Page 1

Heater Insulation Kit

Sta-Rite Pool/Spa Group

293 Wright Street, Delavan, WI 53115

North America: 800-752-0183, FAX 800-582-2217

International: 262-728-5551, FAX: 262-728-4461, TELEX: ITT 4970245

www.sta-ritepool.com

Union City, TN • Delavan, WI • Mississauga, Ont. • Murrieta, CA

© 2003, Sta-Rite Industries, Inc. Printed in U.S.A. S430 (Rev. 2/14/03)

Page 2

Tools/Parts Required

Flat Screwdriver, Phillips Screwdriver

1/4” and 3/8” Socket Sets with Extenders

Sockets needed:1/4”, 5/16, 11/32, 7/16, 1/2, 9/16, 7/8

Rubber Mallet

To rque Wrench calibrated in Inch-Lbs.

High Temperature RTV (600° F. Cont.; 700° F. Intermittent)

Flame Holder/Adapter Plate Gaskets

(2 - Part No. 42001-0065)

14” & 12” Pipe Wrenchs (1 Each) or 2 Channel-Lock Pliers

Optional: Lifting Gear capable of handling 150 Lbs.

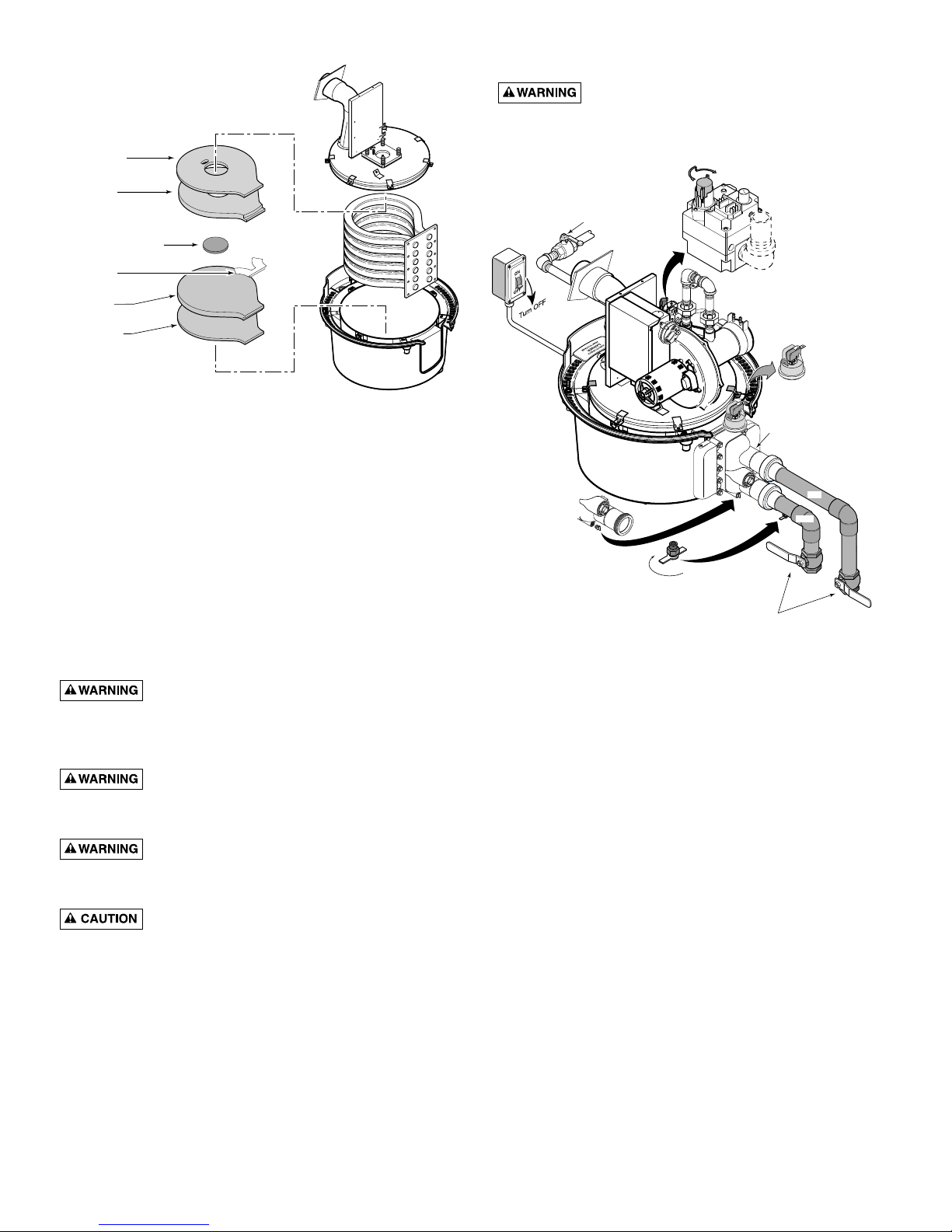

Safety Precautions:

Risk of electrical shock, fire or explosion.

Disconnect all power to the heater and close the external

manual gas valve at start of this procedure. Check for gas

leaks with a soapy water solution after reassembly.

Risk of carbon monoxide poisoning from

indoor units if exhaust vent joints are not sealed. Check

all vent joints for leakage after reassembly.

Heavy parts; can cause personal injury.

When lifting, use all proper precautions for the weights

involved.

Uncured RTV sealants can cause eye irritation. Follow manufacturer’s instructions when using RTV

sealants.

Location

The Insulation is located inside the Combustion Chamber.

Function

The insulation increases the thermal efficiency of the

heater and prevents overheating of parts outside the combustion chamber.

Servicing Procedure (See Figure 1):

Heavy parts; can cause personal injury.

When lifting, use all proper precautions for the weights

involved.

1. Turn off the filter pump and all electrical power to the

heater. Close the external Manual Gas Valve.

2. If the heater is below the water level of the pool, close

the isolation valves to avoid draining the pool.

3. Remove the drain plug under the manifold and drain

the heater.

4. While the heater is draining, remove the upper left and

upper right jacket halves.

5. Remove the switch covers on both sides of the mani-

fold and unplug the wires from the Automatic Gas

Shutoff, the High Limit Thermostat, and the Thermistor

(See Figure 2, Key No. 1). If necessary, disconnect the

Water Pressure Switch and remove it.

6. Disconnect exhaust vent from indoor units.

7. Disconnect the gas pipe at the external union between

the heater and the external manual gas valve.

8. Disconnect the incoming electrical wires at the junction

box and cut the wire tie holding the Wiring Harness to

the Lower Enclosure (See Figure 2, Key No. 2).

9. Disconnect the inlet and outlet unions and move the

heater enough to allow removal of the manifold

adapter and the inlet/outlet manifold as a unit (See

Figure 2, Key No. 3).

1/2" Insulation

OFF

ON

OFF

ON

Figure 1: Isolate and Drain Heater; Disconnect Power

2

Blanket

1" Insulation

Flameholder Insulation

Cap

Condensate

Evaporator

1" Insulation

1/2" Insulation

Blanket

3120 1197

Power

Combination Gas Control Valve OFF

Turn Clockwise

and press down

to turn off gas.

Manual/Gas Valve OFF

O

N

FF

O

VENT

PRESS

TAB

PILOT

O

N

F

F

O

T

N

E

V

S

S

PRE

B

TA

T

O

PIL

Remove Water Pressure

Switch to help Manifold

Drain

Drain Inlet/Outlet

Manifold

Inlet

Open

2704 1196

Drain Cock(s) and Plugs

OPEN

Close Isolation Valves

Outlet

Page 3

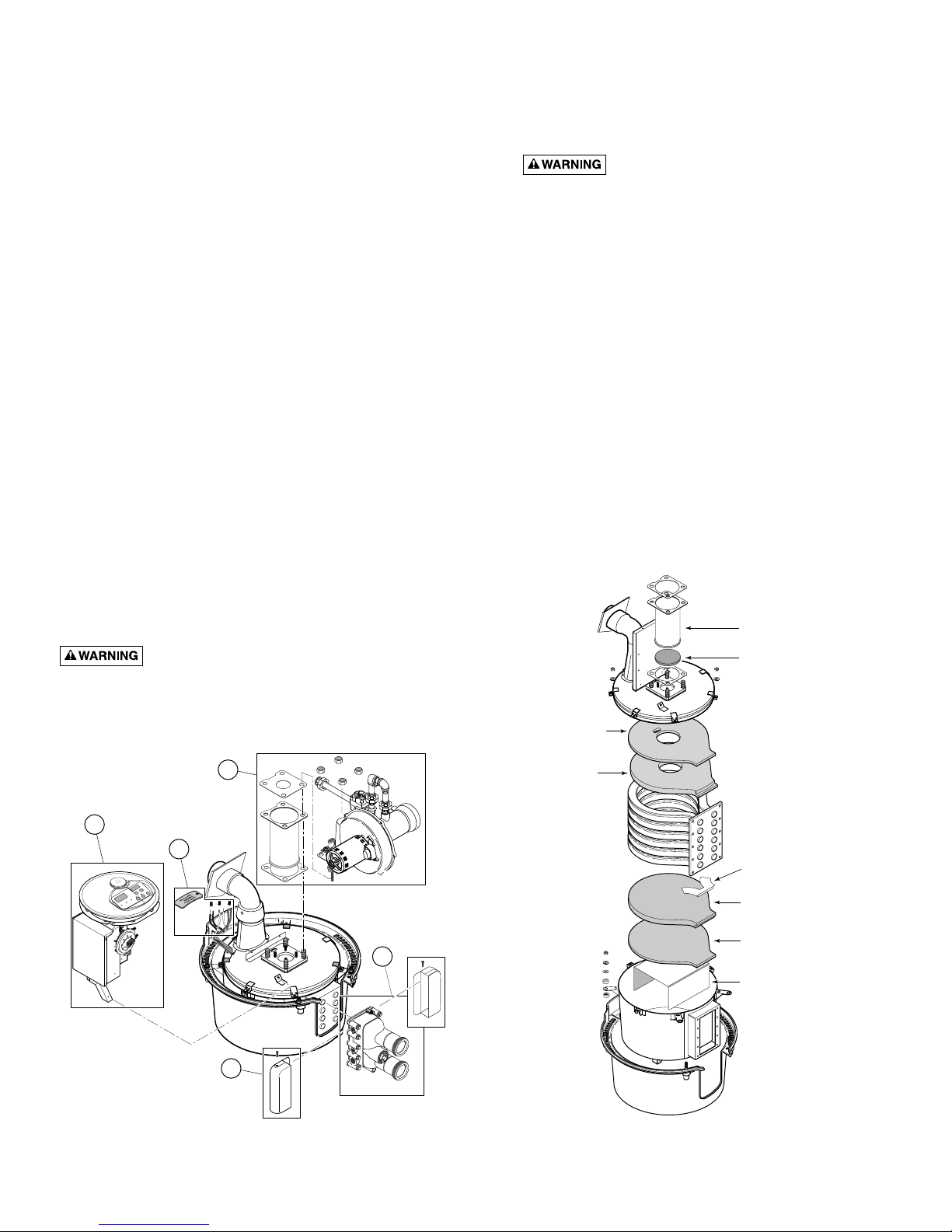

3

10. Unscrew the bolts that attach the manifold adapter to

the tube sheet and remove the manifold adapter and

the inlet/outlet manifold as a unit.

11. Carefully disconnect all three metering tubes from the

Combustion Air Blower Assembly (1 to the Combination

Gas Control Valve, 2 to the Air Flow Switch).

12. Remove the bolt from the Gas Piping Clamp.

13. Unplug all wires to the Control Box. Unscrew three

nuts and remove the Control Box, the Heat Shield, and

the Membrane Pad and Cover as a unit (See Figure 2,

Key No. 4).

14. Unscrew the four nuts holding the Blower Adapter

Plate to the top of the Combustion Chamber and

remove the Combustion Air Blower, the Igniter, the

Combination Gas Valve and associated piping and the

Blower Adapter Plate as a unit (See Figure 2, Key No.

5). Remove the Flameholder and Flameholder Cone (if

used).

NOTICE: BE CAREFUL not to break or crack the igniter

– it is fragile!

15. Unscrew the nuts holding the Combustion Chamber

top to the Combustion Chamber body.

16. Unscrew 4 hold-down nuts from the hangers supporting the Combustion Chamber.

17. Wrap a shop rag around each hanger, one at a time (be

careful; it’s sharp) and hammer down on the Lower

Enclosure while lifting the hanger by the shop rag. This

will lift the hanger up off of the hold-down bolt.

18. Lift the Combustion Chamber out of the Lower

Enclosure.

Heavy parts; can cause personal injury.

When lifting, use all proper precautions for the weights

involved.

19. Cut the RTV all the way around the top of the

Combustion Chamber with a screwdriver.

20. With a mallet and screwdriver, go around the

Combustion Chamber cover tapping up until the RTV

separates and releases the Combustion Chamber cover.

Be careful not to damage the Combustion Chamber.

21. Remove the Combustion Chamber cover.

California’s Proposition 65 lists

Refractory Ceramic Fibers heated to 1800° F or higher

as a possible human carcinogen. See the warning box

on Page 6 for further information. Call 1-800-752-0183

for a Material Data Safety Sheet (MSDS).

22. Remove the top insulation, the Heat Exchanger Coil,

the Condensate Evaporator, the Bottom Insulation, and

the metal spacer from the Combustion Chamber. Do

not remove the RTV that seals the manifold mounting

plate to the combustion chamber.

23. Clean up the Combustion Chamber, the Combustion

Chamber cover, and the Spacer. Be sure to completely

remove all RTV from the Combustion Chamber and

Combustion Chamber top.

24. Reinstall the clean spacer in the Combustion Chamber.

Install one 1/2” white Insulation Blanket on top of the

spacer and one piece of 1” “M” insulation on top of the

Blanket. Make sure that the insulation is centered in the

Combustion Chamber.

NOTICE: Model SR/SRC200 heaters built before 1/1/98

require two 1/2” Insulation Blankets.

Figure 2: Removal of major sub-assemblies

1/2" Top

Blanket

1" Top

Insulation

1/2" Bottom

Blanket

1" Bottom

"M" Insulation

Flameholder

Insulation

Cap (Tape

to bottom of

Flameholder)

Spacer

Condensate

Evaporator

Flameholder

3122 1197

Figure 3: Correct order for installation of insulation.

5

4

2

3

1

Page 4

4

25. Install the new Condensate Evaporator on top of the

insulation.

26. Clean the tubesheet and O-Ring sealing surfaces (see

Figure 4).

27. Reinstall the Heat Exchanger Coil on the Insulation.

Pull the Heat Exchanger Coil and the Bottom Insulation

forward together to align with the mounting plate (see

Figure 5).

28. Install the manifold and manifold bolts. See Figure 6

for long and short bolt positions.

Figure 5: Align bottom insulation and Heat Exchanger

Coil as shown.

C

Figure 4: Clean the Tube Sheet and O-Ring sealing surfaces thoroughly as described above.

Figure 6: Install bolts as shown.

• Install O-rings on tube ends; install manifold.

• SR/SRC200 and SR/SRC400: Tighten all long bolts

HAND TIGHT; then tighten the bolts next to the short

bolts a little more with a wrench.

• Insert and start the two short bolts until they engage

three or four threads, then tighten all bolts according to

the normal torque pattern shown on Page 5.

• SR/SRC333: These models use long bolts only. Tighten

all bolts HAND TIGHT; then tighten according to the

normal torque pattern shown on Page 5.

*Hand-tighten all long bolts; then tighten indicated bolts enough to

allow short bolts to engage.

Clean the tube sheet and O-ring

1.

sealing surface with a nylon brush,

then brighten the tube sheet

surface with 320 grit emery cloth.

NOTE: When cleaning, be careful

not to push the tube sheet into the

combustion chamber. If you do,

thread a couple of bolts into it

and pull it back in place.

Brush off all dust and debris

2.

with a brush and wipe it down

with a cloth.

Apply silicone grease (supplied)

3.

to O-Rings.

4067 0901

A. Center Insulation

in lower enclosure.

Add Evaporator Plate.

Evaporator

Plate

Insulation

B. Center Heating

Coil on Insulation.

Heating

Coil

Models SR200/SRC200

Short Bolt Placement

2-3/4"

*

2-1/2"

*

2-3/4"

Models SR400/SRC400

Short Bolt Placement

2-3/4"

2-1/2"

2-3/4"

*

*

Do not

disturb

RTV in these areas

C. Slide Coil, Insulation,

and Evaporator Plate

into Manifold Mounting

Plate.

Lower

Enclosure

D. No Gaps between insulation

and Tube Sheet

Here and Here

Tube

Sheet

4076 1001

2-3/4"

*

2-1/2"

2-3/4"

*

2-1/2"

Page 5

5

29. Tighten the bolts to the torque spec as shown in Figure 7.

30. Turn on the water and check for leaks between the

Manifold Adapter and the Tube Sheet.

31. Install one piece of 1” top Insulation on top of the Heat

Exchanger and one 1/2” Insulation Blanket over the top

Insulation. Make sure that the insulation is centered on

the coil so that an equal number of heater coil fins

shows around the insulation.

32. Apply fresh High Temperature RTV (600°F Continuous,

700° F. Intermittent rating) all the way around the

inside top of the Combustion Chamber and the outside

of the Combustion Chamber cover (see Figure 8).

33. Reinstall the Combustion Chamber top and fasten with

nuts on studs from Combustion Chamber body.

34. Reinstall the Combustion Chamber in the Lower

Enclosure and fasten with hold-down nuts.

35. Reinstall the Flameholder and Flameholder Cone (if

used), and then the Combustion Air Blower, the Igniter,

the Combination Gas Valve and associated piping and

the Blower Adapter Plate as a unit; use new gaskets.

Be sure to reinstall the Insulation Cap on the bottom of

the Flameholder. Tighten Adapter Plate nuts to 70-80

in.-lbs. torque. See Figure 9.

1. Make sure that all bolts are engaged and hand tight.

2. Torque the bolts in sequence as shown. Some noise

(popping, etc.) is normal as you tighten.

3. Go around the manifold and retighten the bolts as

needed to 75-115 in-lbs. (8.4-12.9 N-m) (you may

have to do this several times).

Figure 7: Torque Specs.

Apply RTV

here

and

here.

Apply RTV bead all the way around

both Combustion Chamber and Cover.

3140 0198

Figure 8: RTV Application For Reassembly

Flameholder/Adapter

Plate Gasket

Flameholder/Combustion

Chamber Gasket

3123 1197

1

2

3

At reassembly, connect tubing

as shown:

1. From Air Inlet Port to

Combination Gas Valve;

2. From Air Inlet Port to

Air Flow Switch;

3. From bottom of Blower to

Air Flow Switch.

3123 1197

Figure 9: Make sure new gaskets are in place when

reassembling combustion chamber.

Tor que Pattern - All Models

98

54

12

3 6

710

75-115 in.-lbs./8.4-12.9 N-m

Page 6

36. Reinstall Control Box and Heat Shield assembly; fasten

with three nuts.

37. Reconnect the water pressure switch (if necessary).

38. Reconnect the metering tubes from the Air Flow Switch

and the Combination Gas Control Valve to the

Combustion Air Blower Assembly (see Figure 9).

39. Reconnect exhaust vent pipe and seal with RTV or

epoxy according to vent manufacturer’s instructions.

Risk of carbon monoxide poisoning. Make

sure that entire exhaust vent is sealed after reinstallation.

40. Reconnect all wiring. See Figure 10 for Junction-box

connections, and see Page 7 for complete wiring

schematic.

41. Before starting the heater, test for gas leaks from piping

and around Combustion Chamber cover with a soapy

water solution.

42. Check for water leaks at unions and at manifold flange

(where it joins the tube sheet).

43. Reinstall jacketing and test heater by running it through

one complete cycle. Test for exhaust leaks from exhaust

vent pipe while cycling heater.

44. Heater is ready for service.

6

Wire into bottom

of Junction-box

in Flexible Conduit

Wiring Harness

to Control Box

Black to Black

White to White

Green (Ground)

to

Green (Ground)

Bonding

Wire

View From Above

(Interior)

Figure 10: Junction Box Wiring Connections

For detailed installation, operation, maintenace

and safety information about the Sta-Rite pool

heater, call customer service at 1-800-752-0183

and request a Sta-Rite Pool/Spa Heater Training

and Service manual, publication S5066.

Prolonged exposure to the ceramic fiber insulation in

the combustion chamber may cause cancer. May also

cause temporary eye, skin, or respiratory tract irritation.

Avoid breathing fiber particulates and dust.

Wear a NIOSH/MSHA approved respirator, loose, long sleeved clothing, eye protection, and gloves when working with

or around insulation. Wash work clothes separately. Rinse washing machine after use.

For first aid:

Eyes: Flush with water.

Skin: Wash with soap and water.

If swallowed: Do not induce vomiting. Get medical attention if gastrointestinal symptoms develop.

If inhaled: Get to fresh, clean air.

If any of the irritations above persist, seek medical attention immediately.

For additional product information or for a Material Safety Data Sheet (MSDS), call

1-800-752-0183

Page 7

7

JMP3

9

1

J6

JMP3

1

JMP3

1

External Control Interface Circuit

Disabled, Heater Membrane Pad

Enabled

External Control Interface

Circuit Enabled, "Pool On"

and "Spa On" Keys Disabled.

"OFF" Key on Membrane

Pad Remains Functional.

CONNECTION DIAGRAM

AGS Switch

Stack Flue Sensor

Gas Valve

Air Flow Switch

Extra Switch 1

Hi-Limit Switch

Pressure Switch

VAL

TH

IND

GND

24VAC

24VAC

FS

THERMISTOR

OPERATING CONTROL

1

PS

HLS

ES1

AFS

AGS

SFS

GAS

CONTROL CENTER

SPA CONTROL

VERSION 1 PAD

MEMBRANE PAD

CONNECTION

Spa Line

Common Line

Pool Line

IGNITION CONTROL

MODULE

DIAGNOSTIC INDICATOR

F1 F2

24

VAC

FC1

FC2

S1/

120

L1

L1

L2

BM

FL

F1

L2S2TH IND

VAL GND

GND

GND

GND

BLOWER

120VAC

120VAC (HOT)

120VAC

IGNITER

MOT

TRANS

TRANS

GROUND (GND)

NEUTRAL (NEU)

JUNCTION BOX

F

I

R

E

M

A

N

S

S

W

I

T

C

H

Replace jumper with leads to

Fireman's Switch (field installed)

24VAC

SEC

PRIM

120VAC

Y/W

Y/W

Y/R

Y/O

Y/BL

BK

GY GY

BK

BK

W

W

BK

W

W

WW

G

G

Y

Y

YY

BK

BK

Y/W

W

W

R

R

BL

BL

O

O

O

O

PR

PR

Y/R

Y/BL

Y/O

Y/W

Y

Y

Y

Y

Y

YY Y Y

BR

BR

3661 0200

External Control Interface

If cable from Membrane Pad

is a 6-Conductor Cable, connect

it to pins 4 - 9 on Operating

Control Board as shown.

Y

9

1

J6

NOTICE: If, while there is 120VAC connected to the heater, you touch

either 120VAC terminal with any 24VAC wire that is connected to the

control board (including the Fireman's Switch jumper), you will

immediately destroy the control board and void the warranty.

Page 8

8

REPAIR PARTS LIST

Key Part Part

No. Description Qty. No.

1 Flameholder Insulation Cap 1 42001-0075

2 1/2” Blanket 1 42001-0071

3 1” Top Insulation 1 42001-0070

4 Condensate Evaporator 1 42001-0065

51”“M” Insulation 1 42001-0072

6 1/2” Blanket* 1 42001-0073

1

2

3

4

6

5

3125 1197

* Model SR/SRC200 heaters built before 1/1/98 use 2 of

Part No. 42001-0073.

Loading...

Loading...