STA-RITE PoolShark Vacuum Owner's Manual

PoolShark®Vacuum

O W N E R’ S M A N U A L

INSTALLATION, OPERATION & PARTS

Sta-Rite Pool/Spa Group

293 Wright Street, Delavan, WI 53115

International: 262-728-5551, FAX: 262-728-7550

www.starite.com

Union City, TN • Delavan, WI • Mississauga, ON • Murrieta, CA

© 2005 S788 (4/12/05)

2

PLEASE READ THE FOLLOWING

BEFORE INSTALLING YOUR NEW

AUTOMATIC POOL CLEANER!

About Safety:

This is the safety alert symbol. When you see this

symbol on your system or in this manual, look for one of

the following signal words and be alert to the potential for

personal injury.

warns about hazards that will cause death,

serious personal injury, or major property damage if

ignored.

warns about hazards that can cause death,

serious personal injury, or major property damage if

ignored.

warns about hazards that will or can cause

minor personal injury or property damage if ignored.

Carefully read and follow all safety instructions in this

manual and on equipment. Keep safety labels in good condition; replace if missing or damaged.

ABOUT YOUR POOL

AND FILTER SYSTEM:

Before installing your cleaner, review and understand all warnings and safety information on the inside

front cover of this manual.

Pre-installation check list

Before installing the cleaner in a vinyl liner pool:

Check liner closely for signs of deterioration or damage

from age, chemicals, pool wall damage, etc. If any damage

is found, have a qualified pool professional make all necessary repairs. Also, if there are stones, roots, etc., under

the liner, remove them before installing the cleaner.

Before installing the cleaner in a gunite pool or a pool

that is partially or completely tiled:

Repair loose tiles and tighten any loose light rings.

Before installing the cleaner, clean your filter system:

Make sure you have cleaned the filter, including backwashing, rinsing, and emptying all baskets. A clean system

is necessary for proper cleaner operation and coverage.

Before installing the cleaner, fill the hose with water:

Always make sure the cleaner head is submerged and the

hose is full of water before connecting the hose to the filtration system (whether through a skimmer or dedicated

wall fitting). Air in the system can damage the pump

through dry running and overheating.

Before installing the cleaner, understand cleaner

coverage:

The cleaner is designed to rid your pool of debris in approximately 4-6 hours. Less time could be needed, depending on the pool size.

The cleaner was not designed to automatically clean steps

or swimouts or to work under a solar cover. It was also not

designed to do initial cleanup for a new pool or when

opening your pool for the season.

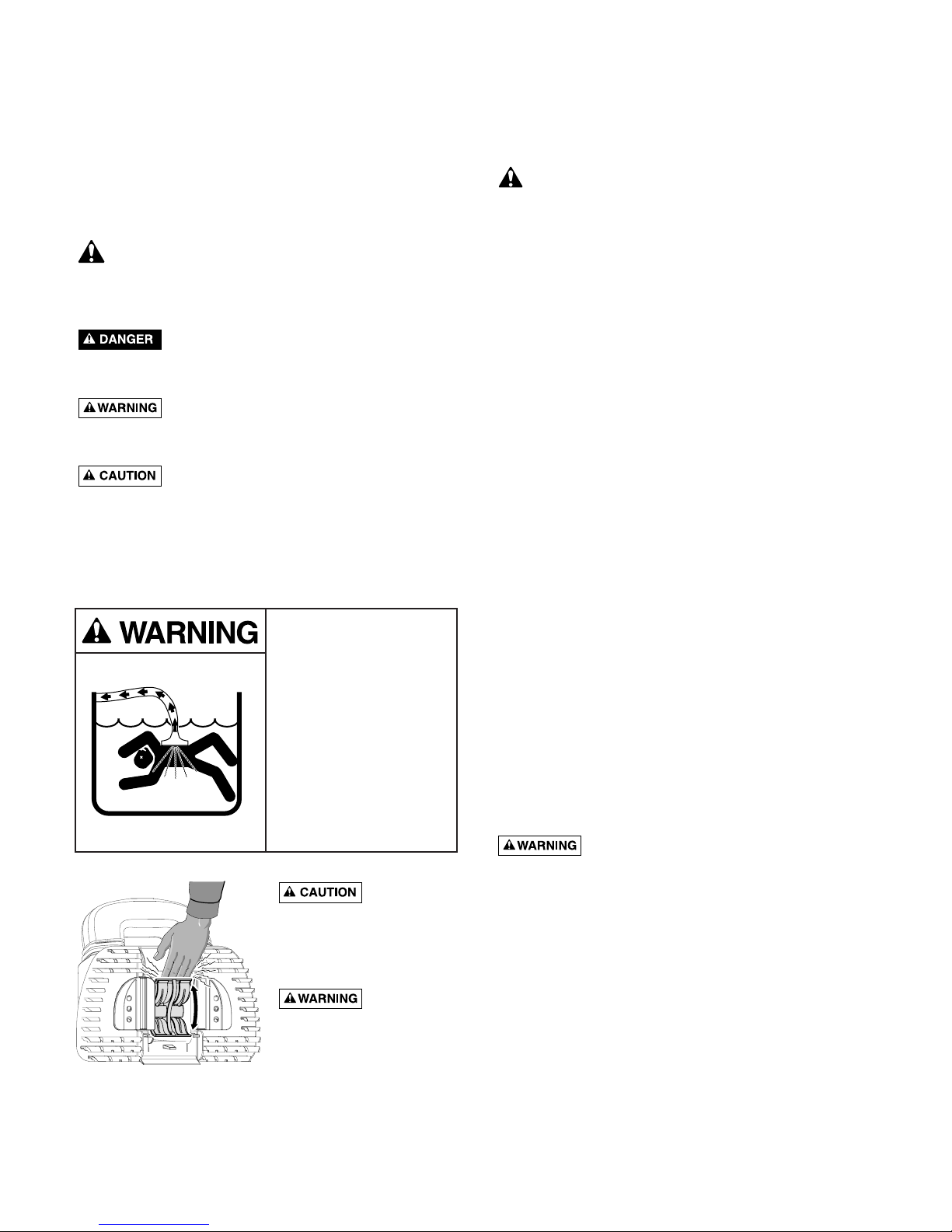

Suction entrapment, injury, and drowning

hazard. If your pool has a dedicated suction port (“vac

port”) for vacuuming or for an automatic pool cleaner, it

must be covered when not in use. A spring loaded safety

cover (a “vac port fitting”) is included with your cleaner.

Install it on the suction port to prevent entrapment and injury. If the cover provided does not fit, purchase one that

does from your local pool store and install it instead. The

cover should conform to IAPMO SPS4-99A.

Hazardous suction.

Can trap and tear

hair or body parts.

Can cause drowning.

Do not play with cleaner

or hose or apply to body.

Do not let children use or

play with pool cleaner.

Stop pump before

attempting to clean unit.

Do not allow swimmers in

pool while pool cleaner is

operating.

Oscillator

may injure hands or fingers. Stop pump before at-

tempting to clean out pool

cleaner head.

Hose can trip

or entangle swimmers.

Do not allow swimmers in

pool while pool cleaner is

operating.

3

CONTENTS:

Safety ..............................................................................2

Installation ...................................................................3-6

Maintenance ...................................................................6

About “Fine-tuning” Vacuum

Adjustments and Connections.........................................7

Disassembly.................................................................8-9

Repair Parts..............................................................10-11

Troubleshooting ............................................................12

Warranty.......................................................................13

INSTALLATION

Please use the convenient, water resistant,

“Installation

Instructions”

card.

Step 1: Install vacuum port door fitting

If there is no spring-loaded door on the vacuum port, install the included cover.

If you pool only has a skimmer, and no dedicated vacuum port, proceed to Step 2.

1. Screw the fitting into the port opening.

2. Orient the fitting so the arrow on the door points up.

3. Secure the cover by tightening the allen-screw below the

door.

Step 2: Straighten hose (Figure 2)

Remove and uncoil the hoses from the carton. Lay them

out in the sunlight, flat and straight.

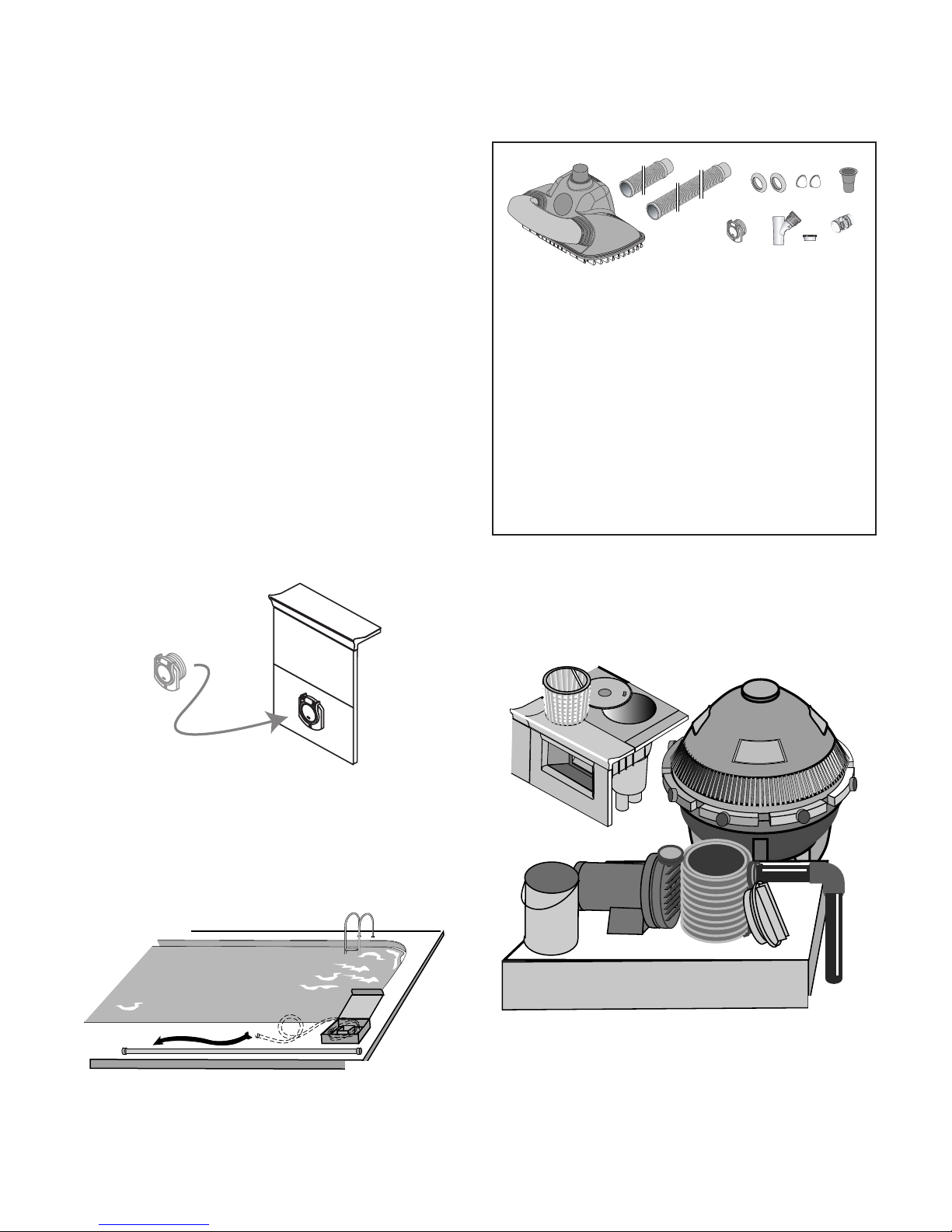

Step 3: Check parts (Figure 3)

Step 4: Clean filter system (Figure 4)

Backwash and clean filter; rinse; clean all baskets, etc.

Start pump.

3894

AB

C

D

EF

H

J

K

G

M

A

X

I

M

U

M

F

L

O

W

M

I

N

I

M

U

M

F

L

O

W

A. Pool Cleaner

B. Short Leader Hose (1 Length, 0.36 Meter)

C. Hose (10 Lengths, 1 Meter Each)

D. Hose Weights (2)

E. Eyeball diverters (2)

F. Reducer Cone

G. Vac Port Fitting

H. Regulator

J . Regulator Cap

K . Flow Gauge

• Short Extension Hose (not illustrated)

Figure 3

Figure 2

Figure 1

5

Figure 4

1880 079

1882 0795

4

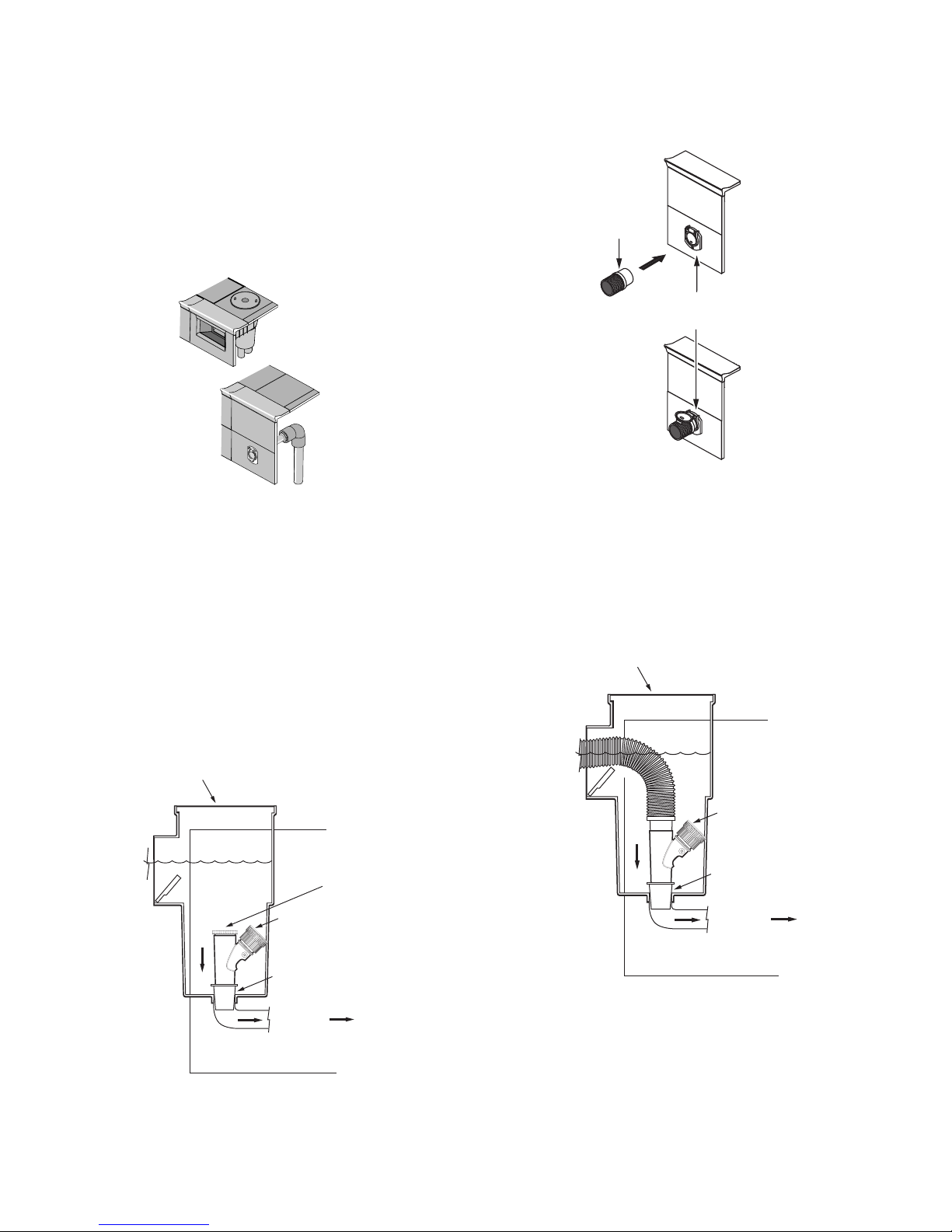

Step 5: Adjust valves for vacuuming (Figure 5)

Decide on the vacuum connection you are going to use

(either a skimmer or a dedicated wall fitting) and adjust

the pump valves (if your system has valves) to direct all

vacuum there.

Close the main drain (also see “About Fine Tuning the

Vacuum”, Page 7).

Step 6: Install Regulator in Pools with a Dedicated

Vacuum Port

The pool regulator adjusts the amount of vacuum in the

line for optimum cleaning.

If your pool has a dedicated wall fitting in addition to the

skimmer, follow the procedure below.

1. Turn off the pool pump.

2. Place the regulator in the skimmer as shown. The cap

must be placed in the top.

Use the adapter cone if needed.

3. Attach one length of hose to the vacuum port.

Step 7: Pools with only a Skimmer

1. Turn off the pool pump.

2. Place the regulator in the skimmer as shown. Do not

install the cap.

Use the adapter cone if needed.

3. Submerge one length of hose so it becomes filled

with water.

4. Insert the “male” end of the hose into the regulator.

Figure 5

Figure 7 - Vacuum Port Connection.

Figure 6 - Regulator in Skimmer.

Figure 8 - Regulator in Skimmer.

Skimmer

Vac

Port

Hose

End

Vac Port

Fitting

Skimmer

Cap

Regulator

Adapter Cone

To Pump

Skimmer

Regulator

Adapter Cone

To Pump

5

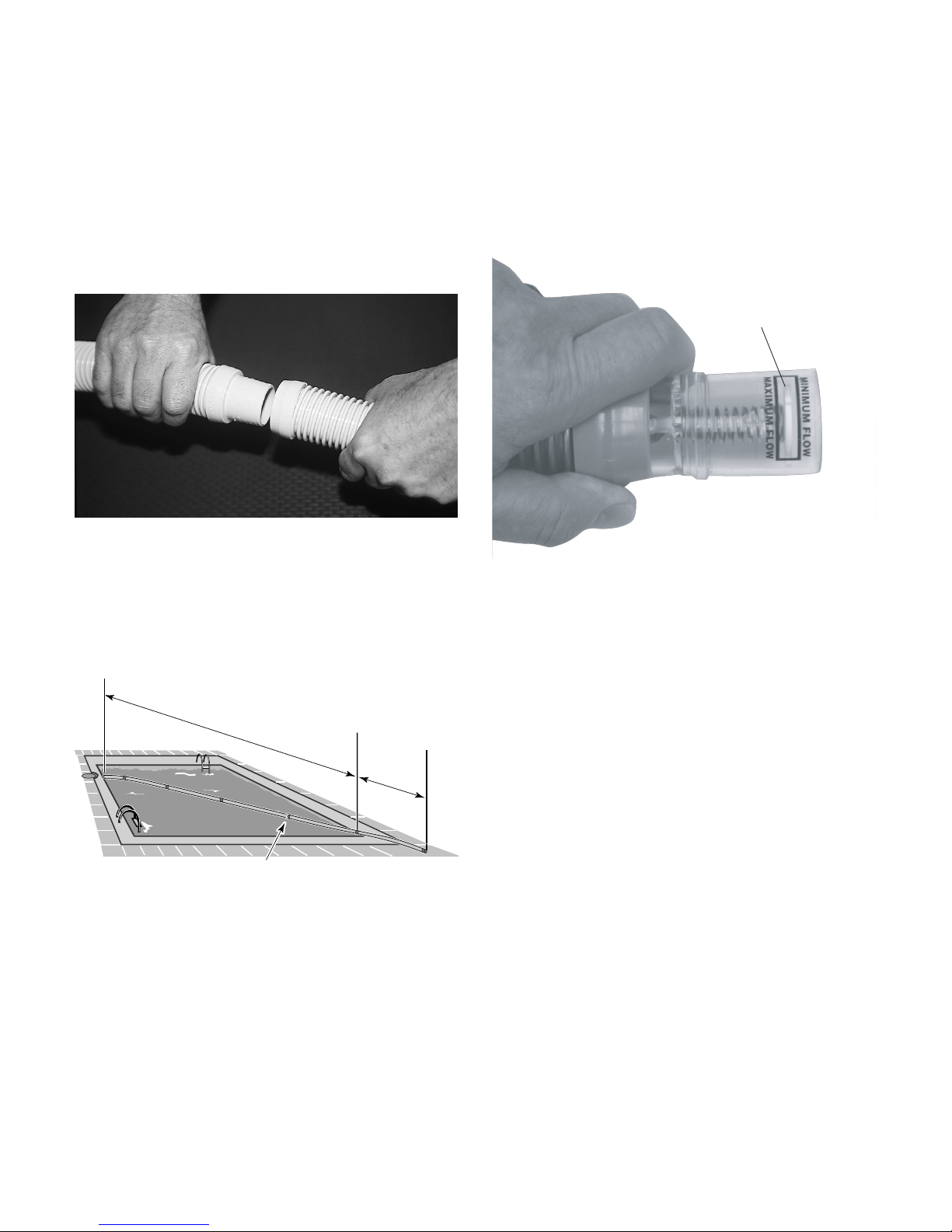

Step 8: Connect the hose sections (Figures 9 and 10).

For best results and to maintain proper operation, use only

original hoses, or direct replacements (See Repair Parts

page).

Join the hose sections one to another by fitting the male

end to the female end of the added section (see Figure 9).

Make sure the connections are snug. The number of

lengths that you will need depends on the size of your

pool.

The overall length of hose needed will be the distance

from:

(a) the point at which you will attach the hose to the suction connection, to (b) the furthest point in the pool from

(a), plus one hose length (Figure 10).

Submerge the hose so it fills with water and expels air from

the hose. Attach one ond of the hose to the vacuum source

as descrbed in Steps 2 and 3. Keep the other end of the

hose accessible.

Step 9: Adjust flow

1. Insert the flow gauge into the open end of the hose,

still underwater.

2. Start the pump.

3. Turn the adjustment knob on the flow regulator until

the indicator on the flow gauge is between the maximum and minimum flow (See Figure 11).

NOTE: If you have a very strong pump and the flow is

still too fast, slightly open the main drain.

4. Turn off the pump.

5. Remove the flow gauge and attache the hose to the

cleaner.

Figure 9

Figure 10

Figure 11 - Flow Indicated on Flow Gauge.

Disc Indicator

Hose must equal longest stretch — —

plus one length.

Add one hose weight to the third cuff from the PoolShark

®

6

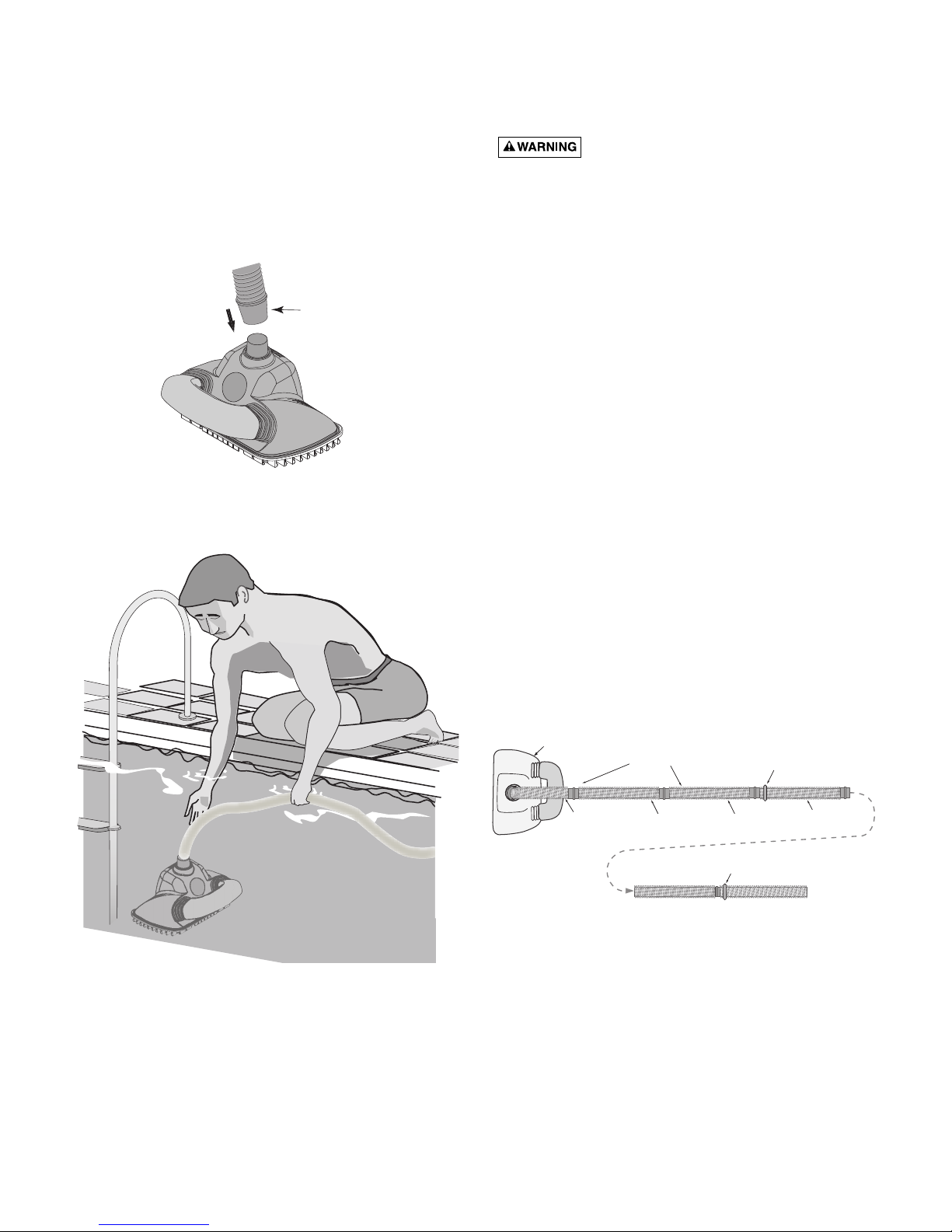

Step 10: Connect Hose to Cleaner.

Connect the hose cuff of the 14" (0.36 m) hose to the

cleaner (correct end of hose is marked). Add other hose

sections as shown in Figure 10.

Fill the cleaner with water and let it sink to the bottom.

Verify hose connections as shown on the following page,

and that gate valves are fully open in the suction line.

MAINTENANCE

Hazardous suction. Suction through the

PoolShark can entrap bathers, causing severe injuries or

drowning. Do not operate the PoolShark cleaner while

people are using the swimming pool. Do not allow anyone

to play with the PoolShark or its hoses.

Your PoolShark can stay in the pool at all times except during chemical shock treatments. However, when people are

using the pool, disconnect the PoolShark and pull it to one

side of the pool.

The PoolShark requires almost no maintenance. Manually

open and close the regulator valve from time to time to

flush away accumulated dirt and debris and ensure smooth

operation. Also, from time to time, visually inspect the

PoolShark to be sure that:

• The oscillator moves freely and is not obstructed by

debris.

• The vacuum pad is not excessively worn. When the

traction pads on the bottom have worn down, it’s time

for replacement.

NOTICE: When storing the PoolShark, do not coil the

hose. Instead, lay it out straight and flat in an area protected from direct sunlight. Use only a genuine PoolShark

hose. The warranty is void if the cleaner is operated with

other than a genuine PoolShark hose.

Balancing the hose

It may or may not be necessary to add weight to your hose,

depending on your pool’s size, shape, and depth. Try the

cleaner first without any hose weights. If the hose is too

buoyant, add the weight as shown in Figure 14.

Figure 13

Figure 12

Figure 14

Hose Cuff

marked

"Connect

to Cleaner"

Pool Shark cleaner

Short leader Second hose

No weight on these

hose cuffs.

Section

Attach second hose weight 1” back from the

end of the fifth section for pools deeper than 6 feet.

Attach first hose weight

1" back from the end of

the third hose section

Third hose

Section

Fourth hose

Section

5049 0605

7

Pool pump suction is hazardous and can

cause entrapment with severe personal injury or

drowning. Use regulator (see instructions below) in pool

cleaner system at all times.

NOTICE: Each pool’s hydraulic system and vacuum

connections are different. Be sure you have installed the

regulator before you “fine-tune” the system. This not only

regulates vacuum, but also acts as a safety device.

About “Fine-Tuning” Vacuum

Adjustments and Connections

Suction entrapment, injury, and drowning hazard. If your

pool has a dedicated suction port (“vac port”) for vacuuming or for an automatic pool cleaner, it must be covered when not in use. Purchase a spring loaded safety

cover from your local pool store and install it on the suction port to prevent entrapment and injury.

For the “NOVICE POOL OWNER” where vacuuming is a

new experience, please read all of the following points, the

installation instructions, and the trouble shooting guide

carefully. Please note the following:

•“

Vacuum

” and “

suction

” are two words meaning the

same thing.

•“

Dedicated suction line

”, “

vac port

”, and “

vac fitting

”

are different terms for a hole in the side wall of pool;

this hole is connected to the pump suction and is dedicated to vacuuming.

• Some pools do not have a vac port. If your pool does

have one, please read the “

Suction Entrapment

” warn-

ing, above.

For the “SEASONED POOL OWNER”: The automatic pool

cleaner connection and vacuum adjustments can be similar to using your manual pool vacuum. Please read on.

Valves (pump, skimmer, and main drain) and

vacuum adjustments

You may need to spend some time adjusting the skimmer

and main drain valves in order to obtain the best vacuum

setting for good cleaner operation. Once you have found

the correct valve settings for best operation, we suggest

you mark the valves to ensure repeated success.

In-Line leaf canisters

If your pool is exposed to large quantities of leaves, we

suggest purchasing and installing an in-line leaf canister. A

leaf canister will provide more debris-loading capacity and

also provides a water by-pass when the canister is full. It is

very important that the pump not starve for water!

Dedicated suction

line/vac port/vac

fitting

Some pools have a dedicated wall fitting just for vacuuming. If the wall fitting

connection is used, you may

notice that the clear pump

lid shows signs of bubbles or

what appears to be the presence of air. To eliminate this, slightly open the main drain

valve to supplement the water intake. The cleaner may

slow down a bit when you change the suction.

Skimmer vac plates

Some pool owners connect the hose to a skimmer vac

plate, which allows the skimmer basket to remain in the

skimmer. If this method is used, empty the basket frequently. Also make sure that the vacuum regulator provided is completely submerged so that it will not suck air

and damage the pump.

Skimmer vac plate vacuum control adjusters

Some pool owners use one of a variety of manufacturer’s

skimmer vac plates. Some have a vacuum control adjuster,

and some do not. The adjuster could be a screw-type, a

spring loaded apparatus, or a dial design. For those vac

plates with adjusters, it is important to adjust them when

fine tuning the vacuum for the cleaner.

Figure 15: Typical Dedicated

Vacuum Port.

Vac

Port

8

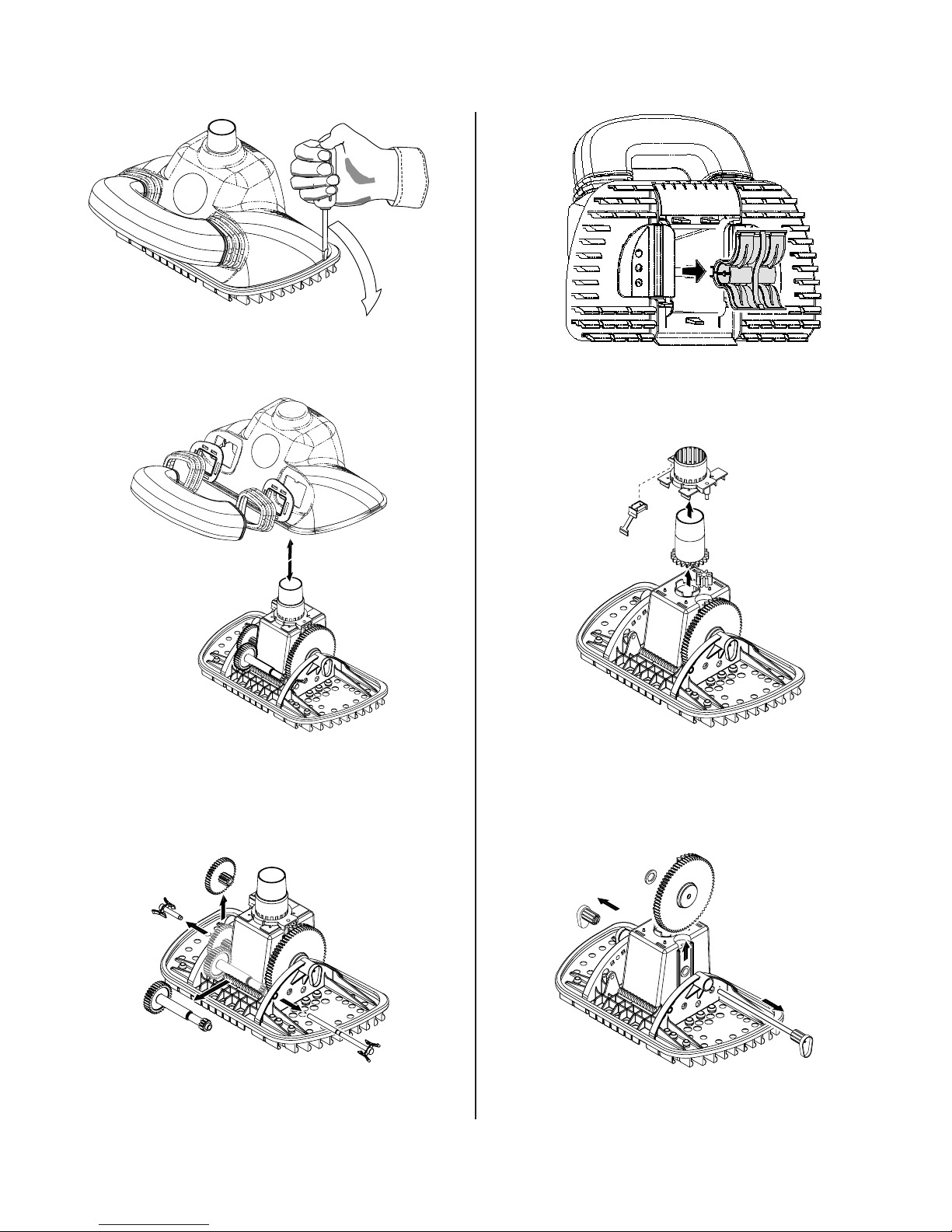

Step 1: With a screwdriver, carefully work the rubber vacuum pad down over the lip of the Outer Housing.

Step 2: Lift the Outer Housing straight up off of the chassis. Squeeze the tabs on the Bumper Clips (inside the

housing) to remove the Bumper. The Bumper, Bumper

Boots, and Bumper Clips pull apart.

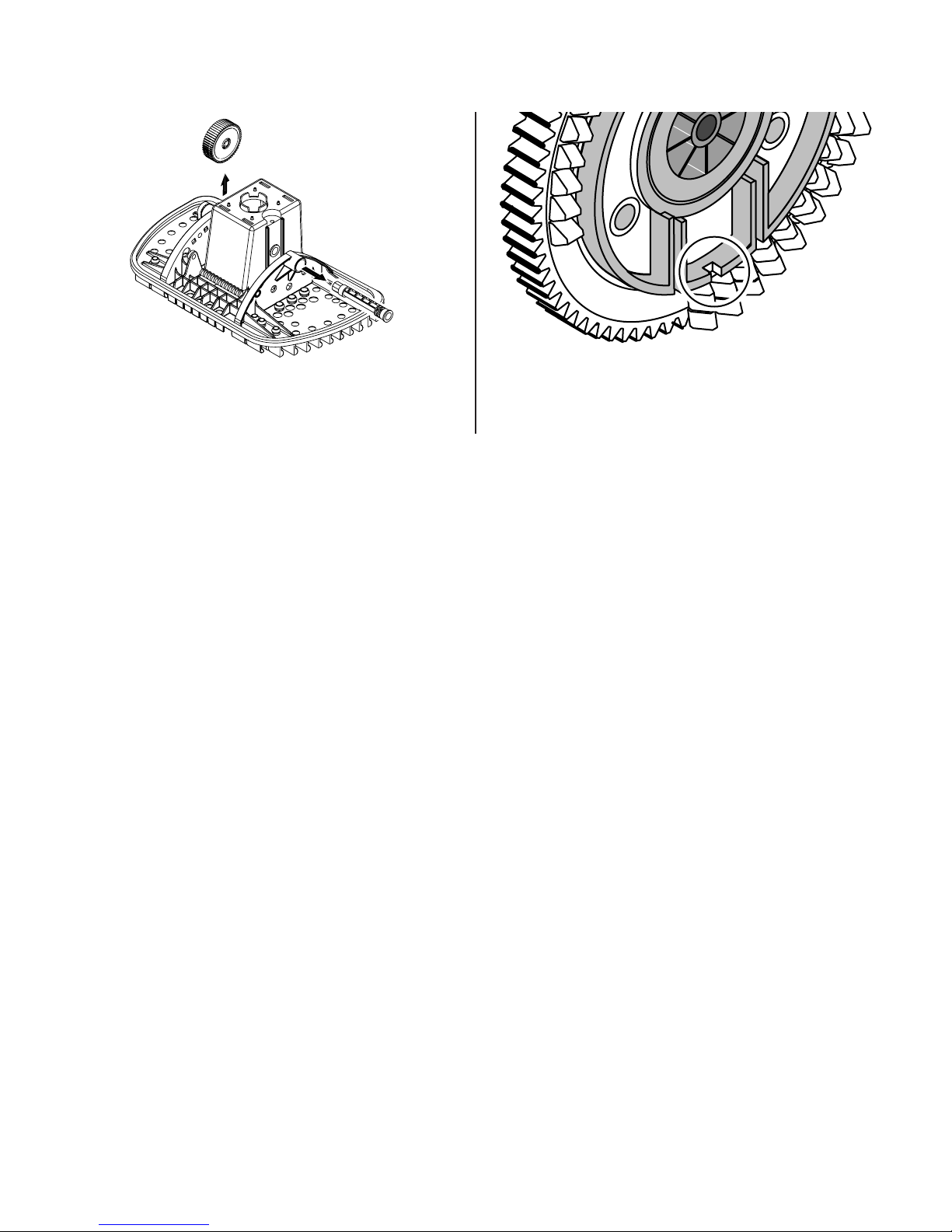

Step 3: Squeeze and pull the Sprocket Clips to release the

Drive Shaft Assembly and Center Sprocket.

Step 5: Squeeze the latching tabs and pull up on the

Swivel Housing and Swivel. The assembly will come up,

releasing the Swivel Sprocket. Squeeze the latching tabs to

remove the Clutch Clip.

Step 6: Remove the Shaft Plug with the stainless steel shaft

and the Large Steering Drive Assembly.

Step 4: Pull the Oscillator Straight out from the bottom of

the Outer Housing. Be careful not to lose the Sliding Seals.

Disassembly

3900 0201

3901 0201

3904 0201

9

Step 7: Remove the Oscillator Sleeve, releasing the

Oscillator Sleeve Bushing and the Clutch assembly.

Reassembly: To reassemble the PoolShark, reverse the steps

above. NOTE: The notch on the center disk of the Large

Steering Drive Assembly must be down (as shown) for assembly.

Disassembly (continued)

3907 0201

3906 0201

10

27

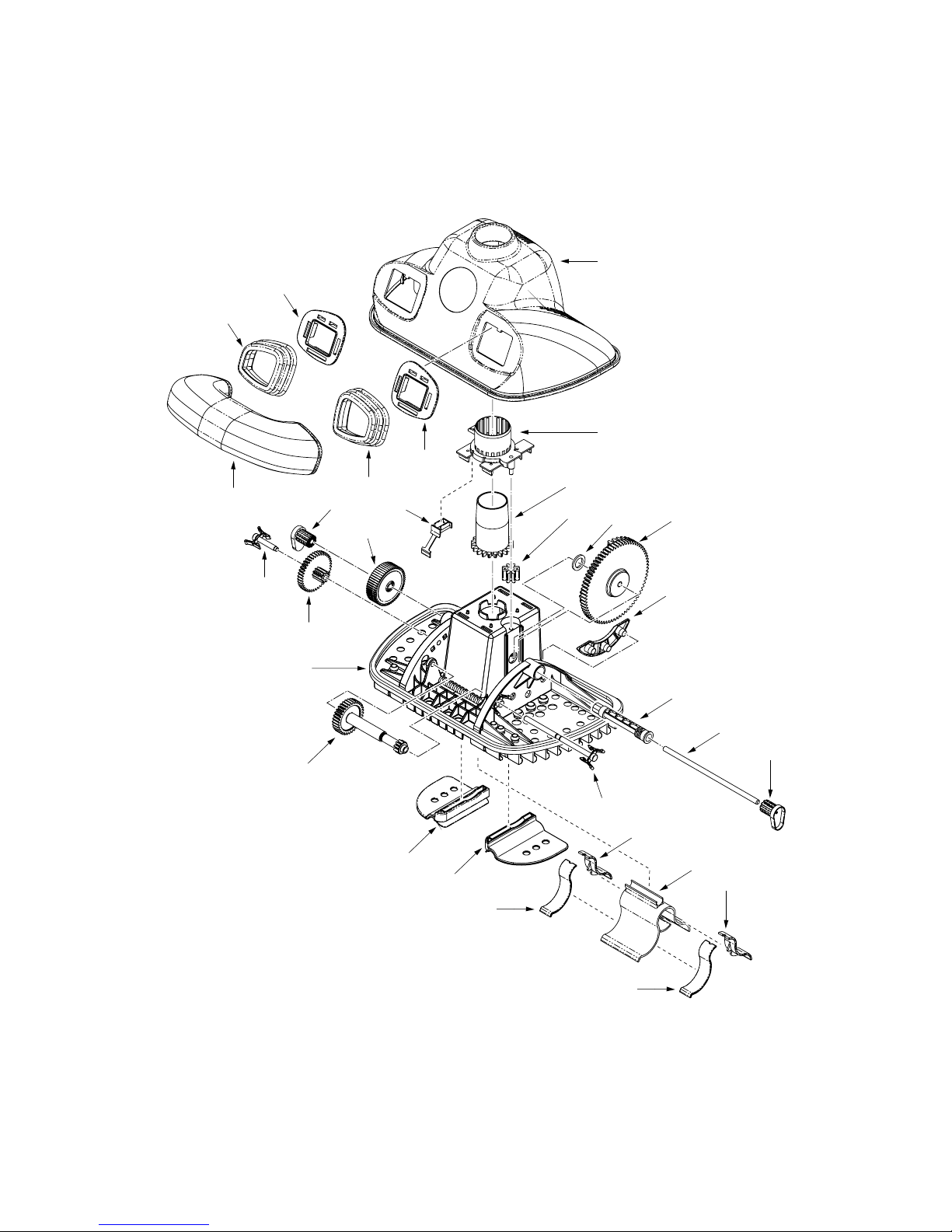

PoolShark Exploded View

26

28

24

25

10

23

21

1

2

3

4

5

6

20

18

17

19

16

15

7

8

9

10

11

12

13

12

14

14

3908 0201

11

Key Part Model Model

No. Description Qty. GW7500 GW7700

• Steering Kit (Incl. Key Nos. 2,3,4) 1 GW7505 GW7515

2 Swivel Housing 1

3 Swivel 1

4 Swivel Sprocket 1

23 Clutch Clip 1

• Clutch Kit (Incl. Key Nos. 5,8,21,23) GW7503 GW7503

5 Oscillator Sleeve Bushing 1

8 Oscillator Sleeve 1

21 Clutch Assembly 1

• Gear Kit (Incl. Key Nos. 6,10,11,17,19,20) GW7504 GW7504

6 Large Steering Drive Assembly 1

10 Shaft Plug 2

11 Long Sprocket Clip 1

17 Drive Shaft Assembly 1

19 Center Sprocket 1

20 Short Sprocket Clip 1

• Oscillator Kit (Incl. Key Nos. 12, 13,14) 1 GW7502 GW7502

12 Small Sliding Seal 2

13 Oscillator 1

14 Large Sliding Seal 2

• Seal Flap Kit (Incl. Key Nos. 15,16) 1 GW7506 GW7506

15 Right Seal Flap 1

16 Left Seal Flap 1

18 Chassis with Pad 1 41201-0242 41201-0242C

• Bumper Kit (Incl. Key Nos. 24,25, 26,27,28) 1 GW7501 GW7511

24 Right Bumper Clip 1

25 Right Bumper Boot 1

26 Bumper 1

27 Left Bumper Boot 1

28 Left Bumper Boot Clip 1

• Accessory Kit 1 77705-0400 77705-0400

Includes: Regulator 1

Regulator Cap 1

Hose Weight 2

Flow Gauge 1

Reducer Cone 1

Eyeball Diverter 2

Vac Port Fitting 1

• Short Leader Hose 1 GW9540 GW9540

• Suction Hose, 1 meter segement 10 41201-0252 41201-0252

Parts Not Available Separately:

1 Outer Housing 1

7 Support Brace 1

9 Stainless Steel Axle 1

PoolShark Repair Parts List

• Not Illustrated.

12

TROUBLESHOOTING

Common Causes of Cleaner Problems:

• Dirty filter Clean the filter

• Dirty basket in pump Clean the basket

hair and lint strainer

• Debris blocking the Remove the Debris

bottom of the PoolShark

• Leaks in the hose Remove the leaky section

• Debris in the regulator Clean the regulator valve

• Low vacuum through Close the main drain

the cleaner

PoolShark doesn’t move or pulsates slowly:

• Make sure that the main drain and all other suction

lines are closed except the suction line to which the

PoolShark is attached.

• Check for debris in the filter or the pump strainer

basket.

• Check for debris in the PoolShark’s oscillator. Debris

may prevent oscillator movement or restrict the flow

through the cleaner.

• Check the oscillator for: damage; lost seals (there

should be 4 seals): obstructed seals (seals should slide

freely on the oscillator).

• Be sure that the short, soft leader hose section is the

first section in the hose assembly (next to the cleaner).

To install the eyeball diverter:

The water flow from the return line can push the

PoolShark’s hose, causing the PoolShark to steer away

from the return line or to remain in one area of the

pool. To correct this, adjust your existing return line diverters or install the eyeball diverters supplied with the

PoolShark as follows:

A. Turn off the main circulation pump.

B. Unscrew the lock rings from the pool’s return line

fittings and remove the original eyeball diverters.

C. Replace them with the PoolShark’s eyeball diverters.

D. Replace the lock rings and tighten them. Be sure

that the openings of the eyeball diverters point

down or to the side (9:00 O’clock position), before

fully tightening the rings.

Usually, directing the return line water flow against

the side of the pool (as described above) works

best. However, you may want to try pointing the

flow downward or in different positions to see

which works best in the pool.

After installing the eyeball diverter, turn the circulation pump on. The PoolShark should begin moving

across the pool floor, vacuuming up the debris in its

path.

E. If the PoolShark’s eyeball diverters do not fit your

existing return line fittings, adjust your existing fittings as best you can as described above.

If the PoolShark tracks in a repetitive pattern:

• Check the pool return line water flow and redirect it as

necessary with a return line eyeball diverter (see “To install the eyeball diverter”, above).

• Check the PoolShark’s hose to be sure that it has not

become bent or kinked. Do not coil the hose, as it will

retain the coiled shape and reduce the cleaning coverage. To check the hose, lay each hose section flat on

the pool deck (or another flat surface) and look down

the length of the hose. It should be perfectly flat and

straight. Replace any sections which are bent or

kinked.

• Check the oscillator for: damage; lost seals (there

should be 4 seals): obstructed seals (seals should slide

freely on the oscillator).

• Be sure that the short, soft leader hose section is the

first section in the hose assembly (next to the cleaner).

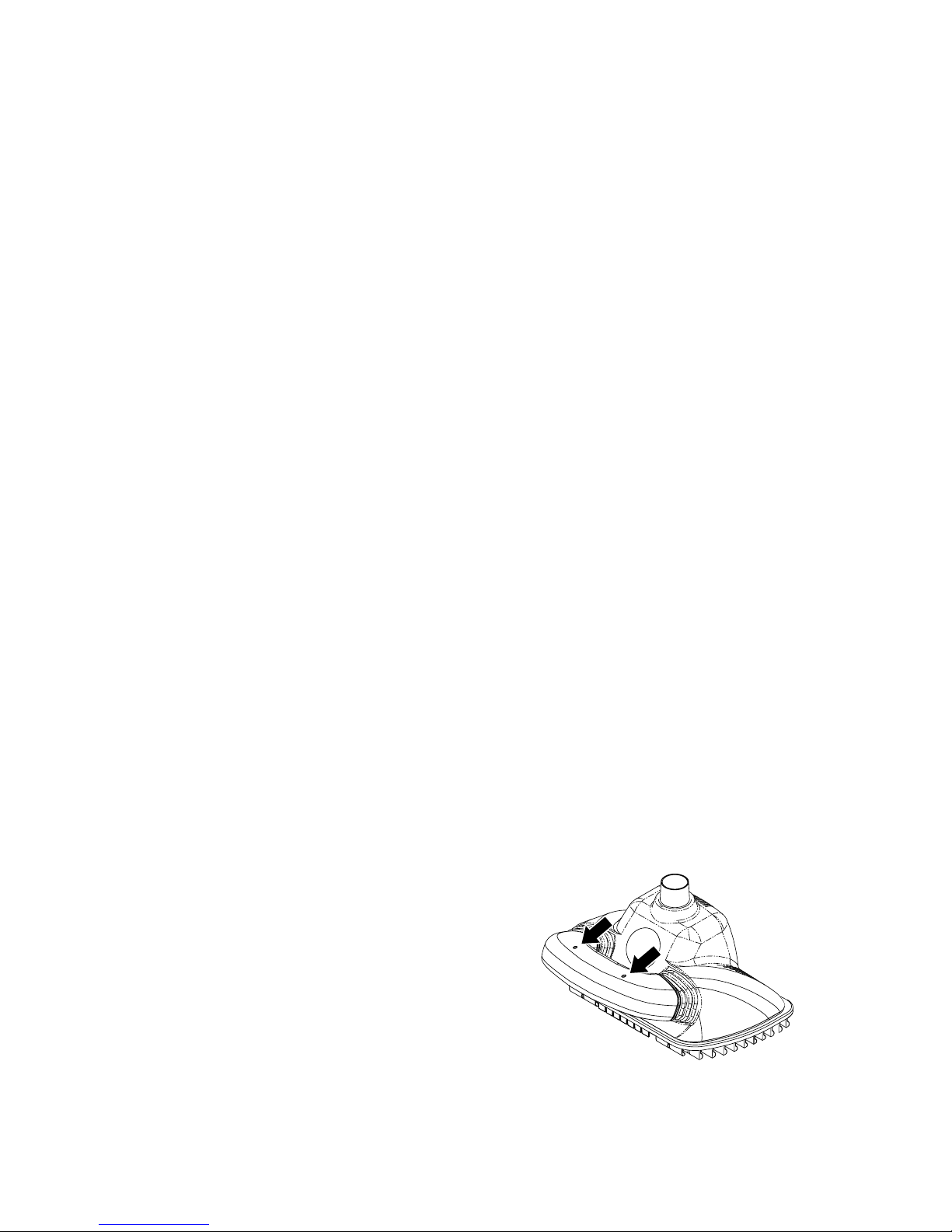

Square Bottom Pools Only:

If the transition radius between your pool’s floor and wall

is small and the PoolShark will not climb the pool walls,

then you have a square bottom pool. If so, remove the

cleaner from the pool and drill two holes in the indentations in the bumper (see Figure 14). This will provide an

outlet for air which would otherwise accumulate in the

hollow bumper. This air, from microscopic bubbles suspended in the pool water, is normally able to escape when

the PoolShark climbs the pool walls.

NOTICE: DO NOT drill the holes if your PoolShark CAN

climb the pool walls!

Figure 16: Drill Bumper if you have a square-bottom pool.

3899 0201

CREATE A RECORD OF YOUR WARRANTY AT STA-RITE:

• Complete a warranty registration at www.staritepool.com by clicking on “Register Products” and selecting Sta-Rite Pool

OR

• Complete bottom portion completely and mail within 10 days of installation to Sta-Rite, Attn.: Pool Warranty Dept., 293 Wright St., Delavan , WI 53115

Warranty Registration Card

Name

Address

City State Zip

Installation (or Purchase) Date

Product Purchased

Model Number

■■ New installation ■■ Replacement

Years pool has been in service ■■ less than 1 ■■ 1-3 ■■ 3-5 ■■ 5-10

This product was purchased from:

Company name

Address

City State Zip

STA-RITE LIMITED WARRANTY

For technical information about this product, contact the installer or call Sta-Rite at 262-728-9181.

Visit www.staritepool.com

• for more information about Sta-Rite products listed above

• to locate a Sta-Rite dealer near you

Product Specific Warranties (from date of installation)

Product Limited

Family Warranty Exceptions

Filters 1 Year System 3 Tank Bodies - 10 Yrs

Filter Valves 1 Year

Pumps 1 Year

Heaters 2 Years *Commercial Application - 1 Yr

Controls 1 Year

Above Ground Systems 1 Year

Lights and Niches 1 Year Lamps and Bulbs - 90 Days

White Goods 1 Year

Maintenance Equipment 90 Days

Drainer/Utility Pumps 90 Days

Replacement Parts 90 Days

Cleaners: Lil Shark 1 Year

Cleaners: Calypso 1 Year

Cleaners: Pool Shark 2 Years Footpad and Seal Flaps - 1 Yr

Cleaners: Great White 2 Years

* Commercial and multi-family application.

Retain this warranty certificate in a

safe and convenient location for your records.

Pumps, filters, skimmers, underwater lights (excluding bulbs), accessories and fittings manufactured by Sta-Rite are warranted to

be free of defects in material and/or workmanship for one (1) year

from the original date of installation.

The foregoing warranties relate to the original consumer purchaser

(“Purchaser”) only. Sta-Rite Industries shall have the option to repair or replace the defective product, at its sole discretion.

Purchasers must pay all labor and shipping charges necessary to

replace the product covered by this warranty. Requests for warranty service must be made through the installing dealer. This warranty shall not apply to any product that has been subject to

negligence, misapplication, improper installation or maintenance,

or other circumstances which are not in Sta-Rite’s direct control.

Failure to have product installed by a professional in compliance

with local codes will void any and all manufacturers warranty.

This warranty sets forth Sta-Rite’s obligation and Purchaser’s exclusive remedy for defective products.

STA-RITE SHALL NOT BE LIABLE FOR ANY CONSEQUENTIAL,

INCIDENTAL OR CONTINGENT DAMAGES WHATSOEVER.

THE FOREGOING WARRANTIES ARE EXCLUSIVE AND IN

LIEU OF ALL OTHER EXPRESS WARRANTIES. IMPLIED WARRANTIES, INCLUDING BUT NOT LIMITED TO THE IMPLIED

WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, SHALL NOT EXTEND BEYOND THE

DURATION OF THE APPLICABLE EXPRESS WARRANTIES

PROVIDED HEREIN.

Some states do not allow the exclusion or limitation of incidental or

consequential damages or limitations on how long an implied warranty lasts, so the above limitations or exclusion may not apply to

you. This warranty gives you specific legal rights and you may also

have other rights which vary from state to state.

Supersedes all previous publications.

S4877PS (Rev. 7/21/04)

Loading...

Loading...