STA-RITE SR6000S Installation & Operation Manual

STA-RITE®

SR6000S

POOL / SPA

CONTROLLER

Software Version

SR6000S Release

Feb. 28, 2003

A1

INSTALLATION &

OPERATION GUIDE

STA-RITE INDUSTRIES

293 Wright Street

Delavan, WI 53115

Ph (800) 752-0183

STA-RITE INSTALLATION & OPERATION GUIDE

1

Table of Contents:

SAFETY PRECAUTIONSa .................................................................................................. 3

WARRANTY .......................................................................................................................... 4

1.0 SR6000S OVERVIEW...................................................................................................... 4

1.1 MODEL SR6000S............................................................................................................ 6

INTRODUCTION............................................................................................................. 6

1.2

1.3

IMPORTANCE OF WATER MAINTENANCE............................................................... 6

2.0 INSTALLATION PROCEDURES ....................................................................................... 7

2.1 INSTALLATION PREPARATION ................................................................................. 7

2.2 MOUNTING THE SR6000S........................................................................................... 7

PLUMBING INSTALLATION ....................................................................................... 8

2.3

2.4

FLOW OR PRESSURE SWITCH..................................................................................... 9

2.5 ELECTRICAL SPECIFICATIONS................................................................................... 9

2.6 ELECTRICAL INSTALLATION.................................................................................. 10

2.7 SENSORS........................................................................................................................ 10

2.8 PH AND ORP ELECTRODES......................................................................................... 11

2.9 ELECTRODE CARE ..................................................................................................... 11

2.10 FINISHING AND TESTING ....................................................................................... 12

3.0 OPERATION OF SR6000S ........................................................................................... 13

3.1 INTRODUCTION ................................................................................................................ 13

3.2 LED SUMMARY TABLE ............................................................................................. 13

3.3 INITIALIZING THE SR6000S............................................................................................. 14

3.4 READING DISPLAY........................................................................................................... 14

3.5 MANUAL FEED................................................................................................................. 15

3.6 PH AND ORP MENU ITEMS............................................................................................... 15

3.7 PH / ORP SET POINTS ...................................................................................................... 16

3.8 CYCLE TIME..................................................................................................................... 16

3.9 ON TIME LIMIT................................................................................................................. 17

3.10 CALIBRATION................................................................................................................. 18

3.11 CALIBRATING PH........................................................................................................... 18

CALIBRATING ORP.......................................................................................................... 18

3.12

3.13 OVERFEED TIME LIMIT................................................................................................. 19

4.0 ADVANCED MENU ............................................................................................................ 19

4.1 CLEAR PH......................................................................................................................... 20

4.2 CLEAR ORP..................................................................................................................... 20

4.3 ACID OR BASE SELECT .................................................................................................... 21

4.4

SET PASSWORD................................................................................................................. 21

4.5 RESET ALL ..................................................................................................................... 22

TROUBLESHOOTING ......................................................................................................... 22

5.0

5.1 PUMP MAINTENANCE............................................................................................... 24

5.2 PUMP TUBE REPLACEMENT.................................................................................... 24

5.3

MAXIUM CHEMICAL CONCENTRATIONS ............................................................ 25

6.0 APPENDIX B: CHEMICAL STANDARDS ............................................................................... 25

STA-RITE INSTALLATION & OPERATION GUIDE

2

SAFETY PRECAUTIONSa

PLEASE READ THIS USER MANUAL completely before installing or operating the

equipment. The SR6000S is a Class 1 product for protection against electric shock and a

Type 1 product with regards to disconnection of the control circuits.

Be sure to observe the following safety precautions:

a– Do not permit anyone untrained or under the age of 18 to use this product.

a– Unit must be properly connected to earth ground.

a– Never apply power when front panel is not secured in the closed position.

a– Never service unit with power applied, always turn OFF main circuit breaker to unit and

all equipment when servicing.

a– Do not disassemble. Touching the controller’s internal parts could result in injury. In

case of a malfunction, only a qualified technician should repair the controller.

a– Risk of Electric Shock. Connect only to a grounding type receptacle protected by a

ground-fault circuit interrupter (GFCI). Contact a qualified electrician if verification on the

receptacle is not protected by GFCI.

a – Do not bury cord. Route cord to eliminate abuse from heater exhaust, lawn mowers,

hedge trimmers, and other equipment.

a– Be careful not to damage any of the cord insulation. Should the cord be damaged,

return it to your dealer for a replacement. Continued use could result in fire or electric

shock.

a– To reduce the risk of electric shock, do not use an extension cord to connect unit to

electric supply; provide a properly located GFCI.

a– Never remove or install any cables between the circuit cards when power is applied,

damage to the components may occur.

WARNING: DANGER - CHEMICAL BURN HAZARD - If possible, make sure

pumps are OFF before drilling into pipes. Securely fasten all electrical, water and

chemical lines. Locate chemical feed pumps and chemical storage tanks in a safe

and secure area. Never turn chemical feed pumps ON when both flow cell valves

are closed. The feed lines will blow off and spray full strength chemicals on you or

anyone near the equipment

SAVE THIS INSTRUCTION GUIDE!

STA-RITE INSTALLATION & OPERATION GUIDE

3

WARRANTY

STA-RITE INC. warrants the SR6000S to be free from defects in

manufacturing and workmanship for a period of Three (3) YEARS from the

date of manufacture for the electronic module. All sensors and flow cells

have a warranty of one (1) year. Other equipment is covered by

manufacturer's own warranty. During the warranty period, any defective

parts will be repaired or replaced when necessary by Sta-Rite.

This warranty does not cover: (a) the buyers' labor or any servicing fees

related to replacement of the Product; (b) damage resulting from the use

of this Product in other than its normal manner; (c) damage from misuse,

accident or neglect; (d) damage from improper testing, operation, or

installation; (e) not operating the Product on a dedicated (separate) circuit

or under conditions other than those recommended or at voltages or

amperages other than the voltage or amperage indicated on the Product;

and (f) acts of Mother Nature (i.e. lightning, electrical storms, floods, etc.).

In addition, attempting to service or modify the Product will render this

Warranty Void. Defective parts should be returned immediately to the

local Sta-Rite dealer, any parts returned to the factory require a return of

material authorization code.

WARRANTY CARD MUST BE COMPLETED AND RETURNED AT ONCE.

1.0 SR6000S OVERVIEW

Sta-Rite, the technological leader in swimming pool automation, congratulates you on

your selection of the SR6000S swimming pool controller. The SR6000S is specifically

designed to be easy to use and install while meeting the needs of the most demanding

applications.

Some of the more outstanding features include:

SUMMARY: The SR6000S is an automation system capable of continuous monitoring

and control of water chemistry.

PROGRAMMABLE FEATURES: Programmable chemical feed cycle on and off times, set

points that specify the pH and ORP set points, selection of pH acid or base feed, off at set

point, off if no flow, overfeed and password protection.

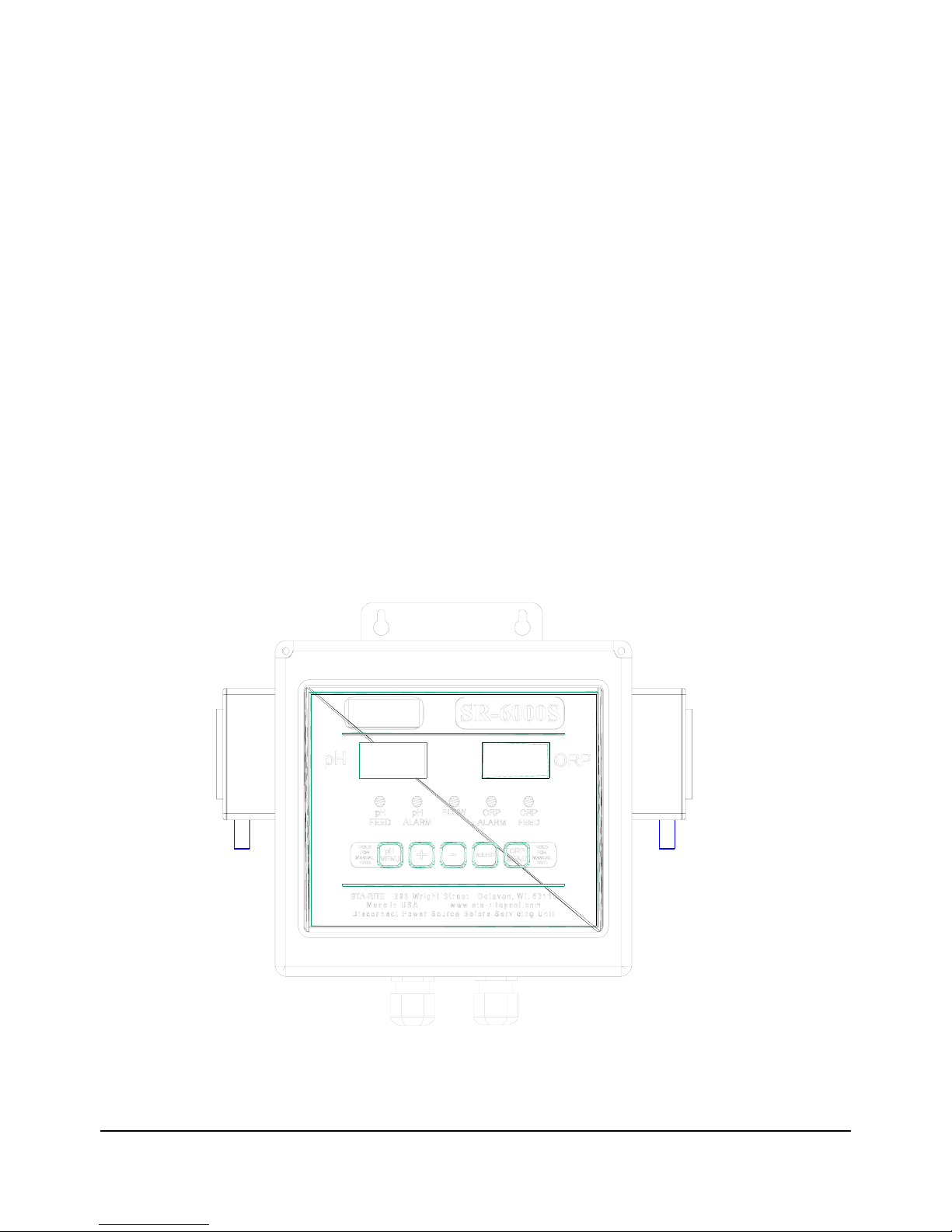

DISPLAY: The SR6000S includes two (2) digital displays with th ree (3) decimal points

each. These displays are visible from distance of over twenty (20) feet and are visible at

night.

STA-RITE INSTALLATION & OPERATION GUIDE

4

LED: The SR6000S uses five (5) indicator LED’s including Flow, ORP Alarm, ORP Feed,

pH Alarm and pH Feed.

BUTTONS: The SR6000S includes five (5) buttons for accessing and changing all

parameters.

MEMORY: In case of power loss the SR6000S shall retain all programmed values. The

values are protected for at least five (5) years without having power applied.

SECURITY: The SR6000S has a password feature to disable the buttons remotely and on

sight.

ALARMS: If the pH or ORP is more than 5% away from set point for 10 minutes or more

the SR6000S will light the LED alarm LEDS.

BUILT IN CHEMICAL FEEDERS: Two 24 volt chemical feed pumps are built onto the

sides of the SR6000S for ease of use and installation.

SENSORS: The SR6000S directly measures pH and ORP. Each sensor has its own

isolated circuitry for direct measurement, without the need for addition hardware of

electronics.

VOLTAGE: The SR6000S includes a selector switch to select the input voltage of 110 or

220 VAC (single or two phase). Both the line and neutral voltages are fused at 5A; the

relay power is routed through a 1A fuse.

STA-RITE INSTALLATION & OPERATION GUIDE

5

1.1 MODEL SR6000S

The SR6000S is a chemical controller capable of maintaining water quality, by

monitoring the ph and ORP of a water source and by automatically feeding chemicals with

two built-in feed pumps. The chemical levels are tightly controlled with timed feed cycles.

To prevent overshoot the feed time has a 5% proportional adjustment. At 5% away form

set point the feed pump will be a maximum feed time. Within 5% of set point th e feed

time will decrease linearly as set point is approached.

1.2 INTRODUCTION

The SR6000S INSTALLATION AND OPERATION MANUAL explains the procedures for proper

installation and operation of the SR6000S series controller. Chapter two (2) the

Installation

installing the electrical and plumbing portions. Chapter three (3) the Programming and

Operation, describes all the available functions of the controller, from navigating to

initializing the SR6000S.

If there are any questions after reading this manual, please contact your local Sta-Rite

dealer or Sta-Rite directly.

section, introduces the parts of the controller and the process to follow when

1.3 IMPORTANCE OF WATER MAINTENANCE

The SR6000S will effectively mainta in the bacteriological and physiological requirements

of state and local Health Departments. In addition, the SR6000S helps to protect the

equipment from the effects of improper water balance.

The National Swimming Pool Foundation recommends the following guidelines for

chemical automation, (local health codes may differ):

Filtration – Minimum turnover rate of six (6) hours for a pool and thirty (30) minutes for

a spa.

Water Balance – pH 7.2 – 7.6, alkalinity 80-120 PPM.

Oxidation Reduction Potential (ORP) – A minimum 650 mV to maximum 750 mV the

preferred.

Total Dissolved Solids – Should not exceed 2000 PPM.

STA-RITE INSTALLATION & OPERATION GUIDE

6

2.0 INSTALLATION PROCEDURES

Listed below are the instructions and information necessary to install your SR6000S

chemical controller system.

2.1 INSTALLATION PREPARATION

As soon as the controller is received, check the shipping carton carefully for damage and

report any directly to the shipping company. Use care when unpacking equipment to avoid

damage or loss of small parts. Go through the shipping list and if anything is missing,

please contact your local Sta-Rite dealer.

• The SR6000S is a simple product to install and begin using. Mapping out

connections prior to installation is recommended. The location of the SR6000S

must be optimized for both electrical and plumbing connections.

• Sta-Rite sends the SR6000S from the factory set to the 110 VAC supply power, in

order to simplify installation.

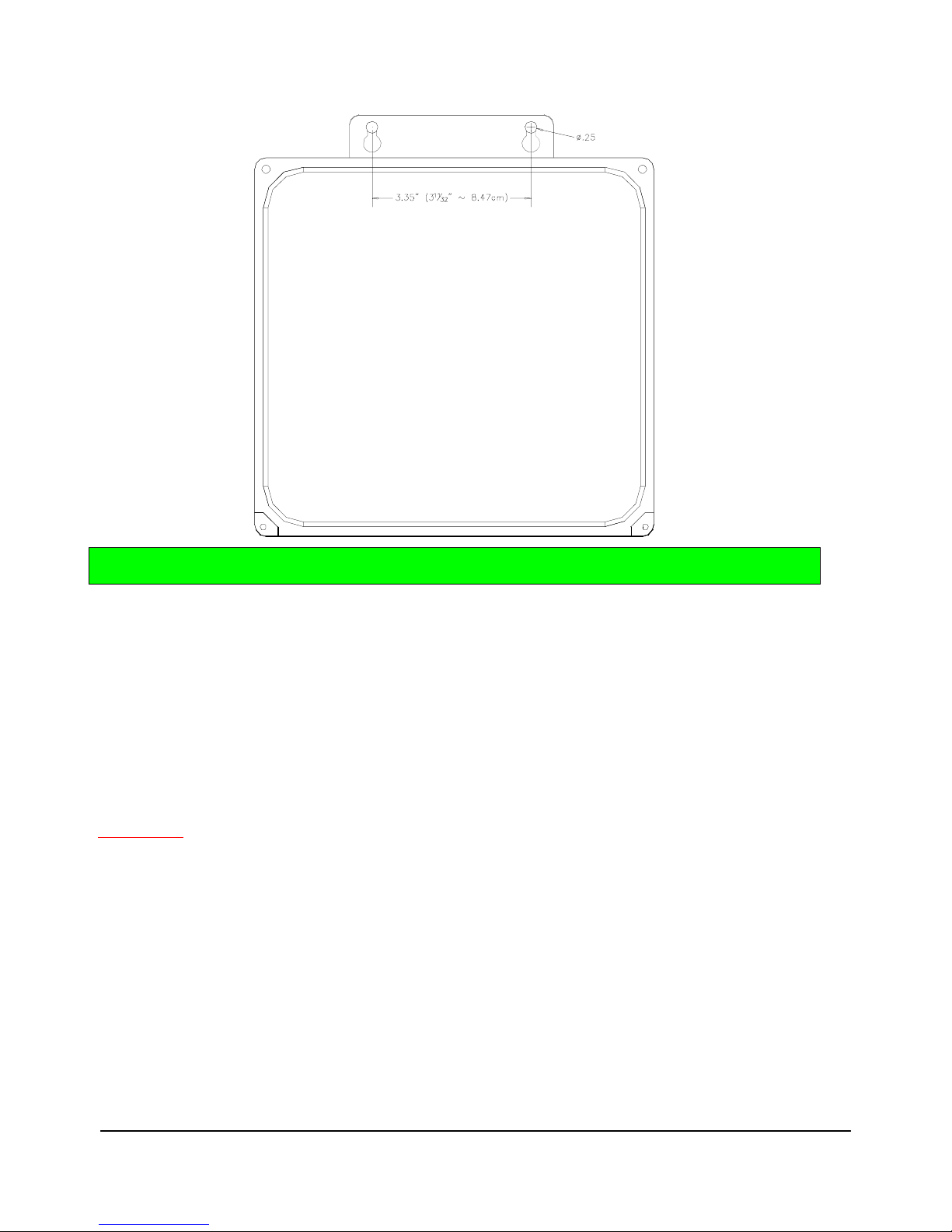

2.2 MOUNTING THE SR6000S

Select a location for mounting the SR6000S, meeting the follow ing recommendations:

At least ten (10) feet from open water.

Close enough for the supplied power cord to reach the supply voltage. The controller will

not operate properly without a solid earth ground connection. WARNING: Proper and safe

operation requires an earth ground connection.

Supply power must be routed to the SR6000S in accordance with the applicable codes in

the area; the supplied cord is not code in some areas.

WARNING: Keep the SR6000S out of direct sunlight and if possible inside a room, a

shade screen must be used for outdoor installations.

The installation surface must be solid and vertical. Do not mount the controller in a

horizontal position.

Maintain adequate clearance for opening the enclosure.

The environment should be free of chemical fumes and excessive heat. The maximum

room temperature is 110 ºF.

Mount as far as possible from sources of electrical interference.

Hold the controller against the mounting surface with a closed lid and mark the four (4)

holes located in the top and bottom brackets connected to the controller. Prepare holes as

necessary and secure controller. Make sure the controller box is not distorted by an

uneven mounting surface.

STA-RITE INSTALLATION & OPERATION GUIDE

7

2.3 PLUMBING INSTALLATION

Mapping out the plumbing installation is recommended since there can be variations to

the installation of the sensors and chemical feed equipment. This section gives the basic

principles to be applied for any specific installation, which are listed as follows:

Identify the new and existing equipment to be connected.

When controlling chemicals locate a location for the AK1200 flow cell (if purchased.)

Determine the water-tap points for the bypass inlet and outlet.

Install the bypass.

Install the pH and ORP sensors.

Test the plumbing for leaks.

WARNING:

IMPORTANT, AS THEY WILL BE FAMILIAR WITH ALL THE CODES IN THE LOCAL AREA.

BE SURE TO HAVE A LICENSED PLUMBER PERFORM ALL PLUMBING; THIS IS

STA-RITE INSTALLATION & OPERATION GUIDE

8

Loading...

Loading...