Star Manufacturing 314HX Parts List

PROVEYOR

MULTI-PURPOSE OVEN

MODEL

314HX, 318HX Series

Installation and

Operation

Instructions

2M-HG0105 Rev. C 10/30/07

®

314HX

1

SAFETY SYMBOL

Using any part other than genuine Star factory supplied parts relieves the

manufacturer of all liability.

Star reserves the right to change specifi cations and product design without

notice. Such revisions do not entitle the buyer to corresponding changes,

improvements, additions or replacements for previously purchased

equipment.

Due to periodic changes in designs, methods, procedures, policies and

regulations, the specifi cations contained in this sheet are subject to change

without notice. While Star Manufacturing exercises good faith efforts to provide

information that is accurate, we are not responsible for errors or omissions

in information provided or conclusions reached as a result of using the

specifi cations. By using the information provided, the user assumes all risks in

connection with such use.

These symbols are intended to alert the user to the presence of

important operating and maintenance instructions in the manual

accompanying the appliance.

RETAIN THIS MANUAL FOR FUTURE REFERENCE

NOTICE

MAINTENANCE AND REPAIRS

Contact your local authorized service agent for service or required maintenance. Please record the model

number, serial number, voltage and purchase date in the area below and have it ready when you call to

ensure faster service.

Model No.

Serial No.

Voltage

Purchase Date

Authorized Service Agent

Reference the listing provided with the unit

or

for an updated listing go to:

Website: www.star-mfg.com

E-mail Service@star-mfg.com

Telephone: (800) 807-9054 Local (314) 781-2777

The Star Service Help Desk

Business 8:00 am to 4:30 p.m. Central Standard Time

Hours:

Telephone: (800) 807-9054 Local (314) 781-2777

Fax: (800) 396-2677 Local (314) 781-2714

E-mail Parts@star-mfg.com

Service@star-mfg.com

Warranty@star-mfg.com

Website: www.star-mfg.com

Mailing Address: Star Manufacturing International Inc.

10 Sunnen Drive

St. Louis, MO 63143

U.S.A

2

2

TABLE OF CONTENTS

PAGE

Maintenance and Repairs 2

Star Contact information 2

Specifi cations 3

General Information Data 4

Inspection & Assembly 4

Assembly and Installation 4

Heating Elements 5

Cooling System 5

Final Check 5

Electrical Connection 5

Stacking Ovens 6

Daily Operation 7

Oven Components 7

Operating Hints & Saftey 7

Cleaning 8

Maintenance Procedures 11

Troubleshooting Guide 13

Limited Equiptment Warranty 14

Wiring Diagram 15-18

Exploded View Illustration 20

Parts List 314HX 21

Parts List 318HX 22

Control Box Confi guration 23

SPECIFICATIONS

314HX

Rating/Connection: 5,400 Watts

NEMA Plug: 6-30P, 3 Phase: 6-30P

Electrical Supply: Separate service per oven - 8.7 Amp, 380/220 VAC, 3 phase, 50 Hz

Approximate Weight (314HX Oven with Legs): Installed - 86 Lbs (40 kg), Shipping - 115 Lbs (52 kg)

Dimensions: Width: 60" (152.4 cm) - Oven with Shelves

Depth: 21 1/4" (54 cm)

Height: 16 1/8" (40 cm) - Single Oven with Legs

318HX

Rating/Connection: 6,200 Watts

NEMA Plug: 6-30P, 3 Phase: 6-30P

Electrical Supply: Separate service per oven - 9.9 Amp, 380/220 VAC, 3 phase, 50 Hz

Approximate Weight (318 Oven with Legs): Installed - 96 Lbs (44 kg), Shipping - 130 Lbs (59 kg)

Dimensions: Width: 60" (152.4 cm)

Depth: 24 7/8" (63.2 cm)

Height: 16 1/8" (40 cm) - Single Oven with Legs

3

GENERAL INSTALLATION DATA

CAUTION

This equipment is designed and sold for commercial use only by personnel trained and

experienced in its operation and is not sold for consumer use in and around the home nor

for use directly by the general public in food service locations.

Before using your new equipment, read and understand all the instructions & labels

associated with the unit prior to putting it into operation. Make sure all people associated

with its use understand the units operation & safety before they use the unit.

All shipping containers should be checked for freight damage both visible and concealed.

This unit has been tested and carefully packaged to insure delivery of your unit in perfect

condition. If equipment is received in damaged condition, either apparent or concealed, a

claim must be made with the delivering carrier.

Concealed damage or loss - if damage or loss is not apparent until after equipment is

unpacked, a request for inspection of concealed damage must be made with carrier within

15 days. Be certain to retain all contents plus external and internal packaging materials for

inspection. The carrier will make an inspection and will supply necessary claim forms.

INSPECTION & ASSEMBLY

UNCRATING AND INSPECTING

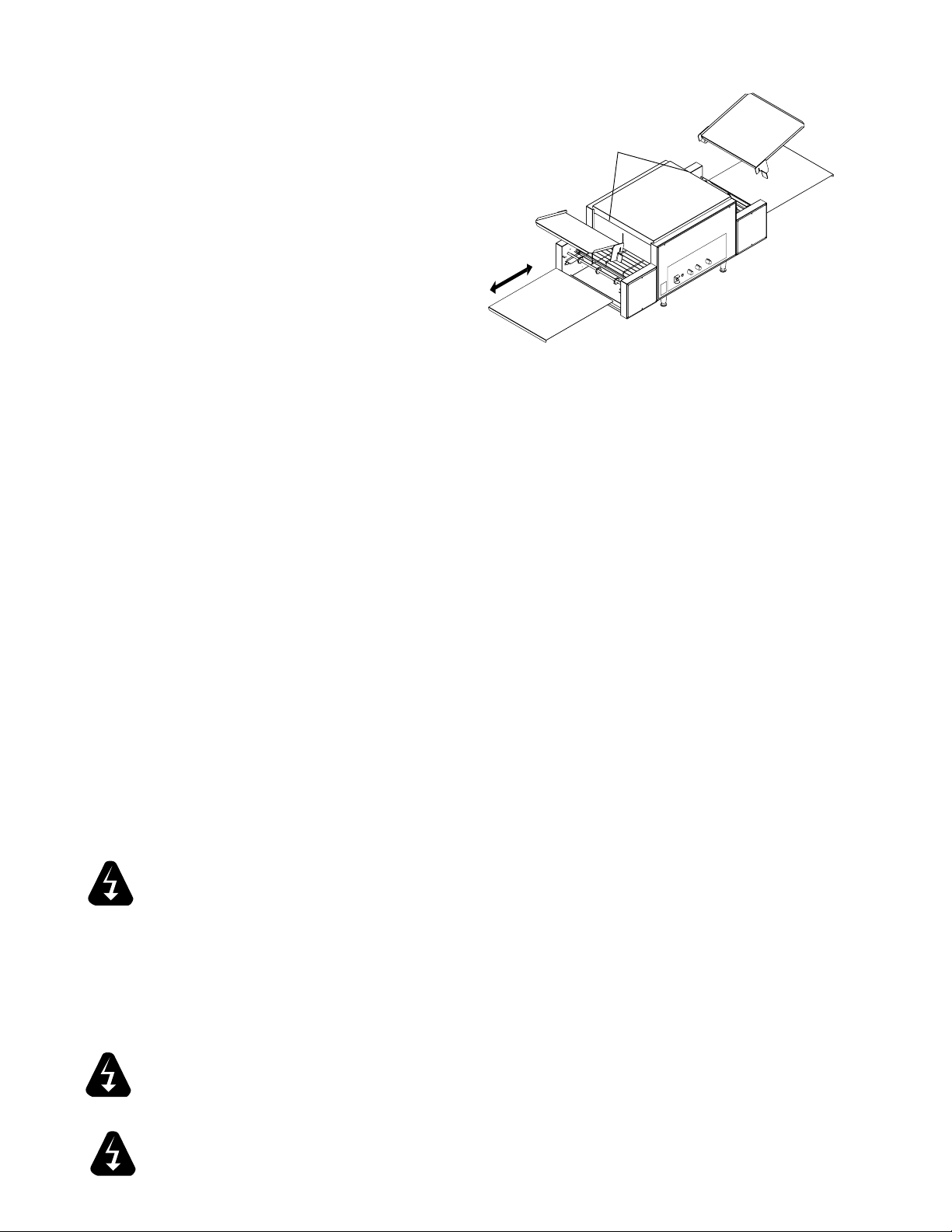

Unpack the unit and components from the shipping container. Remove all visible packing

material and those from inside the cooking chamber. If damage is discovered, fi le a claim

immediately with the carrier that handled the shipment. Do not operate the unit if it was

damaged during shipping.

The following should be included: Proveyor Multi-Purpose Oven, Stainless Steel Load Up &

Unload Trays, 4 Stainless Steel Legs.

CAUTION

REMOVE ALL HEATING ELEMENT SHIPPING SUPPORTS PRIOR TO PLACING YOUR

UNIT INTO OPERATION.

ASSEMBLY AND INSTALLATION

The unit was shipped with certain assembly required, plug into a standard outlet specifi ed

for its voltage and amp draw. If improper electrical supply is determined, contact a qualifi ed

electrician prior to using the unit. Removal and replacement of the power cord and plug will

void the warranty. For assistance, contact your local authorized service agent for service or

required maintenance.

Attach the 4 legs by screwing them into the weld nuts located on the bottom of the unit.

When complete, use two people to carefully turn the unit upright. Level unit by adjusting the

feet (approximately 1/2" adjustment). Never operate unit without proper legs in place.

Before using the unit for the fi rst time, wipe down the exterior with a damp cloth.

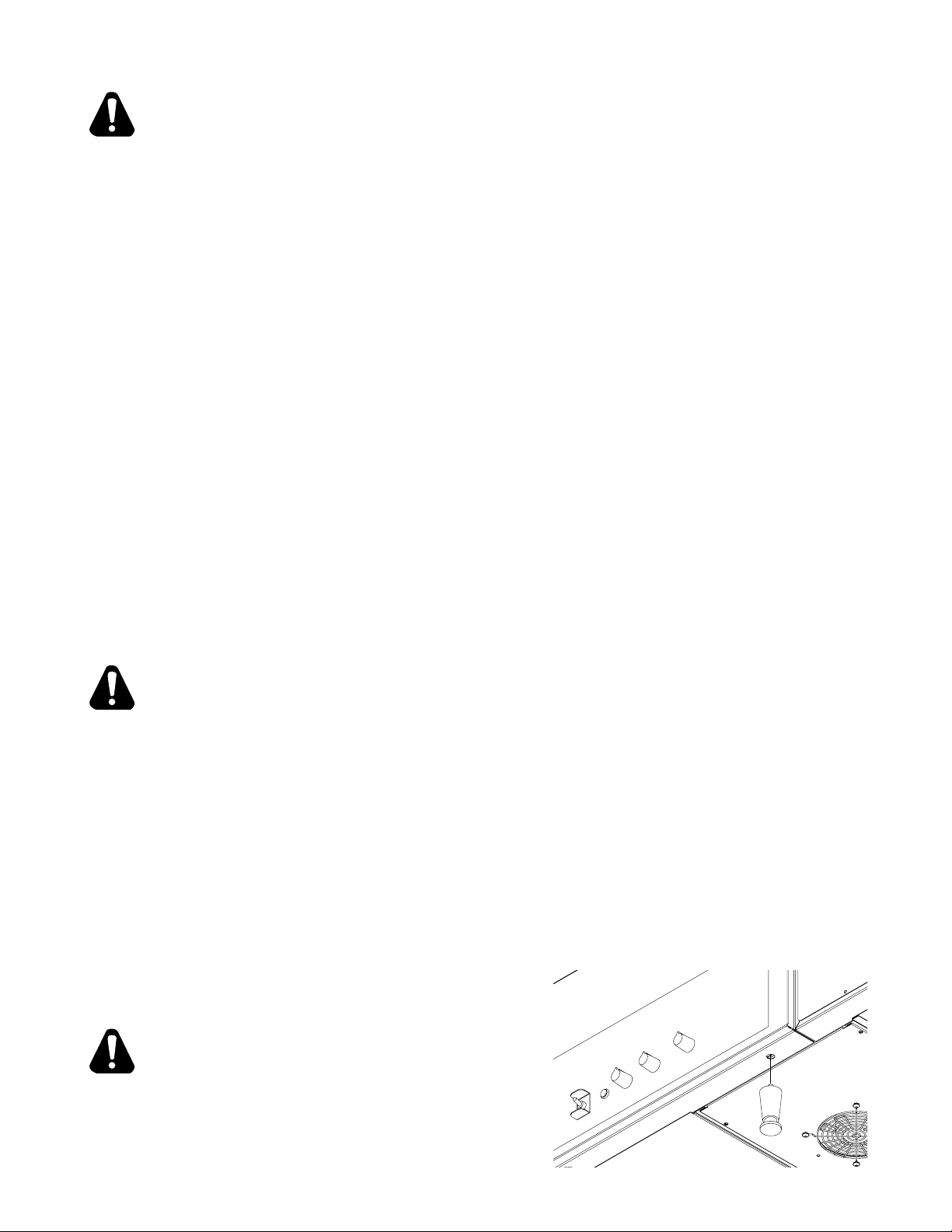

CAUTION

Allow enough space around the oven for adequate

ventilation. Do not operate the unit without the

crumb tray properly positioned. Overheating and

poor baking may occur. Read all labels on the unit

and follow their instructions.

LEG INSTALLATION

4

ASSEMBLY AND INSTALLATION continued

OPERATE

UNLOAD TRAY

LOAD TRAY

CRUMB TRAY

CRUMB TRAY

TYPICAL LEFT TO RIGHT CONFIGURATION

IL1001

ADJUSTABLE

HEAT SHUTTERS

Install unit in its operating position allow

suffi cient space for operating personnel.

Install the Load, Unload and Crumb Trays

as shown, making sure the ends are at

least 6" from any vertical combustible

surfaces.

Have an electrician connect input power

to the unit(s) in accordance with local

electrical codes. A connection terminal

block is inside the left side cavity for

models not provided with a cord and

plug set.

HEATING ELEMENTS

Inspect all heating elements in the unit

for breakage. Every unit is properly tested prior to leaving the factory, but damage may

of occurred during shipping. If a broken tube is found, do not apply power to the unit. If

everything checks out, Turn on Main Power Switch, Turn both heat controls and conveyor

belt speed control to the maximum setting and check all heater tubes and conveyor for

proper operation.

COOLING SYSTEM

After the unit is initially turned on, allow 5 to 8 minutes for the fan cooling system to come

on. Once on, check the air intake area located under the unit and be sure that there is a

suffi cient fl ow of air into the control box. Keep area under the unit clean from obstructions

that may result in restricted air fl ow to the control box. Restricting the air fl ow will cause

the unit to run hotter then designed, causing the Hi-Limit to turn unit off. See the Oven

Components section on page 7 for control box & Hi-Limit Reset locations.

FINAL CHECK

If all heaters and conveyor systems are operating properly, switch the master on/off switch

to the OFF position and allow unit to cool, the fan will continue to circulate air, cooling the

unit until the internal temperatures have been decreased.

If a problem is discovered during any of these start-up procedures, immediately switch the

master on/off switch to the OFF position and notify the Star Service Department at

1-800-807-9054.

ELECTRICAL CONNECTION

WARNING

Before making any electrical connection to this unit, check that the power supply is

adequate for the voltage, amperage and requirements stated on the rating plate.

A wiring diagram is included herewith.

Disconnect the unit from the power source before installing or removing any parts.

Be absolutely sure that the ground connection for the receptacle is properly wired. Do not

connect equipment to power without proper ground connections. Improper grounding may

result in personal injury or fatality.

WARNING

DO NOT CUT OR REMOVE THIS PLUG OR GROUNDING PRONG FROM THE

PLUG.

CONNECT/PLUG UNIT INTO DEDICATED A.C. LINE ONLY SPECIFIED ON THE

DATA PLATE OF THE UNIT.

5

STACKING OVENS

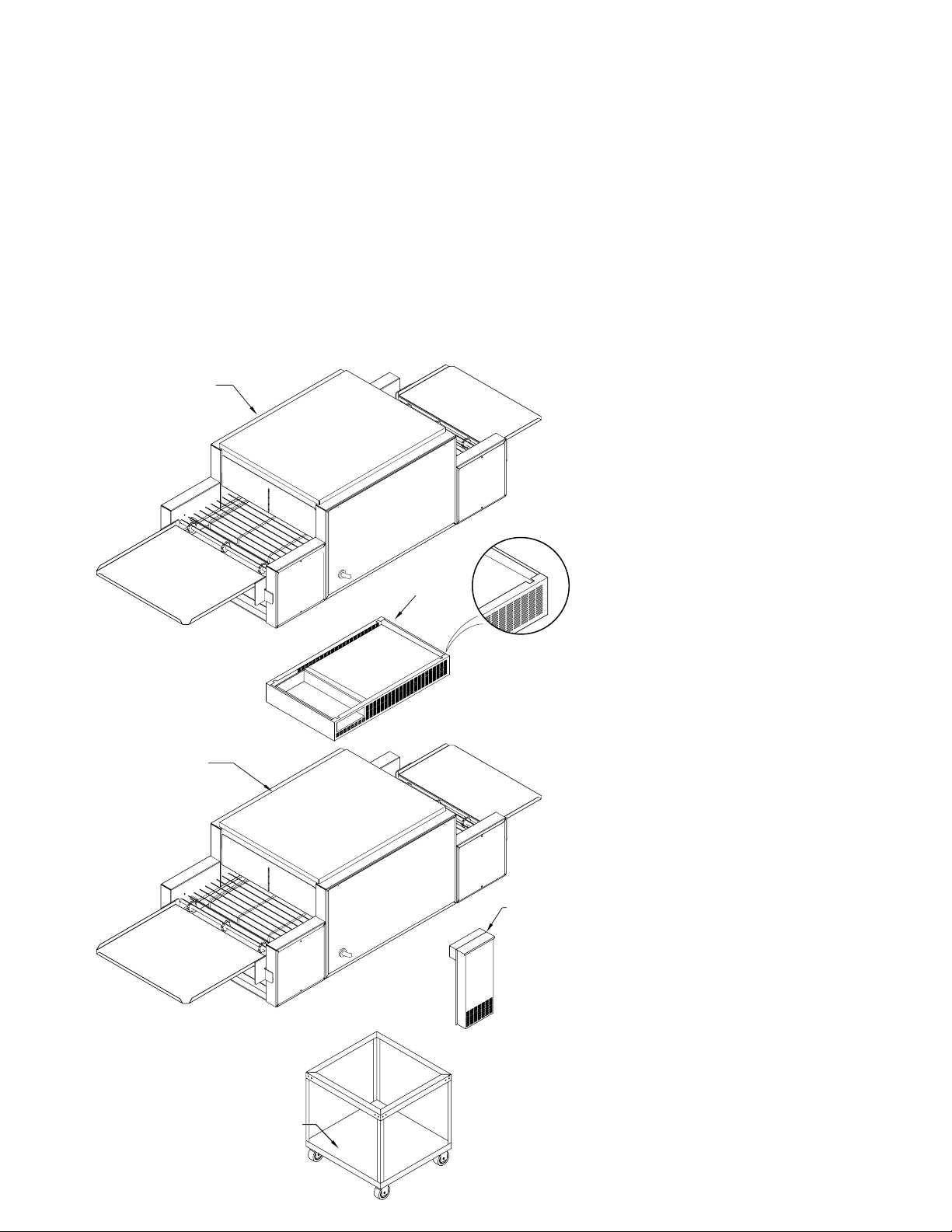

When stacking two Holman Proveyor Ovens a stacking spacer with an external air duct

MUST be used to prevent overheating of the control box of the top oven.

1. If a cart is to be used with units, place bottom unit on cart and align leg holes of unit with

the holes on the cart. Insert 3/8" bolts through cart and into leg holes to secure bottom unit

to cart as shown below.

2. Place stacking spacer on top of bottom oven with internal air duct facing up and towards

the rear of the oven.

3. Mount external air duct on stacking spacer as shown below. External air duct must be

installed for cooling system of top unit to function properly.

4. Screw cap screws (Qty 4) into leg hold on the top oven.

5. Place top oven on stacking spacer. Cap screws will set into cut out in top of stacking

spacer to lock unit into position.

OVEN

NOTE: Air intake of top unit

must fi t over the internal air

duct of stacking spacer to

allow airfl ow into the control

box of the top oven.

OVEN

STACKING SPACER

SET-SCREW

CUT OUTS

EXTERNAL AIR

DUCT

TOP UNIT: cap screw, screws

into leg holes, unit sits on top of

spacer.

STACKING SPACER:

(REQUIRED) Sits on top of bottom

oven.

EXTERNAL AIR DUCT: Mounts

onto spacer, pointing downward.

BOTTOM UNIT: Can be placed on

a counter or mounted on cart as

shown.

Cart: Mounting bolts for bottom

unit screw into leg holes through

the top cart frame.

EQUIPMENT

STAND

6

IL1020

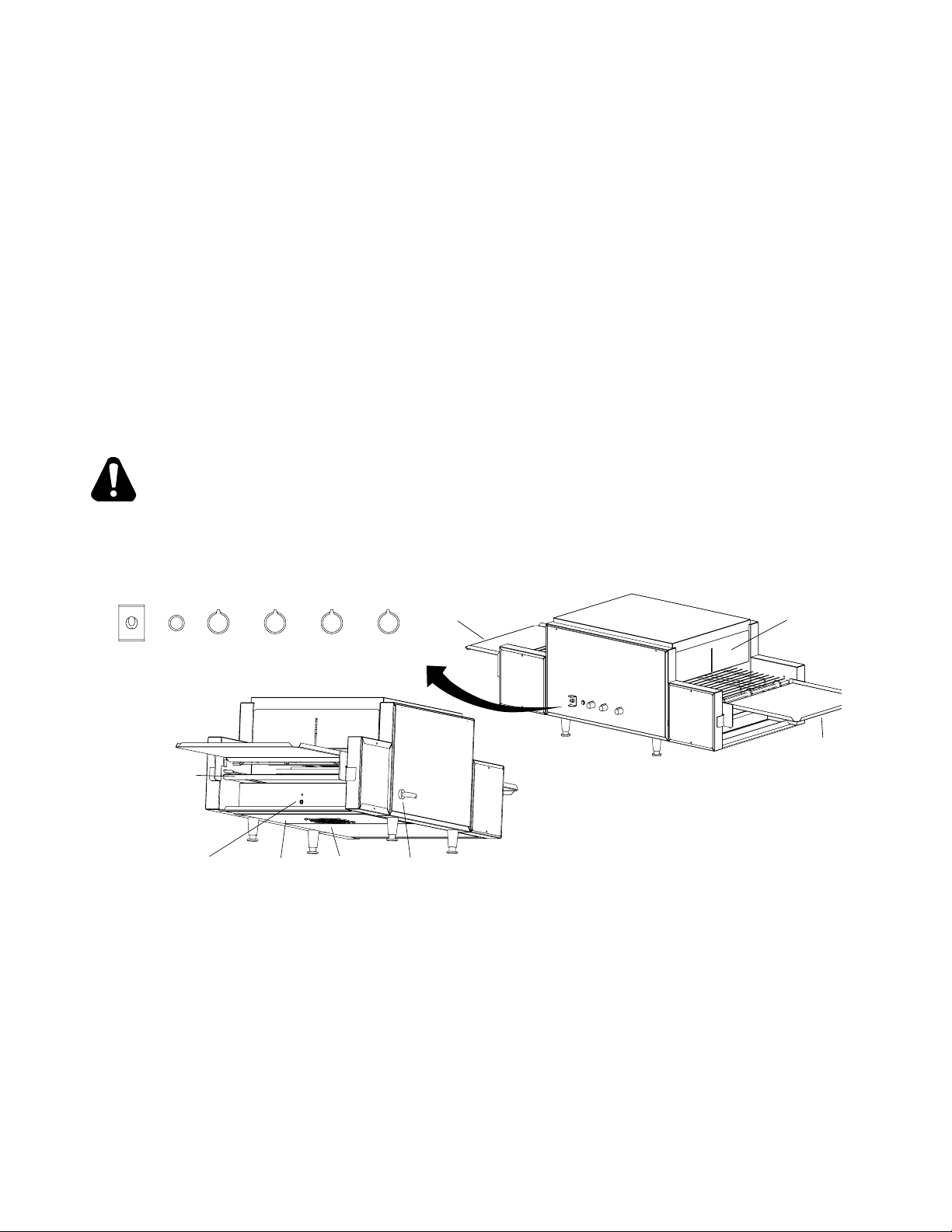

DAILY OPERATION

T

R

0

Baking in these units is a combination of heat and belt speed. Some foods may require

more top heat or visa versa; other foods may require low top and bottom heat and slow

belt speeds. Every product should, therefore, be tested using the separate top & bottom

controls and the variable speed control to arrive at the correct balance of heat and belt

speed. When changing heat and or belt speed setting allow approx. 5 minutes for the oven

to stabilize itself at the new settings.

Check the power cord to insure that it is plugged into a proper outlet.

Always allow 10 to 15 minutes of preheat time before loading the unit with product. Failure

to allow suffi cient preheat time will result in unsatisfactory cooking until the unit reaches

operating temperature.

1) Turn the master on/off switch to the ON position.

2) Set both the top and bottom heat controls to 500°F (260°C).

3-Phase Control Units, set front heat controls to 500°F (260°C)

3) Turn conveyor speed control to the fastest setting.

4) Allow 10 to 15 minutes for initial warm up,

(5 to 8 minutes to reach adjusted temperature, once unit is fully warmed up)

CAUTION

CERTAIN SURFACES ARE EXTREMELY HOT DURING OPERATION AND CARE

SHOULD BE TAKEN WHILE USING THIS UNIT.

ON/OFF

SWITCH

OVEN COMPONENTS

LOAD TRAY

PILOT

LIGHT

CRUMB

TRAY

(QTY 2)

FRONT

HEAT

CONTROL

(3 Phase only)

HI-LIMIT

SWITCH

UPPER

CONTROL

CONTROL

BOX

HEAT

LOWER

HEAT

CONTROL

AIR INTAKE

FAN

CONVEYOR

SPEED

POWER

CORD

OPERATING HINTS AND SAFETY

Disconnect power to the unit with the switch at the end of each day of operation.

Do not leave the unit in operation without an attendant.

ADJUSTABLE HEAT SHU

(QTY 2)

UNLOAD T

IL10

Do not leave the unit at high temperature when not in use or during idle periods. This will

cause food particles and grease fi lm to carbonize. It will take only a few minutes to regain

operating temperature.

7

CLEANING

Preventive maintenance for your Holman Oven consists of the following recommended

cleaning procedures. To keep your oven in its top operating condition, these steps should be

performed on a daily, weekly or as indicated.

WARNING

DISCONNECT UNIT FROM POWER SUPPLY OR TURN POWER OFF AT WALL

BREAKER.

DAILY

1. Turn main power switch to the OFF position. Disconnect unit from power source and

allow to cool.

2. Using a mild detergent, wipe exterior surfaces, clean with a damp cloth.

a. For lightly soiled build-up, clean with a damp cloth.

b. For heavily soiled build-up, use an soft damp cloth and mild detergent.

DO NOT use caustic cleaners.

3. Remove the load & unload tray by lifting them out of position. Clean using mild detergent

and warm water.

4. Remove each crumb tray by sliding each of them out from under the conveyor belt.

Clean crumb trays by wiping with a damp cloth and mild detergent.

DO NOT use caustic cleaners. Place trays back in place prior to putting unit back into

operation.

5. Reconnect power.

WEEKLY

1. Turn main Power switch to the OFF

position. Disconnect unit from power

source and allow to cool.

2. Perform daily cleaning procedures.

3. Using a damp cloth, wipe clean the fan

guard located on the control box cover

under the unit.

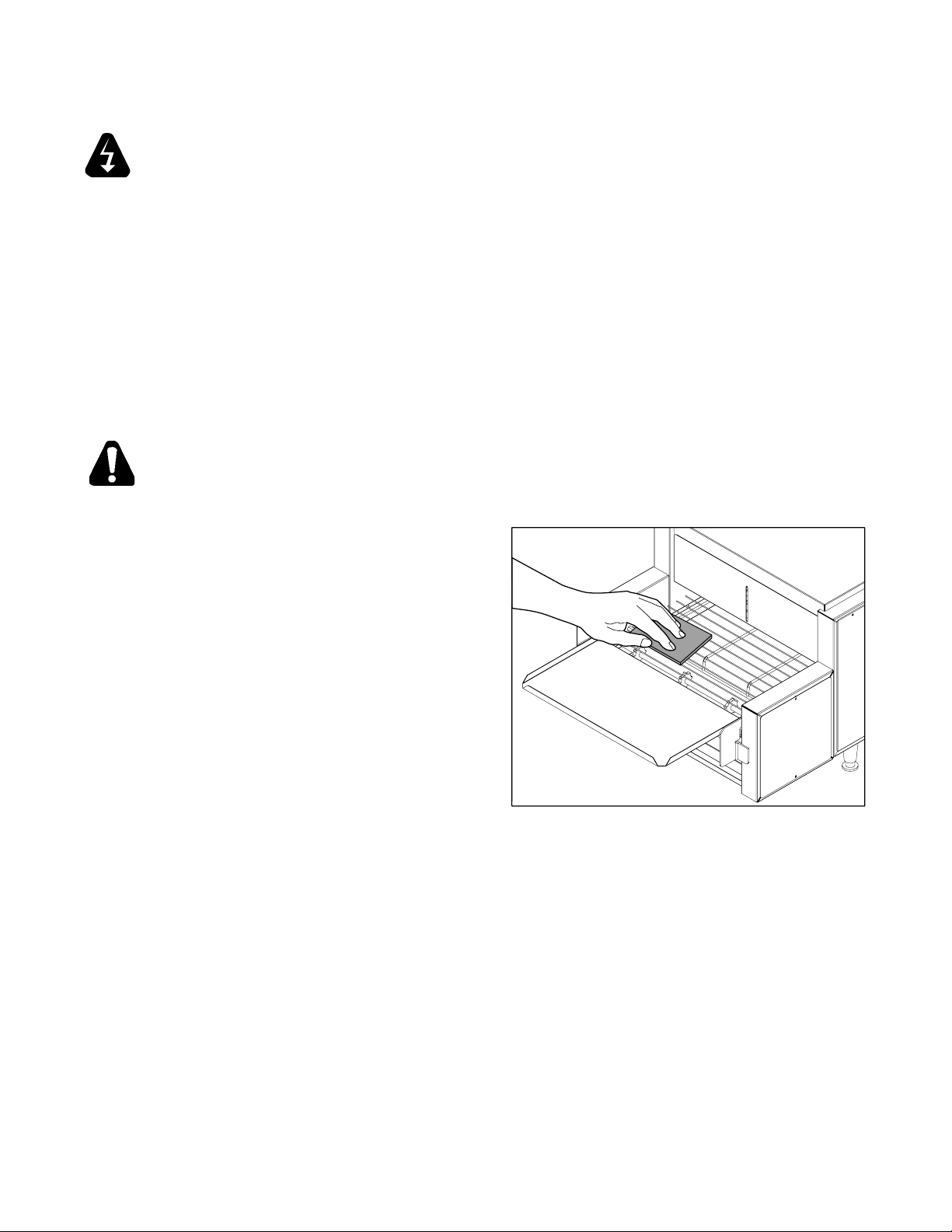

CLEAN CONVEYOR BELT

4. Reconnect power or turn power back on.

5. Switch the ON/OFF switch to the ON position, and turn Conveyor to its fastest setting.

6. With the Conveyor turned on and the crumb trays in place, take a wire grill brush or dry

abrasive pad, clean the exposed surface of Conveyor Belt by passing the brush or pad,

back and forth across the surface of the Conveyor Belt as the belt moves past. Continue

until the entire belt is clean. Make sure the Crumb Tray is installed, this will minimize the

amount of particles that fall into the oven.

CLEANING CONVEYOR BELT

IL1023

7. When the Conveyor Belt is clean, take a damp cloth and wipe the conveyor, removing

any loose particles on the belt surface. Turn Conveyor OFF.

8. Remove the Crumb Trays by sliding out from beneath the conveyor belt. Clean the

Crumb Trays by wiping with a damp cloth and mild detergent.

DO NOT use caustic cleaners.

DO NOT RUN CONVEYOR OVEN WITHOUT CRUMB TRAYS INSTALLED.

8

Loading...

Loading...