Page 1

OWNER’S MANUAL

INSTALLATION AND OPERATING INSTRUCTIONS

REPAIR PARTS LIST

60 CYCLE

SELF-PRIMING CENTRIFUGAL PUMPS

“D” SERIES

MODELS

1 HP 1-1/2 HP 2 HP 2-1/2 HP

DMG-41L DMMG-42L

MEDIUM HEAD DMG3-41 DMMG3-42

DMM2G-42

DHE-50L DHF-51L DHG-52L DHHG-53L

HIGH HEAD DHE3-50 DHF3-51 DHG3-52 DHHG3-53

DH2E3-50

STA-RITE INDUSTRIES, DELAVAN, WISCONSIN 53115

©2005, Sta-Rite Industries S878 (Rev. 9/26/05)

LIMITED WARRANTY

Sta-Rite Industries warrants to the original consumer of the products listed below, that they will be free from defects in material and workmanship for

the Warranty Period from the date of original installation or manufacture as noted.

Product Warranty Period

Water Systems Products – jet pumps,

whichever occurs first:

small centrifugal pumps, submersible pumps 1 year from date of original installation, or

and related accessories 2 years from date of manufacture

Hydro-Flow Filters 1 year from date of purchase

Signature 2000 Fibrewound Tanks 5 years from date of original installa ion

Pro-Source Steel Pressure Tanks 5 years from date of original installation

Pro-Source Epoxy-Line Tanks 3 years from date of original installation

Sump/Sewage/Effluent Products 1 year from date of original installation, or

2 years from date of manufacture

Our warranty will not apply to any product hat has been subject to negligence, misapplication, improper installation or maintenance. In the event

a three phase submersible motor is operated with single phase power through a phase converter, or if three-leg ambient compensated, extra-quick

trip overload relays of recommended size are not used, our warranty is void.

Buyer’s only remedy and Sta-Rite Industries’ only duty is to repair or replace defective products (at Sta-Rite Industries’ choice). Buyer agrees to

pay all labor and shipping charges associated with this warranty and to request warranty service through the installing dealer as soon as a problem is discovered. If warranty service is requested more han 30 days after he Warranty Period has ended, it will not be honored.

STA-RITE INDUSTRIES SHALL NOT BE LIABLE FOR ANY CONSEQUENTIAL, INCIDENTAL, OR CONTINGENT DAMAGES WHATSOEVER.

THE FOREGOING WARRANTIES ARE EXCLUSIVE AND IN LIEU OF ALL OTHER EXPRESS WARRANTIES. IMPLIED WARRANTIES,

INCLUDING BUT NOT LIMITED TO THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE,

SHALL NOT EXTEND BEYOND THE WARRANTY PERIOD PROVIDED HEREIN.

Certain states do not permit he exclusion or limitation of incidental or consequential damages or the placing of limitations on the duration of an

implied warranty, therefore, the limitations or exclusions herein may not apply. This warranty sets forth specific legal rights and obligations, however, additional rights may exist, which may vary from state to state.

Supersedes all previous publications.

Sta-Rite Industries, Inc. 293 Wright St., Delavan, WI 53115

Page 2

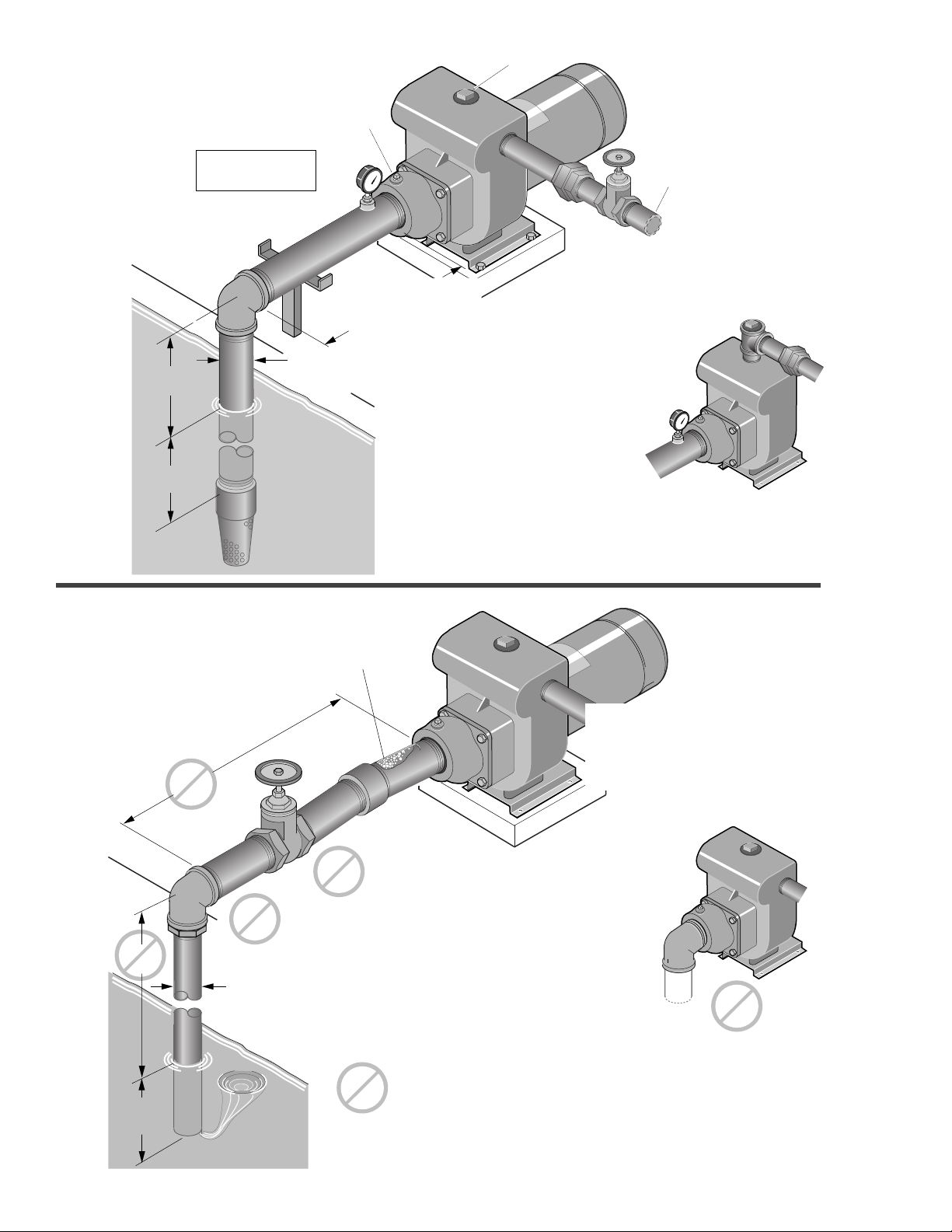

Support suction pipe

as required

Support discharge

pipe as required

As close

as possible

4 x "D"

minimum

Pipe diameter "D"

at least as large as

pump suction connection

Important:

All connections must

be

air tight

Solid, level

base

Priming

Plug

Gate

Valve

Union

Discharge

to service

Recommended pump suction

and discharge connections

Not

recommended pump suction

and discharge connections

Elbow immediately

in front of pump

suction.

High

lift

Pipe diameter "D"

insufficient size

Pipe submerged

less than 4 x "D"

will cause vortexing

Long suction

run

Valve

Unsupported

Pipe

Misaligned pipe causes

air leaks;

high spots along the suction line

result in

air pockets.

Offset suction flange adapter

keeps suction water level

above impeller eye to aid priming.

Use of excess fittings

means potential

air leaks

Straight run, short as

possible but at least 6

times pipe diameter ("D");

slope is

down

going away

from pump.

1239 0894

Some models have top

discharge; these require

a priming tee.

On the discharge

avoid:

Quick closing valves.

Small I.D. pipe.

Numerous fittings.

Misalignment.

Sharp turns in piping run.

Figure 1

Figure 2

2

Page 3

3

LOCATION OF UNIT

Locate the pump as near the liquid source as possible,

using a short, direct suction pipe. Keep the static suction lift (vertical distance between the center line of the

pump and the liquid level) to a minimum. Mount the

pump on a solid, level foundation, which provides a

rigid and vibration-free support. It should be located

where the unit is readily accessible for service and

maintenance. The pump should be protected against

flooding and excessive moisture. Do not allow pump or

any system component to freeze.

PIPING

Both suction and discharge piping should be independently supported at a point near the pump to avoid

strains being placed on the pump. Start all piping at

pump to avoid strains left by a gap at last connection.

SUCTION PIPING

The suction pipe must be kept free of leaks. The suction pipe must have a gradual slope upward to the

pump. Avoid any fittings which may cause an air trap.

On units that have a suction fitting, a check valve is a

built-in feature and no foot valve is required.

DISCHARGE PIPING

A gate valve and union should be installed in the discharge line. For removal of the pump for service, close

the gate valve, and disconnect at union.

Never run pump dry. Running pump

without water may cause pump to overheat, damaging

seal and possibly causing burns to persons handling

pump. Fill pump with water before starting.

Never run pump against closed discharge. To do so can boil water inside pump, caus-

ing hazardous pressure in unit, risk of explosion and

possibly scalding persons handling pump.

PRIMING THE PUMP

A tee installed in the discharge opening of the pump,

and provided with a priming plug at the top position, will

enable you to fill the pump with liquid. Once filled and

the priming plug replaced, the pump will prime. The

pump should prime itself time after time, as long as the

built-in check valve functions.

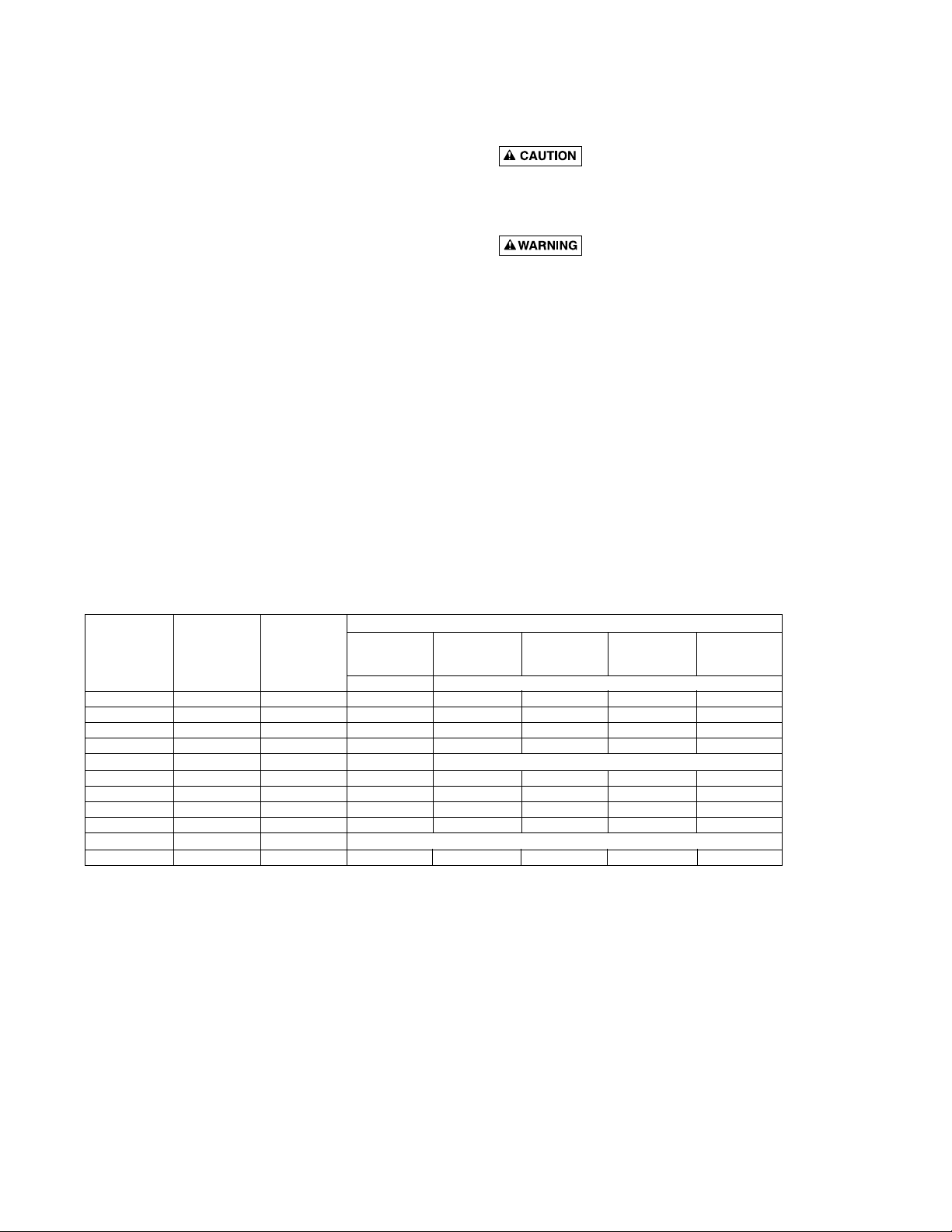

TABLE I - RECOMMENDED FUSING AND WIRING DATA - 60 CYCLE MOTORS

DIAMETER IN FEET FROM MOTOR TO METER

BRANCH 0’ 101’ 201’ 301’ 401’

FUSE* TO TO TO TO TO

MOTOR MAX. LOAD RATING 100’ 200’ 300’ 400’ 500’

HP AMPERES AMPS

115/230 VOLT SINGLE PHASE WIRE SIZE

1 15.3/7.6 20/15 12/14 8/14 6/14 6/12 4/10

1-1/2 19.2/9.6 25/15 10/14 8/14 6/12 4/10 4/10

2 24.0/12.0 30/15 10/14 6/14 6/12 4/10 4/10

2-1/2 26.0/12.0 30/15 10/14 16/14 4/12 4/10 4/10

230/460 VOLT THREE PHASE WIRE SIZE

1 3.6/1.8 15/15 14/14 14/14 14/14 14/14 14/14

1-1/2 4.7/2.35 15/15 14/14 14/14 14/14 14/14 14/14

2 6.8/3.4 15/15 14/14 14/14 14/14 12/14 12/14

2-1/2 8.5/4.25 15/15 14/14 14/14 14/14 12/14 10/14

200/400 VOLT THREE PHASE WIRE SIZE

1 3.8/1.9 15/15 14/14 14/14 14/14 14/14 14/14

*A Fusetron is recommended instead of a fuse in any motor circuit.

IMPORTANT: BE SURE lead wire opening on end of

motor is fully sealed when conduit or a pressure switch

is not used. Failure to seal it properly will allow dirt, rain,

bugs, etc. to enter back compartment of motor through

conduit opening and cause switch malfunction.

Page 4

4

Connection diagram for dual voltage, single-phase

motors. Your dual-voltage motor’s terminal board

(under the motor end cover) will match one of the

diagrams below. Follow that diagram if necesary to

convert motor to 115 Volt power.

Connect power supply wires to L1 and L2. For

3-phase motors, or if motor does not match these

pictures, follow the connection diagram on the motor

nameplate.

THE MOTOR IS SET FOR 230 VOLTS

WHEN SHIPPED.

To change the motor to use 115 volts:

1. Turn off power

2. Remove the back motor cover.

3. Use a screwdriver or 1/2” wrench and turn the voltage selector dial counterclockwise until 115 shows in

the dial opening.

4. Reinstall the motor cover.

Hazardous voltage. Can shock, burn, or

cause death. Disconnect power to motor before working

on pump or motor. Ground motor before connecting to

power supply.

WIRING

Ground motor before connecting to electrical

power supply. Failure to ground motor can

cause severe or fatal electrical shock hazard.

Do not ground to a gas supply line.

To avoid dangerous or fatal electrical shock,

turn OFF power to motor before working on

electrical connections.

Supply voltage must be within ±10% of name-

plate voltage. Incorrect voltage can cause fire

or damage motor and voids warranty. If in doubt

consult a licensed electrician.

Use wire size specified in Wiring Chart (Page

3). If possible, connect pump to a separate

branch circuit with no other appliances on it.

Wire motor according to diagram on motor

nameplate. If nameplate diagram differs from

diagrams above, follow nameplate diagram.

1. Install, ground, wire and maintain this pump in accor-

dance with electrical code requirements. Consult your

local building inspector for information about codes.

2. Provide a correctly fused disconnect switch for pro-

tection while working on motor. Consult local or

national electrical codes for switch requirements.

3. Disconnect power before servicing motor or pump. If the

disconnect switch is out of sight of pump, lock it open

and tag it to prevent unexpected power application.

4. Ground the pump permanently using a wire of the

same size as that specified in wiring chart (Page 3).

Make ground connection to green grounding terminal

under motor canopy marked GRD. or .

5. Connect ground wire to a grounded lead in the ser-

vice panel or to a metal underground water pipe or

well casing at least 10 feet long. Do not connect to

plastic pipe or insulated fittings.

6. Protect current carrying and grounding conductors

from cuts, grease, heat, oil, and chemicals.

7. Connect current carrying conductors to terminals L1 and

L2 under motor canopy. When replacing motor, check

wiring diagram on motor nameplate against Figure 3. If

the motor wiring diagram does not match either diagram

in Figure 3, follow the diagram on the motor.

IMPORTANT: 115/230 Volt single phase models are

shipped from factory with motor wired for 230 volts. If

power supply is 115 volts, remove motor canopy and

reconnect motor as shown in Figure 3. Do not try to run

motor as received on 115 volt current.

8. Motor has automatic internal thermal overload pro-

tection. If motor has stopped for unknown reasons,

thermal overload may restart it unexpectedly, which

could cause injury or property damage. Disconnect

power before servicing motor.

9. If this procedure or the wiring diagrams are confus-

ing, consult a licensed electrician.

ELECTRICAL

Motor Terminal Block Wiring (as viewed from rear of motor, canopy removed)

Figure 3: Changing the Voltage Setting

Figure 4: Motor Set for 115 Volt Operation

Page 5

5

PUMP SERVICE

This centrifugal pump requires little or no service other

than reasonable care and periodic cleaning. Occasionally, however, a shaft seal may become damaged and

must be replaced. The procedure as outlined below will

enable you to replace the seal.

NOTE: Pumps use mechanical seals with a rubber

seat ring or a sealing O-Ring. THESE SEALS ARE

COMPLETELY INTERCHANGEABLE.

NOTE: The highly polished and lapped faces of this

seal are easily damaged. Read instructions and handle

the seal with care.

Some models are equipped with an impeller screw,

which has a left hand thread. Before unscrewing the

impeller, remove the impeller screw.

REMOVAL OF OLD SEAL

1. After unscrewing impeller, carefully remove rotating

part of seal by prying up on sealing washer, using

two screwdrivers (see Figure 5A). Use care not to

scratch motor shaft.

2. Remove seal plate from motor and place on flat surface, face down. Use a screwdriver to push ceramic

seat out from seal cavity (see Figure 5B).

INSTALLATION OF STATIONARY SEAT (Figure 5C)

1. Clean polished surface of stationary seat with clean

cloth.

2. Turn seal plate over so seal cavity is up, clean cavity thoroughly.

3. Lubricate outside rubber surface of ceramic seat

with soapy water and press firmly into seal cavity

with finger pressure. If seat will not locate properly in

this manner, place cardboard washer over polished

face of seat and press into seal cavity using a 3/4”

socket or 3/4” piece of standard pipe.

4. DISPOSE OF CARDBOARD WASHER. Be sure

polished surface of seat is free of dirt and has not

been damaged by insertion. Remove excess soapy

water.

INSTALLATION OF ROTATING

PART OF SEAL UNIT (Figure 5D)

1. Reinstall seal plate using extreme caution not to hit

ceramic portion of seal on motor shaft.

2. Inspect shaft to make sure that it is clean.

3. Clean face of sealing washer with clean cloth.

4. Lubricate inside diameter and outer face of rubber

drive ring with soapy water and slide assembly on

motor shaft (sealing face first) until rubber drive ring

hits shaft shoulder.

5. Screw impeller on shaft until impeller hub hits shaft

shoulder. This will automatically locate seal in place

and move the sealing washer face up against seat

facing. Reinstall impeller screw (if used).

MAINTENANCE

Be sure to drain pump during freezing weather to prevent damage from frost. To drain, remove drain plugs

directly below the suction inlet of the pump. Drain the

suction pipe to a point below the frost line. All other

pipes that may be exposed to freezing temperatures

should also be drained.

FIGURE 5

SERVICE

685 0294

Mechanical seal

Mechanical seal

rotating half

A-Seal removal-rotating half B-Seal removal-stationary half C-Stationary half installation D-Rotating half installation

stationary half

Seal Plate

T

3/4" socket

or pipe

Cardboard

washer

Polished

surface

o

n

v

r

e

u

r

(supplied w/seal)

Rubber

surface

Sealing

face

Shaft

shoulder

Rubber drive

ring

Impeller

Page 6

6

“D” SERIES REPAIR PARTS LIST

60 CYCLE 1 and 1-1/2 HP HIGH HEAD; 2 and 2-1/2 HP MEDIUM HEAD

1 HP 1-1/2 HP 2 HP 2-1/2 HP

DHE-50L DHF-51L DMG-41L DMMG-42L

Key Part No. DHE3-50 DHF3-51 DMG3-41 DMMG3-42

No. Description Used DH2E3-50 DMM2G-42

1 Motor - 115/230V/60 Hz/1 Ph 1 A100ELL A100FLL – –

1 Motor - 230V/60 Hz/1 Ph 1 – – AE100GLL AE100G5LL

1 Motor - 230/460V/60 Hz/3 Ph 1 AP100EL AP100FL AP100GL AP100G5L

1 Motor - 200/400V/60 Hz/3 Ph 1 AP100ELL – – AP100G5L2

2 3/8 - 16 x 1-1/4” Cap Screw 4 U30-75ZP U30-75ZP U30-75ZP U30-75ZP

3 Water Slinger 1 17351-0009 17351-0009 17351-0009 17351-0009

4A Seal Plate 1 – – C3-23 C3-23

4B Seal Plate 1 C3-52 C3-52 – –

5 Seal Plate Gasket 1 C20-21 C20-21 C20-21 C20-21

6 Shaft Seal 1 U109-6A U109-6A U109-6A U109-6A

7A Impeller - (1 Phase) 1 C105-92PLC C105-92PB C105-114PNA C105-80EA

7A Impeller - (3 Phase) 1 C105-92PLA C105-92PBA C105-114PNA C105-80EA

7B Impeller Screw 1 C30-14SS* C30-14SS* C30-14SS C30-14SS

8 Wear Ring 1 C23-27 C23-27 C23-32D C23-32D

9A Diffuser (Includes Key No. 8) 1 – – C101-56C C101-72

9B Diffuser (Includes Key No. 8) 1 C101-212B C101-212B – –

10 Diffuser Ring 1 C21-2 C21-2 C21-2 C21-2

11 1/4 NPT Pipe Plug 3 U78-941ZPV U78-941ZPV U78-941ZPV U78-941ZPV

12A Pump Body 1 C76-1J C76-1J C76-1J C76-1L

12B 1-1/2 NPT Pipe Plug 1 U78-63GPS U78-63GPS U78-63GPS U78-63GPS

13 5/16 - 18 x 3/4” Cap Screw 4 U30-60ZP U30-60ZP U30-60ZP U30-60ZP

14 Base 1 U4-5 U4-5 U4-5 U4-5

15 3/8” Lock Washer 2 U43-12ZP U43-12ZP U43-12ZP U43-12ZP

16 3/8 - 16 x 5/8” Cap Screw 2 U30-71ZP U30-71ZP U30-71ZP U30-71ZP

*3 Phase only.

1

2

3

4B

4A

5

6

7A

8

9A

9B

10

11

12A

12B

11

13

11

14

15

16

1443 1294

7B

Page 7

7

“D” SERIES REPAIR PARTS LIST

60 CYCLE 2 and 2-1/2 HP HIGH HEAD

2 HP 2-1/2 HP

Key Part No. DHG-52L DHHG-53L

No. Description Used DHG3-52 DHHG3-53

1 Motor - 230V/60 Hz/1 Ph 1 AE100GLL AE100G5LL

1 Motor - 230/460V/60 Hz/3 Ph 1 AP100GL AP100G5L

2 3/8 - 16 x 1” Cap Screw 4 U30-74ZP U30-74ZP

3 Water Slinger 1 17351-0009 17351-0009

4 3/8 - 16 x 3/4” Cap Screw 8 U30-72ZP U30-72ZP

5 Seal Plate 1 C103-35 C103-35

6 Seal Plate Gasket 1 C20-46 C20-46

7 Shaft Seal 1 U109-6A U109-6A

8A Impeller 1 C105-214PCA C105-214PA

8B Impeller Screw 1 C30-14SS C30-14SS

9 Wear Ring 1 C23-19 C23-19

10 Diffuser (Includes Key No. 9) 1 C101-77 C101-77

11 Diffuser Ring 1 C21-2 C21-2

12 Pump Body 1 C76-12 C76-12

13 1/4 NPT Drain Plug 2 U78-941ZPV U78-941ZPV

14 5/16 - 18 x 3/4” Cap Screw 4 U30-60ZP U30-60ZP

15 Base 1 U4-5 U4-5

16 3/8” Lock Washer 2 U43-12ZP U43-12ZP

17 3/8 - 16 x 5/8” Cap Screw 2 U30-71ZP U30-71ZP

1

2

3

4

5

6

7

8A

9

10

11

13

15

8B

17

16

1442 1294

12

13

14

Page 8

8

TROUBLE - CAUSES AND REMEDY

TROUBLE AND CAUSE REMEDY

FAILURE TO PUMP

1. Pump not properly primed. 1. Make sure pump casing and suction line are full of water.

See priming instructions.

REDUCED CAPACITY AND/OR HEAD

1. Air pockets or leaks in suction line. 1. Check suction piping.

2. Clogged impeller. 2. Remove and clean.

PUMP LOSES PRIME

1. Air leaks in suction line. 1. Check suction piping

2. Excessive suction lift and operating 2. Move pump nearer to water level.

too near shut-off point.

3. Water level drops while pumping, 3. Check water supply. Add length of pipe to suction

uncovering suction piping. to keep submerged end under water.

MECHANICAL TROUBLES AND NOISE

1. Bent shaft and/or damaged bearings. 1. Take motor to authorized motor repair shop.

2. Suction and/or discharge piping not 2. See that all piping is supported to relieve strain

properly supported and anchored. on pump assembly.

1238 0894

1

2

3

4

5

6

Key Part No. Part

No. Description Used Symbol

1 Valve Plate 1 C61-5SS

2 Gasket - Flange 1 C20-15

3 Valve Washer 1 C43-15SS

4 Machine Screw 1/4-20 x 1/2” 1 U30-50SS

5 Pipe Plug - 1/4” NPT Sq. Hd. 1 U78-57SSS

6 Suction Flange 1-1/2” NPT 1 C3-22

6 Suction Flange 2” NPT 1 C3-22A

• Nut, 1/4-20, Hex 1 BC120-15

Suction Flange Assembly-

Complete 1-1/2” NPT C203-22

Suction Flange Assembly-

Complete 2” NPT C203-22A

Suction Flange Assemblies

Loading...

Loading...