Page 1

Installation/Operation/Parts

For further operating, installation,

or maintenance assistance:

Call 1-262-728-5551

English . . . . . . . . . . . . . . . Pages 2-3

Installation/Fonctionnement/Pièces

Pour plus de renseignements

concernant l’utilisation,

l’installation ou l’entretien,

Composer le

1 (262) 728-5551

Français . . . . . . . . . . . . . Pages 4-5

Instalación/Operación/Piezas

Para mayor información sobre el

funcionamiento, instalación o

mantenimiento de la bomba:

Llame al 1-262-728-5551

Español . . . . . . . . . . . . .Paginas 6-7

©2005 S776 (Rev. 5/11/10)

OWNER’S MANUAL

Steel Pre-Charged Pressure Tank

NOTICE D’UTILISATION

Réservoir sous pression

préchargé en acier

MANUAL DEL USUARIO

Tanque de presión

precargado hecho de acero

PENT AIR W ATER

293 Wright Street

Delavan, WI 53115

Page 2

Safety 2

READ AND FOLLOW

SAFETY INSTRUCTIONS!

This is the safety alert symbol. When you see this

symbol on your pump or in this manual, look for

one of the following signal words and be alert to the

potential for personal injury!

warns about hazards that will cause seri-

ous personal injury, death or major property damage if

ignored.

warns about hazards that can cause serious

personal injury, death or major property damage if

ignored.

warns about hazards that will or can cause

minor personal injury or property damage if ignored.

The label NOTICE indicates special instructions which

are important but not related to hazards.

Carefully read and follow all safety instructions in this

manual and on pump and tank.

Keep safety labels in good condition.

Replace missing or damaged safety labels.

1. Read this manual carefully. Failure to follow these

Instructions could cause serious bodily injury and/or

property damage.

2. Consult installer or licensed plumber for correct relief

valve. Install system according to local codes.

3. Always test water from well for purity before using.

Check local health department for testing procedure.

4. Before installing or servicing tank, BE SURE pump

electric power source is disconnected. Release all

water pressure before working on tank or system.

Release air pressure before removing cover flange.

5. Install a relief valve in pump supply line to tank, as

close to tank as possible.

6. BE SURE the pump electrical circuit is properly

grounded.

7. Remove bleeder orifices, air volume controls or other

air charging devices in existing system.

8. DO NOT USE tank as a surge suppressor.

Hazardous pressure. To prevent possible

serious or fatal injury and/or damage to equipment, system pressure must be less than 100 pounds per square

inch (PSI) (689kPa) under any circumstances. Failure to

follow instruction can result in tank blowup. If system

discharge pressure can exceed 100 PSI (689kPa), install

a relief valve capable of passing the full pump volume at

100 PSI (689kPa).

Do not allow pump, tank, or piping system to freeze.

Freezing can severely damage equipment and may lead

to tank explosion and serious injury. Allowing tank to

freeze voids tank warranty.

LIMITED WARRANTY

PENTAIR WATER warrants to the original consumer purchaser (“Purchaser” or “You”) of the products listed below, that they will be free from

defects in material and workmanship for the Warranty Period shown below.

Product Warranty Period

Water Systems Products –

whichever occurs first:

jet pumps, small centrifugal pumps, 12 months from date of original installation, or

submersible pumps and 18 months from date of manufacture

related accessories

PENTEK INTELLIDRIVE 12 months from date of original installation, or

18 months from date of manufacture

Pro-Source™ Composite Tanks 5 years from date of original installation

Pro-Source™ Steel Pressure Tanks 5 years from date of original installation

Pro-Source™ Epoxy-Line T anks 3 years from date of or iginal installation

Sump/Sewage/Effluent Products 12 months from date of original installation, or

18 months from date of manufacture

Our warranty will not apply to any product that, in our sole judgement, has been subject to negligence, misapplication, improper

installation, or improper maintenance.Without limiting the foregoing, operating a three phase motor with single phase power through a

phase converter will void the warranty. Note also that three phase motors must be protected by three-leg, ambient compensated, extraquick trip overload relays of the recommended size or the warranty is void.

Your only remedy, and PENTAIR WATER’s only duty, is that PENTAIR WATER repair or replace defective products (at PENTAIR WATER’s

choice).You must pay all labor and shipping charges associated with this warranty and must request warranty service through the

installing dealer as soon as a problem is discovered.No request for service will be accepted if received after the Warranty Period has

expired.This warranty is not transferable.

PENTAIR WATER SHALL NOT BE LIABLE FOR ANY CONSEQUENTIAL, INCIDENTAL, OR CONTINGENT DAMAGES WHATSOEVER.

THE FOREGOING WARRANTIES ARE EXCLUSIVE AND IN LIEU OF ALL OTHER EXPRESS AND IMPLIED WARRANTIES,

INCLUDING BUT NOT LIMITED TO THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR

PURPOSE.THE FOREGOING WARRANTIES SHALL NOT EXTEND BEYOND THE DURATION EXPRESSLY PROVIDED HEREIN.

Some states do not allow the exclusion or limitation of incidental or consequential damages or limitations on the duration of an implied

warranty, so the above limitations or exclusions may not apply to You.This warranty gives You specific legal rights and You may also have

other rights which vary from state to state.

This warranty supersedes and replaces all previous warranty publications.

PENTAIR WATER, 293 Wright St.,Delavan, WI 53115

Page 3

Installation 3

INSTALLATION

The tanks listed below are pre-charged, or filled with air

at the factory, as shown under “Product Information –

Pre-Charged Tanks,” below. When installing tank or if

drawdown decreases significantly, check as follows:

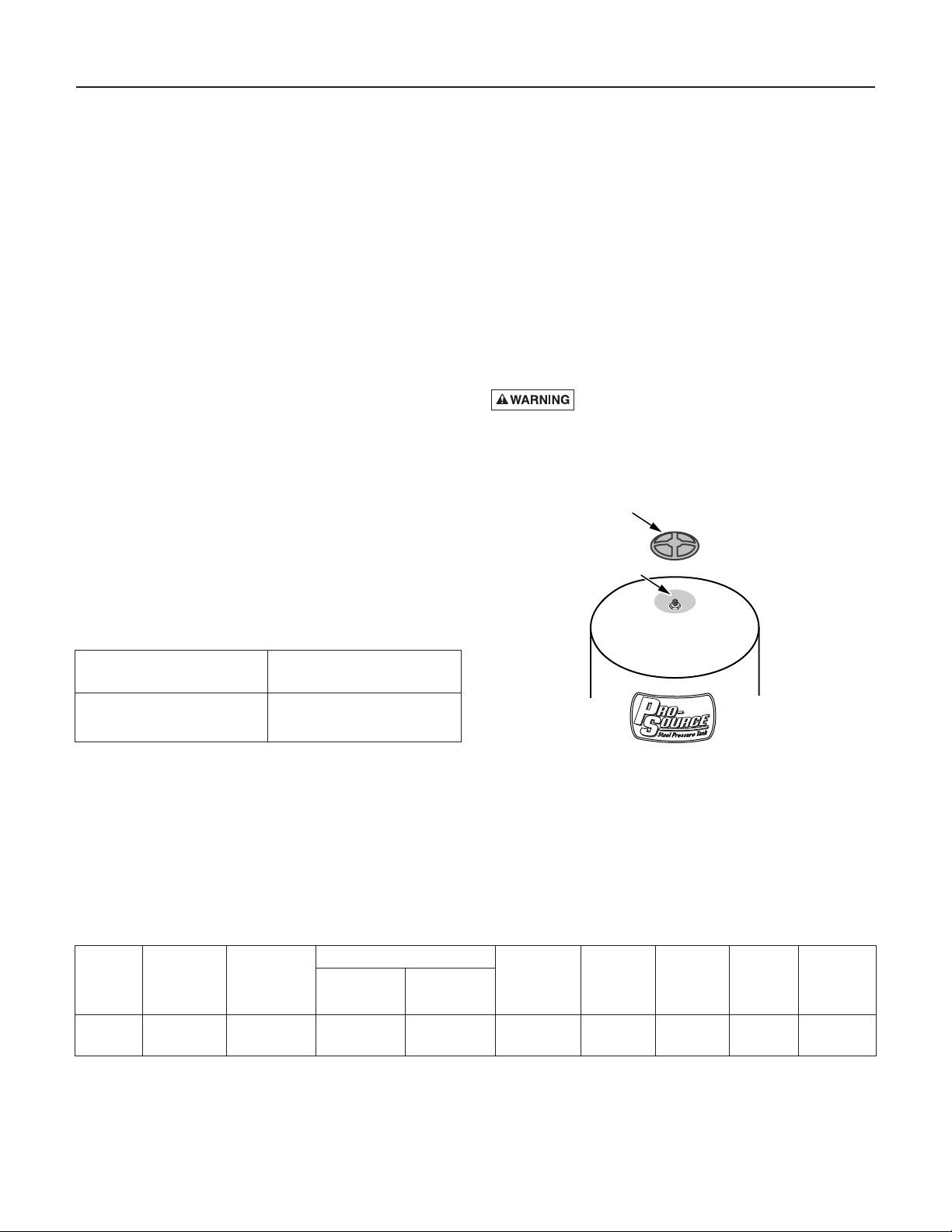

1. To check air charge in tank, shut off electric power to

pump, open faucet near tank, and drain completely.

2. At air valve, unscrew air valve protective cap and

check tank air pressure with tire gauge. See Chart 1

for the correct pressure setting. If needed, adjust the

tank pressure up or down. To do this, bleed air from

or add air to tank through valve on top of tank.

3. Use soap or liquid detergent to check for air leaks

around air valve. Continuous bubbling indicates leak.

If necessary, release air pressure and install new core

in air valve (same as used for automobile tubeless

tires.)

NOTICE: Always set or check tank pre-charge with NO

WATER in tank and no water pressure in system. If you

have already pumped water before setting or checking

the pre-charge pressure, turn the pump off.

NOTICE: Replace and tighten air valve protective cap

after pressure is adjusted correctly. Failure to replace cap

may allow loss of air pressure and lead to tank waterlogging and diaphragm failure.

Chart I

(The first number on the pressure switch is the pump

“ON” setting; the second number is the pump “OFF”

setting.)

This tank is designed to be supported by the system piping either directly above the pump or in a convenient

location in the piping system as close to the pump as

possible.

NOTICE: Tank capacity is different than drawdown. Tank

capacity is the actual physical volume of the sheet metal

that makes up the tank.

STANDARD TANK REPLACEMENT

When replacing a standard tank in a water system with a

pre-charged tank, no bleeder orifices or Air Volume

Control (AVC) are required. When sizing a pre-charged

tank to replace a standard tank, the tanks should have

equivalent drawdowns.

Hazardous voltage and hazardous pressure.

Disconnect all power to pump and bleed all pressure

from system before working on pump, tank, or piping.

When Pressure Switch Adjust Tank

Setting Is Precharge (PSI) To

20-40 PSI (138-276kPa) 18 (124kPa)

30-50 PSI (207-345kPa) 28 (193kPa)

Equivalent

Drawdown - Gals (L)

Maximum to Standard Tank Tank Tank Pre-Charge

Catalog Capacity Tank

20-40 PSI 30-50 PSI Maximum

Diameter Height Discharge Pressure

Number US Gals (L) (US Gals) (L) (138-276kPa) (207-345kPa) Water Temp in. (mm) in. (mm) Tapping PSI (kPa)

PS2 S01 2 (7.6) 6 (23) 0.7 (2.7) 0.6 (2.3) 210°F (99°C) 8.4" (213) 12.6" (319) 3/4" 20 (138)

PS5 S02 5 (19) 15 (58) 1.8 (6.8) 1.5 (5.7) 210°F (99°C) 10.6" (270) 16.2" (411) 3/4" 30 (207)

Product Information – Pre-Charged Tanks

Air Valve

Protective

Cap

Air Valve

Figure 1: Air valve and protective cap.

Page 4

Sécurité 4

LIRE TOUTES CES

INSTRUCTIONS ET LES SUIVRE!

Ce symbole indique qu'il faut être prudent. Lorsque ce

symbole apparaît sur la pompe ou dans cette Notice,

rechercher une des mises en garde qui suivent, car elles

indiquent un potentiel possible de blessures corporelles :

avertit d'un danger qui causera des blessures cor

porelles, la mort ou des dommages matériels importants si on

l'ignore.

avertit d'un danger qui risque de causer des

blessures corporelles, la mort ou des dommages matériels

importants si on l'ignore.

avertit d'un danger qui causera ou qui risquera de

causer des blessures corporelles, la mort ou des dommages

matériels importants si on l'ignore.

Le mot NOTA indique des instructions spéciales et importantes

n'ayant aucun rapport avec les dangers.

Lire attentivement toutes les consignes de sécurité contenues

dans ce manuel et celles collées sur la pompe et le réservoir.

Garder les autocollants de sécurité en bon état;

les remplacer s'ils manquent ou s'ils ont été endommagés.

1. Lire ce manuel avec soin. Le non respect des instructions

peut entraîner des blessures corporelles graves et/ou des

dommages matériels.

2. Consulter l’installateur ou un plombier agréé pour

sélectionner le clapet de surpression qui convient. Procéder à

l’installation en suivant les réglementations des codes locaux.

3. Toujours tester la pureté de l’eau du puits avant son utilisa

tion. Se renseigner auprès du service d’hygiène local pour

les procédures de contrôle à suivre.

4. Avant d’installer et d’intervenir sur le réservoir,

S’ASSURER que la source d’alimentation de la pompe est

bien débranchée. Libérer toute la pression d’eau avant d’in

tervenir sur le réservoir ou sur le système. Libérer toute la

pression d’air avant de déposer la couronne du couvercle.

5. Poser le clapet de surpression dans la canalisation de la

pompe qui mène au réservoir, en installant le clapet aussi

près du réservoir que possible.

6. S’ASSURER que le circuit électrique de la pompe est cor

rectement mis à la terre.

7. Supprimer les prises d’air, les contrôleurs de volume d’air, et

tous les dispositifs de gonflage existant dans le système.

8. NE PAS utiliser le réservoirs en tant que suppresseur de

pompage.

Pression dangereuse. Pour éviter les blessures

graves ou mortelles possibles, et/ou l’endommagement du

matériel, il faut maintenir la pression du système à moins de

689 kilopascals (kPa) (100 PSI) en toutes circonstances. Le nonrespect de cet avertissement peut entraîner l’explosion du réservoir. Si la pression de refoulement du système peut dépasser

689 kPa (100 PSI), installer un clapet de surpression capable

d’assurer le plein débit de la pompe à 689 kPa (100 PSI).

Ne pas soumettre au gel la pompe, le réservoir de la pompe,

ou la canalisation. Le gel peut endommager gravement

l’équipement, et risque d’entraîner l’explosion du réservoir et

de provoquer des blessures graves. L’exposition du réservoir au

gel annule les termes de sa garantie.

LIMITED WARRANTY

PENTAIR WATER garan it au consommateur initial (ci-après appelé l’« Acheteur ») que les produits énumérés dans les présentes sont exempts de défaut de

matériau et de fabrica ion pendant la durée des garanties à compter de la durée des garanties indiquées ci-dessous.

Produits Durée des garanties

Produits de systèmes d’eau —

Selon le premier terme atteint

:

Pompes à éjecteur, petites pompes 12 mois à compter de la date de la première installa ion ou

centrifuges, pompes submersibles et 18 mois à compter de la date de fabrication

tous les accessoires connexes

PENTEK INTELLIDRIVE 12 mois à compter de la date de la première installa ion ou

18 mois à compter de la date de fabrication

Réservoirs composites Pro-Source

TM

5 ans à compter de la date de la première installation

Réservoirs sous pression en acier Pro-Source

TM

5 ans à compter de la date de la première installation

Réservoirs revêtus d’époxyde Pro-Source

TM

3 ans à compter de la date de la première installation

Produits de puisard/d’égout/d’effluents 12 mois à compter de la date de la première installa ion ou

18 mois à compter de la date de fabrication

Nos garanties ne s’appliquent pas aux produits ayant fait l’objet de négligence, d’une mauvaise utilisation, d’une mauvaise installation ou d’un manque

d’entretien adéquat. Sans aucune limitation des présentes, la garantie des moteurs triphasés submersibles sera nulle et non avenue si ces moteurs sont

branchés et fonctionnent sur le courant monophasé par l’intermédiaire d’un déphaseur.Il faut également noter que les moteurs triphasés doivent être

protégés par un relais de surcharge tripolaire thermocompensé à déclenchement extrêmement rapide du calibre recommandé, sinon la garantie sera nulle et

non avenue.

Le seul recours de l’Acheteur et la seule responsabilité de PENTAIR WATER consistent à réparer ou à remplacer (au choix de PENTAIR W ATER) les produits

qui se révéleraient défectueux.L’Acheteur s’engage à payer tous les frais de main d’œuvre et d’expédition du produit couvert par sa garantie et de s’adresser

au concessionnaire-installateur ayant procédé à l’installation dès qu’un problème est découvert pour obtenir un service sous garan ie.Aucune demande de

service en vertu de sa garantie ne sera acceptée après expiration de la durée de sa garantie.Ces garanties ne sont pas transférables.

PENTAIR WATER DÉCLINE TOUTE RESPONSABILITÉ POUR TOUT DOMMAGE INDIRECT OU FORTUIT QUEL QU’IL SOIT.

LES PRÉSENTES GARANTIES SONT EXCLUSIVES ET TIENNENT LIEU DE TOUTE AUTRE GARANTIE FORMELLE ET TACITE, Y COMPRIS, MAIS

SANS S’Y LIMITER, TOUTE GARANTIE TACITE DE QUALITÉ MARCHANDE OU DE CONVENANCE DU PRODUIT À UNE FIN PARTICULIÈRE.LA

DURÉE DES PRÉSENTES GARANTIES NE DEVRA PAS DÉPASSER LA DURÉE DES GARANTIES FORMELLES STIPULÉES DANS LES PRÉSENTES.

Certains états, territoires et certaines provinces ne permettent pas l’exclusion ou la limitation des dommages indirects ou fortuits, ni les limitations relatives à

la durée des garanties tacites. Par conséquent, il se peut que les limita ions ou les exclusions stipulées dans les présentes ne s’appliquent pas dans ce cas.

Ces garanties accordent des droits juridiques précis, bien que l’on puisse bénéficier d’autres droits, selon la province, le territoire ou l’état dans lequel on

réside.

Ces garanties remplacent et annulent toutes les garanties précédemment publiées.

PENTAIR WATER,293 Wright St., Delavan,WI 53115

Page 5

Installation 5

INSTALLATION

Les réservoirs indiqués ci dessous ont été préchargés ou remplis

d’air à l’usine, comme il est stipulé sous la rubrique

« Renseignements sur le produit Réservoirs préchargés » qui

suit. Lorsque l’on installe ce réservoir, ou si le soutirage dimin

ue considérablement, vérifier ce qui suit :

1. Pour vérifier la charge d’air du réservoir, couper le courant

alimentant la pompe, ouvrir le robinet le plus proche du

réservoir, puis vider complètement le réservoir.

2. Dévisser l’obturateur de protection de la valve d’air et vérifi

er la pression d’air dans le réservoir avec un manomètre

pour pneus. Se reporter au Tableau I pour connaître le bon

réglage de la pression. Au besoin, abaisser ou augmenter la

pression du réservoir. Pour cela, purger l’air ou ajouter de

l’air par la valve qui se trouve en haut du réservoir.

3. Appliquer du savon ou du détergent liquide autour de la

valve d’air pour vérifier s’il y a des fuites. La formation de

bulles indique une fuite. Au besoin, dissiper toute la pres

sion d’air et poser un obus de valve neuf (du même type

que celui utilisé sur les pneus sans chambre à air des auto

mobiles).

NOTA : Toujours régler ou vérifier la précharge du réservoir

pendant qu’il ne contient PAS D’EAU et pendant que l’eau

n’est pas sous pression dans le système. Si de l’eau a été pom

pée avant le réglage ou la vérification de la pression de

précharge, arrêter la pompe.

NOTA : Après avoir corrigé la pression d’air dans le réservoir,

reposer et serrer l’obturateur de protection de la valve d’air. Ne

pas remplacer le bouchon de la valve peut provoquer une perte

de pression d’air et mener à un engorgement du réservoir, puis

à une panne de la membrane.

Tableau I

(Le premier chiffre du manostat est celui du réglage de «MISE

EN MARCHE» de la pompe; le deuxième chiffre étant le

réglage d’«ARRÊT» de la pompe.

Ce réservoir est conçu pour être supporté par la tuyauterie du

système, soit directement au dessus de la pompe, soit dans un

endroit pratique du système de la tuyauterie, aussi près que

possible de la pompe.

NOTA : La capacité du réservoir est différente du soutirage. La

capacité du réservoir est le volume physique réel de la tôle qui

constitue le réservoir.

REMPLACEMENT D’UN

RÉSERVOIR STANDARD

Lorsque l’on remplace le réservoir standard d’un système d’eau compor

tant un réservoir préchargé, aucun orifice de purge ou de régulateur de

volume d’air n’est requis. Pour connaître la dimension d’un réservoir

préchargé pour remplacer un réservoir standard, les réservoirs doivent

avoir un soutirage équivalent.

Risque de tension électrique et de pression dangereuses. Toujours débrancher le courant alimentant la pompe

et dissiper toute la pression du système avant d’intervenir sur

la pompe, le réservoir ou la tuyauterie.

Lorsque le réglage Régler la précharge

du manostat est de (lb/po2) du réservoir à

De 20 à 40 lb/po

2

124kPa (18)

(de 138 à 276 kPa)

De 30 à 50 lb/po

2

193kPa (28)

(de 207 à 345 kPa)

Renseignements sur le produit – Réservoirs préchargés

Figure 1 : Valve d’air et obturateur de protection.

Valve d’air

Équivalence

Soutirage - Gal. (L)

avec De 20 à De 30 à

Numéro Capacité un réservoir 40 lb/po250 lb/po2Température Diamètre du Hauteur du Filetage du Pression

de maximum standard de 138 à (de 207 à maximale réservoir réservoir refoulement de précharge

catalogue en gal. US (L) (gal. US) (L) 276 kPa) 345 kPa) de l’eau po (mm) po (mm) du réservoir PSI (kPa)

PS2 S01 2 (7,6) 6 (23) 0,7 (2,7) 0,6 (2,3) 210°F (99°C) 12,6 po (319) 3/4 de po 20 (138)

PS5 S02 5 (19) 15 (58) 1,8 (6,8) 1,5 (5,7) 210°F (99°C) 16,2 po (411) 3/4 de po 30 (207)

Obturateur de protection

de la valve d’air

Page 6

Seguridad 6

LEA Y SIGA LAS INSTRUCCIONES

DE SEGURIDAD!

Este es el símbolo de alerta de seguridad. Cuando usted

vea este símbolo en su bomba o en este manual, busque

alguna de las siguientes palabras de advertencia y esté alerta a

la posibilidad de una herida personal:

advierte acerca de los peligros que ocasionarán

lesiones personales serias, la muerte o un daño severo a la

propiedad si se ignoran dichos peligros.

advierte acerca de los peligros que pueden

ocasionar lesiones personales serias, la muerte o un daño

severo a la propiedad si se ignoran dichos peligros.

advierte acerca de los peligros que ocasion-

arán o podrán ocasionar lesiones personales menores o daños

a la propiedad si se ignoran dichos peligros.

La etiqueta AVISO indica instrucciones especiales que son

importantes pero no relacionados a los peligros.

Lea y observe con attenciÛn todas las instrucciones de seguridad en este manual y en la bomba y el tanque.

Mantenga las etiquetas de seguridad en buenas condiciones.

Reemplace las etiquetas de seguridad faltantes o dañadas.

1. Lea cuidadosamente este manual. La omisión en el respeto

de estas instrucciones puede causar graves daños persona

les, daños a la propiedad o ambas cosas.

2. Consulte al instalador o al fontanero licenciado acerca de la

válvula de alivio correcta. Instale el sistema de conformidad

con los códigos locales.

3. Siempre verifique la pureza del agua del pozo antes de utili

zarla. Consulte con el departamento de salud local sobre los

procedimientos de prueba.

4. Antes de instalar o prestar servicios al tanque ASEGÚRESE

DE QUE la corriente eléctrica a la bomba haya sido

desconectada. Reduzca toda la presión de agua antes de tra

bajar en el tanque o en el sistema. Reduzca la presión de

aire antes de retirar la brida de cubierta.

5. Instale una válvula de alivio en la línea de alimentación de

la bomba al tanque, tan cerca del tanque como sea posible.

6. ASEGÚRESE DE QUE el circuito eléctrico de la bomba esté

puesto adecuadamente a tierra.

7. Retire los accesorios con orificios de purga, los controles

automáticos del volumen de aire y otros dispositivos de car

ga de aire del sistema existente.

8. NO USE el tanques como supresor de picos de presión.

Presión peligrosa. Para impedir posibles

heridas graves o fatales y/o daños al equipo, la presión del sistema debe ser inferior a 100 lib./pulg.

2

(689 kPa) en todo momento. La omisión en el respeto de estas instrucciones puede

producir el reventón del tanque. Si la presión de descarga del

sistema puede superar las 100 lib./pulg.

2

(689 kPa) instale una

válvula capaz de admitir el caudal pleno de la bomba a 100

lib./pulg.

2

(689 kPa).

No permita que la bomba, el tanque o el sistema de tuberías

se congelen. El congelamiento puede producir graves daños al

equipo, provocar la explosión del tanque y causar lesiones graves. La garantía queda nula si se permite que el tanque se congele.

ADVERTENCIA

PRECAUCIÓN

ADVERTENCIA

GARANTÍA LIMITADA

PENTAIR WATER le garan iza al comprador/consumidor original (“Comprador” o “Usted”) de los productos enumerados abajo, que estos estarán libres de defectos en material y mano de obra durante el Período de Garantía indicado a continuación.

Producto Período de Garantía

Productos de sistemas de agua — bombas de chorro,

lo que ocurra primero:

pequeñas bombas centrífugas, bombas sumergibles 12 meses desde la fecha de la instalación inicial, o

y accesorios asociados 18 meses desde la fecha de fabricación

PENTEK INTELLIDRIVE 12 meses desde la fecha

18 meses desde la fecha de fabricación

Tanques de compuesto Pro-Source

MC

5 años desde la fecha de la instalación inicial

Tanques a presión de acero Pro-Source

MC

5 años desde la fecha de la instalación inicial

Tanques con revestimiento epoxídico Pro-Source

MC

3 años desde la fecha de la instalación inicial

Productos para sumideros/aguas residuales/efluente 12 meses desde la fecha de la instalación inicial, o

18 meses desde la fecha de fabricación

Nuestra garantía no se aplicará a ningún producto que, a nuestro sólo juicio, haya sido sometido a negligencia, mal uso, instalación inadecuada o mal

mantenimiento.Sin prejuicio a lo que antecede, la garantía quedará anulada en el caso en que un motor trifásico se haya usado con una fuente de

alimentación monofásica, a través de un convertidor de fase. Es importante indicador que los motores trifásicos deben estar protegidos por relés de

sobrecarga de disparo extra-rápido, con compensación ambiental de tres etapas, del tamaño recomendado, de lo contrario, la garantía quedará anulada.

Su único recurso, y la única obligación de PENTAIR WATER es que PENTAIR WATER repare o reemplace los productos defectuosos (a juicio de PENTAIR

WATER).Usted deberá pagar todos los cargos de mano de obra y de envío asociados con esta garantía y deberá solicitar el servicio bajo garantía a través

del concesionario instalador tan pronto como se descubra un problema. No se aceptará ninguna solicitud de servicio bajo garantía que se reciba después

del vencimiento del Período de Garantía.Esta garantía no se puede transferir.

PENTAIR WATER NO SE HARÁ RESPONSABLE DE NINGÚN DAÑO CONSECUENTE, INCIDENTAL O CONTINGENTE.

LAS GARANTÍAS QUE ANTECEDEN SON EXCLUSIVAS Y EN LUGAR DE TODA OTRA GARANTÍA EXPLÍCITA O IMPLÍCITA, INCLUYENDO PERO SIN

LIMITARSE A LAS GARANTÍAS IMPLÍCITAS DE COMERCIABILIDAD E IDONEIDAD PARA UN FIN ESPECÍFICO. LAS GARANTÍAS QUE ANTECEDEN

NO SE EXTENDERÁN MÁS ALLÁ DE LA DURACIÓN EXPRESAMENTE SUMINISTRADA EN LA PRESENTE.

Algunos estados no permiten la exclusión o limitación de daños incidentales o consecuentes o de limitaciones de tiempo sobre garantías implícitas, de

modo que es posible que las limitaciones o exclusiones que preceden no correspondan en su caso.Esta garantía le otorga derechos legales específicos y

es posible que usted también tenga otros derechos que pueden variar de un estado al otro.

Esta garantía reemplaza toda garantía publicada anteriormente.

PENTAIR WATER,293 Wright St., Delavan,WI 53115

Page 7

Instalación 7

INSTALACIÓN

Los tanques que se indican a continuación vienen de fábrica pre

cargados o rellenos de aire, tal como se muestra a continuación

en “Información sobre el producto Tanques precargados “.

Cuando instale el tanque o en caso de que la aspiración adi

cional disminuya considerablemente, inspeccione lo siguiente:

1. Para verificar la carga de aire en el tanque, cierre la corri

ente eléctrica a la bomba, abra el grifo cerca del tanque, y

drene completamente.

2. En la válvula de aire, destornille el casquete protector de la

válvula de aire y chequee la presión neumática del tanque

con un manómetro para neumáticos. Consulte la Tabla 1

para obtener la graduación correcta de presión. Si se

requiere, ajuste la presión del tanque hacia arriba o hacia

abajo. Para hacer esto, purgue el aire o agregue aire al

tanque por medio de la válvula en la parte superior del

tanque.

3. Use jabón o un detergente líquido para verificar que no

haya fugas de aire alrededor de la válvula neumática. Un

burbujeo continuo indica una fuga. Si es necesario, libere la

presión neumática e instale un nuevo núcleo en la válvula

neumática (el mismo que se usa para las llantas de

automóvil sin cámara de aire).

AVISO: Siempre gradúe o verifique la precarga del tanque SIN

AGUA en el tanque y sin presión de agua en el sistema. Si ya

ha bombeado agua antes de graduar o verificar la presión de

precarga, apague la bomba.

AVISO: Vuelva a colocar y ajuste el casquete protector de la

válvula de aire después de haber regulado la presión correcta

mente. Si no se vuelve a colocar el casquete, existe el riesgo de

que haya una pérdida de presión neumática que puede resultar

en una inundación del tanque y una falla en el diafragma.

Tabla I

(El primer número en el conmutador a presión es la graduación

de “ENCENDIDO” de la bomba; el segundo número es la grad

uación de “APAGADO” de la bomba).

Este tanque ha sido diseñado para que la tubería del sistema lo

soporte ya sea directamente sobre la bomba o en un lugar con

veniente en el sistema de tubería, tan cerca de la bomba como

sea posible.

AVISO: La capacidad del tanque es diferente de la aspiración

adicional. La capacidad del tanque es el volumen físico efecti

vo de la hoja de metal que constituye el tanque.

CAMBIO DE TANQUE ESTÁNDAR

Cuando cambie un tanque estándar en un sistema de agua por

un tanque precargado, no se requerirán orificios de purga ni

Control de Volumen de Aire (CVA). Cuando determine el

tamaño del tanque de precarga para reemplazar un tanque

estándar, los tanques deberán tener aspiraciones adicionales

equivalentes.

Tensión peligrosa y presión peligrosa.

Desconecte toda la corriente hacia la bomba y purgue toda la

presión del sistema antes de realizar trabajos en la bomba, el

tanque o la tubería.

ADVERTENCIA

Cuando la graduación del Ajuste la precarga

conmutador a presión sea: (psi) del tanque a:

20-40 PSI (138-276kPa) 18 (124kPa)

30-50 PSI (207-345kPa) 28 (193kPa)

Información sobre el producto – Tanques precargados

Figura 1: Válvula de aire y casquete protector.

Válvula de aire

Equivalente

Aspiración adicional - Galones (L)

Enrosque

Número Máxima al tanque Temperatura Diámetro Altura del hembra Presión

de capacidad en estándar

20-40 PSI 30-50 PSI

máxima del tanque tanque de descarga de Precarga

catálogo Galones U.S. (L) (Galones U.S.) (L) (138-276kPa) (207-345kPa) del agua plug (mm) plug (mm) del tanque PSI (kPa)

PS2 S01 2 (7.6) 6 (23) 0.7 (2.7) 0.6 (2.3) 210°F (99°C) 8.4" (213) 12.6" (319) 3/4" 20 (138)

PS5 S02 5 (19) 15 (58) 1.8 (6.8) 1.5 (5.7) 210°F (99°C) 10.6" (270) 16.2" (411) 3/4" 30 (207)

Casquete protector de

la válvula de aire

Page 8

Loading...

Loading...