Page 1

LX-100EZ EASYTOUCH POOL/SPA CONTROL SYSTEM

INSTALLATION AND OWNERS MANUAL

IMPORTANT SAFETY INSTRUCTIONS

READ AND FOLLOW ALL INSTRUCTIONS

SAVE THESE INSTRUCTIONS

Important Notice

Attention Installer.

This manual contains important information about the installation, operation and safe use of this

product. This information should be given to the owner/operator of this equipment.

Pentair Pool Products

1620 Hawkins Ave., Sanford, NC 27330 • (919) 774-4151

10951 West Los Angeles Ave., Moorpark, CA 93021 • (805) 523-2400

Rev. F 3-26-04 1 P/N 520050

Page 2

INSTALLATION MANUAL

IMPORTANT SAFETY INSTRUCTIONS ...............................................................................5

SYSTEM INCLUDES............................................................................................................................... 5

EQUIPMENT LOCATION..................................................................................................................... 5

RECOMMENDED HYDRAULIC SCHEMATIC ................................................................... 6

PLUMBING REQUIREMENTS............................................................................................... 7

LX-100 RF POWER/LOAD CENTER .................................................................................... 8

HIGH VOLTAGE WIRING...................................................................................................... 8

GENERAL.................................................................................................................................................. 8

SYSTEM POWER ..................................................................................................................................... 8

EQUIPMENT POWER ............................................................................................................................ 8

LOW VOLTAGE CABLES ...................................................................................................... 9

LOW VOLTAGE WIRING ....................................................................................................... 9

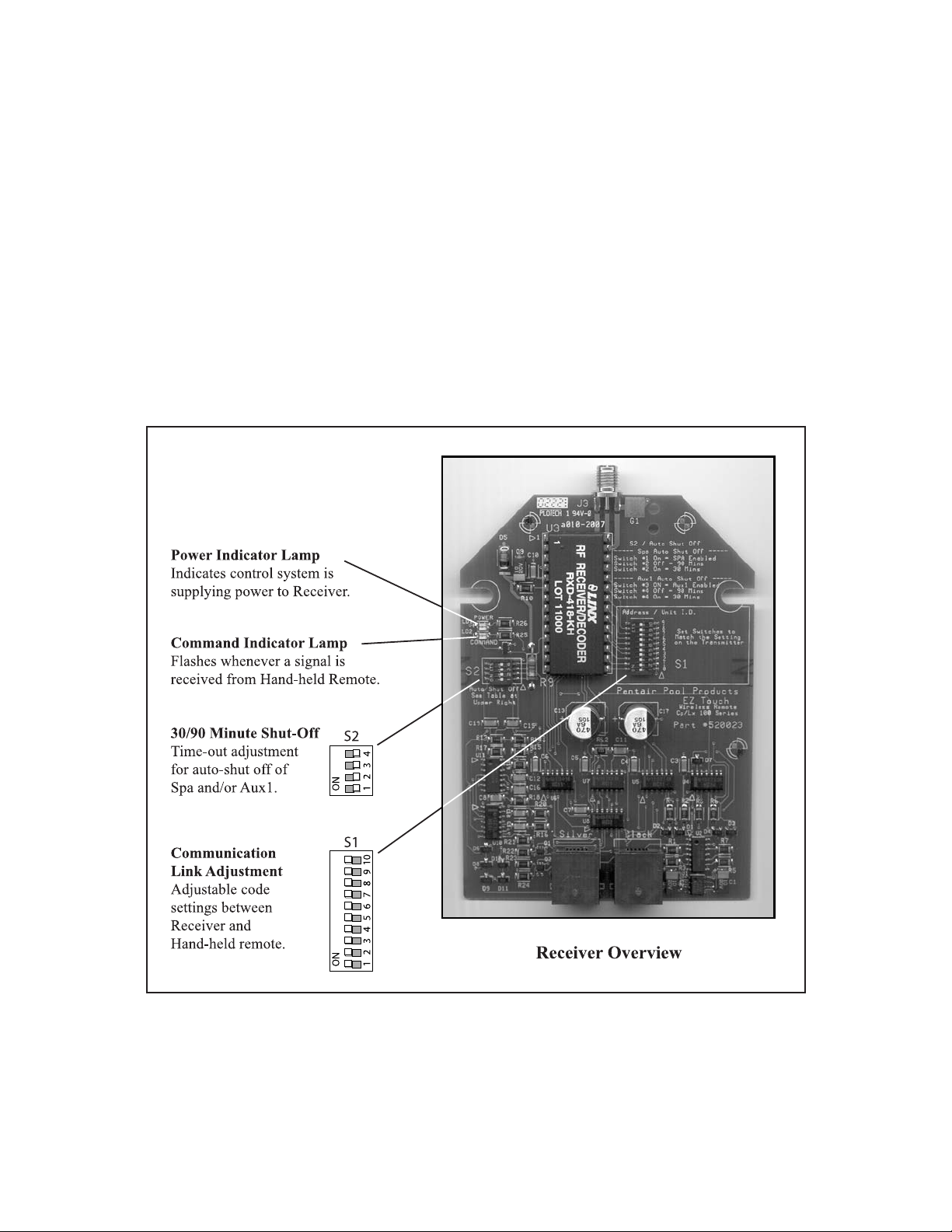

RECEIVER CIRCUIT BOARD ............................................................................................... 10

CUSTOMIZING THE COMMUNICATION LINK .................................................................11

VALVE ACTUATORS ............................................................................................................. 12

RECEIVER ANTENNA ........................................................................................................... 12

HEATER CONNECTIONS ...................................................................................................... 1 3

DUAL THERMOSTAT GAS HEATER ............................................................................................... 13

SINGLE THERMOSTAT GAS HEATER ............................................................................................ 13

ELECTRIC HEATER OR HEAT PUMP ............................................................................................ 13

SYSTEM OPTIONS ............................................................................................................... 1 4

AUTOMATIC COUNTDOWN CYCLE ............................................................................................. 14

SPA-SIDE REMOTE CONTROL ........................................................................................................ 15

POOL CLEANER ................................................................................................................................... 16

AUXILIARY VALVE ............................................................................................................................. 16

WATER TEMPERATURE SENSOR .................................................................................................... 17

CP-100 INDOOR CONTROLLER....................................................................................................... 18

SYSTEM START-UP ........................................................................................................ 19-20

P/N 520050 2 Rev. F 3-26-04

Page 3

OWNER’S MANUAL

IMPORTANT SAFETY INSTRUCTIONS ............................................................................ 2 1

INTRODUCTION .................................................................................................................... 22

SAFETY FEATURES .............................................................................................................. 22

HEATER PROTECTION ....................................................................................................................... 22

POOL CLEANER PROTECTION ....................................................................................................... 22

HAND-HELD REMOTE ......................................................................................................... 22

LX-100 RF POWER/LOAD CENTER ................................................................................. 2 3

FILTER PUMP and POOL CLEANER Time Clocks ....................................................................... 23

SPA Service Switch ................................................................................................................................. 24

FILTER Service Switch .......................................................................................................................... 24

AUX1, AUX2 and AUX3 Service Switches........................................................................................ 24

HEATER Switch ....................................................................................................................................... 24

PUMP DELAY Status Light .................................................................................................................. 24

POWER ON Status Light ....................................................................................................................... 24

MOTORIZED VALVES .......................................................................................................... 25

SYSTEM OPTIONS ............................................................................................................... 2 6

SPA-SIDE REMOTE CONTROL ........................................................................................................ 26

INDOOR CONTROLLER .................................................................................................................... 27

MAINTENANCE ..................................................................................................................... 2 8

CLEANING THE SPA............................................................................................................................ 28

WINTERIZING THE SYSTEM ............................................................................................................ 28

TRANSMITTER BATTERY REPLACEMENT ................................................................................ 28

TROUBLE-SHOOTING .......................................................................................................... 2 9

GENERAL................................................................................................................................................. 29

NOTHING OPERATES .......................................................................................................................... 29

FILTER PUMP DOES NOT OPERATE ............................................................................................. 29

FILTER PUMP DOES NOT TURN OFF ........................................................................................... 29

POOL CLEANER DOES NOT OPERATE ........................................................................................ 29

HEATER DOES NOT OPERATE ........................................................................................................ 29

SPA WATER LEVEL DROPS .............................................................................................................. 29

RF TROUBLE-SHOOTING TABLE ................................................................................................... 30

WARRANTY ............................................................................................................................ 31

Rev. F 3-26-04 3 P/N 520050

Page 4

This page is blank.

P/N 520050 4 Rev. F 3-26-04

Page 5

INSTALLATION MANUAL

LX-100EZ EASYTOUCH POOL-SPA CONTROL SYSTEM

IMPORTANT SAFETY INSTRUCTIONS

READ AND FOLLOW ALL INSTRUCTIONS

CAUTION

All wiring must be performed by a qualified electrician. Basic safety precautions and local codes should always be

followed when installing and using this electrical equipment.

WARNING

To reduce the risk of injury, do not permit children to use this product unless they are closely supervised at all times.

CAUTION

The Hand-held Remote is not waterproof. If it accidentally gets submerged, disassemble by removing screw. Remove

battery and let unit dry out. Reassemble.

SAVE THESE INSTRUCTIONS.

SYSTEM INCLUDES:

N/PrebmuNledoMnoitpircseD

540025TZE001-XL)gnir-odnaannetnahtiw(retneCrewoPFR

540362T42-AVC).ytq2(srotautcAevlaV

810025———).ytq1(etomeRdleh-dnaH

RO

150025LTZE001-XL)gnir-odnaannetnahtiw(retneCdaoLFR

540362T42-AVC).ytq2(srotautcAevlaV

810025———).ytq1(etomeRdleh-dnaH

EQUIPMENT LOCATION

With the exception of the optional Spa-side Remote Control (which is ETL listed for installation right at the

tile-line of the spa), all equipment must be located five feet or more from the water’s edge.

1. LX-100 RF Power/Load Center at the equipment site.

2. Valve Actuators at valves to be motorized.

Rev. F 3-26-04 5 P/N 520050

Page 6

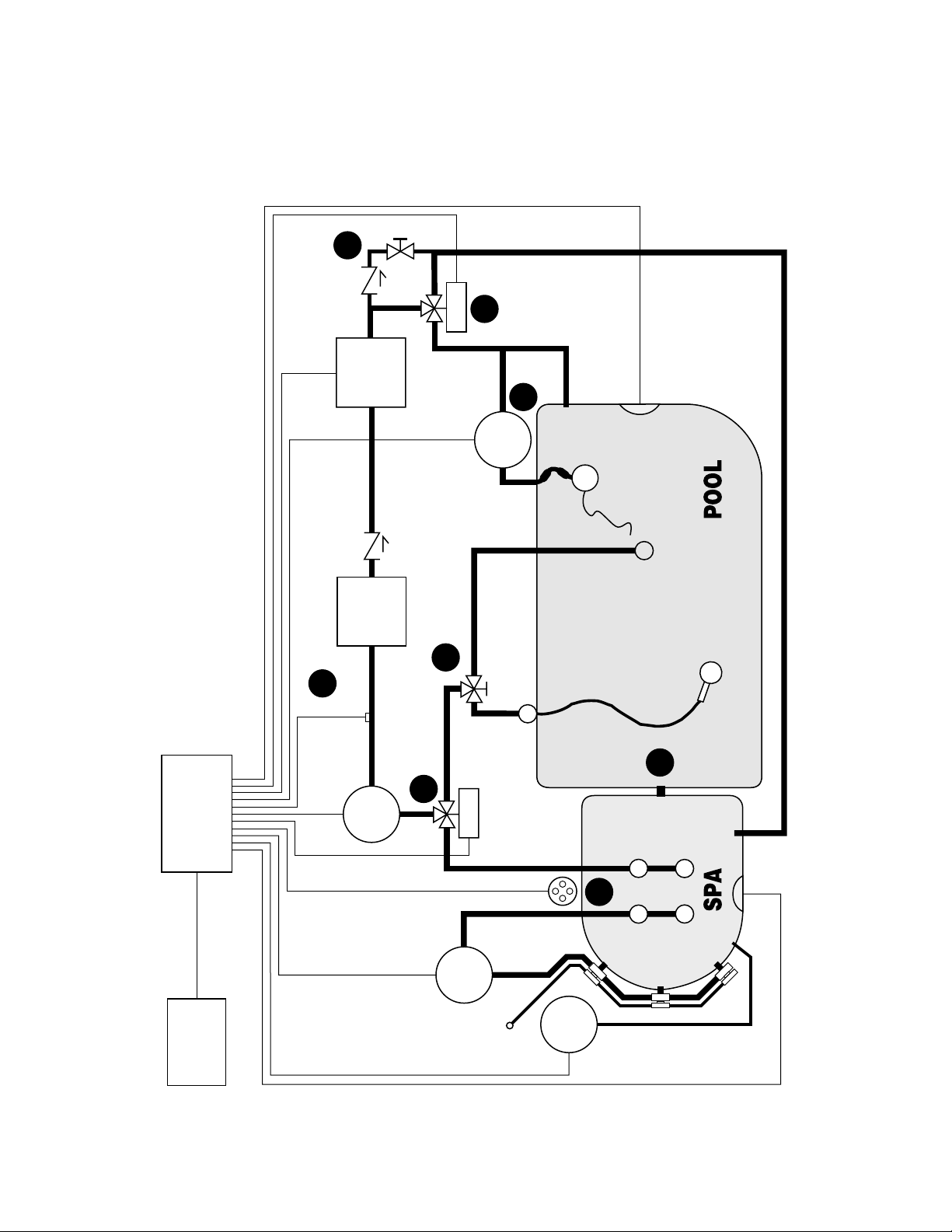

RECOMMENDED HYDRAULIC SCHEMATIC

Refer for “PLUMBING REQUIREMENTS” on page 7.

4

3

CVA-24

LX-100

CENTER

RF POWER/LOAD

9

HEATER

FILTER

SENSOR

WATER

PUMP

FILTER

2

6

POOL

CLEANER

CVA-24

8

PUMP

SKIMMER

REMOTE

SPA-SIDE

5

POOL

LIGHT

MAIN

DRAIN

1

CLEANER

SUCTION

SPA

LIGHT

JET

SPA

PUMP

INTAKE

CP-100

(OPTIONAL)

CONTROLLER

P/N 520050 6 Rev. F 3-26-04

JET AIR

BLOWER

Page 7

PLUMBING REQUIREMENTS

Plumb system in accordance with “RECOMMENDED HYDRAULIC SCHEMATIC” on page 6, local codes

and the following guidelines.

Bring all lines back to the equipment pad.

1. Spa should be at or above the level of the pool.

If spa is attached to pool, provide a dam between the two bodies of water to allow spa overflow into

pool. If spa is not attached to pool, an overflow, sufficient in size to carry full pump-flow, must be

installed at water level in the spa.

2. Plumb a three-port Intake Valve on the suction-side of the filter pump, so that center port of valve is

connected to the pump inlet.

Connect spa suction to one side of Intake Valve, and pool suction to the other side.

3. Plumb a three-port Return Valve on the return-side of the heater, so that return water will enter valve

through the center port.

Connect spa return to one side of Return Valve, and pool return to the other side.

4. A ½” spa make-up line (incorporating a ½” manual gate or ball valve and, for elevated spas, a ½” check

valve) may be provided to bypass the pool return line. This will enable some of the chemically-balanced

water from the pool to cycle through the spa. The manual valve will allow the amount of bypass to be

adjusted.

5. If the spa is to be constructed in concrete, special provision should be made at this time for the installation

of the optional Spa-side Remote Control.

Select a convenient location in the deck or above water level in the spa wall (where the Spa-side Remote

will not be submerged by the spa water), and install a 6” to 12” length of 1-½” PVC pipe to provide a

receptacle for the Spa-side Remote. The pipe should be level and protrude beyond the finished surface of

the spa. It will be cut back at a later date.

Reduce pipe size down to ½” or ¾” conduit, and run to proposed LX-100 RF Power/Load Center

location at equipment pad. Use sweep elbows for turns.

The Spa-side Remote will not be installed until spa construction is complete.

6. For systems which incorporate a skimmer, it is possible to balance the amount of suction between the

skimmer and main drain for maintenance purposes.

This is easily accomplished by installing a manual three-port mixing valve at the suction line.

Plumb one port to the skimmer and the other to the main drain.

7. If a “non-booster pump” pressure-side pool cleaner is being used, plumb a manual three-port valve

between the filter pump and filter, with the third port plumbed to the pool cleaner line, and install a

motorized two-port Pool Cleaner Valve at this line. The motorized valve will automatically open

whenever the Control System activates the pool cleaner.

8. If a booster pump pool cleaner is being used, plumb the booster pump so that its suction-side is

connected to the pool return, after the heater and as close to the ground as practical.

9. If optional water sensor is used with Cp-100 indoor controller, locate between filter pump and filter.

Rev. F 3-26-04 7 P/N 520050

Page 8

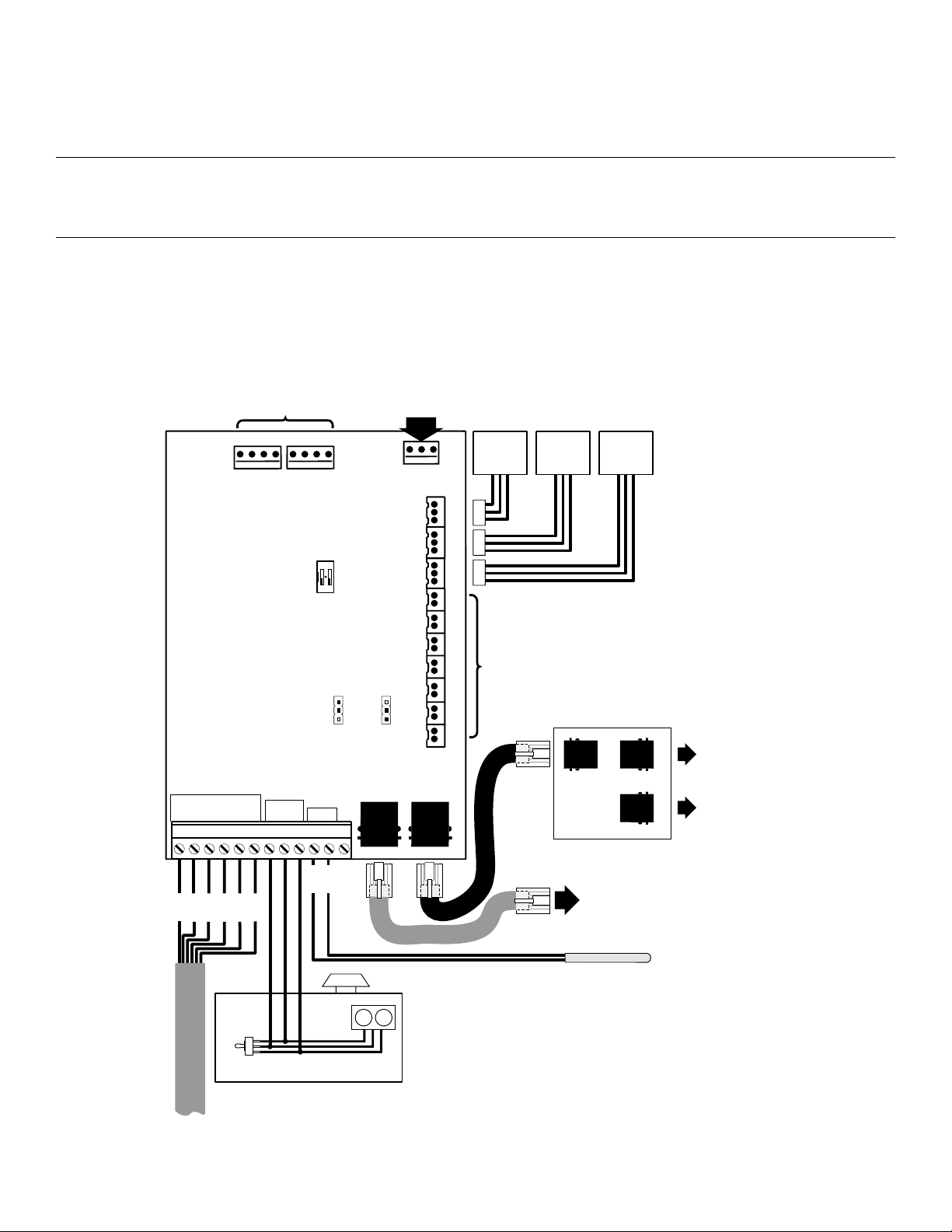

LX-100 RF POWER/LOAD CENTER

Select a convenient location to mount the LX-100 RF Power/Load Center. Ensure that the location is greater than

5 feet from the water’s edge and no further than 15 feet from any motorized valves (otherwise Valve Actuator cables

will need to be extended). The top of the LX-100 RF Power/Load Center should be a minimum 5 feet above the

ground and a minimum 8 feet from any air blower to optimize RF signal reception.

Mount the LX-100 RF Power/Load Center on a flat surface using appropriate screws through the external mounting

points located on the side of the enclosure. Do not drill and mount from inside the enclosure.

Loosen LOCK SCREW of hinged faceplate in left-side of LX-100 RF Power/Load Center, and swing open to expose

the low-voltage compartment. All low-voltage connections are made to the circuit board, in accordance with wiring

diagram located inside door.

The high-voltage wiring compartment is located behind service panel in right-side of LX-100 RF Power/Load Center.

HIGH VOLTAGE WIRING

GENERAL

If using a LX-100EZT System, install an electrical sub-panel with separate breakers for each load at the equipment site.

Circuit breakers should be readily accessible to the spa user, but installed at least 5 feet from the water’s edge.

If using a LX-100EZTL System, the LX-100 RF Power/Load Center has provisions for breakers.

Make sure that the motor(s) on the equipment have built-in thermal protection.

At the LX-100 RF Power/Load Center, remove the service panel (at right) to expose the high-voltage compartment,

and knock-out the appropriate holes at bottom of enclosure to facilitate conduit mounting. Screw terminals are

provided for high-voltage connections.

SYSTEM POWER

Provide a separate circuit breaker to power the system. Either 115 or 230 VAC can be used (115V is preferable).

System draws less than 1-Amp. The breaker will open all ungrounded supply conductors to comply with section

422-20 of the National Electrical Code, ANSI/NFPA 70-1987.

Run appropriate wires from circuit breaker to high-voltage compartment of LX-100 RF Power/Load Center, and

connect to top terminal block in accordance with wiring label, which is marked SYSTEM POWER.

Install two jumper wires for 115V, or one jumper for 230V, according to wiring label.

EQUIPMENT POWER

Provide independent circuit breakers for R1 (FLTR), R2 (AUX1), R3 (AUX2) and R4 (AUX3).

Run appropriate wires from breakers to high-voltage compartment of LX-100 RF Power/Load Center, and connect to

LINE1 and LINE2 screw terminals at each terminal block.

Connect pumps and other high-voltage equipment to LOAD1 and LOAD2 terminals.

Each individual terminal block can be wired for either 115V or 230VAC.

Note:

For 115V equipment, only half of the terminal block will be used (i.e.: LINE1 and LOAD1).

P/N 520050 8 Rev. F 3-26-04

Page 9

LOW VOLTAGE CABLES

Install cable between the low voltage compartment of the LX-100 RF Power/Load Center and the various pieces of

equipment. Provide plastic or metallic conduit where cables run underground, through concrete, etc.

Note

Never install low voltage and high voltage wires in the same conduit. It is advisable to maintain a

minimum distance of 12” between parallel runs of low voltage and AC current-carrying wires.

Valve Actuators are provided with 15 feet of 3-conductor cable.

LOW VOLTAGE WIRING

LX-100/LX-100EZ

TIMER

CONNECTIONS

AUX3

BLU

GAS HTR

C

SLMP

ORG

FLTR TIMER

MOTOR SWITCH

WTRFL

ON

12

AUX1

DELAY

TEMP

SENSOR

S

GRN RED

P

GRN

CONTROLLED BY

YES

NO

JP16 JP17

SILVER

+15

RED

BLU

CLNR TIMER

MOTOR SWITCH

REMOTE SWITCHES

GND

AUX1

SPA

AUX2

LX-100 or LX-100EZ POWER CENTER

YEL

RED

BLK

GRN

TRANSFORMER

CONNECTIONS

18 0

24

YRG

AUX VLV

CLNR

AUX 3

12

BLU

INTAKE

VALVE

ACTUATOR ACTUATOR

INT

VLV

RET

VLV

AUX

VLV

SPA

FLTR

CLNR

AUX1

AUX2

RELAY CONNECTIONS

AUX3

EHTR

DO NOT SHORT THESE PINS

WIRING

RETURN AUXILIARY

VALVE

BLU

POWER ISOLATION PCB

BLU

VALVE

ACTUATOR

EZ-WIRELESS

LX-100

Cp100

to CP-100 or RF RECEIVER BOARD

(1)

to RF RECEIVER

BOARD

to CP-100

WATER TEMPERATURE SENSOR (Optional)

THERMOSTATS

HIGH

OFF

LOW

DUAL THERMOSTAT

to SPA-SIDE REMOTE (Optional)

GAS HEATER

Rev. F 3-26-04 9 P/N 520050

Page 10

RECEIVER CIRCUIT BOARD

Mounted to the back of the LX-100 RF Power/Load Center is the Receiver Circuit Board.

On the circuit board, you will discover the following:

1. A 4-position configuration switch (designated S2), which can be used to configure an automatic

countdown cycle for the Spa and/or the Aux1 circuit. (Aux1 is designated as button “A” on Hand-held

Remote). See page 13 for details.

2. A 10-position configuration switch (designated S1), which can be used to customize the communication

link between the Receiver and Hand-held Remote.

3. 2-qty. status lights (designated POWER and COMMAND), which are used for trouble-shooting:

POWER: Indicates that the Control System is supplying power to the Receiver unit.

COMMAND: Flashes whenever a button is pushed on the Hand-held Remote.

P/N 520050 10 Rev. F 3-26-04

Page 11

CUSTOMIZING THE COMMUNICATION LINK

The communication link between the Receiver and Hand-held Remote can be customized to prevent interference

to or from other RF systems. To accomplish this, there is a 10-position configuration switch located on the

Receiver circuit board and inside the Hand-held Remote. Units are shipped from the factory with all switches in

the “ON” position. If you wish to change this setting, use the end of a paper clip or other blunt instrument and

adjust configuration switches to match. If the configuration switch setting at the Receiver does not match that of

the Hand-held Remote the communication link will not function.

Labels have been provided, marked with the most commonly used functions. These labels may be affixed to the

side of the Hand-held Remote to assist with button identification.

S1

Switch

Receiver Transmitter

COMMUNICATION LINK ADJUSTMENT

NOTE: All Program Switches are Factory set to “ON”.

Matching Code Example: Remote switches 2, 4, 6 “ON”. Receiver switched 2, 4, 6 “ON”.

Affix

Button

ID

Labels

Here

Rev. F 3-26-04 11 P/N 520050

Page 12

VALVE ACTUATORS

Remove knob, handle and four screws from cap of valve(s) to be motorized, and use the four mounting screws

provided to mount Valve Actuator(s) to valve(s).

Run cables to low-voltage wiring compartment of LX-100 RF Power/Load Center, and plug into circuit board at the

appropriate Valve Socket:

Plug intake (suction) valve into INT VLV Socket.

Plug return valve into RET VLV Socket.

Plug auxiliary valve (if applicable) into AUX VLV Socket.

COMPOOL

11056

PART#:PC-LX100

CLNR TIMER

MOTOR SWITCH

LX-100 RF POWER/LOAD CENTER

FLTR TIMER

MOTOR SWITCH

24

18 0

INTAKE

VALVE

ACTUATOR ACTUATOR

INT

VLV

RET

VLV

AUX

VLV

RETURN AUXILIARY

VALVE

RECEIVER ANTENNA

CAUTION

Antenna must be attached with o-ring for proper functioning. Not installing o-ring can lead

to damage of LX-100 RF Power/Load Center.

VALVE

ACTUATOR

Slide orange o-ring over threaded antenna connector protruding from top of the

LX-100 RF Power/Load Center.

Screw on antenna until it stops. O-ring should be compressed by antenna.

ENCLOSURE

P/N 520050 12 Rev. F 3-26-04

Page 13

HEATER CONNECTIONS

DUAL THERMOSTAT GAS HEATER/HEAT PUMP

Inside the heater, connect three 18 AWG wires in parallel with the heater toggle switch or in accordance with the

Heater Manufacturer’s instructions.

Do not disconnect or bypass the flow, pressure or high limit switches.

Place the heater toggle switch in the “OFF” position, and set the thermostats to desired pool and spa temperatures.

Run the three wires to low-voltage compartment of LX-100 RF Power/Load Center.

Strip insulation ¼”, and connect to circuit board at GHTR Screw Terminals, in accordance with wiring diagram

located inside the LX-100 RF Power/Load Center cover:

Connect “High” of heater thermostat to Terminal #S.

Connect “Low” of heater thermostat to Terminal #P.

Connect “Common” of heater thermostat to Terminal #C.

SINGLE THERMOSTAT GAS HEATER/HEAT PUMP

Inside the heater, connect two 18 AWG wires in series with the heater circuitry.

Do not disconnect or bypass the flow, pressure or high limit switches.

Place the heater toggle switch in the “ON” position, and set the thermostat to the desired temperature.

Run the two wires to low-voltage compartment of LX-100 RF Power/Load Center.

Strip insulation ¼”, and connect to GHTR Screw Terminals at Terminals #P and #C.

Make a jumper wire and connect Terminals #P and #S together.

ELECTRIC HEATER

For systems which utilize an electric heater, a 20-Amp Relay Kit (model RLYLX) should be added at the LX-100

RF Power/Load Center.

Install RL-LX in accordance with instructions provided, and plug onto circuit board at the EHTR relay socket.

The relay is capable of controlling an electric heater (rated up to 3KVA), or the magnetic contactor of a larger electric

heater.

Inside the heater , connect two 14 AWG wires in series with the heater thermostat circuitry. Place the heater toggle

switch in the “ON” position, and set the thermostat to the desired temperature.

Run the two wires to the high-voltage compartment of the LX-100 RF Power/Load Center, and connect to LINE1 and

LOAD1 terminals of the electric heater relay.

Rev. F 3-26-04 13 P/N 520050

Page 14

SYSTEM OPTIONS

AUTOMATIC COUNTDOWN CYCLE

There is a 4-position configuration switch (designated S2) located on the Receiver circuit board. This switch can be

used to set a countdown cycle (time-out feature) for the Spa and/or Aux1 circuit. Once this feature has been enabled,

the equipment will automatically turn off after the countdown cycle irrespective of how the circuit was turned on

(by Hand-held Remote or optional Indoor Remote, or Spa-side Remote).

Use the end of a paper clip or other blunt instrument to slide the appropriate switch at S2 to the "ON" or "OFF"

position, in accordance with the following diagram:

P/N 520050 14 Rev. F 3-26-04

Page 15

SPA-SIDE REMOTE CONTROL

The optional Spa-side Remote Control is a double-insulated device which is ETL-listed for installation within 5 feet of

the water’s edge. It is typically installed at the tile-line of the spa wall (above water level), or in the deck within arm’s

reach of the spa.

If the Spa-side Remote is to be installed into the wall of a gunite spa, provision should be made while the spa is being

plumbed. See “RECOMMENDED HYDRAULIC SCHEMATIC” on page 6.

When the spa construction is completed, cut back the 1-½” dia. PVC receptacle flush with the spa wall finish or surface

of deck. See Fig. 1.

Screw Mounting Adapter onto Spa-side Remote, and finger-tighten. Do not use wrench.

Thread cable through conduit to low-voltage compartment of LX-100 RF Power/Load Center.

Carefully glue Mounting Adapter into 1-½” PVC receptacle using PVC cement. For aesthetic purposes, it is suggested

that the Spa-side Remote be installed with the red push-button in the 12 o’clock position. See Fig. 2.

Fig. 1 Fig. 2

At the LX-100 RF Power/Load Center, identify the 6-conductor cable from the Spa-side Remote, and cut-off excess

cable as necessary. Strip insulation of each conductor ¼”, and connect to REMOTE SWITCHES Screw Terminals

at bottom of circuit board in accordance with wiring diagram:

Black conductor (Switch Common) to GND screw terminal.

Red conductor (Red Push-button) to SPA screw terminal.

Yellow conductor (Yellow Push-button) to AUX1 screw terminal.

Green conductor (Green Push-button) to AUX2 screw terminal.

Blue conductor (Blue Push-button) to AUX3 screw terminal.

Orange conductor (LED) to SLMP screw terminal.

A set of adhesive labels is provided for custom identification of individual Spa-side Remote push-buttons.

Use a pair of fine-tip tweezers to carefully adhere the appropriate label at each button.

Rev. F 3-26-04 15 P/N 520050

Page 16

POOL CLEANER

For systems which incorporate a booster pump pool cleaner, it is possible to add a mechanical time clock for

programming the daily cleaning cycles.

Install 24-Hour Time Clock (model TMR-LX) into LX-100 RF Power/Load Center faceplate at the POOL CLEANER

location, and plug into top of circuit board at CLNR TIMER socket, in accordance with instructions provided.

Install a 20-Amp Relay Kit (model RLY-LX) at the LX-100 RF Power/Load Center in accordance with instructions

provided, and plug into circuit board at CLNR relay socket.

AUXILIARY VALVE

It is possible to add a Valve Actuator (P/N 263045) to the system to motorize a two-port or three-port valve for a

custom hydraulic feature (such as a pool cleaner, fountain, waterfall, etc.). The Valve Actuator can be activated from

either the pool cleaner or auxiliary 3 circuit.

Remove knob, handle and four screws from cap of valve to be motorized, and use the four mounting screws provided

to mount Valve Actuator to valve. Run cable to low-voltage compartment of LX-100 RF Power/Load Center, and plug

into circuit board at AUX VLV Valve Socket.

Identify the 2-position AUX VLV Program Switch, which is located at bottom right of LX-100 RF Power/Load Center

circuit board, and use the corner of a small screwdriver or other blunt instrument to adjust the Switch accordingly:

1. To activate valve from the pool cleaner circuit, turn Switch #1 "ON" and Switch #2 "OFF".

2. To activate valve from the auxiliary 3 circuit, turn Switch #1 "OFF" and Switch #2 "ON".

P/N 520050 16 Rev. F 3-26-04

Page 17

WATER TEMPERATURE SENSOR

For use with optional Indoor Control Panel only.

Select a convenient location to mount the Temperature Sensor ( model TS-5L) in the plumbing system between

the filter pump and the heater.

Drill a 5/16” diameter hole in the pipe, and insert the Sensor.

Use a screwdriver to open the hose clamp (included). Position clamp over the Sensor, and gently tighten around

the pipe.

CAUTION

Overtightening of clamp can cause deformation of o-ring seal.

Run 2-conductor cable (25 ft. is included with Installation Hardware package) between Sensor location and

low-voltage compartment of LX-100 RF Power/Load Center.

At the LX-100 RF Power/Load Center, strip insulation of both conductors ¼”, and connect to circuit board at

SNS- and SNS+ Screw Terminals. Pay attention color-coding (green conductor connects to SNS-; red conductor

connects to SNS+).

REMOTE SWITCHES

FRZ

GND

SPA

LX-100 RF POWER/LOAD CENTER

12

+12

AUX1

AUX2

C

AUX3

GHTR

S

P

SNS+

SNS-

RED

GRN

WA TER TEMPERA TURE

SENSOR

Rev. F 3-26-04 17 P/N 520050

Page 18

CP-100 (OPTIONAL) INDOOR CONTROLLER

2 qty. separate 150 foot spools of 6-conductor 26 AWG communication cable are provided (one black and one silver)

to connect to the CP-100 Controller.

NOTE

Cable lubricant must be used when pulling these cables through the conduit.

Select a convenient location inside the house or other weather-protected area to mount the CP-100 Controller.

The overall width of the Controller (with doors open) is 11-½”. The location of the 6-conductor communication cables

(on the centerline of the enclosure) should therefore be at least 5-¼” from any door jamb, wall corner or other obstacle.

Remove backplate from Controller. Temporarily pull cables through large hole in backplate, and position backplate on

surface of wall. Make sure that backplate is level and that “TOP” nomenclature is oriented correctly, and mark the

three mounting points on the surface of the wall. With the backplate removed from the wall, drill 3/16” diameter holes

and insert mounting anchors (included) into the three holes. Pull cables through large hole in backplate, and use the

three 1-¼” screws to mount backplate to wall.

Use the Crimping Tool (model TOOL-6) to attach modular connectors at each end of both cables. See USING THE

CRIMPING TOOL, below.

At the CP-100 Controller, plug the silver cable (with modular connector attached) into the circuit board at Socket #1

(SILVER), and plug the black cable into Socket #2.

Use the four ½” screws (included) to mount CP-100 Controller to the backplate.

At the LX-100 RF Power/Load Center, it will be necessary to use two Cable Splitters (P/N 6CONDDUAL) to

connect to the Main circuit board. Disconnect the existing Receiver circuit board cables from the Main circuit board.

Plug the short cable (attached to single-connector end of each Cable Splitter) into the Power Center circuit board.

Plug Cable Splitters into Socket #1 (SILVER) and black Socket #2.

Paying careful attention to match cable color to

circuit board cables and the Indoor Remote cables into dual-connector end of each of the Cable Splitters.

socket cable color label (silver - silver), reconnect the existing Receiver

Using the Crimping Tool

Make sure that the end of the cable is cut squarely (not diagonally).

Insert the cable between the stripper blades of the tool until it touches the stop. Squeeze the handles and pull the tool,

making sure that the cable stays perpendicular to it. If this is done correctly, the outer jacket of the cable will be

removed without damaging the insulation on the individual conductors.

Place a modular connector in the holder portion of the tool so that the front of the connector is against the stop and the

gold contacts face the crimper. Orient the prepared cable so that the blue conductor is closest to the tool handles, and

insert cable into connector. Make certain that the conductors are flush with the tip of the connector and directly under

the gold contacts. Squeeze the handles firmly to set the contacts and secure the cable.

Note

It is important that the orientation (blue conductor closest to tool handles) is identical at all four cable ends.

P/N 520050 18 Rev. F 3-26-04

Page 19

SYSTEM START-UP

Apply power to the system.

At the LX-100 RF Power/Load Center, verify that the POWER "ON" status light is illuminated, and make sure that

all of the Service Switches are in the “AUTO” position.

If the status light is not on, check the 3 amp circuit breaker which is located above the faceplate. If the circuit breaker

has tripped (indicated by a white tab), push to reset.

On the Hand-held Remote, press the “SPA” Push-button to turn the spa on.

Verify that the Valve Actuators have rotated to spa circulation, the filter pump has been activated and the heater has fired.

Press Push-buttons #A, #B, and #C and check that appropriate equipment is being activated.

At the Intake and Return Valves, flip toggle switch on rear of Actuator(s) between “ON1” and “ON2” positions as

necessary so that valves have rotated to pool circulation.

At the LX-100 RF Power/Load Center, verify that the FILTER PUMP Time Clock is operating.

To set the time of day, rotate the dial in a clockwise direction until the hours and minutes line up with the white arrow at

eight o’clock position on clock face.

To program daily operating cycle(s), depress the desired number of sections around the perimeter of the dial by pushing

towards the center. For each section depressed, the filter pump will operate for 15 minutes.

If the system has a POOL CLEANER Time Clock, verify that it is operating, and check that it also activates the filter

pump when the FILTER PUMP Time Clock is not programmed on.

At the LX-100 RF Power/Load Center, slide the SPA Service Switch to “FILL”, “DRAIN” and back to “AUTO”

position, and verify that the Valve Actuators are rotating accordingly.

If one of the Valve Actuators is 180 degrees out of phase, flip toggle switch on rear of Actuator between “ON1” and

“ON2” position.

At the LX-100 RF Power/Load Center, verify that the filter pump is being activated from the “ON” and “OFF”

positions of the FILTER Service Switch.

Verify that the auxiliary equipment is being activated from the “ON” and “OFF” positions of the AUX1, AUX2 and

AUX3 Service Switches.

Slide FILTER Service Switch to the “ON” position and the HEATER Service Switch to the “SPA & POOL”

position, and verify that the heater has fired.

If the heater doesn’t fire, check the controls inside the heater and also the wiring connections.

At the LX-100 RF Power/Load Center, return the HEATER Service Switch to the “SPA ONLY” position and all the

other Service Switches to the “AUTO” position.

Rev. F 3-26-04 19 P/N 520050

Page 20

CP-100 OPTIONAL INDOOR CONTROL PANEL

If the system has an Indoor Controller, verify that there is a TEMPERATURE Display and check that the

EQUIPMENT STATUS INDICATORS are functioning when the Push-buttons are activated.

If there is no status display, check the connections at each end of the communication cables very carefully. If necessary,

crimp new modular connectors to the cables.

If the TEMPERATURE Display indicates three dashes (- - -) or a very high temperature (400 degrees or more),

check the connections to the Temperature Sensor.

At the Indoor Controller, press appropriate Push-button(s) so that none of the EQUIPMENT STATUS

INDICATORS are illuminated.

At the Indoor Controller, press Push-button #S to turn the spa on.

Verify that the Valve Actuators have rotated to spa circulation, the filter pump has been activated and the heater has

fired.

Press Push-buttons #1, #2 and #3, and check that appropriate equipment is being activated.

A set of adhesive labels is provided for custom identification of equipment.

Use a pair of fine-tip tweezers to adhere the appropriate label(s) below the Push-button(s) on the Indoor Controller.

Calibration of the TEMPERATURE Display has been preset at the factory. However, fine adjustment can be

accomplished if necessary.

Insert a small flat-blade screwdriver through the ADJUST hole which is located behind the right door of the Indoor

Controller, and rotate the Adjustment Screw accordingly.

The system is now ready to be operated as desired.

P/N 520050 20 Rev. F 3-26-04

Page 21

OWNER’S MANUAL

LX-100EZ EASYTOUCH POOL-SPA CONTROL SYSTEM

IMPORTANT SAFETY INSTRUCTIONS

READ AND FOLLOW ALL INSTRUCTIONS.

CAUTION

When operating or servicing this electrical equipment, basic safety precautions should always be observed including the

following:

WARNING

To reduce the risk of injury, do not permit children to use this product unless they are closely supervised at all times.

CAUTION

The Hand-held Remote is not waterproof. If it accidentally gets submerged, disassemble by removing screw. Remove

battery and let unit dry out. Reassemble.

SAVE THESE INSTRUCTIONS.

Rev. F 3-26-04 21 P/N 520050

Page 22

INTRODUCTION

The LX-100EZ is an electronic control system which is designed to coordinate and operate all of the equipment associated

with your swimming pool and spa.

The system is comprised of three principle components:

1. Hand-held Remote.

2. Power Center.

3. Motorized Valves (2 qty).

The Remote provides Push-button control of the equipment from the convenience of your fingertips; the LX-100 RF

Power/Load Center automatically controls the timing of your filter pump and pool cleaner (if applicable) and provides

easy maintenance for your Pool Serviceperson; and the Motorized Valves switch the filter and heater from pool to spa.

Additionally, the Control System incorporates important safety features which protect your pool equipment from accidental

damage.

Your system may also include additional Remote Controls and special options which further add to the convenience, safety

and economy of operating your pool equipment.

SAFETY FEATURES

HEATER PROTECTION

A built-in electronic delay circuit automatically runs the filter pump for an additional 4 minutes whenever the pool or spa

are turned off. This feature enables the heater to cool down, so that the heat exchanger and plumbing are not damaged

from overheating. Some heaters do not require a cool down cycle (i.e. MiniMax), therefore your installer may have turned

this feature off.

POOL CLEANER PROTECTION

If your system incorporates an automatic pool cleaner pump, it will have been plumbed in conjunction with the filter pump

so that it must have water circulation in order to operate.

The LX-100 RF Power/Load Center incorporates the following protection features against possible pump damage if there

is no water circulation:

1. The filter pump will automatically be activated whenever the pool cleaner pump is running, even if the filter

pump is not programmed on.

2. Your pool cleaner will automatically be switched off whenever water is being circulated to the Spa.

HAND-HELD REMOTE

CAUTION

The Hand-held Remote is not waterproof. If it accidentally gets submerged, disassemble by removing screw. Remove

battery and let unit dry out. Reassemble.

The Hand-held Remote will control four circuits.

Push-button “SPA” activates the Spa circuit.

Push-button “A” activates Auxiliary 1 circuit.

Push-button “B” activates Auxiliary 2 circuit.

Push-button “C” activates Auxiliary 3 circuit.

Each of the four functions on the hand-held remote has an "ON" and an "OFF" button.

IMPORTANT: When using the Hand-held Remote, it is necessary to hold the button down for a full one second

to insure that transmission takes place.

It is possible to incorporate a 30-minute or 90-minute countdown cycle for the Spa and/or Auxiliary 1 circuit (useful if

Aux1 is used for a jet pump or air blower). In this instance, whenever those circuits are turned on, they will automatically

shut down (at the end of the countdown cycle) without having to push the "OFF" button.

In order to incorporate the countdown feature, it is necessary to make adjustments to the circuit board located inside the

Receiver unit. See the Installation instructions.

P/N 520050 22 Rev. F 3-26-04

Page 23

LX-100 RF POWER/LOAD CENTER

Located in close proximity to your pool equipment, the LX-100 RF Power/Load Center houses mechanical time clocks

for your filter pump and pool cleaner (if applicable), and manual switches for your Pool Serviceperson.

FILTER PUMP and POOL CLEANER Time Clocks

Check with your Pool Builder or Service Company as to the amount of time required to provide efficient filtration and

cleaning of your pool.

To set the correct time of day, rotate the Dial(s) in a clockwise direction until the hours and minutes line up with the

white arrow at eight o’clock position on clock face.

Pay particular attention to the AM and PM sections of the Dial(s).

To program the daily filtration or cleaning cycle(s), depress the desired number of sections around the perimeter

of the Dial(s) by pushing towards the center. For each section depressed, the equipment will operate for 15 minutes.

NOTE

A built-in protection circuit automatically activates the filter pump whenever the pool cleaner is running, even

if the FILTER PUMP Time Clock is not programmed on. This safeguards against possible damage to the pool

cleaner pump when there is no water circulation.

Rev. F 3-26-04 23 P/N 520050

Page 24

SPA Service Switch

For normal system operation, keep this Switch in the “AUTO” position.

The “FILL” and “DRAIN” positions are used when cleaning the spa.

FILTER Service Switch

For normal system operation keep this Switch in the “AUTO” position.

The “OFF” and “ON” positions allow your Pool Serviceperson to override the FILTER PUMP Time Clock without

altering the program.

CAUTION

If your system incorporates a POOL CLEANER Time Clock, pump damage will occur if the pool cleaner is activated

while the FILTER Service Switch is in the "OFF" position.

AUX1, AUX2 and AUX3 Service Switches

For normal system operation, keep these Switches in the “AUTO” position.

The “OFF” and “ON” positions override the Remote Controls, and provide convenient manual control at the

equipment site.

HEATER Switch

The “SPA ONLY” position will enable heating only when the spa is being circulated.

The “OFF” position will disable the heater.

The “SPA & POOL” position will enable heating whenever the spa or pool is being circulated.

For Dual Thermostat Heaters: At the heater set pool and spa thermostats to desired temperatures. Verify at the

heater that the 3-position “ON/OFF” switch was set to “OFF” during installation.

For Single Thermostat Heaters: To heat the spa only set the spa temperature at the heater and set the LX-100 RF

Power/Load Center Heater switch to “SPA ONLY”. If pool heating is desired, it is necessary to turn the heater

thermostat down to pool temperature and set the LX-100 RF Power/Load Center Heater switch to “SPA & POOL”.

Verify at the heater that the “ON/OFF” switch was set to “ON” during installation.

PUMP DELAY Status Light

A built-in electronic delay circuit will automatically run the filter pump for an additional 4 minutes whenever the spa is

turned off. This enables the heater to cool down, so that the heat exchanger and plumbing are not damaged from

overheating. (See Heater Protection page 22.)

The PUMP DELAY Light indicates that the delay is in effect.

POWER ON Status Light

Indicates that power has been connected to the system.

If this light is not on, consult your Pool Serviceperson.

P/N 520050 24 Rev. F 3-26-04

Page 25

MOTORIZED VALVES

Your control system is designed to activate two motorized valves, which automatically rotate between pool and spa

circulation whenever Push-button #1 (SPA) is activated by the Hand-held Remote. These valves are also activated

from the “FILL” and “DRAIN” positions of the SPA Service Switch at the LX-100 RF Power/Load Center.

An additional motorized valve may have been installed for a custom hydraulic application, such as a fountain or

waterfall, or (in lieu of a booster pump) to activate your pool cleaner.

A toggle switch is located on the rear of each Valve Actuator. This switch is used by the Pool Builder to set the

correct valve rotation direction.

DO NOT ADJUST THIS SWITCH POSITION.

Rev. F 3-26-04 25 P/N 520050

Page 26

SYSTEM OPTIONS

SPA-SIDE REMOTE CONTROL

A 4-button waterproof Remote Control may have been installed into the wall of your spa. This will enable you to

control the equipment while sitting in your spa.

Your Pool Builder should have custom-labeled each button for your specific application.

The RED Button duplicates Push-button SPA by the Hand-held Remote (activates the spa circulation).

The YELLOW Button duplicates Push-button A by the Hand-held Remote.

The GREEN Button duplicates Push-button B by the Hand-held Remote.

The BLUE Button duplicates Push-button C by the Hand-held Remote.

P/N 520050 26 Rev. F 3-26-04

Page 27

INDOOR CONTROLLER

Installed in a convenient location inside your house, the Controller gives you fingertip control of all the equipment

associated with your swimming pool and spa.

Equipment PUSH-BUTTONS #S, #1, #2 and #3

Four Push-buttons are provided for activating the various pieces of equipment. Your Pool Builder has custom-labeled

each Push-button for your specific application.

Equipment Status Indicators

Status Lights are located above each Push-button. The presence of a light indicates that the equipment is running.

The absence of a light indicates that equipment is turned off.

TEMPERATURE Display

A digital display indicates water temperature. Spa temperature is displayed during spa circulation, and pool

temperature is displayed during pool circulation.

Note

The filter pump must be running to provide accurate temperature display.

Using Your Spa

To turn your spa on, simply press Push-button #S.

The motorized valves will rotate to spa circulation, the filter pump will turn on and the heater will fire.

The TEMPERATURE Display will let you know when the spa is ready for use.

Rev. F 3-26-04 27 P/N 520050

Page 28

MAINTENANCE

CLEANING THE SPA

For cleaning or maintenance purposes, it is possible to use the Control System to automatically empty your spa and

then to refill with clean water from the Pool.

At the Power Center:

1. Set the SPA Service Switch to “DRAIN” position.

2. Set the FILTER Service Switch to the “ON” position. The Spa will begin to drain into the Pool.

3. Before the Spa has completely drained, set the FILTER Service Switch to the “OFF” position. Do not

drain the Spa completely or prime will be lost.

4. When cleaning or spa maintenance is complete, set the SPA Service Switch to the “FILL” position and

the FILTER Service Switch to the “ON” position. The Spa will begin to fill with clean water from the

Pool.

5. When the water level in the Spa has returned to normal, return the SPA Service Switch and the FILTER

Service Switch to the “AUTO” position.

CAUTION

Do not leave the equipment unattended when draining or filling the Spa.

WINTERIZING THE SYSTEM

During the winter season, it is possible to partially drain your Swimming Pool and disable the pool equipment, but still

be able to use your Spa.

Consult a qualified Service Company to drain the Pool and protect the plumbing from freeze damage.

The following procedure will disable the pool equipment:

1. With the Hand-held Remote, press Push-button SPA “ON” (to turn the Spa on).

2. At the motorized valves, flip toggle switch on rear of Valve Actuators to the “OFF” position.

3. With the Hand-held Remote, press Push-button SPA “OFF” (to turn the Spa off).

4. At the LX-100 RF Power/Load Center, set the FILTER Service Switch to the “OFF” position (to

disable the Time Clock) or, if daily Spa filtration is required, leave the FILTER Service Switch in the

“AUTO” position and program the FILTER PUMP Time Clock accordingly.

If your Control System incorporates a Recirculating Freeze Sensor, it may not be necessary to winterize the pool.

It is however recommended that all Freeze Sensors be tested by an authorized Serviceperson before the onset of the

winter season.

Testing can be accomplished by placing the Sensor in a glass of ice water, and turning the FILTER Service Switch to

the “OFF” position. If the Sensor is functioning correctly, the filter pump should turn on within ten minutes. This test

should also be conducted on any Auxiliary Freeze Sensors which may have been added for the jet pump or auxiliary

equipment.

HAND-HELD REMOTE BATTERY REPLACEMENT

With normal use the battery should last for several years. In the event the battery must be replaced, slide the battery

cover from the bottom of the Hand-held Remote. Slide battery from retainer clip and discard in accordance with local

and/or state ordinances. Replace with 3V lithium battery number CR2032 or equivalent. Slide battery cover onto

remote and snap in place.

P/N 520050 28 Rev. F 3-26-04

Page 29

TROUBLE-SHOOTING

Your Control System is designed to provide years of trouble-free pool and spa enjoyment. However, if at any time your

System should behave erratically, consult the following Check List, which should help to alleviate any problems caused

by operator error. If you are still unable to solve your particular symptom, refer the situation to a qualified Pool Service

Company.

GENERAL

1. Check all circuit breakers at electrical sub-panel.

2. At the LX-100 RF Power/Load Center, ensure that all the Service Switches are in the “AUTO” position.

NOTHING OPERATES

1. Check 3-amp circuit breaker which is located above FILTER PUMP Time Clock in LX-100 RF Power/

Load Center. Tripped circuit breaker is indicated by a white tab. Push to reset.

2. If circuit breaker continues to trip, refer to a qualified Service Company.

FILTER PUMP DOES NOT OPERATE

1. At the LX-100 RF Power/Load Center, check that the FILTER PUMP Time Clock is programmed on.

2. Turn the FILTER Service Switch to the “ON” position. If the pump still does not operate, consult a

qualified Service Company.

FILTER PUMP DOES NOT TURN OFF

1. At the LX-100 RF Power/Load Center, check that the FILTER Service Switch is not in the “ON”

position.

2. Check that the PUMP DELAY Status Light is not on, indicating that the System is running its 4-minute

cool down cycle.

3. Check that the POOL CLEANER Time Clock is not programmed on, automatically forcing the filter pump on.

4. Turn the FILTER Service Switch to the “OFF” position. If the pump continues to run, consult a

qualified Service Company.

POOL CLEANER DOES NOT OPERATE

1. At the LX-100 RF Power/Load Center, check that the POOL CLEANER Time Clock is programmed on.

2. Make sure that Push-button SPA is not turned on by the Hand-held Remote.

3. Pool cleaner pump may require servicing.

HEATER DOES NOT OPERATE

1. Make sure that filter pump is running.

2. Check heater thermostat setting and pilot light (if applicable).

3. Check filter pressure. If filter is clogged, the heater may not be getting sufficient water flow.

4. Heater may require servicing.

SPA WATER LEVEL DROPS

1. At the LX-100 RF Power/Load Center, check that the SPA Service Switch is in the “AUTO” position.

2. Check that Motorized Valves rotate in both directions by adjusting toggle switch on the

rear of each Valve Actuators. Remember to return switches to their original position after testing.

3. A “check valve” in the system may be leaking. Refer to a qualified Service Company.

Rev. F 3-26-04 29 P/N 520050

Page 30

RF TROUBLE SHOOTING TABLE

Symptom Possible Cause Solution

POWER LED does not light. LX-100 RF Power/Load Center Insure power is being supplied and

does not have power. that the LX-100 RF Load/Power

Center operates correctly without the

receiver installed.

Defective cable or connection to the Verify the function of the board using

LX-100 RF Power/Load Center. known good cable set.

Defective receiver board. Contact factory or service center.

COM LINK LED does not light or Defective cable or connection to the Verify the function of the board using

blink. LX-100 Power/Load Center. known good cable set.

In normal operation LED will blink Defective receiver board. Contact factory or service center.

at least every 2 seconds.

COMMAND LED does not light when Address switches are incorrectly Verify that the address switches on

Hand-held Remote button(s) is configured. the Hand-held Remote and receiver

pressed - unit fails to operate. board are correct and match.

Hand-held Remote battery has failed. Replace Hand-held Remote battery.

Defective Hand-held Remote or Contact factory or service center.

receiver.

Unit functions, but some circuits do Circuit selection switches are Verify settings of S2 on the receiver

not work, or operate the incorrect incorrectly set. board.

circuit.

Unit fails to operate, or fails operate Undue electrical noise. Relocate the LX-100 RF Power/Load

dependably at range. Center away from equipment such as

blower motors.

Too many obstructions between Relocate the LX-100 RF Power/Load

the Hand-held Remote and receiver. Center in a location that provides

fewer obstructions to the area the

user commonly operates the

Hand-held Remote.

Receiver unit is too near the ground. Relocate the LX-100 RF Power/Load

Center to maximize the distance

between the receiver antenna and

the ground.

Unit seems to turn on or off circuits A near by home is operating a similar Select an alternate address code for

without the user / Hand-held Remote. wireless unit. the Hand-held Remote and receiver.

I.e. change the switches on both

boards to an alternate, but matching

setting.

Unit dependably turns equipment "ON", Undue electrical noise is being Relocate the LX-100 RF Power/Load

but once equipment is running it does produced by one or more pieces of Center away from equipment such as

not dependably turn equipment "OFF", equipment in close proximity to the blower motors.

or range is greatly reduced when receiver.

equipment is running. Relocate the LX-100 RF Power/Load

Center in a location that provides

fewer obstructions to the area the

user commonly operates the

Hand-held Remote.

Unit operates, but has greatly reduced Hand-held Remote battery is failing. Replace Hand-held Remote battery.

range compared to prior function.

P/N 520050 30 Rev. F 3-26-04

Page 31

For questions, repairs, replacement parts, or information on possible Authorized Service Centers

within your vicinity call:

Pentair Pool Products ~ 800-831-7133

Or visit us on the Internet at www.pentairpool.com

Rev. F 3-26-04 31 P/N 520050

Page 32

SAVE THESE INSTRUCTIONS.

Pentair Pool Products

1620 Hawkins Ave., Sanford, NC 27330 • (919) 774-4151

10951 West Los Angeles Ave., Moorpark, CA 93021 • (805) 523-2400

P/N 520050 32 Rev. F 3-26-04

Loading...

Loading...