Page 1

Chemical Feed System

O W N E R’ S M A N U A L

INSTALLATION, OPERATION & PARTS

Sta-Rite Pool/Spa Group

293 Wright Street, Delavan, WI 53115

North America: 800-752-0183, FAX 800-582-2217

International: 262-728-5551, FAX: 262-728-4461, TELEX: ITT 4970245

www.sta-ritepool.com

Union City, TN • Delavan, WI • Mississauga, Ont. • Murrieta, CA

© 2003, Sta-Rite Industries, Inc. Printed in U.S.A. S386 (Rev. 1/2/03)

3965 050

SR-4000

Single Pump Chemical System

With Interval Timer

SR-6000

Dual Pump Chemical System

With Interval Timer

This manual should be furnished to

the end user of this system; its use will

reduce service calls and chance of

injury and will lengthen system life.

1

Page 2

2

TABLE OF CONTENTS

Safety ..................................................................2

Description .........................................................2

Application .........................................................3

Installation ......................................................3, 4

PCA Control Layout........................................4, 5

Control Description.........................................5-7

Maintenance.......................................................7

Repair Parts.....................................................8, 9

Warranty...........................................................12

READ AND FOLLOW

SAFETY INSTRUCTIONS!

This is the safety alert symbol. When you see this

symbol on your system or in this manual, look for

one of the following signal words and be alert to the potential for personal injury.

warns about hazards that will cause death,

serious personal injury, or major property damage if

ignored.

warns about hazards that can cause death,

serious personal injury, or major property damage if

ignored.

warns about hazards that will or can cause

minor personal injury or property damage if ignored.

NOTICE indicates special instructions not related to

hazards.

Carefully read and follow all safety instructions in this

manual and on equipment. Keep safety labels in good con-

dition; replace if missing or damaged.

Incorrectly installed or tested equipment

may fail, causing severe injury or property

damage. Read and follow instructions in

owner's manual when installing and operating equipment.

Use equipment only in a pool installation.

Explosion hazard. This feeder is not

explosion proof. Do not install or use in an explosive

atmosphere.

DESCRIPTION

The SR-4000 and the SR-6000 are liquid dispensing systems for pool and spa applications consisting of a peristaltic pump, an interval timer and a duration timer. With

the flexibility of interval choices as well as duration adjustment, they are capable of handling a range of applications.

The SR-4000 is a single pump system. The SR-6000 is a

dual pump system, with a separate control board for each

pump. Either system can be plugged into a standard

115VAC electrical outlet with the cord provided or hardwired to 115VAC, 208VAC, or 230 VAC using the wiring

diagrams provided (See Figure 3, Page 3).

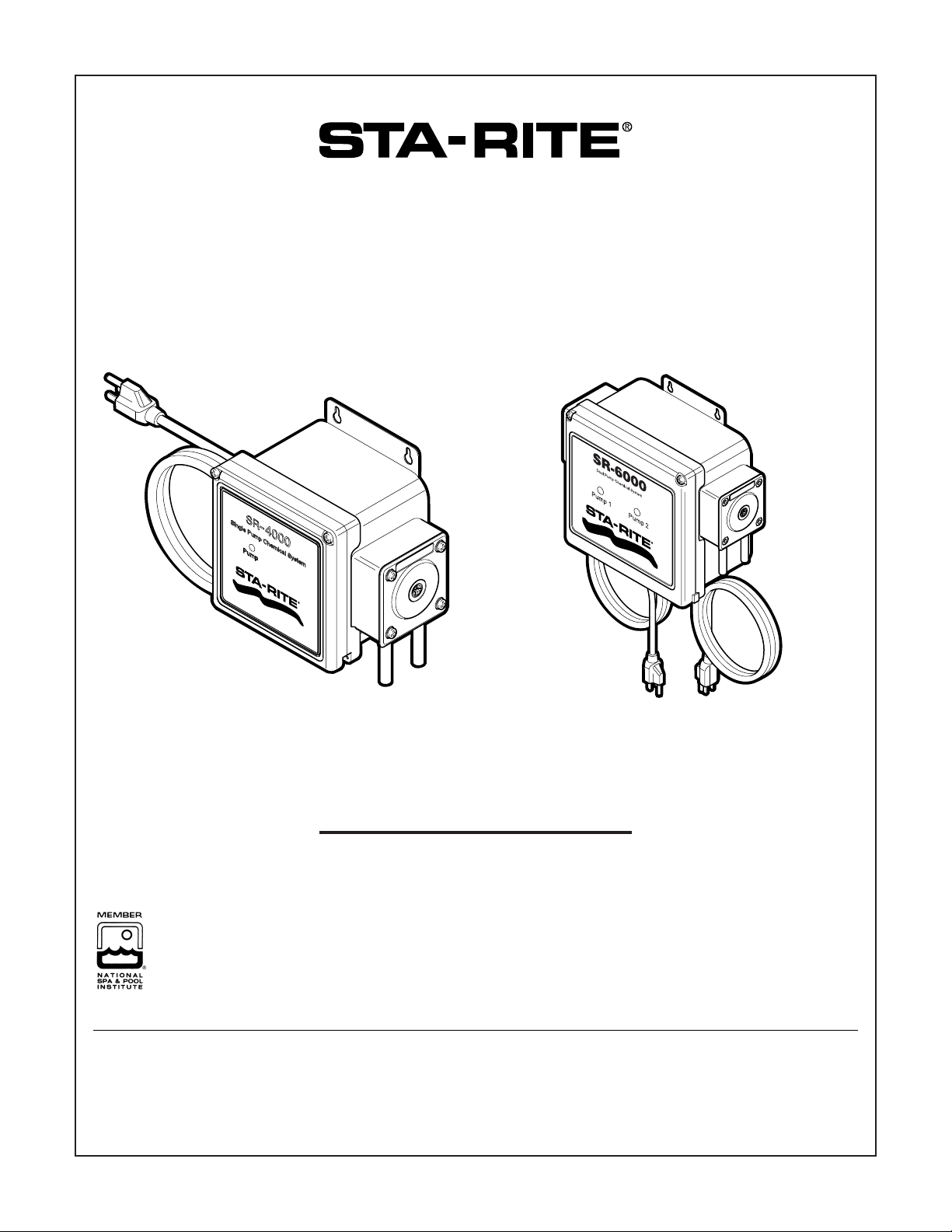

Figure 1: SR-4000 and SR-6000 chemical Feed

Systems.

Dispensers carrying the NSF seal are listed for swimming pools, spas and

hot tubs with the following chemicals:

12.5% SODIUM HYPOCHLORITE 10% HYDROCHLORIC ACID

80% NATURAL ENZYME

When proper materials are selected, they are capable of handling but not

limited to the following solutions:

12.5% ALUMINUM SULPHATE 5% SODIUM CARBONATE

2% CALCIUM HYPOCHLORITE 10% SODIUM HYDROXIDE

Model 300

Pump Assembly

Pump Activate

LED

Pump 1 Activate LED

Model 300 Pump

Assembly

Pump Tube with

Connector Tubes

Pump 1 OFF-ON

Toggle Switch

115 VAC

Power Cord

SR– 4000

Single Pump Chemical System

PUMP

OFF-ON

Toggle Switch

SR–6000

Dual Pump Chemical System

PUMP 1 PUMP 2

Pump Tube with

Connector Tubes

3967 0501

Pump 2 Activate LED

Model 300 Pump

Assembly

Pump Tube with

Connector Tubes

Pump 2 OFF-ON

Toggle Switch

Pump 1 115 VAC

Power Cord

Pump 2 115 VAC

Power Cord

3968 0501

Page 3

3

APPLICATION

Adding pool chemicals automatically on a regular basis will

minimize the high and low swings associated with intermittent manual chemical maintenance. By adding chemicals

automatically on a regular cycle, a more consistent level can

be achieved than is possible with weekly or semi-weekly

manual additions. The pump can lift 15 feet from the supply

tank, and push up to 20 feet vertically and 65-70 feet horizontally to the final injection point. Injecting into pressurized

lines up to 30 PSI is possible without special considerations.

The SR-4000 and SR-6000 can also be set on a continuous

setting and cycled by an automatic controller.

Risk of chemical burns and explosion.

Always consult the chemical manufacturer for

proper storage, use, handling and compatability for use

with a peristaltic pump.

Follow all warnings and instructions provided by the

chemical manufacturer.

Never dispense different chemicals through the

same supply tubing.

Always flush the pump and the supply tubing thoroughly with water prior to changing to another chemical.

Always inject chemicals into the return line downstream from all pool equipment.

Always wear protective clothing and face shield appropriate to the chemical(s) you are handling.

INSTALLATION

Mounting

Mount the SR-4000/SR-6000 Dispenser on a wall near the

chemical supply. The dispenser should be less than 15 feet

from the chemical container and less than 70 feet from the

injection point. Although further distances are possible,

performance may be reduced. Testing is recommended for

greater distances. Use appropriate hardware for the chosen

mounting surface. Mounting location should be protected

from exposure to direct spray and direct sunlight whenever

possible.

Plumbing

Connect the chemical tubing and drum kit following the

instructions included with the plumbing kit. Additional

tubing and hardware may be required depending on distances and configuration. Secure the injection point as required for either a pressure line or an open body of water.

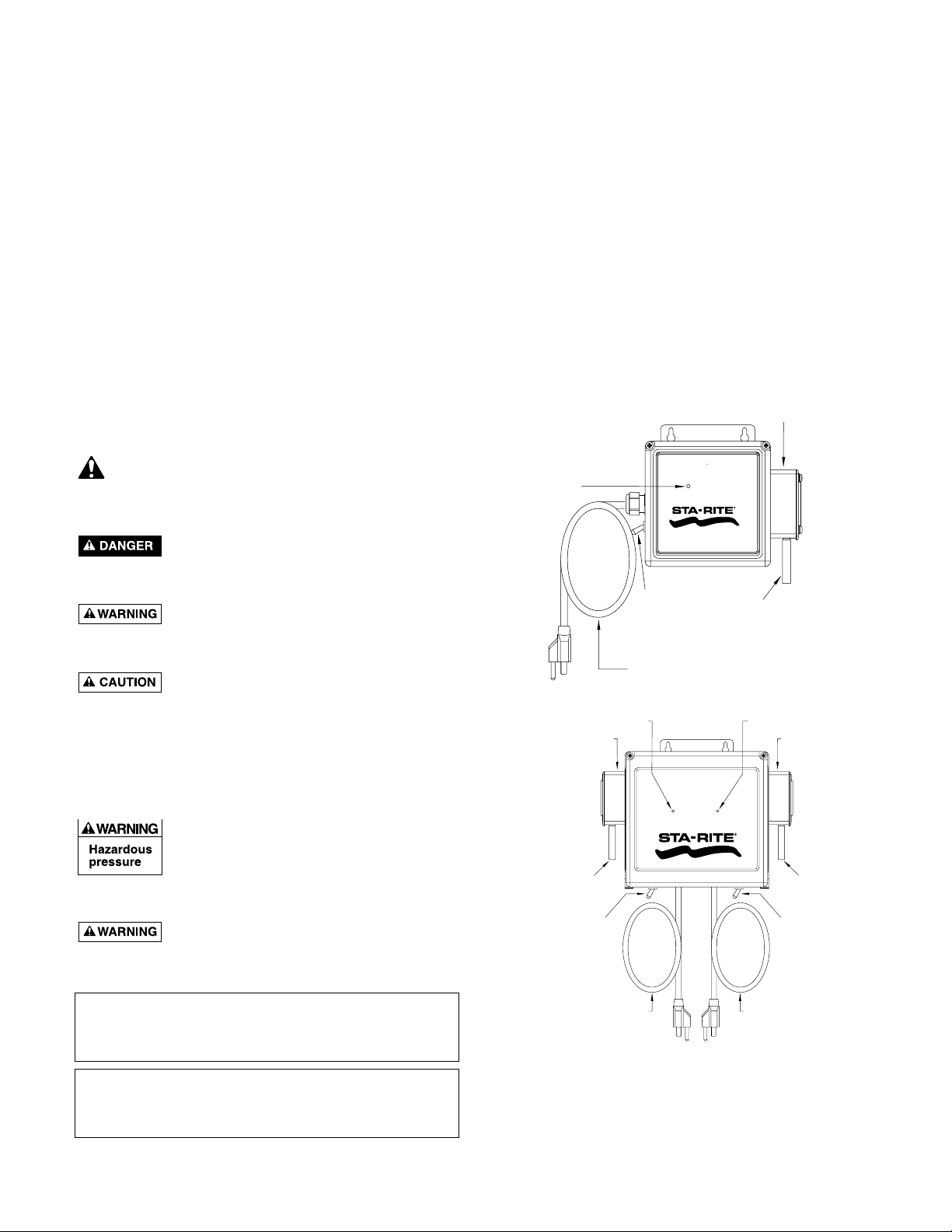

Figure 2: Plumbing Setup.

Figure 3: 24VAC Transformer Connections.

Blue

Yellow

24 VAC

Output to

PCA Board

Orange

Red

Black

White

115 VAC Input

from Power Cord

(Standard)

SR-4000/

SR-6000

To Open Body

of Water

Chemical

Supply

To Pressure

Injection

OR

Water System

Return Line

Body of Water

3969 0501

Blue

Yellow

24 VAC

Output to

PCA Board

Blue

Yellow

24 VAC

Output to

PCA Board

Orange

Red

Black

White

Orange

Red

Black

White

208 VAC Input

from Conduit

230 VAC Input

from Conduit

Page 4

4

Wiring

Chemical burn hazard.

This unit pumps one dose of chemicals when power

is first turned on to the pump. Connect all hoses and

start the main circulation pump before connecting power

to the chemical feed pump.

If this unit continues to operate when the circulator

pump is off, it will build up chemicals at the chemical feed injection point in the circulation system. If the

main circulation system is controlled by a timer, wire the

chemical feed pump through the same timer so that it

cannot operate when the circulator pump is off.

Make sure to have the SR-4000/SR-6000 power switch(s) in

the “OFF” position. The SR-4000/SR-6000 are factory wired

for 115VAC and are equipped with a standard 115VAC

power cord. If a 115VAC outlet is available, plug the cord

into the outlet. In the event 208VAC or 230VAC is required,

the system can be wired accordingly. See Figure 3.

Hazardous voltage (line voltage) in the control box when feeder is plugged in. Always unplug the

power cord(s) to the chemical feeder before opening the

enclosure for any reason except to prime the pump.

When priming the pump, do not put your finger or any

tools inside the control box. Do not attempt to work on,

service, or replace internal box components while the system is plugged in.

Refer to local electrical codes when supply is other then a

standard 115VAC outlet. A qualified electrician may be required for this conversion.

PCA CONTROL LAYOUT

The controls described in this manual refer to the components on the Printed Circuit Assembly (PCA). The PCA is

mounted on the inside of the door of the SR-4000/

SR-6000. To determine the location of these controls on

the PCA, please refer to Figure 4.

Set-up

When a known daily or weekly volume of chemical is required, calculations can determine the proper dose

amount and the interval between subsequent doses to

maintain a desired chemical level. The SR-4000/SR-6000

are factory set at 60 RPM and are equipped with 3cc per

revolution pump tubes. This set-up will deliver approximately 6 fluid ounces per minute per pump. Calibration

may be required to get a more exact rate. In most cases

there are several combinations of dosage times and intervals that achieve the same total daily chemical dose.

EXAMPLE: 24 doses/day at 1 oz./dose =24 oz./day just as

12 doses/day at 2oz/dose = 24 oz./day

3cc/Rev Pump Tube @ 60 RPM

No. of Duration of Dose in Seconds

Doses/Day 123451015202530354045505560

96 9.7 19.5 29.2 38.9 48.6 97.3 145.9 194.6 243.2 291.9 340.5 389.2 437.8 486.5 535.1 583.8

48 4.9 9.7 14.6 19.5 24.3 48.6 73.0 97.3 121.6 145.9 170.3 194.6 218.9 243.2 267.6 291.9

24 2.4 4.9 7.3 9.7 12.2 24.3 36.5 48.6 60.8 73.0 85.1 97.3 109.5 121.6 133.8 145.9

12 1.2 2.4 3.6 4.9 6.1 12.2 18.2 24.3 30.4 36.5 42.6 48.6 54.7 60.8 66.9 73.0

8 0.8 1.6 2.4 3.2 4.1 8.1 12.2 16.2 20.3 24.3 28.4 32.4 36.5 40.5 44.6 48.6

6 0.6 1.2 1.8 2.4 3.0 6.1 9.1 12.2 15.2 18.2 21.3 24.3 27.4 30.4 33.4 36.5

4 0.4 0.8 1.2 1.6 2.0 4.1 6.1 8.1 10.1 12.2 14.2 16.2 18.2 20.3 22.3 24.3

3 0.3 0.6 0.9 1.2 1.5 3.0 4.6 6.1 7.6 9.1 10.6 12.2 13.7 15.2 16.7 18.2

2 0.2 0.4 0.6 0.8 1.0 2.0 3.0 4.1 5.1 6.1 7.1 8.1 9.1 10.1 11.1 12.2

1 0.1 0.2 0.3 0.4 0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.1 4.6 5.1 5.6 6.1

Ounces Per Day

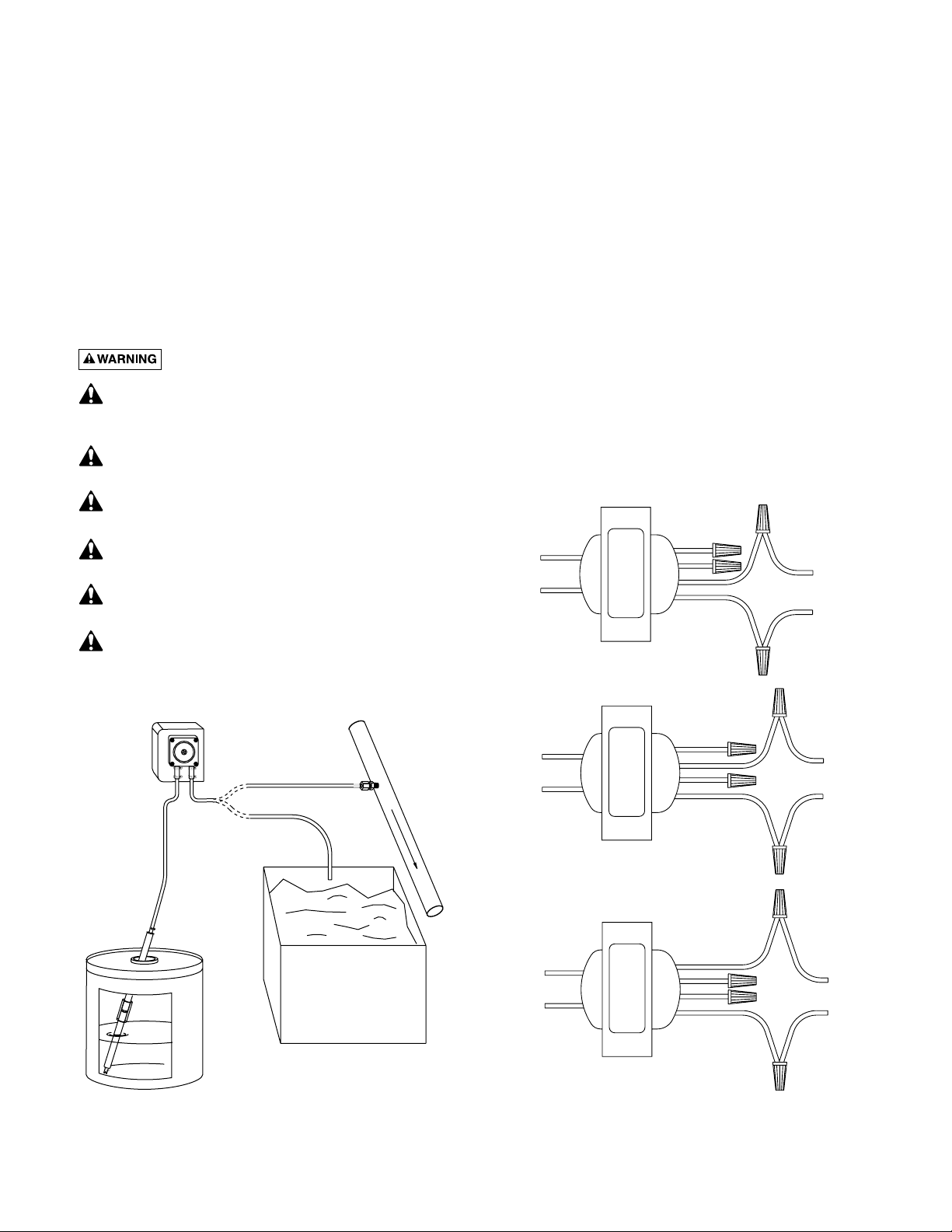

Figure 4: Control Board (PCA) Layout.

SW1: Dose

Duration Adjustment

O

N

SW3

78632

4

321

Pump Speed

Adjustment

Prime Button

145

O

N

SW1

2

1

O

N

SW2

SW3: Dose

Interval Adjustment

SW2: Minutes/Seconds Selection

Page 5

5

Determine the injections per day required and the duration

time of each injection by using the chart on Page 4.

EXAMPLE 1: 6 doses per day at 25 seconds each will deliver 15 ounces per day.

EXAMPLE 2: 8 doses per day at 60 seconds each will deliver 48 ounces per day.

Once the required number of injections and the duration

of each dose are determined, set the switches SW1, SW2,

and SW3 for the correct number of injections and the duration of each dose.

• Durations of 1-255 seconds with 1-second increments

or 1-255 minutes with 1-minute increments are possible.

• Intervals of 15 minutes to 4 weeks are possible (see

Figure 8, Page 6, for a detailed list of possible intervals).

CONTROL DESCRIPTION

Prime Button

Pressing this button activates the pump at full speed. Use

this button to prime and fill the supply and injection lines

Minutes or Seconds Selection (SW2)

The dose duration can be set for minutes or seconds. The

first toggle of the 2 toggle dipswitch SW2 is “DOWN” for

seconds and “UP” for minutes. The second toggle for this

dipswitch is not used. See Figure 5.

Dose Duration (SW1)

The dose duration is the amount of time required for each

dose. The Dose Duration adjustment will set a duration of

from one to 255 units (of either minutes or seconds), but it

doesn’t determine which units to use. To determine

whether duration will be measured in minutes or in seconds, use SW2 “Minutes/Seconds Selection”. Sliding individual toggles of SW1 to the “UP” position programs the

dose duration. Multiple toggles can be switched to add to

the total time. See Figures 6 and 7.

If the main circulator pump operates on a timer, the chemical feeder should only operate when the circulator is running. In this case, wire the chemical feed pump through

the same timer and adjust the dose duration and interval to

allow for intermittent operation.

Figure 5: Minute/Second selection (SW2).

Figure 6: Switch functions of “Dose Duration”

dipswitch (SW1).

EXAMPLE 1: SW1 Settings. No switches up (0 Time).

EXAMPLE 2: SW1 Settings for 25 Seconds or Minutes.

Switches 1,4, and 5 up (1+8+16=25).

EXAMPLE 3: SW1 Settings for 120 Seconds or

Minutes. Switches 4,5,6 and 7 up ( 8+16+32+64=120).

Figure 7: Examples of dip switch settings to set dose

durations.

Switch Toggle Move to 'UP'

No. Amount Position to Add:

111 Sec. or Min.

222 Sec. or Min.

344 Sec. or Min.

488 Sec. or Min.

51616 Sec. or Min.

63232 Sec. or Min.

76464 Sec. or Min.

8 128 128 Sec. or Min.

1 4

O

N

876532

Time Unit Maximum Setting

2

1

O

Seconds 255

N

2

1

O

N

Minutes 255

124

8

163264

128

8

163264

876532

128

1 4

O

N

124

8

163264

876532

128

3974 0501

1 4

O

N

124

Page 6

6

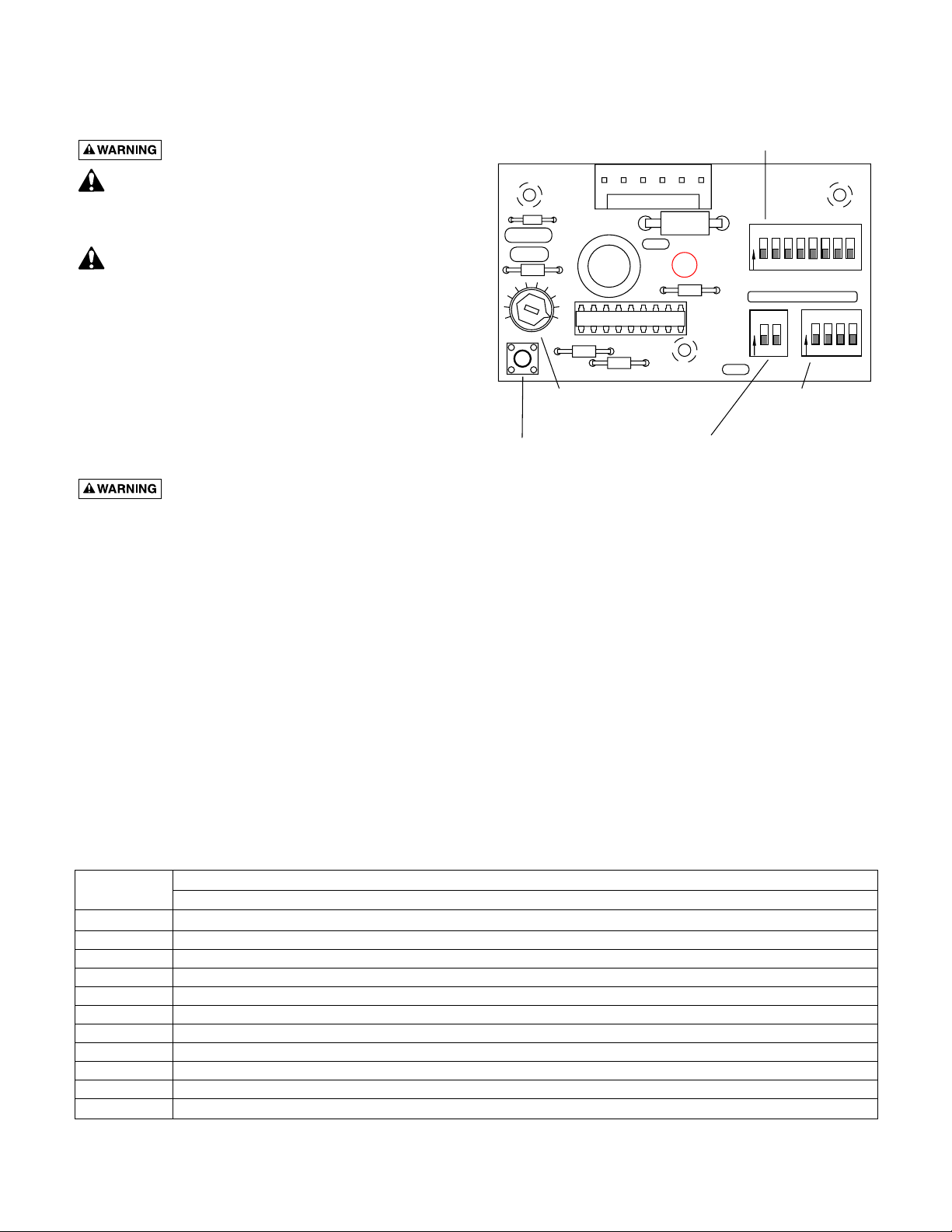

Interval Cycle (SW3)

The interval cycle sets the time between each dose.

Determine the required interval and use the “Dose Interval

Adjustment” chart (Figure 8) to configure the SW3

dipswitch.

Pump Flow

Each peristaltic pump is equipped with a 3cc per revolution pump tube. The maximum flow with this tube at full

speed of 60RPM is 180 cc/minute (6 fluid ounces). This

rate is calculated based on pumping water with no backpressure. Actual flow will vary depending on viscosity of

fluid, distance pumped and actual speed of the pump.

Calibration may be required to determine actual flow with

each installation.

Calibration

The SR-4000/SR-6000 have a nominal flow rate of 6 fluid

ounces per minute per pump (@60 RPM). When pumping

into an open or non-pressurized location, the actual pump

flow can be measured at the output point by pumping actual product into a container of a known volume. In pressure applications, the actual pump flow can be determined

by measuring the amount of actual product that is drawn

out of a container. A good amount to measure is 6 ounces.

Measure (in seconds) the time it takes to pump 6 ounces

and divide that by 60 seconds to determine the time variance from the chart. Use the formula below.

If the main circulator pump operates on a timer, the chemical feeder should only operate when the circulator pump is

running. In this case, adjust interval and dose settings to

allow for intermittent operation.

Thus the calibrated new duration would be set to 27 seconds. This will now deliver the required daily dosage.

Figure 8: SW3 (Dose Interval Adjustment) settings.

Example: If it actually takes 65 seconds to pump 6 fluid ounces,

and you require a nominal 25 second dose time, the calculation

would be:

SW3

Dose Interval Setting

4

321

O

None Off

1 per 28 Days 4 Weeks

2 per 28 Days 2 Weeks

4 per 28 Days 1 Week

14 per 28 Days 2 Days

1 per Day 1 Day/24 Hrs.

2 per Day 12 Hrs.

3 per Day 8 Hrs.

4 per Day 6 Hrs.

6 per Day 4 Hrs.

8 per Day 3 Hrs.

N

4

321

O

N

4

321

O

N

4

321

O

N

4

321

O

N

4

321

O

N

4

321

O

N

4

321

O

N

4

321

O

N

4

321

O

N

4

321

O

N

T = Time in seconds to pump 6 ounces

C = Calibrated amount in seconds

D = Duration in seconds from the chart

T

X

=

D

60

C

65

x 25 = 1.083 x 25 = 27.07 or 27

60

O

12 per Day 2 Hrs.

24 per Day 1 Hr.

48 per Day 30 Min.

96 per Day 15 Mins.

Full On Continuous

N

O

N

O

N

O

N

O

N

4

321

4

321

4

321

4

321

4

321

Page 7

7

Pump Speed Adjustment

The pump speed potentiometer allows for speed adjustment. The pump is factory set with the knob turned as far

as it will go clockwise ( ) for maximum speed (60

RPM). Adjust the interval and duration settings, rather than

the pump speed setting, to meet daily requirements. If you

need a slower pump speed after setting the interval and duration switches, then turn the Pump Speed Adjustment

knob counter-clockwise as necessary to slow the pump.

NOTE: The rate of 6 fluid ounces per minute is based on 60

RPM. Any other speed setting will alter flow calculations.

MAINTENANCE

1. If flow decreases noticeably, check pump tubes for de-

terioration. Check the pump calibration whenever you

replace a pump tube.

2. Replace all pump tubes every six months. Check the

pump calibration whenever you replace a pump tube.

See “Calibration”, Page 6, for calibration instructions.

3. The pump is shipped from the factory with the pump

tubes pre-lubricated with silicone base grease.

Replacement pump tubes come with a packet of lubricant and instructions for replacement and lubrication.

• No additional lubrication should be necessary if

tubes are replaced at 6-month intervals.

• If lubrication should become necessary, use a good

grade of silicone-based grease. DO NOT lubricate

the pump tube with any petroleum-based lubricants they will attack the pump tubes.

• Use only original equipment replacement parts for

these pumps. Use of pump tubes other than factory

authorized replacements may cause leakage, chemical burns, and property damage.

Replacing Pump Tube

Periodic replacement of the pump tube should be made to

avoid unscheduled service calls. To replace or inspect a

pump tube, follow the procedure below.

1. Turn off input power to the dispenser.

2. Remove chemical supply and injection tubing from the

pump.

3. Remove the lower left and upper right 1-5/8” screws

from pump cover to remove the pump from the

dispenser.

4. Remove the remaining two screws from the pump

cover and snap cover off pump housing by grasping

the extended lip of cover on lower edge.

5. Remove pump rotor assembly. DO NOT grasp the

springs.

6. Remove pump tube from pump housing by working

the tube stems out of the pump housing.

7. Install the new tube, making sure to lock tube stems

into pump housing tube stem collars. DO NOT twist

the tube when installing.

8. Lubricate the housing hole and the cover hole for the

rotor assembly shaft, and wherever rollers touch the

pump tube, using silicone-based grease.

9. Install rotor assembly by pressing roller against tubing

at the top of the pump housing.

10. Seat rotor shaft in pump housing hole.

11. Snap pump cover onto rotor and housing and install

upper left and lower right 1-1/4” cover screws. (DO

NOT overtighten.)

12. Using a large blade screwdriver, turn rotor assembly to

see that pump is assembled correctly and operating

properly.

13. Place pump on dispenser motor shaft so that motor

shaft mates with pump rotor. Rotate pump (NOT

motor shaft) so that upper right and lower left pump

cover holes align with holes in dispenser.

14. Install pump mounting screws to attach pump to dispenser (DO NOT overtighten pump mounting screws.)

15. Reinstall chemical supply and injection tubing to the

pump.

Figure 9: Turn knob to adjust pump speed.

This pump is designed only for use as a pool or spa

chemical feeder. Maximum recommended concentrations of chemicals are as follows:

Chemical Maximum Concentration

Aluminum Sulphate 12%

Calcium Hypochlorite 2%

Sodium Carbonate 5%

Sodium Hydroxide 10%

Sodium Hypochlorite 12.5%

Enzymes 80%

0-60 RPM

OFF

Pump Speed Adjustment

FULL

Page 8

8

SR-4000

SR-6000

EXPLODED VIEWS

4

5

17

1

6

21

22

14

7

8

9

18

15

15

14

18

21

11

13

22

17

12

19

16

6

10

2

7

8

9

1

5

4

3

2

20

3

3

2

11

12

13

2

3

10

16

19

Page 9

9

Key

Quantity

No. Description Part Number SR4000 SR6000

1 Pump Assembly, Model 300 41400-0001 1 2

2 10-32 x 1-1/4 SS Pan Head Screw 41400-0002 2 4

3 10-32 x 1-5/8 SS Pan Head Screw 41400-0003 2 4

4 Pump Cover, Smoke, TW 41400-0004 1 2

5 Rotor Assembly 41400-0005 1 2

6 Pump Housing, Grey 41400-0006 1 2

7 Mounting Bracket Kit 41400-0007 1 1

8 Enclosure (SR4000) 41401-0008 1 –

8 Enclosure (SR6000) 41402-0008 – 1

9 Motor Mount Hardware Kit 41400-0009 1 2

10 Ptube, PT, 3.0cc, w/coupler 41400-0010 1 2

10 Ptube, PT, 1.5cc* 41400-0026 1 2

10 Ptube, PT, 2.0cc* 41400-0027 1 2

11 Toggle Switch with Seal 41400-0011 1 2

12 60 RPM Motor, 24VDC 41400-0013 1 2

13 Overlay (SR4000) 41401-0014 1 –

13 Overlay (SR6000) 41402-0014 – 1

14 Waterproof Cable Clamp 41400-0015 1 2

15 18/3 SJT Power Cord, Black 41400-0016 1 2

16 Printed Circuit Assembly 41400-0017 1 2

17 120/208/240-24VAC, 40 VA Trans 41400-0018 1 2

18 #8-32 x 1" Flat-Head Screw 41400-0019 2 4

19 Wiring Harness 41400-0020 1 2

20 PS Accessory Kit 41400-0021 1 2

21 #8 Flat Washer 41400-0022 2 4

22 #8-32 Hex Nut 41400-0023 3 6

• Stacking Shaft Kit for 2 Pump System* 41400-0024

• Stacking Shaft Kit for 3 Pump System* 41400-0025

Repair Parts List

• Not illustrated.

* Accessory item. Purchase separately. A “Stacking Shaft Kit” allows you to run more than one pump per motor.

Page 10

10

Page 11

11

Page 12

▲ Retain Warranty Certificate (upper portion) in a safe and convenient location for your records.

DETACH HERE: Fill out bottom portion completely and mail within 10 days of purchase/installation to:

▼ Sta-Rite, Attn: Warranty Dept., 293 Wright St., Delavan, WI 53115

STA-RITE FULL WARRANTY

The SR-4000 and SR-6000 Chemical Dispensing Systems manufactured by Sta-Rite are warranted to be free of

defects in material and workmanship for two (2) years from date of installation. The pump tubes are an exception and do not have any warranty coverage. Please see Page 7 for pump tube maintenance.

The foregoing warranties relate to the original consumer purchaser (“Purchaser”) only. Sta-Rite shall have the

option to repair or replace the defective product, at its sole discretion. Purchasers will not be responsible for

paying any labor or return shipping charges required to fix the product covered by this warranty. Requests for

warranty service must be made through Customer Service at 800-752-0183. This warranty shall not apply to any

product that has been subject to negligence, misapplication, improper installation or maintenance, or other circumstances which are not in Sta-Rite’s direct control.

This warranty sets forth Sta-Rite’s sole obligation and Purchaser’s exclusive remedy for defective products.

STA-RITE SHALL NOT BE LIABLE FOR ANY CONSEQUENTIAL, INCIDENTAL OR CONTINGENT DAMAGES

WHATSOEVER.

THE FOREGOING WARRANTIES ARE EXCLUSIVE AND IN LIEU OF ALL OTHER EXPRESS WARRANTIES. IMPLIED WARRANTIES, INCLUDING BUT NOT LIMITED TO THE IMPLIED WARRANTIES OF MERCHANTABILITY

AND FITNESS FOR A PARTICULAR PURPOSE, SHALL NOT EXTEND BEYOND THE DURATION OF THE APPLICABLE EXPRESS WARRANTIES PROVIDED HEREIN.

Some states do not allow the exclusion or limitation of incidental or consequential damages or limitations on

how long an implied warranty lasts, so the above limitations or exclusion may not apply to you. This warranty

gives you specific legal rights and you may also have other rights which vary from state to state.

Supersedes all previous publications.

Sta-Rite Industries, Inc., 293 Wright St., Delavan, WI 53115

Warranty Registration Card

Name

Address

City State Zip

Purchase Date

Product Purchased

■■ New installation ■■ Replacement

Type of Pool ■■ Inground ■■ Vinyl ■■ Fiberglass ■■ Gunite

Size of Pool

Years pool has been in service ■■ less than 1 ■■ 1-3 ■■ 3-5 ■■ 5-10

Purchased from:

Company name

Address

City State Zip

Please send me more information on these

other products from Sta-Rite.

■■ Pumps ■■ Filters ■■ Automatic Pool Cleaners

■■ Maintenance Equipment ■■ Test Strips

■■ Heaters

Loading...

Loading...