Page 1

High-Precision Advanced

Tuning Fork Balance

MG-S

Operation

•

To ensure safe and proper use of the balance, please read this

manual carefully.

•

After reading this manual, store it in a safe place near the balance, so

you can review it as needed.

IMPORTANT

Series

Manual

S t a r M i c r o n i c s

450017M21

Page 2

Page 3

-i-

Preface

Thank you very much for having purchased our Tuning-Fork high precision electronic balance MG-S

series.

This document describes how to operate the product.

Instructions

●

The copyright of this document belongs to Star Micronics. Reprinting or duplicating of all or part

of this document without notice shall not be allowed.

●

Please note that product improvement or modification may cause partial discrepancy between

the product and the description of this document.

●

The description of this document is subject to change without notice.

●

This document has been created carefully. In case that, however, any error or imperfection is

found by any chance, please let us know.

●

Documents of which pages are missing or irregularly bound will be exchanged. Please inform

the store where you purchased the product.

●

Trouble related to the product or system will be dealt with in accordance with the individual

maintenance contract. Please note, however, that we will not take responsibility for

consequential trouble such as discontinuation of operation caused by the product trouble.

●

is the registered trademark of Star Micronics. Company names and product

names appearing in this document are the trademarks or registered trademarks of the

respective company concerned.

●

The Bluetooth® word mark and logos are registered trademarks owned by the

Bluetooth SIG, Inc. and any use of such marks by Star Micronics is under license. Other

trademarks and trade names are those of their respective owners.

●

Microsoft, Windows are either trademarks or registered trademarks of Microsoft Corporation in

the Unites States and/or other countries.

Page 4

-ii-

Important Notice

・It should be known that this product contains potential danger. And so

please be sure to observe this document when installing, operating or

servicing this product.

・Star Micronics will not take any responsibility for any injury or damage

caused by the non-observance of this document or misuse or unauthorized

modification of this product.

●

Potential dangers are increasing in the industrial equipment industries due to the advent

of new materials and processing methods, and speeding up of machines. It is

impossible to foresee all situations related to these dangers. In addition, there are so

many “impossible” and “don’ts” and so writing all of them in the operation manual is

impossible. Therefore, it is safe to think that what is not written in the operation manual

“cannot be performed” unless the operation manual positively writes “it is possible.”

When performing installation, operation, maintenance or inspection of this product, not

only observe what is written or indicated in this document or on the product surface but

also pay adequate consideration to safety measures.

●

The copyright of this document is held and reserved by Star Micronics. Duplicating or

disclosing its drawings and engineering materials without prior approval of Star

Micronics in writing is not permitted.

●

For any question or further information concerning this document, please contact the

store where you purchased the product or with its model (type) name and serial number

informed.

●

Manufacturer: Star Micronics America, Inc.

Address: 65 Clyde Road Suite G, Somerset, NJ 08873 U.S.A.

Tel: (800) 782-7636 / (848) 216-3300

Email: support@starmicronics.com

Page 5

-iii-

How to use this document

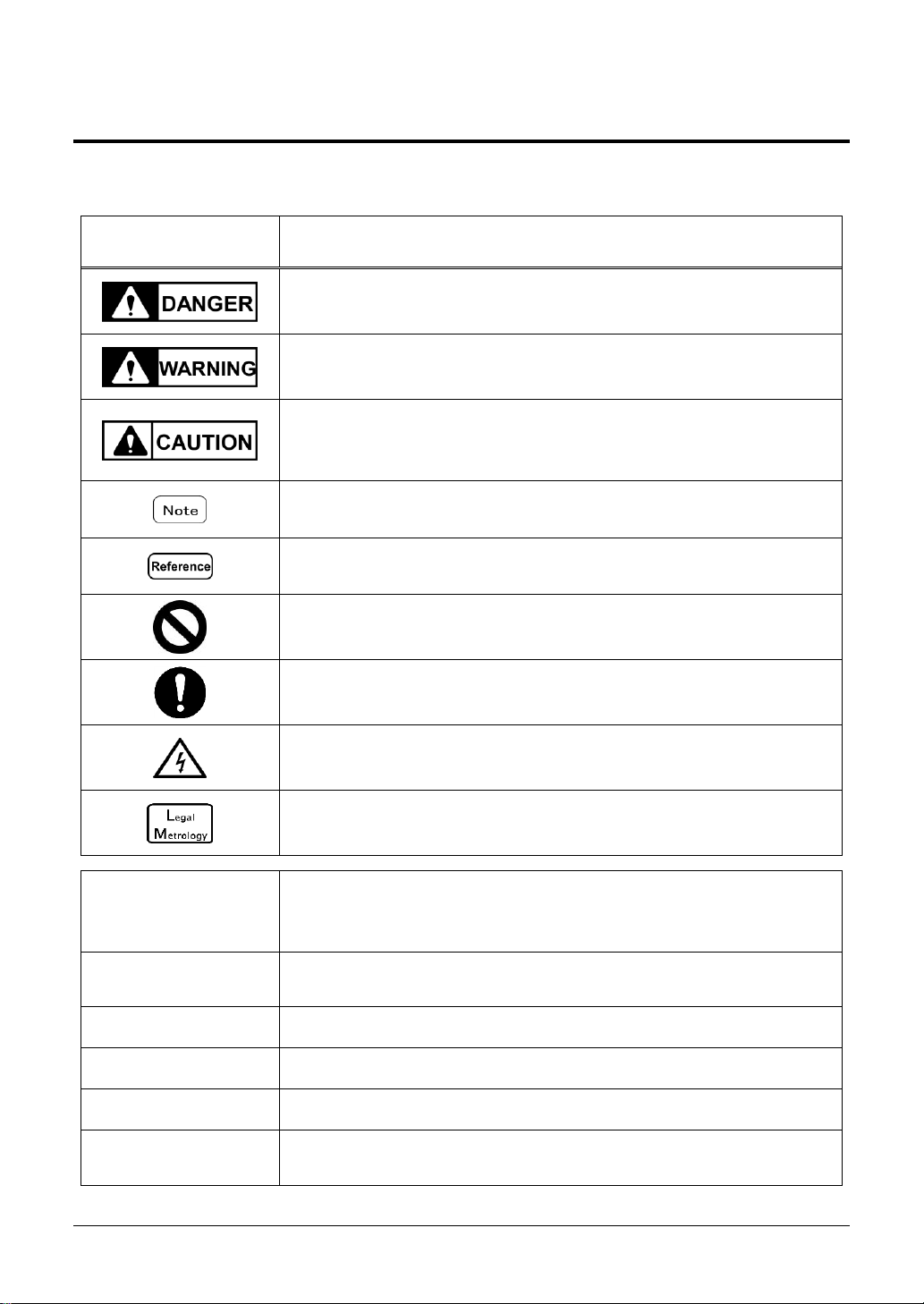

■Symbols used in this document

Understand the meaning of the following symbols and observe the instructions of this document.

Symbols

Meaning

Used for the situation that invites an imminent risk of death or severe injury if

proper precautions are not taken.

Used for the situation that invites a risk of death or serious injury if proper

precautions are not taken.

Used for caution concerning operations that may lead to a light physical

injury to persons or damage of the products/facilities if proper precautions

are not taken.

Used for notation for avoiding from delection, overwrite the weighing data or

for accurate weighing and appropriate usage of the equipment.

Used for reference information on operation

Used for “Prohibition” items

Used for “Mandatory” items requiring positive action

Used for prohibition items to avoid “Electrical shock”.

This symbol indicates the operation/specification related to NTEP approval

and verification.

This product/

The product/

The balance

Refers to the product.

[On/Off] key

The name of an operation key located in front of the main unit is

represented in square brackets “[ ]”.

<message>

A message on the display is represented in angle brackets “< >”.

<<F1>>

“Free key” or “Shortcut” is represented in double angle brackets “<< >>”.

Push the key

Signifies pushing lightly an operation key once.

Push the key long

Signifies keeping pushing an operation key until the designated indication

appears.

Page 6

-iv-

■About how to read this document

This document consists of the following contents:

1

Prior to use

Describes about operating precautions, names and functions of each

section, etc. Please be sure to read this section when using this product

for the first time.

2

Basic usage

Describes about basic usage related to weighing such as how to turn on

and off the power in addition to the setting procedures to set various

functions.

3

Functions related to the

operation

Describes about setting items to change the operation of the balance.

4

Function related to the

performance

Describes about setting items related to the indication stability and the

response speed of the balance.

5

User information

setting

Describes about setting items related to the upper and lower limits and

preset tare weight.

6

External input/output

functions

Describes about setting items related to the specifications and conditions

in regard to the external communication.

7

Functions related to the

lock

Describes about setting items related to change prohibitions and invalid

keystrokes on each menu item.

8

Controlling and

adjustment functions

Describes about setting items related to the product administrator.

9

Troubleshooting

Describes about methods of troubleshooting this product such as how to

respond to errors and when you are in need of help.

10

How to maintain

Describes how to maintain this product.

Appendix

Provides necessary data such as the specifications of this product.

Page 7

-v-

Contents

Preface ........................................................................................................................................ i

Important Notice ....................................................................................................................... ii

How to use this document ...................................................................................................... iii

Contents .................................................................................................................................... v

1 Prior to use .......................................................................................................................... 1

1-1 Operating precautions .................................................................................................... 1

1-2 For more accurate measurement ................................................................................... 3

1-2-1 Precautions related to measuring environment ........................................................... 3

1-2-2 Precautions related to measuring table ....................................................................... 3

1-2-3 Precautions related to a specimen .............................................................................. 4

1-2-4 Precautions related to the main unit of a balance ....................................................... 4

1-3 Check for the articles contained in the box..................................................................... 5

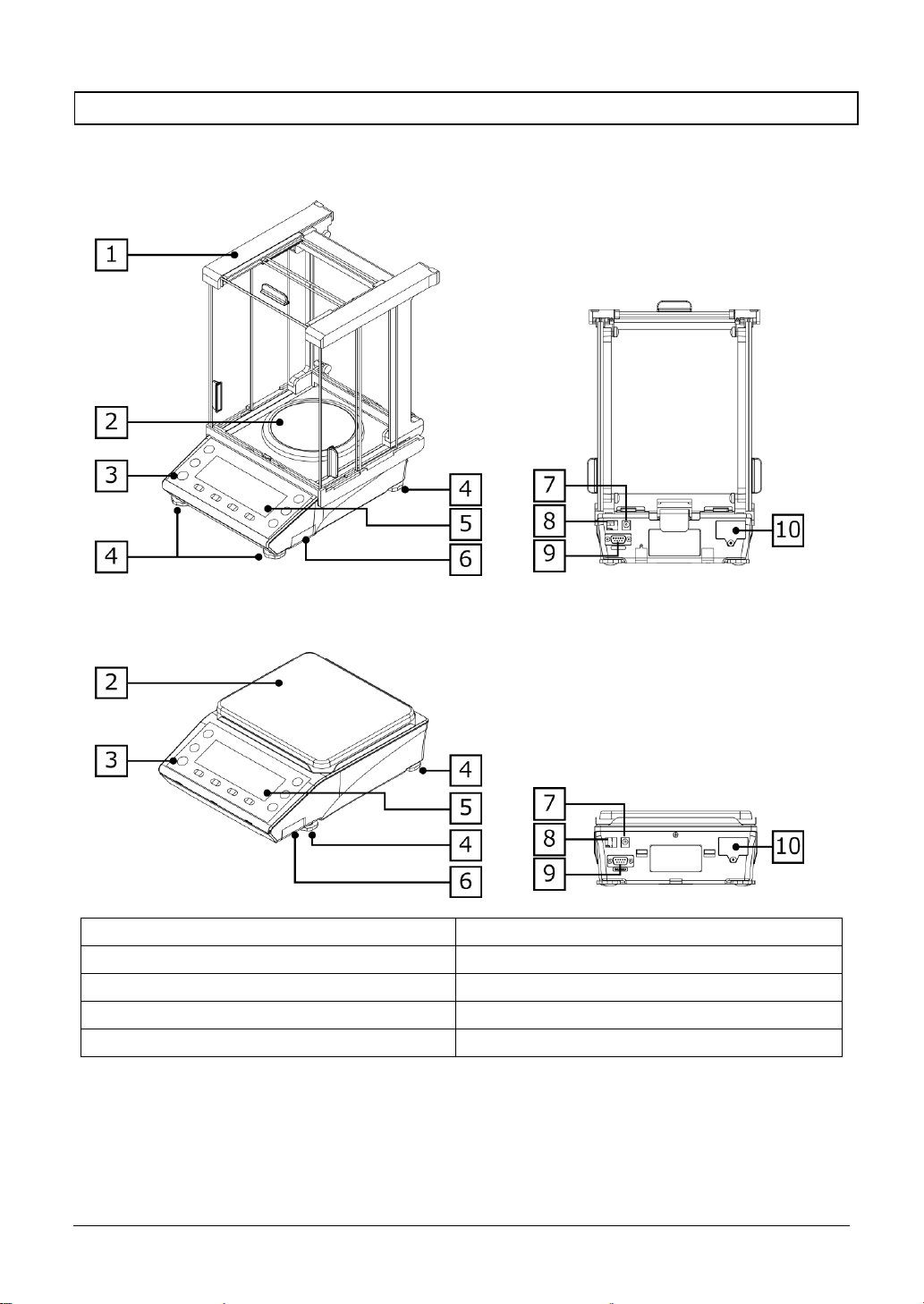

1-4 Name and function of each section ................................................................................ 6

1-5 Assembling and installation of the product ..................................................................... 7

1-5-1 Assembling the balance (Round pan type MG-S322) ................................................. 7

1-5-2 Assembling the balance (Square pan type MG-S1501, MG-S8200) ......................... 8

1-5-3 Level ........................................................................................................................... 9

1-6 Description of the operation keys ................................ ................................................. 10

1-6-1 Basic ......................................................................................................................... 10

1-6-2 Setting value and numeric value inputting................................................................. 11

1-7 How to interpret the display .......................................................................................... 12

1-7-1 Description of segment. ............................................................................................ 12

1-7-2 LCD character font .................................................................................................... 13

2 Basic usage ....................................................................................................................... 14

2-1 Turning on/off the power, and checking for the operation ............................................. 14

2-2 Zero-point adjustment .................................................................................................. 15

2-2-1 Zero-point adjustment range ..................................................................................... 15

2-3 Weighing a sample placed on a container (tare) .......................................................... 15

2-4 Weighing the additional sample ................................................................................... 17

2-5 Basic operation ............................................................................................................ 17

2-5-1 Hierarchy of a setting menu ...................................................................................... 17

2-5-2 Operation of the setting menu ................................................................................... 18

2-5-3 Numeric value input .................................................................................................. 19

2-5-4 [ F ] key switching at each measuring mode ............................................................. 20

3 Functions related to the operation .................................................................................. 21

3-1 Hierarchy of functions related to the operation ............................................................. 21

3-2 Various measuring modes of the balance .................................................................... 22

3-2-1 Weighing mode ......................................................................................................... 22

3-2-2 Counting mode .......................................................................................................... 23

3-2-2 (1) Actual value setting method ................................................................................. 23

3-2-2 (2) Numeric value setting method ............................................................................. 25

3-2-2 (3) Switching the display at Counting mode .............................................................. 26

3-3 Percentage mode ......................................................................................................... 27

3-3-1 Switching the display at percentage mode ................................................................ 29

3-4 Multiplied by Coefficient mode ..................................................................................... 30

3-4-1 Switching the display at Multiplied by Coefficient ...................................................... 31

3-5 Specific gravity mode ................................................................................................... 32

3-5-1 Switching the display at “Specific gravity mode” ....................................................... 33

3-6 Statistics mode ............................................................................................................. 34

Page 8

-vi-

3-6-1 Switching the display at “Statistics mode” ................................................................. 35

3-7 Animal mode ................................................................................................................ 36

3-8 Formulation mode ........................................................................................................ 38

3-8-1 Check the stored data of each component................................................................ 39

3-9 Unit setting ................................................................................................................... 40

3-10 Comparator function ................................................................................................... 40

3-10-1 How to perform discrimination ................................................................................. 40

3-10-2 Comparator function setting .................................................................................... 41

3-11 Adding function ........................................................................................................... 42

3-11-1 Weighing by means of the plus side addition .......................................................... 43

3-11-2 Weighing by means of the minus side addition ....................................................... 44

3-12 Tare-subtraction reminder function ............................................................................. 45

3-13 Zero-point-adjustment reminder function ................................................................... 46

3-14 Bar graph indication ................................................................................................... 46

3-15 Stabilization wait setting ............................................................................................. 47

3-16 Backlight setting ................................................................................................ ......... 47

3-17 Auto power-off ............................................................................................................ 48

3-18 “Simple SCS(Self Counting System) method” setting ................................................ 48

4 Functions related to the performance ............................................................................. 49

4-1 Hierarchy of functions related to the performance ........................................................ 49

4-2 Stability discrimination width ........................................................................................ 49

4-3 Response speed .......................................................................................................... 50

4-4 Zero tracking ................................................................................................................ 50

5 User information setting ................................................................................................... 51

5-1 Hierarchy of user information setting ............................................................................ 51

5-2 Preset tare .................................................................................................................... 52

5-2-1 Preset tare setting ..................................................................................................... 52

5-2-2 Inputting of a preset tare weight value ...................................................................... 52

5-2-2 (1) Actual value setting method ................................................................................. 53

5-2-2 (2) Numeric value setting method ............................................................................. 53

5-2-2 (3) Exiting the preset tare mode ................................................................................ 53

5-3 Setting of the discrimination value of the comparator function ..................................... 54

5-3-1 Actual value setting method ...................................................................................... 55

5-3-2 Numeric value setting method ................................................................................... 55

6 External input/output functions ....................................................................................... 56

6-1 Hierarchy of the external input / output functions ......................................................... 56

6-2 Standard RS-232C Connecter terminal numbers and their functions ........................... 59

6-3 Standard USB Connecter terminal numbers and their functions .................................. 59

6-4 Communication format ................................................................................................. 60

6-4-1 Basic communication specification ........................................................................... 60

6-4-2 Basic data output format / CSP format ...................................................................... 60

6-4-3 Generic format .......................................................................................................... 62

6-5 Input command ............................................................................................................ 64

6-5-1 Transmission procedure ............................................................................................ 64

6-5-2 Input command composition 1 .................................................................................. 65

6-5-2 (1) Zero-point adjustment/Tare/Output control setting command .............................. 65

6-5-2 (2) Date output request and time output request ....................................................... 65

6-5-3 Input command composition 2 .................................................................................. 66

6-5-3 (1) Comparator setting command ............................................................................. 66

6-5-3 (2) Preset tare value setting command ..................................................................... 66

6-5-3 (3) Interval (output) time setting command................................................................ 66

6-6 Response ..................................................................................................................... 67

Page 9

-vii-

6-6-1 Response command format (“A00”/“Exx” format) ..................................................... 67

6-6-1(1) Response command ............................................................................................. 67

6-6-2 Response command format (“ACK”/“NAK” format) ................................................... 67

6-6-2(1) Response command ............................................................................................. 67

6-7 External contact input ................................................................................................... 67

6-8 Communication setting ................................................................................................. 68

6-8-1 RS232C/USB/Bluetooth ............................................................................................ 68

6-8-2 Bluetooth initialization .................................................................................................. 70

7 Functions related to the lock............................................................................................ 71

7-1 Hierarchy of functions related to the lock ..................................................................... 71

7-2 Total lock release ......................................................................................................... 71

7-3 Key lock function ................................ ................................ .......................................... 72

7-4 Menu lock function ....................................................................................................... 72

8 Controlling and adjustment functions ............................................................................. 73

8-1 Hierarchy of controlling and adjustment functions ........................................................ 73

8-2 Shortcut setting for accessing various measuring modes ............................................ 75

8-3 Free key setting ............................................................................................................ 76

8-4 Maintenance settings ................................................................................................... 77

8-4-1 Span calibration and span test .................................................................................. 77

8-4-1(1) Span calibration with external weight.................................................................... 77

8-4-1(2) Span test with external weight .............................................................................. 79

8-5 Balance control setting ................................................................................................. 80

8-5-1 Balance ID setting ..................................................................................................... 80

8-5-2 Password control ...................................................................................................... 80

8-5-2 (1) Administrator password registration..................................................................... 81

8-5-2 (2) User password registration ................................ .................................................. 81

8-5-3 Outputting of the span calibration/ test result ............................................................ 82

8-5-4 Date indication format ............................................................................................... 82

8-5-5 Date setting ............................................................................................................... 82

8-5-6 Time setting............................................................................................................... 83

8-5-7 Direct start setting ..................................................................................................... 84

8-5-8 Initialize ..................................................................................................................... 84

9 Troubleshooting ................................................................................................................ 85

9-1 Error message .............................................................................................................. 85

10 How to maintain ............................................................................................................... 88

10-1 Simple Method for Maintenance (Round pan type MG-S322) .................................... 88

10-2 Simple Method for Maintenance (Square pan type MG-S1501, MG-S8200).............. 89

Appendix ................................................................................................................................. 90

Appendix 1 Specification .................................................................................................... 90

Appendix 1-1 Basic Specification ....................................................................................... 90

Appendix 1-2 Functional specification ................................................................................ 91

Appendix 2 Dimensional outline drawing ............................................................................ 93

Appendix 3 Unit indication and conversion table ................................................................ 94

Appendix 4 Installation of batteries ..................................................................................... 95

Appendix 5 USB communication and bus power input ....................................................... 96

Appendix 6 Balance operation with password control function ........................................... 97

Appendix 6-1 User’s authority setting ................................................................................. 97

Appendix 6-2 User/guest login ........................................................................................... 98

Appendix 7 Windshield assembly instructions .................................................................... 99

Index of Terms ....................................................................................................................... 102

Page 10

Page 11

MG-S series operation manual 1 Prior to use

-1-

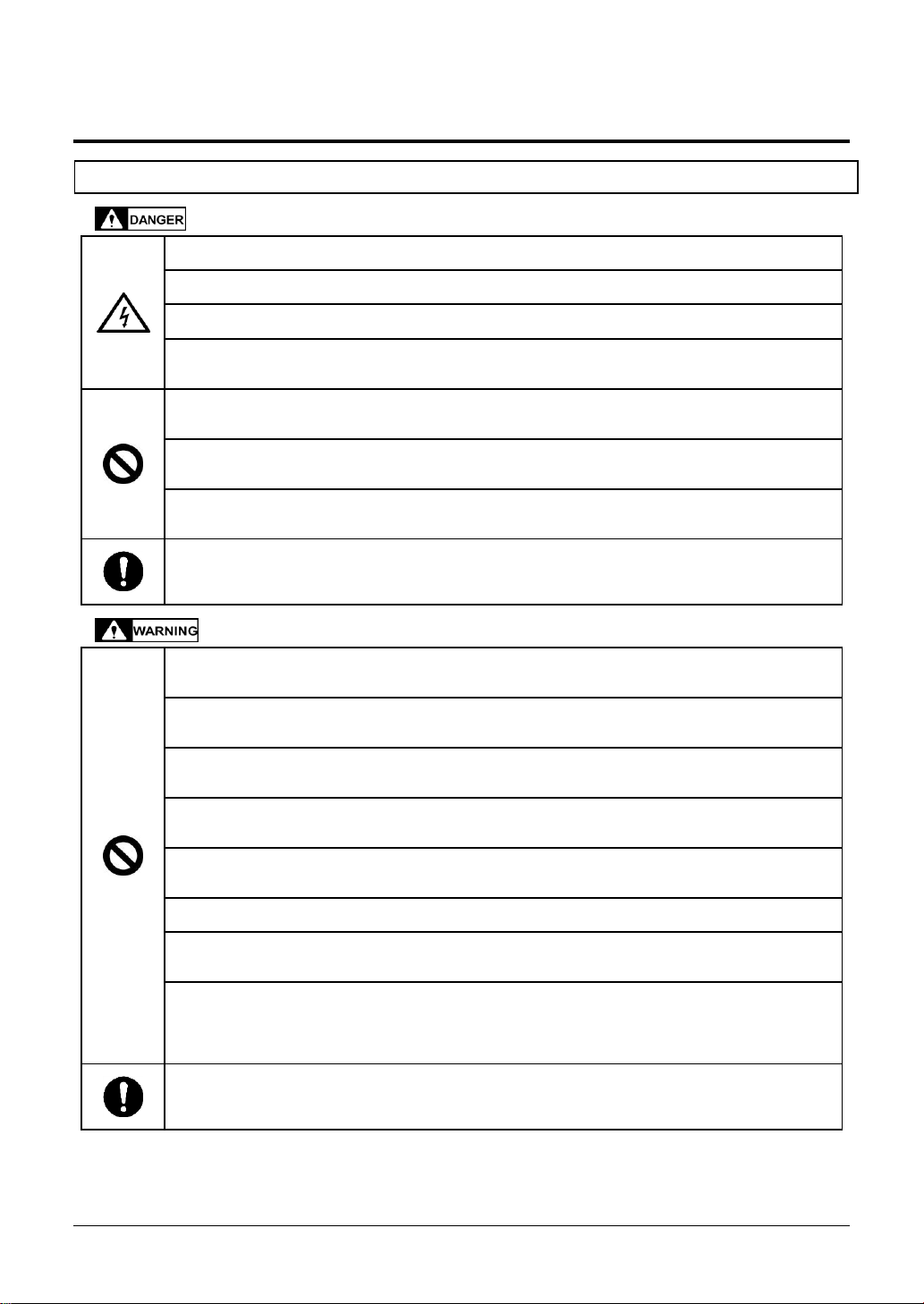

1 Prior to use

1-1 Operating precautions

■Do not wet the AC adapter.

That may cause an electric shock, short-circuiting or failure.

■Do not handle the balance with wet hands.

That may cause short-circuiting or failure.

■Do not use the balance in a wet location.

That may cause an electric shock, short-circuiting or failure.

■Do not connect to the AC adapter cord or communication cable with its connector

or jack being wet.

That may cause an electric shock, short-circuiting or failure.

■Do not use the balance in a dusty location.

That may cause dust explosion or fire.

That may cause short-circuit or malfunction of the balance.

■Do not use the balance in explosive atmosphere.

That may cause explosion or fire.

Please order our explosive-proof balances to weigh in such a hazardous area.

■Never disassemble or modify the batteries. Make sure you insert batteries with the

positive and negative poles correctly inserted, and be careful of short circuits.

Such mishandling could damage the batteries, or cause the balance to fail.

■Obey the MSDS.

Measuring dangerous materials such as flammable liquid could cause an explosion or fire.

■Do not disassemble or modify the product.

Doing so could result in injury, electric shock, fire and other accidents or failures. For inspection and

adjustment, contact the retailer from whom the product was purchased.

■Do not move the product with a sample to be weighed set on the balance.

That may cause the sample to fall from the weighing pan, leading to a bodily injury or destruction of the

sample.

■Do not route the AC cord across passages.

The cord could be tripped on by a passerby and the balance could fall down and break or injure

someone.

■Do not use the product on an unstable table or a place that is subject to vibration.

That may cause the sample to fall from the weighing pan, leading to a bodily injury or destruction of the

sample. Besides inaccurate weighing may result.

■Do not place an unstable sample on the weighing pan.

The sample may fall down, giving rise to a danger. Put an unstable sample in a container (tare) before

weighing it.

■Only use the specified power supply.

Using any power supply other than that specified could cause overheating, fire or failure.

■Do not bring the balance by holding the windshield.

The main body could drop and break down or injury someone. Make sure to hold the main body to bring

the balance.

■Do not use the product in an abnormal condition.

If it should happen that an abnormal event such as smoking or unusual odor occurs, ask the store

where you purchased the product or our sales department for repair. Keeping using the product may

result in an electric shock or fire. In addition, do not ever try to repair it for yourself, or very dangerous

situation is likely to occur.

■Only use the dedicated AC adapter.

Use of other types of power or adapters may result in heat generation or malfunction of the balance.

Page 12

1 Prior to use MG-S series operation manual

-2-

■Do not mix old and new batteries, or batteries of different types or manufacturers.

■Do not use the batteries that leak.

■Do not apply excessive force to or impact the balance.

Doing so could damage or result in failure of the balance. Carefully place samples on the balance.

■Do not use volatile solvents.

The main unit could deform. Wipe the main unit using dry cloth or a cloth moistened with a small

amount of neutral detergent.

■ Dispose of batteries in accordance with local regulations.

■ If the balance is not going to be used for a long time, store it with the batteries

removed.

■Observe the precautions printed on the batteries used.

FCC

caution

■Changes or modifications not expressly approved by the party responsible for

compliance could void the user's authority to operate the equipment.

■Do not install the balance in a place where it is directly exposed to airflow from air-

conditioning or heating equipment.

Due to changes in the ambient temperature, the balance could fail to accurately weigh samples.

■Do not install the balance in a place exposed to direct sunlight.

The internal temperature of the balance could rise and the balance could fail to accurately weigh

samples.

■Do not install the balance where the floor is soft.

When a sample is placed on the balance, the balance could slant and fail to accurately weigh samples.

■Do not install the balance in a place where the ambient temperature or humidity

change significantly.

The balance could fail to accurately weigh samples.

■Adjust (calibrate) the balance when it is installed or relocated.

Failure to do so might result in measurement errors. To ensure accurate measurements be sure to

adjust (calibrate) the balance.

■Check for an error periodically.

Use environment and chronological change cause an error in measured value, leading to an inaccurate

measurement.

■Unplug the AC adapter from the receptacle when the balance is not going to be

used for a long period of time.

Unplug the balance from the receptacle to save energy and prevent degradation.

■Always adjust the level of the balance before use.

A tilted balance generates errors which might cause inaccurate weighting.

■For proper disposal

This product including accessories may not be disposed of in domestic waste in conformance with

the specific requirements in your country or state.

When you dispose of this product, please contact your local authorities or dealer and ask for the correct

method of disposal.

FCC

Note

This device complies with part 15 of the FCC Rules. Operation is subject to the following

two conditions:

(1) This device may not cause harmful interference, and

(2) this device must accept any interference received, including interference that may cause undesired

operation.

This equipment has been tested and found to comply with the limits for a Class A digital device,

pursuant to part 15 of the FCC Rules. These limits are designed to provide reasonable protection

against harmful interference when the equipment is operated in a commercial environment. This

equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in

accordance with the instruction manual, may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause harmful interference in which case

the user will be required to correct the interference at his own expense.

This product contains unlicensed transmitting module:

- Name: Stand-alone dual-mode Bluetooth module OBS421 series

- Model number: CB-OBS421i-i4-01B

- FCC ID: PVH0946

Page 13

MG-S series operation manual 1 Prior to use

-3-

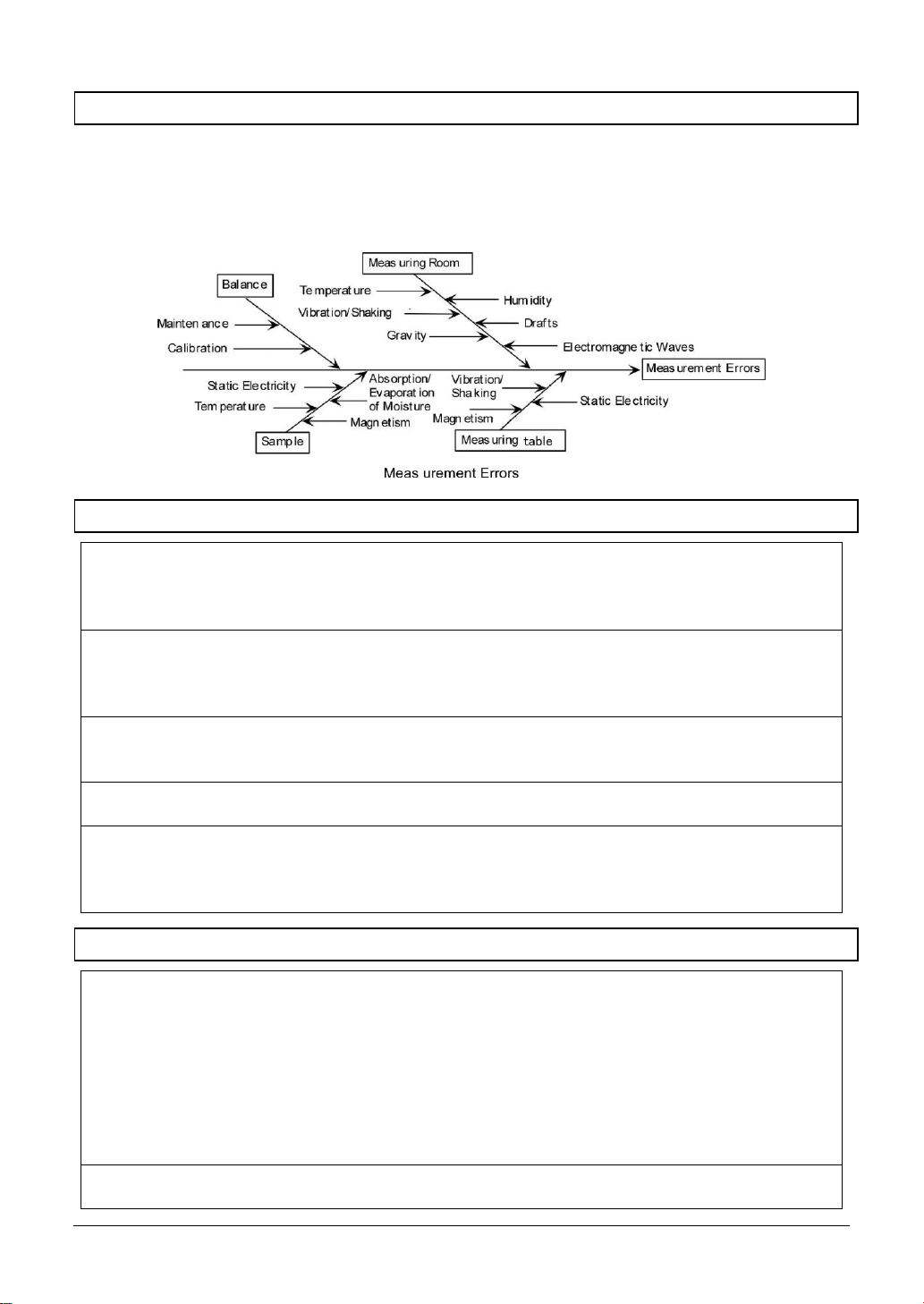

1-2 For more accurate measurement

To make more accurate measurement, it is necessary to lessen error-causing factors in measurement

to the extent possible. Error-causing factors include not only an instrument error and performance of

the balance itself but also the nature and condition of a specimen, measuring environment (vibration,

temperature, humidity, etc.) and the like. These factors will directly affect measurement result in the

case of a balance with high resolution capability.

1-2-1 Precautions related to measuring environment

Temperature/

humidity/

atmospheric

pressure

→

Try to keep the room temperature constant to the extent possible in order to

avoid condensation and indication drift due to change in temperature.

→

Low humidity is likely to cause generation of static electricity, resulting in

inaccurate measurement.

Vibration/shaking

→

It is preferable to locate a measuring room on the first floor or the basement. The

higher the room is, the larger the vibration and shaking become. Therefore, a

highly located room is not suitable for measurement. Rooms near the railway or

road side should also be avoided.

Air draft

→

Places directly exposed to air current from an air-conditioner or to direct sun

generate abrupt temperature change and resultantly cause unstable weight

indication, and therefore, should be avoided.

Gravity

→

The latitude and altitude of a measuring location differentiate the gravity that

affects a specimen, giving a different weight indication to the same specimen.

Electromagnetic

wave

→

At a location where a strong electromagnetic wave generating object is in the

proximity of a balance, the balance is affected by the electromagnetic wave,

making the balance unable to indicate accurate weight, and therefore, such a

location should be avoided.

1-2-2 Precautions related to measuring table

Vibration/shaking

→

Vibrations during measurement destabilizes the indication of measurement

value, leading to inability to make accurate measurement. And so use of a

measurement table that is robust and hardly affected by vibration is required (a

vibration-proof structured table or concrete or stone-made table is suitable). In

addition, placing a sheet of soft cloth or paper under the balance causes shaking

or makes keeping horizontal attitude difficult, and therefore should be avoided.

→

The measurement table should be installed in a position free from vibration to

the extent possible. A corner rather than the center of a room is less affected by

vibration and therefore more suitable for installation of the balance.

Magnetism/Static

electricity

→

Use of the balance on the table that is subject to magnetism or static electricity

should be avoided.

Page 14

1 Prior to use MG-S series operation manual

-4-

1-2-3 Precautions related to a specimen

Static electricity

→

In general, synthetic resin- and glass-made specimens are high in electric

insulation, and so easily charged electrically. Weighing an electrically charged

specimen makes the indication value unstable, reducing the reproducibility of

the test result. Therefore, neutralize an electrically charged specimen before

measurement.

Magnetism

→

Specimens affected by magnetism show different weight in a different position

of the weighing pan, reducing the reproducibility.

When weighing a magnetized specimen, either eliminate the magnetism from

the specimen or place a setting plate on the weighing pan to distance the

specimen from the weighing mechanism of the balance so that the mechanism

may not be affected by the magnetism.

Moisture

absorption/

Evaporation

→

Measuring a moist or evaporating (vaporizing) specimen increases or

decreases the indication value of the balance continuously. When this is the

case, put the specimen in a container equipped with a small mouth and closely

seal the mouth before measurement.

Specimen

temperature

→

Difference in temperature between the specimen and the windshield interior

generates convection flow within the windshield, causing a measurement error.

When the specimen temperature is excessively high or low, allow the specimen

temperature to stabilize at the room temperature before measurement. Also, to

prevent the convection flow from arising within the windshield, make the

windshield interior temperature equal to the room temperature before

measurement.

→

Measurer’s body temperature also affects measurement result. Handle a

specimen with tweezers instead of directly holding it with fingers and refrain

from putting your hands directly in the windshield during measuring operation.

1-2-4 Precautions related to the main unit of a balance

Operating

precautions

→

A dust cover, if equipped, for the balance may possibly make the weight

indication unstable due to static electricity charged on the cover at a low

humidity. When this is the case, wipe the cover with wet cloth or use antistatic

agent or use the balance with the cover removed.

→

For more stable measurement, it is recommended to energize the balance for

longer than 30 minutes and load the balance a few times with a weight

equivalent to the weighing capacity before measurement.

Calibration

→

Calibrate the balance periodically with an external calibration weight. For the

sake of precise calibration, use an external calibration weight weighing nearly

equal to the weighing capacity of the balance.

→

Energize the balance for longer than 30 minutes and load the balance a few

times with a weight equivalent to the weighing capacity before calibration.

→ Calibration is also needed in the following cases:

When using the balance for the first time,

When using the balance after a long period of non-use,

When changing a place of installation, and

When there was a large change in temperature, humidity or atmospheric

pressure.

Maintenance

→

Attachment of dirt such as powder or liquid to the weighing pan or pan base will

cause measurement error or unstable weight indication. For that reason,

frequent cleaning of the balance is required. In cleaning the balance, take care

for the dust or liquid not to enter into the balance.

Page 15

MG-S series operation manual 1 Prior to use

-5-

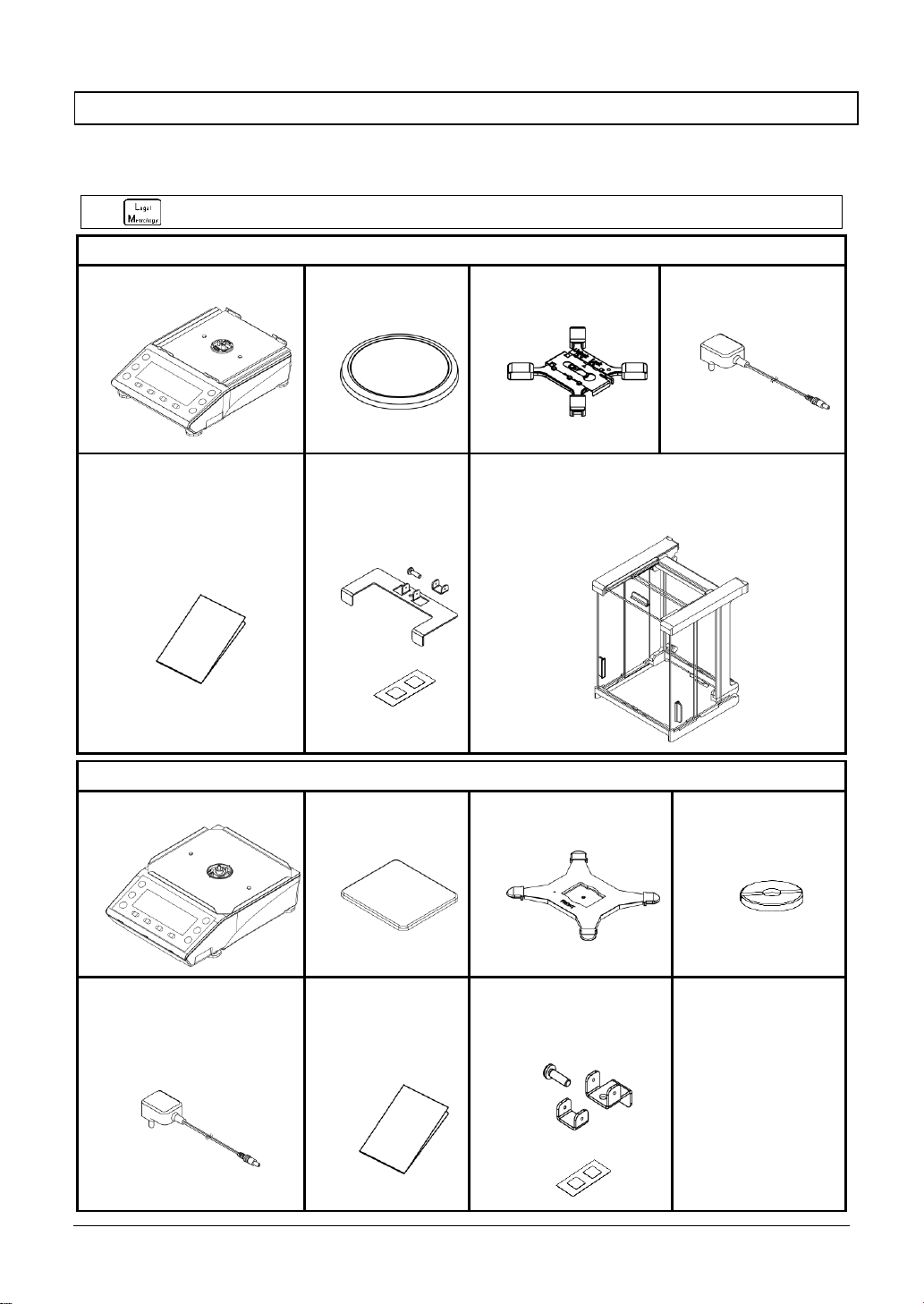

1-3 Check for the articles contained in the box

The package box contains the following;

If anything missing or broken should be found, please inform the store where you purchased the

product.

Sealing kit is already mounted on the verified balance.

Round pan type (MG-S322)

①

Main unit (Round): 1

②

Round pan: 1

③

Pan base (Round): 1

④

AC adapter: 1

⑤

Operation manual: 1

⑥

Sealing kit

(Wire sealing kit

and tamper-proof

stickers)

⑦

Windshield (Assembly type): 1

(Refer to “Appendix 7 Windshield assembly

instructions”)

Square pan type (MG-S1501, MG-S8200)

①

Main unit (Square): 1

②

Square pan: 1

③

Pan base (Square): 1

④

Pan base screw: 1

⑤

AC adapter: 1

⑥

Operation

manual: 1

⑦

Sealing kit

(Wire sealing kit and

tamper-proof stickers)

Page 16

1 Prior to use MG-S series operation manual

-6-

1-4 Name and function of each section

Round pan type (MG-S322)

Square pan type (MG-S1501, MG-S8200)

1

Windshield

2

Weighing pan

3

Level

4

Adjuster

5

Display

6

Battery case

7

AC adapter jack

8

USB connector (Type B)

9

RS-232C connector (D-sub 9 pin male)

10

Bluetooth module

Page 17

MG-S series operation manual 1 Prior to use

-7-

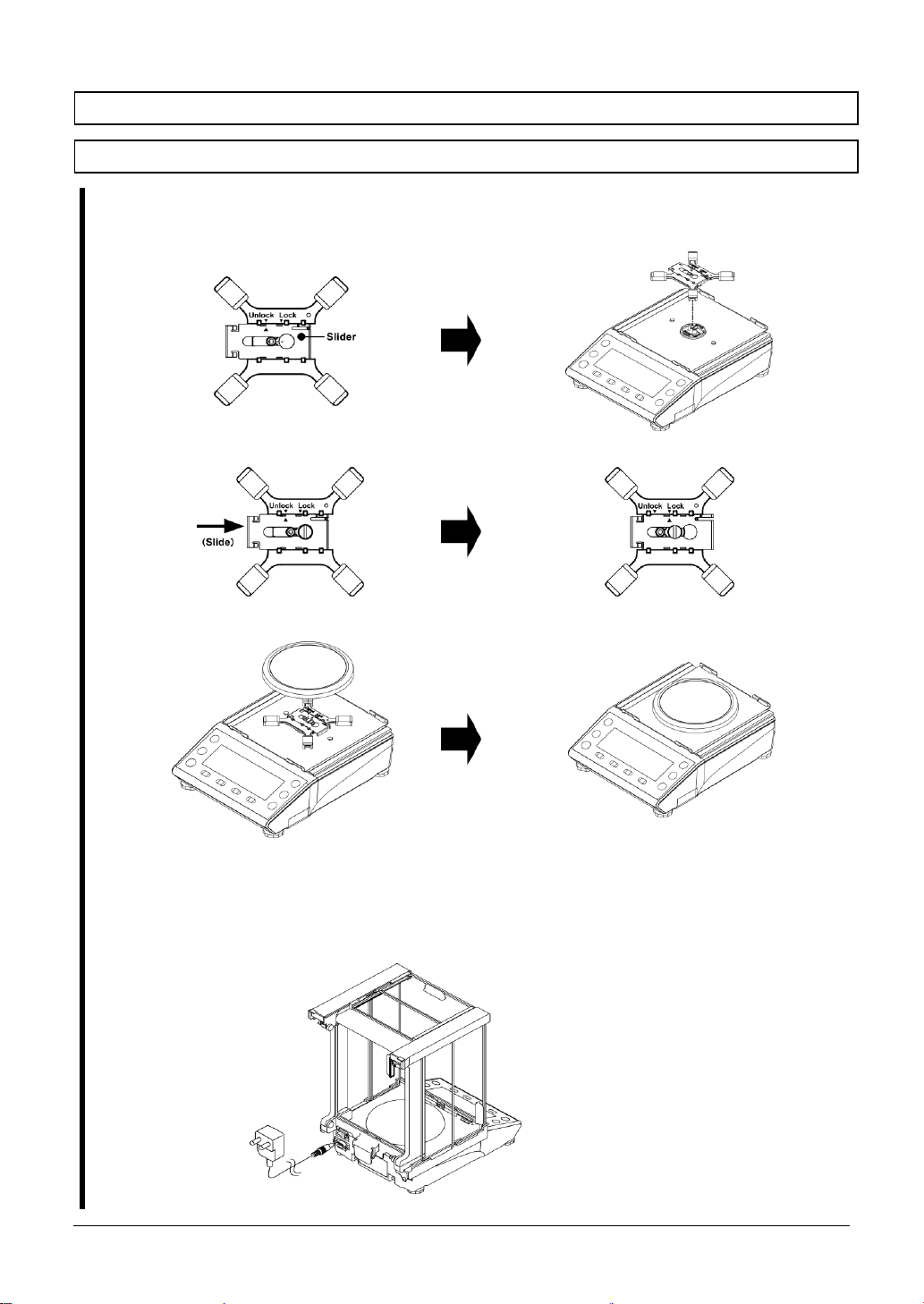

1-5 Assembling and installation of the product

1-5-1 Assembling the balance (Round pan type MG-S322)

1

Attach t he “Pan base”.

"Slider" to check that in the "Unlock” side, then attach to the balance.

2

Move the "Slider" to "Lock" side.

3

Mount the weighing pan.

4

Assemble the windshield.

Refer to “Appendix 7 Windshield assembly instructions” to assemble the windshield.

5

Connect the AC adapter.

Page 18

1 Prior to use MG-S series operation manual

-8-

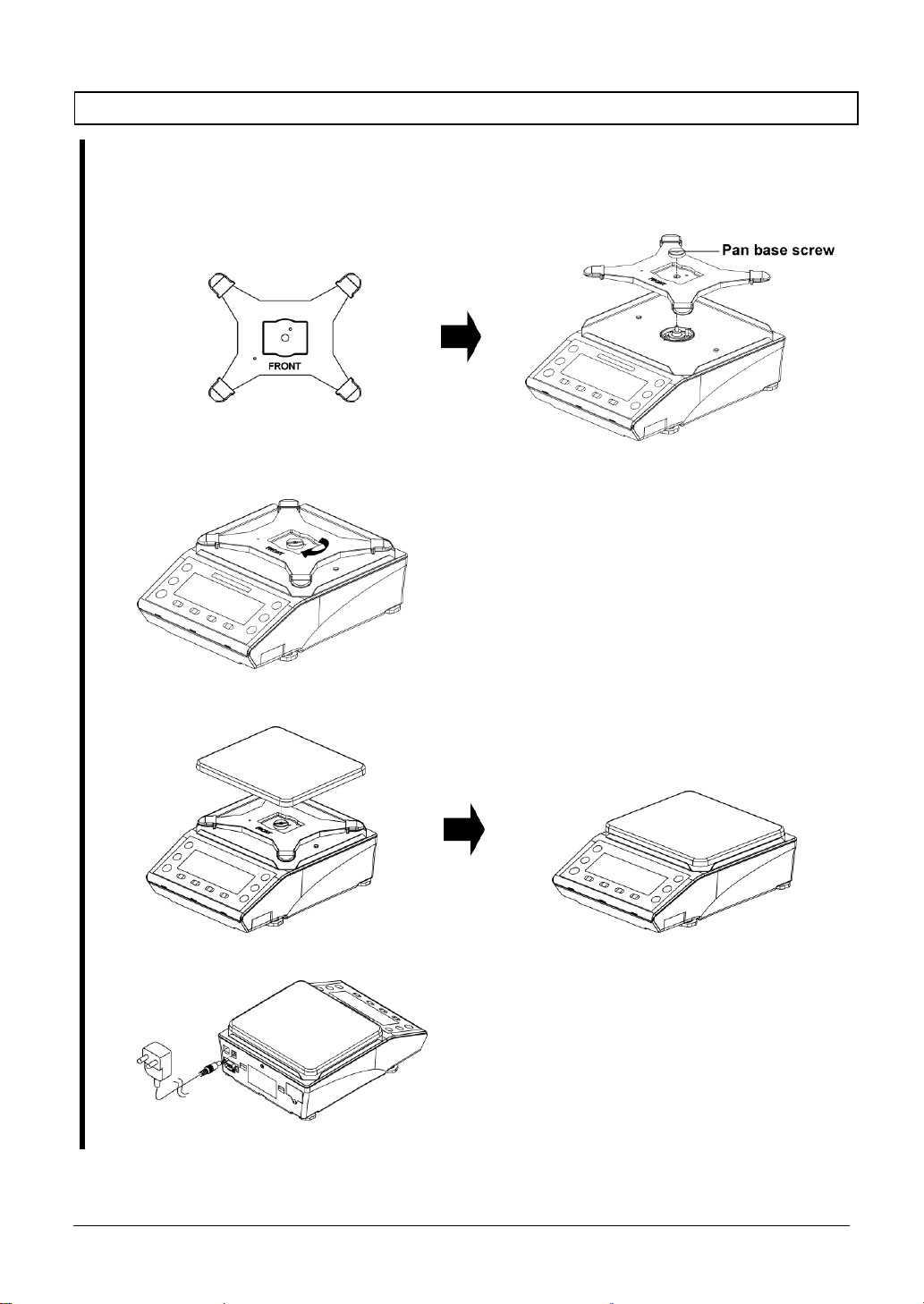

1-5-2 Assembling the balance (Square pan type MG-S1501, MG-S8200)

1

Attach t he “Pan base”.

(1) Direct "FRONT" to the display side.

(2) Attach to the balance, then turn the “Pan base screw” to fix.

2

Tight en the “Pa n ba se screw” firmly.

3

Mount the weighing pan.

4

Connect the AC adapter.

Page 19

MG-S series operation manual 1 Prior to use

-9-

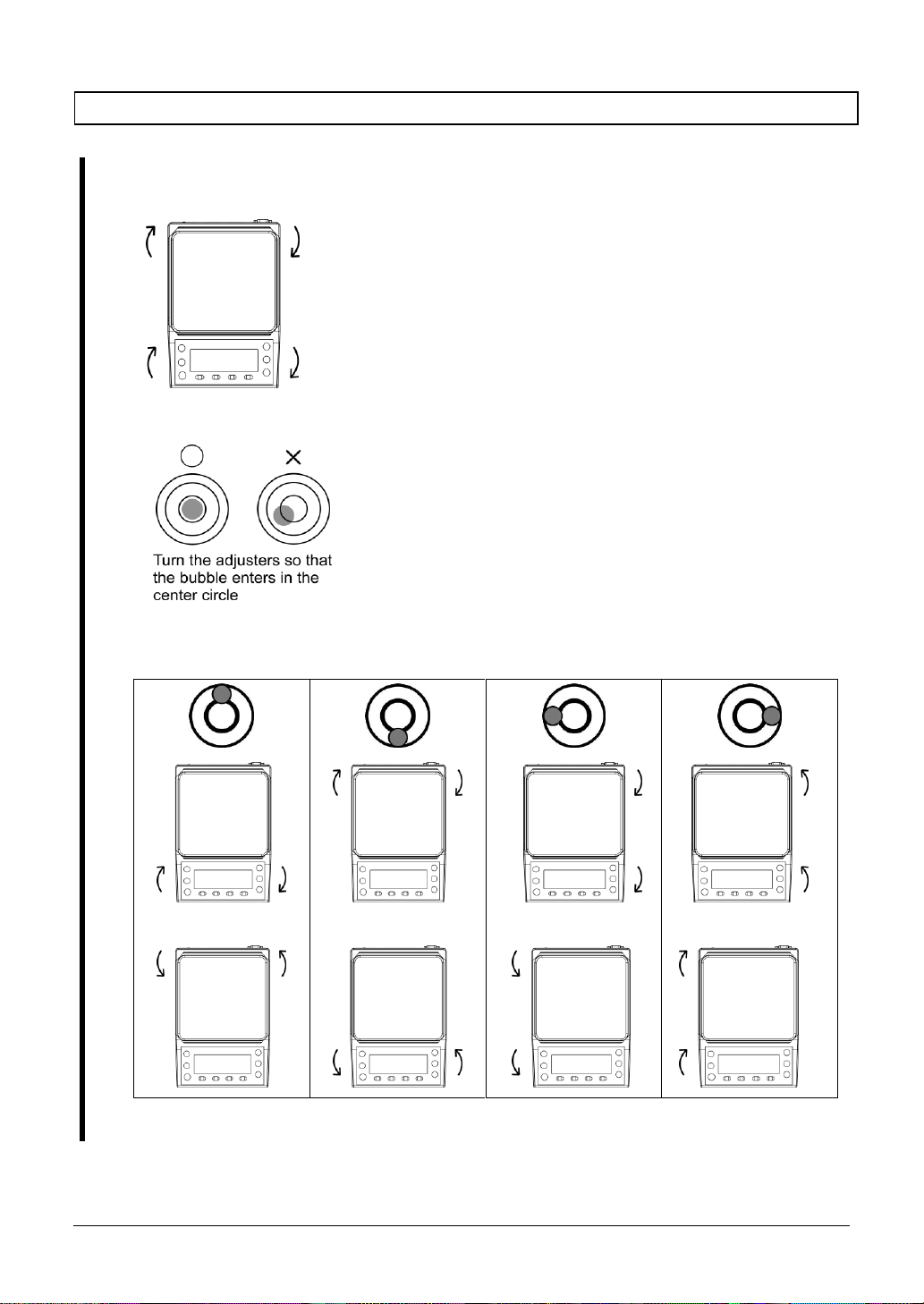

1-5-3 Level

1

Release the transportation lock of the

adjuster.

At the time of shipment, the adjusters provided

at the four corners of the bottom are locked.

Turn them in the direction shown in the figure on

the left to loosen them.

2

Level the balance.

(1)

While watching the level, turn the adjusters

provided on the bottom to level the main unit.

(2)

Bring the bubble enters in the center circle as

shown in the figure on the left.

(3)

When having leveled the main unit, slightly

push the four corners of the balance to make

sure that there is no rattle.

Turn the adjusters as shown below depending on the position of the bubble in the level.

or

or

or

or

Page 20

1 Prior to use MG-S series operation manual

-10-

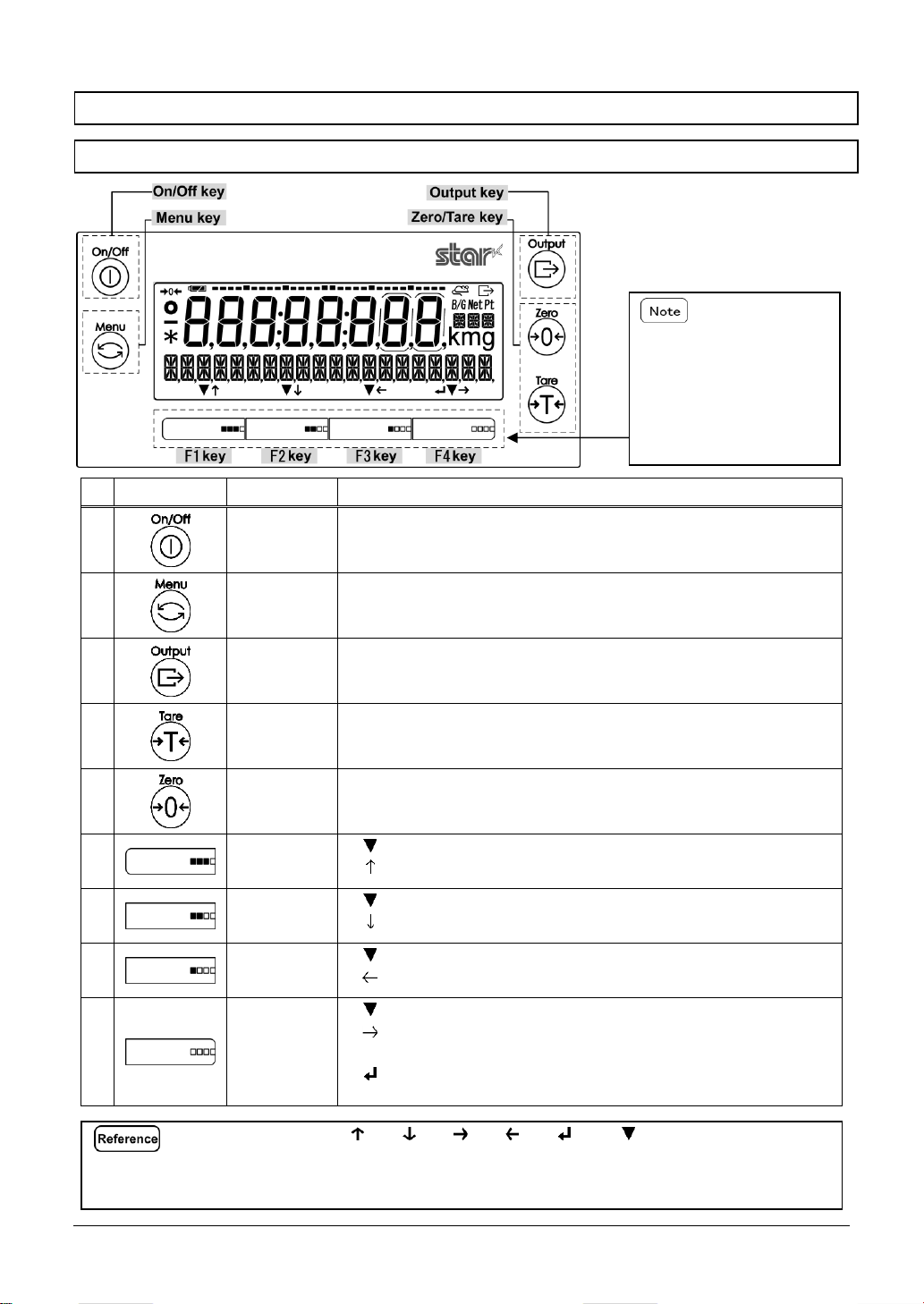

1-6 Description of the operation keys

1-6-1 Basic

No

Key

Name of key

Performance

1 [O n/Off]

Turns on and off the power for the balance.

On: Push the key, Off: Push the key long

2 [Menu]

Used for calling/exiting the setting menu.

Used for canceling the setting value selection and going back to the

measurering mode.

3 [Output]

Use for data outputting.

Use for data importing in the Statistics/Formulation mode.

4 [Tare]

Use for tare subtraction.

5 [Zero]

Use for zero-point adjustment.

6

[F1]

([F] key)

< < > > :

:

Use for selecting the mode, function and item.

Use for moving up to the menu/item selections, or use for

incrementing the numeric values.

7

[F2]

([F] key)

< <

> > : :

Use for selecting the mode, function and item.

Use for moving down to the menu/item selections, or use

for decrementing the numeric value.

8

[F3]

([F] key)

< <

> > : :

Use for selecting the mode, function and item.

Use for moving to the upper menu layer, or use for

selecting the digit to change.

9

[F4]

([F] key)

<

<

<

>

>

>

:

:

:

Use for selecting the mode, function and item.

Use for moving to the lower menu layer, or use for

selecting the digit to change.

Use for entering/executing the selected

menu/item/value, or use for returning to the setting

menu/measuring mode.

The [F] keys on which < >, < >, < >, < >, < > or < > are displayed above are

valid.

Shortcuts for various modes/functions can be assigned to [F] keys. Please refer to

“8-2 Shortcut setting for accessing various measuring modes” and “8-3 Free key setting”.

These keys are called [F]

keys or [F1]-[F4] key in

this manual as a matter of

convenience, while there

are not such indications

around them.

Page 21

MG-S series operation manual 1 Prior to use

-11-

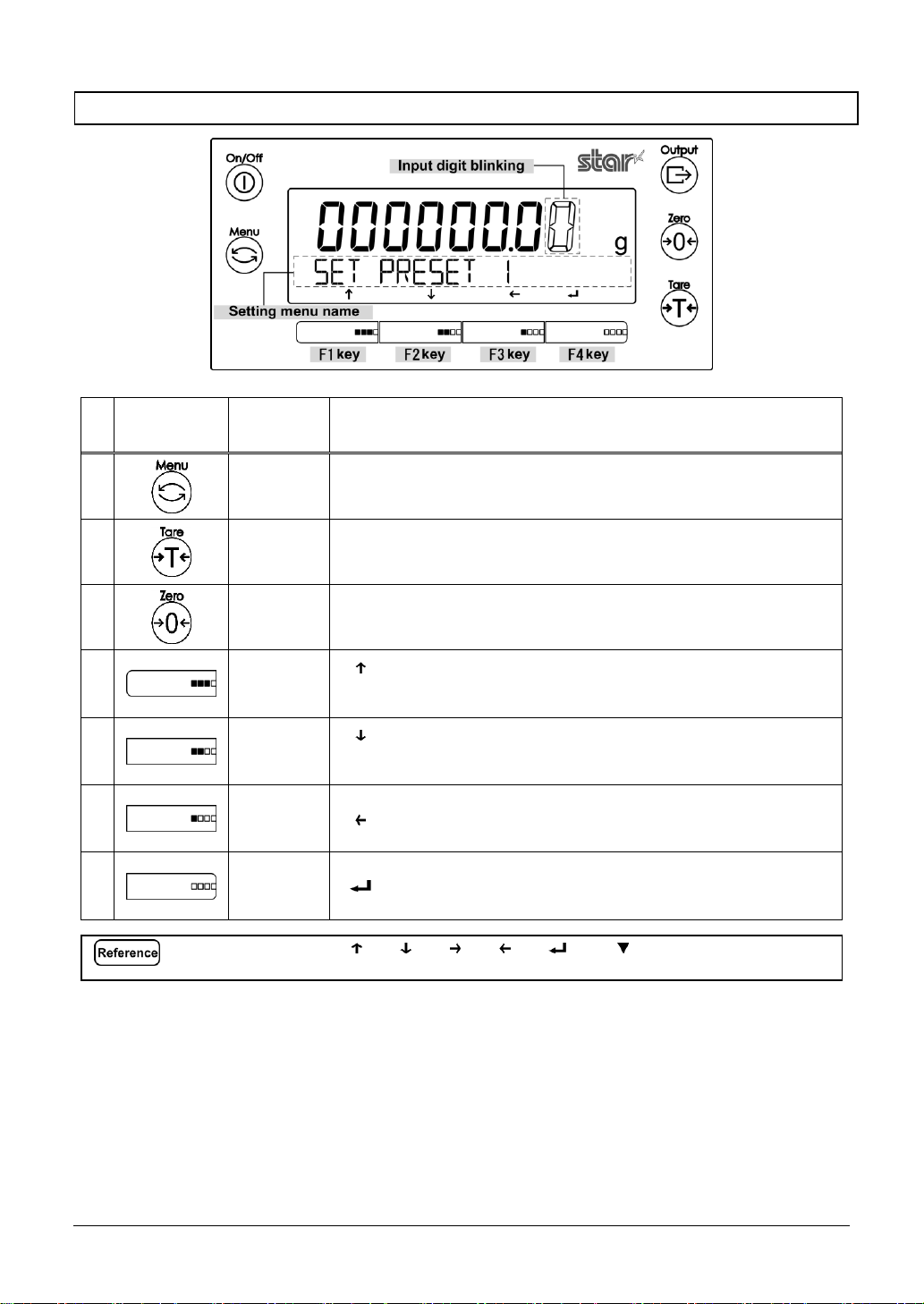

1-6-2 Setting value and numeric value inputting

No

Key

Name of

key

Performance

1 [Menu]

Cancel the input value and go back to the setting menu.

2 [Tare]

Input a decimal point < . > in “Specific Gravity mode”.

3 [Zero]

Use for changing polarity <+/->.

4

[F1]

([F] key)

< > : Use for incrementing the numeric values.

<0 → 1 → 2 →…→ 9 → 0>

5

[F2]

([F] key)

< > : Use for decrementing the numeric values.

<0 → 9 → 8 →…→ 1 → 0>

6

[F3]

([F] key)

< > : Use for selecting the digit to change.

7

[F4]

([F] key)

< > : Use for entering the value.

The [F] keys on which < >, < >, < >, < >, < > or < > are displayed above are

available.

Page 22

1 Prior to use MG-S series operation manual

-12-

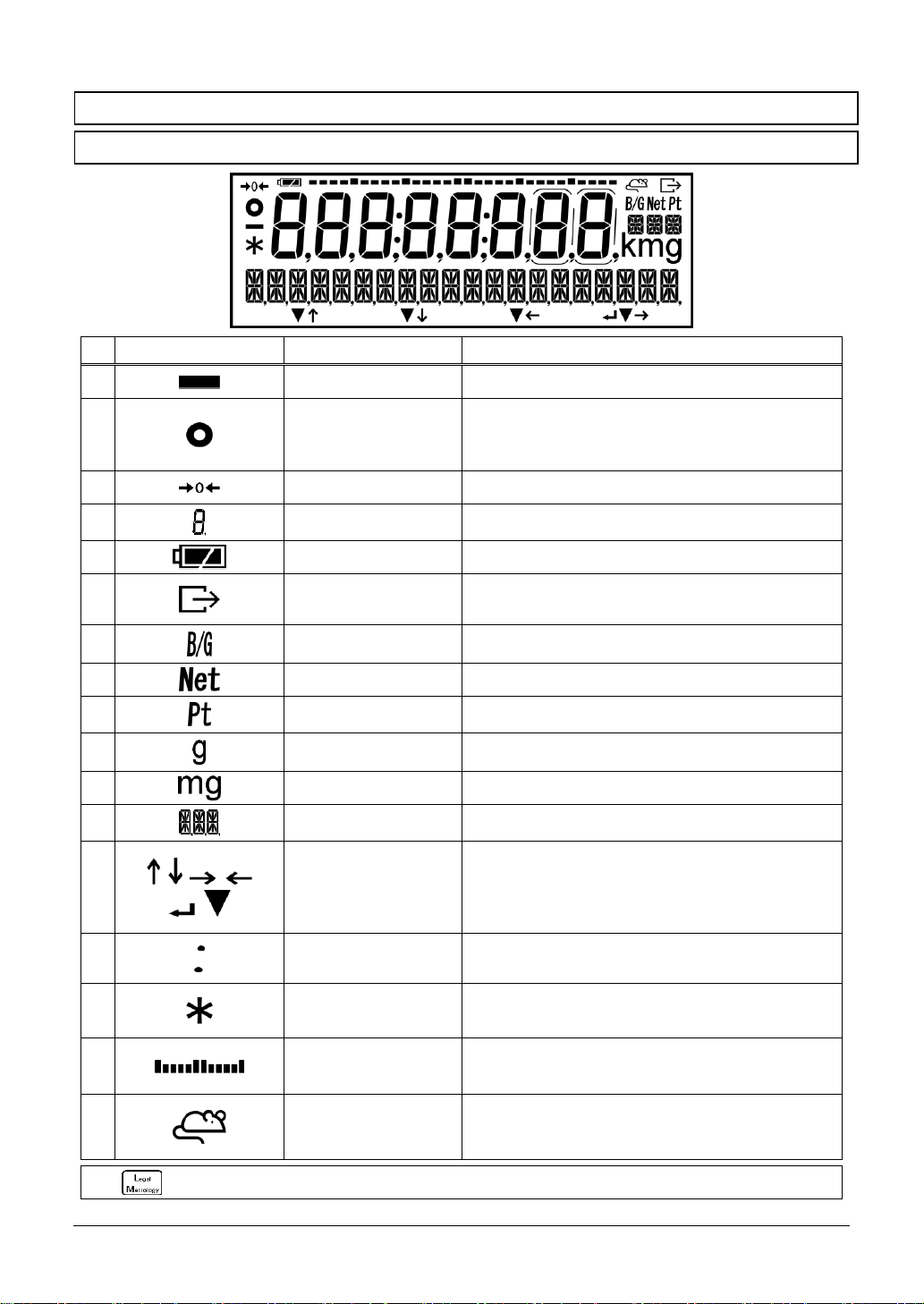

1-7 How to interpret the display

1-7-1 Description of segment.

No

Mark

Name

Description

1 Minus

Indicates the negative weight value and numeric.

2 Stable mark

-

-

When displayed: The balance is in the stable

condition.

When not displayed: The balance is not in the

stable condition.

3 Zero point

Indicates the zero point.

4 7 segment

- - Indicates the weight value

Indicates the simplified character.

5 Battery mark

Display when the balance is powered by batteries.

6 Output

Displayed when data are being output to external

devices.

7 Gross weight

Indicates gross weight.

8 Net weight

Indicates that the tare weight is being subtracted.

9 Preset tared weight

Indicates that the preset tare weight is being

subtracted.

10

Gram

Indicates the gram unit.

11 milligram

Indicates the milligram unit.

12

16 segment message

16 segment unit

- - Displays various messages.

Indicates the various units.

13

Operation of the [F]

key

Displayed when the [F1] – [F4] keys are effective.

14 Colon

Displayed when the date and time display.

15 Asterisk

- Lights in the standby status.

- Indicates addition available status when the

adding function is used.

16 Bar graph

Indicates the present total amount relative to the

weighing capacity defined as 100%.

17

Animal weighing

mode

Displayed when the animal weighing mode.

Nos. 9, 11 and 17 are not indicated on the verified balance.

Page 23

MG-S series operation manual 1 Prior to use

-13-

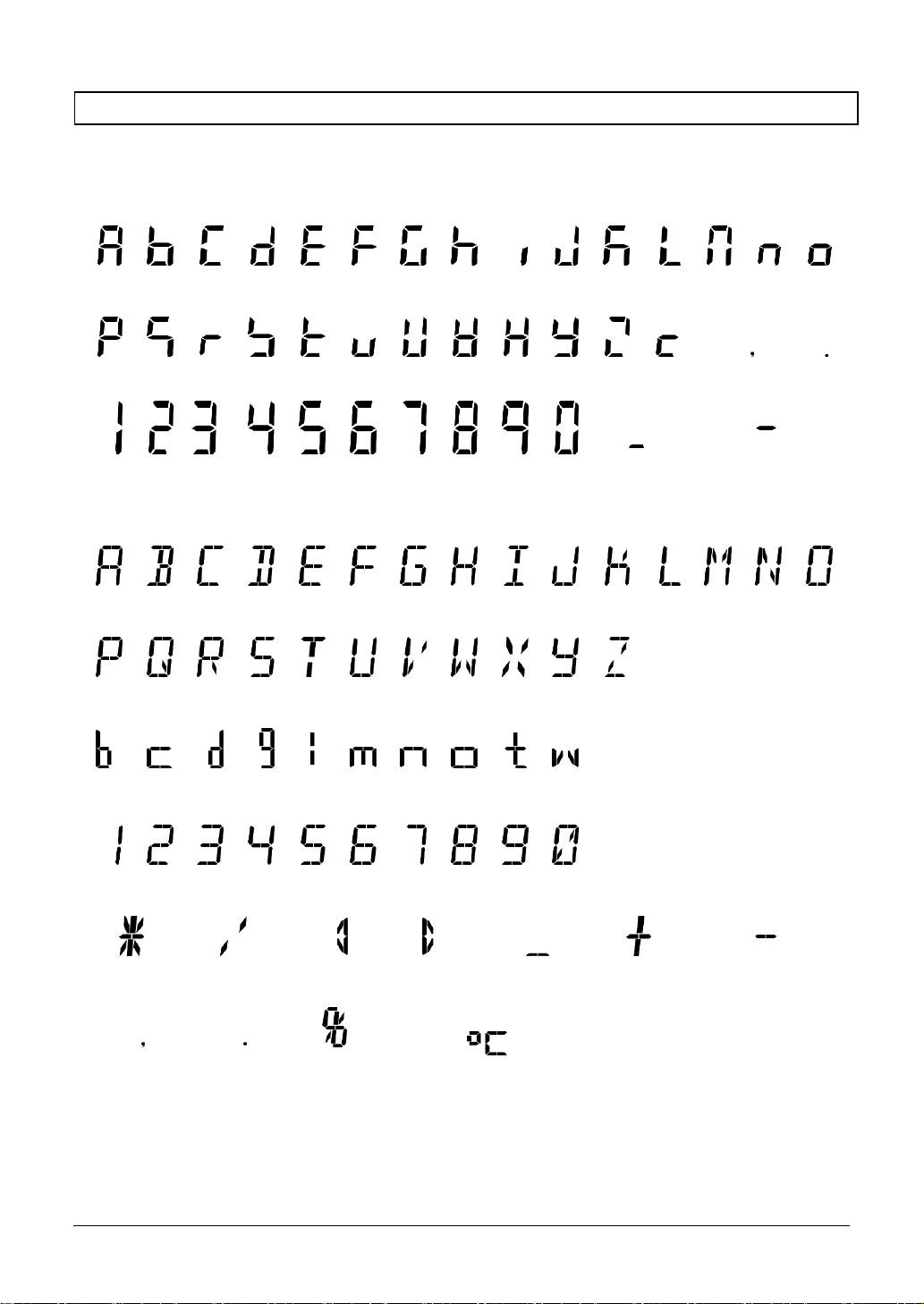

1-7-2 LCD character font

■7-segment

A B C D E F G H I J K L M N O

P Q R S T U V W X Y Z c comma

point

1 2 3 4 5 6 7 8 9 0 space

minus / hyphen

■16-segment

A B C D E F G H I J K L M N O

P Q R S T U V W X Y Z

b c d g l m n o t w

1 2 3 4 5 6 7 8 9

0

asterisk

slash

left arrow

right arrow

space

plus

minus / hyphen

comma

point

percent

Degree Celsius

Page 24

2 Basic usage MG-S series operation manual

-14-

2 Basic usage

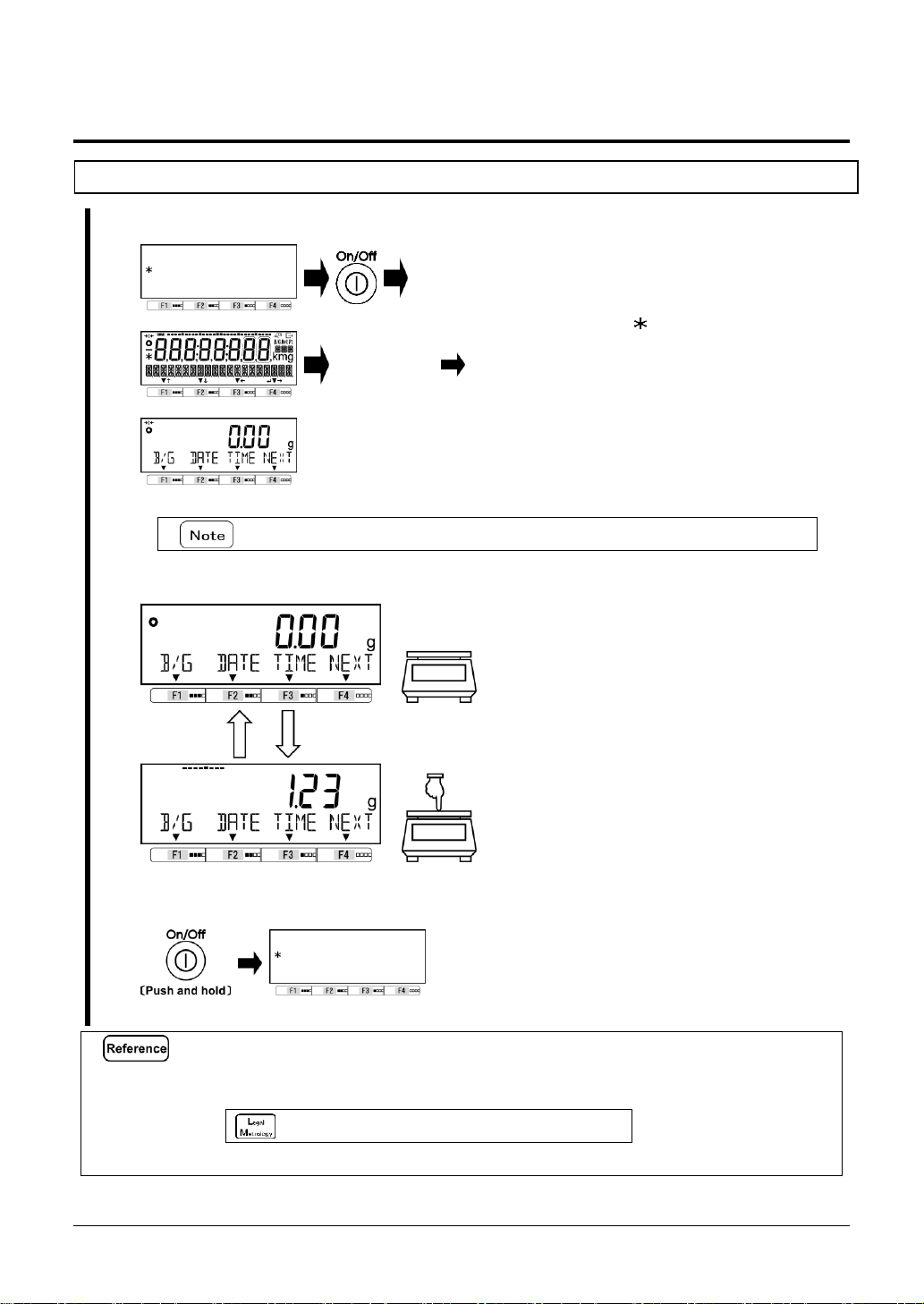

2-1 Turning on/off the power, and checking for the operation

1

Turn on the power for the balance.

“Self-check”

Connect the included AC adapter to the

balance.

When the AC adapter is plugged in, the

balance enters the standby state and an

asterisk < > appears.

Push [On/Off] key.

All displays on the LCD lights, followed by

the self-check of the balance. During the

self-check, the LCD display automatically

changes.

Completion of the self-check is followed by

the weight mode.

Do not push any key during the self-check.

2

Balance operation check.

Press the weighing pan lightly to check if

the indication changes.

3

Turn off the power for the balance.

Push and hold [On/Off] key (About 2

seconds)

(1)

Pushing and holding [On/Off] key obtains the standby status from any operation status.

(2)

When battery driven, the balance on/shutdowns without standby status.

(3)

The balance starts up in the last measuring mode before it was switched off.

Verified balance always starts up in weighing mode.

Page 25

MG-S series operation manual 2 Basic usage

-15-

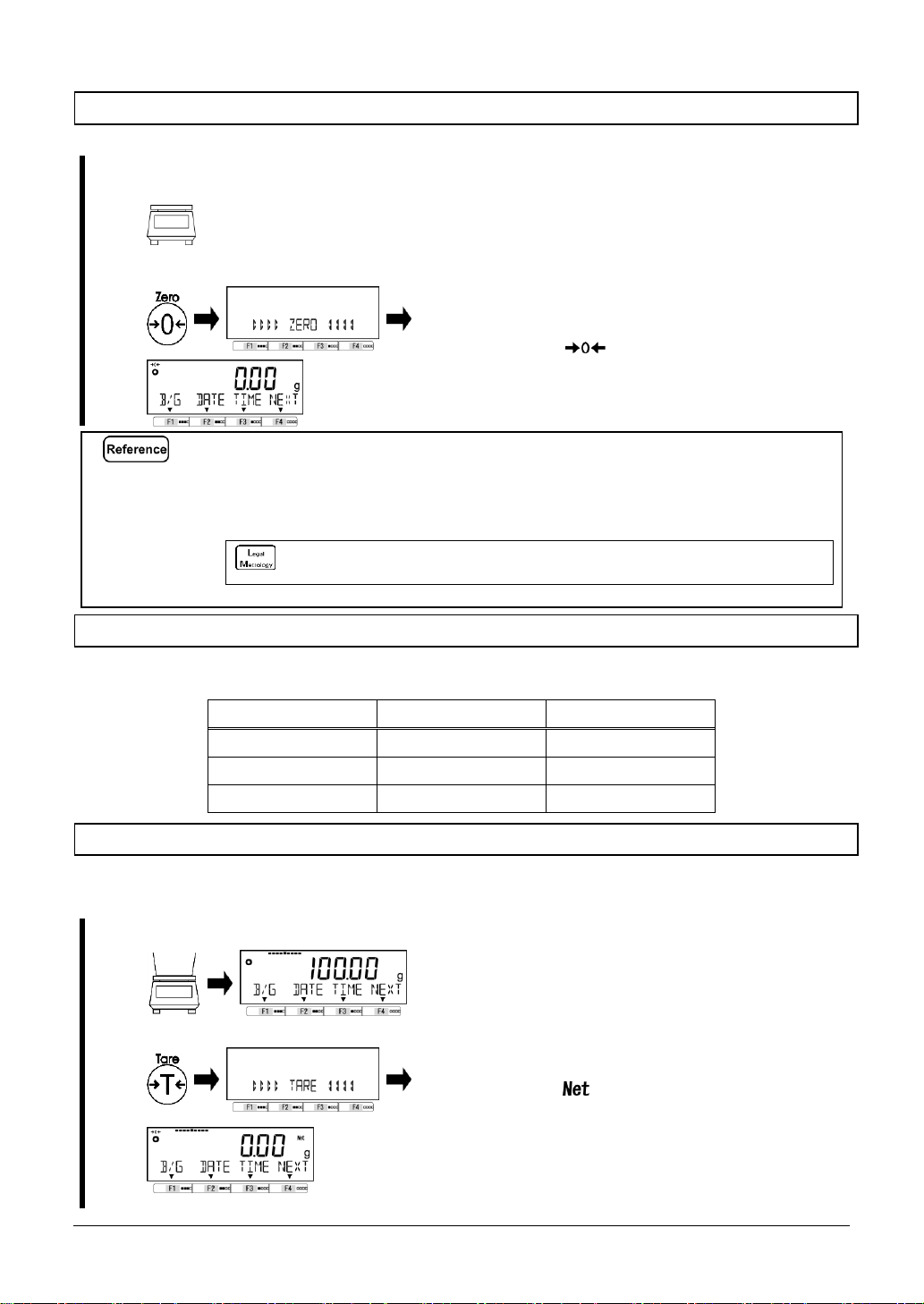

2-2 Zero-point adjustment

Adjusting the indication to zero is called "Zero-point adjustment".

1

Check the weighing pan.

Make sure that nothing is placed on the

weighing pan.

2

Execu te “Zer o-po int adjust ment”.

Push [Zero] key.

After the weight indication is stabilized, the

indication become zero and the symbol

“ ” lights.

(1)

Zero-point adjustment cannot not be performed when a sample whose weight is over the “Zero-

point adjustment range” is placed on the weighing pan. In that case, make the “tare” referring to

the “2-3 Weighing a sample placed on a container (tare)”

(2)

Stability waiting during the Zero-point adjustment can be set using the Setting menu

<17 WT STABLE>.

For verified balance, <17 WT STABLE> is not indicated and the balance always

wait stability during the zero-point adjustment.

2-2-1 Zero-point adjustment range

There is a Zero-point adjustment range (limit) in this product. When the weighing load (gross) exceeds

the upper or lower limit, “Zero-point adjustment” cannot be executed.

Model

Lower limit (g)

Upper limit (g)

MG-S322

-4.80

4.80

MG-S1501

-22.5

22.5

MG-S8200

-123

123

2-3 Weighing a sample placed on a container (tare)

When weighing a sample to be weighed with the object placed on a container (tare), the weight of the

container must be subtracted from the total weight to get the actual weight of the object to be weighed.

This is called “tare subtraction” or “tare”.

1

Place a container on the weighing pan.

The weight of the container is displayed.

2

Perform tare subtraction.

Push [Tare] key.

The indication changes to zero and the

< > symbol lights.

Page 26

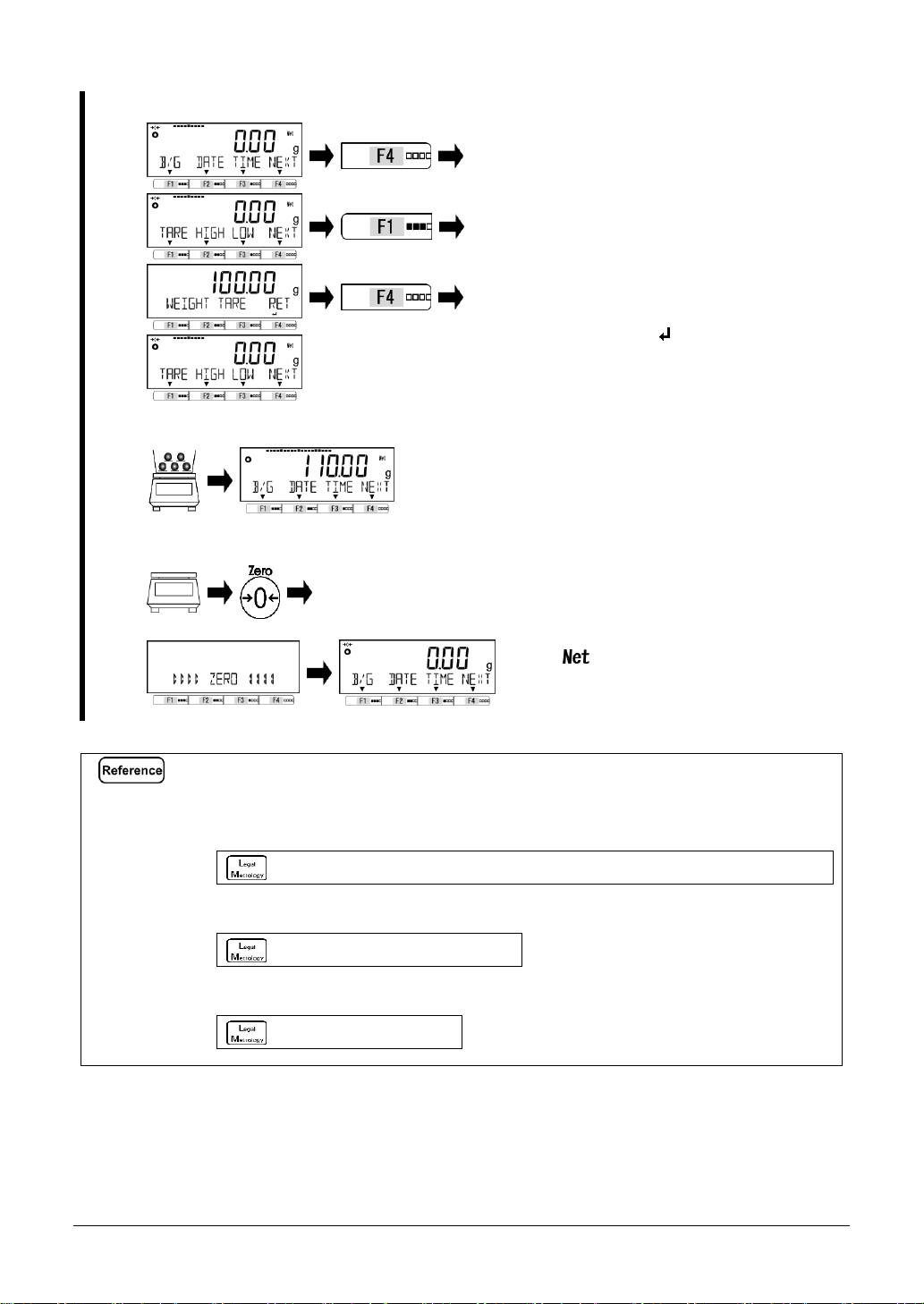

2 Basic usage MG-S series operation manual

-16-

3

Check the tare weight.

The tare weight can be checked by operating

“Free keys” if the <TARE> is assigned to the

Free key.

Refer to “8 Controlling and adjustment

functions” for setting the Free keys.

Push [F4] key to switch the menu bar

and push [F1-F3] key on which <TARE>

is displayed above.

The tare weight is displayed on the display,

then push [F4] < > key to return to the

measuring mode.

4

Put the sample on the tare.

The net weight of the sample is displayed.

5

Clear the tare weight data.

Remove the sample and tare on the

weighing pan, then push [Zero] key.

Therefore, the indication becomes zero and

< > indication disappears.

(1)

Performing the tare narrows the weighing range as much as the amount

of the tare weight mass (tare weight).

Weighable range = weighing capacity - tare weight

(2)

Tare weight can be output at “3 Check the tare weight” by pushing [Output] key.

Check “External input/output functions” to refer the output setting.

(3)

Stability waiting during the tare can be set using the Setting menu <17 WT STABLE>.

The setting of <17 WT STABLE> is not changeable and the balance always wait

stability during tare-subtraction.

(4)

When using a tare whose tare weight is already known, the tare can be performed in advance by

inputting its tare weight (preset tare). For its setting method, refer to “5 User information setting”.

Preset tare function is not available.

(5)

When turning on the power placing a tare that exceeds the initial zero-adjustment range at the

time of power supply, the tare subtraction is executed.

This operation is not valid.

Page 27

MG-S series operation manual 2 Basic usage

-17-

2-4 Weighing the additional sample

Weigh the first sample and the additional sample separately.

1

Place a sample to be weighed.

The mass of the sample to be weighed placed is

indicated.

2

Perform the tare.

Push [Tare] key.

The indication changes to zero and the < >

symbol appears.

3

Place an additional sample to be

weighed.

The mass of the added sample alone is indicated.

2-5 Basic operation

Shortcuts for various modes/functions can be assigned to [F] keys. Please refer to

“8-2 Shortcut setting for accessing various measuring modes” and “8-3 Free key setting”.

2-5-1 Hierarchy of a setting menu

The setting menu of this product is divided into four, from the first layer to the third layer and for various

setings.

Page 28

2 Basic usage MG-S series operation manual

-18-

2-5-2 Operation of the setting menu

To perform settings for various functions from the state of weighing, chiefly execute the following

procedure.

■Go to the menu item to set

■Select the setting value and execute/fix.

Page 29

MG-S series operation manual 2 Basic usage

-19-

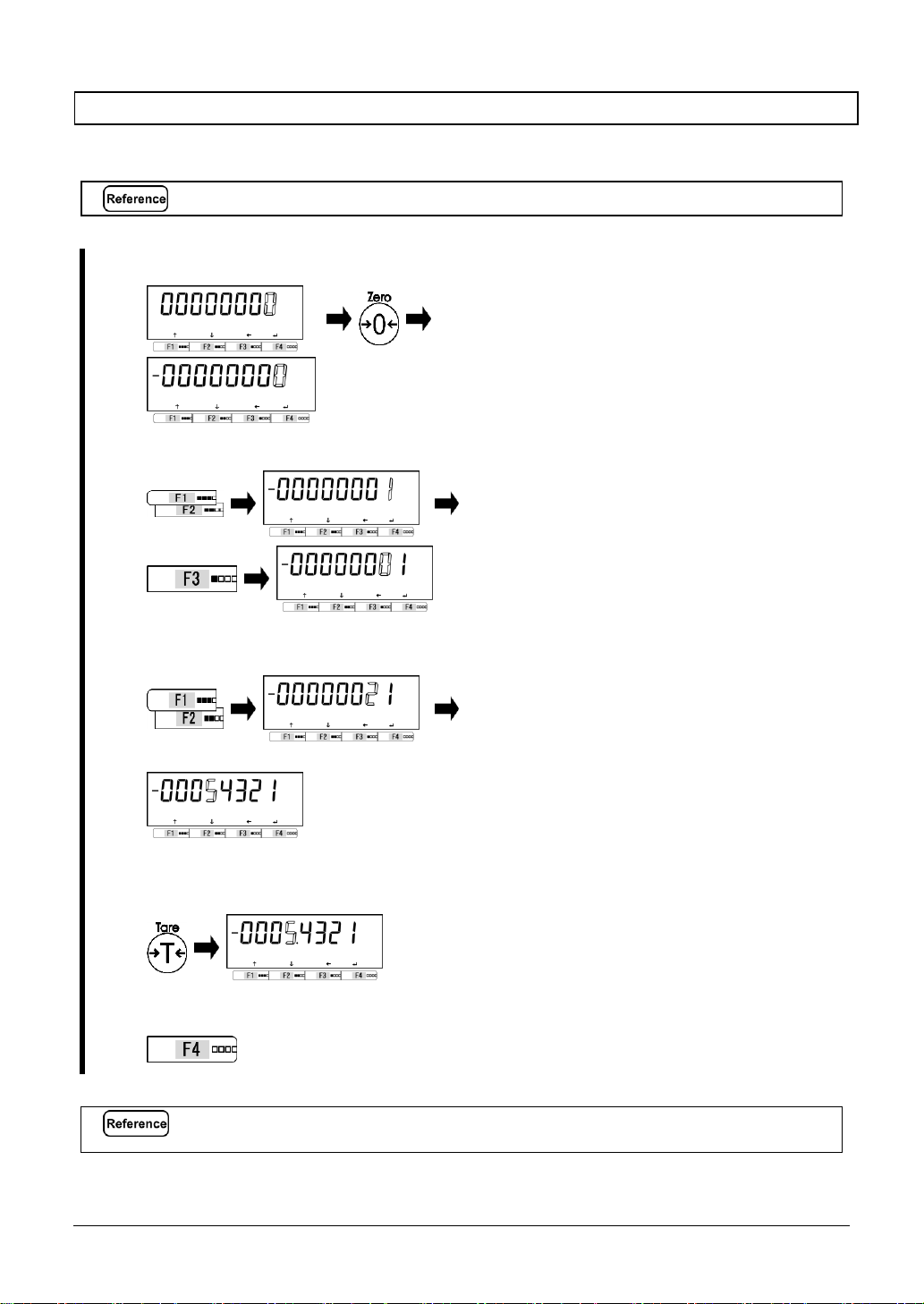

2-5-3 Numeric value input

Input upper/lower limit, reference weight, preset tare weight, coefficient, specific gravity of the media

liquid, water temperature, date/time and ID/password at each mode.

Numeric value inputting is limited to eight digits at a maximum.

e.g.) When inputting “-5.4321”.

1

Input “– “.

Push [Zero] key to change the polarity to

“-”.

2

Input “1 “.

The digit for inputting is blinking.

Push [F1, F2] key to

increment/decrement the digit to “1”.

Push [F3] key to input the next digit.

3

Input “2, 3, 4, 5 “ .

・・・

Input “2, 3, 4, 5” by the procedure above.

4

Input “.” .

Push [Tare] key to input “.” on the

immediately right of the blinking digit.

5

Fix the input value.

Push [F4] key to fix the input value.

“-5.4321” is saved on the balance.

“-” and “ . ” cannot be input in ID or Password setting.

cf. “8-5-1 Balance ID setting”

Page 30

2 Basic usage MG-S series operation manual

-20-

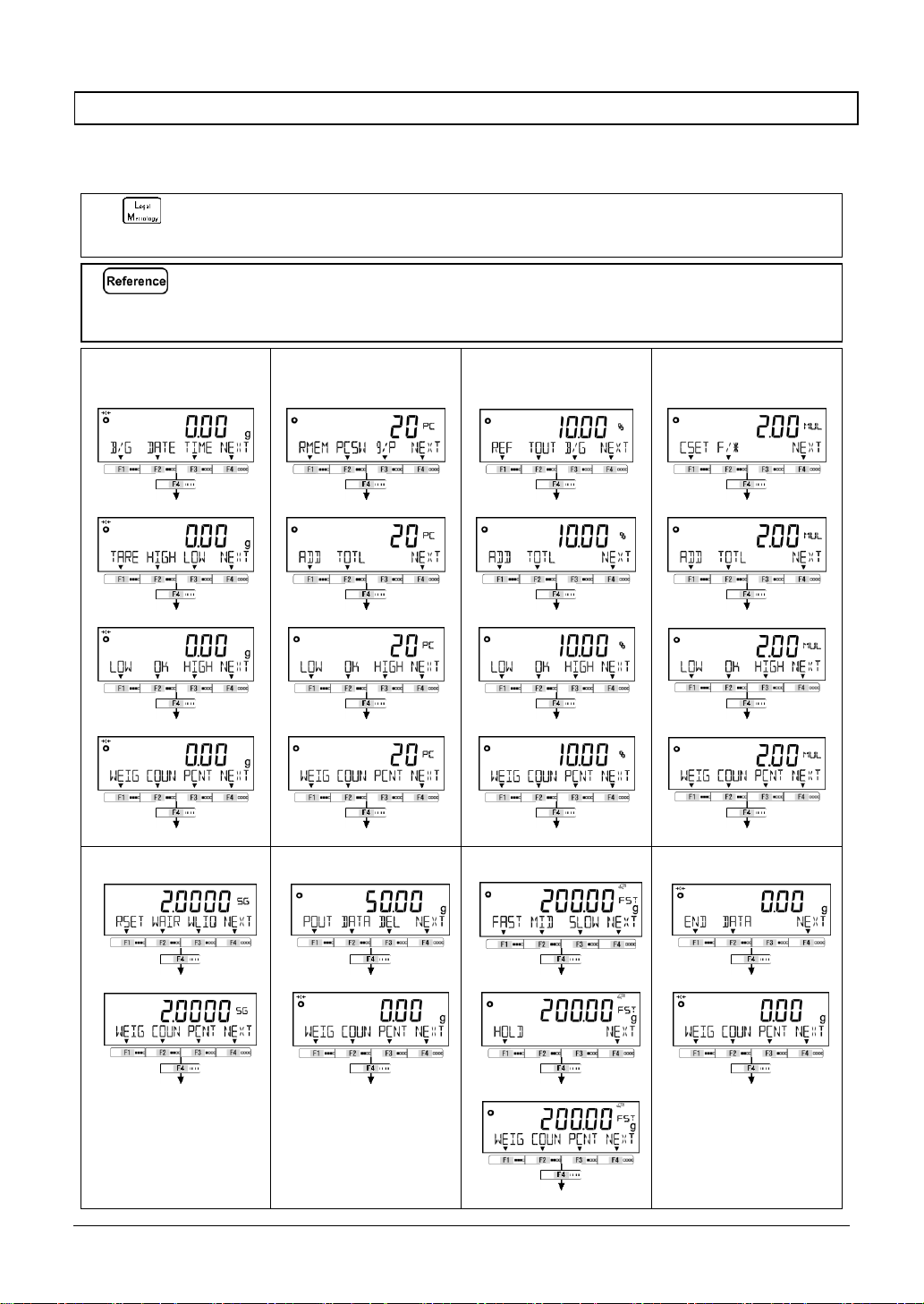

2-5-4 [ F ] key switching at each measuring mode

You can switch the measuring mode, or select and set the function, by operating the [F] keys at each

measuring mode.

This chapter shows the [F] keys switching by pushing the [F4] key.

Refer to “3 Function related to the operation” for the [F1-F3] keys operation.

For verified balance:

-

-

“Adding execution, Sum total” is not available;

“Multuplied by Coefficient mode”, “Statistics mode”, “Animal mode” and “Formulation mode” are

not available.

“"

(1)

In weighing mode, <<F1-F6>> (Free keys) are assigned to [F] keys as described follow;

<<F1>> and <<F4>>: [F1] key, <<F2>> and <<F5>>: [F2] key, <<F3>> and <<F4>>: [F3] key.

Please take care not to confuse <<F1-F4>> to [F1-F4] keys.

(2)

Refer to “8 Controlling and adjustment functions” for assigning “Free keys” and “Modes” to

[F] keys.

Weighing mode

Counting mode

Percentage mode

Multiplied by

Coefficient mode

<<F1-F3>> (Free key)

Counting mode menu

Percentage mode menu

Multiplied by coefficient

mode menu

<<F4-F6>> (Free key)

Adding execution, Sum total

Adding execution, Sum total

Adding execution, Sum total

Comparator setting menu

Comparator setting menu

Comparator setting menu

Comparator setting menu

Measuring mode switching

Measuring mode switching

Measuring mode switching

Measuring mode switching

Return to the first menu item

Return to the first menu item

Return to the first menu item

Return to the first menu item

Specific gravity mode

Statistics mode

Animal mode

Formulation mode

Specific gravity mode menu

Statistics mode menu

Animal mode menu

Formulation mode menu

Measuring mode switching

Measuring mode switching

Animal mode menu

Measuring mode switching

Return to the first menu item

Return to the first menu item

Measuring mode switching

Return to the first menu item

Return to the first menu item

Page 31

MG-S series operation manual 3 Functions related to the operation

-21-

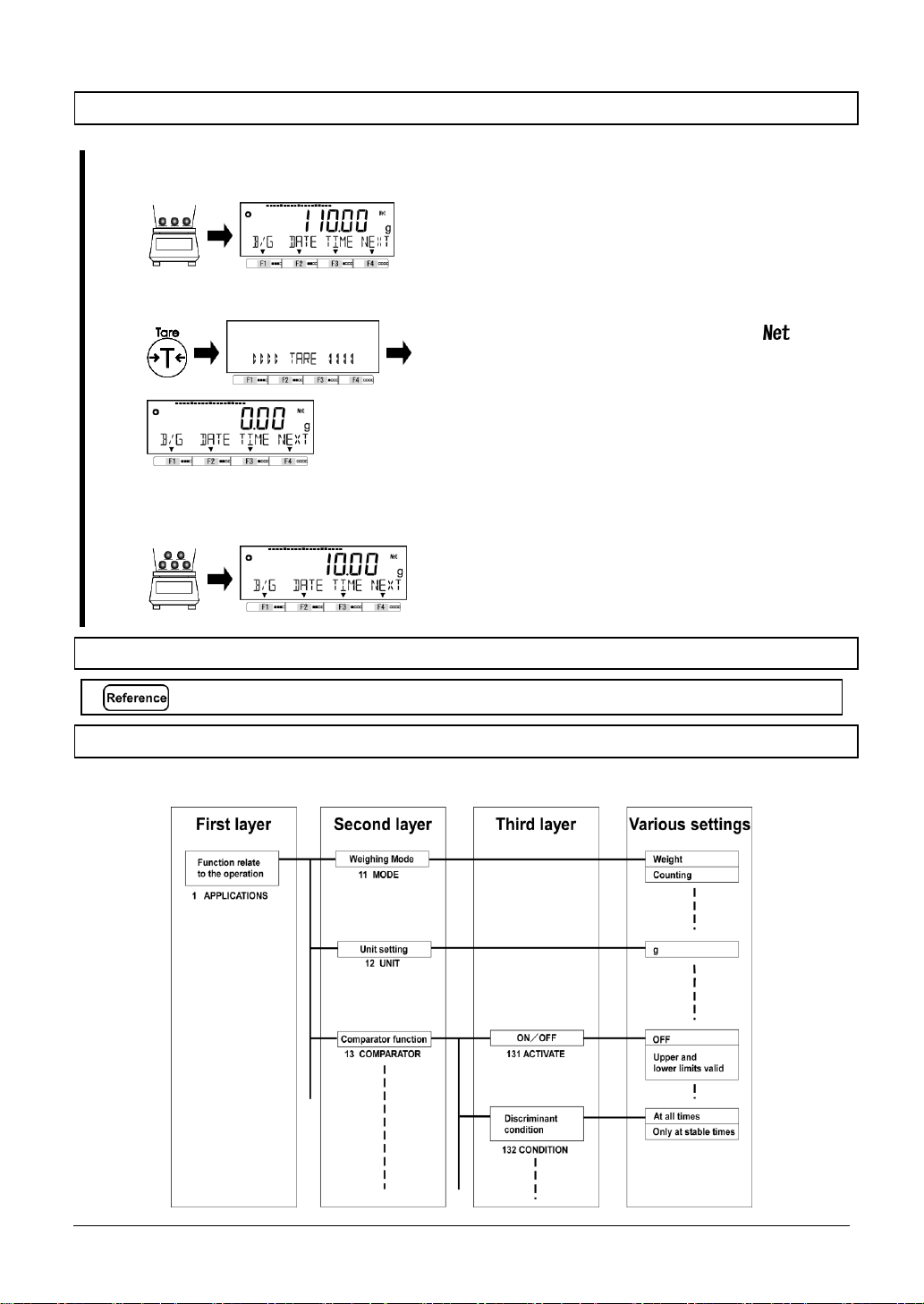

3 Functions related to the operation

Settings to change the balance operations.

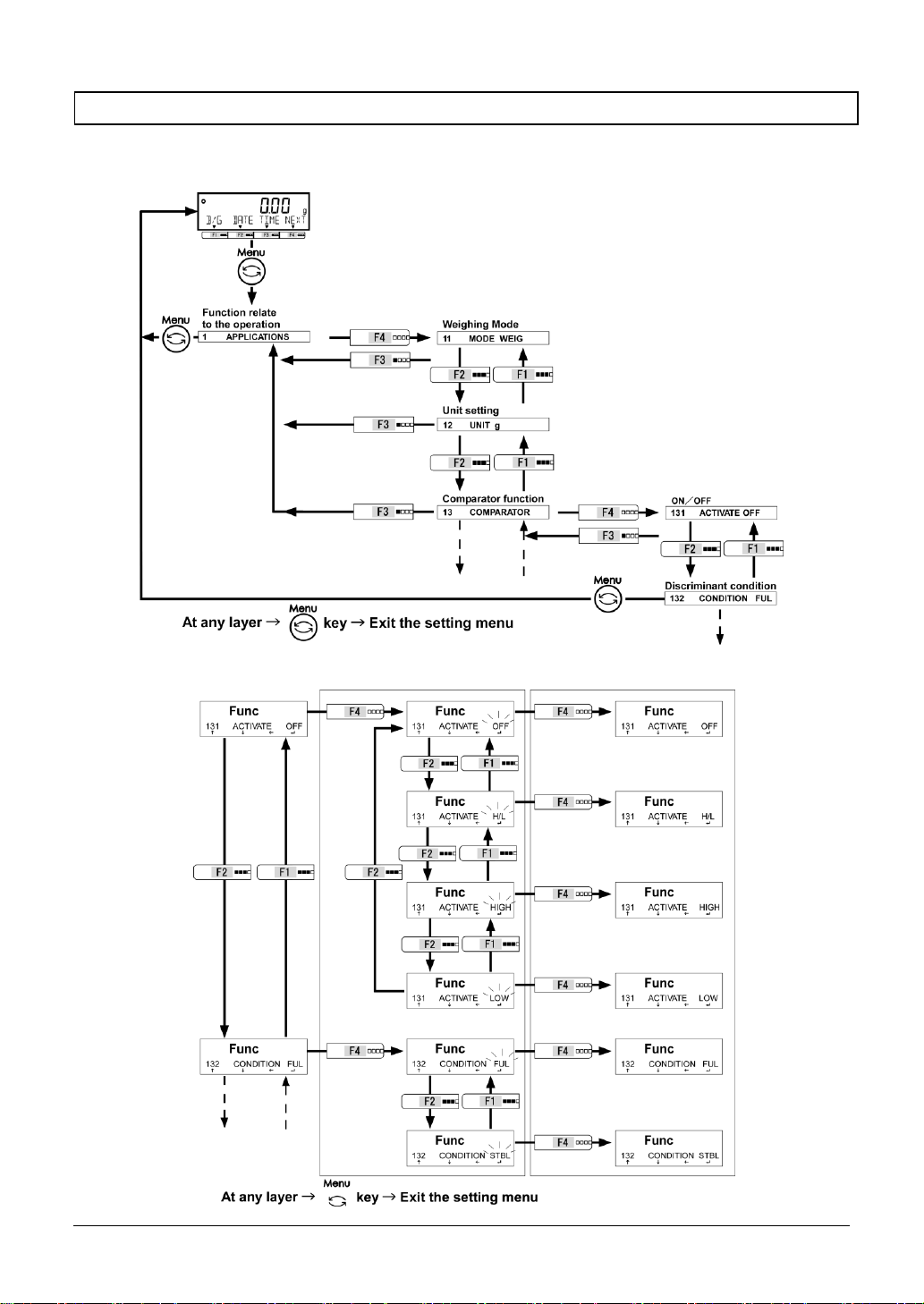

3-1 Hierarchy of functions related to the operation

For verified balance:

- Gray shaded items ( ) are not indicated;

- <17 WT STABLE> is not indicated and fixed to be <ON>;

- <141 ACTIVATE> is not indicated and fixed to be <OFF>;

- “grain” is not selectable on MG-S1501 and MG-S8200;

- “carat” is not selectable on MG-S8200.

Initial setting value of <12 UNIT> is:

- <g>(gram) on MG-S322, MG-S1501, and non-verified MG-8200;

- <LB>(pound) on verified MG-S8200.

★: Initial setting value in a verified balance

Page 32

3 Functions related to the operation MG-S series operation manual

-22-

3-2 Various measuring modes of the balance

Refer to “6 External input/output functions” to output the measuring data to other devices.

3-2-1 Weighing mode

Weighing mode is the basic mode for weighing.

Various functions can be used with weighing mode by pushing the “Free key”. Please refer to “8-3

Free key setting”.

1

Select the weighing mode.

Push [Menu] key, then push [F1-F4] keys

to go to <11 MODE>.

Push [F4] key to change the setting

value.

Push [F1/F2] key to select.

WEIG

:

Weighing mode

Push [F4] key to fix.

2

Exit the setting menu.

Push [Menu] key to shift to the weighing

mode.

3

Execute tare-subtraction

Place the container on the weighing pan if

necessary.

Push [Tare] key

Tare-subtraction is executed, then the

indication changes to zero and the

< > symbol lights.

4

Weigh the sample.

Place the weighed.

The weighing result is displayed.

Page 33

MG-S series operation manual 3 Functions related to the operation

-23-

3-2-2 Counting mode

Counting mode can count the number of items by placing the items for which sampling has been

completed on the balance and dividing the total weight of those items by the recorded unit weight.

(1)

When to use for prescription counting in USA, Class II unit shall be selected.

Class III units are not legal for trade for prescription counting.

Please refer to “Appendix 1-1 Basic Specification” for metrological specification in each weighing unit.

(2)

For verified balance:

- Numeric value setting method is not available;

- Measuring unit indication of pieces is “PC” instead of “PCS”.

The unit weight is inputted by following method:

-

Actual value setting method:

Place the specified number of samples on the balance to record the

average unit weight.

-

Numeric value setting method:

Input numeric value of the unit weight by key operation.

1

Select the Counting mode.

Push [Menu] key, then push [F1-F4]

keys to go to <11 MODE>.

Push [F4] key to change the setting

value.

Push [F1/F2] key to select.

COUN

:

Counting mode

Push [F4] key to fix.

2

Exit the setting menu.

Push [Menu] key to shift to the Counting

mode.

3-2-2 (1) Actual value setting method

Place the specified number of samples on the balance to record the average unit weight internally.

For verified balance:

-

-

-

-

Minimum sample size in pieces “MSS” is 10 PC;

<On 5> in Step 2 is not available;

1 to 9 PC cannot be selected on <on VAR>;

The unit weight (individual piece weight “MPW”) less than 3d and total sample weight

less than 30d cannot be adopted.

1

Select whether or not employ the previous

recorded unit weight.

Push [F3/F4] key to select whether or not

employ the previous data.

When there is no data record, this step is

skipped.

Push [F3/F4] key to select.

NO

:

Change

YES

:

Not Change

When <YES> is selected, go to step 6.

2

Select the “ number of samples mode” .

Place a container (tare) on the weighing pan if

necessary.

Push [F1/F2] key to select.

on 5

:

5 PC

on 10

:

10 PC

on 30

:

30 PC

on 50

:

50 PC

on 100

:

100 PC

on VAR

:

1 – 999 PC

PCSWGT

:

Numeric value setting method

See 3-2-2(2)

Push [F4] key to fix.

Tare-subtraction or zero-point adjustment is

executed automatically.

Page 34

3 Functions related to the operation MG-S series operation manual

-24-

3

Place the samples.

Place the set number of samples on the

container.

4

Record the unit weight.

Push [F4] key to fix.

The unit weight is recorded.

5

Simple SCS method (When enabled).

・・・

When <1C Simple SCS> is valid, Simple SCS

method is activated and the sample counting

indication blinks during this function.

Add more samples, then the number of

samples and unit weight is automatically

updated when the indication becomes stable.

The number of additional samples can be up to

two times the number of the samples of the

latest update.

For example, when “10 PC” is set, add 20 or

less samples.

Repeat this step until the number of the

samples has reached approximately one-fifth

to one-half of the total numbers that you are

intended to count.

Push [F4] key to fix the updated unit

weight.

6

Put samples in place to count them.

Place the samples.

Count result is displayed.

(1)

When <on VAR> is selected in step 2, select the specified number of the sample among 1 to 999

by operating [F1/F2] keys.

For verified balance, 1 to 9 PC cannot be selected on <on VAR>.

(2)

When simple SCS is operating, if the weight of the samples is less

than the “SCS weight” ― 99 times of the minimum readability

(d x 99) ―, <Add> blinks on the display and unit weight cannot be

updated.

In this case, add samples until <Add> indication disappears, or select

the larger number of samples in step 2.

Model

Readability d (g)

SCS weight (g)

MG-S322

0.01

0.99

MG-S1501

0.1

9.9

MG-S8200

1

99

(3)

When simple SCS is operating, if the number of the additional

samples is larger than two times of the sample number of latest

update, <Sub> blinks on the display and unit weight cannot be

updated.

In this case, decrease the number of additional samples.

Page 35

MG-S series operation manual 3 Functions related to the operation

-25-

3-2-2 (2) Numeric value setting method

Input numeric value of the unit weight by key operation.

This moethod is not available for verified balance.

1

Select whether or not employ the previous

recorded unit weight.

Push [F3/F4] key to select whether or

not employ the previous data.

When there is no data record, this step is

skipped.

Push [F3/F4] key to select.

NO

:

Change

YES

:

Not Change

When <YES> is selected, go to step 4.

2

Select the “ unit weight va lue input mode”.

Push [F1/F2] key to select.

PCSWGT

:

Unit weight value input

Push [F4] key to fix.

3

Input the unit weight.

Numeric value input

(Refer to “2-5-3 Numeric value input”)

Input the unit weight.

Push [F4] key to fix.

4

Put samples in place to count result.

Place a container (tare) on the weight pan.

Push [Tare] key.

Place the samples.

The count result is displayed.

Page 36

3 Functions related to the operation MG-S series operation manual

-26-

3-2-2 (3) Switching the display at Counting mode

1

Push [F1-F4] keys to switch the display.

For non

<ADD> and <TOTL> can be used when <14 ADDITION> is activated.

For

Page 37

MG-S series operation manual 3 Functions related to the operation

-27-

3-3 Percentage mode

The weight of a sample to be weighed is indicated in percent relative to the reference weight.

There are two methods to input the reference weight;

-

Actual value setting method ([onW]):

Place the reference weight on the balance to record the

weight.

-

Numeric value setting method ([NUM]):

Input numeric value of the reference weight by key

operation.

(1)

Weight limit.

Models

d (g)

Weight limit (g)

MG-S322

0.01

0.10

MG-S1501

0.1

1.0

MG-S8200

1

10

(2)

The minimum percent to be displayed is automatically set according to the recorded reference

weight.

Readability (%)

Range of reference weight

1

Lower weight limit

<=

Reference weight

<

Lower weight limit X 10

0.1

Lower weight limit X 10

<=

Reference weight

<

Lower weight limit X 100

0.01

Lower weight limit X 100

<=

Reference weight

1

Select the percentage mode.

Push [Menu] key, then push [F1-F4] keys to go

to <11 MODE>.

Push [F4] key to change the setting value.

Push [F1/F2] key to select.

PCNT

:

Percentage mode

Push [F4] key to fix.

2

Exit the setting menu.

Push [Menu] key to shift to the percentage

mode.

3

Select whether or not employ the

previous recorded reference value.

Push [F3/F4] key to select whether or not

employ the previous data.

When there is no data record, this step is skipped.

Push [F3/F4] key to select.

NO

:

Change

YES

:

Not Change

When <YES> is selected, go to step 6.

4

Select the method of setting the

reference value.

Push [F3/F4] key to select.

onW

:

Actual value

NUM

:

Numeric value

Page 38

3 Functions related to the operation MG-S series operation manual

-28-

5

Save the reference value.

In the case of [onW].

Place the reference weight on the balance.

Push [F4] key to record.

In the case of [NUM].

Numeric value input

(Refer to “2-5-3 Numeric value input”)

Input the reference value.

Push [F4] key to fix.

6

Weigh the samples.

The ratio of the weight of the sample to the reference

weight is indicated in percent.

Page 39

MG-S series operation manual 3 Functions related to the operation

-29-

3-3-1 Switching the display at percentage mode

1

Push [F1-F4] keys to switch the display.

For non

<ADD> and <TOTL> can be used when <14 ADDITION> is activated.

For

Page 40

3 Functions related to the operation MG-S series operation manual

-30-

3-4 Multiplied by Coefficient mode

Measured weight is multiplied by the preset coefficient, and the result be displayed.

This mode is not available for verified balance.

1

Select the Multiplied by Coefficient mode.

Push [Menu] key, then push [F1-F4]

keys to go to <11 MODE>.

Push [F4] key to change the setting

value.

Push [F1/F2] key to select.

MULT

:

Multiplied by Coefficient mode

Push [F4] key to fix.

2

Exit the setting menu.

Push [Menu] key to shift to the

Multiplied by Coefficient mode.

3

Select whether or not employ the previous

recorded coefficient.

Push [F3/F4] key to select whether or

not employ the previous data.

When there is no data record, this step is

skipped.

Push [F3/F4] key to select.

NO

:

Change

YES

:

Not Change

When <YES> is selected, go to step 6.

4

Set the coefficient.

Numeric value input

(Refer to “2-5-3 Numeric value input”)

Input the coefficient.

Push [F4] key to fix.

5

Weigh the samples.

The weight of the sample is multiplied by the

coefficient and the result is displayed.

Page 41

MG-S series operation manual 3 Functions related to the operation

-31-

3-4-1 Switching the display at Multiplied by Coefficient

1

Push [F1-F4] keys to switch the display.

<ADD> and <TOTL> can be used when the <14 ADDITION> is activated.

Page 42

3 Functions related to the operation MG-S series operation manual

-32-

3-5 Specific gravity mode

In the specific gravity mode, the ratio of the density of a substance to the density of water at its densest

(4°C) for liquids is calculated.

Specific gravity mode is NOT legal for trade.

Purchase the optional “specific gravity measurement kit” or prepare the equipments ― a water tank,

hanging string/wire, net/basket for placing the sample, thermometer etc.― in accordance with the

samples to be measured.

When purchased with “specific gravity measurement kit”, please refer to the option’s manual.

Procedure to measure the specific gravity:

1.

Prepare the equipments or specific gravity measurement kit

2.

Input the water temperature or the specific gravity of the reference liquid.

3.

Measure the sample weight in the air.

4.

Compensate the buoyancy acting on the net/basket.

5.

Measure the sample weight in the water/liquid.

6.

The specific gravity of the sample is displayed.

1

Select the specific gravity mode.

Push [Menu] key, then push [F1-F4]

keys to go to <11 MODE>

Push [F4] key to change the setting

value.

Push [F1/F2] key to select.

SPGR

:

specific gravity mode

Push [F4] key to fix.

2

Exit the setting menu.

Push [Menu] key to shift to the specific

gravity mode.

3

Select the reference liquid.

Push [F3/F4] key to select the reference

liquid.

OTHER

:

Liquid other than water

H20

:

water

4

Input the specific gravity of the reference

liquid or the temperature of the water.

<OTHER>: Liquid other than water

Numeric value input

(Refer to “2-5-3 Numeric value input”)

Enter the specific gravity of the

reference liquid and push [F4] key to fix.

<H20>: Water

Numeric value input

(Refer to “2-5-3 Numeric value input”)

Enter the temperature of the water and

push [F4] key to fix.

Page 43

MG-S series operation manual 3 Functions related to the operation

-33-

5

Measure the sample weight in the air.

Set the net/basket on the balance and

push [Tare] key.

Load the on the net/basket to measure

the weight of the sample in the air, then

push [F4] key to record it.

6

Compensate the buoyancy acting on the

net/basket.

Remove the sample on the net/basket

and push [Tare] key to tare, then sink

the net/basket into the water/liquid.

Push [Tare] key to compensate the

buoyancy acting on the net/basket.

7

Measure the sample weight in the

water/liquid.

Put the sample on the net/basket in the

water/liquid, then push [F4] key to

record.

The specific gravity of the sample (for the

4°C water) is automatically calculated and

displayed.

3-5-1 Switching the display at “Specific gravity mode”

1

Push [F1-F4] keys to switch the display.

Page 44

3 Functions related to the operation MG-S series operation manual

-34-

3-6 Statistics mode

The statistical operation function collects weight data and indicates maximum, average, and other

statistical values.

This mode is not available for verified balance.

(1)

Only “mg” or “g” can be used.

(2)

Each calculation result except “CV” follows the smallest readability among which are used to

record the weighing data.

(3)

Up to 999 weight data can be saved.

The output timing is fixed to “Once at stable/immediately after [Output] key is pushed” regardless

of the setting value of <413/423 CONDITION> of “6 External input/output function”.

The setting of <17 WT STABLE>

The output condition

ON

Once at stable after [Output] key is pushed

OFF

Once immediately after [Output] key is pushed

1

Select the statistics mode.

Push [Menu] key, then push [F1-F4] keys to

go to <11 MODE>.

Push [F4] key to change the setting value.

Push [F4] key to select.

STAT

:

Statistics mode

Push [F4] key to fix.

2

Exit the setting menu.

Push [Menu] key to shift to the statistics

mode.

3

Choose whether or not clear all the

data.

Push [F3/F4] key to select whether or not

clear all the data.

When there is no data stored, this step is skipped.

YES

:

Clear

NO

:

Not clear

When <NO> is selected, weighing step of the next

statistics data starts.

4

Store weighing data.

Place the sample in the weighing pan.

Push [Output] key to store the sample weight.

Weighing data is collected and then output.

Page 45

MG-S series operation manual 3 Functions related to the operation

-35-

5

Collect more weighing data.

Store data in the same way as in step 4.

Repeat placing samples, storing data, and

removing the samples until the required number of

data items are collected.

6

Display the statistical operation result.

・・・

Push [F2] key (<DATA>).

The display changes to the statistical operation

display

Push [F1/F2] key to switch to another

calculated item.

Sum total

Maximum value

Minimum value

Range (Max – Min)

Average value

Standard deviation

Coefficient of variation

3-6-1 Switching the display at “Statistics mode”

1

Push [F1-F4] keys to switch the display.

Page 46

3 Functions related to the operation MG-S series operation manual

-36-

3-7 Animal mode

The balance can accurately weigh animals and other samples that move during measurement.

Even when animals and other samples move during measurement, when weight variations fit within the

set value range, the indication is held (hold) and the measurement result can be read.

This mode is not available for verified balance.

(1)