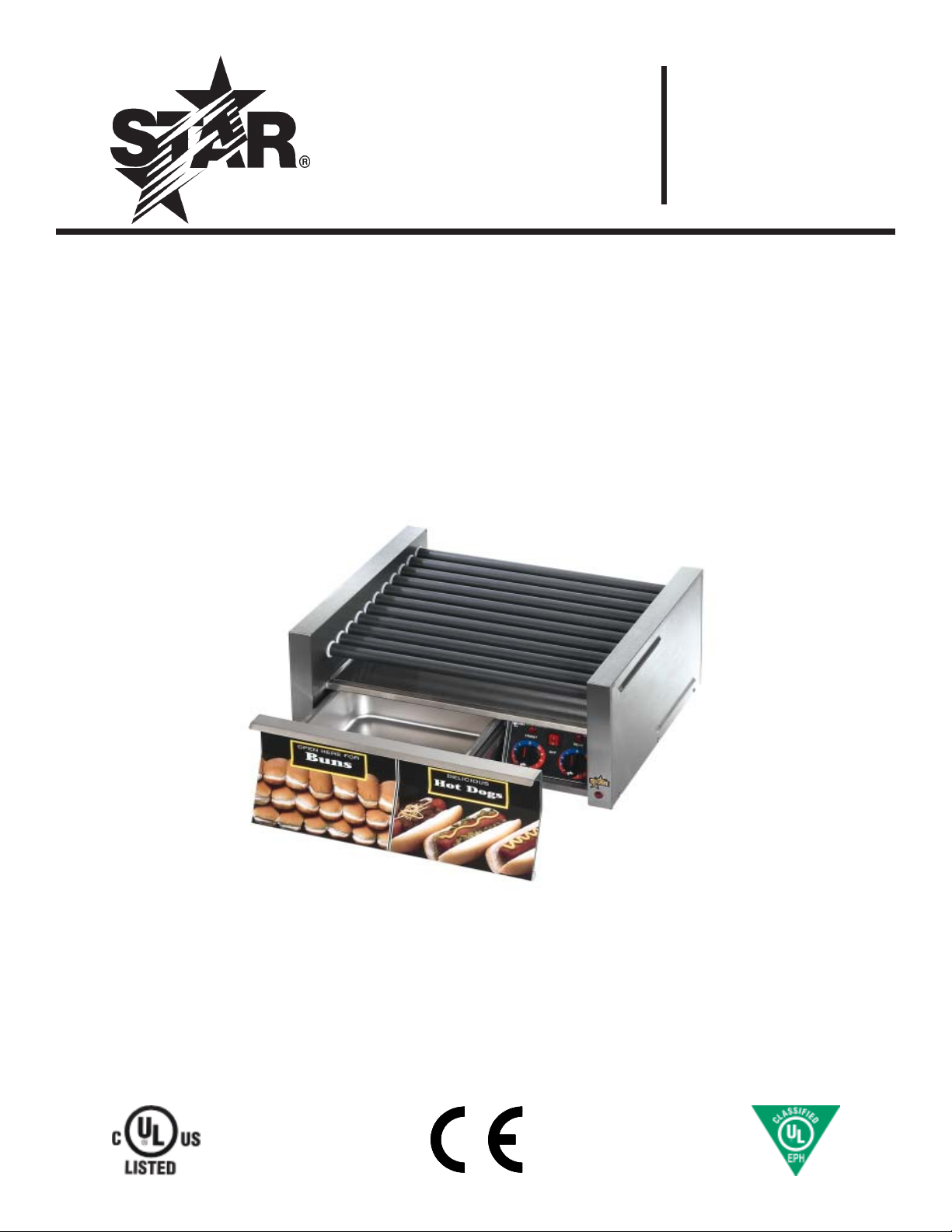

Star Manufacturing SERIES 30, SERIES 45A, SERIES 50, SERIES 75A Operation Manual

Star

Manufacturing

International Inc.

10 Sunnen Drive

St. Louis, MO 63143

Phone: (314) 781-2777

Fax: (314) 781-3636

2M-Z3201 Rev. J 3/29/04

Installation

and

Operating

Instructions

STAR GRILL-MAX ROLLER GRILLS

SERIES 20, 30, 45A, 50 and 75A

Model 30SBB

1

SAFETY SYMBOL

This symbol is intended to alert the user to the presence of important

operating and maintenance instructions in the manual accompanying

the appliance.

RETAIN THIS MANUAL FOR FUTURE REFERENCE

NOTICE

Using any part other than genuine Star factory supplied parts relieves

the manufacturer of all liability.

NOTICE

Star reserves the right to change specifications and product design

without notice. Such revisions do not entitle the buyer to corresponding changes, improvements, additions or replacements for

previously purchased equipment.

MAINTENANCE AND REPAIRS

Contact your local authorized service agent for service or required maintenance. Refer to the authorized service

center listing provided with the unit. The Star Service Help Desk (1-800-807-9054) is available during normal

business hours to answer any questions that may arise. Please have your model number and serial number for faster

service.

2

CAUTION

This equipment is designed and sold for commercial

use only by personnel trained and experienced in its

operation and is not sold for consumer use in and

around the home nor for use directly by the general

public in food service locations. For equipment to be

used by the general public, please contact the factory.

INSTALLATION

This grill is equipped for the voltage shown on the

nameplate. It will operate on alternating current only,

however, the specified voltage must be applied.

CAUTION

DO NOT CONNECT TO DIRECT CURRENT

(DC).

CONNECTION LOAD:

MODEL SERIES WATTAGE

20, 20S 930

30, 30S, 30F, 30SF, 30BB, 30BBC,

30SBB, 30DV 1150

45A, 45SA, 45ABB, 45SABB, 45ADV 1650

50, 50S, 50F, 50SF, 50BB, 50BBC,

50SBB, 50DV 1535

75A, 75SA, 75ABB, 75SABB, 7FAF,

75SAF 208/240V 1810/2400

75A, 75SA, 75ABB, 75SABB,

75ADV 230V 2210

75A, 75AF, 75SA, 75SAF, 75ABB,

75SABB, 75ADV 120V 1700

75AFV 120V 2880

The grill should be connected to a wall type receptacle,

a direct line or individual branch circuit. An individual

branch circuit is preferred. If connected to an

overloaded circuit the grill will not operate properly.

The unit should be level when installed. Models

equipped with bun boxes must be level to utilize the

self-closing feature of the bun drawer. Adjustable 4inch legs are standard on the 75A series and available

for all other models.

GENERAL OPERATING PROCEDURES

The main switch located on the control panel controls

all the power to the unit. With the main switch on, the

rollers will turn, but no heat will be supplied unless the

heat controls are turned on. For flexibility the heating

section of the grill is divided into two individually

controlled heat sections. The right control regulates

the heat to the rear section and the left control

regulates the heat to the front section. The switch is

lighted to indicate when the unit is turned on (model

75AFV is not lighted). A signal light is provided above

each heat control and indicates when the heated

section is on. An additional light is provided on the end

housing of the unit. This light indicates the position of

the main power switch when either the optional bun

drawer front or merchandising door obstructs the

control panel view. Bun box equipped models require

the removal of the bun drawer to remove the bun pan

and to remove the drip tray when access to the rear

of the unit is obstructed. To remove the bun drawer,

grab the drawer by both sides and pull it out all the way.

Lift the front to unhook the drawer slide from rear

drawer roller. Pull the drawer the remainder of the

way out. Use caution not to drop the drawer when

reaching the end of the drawer slide travel. To reinsert

the drawer, first hook the drawer slide over the front

roller then the back roller. Do not operate the grill

without the drip tray in place.

CAUTION

USE ONLY PLASTIC OR COATED UTENSILS

FOR HANDLING THE FOOD PRODUCT.

METAL COULD SCRATCH THE ROLLER

COATING AND AFFECT THE CLEANABILITY

OF THE ROLLERS.

3

COOKING

The heat controls provide an infinite range of settings

for a wide variety of food products and installation

conditions. The size, content and shape of the product

and the installation of any sanitary food shields or

sneeze guards will determine the proper heat setting.

The National Sanitation Foundation requires that

perishable foods be kept at 140°F or above during

serving periods. Do not keep the food product on a

low setting for more than two hours. The product

should be kept refrigerated until ready for use. Cooking

time will vary depending on the starting temperature

and the qualities of the product. For best results when

cooking hot dogs use a hot dog made for grilling.

CAUTION

DO NOT USE STEEL WOOL OR ABRASIVE

CLEANERS ON THE ROLLERS. SCRAPES WILL

VOID THE WARRANTY. USE CAUTION WHEN

CLEANING A HOT GRILL TO PREVENT BURNS

OR BODILY INJURY.

CLEANING

Before cooking for the first time, wash the rollers with

mild soap and water using a soft cloth. Do not use

metal utensils when cooking. Scratches and scrapes

will hamper the ability to easily clean the rollers.

Never use steel wool or abrasive cleaners on the

rollers. This will damage the finish and the roller

bearings. The rollers clean most easily when hot. Use

caution when cleaning to prevent burns and bodily

injury. Clean the rollers with a clean wet cloth. Wipe

from the ends to the center to prevent forcing debris

into the roller seals. Do not allow the food product to

build up and bake onto the roller surface. The exterior

of the unit should be cleaned using a mild detergent or

non-abrasive cleaner. Clean the entire unit daily to

insure long life and satisfactory performance as well as

to maintain an attractive appearance. Do not clean

with water jet equipment.

MAINTENANCE AND REPAIRS

Contact the factory, a service representative or a local

service company for service or required maintenance.

Replacement cord sets must be purchased from Star

Manufacturing International, Inc.

RETAIN THIS MANUAL FOR FUTURE REFERENCE

Part No. 2M-Z3201 Rev. J 3/29/04

4

Loading...

Loading...