Page 1

1. GENERAL SAFETY GUIDELINES

2. NOMENCLATURE

2.1 Motors

2.2 Drives

2.3 Submersible Motor Controls

3. INSTALLATION AND SETUP

3.1 General Installation Guidelines

3.2 Proper Grounding

3.3 Corrosive Water and Ground

3.4 Check Valves

3.5 Start Up

4. ELECTRICAL POWER

4.1 Mixing Wire Size

4.2 Wire Splicing

4.3 Three-Phase Starters

4.4 Checking Motor Rotation

4.5 Three-Phase Current Balancing

4.6 Transformer Sizing

4.7 Using a Generator

4.8 Special Applications

5. XE-SERIES 4" SUBMERSIBLE MOTORS –

60 HZ

5.1 Motor Inspection

5.2 Testing

5.3 Storage and Transportation

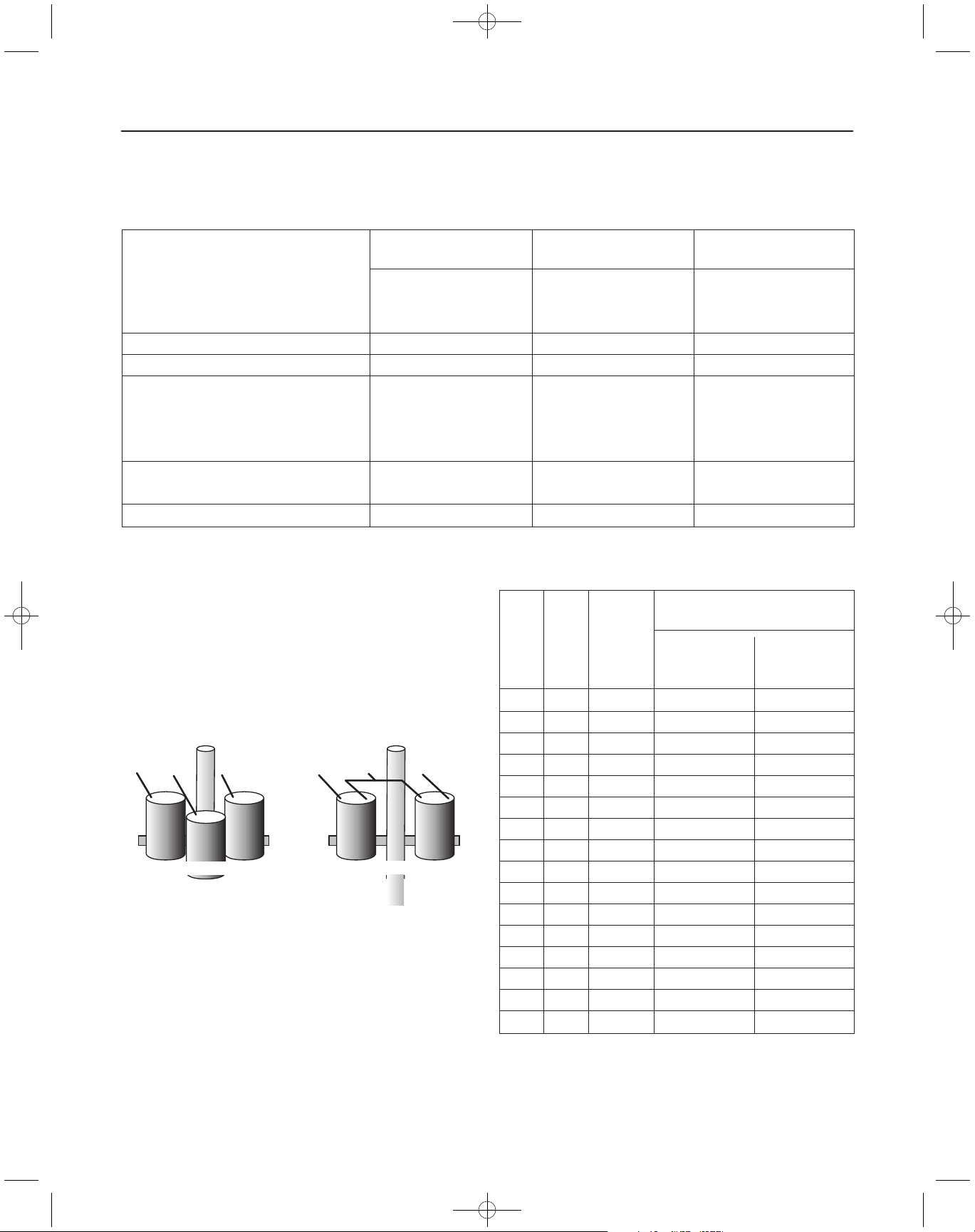

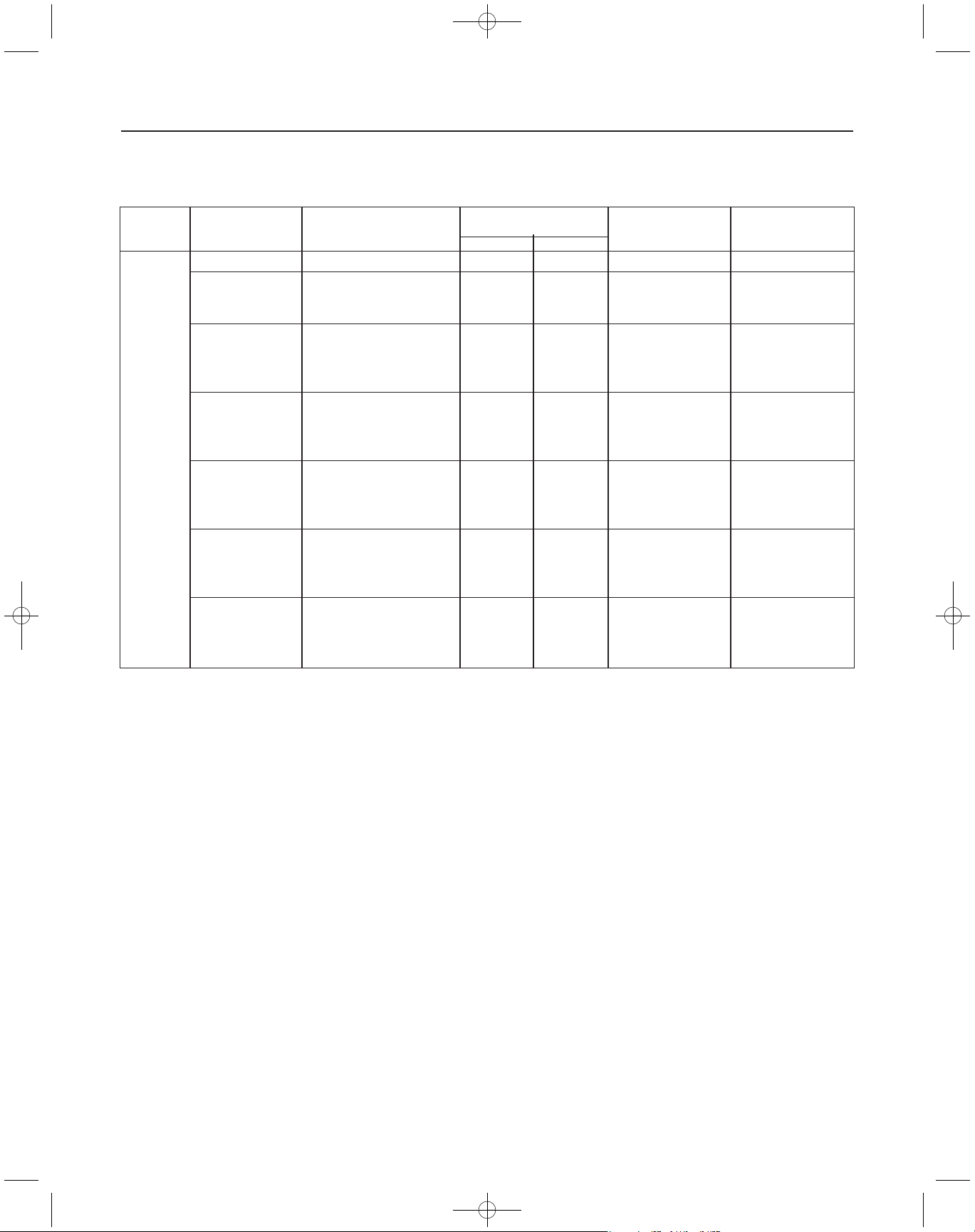

5.4 4” Motor Specifications

5.5 4” Motor Dimensions

5.6 4” Motor Fuse Sizing

5.7 Cable Lengths

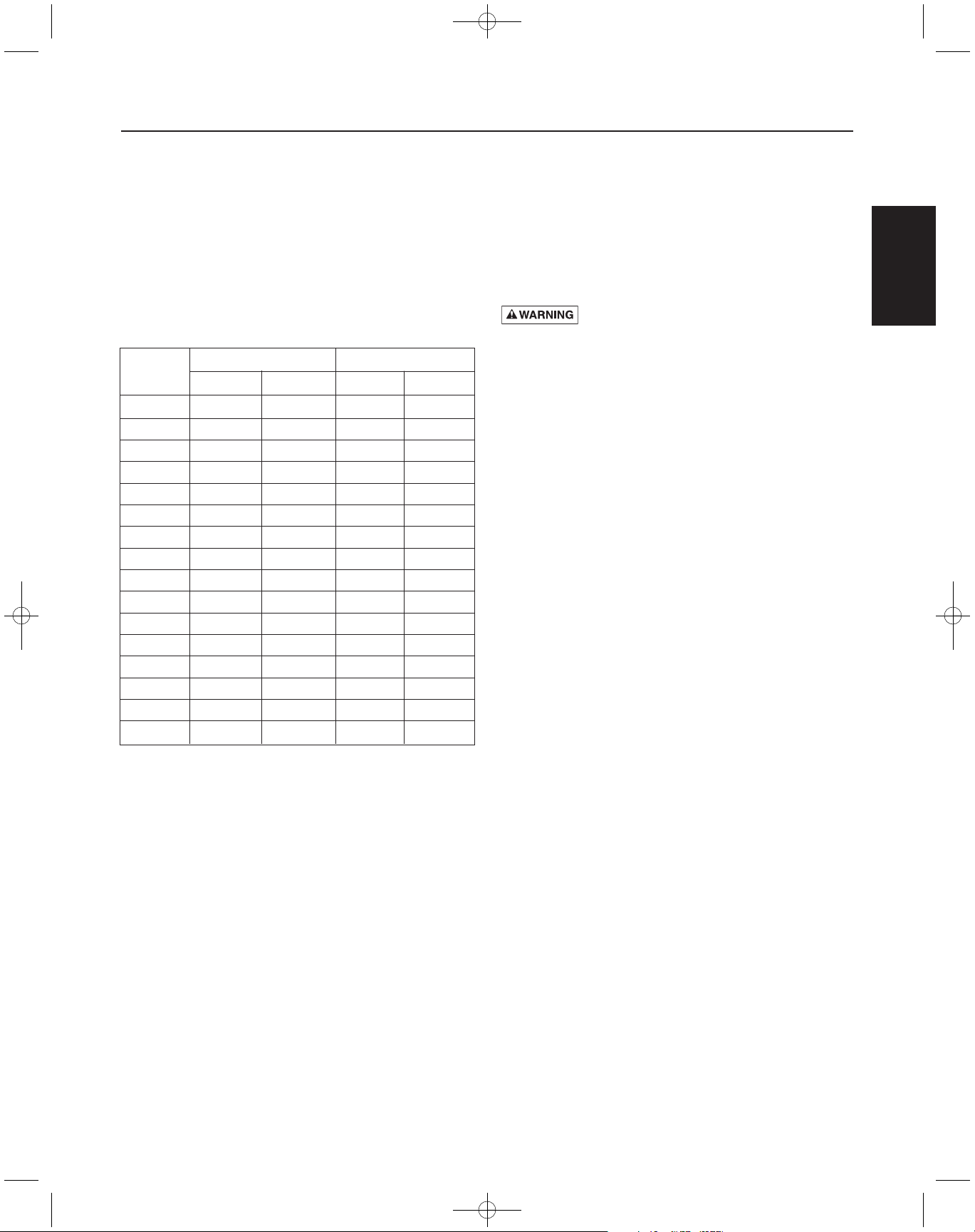

5.8 4” Motor Overload Protection

5.9 Motor Cooling

5.10 Starting Frequency

6. VARIABLE FREQUENCY DRIVES

PID-1, PID-6 INTELLIDRIVE SERIES

6.1 General Safety

6.2 Description

6.3 Installation

6.4 Initial Startup Programming Procedure

6.5 Advanced Programming

6.6 I/O Connections

6.7 Troubleshooting

6.8 Wire Sizing, Repair Parts, Specifications

7. VARIABLE FREQUENCY DRIVES – PPC20

7.1 How Drives Work

7.2 How the PPC20 Drive Works

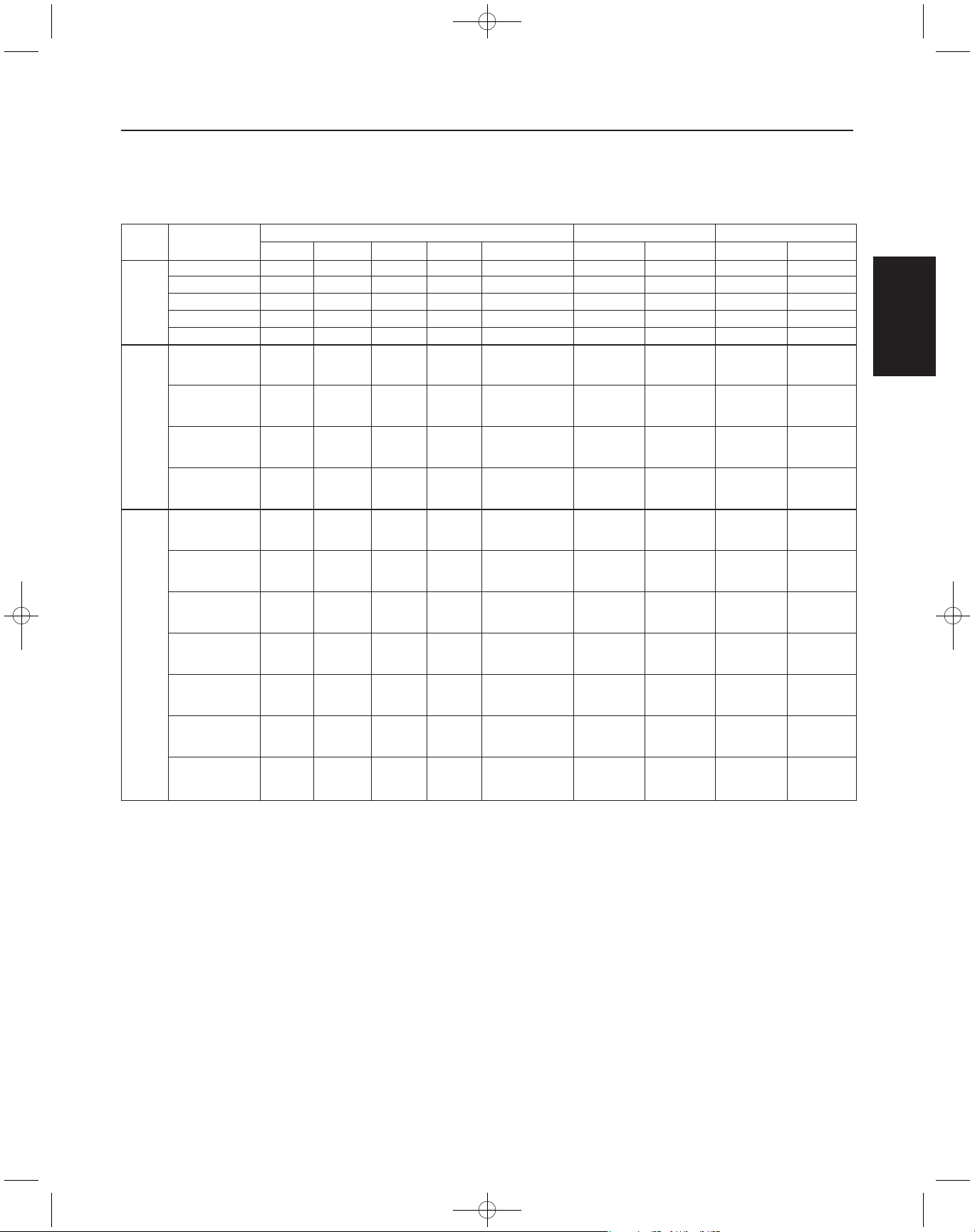

7.3 PPC20 Specifications

7.4 PPC20 Mounting and Installation

7.5 Wiring Connections

7.6 Start-up Operation

7.7 LED Fault Codes

7.8 PPC20 Replacement Parts

8. VARIABLE FREQUENCY DRIVES –

50/60 HZ; PPC3, PPC5 SERIES

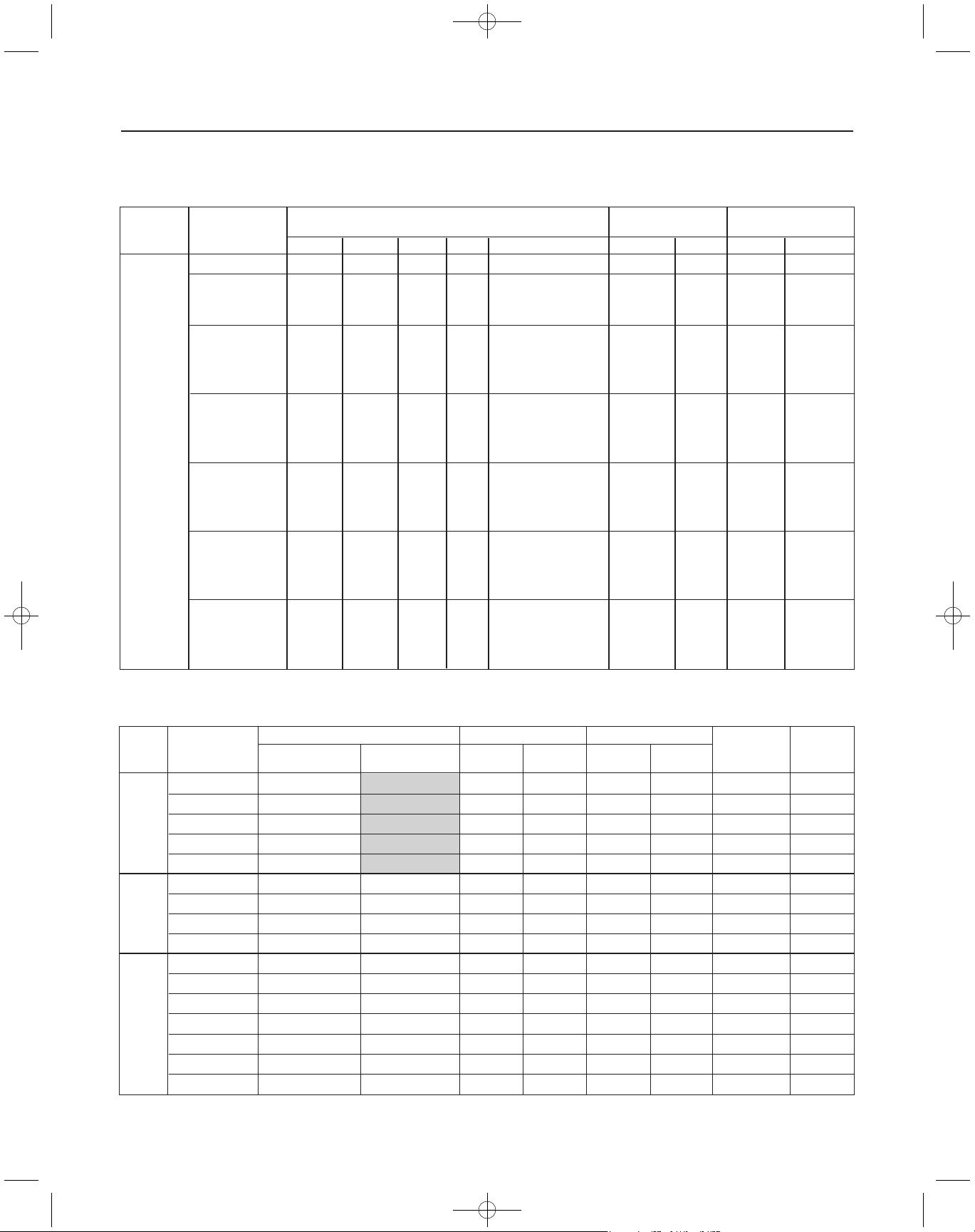

8.1 PENTEK PPC3 and PPC5 Drives

8.2 PPC3 Specifications

8.3 PPC5 Specifications

8.4 Wiring Conections

8.5 Transducer Connection

8.6 PENTEK Assistant

8.7 Timer Function

8.8 Helpful Hints

8.9 PPC3 and PPC5 Tank Sizing

8.10 Reactors and Filters

9. SUBMERSIBLE MOTOR CONTROLS –

50/60 HZ

9.1 How It Works

9.2 Specifications

9.3 Mounting and Installation

9.4 Wiring Connections and Replacement Parts

10. MOTOR PROTECTION DEVICES –

50/60 HZ

10.1 How They Work

10.2 Specifications

10.3 Mounting and Installation

10.4 Wiring Connections

PN793 (Rev. 11/09)

Table of Contents 1

PN793 11/20/09 9:21 AM Page 1

Page 2

Table of Contents 2

SECTION 1: General Safety Guidelines

11. TROUBLESHOOTING

11.1 System Troubleshooting

11.2 Motor Troubleshooting

11.3 Variable Speed Drive Troubleshooting

11.4 Motor Protection Troubleshooting

11.5 Submersible Controls Troubleshooting

12. APPENDIX

12.1 Installation Checklist

12.2 Choosing a Pump System

12.3 Sizing Submersible Pump, Motor,

and Tanks

12.4 How to Select the Correct

Pumping Equipment

12.5 Sizing Tanks

12.6 Record of Installation

PN793

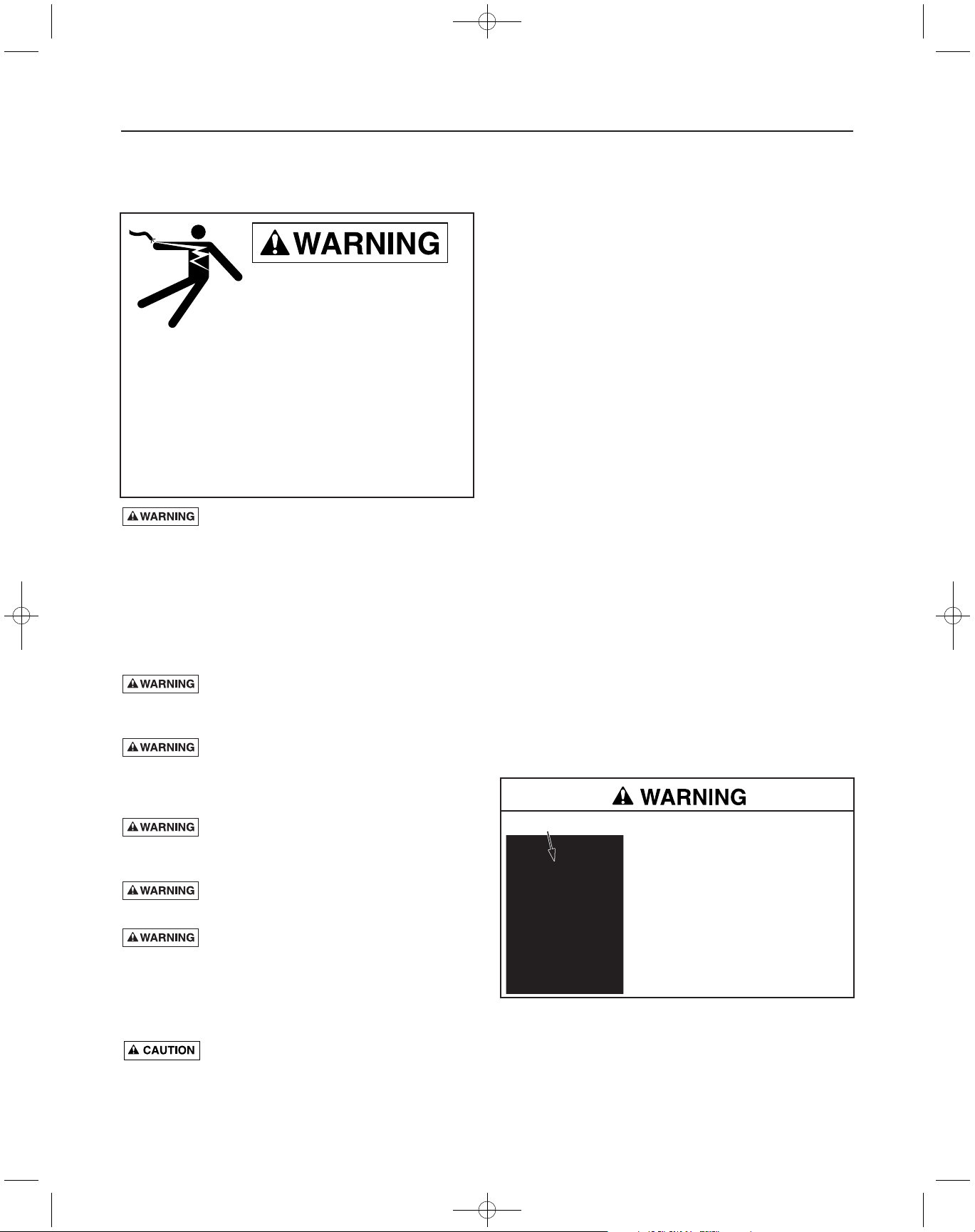

READ AND FOLLOW

SAFETY INSTRUCTIONS!

This is the safety alert symbol. When you see this

symbol on your pump or in this manual, be alert to the

potential for personal injury.

warns about hazards that will cause serious

personal injury, death or major property damage if ignored.

warns about hazards that can cause serious

personal injury, death or major property damage if ignored.

warns about hazards that will or can cause

minor personal injury or property damage if ignored.

The word NOTICE indicates special instructions which are

important but not related to hazards.

Carefully read and follow all safety instructions in this

manual and on pump.

Keep safety labels in good condition.

Replace missing or damaged safety labels.

Fatal Electrical Shock Hazard.

• Ground motor, controls, all metal pipe and accessories

connected to the motor, to the power supply ground

terminal. Ground wire must be at least as large as

motor supply cables.

• Disconnect power before working on the system.

• Do not use the motor in a swimming area.

Hazardous voltage.

Can shock, burn, or

cause death.

Ground pump before

connecting to power

supply.

All work must be done by a

trained and qualified installer

or service technician.

PN793 11/20/09 9:21 AM Page 2

Page 3

SECTION 2: Nomenclature 3

PN793

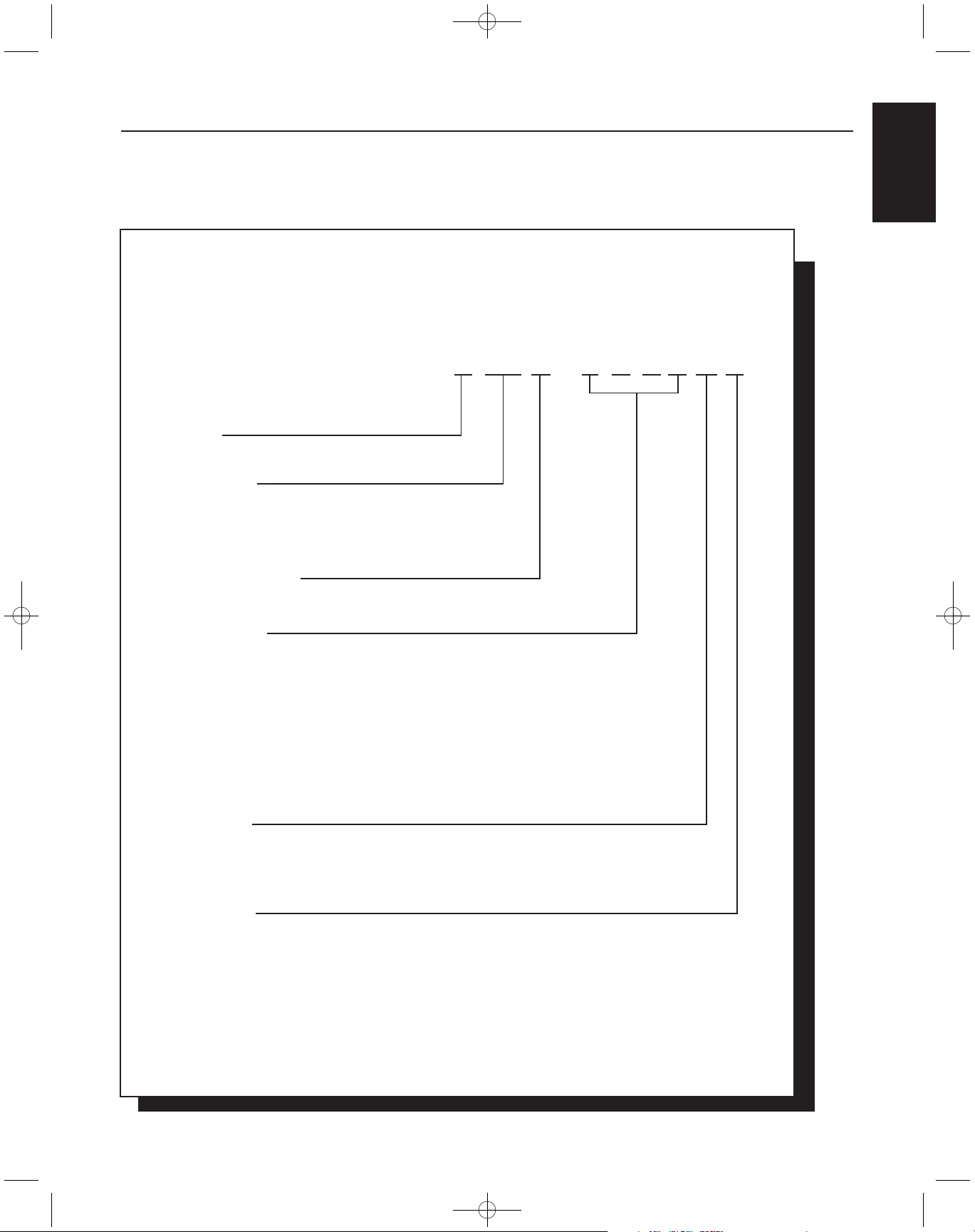

2.1 MOTORS

TABLE 2-1: Motor Nomenclature

Nomenclature

PN793 11/20/09 9:21 AM Page 3

Sample:

P43B0010A2 is a PENTEK 4" Stainless Steel Motor

1 HP, 60 Hz., 230 V, 1 PH

NAME PLATE EXAMPLE:

BRAND

P = PENTEK

MOTOR SIZE

42 = 4 Inch, 2-Wire

43 = 4 Inch, 3-Wire

MOTOR MATERIAL

B = All Stainless Steel

HORSEPOWER

0005 = 0.5 HP

0007 = 0.75 HP

0010 = 1 HP

0015 = 1.5 HP

0020 = 2 HP

0030 = 3 HP

0050 = 5 HP

0075 = 7.5 HP

P43B 001 A

0 2

FREQUENCY

A = 60 Hz.

B = 50 Hz.

C = 50/60 Hz.

VOLTAGE

1 = 115V, 1 PH

2 = 230V, 1 PH

3 = 230V, 3 PH

4 = 460V, 3 PH

5 = 575

V, 3 PH

8 = 200V, 3 PH

Page 4

SECTION 2: Nomenclature 4

PN793

2.2 DRIVES

2.2.1 Variable / High Speed Drive

Nomenclature

The chart below shows the naming for a PPC5, 460 volt, 4

amp drive with a NEMA 1 enclosure.

Note that the output current (amps) of the control must be

greater than or equal to the maximum rated motor current.

Output of all drives is 3-phase power.

2.2.2 PID Variable frequency drive

Nomenclature

2.3 SUBMERSIBLE MOTOR

CONTROLS

The chart below shows the naming for a Submersible

Motor control, Standard box, capacitor run, 10 horse

power, 230 volt single phase drive.

Series Input Voltage Output Amp Rating Enclosure

PPC5 2 (230 V, 3 ph.) 4A1 1 (NEMA 1)

PPC3 4 (460 V), 3 ph.) 4 (NEMA 4)

5 (575 V), 3 ph.) 12 (NEMA 12)

1 (230 V, 1 ph.) 3 (NEMA3R)

PPC5-4-4A1-1

4A1 = 4.1 amps

(Amps A tenths)

SMC

Voltage Rating:

1 = 190–265 Volt 1-Phase In,

3-Phase Out

6 = 190–265 Volt 1-Phase In,

1-Phase Out

PID – 1 – 10A1 – 1

PID-1- 10A1-1:

Product Family

PID = Pentek IntelliDrive

Max Amp Rating:

4A7 = 4.7 Amps

7A6 = 7.6 Amps

9A7 = 9.7 Amps

10A1 = 10.1 Amps

12A2 = 12.2 Amps

Enclosure Type:

1 = NEMA 1 (Indoor Rated)

3 = NEMA 3R (Outdoor Rated)

PN793 11/20/09 9:21 AM Page 4

- CR 100 2 1

Series

SMC_(Std.)

SMC5 (50 Hz)

Style

CR (Cap Run)

IR (Induction Run)

CRP (Cap Run

with contactor)

HP x 10

05 (0.5 hp)

07 (.75 hp)

10 (1 hp)

15 (1.5 hp)

20 (2 hp)

30 (3 hp)

50 (5 hp)

75 (7.5 hp)

100 (10 hp)

150 (15 hp)

Voltage

1 (115 v)

2 (230 v)

Phase

1 (Single)

Page 5

3.1 GENERAL INSTALLATION

GUIDELINES

• In order to avoid abrasion to the power and control

cables, pad the top of the well casing (a rubber pad is

recommended) where the cable will pass over it; use a

cable reel for cable control.

• The unit must always be easy to rotate in the hoisting

gear.

• Lay power and control cables out straight on the

ground (no loops) before installation. Guide cables

during lowering so that they are not stretched or

squeezed while pump is being installed. Make sure

that cable insulation is not nicked or damaged before

or during installation. Never use the electrical cables to

move the motor/pump.

• The pump and motor are heavy. Make sure that all

connections are secure and that the hoisting gear is

adequate to do the job before starting to lift pump.

Don’t stand under the unit. Don’t allow extra people

into the area while hoisting the unit.

• If motor or pump/motor unit are attached to a

supporting girder, do not remove girder until unit is

vertical.

• Install pump at least 10’ (3m) below the lowest water

level during pumping, but at least 6’ (2m) above the

bottom of the well.

• 6" motors must be installed in a vertical position only.

• 4" motors can be operated in vertical or horizontal

positions. Note that the thrust bearing will have shorter

life in a non-vertical application. In such an

installation, keep frequency of starts to less than 10 per

day.

3.2 PROPER GROUNDING

Hazardous voltage. Can shock, burn or

cause death. Installation or service to electrical equipment

should only be done by qualified electrician.

Control panels must be connected to supply ground

Proper grounding serves two main purposes:

1. It provides a path to ground in case of a ground-fault.

Otherwise the current would present a shock or

electrocution hazard.

2. It protects equipment from electrical surges.

Use wire the same size as, or larger than motor’s currentcarrying wires (consult Tables in the motor section).

Installations must comply with the National Electric Code

as well as state and local codes.

All systems must have lightning (surge) protection with a

secure connection to ground.

The grounding should extend to the water-bearing layer to

be effective.

Ground to casing if it is metal, and extends within 20’ of

motor.

If a metal drop pipe is used, then ground to the drop pipe.

Do not ground only to the supply ground or driven

grounding rod. These will not protect the pump.

All motors are internally grounded and requires a 3 or

4-wire drop cable.

3.3 CORROSIVE WATER AND

GROUND

Some waters are corrosive, and can eventually corrode the

ground wire. If the installation uses a metal well casing,

any ground current will flow through it. In the case of

plastic piping and casing, the water column would carry

the current in a ground fault situation.

To prevent this, route the motor ground wire and the motor

power leads through a GFCI with a 10 mA set point. In this

way, the GFCI will trip when a ground fault has occurred

AND the motor ground wire is no longer functional.

3.4 CHECK VALVES

Check valve installation is necessary for proper pump

operation. The pump should have a check valve on its

discharge, or within 25 feet (7.62 m) of the pump. For

very deep wells, locate a check valve at least every 200

feet (61 m).

• Use only spring type or gravity-poppet check valves.

Swing type valves can cause water hammer problems.

• Do not use drain-back style check valves (drilled).

Check valves serve the following purposes:

•

Maintain Pressure:

Without a check valve, the pump

has to start each cycle at zero head, and fill the drop

pipe. This creates upthrust in the motor, and would

eventually damage both the pump and motor.

•

Prevent Water Hammer:

If two check valves are used,

and the lower one leaks, then a partial vacuum forms

in the pipe. When the pump next starts, the flow fills

the void area quickly, and creates a shock wave that

can break piping and damage the pump. If you get

water hammer on pump start, this may be the cause.

•

Prevent Back-Spin:

Without a functioning check valve,

upon shutoff, the water drains back through the pump,

and cause it to rotate backwards. This can create

excessive wear on the thrust bearing, and if the pump

restarts as water is flowing down the pipe, it will put an

excessive load on the system.

SECTION 3: Installation and Setup 5

PN793

Installation

and Setup

PN793 11/20/09 9:21 AM Page 5

Page 6

PN793

SECTION 3: Installation and Setup 6

3.5 START-UP

NOTICE: To avoid sand-locking pump, follow procedure

below when starting pump for the first time. NEVER start a

pump with discharge completely open unless you have

done this procedure first.

1. Connect a pipe elbow, a short length of pipe and a

gate valve to pump discharge at well head.

2. Make sure that controls will not be subjected to

extreme heat or excess moisture.

3. Make sure power is OFF. DO NOT START PUMP YET.

4. Set gate valve on discharge 1/3 open; start pump.

5 Keep gate valve at this setting while water pumps out

on ground. Let it run until water is clear of sand or silt.

(To check solids in water, fill a glass from pump and let

solids settle out).

6. When water is completely clear at 1/3 setting, open

gate valve to approximately two-thirds open and repeat

process.

7. When water is completely clear at 2/3 setting, open

gate valve completely and run pump until water is

completely clear.

8. Do not stop the pump until the water is clear.

Otherwise sand will accumulate in the pump stages

which may bind or freeze the pump.

9. Remove gate valve and make permanent installation.

NOTICE: The motor may draw higher than normal current

while the riser pipe is filling. After the riser pipe is full, the

amp draw should drop back to less than the allowed

current given on the motor nameplate.

When pump is in service, the amp draw must be

approximately equal to or lower than the service factor

amps given on the motor nameplate. If not, recheck entire

installation and electrical hook-up to find out why amp

draw is higher than normal.

Motor Torque

The motor exerts a strong torque force on the downpipe

and any other supporting structures when it starts. This

torque is usually in the direction that would unscrew righthand threads (the motor’s reaction movement is clockwise

as seen from above).

All pipe and pump joints must be tightened to safely

handle the starting torque. Tighten all threaded joints

to a minimum of 10 ft.-lb per horsepower. i.e.

20 HP = 200 ft.-lb; 50 HP = 500 ft.-lb.

Tack welding or strap welding may be required with higher

horsepower pumps.

PN793 11/20/09 9:21 AM Page 6

Page 7

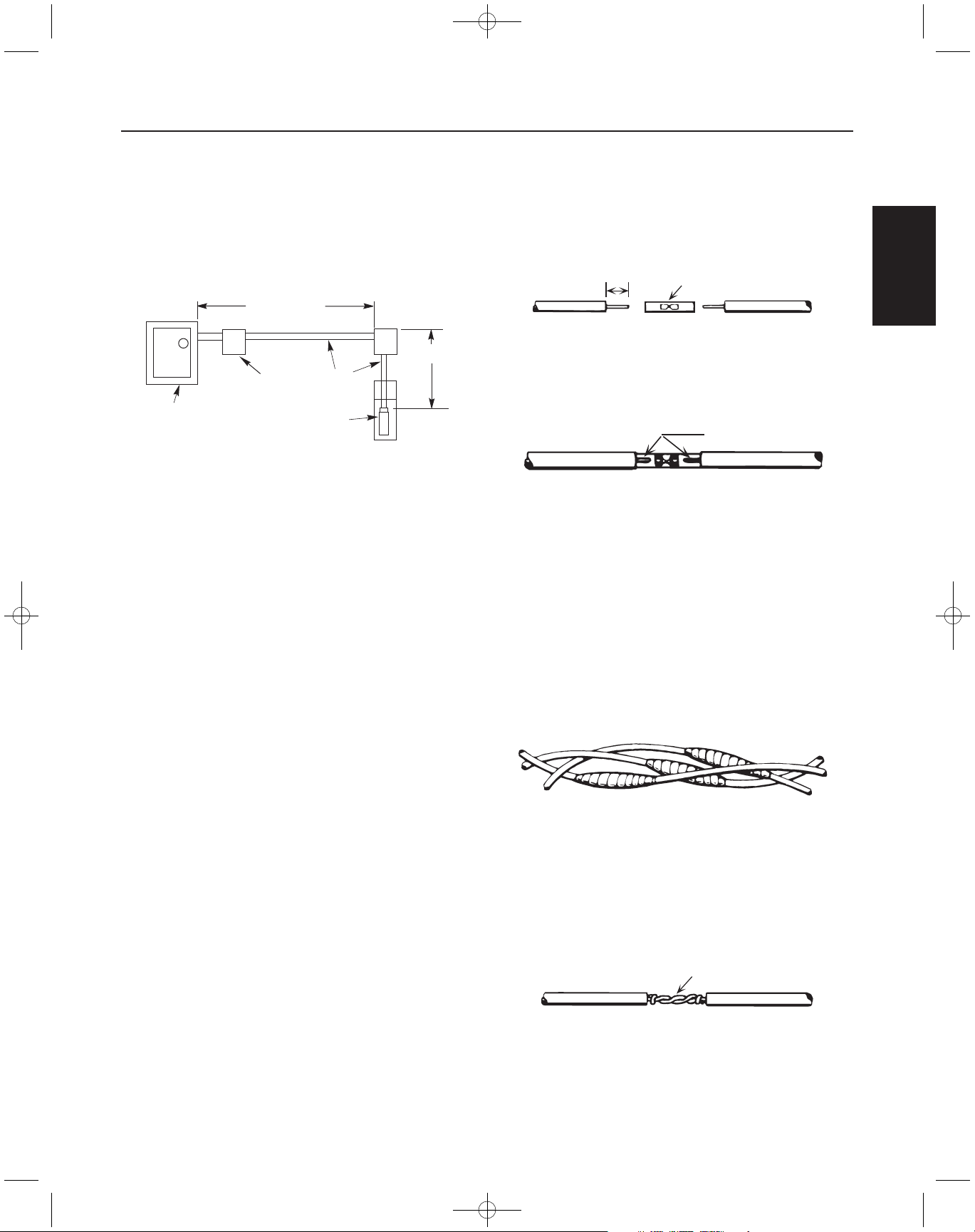

4.1 MIXING WIRE SIZE WITH

EXISTING INSTALLATION

Using two different cable sizes.

Sometimes conditions make it desirable to use more than

one size cable, such as replacing a pump in an existing

installation.

For example: Installing a pump with a 6”, 5 HP, 230 volt,

single phase motor, with the motor setting at 250' (76.2 m)

down the well and with 120' (36.5 m) of #8 cable buried

between the service entrance and the well head. In order

to avoid replacing the buried cable, the question is: What

size cable is required in the well? Calculate as follows:

1. According to Table 7-7, a total of 269' (82 m) of #8

cable is the maximum length cable to power a 5 HP

motor. The percent of this total that has been used by

the 120' (36.5 m) of cable in the buried run is:

120'/269' = .446 = 45%.

2. With 45% of the allowable cable already used, 55% of

the total length is left for use in the well. To avoid

running a cable that is too small (gauge) and lowering

the voltage to the motor, we have to find a cable size

large enough so that 250' (76.2 m) is less than 55% of

the total length allowed for that size.

3. 250 ÷ 55% = 455 feet.

4. From Table 7-7 we find that the total allowable length

for #4 cable is 667'.

This is longer than needed. Therefore, #4 cable can be

used for the 250' (76.2 m) of cable in the well.

Any combination of sizes can be used, provided that

the total percentage of the length of the two sizes of

cable is not less than 100% of the allowed lengths.

4.2 WIRE SPLICING

Splice wire to motor leads. Use only copper wire for

connections to pump motor and control box.

1. Taped splice (for larger wire sizes)

A. Stagger lead and wire length so that 2nd lead is 2"

(50mm) longer than 1st lead and 3rd lead is 2"

(50mm) longer than second.

B. Cut off power supply wire ends. Match colors and

lengths of wires to colors and lengths of motor

leads.

C. Trim insulation back 1/2" (13mm) from supply wire

and motor lead ends.

D. Insert motor lead ends and supply wire ends into

butt connectors. Match wire colors between supply

wires and motor leads.

E. Using crimping pliers, indent butt connector lugs to

attach wires.

F. Cut Scotchfil

TM

electrical insulation putty into 3

equal parts and form tightly around butt connectors.

Be sure Scotchfil overlaps insulated part of wire.

G. Using #33 Scotch tape, wrap each joint tightly;

cover wire for about 1-1/2" (38mm) on each side of

joint. Make four passes with the tape. When

finished you should have four layers of tape tightly

wrapped around the wire. Press edges of tape firmly

down against the wire.

NOTICE: Since tightly wound tape is the only means of

keeping water out of splice, efficiency of splice will

depend on care used in wrapping tape.

NOTICE: For wire sizes larger than No. 8 (7mm

2

), use

soldered joint rather than Scotchfil putty.

Figure 4-1: Mixing Wire Sizes: Example

Cable

Pump

Controls

Service Entrance

(Main Fuse Box

From Meter)

5 HP (4.9 kw)

230V 1Ph Motor

120 Ft. AWG 8

250 Ft.

Figure 4-2: Insert Wires

Indent here

Figure 4-4:Wrap Splices

Completed splice

Alternate method

twist and solder

Electrical Power

Figure 4-5:Twist Wires

Figure 4-3: Indent Connectors

SECTION 4: Electrical Power 7

PN793

PN793 11/20/09 9:21 AM Page 7

1/2"

(12.7mm)

Butt Connector

Page 8

PN793

2. Heat shrink splice (For wire sizes #14, 12 and 10 AWG

(2, 3 and 5mm2):

A. Remove 3/8" (9.5mm) insulation from ends of motor

leads and power supply wires.

B. Put plastic heat shrink tubing over motor leads

between power supply and motor.

C. Match wire colors and lengths between power

supply and motor.

D. Insert supply wire and lead ends into butt connector

and crimp. Match wire colors between power

supply and motor. Pull leads to check connections.

E. Center tubing over butt connector and apply heat

evenly with a torch (match or lighter will not supply

enough heat).

NOTICE: Keep torch moving. Too much concentrated heat

may damage tubing.

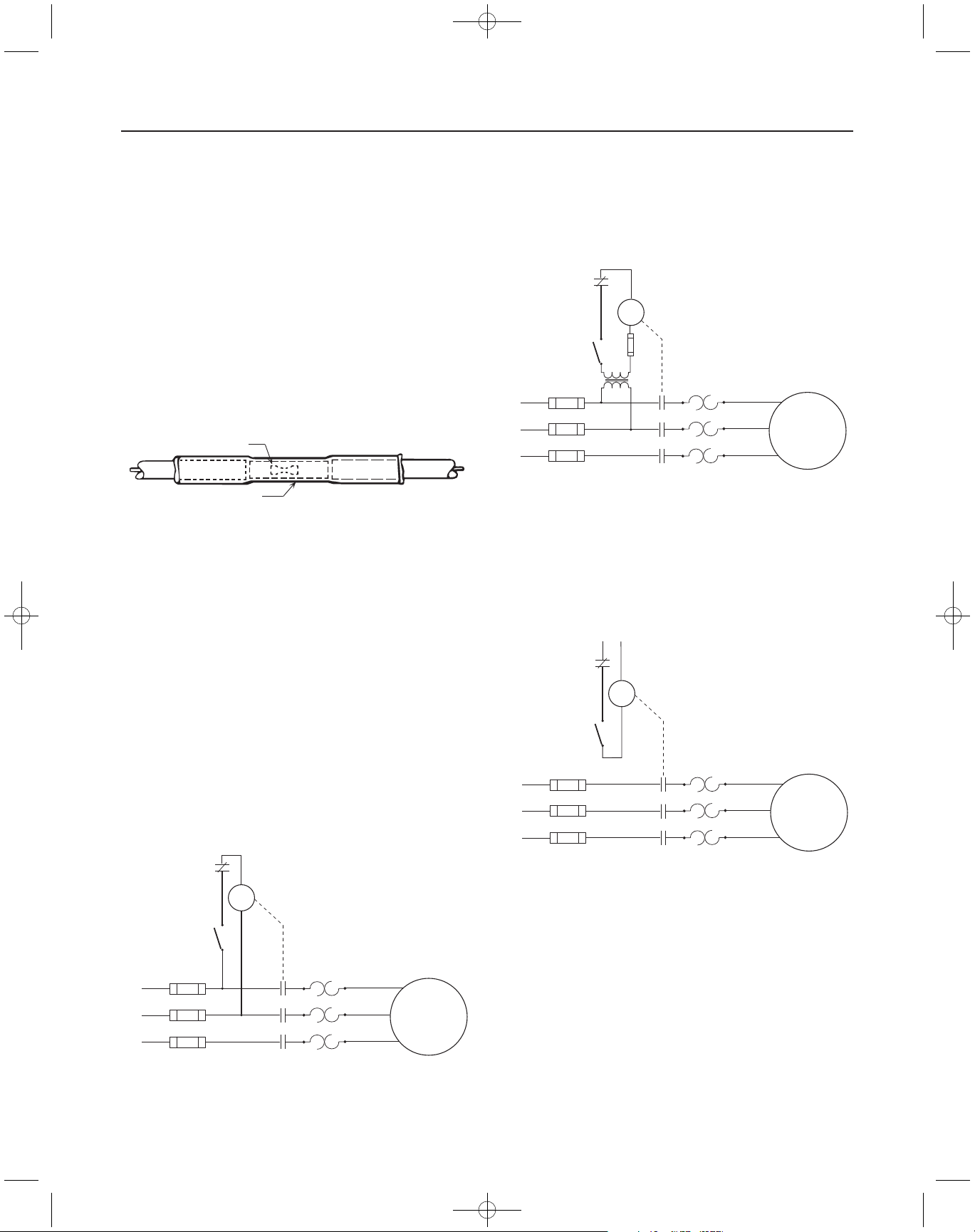

4.3 THREE-PHASE STARTERS

Starters are used to start the motor by engaging contacts

that will energize each line simultaneously. The contacts

are closed when the coil is energized.

Figures 4-7 through 4-9 show three types of starters used

on the motors. The control device in the secondary circuit

is typically a pressure switch. Other control could be

provided by level control, timers or manual switches.

Line Voltage Control

This commonly-used control has a coil energized by line

voltage. The coil voltage matches the line voltage.

Low Voltage Control

This starter arrangement uses a transformer to allow the

coil to be energized by a lower voltage. Note that the

secondary circuit must be fused, and the coil sized for the

secondary voltage.

Separate Voltage Control

This arrangement uses power from a separate source to

energize the coil.

SECTION 4: Electrical Power 8

Figure 4-6: Heat-Shrink Tubing Applied

Connector

Heat shrink tubing

Figure 4-8: Low Voltage Control

Figure 4-9: Separate Voltage Control

Figure 4-7: Line Voltage Control

PN793 11/20/09 9:21 AM Page 8

Overload

Control

Coil

Control

Device

Thermal

Overload

L1

L2

Heaters

3-Phase

Motor

L3

Separate

Voltage

Overload

Control

Coil

Control

Device

Thermal

Overload

L1

L2

Heaters

3-Phase

Motor

L3

Overload

Control

Coil

Control

Device

L1

L2

L3

Thermal

Overload

Heaters

3-Phase

Motor

Page 9

PN793

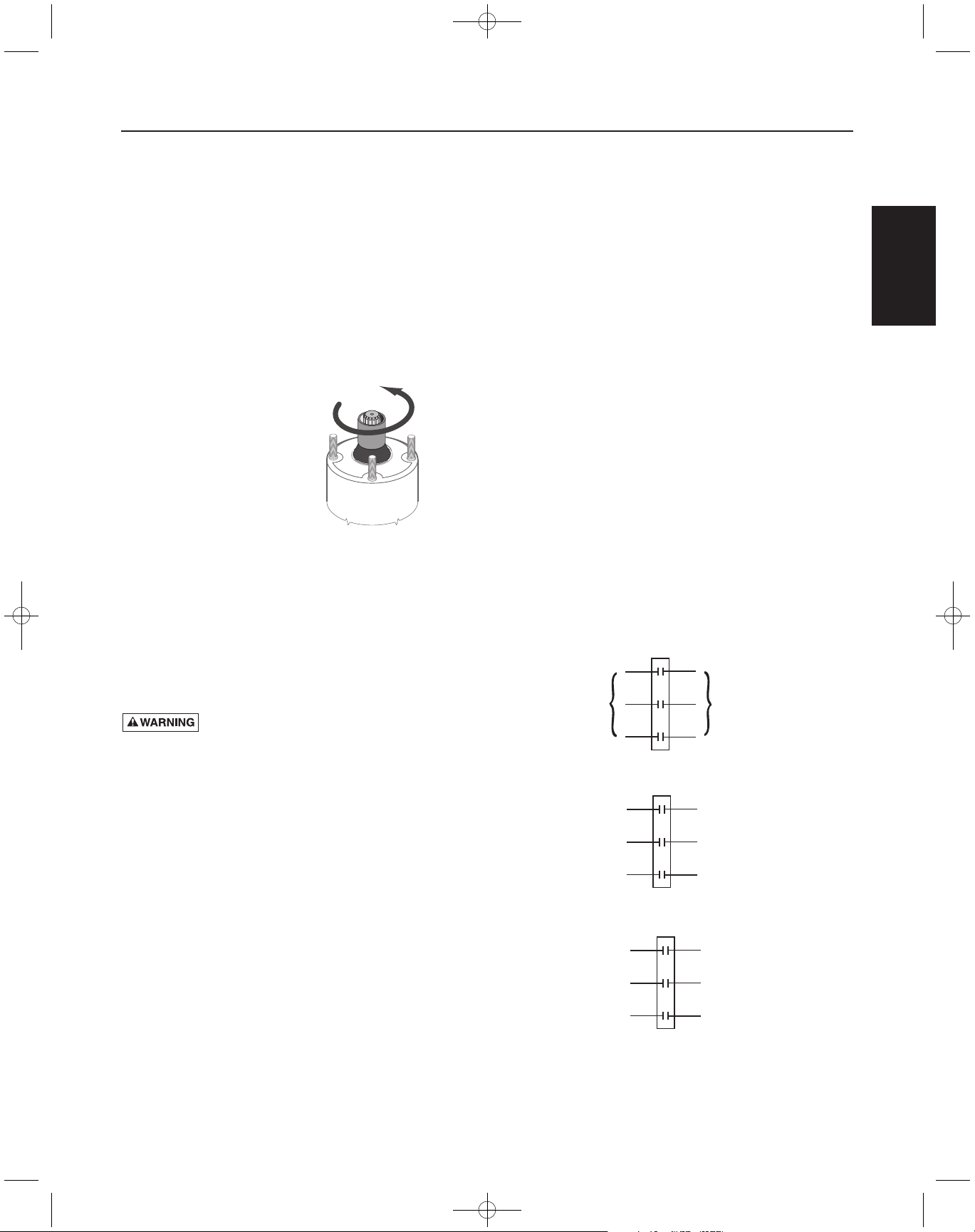

4.4 CHECKING MOTOR ROTATION

To check rotation before the pump is installed, follow

these steps:

During testing or checking rotation (such as “bumping” or

“inching”) the number of “starts” should be limited to 3

and total run time of less than 15 seconds.

Bumping must be done while motor is in horizontal

position and followed by a full 15-minute cooling-off

period before any additional “starts” are attempted.

Energize the motor briefly, and observe the direction of

rotation. It should be counter-clockwise when viewed from

the pump (shaft) end.

To check rotation after

the pump is installed:

NOTICE: NEVER

continuously operate a

pump with the discharge

valve completely closed

(dead head). This can

overload the motor or

destroy the pump and

will void the warranty.

After energizing the motor, check the flow and pressure of

the pump to make sure that the motor is rotating in the

correct direction. To correct a wrong rotation, switch “any

two of the three cable connections. (Three-phase motor

only). The setting that gives the most flow and pressure is

correct.

A cooling-off period of 15 minutes is required between

starts.

Hazardous voltage. Disconnect power

before working on wiring.

Input voltage, current and insulation resistance values

should be recorded throughout the installation and should

be used for preventive maintenance.

4.5 3-PHASE CURRENT BALANCING

Current Unbalance Test

Before checking for current unbalance, the pump must be

started, and rotation direction determined.

Determine current unbalance by measuring current in each

power lead. Measure current for all three possible hookups

(Figure 4-11). Use example and worksheet on the

Installation Checklist and Record in Section 12 to calculate

current unbalance on a three phase supply system and

retain for future reference.

NOTICE: Current unbalance between leads should not

exceed 5%. If unbalance cannot be corrected by rolling

the leads, locate the source of the unbalance.

Here is an example of current readings at maximum pump

loads on each leg of a three wire hookup. Make calculations for all three possible hookups.

A. For each hookup, add the readings for the three legs.

B. Divide each total by three to get average amps.

C. For each hookup, find current value farthest from aver-

age (Calculate the greatest current difference from the

average).

D. Divide this difference by the average and multiply by

100 to obtain the percentage of unbalance.

Use smallest percentage unbalance, in this case

Arrangement 2 (Table 4.1).

Use the Current-Balance worksheet located in

the Installation Record

After trying all three lead hookups, if the reading furthest

from average continues to show on the same power lead,

most of the unbalance is coming from the power source.

Call the power company.

If the reading furthest from average changes leads as the

hookup changes (that is, stays with a particular motor

lead), most of the unbalance is on the motor side of the

starter. This could be caused by a damaged cable, leaking

splice, poor connection, or faulty motor winding.

SECTION 4: Electrical Power 9

Starter

Electrical

Power

Supply

To Motor

L1

L2

L3

T1

T2

T3

Arrangement 1

Starter

L1

L2

L3

T1

T2

T3

Arrangement 2

Starter

L1

L2

L3

T1

T2

T3

Arrangement 3

Figure 4-10: Motor Rotation

Figure 4-11: 3-Phase Current

Unbalance: Example

Electrical Power

PN793 11/20/09 9:21 AM Page 9

Page 10

PN793

Use this worksheet to calculate current unbalance for your

installation.

4.6 TRANSFORMER SIZING

The power supply to the installation must be capable of

furnishing enough power to the pump and associated

equipment.

Three-phase power may be furnished either through a

Delta-Delta, Wye-Delta or open Delta configuration. The

Delta-Delta uses three transformers to supply power to the

facility. The Wye-Delta and open Delta configuration use

only two transformers.

Transformers are rated by KVA capacity. This must be high

enough capacity for the motor being installed. If the

transformer capacity is too small, the motor will receive

reduced voltage and may be damaged.

Any other loads in the system would be in addition to the

motor alone.

Refer to the chart below. Note that the open delta

configuration can only use 87% of the rated power of the

two transformers.

SECTION 4: Electrical Power 10

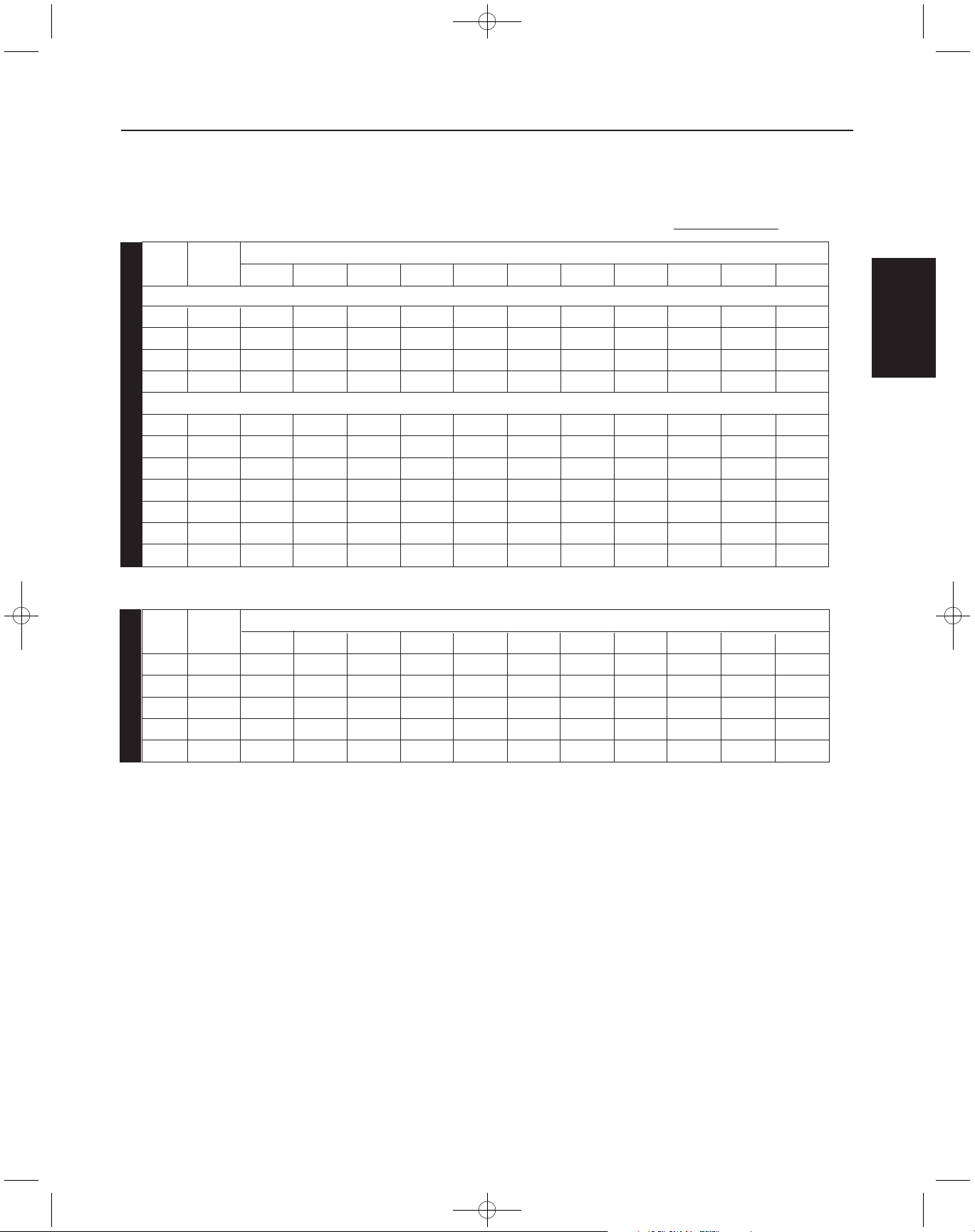

Arrangement 1 Arrangement 2 Arrangement 3

Amps Amps Amps

L1–T1=17 L1–T3=16.7 L1–T2=16.7

L2–T2=15.3 L2–T1=16.3 L2–T3=16

L3–T3=17.7 L3–T2=17 L3–T1=17.3

Total Amps 50 50 50

Average Amps 50 ÷ 3 = 16.7 50 ÷ 3 = 16.7 50 ÷ 3 =16.7

From Average Amps

Deviation L1 0.3 0.0 0.0

Deviation L2 1.4 0.4 0.7

Deviation L3 1.0 0.3 0.6

% Current Unbalance

Largest Deviation 1.4 ÷ 16.7 0.3 ÷ 16.7 0.7 ÷ 16.7

% Unbalance + 8.4% 1.8% 4.2%

TABLE 4-1: Electrical Current Unbalance Example

EXAMPLE

Figure 4-12: Three Phase Power

L1 L2 L3

Wye or Open Delta 3-Phase

L1

L2

L3

Full 3-Phase (Delta)

KVA Rating (smallest)

For Each Transformer

Open WYE Closed WYE

Required or D or D

HP kW KVA 2 Transformers 3 Transformers

1/2 0.37 1.5 1.0 0.5

3/4 0.55 1.5 1.0 0.5

1 0.75 2.0 1.5 0.75

1-1/2 1.1 3.0 2.0 1.0

2 1.5 4.0 2.0 1.5

3 2.2 5.0 3.0 2.0

5 3.7 7.5 5.0 3.0

7.5 5.5 10.0 7.5 5.0

10 7.5 15.0 10.0 5.0

15 11.0 20.0 15.0 7.5

20 15.0 25.0 15.0 10.0

25 18.5 30.0 20.0 10.0

30 22.0 40.0 25.0 15.0

40 30.0 50.0 30.0 20.0

50 37.0 60.0 35.0 20.0

60 45.0 75.0 40.0 25.0

TABLE 4-2: Transformer Capacity

PN793 11/20/09 9:21 AM Page 10

Page 11

PN793

4.7 USING A GENERATOR

Selecting a generator

Select a generator that can supply at least 65% of rated

voltage upon start-up of the motor.

The chart shows ratings of generators, both externally and

internally regulated. This chart is somewhat conservative.

Consult the generator manufacturer if you are uncertain.

Frequency

It is highly important that the generator maintain constant

frequency (Hz), since the motor’s speed depends upon

frequency.

A drop of just 1 to 2 Hz can noticeably lower pump

performance. An increase of 1 to 2 Hz can cause overload

conditions.

Voltage Regulation

There is a significant difference in the performance of

internally and externally regulated generators.

An external regulator senses output voltage dips and

triggers an increase in the voltage output of the generator.

An internal regulator, senses current and responds to

increased current by supplying more voltage.

Generator Operation

Start the generator before starting the pump motor.

The motor must be stopped before turning off the

generator.

If the generator runs out of fuel, and the pump is still

connected, it will put excess strain on the thrust bearings

as the generator slows.

Electrocution Hazard. Use transfer switches

when the generator is used as a backup to the power grid.

contact your power company for proper use of standby or

backup generators.

4.8 SPECIAL APPLICATIONS

4.8.1 Using Phase Converters

Phase converters allow three-phase motors to operate from

one-phase supply. Various styles of phase converters are

available. Many converters do not supply a properly

balanced voltage, and using these will void the motor’s

warranty unless approval is obtained first.

GUIDELINES FOR PHASE CONVERTERS:

• Current unbalance must be less than 5%.

• Converter to be sized to service factor capacity

• Maintain motor cooling with a cooling flow of at least

3’ per second.

• Fuses and circuit breakers must be time-delay type.

MOTOR STARTING WITH REDUCED VOLTAGE

Starting a motor with full voltage will bring it to full speed

in less than 1/2 second. This can:

• Spike the load current, causing brief voltage dips in

other equipment.

• Over-stress pump and piping components because of

high torque.

• Cause water hammer.

4.8.2 Motor Starters (3-Phase Only)

Various types of motor starters are available.

Autotransformers are recommended because of reduced

current draw.

When motor starters are used, they should supply a

minimum of 55% of rated voltage for adequate starting

torque.

SECTION 4: Electrical Power 11

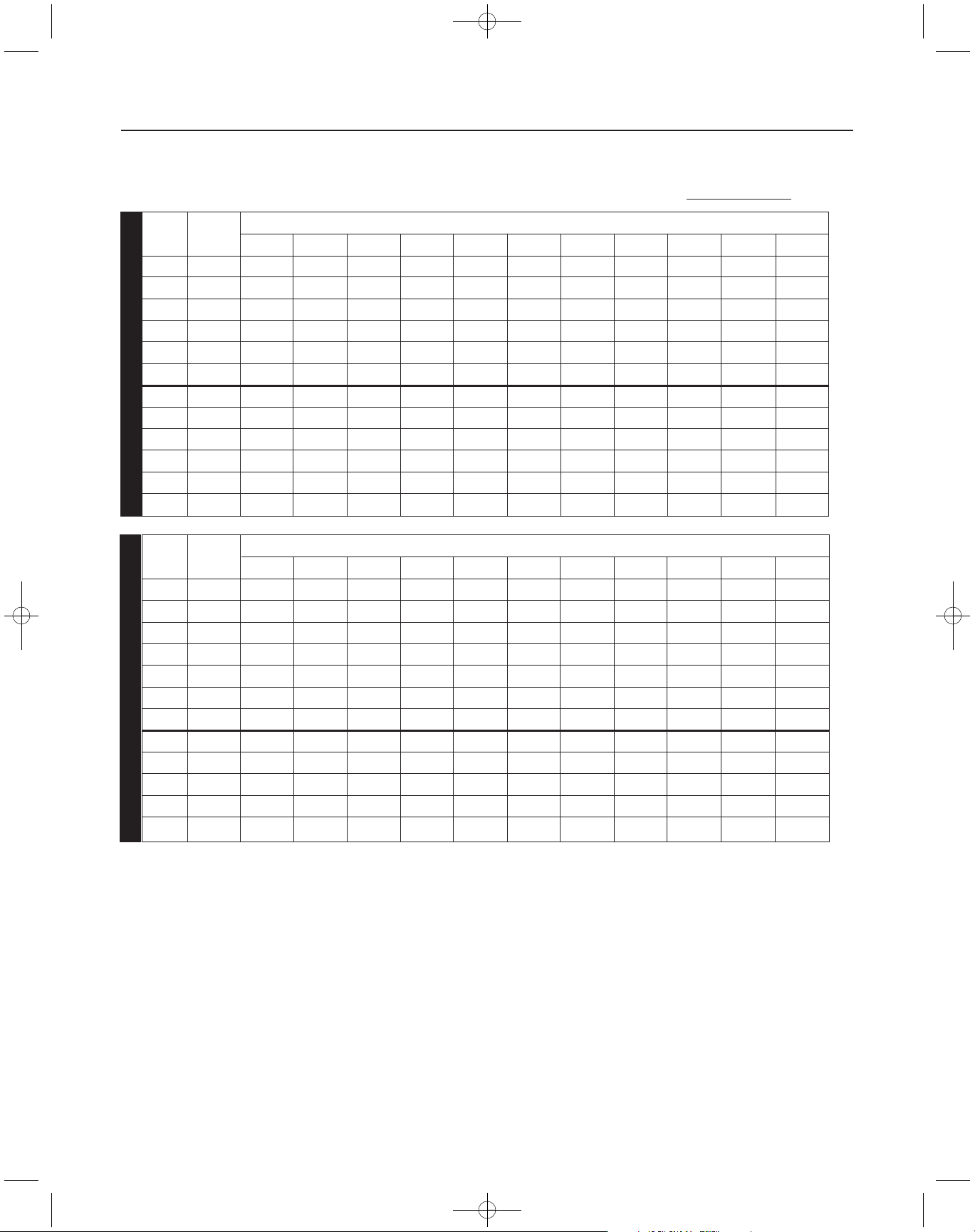

Motor

Externally Regulated Internally Regulated

HP kW KVA kW KVA

1/2 2.0 2.5 1.5 1.9

3/4 3.0 3.8 2.0 2.5

1 4.0 5.0 2.5 3.1

1-1/2 5.0 6.3 3.0 3.8

2 7.5 9.4 4.0 5.0

3 10.0 12.5 5.0 6.25

5 15.0 18.8 7.5 9.4

7-1/2 20.0 25.0 10.0 12.5

10 30.0 37.5 15.0 18.8

15 40.0 50.0 20.0 25.0

20 60.0 75.0 25.0 31.0

25 75.0 94.0 30.0 37.5

30 100.0 125.0 40.0 50.0

40 100.0 125.0 50.0 62.5

50 150.0 188.0 60.0 75.0

60 175.0 220.0 75.0 94.0

TABLE 4-3: Ratings of Generators

Electrical Power

PN793 11/20/09 9:21 AM Page 11

Page 12

5.1 MOTOR INSPECTION

Check the motor for damage in shipping.

Before installation, check the following.

• Check over all tools, especially the hoisting gear, for

wear or damage before hoisting unit.

• Inspect the motor cable for any nicks or cuts.

• Verify that motor nameplate data matches registration

card information exactly.

• Verify that motor nameplate voltage is correct for

available power supply voltage. Voltage must not vary

more than +/-10% from nameplate rated voltage.

• Verify that the well diameter is large enough to

accommodate the motor/pump unit all the way to the

pump setting depth.

• For installations with tight well casings, make sure that

riser pipe flanges are recessed to protect the power and

control cables from abrasion and squeezing during

installation.

Heavy object. Lifting equipment must be

capable of lifting motor and attached equipment.

• If the total length of the pump motor unit (without any

riser pipe) exceeds 10’ (3m), the unit must be

supported with a girder while hoisting. Do not remove

supporting girder until unit is standing vertically in the

hoist. Check for damage.

5.2 TESTING

Insulation Resistance

To check for insulation resistance:

Disconnect power to the motor for this test.

Connect an Ohm meter (resistance in Ω) between the

power leads and the motor ground or well casing.

20KΩ Damaged motor, possible result of

lightning strike.

500KΩ Typical of older installed motor in well.

2 MΩ Newly installed motor

10 MΩ Used motor, measured outside of well

20 MΩ New motor without cable

5.3 STORAGE AND TRANSPORTATION

Storage site should be clean, well vented, and cool.

Keep humidity at the storage site as low as possible.

Protect motor and cables from direct sunlight.

Protect power supply cables and control cables from

moisture by taping the cable ends with electrician’s tape.

Do not kink power supply or control cables.

Take care when moving unit (packed or unpacked) with

crane or hoisting gear not to knock it against walls, steel

structure, floors, etc. Do not drop motor.

Do not lift motor or motor/pump unit by power supply or

control cables.

SECTION 5: XE-Series 4" Submersible Motors - 60 Hz 12

PN793

PN793 11/20/09 9:21 AM Page 12

Page 13

5.4 4" MOTOR SPECIFICATIONS

SECTION 5: XE-Series 4" Submersible Motors - 60 Hz 13

XE-Series Motors

PN793

Motor

PENTEK

Rating Full Load Maximum (S.F. Load)

Type Part Number HP kW Volts Hz. Service Factor Amps Watts Amps Watts

P42B0005A1 1/2 0.37 115 60 1.6 7.4 845 9.5 1088

4" P42B0005A2 1/2 0.37 230 60 1.6 3.7 834 4.7 1073

2-Wire P42B0007A2 3/4 0.55 230 60 1.5 5.0 1130 6.4 1459

P42B0010A2 1 0.75 230 60 1.4 7.9 1679 9.1 1990

P42B0015A2 1-1/2 1.1 230 60 1.3 9.2 2108 11.0 2520

Y - 11.0 Y - 12.6

P43B0005A1 1/2 0.37 115 60 1.6 B - 11.0 733 B - 12.6 1021

R - 0.0 R - 0

Y - 5.5 Y - 6.3

P43B0005A2 1/2 0.37 230 60 1.6 B - 5.5 745 B - 6.3 1033

CSIR R - 0 R - 0

3-Wire Y - 7.2 Y - 8.3

P43B0007A2 3/4 .55 230 60 1.5 B - 7.2 1014 B - 8.3 1381

R - 0 R - 0

Y - 8.4 Y - 9.7

P43B0010A2 1 0.75 230 60 1.4 B - 8.4 1267 B - 9.7 1672

R - 0 R - 0

Y - 4.1 Y - 4.9

P43B0005A2 1/2 0.37 230 60 1.6 B - 4.1 720 B - 4.4 955

R - 2.2 R - 2.1

Y - 5.1 Y - 6.3

P43B0007A2 3/4 0.55 230 60 1.5 B - 5.0 1000 B - 5.6 1300

R - 3.2 R - 3.1

Y - 6.1 Y - 7.2

P43B0010A2 1 0.75 230 60 1.4 B - 5.7 1205 B - 6.3 1530

R - 3.3 R - 3.3

CSCR

Y - 9.7 Y - 11.1

P43B0015A2 1-1/2 1.1 230 60 1.3 B - 9.5 1693 B - 11.0 2187

3-Wire

R - 1.4 R - 1.3

Y - 9.9 Y - 12.2

P43B0020A2 2 1.5 230 60 1.25 B - 9.1 2170 B - 11.7 2660

R - 2.6 R - 2.6

Y - 14.3 Y - 16.5

P43B0030A2 3 2.2 230 60 1.15 B - 12.0 3170 B - 13.9 3620

R - 5.7 R - 5.6

Y - 24.0 Y - 27.0

P43B0050A2 5 3.7 230 60 1.15 B - 19.1 5300 B - 22.0 6030

R - 10.2 R - 10.0

TABLE 5-1: SINGLE PHASE Motor Specifications (115 and 230 Volt, 60 Hz, 3450 RPM)

PN793 11/20/09 9:21 AM Page 13

Page 14

SECTION 5: XE-Series 4" Submersible Motors - 60 Hz 14

PN793

Maximum Load

Motor PENTEK Rating Full Load (SF Load)

Type Part Number HP kW Volts Hz Service Factor Amps Watts Amps Watts

P43B0007A8 3/4 0.55 200 60 1.5 3.8 812 4.5 1140

P43B0010A8 1 0.75 200 60 1.4 4.6 1150 5.5 1500

P43B0010A3 1 0.75 230 60 1.4 4.0 1090 4.7 1450

P43B0010A4 1 0.75 460 60 1.4 2.2 1145 2.5 1505

P43B0015A8 1 1/2 1.1 200 60 1.3 6.3 1560 7.2 1950

P43B0015A3 1 1/2 1.1 230 60 1.3 5.2 1490 6.1 1930

P43B0015A4 1 1/2 1.1 460 60 1.3 2.8 1560 3.2 1980

P43B0015A5 1 1/2 1.1 575 60 1.3 2 1520 2.4 1950

3-Phase P43B0020A8 2 1.5 200 60 1.25 7.5 2015 8.8 2490

P43B0020A3 2 1.5 230 60 1.25 6.5 1990 7.6 2450

P43B0020A4 2 1.5 460 60 1.25 3.3 2018 3.8 2470

P43B0020A5 2 1.5 575 60 1.25 2.7 1610 3.3 2400

P43B0030A8 3 2.2 200 60 1.15 10.9 2890 12.0 3290

P43B0030A3 3 2.2 230 60 1.15 9.2 2880 10.1 3280

P43B0030A4 3 2.2 460 60 1.15 4.8 2920 5.3 3320

P43B0030A5 3 2.2 575 60 1.15 3.7 2850 4.1 3240

P43B0050A8 5 3.7 200 60 1.15 18.3 4850 20.2 5515

P43B0050A3 5 3.7 230 60 1.15 15.7 4925 17.5 5650

P43B0050A4 5 3.7 460 60 1.15 7.6 4810 8.5 5530

P43B0050A5 5 3.7 575 60 1.15 7.0 5080 7.6 5750

P43B0075A8 7 1/2 5.6 200 60 1.15 27.0 7600 30.0 8800

P43B0075A3 7 1/2 5.6 230 60 1.15 24.0 7480 26.4 8570

P43B0075A4 7 1/2 5.6 460 60 1.15 12.2 7400 13.5 8560

P43B0075A5 7 1/2 5.6 575 60 1.15 9.1 7260 10.0 8310

TABLE 5-2: THREE PHASE Motor Specifications (230, 460, 200 and 575 Volt, 60 Hz, 3450 RPM,

60° and 75° C.)

TABLE 5-3: SINGLE PHASE 4” Motor Electrical Parameters (115 and 230 Volt, 60 Hz, 3450 RPM,

2 and 3 wire)

Winding Efficiency % Power Factor %

Locked

Motor PENTEK M = Main S = Start Rotor KVA

Type Part Number Resistance* Resistance F.L. S.F. F.L. S.F. Amps Code

P42B0005A1 M 1.3-1.8 49 61 99 99 36.4 K

P42B0005A2 M 4.5-5.2 50 62 97 99 19.5 K

PSC P42B0007A2 M 3.0-4.8 55 65 97 99 24.8 J

2-W

P42B0010A2 M 4.2-5.2 58 65 94 96 21.7 F

P42B0015A2 M 1.9-2.3 59 64 99 99 42.0 H

P43B0005A1 M 0.9-1.6 S 5.7-7.0 51 59 54 69 49.6 N

CSIR P43B0005A2 M 4.2-4.9 S 17.4-18.7 50 58 58 71 22.3 M

3-W

P43B0007A2 M 2.6-3.6 S 11.8-13.0 55 61 61 72 32.0 L

P43B0010A2 M 2.2-3.2 S 11.3-12.3 59 62 66 75 41.2 L

P43B0005A2 M 4.2-4.9 S 17.4-18.7 52 62 76 85 22.3 M

P43B0007A2 M 2.6-3.6 S 11.8-13.0 56 65 85 90 32.0 L

P43B0010A2 M 2.2-3.2 S 11.3-12.3 62 68 86 92 41.2 L

CSCR P43B0015A2 M 1.6-2.3 S 7.9-8.7 66 67 80 85 47.8 J

3-W

P43B0020A2 M 1.6-2.2 S 10.8-12.0 68 69 96 95 49.4 G

P43B0030A2 M 1.1-1.4 S 2.0-2.5 72 72 96 97 76.4 G

P43B0050A2 M0.62-0.76 S 1.36-1.66 71 71 97 98 101.0 E

* Main winding is between the yellow and black leads. Start winding is between the yellow and red leads.

PN793 11/20/09 9:21 AM Page 14

Page 15

SECTION 5: XE-Series 4" Submersible Motors - 60 Hz 15

TABLE 5-4: THREE PHASE Motor Electrical Parameters (230, 460, 200 and 575 Volt, 60 Hz, 3450

RPM, 60° and 75° C.)

PN793

Locked

Motor Pentek Line to Line Efficiency % Rotor KVA

Type Part Number Resistance (Ohms) FL SF Amps Code

P43B0007A8 2.6-3.0 69 74 32.0 R

P43B0010A8 3.4-3.9 66 70 29.0 M

P43B0010A3 4.1-5.1 69 72 26.1 M

P43B0010A4 17.8-18.8 65 69 13.0 M

P43B0015A8 1.9-2.5 72 74 40.0 L

P43B0015A3 2.8-3.4 75 76 32.4 L

P43B0015A4 12.3-13.1 72 73 16.3 L

P43B0015A5 19.8-20.6 73 74 11.5 J

P43B0020A8 1.4-2.0 74 75 51.0 K

3-Phase P43B0020A3 1.8-2.4 75 75 44.0 K

P43B0020A4 8.0-8.7 74 75 23.0 K

P43B0020A5 9.4-9.7 78 78 21.4 M

P43B0030A8 0.9-1.3 77 77 71.0 K

P43B0030A3 1.3-1.7 77 77 58.9 J

P43B0030A4 5.9-6.5 76 77 30.0 J

P43B0030A5 9.4-9.7 78 78 21.4 J

P43B0050A8 0.4-0.8 76 76 113.0 J

P43B0050A3 .85-1.25 76 76 93.0 J

P43B0050A4 3.6-4.0 77 77 48.0 J

P43B0050A5 3.6-4.2 75 75 55.0 M

P43B0075A8 0.5-0.6 74 74 165.0 J

P43B0075A3 0.55-0.85 75 75 140.0 J

P43B0075A4 1.9-2.3 76 76 87.0 L

P43B0075A5 3.6-4.2 77 77 55.0 J

PN793 11/20/09 9:21 AM Page 15

Page 16

PN793

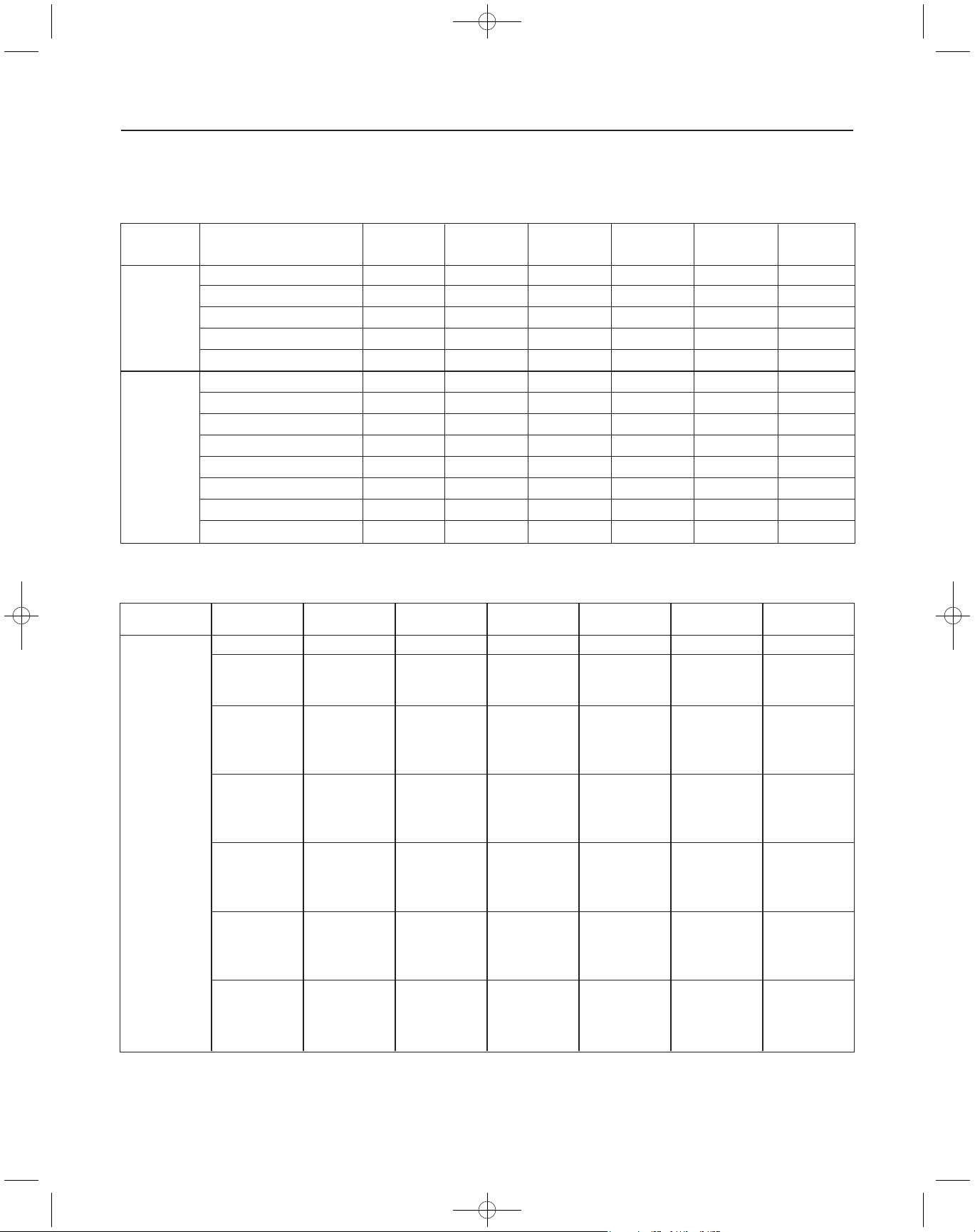

5.5 4" MOTOR DIMENSIONS

Motor PENTEK Length Length Weight Weight

Type Part Number HP kW (in) (mm) (lbs) (kg)

P42B0005A1 1/2 0.37 11.0 279 19.2 8.7

4-Inch P42B0005A2 1/2 0.37 11.0 279 19.2 8.7

2-Wire P42B0007A2 3/4 0.56 12.4 314 22.7 10.3

P42B0010A2 1 0.75 13.3 337 24.5 11.1

P42B0015A2 1-1/2 1.10 14.9 378 28.9 13.1

P43B0005A1 1/2 0.37 10.0 253 18.9 8.6

P43B0005A2 1/2 0.37 9.7 246 18.1 8.2

P43B0007A2 3/4 0.56 10.8 275 21.4 9.7

4-Inch

P43B0010A2 1 0.75 11.7 297 23.1 10.5

3-Wire

P43B0015A2 1-1/2 1.10 13.6 345 27.4 12.4

P43B0020A2 2 1.50 15.1 383 31.0 14.1

P43B0030A2 3 2.20 18.3 466 40.0 18.1

P43B0050A2 5 3.70 27.7 703 70.0 31.8

TABLE 5-5: SINGLE PHASE Motor Dimensions (115 and 230 Volt, 60 Hz, 3450 RPM)

SECTION 5: XE-Series 4" Submersible Motors - 60 Hz 16

Motor Pentek Length Length Weight Weight

Type Part Number HP kW Inches mm Lb Kg

P43B0007A8 3/4 0.55 10.8 275 21.4 9.7

P43B0010A8 1 0.75 11.7 297 23.1 10.5

P43B0010A3 1 0.75 11.7 297 23.1 10.5

P43B0010A4 1 0.75 11.7 297 23.1 10.5

P43B0015A8 1 1/2 1.1 11.7 297 23.1 10.5

P43B0015A3 1 1/2 1.1 11.7 297 23.1 10.5

P43B0015A4 1 1/2 1.1 11.7 297 23.1 10.5

P43B0015A5 1 1/2 1.1 11.7 297 23.1 10.5

P43B0020A8 2 1.5 13.8 351 27.4 12.4

P43B0020A3 2 1.5 13.8 351 27.4 12.4

P43B0020A4 2 1.5 13.8 351 27.4 12.4

3-Phase P43B0020A5 2 1.5 15.3 389 32.0 14.5

P43B0030A8 3 2.2 15.3 389 32.0 14.5

P43B0030A3 3 2.2 15.3 389 32.0 14.5

P43B0030A4 3 2.2 15.3 389 32.0 14.5

P43B0030A5 3 2.2 15.3 389 32.0 14.5

P43B0050A8 5 3.7 21.7 550 55.0 24.9

P43B0050A3 5 3.7 21.7 550 55.0 24.9

P43B0050A4 5 3.7 21.7 550 55.0 24.9

P43B0050A5 5 3.7 27.7 703 70.0 31.8

P43B0075A8 7 1/2 5.6 27.7 703 70.0 31.8

P43B0075A3 7 1/2 5.6 27.7 703 70.0 31.8

P43B0075A4 7 1/2 5.6 27.7 703 70.0 31.8

P43B0075A5 7 1/2 5.6 27.7 703 70.0 31.8

TABLE 5-6: THREE PHASE Motor Dimensions (230, 460, 200 and 575 Volt, 60 Hz, 3450 RPM)

PN793 11/20/09 9:21 AM Page 16

Page 17

PN793

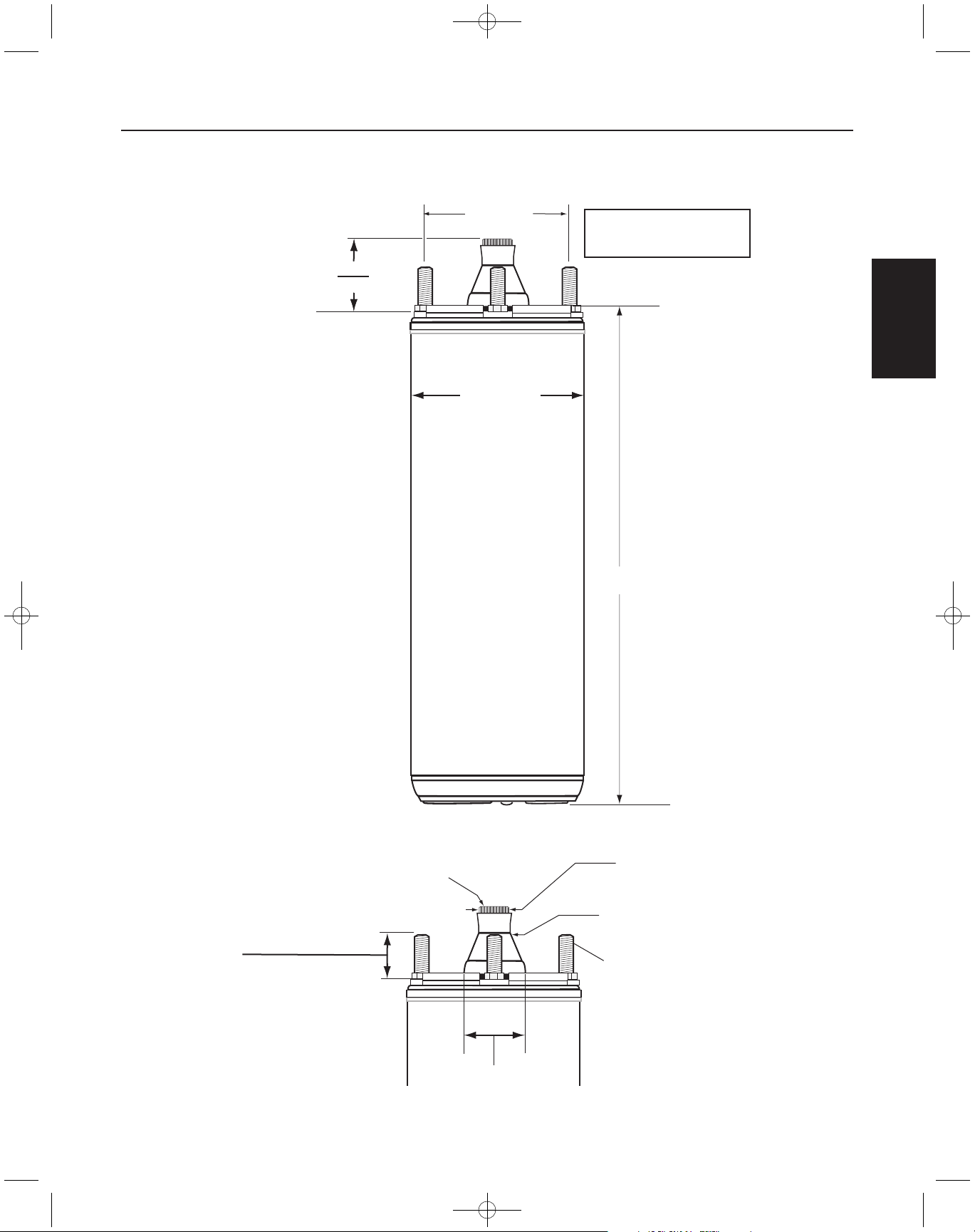

Figure 5-1:“XE” Series 4" Motor Dimensions – Single and Three Phase

SECTION 5: XE-Series 4" Submersible Motors - 60 Hz 17

XE-Series Motors

PN793 11/20/09 9:21 AM Page 17

1.508 (38.30)

1.498 (38.05)

All dimensions

in inches (mm)

3.00 (7.62)

3.750 (95.2)

4” Motor

Shaft free end-play

.005 -.040 (.127 - 1.02)

Length

14 Teeth 24/48 Pitch

30 Degee Pressure Angle

Min 0.50 (23.1) Full Spline

ANSI B92.1 Compliant

0.97 (24.6) max

0.79 (20.1) min

1.5 (38.1)max.

0.6255 (15.89)

0.6245 (15.86)

Sand Boot

(4) 5/16 - 24

UNF-2A Threaded

Studs on 3” (76.2)

Dia. Circle

Page 18

PN793

SECTION 5: XE-Series 4" Submersible Motors - 60 Hz 18

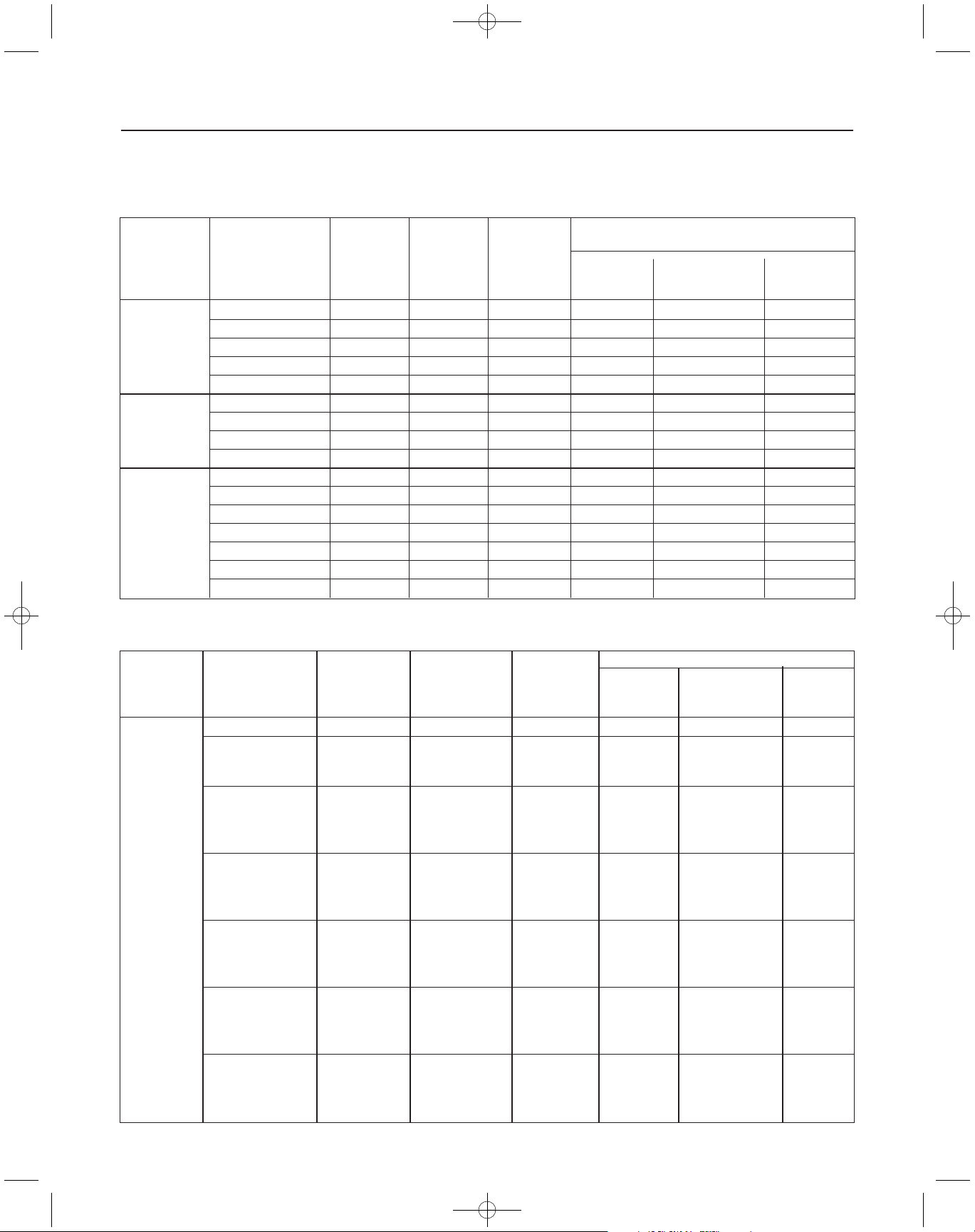

5.6 4" MOTOR FUSE SIZING

TABLE 5-7: SINGLE PHASE Motor Fuse Sizing (115 and 230 Volt, 60 Hz, 3450 RPM)

Volts and Circuit Breaker Amps

(Maximum Rating per NEC)

Dual Element

Motor PENTEK Standard Time Delay Circuit

Type Part Number HP kW Volts Fuse Fuse Breaker

P42B0005A1 0.5 0.37 115 25 15 20

4" P42B0005A2 0.5 0.37 230 15 10 10

2-Wire P42B0007A2 0.75 0.55 230 20 10 15

P42B0010A2 1 0.75 230 25 15 20

P42B0015A2 1.5 1.1 230 30 15 25

P43B0005A1 0.5 0.37 115 30 20 30

4"

P43B0005A2 0.5 0.37 230 15 10 15

3-Wire

P43B0007A2 0.75 0.55 230 20 10 20

CSIR

P43B0010A2 1 0.75 230 25 15 25

P43P0005A2 0.5 0.37 230 15 10 10

P43B0007A2 0.75 0.55 230 20 10 15

4" P43B0010A2 1.0 0.75 230 20 10 15

3-Wire P43B0015A2 1.5 1.1 230 30 15 25

CSCR P43B0020A2 2.0 1.5 230 30 20 25

P43B0030A2 3.0 2.2 230 45 25 40

P43B0050A2 5.0 3.7 230 70 40 60

Fuse Sizing Based on NEC

Dual Element

Motor PENTEK Standard Time Delay Circuit

Type Part Number HP kW Volts Fuse Fuse Breaker

P43B0007A8 3/4 0.55 200 15 10 10

P43B0010A8 1 0.75 200 15 10 10

P43B0010A3 1 0.75 230 15 6 10

P43B0010A4 1 0.75 460 6 3 6

P43B0015A8 1 1/2 1.1 200 20 10 15

P43B0015A3 1 1/2 1.1 230 20 10 15

P43B0015A4 1 1/2 1.1 460 8 6 6

P43B0015A5 1 1/2 1.1 575 6 3 6

P43B0020A8 2 1.5 200 25 15 20

P43B0020A3 2 1.5 230 20 15 20

P43B0020A4 2 1.5 460 15 6 10

3-Phase P43B0020A5 2 1.5 575 10 6 10

P43B0030A8 3 2.2 200 35 20 30

P43B0030A3 3 2.2 230 30 15 25

P43B0030A4 3 2.2 460 15 10 15

P43B0030A5 3 2.2 575 15 10 10

P43B0050A8 5 3.7 200 60 35 50

P43B0050A3 5 3.7 230 45 30 40

P43B0050A4 5 3.7 460 25 15 20

P43B0050A5 5 3.7 575 25 15 20

P43B0075A8 7 1/2 5.6 200 80 50 70

P43B0075A3 7 1/2 5.6 230 70 45 60

P43B0075A4 7 1/2 5.6 460 40 25 35

P43B0075A5 7 1/2 5.6 575 30 20 25

TABLE 5-8: THREE PHASE Motor Fuse Sizing (230, 460, 200 and 575 Volt, 60 Hz, 3450 RPM,

60° and 75° C.)

PN793 11/20/09 9:21 AM Page 18

Page 19

PN793

SECTION 5: XE-Series 4" Submersible Motors - 60 Hz 19

TABLE 5-9: Cable Lengths, SINGLE PHASE 115 and 230 Volt, 60 Hz, 3450 RPM, 2- and 3-wire

Motors, 60° and 75° C. Service Entrance to Motor: Maximum Length in F

eet

5.7 CABLE LENGTHS

XE-Series Motors

Wire Size, AWG

HP Volt 14 12 10 8 6 4 3 2 1 0 00

CSIR Control Boxes

1/2 115 87 138 221 349 544 867 1090 1376 1734 2188 2761

1/2 230 348 553 883 1398 2175 3467 4359 5505 6935 8753 –

3/4 230 264 420 670 1061 1651 2632 3309 4178 5264 6644 8383

1 230 226 359 573 908 1413 2252 2831 3575 4504 5685 7173

CSCR Control Boxes

1/2 230 447 711 1135 1797 2796 4458 5604 7078 8916 11254 –

3/4 230 348 553 883 1398 2175 3467 4359 5505 6935 8753 11044

1 230 304 484 772 1223 1903 3034 3814 4817 6068 7659 9663

1 1/2 230 197 314 501 793 1234 1968 2474 3124 3936 4968 6268

2 230 180 286 456 722 1123 1790 2251 2843 3581 4520 5703

3 230 133 211 337 534 830 1324 1664 2102 2648 3342 4217

5 230 – – 206 326 507 809 1017 1284 1618 2042 2577

* Table data are generated per NEC standards.

Wire Size, AWG

HP Volt 14 12 10 8 6 4 3 2 1 0 00

1/2 115 115 183 293 463 721 1150 1445 1825 2299 2902 3662

1/2 230 466 742 1183 1874 2915 4648 5843 7379 9295 11733 –

3/4 230 342 545 869 1376 2141 3413 4291 5419 6826 8617 10871

1 230 241 383 611 968 1506 2400 3018 3811 4801 6060 7646

1 1/2 230 199 317 505 801 1246 1986 2496 3153 3972 5013 6325

3-Wire in Feet

2-Wire in Feet

PN793 11/20/09 9:21 AM Page 19

Page 20

PN793

SECTION 5: XE-Series 4" Submersible Motors - 60 Hz 20

TABLE 5-10: Cable Lengths, THREE PHASE 230, 460, 200 and 575 Volt, 60 Hz, 3450 RPM

Motors, 60° and 75° C. Service Entrance to Motor: Maximum Length in F

eet

Wire Size, AWG

HP Volt 14 12 10 8 6 4 3 2 1 0 00

1 230 466 742 1183 1874 2915 4648 5843 7379

1 1/2 230 359 571 912 1444 2246 3581 4502 5685 7162 9040

2 230 288 459 732 1159 1803 2874 3613 4563 5748 7256 9155

3 230 217 345 551 872 1357 2163 2719 3434 4326 5460 6889

5 230 — — 318 503 783 1248 1569 1982 2496 3151 3976

7 1/2 230 — — — 334 519 827 1040 1314 1655 2089 2635

1 460 1753 2789 4448 7045

1 1/2 460 1370 2179 3475 5504

2 460 1153 1835 2926 4635 7212

3 460 827 1315 2098 3323 5171

5 460 516 820 1308 2072 3224 5140

7 1/2 460 325 516 824 1305 2030 3236 4068 5138 6472

* Table data are generated per NEC standards.

Wire Size, AWG

HP Volt 14 12 10 8 6 4 3 2 1 0 00

3/4 200 423 674 1074 1702 2648

1 200 346 551 879 1392 2166 3454 4342

1 1/2 200 265 421 672 1064 1655 2638 3317

2 200 217 344 549 870 1354 2158 2714 3427 4317 5449

3 200 159 253 403 638 993 1583 1990 2513 3166 3996

5 200 94 150 239 379 590 940 1182 1493 1881 2374 2995

7 1/2 200 64 101 161 255 397 633 796 1005 1266 1598 2017

1 1/2 575 2283 3631 5792

2 575 1660 2641 4212 6671

3 575 1336 2126 3390 5370

5 575 721 1147 1829 2897 4507

7 1/2 575 548 871 1390 2202 3426

Three Phase

Three Phase

PN793 11/20/09 9:21 AM Page 20

Page 21

5.8 4" MOTOR OVERLOAD

PROTECTION

Single Phase Motors

Single phase motors have overload protection either in the

motor or in the control box. Motors less than or equal to

1 HP have built-in protection. This automatic protection

will continue to cycle under a locked or stalled rotor

condition.

Single phase motors larger than 1 HP use overload

protection located in the SMC (Submersible Motor

Controls). These are manual overloads and must be

manually reset if an overload condition occurs.

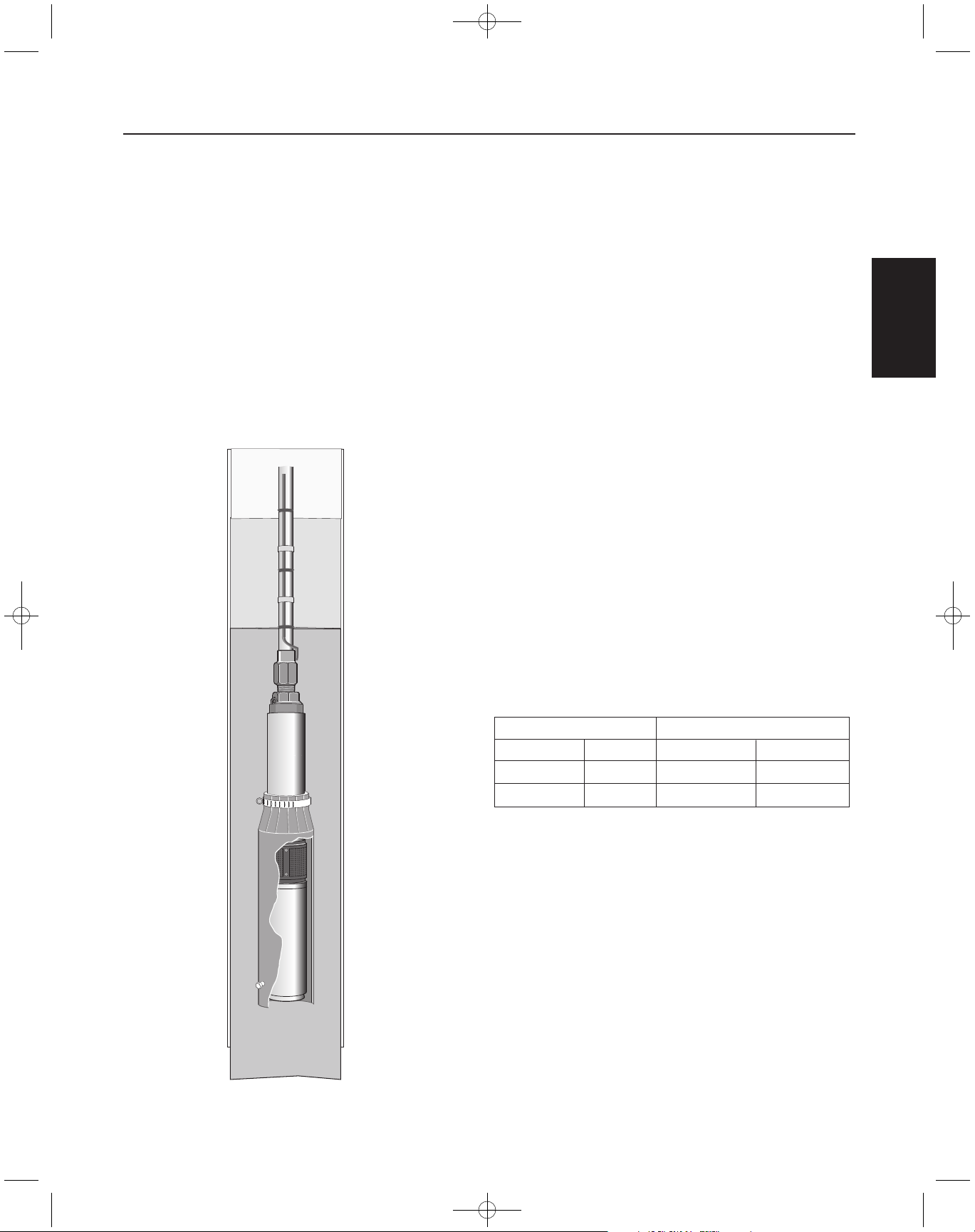

5.9 MOTOR COOLING

PENTEK 4" XE-Series motors are designed to operate to a

maximum SF (Service Factor) horsepower in water up to

86° F (30° C).

4" MOTORS: MINIMUM COOLING WATER FLOW OVER 3 HP

I.D of casing Flow GPM (LPM) required

4 1.2 (4.5

5 7 (26.5)

6 13 (49)

7 20 (76)

8 30 (114)

10 50 (189)

12 80 (303)

14 110 (416)

16 150 (568)

If the flow is less than specified, a flow-inducer sleeve can

be installed. This will act like a smaller casing size, and

force flow around the motor to aid cooling.

5.10 STARTING FREQUENCY

To extend the life of the pump motor and control, limit the

number of starts to 300 per day.

If higher starting frequencies are necessary, consult your

factory.

To prevent overheating, run motor for a minimum of one

minute.

Figure 5-2: Flow Inducer Sleeve

Motor Rating Maximum Starts in 24 Hours

HP KW Single Phase Three Phase

1/5 to 3/4 HP Up to .55 300 300

1 to 1-1/2 .75 thru 4 100 300

TABLE 5-11: Maximum starts in 24 hours

SECTION 5: XE-Series 4" Submersible Motors - 60 Hz 21

XE-Series Motors

PN793 11/20/09 9:21 AM Page 21

Page 22

SECTION 6:Variable Frequency Drives 22

PID-1, PID-6 INTELLIDRIVE Series

PN793

6.1 GENERAL SAFETY

Risk of high-voltage electrical shock from

the EMI/RFI Filter if the front cover of the VFD is open or

removed while power is connected to the VFD or the VFD

is running. The front cover of the VFD must be closed

during operation.

• After allowing at least 5 minutes for the EMI/RFI Filter

to discharge and before starting any wiring or

inspection procedures, check for residual voltage with

a voltage tester.

Risk of electrical shock if VFD is connected

to the power wiring before hanging the box. Always hang

the VFD box before connecting the wires to it.

Risk of electrical shock if the VFD is

handled or serviced with wet or damp hands. Always

make sure your hands are dry before working on the VFD.

Perform all operations on the HMI with dry hands.

Risk of electrical shock and hand injury. Do

not reach into or change the cooling fan while power is on

to the VFD.

Risk of electrical shock. Do not touch the

printed circuit board when power is on to the VFD.

Fire hazard if installed with incorrect or

inadequate circuit breaker protection. To make sure of

protection in the event of an internal fault in the VFD,

install the VFD on an independent branch circuit protected

by a circuit breaker (see Table 6-2, Page 23 for circuit

breaker sizing), with no other appliances on the circuit.

Risk of burns. The drive can become hot

during normal operation. Allow it to cool for 10 minutes

after shut-down before handling it to avoid burns.

NOTE: To avoid damage to the drive or problems with

the drive:

• Connect the output cables to 3-wire and 3-phase

motors as follows: Red to R, Yellow to Y, Black to B.

Any other order will reverse the motor rotation and

may damage the motor.

• Do not modify the equipment.

• Do not use power factor correction capacitors with this

VFD; they will damage both the motor and the VFD.

• Do not remove any parts unless instructed to do so in

the owner’s manual.

• Do not use a magnetic contactor on the VFD for

frequent starting/stopping of the VFD.

• Do not install or operate the VFD if it is damaged or

parts are missing.

• Before starting a VFD that has been stored for a long

time, always inspect it and test operation.

• Do not carry out a megger (insulation resistance) test

on the control circuit of the VFD.

• Do not allow loose foreign objects which can conduct

electricity (such as screws and metal fragments) inside

the VFD box at any time. Do not allow flammable

substances (such as oil) inside the VFD box at any

time.

• Ground the VFD according to the requirements of the

National Electrical Code Section 250, IEC 536 Class 1,

or the Canadian Electrical Code (as applicable), and

any other codes and ordinances that apply.

• All installation, service work, and inspections must be

done by a qualified electrician.

Carefully read and follow all safety instructions in this

manual or on drive.

Risk of high-voltage electrical shock

from EMI/RFI Filter inside Drive.

Make all wiring connections, then

close and fasten the cover before

turning on power to Drive.

DO NOT open the box when power is

connected to the Drive .

Before doing any

service or maintenance

inside the Drive:

1. DISCONNECT power.

2. WAIT 5 minutes for

retained voltage to

discharge.

3. Open box.

Before connecting or

disconnecting any wires

inside the Drive:

1. DISCONNECT power.

2. WAIT 5 minutes for

retained voltage to

discharge.

3. Open box.

EMI/RFI Filter

Hazardous voltage.

Drive internal components retain

high voltage for up to 5 minutes

after input power is disconnected.

EMI/RFI Filter carries high voltage

when pump is running.

Disconnect power and wait

5 minutes before opening and

removing VFD cover.

PN793 11/20/09 9:21 AM Page 22

Page 23

SECTION 6:Variable Frequency Drives 23

PID-1, PID-6 INTELLIDRIVE Series

PN793

6.2 DESCPRIPTION

The PENTEK INTELLIDRIVE is specifically designed to

operate 4” submersible pumps in water well applications.

Each drive is rated for horsepower and amp draw. Any use

of the drive outside of its intended use and design

parameters will void the warranty.

Transducer

The drive uses a 4-20mA, 0-100PSI pressure transducer to

control the speed of the motor.

The transducer senses pressure in the pipe and converts it

to an electrical signal which it sends to the drive. The drive

processes the signal in the PID (Proportional, Integration,

Derivative) control. When operating in PID mode the drive

increases and decreases the speed of the pump motor as

needed to maintain constant pressure in the system.

Fan

The PENTEK INTELLIDRIVE has a thermostatically

controlled internal fan. The fan may not operate under

normal operating conditions. It will automatically start

when necessary to cool the drive.

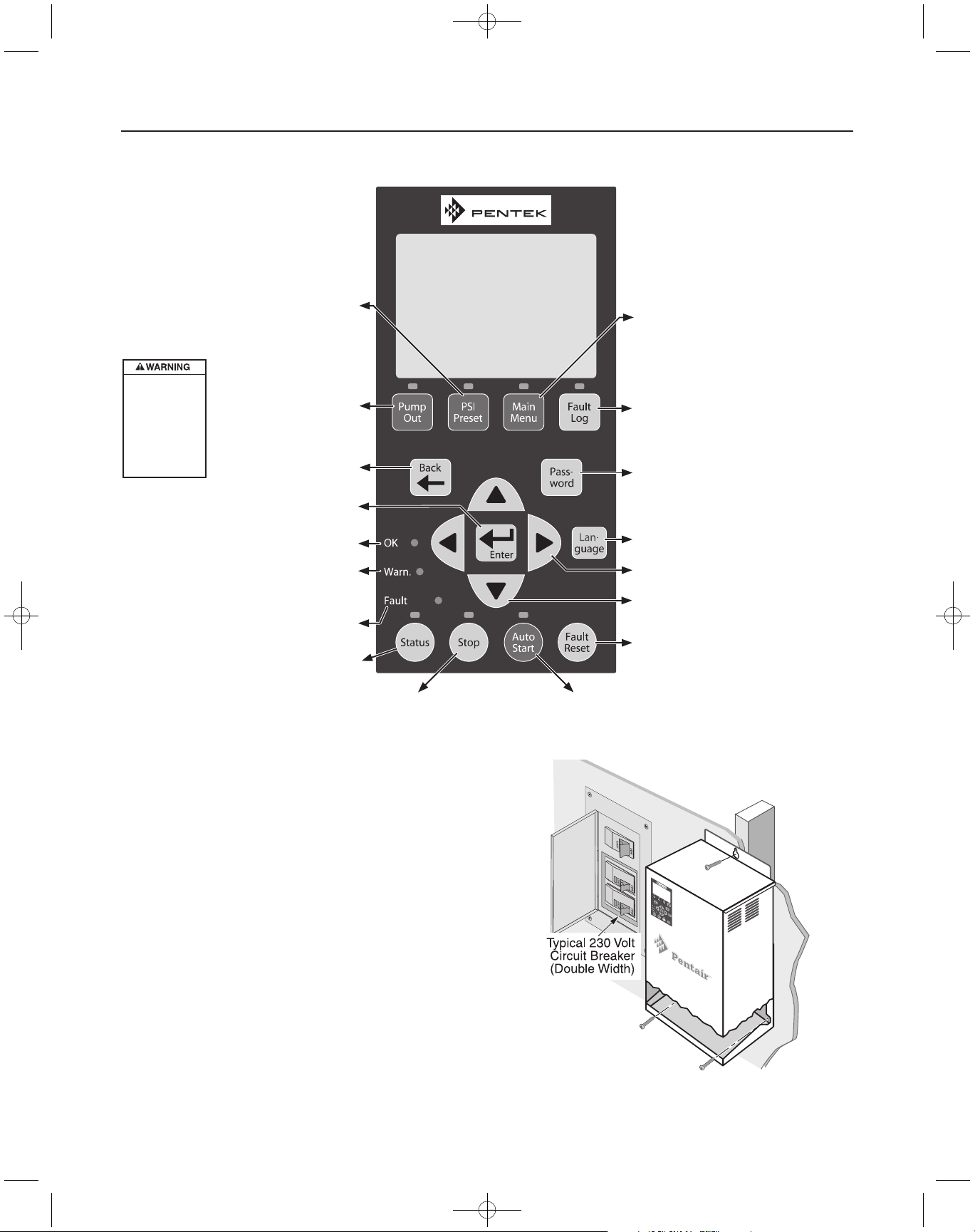

Keypad

The Keypad programs the drive, monitors the status of the

pump, and views faults if they occur. Each button has a

unique function (see Page 22). The LCD display shows a

text display of the status of the drive’s operation. Other

LEDs light up to indicate when certain buttons are pressed

or certain events occur.

VFD

PID-1, PID-6

Table 6-1: Model Number Structure

Voltage Rating:

1 = 190–265 Volt 1-Phase In,

3-Phase Out

6 = 190–265 Volt 1-Phase In,

1-Phase Out

PID – 1 – 10A1 – 1

PID-1- 10A1-1:

Product Family

PID = Pentek IntelliDrive

Max Amp Rating:

4A7 = 4.7 Amps

7A6 = 7.6 Amps

9A7 = 9.7 Amps

10A1 = 10.1 Amps

12A2 = 12.2 Amps

Enclosure T ype:

1 = NEMA 1 (Indoor Rated)

3 = NEMA 3R (Outdoor Rated)

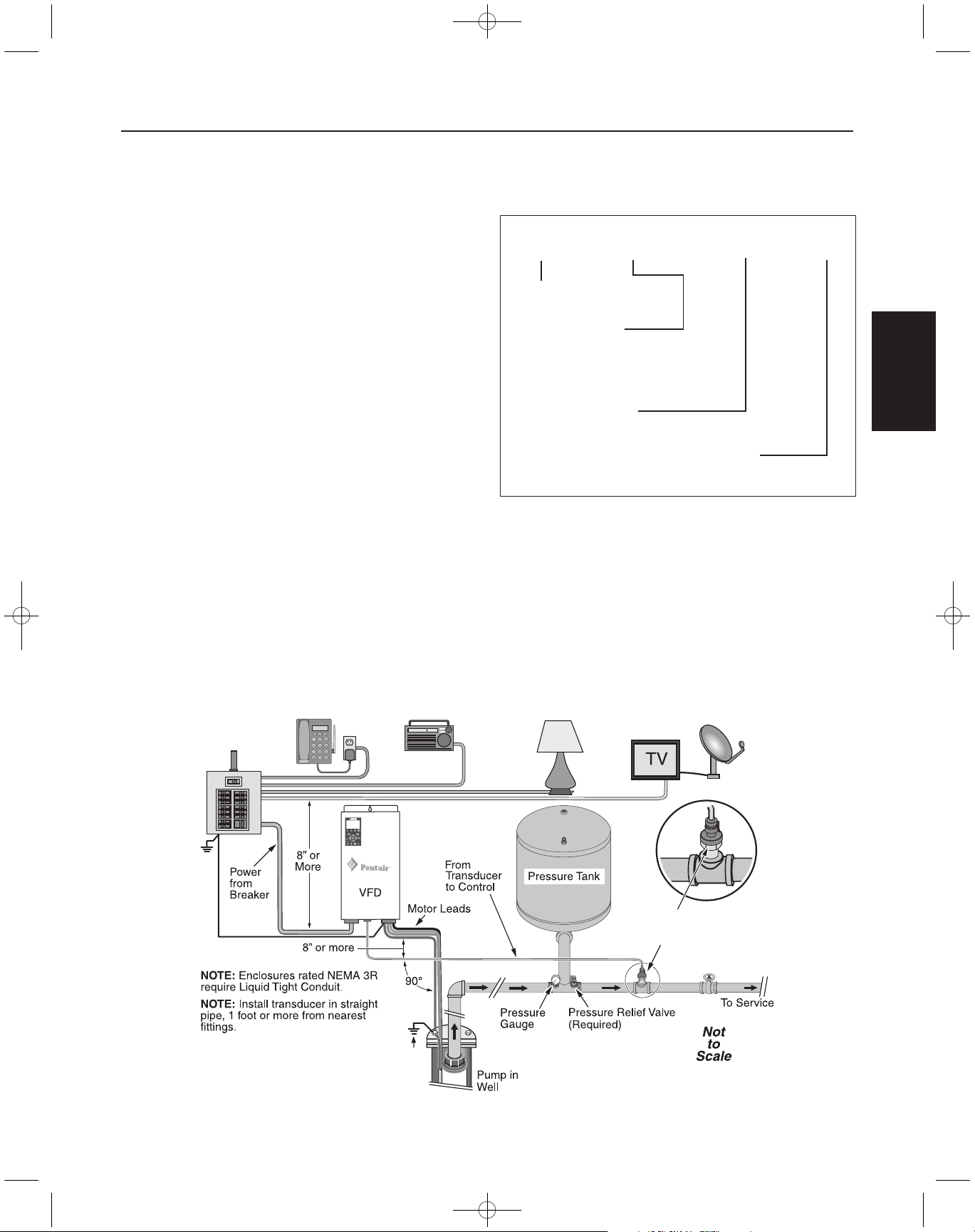

Figure 6-1: Overall Layout – Typical installation

PN793 11/20/09 9:21 AM Page 23

Transducer; install at

least one foot away from

pipe fittings on each side.

Grnd

6004 0509

Page 24

SECTION 6:Variable Frequency Drives 24

PID-1, PID-6 INTELLIDRIVE Series

PN793

6.3 INSTALLATION

Mounting (See Figure 6-3)

Mount the drive in an easily accessible area with

temperature maintained between –4°F and 104°F (–20°C

to 40°C). NEMA 1 enclosures must be mounted indoors;

NEMA 3R enclosures may be mounted outdoors with the

same ambient temperature limits.

To mount the drive, mark the location of the top keyhole

on the wall or stud. Drive a screw into the structure and

hang the drive on it. Back out the screw on the bottom of

the front cover and lift the cover off. Mark the locations of

the bottom two mounting holes. Mount the drive with

screws in all three holes.

Be sure that the ventilation holes are not blocked and that

there is enough space around the drive to allow free air

flow (minimum 3” clearance, top, bottom, and sides).

Once the drive is mounted, you are ready to connect

the wires.

Figure 6-2: Keypad functions

5997 0509

Figure 6-3

PN793 11/20/09 9:21 AM Page 24

Toggles the pressure setpoint

Hazardous

pressure.

Do not connect to

system or restrict

discharge flow

when running in

“Pump Out”

mode.

confirms numeric value changes

between 40, 60, and 70 PSI

(default is 60)

Runs the Drive at 45 Hz

(with no pressure control)

to allow the installer

to pump out the well

Changes the display to

the previous screen

Selects menu items and

Power is on to the Drive

Views and changes parameters

Shows the last 15 faults

With code, locks and unlocks the

password protected keys (default

password is 7777)

Toggles between English, Spanish,

and French (Default is English )

The Drive is in Temporary Performance

Mode (TPM) or Jam condition

A fault has occurred

Displays the Drive’s

urrent oper

c

changes the display parameters

ating conditions and

Stops the motor

Checks for line fill, then

starts the pump in constant

pressure mode

The left and right arrows

move the cursor.

The up and down arrows scroll through

the menus and change numeric values.

Resets the fault

that stopped the pump

6007 0509

Page 25

SECTION 6:Variable Frequency Drives 25

PID-1, PID-6 INTELLIDRIVE Series

PN793

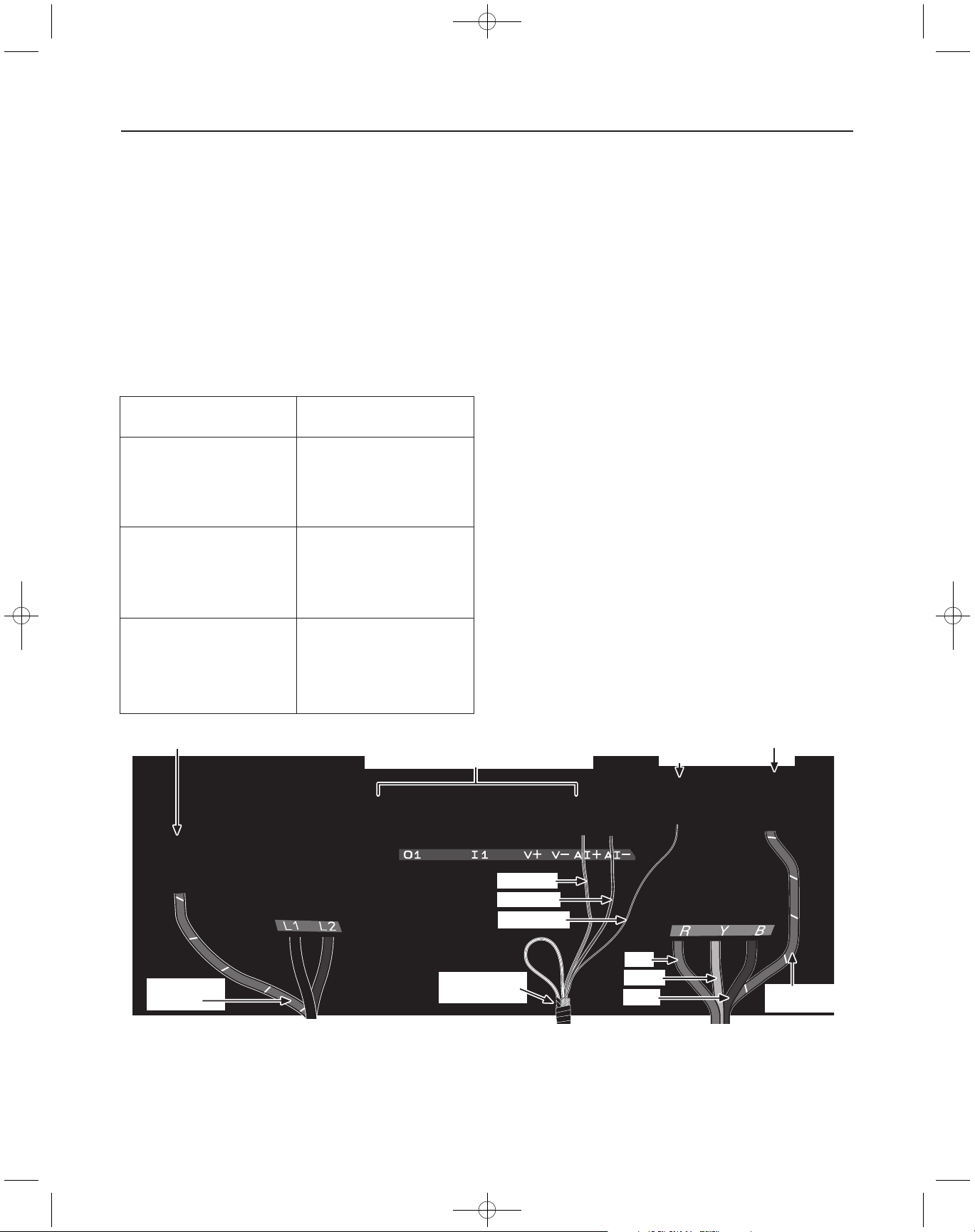

Wiring

To allow for ease of wiring, the wiring area is free of

electronics other than the terminals. Conduit holes and

knockouts are located so that the wire can be fed straight

through to the connectors, with minimal bending. The

terminals accept 6-14 AWG wire.

NOTE: For convenience in wiring, the input and motor

terminals unplug from the box. Pull them down to remove

them for ease of access. See Figure 6-4.

BE SURE that when you replace them, they are completely

pushed in and seated.

Note: The best practice is to connect all output wires first

and all input wires last.

Output Connections (See Figure 6-5, Page 24):

See Tables 6-5 and 6-6, Page 32, for correct wires sizes,

VFD to motor.

The output of PID-1 Series drives is 230V three phase

power.

The output of PID-6 Series drives is 230V single phase

power.

NOTE: PID-1 series drives will not operate single phase

motors. PID-6 series drives will not operate three phase

motors.

The output power terminals (motor wire connections) are

located on the lower right side of the drive and are labeled

R (Red), Y (Yellow), and B (Black). Feed the motor cable

through the 3/4” conduit hole on the bottom right side and

into the appropriate terminals. If the wire is large enough

to require a larger conduit hole, remove the 1-1/4”

knockout and use the appropriate conduit connections.

Attach the motor ground wire to the grounding lug, located

to the upper right of the terminal block. Attach the motor

power wires to the terminals as shown in Figure 6-5,

Page 24.

VFD

PID-1, PID-6

Wire Size Minimum 240VAC

Controller Motor CB to VFD C.B. Size Generator

Model No. Volts/Hz/Ph H.P. Amps (AWG) (Amps) Cap’y (kVA)

PID-1-4A7-X 230/60/3 1 4.7 12 20 4.2 kVA

PID-1-7A6-X

230/60/3 1.5 6.1

10 30 6.9

230/60/3 2 7.6

PID-1-10A1-X 230/60/3 3 10.1 8 40 9.1

230/60/1 0.5 4.9

PID-6-9A7-X 230/60/1 0.75 6.3 12 20 4.4

230/60/1 1 7.2

PID6-12A2-X

230/60/1 1.5 11.1

10 30 7.4

230/60/1 2 12.2

Table 6-2: Circuit Breaker and Wire Sizes

Figure 6-4: Pull the input and motor terminals down to

unplug them for ease of wiring.

PN793 11/20/09 9:21 AM Page 25

Page 26

SECTION 6:Variable Frequency Drives 26

PID-1, PID-6 INTELLIDRIVE Series

PN793

Pressure Tank Recommendations:

Minimum tank size is 5 gallons. Use a pre-charged

pressure tank with the Drive. The tank size must equal at

least 20% of the pump’s rated flow in gallons per minute

(GPM), but cannot be less than 5 gallons capacity. For

example, a pump rated at 10 GPM would require a tank of

5 gallons capacity or larger. A pump rated at 50 GPM

would require a 10 gallon tank or larger. A larger tank will

reduce cycling of the pump.

NOTE: Set the pressure tank’s pre-charge to 70% of the

system operating pressure. When using an external set

point as well as an internal set point, pre-charge the tank to

70% of the lower set point of the two. Some applications

may require a different percentage when figuring the set

point.

Transducer Connections (See Figure 6-5):

Use the transducer provided with the drive. Install the

transducer downstream of the tank. Install the transducer in

a tee in a straight section of pipe with at least 1 foot of

straight pipe on each side of the tee (that is, all fittings must

be at least one foot away from the transducer).

Feed the transducer cable through the open 1/2” conduit

hole on the bottom of the drive enclosure.

The transducer terminals, marked AI+ and AI-, are located

to the left of the output terminals. Connect the red wire of

the transducer cable to AI+, connect the black wire to AI–,

and connect the cable shield to the metal lug to the right.

NOTE: Do not use the clear wire on the transducer cable

for any connections; tape the end and tie it back to the

cable with electrical tape so that it does not touch any

other components or connections.

Note: To connect the wires;

1. If the wire ends are not pre-stripped, strip them back

about 1/2”.

2. Push the spring terminals up (back).

3. Insert the wires.

4. Release the spring terminals.

Table 6-3: Control Pressure Set Point and Tank

Pre-Charge Pressure Values (PSI)

Pressure Point Precharge

Setting (PSI) Pressure (PSI)

25 18

30 21

35 25

40 28

45 32

50 35

55 39

60 (Default) 42

65 46

70 49

75 53

80 56

85 60

90 63

95 67

Cable Shield

Clear Wire; tape

end to cable.

Red to AI+

Black to AI–

Transducer Cable

Connections

Connections for Both 3-Phase

and 3-Wire Motors.

Cable Shield Lug

Output Ground Screw

Input Power Connections

Input Ground Screw

See Figures 5–9, Page 11, for information

about I/O Connections O1, I1,V+, and V–.

Red

Yellow

Black

Green/Yellow

(Ground)

Green/Yellow

(Ground)

6012 0509

Figure 6-5: Basic Wiring Connections for Startup.

NOTE: Do not connect the clear wire on the transducer cable to any terminal; instead, tie it back with electrician’s tape so

that it cannot touch any other components or connections.

PN793 11/20/09 9:21 AM Page 26

Page 27

SECTION 6:Variable Frequency Drives 27

PID-1, PID-6 INTELLIDRIVE Series

PN793

Input Connections (See Figure 6-5):

The input power terminals are located on the lower left

side and marked L1 and L2 (see Figure 6-5); there is a

ground lug for the input ground wire to the left of the

connector. Feed the wire through the 3/4” conduit hole on

the bottom left side and into the appropriate terminals. If

the wire is large enough to require a larger conduit hole,

remove the 1-1/4” knockout and use the appropriate

conduit connections.

To determine the correct wire sizes for your installation,

see Table 6-2, Page 23.

NOTE: The drive only accepts 230V single phase input

power. If your incoming power does not match this, have a

competent electrician alter it to 230V/1Ph before

connecting the drive.

Lightning/Surge Protection

Lightning arrestors or other surge suppressing devices can

be used with this product. MOV (Metal Oxide Varistor),

SOV (Silicon Oxide Varistor), or a flashover type can be

used when wired between the drive and the circuit

breaker. If a lightning arrestor is to be used between the

drive and the motor, a flashover type arrestor is

recommended.

6.4 INITIAL STARTUP

PROGRAMMING PROCEDURE

Be Sure that the cover is installed before operating the

drive.

Most installations will only require the initial startup

settings. However, the installer may need to set additional

parameters occasionally. See “Advanced Programming”,

Page 26, for information about accessing all parameters,

explanations of their functions, and procedures for

changing parameter values, if necessary.

1. Program the Drive: Apply power to the PENTEK

INTELLIDRIVE. “Setup Guide” will appear.

A. Service Factor Amps (See Sidebar, “Service Factor

Amps”)

1. Use DIRECTIONAL Arrows to enter the correct

service factor amps (see Table 6-4)

2. Press ENTER to save the entry.

B. Current Time:

1. Use DIRECTIONAL Arrows to scroll to correct

time

2. Press ENTER to save the time.

C. Current Date:

1. Use DIRECTIONAL Arrows to scroll to

correct date

2. Press ENTER to save the date.

• To change any values, press Back to return to the

previous screen.

• To change any values after startup, go to Main Menu

and edit the parameters as needed.

VFD

PID-1, PID-6

Service Factor Amps (See Table 6-4)

To get the best performance out of your pump, be

sure you enter the correct Service Factor Amps

(SF Amps) in the PENTEK INTELLIDRIVE.

• Entering SF Amps

higher

than the motor rating

lets the drive supply more amps to the motor

than the motor is designed for and may allow the

motor to overheat;

• Entering SF Amps

lower

than the motor rating

limits the output amps to less than the motor is

designed for and will reduce the performance of

the pump.

• For any 1-Phase motor, the correct Ser vice

Factor Amp rating for the PENTEK

INTELLIDRIVE is Cap Start/Cap Run amps. This

may not match the motor nameplate, which (for a

3-Wire, Single Phase motor) will generally be

Cap Start/ Induction Run Amps.

• For any 3-Phase motor, use the motor nameplate

Service Factor Amp rating.

NOTE: PENTEK submersible motors may differ

from motors of the same horsepower from other

manufacturers.For 3-Wire, 1-Phase motors from

all other submersible motor manufacturers,

enter the motor manufacturer’s CS/CR ser vice

factor amps for your motor. For 3-Phase motors,

use the motor nameplate amps.

Part Number Volts/Hz/Ph HP S.F. Amps

Three Phase Motors

P43B0010A3 230/60/3 1.0 4.7

P43B0015A3 230/60/3 1.5 6.1

P43B0020A3 230/60/3 2.0 7.6

P43B0030A3 230/60/3 3.0 10.1

3-Wire Single Phase Motors

P43B0005A2 230/60/1 0.5 4.9

P43B0007A2 230/60/1 0.75 6 .3

P43B0010A2 230/60/1 1.0 7.2

P43B0015A2 230/60/1 1.5 11.1

P43B0020A2 230/60/1 2.0 12.2

Table 6-4: Pentek Motor Service Factor Amps

PN793 11/20/09 9:21 AM Page 27

Page 28

SECTION 6:Variable Frequency Drives 28

PID-1, PID-6 INTELLIDRIVE Series

PN793

2. 80 Hz Operation (if necessary—See “60 to 80 Hz

Operation,” below):

A. Press MAIN MENU button,

B. Use DIRECTIONAL Arrows to scroll to motor; press

ENTER.

C. Use DIRECTIONAL Arrows to scroll to Set Max

Frequency; press ENTER.

D. Use DIRECTIONAL Arrows to change to 80 Hz;

press ENTER.

3. Pump out the well (if necessary):

Direct the pump’s discharge to an appropriate location

not connected to the system and press Pump Out. The

pump will run at 45 Hz.

Adjust frequency as appropriate:

A. Press ENTER

B. Change frequency value

C. Press ENTER again.

Run the drive in this mode until the well discharge runs

clear, then press the ‘Stop’ button to stop the drive.

Hazardous pressure. In Pumpout mode,

the pump runs at a constant speed, which can cause

very high pressure if flow is restricted.

4. Check List:

Make sure that the system has a properly sized relief

valve and pressure tank.

Make sure that the pressure tank’s precharge is

correct. See Table 6-3, Page 24.

Make sure that the pump discharge is connected to the

system.

5. System Start:

Open valves at the ends of lines so that air will escape

during pressurization.

Press Auto Start; close valves at the ends of lines after

all air has escaped.

The system goes into Constant Pressure Operation as

soon as the transducer registers 10 PSI. If system

pressure does not reach 10 PSI within 3 minutes, the

drive will stop. Press AutoStart again to restart line fill.

60 to 80 Hz Operation (See 2, above):

When installing the PID-1 Series PENTEK INTELLIDRIVE

with a motor and liquid end of the same HP rating, operate

it at 60 Hz (the default value). The drive can be operated at

frequencies of up to 80 Hz when the installation uses a

large motor with a small pump (For example, a 1 HP pump

with a 2 HP 3-Phase motor. This combination will equal

the performance of a conventional 2 HP pump.).

Go to Main Menu as described in No. 2 (above). Be sure

to press Enter to save the new Max Frequency selected.

The drive will now use the new value selected.

NOTE: The drive will not allow the output amps to go

above the Service Factor Amps selected on the keypad.

Because of this, some 80 Hz operations may be limited by

a “TPM: Service Amps” warning. This protects the motor

and may be a common occurance.

6.5 ADVANCED PROGRAMMING

Locking & Unlocking the Keypad

Password: The password locks or unlocks the blue buttons

on the keypad. All PENTEK IntelliDrive units are shipped

from the factory with the default password ‘7777’. It can

be changed to any other 1 to 4 digit number. To reset the

password to a unique password for your unit, unlock the

key pad (see below) and go to “SETTINGS/Password”,

Page 27.

If the installer does not press the PASSWORD button, then

the Keypad will automatically lock 60 minutes after the

drive is powered up. The timeout period is adjustable

through the Main Menu/Settings/Password.

To unlock the keypad press PASSWORD, use the

directional arrows to enter the proper numeric code, and

press ENTER.

Note: For more detailed information on Keypad functions,

see the “Parameters” section.

Changing a Parameter Value:

NOTE: This procedure works for ANY parameter.

1. Find the parameter and display the current parameter

value on the screen.

2. Press ENTER to enable editing of the parameter.

3. Use the UP, DOWN, LEFT, and RIGHT arrows to

change the parameter values.

4. Press ENTER again to save the new parameter value.

NOTE: A “shorthand” way to remember this is:

• Press ENTER to change a value;

• Press ENTER again to save it.

• If you don’t save the new value, then as soon as you

change the screen, you lose it.

Keypad Access Parameters

Pump Out Speed: Press Pump Out. The Drive will start the

pump in a constant speed mode (default 45 Hz). The

pump will run until you push Stop or Auto Start. If

necessary to change the speed, Follow steps 2-4 above to

change the parameter.

PSI Preset: Press PSI Preset; follow steps 2-4 above to

change the parameter. The default is 60 PSI, but the

parameter can be set to 40, 60, or 70 PSI.

PN793 11/20/09 9:21 AM Page 28

Page 29

SECTION 6:Variable Frequency Drives 29

PID-1, PID-6 INTELLIDRIVE Series

PN793

Pressure Setpoint: Press Auto Start, then follow steps 2-4

under “Changing a Parameter Value,” Page 26. Use the

directional arrows to change the pressure by 1 or 10 PSI

increments.

• NOTE: This parameter allows you to change either the

Internal or the External Setpoint, depending on which

one is referenced at the time you are making the

change.

• NOTE: To change the setpoint before starting the

pump, go to the Main Menu/Settings/Setpoints/

Internal Setpoint.

• NOTE: If this value is changed from the default value

of 60 PSI, you must adjust the tank pressure

accordingly (see Table 6-3, Page 24).

Language: Press Language; follow steps 2-4 under

“Changing a Parameter Value,” Page 26, using the UP or

DOWN arrows to scroll through the available languages

(English, French, or Spanish; default is English).

• NOTE: To change the setpoint before startup, go to the

Main Menu under “Settings”.

Main Menu Parameters

The Main Menu has six secondary menus (plus a Reset)

that allow access to the Advanced Programming

parameters: 1) SETTINGS, 2) MOTOR, 3) SENSOR, 4) PIPE

BREAK, 5) DRY RUN, 6) I/O. The basic structure and

navigation instructions are listed below. Use the UP and

DOWN arrows to scroll to the next secondary menu or

submenu, or to a parameter. Press Enter to go into a

Submenu or to edit a parameter.

1) SETTINGS: (HAS 5 SUBMENUS)

Time (2 parameters):

Hour:

Allows you to change the time of day.

Date:

Allows you to change the calendar day.

PID Control: Changing these parameters is NOT

recommended. These parameters control the drive’s

reaction to pressure changes in the system. They

should be considered as a group. If it seems necessary

to alter anything in this group, please call Pentek

Customer Service at 1-866-9PENTEK (1-866-973-

6835) BEFORE YOU START. Also, note that the last

item on the main menu resets ALL parameters to the

default values.

Sleep (5 parameters plus Reset):

Boost Differential:

Raises the system pressure

slightly before going into sleep mode. Units are in

PSI. The default boost value is 3 PSI. (i.e., with

Boost Differential set to 3 PSI and Pressure Setpoint

set to 60 PSI, the system pressure will rise to 63 PSI

before the drive goes to sleep). Maximum is 10 PSI,

minimum is 3 PSI.

Boost Delay:

The length of time (in seconds) that

the drive monitors the system before boosting the

pressure. Default is 60 seconds, maximum is 300

seconds, minimum is 30 seconds.

Wakeup Differential:

The total pressure drop from

the setpoint that the drive must see to come out of

Sleep mode. The default setting is 5 PSI. (i.e., with

the Wakeup Differential set to 5 PSI, the drive will

wake up when the pressure in the system has

dropped 5 PSI below the system Pressure Setpoint.)

Maximum is 15 PSI, minimum is 5 PSI.

Wake Delay:

The time it takes to ramp down to the

Wake Up pressure. Default is 15 seconds,

maximum is 120 seconds, minimum is 3 seconds.

Sleep 2 PSI:

A setting to prevent Over-Pressure. If

the system pressure rises enough that the drive

reaches the Sleep 2 PSI setpoint, the drive will go

to sleep for one minute. Default pressure is 80 PSI,

maximum is ‘Max Sensor’ value minus 3 PSI,

minimum is 15 PSI.

• NOTE: If the Internal or External Setpoint is set to

a value that is near, at, or above the Sleep 2 PSI

setpoint, you may experience nuisance tripping.

In this case, raise the Sleep 2 PSI setpoint until

the nuisance tripping stops.

Reset to defaults:

Default value is NO. Change to

YES to reset all Sleep parameters to their default

values.

Password (2 parameters):

Password Timeout:

Sets the time (in minutes) that

the drive takes to lock out the password-protected

(blue) buttons on the keypad. The range is 1 – 360

minutes; the default is 60 minutes. When drive

programming is complete, a timer starts. Once it

reaches the time set in this parameter the buttons

automatically lockout.

Password:

The Password locks or unlocks the blue

buttons on the keypad. The password is a number

(default is 7777) and can be changed to any 1- to

4-digit number.

Setpoints (2 Parameters):

Internal Setpoint:

The main pressure setting used by

the drive. The default value is 60 PSI. Maximum is

the ‘Max Sensor’ value minus 3 PSI, minimum is

15 PSI.

External Setpoint:

The Drive’s pressure reference

when the External Input is set to External Setpoint

and the proper drive is connected to it (see I/O