Star Manufacturing SPDE1HP, SPDE1ARB-120V Parts List

HEATED

PERISTALTIC DISPENSER

MODEL

SPDE1ARB, SPDE2ARB

SPDE1HP

Installation and

Operation

Instructions

2M-Z7537 Rev. G 2/16/07

SPDE2ARB

1

SAFETY SYMBOL

Using any part other than genuine Star factory supplied parts relieves the

manufacturer of all liability.

Star reserves the right to change specifi cations and product design without

notice. Such revisions do not entitle the buyer to corresponding changes,

improvements, additions or replacements for previously purchased

equipment.

Due to periodic changes in designs, methods, procedures, policies and

regulations, the specifi cations contained in this sheet are subject to change

without notice. While Star Manufacturing exercises good faith efforts to provide

information that is accurate, we are not responsible for errors or omissions

in information provided or conclusions reached as a result of using the

specifi cations. By using the information provided, the user assumes all risks in

connection with such use.

These symbols are intended to alert the user to the presence of

important operating and maintenance instructions in the manual

accompanying the appliance.

RETAIN THIS MANUAL FOR FUTURE REFERENCE

NOTICE

MAINTENANCE AND REPAIRS

Contact your local authorized service agent for service or required maintenance. Please record the model

number, serial number, voltage and purchase date in the area below and have it ready when you call to

ensure faster service.

Model No.

Serial No.

Voltage

Purchase Date

Authorized Service Agent

Reference the listing provided with the unit

or

for an updated listing go to:

Website: www.star-mfg.com

E-mail Service@star-mfg.com

Telephone: (800) 807-9054 Local (314) 781-2777

The Star Service Help Desk

Business 8:00 am to 4:30 p.m. Central Standard Time

Hours:

Telephone: (800) 807-9054 Local (314) 781-2777

Fax: (800) 396-2677 Local (314) 781-2714

E-mail Parts@star-mfg.com

Service@star-mfg.com

Warranty@star-mfg.com

Website: www.star-mfg.com

Mailing Address: Star Manufacturing International Inc.

10 Sunnen Drive

St. Louis, MO 63143

U.S.A

2

2

SPECIFICATIONS

SPDE1ARB-120V

Capacity: One 160 ounce pouch

Electrical: 120V, 60 hertz, single phase, 820 Watts, 7 amps

Cord: 6 ft. length

Plug: 120V - NEMA 5-15P

Dimensions: 9-7/16" W x 19-9/16" D x 30-5/16" H (23.97 W x 49.69 D x 77.0 H cm)

Net Weight: 42 lbs. (19.1 kg)

SPDE1ARB-230V

Capacity: One 160 ounce pouch

Electrical: 230V, 60 hertz, single phase, 820 Watts, 3.5 amps

Cord: 8 ft. length

Plug: 250V 10 amp NEMA-CEE7-7 Euro

Dimensions: 9-7/16" W x 19-9/16" D x 30-5/16" H (23.97 W x 49.69 D x 77.0 H cm)

Net Weight: 42 lbs. (19.1 kg)

SPDE1HP

Capacity: One 160 ounce pouch

Electrical: 120V, 60 hertz, single phase, 820 Watts, 7 amps

Cord: 6 ft. length

Plug: 120V - NEMA 5-15P

Dimensions: 9-7/16" W x 19-9/16" D x 27-5/16" H (23.97 W x 49.69 D x 69.4 H cm)

Net Weight: 42 lbs. (19.1 kg)0V

SPDE2ARB-120V

Capacity: Two 128 ounce pouches

Electrical: 120V, 60 hertz, single phase, 1000 Watts, 8.5 amps

Cord: 6 ft. length

Plug: 120V - NEMA 5-15P

Dimensions: 10 29/32" W x 21 15/32" D x 32 1/4" H (27.8 W x 54.5 D x 81.9 H cm)

Net Weight: 60 lbs. (27.2 kg)

3

CAUTION

This equipment is designed and sold for commercial use only by personnel trained and experienced

in its operation and is not sold for consumer use in and around the home nor for use directly by

the general public in food service locations.

Before using your new equipment, read and understand all the instructions & labels associated with

the unit prior to putting it into operation. Make sure all people associated with its use understand

the units operation & safety before they use the unit.

All shipping containers should be checked for freight damage both visible and concealed. This

unit has been tested and carefully packaged to insure delivery of your unit in perfect condition.

If equipment is received in damaged condition, either apparent or concealed, a claim must be

made with the delivering carrier.

Concealed damage or loss - if damage or loss is not apparent until after equipment is unpacked, a

request for inspection of concealed damage must be made with carrier within 15 days. Be certain

to retain all contents plus external and internal packaging materials for inspection. The carrier will

make an inspection and will supply necessary claim forms.

GENERAL INSTALLATION DATA

This peristaltic dispenser is equipped for the voltage and wattage indicated on the nameplate

mounted on the back of the unit and is designed for use on alternating current (AC) only.

NOTE: The peristaltic dispenser should not be installed without

the legs provided with the machine. The legs screw into the nuts

on the bottom of the dispenser.

WARNING

DO NOT CONNECT TO DIRECT CURRENT (DC).

GENERAL OPERATING INSTRUCTIONS

The SPDE1 heated dispenser is designed to be used with a 9” x 18”

(22.8 x 45.7cm) poly bag with a 1 inch (2.5cm) outlet fi tment. The peristaltic dispenser is

designed to be used with 1/4 inch ID (.6cm) to 1/2 inch id. (1.3cm) tubing with 1/16 inch (.16cm)

wall thickness. SPDE2 slightly smaller.

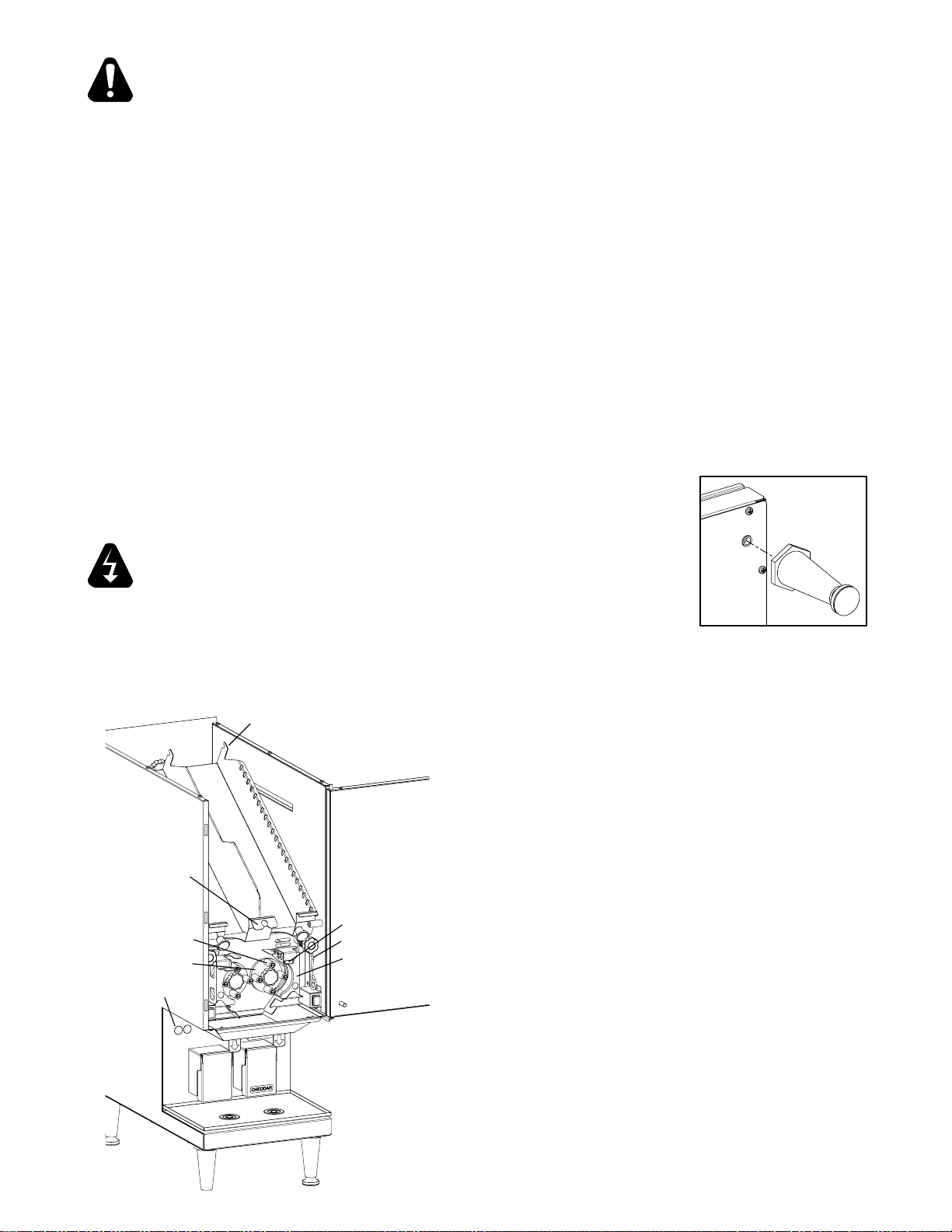

Loading Product:

1. Turn the dispenser OFF.

2. Unhook the tension spring from the catch.

3. Slide the pump block away from the pump head.

4. The product should be preheated according to the

manufacturer's instructions and should be a minimum

of 140°F (60°C) before dispensing.

5. Insert the new bag into the tray making sure the fi tment

rests on the block track and route the tube around the

rollers.

SPDE2ARB models have a Tube Changing Bracket,

when loading only one bag, clip the tube of the second

bag in the bracket, to prevent product from leaking.

(NOTE: Make sure tube is not twisted.)

6. Hook the top of the bag on the bag hooks, some

models.

7. Place the end of the tube in the slot of the bottom

bracket.

8. Slide the pump block toward the pump head.

9. Hook the tension spring onto the catch.

10. Route the tube through the hole in the tube cover leaving

1/2" of the tube below the cover.

1 1. Dispense a small amount of product to insure the tube

is seated correctly and the product is fl owing.

4

Tube Changing

Bracket

(SPDE2ARB only)

Rollers

Pump

Head

Portion Controls

Bag Hook (some models)

Catch

Tension Spring

Pump Block

IL1234

IL1235

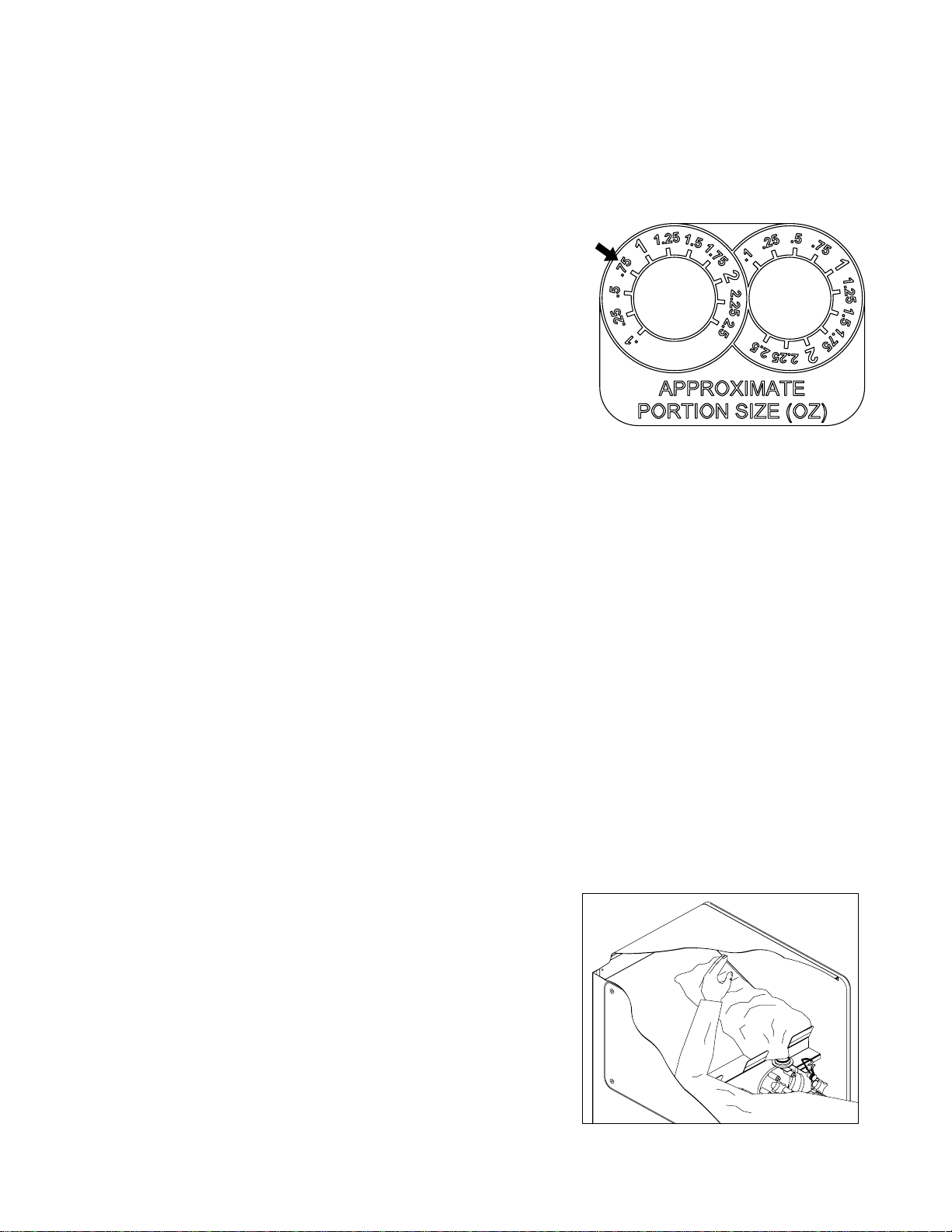

PORTION CONTROL

This dispenser is supplied with a portion control timer. This portion control is based on a time

setting. Variations in product temperature and consistency will affect the dispensed amount.

To insure a consistent portion, use product that is at the correct temperature (145°F to 160°).

SPDE2 models have a Portion Control Label showing approximate settings for portion size

in oz, see Fig 1. The units are pre-set at the factory for 0.75oz, this is a general guideline, and

following procedures still need to be followed to complete calibration.

To set portion:

1. Load preheated product bag into dispenser.

2. Dispense product until there is a steady fl ow.

3. Dispense the product into a clean container and

measure the product to verify the dispensed

amount.

4. Using a small screwdriver, remove the round plug

covering the adjustment knob located on the front

of the unit below the tube cover.

5. Turn the control dial clockwise for more product

and counterclockwise for less product.

6. Repeat steps 3 and 5 until the desired amount

is reached.

Figure 1, Portion Control Label,

SPDE2 models only.

IL1268

OPERATION NOTES

The product should be preheated according to the manufacturer's instructions.

The product should be a minimum of 140°F before dispensing.

The digital temperature readout displays the cabinet air temperature and will fl uctuate during

normal operation. The product temperature should be close to the temperature set point, but

the actual product temperature should be checked periodically to ensure proper operation.

The dispenser will not function correctly if the product is not at the correct temperature.

CHECKING PRODUCT TEMPERATURE

The dispenser should be plugged in and turned on with product in the dispenser for a least 5

hours.

1. Dispense at least 3 inches of product into an insulated cup.

2. Without hesitation, insert the thermometer to the bottom of the cup and stir the product

gently with the stem of the thermometer.

3. Position the tip of the thermometer in the center of the product mass.

4. The temperature should read between 140°F and 160°F.

The dispenser is designed to operate 24 hours a day. Once the product is placed in the

dispenser it should not be removed until the bag is empty or the holding period of the product

has expired.

NOTE: To increase the evacuation,

open the dispenser and pull the

product toward the outlet 3 or 4 times

during operation, see Fig 2.

IL1269

Figure 2, Pull product down once or

twice during operation.

5

Loading...

Loading...