Sta-Rite CIC60P Installation Manual

®

IntelliChlor

Electronic Chlorine Generator

(Model CIC60P, CIC60S)

Patents pending

Certified to NSF/ANSI 50

Installation and User’s Guide

IMPORTANT SAFETY INSTRUCTIONS

READ AND FOLLOW ALL INSTRUCTIONS

SAVE THESE INSTRUCTIONS

WARNING - Salt is an inherently corrosive material. While the levels of salt required for proper operation

of the IntelliChlor Electronic Chlorine Generator are relatively low when compared to sea water and other salt

solutions, placing any amount of salt in your pool increases the likelihood of corrosion or other deterioration of

pool equipment and any surfaces used in and around your pool. Metal parts and certain natural and man-made

surfaces are particularly susceptible to corrosion and deterioration when used in and around salt water pools.

Pentair Water Pool and Spa does not represent or otherwise guarantee that the proper use of the IntelliChlor

Electronic Chlorine Generator will prevent corrosion or other deterioration of pool equipment and any surfaces

used in and around your pool. Consult your experienced pool professional, who should be able to advise you on

the proper material selection, installation techniques for those materials, and the proper use, care and

maintenance of those materials for your specific pool type and location in order to minimize the corrosion and

deterioration that is inherent in and around salt water pools.

© 2009 Pentair Water Pool and Spa, Inc. All rights reserved

This document is subject to change without notice

1620 Hawkins Ave., Sanford, NC 27330 • (919) 566-8000

10951 West Los Angeles Ave., Moorpark, CA 93021 • (805) 553-5000

IntelliChlor®, IntelliTouch®, EasyTouch® and Pentair Water Commercial Pool and Spa™ are trademarks or registered

trademarks of Pentair Water Pool and Spa, Inc. and/or its affili-ated companies in the United States and/or other

counties. Unless noted, names and brands of others that may be used in this document are not used to indicate an

affiliation or endorsement between the proprietors of these names and brands and Pentair Water Pool and Spa, Inc.

Those names and brands may be the trademarks or registered trademarks of those parties or others.

P/N 521011 Rev A - 04/03/09

Contents

Important Safety Precautions ........................................................................................................... iii - iv

IntelliChlor and Controller System Part Numbers ......................................................................................... v

Technical Support ........................................................................................................................................ v

IntelliChlor® Electronic Chlorine Generator Overview ................................................................................... 1

Features .................................................................................................................................................. 1

IntelliChlor Commercial System Components .............................................................................................. 2

Acu-Trol panel with ORP sensor (sold separately) ........................................................................................ 2

PC100 Commercial Power Center - No ORP ................................................................................................ 2

CPC100 Commercial Power Center with ORP .............................................................................................. 2

IntelliChlor Electronic Chlorine Generator Control Panel and Cell Description ............................................... 3

IntelliChlor Power Center .............................................................................................................................. 4

System Schematic Diagram ........................................................................................................................ 5

Install Chlorine/Bromine Feeders after the IntelliChlor Cell ........................................................................... 5

IntelliChlor Plumbing Diagram (For single CIC60 cell system) ...................................................................... 6

Loop Plumbing Diagram (For single CIC60 cell system)............................................................................... 6

Section 1: IntelliChlor Control Panel .........................................................................................7

Salt Level Status LEDs ............................................................................................................................... 7

Status LEDs ................................................................................................................................................ 7

Sanitizer Output LED Indicators .................................................................................................................. 8

Self-Cleaning ............................................................................................................................................... 8

More and Less Output Buttons .................................................................................................................... 8

Boost ON/OFF ............................................................................................................................................ 8

Self-Cleaning ............................................................................................................................................... 8

Section 2: Pool Water and Chemistry, Conditions and Precautions ....................................... 9

Pool Water Chemistry, Conditions and Precautions ...................................................................................... 9

Optimum Pool Water Conditions for Salt Water Pools (using the IntelliChlor Electronic Chlorine Generator) 10

Covered Pools and Vinyl Liner Pool and Lowering Chlorine Output Levels .................................................. 10

Chlorine Testing ......................................................................................................................................... 11

What Type of Salt to Use ........................................................................................................................... 11

How Much Salt to Use ............................................................................................................................... 11

Calculating the Saturation Index ................................................................................................................ 12

Saturation Index Factors ....................................................................................................................... 12

How to Add Salt to the Pool ....................................................................................................................... 13

Table 1. Approximate Pounds (Kg) of salt needed to obtain 3,400 ppm in pool...................................... 13

Table 2. Approximate Pounds (Kg) of salt needed to maintain 3,000 ppm in pool .................................. 14

Table 3. Approximate amount of cyanuric acid to obtain 75 ppm in pool................................................ 14

Pool Water Preparation ............................................................................................................................... 15

Determining Pool Size (Gallons of Water in Your Pool) ........................................................................... 15

Determining Pool Size (liters of water in your pool) ................................................................................ 15

Section 3: Operating IntelliChlor .............................................................................................17

Initial Start up Period ................................................................................................................................. 17

Operation .............................................................................................................................................. 17

Use of an external Pool Pump Timer is not required .............................................................................. 17

If you use a Pool Pump Timer ............................................................................................................... 17

Startup Procedure (Super Chlorination) ...................................................................................................... 18

Sanitizer Output Settings and Adjustments ............................................................................................... 18

Operating in Winter .................................................................................................................................... 18

General Recommendations ................................................................................................................... 19

General Cautions .................................................................................................................................... 19

i

IntelliChlor Electronic Chlorine Generator Installation and User’s Guide

ii

Contents (Continued)

Section 4: User Maintenance.................................................................................................... 21

Daily service .............................................................................................................................................. 21

Weekly service .......................................................................................................................................... 21

Monthly Service......................................................................................................................................... 21

IECG Usage Hours Meter .......................................................................................................................... 22

Cleaning the IECG Cell Blades .................................................................................................................. 22

Winterizing ................................................................................................................................................. 23

Section 5: Installation ...............................................................................................................25

Kit Contents .............................................................................................................................................. 25

Required Tools ........................................................................................................................................... 25

IntelliChlor “Dummy” Cell ........................................................................................................................... 26

Installing the IntelliChlor Cell Assembly ..................................................................................................... 26

Connecting the Cell Power Cable to the Power Center ........................................................................... 27

Section 6: Troubleshooting ......................................................................................................29

Table 1: Troubleshooting ............................................................................................................................ 29

System Specifications - 115 VAC and 240 VAC Wiring ..............................................................................31

Basic System Wiring with ORP ............................................................................................................. 31

Warranty ...................................................................................................................................... 33

Technical Support

Sanford, North Carolina (8 A.M. to 5 P.M. Eastern Time)

Moorpark, California (8 A.M. to 5 P.M. Pacific Time)

Phone: (800) 831-7133

Fax: (800) 284-4151

visit www.pentairpool.com and www.staritepool.com

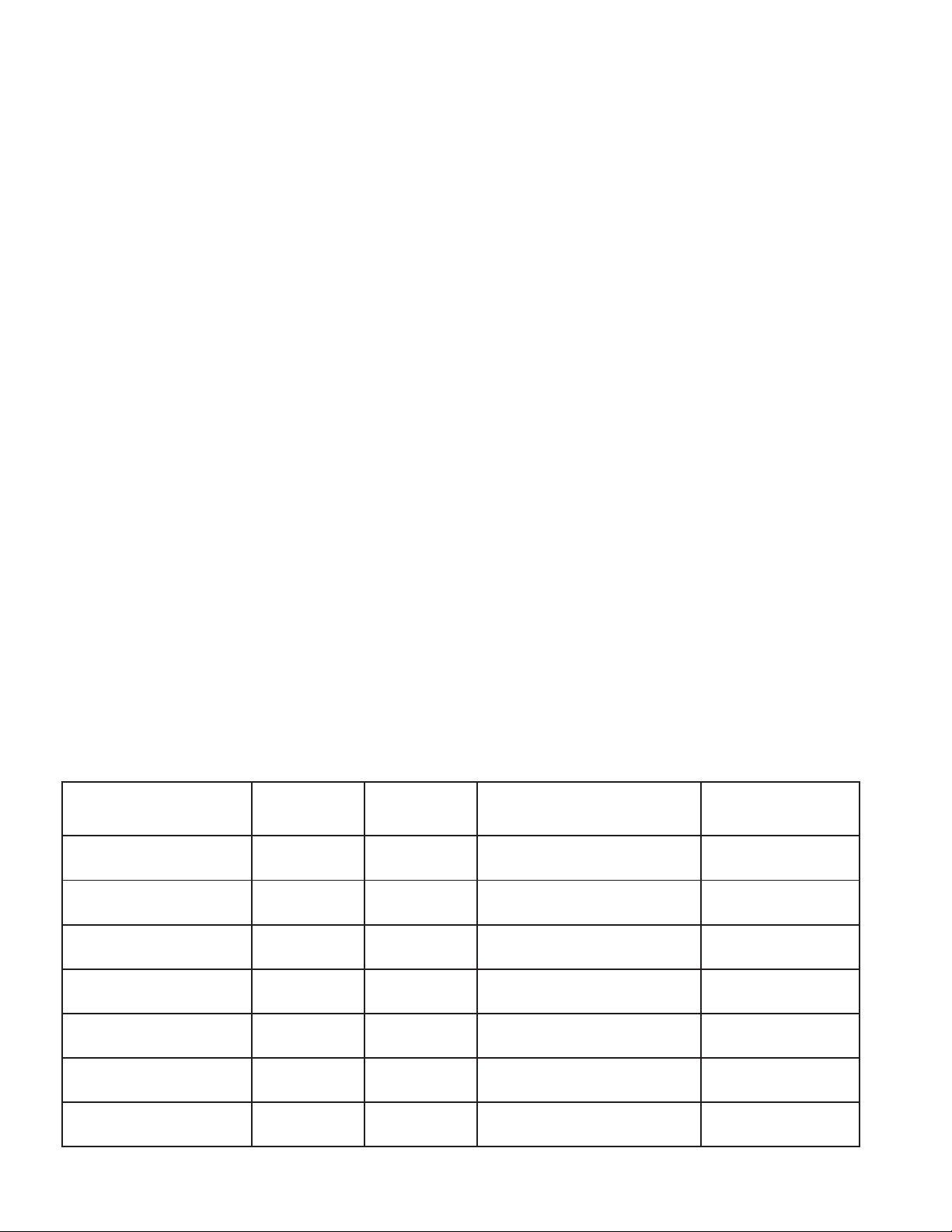

Recommended Pool Sizing Chart for Commercial Applications

The following chart represents recommended commercial IntelliChlor systems for given pool sizes. A commercial

system requires an external ORP panel and sensor to produce chlorine upon demand as needed and is sold separately

(The Acu-Trol AK110 pH/ORP system is recommended). Commercial systems (COMSYS) can be expanded to support

larger pool sizes, for example a 150,000 gallon pool would use a COMSYS 16 and seven additional secondary cells and

additional manifolds.

noitpircseDmetsyS

4-SYSMOC:2

6-SYSMOC:3

8-SYSMOC:4

01-SYSMOC:5

21-SYSMOC:6

41-SYSMOC:

61-SYSMOC:8

7

forebmuN

rewoP

sretneC

yramirP1

yradnoceS1

yramirP1

yradnoceS2

yramirP1

yradnoceS3

yramirP1

yradnoceS4

yramirP1

yradnoceS5

yramirP1

yradnoceS6

yramirP1

yradnoceS7

forebmuN

slleC

:sllec2

P06CIC1

S06CIC1

:sllec3

P06CIC1

S0

6CIC2

:sllec4

P06CIC1

S06CIC3

:sllec5

P06CIC1

S06CIC4

:sllec6

P06CIC1

S06CIC5

:sllec7

P06CIC1

S06CIC6

:sllec8

P06CIC1

S06CIC7

.srH42ni

)llecrep.sbl2(

.sbl4000,02

.sbl6000,03

.sbl8000,04

.sbl01000,05

.sbl21000,06

.sbl41000,07

.

sbl61000,08

P

decudorpenirolhCfo.sbl

eziSloo

).snollag

)retaWfosnollaG(

000,01=llec1(

IntelliChlor Electronic Chlorine Generator Installation and User’s Guide

IMPORTANT SAFETY PRECAUTIONS

SAVE THESE INSTRUCTIONS

Important Notice: Attention Installer: This manual contains important information about the

installation, operation and safe use of this product. This information should be given to the owner and/or

operator of this equipment. When installing and using this electrical equipment, basic safety precautions should

always be followed, including the following:

WARNING: IMPORTANT SAFETY INSTRUCTIONS PERTAINING TO A RISK OF FIRE,

ELECTRIC SHOCK, OR INJURY TO PERSONS. READ AND FOLLOW ALL

INSTRUCTIONS.

Before installing this product, read and follow all warning notices and instructions which are

included. Failure to follow safety warnings and instructions can result in severe injury, death,

or property damage. Call (800) 831-7133 for additional free copies of these instructions, or

obtain a copy of these instructions at:

http://www.pentairpool.com/misc/owners_manuals/sanitizers/IntelliChlor_Owners.pdf

iii

WARNING: To reduce the risk of injury, do not permit children to use this product.

WARNING: CHLORINE GAS BUILDUP CAN OCCUR WITH IMPROPER WIRING: To reduce the risk of

personal injury the IntelliChlor® Electronic Chlorine Generator (IECG) Power Center must be installed on and

wired to the load side of the time clock, electronically controlled switch, or relay load side, so that it will

receive power only when the pool pump is on. Otherwise, dangerous chlorine gas buildup can occur. The IECG

should never be energized when the pool pump is OFF and water is not flowing through the unit.

WARNING: To reduce the risk of injury, service should only be personnel by a qualified pool

service professional.

WARNING: Never operate the IntelliChlor

water circulation. A build-up of flammable gases will result in hazardous conditions.

CAUTION - IntelliChlor Electronic Chlorine Generator (IECG) is for use with permanently-installed pools

and may also be used with hot tubs and spas if so marked. Do not use with storable pools. A permanentlyinstalled pool is constructed in or on the ground or in a building such that it cannot be readily disassembled for

storage. A storable pool is constructed so that it is capable of being readily disassembled for storage and

reassembled to its original integrity.

Electronic Chlorine Generator (IECG) without proper flow or

WARNING: When mixing acid with water, ALWAYS ADD ACID TO WATER. NEVER ADD

WATER TO ACID.

IntelliChlor Electronic Chlorine Generator Installation and User’s Guide

iv

IMPORTANT SAFETY PRECAUTIONS

SAVE THESE INSTRUCTIONS

CAUTION - Use of chemicals other than those recommended may be hazardous. Even proper use of the

recommended chemicals can be hazardous. Follow the Chemical Manufacturer’s Instructions.

CAUTION - To reduce the risk of electric shock, install IntelliChlor Electronic Chlorine Generator (IECG)

a minimum of five (5) feet away from the inside wall of the pool.

CAUTION - Install the IECG a minimum of three (3) feet away from the heater outlet.

CAUTION - It is recommended to install a Pentair two (2) inch CHECK VALVE (P/N 263042) between

the input side of the IECG and the main heater output pipe.

CAUTION - A solid copper, bonding conductor not smaller than No. 8 AWG (8.4 mm) should be connected

from the accessible wire connector on the unit to all metal parts of the swimming pool, spa, or hot tub structure

and to all electrical equipment, metal conduit, and metal piping within five (5) feet (1.5 m) of the inside walls of a

swimming pool, spa, or hot tub, when the unit is installed within five (5) feet of the inside walls of the swimming

pool, spa, or hot tub.

Canada - Industry Canada (IC) - This device complies with RSS210 of Industry Canada. (1999)

FCC Standard - 47 CFR Part 15, Subpart C (Section 15.247). This version is limited to chapter 1 to chapter 11

by specified firmware controlled in the U.S.A.

Federal Communications Commission (FCC) - This device complies with Part 15 of the FCC Rules.

Operation is subject to the following two conditions: (1) this device may not cause interference, and (2) this

device must accept any interference, including interference that may cause undesired operation of the device.

Interference Statement - This equipment has been tested and found to comply with the limits for a Class B

digital device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection

against harmful interference in a residential installation. This equipment generates, uses and can radiate radio

frequency energy and, if not installed and used in accordance with the instructions, may cause harmful

interference to radio communications. However, there is no guarantee that interference will not occur in a

particular installation. If this equipment does cause harmful interference to radio or television reception, which

can be determined by turning the equipment off and on, the user is encouraged to try to correct the interference

by one or more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

• Consult the dealer or an experienced radio/TV technician for help.

Note: Modifications not expressly approved by the party responsible for FCC compliance could void the user’s

authority to operate the device.

IntelliChlor Electronic Chlorine Generator Installation and User’s Guide

IntelliChlor® Electronic Chlorine Generator Overview

The IntelliChlor Electronic Chlorine Generator (IECG) salt chlorinator uses a process known as electrolysis to

produce chlorine gas which immediately dissolves into a solution to create Hypochlorite (a pool and spa water

sanitizer) from a low concentration of salt added to the pool water. Hypochlorite kills bacteria, oxidizes organic

material, and kills algae, then reverts back to salt. The IECG then reuses the salt and the process starts over

again. The IntelliChlor system is comprised of the IECG and Power Center.

CAUTION - The IntelliChlor Electronic Chlorine Generator (IECG) is designed only to produce chlorine. The

IECG does not monitor or control chlorine levels in the pool or spa water. It is the pool owner’s responsibility for

monitoring and maintaining free chlorine levels at the APSP recommended range of 2.0 to 4.0 parts per million

(ppm). It is the pool owner’s responsibility to check, on a regular basis, the free chlorine level while the pool

pump is running, and adjust the IntelliChlor Electronic Chlorine Generator accordingly.

WARNING - Salt is an inherently corrosive material. While the levels of salt required for proper operation

of the IntelliChlor Electronic Chlorine Generator are relatively low when compared to sea water and other salt

solutions, placing any amount of salt in your pool increases the likelihood of corrosion or other deterioration of

pool equipment and any surfaces used in and around your pool. Metal parts and certain natural and man-made

surfaces are particularly susceptible to corrosion and deterioration when used in and around salt water pools.

Pentair Water Pool and Spa does not represent or otherwise guarantee that the proper use of the IntelliChlor

Electronic Chlorine Generator will prevent corrosion or other deterioration of pool equipment and any surfaces

used in and around your pool. Consult your experienced pool professional, who should be able to advise you on

the proper material selection, installation techniques for those materials, and the proper use, care and

maintenance of those materials for your specific pool type and location in order to minimize the corrosion and

deterioration that is inherent in and around salt water pools.

1

CAUTION - Do not operate the IECG with newly poured pool plaster or newly constructed pool,

regardless of pool lining material. Severe salt damage can occur. FOR ALL NEW POOLS wait at least

ONE (1) MONTH after construction and filling of pool water before operating IECG.

Replacement CIC60P and CIC60S Cell Part Numbers

• CIC60P - P/N 521151

• CIC60S - P/N 521005

Features

• Superior design combines cell and control panel as one assembly.

• Connects to ORP system via dry contact wires, to switch on or off based on chlorine demand.

• Can be operated without ORP, on a timed basis, using the MORE and LESS buttons on the cell.

• Cell blades are made from a titanium metal base and coated with precious metal Ruthenium oxide.

• Cell blades are capable of producing chlorine for at least 10,000 hours, when the IECG is used properly.

• The IECG can be installed horizontally or vertically.

• Separate Power Center mounts to wall at equipment pad, for easy AC wiring.

• Electronics run cool for long, reliable life.

• Cell hour meter reports current usage to determine how many hours remain in the life of the unit.

• CIC60P and CIC60S cell produces up to 2.00 lbs of chlorine per 24 hours.

• Salt level LED indicators show four ranges for the amount of salt in pool.

• Red and green LED indicators show system status for power, water flow, and cell status.

• Cell lifetime is tracked with at-a-glance green LED indicators.

• UL listed to UL1081 standards for swimming pool chlorinators.

• Approved NSF regulatory standards.

IntelliChlor Electronic Chlorine Generator Installation and User’s Guide

2

IntelliChlor Commercial System Components

An IntelliChlor Commercial System components can be configured as follows:

• Stand-alone - No ORP: This system consists of one CIC60P cell, one PC100 power center, and no

oxidation reduction potential (ORP) sensor/panel. Chlorine is dispensed on a timed basis, set by the

MORE and LESS buttons on the cell.

• Stand-alone with ORP: This system consists of one CIC60P cell, one CPC100 power center, and

an oxidation reduction potential (ORP) sensor/panel system (sold separately). The chlorine is

dispensed on demand from the ORP sensor.

• Multi-Cell with ORP: This system consists of one CIC60P cell and multiple secondary cells,

CIC60S, multiple power centers, and an oxidation reduction potential (ORP) sensor/panel system

(sold separately). The chlorine is dispensed on demand from the ORP sensor. For multiple cell

systems, there is one CIC60P cell, labeled PRIMARY and additional CIC60S cells labeled

SECONDARY. The SECONDARY cells communicate with the PRIMARY cell. Note: There can

only be one PRIMARY cell in a multiple cell system.

Acu-Trol panel with ORP sensor (sold separately)

The Acu-Trol panel contains an oxidation reduction potential (ORP) sensor that is placed in the water stream

to detect the amount of sanitizing ability in the water and according to a user-preset trip point, calls for chlorine

when low, and cancels chlorine when satisfied. This panel provides a dry-contact output that connects to the

IntelliChlor system. When the dry-contact terminals are closed, chlorine is required. When the dry contact

terminals are open, no chlorine is required. The Acu-Trol panel is not used for a stand-alone-No ORP system.

PC100 Commercial Power Center - No ORP

The PC100 commercial power center provides power to one CIC60P cell, but does not interconnect to an

ORP system. The CIC60P cell will operate on a timed basis, set by the MORE and LESS buttons on the cell.

This system may be used with a time clock to control operations.

CPC100 Commercial Power Center with ORP

The CPC100 commercial power center, with ORP provides power to each cell. The power center labeled

PRIMARY contains the dry-contact wires that connect to the external ORP system. When the dry-contact

wires are closed, the “Primary” panel sends a 100% command to the cell; chlorine is being produced. When

the dry-contact wires are opened, the Primary panel sends a 0% output command to the cell, to stop producing

chlorine.

Example 1:

Small hotel pool requires a two (2) lb. system.

Equipment used: One CIC60P cell

One CPC100 power center (one power center)

Acu-Trol panel with ORP sensor

Example 2:

Health club spa requires a four (4) lb. system

Equipment used: Use multiple-cell system COMSYS-4

Sizing:

To correctly size the chlorine requirements of a commercial pool, use the following rule:

• Two (2) lbs. of chlorine per 10,000 gallons of water

To size a commercial spa, use this general rule:

• One pound of chlorine per 2,000 gallons of water

These rules appear oversized, but ensure rapid chlorine make-up time, essential for commercial health codes.

IntelliChlor Electronic Chlorine Generator Installation and User’s Guide

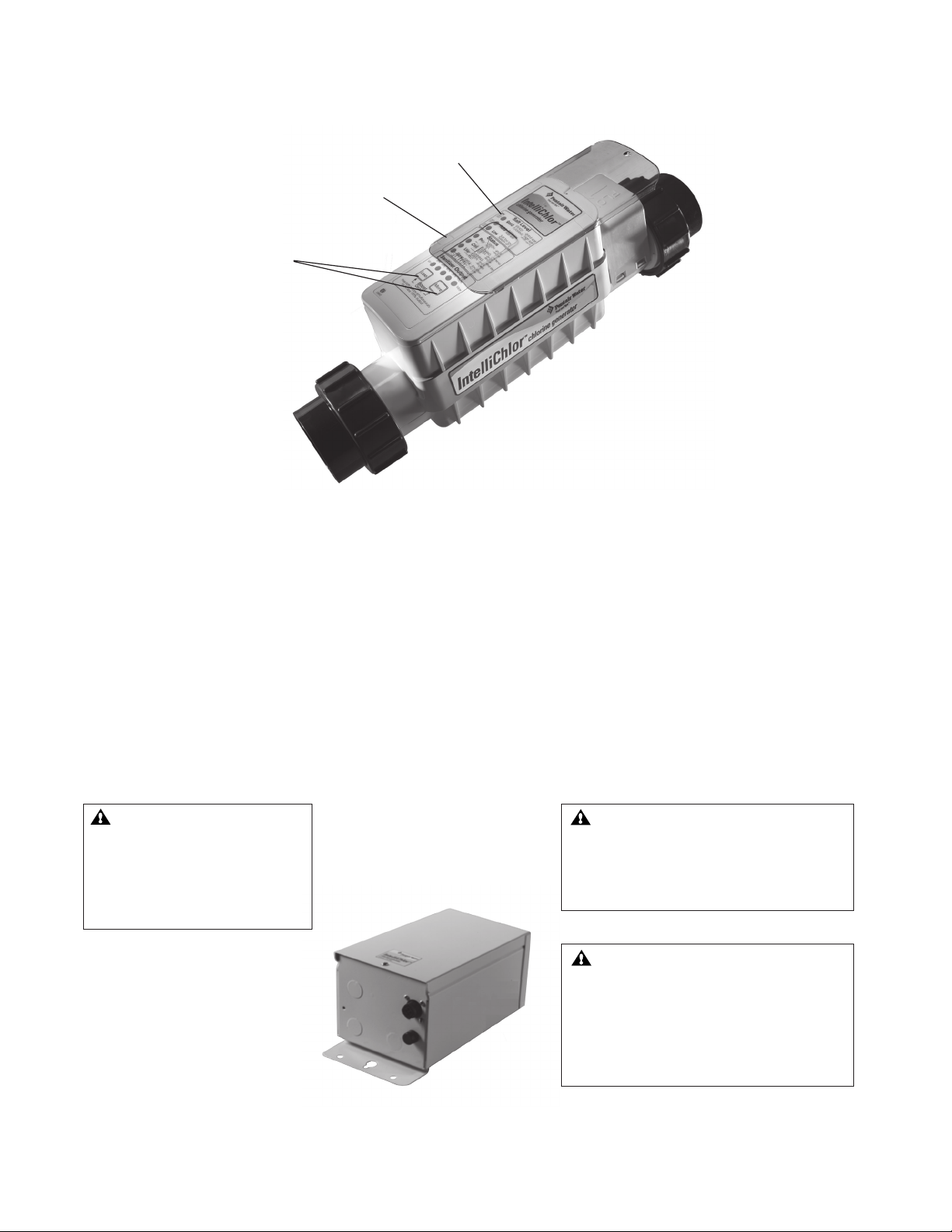

IntelliChlor Electronic Chlorine Generator Control Panel and Cell Description

The IntelliChlor Electronic Chlorine Generator (IECG) includes a control panel with buttons and LED

indicators to control the IECG and produce chlorine. The IECG measures the water temperature and salt level

to produce chlorine at the defined output. If the salt level in the pool water is too low (red on salt display), the

cell is turned off until salt is added to the pool. The controller has a self-cleaning cycle which reverses the cell

polarity, reducing calcium buildup. This feature turns the cell on and off at regular intervals to prevent calcium

and scale buildup and further maximizes cell life.

The IECG contains the control electronics and bipolar electrodes that electrically produces chlorine when

energized with DC current. Chlorine is generated as pool water containing salt passes through the cell. The

chlorine production can be varied by either adjusting the sanitizer output level on the control panel and/or by

varying the number of hours the IECG is on each day. The IECG automatically reverses the cell electrode

blades every few hours to help clean the cell. This process does not interrupt the production of Chlorine.

The IECG also contains a mechanical flow sensor to ensure the proper amount of water is passing through the

cell to allow chlorination to occur. The IECG automatically measures the water salinity and temperature and

displays four (4) salinity ranges on the control panel using LED indicators. The IECG includes a 15 ft. UL

approved four conductor 16-gauge cable for connection to the Power Center.

• Flow Sensor: A flow sensor assures that there will always be adequate water flow through the

IECG. If the IECG is not properly plumbed and/or does not receive adequate water flow, no chlorine

will be produced.

3

• Temperature Sensor: To protect the IECG from operation and potential damage when the

temperature of the pool water falls below 52° F, ±3° F (11° C, ±1.67° C), the temperature sensor

switches the IECG off, and no chlorine is being produced.

• Salt Sensor: Two salt sensor probes in the IECG are activated each time the IECG is switched on

and again during every eight (8) hours of continuous running. At each of those times, the salt level

LED indicator lights flash in a scrolling sequence for two (2) minutes to indicate that the IECG is in

analysis mode. After two (2) minutes, the LED indicators lights will signal one (1) of four (4) salinity

ranges. For more information, see “Salt Level Status LEDs” on page 7.

Note: The salt sensor reading is within +/- 500 ppm accuracy.

IntelliChlor Electronic Chlorine Generator Installation and User’s Guide

4

Control Panel

status LEDs

Clear sliding

cover

MORE and LESS

output buttons

IntelliChlor Electronic Chlorine Generator

IntelliChlor Power Center

The IntelliChlor Power Center converts AC electrical current to a low-voltage DC electrical current which is

required to produce chlorine. The power supply is connected with the pool circulation pump electrical source

so that the IECG only operates when the pool pump is on. The Power Center should be mounted vertically on

the wall up to fifteen (15) feet away from the IECG. The Power Center contains the transformer, fuse,

connector to the cell and the AC electrical current wiring configuration with the DC electrical current output

cable to the IECG. A fuse holder is mounted on the bottom of the Power Center for additional protection.

There are no other controls or lights on the Power Center. For information about installing and proper use of

the Power Center. For more information, refer to the system power center installation guide.

CAUTION - The IntelliChlor

Power Center does NOT control

the pump. The IntelliChlor

Electronic Chlorine Generator

only produces chlorine when the

pool pump is on.

CAUTION - Before plugging or

unplugging the IntelliChlor Electronic

Chlorine Generator to the Power Center,

first switch off the AC power to the Power

Center.

CAUTION - Only plug CIC60P and

CIC60S into PC100 or CPC100 Power

Centers. DO NOT plug into IntelliTouch

EasyTouch, or SunTouch automation

systems with integrated power sources.

This will cause the circuit breaker to

repeatedly trip.

IntelliChlor Power Center (Model PC 100 and CPC 100)

IntelliChlor Electronic Chlorine Generator Installation and User’s Guide

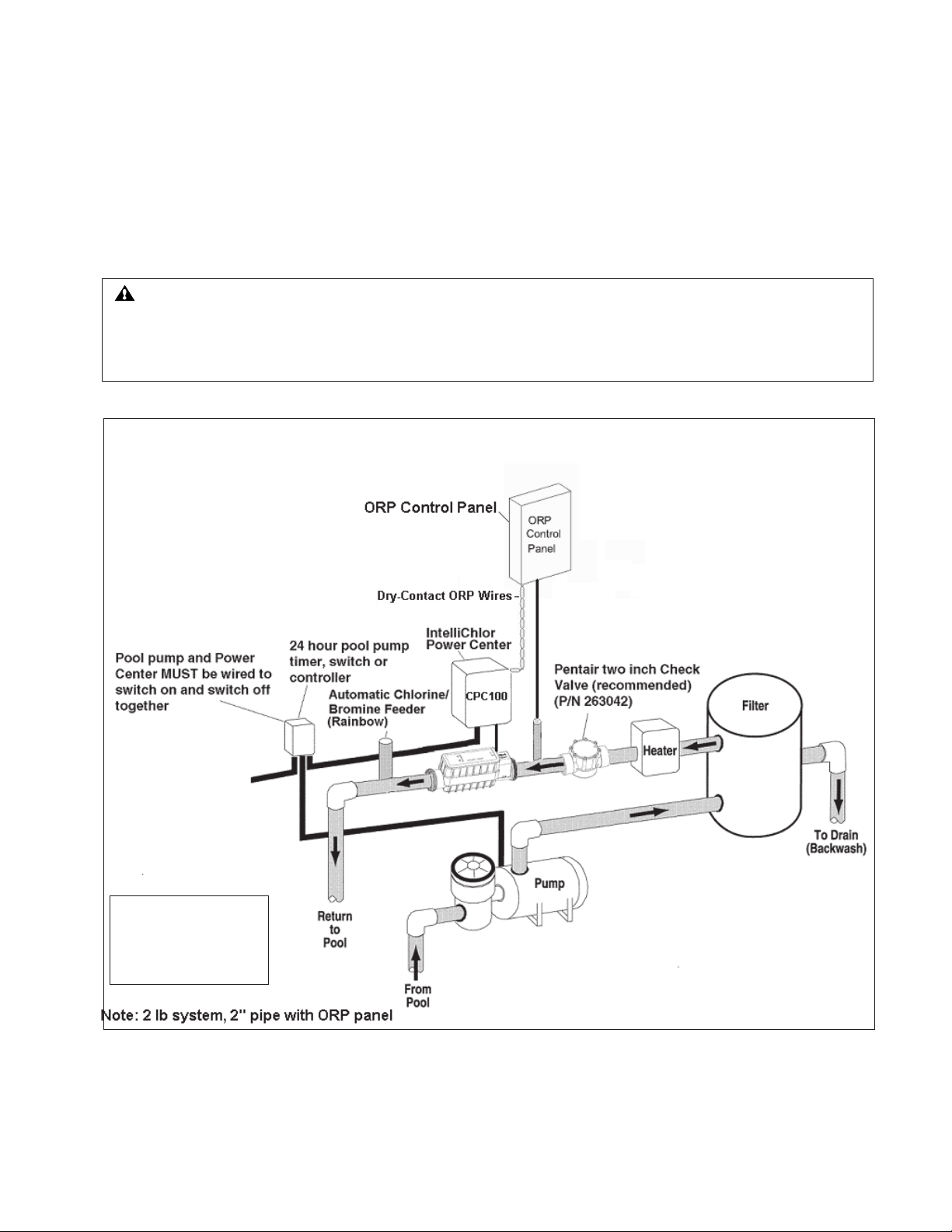

System Schematic Diagram

The following schematic diagram shows a typical IntelliChlor system installation. It is recommended that a two

(2) inch check valve be installed between the input side of the IntelliChlor Electronic Chlorine Generator and

the main heater output pipe, as shown below. Note: This schematic diagram is not drawn to scale. Refer to

the relevant portions of this Installation and User’s Guide for information regarding proper placement

and spacing of all equipment depicted in this diagram.

Install Chlorine/Bromine Feeders after the IntelliChlor Cell

CAUTION - To avoid permanent damage to the IntelliChlor cell, automatic in-line chlorine/bromine feeders

(such as Rainbow) MUST be installed AFTER the IntelliChlor cell as shown below. When using the

IntelliChlor with an in-floor cleaner pressure system, it is recommended that a separate return line be used for

the cleaner to reduce the increased water pressure stress on the IntelliChlor cell.

5

Note: For best flow

sensing, provide at

least 12"-18" of straight

pipe in front of the cell

inlet.

NOT TO SCALE

IntelliChlor Electronic Chlorine Generator Installation and User’s Guide

6

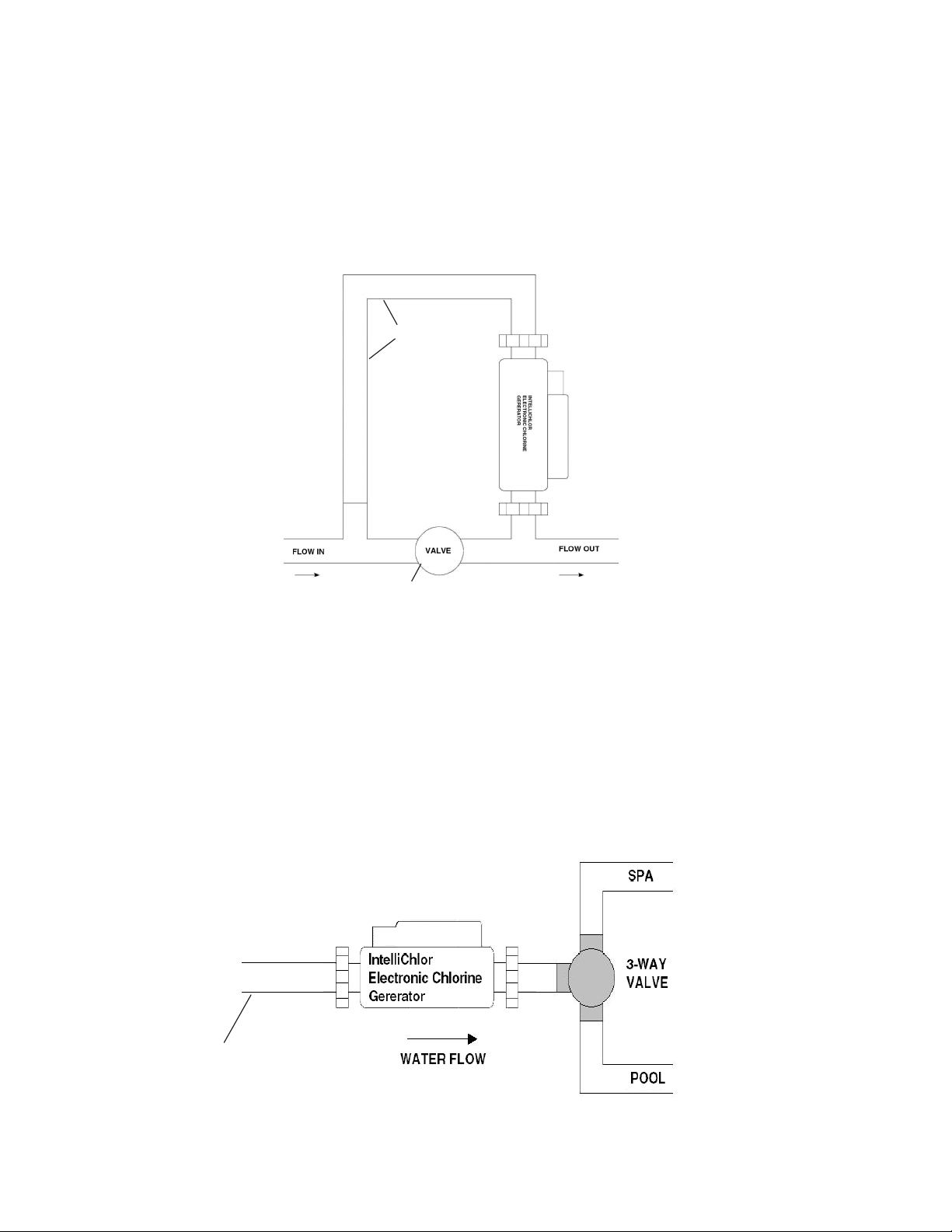

Loop Plumbing Diagram (For single CIC60 cell system)

The IntelliChlor Electronic Chlorine Generator is designed to operate with water flow rates from 25 gallons per

minute (gpm) up to 105 gpm. Do not exceed 105 gpm or pipe manufacturers recommended flow rate,

whichever is less. For flow rates over 80 gpm, it is recommend that you use a bypass loop (as shown below)

for best chlorine production. Installations with flow rates over 80 gallons per minute are those that have

in-floor cleaning systems or booster pumps. These single CIC60 cell systems should use a bypass loop with the

IECG with a flow control valve that assures that the flow through the IECG is maintained within its designed

operating water flow rates.

Bypass loop

NOT TO SCALE

Flow control valve

IntelliChlor Plumbing Diagram (For single CIC60P cell system)

Plumbing the IntelliChlor Electronic Chlorine Generator (IECG) for a single CIC60P cell system:

• Always install the IntelliChlor Electronic Chlorine Generator AFTER the filter and heater (see

“System Diagram” on page 4). The ICEG should be no closer than three (3) feet away from the

heater outlet.

• If the IECG is installed on a pool/spa combination system, install (see diagram below) the IECG

BEFORE the pool/spa return valve to allow proper chlorination of both the pool and spa and also to

avoid creating gas traps in the pipes.

Note: If a multiple cell system is used, refer to the Installation guide for that system. The kit comes with

prepared plumbing manifolds.

Note: For best flow

sensing, provide at

least 12"-18" of straight

pipe in front of the cell

inlet.

Note: Single CIC60 cell system. NOT FOR MULTIPLE CELL SYSTEMS.

IntelliChlor Electronic Chlorine Generator Installation and User’s Guide

NOT TO SCALE

Loading...

Loading...