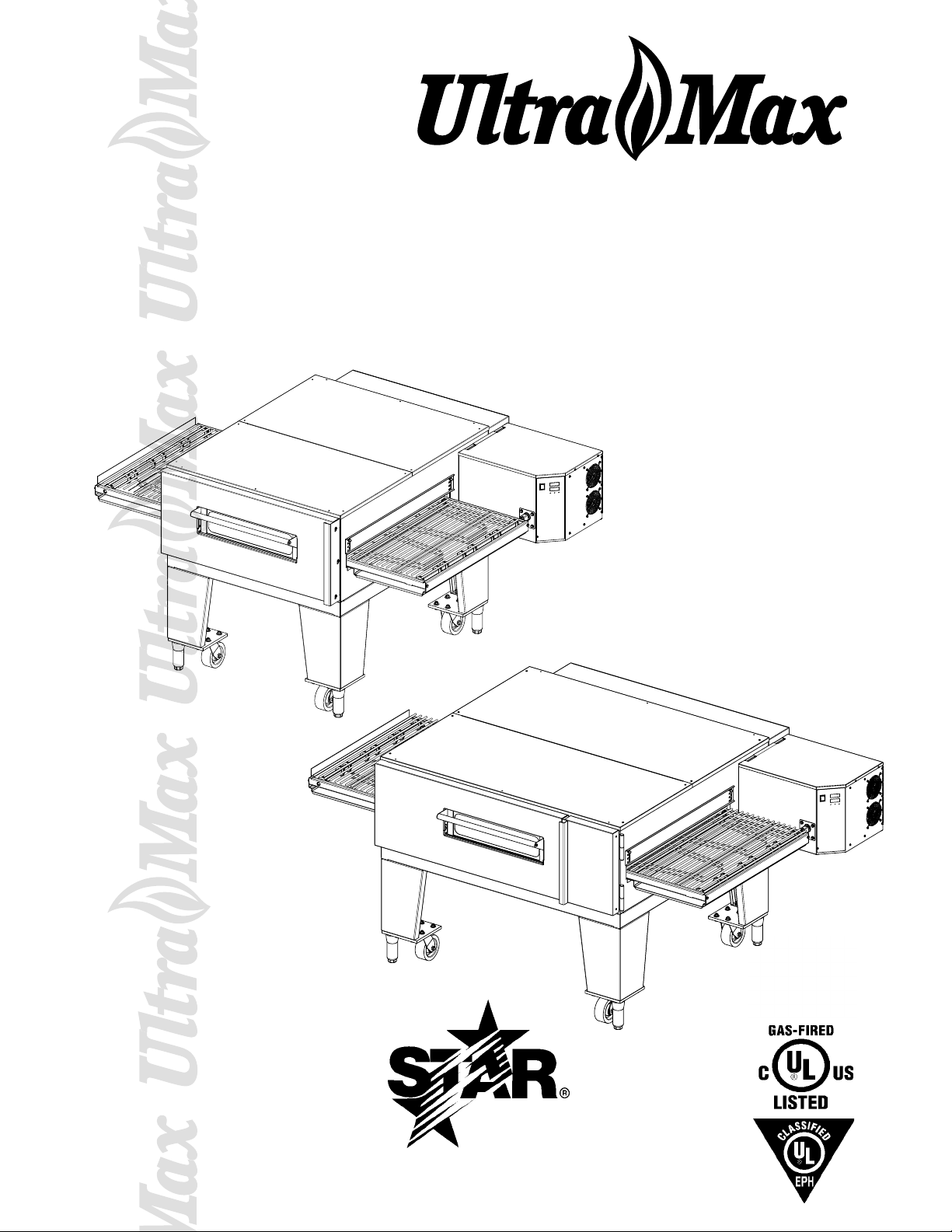

Star Manufacturing UM3255, UM3200 Installation Manual

®

CONVEYOR

OVEN

MODEL

UM3240

UM3255

Installation and

Operation

Instructions

2M-Z9045 Rev. D 6/26/2007

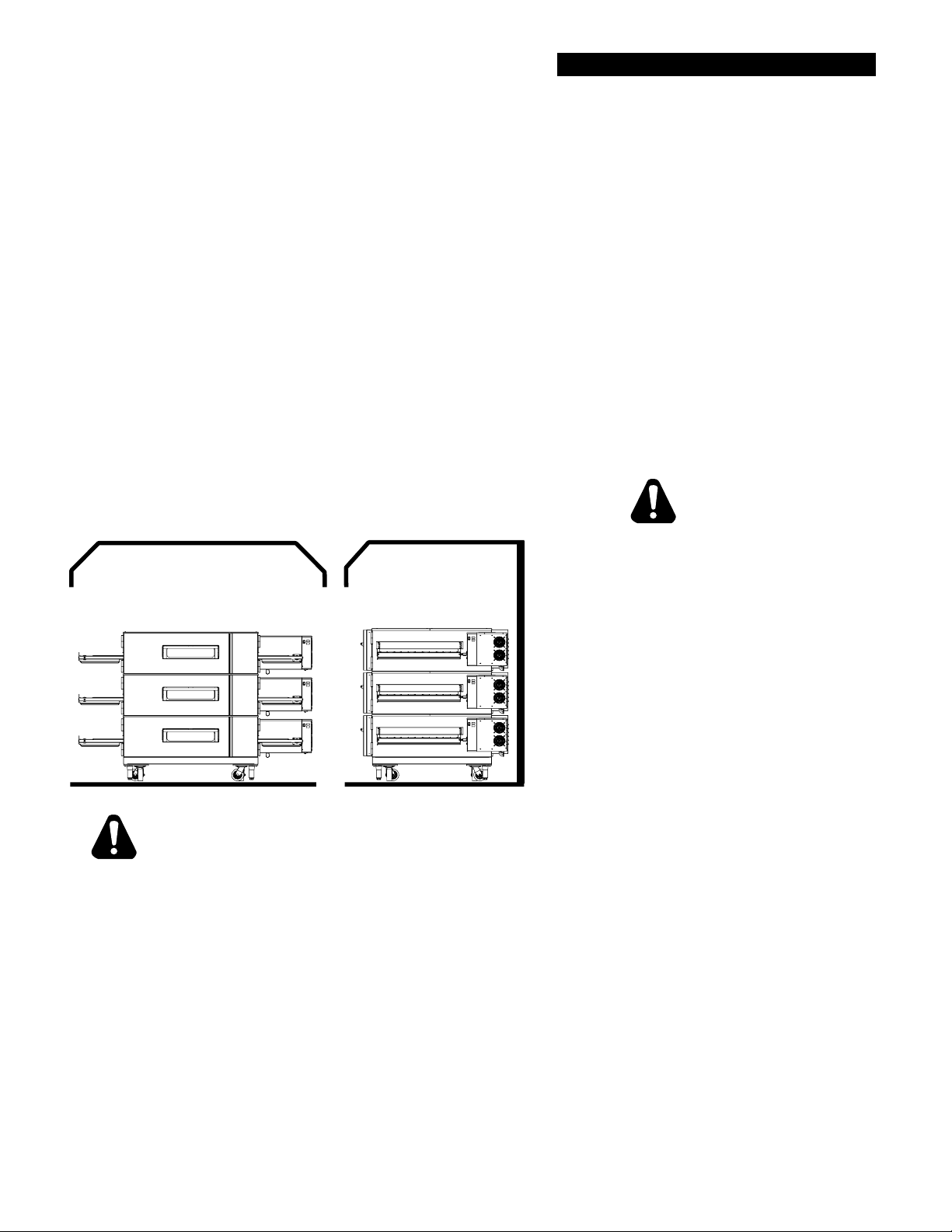

UM3240

UM3255

1

SAFETY SYMBOL

Using any part other than genuine Star factory supplied parts relieves the

manufacturer of all liability.

Star reserves the right to change specifi cations and product design without

notice. Such revisions do not entitle the buyer to corresponding changes,

improvements, additions or replacements for previously purchased

equipment.

Due to periodic changes in designs, methods, procedures, policies and

regulations, the specifi cations contained in this sheet are subject to change

without notice. While Star Manufacturing exercises good faith efforts to provide

information that is accurate, we are not responsible for errors or omissions

in information provided or conclusions reached as a result of using the

specifi cations. By using the information provided, the user assumes all risks in

connection with such use.

These symbols are intended to alert the user to the presence of

important operating and maintenance instructions in the manual

accompanying the appliance.

RETAIN THIS MANUAL FOR FUTURE REFERENCE

NOTICE

MAINTENANCE AND REPAIRS

Contact your local authorized service agent for service or required maintenance. Please record the model

number, serial number, voltage and purchase date in the area below and have it ready when you call to

ensure faster service.

Model No.

Serial No.

Voltage

Purchase Date

Authorized Service Agent

Reference the listing provided with the unit

or

for an updated listing go to:

Website: www.star-mfg.com

E-mail Service@star-mfg.com

Telephone: (800) 807-9054 Local (314) 781-2777

The Star Service Help Desk

Business 8:00 am to 4:30 p.m. Central Standard Time

Hours:

Telephone: (800) 807-9054 Local (314) 781-2777

Fax: (800) 396-2677 Local (314) 781-2714

E-mail Parts@star-mfg.com

Service@star-mfg.com

Warranty@star-mfg.com

Website: www.star-mfg.com

Mailing Address: Star Manufacturing International Inc.

10 Sunnen Drive

St. Louis, MO 63143

U.S.A

2

2

3

CAUTION

CAUTION

IMPORTANT

POST, IN A PROMINENT LOCATION, THE EMERGENCY TELEPONE NUMBER OF YOU

LOCAL GAS SUPPLIER AND INSTRUCTIONS TO BE FOLLOWED IN THE EVENT YOU

SMELL GAS.

Instructions to be followed in the event you smell gas shall be obtained by consulting the local

gas supplier. If the smell of gas is detected, immediately call the emergency phone number of

your local gas company. There personnel and provisions available to correct the problem.

FOR YOUR SAFETY DO NOT STORE OR USE GASOLINE OR OTHER

FLAMMABLE VAPORS AND LIQUIDS IN THE VICINITY OF THIS OR ANY OTHER

APPLIANCE.

The installation of the Appliance must conform to the NATIONAL FUEL GAS CODE

"ANSI Z223.1 - LATEST EDITION" AND ALL LOCAL GAS COMPANY RULES AND

REGULATIONS.

IN CANADA INSTALLATION SHALL BE IN ACCORDANCE WITH THE CURRENT CAN/

CGA-B149.1 NATURAL GAS INSTALLATION CODE OR CAN/CGA-B149.2 PROPANE

INSTALLATION CODE AND LOCAL CODES WHERE APPLICABLE.

IMPROPER INSTALLATION, ADJUSTMENT, ALTERATION, SERVICE, OR

MAINTENANCE CAN CAUSE PROPERTY DAMAGE, INJURY, OR DEATH. READ

ALL INSTRUCTIONS THOROUGHLY BEFORE INSTALLING OR SERVICING THIS

EQUIPMENT.

IMPORTANT

An electrical wiring diagram for the oven is located on the inside cover of the

Control Box Top Lid.

NOTICE

THIS APPLIANCE SHALL BE INSTALLED IN CONFORMITY WITH CURRENT

REGULATIONS & USED ONLY IN A WELL VENTILATED LOCATION. CONSULT THE

INSTRUCTIONS BEFORE INSTALLING AND USING THE APPLIANCE.

AT, CH, CZ, DK, ES, FI,

GB, GR, HU, IE, IT, NO,

PT, SE

GAS I2H I2L I2E I2E+

P

(mBAR)

G20 @ 20 G25 @ 25 G20 @ 20 G20 @ 20/25

Gas/Country Designations

NL LU, DE BE, FR

1

®

UM3240 - UM3255 CONVEYOR OVEN

TABLE OF CONTENTS

page

Important Warnings 1

Specifi cations 3

Oven Components 4

General Information 5

Purchaser’s Responsibilities 5

Important Safety Information 6

INSTALLATION INFORMATION 7

Location 7

Gas Supply Rating & Sizing 7

Access Considerations 7

Electrical Connection 8

IEC/CEE Equipotential Ground 8

Pressure Regulation 9

Pressure Testing 9

Ventilation 10

Smoke Candle Test 10

Base Pad Assembly 11

Oven to Base Assembly 11

Stacking Instructions 12

Conveyor Installation 13

Conveyor Belt Direction 14

Restraint Requirement 15

OPERATING INSTRUCTIONS

Safety Operating Instructions 16

Operation 16

Turn Unit On 17

Adjusting Time & Temp 17

Shut Down Procedures 17

DISPLAY INFORMATION

Store Level 18

Manger Level 18

Additional Functions 18

Error Codes 18

Bake Time versus Temp 19

Conveyor Speed 19

Time of Delivery 19

MAINTENANCE INSTRUCTIONS

Daily, Monthly, 3 Months, Annually 20-21

Nozzle Finger Assembly / Dissembly 21

Conveyor Belt Tension 22

Conveyor Belt Link Removal 22

Wiring Diagram 23

EXPLODED VIEW & PARTS LIST

Front Panel Assembly 24-25

Rear Panel Assembly 26-27

Conveyor Assembly 28-29

Control Box Assembly 30-31

Control Box Door Assembly 32-33

Manifold & Blower/Burner Assembly 34-35

Warranty 36

2

SPECIFICATIONS

UM3240-NAT, UM3240-LP

Gas Rating/Connection: 120,000 BTU/hr (504 kcal/min)

3/4" NPT female pipe connection (BSP adapter supplied on CE models)

Gas Supply Pressure: Natural - 5-6" water column (15-30 mBar) @ rated fl ow

Propane - 11-12" water column (27.5-30 mBar) @ rated fl ow

Electrical Supply: Separate 15 Amp 208-240VAC, single phase, 50/60 Hz service per Oven

Approximate Weight (Single Oven without base): Shipping - 868 Lbs (393.7 kg)

(Single/Double Base): Shipping - 177.3 Lbs (80.4 kg)

(Triple Base): Shipping - 188.3 Lbs (85.4 kg)

(Fingers): Shipping - 91.5 Lbs (41.5 kg)

(Single Oven with base): Installed - 717 Lbs (325.2 kg)

(Double Oven with base): Installed - 1292 Lbs (586 kg)

(Triple Oven with base): Installed - 1878 Lbs (851.8 kg)

Dimensions: Width: 80.2" (203.7 cm) - w/control panel door closed

96.2" (244.3 cm) - w/control panel door open

Depth: 60.5" (153.7 cm) - Front Door(s) Closed

102.9" (261.4 cm) - Front Door(s) Open

Height: 43.1" (109.5 cm) - Single Oven with Stand

61.1" (155.2 cm) - Double Oven with Stand

63.5" (161.4 cm) - Triple Oven with Dolly

Recommended Minimum Clearances:

Rear of Oven to Wall 0" (0 cm)

Conveyor Extensions to Wall 6" (0 cm)

Allowing 16.25" on the control panel door to open will allow for easier service

UM3255-NAT, UM3255-LP

Gas Rating/Connection: 150,000 BTU/hr (630 kcal/min)

3/4" NPT male pipe connection (BSP adapter supplied on CE models)

Gas Supply Pressure: Natural - 5-6" water column (15-30 mBar) @ rated fl ow

Propane - 11-12" water column (27.5-30 mBar) @ rated fl ow

Electrical Supply: Separate 15 Amp 208-240VAC, single phase, 50/60 Hz service per Oven

Approximate Weight (Single Oven without base): Shipping - 922 Lbs (418.2 kg)

(Single/Double Base): Shipping - 205.3 Lbs (93.1 kg)

(Triple Base): Shipping - 216.3 Lbs (98.1 kg)

(Fingers): Shipping - 122 Lbs 55.3 kg)

(Single Oven with base): Installed - 827 Lbs (375.1 kg)

(Double Oven with base): Installed - 1484 Lbs (673.1 kg)

(Triple Oven with base): Installed - 2152 Lbs (976.1 kg)

Dimensions: Width: 94.6" (240.3 cm) - w/control panel door closed

110.6" (280.9 cm) - w/control panel door open

Depth: 60.5" (153.7 cm) - Front Door(s) Closed

102.9" (261.4 cm) - Front Door(s) Open

Height: 43.1" (109.5 cm) - Single Oven with Stand

61.1" (155.2 cm) - Double Oven with Stand

63.5" (161.4 cm) - Triple Oven with Dolly

Recommended Minimum Clearances:

Rear of Oven to Wall 0" (0 cm)

Conveyor Extensions to Wall 6" (0 cm)

Allowing 16.25" on the control panel door to open will allow for easier service

3

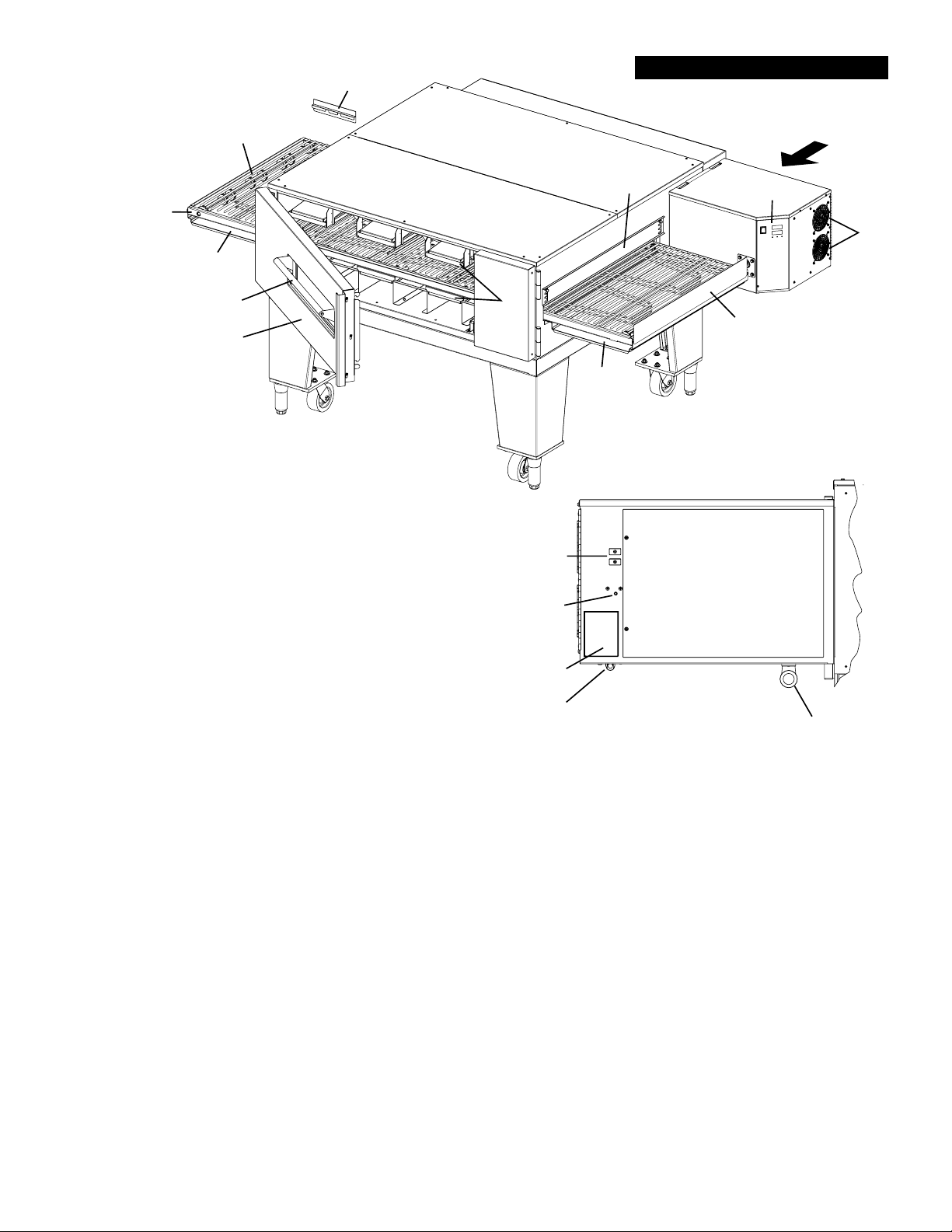

OVEN COMPONENTS

I

A

G

VIEW A

C

B

H

F

J

I

E

H

IL1173

OVEN COMPONETS DESCRIPTION

A: Conveyor Belt: Moves the product through the oven

B: Conveyor Assembly: Supports the Conveyor Belt, the

ends fold up for easy removal.

C: Control Panel: Bright Red Display for easy notifi cation

of ovens current operation, and buttons for making quick

modifi cations.

D: Air Intake: Located on the end of the control box to pre-

vent the electronic controls from overheating as well as

to allow for a more direct air fl ow into the blowers. DO

NOT BLOCK these air intakes and wipe them clean on a

regular basis.

E: Machinery Compartment Access Door: Allows access

to the oven’s interior Finger components.

F: Access Window: This allows easy access to the cooking chamber, for product to be placed in to give

a shorter or additional cooking time to the product.

G: Heat Shutter: Can be adjusted to various settings, depending on product being placed in the oven, to

prevent heat loss

H: Crumb Tray: Catches crumbs and other material that drops through the conveyor belt. Located at

each end of the conveyor assembly.

I: Conveyor End & Side Stops: Prevents product from falling off of the moving conveyor.

J: Fingers: Projects streams of hot air onto the product.

K: Circuit Breaker 10Amp: Protects components from over amperage.

L: Hi-Limit Reset: Monitors inside cooking temperature and will only trip when unitended temperature is

reached.

M: Nameplate: Has specifi c information regaring this units electrical & gas requirements as well as the

units serial number which is needed for any service that will be required. This number should be written

in the inside cover of this manual and kept for future needs

N: Electrical Input: Electrical Supply connection must meet all national and local electrical code

requiremtns.

O: Gas Connection: The installation must confi rm with local codes or in the absence of local codes, with

the National Fuel Gas Code, ANSI Z2223.1 latest edition.

K

L

M

N

VIEW A

O

D

4

GENERAL INFORMATION

This equipment is designed and sold for commercial use only by personnel trained and experienced

in its operation and is not sold for consumer use in and around the home nor for use directly by

the general public in food service locations.

Before using your new equipment, read and understand all the instructions & labels

associated with the unit prior to putting it into operation. Make sure all people associated

with its use understand the units operation & safety before they use the unit.

First and foremost, each crate should be examined before signing the Bill of Lading to report any

visible damage by the freight carrier in transit and to account for the proper number of crates.

If there is apparent damage, arrangements should be made to fi le a claim against the carrier

within 15 days. Interstate Commerce Regulations require that the claim must be initiated by the

consignee. Proper and secure storage facilities should be arranged for the oven(s) if necessary

to protect it from outdoor or damp conditions at all times before installation.

-IMPORTANT-

When you have all the crates unloaded, open the crates and remove all plastic covers. Inspect

at once for concealed damage. If anything appears to be damaged, contact the appropriate

persons immediately to fi le a damage claim. After completing this inspection, fi nish unpacking

the oven. Be sure to remove all paper protection and packing material from the unit prior

to lighting.

NOTICE

This appliance must be installed with a stand and casters designed by Star Manufacturing as part

of a complete installation. The installation must also include a connector complying with either

ANSI Z21.69 or CAN/CGA-6.16 and a quick-disconnect device complying with either ANSI Z21.41

or CAN1-6.9. It must also be installed with restraining means to guard against transmission of

strain to the connector as specifi ed in the appliance manufacturer's instructions.

For your protection, we recommend a qualifi ed installing agency install this appliance. They

should be familiar with gas installations and your local gas requirements. In any case, your gas

company should be called to approve the fi nal installation.

This appliance, its pressure regulator, and its individual shutoff valve must be disconnected

from the gas supply piping system during any pressure testing of that system at test pressures

in excess of 1/2 PSIG. This appliance and its pressure regulator must be isolated from the gas

supply piping system by closing its individual manual shutoff valve during any pressure testing

of the gas supply piping system at test pressures equal to or less than 1/2 PSIG.

PURCHASER'S RESPONSIBILITY

It is the responsibility of the purchaser:

1. To see that the gas and electric services for the oven are installed on site in accordance

with the manufacturer's specifi cations and municipal codes.

2. To see that all gas and electric services are connected properly by a qualifi ed installer of your

choice. All such connections must be in accordance with applicable code requirements.

3. To arrange for inspection and operation check-out by an authorized service technician.

The warranty becomes effective upon verifi cation of proper installation.

5

CAUTION

CAUTION

CAUTION

IMPORTANT SAFETY INFORMATION

Do not attempt to operate the oven until connection of utility service has been fully inspected

by an authorized service technician or a Star Service Representative. This service is required

by Star in order to assist the purchaser in proper start-up of the oven on site. Please note

the specifi c details on the Warranty and make certain that service connections are made to

proper utility services.

The warranty shall not apply if the oven is started up and operated prior to the utilities and

oven being inspected and check-out made by an authorized service technician or a Star

Service Representative.

IMPROPER INSTALLATION, ADJUSTMENT, ALTERATION, SERVICE, OR

MAINTENANCE CAN CAUSE PROPERTY DAMAGE, INJURY, OR DEATH. READ

ALL INSTRUCTIONS THOROUGHLY BEFORE INSTALLING OR SERVICING THIS

EQUIPMENT.

Post in a prominent location the emergency telephone number of your local

gas supplier and instructions to be followed in the event you smell gas. If the

smell of gas is detected, immediately call the emergency phone number of

your local gas company. They will have personnel and provisions available to

correct the problem.

It is required that the oven be placed under a ventilation hood to provide for

adequate air supply and ventilation.

CAUTION

CAUTION

CAUTION

WARNING

Minimum clearances must be maintained from all walls and combustible

materials. Minimum clearances for this unit should be 0 inches from the rear

and 6 inches from both sides. Keep the oven free and clear of all combustible

material, for use only on Non-Combustable fl oors.

Adequate clearance for air openings to the combustion control chamber on the

right side of the oven is required. Do not obstruct the ventilation holes in the

control panels as these provide the combustion air for the burner and cooling

air for the controls.

The oven is to be operated only on the type of gas and electricity shown on the

specifi cation plate. The burner will not operate and gas will not fl ow through

the burner without electric power.

If the supply cord is damaged, it must be replaced by the manufacture,

its service agent or similarly qualifi ed persons in order to avoid a hazard.

Star replacement parts are listed in the parts list section of this manual.

6

INSTALLATION INFORMATION

THE INSTALLATION INSTRUCTIONS CONTAINED HEREIN ARE FOR THE USE OF

QUALIFIED INSTALLATION AND SERVICE PERSONNEL ONLY. INSTALLATION OR

SERVICE BY OTHER THAN QUALIFIED PERSONNEL MAY RESULT IN DAMAGE TO THE

OVEN AND/OR INJURY TO THE OPERATOR.

Qualifi ed installation personnel are individuals, a fi rm, a corporation, or a company which either

in person or through a representative are engaged in and responsible for:

1. The installation or replacement of gas piping and the connection, installation, repair, or

servicing of equipment.

2. The installation of electrical wiring from the electric meter, main control box, or service outlet

to the electric appliance.

Qualifi ed installation personnel must be experienced in such work, familiar with all precautions

required, and have complied with all requirements of state or local authorities having

jurisdiction.

UTILITY INSTALLATION

LOCATION

The well-planned and proper placement of your oven will result in long-term operator convenience

and satisfactory performance.

NOTE: On gas conveyor ovens, routine servicing can usually be accomplished within the limited

movement provided by the gas hose restraint. If the oven needs to be moved further from the

wall, the gas must fi rst be turned off and disconnected from the oven before removing the restraint.

Reconnect the restraint after the oven has been returned to its regular position.

It is essential that an adequate air supply to the oven be maintained to provide a suffi cient fl ow

of combustion and ventilation air. Follow these guidelines:

1. Place the oven in an area that is free of drafts.

2. Keep the oven area free and clear of all combustibles such as paper, cardboard, fl ammable

liquids, and solvents. Oven should only be used on Non-Combustible Floors.

3. Do not place the oven on a curb base or seal to a wall. This will restrict the fl ow of air and

prevent proper ventilation to the blower motors. This condition must be corrected to prevent

permanent damage to the oven.

4. On all models, tripping of the blower motor's thermal overload device indicates an excessive

ambient temperature at the back of the oven. This condition must be corrected to avoid

permanent damage to the oven.

GAS SUPPLY RATING AND SIZING

Calculations for pipe sizing must take into account the maximum usage rate of all other appliances

in the kitchen or one or more of the appliances will suffer from inadequate or dangerous

performance. The 3/4" NPT connection for the oven is generously sized for use in the control

box of the oven. However, unless the oven installation is within 10 feet of the main building gas

supply, the supply must be larger. For each oven, a 3/4" NPT fl exible quick connect hose and

full port gas shut-off valve is recommended as a MINIMUM. The main pipe supplying each oven

branch may need to be larger depending on the number of appliances serviced, the number

of elbows in the piping, and the pressure. This should be sized and installed by a professional

familiar with any local codes that may also affect the installation.

ACCESS CONSIDERATIONS

Locating the gas valve(s), quick connect hose(s) and electrical outlet(s) at the control box end

of the oven will allow easier access for any service visits. This improved access should make

any necessary service quicker resulting in less kitchen disruption. It will also allow easier

disconnection of electricity, gas, and restraints for cleaning around and behind the oven.

7

WARNING

CAUTION

WARNING

ELECTRICAL CONNECTION

UTILITY INSTALLATION

Before making any electrical connections to this unit, check that the power supply is adequate

for the voltage, amperage, and phase requirements stated on the rating plate. A wiring diagram

is included herewith.

ENSURE THAT BOTH THE CIRCUIT BREAKER AND THE POWER (ON/OFF) SWITCH

IS IN THE OFF POSITION BEFORE PROCEEDING.

BE CERTIAN THAT ALL PACKING MATERIAL HAS BEEN REMOVED FROM INSIDE

THE OVEN'S CHAMBER.

When installed, this appliance must be electrically grounded and its installation must comply with

the National Electric Code, ANSI-NFPA 70, latest version, manufacturer's installation instructions,

and applicable local municipal building codes. In Canada, all electrical connections are to be in

accordance with CSA C22.1 - Canadian Electrical Code Part 1 and/or local codes.

This device is equipped with a 3-prong (grounded) plug for your protection against shock

hazard and should be plugged directly into a properly grounded three prong receptacle.

DO NOT cut or remove the grounded prong from this plug.

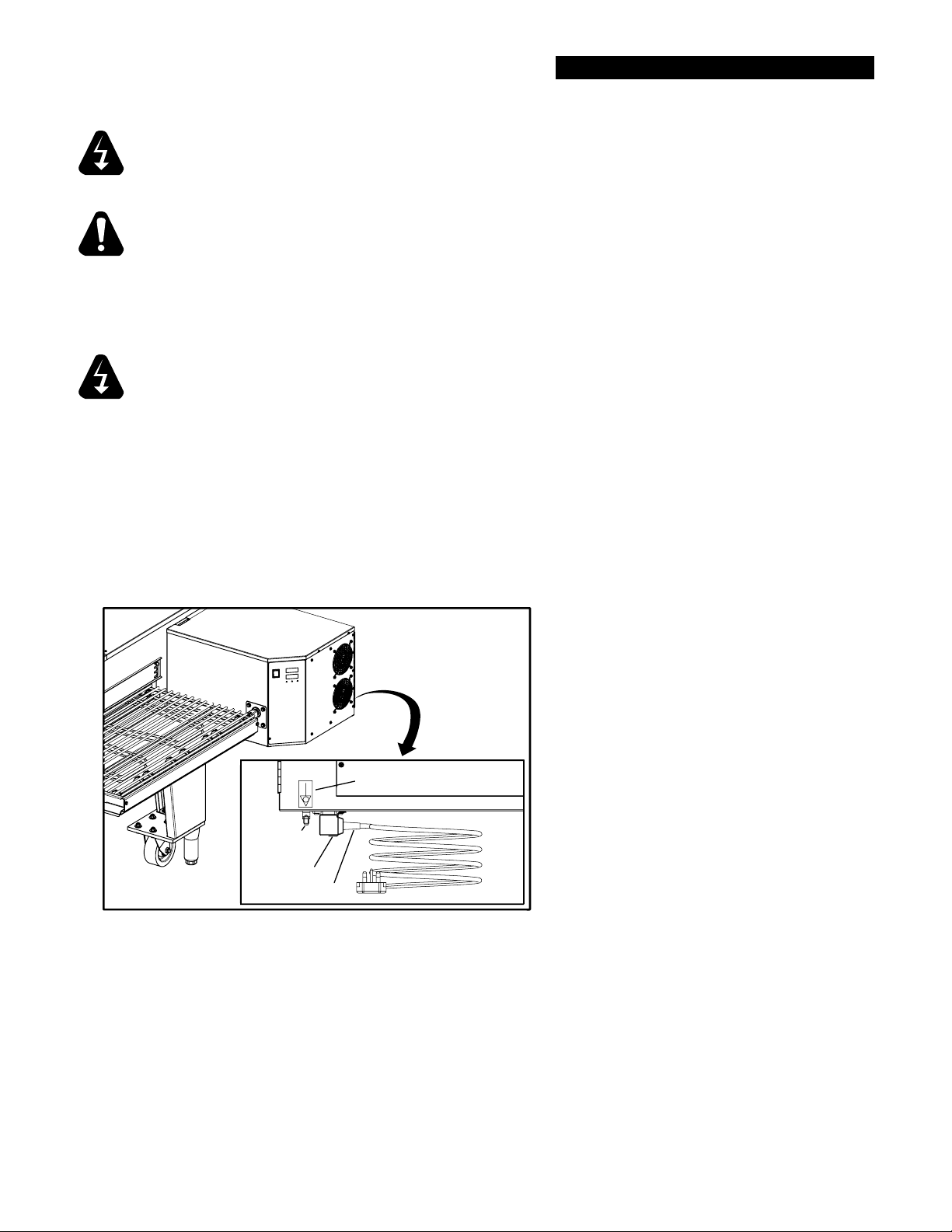

EQUIPOTENTIAL GROUNDING - CE ONLY

On CE units, connect an equipotental ground wire to the ground lug shown in the fi gure below.

The equipotential ground connection must meet current IEC/CEE and local code requirements.

The ground lug is found on the rear side of the control box, below the equipotential ground

symbol.

On certain CE/UK models install the IEC plug using the cord holder provided.

Symbol

Equipotential

Ground Lug

Cord Holder

IEC Plug

IL1242

IEC/CEE Equipotential Ground Connection

8

CAUTION

WARNING

UTILITY INSTALLATION

PRESSURE TESTING GAS SUPPLY LINE

During pressure testing note the following:

1. The oven and its individual manual shut-off valve must be disconnected from the gas supply piping

system during any pressure testing of that system at test pressures in excess of 1/2 psig (3.45 kPa).

Turn OFF main gas shut-off valve or main gas supply line.

2. The oven must be isolated from the gas supply piping system by closing its individual manual shutoff valve during any pressure testing of the gas supply piping system at test pressures equal to or

less than 1/2 psig (3.45 kPa).

3. If incoming pressure is over 14" water column, a separate regulator for the oven must be installed

before the gas supply to the oven.

To prevent damage to the control valve regulator during the initial turn-on of

gas, it is very important to open the manual shut-off valve very slowly. After the

initial gas turn-on, the manual shut-off valve must remain open except during

pressure testing as outlined in the above steps or when necessary during service

maintenance.

NOTE: The supplied regulator is evaluated for a maximum gas supply pressure of

14" water column (34.5 mBar). The recommended maximum gas supply pressure

is 12" water column (29.9 mBar).

Installation must conform with local codes or, in the absence of local codes, with the National

Fuel Gas Code, NFPA54/ANSI Z223.1 - Latest Edition, the Natural Gas Installation Code

CAN/CGA-B149.1 or the Propane Installation Code CAN/CGA-B149.2 as applicable.

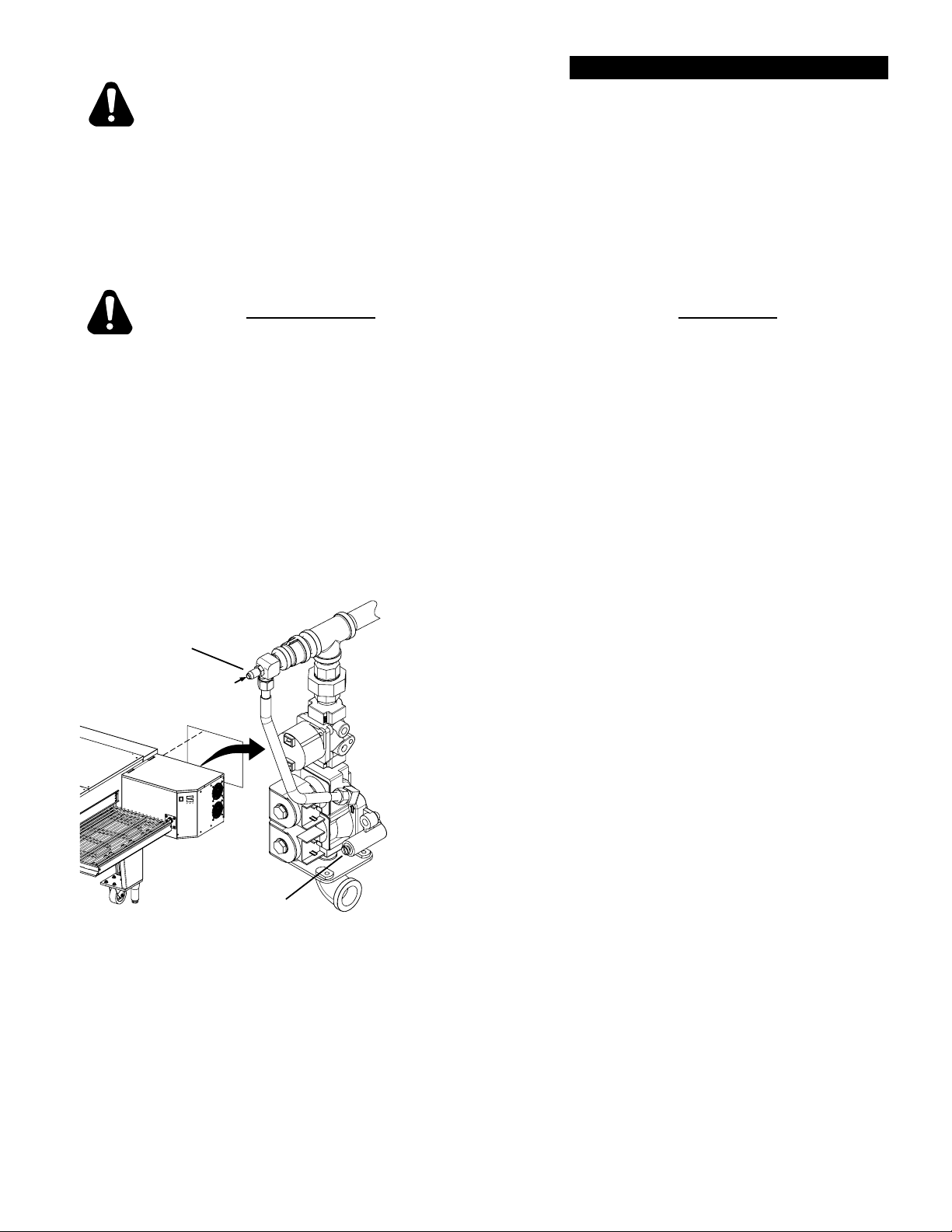

PRESSURE READING

TEST NIPPLE

SET-SCREW

GAS PRESSURE

ADJUSTMENT SCREW

IS UNDER CAP

Oven Manifold Regulator, w/Set Screw

IL1191

OVEN MANIFOLD PRESSURE REGULATION

Each oven has been adjusted at the factory to operate with

the gas specifi ed on the nameplate.

Each oven is supplied with a regulator to maintain the proper

gas pressure. The regulator is essential to the proper

operation of the oven and should not be removed or replaced

by another model unless approved by Star Manufacturing.

A pressure reading can be taken at the test nipple provided.

You must back the set-screw one turn for this test, be certain

to re-tighten when you are done. Failure to reset the setscrew to its original position will create a gas leak once the

unit is back in operation. The reading should be taken while

the oven is heating up & at high fi re. The regulator is located

on the bottom of the gas combination valve, just inside the

control box. Adjust gas manifold regulator gas pressure by

removing the cap and adjusting the regulator adjustment

screw to match the pressure listed on the name plate (3.5"

Nat, 4.8" Propane). Clockwise to increase, counterclockwise

to decrease.

9

VENTILATION

INSTALLATION VENTILATION

A VENT IS REQUIRED: Local codes prevail. These are the "authority having

jurisdiction" as stated by the National Fire Protection Association, Inc. in NFPA

96-Latest Edition. For further ventilation information see below.

A ventilation hood is required to remove heat and cooking odors. For gas ovens, a ventilation

hood is also required to remove the products of combustion. The hood and HVAC installation

must meet local codes to gain approval by the authority having jurisdiction. Requirements may

vary depending on the location by city, county, and state. Obtain information from the authority

having jurisdiction to determine the requirements for your installation. Obtain information and

review copies of codes or documents that will be used to inspect and approve your installation.

Your ventilation hood supplier and HVAC contractor should be contacted to provide guidance. A

properly engineered and installed ventilation hood and HVAC system will expedite approval and

reduce oven maintenance costs. Proper ventilation is the responsibility of the oven's owner.

The ventilation hood must operate in harmony with the building HVAC system. (The effi ciency

of various hood designs makes it necessary to specify such a wide range of ventilator CFM.)

Make-up air must be supplied by either a hood design or the HVAC system to avoid a negative

pressure condition. This will vary with hoods from various manufacturers. Air supplied directly

from outside the building to the kitchen or oven area, non-tempered, could be used as supply

air but the design would have to accommodate potential operational changes.

CAUTION

Prevent airfl ow through the cooking

VENTILATION

CAPTURE AREA

VENTILATION

CAPTURE AREA

RIGHT SIDE FRONT SIDE

tunnel. Air must NOT be directed onto

the oven's front or rear or to the sides

of the cooking area.

The following drawing shows a typical

installation and is intended to be a guideline.

This is not a rigid specification. Hood

dimensions and positioning over the oven

will vary with hood manufacturer & local

guidelines.

CAUTION

Damage sustained as a direct result of

improper ventilation will not be covered by

IL1177

the warranty.

Failure to properly vent the oven can be hazardous to the health of the operator

and may result in operational problems, unsatisfactory baking, and possible

damage to the equipment.

SMOKE CANDLE TEST

In order to verify the proper function of your ventilation system, a smoke candle test should

be done. If testing a multiple oven system, this test should be done on the bottom oven. The

conveyor coupling should be disconnected so conveyor does not move and the oven temperature

must be set and operating at a minimum of 480°F (249°C).

Test Procedure:

1. Wear heat-resistant gloves to prevent burns.

2. Put the smoke candle in an cake pan.

3. Insert candle through conveyor tunnel or oven

door. (Use Star Smoke Candle 2W-Z5668.)

4. Light the fuse of the smoke candle and

immediately center the pan in the oven cavity on

the conveyor belt (keeping the oven door and

window closed).

10

5. Observe the smoke pattern coming out of

all oven openings and the collection of this

smoke by the ventilation system.

6. All smoke from the oven must be captured

by the ventilation system.

Loading...

Loading...