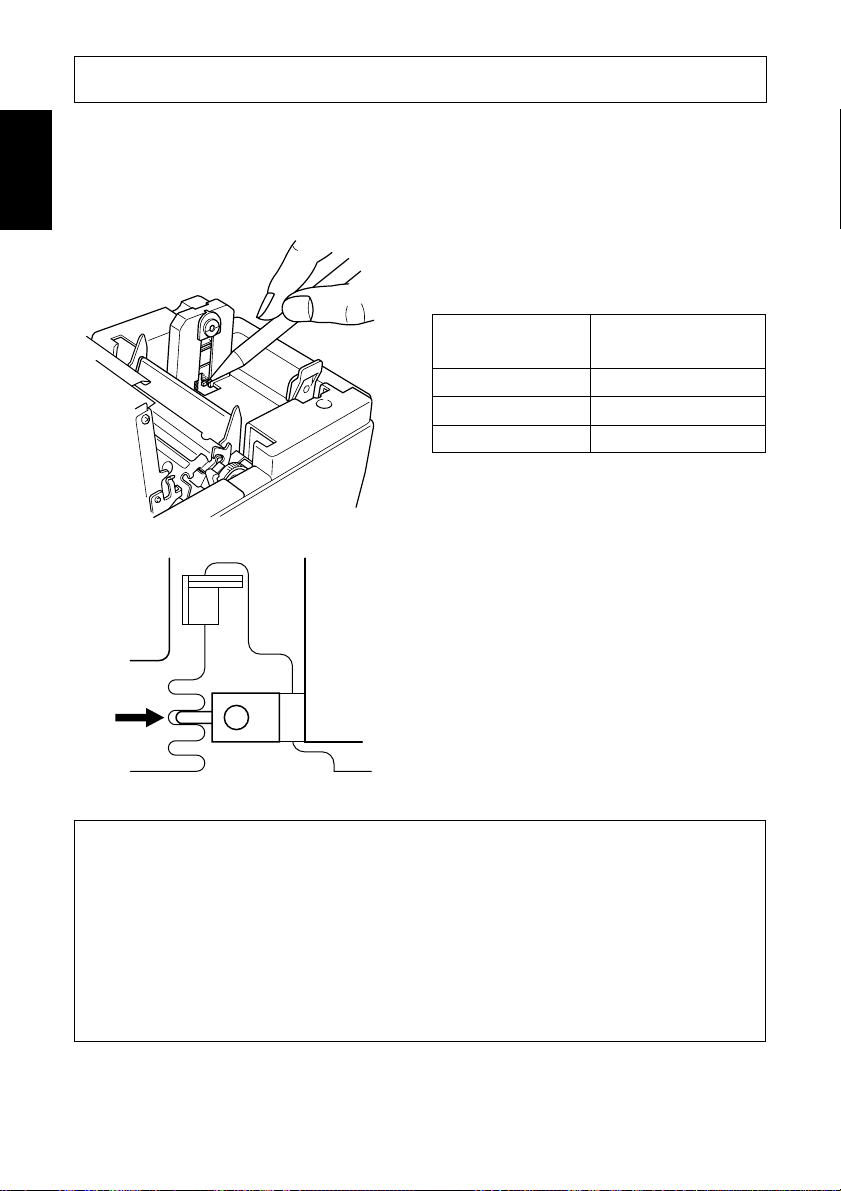

4. Near-End Sensor

ENGLISH

This printer is equipped with a sensor that detects when a roll of paper is near the

end. Read the following if you are going to use this sensor.

1 Open the cover.

2 Refer to the table below and set the

detection position for the diameter

of the roll being used.

Roll Diameter

Position

Approx. 22mm Step 1

Approx. 26mm Step 2

Approx. 30mm Step 3

3 Move the sensor and adjust the

guraduation of the sensor to the

adjusted position that corresponds

to the diameter of the roll selected.

Press this hole with a ball point pen or

similar pointed object and slide it into

position. Make sure that the protruding

section (shown by arrow) is securely in

the groove, especially at step 2.

Cautions

1) The factory setting is step 1.

2) Always use a paper roll with a core that has an inside diameter of 12 mm and

an outside diameter of 18 mm in order to ensure proper detection of the

remaining paper amount.

3) The near-end sensor is disabled when shipped from the factory. It can be

enabled by rewriting the memory switch. Refer to the “Programmer’s

Manual” for details.

Adjustment

– 8 –

Page 13

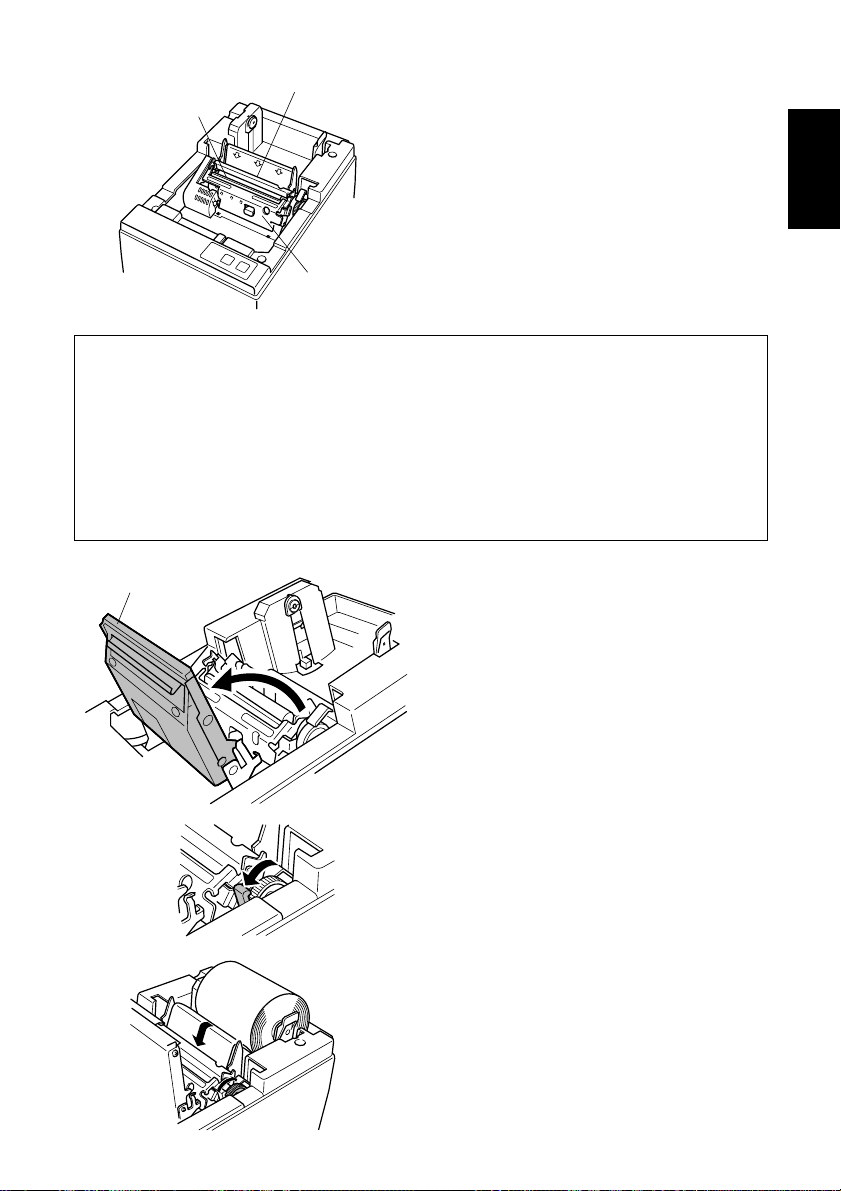

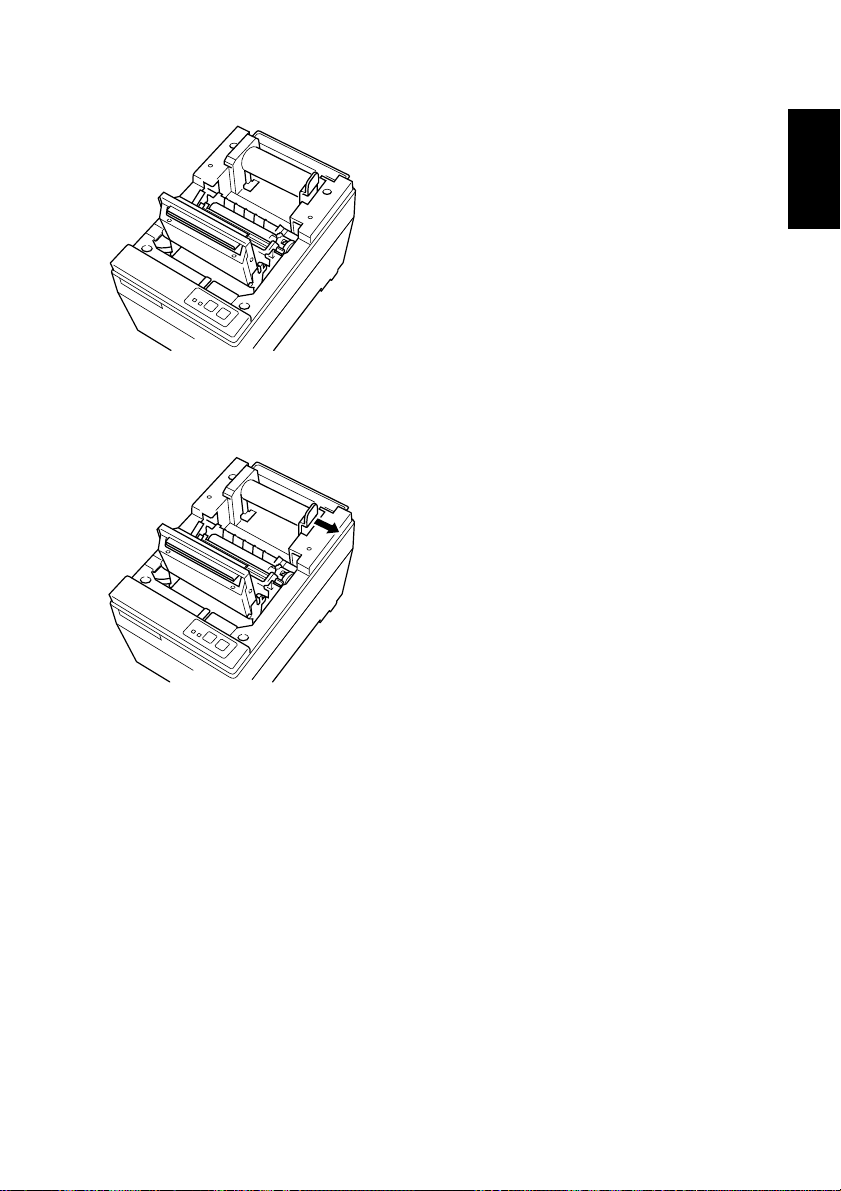

5-1. Loading Paper

5. Loading Paper

Paper roll

Core

1 Procure a roll of paper and fold in

the corners as shown in the illustration.

2 Open the printer cover.

3 Open the holder lever by pressing it

in the direction indicated by the

arrow. Load the paper in the direction shown in the illustration. Make

sure that the core of the paper roll is

held securely by the holder.

ENGLISH

Holder

Holder lever

– 9 –

Page 14

ENGLISH

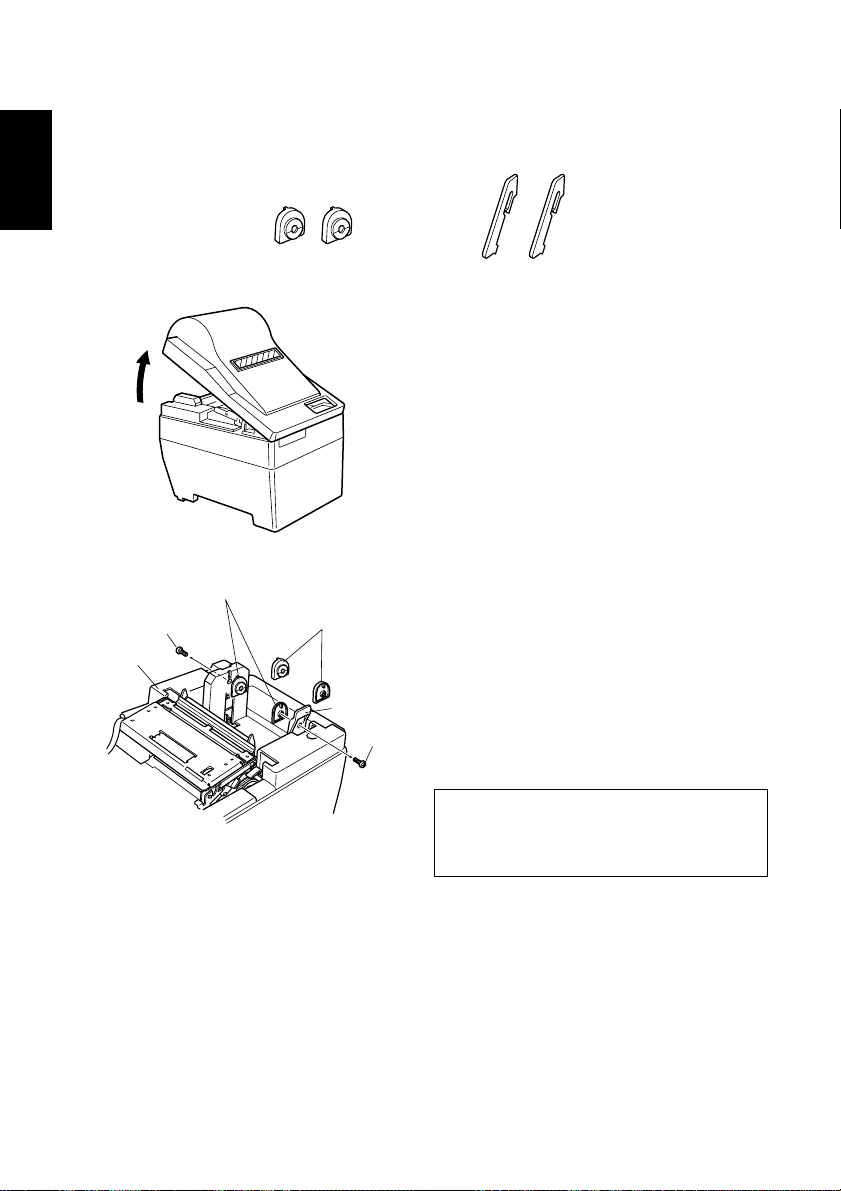

Auto cutter unit

Paper exit

Auto cutter

unit

Feed switch

Paper feeder

Paper guide

Feed knob

Support guide

Head-up lever

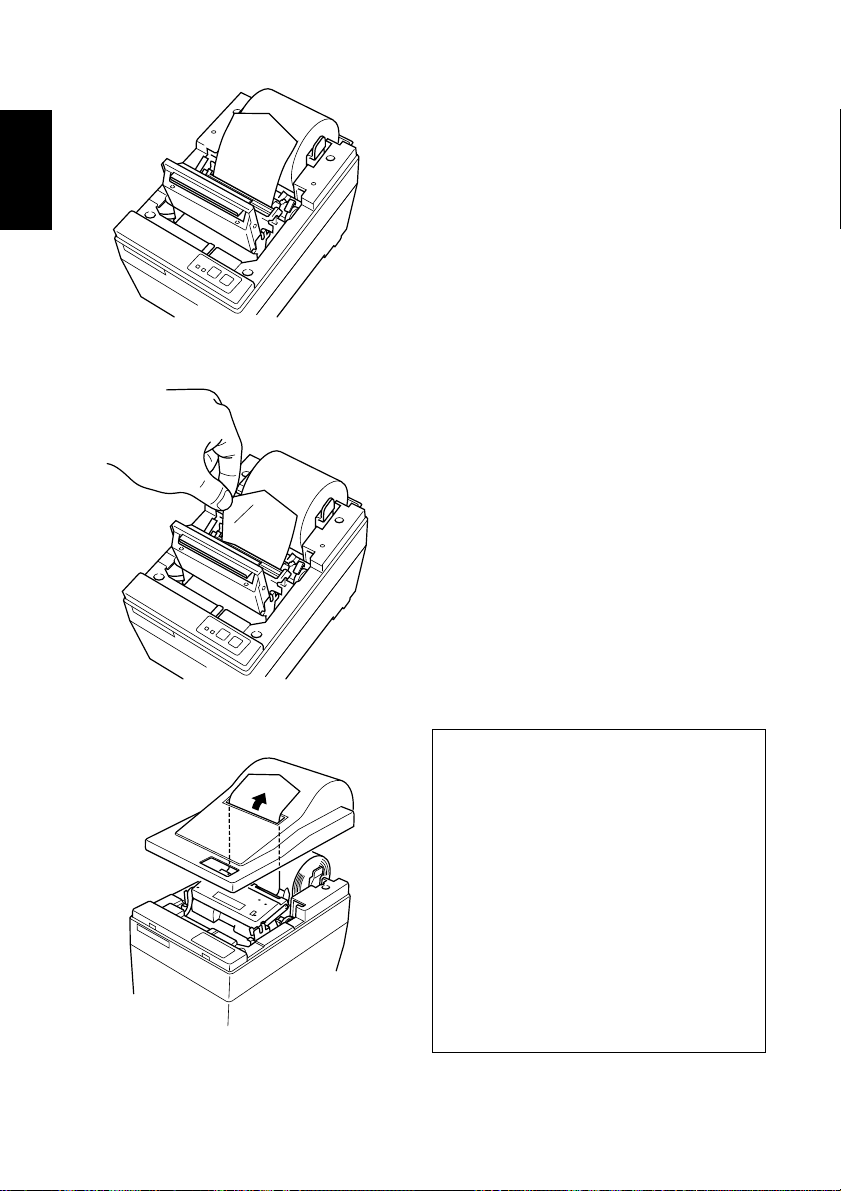

4 (Using the auto loading function)

• With the auto cutter installed.

1) The unit is shipped with the head-up

lever in the up position. Press the

lever back to put it in the closed

position. See “Chapter 3: Printer

Connection” for details.

2) Insert the edge of the paper into the

paper feeder. If inserted correctly,

the edge of the paper will pass

through the paper exit.

Caution

If the paper is not completely straight

when it is inserted into the unit, the

paper will “skew”

*1) and the edges

will fold. Depending upon the degree

of the skew, the flow of paper can be

automatically corrected by pressing

the FEED switch

*2) to adjust the

flow of paper. However, should the

paper become extremely skewed, a

paper jam may occur. To clear the

jam, pull the auto cutter unit all the

way back in the direction indicated

by the arrow until the lock engages.

With the lever in the “head-up” position, pull out the paper from the paper

feeder.

– 10 –

1)

Skew: When paper is fed unevenly

*

into the printer.

2)

See “Chapter 6: Control Panel” for

*

details on operating the FEED

switch.

Page 15

Paper feeder

Paper exit

• Without an auto paper cutter.

1) Same as 4-1.

2) Insert the edge of the paper into the

paper feeder. If inserted correctly,

the edge of the paper will pass

through the paper exit.

Printer mechanism

Caution

If the paper is not completely straight when it is inserted into the unit, the paper

will “skew” and the edges will fold. Depending upon the degree of the skew,

the flow of paper can be automatically corrected by pressing the FEED switch.

However, should the paper become extremely skewed, a paper jam may occur.

To clear the jam, pull the head-up lever forward. With the lever in the “headup” position, pull out the paper from the paper feeder.

ENGLISH

Auto cutter unit

5 (Manual loading)

1) Move the auto cutter unit all the way

back in the direction indicated by

the arrow until the lock engages

(unnecessary if an auto cutter unit is

not installed).

2) Pull the head-up lever forward into

the “head-up” position. The headup lever is shipped from the factory

in the “head-up” position.

See “Chapter 3: Printer Connection” for details.

3) Insert the edge of the paper into the

paper feeder. Turn the feed knob

(green) until the edge of the paper

passes through the printer mechanism’s paper exit.

– 11 –

Page 16

ENGLISH

4) Once the paper has passed through

the printer mechanism’s paper exit,

pull the paper straight to correctly

position it.

5) Make sure that the paper is straight

with approximately 15-20 centimeters

exposed and lower back the head-up

cutter.

6) Take the edge of the paper and cut it

by pressing it up against the head.

Be careful not to cut yourself on the

edge of the auto cutter unit during

this step.

7) Close the auto cutter unit (unnecessary if an auto cutter unit is not

installed).

8) Close the cover, turn on the ON

LINE switch and make sure that the

ON LINE indicator turns on.

See “Chapter 6: Control Panel” for

details on the ON LINE indicator

and switch.

Caution

When using the auto loading function, part of the paper will be exposed

after loading. Be sure to pass this

length of the paper through the paper

exit of the printer cover before closing the cover.

When loading paper manually, make

sure that paper has passed through

the paper exit of the printer cover

after closing the cover and pressing

the FEED switch.

– 12 –

Page 17

5-2. Refilling the Paper Supply

1 When the paper sensor detects that

the printer is out of paper, press the

FEED switch until the paper feeding action stops. If the near-end

sensor is operating and there is still

paper on the roll, cut the paper just

in front of the paper feeder and press

the FEED switch until the paper

feeding action stops. See “Chapter

4: Near-end Sensor” for details.

2 Open the cover, pull the head-up

lever forward into the “head-up”

position and pull out the paper.

3 Open the holder lever in the direc-

tion indicated by the arrow and remove the core and any left over

paper.

4 See “5-1: Loading Paper” and fol-

low the directions provided to refill

the paper supply.

ENGLISH

– 13 –

Page 18

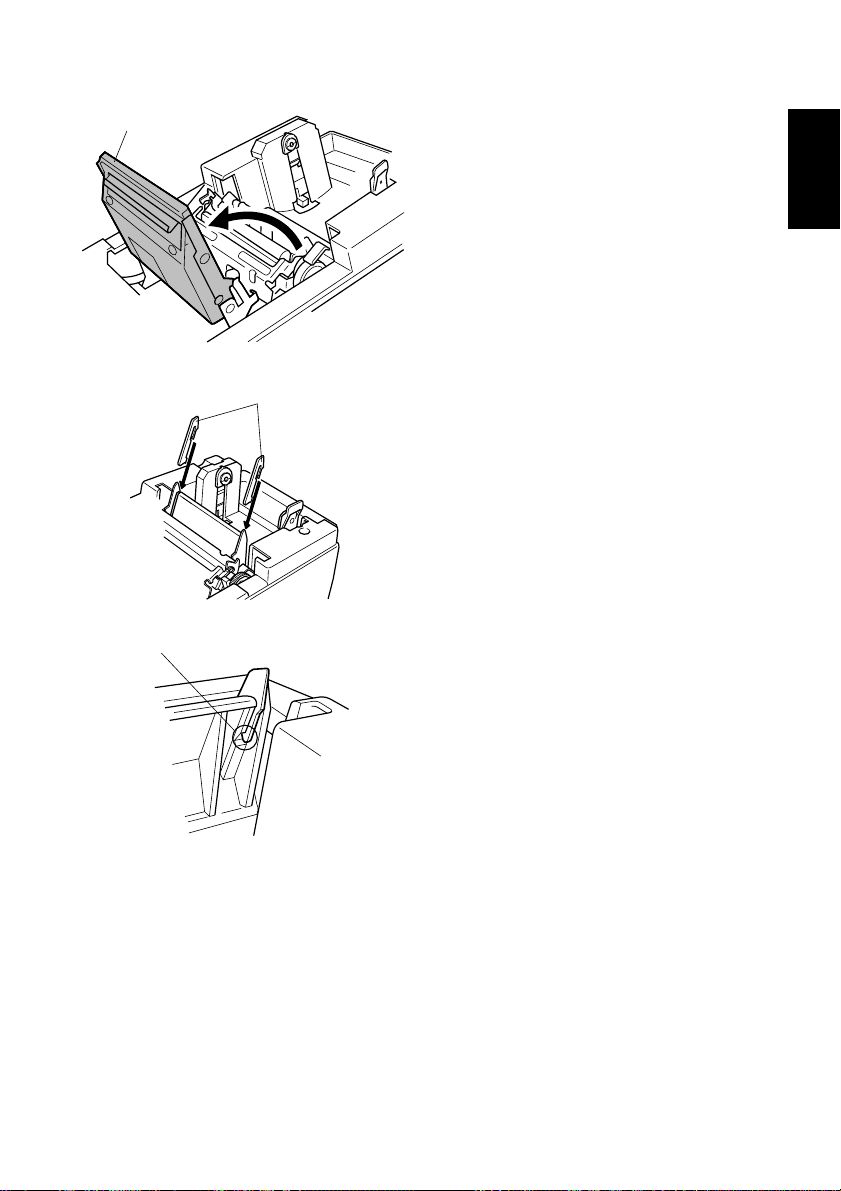

5-3. 76mm Width Support

76mm width support is an available accessory when adding to or changing the

ENGLISH

configuration of the printer.

M2 screw

Upper case

76mm holders

80mm holders

76mm holders

Holder lever

M2 screw

Support spacers

1 Open the printer cover.

2 Use a screwdriver to remove the

M2 screws that fasten the 80mm

holders to the upper case and the

holder lever. Replace the 80mm

holders with the optional 76mm

holders.

Caution

Be careful not to drop any of the

screws.

– 14 –

Page 19

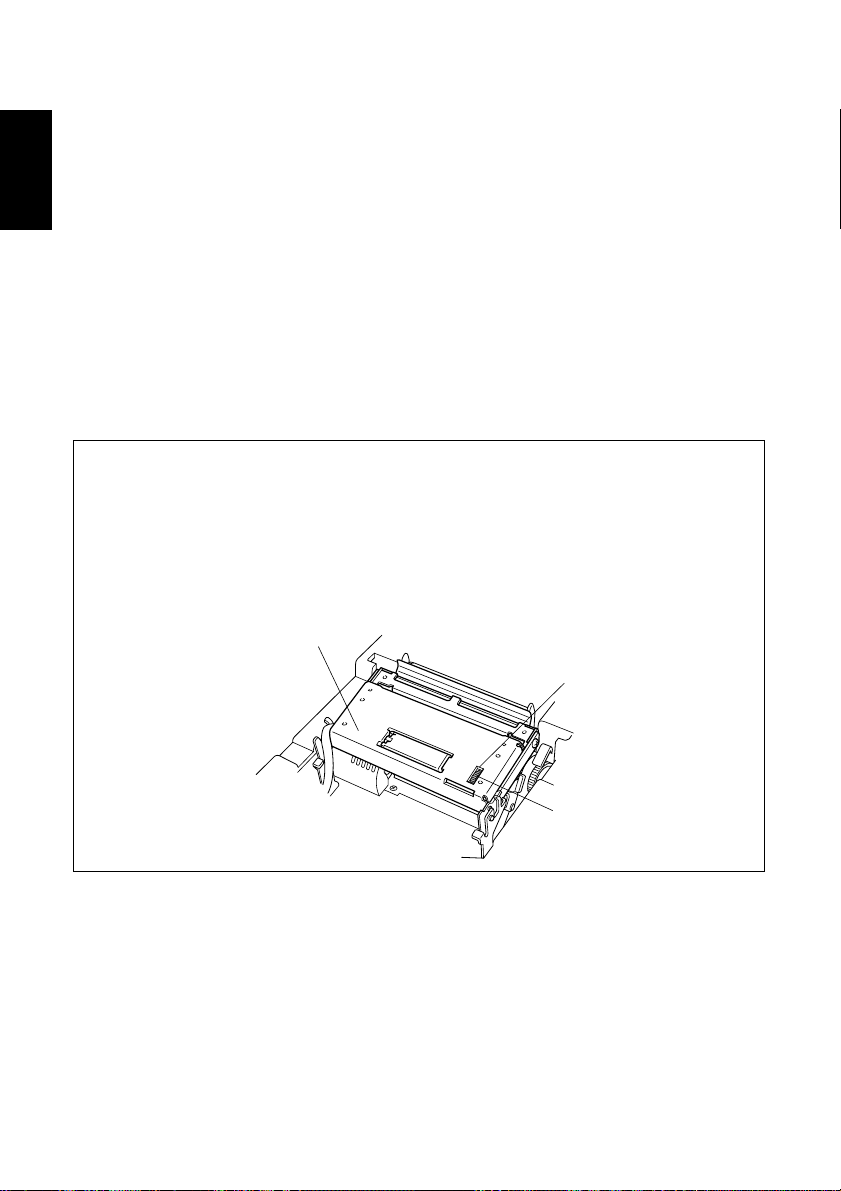

Auto cutter unit

Support spacer

Where the catch locks

3 Move the auto cutter unit in the

direction of the arrow until the lock

engages (unnecessary if an auto

cutter unit is not installed).

4 Insert the support spacers for 76mm

paper into the inner left and right

sides of the support guides as shown

in the illustration. Make sure that

the catches on the support spacers

lock onto the holes in the support

guides.

ENGLISH

5 Close the auto cutter unit (unneces-

sary if an auto cutter unit is not

installed).

– 15 –

Page 20

5-4. Clearing Paper Jams

ENGLISH

1 Turn the power to the printer OFF and open the cover.

2 Move the auto cutter unit in the direction of the arrow until the lock engages

(unnecessary if an auto cutter unit is not installed).

3 Cut some of the paper from the roll just in front of the paper feeder to clear the

paper jam.

4 Using the same procedure described for cleaning the head, push the head-open

lever back and release the set cover to enable the head-open position. See

“Appendix E: Cleaning” for details.

5 Clear away the jammed paper. If the jammed paper cannot be reached, turn the

feed knob and remove the paper.

6 Once the paper jam has been removed, press the top of the set cover and engage

the head-open lever.

Cautions

* If a paper jam should occur in the auto cutter, place a screwdriver into the

opening located on the upper right surface of the auto cutter unit; using the

screwdriver, turn the knob to move the blade and remove the jammed paper.

* Certain parts of the printer, especially the metal fixtures, can cause injuries if

handled improperly. Please be careful when handling the printer.

Auto cutter unit

Opening

– 16 –

Knob

Page 21

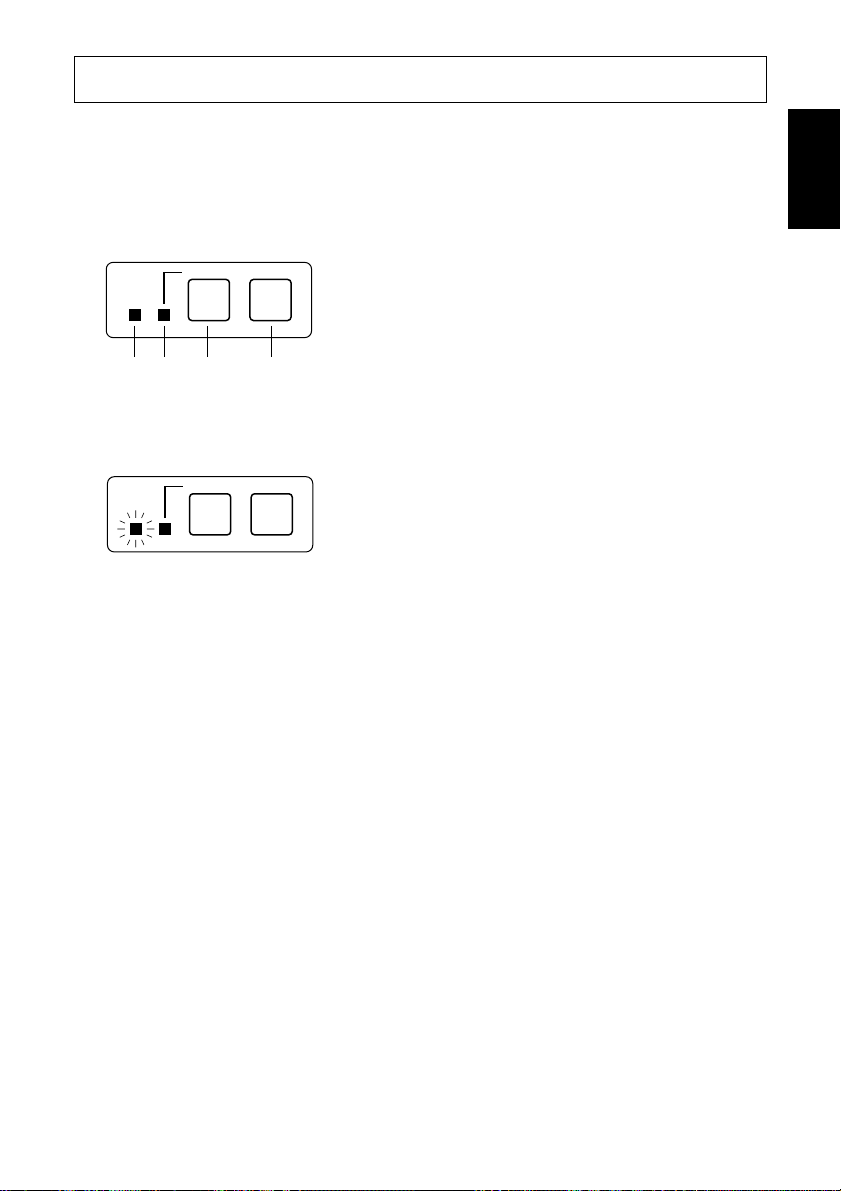

6-1. Power ON

Operating Panel

Paper - Yes

POWER

12 3 4

Paper - No

ON LINE

FEED

6. Control Panel

1 Power Lamp (Green LED)

2 On-Line Lamp (Green LED)

3 On-Line Switch

4 Feed Switch

ENGLISH

POWER

ON LINE

FEED

When the power switch is turned on, the Power Lamp and On-Line Lamp will

come on. If there is no paper, the Power Lamp will flash at approximately one

second intervals.

ON LINE Switch Indicator (Star mode only)

Used to switch between the off-line and on-line modes.

The ON LINE indicator turns on when the printer is on-line.

When the printer is off-line, printing will stop and data from the host computer

cannot be received.

FEED Switch

Each press of the FEED switch feeds paper through the printer one line at a time.

Paper is fed continuously when the FEED switch is pressed and held.

The functions of the FEED switch are supported by both the on-line and off-line

modes.

Power Indicator

The power indicator turns on when power is being supplied to the printer.

– 17 –

Page 22

6-2. Combined Control Panel Operations

The following settings can be made when the power switch is set to on.

ENGLISH

1 Test print

The buzzer will beep when the FEED switch is pressed and held while the

power is turned on.

– 18 –

Page 23

2 HEX dump

The buzzer will beep when the ON LINE switch is pressed and held while the

power is turned on.

ENGLISH

– 19 –

Page 24

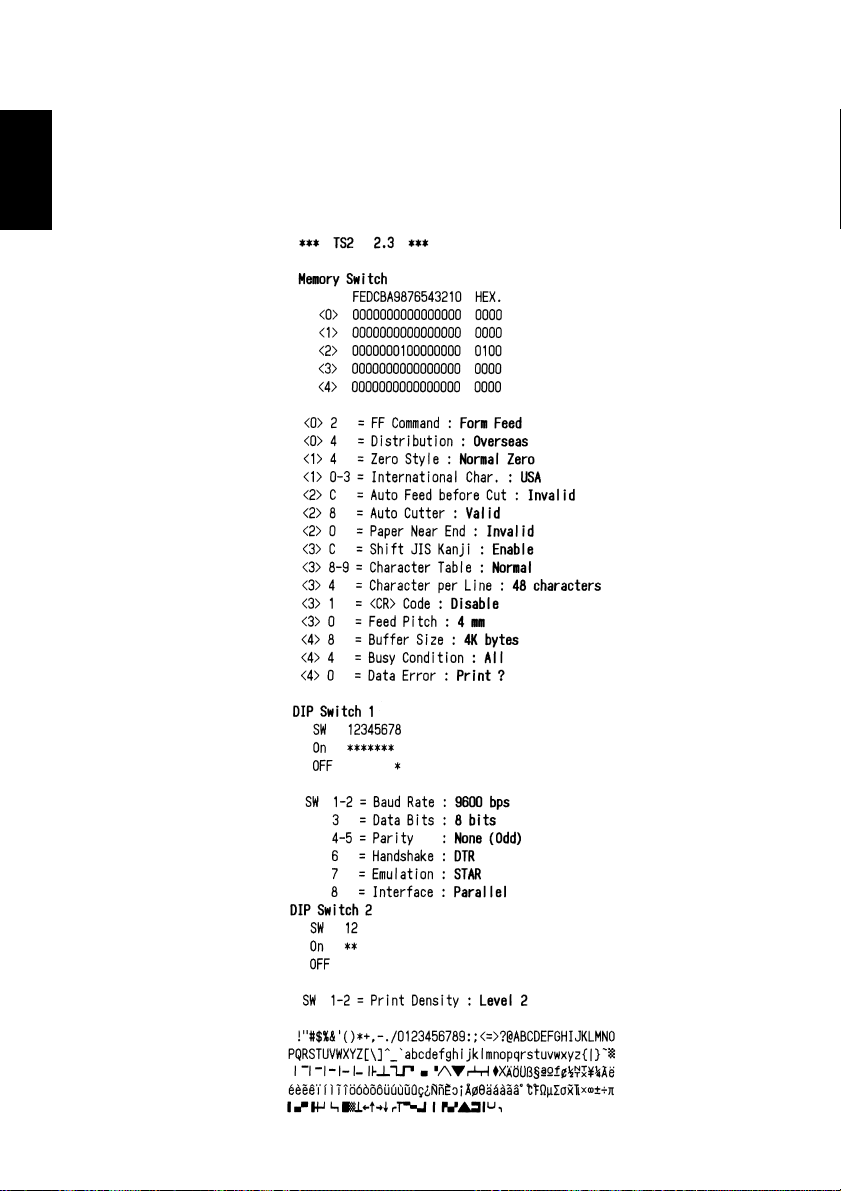

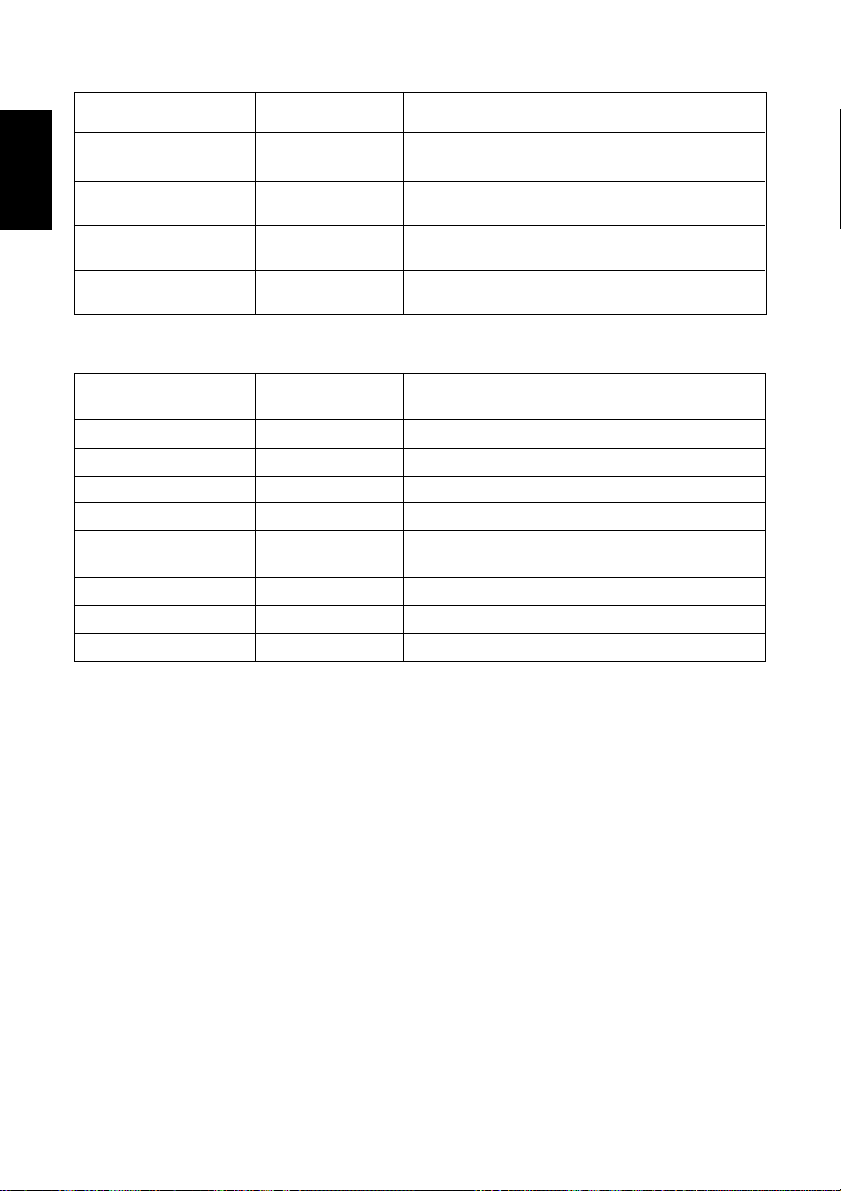

6-3. Errors

1) Automatic Recovery (Power Lamp: Flashing; On-Line Lamp: On)

ENGLISH

Error Description

Abnormal head

temperature

Power Lamp Flashing Pattern Recovery Conditions

Approx. 1 Sec Approx. 1 Sec

Automatic recovery after head

temperature lowers.

2) Recoverable Errors (Power Lamp: Flashing; On-Line Lamp: Off)

Error Description

No paper

Power Lamp Flashing Pattern Recovery Conditions

Approx. 1 Sec Approx. 1 Sec

Insert paper and press on-line

switch. (Star)

Insert paper and close cover. (ESC/

POS)

Head up

Approx. 250 msApprox. 250 ms

Lower head and press on-line

switch. (Star)

Lower head and close cover. (ESC/

POS)

Paper near end of

roll

Approx. 2 Sec Approx. 2 Sec

Press on-line switch and printing

will continue. Both lamps light

when printing and power lamp

flashes and on-line lamp lights

when on-line. (Star)

Same as “No paper”. (ESC/POS)

Cover is open

500 ms

Approx.

500 ms

Close cover and press on-line

switch. (Star)

Approx.

Close cover. (ESC/POS)

Error during paper

cutting

Approx. 125 msApprox. 125 ms

If the blade is at the home position,

press on-line switch to continue

printing. If the blade is not at the

home position, it is not a recoverable error. (Star)

Command (ESC/POS)

3) Fatal Error (Power Lamp: Flashing; On-Line Lamp: Flashing) the unit

will have to be repaired.

– 20 –

Page 25

6-4. Buzzer Indicators (Star Mode Only)

P: 50ms Pi: 100ms

1 On-line/off-line P

2 No paper error PPPP PPPP

3 Head-up error PiPiPi

4 Paper near-end sensor error PP PP

5 Cover open error PPPP

6 Cutter error Pi PPP PPiPiP PPPPPi PiPiPiPiPi PiPiPiPiPi

7 Command buzzer Pi

ENGLISH

– 21 –

Page 26

7. Cautions

ENGLISH

7-1. Operating Cautions

1 The service life of the thermal print head cannot be guaranteed if any paper

other than the recommended paper is used. There will be a noticeable decline

in the service life of the thermal element of the print head when the paper used

contains (Na+, K++, CI-).

2 Never print when there is water or any form of moisture, such as from

condensation, on the surface of the print head.

7-2. Safety Cautions

1 Never touch the thermal print head or motor during printing or immediately

after printing as these components are very hot.

2 Never touch any moving parts, such as gears or knobs, during printing.

3 Always use care near the edges of printer components, especially metal

components, as they may cause injury.

– 22 –

Page 27

8. Command summary

8-1. Star Mode

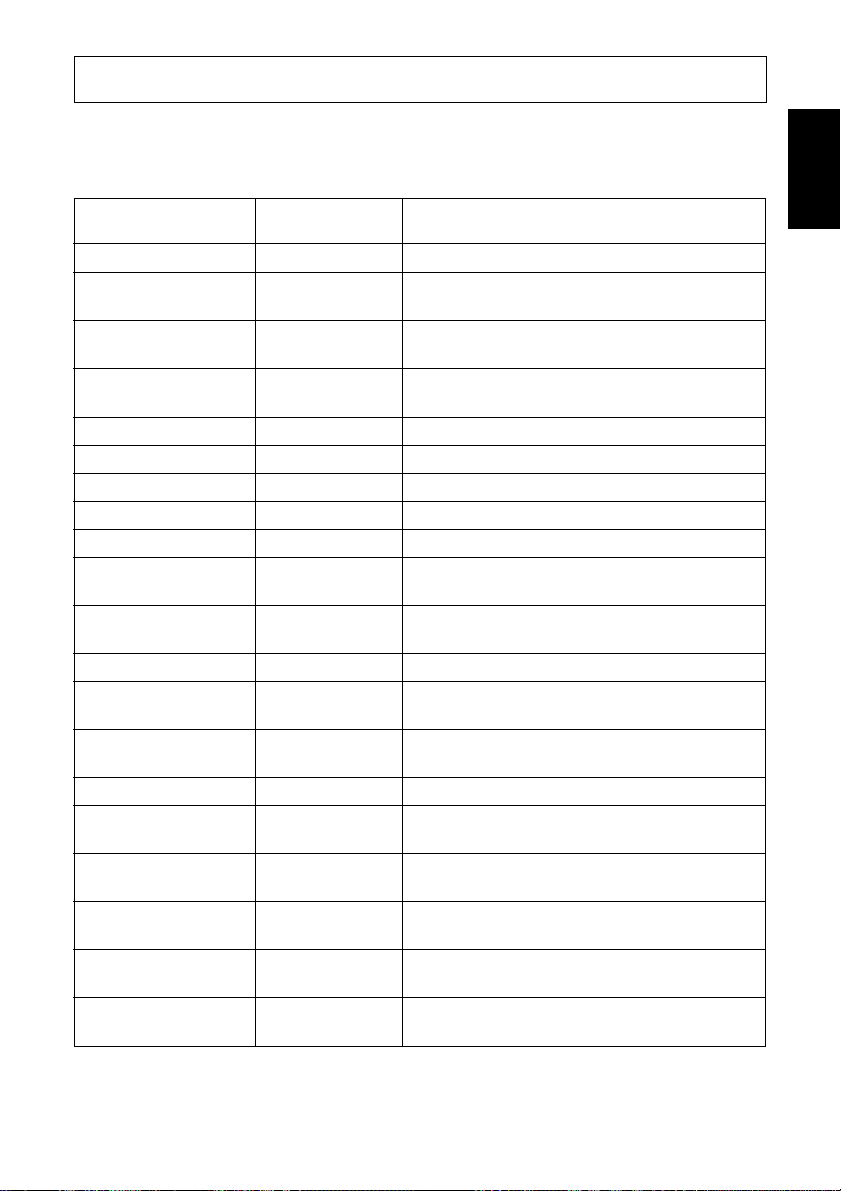

Commands to Select Characters

Control codes

<ESC> “R” n 1B 52 n Select international character set

<ESC> “/” “1” 1B 2F 31

<ESC> “/” <1> 1B 2F 01

<ESC> “/” “0” 1B 2F 30

<ESC> “/” <0> 1B 2F 00

<ESC> “b” n1 n2 n3 n4 1B 62 n1 n2 n3 n4 Select bar code printing

d1 ... <RS> d1 ... 1E

<ESC> “M” 1B 4D Select 12-dot pitch printing

<ESC> “p” 1B 70 Select 14-dot pitch printing

<ESC> “P” 1B 50 Select 15-dot pitch printing

<ESC> “:” 1B 3A Select 16-dot pitch printing

<ESC> <SP> n 1B 20 n Set character spacing

<SO> 0E Sets the printing magnified double in

<DC4> 14 Resets the printing magnified in

<ESC> “W” n 1B 57 n

<ESC> <SO> 1B 0E Sets the printing magnified double in

<ESC> <DC4> 1B 14 Resets the printing magnified in character

<ESC> “h” n 1B 68 n

<ESC> “i” n1 n2 1B 69 n1 n2 Sets the magnification rates in character

<ESC> “–” “1” 1B 2D 31

<ESC> “–” <1> 1B 2D 01

<ESC>“–” “0” 1B 2D 30

<ESC> “–” <0> 1B 2D 00

<ESC> “_” “1” 1B 5F 31

<ESC> “_” <1> 1B 5F 01

<ESC> “_” “0” 1B 5F 30

<ESC> “_” <0> 1B 5F 00

Hexadecimal

codes

Function

Select slash zero

Select normal zero

character width.

character width.

Sets the magnification rate in character width.

character height.

height.

Sets the magnification rate in character height

width and height.

Select underlining

Cancel underlining

Select overlining

Cancel overlining

ENGLISH

.

– 23 –

Page 28

Control codes

<ESC> “4” 1B 34 Select highlight printing

ENGLISH

<ESC> “5” 1B 35 Cancel highlight printing

<SI> 0F Inverted printing

<DC2> 12 Cancel inverted printing

<ESC> “E” 1B 45

<ESC> “G” 1B 47

<ESC> “F” 1B 46

<ESC> “H” 1B 48

Hexadecimal

codes

Function

Select emphasized printing

Cancel emphasized printing

Commands to Set the Page Format

Control codes

<ESC> “C” n 1B 43 n Set page length in lines

<ESC> “C” <0> n 1B 43 00 n Set page length in inches

<ESC> “N” n 1B 4E n Set bottom margin

<ESC> “O” 1B 4F Cancel bottom margin

<ESC> “l” n 1B 6C n Set left margin

<ESC> “Q” n 1B 51 n Set right margin

Hexadecimal

codes

Function

Commands to Move the Print Position

Control codes

<LF> 0A Line feed

<CR> 0D Carriage Return

<ESC> “a” n 1B 61 n Feed paper n lines

<FF> 0C Form feed

<HT> 09 Horizontal tab

<VT> 0B Vertical tab

<ESC> “z” “1” 1B 7A 31

<ESC> “z” <1> 1B 7A 01

<ESC> “0” 1B 30 Set line spacing to 3 mm

<ESC> “J” n 1B 4A n One time n/4 mm feed

<ESC> “j” n 1B 6A n One time n/4 mm backfeed

<ESC> “B” n1 n2 ... <0> 1B 42 n1 n2 ... 00 Set vertical tab stops

<ESC> “D” n1 n2 ... <0> 1B 44 n1 n2 ... 00 Set horizontal tab stops

Hexadecimal

codes

Function

Set line spacing to 4 mm

– 24 –

Page 29

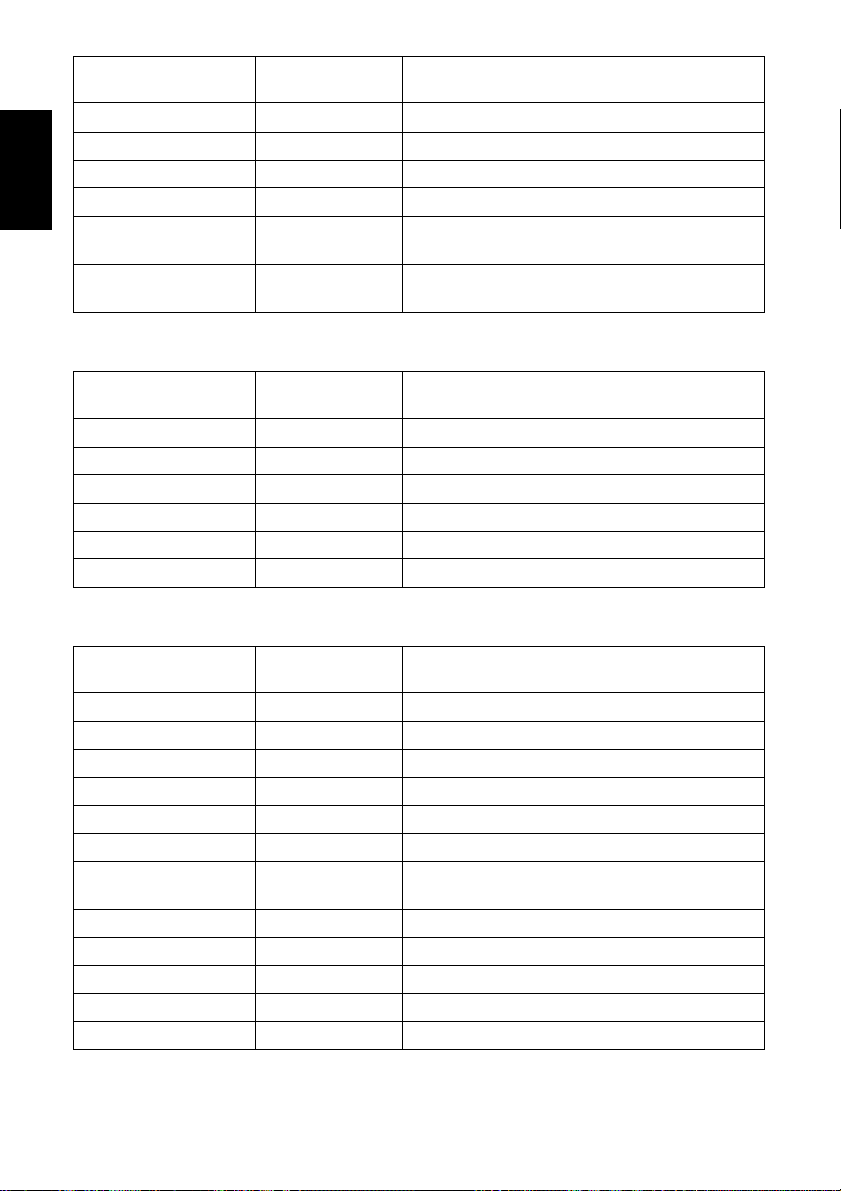

Commands to Print Dot Graphics

Control codes

<ESC> “K” n <0> 1B 4B n 00 m1 m2 Print normal density graphics

m1 m2 ... ...

<ESC> “L” n1 n2 1B 4C n1 n2 m1 m2 Print high density graphics

m1 m2 ... ...

<ESC> “k” n <0> m1 ... 1B 6B n 00 m1 ... Print fine density graphics

Hexadecimal

codes

Function

Commands to Print Download Characters

Control codes

<ESC> “&” “1” “1” 1B 26 31 31 n

n m1 m2 ... m48 m1 m2 ... m48

<ESC> “&” <1> <1> 1B 26 01 01

n m1 m2 ... m48 n m1 m2 ... m48

<ESC> “&” “1” “0” n 1B 26 31 30 n

<ESC> “&” <1> <0> n 1B 26 01 00 n

<ESC> “%” “1” 1B 25 31

<ESC> “%” <1> 1B 25 01

<ESC> “%” “0” 1B 25 30

<ESC> “%” <0> 1B 25 00

Hexadecimal

codes

Function

Define download character

Delete a download character

Enable download character set

Disable download character set

ENGLISH

Commands to Control Peripheral Devices

Control codes

<ESC> <BEL> n1 n2 1B 07 n1 n2 Define drive pulse width for peripheral

<BEL> 07 Control peripheral device #1

<FS> 1C Control peripheral device #1 immediately

<EM> 19 Control peripheral device #2 immediately

<SUB> 1A Control peripheral device #2 immediately

Hexadecimal

codes

Function

device #1

– 25 –

Page 30

Commands to Control Auto Cutter

Control codes

ENGLISH

<ESC> “d” “0” 1B 64 30

<ESC> “d” <0> 1B 64 00

<ESC> “d” “1” 1B 64 31

<ESC> “d” <1> 1B 64 01

<ESC> “d” “2” 1B 64 32

<ESC> “d” <2> 1B 64 02

<ESC> “d” “3” 1B 64 33

<ESC> “d” <3> 1B 64 03

Hexadecimal

codes

Function

Full-cut command to the auto cutter

Partial-cut command to the auto cutter

Feed paper to the cutting position and perform a full-cut.

Feed paper to the cutting position and perform a partial-cut.

Other Commands

Control codes

<CAN> 18 Cancel last line & Initialize printer

<DC3> 13 Deselect printer

<DC1> 11 Set select mode

<RS> 1E Beep the buzzer

<ESC> “#N, n1 n2 n3 n4”

<LF> <NUL> 0A 00

<ESC> “@” 1B 40 Initialize printer

<ENQ> 05 Enquiry

<ESC> “?” <LF> <NUL> 1B 3F 0A 00 Reset printer hardware

Hexadecimal

codes

1B 23 N 2C n1 n2 n3 n4

Function

Set memory switch

– 26 –

Page 31

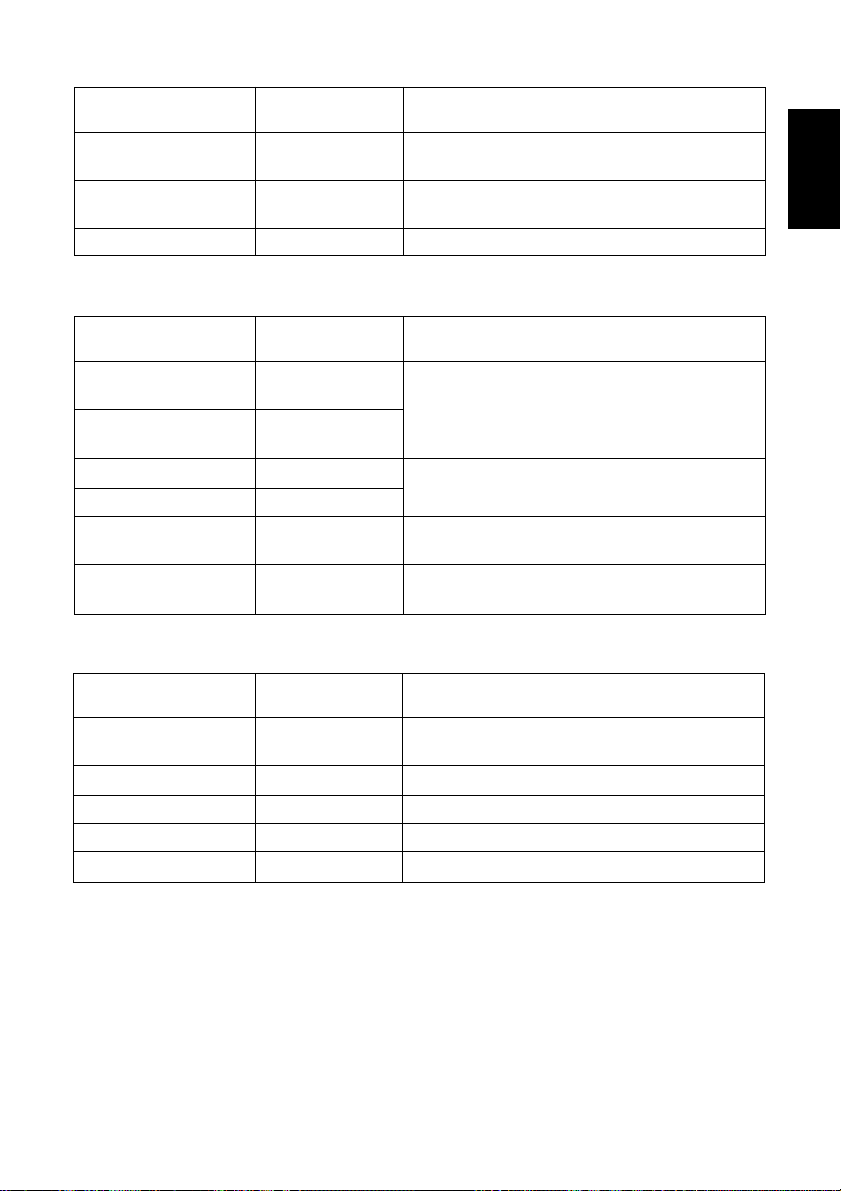

8-2. ESC/POS Mode

Control Code Hexadecimal Code Function

HT 09 Horizontal tab

LF 0A Print line feed

FF 0C Page mode print and return

DLE EOT 10 04 Real time transmission of status

DLE ENQ 10 05 Real time request to printer

CAN 18 Cancel print data in page mode

ESC FF 1B FF Print page mode data

ESC SP 1B 20 Set right space amount of character

ESC ! 1B 21 Universal print mode designation

ESC # 1B 23 Set memory switch

ESC $ 1B 24 Designate absolute printing

ESC % 1B 25 Designate/cancel download character set

ESC & 1B 26 Define download characters

ESC

*

ESC - 1B 2 D Designate/cancel underline

ESC 2 1B 32 Set 1/6 inch line feed amount

ESC 3 1B 33 Set line feed amount

ESC = 1B 3D Select peripheral equipment

ESC ? 1B 3F Delete download characters

ESC @ 1B 40 Initialize printer

ESC D 1B 44 Set horizontal tab position

ESC E 1B 45 Designate/cancel emphasized print

ESC G 1B 47 Designate/cancel double print

ESC J 1B 4A Print and paper feed

ESC L 1B 4C Select page mode

ESC R 1B 52 Select international characters

ESC S 1B 53 Select standard mode

ESC T 1B 54 Select character print direction in print mode

ESC V 1B 56 Designate/cancel 90° character rotation

ESC W 1B 57 Set print range in page mode

ESC \ 1B 5C Designate relative position

ESC a 1B 61 Align position

ESC c4 1B 63 34 Select no valid paper detector at print stop

ESC c5 1B 63 35 Enable/disable panel switch

ESC d 1B 64 Print and paper feed “n” lines

ESC i 1B 69 Partial cut (one section remaining)

ESC p 1B 70 Designate pulse generation

ESC t 1B 74 Select character code table

1B 2A Designate bit image mode

ENGLISH

– 27 –

Page 32

Control Code Hexadecimal Code Function

ENGLISH

ESC u 1B 75 Transmission of peripheral equipment status

ESC v 1B 76 Transmission of paper detection status

ESC { 1B 7B Designate/cancel inverted printing

GS ! 1D 21 Designate character size

GS $ 1D 24 Designate absolute position of vertical direction of

GS

*

GS / 1D 2F Print download bit image

GS : 1D 3A Start/finish macro definition

GS B 1D 42 Designate/cancel reverse printing

GS H 1D 48 Select print position of HRI characters

GS I 1D 49 Printer ID transmission

GS L 1D 4C Set left margin

GS P 1D 50 Set basic calculated pitch

GS V 1D 56 Paper cut

GS W 1D 57 Set print range

GS \ 1D 5C Designate the relative position of vertical characters when

GS ^ 1D 5E Execute macro

GS a 1D 61 Enable/disable automatic status transmission

GS f 1D 66 Select HRI character font

GS h 1D 68 Set bar code height

GS k 1D 6B Printing of bar code

GS r 1D 72 Transmission of status

GS w 1D 77 Set lateral size of bar code

1D 2A Define download bit image

characters in page mode

printing in the page mode

– 28 –

Page 33

Table des matières

1. Déballage et inspection........................................................................31

1-1. Déballage ...................................................................................31

1-2. Emplacement de l’imprimante ...................................................31

2. Identification des pièces et nomenclature............................................32

3. Connexion de l’imprimante .................................................................33

3-1. Câble d’interface ........................................................................33

3-2. Tore de ferrite *Uniquement pour l’Europe ..............................35

3-3. l’adaptateur secteur optionnel ....................................................37

4. Capteur de fin de rouleau ....................................................................38

5. Mise en place du papier ....................................................................... 39

5-1. Mise en place du papier .............................................................39

5-2. Changement de rouleau de papier ..............................................43

5-3. Support de 76 mm de large ........................................................44

5-4. Correction des bourrages de papier............................................46

6. Tableau de commande ......................................................................... 47

6-1. Mise sous tension .......................................................................47

6-2. Opérations combinées du panneau de commande .....................48

6-3. Erreurs........................................................................................50

6-4. Indications de la sonnerie (mode Star seulement) .....................51

7. Precautions ..........................................................................................52

7-1. Précautions relatives à l’utilisation ............................................52

7-2. Précautions relatives à la sécurité ..............................................52

FRANÇAIS

8. Resume des commandes......................................................................53

8-1. Mode Star...................................................................................53

8-2. Mode ESC/POS..........................................................................57

L’appendice n’est pas traduit.

Page 34

Page 35

1. Déballage et inspection

1-1. Déballage

Contrôler à l’aide de la figure 1-1 ci-dessous que chaque élément décrit se trouve

dans la boîte.

Si tout élément semble manquer, contacter le fournisseur.

Imprimante

Echantillon de

rouleau de papier

Supports de

76mm

Guide d’utilisation

Pièce d'écartement

du support

Tore de ferrite

pour câble

d’appareil

périphérique

(uniquement pour

l’Europe)

Attache

(uniquement

pour l’Europe)

Figure 1-1

1-2. Emplacement de l’imprimante

Avant d’entamer l’installation de l’imprimante, s’assurer que le futur emplacement est approprié. En d’autres termes, il convient que cet emplacement soit:

• à proximité d’une prise secteur d’accès aisé;

• une surface stable et de niveau non-soumise à des vibrations excessives;

• à l’abri de températures excessivement élevées (à la lumière directe du soleil,

à proximité d’appareils de chauffage, etc.)

• à l’abri de toute humidité excessive;

• à l’abri d’une quantité excessive de poussière;

• alimenté par une source secteur non-soumise à de brusques variations de

tension. Ainsi, ne pas alimenter l’imprimante via un circuit alimentant déjà un

gros consommateur de courant et producteur de bruit tel qu’un réfrigérateur

ou un climatiseur.

N.B.: S’assurer que la tension du secteur correspond bien à la tension spécifiée

par le fabricant sur la plaque d’identification de l’imprimante.

– 31 –

FRANÇAIS

Page 36

Capot

Protège l'imprimante contre

la poussière et réduit le bruit.

FRANÇAIS

Ne pas ouvrir le capot

pendant l'impression.

Connecteur de câble

d’adaptateur secteur

Ce connecteur vous permet de

connecter le câble de l’adaptateur

secteur. Ne déconnectez pas le

câble lorsque l’imprimante est

sous tension.

2. Identification des pièces et nomenclature

Tableau de commande

Ce tableau comprend

deux commandes et deux

témoins indiquant l'état de

l'imprimante.

Interrupteur

d’alimentation

Cet interrupteur vous permet

de mettre l’imprimante sous

tension et hors tension.

Connecteur d'interface

Ce connecteur permet de

raccorder l'imprimante à

l'ordinateur-hôte.

Figure 2-1 Vue externe de l’imprimante

Connecteur de circuit d'entraînement

d'appareil périphérique

Ce connecteur permet de raccorder

l'imprimante à des appareils périphériques

tels que des caisses enregistreuses, etc.

Ne pas connecter l'imprimante à un téléphone.

– 32 –

Page 37

3. Connexion de l’imprimante

Préparer les éléments suivants avant d’effectuer les connexions à l’imprimante.

Avant d’effectuer toute connexion, toujours veiller à ce que l’imprimante soit

hors tension.

• Câble d’interface

• Tore de ferrite (uniquement pour l’Europe)

• Adaptateur secteur en option

3-1. Câble d’interface

Levier de tête

d'imprimante

[Tête en position haute]

Bouton

d’avance

[Tête en position basse]

1 Ouvrir le capot.

FRANÇAIS

2 Pousser le levier vert de la tête de

l’imprimante vers l’arrière.

Attention

Si l’imprimante doit être expédiée ou

rangée pour une période prolongée,

s’assurer de toujours tirer le levier

vert de la tête de l’imprimante vers

l’avant afin d’amener la tête d’impression en position supérieure. Ceci

permet de protéger la tête thermique

et d’éviter toute déformation de la

plaque d’impression.

3 Fermer le capot.

– 33 –

Page 38

FRANÇAIS

Screwdriver

Tournevis

Vis

Screws

4 Raccorder le connecteur du câble

d’interface dans le connecteur pour

interface de l’imprimante et fixer le

connecteur de l’interface en série à

l’aide de vis ou le connecteur de

l’interface parallèle à l’aide des agrafes prévues.

– 34 –

Page 39

3-2. Tore de ferrite *Uniquement pour l’Europe

Fastener

N.B.: Effectuer les démarches ci-dessous avec un soin particulier.

■ L’imprimante est fournie avec un

filtre antibruit à tore de ferrite destiné au câble de l’appareil périphérique.

■ Le tore de ferrite est normalement

ouvert à la livraison, comme le montre la figure 3-1.

Ferrite core (28mm diameter)

Tore de ferrite (28 mm de diamètre)

• Faire passer l’attache par le tore de

ferrite.

Figure 3-3

Attache

FRANÇAIS

One loop

Une boucle

Figure 3-1

Si ce n’est pas le cas, débloquer le

système de verrouillage en plastic

du tore de ferrite à l’aide d’un objet

pointu de la manière illustrée (3-2).

Prendre garde de ne pas abîmer le

système de verrouillage lors de

l’ouverture de ce dernier.

Figure 3-2

Pull and cut

Tirer et couper

• Faire passer l’attache autours du

câble et la bloquer.

Couper la partie de l’attache ressortant

du mécanisme de blocage à l’aide d’une

paire de ciseaux.

Figure 3-4

– 35 –

Page 40

■ Serrer le tore de ferrite autours du câble d’appareil périphérique en effectuant

une boucle de la manière illustrée (3-1).

• Veiller à ne pas endommager le câble lors de l’installation du tore de ferrite.

• Le tore de ferrite doit être correctement fixé à l’aide de l’attache fournie (se

reporter aux figures 3-3 et 3-4).

• Veiller à ne pas oublier de faire une boucle dans le câble.

FRANÇAIS

Fastener

Attache

Une boucle

One loop

Connecteur

Connector

Tore de ferrite

Ferrite core

Vis M3 × 4

Screw M3×4

Connecteur de circuit

Peripheral unit drive

d’entraînement

circuit connector

d’appareil périphérique

Figure 3-5

– 36 –

Fil de masse séparé

Separate ground wire

Page 41

3-3. l’adaptateur secteur optionnel

Remarque:Avant de connecter ou déconnecter l’adaptateur secteur, veillez

à ce que l’imprimante et tous les appareils qui y sont connectés

soient hors tension. Veillez également à débrancher le câble

d’alimentation de la prise secteur.

1 Connectez l’adaptateur secteur au câble d’alimentation.

Remarque:Utilisez exclusivement l’adaptateur secteur et le câble d’alimen-

tation destinés à l’imprimante.

2 Connectez l’adaptateur à la borne de l’imprimante.

3 Branchez la prise du câble d’alimentation à la prise secteur.

Interrupteur

d'alimentation

FRANÇAIS

Figure 3-6

– 37 –

Page 42

4. Capteur de fin de rouleau

Cette imprimante est équipée d’un capteur détectant l’approche de la fin de

rouleau. Pour savoir comment utiliser cette fonction, lire les instructions cidessous.

FRANÇAIS

1 Ouvrir le capot.

2 Régler la position de détection en

fonction du diamètre du rouleau de

papier utilisé à l’aide du tableau cidessous.

Diamètre de

rouleau

Environ 22 mm Cran 1

Environ 26 mm Cran 2

Environ 30 mm Cran 3

3 Déplacer le capteur jusqu’au cran

correspondant au diamètre du rouleau employé.

Introduire la pointe d’un stylo à bille ou

d’un objet pointu similaire dans l’orifice du capteur et faire glisser ce dernier jusqu’au cran approprié. S’assurer

que l’ergot du capteur (indiqué par la

flèche sur la figure ci-contre) est correctement inséré dans le cran, tout spécialement s’il s’agit du cran 2.

Attention

1) Le capteur de fin de rouleau est positionné sur le cran 1 à la sortie d’usine.

2) Afin d’assurer une détection correcte de la quantité de papier restant sur le

rouleau, toujours employer un rouleau de papier dont les diamètres interne

et externe du rouleau de carton correspondent respectivement à 12 mm et 18

mm.

3) Le capteur de fin de rouleau n’est pas activé à la sortie d’usine. Il convient

de l’activer en modifiant le commutateur de mémorisation. Pour plus de

détails, se reporter au “Manuel du Programmeur”.

Position

– 38 –

Page 43

5. Mise en place du papier

5-1. Mise en place du papier

1 Se procurer un rouleau de papier et

plier les coins de la façon illustrée.

FRANÇAIS

2 Ouvrir le Capot.

Rouleau de

papier

Rouleau

Axe

Levier du support

3 Ecarter le levier du support en ap-

puyant dessus dans le sens de la

flèche. Installer le rouleau de papier

de la manière illustrée ci-contre.

S’assurer que le noyau du rouleau

de papier est maintenu fermement

en place par le support.

– 39 –

Page 44

FRANÇAIS

Fente de sortie

de papier

Mécanisme

de découpe

automatique

Mécanisme

de découpe

automatique

Touche

d’avance

Mécanisme

d’avance de

papier

Guide de papier

Bouton

d’avance

Guide du

support

Levier de tête

d'imprimante

4 (Utilisation de la fonction de char-

gement automatique)

• Avec le mécanisme de découpe

automatique en place.

1) L’imprimante est livrée avec le le-

vier de soulèvement de la tête d’im-

primante en position haute. Appuyer

sur le levier pour refermer la tête.

Voir “Chapitre 3 : Raccordement de

l’imprimante” pour les détails.

2) Insérer le bord du papier dans le

mécanisme d’avance de papier. S’il

est inséré correctement, le bord du

papier ressortira par la fente de sortie de papier.

Attention

Si le papier n'est pas inséré dans l'imprimante parfaitement droit, il se "mettra

en travers" *1) et les bords se plieront.

Suivant l’angle pris par le papier, il est

possible que l'avance du papier puisse

être corrigée automatiquement en appuyant sur la touche d’avance FEED

*2) pour la réguler. Néanmoins, si le

papier prend un angle trop important,

un bourrage de papier surviendra. Pour

corriger le bourrage de papier, tirer

complètement le mécanisme de dé-

coupe automatique dans le sens de la

flèche jusqu'à ce qu'il se verrouille.

Avec le levier de la tête en position

haute, tirer le papier à l'extérieur du

mécanisme d'avance de papier.

– 40 –

1)

Mise en travers : Quand le papier

*

est entraîné irrégulièrement dans

l’imprimante.

2)

*

Voir "Chapitre 6 : Tableau de commande" pour des détails sur le fonctionnement de la touche d’avance

FEED.

Page 45

Mécanisme

Fente de sortie

de papier

d’avance de

papier

• Sans mécanisme de découpe

automatique.

1) Comme pour 4-1.

2) Insérer le bord du papier dans le

mécanisme d’avance de papier. Si

le papier est inséré correctement, le

bord du papier ressortira par la fente

de sortie de papier.

Mécanisme

d’impression

Attention

Si le papier n’est pas inséré dans l’imprimante parfaitement droit, il se “mettra

en travers” et les bords se plieront. Suivant l’angle pris par le papier, il est

possible que l’avance du papier puisse être corrigée automatiquement si vous

appuyez sur la touche d’avance FEED pour la réguler. Néanmoins, si le papier

prend un angle trop important, un bourrage de papier surviendra. Pour dégager

le bourrage de papier, tirer le levier de soulèvement de la tête d’imprimante vers

l’avant. Avec le levier de la tête en position haute, tirer le papier à l’extérieur

du mécanisme d’avance de papier.

FRANÇAIS

Mécanisme de découpe

automatique

5 (Chargement manuel)

1) Tirer complètement le mécanisme

de découpe automatique dans le sens

de la flèche jusqu’à ce qu’il se ver-

rouille (ignorer cette étape si l’ap-

pareil ne dispose pas de mécanisme

de découpe automatique).

2) Tirer le levier de soulèvement de la

tête d’imprimante vers l’avant pour

mettre la tête en position haute.

L’imprimante est livrée avec le le-

vier de soulèvement de la tête d’im-

primante dans cette position.

Voir “Chapitre 3 : Raccordement de

l’imprimante” pour les détails.

3) Insérer le bord du papier dans le mé-

canisme d’avance de papier. Tourner

le bouton d’avance de papier (vert)

jusqu’à ce que le bord du papier ressorte par la fente de sortie de papier du

mécanisme d’impression.

– 41 –

Page 46

FRANÇAIS

4) Une fois que le papier est ressorti par la

fente de sortie de papier du mécanisme d’impression, tirer tout droit

sur le papier pour corriger sa position.

5) S’assurer que le papier est bien droit

avec environ 15 à 20 centimètres

exposés , puis abaisser la tête qui

était en position haute.

6) Saisir le bord du papier et le couper

en appuyant ce dernier contre la

tête. Faire attention à ne pas se cou-

per sur le bord tranchant du méca-

nisme de découpe automatique.

7) Refermer le mécanisme de découpe

automatique (ignorer cette étape si

l’appareil ne dispose pas de méca-

nisme de découpe automatique).

8) Refermer le capot, appuyer sur le

commutateur ON LINE (en ligne)

et s’assurer que le témoin ON LINE

s’allume.

Voir “Chapitre 6 : Tableau de com-

mande” pour des détails sur le té-

moin et le commutateur ON LINE.

Attention

En cas de chargement automatique,

une partie du papier sera exposée

après le chargement. Veiller à faire

passer cette longueur de papier dans

la sortie de papier du capot de l’im-

primante avant de refermer le capot.

En cas de chargement manuel, s’assurer que le papier est passé dans la

sortie de papier du capot de l’impri-

mante après la fermeture du capot et

une pression sur la touche d’avance

FEED.

– 42 –

Page 47

5-2. Changement de rouleau de papier

1 Quand le capteur de papier détecte

l’absence de papier dans l’impri-

mante, appuyer sur la touche FEED

jusqu’à ce que l’avance du papier

cesse. Quand le capteur de fin de

rouleau proche fonctionne alors qu’il

reste du papier sur le rouleau, couper le papier juste avant le mécanisme d’avance de papier et appuyer sur la touche FEED jusqu’à

ce que l’avance du papier cesse.

Voir “Chapitre 4 : Capteur de fin de

rouleau proche” pour des détails.

2 Ouvrir le capot et tirer le levier de

soulèvement de la tête d’imprimante

vers l’avant pour mettre cette der-

nière en position haute, puis tirer sur

le papier pour l’extraire.

3 Tirer le levier du support dans le

sens de la flèche et enlever le noyau

et tout le papier restant.

4 Voir”5-1 : Mise en place du papier:

et suivre les instructions fournies

pour changer le rouleau de papier.

FRANÇAIS

– 43 –

Page 48

5-3. Support de 76 mm de large

Un support de 76 mm de large est disponible pour compléter ou modifier la

configuration de l’imprimante.

FRANÇAIS

Partie

supérieure

Supports de 80 mm

Vis M2

Supports de 76 mm

Supports de 76 mm

Levier du

support

Vis M2

Pièce d’écartement du support

1 Ouvrir le capot.

2 Utiliser un tournevis pour enlever

les vis M2 qui attachent les supports de 80 mm à la partie supé-

rieure du coffret et au levier du

support. Remplacer les supports de

80 mm par les supports de 76 mm en

option.

Attention

Faire attention à ne laisser tomber

aucune des vis.

– 44 –

Page 49

Mécanisme de

découpe

automatique

Pièce d’écartement du support

Quand une encoche

s’encliquette

3 Déplacer le mécanisme de découpe

automatique dans le sens de la flè-

che jusqu’à ce qu’il se verrouille

(ignorer cette étape si l’appareil ne

dispose pas de mécanisme de dé-

coupe automatique).

FRANÇAIS

4 Insérer les pièces d’espacement de

support pour papier de 76 mm à

l’intérieur, des côtés gauche et droit

des guides du support comme indiqué dans l’illustration. Veiller à ce

que les encoches des pièces d’espa-

cement de support s’encliquettent

dans les trous des guides de support.

5 Refermer le mécanisme de découpe

automatique (ignorer cette étape si

l’appareil ne dispose pas de méca-

nisme de découpe automatique).

– 45 –

Page 50

5-4. Correction des bourrages de papier

1 Mettre l’imprimante hors tension et ouvrir le capot.

2 Déplacer le mécanisme de découpe automatique dans le sens de la flèche

jusqu’à ce qu’il se verrouille (ignorer cette étape si l’appareil ne dispose pas

de mécanisme de découpe automatique).

3 Couper un peu de papier du rouleau devant la sortie du mécanisme d’avance

FRANÇAIS

de papier pour corriger le bourrage de papier.

4 En utilisant la procédure décrite pour le nettoyage de la tête, pousser le levier

de soulèvement de la tête vers l’arrière et libérer le cache pour permettre

l’ouverture de la tête. Voir “Appendice E : Nettoyage” pour des détails.

5 Corriger le bourrage de papier. Si cela est impossible, tourner le bouton

d’avance et retirer le papier.

6 Une fois le bourrage de papier corrigé, appuyer sur le dessus du cache de sorte

à bloquer ce dernier via les leviers d’ouverture de la tête de l’imprimante.

Attention

* Si un bourrage de papier survient dans le mécanisme de découpe automatique,

insérer un tournevis dans l’ouverture se trouvant sur la surface supérieure

droite du mécanisme de découpe automatique; en utilisant le tournevis,

tourner le bouton pour déplacer la lame et enlever le papier coincé.

* Certaines parties de l’imprimante, en particulier les pièces métalliques,

peuvent provoquer des blessures si elles sont manipulées de façon incorrecte.

Faire très attention pour la manipulation de l’imprimante.

Mécanisme

de découpe

automatique

Ouverture

– 46 –

Bouton

Page 51

6. Tableau de commande

6-1. Mise sous tension

Tableau de commande

Papier chargé

1 Témoin d’alimentation POWER

(DEL verte)

POWER

ON LINE

FEED

2 Témoin ON LINE (en ligne) (DEL

verte)

3 Commutateur ON LINE (en ligne)

4 Touche d’avance FEED

12 3 4

Pas de papier chargé

POWER

ON LINE

FEED

Lorsque l’imprimante est mise sous tension, les témoins d’alimentation POWER

et ON LINE (en ligne) s’allument. Si l’imprimante ne contient pas de papier, le

témoin POWER clignote à intervalles d’environ une seconde.

Témoin de commutateur ON LINE (mode Star seulement)

Utiliser pour commuter entre les modes hors ligne et en ligne.

Le témoin ON LINE s’allume quand l’imprimante est en ligne.

Quand l’imprimante est hors ligne, L’impression s’arrête et les données de

l’ordinateur hôte ne peuvent pas être reçues.

FRANÇAIS

Touche d’avance FEED

A chaque pression sur la touche d’avance FEED, le papier avance dans l’impri-

mante une ligne à la fois. Le papier avance en continu quand vous maintenez la

touche FEED enfoncée.

Les fonctions de la touche FEED sont supportées aussi bien dans le mode en ligne

que dans le mode hors ligne.

Témoin d’alimentation POWER

Le témoin d’alimentation POWER s’allume quand l’imprimante est sous tension.

– 47 –

Page 52

6-2. Opérations combinées du panneau de commande

Les réglages suivants peuvent être effectués quand l’imprimante est sous tension.

1 Essai d’impression

Une sonnerie retentit quand la touche FEED est maintenue enfoncée alors que

l’imprimante est sous tension.

FRANÇAIS

– 48 –

Page 53

2 Vidage hexadécimal

Une sonnerie retentit quand le commutateur ON LINE est maintenue enfoncé

alors que l’imprimante est sous tension.

FRANÇAIS

– 49 –

Page 54

6-3. Erreurs

1) Erreurs à correction automatique (témoin POWER clignotant; témoin

ON LINE allumé)

Description de l’erreur

T° anormale de la

tête

FRANÇAIS

2) Erreurs corrigibles (témoin POWER clignotant; témoin ON LINE éteint)

Description de l’erreur

Pas de papier

chargé

Cycle de clignotement du témoin POWER Correction d’erreur

Environ 1 sec.

Approx. 1 Sec Approx. 1 Sec

Environ 1 sec.

Correction automatique après

baisse de la t° de la tête.

Cycle de clignotement du témoin POWER Correction d’erreur

Environ 1 sec.

Approx. 1 Sec Approx. 1 Sec

Environ 1 sec.

Insérer le papier et appuyer sur le

commutateur ON-LINE. (Star)

Insérer le papier et refermer le

capot. (ESC/POS)

Tête en position

supérieure

Fin du rouleau de

papier proche

Le couvercle est

ouvert.

Erreur durant la

découpe du papier

Environ 250 ms Environ 250 ms

Approx. 2 Sec Approx. 2 Sec

Environ 2 sec. Environ 2 sec.

Environ

Environ

500 ms

500 ms

Environ 125 ms Environ 125 ms

Approx. 250 msApprox. 250 ms

Approx. 125 msApprox. 125 ms

Abaisser la tête d’impression et

appuyer sur le commutateur ONLINE. (Star)

Abaisser la tête d’impression et

refermer le capot. (ESC/POS)

Appuyer sur le commutateur ONLINE et l’impression se poursuit.

Les deux témoins sont allumés

pendant l’impression ; le témoin

POWER clignote et le témoin ONLINE est allumé lorsque l’appareil

est en ligne. (Star)

Voir l’erreur “Pas de papier”.

(ESC/POS)

Refermer le capot et appuyer sur le

commutateur ON-LINE. (Star)

Refermer le capot. (ESC/POS)

Si la lame est à sa position

d’origine, appuyer sur commutateur

ON-LINE afin de poursuivre

l’impression. Si la lame n’est pas à

sa position d’origine, l’erreur n’est

pas réparable. (Star)

Commande (ESC/POS)

3) Erreur non-corrigible (témoin POWER clignotant; témoin ON LINE

clignotant), il convient de faire réparer l’imprimante.

– 50 –

Page 55

6-4. Indications de la sonnerie (mode Star seulement)

P : 50 ms Pi : 100ms

1 En ligne/hors ligne P

2 Erreur pas de papier PPPP PPPP

3 Erreur tête en position haute PiPiPi

Erreur capteur de fin de rouleau proche

4

5 Erreur capot ouvert PPPP

6 Erreur mécanisme de découpe

7 Sonnerie de commande Pi

PP PP

Pi PPP PPiPiP PPPPPi PiPiPiPiPi PiPiPiPiPi

FRANÇAIS

– 51 –

Page 56

7. Precautions

7-1. Précautions relatives à l’utilisation

1 La durée de vie de la tête d’imprimante thermique ne peut être garantie si tout

autre papier que celui recommandé est employé. Si le papier utilisé contient

FRANÇAIS

du Na+, K++, CI–, la durée de vie de l’élément thermique de la tête

d’impression sera considérablement réduite.

2 Ne jamais effectuer d’impression lorsque la surface de la tête d’impression est

couverte d’eau ou de toute forme d’humidité, telle que la condensation.

7-2. Précautions relatives à la sécurité

1 Ne jamais toucher la tête d’imprimante thermique ou le moteur durant

l’impression ou immédiatement après l’impression. En effet, ces éléments

sont alors extrêmement chauds.

2 Ne jamais toucher les éléments mobiles tels que les rouages ou les boutons

durant l’impression.

3 Les bords des éléments de l’imprimante, surtout ceux en métal, sont à manier

avec une prudence particulière. En effet, ceux-ci pourraient causer des

blessures.

– 52 –

Page 57

8. Resume des commandes

8-1. Mode Star

Commandes de sélection de caractères

Code de contrôle

<ESC> “R” n 1B 52 n Sélection du jeu de caractères internationaux

<ESC> “/” “1” 1B 2F 31

<ESC> “/” <1> 1B 2F 01

<ESC> “/” “0” 1B 2F 30

<ESC> “/” <0> 1B 2F 00

<ESC> “b” n1 n2 n3 n4 1B 62 n1 n2 n3 n4

d1 ... <RS> d1 ... 1E

<ESC> “M” 1B 4D Sélection d’impression de pas 12 points

<ESC> “p” 1B 70 Sélection d’impression de pas 14 points

<ESC> “P” 1B 50 Sélection d’impression de pas 15 points

<ESC> “:” 1B 3A Sélection d’impression de pas 16 points

<ESC> <SP> n 1B 20 n Réglage d’espacement de caractère

<SO> 0E Réglage d’impression d’agrandissement

<DC4> 14 Nouveau réglage d’impression d’agrandissement

<ESC> “W” n 1B 57 n Réglage d’agrandissement de largeur de caractère

<ESC> <SO> 1B 0E Réglage d’impression d’agrandissement

<ESC> <DC4> 1B 14 Nouveau réglage d’impression d’agrandissement

<ESC> “h” n 1B 68 n Réglage d’agrandissement de hauteur de caractère

<ESC> “i” n1 n2 1B 69 n1 n2 Réglage d’agrandissements de largeur et de

<ESC> “–” “1” 1B 2D 31

<ESC> “–” <1> 1B 2D 01

<ESC>“–” “0” 1B 2D 30

<ESC> “–” <0> 1B 2D 00

<ESC> “_” “1” 1B 5F 31

<ESC> “_” <1> 1B 5F 01

<ESC> “_” “0” 1B 5F 30

<ESC> “_” <0> 1B 5F 00

Codes

hexadécimaux

Fonction

Sélection du zéro barré

Sélection du zéro normal

Sélection d’impression de code à barres

double de largeur de caractère

de largeur de caractère

double de hauteur de caractère

de hauteur de caractère

hauteur de caractère

Sélection de soulignement

Annulation de soulignement

Sélection de surlignement

Annulation de surlignement

FRANÇAIS

– 53 –

Page 58

Code de contrôle

<ESC> “4” 1B 34 Sélection d’impression surintensifiée

<ESC> “5” 1B 35 Annulation d’impression surintensifiée

<SI> 0F Impression inversée

<DC2> 12 Annulation d’impression inversée

<ESC> “E” 1B 45

FRANÇAIS

<ESC> “G” 1B 47

<ESC> “F” 1B 46

<ESC> “H” 1B 48

Codes

hexadécimaux

Fonction

Sélection d’impression mise en valeur

Annulation d’impression mise en valeur

Commandes de réglage du format de page

Code de contrôle

<ESC> “C” n 1B 43 n Réglage de la longueur de page en lignes

<ESC> “C” <0> n 1B 43 00 n Réglage de la longueur de page en pouces

<ESC> “N” n 1B 4E n Réglage de la marge inférieure

<ESC> “O” 1B 4F Annulation de la marge inférieure

<ESC> “l” n 1B 6C n Réglage de la marche gauche

<ESC> “Q” n 1B 51 n Réglage de la marge droite

Codes

hexadécimaux

Fonction

Commandes de déplacement de la position d’impression

Code de contrôle

<LF> 0A Avance de ligne

<CR> 0D Retour de chariot

<ESC> “a” n 1B 61 n Avance de n lignes de papier

<FF> 0C Saut de page

<HT> 09 Tabulation horizontale

<VT> 0B Tabulation verticale

<ESC> “z” “1” 1B 7A 31

<ESC> “z” <1> 1B 7A 01

<ESC> “0” 1B 30 Réglage d’espacement de ligne à 3 mm

<ESC> “J” n 1B 4A n Avance de n/4 mm à la fois

<ESC> “j” n 1B 6A n Recul de n/4 mm à la fois

<ESC> “B” n1 n2 ... <0> 1B 42 n1 n2 ... 00 Réglage d’arrêts de tabulation verticale

<ESC> “D” n1 n2 ... <0> 1B 44 n1 n2 ... 00 Réglage d’arrêts de tabulation horizontale

Codes

hexadécimaux

Fonction

Réglage d’espacement de ligne à 4 mm

– 54 –

Page 59

Commandes d’impression de graphiques en points

Code de contrôle

<ESC> “K” n <0> 1B 4B n 00 m1 m2

m1 m2 ... ...

<ESC> “L” n1 n2 1B 4C n1 n2 m1 m2

m1 m2 ... ...

<ESC> “k” n <0> m1 ... 1B 6B n 00 m1 ... Impression de graphiques densité fine

Codes

hexadécimaux

Fonction

Impression de graphiques densité normale

Impression de graphiques haute densité

Commandes d’impression de caractères téléchargés

Code de contrôle

<ESC> “&” “1” “1” 1B 26 31 31 n

n m1 m2 ... m48 m1 m2 ... m48

<ESC> “&” <1> <1> 1B 26 01 01

n m1 m2 ... m48 n m1 m2 ... m48

<ESC> “&” “1” “0” n 1B 26 31 30 n

<ESC> “&” <1> <0> n 1B 26 01 00 n

<ESC> “%” “1” 1B 25 31

<ESC> “%” <1> 1B 25 01

<ESC> “%” “0” 1B 25 30

<ESC> “%” <0> 1B 25 00

Codes

hexadécimaux

Fonction

Définition de caractère téléchargé

Suppression de caractère téléchargé

Validation d’un jeu de caractères téléchargés

Invalidation d’un jeu de caractères téléchargés

FRANÇAIS

Commandes de pilotage des périphériques

Code de contrôle

<ESC> <BEL> n1 n2 1B 07 n1 n2 Définition de la largeur d’impulsion d’entraîne-

<BEL> 07 Pilotage du périphérique #1

<FS> 1C Pilotage immédiat du périphérique #1

<EM> 19 Pilotage immédiat du périphérique #2

<SUB> 1A Pilotage immédiat du périphérique #2

Codes

hexadécimaux

Fonction

ment du périphérique #1

– 55 –

Page 60

Commandes de pilotage du mécanisme automatique de découpe

Code de contrôle

<ESC> “d” “0” 1B 64 30 Commande de découpe complète au mécanisme

<ESC> “d” <0> 1B 64 00 automatique

<ESC> “d” “1” 1B 64 31 Commande de découpe partielle au mécanisme

<ESC> “d” <1> 1B 64 01 automatique

FRANÇAIS

<ESC> “d” “2” 1B 64 32 Avance du papier sur la position de découpe et

<ESC> “d” <2> 1B 64 02 découpe complète du papier.

<ESC> “d” “3” 1B 64 33 Avance du papier sur la position de découpe et

<ESC> “d” <3> 1B 64 03 découpe partielle du papier.

Codes

hexadécimaux

Fonction

Autres commandes

Code de contrôle

<CAN> 18 Annulation de la dernière ligne et initialisation

<DC3> 13 Désélection de l’imprimante

<DC1> 11 Réglage du mode de sélection

<RS> 1E Retentissement de l’avertisseur

<ESC> “#N, n1 n2 n3 n4”

<LF> <NUL> 0A 00

<ESC> “@” 1B 40 Initialisation de l’imprimante

<ENQ> 05 Interrogation

<ESC> “?” <LF> <NUL> 1B 3F 0A 00 Initialisation de l’imprimante

Codes

hexadécimaux

1B 23 N 2C n1 n2 n3 n4

Fonction

de l’imprimante

Réglage du commutateur de mémorisation

– 56 –

Page 61

8-2. Mode ESC/POS

Code de

commande

HT 09 Tabulation horizontale

LF 0A Avance de ligne

FF 0C Impression mode de page et retour

DLE EOT 10 04 Transmission d’état en temps réel

DLE ENQ 10 05 Demande à l’imprimante en temps réel

CAN 18 Annulation des données d’impression en mode de page

ESC FF 1B FF Impression des données en mode de page

ESC SP 1B 20 Réglage d’espacement des caractères

ESC ! 1B 21 Désignation du mode d’impression universel

ESC # 1B 23 Commutateur de réglage de la mémoire

ESC $ 1B 24 Désignation de l’impression absolue

ESC % 1B 25 Désignation/annulation du jeu de caractères téléchargés

ESC & 1B 26 Définition des caractères téléchargés

ESC

*

ESC - 1B 2 D Désignation/annulation du soulignement

ESC 2 1B 32 Réglage de l’avance de ligne de 1/6ème de pouce

ESC 3 1B 33 Réglage de l’avance de ligne

ESC = 1B 3D Sélection de l’équipement périphérique

ESC ? 1B 3F Effacement des caractères téléchargés

ESC @ 1B 40 Initialisation de l’imprimante

ESC D 1B 44 Réglage de la position de la tabulation horizontale

ESC E 1B 45 Désignation/annulation d’impression mise en valeur

ESC G 1B 47 Désignation/annulation d’impression double

ESC J 1B 4A Impression et avance de papier

ESC L 1B 4C Sélection du mode de page

ESC R 1B 52 Sélection des caractères internationaux

ESC S 1B 53 Sélection du mode standard

ESC T 1B 54 Sélection de la direction d’impression des caractères en

ESC V 1B 56 Désignation/annulation de la rotation de 90° des caractères

ESC W 1B 57 Réglage de la plage d’impression en mode de page

ESC \ 1B 5 C Désignation de la position relative

ESC a 1B 61 Alignement de la position

ESC c4 1B 63 34 Pas de sélection de papier valide à l’arrêt d’impression

ESC c5 1B 63 35 Activation/désactivation des commandes du panneau

ESC d 1B 64 Impression et alimentation du papier de “n” lignes

ESC i 1B 69 Découpe partielle (une partie reste attachée)

ESC p 1B 70 Désignation de la génération d’impulsions

ESC t 1B 74 Sélection du tableau des codes de caractères

Code hexadécimal Fonction

1B 2A Désignation du mode d’image de bit

mode d’impression

FRANÇAIS

– 57 –

Page 62

Code de

commande

ESC u 1B 75 Transmission de l’état de l’équipement périphérique

ESC v 1B 76 Transmission de l’état de détection du papier

ESC { 1B 7B Désignation/annulation de l’impression inversée

GS ! 1D 21 Désignation de la taille de caractères

GS $ 1D 24 Désignation de la position absolue de la direction verticale

FRANÇAIS

GS

*

GS / 1D 2F Impression de l’image bit téléchargée

GS : 1D 3A Début/fin de la définition macro

GS B 1D 42 Désignation/annulation de l’impression à l’envers

GS H 1D 48 Sélection de la position d’impression des caractères HRI

GS I 1D 49 Transmission de l’identification de l’imprimante

GS L 1D 4C Réglage de la marge de gauche

GS P 1D 50 Réglage du pas calculé de base

GS V 1D 56 Coupure du papier

GS W 1D 57 Réglage de la plage d’impression

GS \ 1D 5C Désignation de la position relative des caractères verticaux

GS ^ 1D 5E Exécution de macro

GS a 1D 61 Activation/désactivation de la transmission de l’état

GS f 1D 66 Sélection de fonte de caractères HRI

GS h 1D 68 Réglage de la hauteur de codes à barres

GS k 1D 6B Impression de codes à barres

GS r 1D 72 Transmission d’état

GS w 1D 77 Réglage de la taille latérale de codes à barres

Code hexadécimal Fonction

des caractères en mode de page

1D 2A Définition de l’image bit téléchargée

lors de l’impression en mode de page

automatique

– 58 –

Page 63

Inhaltsverzeichnis

1. Auspacken und Prüfung ......................................................................61

1-1. Auspacken..................................................................................61

1-2. Wahl eines Aufstellungsorts ......................................................61

2. Funktion und Bezeichnung der Teile ..................................................62

3. Druckerverbindung..............................................................................63

3-1. Schnittstellenkabel .....................................................................63

3-2. Ferritkern *nur Europa...............................................................65

3-3. Optionales Netzteil.....................................................................67

4. Papiervorrat-Sensor .............................................................................68

5. Papier einlegen ....................................................................................69

5-1. Papier einlegen...........................................................................69

5-2. Nachfüllen der Papierversorgung...............................................73

5-3. 76 mm Breit-Stütze ....................................................................74

5-4. Papierstau beheben.....................................................................76

6. Bedienfeld............................................................................................77

6-1. Einschalten .................................................................................77

6-2. Kombinierte Bedienfeld-Verfahren ...........................................78

6-3. Fehlermeldungen........................................................................80

6-4. Signalton-Anzeigen (nur Star-Modus).......................................81

7. Behandlung des Druckers....................................................................82

7-1. Vorsichtsmaßregeln zum Betrieb...............................................82

7-2. Sicherheitsregeln ........................................................................82

DEUTSCH

8. Zusammenfassung der Befehle............................................................ 83

8-1. Star-Betriebsart ..........................................................................83

8-2. ESC/POS Betrieb .......................................................................87

Der Anhand dieser Bedienungsanleitung ist nur in englischer Sprache.

Page 64

Page 65

1. Auspacken und Prüfung

1-1. Auspacken

Überprüfen Sie an Hand von Abbildung 1 die Teile in der Verpackung, und stellen

Sie sicher, daß alle nötigen Positionen geliefert wurden; es sollten fünf sein.

Falls eines der Teile fehlen sollte, wenden Sie sich bitte an Ihren Händler.

StützDistanzstücke

Ferritkern für

PeripheriegerätKabel (nur EU)

Kabelband

(nur EU)

Drucker

Mitgelieferte

Papierrolle

Abb. 1-1

76mm Haiter

Bedienungsanleitung

1-2. W ahl eines Aufstellungsorts

Bevor Sie mit der Aufstellung des Druckers beginnen, stellen Sie sicher, daß ein

geeigneter Aufstellungsort vorhanden ist. Mit “geeignetem Aufstellungsort” ist

ein Ort gemeint, der folgenden Bedingungen entspricht:

• Nahe an einer gut zugänglichen Steckdose

• Feste, ebene Oberfläche mit geringen Vibrationen

• Ausreichender Abstand zu Hitzequellen (wie direktem Sonnenlicht, Heizkör-

pern etc.)

• Keine zu hohe Luftfeuchtigkeit

• Wenig Staub

• Zugang zu einer Netzsteckdose, die keine Spannungsschwankungen auf-

weist. So sollte der Drucker z.B. nicht an die gleiche Steckdose wie ein großes,

Störungen erzeugendes Haushaltsgerät wie ein Kühlschrank oder eine Klimaanlage angeschlossen werden.

HINWEIS: Sicherstellen, daß die Netzspannung der auf dem Typenschild des

Druckers angegebenen Spannung entspricht.

– 61 –

DEUTSCH

Page 66

Oberteil

Schützt den Drucker vor

Staub und reduziert das

Betriebsgeräusch.

Nicht während des

Druckens öffnen.

DEUTSCH

2. Funktion und Bezeichnung der Teile

Bedienfeld

Enthält zwei

Steuertasten und zwei

Anzeigen zur Darstellung

des Druckerstatus.

Netzschalter

Zum Ein- und Ausschalten

des Druckers.

Netzteil-Anschlußbuchse

Zum Anschließen des

Betriebsstromkabels vom Netzteil.

Den Stecker nicht bei

eingeschaltetem Drucker

abziehen.

Schnittstellenbuchse

Zur Verbindung des

Druckers mit dem

Host-Rechner.

Abb. 2-1 Außenansicht des Druckers

Anschlußbuchse für Peripheriegerät

Zur Verbindung mit Peripheriegeräten

wie Registrierkassen etc. Hier kein

Telefon anschließen.

– 62 –

Page 67

3. Druckerverbindung

Vor dem Herstellen von Verbindungen folgende Vorbereitungen treffen. Immer

Netzschalter in Aus-Stellung stellen, während Verbindungen hergestellt werden.

• Schnittstellenkabel

• Ferritkern (nur EU)

• Optionales Netzteil

3-1. Schnittstellenkabel

1 Das Oberteil öffnen.

2 Den Kopfhebel (grün) nach hinten

drücken.

DEUTSCH

Kopfhebel

[Kopf-Oben-Stellung]

Zuführknopf

[Kopf-Geschlossen-Stellung]

Achtung

Wenn der Drucker transportiert oder

längere Zeit weggestellt werden soll,

immer den Kopfhebel nach vorne ziehen, so daß der Druckerkopf in ObenStellung ist. Dadurch wird der

Thermalkopf geschützt und Deformation der Auflagerolle vermieden.

3 Das Oberteil schließen.

– 63 –

Page 68

DEUTSCH

Screws

Schrauben

Schraubenzieher

Screwdriver

4 Den druckerseitigen Stecker des

Schnittstellenkabels in die

Schnittstellenbuchse des Druckers

stecken und mit den Befestigungsschrauben oder einem Haltebügel

befestigen.

– 64 –

Page 69

3-2. Ferritkern *nur Europa

Fastener

HINWEIS: Die folgenden Arbeiten besonders sorgfältig ausführen.

■ Ein Ferritkern-Rauschfilter für das

Peripheriegerät wird mit dem Drukker mitgeliefert.

■ Der Ferritkern ist normalerweise in

geöffnetem Zustand verpackt, wie

in Abbildung 3-1 gezeigt.

Ferrite core (28mm diameter)

Ferritkern (28 mm Durchmesser)

One loop

Eine Schleife

Abb. 3-1

• Das Kabelband durch den Ferritkern ziehen.

Kabelband

Abb. 3-3

Ziehen und

Pull and cut

abschneiden

DEUTSCH

Wenn Sie den Ferritkern in nicht

geöffnetem Zustand vorfinden: Mit

einem scharfen Gegenstand die