Page 1

Thermal Printer

TSP200 Series

Programmer’s Manual

Page 2

Page 3

TABLE OF CONTENTS

1. OUTLINE..............................................................................................1

2. MEMORY SWITCH AND DIP SWITCH ...........................................2

2-1. Memory Switch............................................................................2

2-2. DIP Switch ...................................................................................2

3. DISPLAY PANEL AND FUNCTIONS ...............................................4

3-1. LED..............................................................................................4

3-2. Switches .......................................................................................4

3-3. Switch Operation (Combined Switch Operation) ........................4

4. SERIAL INTERFACE ..........................................................................5

4-1. Interface Specifications................................................................5

4-2. Interface Circuit ...........................................................................6

4-2-1. RS-232C Interface .............................................................6

4-3. Connectors and Signal Names .....................................................7

4-3-1. RS-232C Interface .............................................................7

4-4. Interface Connections ..................................................................9

4-5. Data Protocol..............................................................................10

4-5-1. DTR mode .......................................................................10

4-5-2. X-ON/X-OFF mode.........................................................12

5. PARALLEL INTERFACE.................................................................. 13

5-1. Interface Specifications.............................................................. 13

5-2. Interface Timing.........................................................................13

5-3. Connectors and Signal Names ...................................................14

6. PERIPHERAL UNIT DRIVE CIRCUIT ............................................16

7. ERRORS..............................................................................................19

7-1. Automatic Recovery (Power Lamp: Flashing;

On-Line Lamp: On)....................................................................19

7-2. Recoverable Errors (Power Lamp: Flashing;

On-Line Lamp: Off) ...................................................................19

7-3. Fatal Error (Power Lamp: Flashing;

On-Line Lamp: Flashing)...........................................................20

7-4. Type of buzzer sound (only Star mode) P: 50ms Pi: 100ms......20

8. CONTROL CODES/STAR MODE .................................................... 21

8-1. Star Mode Command Summary.................................................21

8-2. Command Specification .............................................................25

9. CONTROL CODES/ESC/POS MODE ..............................................57

10. CHARACTER CODE TABLES .......................................................59

11. AUTOMATIC CUTTER...................................................................73

Page 4

Page 5

1. OUTLINE

The TSP200 series is ideal for printing text, bar code and graphics.

The TSP200 series has the following features:

1. extremely quiet and fast printing (maximum 50 mm/sec.) using the direct line

thermal printing method

2. support many bar code types

(UPC-A, UPC-E, JAN/EAN-8, JAN/EAN-13, CODE 39, IFT 2 OF 5, CODE

128, CODE 93, NW-7)

3. dual interfaces (RS232C, Parallel)

4. memory switches that enable wide selection of printer default settings

The printer has two different software modes which can be selected using the DIP

switch.

(Factory setting: Star Mode)

Star Mode: DIP switch 1-7 ON

This mode is compatible with Star Receipt printers, such as the SP300 and SP200

series.

ESC/POS Mode: DIP switch 1-7 OFF

This mode is compatible with the printers supporting ESC/POS command.

ESC/POS is a trademark of Seiko Epson Corporation.

For improvement purposes, the descriptions and specifications in this manual are

subject to change without notice.

– 1 –

Page 6

2. MEMORY SWITCH AND DIP SWITCH

Functional settings are made using the printer’s EEPROM memory switches and

the DIP switches.

2-1. Memory Switch

Each memory switch is a 16-bit word stored in EEPROM.

The printer is shipped with the factory setting which is made in accordance with

its product type.

For the detailed functions and the settings of the Memory switches, please refer

to “Chapter 8”.

The factory settings are shown in the table below.

Memory switch TSP212 TSP242

#0 0000 0000

#1 0000 0000

#2 0000 0100

#3 0000 0000

#4 0000 0000

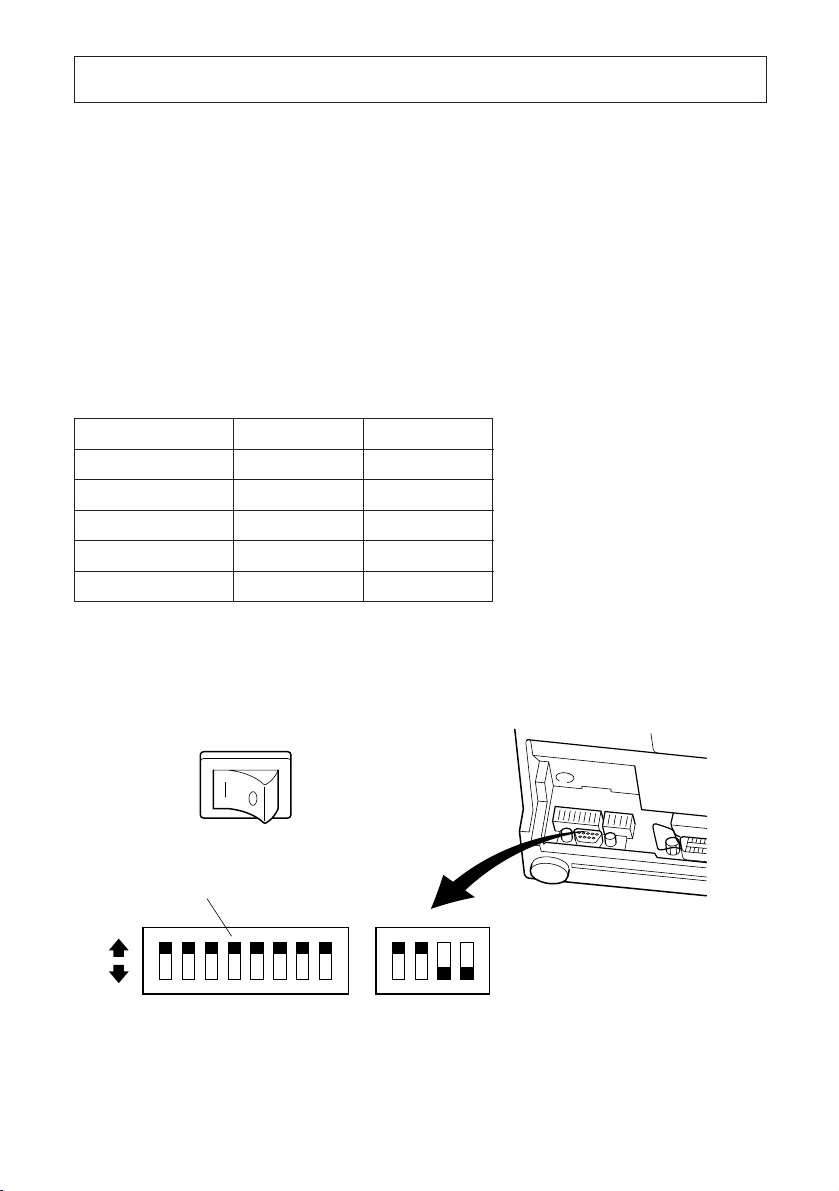

2-2. DIP Switch

Be sure to turn off the power of the printer before changing the setting of the

DIP switches.

Power off

DIP switch

ON

OFF

DIP switch 1

8141

DIP switch 2

DIP switch array

– 2 –

Page 7

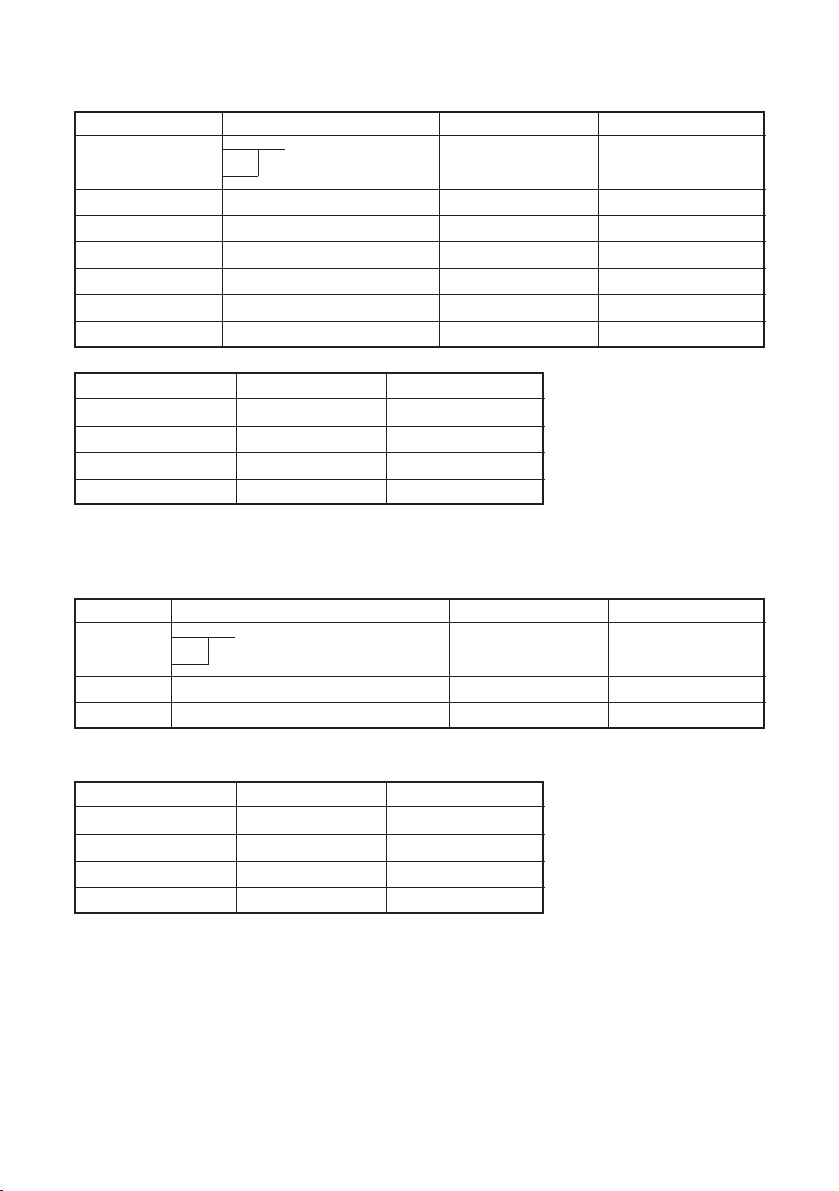

DIP switch #1

The factory settings of DIP switch 1 are all on.

Switch Contents ON OFF

1-1 Baud Rate

1-2

1-3 Data Length 8 bit 7 bit

1-4 Parity Check Disabled Enabled

1-5 Parity Selection Odd Even

1-6 Handshake DTR XON/XOFF

1-7 Operating Mode Star ESC/POS

1-8 Interface RS232C Parallel

Baud Rate 1-1 1-2

2400BPS OFF OFF

4800BPS ON OFF

9600BPS ON ON

19200BPS OFF ON

DIP Switch #2

Factory settings: 2-1 and 2-2 are on; 2-3 and 2-4 are off.

Switch Contents ON OFF

2-1 Print Density

2-2

2-3 Serial I/F No. 6 Pin Reset Signal Enabled Disabled

2-4 Serial I/F No. 8 Pin Reset Signal Enabled Disabled

Print Density 2-1 2-2

Light OFF OFF

Standard ON ON

Somewhat Heavy ON OFF

Heavy OFF ON

– 3 –

Page 8

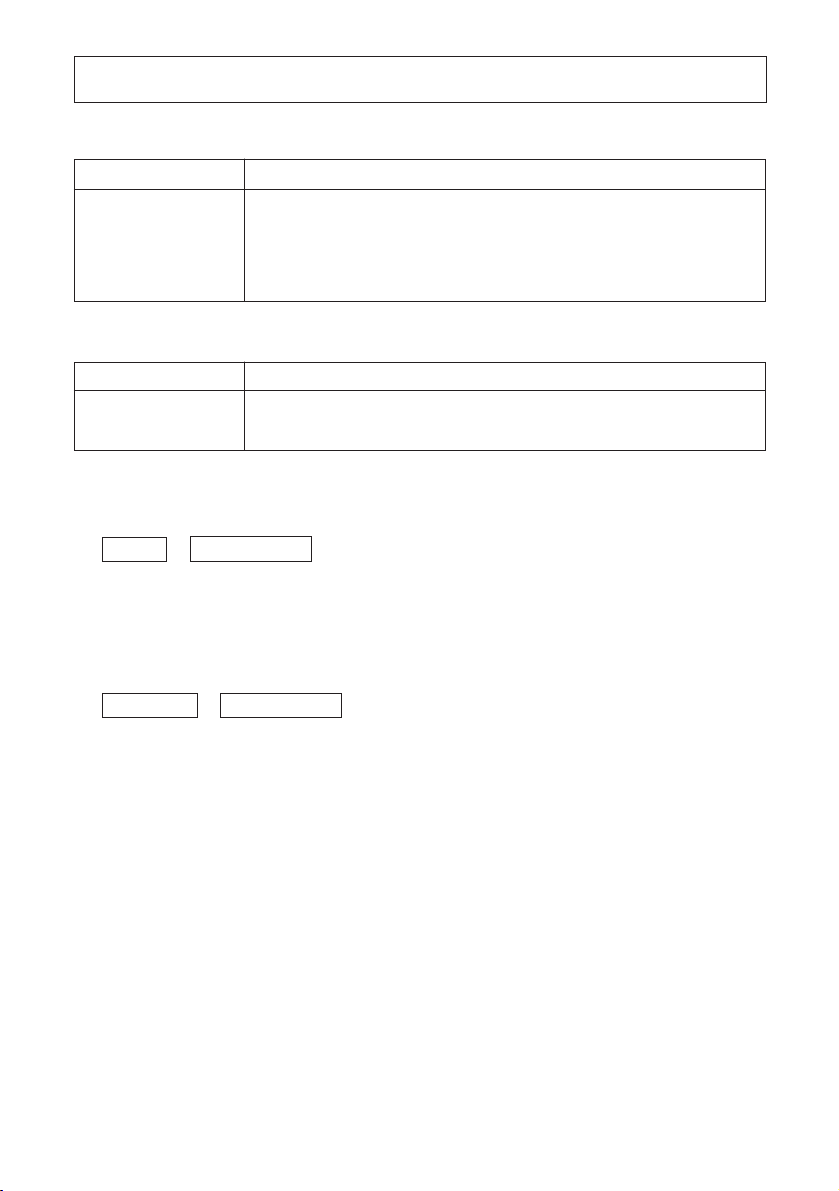

3. DISPLAY PANEL AND FUNCTIONS

3-1. LED

LED Function

POWER Lights up when the printer is turned on.

Blinks when an error occurs (Refer to 7. ERRORS.)

ON LINE Lights up when the printer is on line; goes off when the printer

is off line or error occurs (Refer to 7. ERRORS.)

3-2. Switches

Switch Function

ON LINE Switches between on line and off line

FEED Feeds the paper while pressed

3-3. Switch Operation (Combined Switch Operation)

1) <SELF PRINTING>

FEED + POWER ON (Turn the power on while holding the FEED switch

depressed.)

Self-printing will be performed. VER. NO., Memory switch settings, DIP

switch settings and character order will be printed out.

2) <Hexadecimal dump mode>

ON LINE + POWER ON (Turn the power on while holding the ON LINE

switch depressed.)

Each of the signals sent from the computer to the printer will be printed out

in hexadecimal code.

This function allows you to check if a control code sent to the printer by the

program being used is correct or not. The last line is not printed if its data is

less than one full line. However, if the ON LINE switch is pressed to set the

off line mode, the last line will be printed. To turn off the mode, it is necessary

to turn off the printer completely.

– 4 –

Page 9

4. SERIAL INTERFACE

4-1. Interface Specifications

Transmission type.................Asynchronous serial interface

Baud rate (bps) .....................2400, 4800, 9600, or 19200

(Selected by DIP switch)

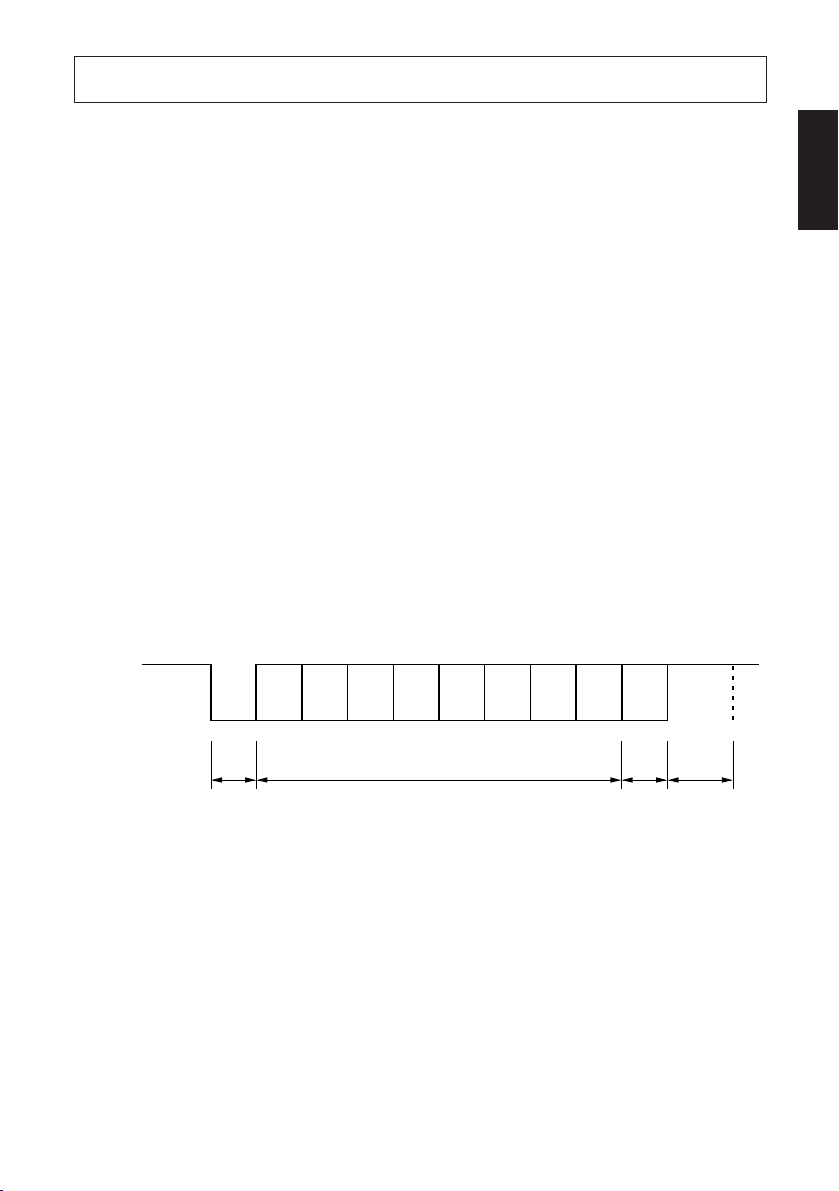

Word format

Start bit: ......................1

Data bits: ....................7 or 8 (Selected by DIP switch)

Parity: .........................Odd, Even, or None

(Selected by DIP switch)

Stop bit: ......................1

Signal polarities

RS-232C .....................Mark = Logic “1” (–3V to –15V)

Space = Logic “0” (+3V to +15V)

Handshaking .........................DTR or XON/XOFF mode (Selected by DIP

switch)

Mark [1]

b0 b1 b2 b3 b4 b5 b6 (b7)

SERIAL

Space [0]

ABCD

A: Start bit

B: Data bits

C: Vertical parity bit

D: Stop bit

– 5 –

Page 10

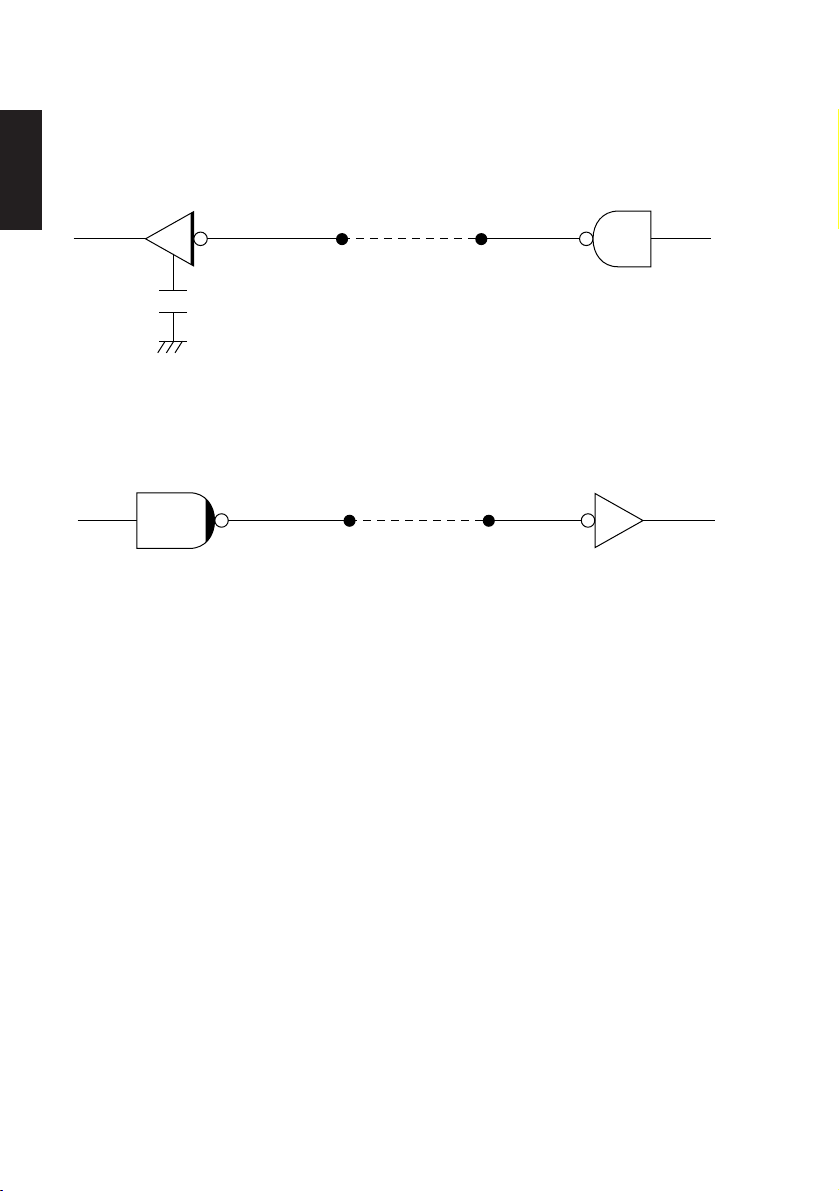

4-2. Interface Circuit

4-2-1. RS-232C Interface

SERIAL

Input (RXD, DSR)

Printer Host computer

Output (DTR, FAULT, TXD, RTS)

Printer Host computer

75188 or equivalent

– 6 –

Page 11

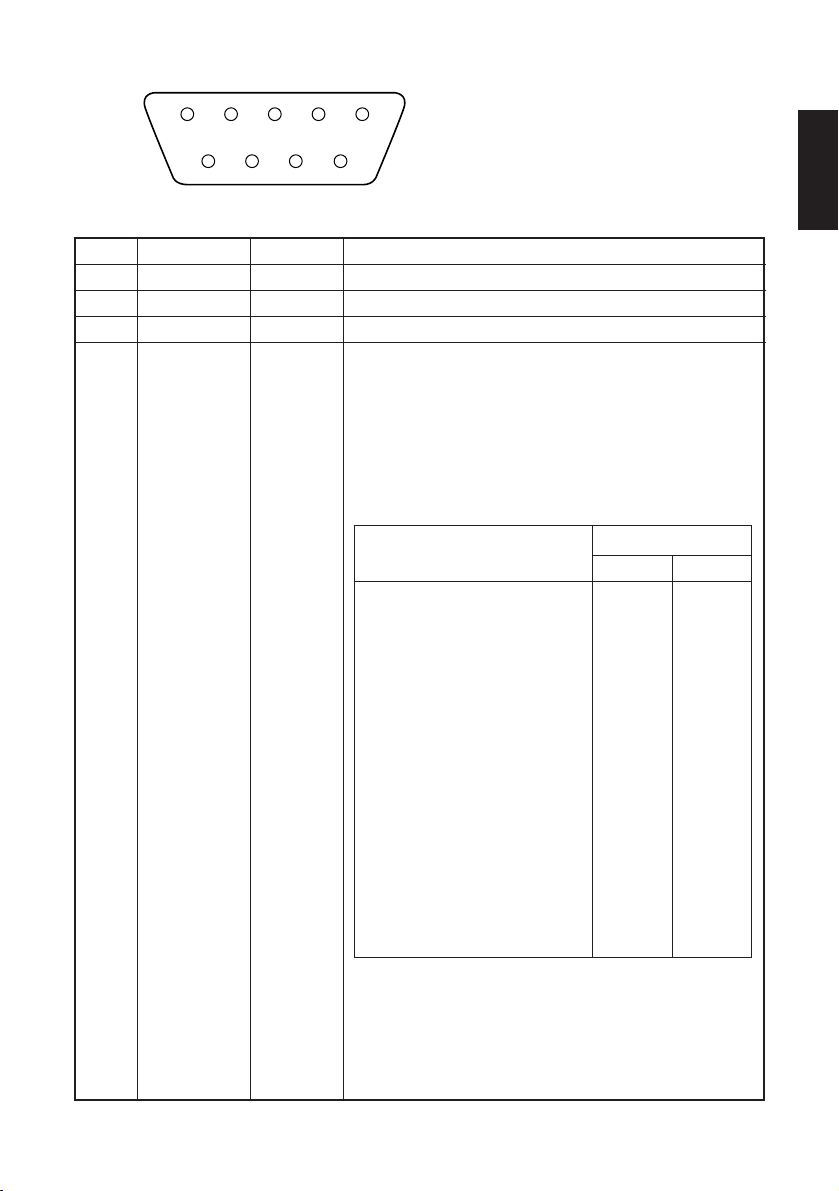

4-3. Connectors and Signal Names

51

9

6

4-3-1.RS-232C Interface

Pin No.

1 FG – Frame ground

2 RXD IN Receiving data

3 TXD OUT Transmission data

4 DTR OUT ESC/POS mode

Signal name

Direction

1) DTR/DSR communication mode

Indicates if printer is busy or not.

Space: Printer ready

Mark: Printer busy

The conditions for busy will vary according to

the memory switch settings.

Printer Status

1. From when the power

is turned on or I/F reset

until communication

possible

2. Test printing

3. Cover open

4. Paper feed by paper feed

switch

5. Stop due to no paper

6. During waiting for

switch input in macro

execution

7. Other errors

8. Receiving buffer full

SERIAL

Function

Memory SW #4-4

10

BUSY BUSY

BUSY BUSY

– – – BUSY

– – – BUSY

– – – BUSY

– – – BUSY

– – – BUSY

BUSY BUSY

2) XON/XOFF Communication mode

Indicates when printer can receive data from

host. This is space, except for the following.

1. After reset until communication possible.

2. During test printing.

– 7 –

Page 12

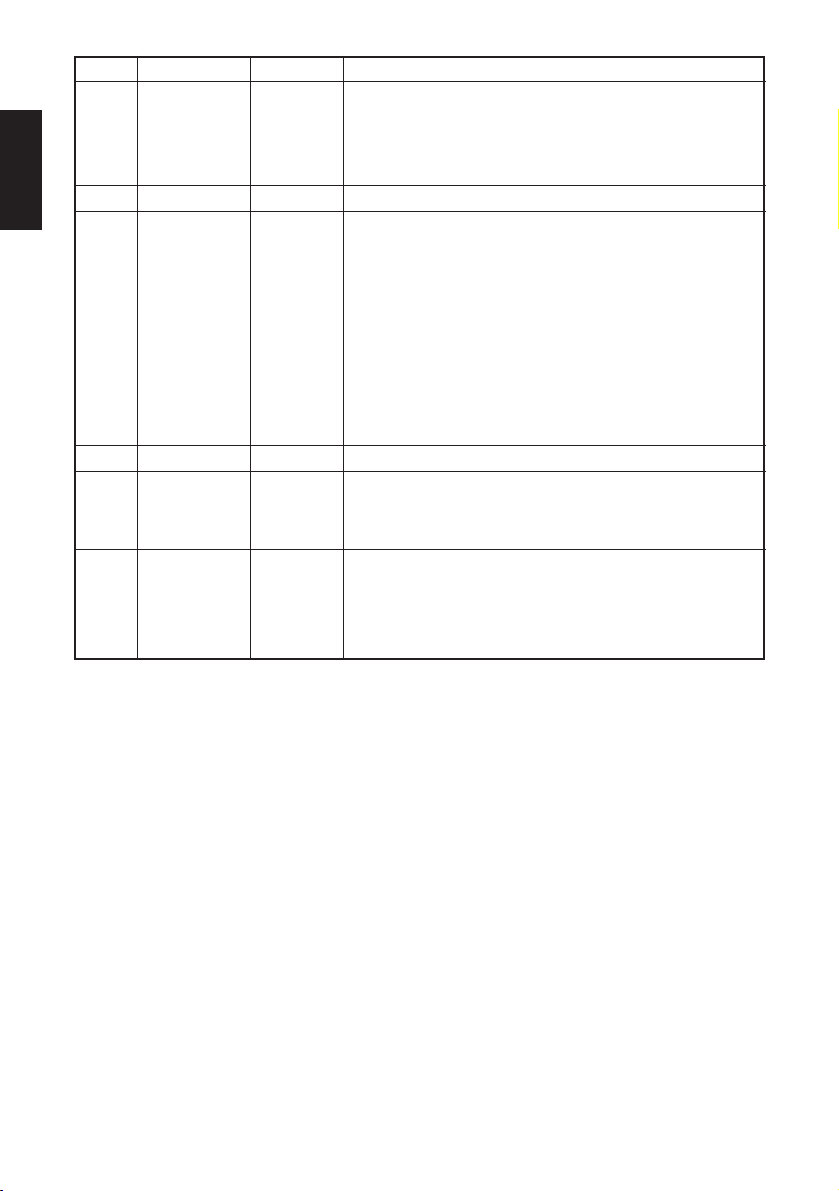

SERIAL

Pin No.

Signal name

Direction

Function

Star mode

Data terminal ready signal.

When the printer is ready to receive data, this

signal changes to “SPACE”.

5 SG — Signal ground

6 DSR IN Signal line that indicates whether the host can

receive data

Space: Host can receive data

Mark : Host cannot receive data

Does not confirm the status of this signal in XON/

XOFF communication or STAR mode.

This signal line can be used as an external reset

signal by setting the DIP switches. A pulse width of

1 ms or more mark state activates reset.

7 RTS OUT Same as DTR signal.

8 INIT IN This signal line can be used as an external reset

signal by setting the DIP switches. A pulse width of

1 ms or more space state activates reset.

9 FAULT OUT In the Star mode, the printer will enter the mark

state during the following errors: no paper, head up,

cutter error. In ESC/POS mode, this is normally

space.

– 8 –

Page 13

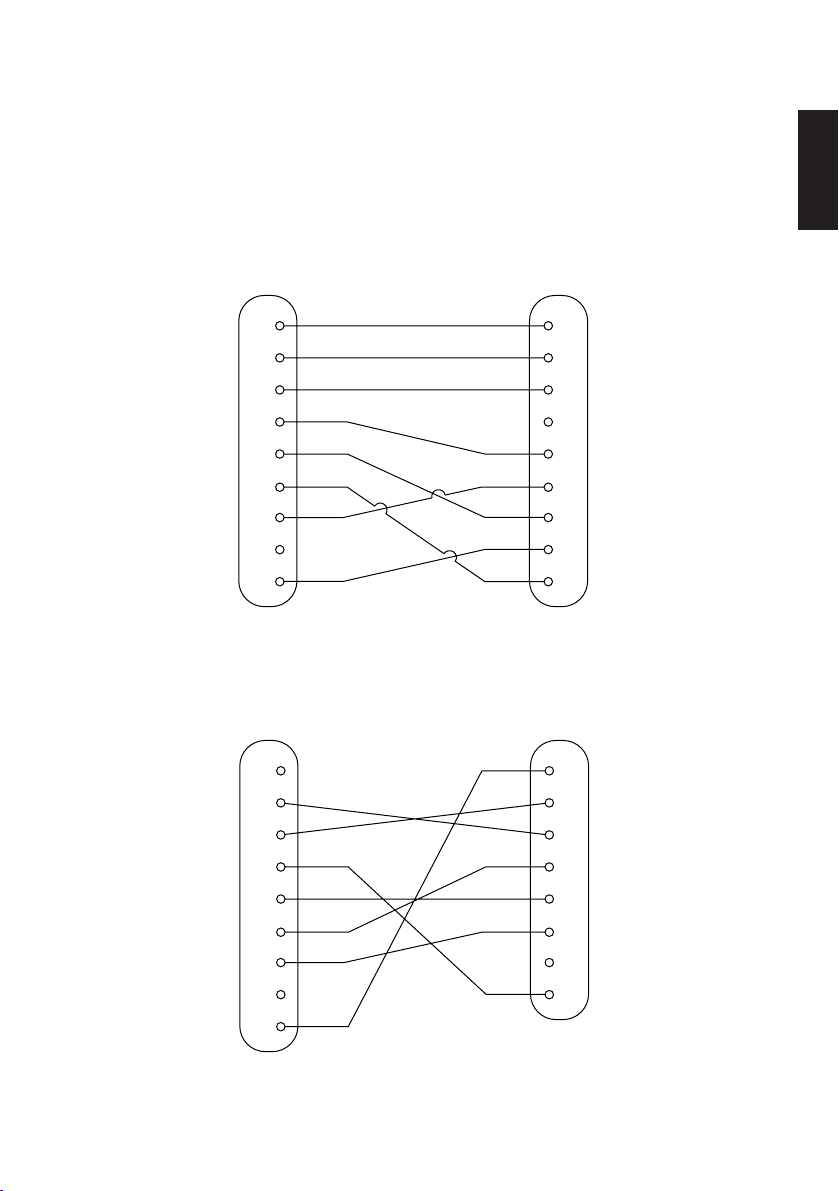

4-4. Interface Connections

Refer to the host computer’s interface specifications for details of how to connect

the interface. The following illustrations show typical connection configurations.

[RS-232C]

Printer side IBM PC side (25 pin)

F-GND

RXD

TXD

DTR

S-GND

RTS

INIT

FAULT

F-GND

RXD

TXD

DTR

S-GND

RTS

INIT

FAULT

1

2

3

4

5

6DSR

7

8

9

Printer side IBM PC side (9 pin)

1

2

3

4

5

6DSR

7

8

9

20

SERIAL

F-GND

1

TXD

2

RXD

3

RTS

4

CTS

5

DSR

6

S-GND

7

DCD

8

DTR

DCD

1

RXD

2

TXD

3

DTR

4

S-GND

5

DSR

6

RTS

7

8

CTS

– 9 –

Page 14

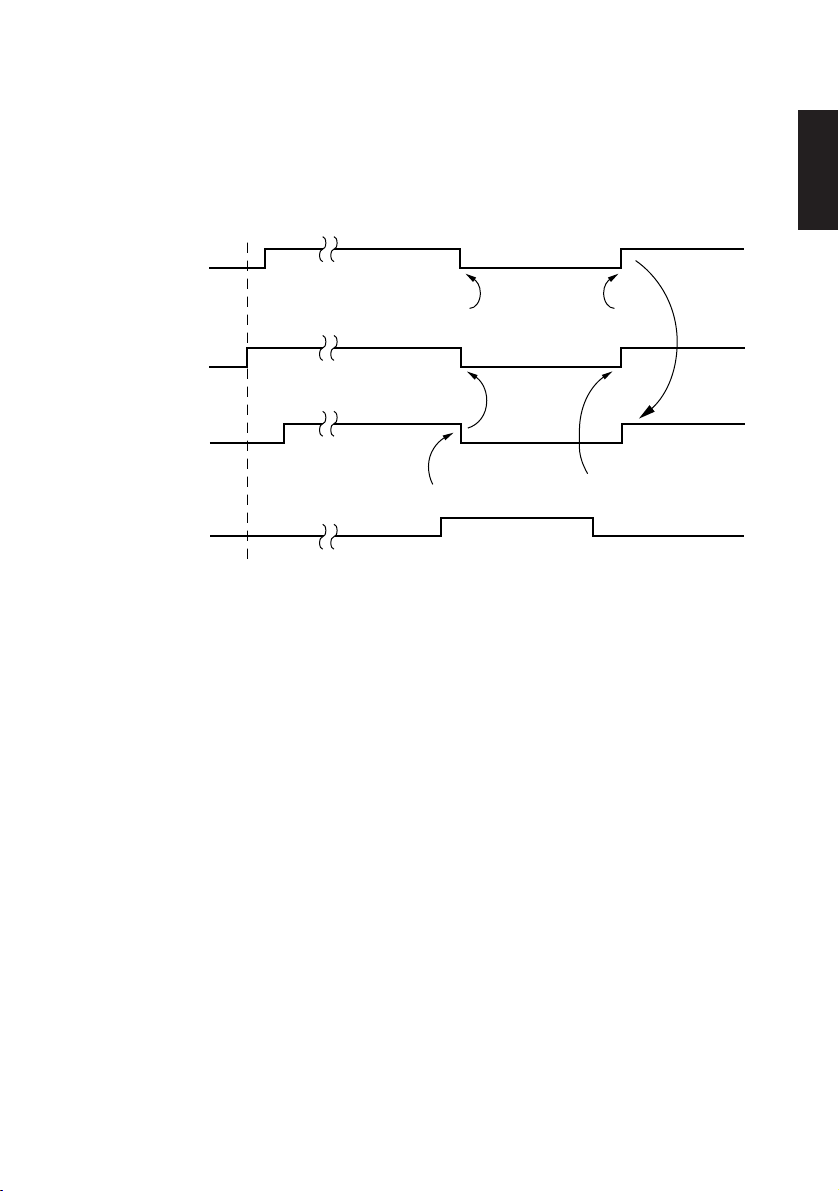

4-5. Data Protocol

4-5-1. DTR mode

SERIAL

This mode is accessed when the DIP switch 1-6 is set to ON.

Signals are controlled using the DTR line as a BUSY flag.

RXD

DTR

Printing

Power ON

Data Data Data

Buffer full Buffer empty

Immediately after power on (provided that no error occurs), the printer sets DTR

to “SPACE” to indicate that it is ready to receive data. When the host detects that

DTR is in “SPACE” condition, it begins sending text data over the RXD line.

When the printer’s remaining buffer space falls to *256 bytes or less, the printer

sets DTR to “MARK.” The host responds by halting the data transfer. However,

note that the printer remains capable of receiving data until the buffer becomes

full.

Available buffer space increases as the printer prints the buffered data. When the

printer has cleared all but the last *256 bytes of data, it sets DTR back to “SPACE”

to indicate that it is ready to receive more data.

Data buffer full Nearly full

*256 bytes

remaining

DTR

“MARK”

* 16 bytes when the buffer size is set to 45 bytes

– 10 –

Nearly empty Empty

*256 bytes

DTR

“SPACE”

Page 15

■ Error Condition

Upon detecting an error, the printer immediately sets DTR to “MARK” and goes

offline. If the error was caused by a paper-out condition, you can clear it by

loading new paper and then pressing the ON LINE switch (Star mode) or closing

the cover (ESC/POS mode).

When paper is out

RXD

OFF LINE ON LINE

DTR

Printing

SERIAL

PAPER OUT signal

Power ON

Paper out

Press the ON LINE switch after

loading paper (Star mode).

– 11 –

Page 16

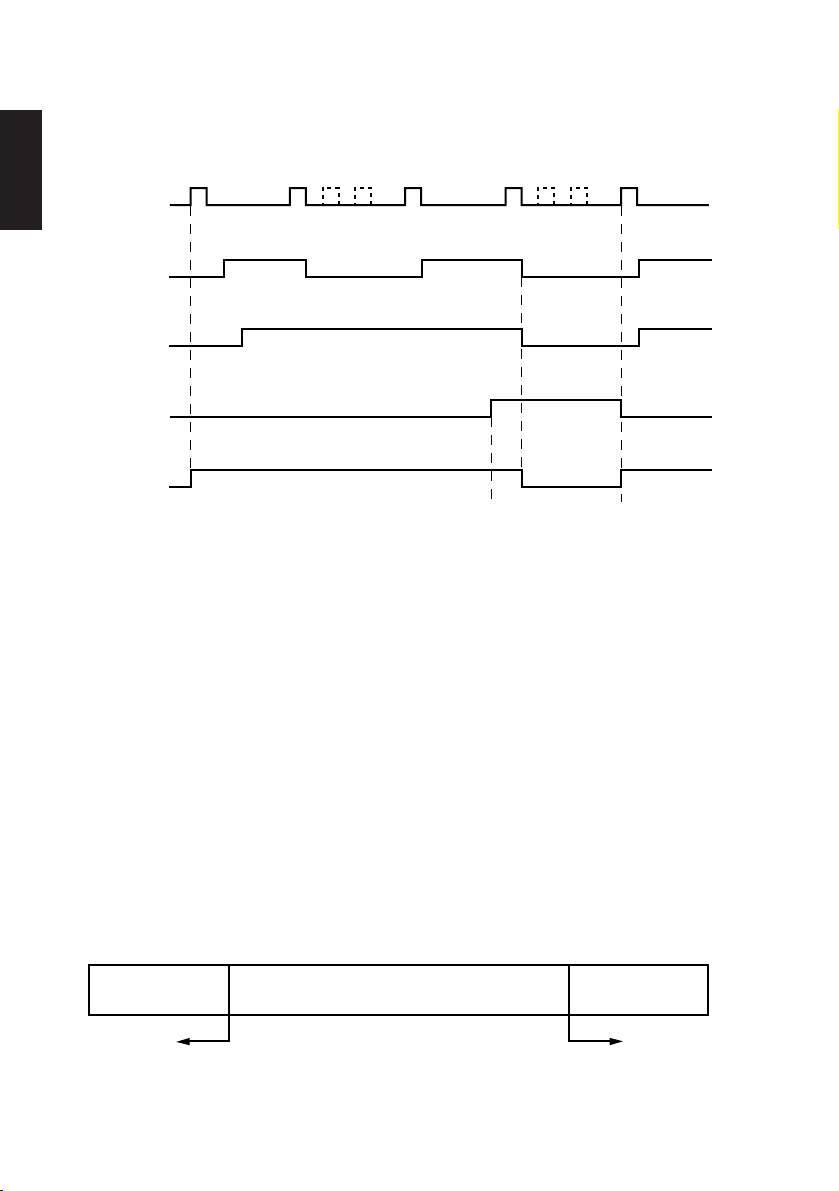

4-5-2. X-ON/X-OFF mode

This mode is accessed when DIP switch 1-6 is set to OFF.

SERIAL

X–OFF

X–ON X–OFF X–OFF X–ON X–OFF X–OFF

TXD

X–OFF

X–ON

RXD

Printing

PAPER OUT

signal

ON LINE

indicator

ON

OFF

Power ON Load paper and press

Data Data Data

Paper out

the ON LINE switch (Star mode).

Immediately after power on (provided that no error occurs), the printer informs

the host that it is ready to receive data by outputting the X-ON signal (control code

DC1; value = 11H) over the TXD line. If necessary the printer repeats the signal

every three seconds until the host begins sending text data over the RXD line.

When the printer’s remaining buffer space falls to *256 bytes or less, the printer

begins to output X-OFF signals (DC3, value = 13H) over the TXD line. The host

responds by halting the data transfer. Note that the printer remains capable of

receiving data until the buffer becomes full.

Available buffer space increases as the printer prints the buffered data. When the

printer has cleared all but the last *256 bytes of data, it again outputs the X-ON

signal.

Data buffer full Nearly full

*256 bytes

remaining

Printer outputs

X-OFF.

Nearly empty Empty

*256 bytes

Pinter outputs

X-ON.

* 16 bytes when the buffer size is set to 45 bytes

– 12 –

Page 17

5. PARALLEL INTERFACE

5-1. Interface Specifications

Interface: Conforms with Centronics parallel interface standard

Data transfer speed: 1000 ~ 5000 CPS

Synchronization: External strobe pulse

Handshaking: Using ACK and BUSY

Logic level: TTL-level compatible

5-2. Interface Timing

A C K

DATA

STROBE

BUSY

PARALLEL

Approx. 9ms

TTT

T: At least 0.5ms

– 13 –

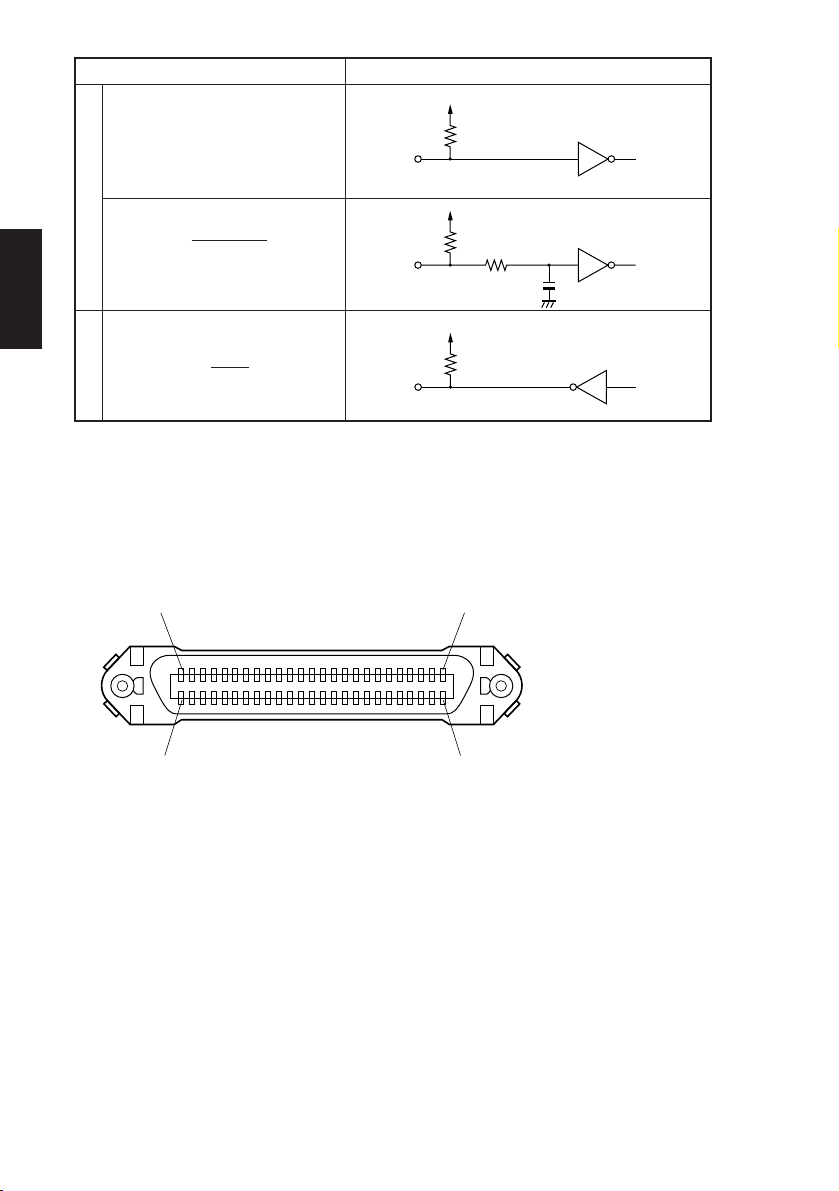

Page 18

Signal Name Sample Circuit

4.7k

DATA 1

~

W

74LS-equivalent

DATA 8

Input

PARALLEL

STROBE

BUSY

Output

ACK

5-3. Connectors and Signal Names

(18) (1)

(36) (19)

(Printer Side)

1kW

1.8kW

100W

1000pF

74LS-equivalent

74LS-equivalent

Conforms to Amphenol

connector 57-30360

Figure 5-1. Parallel Interface Connector

– 14 –

Page 19

Pin no Signal name

1 STROBE IN Strobe pulse for data read. Usually HIGH;

Direction

Function

goes LOW to trigger data read.

2-9 DATA 1~8 IN Parallel data lines for eight-bit data. HIGH

is “1”; LOW is “0”.

10 ACK OUT Printer outputs this pulse for approxi-

mately 9µs to indicate that data read is

completed. Printer becomes ready to

receive new data at the moment the ACK

pulse ends.

11 BUSY OUT DC-level signal indicating printer’s cur-

rent status. LOW indicates that printer is

ready to receive the next data; HIGH

indicates that printer is unable to receive.

12 PAPER OUT OUT DC-level signal indicating whether printer

has paper. The signal stays LOW while paper

is present; it goes HIGH to indicate that paper

has run out.

13 SELECTED OUT DC-level signal; stays HIGH while printer is

online.

14-15 N/C Not used

16 SIGNAL GND Signal ground

17

18 +5V Outputs +5V (Max. 50mA)

19-30 TWISTED Return pins for various signals. Each pin is

31 RESET IN LOW level causes printer to reset its control

32 ERROR OUT Goes LOW to indicate that printer is unable to

33 EXT GND Ground terminal for external connection

34-35 N/C Not used

36 – – Fixed “HIGH” at printer side

CHASSIS GND

PAIR RETURN

Printer-frame ground

connected to the corresponding signal line by

twisted pair line.

circuitry and return to its initial state.

print.

PARALLEL

– 15 –

Page 20

6. PERIPHERAL UNIT DRIVE CIRCUIT

A drive circuit for driving peripheral units (such as cash drawers) is featured on

the main logic board of this printer. A modular connector for driving peripheral

units is featured on the output side on the drive circuit. When using this circuit,

connect the cable for the peripheral unit. (Cables must be prepared by the user.)

Use cables which meet the following specifications.

1. Use the modular plug as shown in Figure 6-1.

2. Separate ground wire is required for Europe only.

3. If the printer is to be used in Europe, the noise filter should be attached to the

cable, as shown in Figure 6-2.

CAUTION: DO NOT connect any other plug to the peripheral unit connector.

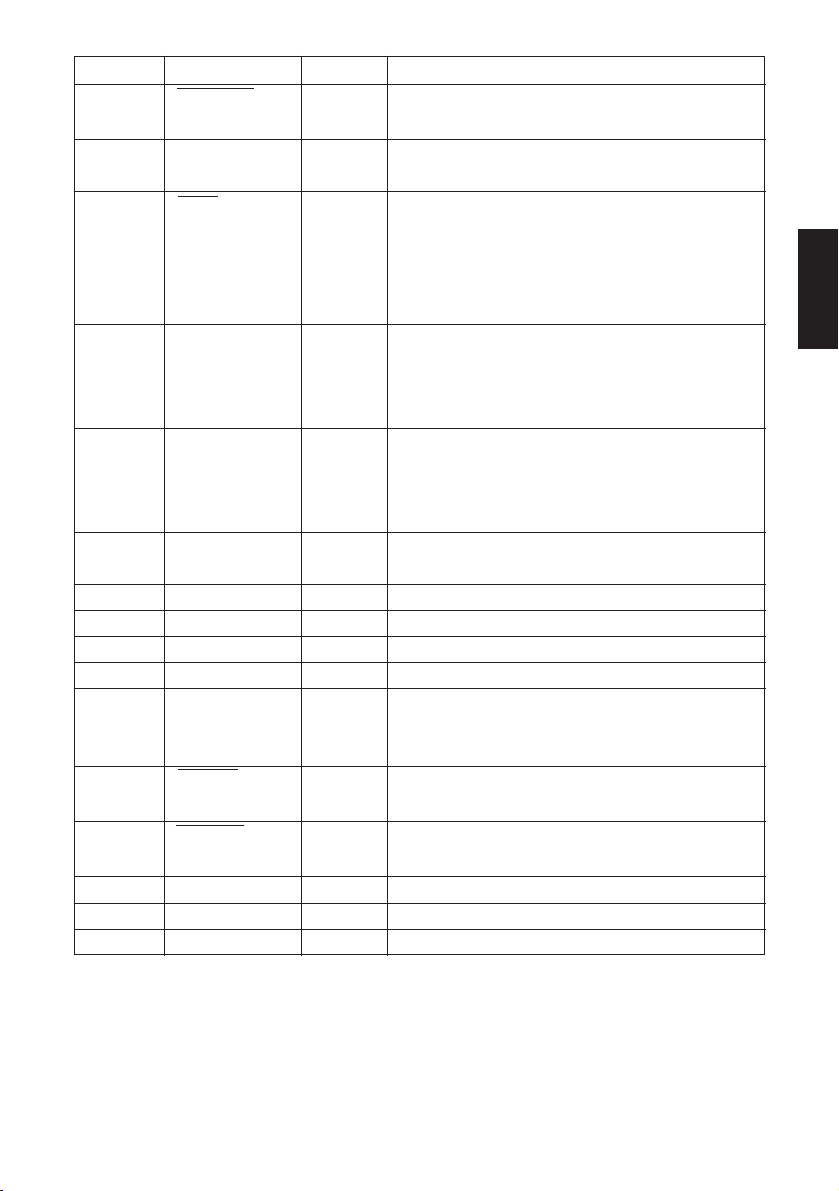

Modular plug MOLEX 90075-0007,

AMP641337 or JAPAN BURNDY B-66-4

16

Shield

Wire lead

Separated Ground wire

connected to shield (Europe only).

Figure 6-1. Cable specifications for peripheral unit.

– 16 –

Page 21

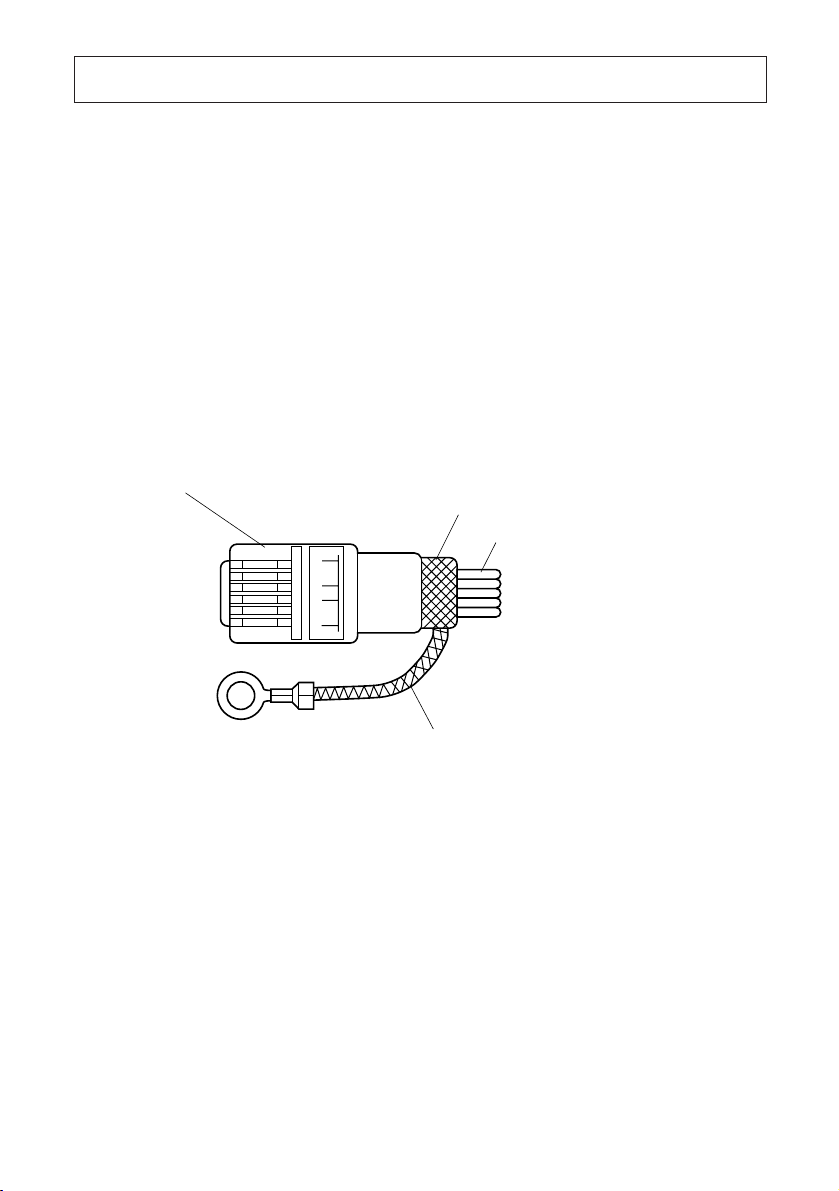

Fastener

One loop

Ferrite core

Screw M3×4

Separate ground wire

Peripheral unit drive

circuit connector

Figure 6-2. Separate ground wire and noise filter are required for Europe.

– 17 –

Page 22

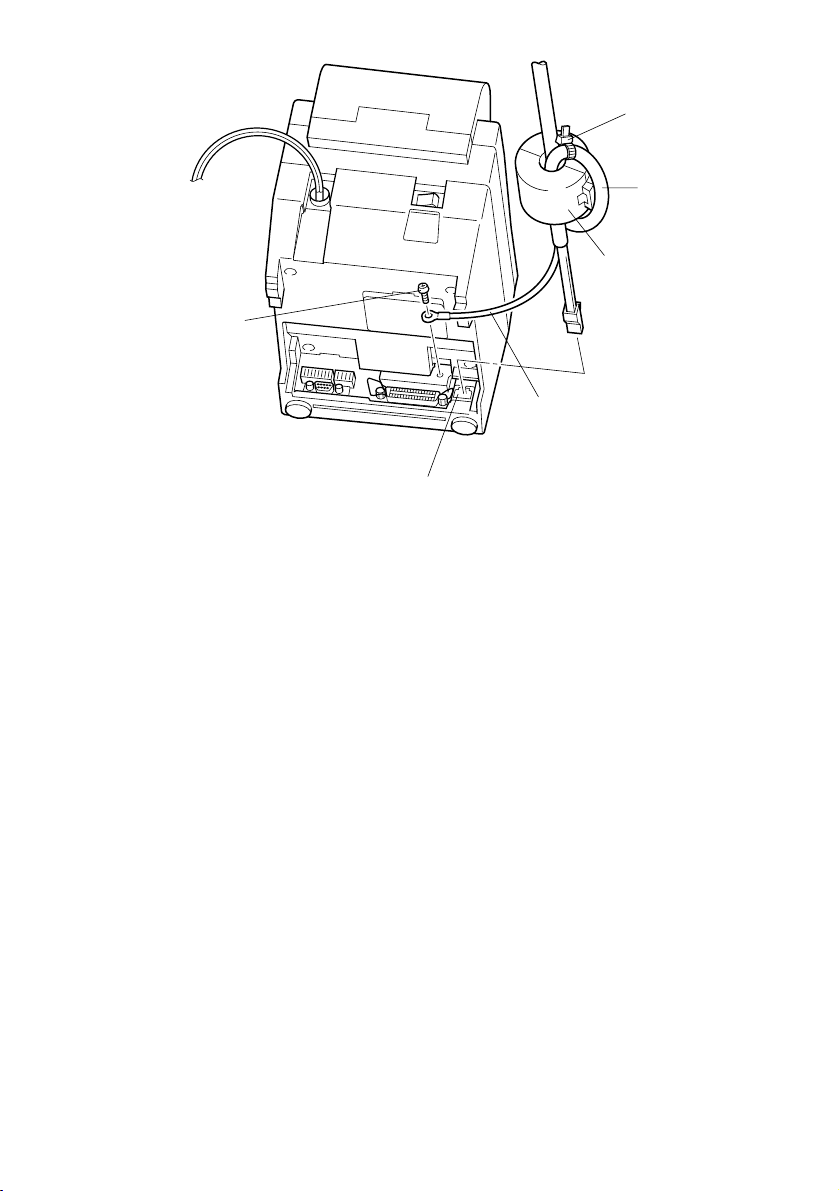

■ Drive circuit

The recommended drive circuit is shown.

[Drive output 24V, max. 1.0 A]

F.G

M-GND

M-GND

TR3

TR1

TR2

+5V

+24V

R2

D1

7824

D2

R1

1

2

3

4

5

6

With shield

L1

L2

Peripheral

unit 2

Frame

ground

Peripheral

unit 1

R3

4.7kΩ

1/4W

Compulsion

switch

NOTES:

1. Peripheral units #1 and #2 cannot be driven simultaneously.

When driving a device continuously, do not use drive duty above 20%.

2. Compulsion switch status is available as status data.

3. Resistance for coils L1 and L2 is not less than 24 ohms.

4. Absolute maximum ratings for diodes D1 and D2 (at Ta=25˚C):

Average rectified current Io = 1A

Maximum forward surge current (60Hz,1-cycle sine wave) I

FSM=40A

5. Absolute maximum rating for transistors TR1 and TR2 (at Ta = 25˚C):

Collector current Ic = 2A

– 18 –

Page 23

7. ERRORS

The various types of errors can be identified by the buzzer’s sound and the lit

LEDs.

Buzzer: The circled numbers refer to “7-4. Type of buzzer sound”.

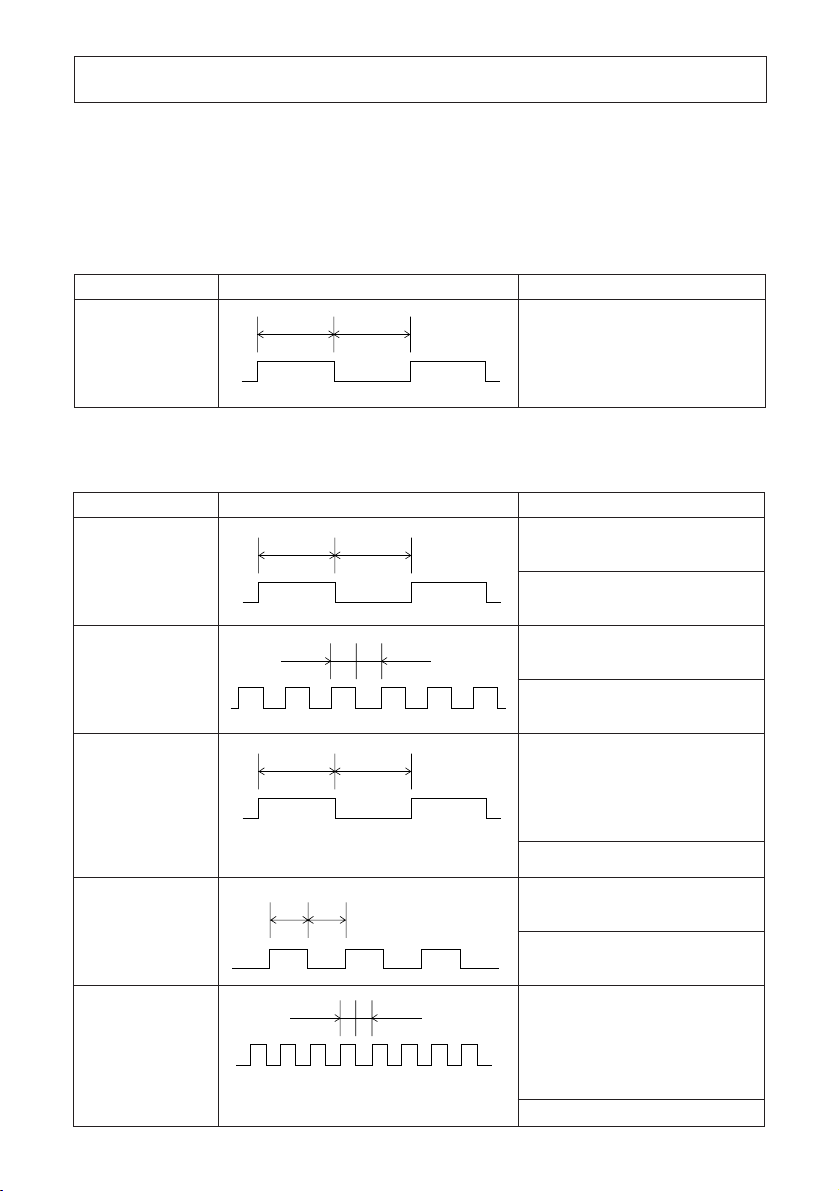

7-1. Automatic Recovery (Power Lamp: Flashing; On-Line

Lamp: On)

Error Description

Abnormal head

temperature

7-2. Recoverable Errors (Power Lamp: Flashing; On-Line

Lamp: Off)

Error Description

No paper

Power Lamp Flashing Pattern Recovery Conditions

Approx. 1 Sec Approx. 1 Sec

Power Lamp Flashing Pattern Recovery Conditions

Approx. 1 Sec Approx. 1 Sec

Automatic recovery after head

temperature lowers

upper: Star mode

lower: ESC/POS mode

Insert paper and press on-line

2

switch.

Insert paper and close cover.

Head up

Paper near end of

roll

Cover is open

Error during paper

cutting

Approx. 2 Sec Approx. 2 Sec

Approx.

Approx.

500 ms

500 ms

Approx. 125 msApprox. 125 ms

Approx. 250 msApprox. 250 ms

– 19 –

Lower head and press on-line

3

switch.

Lower head and close cover.

Press on-line switch and printing

4

will continue. Both lamps light

when printing and power lamp

flashes and on-line lamp lights

when on line.

Same as no paper

Close cover and press on-line

5

switch.

Close cover.

If the blade is at the home position,

6

press the on-line switch for printing

to continue. If the blade is not at the

home position, it is not a recoverable error.

Command

Page 24

7-3. Fatal Error (Power Lamp: Flashing; On-Line Lamp:

Flashing)

The unit will have to be repaired.

7-4. Type of buzzer sound (only Star mode) P: 50ms Pi: 100ms

1 Online, Offline P

2 No Paper PPPP PPPP

3 Head Up PiPiPi

4 Near End PP PP

5 Cover Open PPPP

6 Cutter Error Pi PPP PPiPiP PPPPPi PiPiPiPiPi PiPiPiPiPi

7 Buzzer by command Pi

– 20 –

Page 25

8. CONTROL CODES/STAR MODE

8-1. Star Mode Command Summary

The details of each command are shown in the following sections.

Commands to Select Characters

Control codes

<ESC> “R” n 1B 52 n Select international character set 25

<ESC> “/” “1” 1B 2F 31

<ESC> “/” <1> 1B 2F 01

<ESC> “/” “0” 1B 2F 30

<ESC> “/” <0> 1B 2F 00

<ESC> “b” n1 n2 n3 n4 1B 62 n1 n2 n3 n4

d1 ... <RS> d1 ... 1E

<ESC> “M” 1B 4D Select 12-dot pitch printing 30

<ESC> “p” 1B 70 Select 14-dot pitch printing 30

<ESC> “P” 1B 50 Select 15-dot pitch printing 30

<ESC> “:” 1B 3A Select 16-dot pitch printing 30

<ESC> <SP> n 1B 20 n Set character spacing 30

<SO> 0E Sets the printing magnified double in

<DC4> 14 Resets the printing magnified in

<ESC> “W” n 1B 57 n

<ESC> <SO> 1B 0E Sets the printing magnified double in

<ESC> <DC4> 1B 14 Resets the printing magnified in character

<ESC> “h” n 1B 68 n

<ESC> “i” n1 n2 1B 69 n1 n2 Sets the magnification rates in character

<ESC> “–” “1” 1B 2D 31

<ESC> “–” <1> 1B 2D 01

<ESC>“–” “0” 1B 2D 30

<ESC> “–” <0> 1B 2D 00

<ESC> “_” “1” 1B 5F 31

<ESC> “_” <1> 1B 5F 01

<ESC> “_” “0” 1B 5F 30

<ESC> “_” <0> 1B 5F 00

Hexadecimal

codes

Function Page

Select slash zero 25

Select normal zero 25

Select bar code printing 26

character width.

character width.

Sets the magnification rate in character width.

character height.

height.

Sets the magnification rate in character height

width and height.

Select underlining 32

Cancel underlining 32

Select upperlining 33

Cancel upperlining 33

.32

STAR MODE

31

31

31

31

31

32

– 21 –

Page 26

Control codes

<ESC> “4” 1B 34 Select highlight printing 33

<ESC> “5” 1B 35 Cancel highlight printing 33

<SI> 0F Inverted printing 33

<DC2> 12 Cancel inverted printing 33

<ESC> “E” 1B 45

<ESC> “G” 1B 47

<ESC> “F” 1B 46

<ESC> “H” 1B 48

STAR MODE

Commands to Set the Page Format

Hexadecimal

codes

Function Page

Select emphasized printing 34

Cancel emphasized printing 34

Control codes

<ESC> “C” n 1B 43 n Set page length in lines 35

<ESC> “C” <0> n 1B 43 00 n Set page length in inches 35

<ESC> “N” n 1B 4E n Set bottom margin 35

<ESC> “O” 1B 4F Cancel bottom margin 35

<ESC> “l” n 1B 6C n Set left margin 36

<ESC> “Q” n 1B 51 n Set right margin 36

Hexadecimal

codes

Function Page

Commands to Move the Print Position

Control codes

<LF> 0A Line feed 37

<CR> 0D Carriage Return 37

<ESC> “a” n 1B 61 n Feed paper n lines 37

<FF> 0C Form feed 37

<HT> 09 Horizontal tab 37

<VT> 0B Vertical tab 38

<ESC> “z” “1” 1B 7A 31

<ESC> “z” <1> 1B 7A 01

<ESC> “0” 1B 30 Set line spacing to 3 mm 38

<ESC> “J” n 1B 4A n One time n/4 mm feed 38

<ESC> “j” n 1B 6A n One time n/4 mm backfeed 39

<ESC>“I” n 1B 49 n One time n/8 mm feed 39

<ESC> “B” n1 n2 ... <0> 1B 42 n1 n2 ... 00 Set vertical tab stops 39

<ESC> “D” n1 n2 ... <0> 1B 44 n1 n2 ... 00 Set horizontal tab stops 40

Hexadecimal

codes

Function Page

Set line spacing to 4 mm 38

– 22 –

Page 27

Commands to Print Dot Graphics

Control codes

<ESC> “K” n <0> 1B 4B n 00 m1 m2

m1 m2 ... ...

<ESC> “L” n1 n2 1B 4C n1 n2 m1 m2

m1 m2 ... ...

<ESC> “k” n <0> d1 ... 1B 6B n 00 d1 ... Print fine density graphics 44

<ESC> “X” n1 n2 m1 ... 1B 58 n1 n2 d1 ... Print fine density graphics 47

Hexadecimal

codes

Function Page

Print normal density graphics 41

Print high density graphics 43

Commands to Print Download Characters

Control codes

<ESC> “&” <1> <1> 1B 26 01 01 n

n m1 m2 ... m48 m1 m2 ... m48

<ESC> “&” “1” “1” 1B 26 31 31 n

n m1 m2 ... m48 m1 m2 ... m48

<ESC> “&” <1> <0> n 1B 26 01 00 n

<ESC> “&” “1” “0” n 1B 26 31 30 n

<ESC> “%” “1” 1B 25 31

<ESC> “%” <1> 1B 25 01

<ESC> “%” “0” 1B 25 30

<ESC> “%” <0> 1B 25 00

Hexadecimal

codes

Function Page

Define download character 48

Delete a download character 49

Enable download character set 49

Disable download character set 50

STAR MODE

Commands to Control Peripheral Devices

Control codes

<ESC> <BEL> n1 n2 1B 07 n1 n2 Define drive pulse width for peripheral

<BEL> 07 Control peripheral device #1 51

<FS> 1C Control peripheral device #1 immediately 51

<EM> 19 Control peripheral device #2 immediately 51

<SUB> 1A Control peripheral device #2 immediately 51

Hexadecimal

codes

Function Page

device #1

Commands to Control Auto Cutter

Control codes

<ESC> “d” “0” 1B 64 30

<ESC> “d” <0> 1B 64 00

<ESC> “d” “1” 1B 64 31

<ESC> “d” <1> 1B 64 01

Hexadecimal

codes

Function Page

Full-cut command to the auto cutter 52

Partial-cut command to the auto cutter 52

– 23 –

51

Page 28

Other Commands

Control codes

<CAN> 18 Cancel last line & Initialize printer 53

<DC3> 13 Deselect printer 53

<DC1> 11 Set select mode 53

<RS> 1E Beep the buzzer 53

<ESC> “#N, n1 n2 n3 n4”

<LF> <NUL> 0A 00

<ESC> “@” 1B 40 Initialize printer 55

STAR MODE

<ENQ> 05 Enquiry 55

<ESC> “?” <LF> <NUL> 1B 3F 0A 00 Reset printer hardware 56

Hexadecimal

codes

1B 23 N 2C n1 n2 n3 n4

Function Page

Set memory switch 54

– 24 –

Page 29

8-2. Command Specification

Commands to Select Characters

FUNCTION

CODE <ESC> “R” n

HEX

REMARKS

Select international character set

1B 52 n

Selects an international character set according to the value of n,

as shown below:

n Character set n Character set

0 U.S.A. 7 Spain I

1 France 8 Japan

2 Germany 9 Norway

3 England 10 Denmark II

4 Denmark I 11 Spain II

5 Sweden 12 Latin America

6 Italy

When the value of n is 0 to 9, 0(00H) to 9(09H) or “0”(30H) to

“9”(39H) can be set. When the value of n is 10 to 12, 10(0AH) to

12(0CH) or “A”(41H) to “C”(43H) can be set.

FUNCTION

CODE <ESC> “/” n

HEX

REMARKS

Select zero style

1B 2F n

Causes subsequent zero characters to be printed with a slash when

n is 1, and without a slash when n is 0.

The value of n can be set to 0(00H) or “0”(30H), or 1(01H) or

“1”(31H).

STAR MODE

– 25 –

Page 30

FUNCTION

CODE

HEX

REMARKS

STAR MODE

Select bar code printing

<ESC> “b” n1 n2 n3 n4 di ... dk <RS>

1B 62 n1 n2 n3 n4 di ... dk 1E

Prints bar code according to the value of n1, as shown below:

n1: Type of bar code

0 UPC-E

1 UPC-A

2 JAN/EAN-8

3 JAN/EAN-13

4 CODE 39

5 ITF

6 CODE 128

7 CODE 93

8 NW-7

The value of n1 can be set to 0(00H) or 8(08H) or “0”(30H) to

“8”(38H).

n2: Printing character below bar code or line feed

1 Character below bar code is not printed, Line feed is

performed after execution of command.

2 Character below bar code is printed, Line feed is

performed after execution of command.

3 Character below bar code is not printed, Line feed is

not performed after execution of command.

4 Character below bar code is printed, Line feed is not

performed after execution of command.

The value of n2 can be set to 1(01H) to 4(04H) or “1”(31H) to

“4”(34H).

n3: Mode of bar code

UPC-E, UPC-A, JAN/EAN-8, JAN/EAN-13, CODE 128,

CODE 93

1 Minimum module 2 dots

2 Minimum module 3 dots

3 Minimum module 4 dots

– 26 –

Page 31

CODE 39, NW-7, ITF

CODE 39, NW-7 ITF

1 Narrow : wide 2:6 dots 2:5 dots

2 Narrow : wide 3:9 dots 4:10 dots

3 Narrow : wide 4:12 dots 6:15 dots

4 Narrow : wide 2:5 dots 2:4 dots

5 Narrow : wide 3:8 dots 4:8 dots

6 Narrow : wide 4:10 dots 6:12 dots

7 Narrow : wide 2:4 dots 2:6 dots

8 Narrow : wide 3:6 dots 3:9 dots

9 Narrow : wide 4:8 dots 4:12 dots

When the value of n3 is UPC-E, UPC-A, JAN/EAN-8, JAN/EAN13, CODE128 or CODE93, 1(01H) to 3(03H) or “1”(31H) to

“3”(33H) can be set. When the value of n3 is CODE39, NW-7 or

ITF, 1(01H) to 9(09H) or “1”(31H) to “9”(39H) can be set.

n4: Height of bar code

Can be up to 255 dots (31.9mm).

If the bar code height is larger than the line feed amount, the

line feed amount is automatically multiplied by an integer.

di...dk: Bar code data

STAR MODE

UPC-E/UPC-A: K = 11 (or 12)

The check digit at the 12th digit is automatically added,

and ignored even if it is specified.

JAN/EAN-8: K = 7 (or 8)

The check digit at the 8th digit is automatically added,

and ignored even if it is specified.

JAN/EAN-13: K = 12 (or 13)

The check digit at the 13th digit is automatically added,

and ignored even if it is specified.

CODE39: The value of k is optional, and the maximum

value also differs according to the modes (21

digits maximum in mode 7).

The start/stop code (“

– 27 –

”) is automatically added.

*

Page 32

STAR MODE

ITF: The value of k is optional, and the maximum

value also differs according to the modes (40

digits maximum in mode 4).

If the data is number of an odd digits, 0 is

automatically added at the beginning of the data.

CODE 128: The value of k is optional, and the maximum

value also differs according to the modes and the

types of character number (51 digits maximum in

mode 1).

The check character is automatically added.

CODE93: The value of k is optional, and the maximum value

also differs according to the modes and the types

of character (30 digits maximum in mode 1).

The check characters (C and K) are automatically

added.

NW-7: The value of k is optional, and the maximum

value also differs according to the modes and the

types of character number (29 digits maximum in

mode 7).

The start/stop code is also contained in the data (it

is not automatically added).

The bar code printing start position is at the upper end of the

current line.

If the bar code is positioned beyond the right margin, neither

the bar code nor the character below the bar code will be

printed.

Data of CODE 128 and CODE 93

When <LF> is used in a command, some kinds of control code

cannot be sent by the host PC. The control code should be sent

as the data as shown below:

• When sending the following data, express as a set of two

characters.

Express “% (25H)” as “%0 (25H30H)”.

Add “40H - 5FH” after “%” for the control codes (00H - 1FH).

Express the control code (7FH) as “%5(25H35H)”.

Add “1 - 4 (31H - 34H)” after “%” for the function code.

Add “6 - 8 (36H - 38H)” after “%” for the start code.

– 28 –

Page 33

3) 2-character codes

Control codes

CODE FORMAT

NUL 00H %@ 25H 40H

SOH 01H %A 25H 41H

STX 02H %B 25H 42H

ETX 03H %C 25H 43H

EOT 04H %D 25H 44H

ENQ 05H %E 25H 45H

ACK 06H %F 25H 46H

BEL 07H %G 25H 47H

BS 08H %H 25H 48H

HT 09H %I 25H 49H

LF 0AH %J 25H 4AH

VT 0BH %K 25H 4BH

FF 0CH %L 25H 4CH

CR 0DH %M 25H 4DH

SO 0EH %N 25H 4EH

SI 0FH %O 25H 4FH

DLE 10H %P 25H 50H

DC1 11H %Q 25H 51H

DC2 12H %R 25H 52H

DC3 13H %S 25H 53H

DC4 14H %T 25H 54H

NAK 15H %U 25H 55H

SYN 16H %V 25H 56H

ETB 17H %W 25H 57H

CAN 18H %X 25H 58H

EM 19H %Y 25H 59H

SUB 1AH %Z 25H 5AH

ESC 1BH %[ 25H 5BH

FC 1CH %¥ 25H 5CH

GS 1DH %] 25H 5DH

RS 1EH %^ 25H 5EH

US 1FH %_ 25H 5FH

DEL 7FH %5 25H 35H

Special code

CODE FORMAT

% 25H %0 25H 30H

Function codes

CODE FORMAT

FNC1 %1 25H 31H

FNC2 %2 25H 32H

FNC3 %3 25H 33H

FNC4 %4 25H 34H

Start codes

CODE FORMAT

START A %6 25H 36H

START B %7 25H 37H

START C %8 25H 38H

✩ For CODE 128 only.

✩

✩

✩

✩

STAR MODE

✩

✩

✩

– 29 –

Page 34

FUNCTION

CODE

HEX

REMARKS

Select 12-dot pitch printing

<ESC> “M”

1B 4D

Prints 12-dot pitch characters without an extra space.

FUNCTION

CODE

HEX

STAR MODE

REMARKS

FUNCTION

CODE

HEX

REMARKS

FUNCTION

CODE

HEX

REMARKS

FUNCTION

CODE

Select 14-dot pitch printing

<ESC> “p”

1B 70

Prints 12-dot pitch characters with 2-dot spacing between characters.

Select 15-dot pitch printing

<ESC> “P”

1B 50

Prints 12-dot pitch characters with 3-dot spacing between characters.

Select 16-dot pitch printing

<ESC> “:”

1B 3A

Prints 12-dot pitch characters with 4-dot spacing between characters.

Set the character spacing

<ESC> <SP> n

HEX

REMARKS

1B 20 n

Sets the space between characters to n dots, where n is a number

from 0 to 15.

When the value of n is 0 to 9, 0(00H) to 9(09H) or “0”(30H) to

“9”(39H) can be set. When the value of n is 10 to 15, 10(0AH) to

15(0FH) or “A”(41H) to “F”(46H) can be set.

– 30 –

Page 35

FUNCTION

CODE

HEX

REMARKS

Sets the printing magnified double in character width.

<SO>

0E

Prints the subsequent data including a character spacing set by

<ESC><SP> n, magnified double in character width.

FUNCTION

CODE

HEX

REMARKS

FUNCTION

CODE

HEX

REMARKS

FUNCTION

CODE

HEX

REMARKS

Resets the printing magnified in character width.

<DC4>

14

Resets the printing magnified in character width set by <SO>,

<ESC>“W”n and <ESC>“i”n1n2.

Sets the magnification rate in character width.

<ESC> “W” n

1B 57 n

Prints the subsequent data including a character spacing set by

<ESC><SP> n, magnified in character width by a rate specified by

the value of n.

n Character width n Character width

0 Unmagnify 3 Quadruple

1 Double 4 Quintuple

2 Triple 5 Sextuple

The value of n can be set to 0(00H) to 5(05H) or “0”(30H) to

“5”(35H).

Sets the printing magnified double in character height.

<ESC><SO>

1B 0E

Prints the subsequent data magnified double in character height.

STAR MODE

FUNCTION

CODE

HEX

REMARKS

Resets the printing magnified in character height.

<ESC><DC4>

1B 14

Resets the printing magnified in character height set by

<ESC><SO>, <ESC>“h”n and <ESC>“i”n1n2.

– 31 –

Page 36

FUNCTION

CODE

HEX

REMARKS

STAR MODE

Sets the magnification rate in character height.

<ESC> “h” n

1B 68 n

Prints the subsequent data magnified in character height by a rate

specified by the value of n.

n Character height n Character height

0 Unmagnify 3 Quadruple

1 Double 4 Quintuple

2 Triple 5 Sextuple

The value of n can be set to 0(00H) to 5(05H) or “0”(30H) to

“5”(35H).

FUNCTION

CODE

HEX

REMARKS

FUNCTION

CODE

HEX

REMARKS

Sets the magnification rates in character width and height.

<ESC> “i” n1 n2

1B 69 n1 n2

Prints the subsequent data in the size specified by n1, n2.

n1 indicates the height magnification and n2 indicates the width

magnification.

n1 (n2) = 0 Normal height (or width) size.

1 Double height (or width) size.

2 Triple height (or width) size.

3 Quadruple height (or width) size.

4 Quintuple height (or width) size.

5 Sextuple height (or width) size.

The values of n1, n2 are 0(00H) to 5(05H) or “0”(30H)” to

“5”(35H).

Underlining

<ESC> “–” n

1B 2D n

When the value of n is 1, underlines the subsequent data including

a character spacing set by <ESC><SP> n.

The part to be skipped by the horizontal tab setting and the block

graphic characters are not underlined.

Resets the underline mode when the value of n is 0.

The value of n can be set to 0(00H) or “0”(30H), or 1(01H) or

“1”(31H).

– 32 –

Page 37

FUNCTION

CODE

HEX

REMARKS

Upperlining

<ESC> “_” n

1B 5F n

When the value of n is 1, overlines the subsequent data including

a character spacing set by <ESC><SP> n.

The part to be skipped by the horizontal tab setting and the block

graphic characters are not upperlined.

Resets the upperline mode when the value of n is 0.

The value of n can be set to 0(00H) or “0”(30H), or 1(01H) or

“1”(31H).

FUNCTION

CODE

HEX

REMARKS

FUNCTION

CODE

HEX

REMARKS

FUNCTION

CODE

HEX

REMARKS

FUNCTION

CODE

HEX

REMARKS

Select highlight printing

<ESC> “4”

1B 34

Prints the subsequent data including a character spacing set by

<ESC><SP> n reversed.

The part to be skipped by the horizontal tab setting is not reversed.

Cancel highlight printing

<ESC> “5”

1B 35

Cancels highlight printing.

Inverted printing

<SI>

0F

Causes subsequent characters to be inverted.

Cancel inverted printing

<DC2>

12

Cancels inverted printing.

STAR MODE

– 33 –

Page 38

FUNCTION

CODE

HEX

CODE

HEX

REMARKS

Select emphasized printing

<ESC> “E”

1B 45

<ESC> “G”

1B 47

Causes subsequent characters to be emphasized.

FUNCTION

STAR MODE

CODE

HEX

CODE

HEX

REMARKS

Cancel emphasized printing

<ESC> “F”

1B 46

<ESC> “H”

1B 48

Cancels emphasized printing.

– 34 –

Page 39

Commands to Set the Page Format

FUNCTION

CODE <ESC> “C” n

HEX

REMARKS

Set page length in lines

1B 43 n

Sets the page length using the current line spacing, where n is

between 1 and 127.

Changing the line spacing later does not alter the physical page

length.

The current line becomes the top of the page.

Resets the bottom margin.

Default page length is 42 lines.

FUNCTION

CODE <ESC> “C” <0> n

HEX

REMARKS

Set page length in inches

1B 43 00 n

Sets the page length to n × 24 mm, where n is between 1 and 22.

The current line becomes the top of the page.

Resets the bottom margin.

FUNCTION

CODE <ESC> “N” n

HEX

REMARKS

Set bottom margin

1B 4E n

Sets the bottom margin to n lines at the current line spacing, where

n is between 0 and 127.

Bottom margin is reset when you change the page length.

Setting is invalid if the printing area on one page is 36 mm or less.

STAR MODE

FUNCTION

CODE <ESC> “O”

HEX

REMARKS

Cancel bottom margin

1B 4F

Cancels the bottom margin.

– 35 –

Page 40

FUNCTION

CODE

HEX

REMARKS

Set left margin

<ESC> “l” n

1B 6C n

Sets the left margin at column n (where n is between 0 and 255) at

the current character pitch.

The left margin does not move if the character pitch is changed

later.

Setting is invalid if the printing area for one line would be 36mm

or less.

STAR MODE

FUNCTION

CODE

HEX

REMARKS

Set right margin

<ESC> “Q” n

1B 51 n

Sets the right margin at column n (where n is between 1 and 255)

at the current character pitch.

The right margin does not move if the character pitch is changed

later.

Setting is invalid if column n is beyond the right edge of the

printing area.

Setting is invalid if the printing area for one line would be 36mm

or less.

– 36 –

Page 41

Commands to Move the Print Position

FUNCTION

CODE <LF>

HEX

REMARKS

FUNCTION

CODE <CR>

HEX

REMARKS

Line feed

0A

Prints the current line and feeds the paper to the next line.

Carriage return

0D

Prints the current line and feeds the paper to the next line.

This command is ignored when CR code is invalid.

FUNCTION

CODE <ESC> “a” n

HEX

REMARKS

Feed paper n lines

1B 61 n

Prints the current line and feeds the paper n lines (where n is

between 1 and 127).

FUNCTION

CODE <FF>

HEX

REMARKS

Form feed

0C

Feeds the paper to the top of the next page, according to the page

length set by <ESC>“C”n or <ESC>“C”<0>n when memory switch

1-2 is set to 0. If memory switch 1-2 is set to 1, the paper is fed 18 mm,

cut fully, and then feed back 18 mm. The print position is at the left

margin in both cases.

STAR MODE

FUNCTION

CODE <HT>

HEX

REMARKS

Horizontal tab

09

Moves the print position to the next horizontal tab stop. Ignored if

there is no next horizontal tab stop on the current line.

– 37 –

Page 42

FUNCTION

CODE

HEX

REMARKS

Vertical tab

<VT>

0B

Prints the current line and feeds the paper to the next vertical tab

stop and moves the print position to the left margin.

Performs paper feed if no vertical tabs are set or if the current line

is at or below the last vertical tab stop.

FUNCTION

STAR MODE

CODE

HEX

REMARKS

FUNCTION

CODE

HEX

REMARKS

FUNCTION

CODE

HEX

REMARKS

Set line spacing to 4 mm

<ESC> “z” “1” or <ESC> “z” <1>

1B 7A 31 or 1B 7A 01

Sets the distance the paper advances in subsequent line feeds to

4 mm.

Set line spacing to 3 mm

<ESC> “0”

1B 30

Sets the distance the paper advances in subsequent line feeds to

3 mm.

One time n/4 mm feed

<ESC> “J” n

1B 4A n

Performs a line feed of n/4mm once only.

The value of n is 1 to 255.

Space setting for lines is not changed.

– 38 –

Page 43

FUNCTION

CODE

HEX

REMARKS

One time n/4 mm backfeed

<ESC> “j” n

1B 6A n

Feeds the paper back n/4mm once only.

The value of n is 1 to 255.

Space setting for one line is not changed.

This command can also feed the paper back to the page before the

current page. In this case, the position of the line on the previous

page is determined by the page length control.

FUNCTION

CODE

HEX

REMARKS

FUNCTION

CODE

HEX

REMARKS

One time n/8 mm feed

<ESC> “I” n

1B 49 n

Performs a line feed n/8mm once only.

The value of n is 1 to 255.

Space setting for lines is not changed.

Set vertical tab stops

<ESC> “B” n1 n2 ... <0>

1B 42 n1 n2 ... 00

Cancels all current vertical tab stops and sets new vertical tab stops

at lines n1, n2, etc., where n1, n2, etc. are numbers between 0 and

255. A maximum of 16 vertical tab stops can be set.

The tab stops must be specified in ascending order; any violation

of ascending order terminates the tab stop list. Standard termination is by the <0> control code.

The vertical tab stops are set in terms of the current line spacing and

do not move if the line spacing is changed later.

STAR MODE

– 39 –

Page 44

FUNCTION

CODE

HEX

REMARKS

STAR MODE

Set horizontal tab stops

<ESC> “D” n1 n2 ... <0>

1B 44 n1 n2 ... 00

Cancels all current horizontal tab stops and sets new tab stops at

columns n1, n2, etc. at the current character pitch, where n1, n2,

etc. are numbers between 1 and 255. A maximum of 16 horizontal

tab stops can be set.

The tab stops must be specified in ascending order; any violation

of ascending order terminates the tab stop list. Standard termination is by the <0> control code.

– 40 –

Page 45

Commands to Print Dot Graphics

FUNCTION

Print normal density graphics

CODE <ESC> “K” n <0> m1 m2 ...

HEX

REMARKS

1B 4B n 00 m1 m2 ...

Prints normal density dot graphics. The graphics image is 24 dots

high and n × 3 dots wide. Maximum width is 576 dots.

m1, m2, ... are the dot data, each a 1-byte value from 0 to 255

representing 24 vertical dots, with the most significant bit representing the top three and the least significant bit representing the

bottom three.

The number of data bytes must be n.

Dots beyond the right margin are ignored.

Relationship between image data and print dots

DOT Position

1

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

23

MSB

D8

D7 D6 D5 D4 D3 D2 D1

Image data LSB

STAR MODE

– 41 –

Page 46

EXAMPLE

We will create the design below using a bit image.

m1 m2 m3 m4 m5 m6 m7 m8 m9 m10 m11 m12 m13 m14 m15 m16 m17 m18 m19 m20 m21 m22 m23 m24 m25 m26 m27 m28 m29 m30

D8

D7

D6

D5

D4

D3

D2

D1

STAR MODE

Printing Sample

First, since the volume of data is 30, n1 = (1E)

H. If the data m1 ~

m30 is converted to hexadecimal, it appears as shown below.

Data Binary

Hexa-

decimal

m1 00000001 01

m2 00011110 1E

m3 00111110 3E

m4 01011111 5F

m5 00011111 1F

m6 01011110 5E

m7 00011110 1E

m8 00111111 3F

m9 00101111 2F

m10 00111110 3E

Data Binary

m11 00111110 3E

m12 00000010 02

m13 00000010 02

m14 00111110 3E

m15 00111110 3E

m16 00101111 2F

m17 00101111 2F

m18 00111110 3E

m19 00101110 2E

m20 00101110 2E

Hexa-

Data Binary

decimal

m21 00111110 3E

m22 00101110 2E

m23 00101110 2E

m24 00111110 3E

m25 00101111 2F

m26 00101111 2F

m27 00111110 3E

m28 00111110 3E

m29 00000010 02

m30 00000010 02

decimal

Hexa-

– 42 –

Page 47

FUNCTION

CODE

HEX

REMARKS

Print high density graphics

<ESC> “L” n1 n2 m1 m2 ...

1B 4C n1 n2 m1 m2 ...

Prints high density dot graphics. The graphics image is 24 dots

high and n1 + n2 × 256 dots wide. Maximum width is 576 dots.

m1, m2, ... are the dot data, each a 1-byte value from 0 to 255

representing 24 vertical dots, with the most significant bit representing the top three and the least significant bit representing the

bottom three.

The number of data bytes must be n1 + n2 × 256.

Dots beyond the right margin are ignored.

Relationship between image data and print dots

DOT Position

1

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

MSB

D8

D7 D6 D5 D4 D3 D2 D1

Image data LSB

STAR MODE

– 43 –

Page 48

EXAMPLE

STAR MODE

We will create the design below using a bit image.

m1 m2 m3 m4 m5 m6 m7 m8 m9 m10 m11 m12 m13 m14 m15 m16 m17 m18 m19 m20 m21 m22 m23 m24 m25 m26 m27 m28 m29 m30

D8

D7

D6

D5

D4

D3

D2

D1

First, since the volume of data is 30, n1 = (1E)

H. If the data m1 ~

m30 is converted to hexadecimal, it appears as shown below.

Data Binary

Hexa-

decimal

m1 00000001 01

m2 00011110 1E

m3 00111110 3E

m4 01011111 5F

m5 00011111 1F

m6 01011110 5E

m7 00011110 1E

m8 00111111 3F

m9 00101111 2F

m10 00111110 3E

Data Binary

m11 00111110 3E

m12 00000010 02

m13 00000010 02

m14 00111110 3E

m15 00111110 3E

m16 00101111 2F

m17 00101111 2F

m18 00111110 3E

m19 00101110 2E

m20 00101110 2E

Hexa-

Data Binary

decimal

m21 00111110 3E

m22 00101110 2E

m23 00101110 2E

m24 00111110 3E

m25 00101111 2F

m26 00101111 2F

m27 00111110 3E

m28 00111110 3E

m29 00000010 02

m30 00000010 02

decimal

Hexa-

Printing Sample

FUNCTION

CODE

HEX

REMARKS

Horizontal density is three times that of the bit image for <ESC>“k”.

(Compare the print samples.)

Print fine density bit image

<ESC> “k” n <0> d1...dk [k = n * 24]

1B 6B n 00 d1...dk [k = n * 24]

Prints a bit image using 1 horizontal dot and 1 vertical dot for 1 dot

of input data.

n is designated by the number of data bytes in the horizontal

direction and n must be within the range 1 to 72.

The data is ignored if it is longer than 72 digits or goes beyond the

right margin. Relationship between the input data and actual

printing is shown below.

– 44 –

Page 49

Relationship between image data and print dots

Dot position

b7 b6 b5 b4 b3 b2 b1 b0

d1

dn+1

b7 b6 b5 b4 b3 b2 b1 b0

d2n+1

b7 b6 b5 b4 b3 b2 b1 b0

d3n+1

b7 b6 b5 b4 b3 b2 b1 b0

d4n+1

b7 b6 b5 b4 b3 b2 b1 b0

d5n+1

b7 b6 b5 b4 b3 b2 b1 b0

d6n+1

b7 b6 b5 b4 b3 b2 b1 b0

d7n+1

b7 b6 b5 b4 b3 b2 b1 b0

d8n+1

b7 b6 b5 b4 b3 b2 b1 b0

d9n+1

b7 b6 b5 b4 b3 b2 b1 b0

d10n+1

b7 b6 b5 b4 b3 b2 b1 b0

d11n+1

b7 b6 b5 b4 b3 b2 b1 b0

d12n+1

b7 b6 b5 b4 b3 b2 b1 b0

d13n+1

b7 b6 b5 b4 b3 b2 b1 b0

d14n+1

b7 b6 b5 b4 b3 b2 b1 b0

d15n+1

b7 b6 b5 b4 b3 b2 b1 b0

d16n+1

b7 b6 b5 b4 b3 b2 b1 b0

d17n+1

b7 b6 b5 b4 b3 b2 b1 b0

d18n+1

b7 b6 b5 b4 b3 b2 b1 b0

d19n+1

b7 b6 b5 b4 b3 b2 b1 b0

d20n+1

b7 b6 b5 b4 b3 b2 b1 b0

d21n+1

b7 b6 b5 b4 b3 b2 b1 b0

d22n+1

b7 b6 b5 b4 b3 b2 b1 b0

d23n+1

b7 b6 b5 b4 b3 b2 b1 b0

b7 b6 b5 b4 b3 b2 b1 b0

b7 b6 b5 b4 b3 b2 b1 b0

b7 b6 b5 b4 b3 b2 b1 b0

b7 b6 b5 b4 b3 b2 b1 b0

b7 b6 b5 b4 b3 b2 b1 b0

b7 b6 b5 b4 b3 b2 b1 b0

b7 b6 b5 b4 b3 b2 b1 b0

b7 b6 b5 b4 b3 b2 b1 b0

b7 b6 b5 b4 b3 b2 b1 b0

b7 b6 b5 b4 b3 b2 b1 b0

b7 b6 b5 b4 b3 b2 b1 b0

b7 b6 b5 b4 b3 b2 b1 b0

b7 b6 b5 b4 b3 b2 b1 b0

b7 b6 b5 b4 b3 b2 b1 b0

b7 b6 b5 b4 b3 b2 b1 b0

b7 b6 b5 b4 b3 b2 b1 b0

b7 b6 b5 b4 b3 b2 b1 b0

b7 b6 b5 b4 b3 b2 b1 b0

b7 b6 b5 b4 b3 b2 b1 b0

b7 b6 b5 b4 b3 b2 b1 b0

b7 b6 b5 b4 b3 b2 b1 b0

b7 b6 b5 b4 b3 b2 b1 b0

b7 b6 b5 b4 b3 b2 b1 b0

b7 b6 b5 b4 b3 b2 b1 b0

d2

dn+2

d2n+2

d3n+2

d4n+2

d5n+2

d6n+2

d7n+2

d8n+2

d9n+2

d10n+2

d11n+2

d12n+2

d13n+2

d14n+2

d15n+2

d16n+2

d17n+2

d18n+2

d19n+2

d20n+2

d21n+2

d22n+2

d23n+2

Image data

b7 b6 b5 b4 b3 b2 b1 b0

•••

•••

•••

•••

•••

•••

•••

•••

•••

•••

•••

•••

•••

•••

•••

•••

•••

•••

•••

•••

•••

•••

•••

•••

b7 b6 b5 b4 b3 b2 b1 b0

b7 b6 b5 b4 b3 b2 b1 b0

b7 b6 b5 b4 b3 b2 b1 b0

b7 b6 b5 b4 b3 b2 b1 b0

b7 b6 b5 b4 b3 b2 b1 b0

b7 b6 b5 b4 b3 b2 b1 b0

b7 b6 b5 b4 b3 b2 b1 b0

b7 b6 b5 b4 b3 b2 b1 b0

b7 b6 b5 b4 b3 b2 b1 b0

b7 b6 b5 b4 b3 b2 b1 b0

b7 b6 b5 b4 b3 b2 b1 b0

b7 b6 b5 b4 b3 b2 b1 b0

b7 b6 b5 b4 b3 b2 b1 b0

b7 b6 b5 b4 b3 b2 b1 b0

b7 b6 b5 b4 b3 b2 b1 b0

b7 b6 b5 b4 b3 b2 b1 b0

b7 b6 b5 b4 b3 b2 b1 b0

b7 b6 b5 b4 b3 b2 b1 b0

b7 b6 b5 b4 b3 b2 b1 b0

b7 b6 b5 b4 b3 b2 b1 b0

b7 b6 b5 b4 b3 b2 b1 b0

b7 b6 b5 b4 b3 b2 b1 b0

b7 b6 b5 b4 b3 b2 b1 b0

b7 b6 b5 b4 b3 b2 b1 b0

dn

d2n

d3n

d4n

d5n

d6n

d7n

d8n

d9n

d10n

d11n

d12n

d13n

d14n

d15n

d16n

d17n

d18n

d19n

d20n

d21n

d22n

d23n

d24n

STAR MODE

– 45 –

Page 50

EXAMPLE

MSB LSB MSB LSB

d1

d3

d5

d7

d9

d11

d13

d15

d17

d19

d21

d23

STAR MODE

d25

d27

d29

d31

d33

d35

d37

d39

d41

d43

d45

d47

Printing Sample

d2

d4

d6

d8

d10

d12

d14

d16

d18

d20

d22

d24

d26

d28

d30

d32

d34

d36

d38

d40

d42

d44

d46

d48

BinaryData

Hexa-

decimal

d1 00000000 00

d3 00011111 1F

d5 00111111 3F

d7 01110111 77

d9 11111000 F8

d11 11111000 F8

d13 11111000 F8

d15 00001111 0F

d17 00011111 1F

d19 00011111 1F

d21 00111110 3E

d23 00111000 38

d25 011111001 79

d27 01110011 73

d29 01110011 73

d31 11111001 F9

d33 11111000 F8

d35 11111110 FE

d37 11111111 FF

d39 11111111 FF

d41 00000000 00

d43 00000000 00

d45 00000000 00

d47 00000000 00

BinaryData

Hexa-

decimal

d2 00000000 00

d4 11111000 F8

d6 11111100 FC

d8 01110111 EE

d10 00011111 1F

d12 00011111 1F

d14 00011111 1F

d16 11110000 F0

d18 11111000 F8

d20 11111000 F8

d22 01111100 7C

d24 00011100 1C

d26 10011110 9E

d28 11001110 CE

d30 11001110 CE

d32 10011111 9F

d34 00011111 1F

d36 01111111 7F

d38 11111111 FF

d40 11111111 FF

d42 00000000 00

d44 00000000 00

d46 00000000 00

d48 00000000 00

– 46 –

Page 51

FUNCTION

CODE

HEX

REMARKS

Print fine density graphics

<ESC> “X” n1 n2 d1...d [(n1+n2*256)*3]

1B 5 n1 n2 d1...d [(n1+n2*256)*3]

Prints a bit image of the input data using horizontal and vertical

resolutions of 8 dots/mm.

Data extending past the right margin is ignored.

The relationship between the input data and the actual printing is

shown below.

n1 + n2 × 256 576

1

Dot

Position

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

MSB

b7 b6 b5 b4 b3 b2 b1 b0

d1•••

LSB

MSB LSB

b7 b6 b5 b4 b3 b2 b1 b0

d2•••

MSB LSB

b7 b6 b5 b4 b3 b2 b1 b0

d3•••

STAR MODE

– 47 –

Page 52

Commands to Print Download Characters

FUNCTION

CODE <ESC> “&” <1> <1> nm1m2... m48

HEX

CODE <ESC> “&” “1” “1” nm1m2... m48

HEX

REMARKS

STAR MODE

EXAMPLE

Define download character

1B 26 01 01 nm1m2... m48

1B 26 31 31 nm1m2... m48

Defines one new character and stores it in RAM for later use.

n is the character code of the character defined and must be

between 32 and 127.

If the maximum of 32 external characters have already been stored,

the oldest stored external character are deleted so that new external

character can be stored.

The character matrix is 12 dots wide and 24 dots high.

Relationship between the character pattern and the character data

is shown below.

MSB LSB MSB LSB

m1

m3

m5

m7

m9

m11

m13

m15

m17

m19

m21

m23

m25

m27

m29

m31

m33

m35

m37

m39

m41

m43

m45

m47

m2

m4

m6

m8

m10

m12

m14

m16

m18

m20

m22

m24

m26

m28

m30

m32

m34

m36

m38

m40

m42

m44

m46

m48

– 48 –

Ignored

4 bits

Page 53

BinaryData

m1 00011000 18

m3 00111000 38

m5 01111000 78

m7 00011000 18

m9 00011000 18

m11 00011000 18

m13 00011000 18

m15 00011001 19

m17 00011011 1B

m19 00000110 06

m21 00001100 0C

m23 00011011 1B

m25 00110111 37

m27 01100110 66

m29 00000000 00

m31 00000000 00

m33 00000001 01

m35 00000011 03

m37 00000111 07

m39 00000111 07

m41 00000000 00

m43 00000000 00

m45 00000000 00

m47 00000000 00

Hexa-

decimal

BinaryData

m2 00000000 00

m4 00000000 00

m6 00000000 00

m8 00000000 00

m10 00000000 00

m12 01100000 60

m14 11000000 C0

m16 10000000 80

m18 00000000 00

m20 00000000 00

m22 00000000 00

m24 11000000 C0

m26 11100000 E0

m28 01100000 60

m30 01100000 60

m32 11000000 C0

m34 10000000 80

m36 00000000 00

m38 11100000 E0

m40 11100000 E0

m42 00000000 00

m44 00000000 00

m46 00000000 00

m48 00000000 00

Hexa-

decimal

STAR MODE

FUNCTION

Delete a download character

CODE <ESC> “&” <1> <0> n

HEX

1B 26 01 00 n

CODE <ESC> “&” “1” “0” n

HEX

REMARKS

FUNCTION

1B 26 31 30 n

Deletes the download character which was assigned the value n.

Enable download character set

CODE <ESC> “%” “1” or <ESC> “%” <1>

HEX

REMARKS

1B 25 31 or 1B 25 01

Enables the download character set.

– 49 –

Page 54

FUNCTION

CODE

HEX

REMARKS

STAR MODE

Disable download character set

<ESC> “%” “0” or <ESC> “%” <0>

1B 25 30 or 1B 25 00

Disables the selected download character set and returns to the

built-in ROM character set.

– 50 –

Page 55

Commands to Control Peripheral Devices

FUNCTION

CODE <ESC><BEL> n1 n2

HEX

REMARKS

Define drive pulse width for peripheral device #1

1B 07 n1 n2

Defines the drive pulse width for peripheral devices requiring

other than standard 200 ms pulse time and delay time.

n1 indicates the energizing time and n2 indicates the delay time,

using 10ms units.

FUNCTION

CODE <BEL>

HEX

REMARKS

FUNCTION

CODE <FS>

HEX

REMARKS

FUNCTION

CODE <EM>

HEX

REMARKS

Control peripheral device #1

07

Executes drive pulse for peripheral device #1.

Control peripheral device #1 immediately

1C

Executes drive pulse for peripheral device #1 immediately.

Control peripheral device #2 immediately

19

Drives peripheral device #2. The drive pulse width and delay time

are fixed at 200 ms.

STAR MODE

FUNCTION

CODE <SUB>

HEX

REMARKS

Control peripheral device #2 immediately

1A

Drives peripheral device #2. The drive pulse width and delay time

are fixed at 200 ms.

– 51 –

Page 56

Commands to Control Auto Cutter

FUNCTION

CODE <ESC> “d” “0” or <ESC> “d” <0>

HEX

REMARKS

FUNCTION

STAR MODE

CODE <ESC> “d” “1” or <ESC> “d” <1>

HEX

REMARKS

Full-cut command to the auto cutter

1B 64 30 or 1B 64 00

Cuts the paper fully when memory switch 2-C is set to 0. If memory

switch 2-C is set to 1, the paper is fed to 18 mm and cut fully.

When auto cutter is invalid, this command is not valid.

Partial-cut command to the auto cutter

1B 64 31 or 1B 64 01

Cuts the paper partially when memory switch 2-C is set to 0. If

memory switch 2-C is set to 1, the paper is fed to 18 mm and cut

partially.

– 52 –

Page 57

Other Commands

FUNCTION

CODE <CAN>

HEX

REMARKS

Cancel last line & Initialize printer

18

Clears the line buffer, and initializes the commands set already.

Does not affect the external equipment drive conditions set by the

code <ESC> <BEL> n1 n2. (This is the same during a mechanical

error.)

(Line buffer means the print data expansion area.)

FUNCTION

CODE <DC3>

HEX

REMARKS

Deselect printer

13

Deselects the printer. The printer disregards all subsequent characters and commands except <DC1>, which activates the printer.

FUNCTION

CODE <DC1>

HEX

REMARKS

Set select mode

(11)H

When the printer receives a <DC1> code, the deselect mode is

canceled and data following this code is input to the buffer.

STAR MODE

FUNCTION

CODE <RS>

HEX

REMARKS

Beep the buzzer

1E

Sounds a brief beep tone.

– 53 –

Page 58

FUNCTION

CODE

HEX

REMARKS

STAR MODE

Set memory switch

<ESC> “# N , n1n2n3n4” <LF> <NUL>

1B 23 N 2C n1n2n3n4 0A 00

Set the memory switch. In order to enable changed memory switch

setting, turn the printer OFF and ON again or send printer reset

command (<ESC> “?”) to the printer. Changed memory switch

settings are stored in EEPROM and these setting will be stored as

long as the time when they are changed again.

N :Memory switch number (0, 1, 2, 3, 4)

n1n2n3n4 :Mode settings (For details see below)

1)N=0

n1 :Always “0”

n2 :Always “0”

n3 :Always “0”

Parameter

n4

Setting

FF command

(Default)

0

Form Feed

4

Paper Feed,

Cut & Back

: Available

Star ESC/POS

–

2) N=1

n1 :Always “0”

n2 :Always “0”

Parameter

n3

n4

Setting

Zero style

International character

set

(Default)

0

Normal zero

1

Slashed zero

See below

Star

: Available

ESC/POS

–

–

n4 Country

0 USA

1 France

2 Germany

n4 Country

C Latin America

n4 Country

3UK

4 Denmark #1

5 Sweden

– 54 –

n4 Country

6 Italy

7 Spain #1

8 Japan

n4 Country

9 Norway

A Denmark #2

B Spain #2

Page 59

3)N=2

Parameter

n1

n2

n4

4) N=3

Parameter

n2

n3

n4

5)N=4

Parameter

n2

n3

n4

n3 :Always “0”

Setting

ESC d command

Cutter

Paper near end

n1 :Always “0”

Setting

Character table

Print column

CR code

Line feed (mm)

n1 :Always “0”

Setting

Buffer size

Busy conditions

Data receive error

(Default)

0

Cut

Invalid

(TSP212)

Invalid

(Default)

0

Normal

48

Invalid

4

1

IBM

38

Invalid

3

(Default)

0

4 Kbytes

See 4-3-1 RS-232C Interface

Print “?”

Paper feed

& cut

Valid

(TSP242)

Valid

Katakana

–

Same as

<LF>

4

45 bytes

Ignore

1

IBM

–

Same as

<LF>

3

1

: Available

ESC/POS

Star

–

–

: Available

Star2

: Available

ESC/POSStar

–

–

ESC/POS

–

–

–

STAR MODE

3

FUNCTION

Initialize printer

CODE <ESC> “@”

HEX

REMARKS

1B 40

Reinitializes the printer. Clears the print buffer and returns settings

to their power-up values.

Does not clear the input buffer, downloaded characters, or conditions for peripheral devices.

FUNCTION

CODE <ENQ>

HEX

REMARKS

Enquiry

05

Causes the printer to transmit a status byte.

– 55 –

Page 60

Status byte

STAR MODE

b7 b6 b5 b4 b3 b2 b1 b0

0

Constantly

set at “0” Vertical Parity error

1 : error

Framing error

1 : error

Mechanical error

1 : error

Paper empty

1 : empty

Buffer empty

1 : empty

Buffer overflow

1 : overflow

Compulsion switch

High level

(Switch is set to ON)

FUNCTION

Reset the printer hardware.

CODE <ESC> “?” <LF><NUL>

HEX

REMARKS

1B 3F 0A 00

Resets the printer hardware.

– 56 –

Page 61

9. CONTROL CODES/ESC/POS MODE

Control Code Hexadecimal Code Function

HT 09 Horizontal tab

LF 0A Print line feed

FF 0C Page mode print and return

DLE EOT 10 04 Real time transmission of status

DLE ENQ 10 05 Real time request to printer

CAN 18 Cancel print data in page mode

ESC FF 1B FF Print page mode data

ESC SP 1B 20 Set right space amount of character

ESC ! 1B 21 Universal print mode designation

ESC # 1B 23 Set memory switch

ESC $ 1B 24 Designate absolute printing

ESC % 1B 25 Designate/cancel download character set

ESC & 1B 26 Define download characters

ESC

*

ESC - 1B 2D Designate/cancel underline

ESC 2 1B 32 Set 1/6 inch line feed amount

ESC 3 1B 33 Set line feed amount

ESC = 1B 3D Select peripheral equipment

ESC ? 1B 3F Delete download characters

ESC @ 1B 40 Initialize printer

ESC D 1B 44 Set horizontal tab position

ESC E 1B 45 Designate/cancel emphasized print

ESC G 1B 47 Designate/cancel double print

ESC J 1B 4A Print and paper feed

ESC L 1B 4C Select page mode

ESC R 1B 52 Select international characters

ESC S 1B 53 Select standard mode

ESC T 1B 54 Select character print direction in print mode

ESC V 1B 56 Designate/cancel 90° character rotation

ESC W 1B 57 Set print range in page mode

ESC \ 1B 5C Designate relative position

ESC a 1B 61 Align position

ESC c4 1B 63 34 Select no valid paper detector at print stop

ESC c5 1B 63 35 Enable/disable panel switch

ESC d 1B 64 Print and paper feed “n” lines

ESC i 1B 69 Partial cut (one section remaining)

ESC p 1B 70 Designate pulse generation

ESC t 1B 74 Select character code table

1B 2A Designate bit image mode

ESC/POS

– 57 –

Page 62

ESC u 1B 75 Transmission of peripheral equipment status

ESC v 1B 76 Transmission of paper detection status

ESC { 1B 7B Designate/cancel inverted printing

GS ! 1D 21 Designate character size

GS $ 1D 24 Designate absolute position of vertical direction of

GS

GS / 1D 2F Print download bit image

GS : 1D 3A Start/finish macro definition

GS B 1D 42 Designate/cancel reverse printing

GS H 1D 48 Select print position of HRI characters

GS I 1D 49 Printer ID transmission

GS L 1D 4C Set left margin

GS P 1D 50 Set basic calculated pitch

GS V 1D 56 Paper cut

ESC/POS

GS W 1D 57 Set print range

GS \ 1D 5C Designate the relative position of vertical characters when

GS ^ 1D 5E Execute macro

GS a 1D 61 Enable/disable automatic status transmission

GS f 1D 66 Select HRI character font

GS h 1D 68 Set bar code height

GS k 1D 6B Printing of bar code

GS r 1D 72 Transmission of status

GS w 1D 77 Set lateral size of bar code

Control Code Hexadecimal Code Function

characters in page mode

*

1D 2A Define download bit image

printing in the page mode

– 58 –

Page 63

Star Mode

10. CHARACTER CODE TABLES

Hexa-

decimal

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

01234567

<NUL> SP 0 @ P ` p

0 163248648096112

<DC1> !1AQaq

1 173349658197113

<DC2> ”2BRbr

2 183450668298114

<DC3> #3CScs

3 193551678399115

<DC4> $4DTdt

4 2036526884100116

<ENQ> %5EUeu

5 2137536985101117

&6FVfv

6 2238547086102118

<BEL> ’7GWgw

7 2339557187103119

<CAN> (8HXhx

8 2440567288104120

<HT> <EM> )9IYiy

9 2541577389105121

<LF> <SUB> *:JZjz

10 26 42 58 74 90 106 122

<VT> <ESC> +;K[k{

11 27 43 59 75 91 107 123

<FF> <FS> ,<L\l|

12 28 44 60 76 92 108 124

<CR> –=M]m}

13 29 45 61 77 93 109 125

<SO> <RS> .>N^n~

14 30 46 62 78 94 110 126

<SI> /?O_o

15 31 47 63 79 95 111 127

– 59 –

Page 64

Star Mode

(Character table: Normal)

Hexa-

decimal

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

89ABCDEF

Ä

128 144 160 176 192 208 224 240

Ö

129 145 161 177 193 209 225 241

Ü

130 146 162 178 194 210 226 242

éù

è

e û °

u â

ßêç°C

131 147 163 179 195 211 227 243

§ï¿°F

132 148 164 180 196 212 228 244

133 149 165 181 197 213 229 245

134 150 166 182 198 214 230 246

ª

º

í N Ω

ì n µ

f E ∑

135 151 167 183 199 215 231 247

¢î σ

136 152 168 184 200 216 232 248

1

/

2

137 153 169 185 201 217 233 249

N

138 154 170 186 202 218 234 250

139 155 171 187 203 219 235 251

T

T

X

öix

ó

Å

ò X

¥ o θ∞

140 156 172 188 204 220 236 252

1

/

4

141 157 173 189 205 221 237 253

A üá÷

142 158 174 190 206 222 238 254

ôä±

ëúàπ

143 159 175 191 207 223 239 255

a

TL

– 60 –

Page 65

Star Mode

(Character table: katakana)

– 61 –

Page 66

Star Mode

(Character table: IBM)

Hexa-

decimal

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

89ABCDEF

Ç Éá α≡

128 144 160 176 192 208 224 240

üæí β±

129 145 161 177 193 209 225 241

é Æó Γ≥

130 146 162 178 194 210 226 242

âôú π≤

131 147 163 179 195 211 227 243

ä öñ ∑

132 148 164 180 196 212 228 244

à ò

133 149 165 181 197 213 229 245

å û

134 150 166 182 198 214 230 246

çù

135 151 167 183 199 215 231 247

Ñ

ª

º

êÿ¿ Φ°

136 152 168 184 200 216 232 248

ë

è

ï δ

î£ ∞

Ì

Ä

Å

Ö

137 153 169 185 201 217 233 249

Ü

138 154 170 186 202 218 234 250

1

/

139 155 171 187 203 219 235 251

140 156 172 188 204 220 236 252

2

1

/

4

¥i

141 157 173 189 205 221 237 253

P

t

142 158 174 190 206 222 238 254

« ∈

ƒ» ∩

143 159 175 191 207 223 239 255

σ

µ÷

τ≈

Θ

Ω –

∩

2

– 62 –

Page 67

Star Mode

International Character Set

35 36 64 91 92 93 94 96 123 124 125 126

U. S. A. #$@[\]ˆ`{|}

France #$à°ç§ˆ`éùè¨

Germany #$§ÄÖ܈`äöüß

~

England £$@[\]ˆ`{|}

Denmark 1 #$@ÆØň`æøå

Sweden #¤ЙДЦЕЬйдцеь

Italy #$@°\йˆщатим

Spain 1 $@¡ Ñ¿ ˆ ’ ¨ ñ }

Japan #$@[¥]ˆ`{ | }

Norway #¤ЙЖШЕЬйжшеь

Denmark 2 #$ЙЖШЕЬйжшеь

Spain 2 #$á¡Ñ¿é’ íñóú

Latin America #$б¡С¿йьнсуъ

~

~

~

~

– 63 –

Page 68

ESC/POS Mode

Hexa-

decimal

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

01234567

<NUL> <DLE> SP 0 @ P ` p

0 163248648096112

<XON> !1AQaq

1 173349658197113

”2BRbr

2 183450668298114

<XOFF> #3CScs

3 193551678399115

<EOT> $4DTdt

4 20 36 52 68 84 100 116

<ENQ> %5EUeu

5 21 37 53 69 85 101 117

&6FVfv

6 22 38 54 70 86 102 118

’7GWgw

7 23 39 55 71 87 103 119

<CAN> (8HXhx

8 24 40 56 72 88 104 120

<HT> )9IYiy

9 25 41 57 73 89 105 121

<LF> *:JZjz

10 26 42 58 74 90 106 122

<ESC> +;K[k{

11 27 43 59 75 91 107 123

<FF> ,<L\l|

12 28 44 60 76 92 108 124

<GS> –=M]m}

13 29 45 61 77 93 109 125

.>N^n~

14 30 46 62 78 94 110 126

/?O_oSP

15 31 47 63 79 95 111 127

– 64 –

Page 69

ESC/POS Mode

Page 0 (PC437: USA, Standard Europe)

Hexa-

decimal

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

89ABCDEF

Ç

üæí β±

é Æó Γ≥

âôú π≤

ä öñ ∑

à ò

å û

É

128 144 160 176 192 208 224 240

129 145 161 177 193 209 225 241

130 146 162 178 194 210 226 242

131 147 163 179 195 211 227 243

132 148 164 180 196 212 228 244

133 149 165 181 197 213 229 245

134 150 166 182 198 214 230 246

çù

135 151 167 183 199 215 231 247

êÿ¿ Φ°

136 152 168 184 200 216 232 248

ë

è

Ö

137 153 169 185 201 217 233 249

Ü