Sta-Rite DE-35 Installation Manual

DE

FILTER

INSTALLATION, OPERATION

&

SERVICE MANUAL

FILTER IS DESIGNED AND INTENDED FOR USE TO FILTER WATER

SWlMNllNG POOLS AND SPAS

IN

*

PATENT PENDING

STARBRIGHT SYSTEMS

P.O. BOX 1205

SANFORD, NORTH CAROLINA 27330

INSTALLATION INSTRUCTIONS

WARNING

FILTERS SHOULD NEVER BE TESTED OR

SUBJECTED TO AIR OR GAS UNDER PRESSURE. ALL GASES ARE COMPRESSIBLE AND

UNDER PRESSURE CREATE A DANGER.

SEVERE BODILY INJURY OR PROPERTY

DAMAGE COULD OCCUR IF THE FILTER IS

SUBJECTED TO AIR OR GAS PRESSURE.

1.

Remove all components from the carton and inspect

for damage that may have occured in shipment.

2.

Place the filter in its permanent location on a level

slab. DO NOT use sand to

wash away, leaving

tion will cause poor filter performance.

3.

~e certain the piping is asfollows: A) From the pool to

the

to the

the pool.

Of

the

inletof the filter; C) From the outletof the filter to

the filter out of level. This condi-

pump;

level the filter as it may

B,

From

the

the

pump

INTRODUCTION

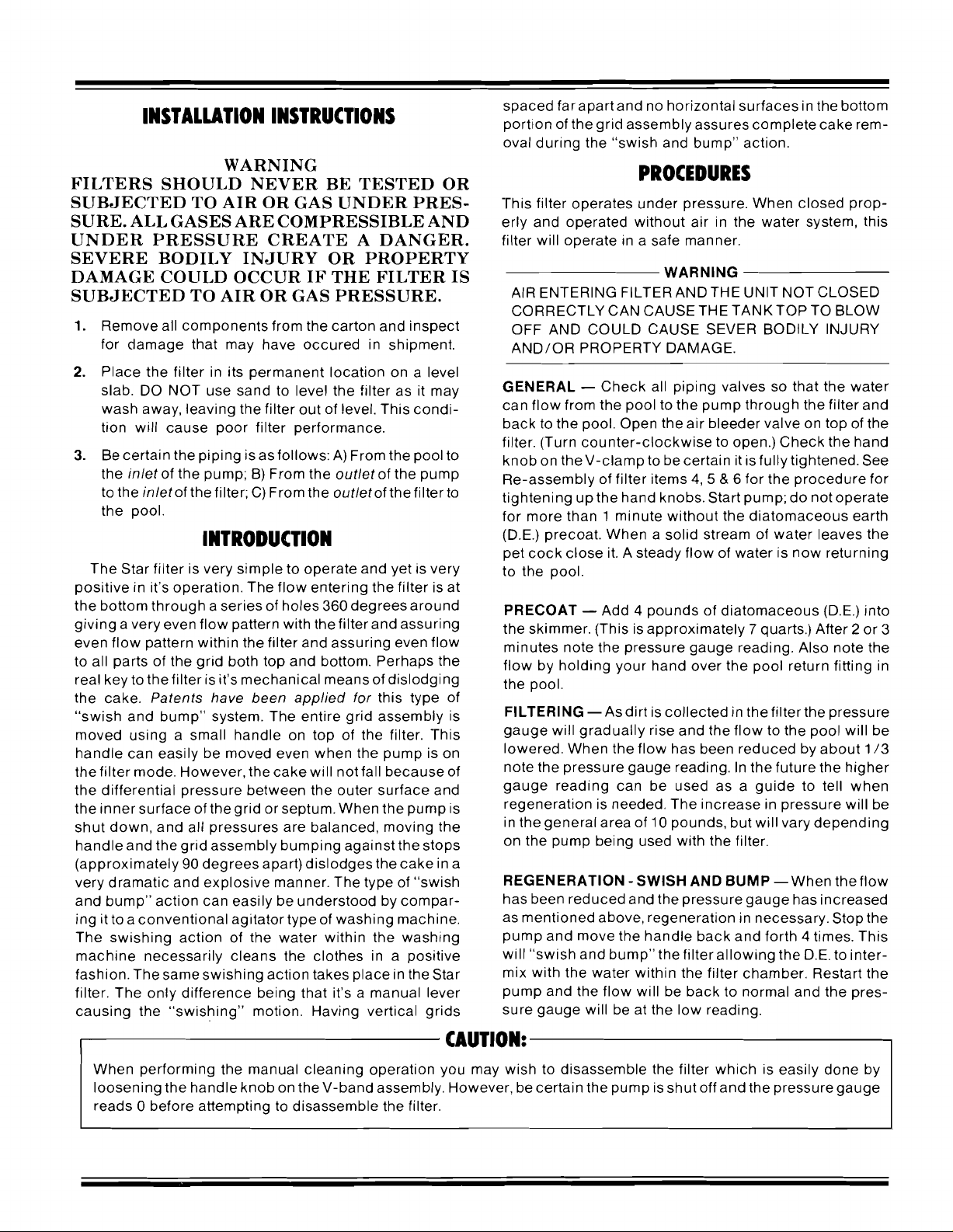

The Star filter is very simple to operate and yet is very

positive in it's operation. The flow entering the filter is at

the bottom through a series of holes 360 degrees around

giving a very even flow pattern with

even flow pattern within the filter and assuring even flow

to all parts of the grid both top and bottom. Perhaps the

real key to the filter is it's mechanical meansof dislodging

the cake. Patents have been applied

and bump" system, -rhe entire grid assembly is

moved using a small handle

handle can easily be moved

the filter mode. However, the cake will not fall because of

the differential pressure between the outer surface and

the inner surface ofthe or septum, when the

shut down, and all pressures are

handle and the grid assembly bumping against the stops

(approximately 90 degrees apart) dislodges the cake in a

very dramatic and explosive manner. The type of "swish

and bump" action can easily be understood by

ing it to a conventional agitator type of washing machine.

The swishing action of the water within the washing

machine necessarily cleans the clothes in a positive

fashion. The same swishing action takes place in the Star

filter. The only difference being that it's a manual lever

causing the "swishing" motion. Having vertical grids

the filter and assuring

for

this type of

on top of the filter. This

even

when the pump is on

pump

balanced, moving the

compar-

is

spaced far apart and no horizontal surfaces in the bottom

portion of the grid assembly assures complete cake removal during the "swish and bump" action.

PROCEDURES

This filter operates under pressure. When closed properly and operated without air in the water system, this

filter will operate in a safe manner.

WARNING

AIR ENTERING FILTER AND THE UlVlT NOT CLOSED

CORRECTLY CAN CAUSE THE

OFF AND COULD CAUSE SEVER BODILY INJURY

AND/OR PROPERTY DAMAGE.

GENERAL

can flow from the pool tothe pump through the filter and

back to the pool. Open the air bleeder valve on top of the

filter. (Turn counter-clockwise to open.) Check the hand

knob

Re-assembly of filter items

tightening

for more than 1 minute without the diatomaceous earth

(D.E.) precoat. When a solid stream of water leaves the

pet cock close it. A steady flow of water is now returning

to the pool.

PRECOAT

the skimmer. (This is approximately 7 quarts.) After 2 or 3

,inUtes note the

flow by holding your hand over the pool return fitting in

the pool.

FILTERING

gauge will gradually rise and the flow to the pool will be

lowered. When the flow has been reduced by about

note the pressure gauge reading. In the future the higher

gauge reading can

regenerati0n is needed. The increase in pressure will be

in thegeneral area of 10 pounds, but will vary depending

On

the

REGENERATION -SWISH AND BUMP

has been reduced and the pressure gauge has increased

as mentioned above, regeneration in necessary. Stop the

pump and move the handle back and forth

will "swish and bump" the filter allowing the D.E. to inter-

mix with the water within the filter chamber. Restart the

pump and the flow will be back to normal and the

sure gauge will be at the low reading.

-

Check all piping valves

0,

thev-clamp to be certain it is fully tightened. See

up

the hand knobs,

-

Add 4 pounds of diatomaceous (D.E.) into

pressure

-Asdirt is collected in the filterthe pressure

be

used as a guide

pump being

used

with

TANKTOP TO BLOW

SO

that the water

4,

5 & 6 for the procedure for

start

gauge

the

pump; do

reading, p,lso

filter.

not

operate

note

tell when

-

When the flow

4

times. This

the

1

/3

pres-

CAUTION:

When performing the manual cleaning operation you may wish to disassemble the filter which is easily done by

loosening the handle knob on

reads

0 before attempting to disassemble the filter.

theV-band assembly. However, be certain the pump is shut off and the pressuregauge

Loading...

Loading...