Page 1

Steel Pressurized Tanks

™

PS62

PS19S

PS119

PS19H

PS50

PS2

PS32

PS19T

PS35

PS6H

PS85

PS5

PS6

APPLICATIONS

■

Use wherever pressurized

tanks are needed in water

systems applications.

SPECIFICATIONS

Shell – Heavy gauge steel

Base – High-impact composite, ABS

Finish – Electrostatically applied,

baked-on polyester paint

Water Cell – One piece seamless

PVC, made from FDA listed material

Flange – Reinforced polypropylene

Service Connection – Reinforced

polypropylene integral to flange

Air Valve – Rubber stem/brass

body Schrader valve assembly

UV Valve Cover – High density

polyethylene

ORDERING INFORMATION

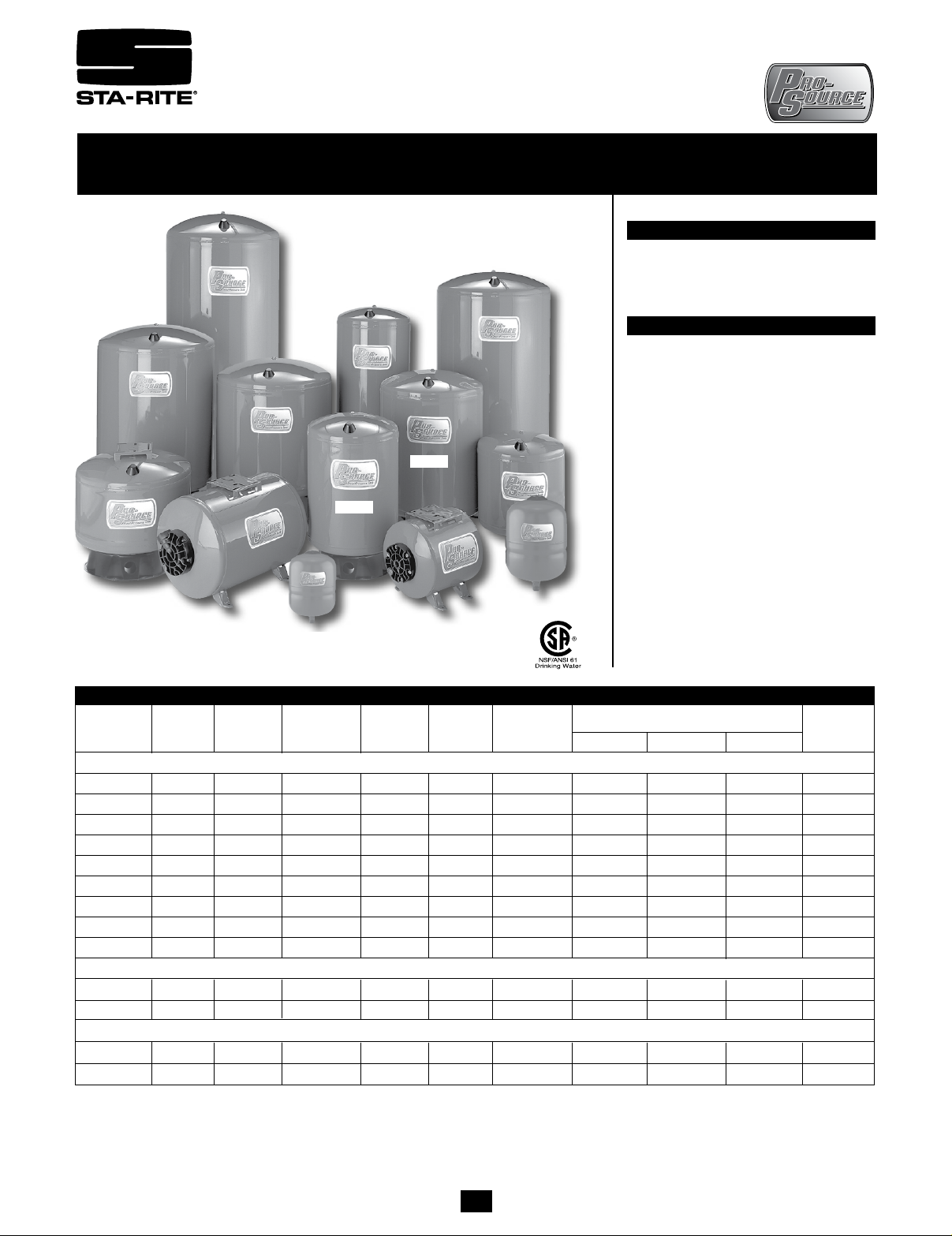

Maximum Connection

Catalog Capacity Diameter* Height* Length Precharge Size

Number gal/liter inch/cm inch/cm inch/cm PSI/kPa Female 20-40 30-50 40-60 lbs/kg

VERTICAL MODELS

PS6-S02 6.0 / 22.7 12 / 30.5 16.1 / 40.9 – 40 / 276 3/4" NPT 2.2 / 8.3 1.8 / 6.8 1.6 / 6.0 18 / 8.2

PS19S-T02 19 / 72 16 / 40.6 21 / 53.3 – 40 / 276 1" NPT 6.9 / 26.1 5.8 / 21.9 5.0 / 18.9 45 / 20.4

PS19T-T02 19 / 72 16 / 40.6 27.5 / 70 – 40 / 276 1" NPT 6.9 / 26.1 5.8 / 21.9 5.0 / 18.9 40 / 18.1

PS32-T03 32 / 122 20 / 51 43 / 109 – 40 / 276 1" NPT 11.6 / 43.9 9.8 / 37.1 8.5 / 32.2 56 / 25.4

PS35-T05 35 / 133 16 / 40.6 33 / 84 – 40 / 276 1" NPT 12.7 / 48.1 10.7 / 40.5 9.3 / 35.2 66 / 29.9

PS50-T50 50 / 189 20 / 51 32.5 / 83 – 40 / 276 1-1/4" NPT 18.3 / 69.3 15.5 / 58.7 13.4 / 50.7 84 / 38.1

PS62-T51 62 / 235 24 / 61 39.5 / 100 – 40 / 276 1-1/4" NPT 21.4 / 81.0 18.3 / 69.3 16.0 / 60.6 112 / 50.8

PS85-T52 85 / 322 24 / 61 51 / 130 – 40 / 276 1-1/4" NPT 30 / 113.6 26 / 98.4 22 / 83.3 124 / 56.2

PS119-TR50 119 / 450 24 / 61 68 / 173 – 40 / 276 1-1/4" NPT 41.3 / 156.3 35.4 / 134.0 31.0 / 117.3 140/ 63.5

IN-LINE VERTICAL MODELS

PS2-S01 2.0 / 7.6 8.4 / 21.3 12.6 / 32.0 – 20 / 137.8 3/4" NPTM 0.7 / 2.65 0.6 / 2.2 NA 12.6 / 5.7

PS5-S02 5.0 / 18.9 10.6 / 26.9 16.2 / 41.1 – 30 / 206.8 3/4" NPTM 2.2 / 8.33 1.8 / 6.8 1.8 / 6.8 16.2 / 7.3

HORIZONTAL MODELS

PS6H-S05 6.0 / 22.7 12 / 30.5 13.8 / 35.0 16 / 40.6 40 / 276 3/4" NPT 2.2 / 8.3 1.8 / 6.8 1.6 / 6.0 22 / 10

PS19H-S00 19 / 72 16 / 40.6 17.5 / 44.5 28 / 71.1 40 / 276 1" NPT 6.9 / 26.1 5.8 / 21.9 5.0 / 18.9 40 / 18

* Subject to change without notice. Maximum Operating Pressure = 100 PSI

Maximum Liquid Temperature: 120°F (49°C) Maximum External (Ambient) Temperature: 125°F (52°C)

PRO-Source™ is a trademark of Pentair Water.

In order to provide the best products possible, specifications are subject to change.

Drawdown in Gallons/Liter

Weight

Customer Service: (888) 782-7483

Fax Orders: (800) 426-9446 www.sta-rite.com

•

1

Pentair Water

•

Delavan, WI 53115 USA

•

S5530WS (5/11)

•

Page 2

Steel Pressurized Tanks

™

FEATURES

Heavy Gauge Metal Construction –

Sturdy “welded wrapper and head

design.” Built to last.

Polyester Paint Finish – Electrostatically powder painted, then

oven baked for a smooth high-gloss,

appliance-quality finish. Resists

corrosion.

Elongated, Seamless

Water Cell –

– Controlled 2-dimensional cell

expansion.

– Rugged, seamless “water cell”

prevents the most common cause

of pump failure – “waterlogging.”

– Water never touches the steel tank

material.

– Translucent bag material facilitates

manufacturing quality control

inspection.

Composite Sealing Flange –

– Corrosion-resistant.

– Integral o-ring groove better traps

the water cell’s sealing ring.

– Reinforcing ribs strengthen and

maintain a flat smooth sealing

surface.

Integral Stand Pipe – Keeps the

water cell standing erect, promoting

complete flushing of the water

entering/exiting the tank.

Nitrogen-Rich Precharge –

Decreases air permeation three to

four times over straight air precharge.

40 PSI Precharge – Ready for use

with 40/60 pressure range systems.

Enables installer to reduce pressure

depending on pressure switch setting.

Sturdy Base – Tested-tough

composite construction.

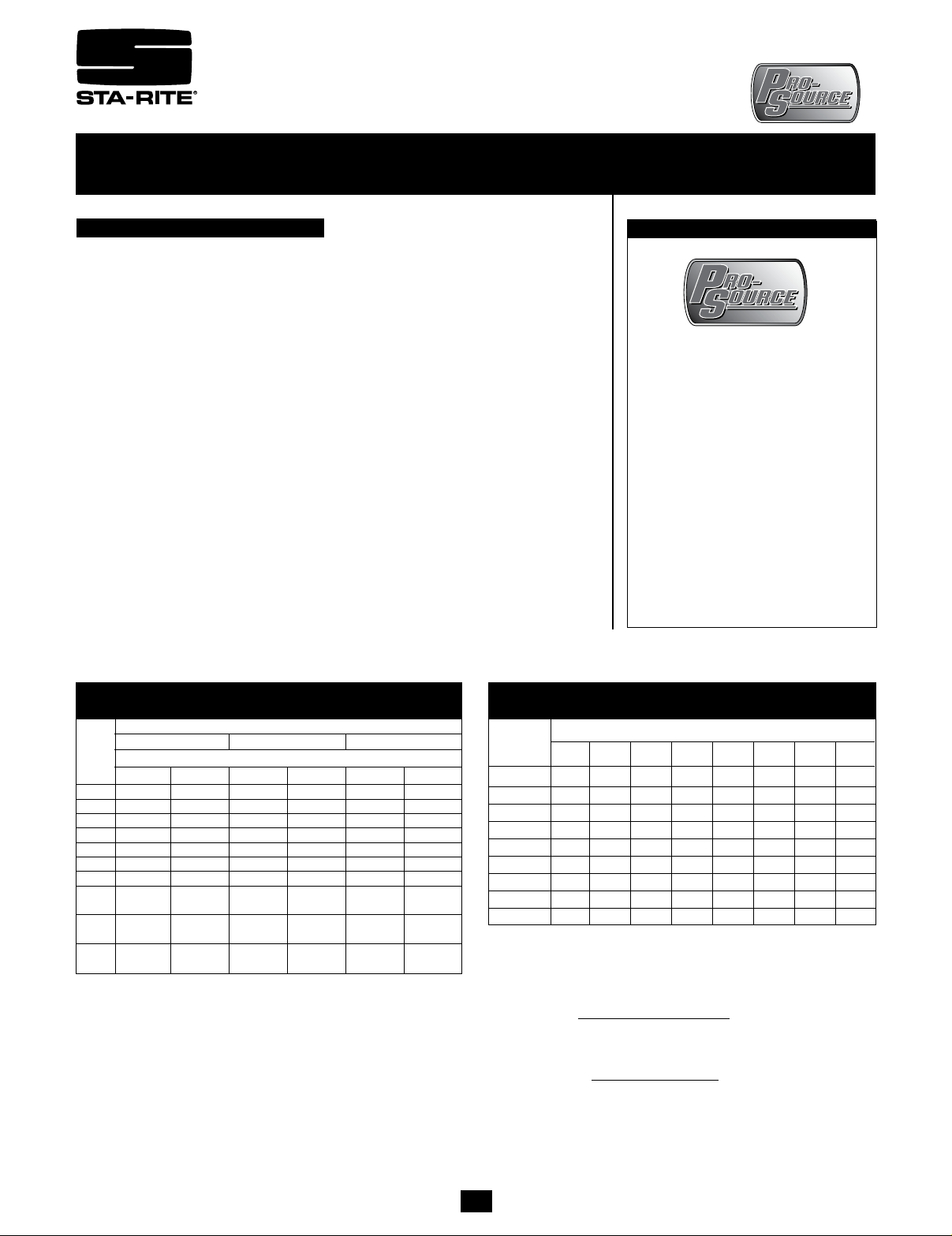

TANK SIZING RULE:

™

Size tank for one gallon

of drawdown for each

gallon per minute at

pump capacity.

EXAMPLE: For a 1 HP, 20 GPM

unit pumping 20 gallons per

minute on a 30-50 pressure

switch setting, the properly

sized PRO-Source™ tank

is a PS85-T52 which has a

26 gallon drawdown.

CHART A –

TANK SELECTION CHART

Pump

GPM

1 Minute 2 Minute 1 Minute 2 Minute 1 Minute 2 Minute

5 PS19T PS32 PS19T PS35 PS19T PS35

7-1/2 PS32 PS35 PS32 PS50 PS32 PS62

10 PS32 PS62 PS35 PS62 PS35 PS85

12-1/2 PS35 PS62 PS50 PS85 PS50 PS85

15 PS50 PS85 PS50 PS50 (2) PS62 PS62 (2)

20 PS62 PS62 (2) PS62 PS62 (2) PS85 PS85 (2)

30 PS285 PS85 (2) PS50 (2) PS85 (2) PS62 (2) PS85 (3)

30

PS85

50 PS62 +

PS85

50

PS62

NOTE: Drawdown will be affected by operating temperature

–

PS119 (2) +

–

of the system, accuracy of the pressure switch and

gauge, the actual precharge pressure, and rate of fill.

Pumps installed with a PRO-Source™ tank require a

100 PSI relief valve. Relief valve must be capable of

relieving entire flow of pump at relief pressure.

System Pressure Switch Setting – PSI

20-40 30-50 40-60

Run Times

–

PS85 (3) PS85 (2) PS85 (4) PS85 (2) PS85 (5)

PS119

–

PS119 +

PS119 (3) PS119 (2) PS119 (4)

PS119 PS119 (2)

CHART B –

DRAWDOWN VOLUME MULTIPLIER* (APPROX.)

Pump Off

Pressure

20 0.26

30 0.41 0.22

40 0.37 0.18

50 0.46 0.31 0.15

60 0.40 0.27 0.13

70 0.47 0.35 0.24 0.12

80 0.42 0.32 0.21 0.11

90 0.48 0.38 0.29 0.19 0.10

100 0.44 0.35 0.26 0.17

* Utilize this chart if proper selection cannot be made using

Chart A. Drawdown based on Boyle’s Law.

Procedure: 1. Identify drawdown multiplier relating to specific application.

2. Insert multiplier (X) into the following formula:

Pump GPM x Min Run Time

Multiplier (X)

Example: An example of a 20 GPM pump with a minimum run time of

20 GPM x 1 minute =

.24 (factor) from Chart B

Referring to “Ordering Information” chart, the model PS85-T52 has the

closest U.S. gal lon capacity that is greater or equal to the minimum volume

requirement of 83.3 U.S. gallons.

PSI

10 20 30 40 50 60 70 80

1 minute, installed on a 50 - 70 PSIG system pressure range:

Pump Start Pressure – PSI

Minimum Tank

=

Capacity Required

83.3 minimum U.S.

tank capacity required

gal.

Customer Service: (888) 782-7483

Fax Orders: (800) 426-9446 www.sta-rite.com

•

2

Pentair Water

•

Delavan, WI 53115 USA

•

S5530WS (5/11)

•

Page 3

Steel Pressurized Tanks

PRESSURE

SWITCH

TO SERVICE

PIPING

FROM WELL

TANKS

Figure 1

PRESSURE

SWITCH

TO SERVICE

PIPING

FROM WELL

TANKS

Figure 2

OPERATING CYCLE

™

1. Separator is completely empty –

A new cycle is ready to begin.

Simple, positive action produces

maximum draw down on every cycle.

2. Water begins to enter the

tank – Air is compressed

around the water separator

as it fills with water.

3. Pump up cycle completed

– Air is now com pressed

to the cut-off setting of

pressure switch.

4. Water is being drawn from

the tank – Compressed air in

the tank forces water out of

the separator.

ACCESSORIES

PKG 111,

PKG 112 or

PKG 198

Universal Jet

Mounting

PKG 207

Jet Pump-to-Tank

Mounting Pkg.

Bracket

ORDERING INFORMATION

PKG 198 – Jet Pump Mounting Bracket

PKG 111 – Pump to Tank Fitting Package for composite jet pumps

PKG 112 – Pump to Tank Fitting Package for cast iron series jet pumps with composite fittings

PKG 207 – Pump to Tank Fitting Package for cast iron series jet pumps, with galvanized fittings

MULTIPLE TANK INSTALLATIONS

PRO-Source™ tanks can be connected together to increase the supply of usable water (drawdown). Two tanks of

the same size will double the supply and three tanks will triple the supply. See Figures No. 1 and 2 for the typical

installations of this kind.

Customer Service: (888) 782-7483

Fax Orders: (800) 426-9446 www.sta-rite.com

•

3

Pentair Water

•

Delavan, WI 53115 USA

•

S5530WS (5/11)

•

Page 4

Steel Pressurized Tanks

C

E

D

A

B

F

A

D

IN-LINE VERTICAL MODELS

OUTLINE DIMENSIONS

B

F

16" CONFIGURATION

30∞

E

™

12" CONFIGURATION

C

D

A

Catalog Discharge

Number NPT A B C D E F

VERTICAL MODELS

PS6-S02 3/4” 12.0 – – 16.1 – –

PS19T-T02 1" 16.1 15.5 2.0 27.8 – 3.9

PS32-T03 1" 16.1 15.5 2.0 43.0 – 2.3

PS19S-T02 1" 20.1 15.5 2.0 – 21.5 2.3

PS35-T05 1" 20.1 15.5 2.0 33.0 – 2.3

PS50-T50 1-1/4" 24.1 22.7 2.5 33.2 – 5.5

PS62-T51 1-1/4" 24.1 22.7 2.5 40.1 – 5.5

PS85-T52 1-1/4" 24.1 22.7 2.5 51.5 – 5.5

PS119-TR50 1-1/4" 24.1 22.7 2.5 68.6 – 5.5

IN-LINE VERTICAL MODELS

PS2-S01 3/4” 18.4 – – 12.6 – –

PS5-S02 3/4” 10.6 – – 16.2 – –

HORIZONTAL MODELS

PS6H 3/4” 12.1 16.9 6.9 10.0 13.3 6.1

PS19H 1" 16.2 26.6 8.7 12.5 17.5 13.8

Customer Service: (888) 782-7483

Dimensions (in inches) are for estimating purposes only.

Fax Orders: (800) 426-9446 www.sta-rite.com

•

4

Pentair Water

•

Delavan, WI 53115 USA

•

S5530WS (5/11)

•

Page 5

Steel Pressurized Tanks

SEQUENCE OF OPERATION

™

WATER CELL IS

COMPLETELY EMPTY:

A new cycle is ready to

begin. Simple, positive

action produces maximum

draw down on every cycle.

WATER BEGINS TO

ENTER THE TANK:

Air is compressed around

the water cell as it fills

with water.

PUMP-UP CYCLE

COMPLETED:

Air is now com pressed

to the cut-off setting of

pressure switch.

WATER IS BEING

DRAWN FROM THE

TANK:

Compressed air

in the tank forces water

out of the water cell.

Customer Service: (888) 782-7483

Fax Orders: (800) 426-9446 www.sta-rite.com

•

5

Pentair Water

•

Delavan, WI 53115 USA

•

S5530WS (5/11)

•

Loading...

Loading...