Page 1

THERMAL PRINTER

TSP2000 SERIES

USER’S MANUAL

MODE D’EMPLOI

BEDIENUNGSANLEITUNG

MANUALE DI ISTRUZIONI

Page 2

Federal Communications Commission

Radio Frequency Interference

Statement

This equipment has been tested and found to comply with the limits for a Class A digital

device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference when the equipment is operated in a

commercial environment. This equipment generates, uses and can radiate radio frequency

energy and, if not installed and used in accordance with the instruction manual, may cause

harmful interference to radio communications. Operation of this equipment in a residential

area is likely to cause harmful interference in which case the user will be required to correct

the interference at his own expense.

For compliance with the Federal Noise Interference Standard, this equipment requires a

shielded cable.

This statement will be applied only for the printers marketed in U.S.A.

Statement of

The Canadian Department of Communications

Radio Interference Regulations

This digital apparatus does not exceed the Class A limits for radio noise emissions from

digital apparatus set out in the Radio Interference Regulations of the Canadian Department

of Communications.

Le présent appareil numérique n’émet pas de bruits radioélectriques dépassant les limites

applicables aux appareils numériques de la classe A prescrites dans le Règlement sur le

brouillage radioélectrique édicté par le ministère des Communications du Canada.

The above statement applies only to printers marketed in Canada.

Manufacturer’s Declaration of Conformity

CE

EC Council Directive 89/336/EEC of 3 May 1989

This product, has been designed and manufactured in accordance with the International

Standards EN 50081-1/01.92 and EN 50082-1/01.92, following the provisions of the

Electro Magnetic Compatibility Directive of the European Communities as of May 1989.

EC Council Directive 73/23/EEC and 93/68/EEC of 22 July 1993

This product, has been designed and manufactured in accordance with the International

Standards EN 60950, following the provisions of the Low Voltage Directive of the

European Communities as of July 1993.

The above statement applies only to printers marketed in EU.

Trademark acknowledgments

TSP2000: Star Micronics Co., Ltd.

ESC/POS: Seiko Epson Corporation

Notice

• All rights reserved. Reproduction of any part of this manual in any form whatsoever,

without STAR’s express permission is forbidden.

• The contents of this manual are subject to change without notice.

• All efforts have been made to ensure the accuracy of the contents of this manual at the

time of going to press. However, should any errors be detected, STAR would greatly

appreciate being informed of them.

• The above notwithstanding, STAR can assume no responsibility for any errors in this

manual.

©

Copyright 2000 Star Micronics Co., LTD.

Page 3

TABLE OF CONTENTS

1. Parts Identification and Nomenclature .........................................................1

2. Consumable Parts and AC Adapter ..............................................................3

3. Connecting Cables and AC Adapter..............................................................4

3-1. Interface Cable .......................................................................................4

3-2. Connecting to a Peripheral Unit.............................................................6

3-3. Connecting the Optional AC Adapter ....................................................8

3-4. Turning Power On .................................................................................9

4. Control Panel .................................................................................................10

4-1. PAPER FEED Switch ..........................................................................10

4-2. POWER LED (green LED) .................................................................10

4-3. ERROR LED (red LED) ......................................................................10

5. Loading Paper................................................................................................11

5-1. Loading New Roll Paper......................................................................11

5-2. Removing Remaining Paper ................................................................13

6. Near-end Sensor.............................................................................................14

7. Preventing and Clearing Paper Jams ..........................................................16

7-1. Preventing Paper Jams .........................................................................16

7-2. Removing Paper Jam ...........................................................................16

7-3. Releasing a Locked Cutter ...................................................................17

8. Test Print Method..........................................................................................19

8-1. Producing a Test Print..........................................................................19

8-2. Hexadecimal Dump .............................................................................19

9. Periodical Cleaning .......................................................................................20

9-1. Cleaning the Thermal Head .................................................................20

9-2. Cleaning the Paper Holder ...................................................................20

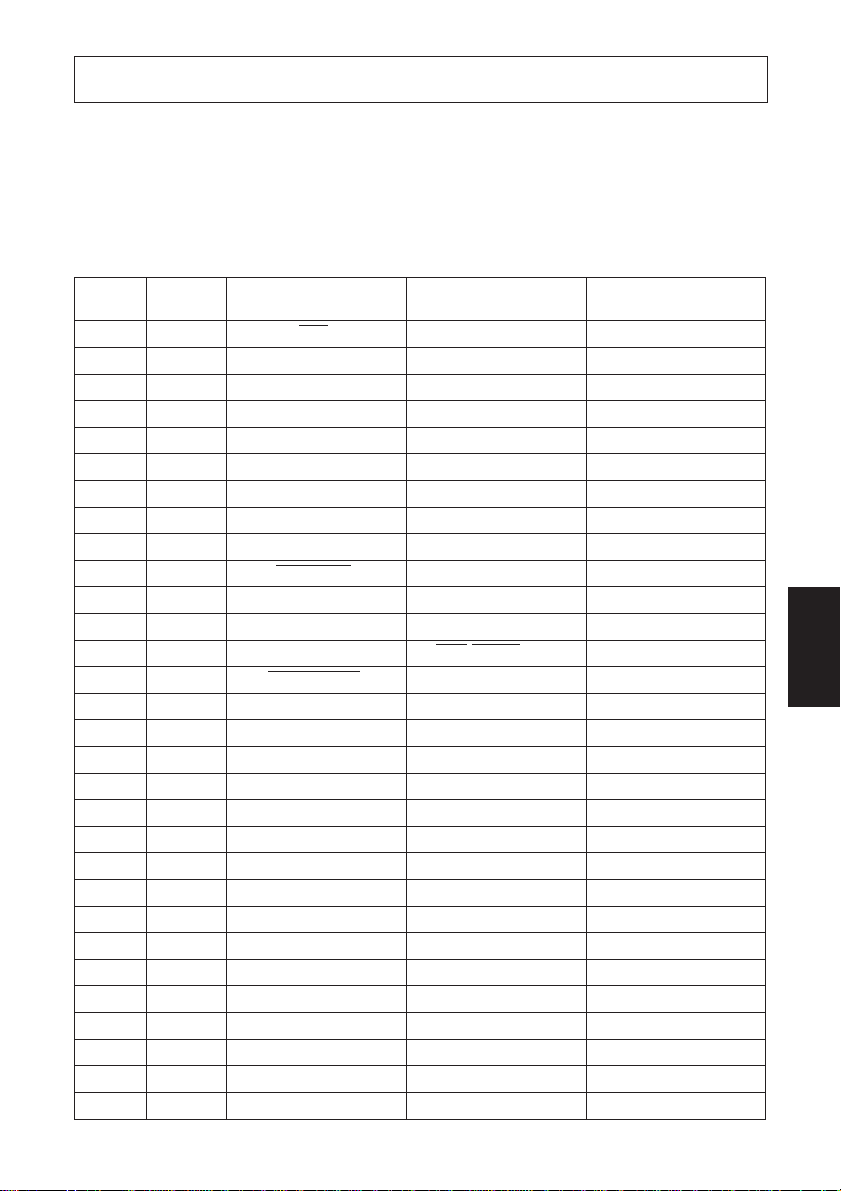

Appendix A: Specifications...............................................................................87

A-1. General Specifications .........................................................................87

A-2. Print Specifications ..............................................................................88

A-3. Auto Cutter Specifications ...................................................................88

A-4. Interface ...............................................................................................88

A-5. Power Supply .......................................................................................88

A-6. Environmental Requirements...............................................................89

A-7. Reliability.............................................................................................89

Appendix B: Dip Switch Setting.......................................................................90

B-1. Serial Interface Type............................................................................91

B-2. Parallel Interface Type.........................................................................92

Appendix C: Parallel Interface ........................................................................93

C-1. Table of Connection Signals for Each Mode.......................................93

C-2. Function for Compatibility Mode ........................................................95

ENGLISH

Page 4

ENGLISH

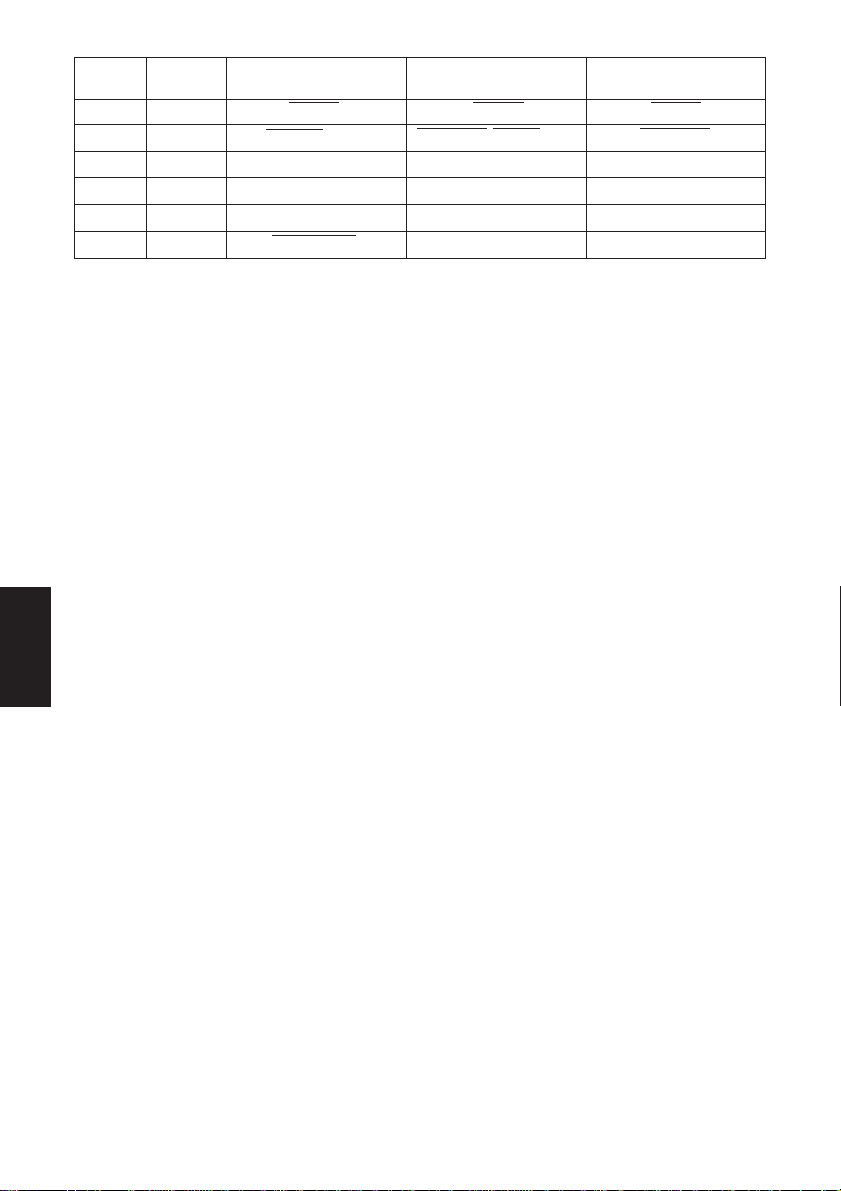

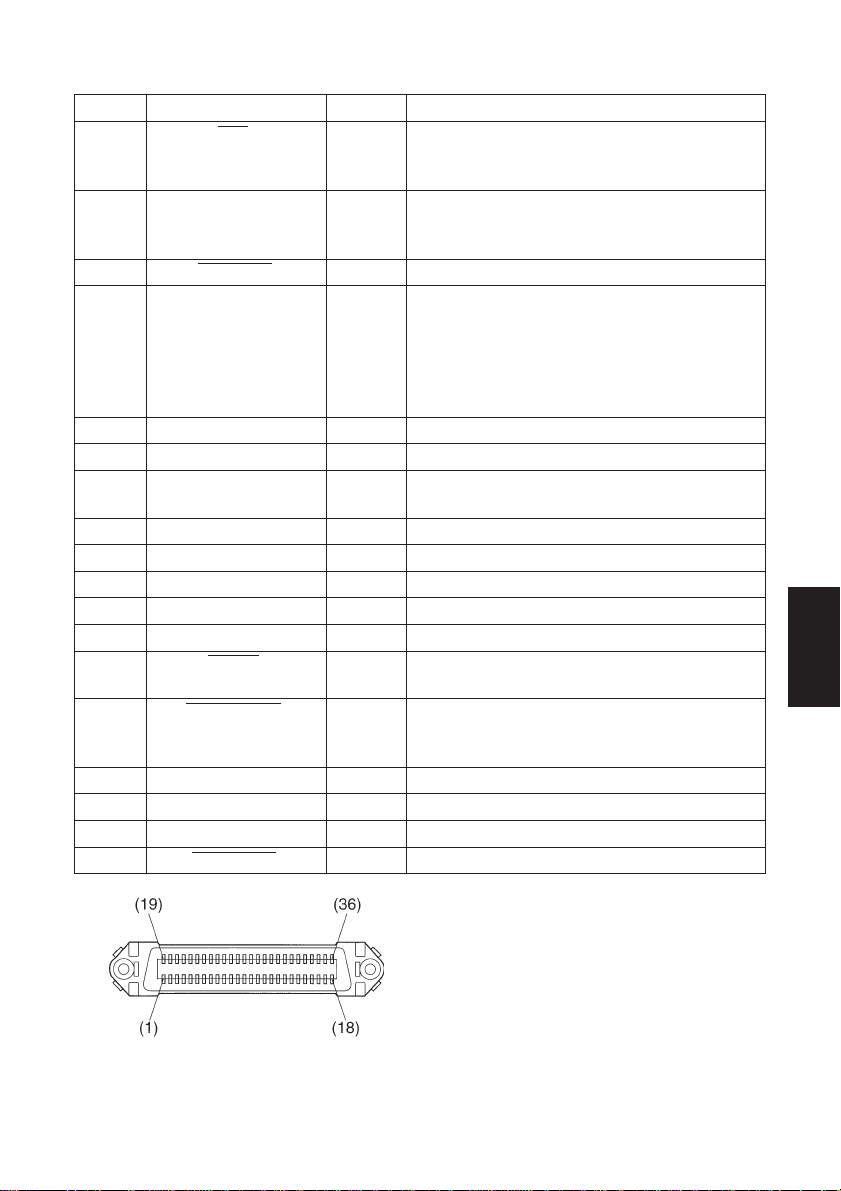

Appendix D: Serial Interface............................................................................96

D-1. RS-232C Connector .............................................................................96

D-2. Cable Connections ...............................................................................97

D-3. Electrical Characteristics .....................................................................97

Appendix E: Periheral Unit Drive Circuit ......................................................98

E-1. Peripheral Drive Connector .................................................................98

Please access the following URL

http://www.star-micronics.co.jp/service/sp_sup_e.htm

for the lastest revision of the manual.

ENGLISH

Page 5

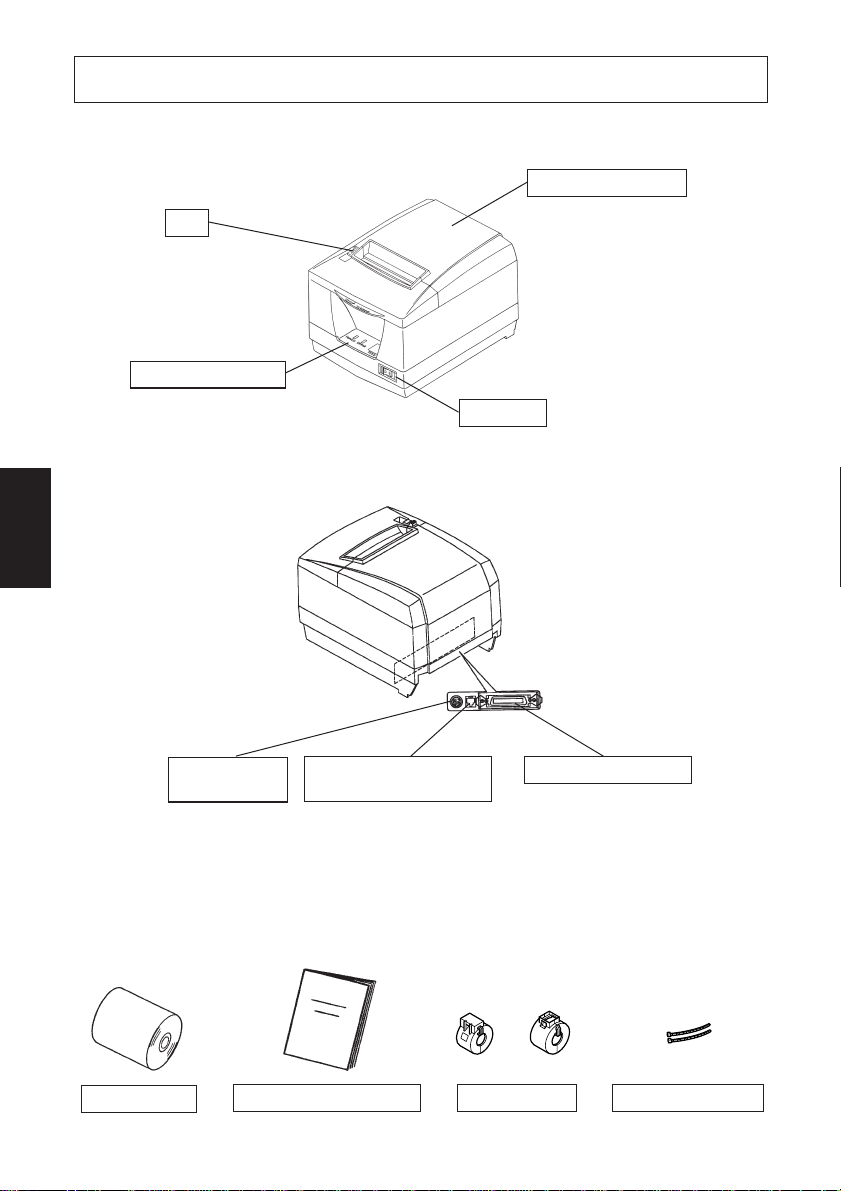

1. Parts Identification and Nomenclature

Printer cover

Lever

Pull this lever

in the

direction of

the arrow to

open the

printer cover.

Control panel

Features LED indicators to indicate printer

status and switches to

operate the printer.

Open this cover to

load or replace paper.

Switch

Used to turn on/off

power to the printer.

ENGLISH

Power connector

For connection of

the AC adapter.

Never unplug the

AC adapter while

the printer is on.

Roll paper

Peripheral drive connector

Connects to peripheral

units such as cash

drawers, etc.

Do not connect this to a

telephone.

User’s manual

– 1 –

Interface connector

For connection to a

host computer.

Ferrite Cores Fasteners

Page 6

Choosing a place for the printer

ENGLISH

Before actually unpacking the printer, you should take a few minutes to

think about where you plan to use it. Remember the following points

when doing this.

✓ Choose a firm, level surface where the printer will not be exposed to

vibration.

✓ The power outlet you plan to connect to for power should be nearby

and unobstructed.

✓ Make sure that the printer is close enough to your host computer for

you to connect the two.

✓ Make sure that the printer is not exposed to direct sunlight.

✓ Make sure that the printer is well away from heaters and other sources

of extreme heat.

✓ Make sure that the surrounding area is clean, dry, and free of dust.

✓ Make sure that the printer is connected to a reliable power outlet. It

should not be on the same electric circuit as copiers, refrigerators, or

other appliances that cause power spikes.

✓ Make sure that the room where you are using the printer is not too

humid.

– 2 –

Page 7

2. Consumable Parts and AC Adapter

When consumable parts have run out, use those specified in the table below.

Make sure that the AC adapter specified in the table is used.

Use of consumable parts or AC adapter which are not specified in the table may

result in damage to the printer, fire or electric shock.

Parts Name Specifications

Roll paper Thermal paper

Thickness: 0.06 to 0.08 mm

Width: 80 mm

Outer roll diameter: ø90 mm or less

Core outer diameter: ø18 mm

Core inner diameter: ø12 ±0.5 mm

Recommended paper (normal type paper)

Recommended paper (medium image stability paper)

Recommended paper (high image stability paper)

AC adapter (Option) Input: 100 to 240 V AC, 50-60 Hz

UP06021240 Output: 24 V DC±5 %, 2.5 A

0

- 1.0

+0.5

0

TF50KS-E2C (Nippon Paper Industries)

P220AG (Mitsubishi Paper Mills Limited)

PD-160R-N (Oji Paper Co., Ltd.)

AFP235 (Mitsubishi Paper Mills Limited)

ENGLISH

Important!

Access the following URL for the information of the recommended paper.

http://www.star-micronics.co.jp/

– 3 –

Page 8

3. Connecting Cables and AC Adapter

ENGLISH

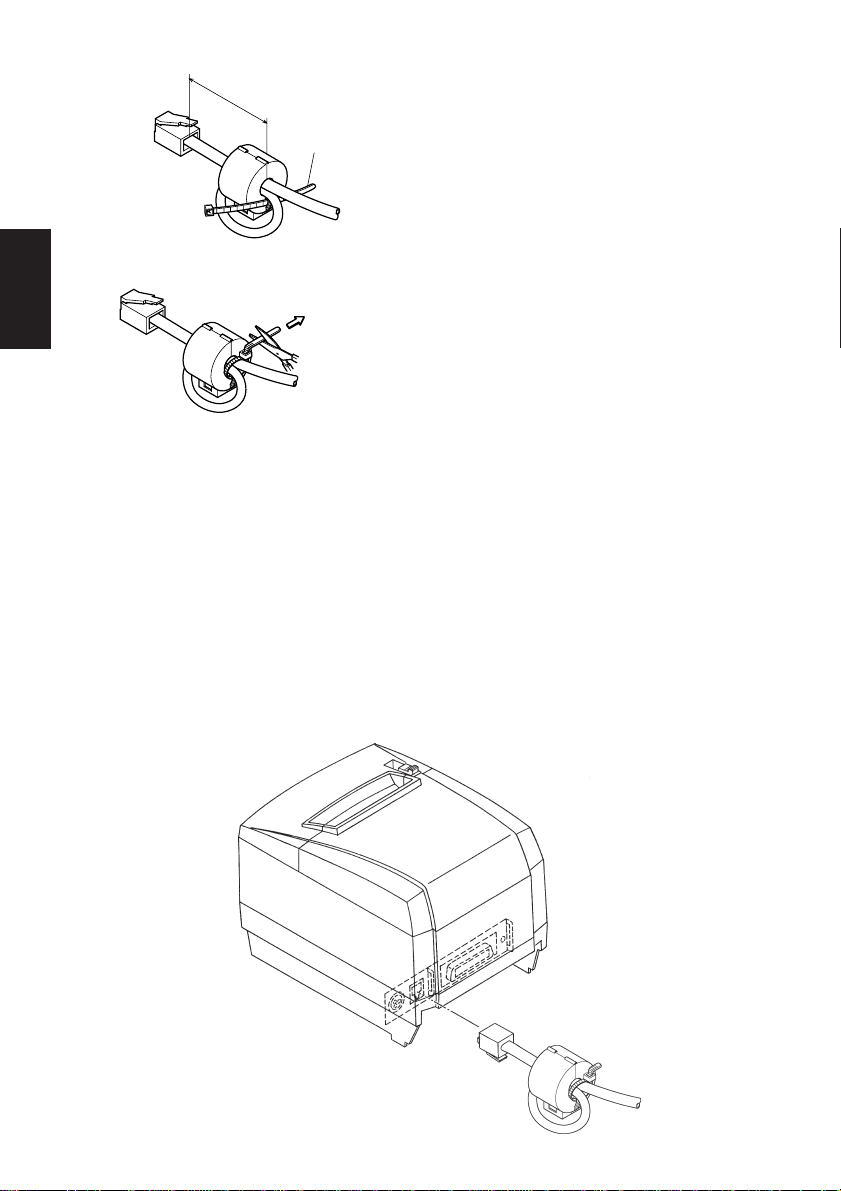

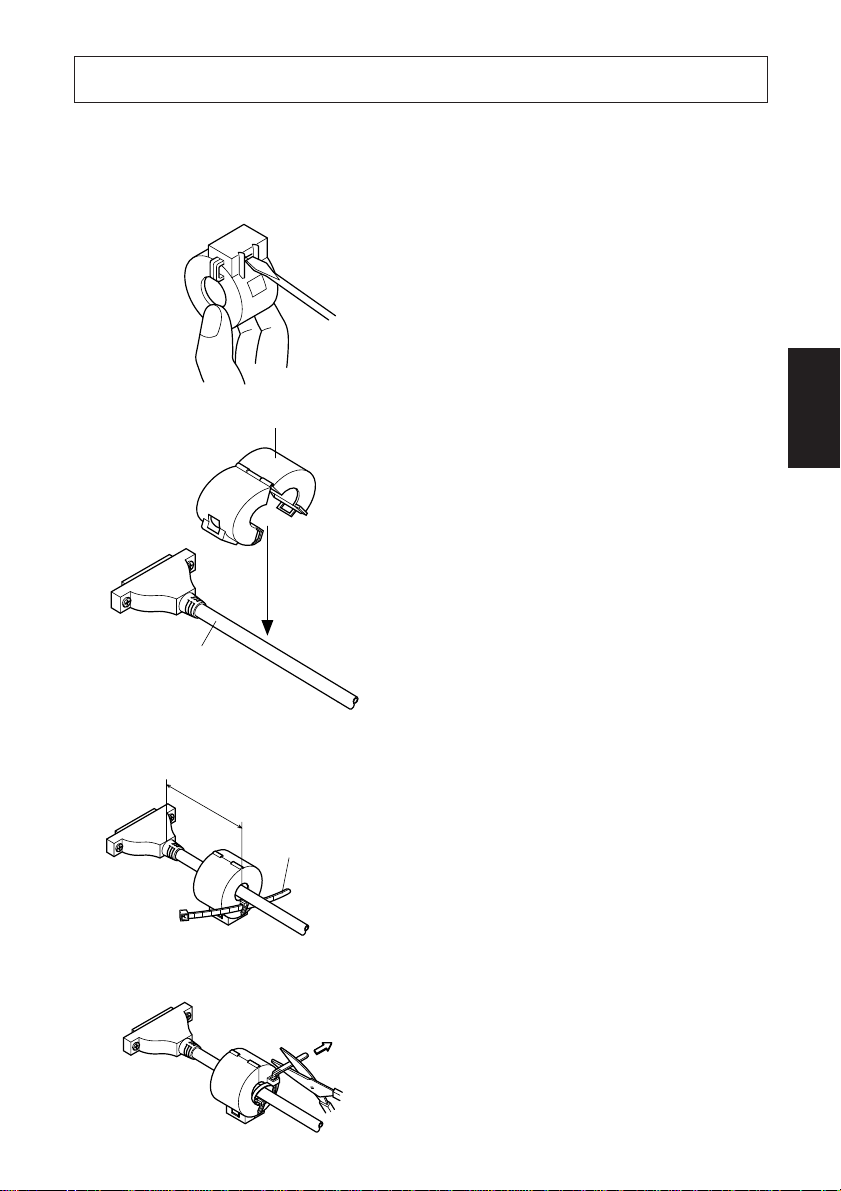

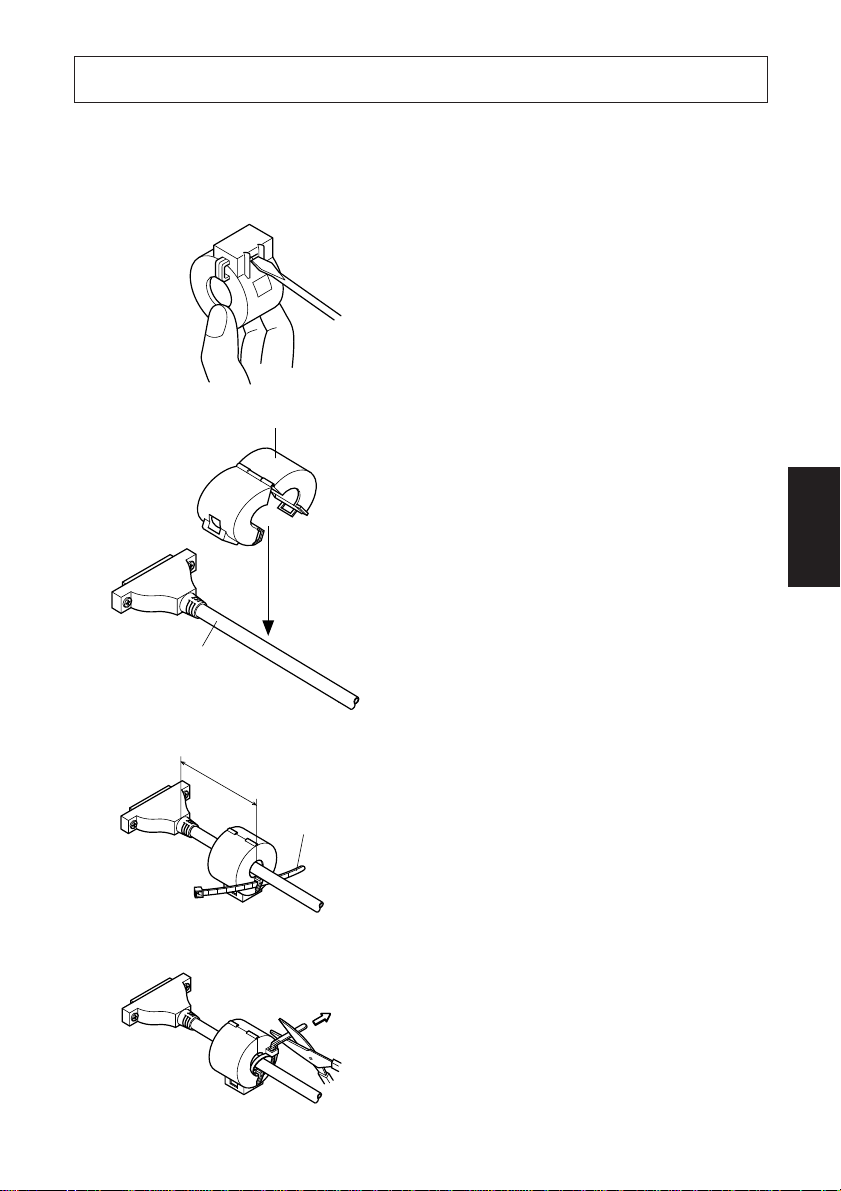

3-1. Interface Cable 3-1-1. Ferrite Core Installation

Ferrite core (27 mm wide)

Interface cable

(1)Affix the larger ferrite core onto the

cable as shown in the illustration

below.

5 cm

maximum

Fastener

Pull and cut

(2)Pass the fastener through the ferrite

core.

(3)Loop the fastener around the cable

and lock it. Use scissors to cut off

any excess.

– 4 –

Page 9

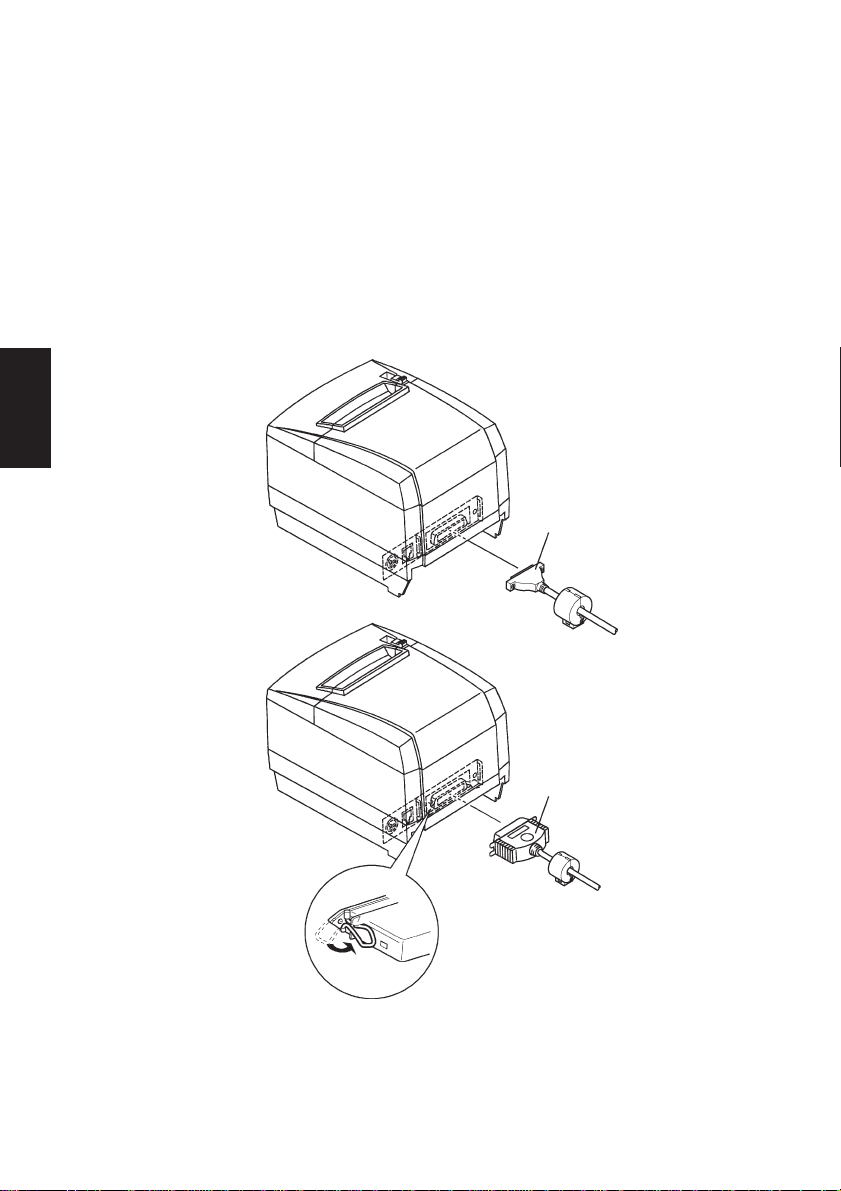

3-1-2. Connecting the Interface Cable

Note: Before connecting/disconnecting the interface cable, make sure that

power to the printer and all the devices connected to the printer is

turned off. Also make sure the power cable plug is disconnected from

the AC outlet.

(1)Connect the interface cable to the connector on the rear panel of the printer.

(2)In the case of a serial interface, tighten the connector screws. In the case of a

parallel interface, fasten the connector clasps.

Serial interface cable

ENGLISH

– 5 –

Parallel interface cable

Page 10

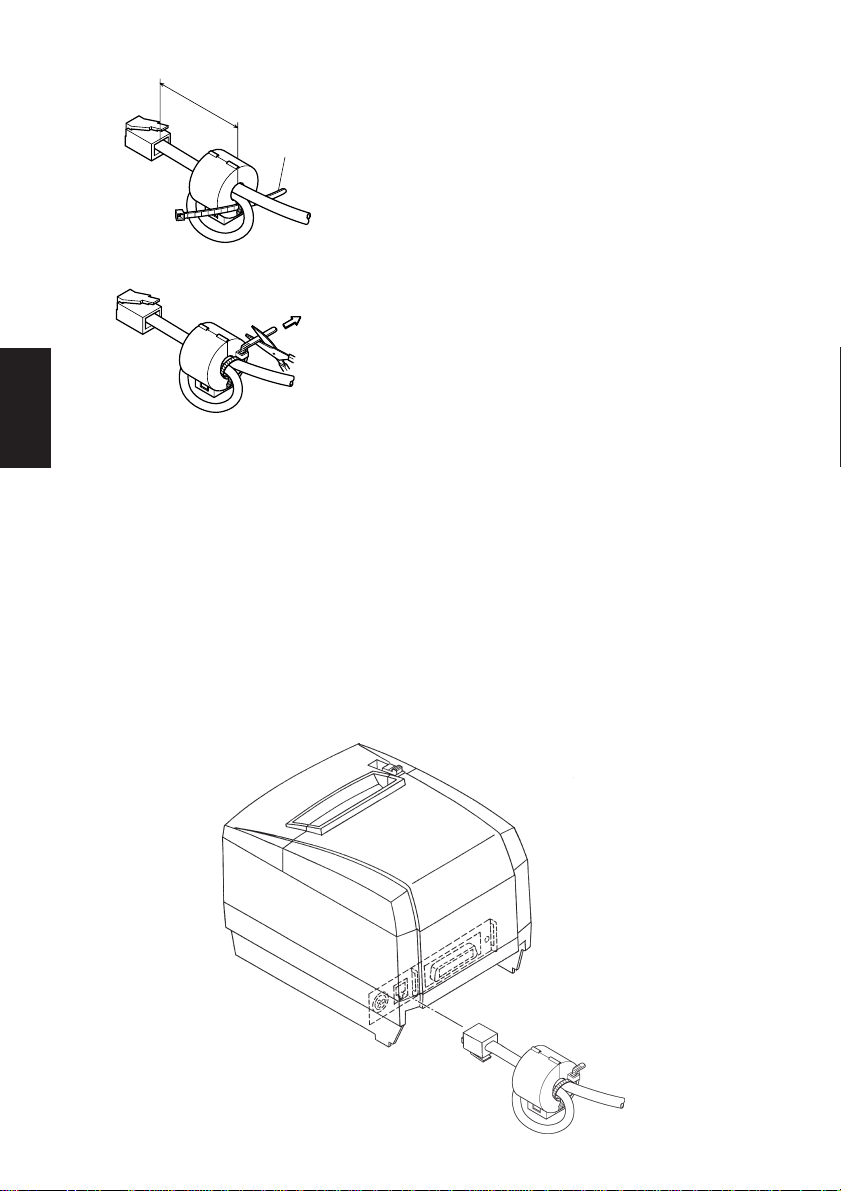

3-2. Connecting to a Peripheral Unit

You can connect a peripheral unit to the printer using a modular plug. The

ENGLISH

following describes how to install the ferrite core and make the actual connection.

See “Modular plug” on page 98 for details about the type of modular plug that is

required. Note that this printer does not come with a modular plug or wire, so it

is up to you to obtain one that suits your needs.

Important!

Make sure that the printer is turned off and unplugged from the AC outlet and

that the computer is turned off before making connections.

(1) Affix the smaller ferrite core onto

the modular wire as shown in the

illustration below.

Ferrite core (17.5 mm wide)

Connector

One loop

cable

– 6 –

Page 11

5 cm

maximum

Fastener

(2)Pass the fastener through the ferrite

core.

(3)Loop the fastener around the cable

Pull and cut

and lock it. Use scissors to cut off

any excess.

(4)Plug one end of the modular cable

into the modular jack of the peripheral.

(5)Remove the modular jack cover

from the back of the printer and plug

the other end of the modular cable

into the jack of the printer.

Note: Before connecting/disconnecting the peripheral drive cable, make

sure that power to the printer and all the devices connected to the

printer is turned off. Also make sure the power cable plug is disconnected from the AC outlet.

ENGLISH

(1)Connect the peripheral drive cable to the connector on the rear panel of the

printer.

– 7 –

Page 12

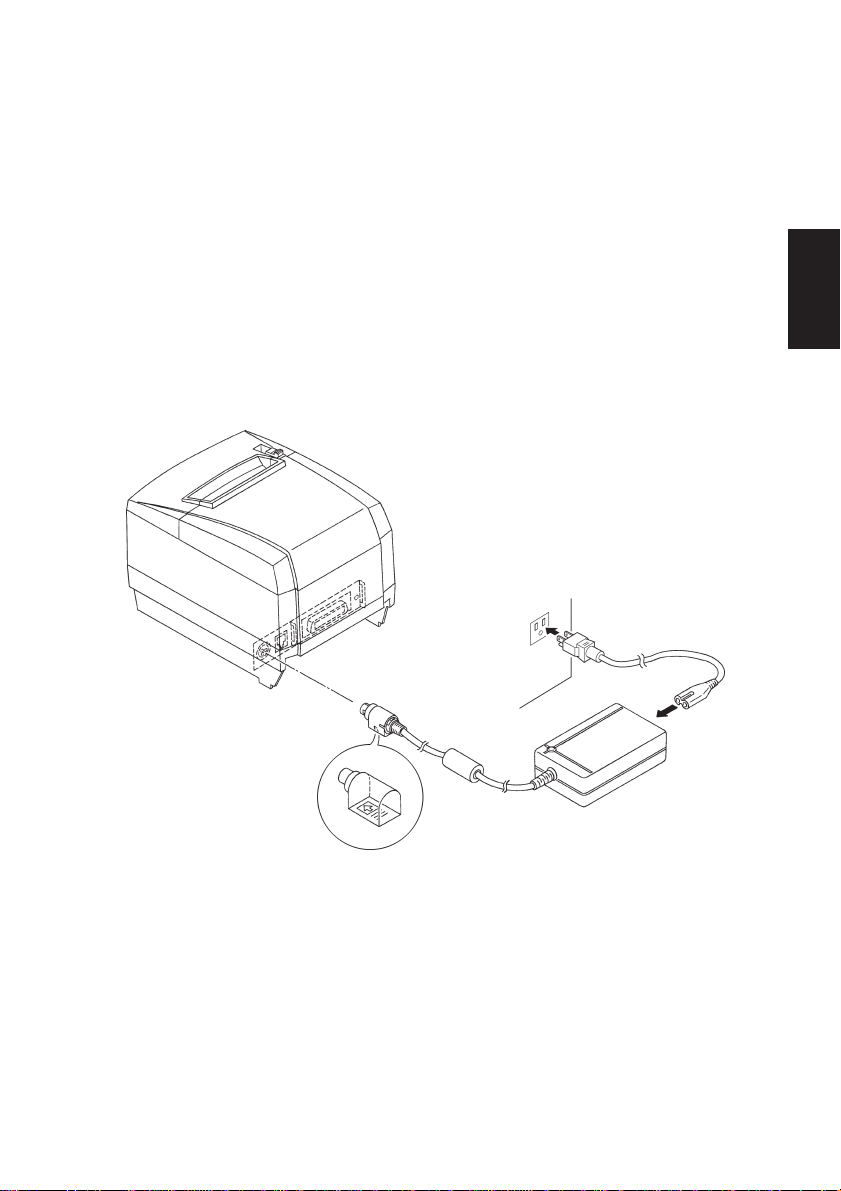

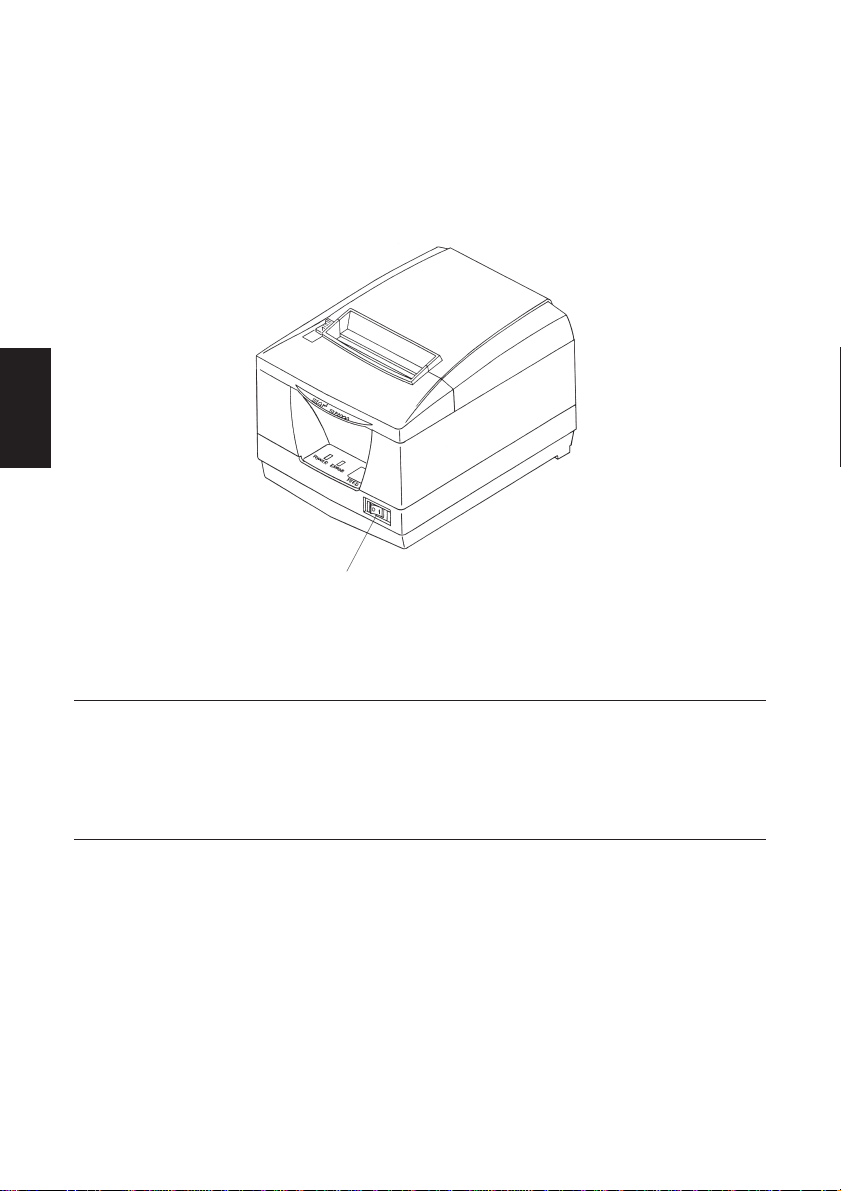

3-3. Connecting the Optional AC Adapter

ENGLISH

Note: Before connecting/disconnecting the AC adapter, make sure that

power to the printer and all the devices connected to the printer is

turned off. Also make sure the power cable plug is disconnected from

the AC outlet.

(1)Connect the AC adapter to the power cable.

Note: Use only the standard AC adapter and power cable.

(2)Connect AC adapter to the connector on the printer.

(3)Insert the power cable plug into an AC outlet.

– 8 –

Page 13

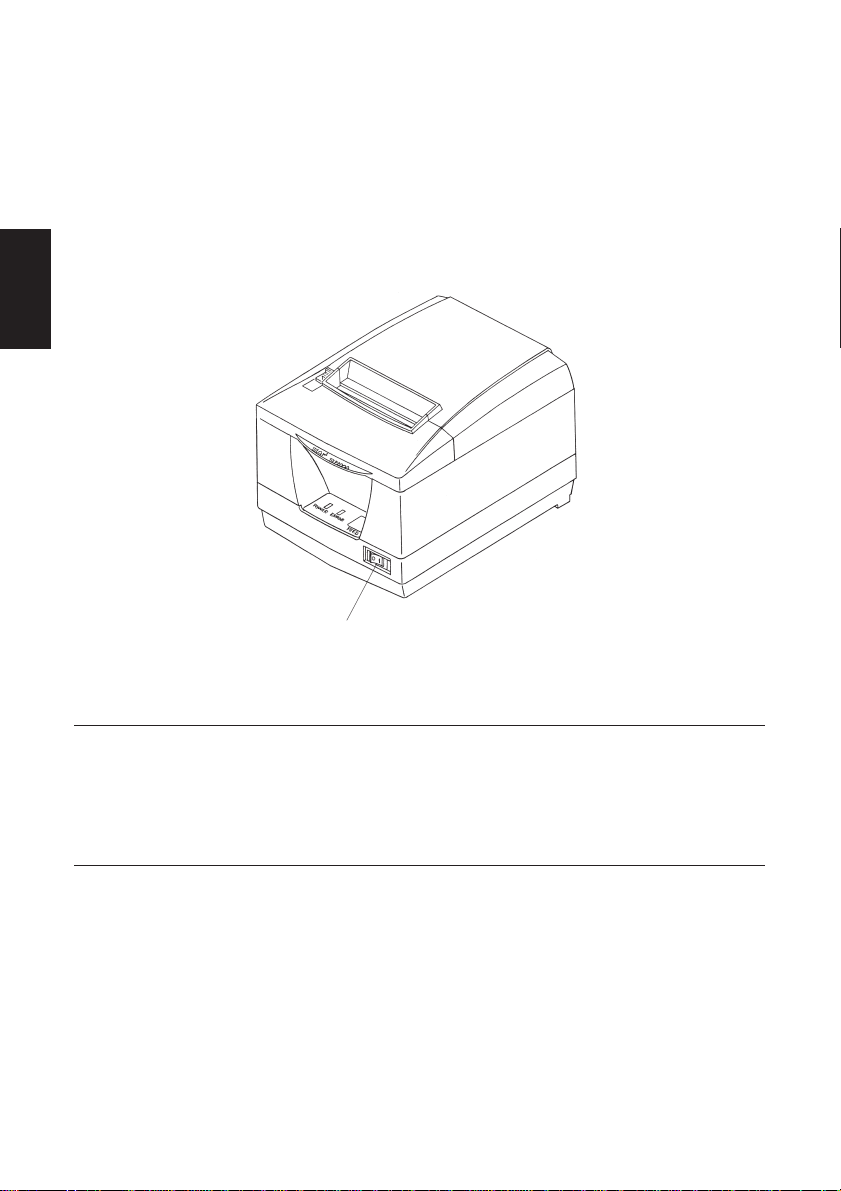

3-4. Turning Power On

Make sure that the AC adapter has been connected as described in 3-3.

(1)Set the power switch located on the front of the printer to on.

The POWER lamp on the control panel will light up.

Power switch

ENGLISH

Important!

We recommend that you unplug the printer from the power outlet

whenever you do not plan to use it for long periods. Because of this, you

should locate the printer so that the power outlet it is plugged into is

nearby and easy to access.

– 9 –

Page 14

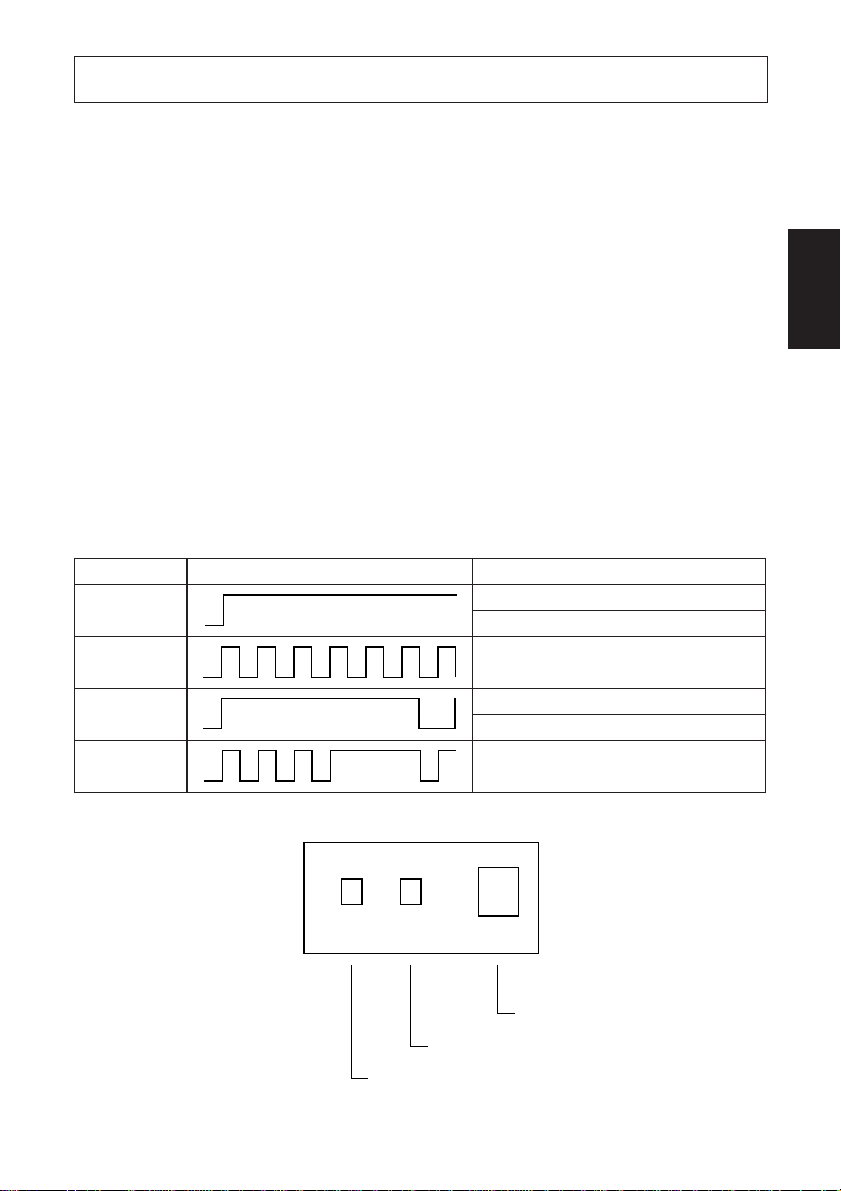

4. Control Panel

ENGLISH

4-1. PAPER FEED Switch

Each time this switch is pressed, the paper feeds on line. When it is kept

depressed, the paper feeds continuously.

Note: This switch will be ineffective if no paper is loaded.

4-2. POWER LED (green LED)

This LED lights up when the power switch is set to on and power is supplied to

the printer.

4-3. ERROR LED (red LED)

This LED lights up or blinks when any of the following errors occurs.

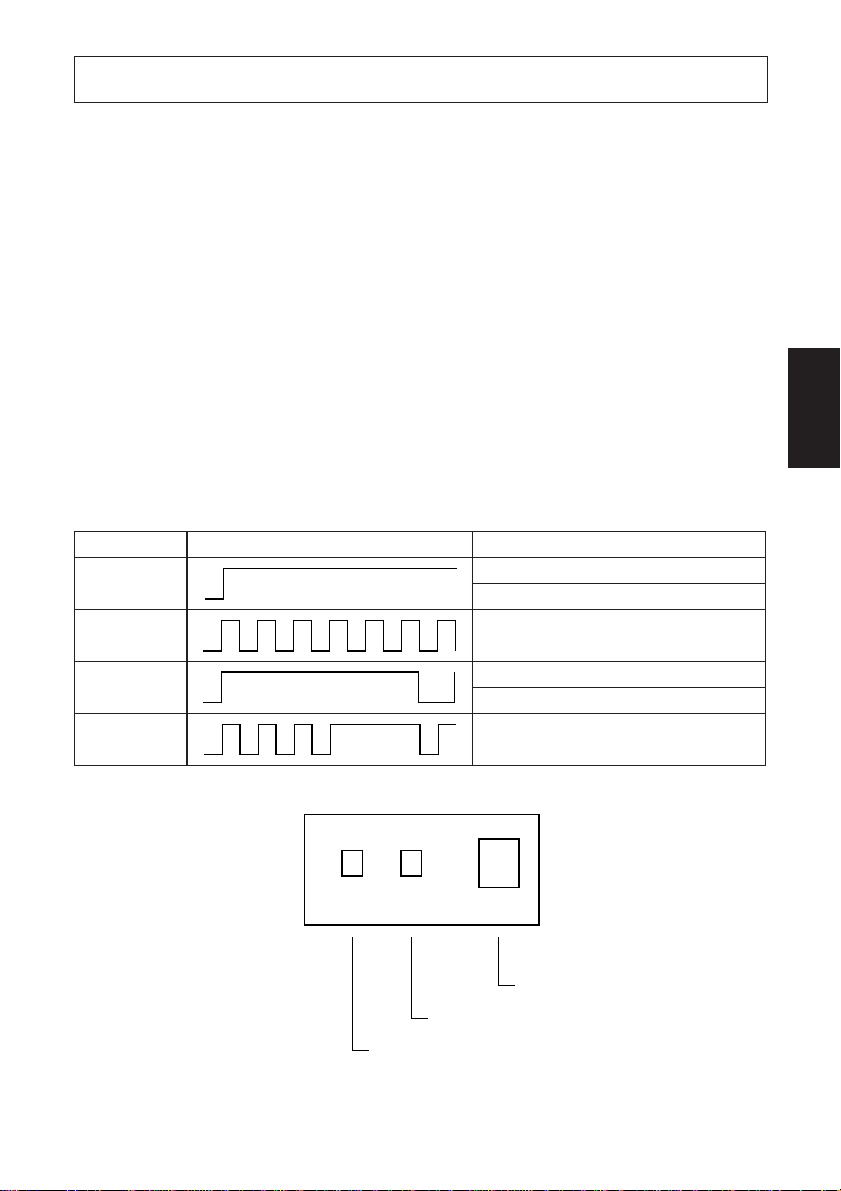

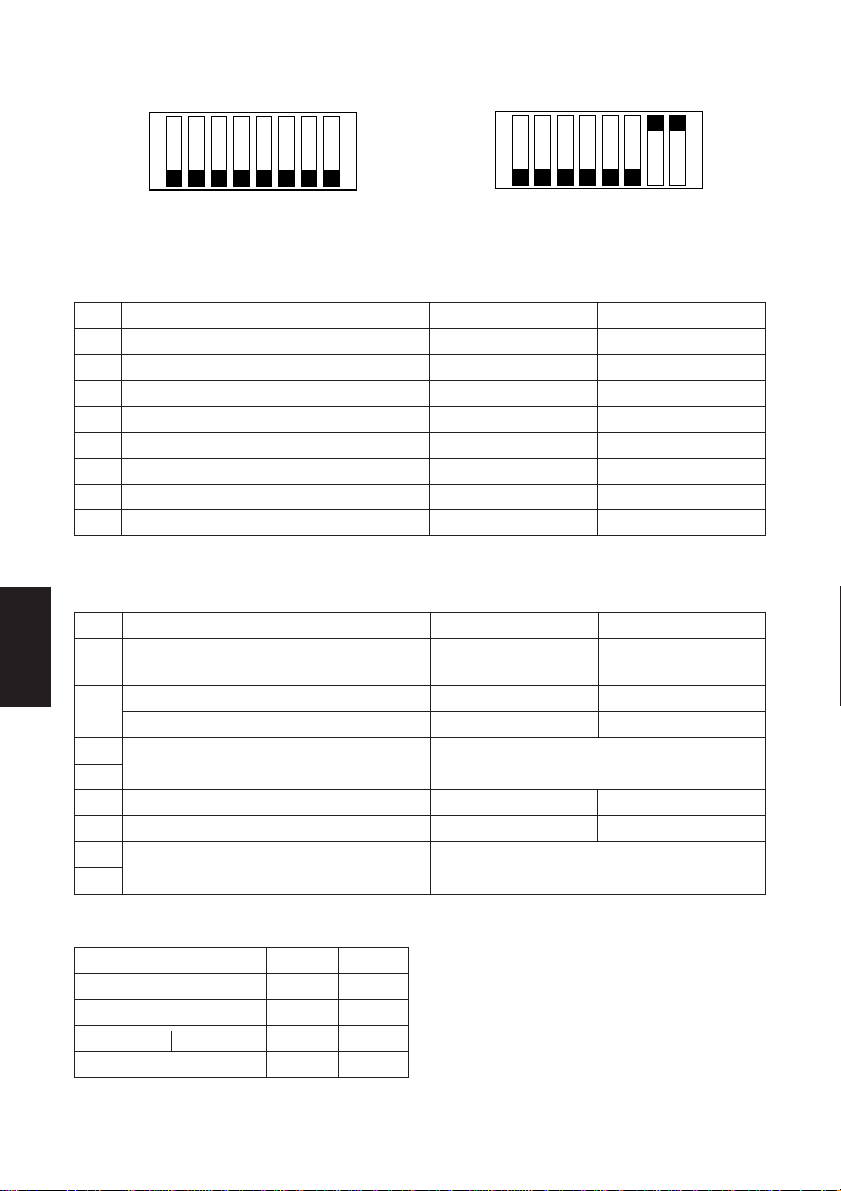

Error LED flashing pattern Error description

Light on Printer cover is open

Light flashing Paper has run out

Light on

Light flashing

Light on Abnormal head temperature (90°C)

Light flashing Malfunction in head connection

Light on

Light flashing

Paper is about to run out

Automatic cutter error

POWER ERROR FEED

Error LED (red)

Power LED (green)

– 10 –

Paper feed switch

Page 15

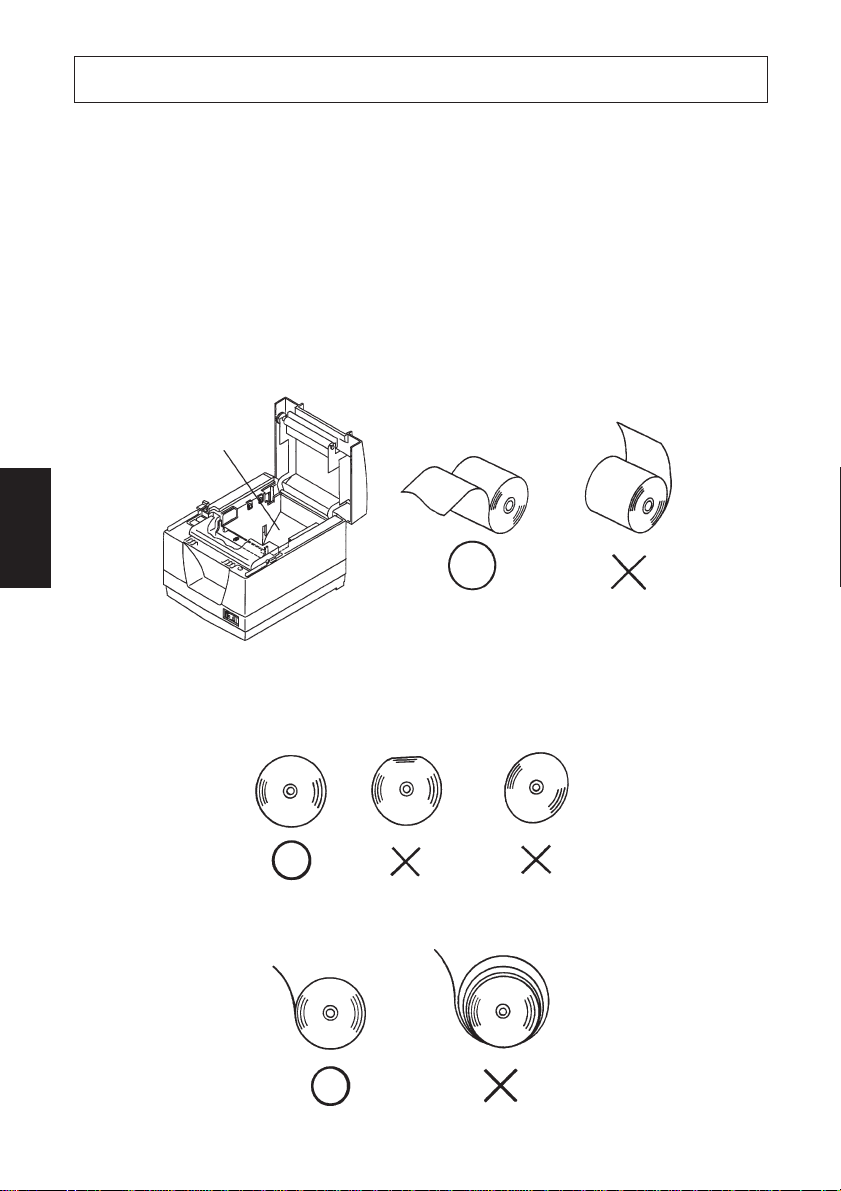

5. Loading Paper

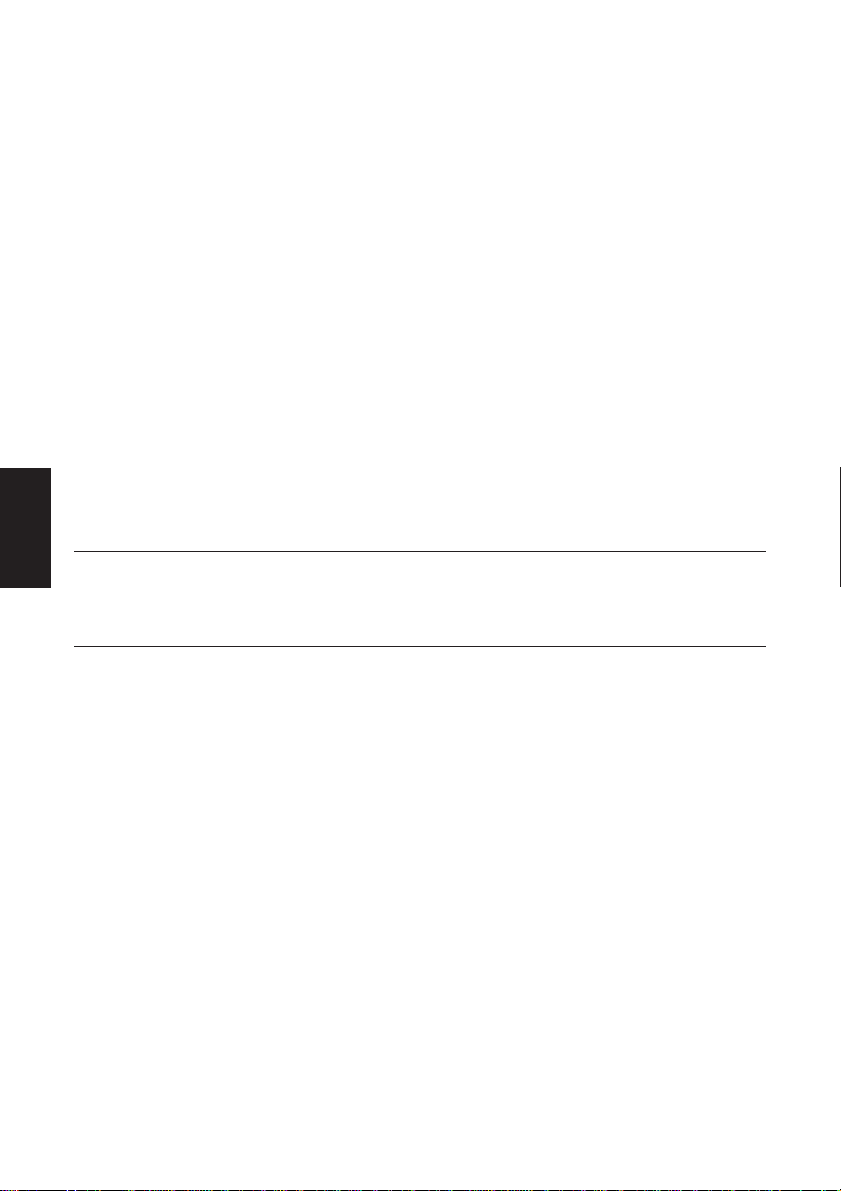

5-1. Loading New Roll Paper

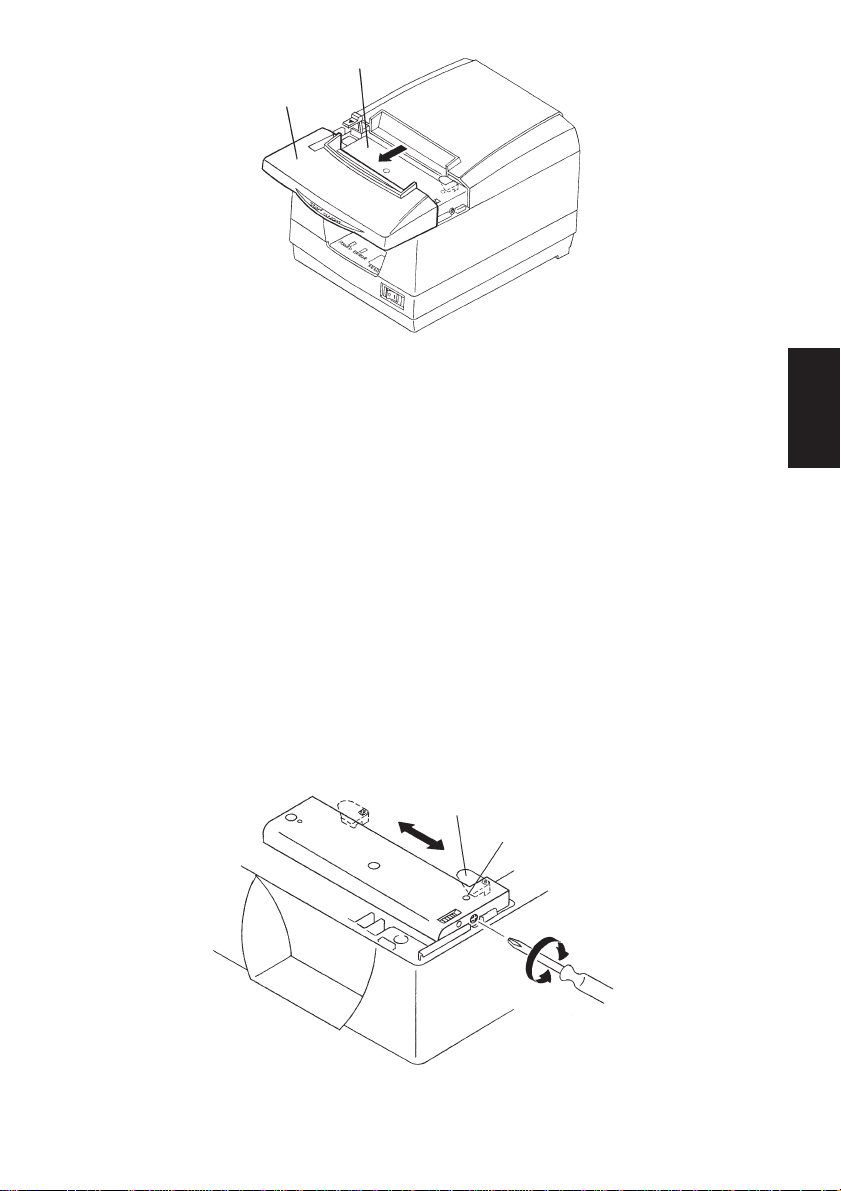

(1)Pull the lever toward you to open the printer cover.

Note: Make sure that the lever is pulled until it stops at the stopper. If the lever

is not pulled up to the stopper, the printer cover may not open.

(2)Peel the adhesive end off the paper.

Note: Make sure that the entire adhesive area is removed, since no printing

can be performed on that area.

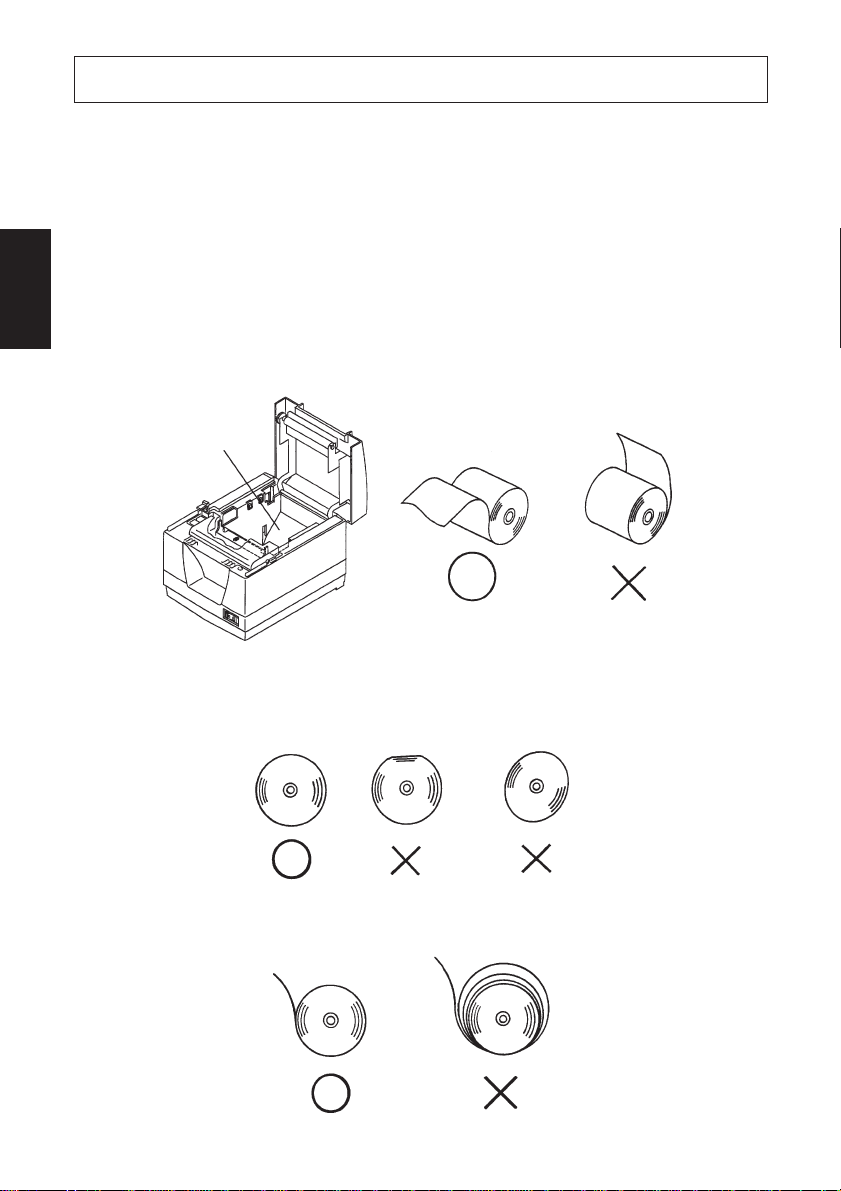

(3)Position the paper in the direction as shown below and place it into the paper

holder gently.

Paper holder

ENGLISH

Note 1: Make sure that the paper is not deformed. If a roll paper like those

shown below is used, a malfunction may result.

Note 2: If the paper sags as shown below after it has been loaded into the

paper holder, make the paper taut.

– 11 –

Page 16

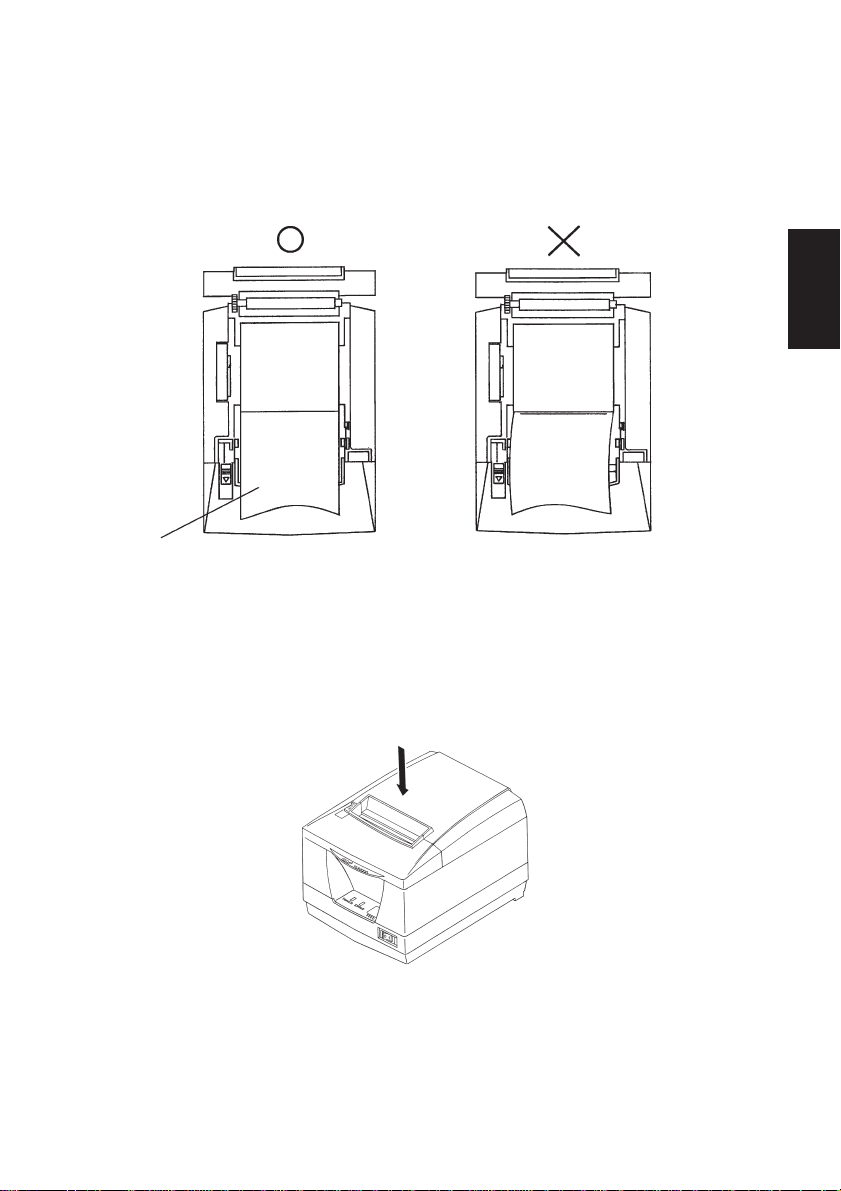

(4)Make sure that the paper is positioned straight, then close the printer cover

gently.

ENGLISH

Note 1: Make sure that the paper is positioned straight. If the printer cover

is closed with the paper skewed as shown below, a paper jam may

result.

Paper

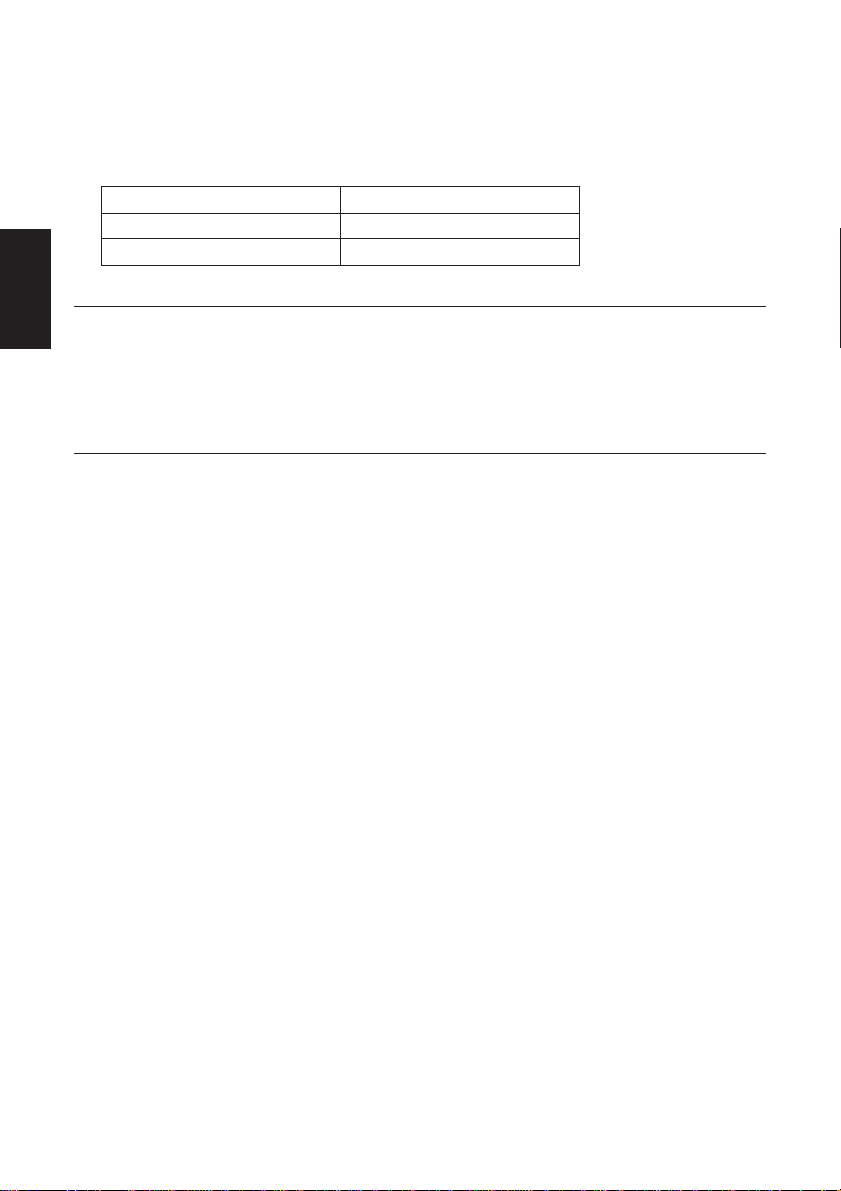

Note 2: Lock the printer cover by pressing on the center of the cover

(indicated by an arrow in the figure below). If any part of the cover

other than the center is pressed, the cover may not be locked

properly. This may sometimes disables printing.

– 12 –

Page 17

(5)If the power switch is set to OFF, set it to ON to turn on the printer. Make sure

that the ERROR LED is not lit.

Note: While the ERROR LED is lit, the printer will not accept any commands

such as the print command, so make sure that the printer cover is locked

properly.

(6)Once the printer cover is locked, the paper end will be ejected and the end cut

off automatically.

5-2. Removing Remaining Paper

(1)Pull the lever toward you to open the printer cover.

Note: Make sure that the lever is pulled until it stops at the stopper. If the lever

is not pulled up to the stopper, the printer cover may not open.

(2)Remove the remaining paper.

ENGLISH

– 13 –

Page 18

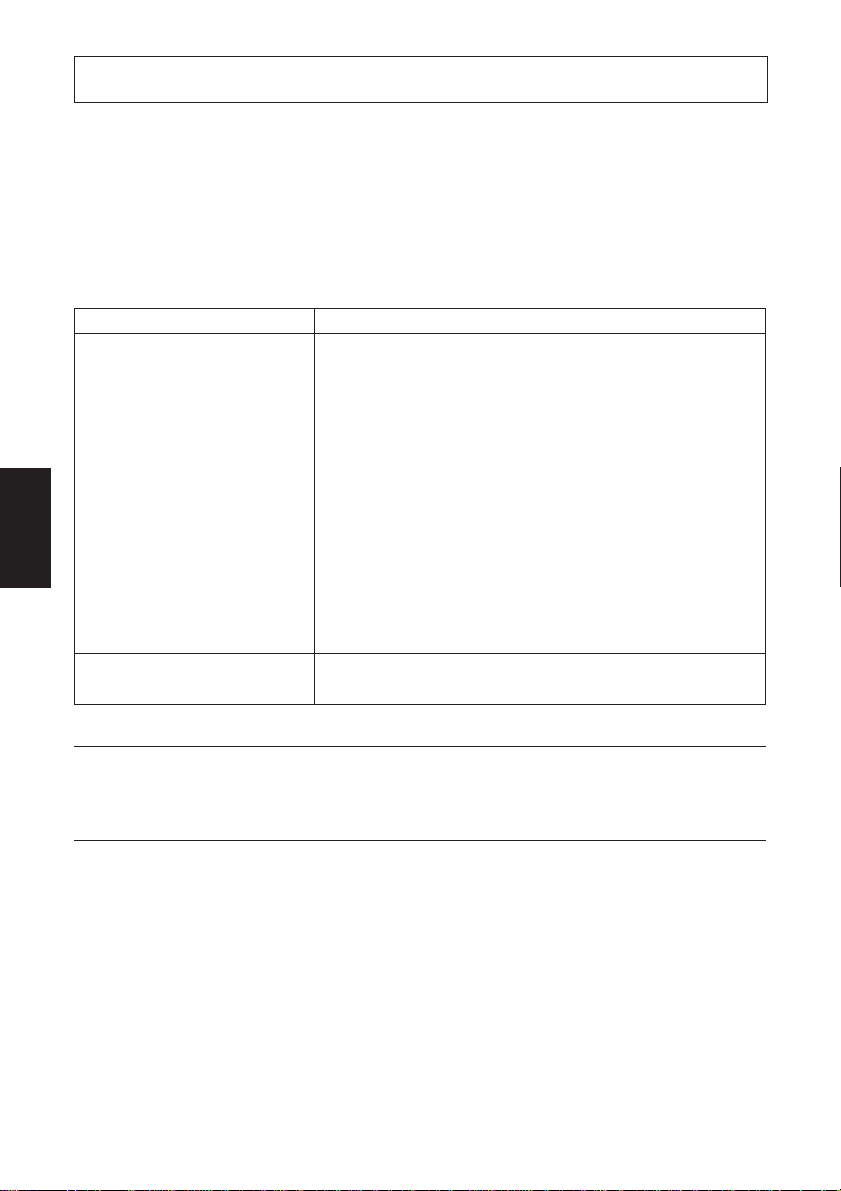

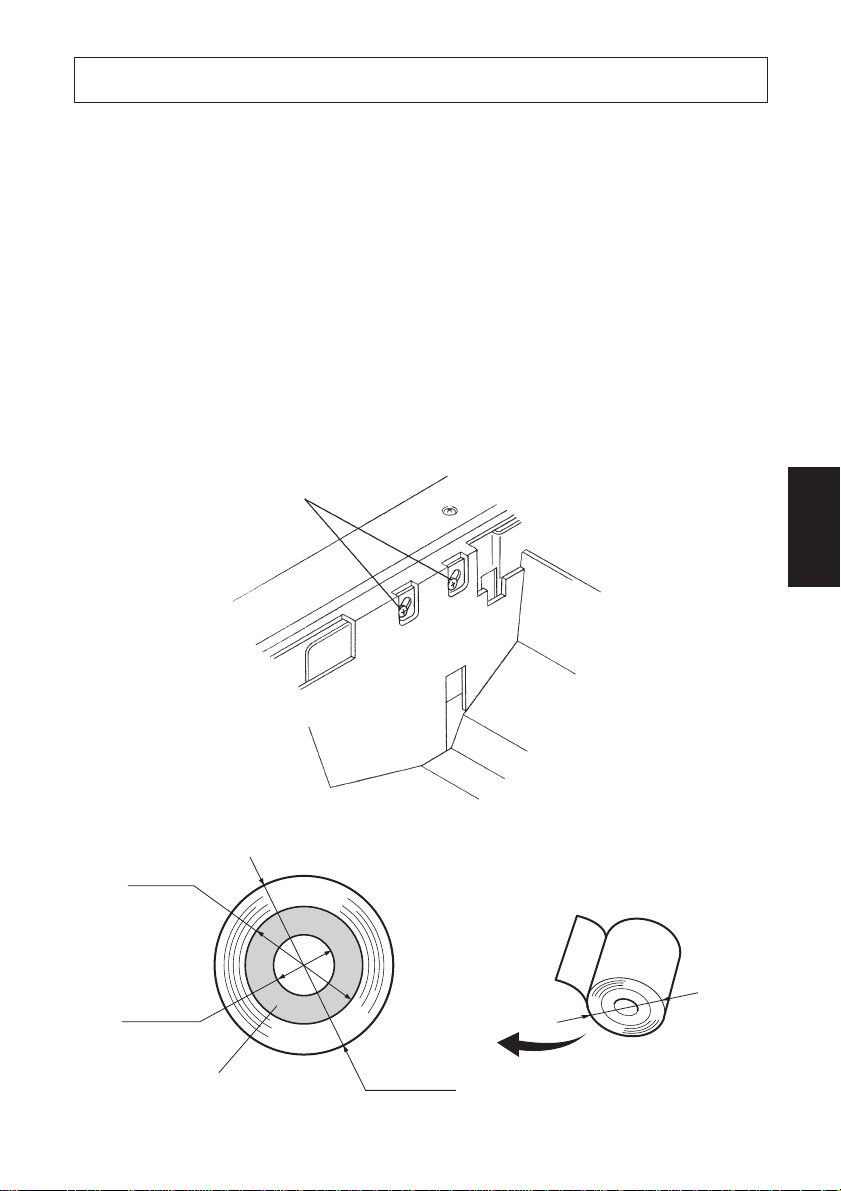

6. Near-end Sensor

ENGLISH

This printer is equipped with a sensor that detects when a roll of paper is near the

end. Read the following if you are going to use this sensor.

(1)Pull the lever in the direction indicated on it, and then open the printer cover.

(2)Loosen the two sensor fixing screws.

(3)Slide the sensor unit up or down, and then adequately tighten its screws.

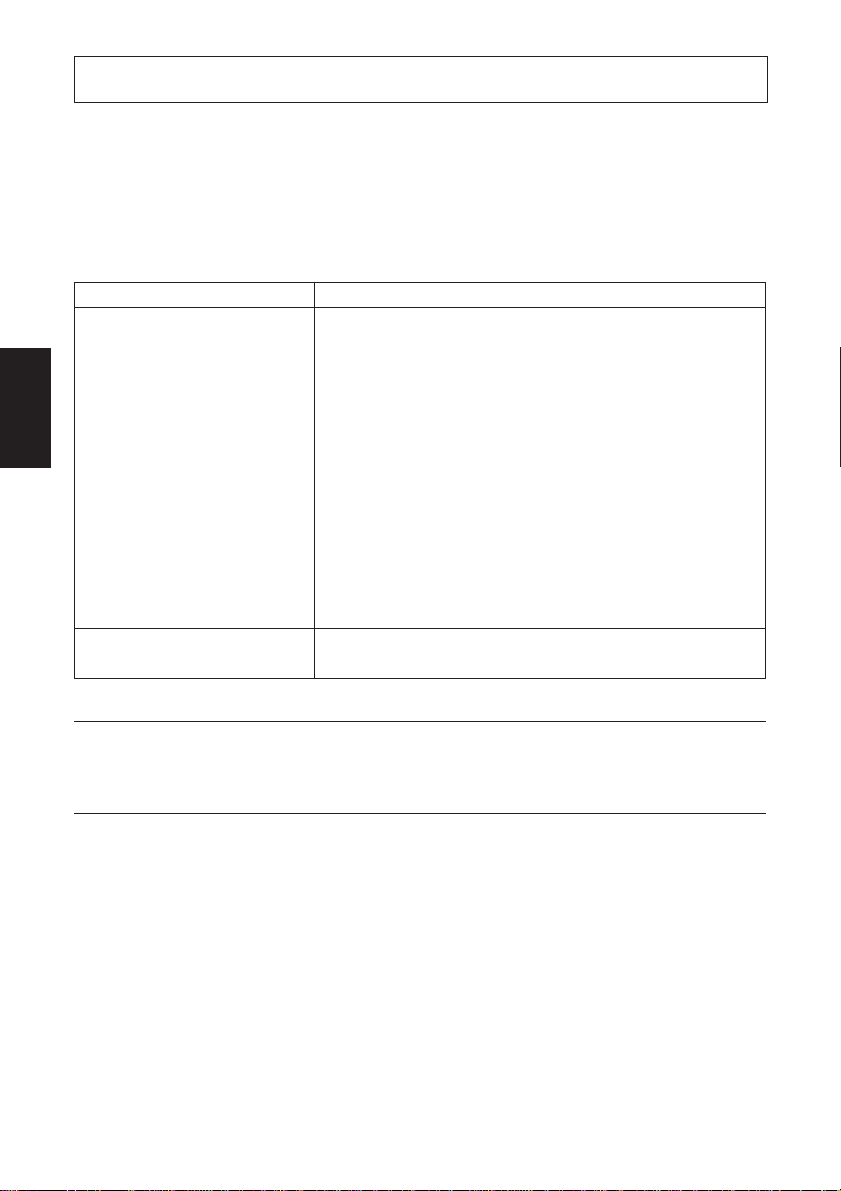

The following table shows the diameter of the paper that would remain on the

roll in order for the sensor, installed at the specified sensor fixing screw

position, to detect it.

Sensor fixing screws

(Level 1)

ø18 mm

ø12 mm

Roll paper core

A

A

– 14 –

Page 19

(4)Insert the paper roll, and check that the sensor correctly detects that the paper

roll is about to run out.

Error LED LED goes out when there is paper.

LED flashes when the paper is about to run out.

Diameter of remaining paper A Screw position

Approx. ø22 mm Level 1 (bottom)

Approx. ø26 mm Level 2 (top)

Cautions

1) The factory setting is level 1.

2) Always use a paper roll with a core that has an inside diameter of 12 mm and

an outside diameter of 18 mm in order to ensure proper detection of the

remaining paper amount.

ENGLISH

– 15 –

Page 20

7. Preventing and Clearing Paper Jams

ENGLISH

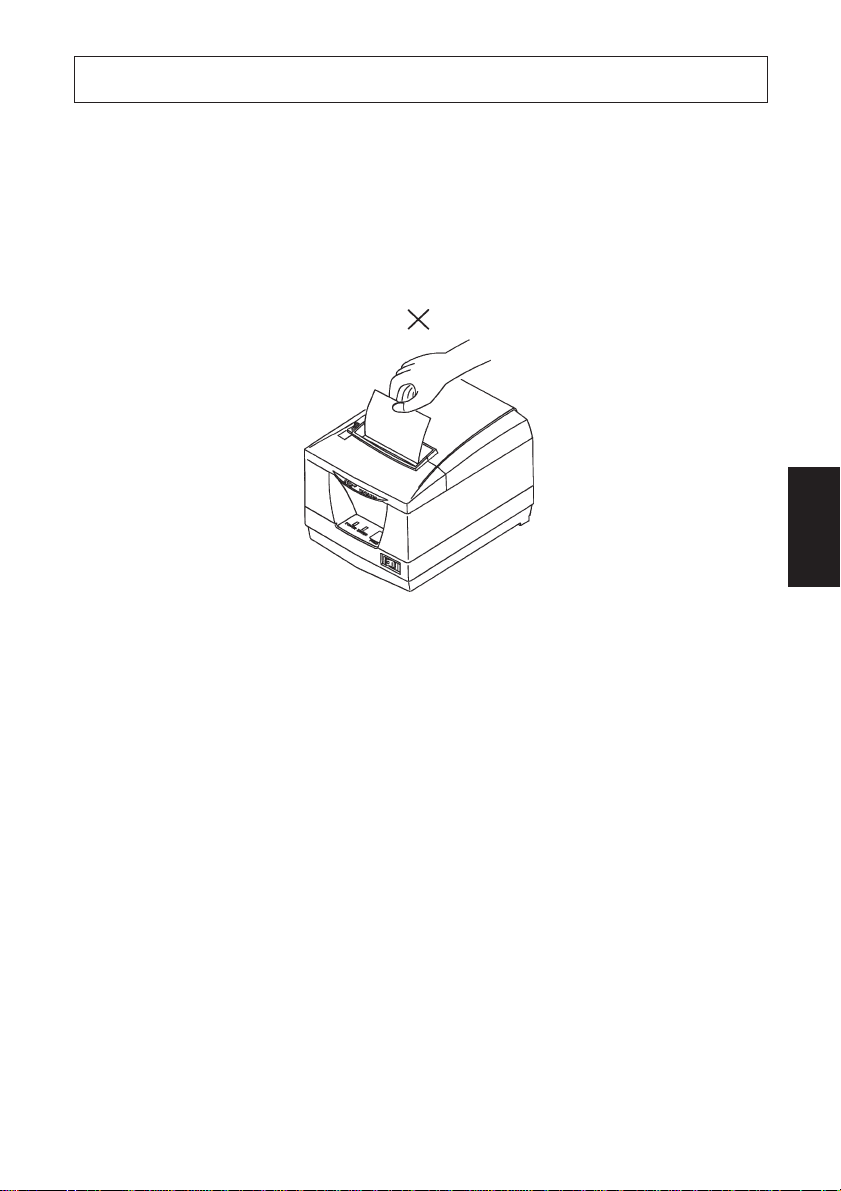

7-1. Preventing Paper Jams

The paper should not be touched during ejection and before it is cut.

Pressing or pulling the paper during ejection may cause a paper jam, paper cutting

failure or line feed failure. Do not open the printer cover during cutting.

7-2. Removing Paper Jam

If a paper jam occurs, clear it as described below.

(1)Set the power switch to off to turn off power to the printer.

(2)Pull the lever toward you to open the printer cover.

Note: Make sure that the lever is pulled until it stops at the stopper. If the lever

is not pulled up to the stopper, the printer cover may not open.

(3)Remove the jammed paper.

Note: Take care not to damage the printer when removing the jammed paper.

Since it is easy to damage the thermal head in particular, take care not

to touch it.

– 16 –

Page 21

(4)Position the roll paper straight and close the printer cover gently.

Note 1: Make sure that the paper is positioned straight. If the printer cover

is closed with the paper skewed, a paper jam may result.

Note 2: Lock the printer cover by pressing on the center of the cover. If any

part of the cover other than the center is pressed, the cover may not

be locked properly. This may sometimes disable printing.

(5)Set the power switch to on to turn on power to the printer. Make sure that the

ERROR LED is not lit.

Note: While the ERROR LED is lit, the printer will not accept any commands

such as the print command, so make sure that the printer cover is locked

properly.

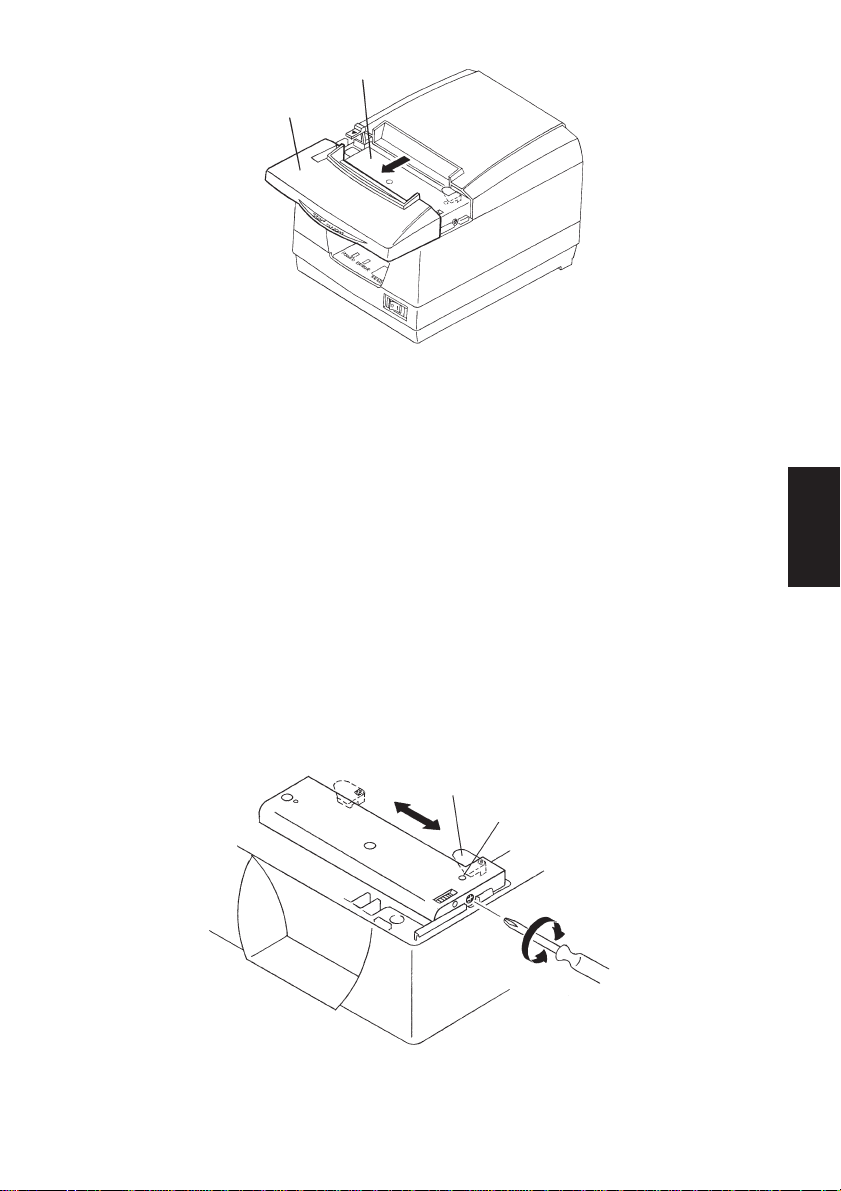

7-3. Releasing a Locked Cutter

If the auto cutter locks up or fails to cut the paper, follow the steps below.

Caution

Since working on the cutter may be dangerous, be sure to turn off the printer first.

(1)Set the power switch to OFF to turn off the printer.

(2)Slide off the front cover to reveal the auto cutter.

ENGLISH

(3)Remove any jammed paper.

Note: Be careful not to damage the printer while removing any jammed

paper.

Since the thermal print head is particularly sensitive, be sure not to

touch it.

Auto cutter

Front cover

– 17 –

Page 22

(4)If the cutter’s moving blade is protruding, use a Phillips screwdriver to turn

the Phillip-head screw and return the moving blade to its home position.

ENGLISH

When the check window is completely white, the moving blade is at its home

position.

Note 1: Do not apply extreme pressure to the moving blade.

Note 2: If the moving blade is protruding too much, the printer cover cannot

be opened. Trying to open the printer cover may damage the cutter.

(5) Open the printer cover, remove any jammed paper, and then re-install the

paper roll.

(6)Install the front cover, and then set the power switch to ON.

Moving blade

Check window

– 18 –

Page 23

8. Test Print Method

8-1. Producing a Test Print

To start test print, set the power switch to off, set the paper in place, then set the

power switch to on while holding down the FEED switch. Release the switch

within three seconds.

When a certain amount of printing is performed, the printer will cut the paper and

stop automatically.

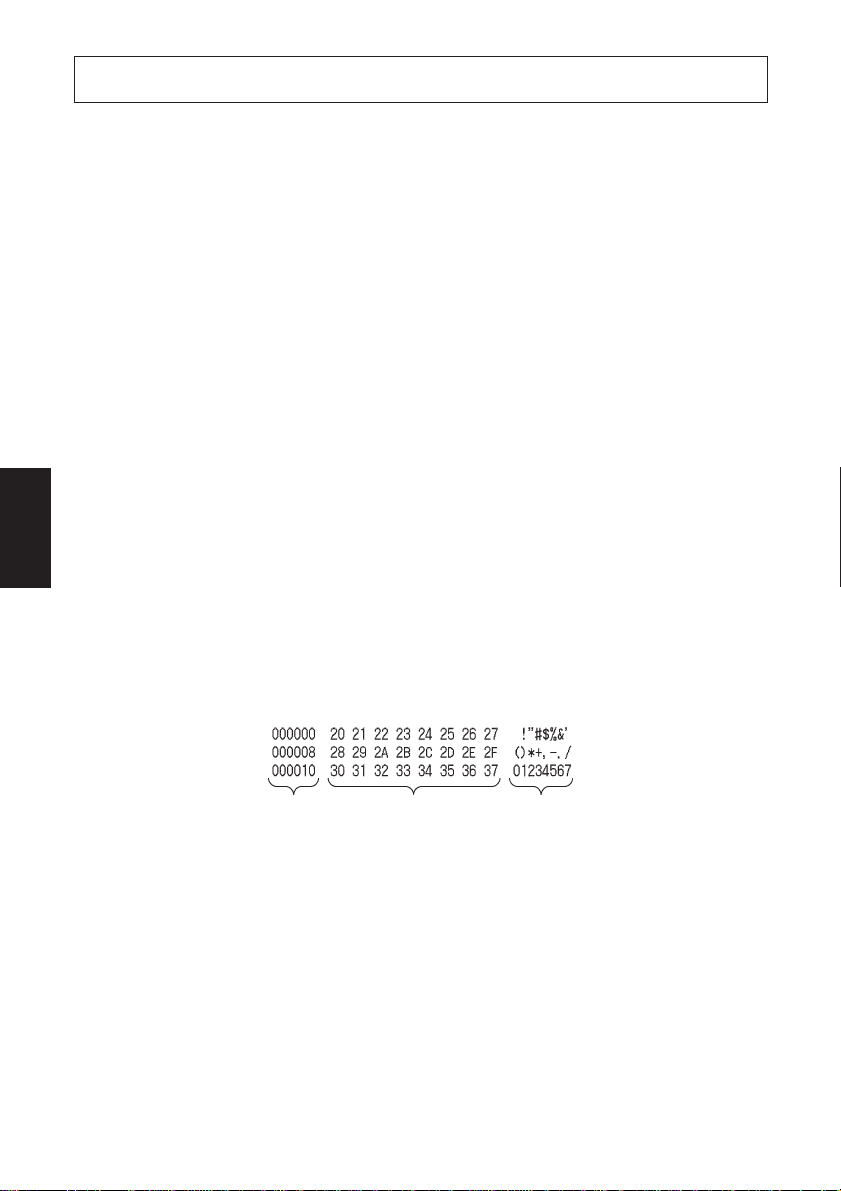

8-2. Hexadecimal Dump

This prints data sent from the host in hexadecimal format and in the corresponding ASCII characters. This is useful for debugging applications and for analyzing

scrambled characters.

Starting and stopping Hex Dump printing

While holding down the Feed switch, turn the power on. Hold down the switch

for five seconds; Hex Dump will begin operation when the switch is released.

If the switch is released within three seconds, the Self Test will run.

Stop Hex Dump by turning the power off.

The received data is printed as follows.

ENGLISH

Address Hexadecimal data ASCII data

– 19 –

Page 24

9. Periodical Cleaning

ENGLISH

Printed characters may become partially unclear due to accumulated paper dust

and dirt. To prevent such a problem, paper dust collected in the paper holder and

paper transport section and on the surface of the thermal head must be removed

periodically. Such cleaning is recommended to be carried out once a month.

9-1. Cleaning the Thermal Head

To remove blackish dust collected on the surface of the thermal head, wipe it with

alcohol (IPA).

Note: The thermal head is easy to damage, so clean it gently with a soft cloth.

Take sufficient care not to scratch it when cleaning it.

9-2. Cleaning the Paper Holder

Use a soft cloth to remove paper dust from the paper holder and paper transport

section.

– 20 –

Page 25

TABLE DES MATIERES

1. Identification des pièces et nomenclature....................................................22

2. Consommables et adaptateur secteur ..........................................................24

3. Câbles de connexion et adaptateur secteur .................................................25

3-1. Câble d’interface ..................................................................................25

3-2. Raccordement d’un appareil périphérique ...........................................27

3-3. Connexion de l’adaptateur secteur optionnel.......................................29

3-4. Mise sous tension de l’imprimante ......................................................30

4. Panneau des commandes ..............................................................................31

4-1. Touche d’avance de papier PAPER FEED ..........................................31

4-2. DEL d’alimentation POWER (DEL verte) ..........................................31

4-3. DEL d’erreur ERROR (DEL rouge) ....................................................31

5. Chargement du papier ..................................................................................32

5-1. Chargement d’un rouleau de papier neuf .............................................32

5-2. Retrait du papier...................................................................................34

6. Capteur de fin de rouleau .............................................................................35

7. Prévention et correction de bourrages de papier .......................................37

7-1. Prévention des bourrages de papier .....................................................37

7-2. Correction de bourrages de papier .......................................................37

7-3. Libération d’une unité de découpage bloquée .....................................38

8. Test d’impression...........................................................................................40

8-1. Exécution d’un test d’impression.........................................................40

8-2. Vidage hexadécimal .............................................................................40

9. Nettoyage ........................................................................................................41

9-1. Nettoyage de la tête d’impression ........................................................41

9-2. Nettoyage du support de papier ...........................................................41

APPENDICE......................................................................................................87

FRANÇAIS

L’appendice n’est pas traduit.

Pour obtenir la dernière version de ce manuel, consultez l’adresse URL suivante:

http:/www.star-micronics.co.jp/service/sp_sup_e.htm.

– 21 –

Page 26

FRANÇAIS

1. Identification des pièces et nomenclature

Capot de

l’imprimante

Levier

Tirez ce levier

dans le sens de

la flèche pour

ouvrir le capot de

l’imprimante.

Panneau des commandes

Le panneau est équipé de

commutateurs permettant la

commande de l’imprimante et

de DELs indiquant les statuts.

Interrupteur

Permet la mise sous et

hors tension de

l’appareil.

Ouvrez ce capot

pour charger ou

remplacer le

papier.

Connecteur

d’alimentation

Ce connecteur

vous permet de

connecter le câble

de l’adaptateur

secteur. Ne

déconnectez pas

le câble lorsque

l’imprimante est

sous tension.

Rouleau de papier Mode d’emploi

Connecteur d’appareil

périphérique

Ce connecteur vous

permet de raccorder

l’imprimante à des

appareils périphériques

tels que des tiroirscaisses, etc.

Ne pas raccorder à un

téléphone.

Connecteur

d’interface

Ce connecteur

vous permet de

connecter

l’imprimante à

l’ordinateur-hôte.

Tore de ferrite Attache

– 22 –

Page 27

Emplacement de l’imprimante

Avant de déballer l’imprimante, déterminez l’emplacement où vous

souhaitez l’installer. Veuillez observer les points ci-dessous lors de votre

choix.

✓ Choisissez une surface stable et de niveau sur laquelle l’imprimante

ne sera exposée à aucune vibration.

✓ Assurez-vous que l’emplacement dispose d’une prise secteur proche

et d’accès aisé.

✓ Assurez-vous que la distance entre l’imprimante et l’ordinateur-hôte

vous permet de les raccorder aisément.

✓ Assurez-vous que l’imprimante n’est pas exposée directement aux

rayons du soleil.

✓ Tenez l’imprimante à l’écart des sources de chaleur importante, telles

que les appareils de chauffage, etc.

✓ Assurez-vous que le lieu où vous souhaitez installer l'imprimante est

propre, sec et n'est pas poussiéreux.

✓ Assurez-vous que la prise secteur à laquelle vous raccordez l’impri-

mante délivre une tension stable. Evitez de raccorder l’imprimante à

la prise secteur d’un circuit alimentant de gros consommateurs de

courant, tels qu’un photocopieur, réfigérateur, etc.

✓ Assurez-vous que le lieu où vous installez l’imprimante n’est pas

excessivement humide.

FRANÇAIS

– 23 –

Page 28

2. Consommables et adaptateur secteur

Il convient d’utiliser exclusivement les types de papier figurant dans le tableau

ci-dessous. Veillez également à utiliser l’adaptateur secteur qui figure dans le

tableau.

L’utilisation d’un type de papier et d’adaptateur ne figurant pas dans le tableau

FRANÇAIS

risque d’endommager l’imprimante, de causer un incendie ou une décharge

électrique.

Nom de pièce Caractéristiques

Rouleau de papier Papier thermique

Épaisseur: 0,06 à 0,08 mm

Largeur: 80 mm

Diamètre extérieur du rouleau : ø90 mm ou moins

Diamètre extérieur du support de rouleau : ø18 mm

Diamètre intérieur du support de rouleau : ø12 ±0,5 mm

Papier conseillé (pour impression thermique normale)

Papier conseillé (pour stockage de durée moyenne)

Papier conseillé (pour stockage de longue durée)

Adaptateur secteur (optionnel) Entrée: 100 à 240 V CA, 50-60 Hz

UP06021240 Sortie: 24 V CC±5 %, 2,5 A

0

- 1,0

TF50KS-E2C (Nippon Paper Industries)

P220AG (Mitsubishi Paper Mills Limited)

PD-160R-N (Oji Paper Co., Ltd.)

AFP235 (Mitsubishi Paper Mills Limited)

+0,5

0

Attention!

Pour obtenir des informations concernant le papier recommandé, consultez l’adresse URL suivante : http://www.star-micronics.co.jp/.

– 24 –

Page 29

3. Câbles de connexion et adaptateur secteur

3-1. Câble d’interface 3-1-1. Installation du tore de ferrite

(1)Fixez la grande gaine en ferrite sur

le câble comme illustré.

Tore de ferrite (27 mm de largeur)

Interface câble

FRANÇAIS

5 cm

maximum

Tirez et coupez

(2)Passez l’attache dans le tore de fer-

rite.

Attache

(3) Passez l’attache autour du tore de

ferrite et serrez-la. Coupez l’extrémité de l’attache à l’aide de ciseaux.

– 25 –

Page 30

3-1-2. Connexion du câble d’interface

Remarque:Avant de connecter ou déconnecter le câble d’interface, veillez à

ce que l’imprimante et tous les appareils qui y sont connectés

soient hors tension. Veillez également à débrancher le câble

d’alimentation de la prise secteur.

FRANÇAIS

(1)Connectez le câble d’interface à la borne figurant sur le panneau arrière de

l’imprimante.

(2)Dans le cas d’une interface série, resserrez les vis du connecteur. Dans le cas

d’une interface parallèle, fixez le connecteur avec les fermoirs.

Câble d’interface série

– 26 –

Câble d’interface parallèle

Page 31

3-2. Raccordement d’un appareil périphérique

Vous pouvez raccorder un appareil périphérique à l’imprimante à l’aide d’une

fiche modulaire. Nous expliquons ci-dessous comment installer le tore de ferrite

et faire le raccordement proprement dit. Pour les détails sur le type de fiche

modulaire à utiliser, reportez-vous à la page 98. Notez que le fil ou la fiche

modulaires ne sont pas fournis avec l’imprimante. Vous devrez donc vous les

procurer.

Attention!

Assurez-vous que l’imprimante est hors tension, qu’elle est débranchée de la

prise secteur et que l’ordinateur est hors tension avant d’effectuer les connexions.

(1)Fixez la petite gaine en ferrite sur le

câble modulaire comme illustré cidessous.

Tore de ferrite (17,5 mm de largeur)

FRANÇAIS

Connecteur

Une boucle

Câble

– 27 –

Page 32

FRANÇAIS

Remarque:Avant de connecter ou déconnecter le câble du pilote de périphé-

5 cm

maximum

Attache

(2)Passez l’attache dans le tore de fer-

rite.

(3) Passez l’attache autour du tore de

Tirez et coupez

ferrite et serrez-la. Coupez l’extrémité de l’attache à l’aide de ciseaux.

(4) Raccordez une extrémité du câble

modulaire à la prise modulaire du

périphérique.

(5)Retirez le cache de prise modulaire

au dos de l’imprimante, et raccordez l’autre extrémité du câble modulaire dans la prise de l’imprimante.

rique, veillez à ce que l’imprimante et tous les appareils qui y sont

connectés soient hors tension. Veillez également à débrancher le

câble d’alimentation de la prise secteur.

(1)Connectez le câble de pilote de périphérique à la borne figurant sur le panneau

arrière de l’imprimante.

– 28 –

Page 33

3-3. Connexion de l’adaptateur secteur optionnel

Remarque:Avant de connecter ou déconnecter l’adaptateur secteur, veillez

à ce que l’imprimante et tous les appareils qui y sont connectés

soient hors tension. Veillez également à débrancher le câble

d’alimentation de la prise secteur.

(1)Connectez l’adaptateur secteur au câble d’alimentation.

Remarque:Utilisez exclusivement l’adaptateur secteur et le câble d’alimen-

tation destinés à l’imprimante.

(2)Connectez l’adaptateur secteur à la borne de l’imprimante.

(3)Branchez la prise du câble d’alimentation à la prise secteur.

FRANÇAIS

– 29 –

Page 34

3-4. Mise sous tension de l’imprimante

Assurez-vous d’avoir bien connecté l’adaptateur secteur comme décrit à la

section 3-3.

(1)Placez l’interrupteur d’alimentation, situé à l’avant de l’imprimante, sur la

position sous tension.

FRANÇAIS

La DEL POWER s’allume au panneau des commandes.

Interrupteur

d’alimentation

Attention!

Nous vous recommandons de débrancher l’imprimarte du secteur lorsque vous ne comptez pas l’utiliser pendant une période prolongée. Par

ailleurs, veillez lors de l’installation à ce que la prise secteur alimentant

l’imprimante soit proche et d’accès facile.

– 30 –

Page 35

4. Panneau des commandes

4-1. Touche d’avance de papier PAPER FEED

Le papier avance d’une ligne à chaque pression sur cette touche. Une pression

continue sur la touche fera avancer le papier de façon continue.

Remarque:Une pression sur cette touche n’a d’effet que si du papier est

chargé dans l’imprimante.

4-2. DEL d’alimentation POWER (DEL verte)

Cette DEL s’allume lorsque l’interrupteur d’alimentation est placé sur hors

tension et que l’appareil est alimenté par le secteur.

4-3. DEL d’erreur ERROR (DEL rouge)

Cette DEL s’allume ou clignote lorsqu’une des erreurs énumérées ci-dessous se

produit.

Mode d’éclairage de la DEL d’erreur Description de l’erreur

Allumée Capot d’imprimante ouvert

Clignotante Papier épuisé

Allumée

Clignotante

Allumée

Clignotante

Allumée

Clignotante

Le papier est presque épuisé

Température anormale de la tête d’imprimante (90°C)

Dysfonctionnement dans la connexion de la tête

Erreur de l’unité de découpage automatique

FRANÇAIS

POWER ERROR FEED

DEL d’erreur (rouge)

DEL d’alimentation (verte)

– 31 –

Touche d’avance de papier

Page 36

5. Chargement du papier

5-1. Chargement d’un rouleau de papier neuf

(1)Tirez le levier vers le bas afin d’ouvrir le capot de l’imprimante.

Remarque:Veillez à tirer le levier tout à fait jusqu’à sa butée. Si le levier n’est

FRANÇAIS

(2)Retirez l’adhésif de l’extrémité du papier.

Remarque:Veillez à bien retirer l’intégralité de l’adhésif. En effet, l’impres-

(3)Placez le papier dans la direction indiquée ci-dessous et insérez-le avec soin

dans le support du papier.

Support du papier

pas tiré tout à fait, le capot pourrait ne pas s’ouvrir.

sion ne peut s’effectuer sur celui-ci.

Remarque 1: Veillez à ce que le rouleau de papier soit en bon état. Si le

rouleau est déformé comme illustré ci-dessous, des problèmes risquent de survenir.

Remarque 2: Si le papier se déroule comme illustré ci-dessous après son

chargement dans le support de papier, il convient de le

tendre.

– 32 –

Page 37

(4)Veillez à ce que le papier soit placé bien droit, puis refermez doucement le

capot de l’imprimante.

Remarque 1: Le papier doit être placé bien droit. Si vous refermez le capot

de l’imprimante alors que le papier est de travers (voir

illustration), un bourrage peut se produire.

Papier

Remarque 2: Verrouillez le cache de l’imprimante en appuyant à l’endroit

du capot repéré par la flèche dans l’illustration ci-dessous. Si

vous appuyez à tout autre endroit, le capot risque de ne pas

être verrouillé, ce qui pourrait empêcher l’impression.

FRANÇAIS

– 33 –

Page 38

(5)Si l’interrupteur d’alimentation est sur la position hors tension OFF, réglez-

le sur la position sous tension ON pour mettre l’imprimante sous tension.

Assurez-vous que la DEL ERROR n’est pas allumée.

Remarque:Tant que la DEL ERROR est allumée, l’imprimante n’accepte

aucune commande. Il faut donc veiller à ce que le capot de

l’imprimante soit verrouillé.

FRANÇAIS

(6)Une fois que le capot d’imprimante est verrouillé, l’extrémité du papier sera

éjectée et coupée automatiquement.

5-2. Retrait du papier

(1)Tirez le levier vers le bas afin d’ouvrir le capot de l’imprimante.

Remarque:Veillez à tirer le levier tout à fait jusqu’à sa butée. Si le levier n’est

pas tiré tout à fait, le capot pourrait ne pas s’ouvrir.

(2)Retirez le papier.

– 34 –

Page 39

6. Capteur de fin de rouleau

Cette imprimante est équipée d’un capteur détectant l’approche de la fin de

rouleau. Pour savoir comment utiliser cette fonction, lire les instructions cidessous.

(1) Tirez sur le levier dans le sens indiqué dessus, puis ouvrez le capot de

l’imprimante.

(2)Desserrez les deux vis de montage du capteur.

(3)Faites glisser le capteur vers le haut ou vers le bas, puis serrez correctement

ses vis.

Le tableau suivant indique le diamètre du papier devant rester sur le rouleau

afin que le capteur installé dans la position spécifiée de la vis de montage du

capteur puisse le détecter.

FRANÇAIS

Vis de montage du capteur

(Cran 1)

ø18 mm

ø12 mm

Mandrin du rouleau

de papier

A

A

– 35 –

Page 40

(4)Insérez le rouleau de papier, puis vérifiez que le capteur identifie correctement

le moment où le papier va être épuisé.

DEL d’erreur La DEL s’éteint quand il y a du papier.

La DEL clignote quand le papier va être épuisé.

Diamètre du papier restant A Position de la vis

FRANÇAIS

Environ ø22 mm Cran 1 (bas)

Environ ø26 mm Cran 2 (haut)

Attention

1) Le capteur de fin de rouleau est positionné sur le cran 1 à la sortie d’usine.

2) Afin d’assurer une détection correcte de la quantité de papier restant sur le

rouleau, toujours employer un rouleau de papier dont les diamètres interne et

externe du rouleau de carton correspondent respectivement à 12 mm et 18 mm.

– 36 –

Page 41

7. Prévention et correction de bourrages de papier

7-1. Prévention des bourrages de papier

Il convient de ne jamais toucher le papier pendant son éjection et avant qu’il soit

coupé. Appuyer ou tirer sur le papier pendant son éjection risque de provoquer

un bourrage, des problèmes de coupure ou d’avance de ligne. Ne pas ouvrir le

capot d’imprimante pendant la coupure.

FRANÇAIS

7-2. Correction de bourrages de papier

En cas de bourrage de papier, procédez comme suit afin d’y remédier :

(1)Mettez l’appareil hors tension.

(2)Tirez le levier tout à fait vers le bas afin d’ouvrir le capot de l’imprimante.

Remarque:Veillez à tirer le levier jusqu’à sa butée. Si le levier n’est pas tiré

tout à fait, le capot pourrait ne pas s’ouvrir.

(3)Retirez le papier bloqué.

Remarque:Veillez à ne pas endommager l’imprimante lors du retrait du

papier bloqué.

Veillez particulièrement à ne pas toucher la tête d’impression

thermique en raison de sa fragilité.

– 37 –

Page 42

(4)Veillez à insérer le rouleau de papier tout droit et refermez avec soin le capot

de l’imprimante.

Remarque 1: Le papier doit être placé bien droit. Si vous refermez le capot

de l’imprimante alors que le papier est de travers (voir

illustration), un bourrage peut se produire.

Remarque 2: Verrouillez le cache de l’imprimante en appuyant à l’endroit

FRANÇAIS

du capot repéré par la flèche dans l’illustration ci-dessous. Si

vous appuyez à tout autre endroit, le capot risque de ne pas

être verrouillé, ce qui pourrait empêcher l’impression.

(5)Mettez l’imprimante sous tension. Assurez-vous que la DEL ERROR n’est

pas allumée.

Remarque:Tant que la DEL ERROR est allumée, l’imprimante n’accepte

aucune commande. Il faut donc veiller à ce que le capot de

l’imprimante soit verrouillé.

7-3. Libération d’une unité de découpage bloquée

Si l’unité de découpage automatique se bloque ou ne coupe pas le papier, suivez

les étapes ci-dessous.

Attention

Le travail sur l’unité de découpage étant dangereux, n’oubliez pas de mettre

avant tout l’imprimante hors tension.

(1)Réglez l’interrupteur d’alimentation sur la position hors tension OFF pour

mettre l’imprimante hors tension.

(2)Faites glisser le couvercle avant pour dégager l’unité de découpage automa-

tique.

(3)Enlevez le papier coincé.

Remarque:Faites attention à ne pas endommager l’imprimante pendant que

vous enlevez le papier coincé.

La tête d’impression thermique étant particulièrement sensible,

veillez à ne pas la toucher.

– 38 –

Page 43

Unité de découpage

automatique

Couvercle avant

(4) Si la lame mobile de l’unité de découpage dépasse, utilisez un tournevis

cruciforme pour tourner la vis cruciforme et ramener la lame dans sa position

d’origine.

Quand la fenêtre de contrôle est complètement blanche, la lame mobile est

dans sa position d’origine.

Remarque 1: N’appliquez pas de pression excessive sur la lame mobile.

Remarque 2: Si la lame mobile dépasse trop, le capot de l’imprimante ne

pourra pas être ouvert. Vous risquez d’endommager l’unité

de découpage automatique en essayant d’ouvrir le capot de

l’imprimante.

FRANÇAIS

(5)Ouvrez le capot de l’imprimante, enlevez le papier coincé, puis remettez le

rouleau de papier en place.

(6)Installez le couvercle avant, puis réglez l’interrupteur d’alimentation sur la

position sous tension.

Lame mobile

Fenêtre de contrôle

– 39 –

Page 44

8. Test d’impression

8-1. Exécution d’un test d’impression

Avant d’effectuer un test d’impression, commencez par mettre l’imprimante hors

tension, insérez le papier, puis remettez l’imprimante sous tension tout en

maintenant la touche d’avance FEED enfoncée. Relâchez la pression sur la

FRANÇAIS

touche dans les trois secondes qui suivent.

Après avoir imprimé pendant un certain temps, l’imprimante coupe le papier et

s’arrête automatiquement.

8-2. Vidage hexadécimal

Cette commande entraîne l’impression des données envoyées par l’hôte dans le

format hexadécimal et dans les caractères ASCII correspondants. Cette fonction est

pratique pour le débogage des applications et l’analyse des caractères embrouillés.

Lancement et arrêt de l’impression de vidage hexadécimal

Tout en maintenant la touche d’avance de papier enfoncée, mettez l’appareil

sous tension. Maintenez la touche enfoncée pendant cinq secondes ; le vidage

hexadécimal commencera quand vous relâcherez la pression sur la touche. Si

vous relâchez la pression sur la touche dans les trois secondes, l’autotest

commencera.

Arrêtez le vidage hexadécimal en mettant l’appareil hors tension.

Les données reçues sont imprimées comme suit :

Adresse

Données hexadécimales Données ASCII

– 40 –

Page 45

9. Nettoyage

Les caractères imprimés pourraient devenir partiellement illisibles en raison de

l’accumulation de la poussière de papier et de crasse. Afin de prévenir ce genre

de problème, il convient de nettoyer régulièrement la poussière qui s’accumule

sur le support de papier, les passages du papier et la surface de la tête d’impression. Il est recommandé d’effectuer ce nettoyage une fois par mois.

9-1. Nettoyage de la tête d’impression

Nettoyez la poussière noirâtre accumulée sur la surface de la tête d’impression à

l’alcool isopropylique.

Remarque:La tête d’impression thermique est fragile, il convient donc de

procéder avec précaution. Prenez soin de ne pas la griffer.

9-2. Nettoyage du support de papier

Nettoyez la poussière de papier accumulée sur le support de papier et sur les

passages du papier à l’aide d’un chiffon doux.

FRANÇAIS

– 41 –

Page 46

FRANÇAIS

– 42 –

Page 47

INHALTSVERZEICHNIS

1. Beschreibung und Bezeichnung der Geräteteile.........................................44

2. Verbrauchsteile und Netzteil ........................................................................46

3. Anschlußkabel und Netzteil..........................................................................47

3-1. Schnittstellenkabel ...............................................................................47

3-2. Anschluß an ein Peripheriegerät ..........................................................49

3-3. Anschließen des optionalen Netzteils ..................................................51

3-4. Einschalten ...........................................................................................52

4. Bedienfeld .......................................................................................................53

4-1. Papiereinzugknopf (PAPER FEED) ....................................................53

4-2. Netz-LED (POWER) (grüne LED)......................................................53

4-3. Fehler-LED (ERROR) (rote LED).......................................................53

5. Einlegen von Papier.......................................................................................54

5-1. Einlegen einer neuen Papierrolle .........................................................54

5-2. Entfernen des restlichen Papiers ..........................................................56

6. Papiervorrat-Sensor ......................................................................................57

7. Verhindern und Beheben von Papierstau ...................................................59

7-1. Verhindern von Papierstau...................................................................59

7-2. Beheben von Papierstau .......................................................................59

7-3. Freigeben eines gesperrten Schneidmessers ........................................60

8. Testdruck-Verfahren ....................................................................................62

8-1. Erstellen eines Testdrucks....................................................................62

8-2. Sedezimaler Datenausdruck .................................................................62

9. Regelmäßige Reinigung.................................................................................63

9-1. Reinigen des Thermalkopfes................................................................63

9-2. Reinigen des Papierhalters ...................................................................63

ANHANG ...........................................................................................................87

DEUTSCH

Der Anhand dieser Bedienungsanleitung ist nur in englischer Sprache.

Bitte wenden Sie sich an die folgende Internet-Address:

http://www.star-micronics.co.jp/service/sp_sup_e.htm,

wenn Sie die neueste Revision dieses Handbuches lesen möchten.

– 43 –

Page 48

DEUTSCH

1. Beschreibung und Bezeichnung der Geräteteile

Abdeckung

Hebel

Diesen Hebel in

Pfeilrichtung

ziehen, um die

Druckerabdeckung zu

öffnen.

Bedienfeld

Mit LED-Anzeigen zur

Anzeige des Druckerstatus und Schalter zur

Druckerbedienung.

Schalter

Zum Ein- oder Ausschalten

des Druckers.

Diese Abdeckung

öffnen, um Papier

einzusetzen oder

zu entnehmen.

Betriebsstroman-

schluß

Zum Anschließen

des Betriebsstromkabels vom

Netzteil. Den

Stecker nicht bei

eingeschaltetem

Drucker abziehen.

Rollenpapier Bedienungsanleitung

Peripherie-Treiberan-

schluß

Zum Anschluß an

Peripheriegeräte wie

Registrierkassen etc.

Nicht zum Anschluß an

ein Telefon!

– 44 –

Schnittstellenbuchse

Zum Anschließen an

den Hostcomputer.

Ferritkern Befestigungs band

Page 49

Wahl eines Aufstellungsorts für den Drucker

Bevor Sie den Drucker auspacken, sollten Sie einige Minuten damit

verbringen, einen geeigneten Aufstellungsort auszusuchen. Denken Sie

dabei an die folgenden Punkte:

✓ Den Drucker auf einem flachen, aber festen Untergrund aufstellen,

wo keine Vibrationen vorhanden sind.

✓ Die verwendete Steckdose soll in der Nähe und frei zugänglich sein.

✓ Sicherstellen, daß der Drucker nahe genug am Computer ist, um die

Geräte mit dem Druckerkabel verbinden zu können.

✓ Sicherstellen, daß der Drucker vor direktem Sonnenlicht geschützt

ist.

✓ Sicherstellen, daß der Drucker ausreichend weit von Heizkörpern

entfernt steht.

✓ Dafür sorgen, daß die Umgebung des Druckers sauber, trocken und

staubfrei ist.

✓ Sicherstellen, daß der Drucker an eine einwandfreie Stromzufuhr

angeschlossen ist. Er sollte nicht an Steckdosen angeschlossen werden, an denen bereits Geräte mit möglichen Netzstörungen wie

Kopierer, Kühlschränke u.a. angeschlossen sind.

✓ Den Drucker nicht an Orten mit hoher Luftfeuchtigkeit aufstellen.

DEUTSCH

– 45 –

Page 50

2. Verbrauchsteile und Netzteil

Wenn die Verbrauchsteile verbraucht sind, besorgen Sie Ersatz entsprechend der

unten gezeigten Tabelle.

Verwendung von Verbrauchsteilen oder Netzteilen, die nicht den unten aufgeführten Beschreibungen entsprechend, kann zu Schäden am Drucker, Bränden

oder elektrischen Schlägen führen.

Bezeichnung Beschreibung

Rollenpapier Thermopapier

DEUTSCH

Netzteil (option) Eingang: 100 bis 240 V WS, 50-60 Hz

UP06021240 Ausgang: 24 V GS±5 %, 2,5 A

Dicke: 0,06 bis 0,08 mm

Breite: 80 mm

Rollen-Außendurchmesser: ø90 mm oder weniger

Kern-Außendurchmesser: ø18 mm

Kern-Innendurchmesser: ø12 ±0,5 mm

Empfohlenes Papier (normales Thermopapier)

Empfohlenes Papier (Papier mit mittlerer Bildstabilität)

Empfohlenes Papier (Papier mit langer Haltbarkeit)

0

- 1,0

+0,5

0

TF50KS-E2C (Nippon Paper Industries)

P220AG (Mitsubishi Papier Mills Ltd.)

PD-160R-N (Oji Papier Co.)

AFP235 (Mitsubishi Papier Mills Ltd.)

Wichtig!

Empfehlungen zu den zu verwendenden Papiersorten sind im Internet

bei der folgenden URL erhältlich: http://www.star-micronics.co.jp/

– 46 –

Page 51

3. Anschlußkabel und Netzteil

3-1. Schnittstellenkabel 3-1-1. Anbringen des Ferritkerns

(1) Befestigen Sie den großen Ferrit-

Ferritkern (27 mm breit)

Kable

kern am Kabel, wie das in der folgenden Abbildung gezeigt wird.

DEUTSCH

Maximum

5 cm

Kabelbinder

Ziehen und

abschneiden

(2)Führen Sie den Kabelbinder durch

den Ferritkern.

(3)Führen Sie den Kabelbinder um das

Kabel und sperren Sie ihn.

Schneiden Sie überschüssiges Band

mit einer Schere ab.

– 47 –

Page 52

3-1-2. Anschließen des Schnittstellenkabels

Hinweis:Vor dem Anschließen/Abtrennen des Schnittstellenkabels stellen

Sie sicher, daß der Drucker und alle angeschlossenen Gerät ausgeschaltet sind. Außerdem sollte der Netzstecker abgezogen sein.

(1) Schließen Sie das Schnittstellenkabel an die Buchse an der Rückseite des

Druckers an.

(2) Bei einer seriellen Schnittstelle ziehen Sie die Steckerschrauben fest. Bei

einer parallelen Schnittstelle befestigen Sie die Steckerklammern.

DEUTSCH

Serielles Schnittstellenkabel

– 48 –

Paralleles Schnittstellenkabel

Page 53

3-2. Anschluß an ein Peripheriegerät

Es kann ein Peripheriegerät an den Drucker mit einem Modularstecker angeschlossen werden. Im folgenden wird beschrieben, wie der Ferritkern angebracht

und die Verbindung hergestellt wird. Siehe “Modularstecker” auf Seite 98 für den

Typ von Modularstecker, der dazu erforderlich ist. Beachten Sie, daß der Drucker

nicht mit einem Modularstecker oder Kabel ausgestattet ist. Diese Teile müssen

vom Anwender besorgt werden.

Wichtig!

Vor dem Anschließen der Kabel sicherstellen, daß der Drucker ausgeschaltet

und vom Netz getrennt ist.

(1)Befestigen Sie den kleineren Ferrit-

kern am seriellen Kabel, wie das in

der folgenden Abbildung gezeigt

wird.

Ferritkern (17,5 mm breit)

DEUTSCH

Modularstecker

Eine Schleife

Kabel

– 49 –

Page 54

DEUTSCH

Hinweis:Vor dem Anschließen/Abtrennen des Schnittstellenkabels stellen

Maximum

5 cm

Kabelbinder

(2)Den Kabelbinder durch den Ferrit-

kern führen.

(3)Das Befestigungsband um das Ka-

Ziehen und

abschneiden

bel wickeln und sperren. Schneiden

Sie überschüssiges Band mit einer

Schere ab.

(4) Einen Stecker des Modularkabels

in die Modularbuchse am

Peripheriegerät stecken.

(5)Die Modularbuchsenabdeckung von

der Rückseite des Druckers abnehmen, und den anderen Stecker des

Modularkabels in die Modularbuchse am Drucker stecken.

Sie sicher, daß der Drucker und alle angeschlossenen Gerät ausgeschaltet sind. Außerdem sollte der Netzstecker abgezogen sein.

(1)Schließen Sie das Peripheriegerätekabel an die Buchse an der Rückseite des

Druckers an.

– 50 –

Page 55

3-3. Anschließen des optionalen Netzteils

Hinweis:Vor dem Anschließen/Abtrennen des Netzteils stellen Sie sicher,

daß der Drucker und alle angeschlossenen Gerät ausgeschaltet sind.

Außerdem sollte der Netzstecker abgezogen sein.

(1)Schließen Sie das Netzteil an das Netzkabel an.

Hinweis:Verwenden Sie nur das vorgesehene Netzteil und Netzkabel.

(2)Das Netzteil am Stecker des Druckers anschließen.

(3)Stecken Sie den Netzstecker des Netzteils in eine Steckdose ein.

DEUTSCH

– 51 –

Page 56

3-4. Einschalten

Stellen Sie sicher, daß das Netzteil angeschlossen ist, wie in 3-3 beschrieben.

(1)Den Netzschalter vorne am Gerät auf Ein (ON) stellen. Das POWER-

Lämpchen am Bedienfeld leuchtet auf.

DEUTSCH

Netzschalter

Wichtig!

Wir empfehlen, den Netzstecker aus der Steckdose zu ziehen, wenn der

Drucker längere Zeit lang nicht benutzt werden soll. Der Drucker sollte

vorzugsweise an einem Platz aufgestellt werden, der leichten Zugang zur

Netzsteckdose gewährt.

– 52 –

Page 57

4. Bedienfeld

4-1. Papiereinzugknopf (PAPER FEED)

Bei jedem Drücken dieses Knopfes wird das Papier um eine Zeile vorgeschoben.

Wenn der Knopf gedrückt gehalten wird, wird das Papier kontinuierlich vorgeschoben.

Hinweis: Dieser Knopf ist unwirksam, wenn kein Papier eingelegt ist.

4-2. Netz-LED (POWER) (grüne LED)

Diese LED leuchtet auf, wenn der Netzschalter in Ein-Stellung ist und Betriebsstrom am Drucker anliegt.

4-3. Fehler-LED (ERROR) (rote LED)

Diese LED leuchtet oder blinkt, wenn einer der folgenden Fehler auftritt.

Fehler-LED Blinkmuster Fehlerbeschreibung

Leuchtet

Blinkt

Leuchtet

Blinkt

Leuchtet Anormale Kopftemperatur (90°C)

Blinkt Fehlfunktion in Kopfverbindung

Leuchtet

Blinkt

Druckerabdeckung offen

Papier verbraucht

Das Papier ist fast verbraucht

Automatikschneidwerk-Fehler

DEUTSCH

POWER ERROR FEED

Fehler-LED (rot)

Betriebsstrom-LED (grün)

– 53 –

Papiervorschubschalter

Page 58

5. Einlegen von Papier

5-1. Einlegen einer neuen Papierrolle

(1)Ziehen Sie den Hebel nach vorne, um die Druckerabdeckung zu öffnen.

Hinweis:Stellen Sie sicher, daß der Hebel gezogen wird, bis er am Anschlag

stoppt. Wenn der Hebel nicht bis zum Anschlag gezogen wird, kann

es sein, daß sich die Druckerabdeckung nicht öffnen läßt.

(2)Das Klebestück am Papierende abziehen.

Hinweis:Stellen Sie sicher, daß der gesamte Klebebereich entfernt ist, da in

diesem Bereich nicht gedruckt werden kann.

(3)Positionieren Sie das Papier wie in der Abbildung unten gezeigt, und setzen

DEUTSCH

Sie es vorsichtig in den Papierhalter ein.

Papierhalter

Hinweis 1: Stellen Sie sicher, daß das Papier nicht verformt ist. Wenn eine

Papierrolle wie die unten gezeigte verwendet wird, können

Betriebsstörungen auftreten.

Hinweis 2: Wenn das Papier durchhängt wie unten gezeigt, nachdem es

eingesetzt ist, ziehen Sie es straff.

– 54 –

Page 59

(4)Stellen Sie sicher, daß das Papier gerade ausgerichtet ist, und schließen Sie die

Druckerabdeckung vorsichtig.

Hinweis 1: Stellen Sie sicher, daß das Papier gerade ausgerichtet ist. Wenn

die Druckerabdeckung bei schief liegendem Papier geschlossen

wird, wie unten gezeigt, kann ein Papierstau auftreten.

Papier

Hinweis 2: Sperren Sie die Druckerabdeckung durch Drücken auf die Mitte

der Abdeckung (in der Abbildung unten durch einen Pfeil

gekennzeichnet). Wenn ein anderer Teil der Abdeckung als die

Mitte gedrückt wird, kann die Abdeckung nicht richtig geschlossen werden. Dadurch kann u.U. der Druck unmöglich werden.

DEUTSCH

– 55 –

Page 60

(5)Wenn der Netzschalter auf Aus (OFF) gestellt ist, auf Ein (ON) stellen, um den

Drucker einzuschalten. Stellen Sie sicher, daß die ERROR-LED nicht leuchtet.

Hinweis:Während die ERROR-LED leuchtet, akzeptiert der Drucker keine

Befehle wie Druckbefehl; stellen Sie deshalb sicher, daß die Abdeckung richtig geschlossen ist.

(6)Wenn die Druckerabdeckung verriegelt ist, wird das Papierende ausgegeben,

und das Ende automatisch abgeschnitten.

5-2. Entfernen des restlichen Papiers

(1)Ziehen Sie den Hebel nach vorne, um die Druckerabdeckung zu öffnen.

DEUTSCH

Hinweis:Stellen Sie sicher, daß der Hebel gezogen wird, bis er am Anschlag

stoppt. Wenn der Hebel nicht bis zum Anschlag gezogen wird, kann

es sein, daß sich die Druckerabdeckung nicht öffnen läßt.

(2)Entfernen Sie das verbleibende Papier.

– 56 –

Page 61

6. Papiervorrat-Sensor

Der Drucker ist mit einem Sensor ausgestattet, der erkennt, wenn das Ende einer

Papierrolle fast erreicht ist. Zum Einsatz dieses Sensors wie folgt verfahren.

(1) Den Hebel in der angezeigten Richtung ziehen, und dann die Druckerab-

deckung öffnen.

(2)Die beiden Sensorhalteschrauben lösen.

(3)Die Sensoreinheit nach oben oder unten schieben, und dann die Schrauben

richtig festziehen.

Die folgende Tabelle zeigt den Durchmesser des Papiers, das auf der Rolle

bleiben würde, damit der Sensor, an der richtigen Sensorschraubenposition

installiert, es erkennen kann.

Sensorhalteschrauben

(Position 1)

DEUTSCH

ø18 mm

ø12 mm

Kern der

Papierrolle

A

A

– 57 –

Page 62

(4)Die Papierrolle einsetzen, und prüfen ob der Sensor richtig erkennt, daß das

Papier fast verbraucht ist.

Fehler-LED Die LED geht aus, wenn Papier vorhanden ist.

Die LED blinkt, wenn das Papier fast verbraucht ist.

Durchmesser des verbleibenden Papiers A

Ca. ø22 mm Position 1 (unten)

Ca. ø26 mm Position 2 (oben)

Schraubenposition

Vorsichtsmaßregeln

DEUTSCH

1) Die werksseitige Einstellung ist Position 1.

2) Immer eine Papierrolle mit einem Kern verwenden, der einen Innendurch-

messer von 12 mm und einen Außendurchmesser von 18 mm hat, um richtige

Erkennung der Restpapiermenge zu gewährleisten.

– 58 –

Page 63

7. Verhindern und Beheben von Papierstau

7-1. Verhindern von Papierstau

Das Papier soll beim Ausgeben und vor dem Schneiden nicht berührt werden.

Wenn das Papier beim Ausgeben gedrückt oder gezogen wird, kann ein Papierstau, ein Abschneidfehler oder ein Zeilenvorschubfehler verursacht werden. Nicht

die Druckerabdeckung während des Abschneidensöffnen.

DEUTSCH

7-2. Beheben von Papierstau

Wenn ein Papierstau auftritt, beheben Sie ihn wie folgt.

(1)Stellen Sie den Netzschalter auf Aus, um den Drucker auszuschalten.

(2)Ziehen Sie den Hebel nach vorne, um die Druckerabdeckung zu öffnen.

Hinweis:Stellen Sie sicher, daß der Hebel gezogen wird, bis er am Anschlag

stoppt. Wenn der Hebel nicht bis zum Anschlag gezogen wird, kann

es sein, daß sich die Druckerabdeckung nicht öffnen läßt.

(3)Entfernen Sie das gestaute Papier.

Hinweis:Achten Sie darauf, den Drucker beim Entfernen des gestauten

Papiers nicht zu beschädigen. Insbesondere der Thermaldruckkopf

läßt sich leicht beschädigen; achten Sie darauf, ihn nicht zu berühren.

– 59 –

Page 64

(4)Stellen Sie sicher, daß das Papier gerade ausgerichtet ist, und schließen Sie die

Druckerabdeckung vorsichtig.

Hinweis 1: Stellen Sie sicher, daß das Papier gerade ausgerichtet ist. Wenn

die Druckerabdeckung bei schief liegendem Papier geschlossen

wird, kann ein Papierstau auftreten.

Hinweis 2: Sperren Sie die Druckerabdeckung durch Drücken auf die Mitte

der Abdeckung. Wenn ein anderer Teil der Abdeckung als die

Mitte gedrückt wird, kann die Abdeckung nicht richtig geschlossen werden. Dadurch kann u.U. der Druck unmöglich werden.

(5)Stellen Sie den Netzschalter in Ein-Stellung, um den Drucker einzuschalten.

DEUTSCH

Stellen Sie sicher, daß die ERROR-LED nicht leuchtet.

Hinweis:Während die ERROR-LED leuchtet, akzeptiert der Drucker keine

Befehle wie Druckbefehl; stellen Sie deshalb sicher, daß die Abdeckung richtig geschlossen ist.

7-3. Freigeben eines gesperrten Schneidmessers

Wenn das automatische Schneidmesser sperrt oder das Papier nicht schneidet,

wie folgt verfahren.

Achtung:

Da Arbeiten am Schneidmesser gefährlich sein können, immer zuerst den

Drucker ausschalten.

(1)Den Netzschalter auf Aus (OFF) stellen, um den Drucker auszuschalten.

(2)Die Frontabdeckung abschieben, um das Schneidmesser freizulegen.

(3)Gestautes Papier entfernen.

Hinweis:Darauf achten, nicht den Drucker nicht beim Entfernen von gestau-

tem Papier zu beschädigen.

Da der Thermalkopf besonders empfindlich ist, darauf achten, ihn

nicht zu berühren.

– 60 –

Page 65

Automatisches Schneidmesser

Frontabdeckung

(4) Wenn die bewegliche Klinge des Schneidmessers hervorsteht, mit einem

Kreuzschlitzschraubenzieher die Kreuzschlitzschraube drehen, und die be-

wegliche Klinge in Grundstellung zurückstellen. Wenn das Prüffenster voll-

ständig weiß ist, ist die bewegliche Klinge in Grundstellung.

Hinweis 1: Nicht starken Druck auf die bewegliche Klinge ausüben.

Hinweis 2: Wenn die bewegliche Klinge zu sehr hervorsteht, kann die

Druckerabdeckung nicht geöffnet werden. Wenn versucht wird,

die Abdeckung zu öffnen, kann das Schneidmesser beschädigt

werden.

(5) Die Druckerabdeckung öffnen, gestautes Papier entfernen, und dann die

Papierrolle wieder einsetzen.

DEUTSCH

(6)Die Frontabdeckung wieder einsetzen, und den Netzschalter auch Ein (ON)

stellen.

Bewegliche Klinge

Prüffenster

– 61 –

Page 66

8. Testdruck-Verfahren

8-1. Erstellen eines Testdrucks

Zum Starten des Testdrucks schalten Sie den Drucker mit dem Netzschalter aus,

setzen das Papier richtig ein, und schalten dann den Drucker bei gedrückt

gehaltener FEED-Knopf ein. Den Schalter innerhalb von drei Sekundenfreigeben.

Der Testdruck stoppt automatisch nach dem Ausdruck der vorgegebenen Druckmenge, und der Drucker schneidet das Papier ab.

8-2. Sedezimaler Datenausdruck

DEUTSCH

Dies druckt vom Hostgesendete Daten im Sedezimalformat und den entsprechenden ASCII-Zeichenaus. Dies ist nützlich zum Debugging von Applikationen und zum Analysieren verzerrter Zeichen.

Starten und Stoppen des Sedezimal-Datenausgabedrucks

Während der Vorschubschalter gedrückt gehalten wird, das Gerät einschalten.

Den Schalter fünf Sekunden lang gedrückt halten; der Sedezimal-Datenausgabe-

druck beginnt, wenn der Schalter losgelassen wird. Wenn der Schalter innerhalb

von drei Sekunden losgelassen wird, wird der Selbsttest ausgeführt.

Sedezimal-Datenausgabedruck durch Ausschalten abbrechen.

Die empfangenen Daten werden wie folgt ausgedruckt.

Adresse Sedezimale Daten ASCII-Daten

– 62 –

Page 67

9. Regelmäßige Reinigung

Die Druckzeichen können durch Ansammlung von Papierstaub und anderem

Schmutz unscharf werden. Um das zu verhindern, muß im Papierhalter und in der

Papiertransportstufe angesammelter Staub von Zeit zu Zeit entfernt werden. Eine

derartige Reinigung sollte etwa einmal im Monat ausgeführt werden.

9-1. Reinigen des Thermalkopfes

Zum Entfernen von schwärzlichem Staub auf der Oberfläche des Thermalkopfes

diesen mit Isopropylalkohol (IPA) abwischen.

Hinweis:Der Thermalkopf läßt sich leicht beschädigen. Zum Abwischen

immer einen sehr weichen Lappen verwenden und sicherstellen,

daß er nicht zerkratzt wird.

9-2. Reinigen des Papierhalters

Verwenden Sie einen weichen Lappen zur Entfernung von Papierstaub vom

Papierhalter und aus der Papiertransportstufe.

DEUTSCH

– 63 –

Page 68

DEUTSCH

– 64 –

Page 69

INDICE

1. Identificazione delle parti e nomenclatura..................................................66

2. Parti soggette a consumo e trasformatore CA ............................................68

3. Cavi di collegamento e trasformatore CA...................................................69

3-1. Cavo interfaccia ...................................................................................69

3-2. Collegamento ad un’unità periferica....................................................71

3-3. Collegamento del trasformatore CA opzionale....................................73

3-4. Accensione ...........................................................................................74

4. Pannello di controllo......................................................................................75

4-1. Interruttore PAPER FEED ...................................................................75

4-2. Spia POWER (LED verde) ..................................................................75

4-3. Spia ERROR (LED rosso) ...................................................................75

5. Caricamento della carta................................................................................76

5-1. Caricamento di un nuovo rotolo di carta..............................................76

5-2. Rimozione della carta rimanente .........................................................78

6. Sensore di rilevamento fine carta.................................................................79

7. Prevenzione e soluzione degli inceppamenti della carta ............................81

7-1. Prevenzione degli inceppamenti della carta.........................................81

7-2. Eliminazione degli inceppamenti della carta .......................................81

7-3. Rilascio della taglierina bloccata .........................................................82

8. Metodo per la stampa di prova ....................................................................84

8-1. Produzione di uno stampato di prova...................................................84

8-2. Scaricamento esadecimali ....................................................................84

9. Pulizia periodica ............................................................................................85

9-1. Pulizia della testina termica .................................................................85

9-2. Pulizia del comparto carta....................................................................85

APPENDICE......................................................................................................87

ITALIANO

L’Appendice appare solo nella sezione in inglese di questo manuale.

Visitare il seguente indirizzo URL

http://www.star-micronics.co.jp/service/sp_sup_e.htm

per accedere alla versione più recente del manuale.

– 65 –

Page 70

ITALIANO

1. Identificazione delle parti e nomenclatura

Coperchio stampante

Leva

Tirare questa leva

in direzione della

freccia per aprire il

coperchio della

stampante.

Pannello di controllo

Dispone di indicatori LED

che indicano lo stato della

stampante e di interruttori

per controllare la stampante.

Interruttore

Usarlo per accendere/

spegnere la stampante.

Aprire questo coperchio per inserire o

sostituire la carta.

Per il collegamento del

trasformatore

CA. Non

scollegare mai il

trasformatore

CA mentre la

stampante è

accesa.

Carta in rotolo

Connettore di

alimentazione

Manuale dell’utilizzatore

Connettore di controllo

periferiche

Per il collegamento a

unità periferiche come

registri di cassa, ecc. Non

collegarlo ad un telefono.

Anello di ferrite Fascettadi fissaggio

– 66 –

Connettore interfaccia

Per il collegamento al

computer ospite.

Page 71

Scelta di un luogo per la stampante

Prima di disimballare la stampante, decidere dove si desidera installarla.

Tenere presenti i seguenti punti.

✓ Scegliere una superficie stabile e in piano, dove la stampante non sia

esposta a vibrazioni.

✓ La presa di corrente che si intende usare per la stampante deve essere

vicina e libera da ostacoli.

✓ La stampante deve essere abbastanza vicina al computer da permet-

tere il collegamento tra i due.

✓ Assicurarsi che la stampante non sia esposta alla luce solare diretta.

✓ Assicurarsi che la stampante sia lontana da caloriferi e altre fonti di

calore elevato.

✓ Assicurarsi che l'area circostante sia pulita, asciutta e priva di polvere.

✓ Assicurarsi che la stampante sia collegata ad una presa di corrente

affidabile. Non deve essere la stessa presa di corrente di copiatrici,

frigoriferi e altre apparecchiature che causano picchi di corrente.

✓ Assicurarsi che la stanza dove si usa la stampante non sia troppo

umida.

ITALIANO

– 67 –

Page 72

2. Parti soggette a consumo e trasformatore CA

Quando le parti soggette a consumo si sono esaurite, usare quelle specificate nella

seguente tabella. Assicurarsi di usare il trasformatore CA specificato nella

tabella.

L’uso di parti soggette a consumo o di un trasformatore CA diversi da quanto

specificato nella tabella può causare danni alla stampante, incendi o scosse

elettriche.

Nome della parte Specifiche

Carta in rotolo Carta termica

Spessore: Da 0,06 a 0,08 mm

Larghezza: 80 mm

Diametro esterno rullo: ø90 mm o meno

Diametro esterno nucleo: ø18 mm

ITALIANO

Trasformatore CA (opzionale) Ingresso: Da 100 a 240 V CA, 50-60 Hz

UP06021240 Uscita: 24 V CC±5 %, 2,5 A

Diametro interno nucleo: ø12 ±0,5 mm

Carta consigliata (carta termica generica)

TF50KS-E2C (Nippon Paper Industries)

P220AG (Mitsubishi Paper Mills Limited)

Carta consigliata (carta a stabilità immagine media)

PD-160R-N (Oji Paper Co., Ltd.)

Carta consigliata (carta conservabile per lunghi periodi)

AFP235 (Mitsubishi Paper Mills Limited)

- 1,0

0

+0,5

0

Importante!

Accedere alla seguente URL per informazioni sulla carta consigliata.

http://www.star-micronics.co.jp/

– 68 –

Page 73

3. Cavi di collegamento e trasformatore CA

3-1. Cavo interfaccia 3-1-1. Installazione dell’anello di ferrite

(1)Fissare l’anello di ferrite più grande

al cavo come mostrato nell’illustrazione qui sotto.

Anello di ferrite (larghezza 27 mm)

Cavo

ITALIANO

5 cm massimo

Fascetta di

fissaggio

Tirare e

tagliare

(2)Far passare la fascetta di fissaggio

attraverso l’anello di ferrite.

(3)Avvolgere la fascetta intorno al cavo

e fissarla. Usare delle forbici per

tagliare la parte in eccesso.

– 69 –

Page 74

3-1-2. Collegamento del cavo interfaccia

Nota: Prima di collegare/scollegare il cavo interfaccia, assicurarsi che la

stampante e tutti i dispositivi collegati alla stampante siano spenti.

Inoltre assicurarsi che la spina del cavo di alimentazione sia scollegata

dalla presa di corrente.

(1)Collegare il cavo interfaccia al connettore sul pannello posteriore della

stampante.

(2)Nel caso di un interfaccia seriale, serrare le viti del connettore. Nel caso

di un interfaccia parallelo, fissare i morsetti del connettore.

ITALIANO

Cavo interfaccia seriale

– 70 –

Cavo interfaccia parallelo

Page 75

3-2. Collegamento ad un’unità periferica

Si può collegare un’unità periferica alla stampante usando una spina modulare.

Di seguito descriviamo come installare l’anello di ferrite ed eseguire il collegamento. Vedere “Modulare necessario” a pagina 98 per dettagli sul tipo di spina

modulare necessario. Notare che la stampante non è dotata di spina o filo

modulare, che devono essere acquistati in base alle esigenze di impiego.

Importante!

Assicurarsi che la stampante sia spenta e scollegata dalla presa di corrente e che

il computer sia spento prima di eseguire il collegamento.

(1)Fissare l’anello di ferrite più picco-

lo al cavo modulare come mostrato

nell’illustrazione qui sotto.

Connector

Anello di ferrite (larghezza 17,5 mm)

Cappio

Cavo

ITALIANO

– 71 –

Page 76

ITALIANO

5 cm

massimo

Fascetta di

fissaggio

(2)Far passare la fascetta di fissaggio

attraverso l’anello di ferrite.

(3)Avvolgere la fascetta intorno al cavo

Tirare e tagliare

e fissarla. Usare delle forbici per

tagliare la parte in eccesso.

(4)Collegare un capo del cavo modula-

re alla presa modulare della periferica.

(5)Rimuovere il coperchio presa mo-

dulare dal retro della stampante e